Geological Constraints on the Gas-Bearing Properties in High-Rank Coal: A Case Study of the Upper Permian Longtan Formation from the Songzao Coalfield, Chongqing, Southwest China

Abstract

1. Introduction

2. Geological Setting

2.1. Regional Structural Features

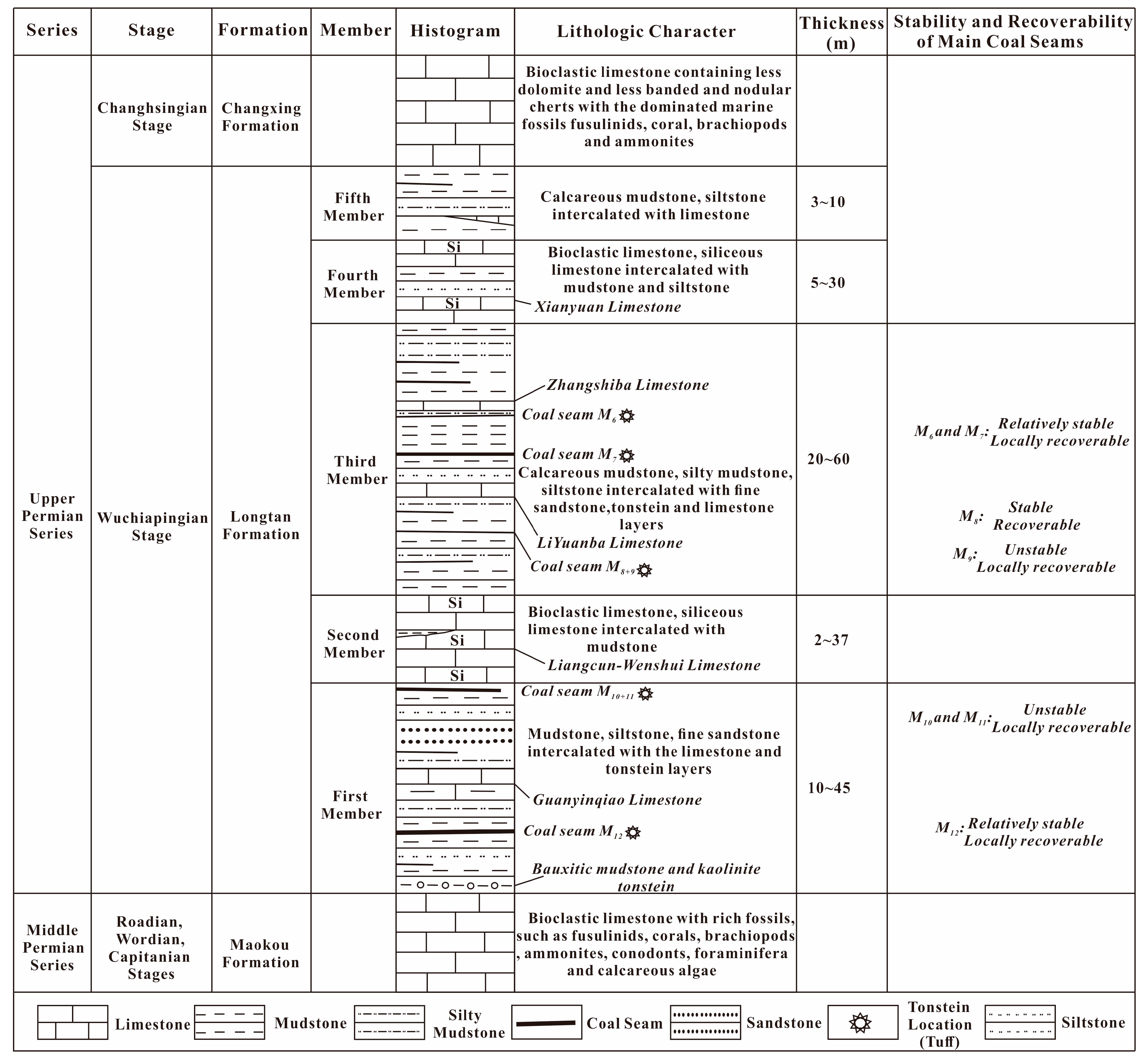

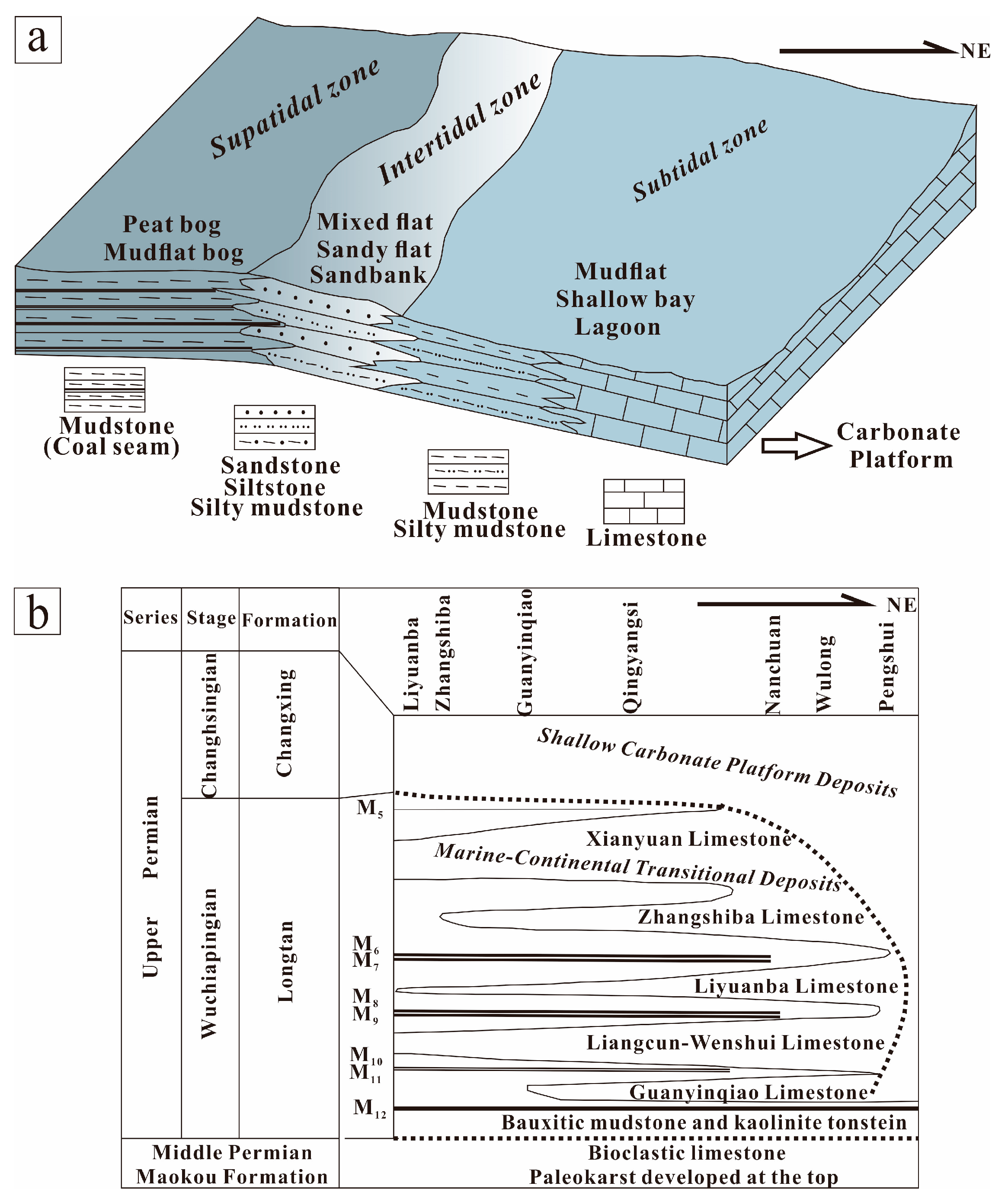

2.2. Coal-Bearing Stratigraphic Characteristics

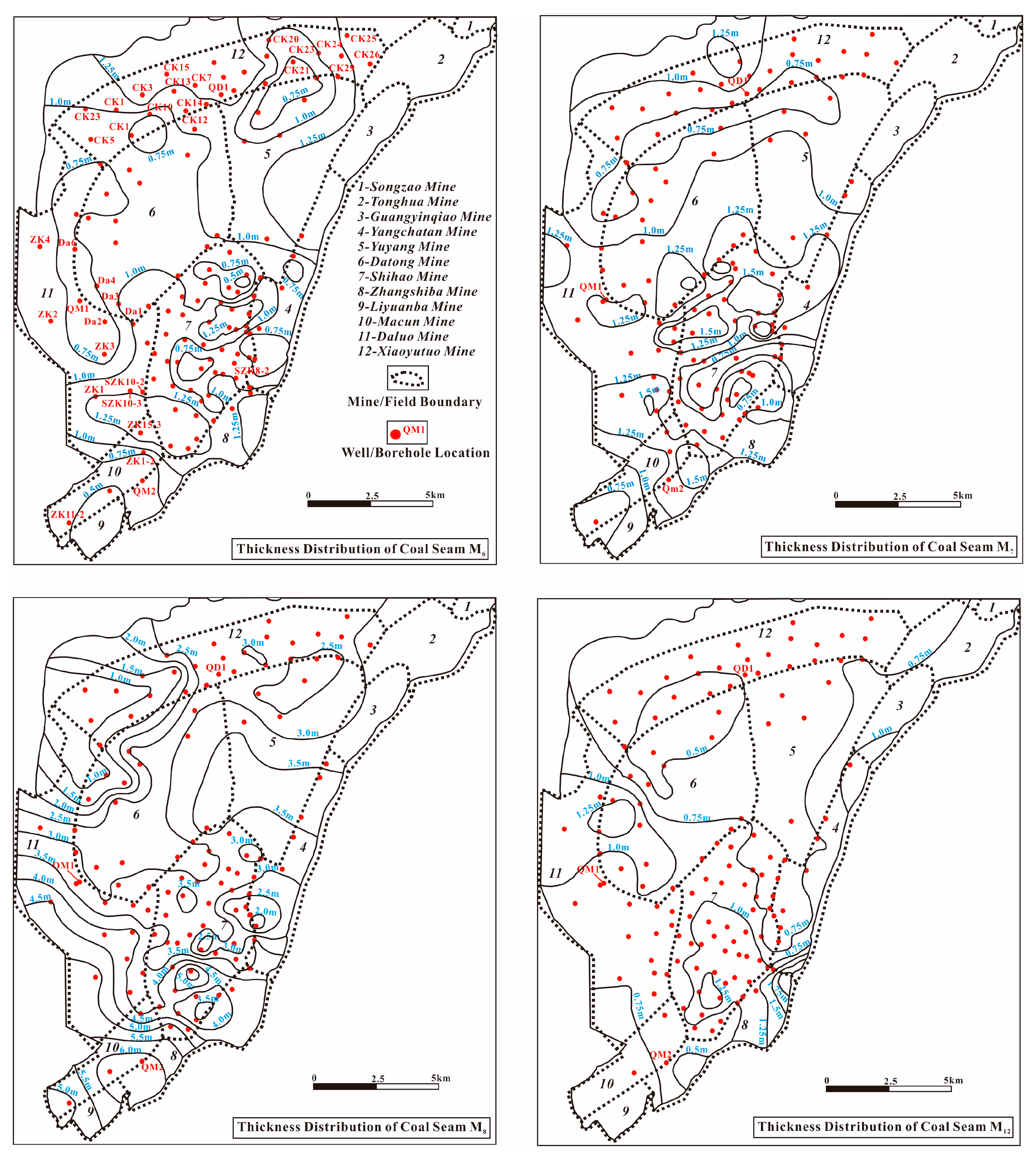

2.3. Thickness and Distribution of the Main Coal Seams

3. Sampling and Methods

3.1. Evaluation of the Samples

3.2. Analytical Methods

4. Results

4.1. Coal Geochemical Characterization

4.2. Coal Reservoir Characterization

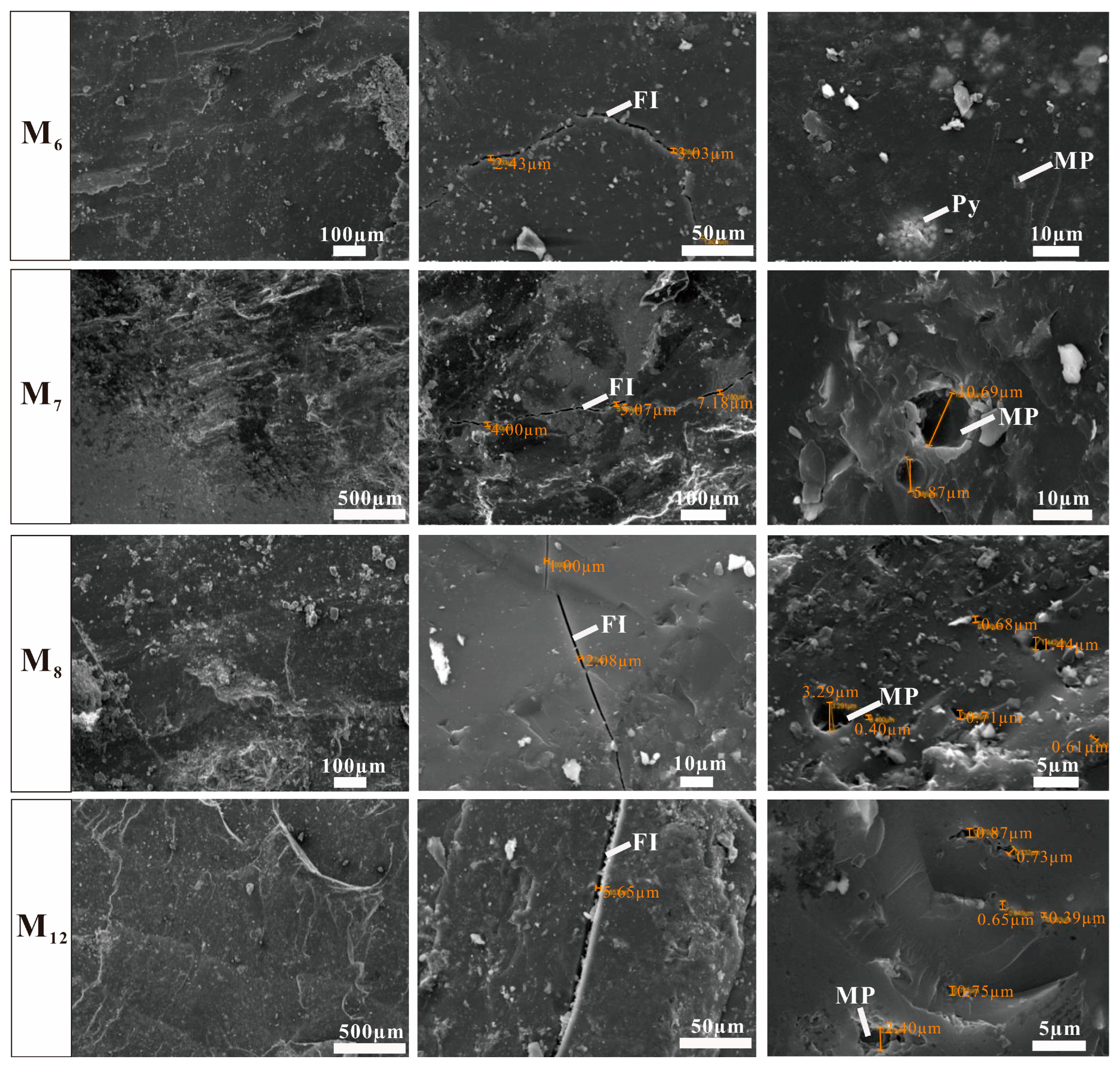

4.2.1. Pore Structure

4.2.2. Porosity and Permeability

4.3. Coal Gas-Bearing Properties

4.3.1. Composition of CBM

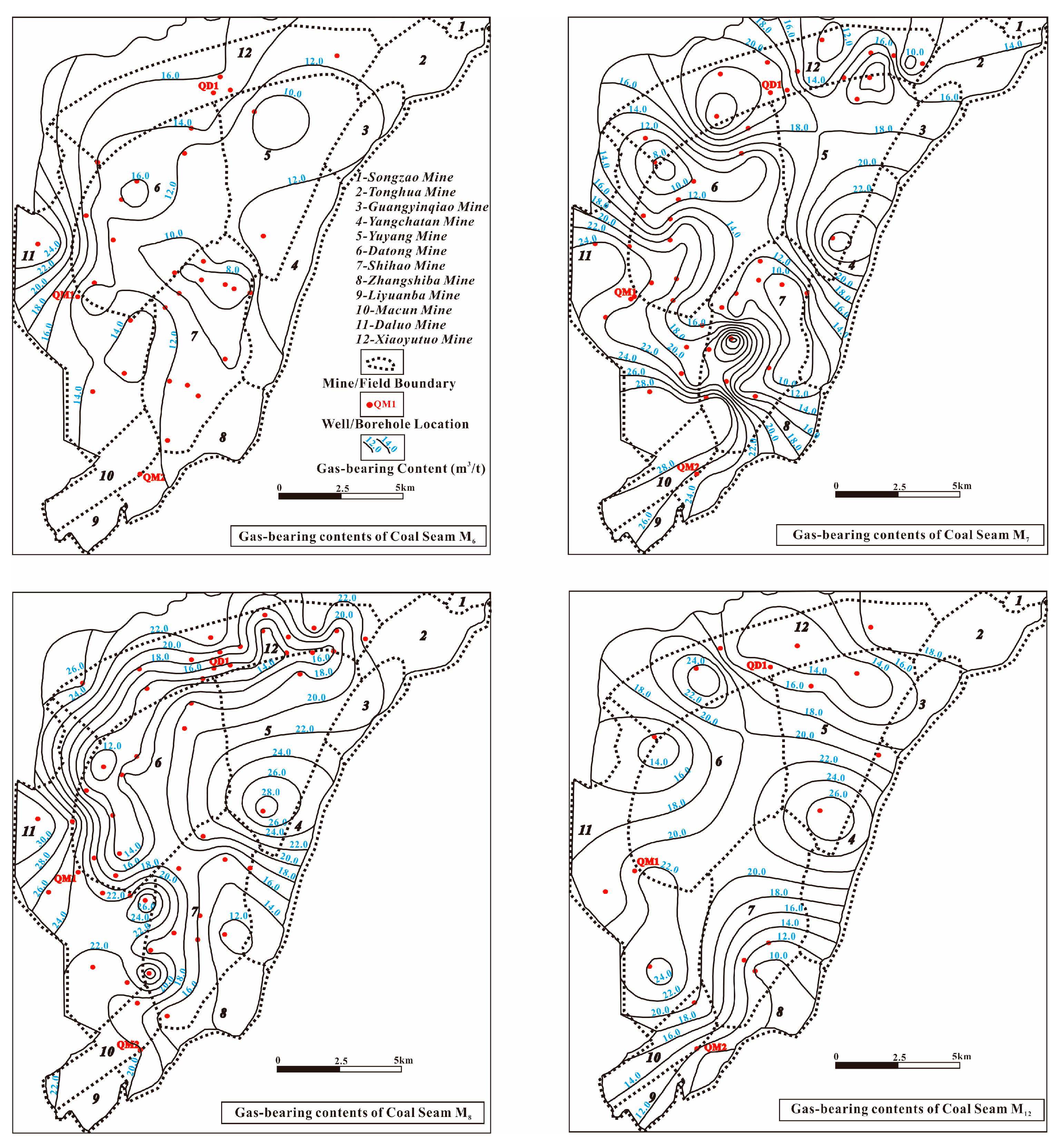

4.3.2. Distribution of the CBM Gas Contents

4.3.3. Adsorption–Desorption Characteristics

5. Discussion

5.1. Constraint of the Depositional Environment on Coal Formation

5.2. Tectono-Thermal Evolution Constraining the CBM Production Potential

5.3. Effect of the Regional Geological Structure on CBM Accumulation

6. Conclusions

- (1)

- The high-rank coals in the coal seams M6, M7, M8, and M12 of the Permian Longtan Formation from the Songzao coalfield have high vitrinite and TOC contents (60.1~69.0%, 31.49~51.32 wt%), high Tmax and R0 values (averaging 539 °C, 2.17%), low HI values (averaging 15.21 mg HC/g TOC), high porosity and low permeability, and comparatively high gas contents.

- (2)

- The frequent changes among shallow bay, tidal flat, and lagoon depositional environments triggered the formation of multiple coal seams and furnished the material basis for CBM generation. The multistage tectono-thermal evolution caused by the Emeishan mantle plume activity provided favorable temperatures and the necessary time for the overmaturation and thermal metamorphism of the coal seams and the acceleration of pyrolytic CBM formation.

- (3)

- The effective regional structures, such as the enclosed fold regions like the plunging crown of the anticline and the trap area between two anticlines, directly optimized the conditions for CBM enrichment in the high-rank coals.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, Q.Z.; Yang, Y.H.; Zuo, Y.Q.; Song, Y.; Guo, W.; Tang, F.; Ren, J.; Wang, G. On the scientific exploitation of high-rank CBM resources. Nat. Gas Ind. B 2020, 7, 403–409. [Google Scholar] [CrossRef]

- Sang, S.X.; Han, S.J.; Liu, S.Q.; Zhou, X.Z.; Li, M.X.; Hu, Q.J.; Zhang, C. Comprehensive study on the enrichment mechanism of coalbed methane in high rank reservoirs. J. China Coal Soc. 2022, 47, 388–403, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhu, Q.Z. Improving the production efficiency of high rank coal bed methane in the Qinshui Basin. Nat. Gas Ind. B 2022, 9, 477–486. [Google Scholar] [CrossRef]

- Shao, L.Y.; Hou, H.H.; Tang, Y.; Lu, J.; Qiu, H.J.; Wang, X.T.; Zhang, J.Q. Selection of strategic replacement areas for CBM exploration and development in China. Nat. Gas Ind. B 2015, 2, 211–221. [Google Scholar] [CrossRef][Green Version]

- Zou, C.N.; Yang, Z.; Huang, S.P.; Ma, F.; Sun, Q.P.; Li, F.H.; Pan, S.Q.; Tian, W.G. Resource types, formation, distribution and prospects of coal-measure gas. Pet. Explor. Dev. 2019, 46, 433–442. [Google Scholar] [CrossRef]

- Qin, Y. Strategic thinking on research of coal measure gas accumulation system and development geology. J. China Coal Soc. 2021, 46, 2387–2399, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, Y.; Pan, S.P.; Ning, S.Z.; Shao, L.Y.; Jing, Z.H.; Wang, Z.S. Coal measure metallogeny: Metallogenic system and implication for resource and environment. Sci. China Earth Sci. 2022, 65, 1211–1228. [Google Scholar] [CrossRef]

- Tang, S.L.; Tang, D.Z.; Xu, H.; Tao, S.; Li, S.; Geng, Y.G. Geological mechanisms of the accumulation of coalbed methane induced by hydrothermal fluids in the western Guizhou and eastern Yunnan regions. J. Nat. Gas Sci. Eng. 2016, 33, 644–656. [Google Scholar] [CrossRef]

- Qin, Y.; Moore, T.A.; Shen, J.; Yang, Z.B.; Shen, Y.L.; Wang, G. Resources and geology of coalbed methane in China: A review. Int. Geol. Rev. 2017, 60, 777–812. [Google Scholar] [CrossRef]

- Bi, C.Q.; Zhang, J.Q.; Shan, Y.S.; Hu, Z.F.; Wang, F.G.; Chi, H.P.; Tang, Y.; Yuan, Y.; Liu, Y.R. Geological characteristics and co-exploration and co-production methods of Upper Permian Longtan coal measure gas in Yangmeishu syncline, western Guizhou Province, China. China Geol. 2020, 3, 38–51, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Cao, D.Y.; Ning, S.Z.; Guo, A.J.; Li, H.T.; Chen, L.M.; Liu, K.; Tan, J.Q.; Zheng, Z.H. Coalfield structure and structural controls on coal in China. Int. J. Coal Sci. Technol. 2020, 7, 220–239. [Google Scholar] [CrossRef]

- Liu, D.M.; Jia, Q.F.; Cai, Y.D.; Gao, C.J.; Qiu, F.; Zhao, Z.; Chen, S.Y. A new insight into coalbed methane occurrence and accumulation in the Qinshui Basin, China. Gondwana Res. 2022, 111, 280–297. [Google Scholar] [CrossRef]

- Sang, S.X.; Zheng, S.J.; Yi, T.S.; Zhao, F.P.; Han, S.J.; Jia, J.L.; Zhou, X.Z. Coal measures superimposed gas reservoir and its exploration and development technology modes. Coal Geol. Explor. 2022, 50, 13–21, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Cheng, J.; Li, D.H.; Liu, D.; Yao, G.H.; Ren, S.C.; Li, C.L.; Zhang, L.H.; Tang, B.F. Coal-Forming Pattern and Quantitative Forecast of the Coal Resources in the Chongqing City; China University of Geosciences Press: Wuhan, China, 2015; 282p. (In Chinese) [Google Scholar]

- Zhu, Q.Z.; Zuo, Y.Q.; Yang, Y.H. How to solve the technical problems in the CBM development: A case study of a CMB gas reservoir in the southern Qinshui Basin. Nat. Gas Ind. B 2015, 35, 106–109. [Google Scholar] [CrossRef]

- Li, Z.T.; Liu, D.M.; Ranjith, P.G.; Cai, Y.D. Geological controls on variable gas concentrations: A case study of the northern Gujiao Block, northwestern Qinshui Basin, China. Mar. Pet. Geol. 2018, 92, 582–596. [Google Scholar] [CrossRef]

- Liang, J.T.; Huang, W.H.; Wang, H.L.; Blum, M.J.; Chen, J.; Wei, X.L.; Yang, G.Q. Organic geochemical and petrophysical characteristics of transitional coalmeasure shale gas reservoirs and their relationships with sedimentary environments: A case study from the Carboniferous-Permian Qinshui Basin, China. J. Pet. Sci. Eng. 2020, 184, 106510. [Google Scholar] [CrossRef]

- Zhu, Q.Z. New Technologies and Practice of Exploration and Development for High-Rank Coal Bed Methane; Petroleum Industry Press: Beijing, China, 2021; 268p. (In Chinese) [Google Scholar]

- Jiang, W.P.; Zhang, P.H.; Li, D.D.; Li, Z.C.; Wang, J.; Duan, Y.N. Reservoir characteristics and gas production potential of deep coalbed methane: Insights from the no. 15 coal seam in shouyang block, Qinshui Basin, China. Unconv. Resour. 2022, 2, 12–20. [Google Scholar] [CrossRef]

- Cao, L.; Yao, Y.; Cui, C.; Sun, Q. Characteristics of in-situ stress and its controls on coalbed methane development in the southeastern Qinshui Basin, North China. Energy Geosci. 2020, 1, 69–80. [Google Scholar] [CrossRef]

- Zhang, P.; Ya, M.; Liu, C.; Guo, Y.; Yan, X.; Cai, L.M.; Cheng, Z. In-situ stress of coal reservoirs in the Zhengzhuang area of the southern Qinshui Basin and its effects on coalbed methane development. Energy Geosci. 2023, 4, 100144. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zhang, Y.; Mei, Y.; Ding, R. Insights into moisture content in coals of different ranks by low field nuclear resonance. Energy Geosci. 2020, 1, 93–99. [Google Scholar] [CrossRef]

- Lv, Y.M.; Tang, D.Z.; Xu, H.; Luo, H.H. Production characteristics and the key factors in high-rank coalbed methane fields: A case study on the Fanzhuang Block, Southern Qinshui Basin, China. Int. J. Coal Geol. 2012, 96-97, 93–108. [Google Scholar] [CrossRef]

- Yao, H.F.; Kang, Z.Q.; Li, W. Deformation and reservoir properties of tectonically deformed coals. Pet. Explor. Dev. 2014, 41, 460–467. [Google Scholar] [CrossRef]

- Gui, B.L. Geological characteristics and enrichment controlling factors of coalbed methane in Liupanshui region. Acta Petrol. Sin. 1999, 20, 31–37, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Li, S.; Tang, D.Z.; Pan, Z.J.; Xu, H.; Guo, L.L. Evaluation of coalbed methane potential of different reservoirs in western Guizhou and eastern Yunnan, China. Fuel 2015, 139, 257–267. [Google Scholar] [CrossRef]

- Shen, Y.L.; Qin, Y.; Guo, Y.H.; Yi, T.S.; Yuan, X.X.; Shao, Y.B. Characteristics and sedimentary control of a coalbed methane-bearing system in Lopingian (late Permian) coal-bearing strata of western Guizhou Province. J. Nat. Gas Sci. Eng. 2016, 33, 8–17. [Google Scholar] [CrossRef]

- Luo, W.; Hou, M.C.; Liu, X.C.; Huang, S.G.; Chao, H.; Zhang, R.; Deng, X. Geological and geochemical characteristics of marine-continental transitional shale from the Upper Permian Longtan formation, Northwestern Guizhou, China. Mar. Pet. Geol. 2018, 89 Pt 1, 58–67. [Google Scholar] [CrossRef]

- Luo, Q.Y.; Xiao, Z.H.; Dong, G.Y.; Ye, X.Z.; Li, H.J.; Zhang, Y.; Ma, Y.; Ma, L.; Xu, Y.H. The geochemical characteristics and gas potential of the Longtan formation in the eastern Sichuan Basin, China. J. Pet. Sci. Eng. 2019, 179, 1102–1113. [Google Scholar] [CrossRef]

- Shen, S.Z.; Zhang, H.; Zhang, Y.C.; Yuan, D.X.; Chen, B.; He, W.H.; Mu, L.; Lin, W.; Wang, W.Q.; Chen, J.; et al. Permian integrative stratigraphy and timescale of China. Sci. China Earth Sci. 2019, 62, 154–188. [Google Scholar] [CrossRef]

- Zhang, Y.C.; Li, C.L.; Hong, X.F.; Yuan, Y.C.; Wang, X.H.; Huang, Y.A.; Tang, D.Y.; Zhu, C.S.; Gu, K.S.; Yuan, P.S. Sedimentary Environments and Coal Accumulation of Late Permian Coal Formation in Southern Sichuan, China; Guizhou Science and Technology Press: Guiyang, China, 1993; 204p, (In Chinese with English Abstract). [Google Scholar]

- China National Administration of Coal Geology. Sedimentary Environments and Coal Accumulation of Late Permian Coal Formation in Western Guizhou, Southern Sichuan and Eastern Yunnan, China; Chongqing University Press: Chongqing, China, 1996; 277p, (In Chinese with English Abstract).

- Dai, S.F.; Zhou, Y.P.; Ren, D.Y.; Wang, X.B.; Li, D.; Zhao, L. Geochemistry and mineralogy of the Late Permian coals from the Songzao Coalfield, Chongqing, southwestern China. Sci. China-Earth Sci. 2007, 50, 678–688. [Google Scholar] [CrossRef]

- Dai, S.F.; Wang, X.B.; Chen, W.M.; Li, D.H.; Chou, C.L.; Zhou, Y.P.; Zhu, C.S.; Li, H.; Zhu, X.W.; Xing, Y.W.; et al. A high-pyrite semianthracite of Late Permian age in the Songzao Coalfield, southwestern China: Mineralogical and geochemical relations with underlying mafic tuffs. Int. J. Coal Geol. 2010, 83, 430–445. [Google Scholar] [CrossRef]

- Dai, S.F.; Wang, X.B.; Zhou, Y.P.; Hower, J.C.; Li, D.H.; Chen, W.M.; Zhu, X.W.; Zou, J.H. Chemical and mineralogical compositions of silicic, mafic, and alkali tonsteins in the late Permian coals from the Songzao coalfield, Chongqing, Southwest China. Chem. Geol. 2011, 282, 29–44. [Google Scholar] [CrossRef]

- Dai, S.F.; Li, T.; Seredin, V.V.; Ward, C.R.; Hower, J.C.; Zhou, Y.P.; Zhang, M.Q.; Song, X.L.; Zhao, C.L. Origin of minerals and elements in the Late Permian coals, tonsteins, and host rocks of the Xinde Mine, Xuanwei, eastern Yunnan, China. Int. J. Coal Geol. 2014, 121, 53–78. [Google Scholar] [CrossRef]

- Zhao, L.; Ward, C.R.; French, D.; Graham, I.T. Mineralogical composition of Late Permian coal seams in the Songzao Coalfield, southwestern China. Int. J. Coal Geol. 2013, 116–117, 208–226. [Google Scholar] [CrossRef]

- Tian, X.S.; Shi, Z.J.; Yin, G.; Long, H.Y.; Wang, K. A correlation between the Large Igneous Provinces and mass extinctions: Constraint on the end-Guadalupian mass extinction and the Emeishan LIP in South China, eastern Tethys. Int. Geol. Rev. 2016, 58, 1215–1233. [Google Scholar] [CrossRef]

- Tian, X.S.; Shi, Z.J.; Yin, G.; Wang, Y.; Tan, Q. Carbonate diagenetic products and processes from various diagenetic environments in Permian paleokarst reservoirs: A case study of the limestone strata of Maokou formation in Sichuan Basin, South China. Carbonates Evaporites 2017, 32, 215–230. [Google Scholar] [CrossRef]

- Wu, X.J.; Li, Z.F.; Sun, D.F. Coal seam M8 stoping face water gushing characteristics and countermeasures in Songzao Mining Area. Coal Geol. China 2015, 27, 35–38, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Wu, G.D.; Zeng, C.L.; Cheng, J.; Guo, D.X.; Wang, J.; Wang, D.; Xie, Q.M. Characteristics of groundwater dynamic field and its effect on coalbed methane accumulation in Songzao mining area. Coal Geol. Explor. 2018, 46, 55–60, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- SY/T 6414-2014; Maceral Identification and Statistical Methods on Polished Surface of Whole Rocks. Petroleum Geology Exploration Standardization Committee: Beijing, China, 2014. (In Chinese)

- SY/T 5124-2012; Method of Determining Microscopically the Reflectance of Vitrinite in Sedimentary. Petroleum Geology Exploration Standardization Committee: Beijing, China, 2012. (In Chinese)

- GB/T 18602-2012; Rock Pyrolysis Analysis. Chinese Standard: Beijing, China, 2012. (In Chinese)

- SY/T 5162-2014; Analytical Method of Rock Sample by Scanning Electron Microscope. Petroleum Geology Exploration Standardization Committee: Beijing, China, 2014. (In Chinese)

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Kenneth, S.W.S. Characterization of porous solids: An introductory survey. Stud. Surf. Sci. Catal. 1991, 62, 1–9. [Google Scholar] [CrossRef]

- GB/T 21650.1-2008; Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption-Part 1: Mercury Porosimetry. Chinese Standard: Beijing, China, 2008. (In Chinese)

- SY/T 6385-2016; Porosity and Permeability Measurement under Overburden Pressure. Petroleum Geology Exploration Standardization Committee: Beijing, China, 2016. (In Chinese)

- GB/T 19559-2008; Method of Determining Coalbed Gas Content. Chinese Standard: Beijing, China, 2008. (In Chinese)

- Alafnan, S.; Awotunde, A.; Glatz, G.; Adjei, S.; Alrumaih, I.; Gowida, A. Langmuir adsorption isotherm in unconventional resources: Applicability and limitations. J. Pet. Sci. Eng. 2021, 207, 109172. [Google Scholar] [CrossRef]

- GB/T 13610-2014; Analysis of Natural Gas Composition-Gas Chromatography. Chinese Standard: Beijing, China, 2014. (In Chinese)

- Dai, S.F.; Bechtel, A.; Eble, C.F.; Flores, R.M.; French, D.; Graham, I.T.; Hood, M.M.; Hower, J.C.; Korasidis, V.A.; Moore, T.A.; et al. Recognition of peat depositional environments in coal: A review. Int. J. Coal Geol. 2020, 219, 103383. [Google Scholar] [CrossRef]

- Damoulianou, M.E.; Kalaitzidis, S.; Pasadakis, N. Turonian-Senonian organic-rich sedimentary strata and coal facies in Parnassos-Ghiona Unit, Central Greece: An assessment of palaeoenvironmental setting and hydrocarbon generation potential. Int. J. Coal Geol. 2022, 258, 104029. [Google Scholar] [CrossRef]

- Wang, E.Z.; Guo, T.L.; Liu, B.; Li, M.W.; Xiong, L.; Dong, X.X.; Zhang, N.X.; Wang, T. Lithofacies and pore features of marine-continental transitional shale and gas enrichment conditions of favorable lithofacies: A case study of Permian Longtan Formation in the Lintanchang area, southeast of Sichuan Basin, SW China. Pet. Explor. Dev. 2022, 49, 1310–1322. [Google Scholar] [CrossRef]

- Abbaszadeh Shahri, A.; Shan, C.L.; Larsson, S. A hybrid ensemble-based automated deep learning approach to generate 3D geo-models and uncertainty analysis. Eng. Comput. 2023. [Google Scholar] [CrossRef]

- Ali, J.R.; Thompson, G.M.; Zhou, M.F.; Song, X.Y. Emeishan large igneous province, SW China. Lithos 2005, 79, 475–489. [Google Scholar] [CrossRef]

- He, B.; Xu, Y.G.; Wang, Y.M.; Luo, Z.Y. Sedimentation and lithofacies paleogeography in Southwestern China before and after the Emeishan flood volcanism: New Insights into surface response to mantle plume activity. J. Geol. 2006, 114, 117–132. [Google Scholar] [CrossRef]

- Shellnutt, J.G. The Emeishan large igneous province: A synthesis. Geosci. Front. 2014, 5, 369–394. [Google Scholar] [CrossRef]

- Xu, Y.G.; Chung, S.L.; Jahn, B.M.; Wu, G.Y. Petrologic and geochemical constraints on the petrogenesis of Permian-Triassic Emeishan flood basalts in southwestern China. Lithos 2001, 58, 145–168. [Google Scholar] [CrossRef]

- Yang, J.H.; Cawood, P.A.; Du, Y.S.; Huang, H.; Huang, H.W.; Tao, P. Large Igneous Province and magmatic arc sourced Permian-Triassic volcanogenic sediments in China. Sediment. Geol. 2012, 261–262, 120–131. [Google Scholar] [CrossRef]

- Dai, S.F.; Ward, C.R.; Graham, I.T.; French, D.; Hower, J.C.; Zhao, L.; Wang, X.B. Altered volcanic ashes in coal and coal-bearing sequences: A review of their nature and significance. Earth-Sci. Rev. 2017, 175, 44–74. [Google Scholar] [CrossRef]

- He, L.J.; Xu, H.H.; Wang, J.Y. Thermal evolution and dynamic mechanism of the Sichuan Basin during the Early Permian-Middle Triassic. Sci. China-Earth Sci. 2011, 54, 1948–1954. [Google Scholar] [CrossRef]

- Zhu, C.Q.; Hu, S.B.; Qiu, N.S.; Rao, S.; Yuan, Y.S. The thermal history of the Sichuan Basin, SW China: Evidence from the deep boreholes. Sci. China Earth Sci. 2016, 59, 70–82. [Google Scholar] [CrossRef]

- Zhu, C.Q.; Hu, S.B.; Qiu, N.S.; Jiang, Q.; Rao, S.; Liu, S. Geothermal constraints on Emeishan mantle plume magmatism: Paleotemperature reconstruction of the Sichuan Basin, SW China. Int. J. Earth Sci. 2018, 107, 71–88. [Google Scholar] [CrossRef]

- Jiang, Q.; Qiu, N.S.; Zhu, C.Q. Heat flow study of the Emeishan large igneous province region: Implications for the geodynamics of the Emeishan mantle plume. Tectonophysics 2018, 724–725, 11–27. [Google Scholar] [CrossRef]

- He, L.J. Emeishan mantle plume and its potential impact on the Sichuan Basin: Insights from numerical modeling. Phys. Earth Planet. Inter. 2022, 323, 106841. [Google Scholar] [CrossRef]

- Zhou, Y.P.; Ren, Y.L.; Bohor, B.F. Origin and distribution of tonsteins in late Permian coal seams of Southwestern China. Int. J. Coal Geol. 1982, 2, 49–77. [Google Scholar] [CrossRef]

- Zhou, Y.P.; Bohor, B.F.; Ren, Y.L. Trace element geochemistry of altered volcanic ash layers (tonsteins) in Late Permian coal-bearing formations of eastern Yunnan and western Guizhou Provinces, China. Int. J. Coal Geol. 2000, 44, 305–324. [Google Scholar] [CrossRef]

- Shen, M.L.; Dai, S.F.; Rechaev, V.P.; French, D.; Graham, I.T.; Liu, S.D.; Chekryzhov, I.Y.; Tarasenko, I.A.; Zhao, S.W. Provenance changes for mineral matter in the latest Permian coals from western Guizhou, southwestern China, relative to tectonic and volcanic activity in the Emeishan Large Igneous Province and Paleo-Tethys region. Gondwana Res. 2023, 113, 71–88. [Google Scholar] [CrossRef]

- Chen, Z.S.; Wu, Y.D. Late Permian Emeishan basalt and coal-bearing formation in southern Sichuan area. Coal Geol. China 2010, 22, 14–18, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Feng, Q.Q.; Qiu, N.S.; Fu, X.D.; Li, W.Z.; Xu, Q.; Li, X.; Wang, J.S. Permian geothermal units in the Sichuan Basin: Implications for the thermal effect of the Emeishan mantle plume. Mar. Pet. Geol. 2021, 132, 105226. [Google Scholar] [CrossRef]

- He, B.; Xu, Y.G.; Chung, S.L.; Xiao, L.; Wang, Y.M. Sedimentary evidence for a rapid, kilometer-scale crustal doming prior to the eruption of the Emeishan food basalts. Earth Planet. Sci. Lett. 2003, 213, 391–405. [Google Scholar] [CrossRef]

- Tang, S.L.; Tang, D.Z.; Li, S.; Xu, H.; Tao, S.; Geng, Y.G.; Ma, L.; Zhu, X.G. Fracture system identification of coal reservoir and the productivity differences of CBM wells with different coal structures: A case in the Yanchuannan Block, Ordos Basin. J. Pet. Sci. Eng. 2018, 161, 175–189. [Google Scholar] [CrossRef]

- Ju, Y.W.; Qiao, F.; Wei, M.M.; Li, X.; Xu, F.Y.; Feng, G.R.; Li, Y.; Wu, C.F.; Cao, Y.X.; Li, G.F.; et al. Typical coalbed methane (CBM) enrichment and production modes under the control of regional structure and evolution. Coal Geol. Explor. 2022, 50, 2, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Song, Y.; Liu, H.L.; Feng, H.; Qin, S.F.; Liu, S.B.; Li, G.Z.; Zhao, M.J. Syncline reservoir pooling as a general model for coalbed methane (CBM) accumulations: Mechanisms and case studies. J. Nat. Gas Sci. Eng. 2012, 88–89, 5–12. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, D.Z.; Xu, H.; Li, Y.; Meng, Y.J. Structural controls on coalbed methane accumulation and high production models in the eastern margin of Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 23, 524–537. [Google Scholar] [CrossRef]

| Coal Seam Number | Depth of Coal Seams (m) | Thickness (m) | Coal Seam Interlayer Spacings (m) | Tonstein Thickness (m) | Lithological Characters of Coal Seam Roof and Floor | Stable and Recoverable | |

|---|---|---|---|---|---|---|---|

| Minimum–Maximum | Minimum–Maximum | Coal Seam Floor | Coal Seam Roof | ||||

| Average | Average | ||||||

| M6 | 400~1700 | 0.4~1.47 | 7.1 | 0.03~0.24 | mudstone–siltstone | mudstone–siltstone | relatively stable locally recoverable |

| 0.94 | 0.11 | ||||||

| M7 | 0.71~1.62 | 0.01~0.57 | mudstone–siltstone | mudstone | relatively stable locally recoverable | ||

| 1.11 | 6.6 | 0.26 | |||||

| M8 | 0.83~6.43 | 0.03~0.58 | sandstone–siltstone | mudstone–siltstone | stable recoverable | ||

| 3.04 | 22.6 | 0.24 | |||||

| M12 | 0.31~3.33 | 0.01~0.1 | siltstone–sandy mudstone | siltstone–sandy mudstone | relatively stable locally recoverable | ||

| 0.86 | 0.04 | ||||||

| Coal Seam Number | Coal Macerals from Main Coal Seams | |||||||

|---|---|---|---|---|---|---|---|---|

| Organic Component | Inorganic Component | |||||||

| Vitrinite (%) | Inertinite (%) | Subtotal (%) | Clay Mineral (%) | Sulfide Mineral (%) | Oxide Mineral (%) | Carbonate Mineral (%) | Subtotal (%) | |

| M7 | ||||||||

| M8 | ||||||||

| M12 | ||||||||

| Coal Seam Number | S1 (mg/g) | S2 (mg/g) | Tmax (°C) | HI (mg/g) | TOC (wt%) | R0 (%) |

|---|---|---|---|---|---|---|

| M6 | 0.0975 | 7.183 | 534 | 15.66 | 45.86 | 2.13 |

| M7 | 0.12 | 8.4797 | 535 | 16.52 | 51.32 | 2.09 |

| M8 | 0.0916 | 7.3502 | 535 | 14.81 | 49.63 | 2.24 |

| M12 | 0.1047 | 4.3565 | 549 | 13.83 | 31.49 | 2.2 |

| Coal Seam Number | Buried Depth (m) | Pore Volume (10−4cm3/g) | Pore Volume Ratio (%) | Well/Borehole Number | |||||

|---|---|---|---|---|---|---|---|---|---|

| V1 | V2 | V3 | Vt | V1/Vt | V2/Vt | V3/Vt | |||

| M6 | 886.20 | 7.87 | 3.47 | 8.56 | 19.90 | 39.55 | 17.44 | 43.02 | QM1 Well |

| 1661.85 | 11.12 | 6.43 | 22.00 | 39.55 | 28.12 | 16.26 | 55.56 | Daluo Mine, ZK1 | |

| 1381.45 | 15.29 | 6.99 | 20.30 | 42.58 | 35.91 | 16.42 | 47.67 | Daluo Mine, ZK4 | |

| 912.41 | 15.32 | 5.16 | 13.70 | 34.18 | 44.82 | 15.10 | 40.08 | Shihao Mine, SZK8-2 | |

| 1074.34 | 25.22 | 11.40 | 48.40 | 85.02 | 29.66 | 13.41 | 56.93 | Shihao Mine, SZK10-2 | |

| 1444.85 | 19.75 | 6.89 | 15.50 | 42.14 | 46.87 | 16.35 | 36.78 | Shihao Mine, SZK10-3 | |

| M7 | 1672.09 | 15.84 | 2.23 | 3.24 | 21.31 | 74.33 | 10.46 | 15.20 | Daluo Mine, ZK1 |

| 1393.31 | 15.73 | 2.50 | 5.98 | 24.21 | 64.97 | 10.33 | 24.70 | Daluo Mine, ZK4 | |

| 917.76 | 14.77 | 3.32 | 6.52 | 24.61 | 60.01 | 13.49 | 26.49 | Shihao Mine, SZK8-2 | |

| 1452.42 | 14.39 | 5.27 | 6.55 | 26.20 | 54.92 | 20.11 | 25.00 | Shihao Mine, SZK10-3 | |

| 1081.12 | 14.64 | 3.12 | 10.00 | 27.76 | 52.74 | 11.24 | 36.02 | Shihao Mine, SZK10-2 | |

| 898.70 | 14.20 | 3.76 | 8.05 | 26.01 | 54.59 | 14.46 | 30.95 | QM1 Well | |

| M8 | 1685.02 | 18.97 | 2.19 | 3.54 | 24.70 | 76.80 | 8.87 | 14.33 | Daluo Mine, ZK1 |

| 1400.17 | 14.54 | 3.16 | 9.11 | 26.81 | 54.23 | 11.79 | 33.98 | Daluo Mine, ZK4 | |

| 929.95 | 14.36 | 3.13 | 5.37 | 22.86 | 62.82 | 13.69 | 23.49 | Shihao Mine, SZK8-2 | |

| 1461.11 | 16.48 | 5.19 | 14.60 | 36.27 | 45.44 | 14.31 | 40.25 | Shihao Mine, SZK10-3 | |

| 1091.12 | 18.45 | 5.45 | 14.00 | 37.90 | 48.68 | 14.38 | 36.94 | Shihao Mine, SZK10-2 | |

| 905.90 | 16.68 | 1.48 | 2.34 | 20.50 | 81.37 | 7.22 | 11.41 | QM1 Well | |

| M12 | 1704.07 | 10.89 | 3.50 | 7.51 | 21.90 | 49.73 | 15.98 | 34.29 | Daluo Mine, ZK1 |

| 1431.64 | 27.24 | 2.74 | 6.32 | 36.30 | 75.04 | 7.55 | 17.41 | Daluo Mine, ZK4 | |

| 1114.23 | 20.42 | 10.90 | 24.50 | 55.82 | 36.58 | 19.53 | 43.89 | Shihao Mine, SZK10-2 | |

| 934.30 | 14.76 | 2.10 | 3.14 | 20.00 | 73.80 | 10.50 | 15.70 | QM1 Well | |

| Coal Seam Number | Burying Depth (m) | Porosity (%) | Permeability (mD) | Well/Borehole Number |

|---|---|---|---|---|

| M6 | 1662 | 4.25 | 0.0063 | Daluo Mine, ZK1 |

| 1381 | 4.32 | 0.0065 | Daluo Mine, ZK4 | |

| 1445 | 3.82 | 0.0077 | Shihao Mine, SZK10-3 | |

| 912 | 4.57 | 0.0050 | Shihao Mine, SZK8-2 | |

| 1074 | 4.67 | 0.0063 | Shihao Mine, SZK10-2 | |

| M7 | 899 | 2.36 | 0.0221 | QM1 Well |

| 1672 | 5.01 | 0.0062 | Daluo Mine, ZK1 | |

| 1393 | 3.95 | 0.0054 | Daluo Mine, ZK4 | |

| 918 | 5.08 | 0.0059 | Shihao Mine, SZK8-2 | |

| 1452 | 4.68 | 0.0086 | Shihao Mine, SZK10-3 | |

| 1081 | 3.54 | 0.0072 | Shihao Mine, SZK10-2 | |

| M8 | 1685 | 3.95 | 0.0043 | Daluo Mine, ZK1 |

| 930 | 5.26 | 0.0068 | Shihao Mine, SZK8-2 | |

| 1461 | 4.16 | 0.0094 | Shihao Mine, SZK10-3 | |

| 1091 | 4.19 | 0.0031 | Shihao Mine, SZK10-2 | |

| 1400 | 3.94 | 0.0050 | Daluo Mine, ZK4 | |

| M12 | 1704 | 4.31 | 0.0075 | Daluo Mine, ZK1 |

| 1432 | 4.21 | 0.0042 | Daluo Mine, ZK4 | |

| 1114 | 5.18 | 0.0029 | Shihao Mine, SZK10-2 |

| Well Number | Coal Seam Number | Content without Air of Components (Volume)/% | |||

|---|---|---|---|---|---|

| N2 | CO2 | CH4 | C2+ | ||

| QD1 Well | M6 | 6.90 | 0.88 | 92.18 | 0.04 |

| QM1 Well | 2.56 | 1.12 | 96.21 | 0.11 | |

| QM2 Well | 7.81 | 0.90 | 91.12 | 0.18 | |

| QM2 Well | M7 | 1.51 | 0.90 | 97.44 | 0.16 |

| QM1 Well | 9.54 | 0.65 | 89.71 | 0.10 | |

| QD1 Well | M8 | 6.26 | 0.89 | 92.84 | 0.01 |

| QM1 Well | 6.72 | 1.05 | 92.15 | 0.08 | |

| QM1 Well | 0.00 | 0.50 | 99.41 | 0.09 | |

| QM2 Well | 9.71 | 1.55 | 88.62 | 0.13 | |

| QM2 Well | 8.69 | 1.24 | 89.92 | 0.15 | |

| QM2 Well | 2.08 | 1.24 | 96.50 | 0.18 | |

| QD1 Well | M12 | 3.72 | 1.23 | 95.05 | 0.00 |

| QM2 Well | 1.21 | 0.83 | 97.74 | 0.23 | |

| QM2 Well | 0.45 | 0.53 | 98.85 | 0.17 | |

| QM1 Well | 0.35 | 0.48 | 99.03 | 0.13 | |

| Coal Mine | Coal Seam | Average Depth (m) | Average Gas Content (m3/t) |

|---|---|---|---|

| Xiaoyutuo | M6 | 776.98 | 12.47 |

| M7 | 850.29 | 15.42 | |

| M8 | 918.95 | 21.45 | |

| M12 | 1057.1 | 18.14 | |

| Datong | M6 | 533.39 | 11.99 |

| M7 | 640.27 | 15.92 | |

| M8 | 690.34 | 16.98 | |

| Daluo | M7 | 1152.59 | 26.14 |

| M8 | 1549.19 | 26.25 | |

| M12 | 1587.06 | 28.18 | |

| Shihao | M6 | 885.48 | 11.17 |

| M7 | 1025.49 | 17.42 | |

| M8 | 1076.72 | 17.02 | |

| M12 | 1079.65 | 11.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Wang, J.; Tian, X.; Guo, D.; Zhang, Y.; Zeng, C. Geological Constraints on the Gas-Bearing Properties in High-Rank Coal: A Case Study of the Upper Permian Longtan Formation from the Songzao Coalfield, Chongqing, Southwest China. Energies 2024, 17, 1262. https://doi.org/10.3390/en17051262

Chen D, Wang J, Tian X, Guo D, Zhang Y, Zeng C. Geological Constraints on the Gas-Bearing Properties in High-Rank Coal: A Case Study of the Upper Permian Longtan Formation from the Songzao Coalfield, Chongqing, Southwest China. Energies. 2024; 17(5):1262. https://doi.org/10.3390/en17051262

Chicago/Turabian StyleChen, Dishu, Jinxi Wang, Xuesong Tian, Dongxin Guo, Yuelei Zhang, and Chunlin Zeng. 2024. "Geological Constraints on the Gas-Bearing Properties in High-Rank Coal: A Case Study of the Upper Permian Longtan Formation from the Songzao Coalfield, Chongqing, Southwest China" Energies 17, no. 5: 1262. https://doi.org/10.3390/en17051262

APA StyleChen, D., Wang, J., Tian, X., Guo, D., Zhang, Y., & Zeng, C. (2024). Geological Constraints on the Gas-Bearing Properties in High-Rank Coal: A Case Study of the Upper Permian Longtan Formation from the Songzao Coalfield, Chongqing, Southwest China. Energies, 17(5), 1262. https://doi.org/10.3390/en17051262