A New Method for Determining Economic Well Pattern Density and Infilling Time of Tight Gas Reservoirs

Abstract

1. Introduction

2. Construction of Evaluation Standards and Numerical Model

2.1. Evaluation Standards

- (1)

- Average single well Estimated Ultimate Recovery (EUR): Calculated considering the cost of drilling, completion, and surface projects, the economic limit for the EUR of a basic well is 1600 × 104 m3.

- (2)

- Production interference ratio:

- (1)

- Production increment of an infilled well: Calculated with the cost of drilling and completion, which is independent of the surface projects, the economic limit production increment of an infilled well is 1100 × 104 m3.

- (2)

- Infilling time standard: The adjustment time is defined by the recovery of the sand body following the infilling of a well. The infilling time, which marks the economically effective period, is determined by the maximum sand body recovery that meets the gas production increment standard. In other words, infilling a well before reaching this infilling time is considered economically effective.

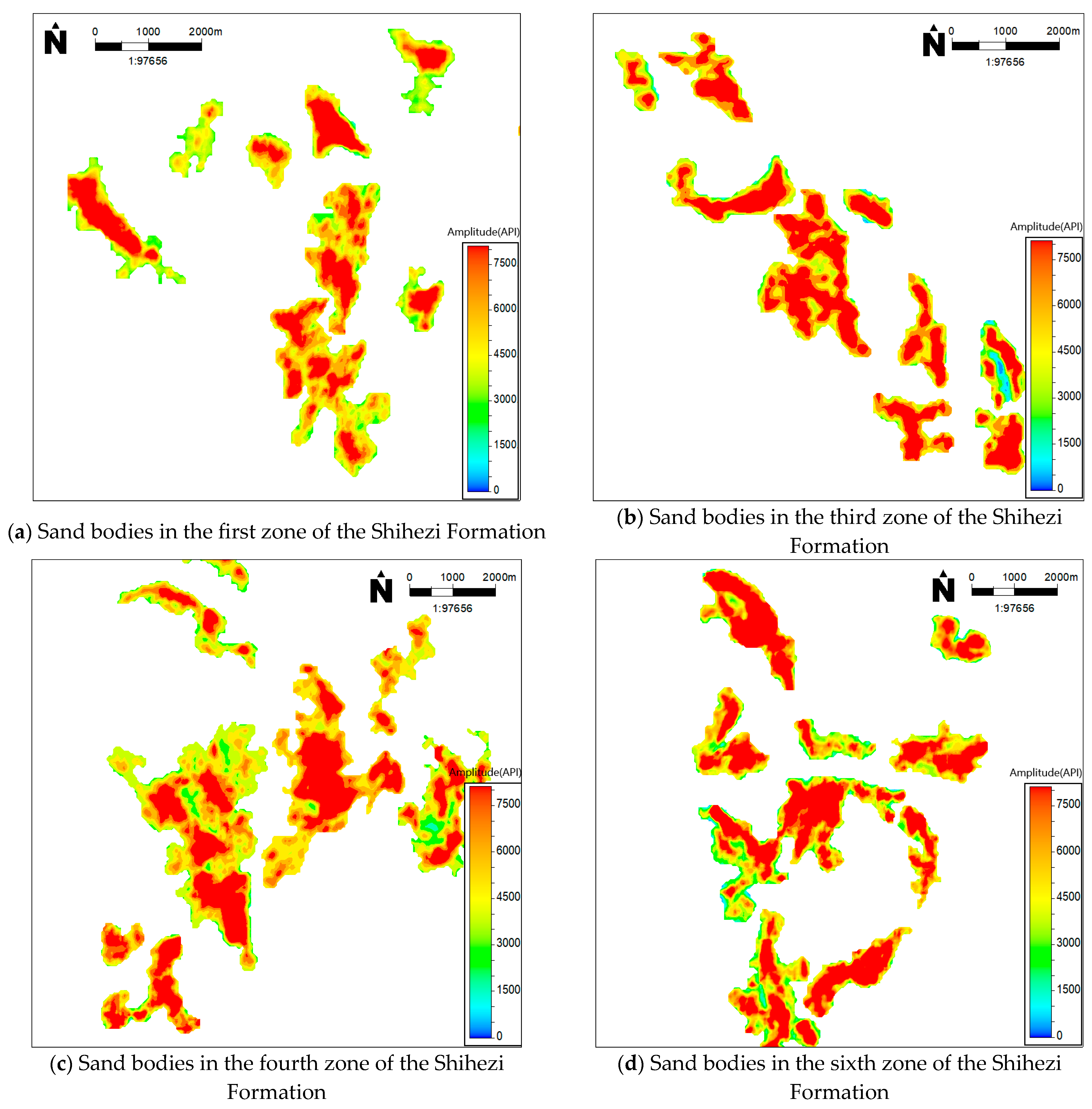

2.2. Geologic Setting

2.3. Data and Methods

2.4. Numerical Model

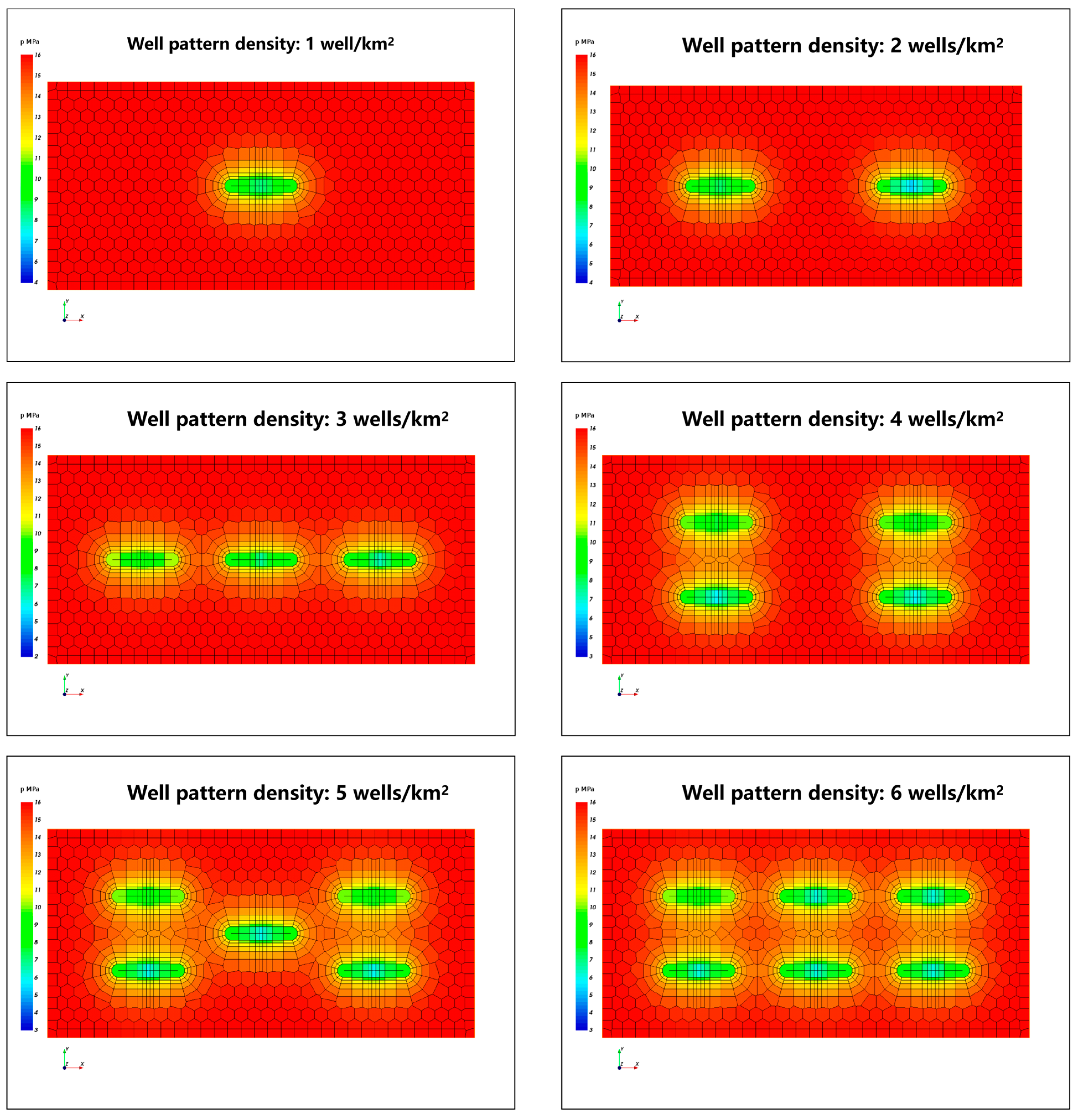

3. Analysis of Numerical Simulation

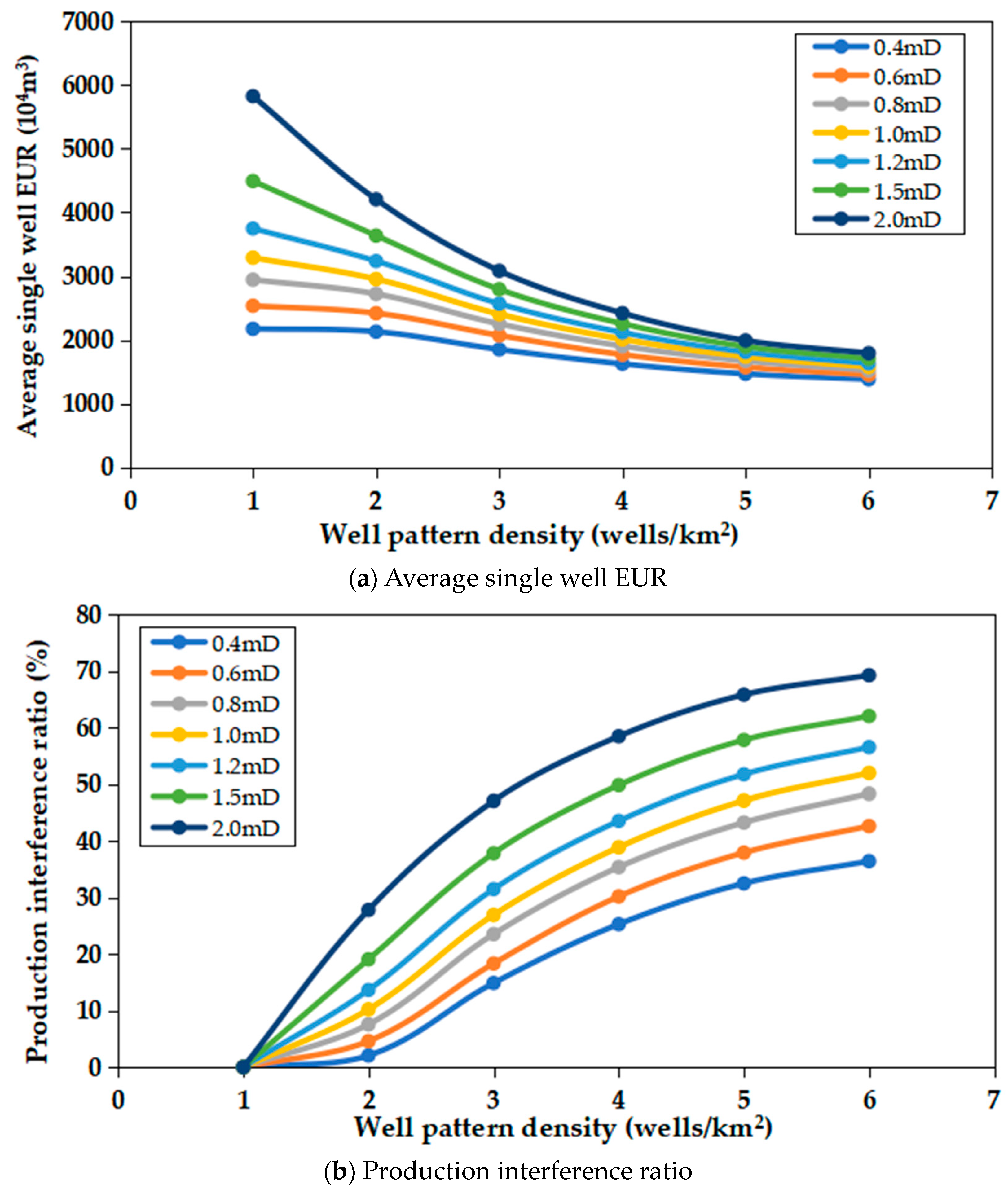

3.1. Simulation Results of Economic Well Pattern Density

3.1.1. Sensitivity Analysis of Permeability and Economic Well Pattern Density

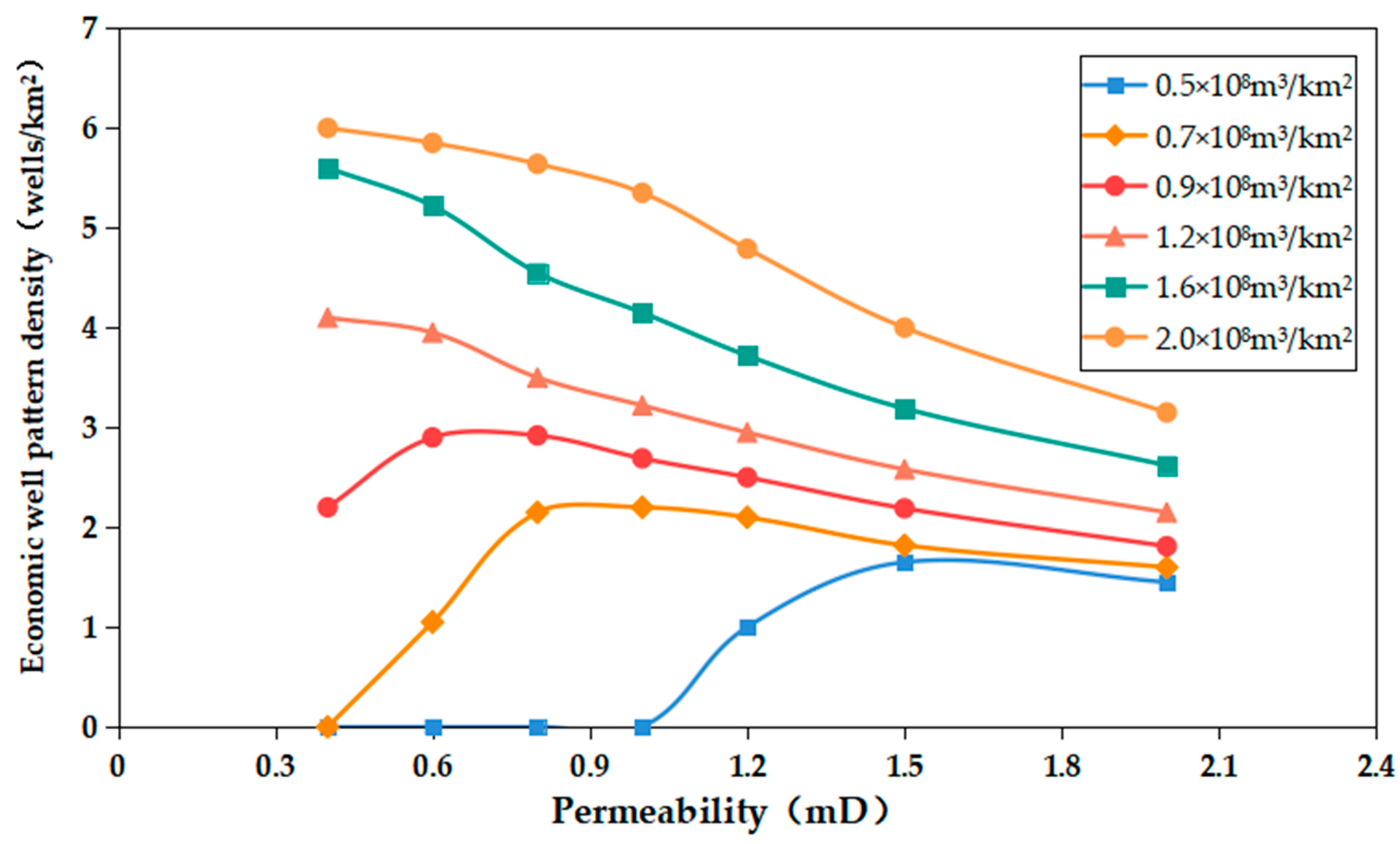

3.1.2. Sensitivity Analysis of Reserve Abundance and Economic Well Pattern Density

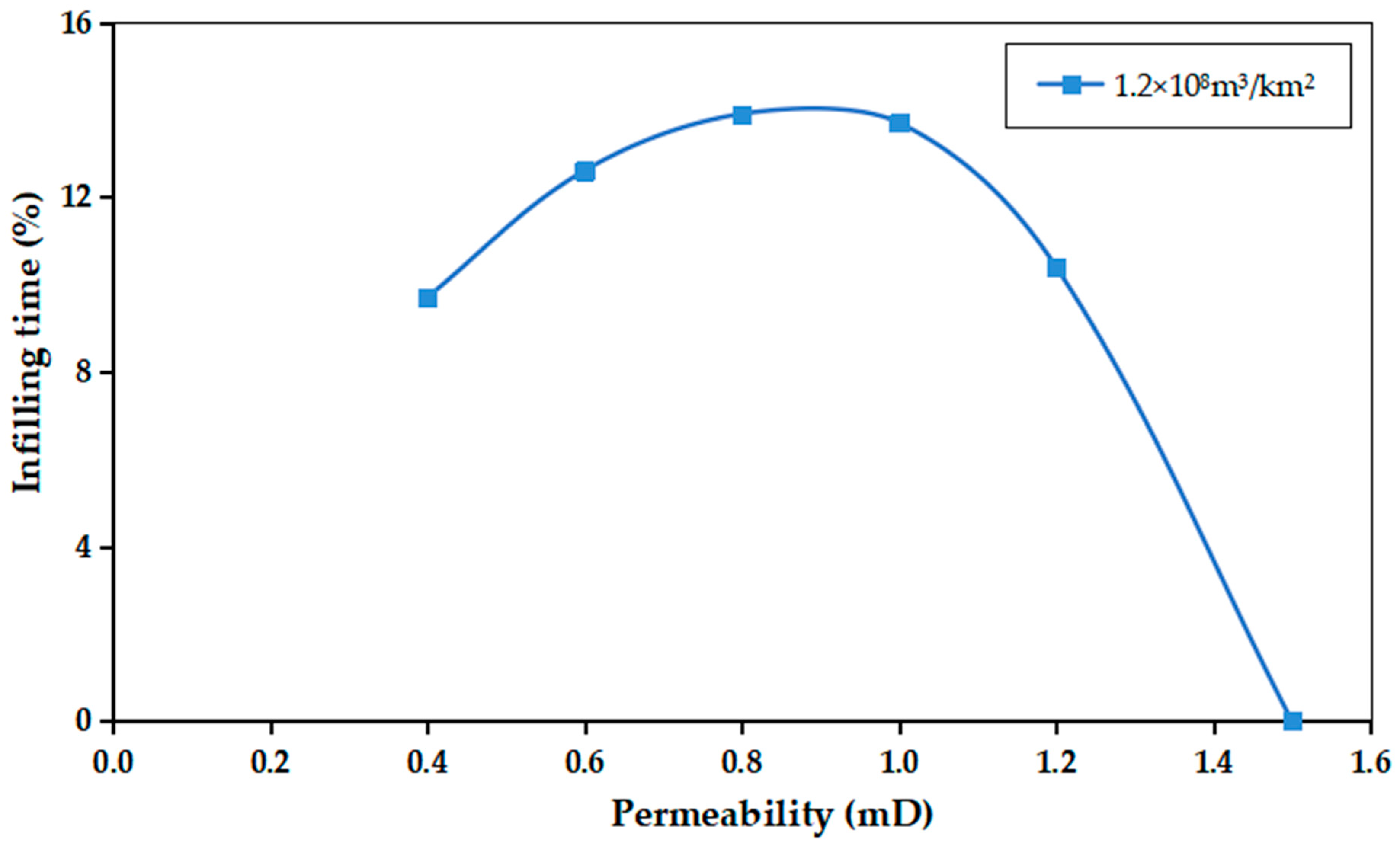

3.2. Simulation Results of Infilling Time

3.2.1. Sensitivity Analysis of Permeability and Infilling Time

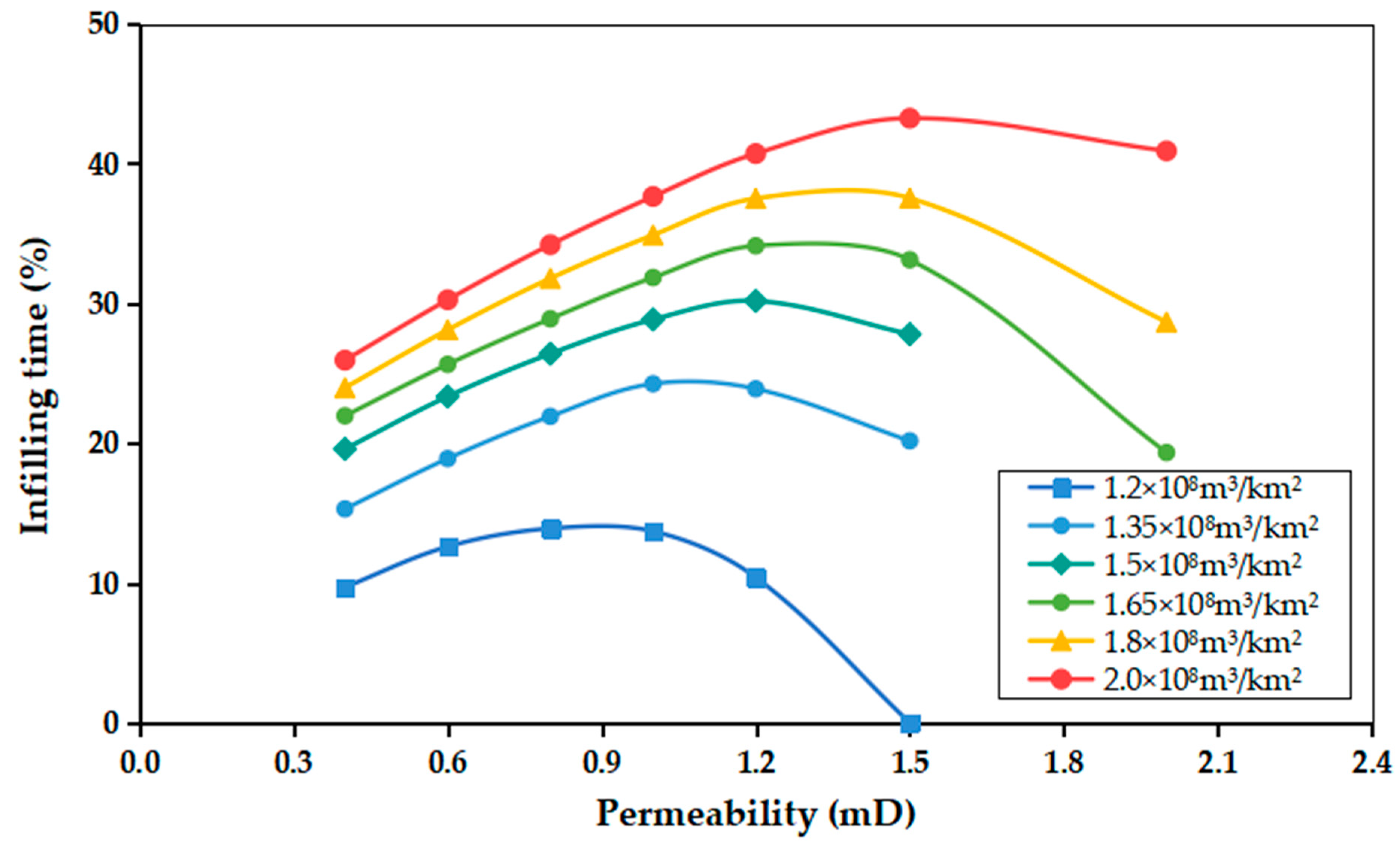

3.2.2. Sensitivity Analysis of Reserve Abundance and Infilling Time

4. Example and Application

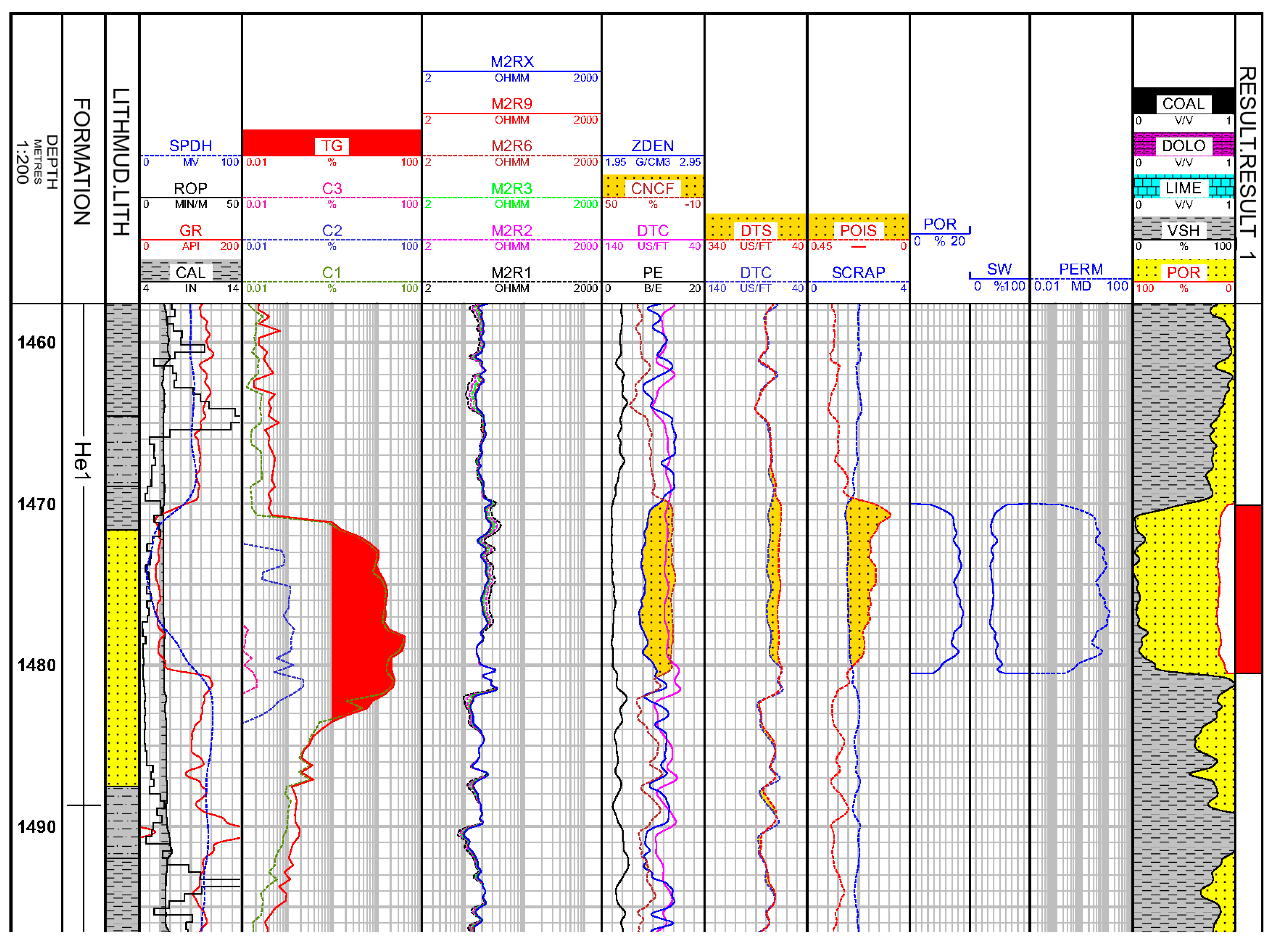

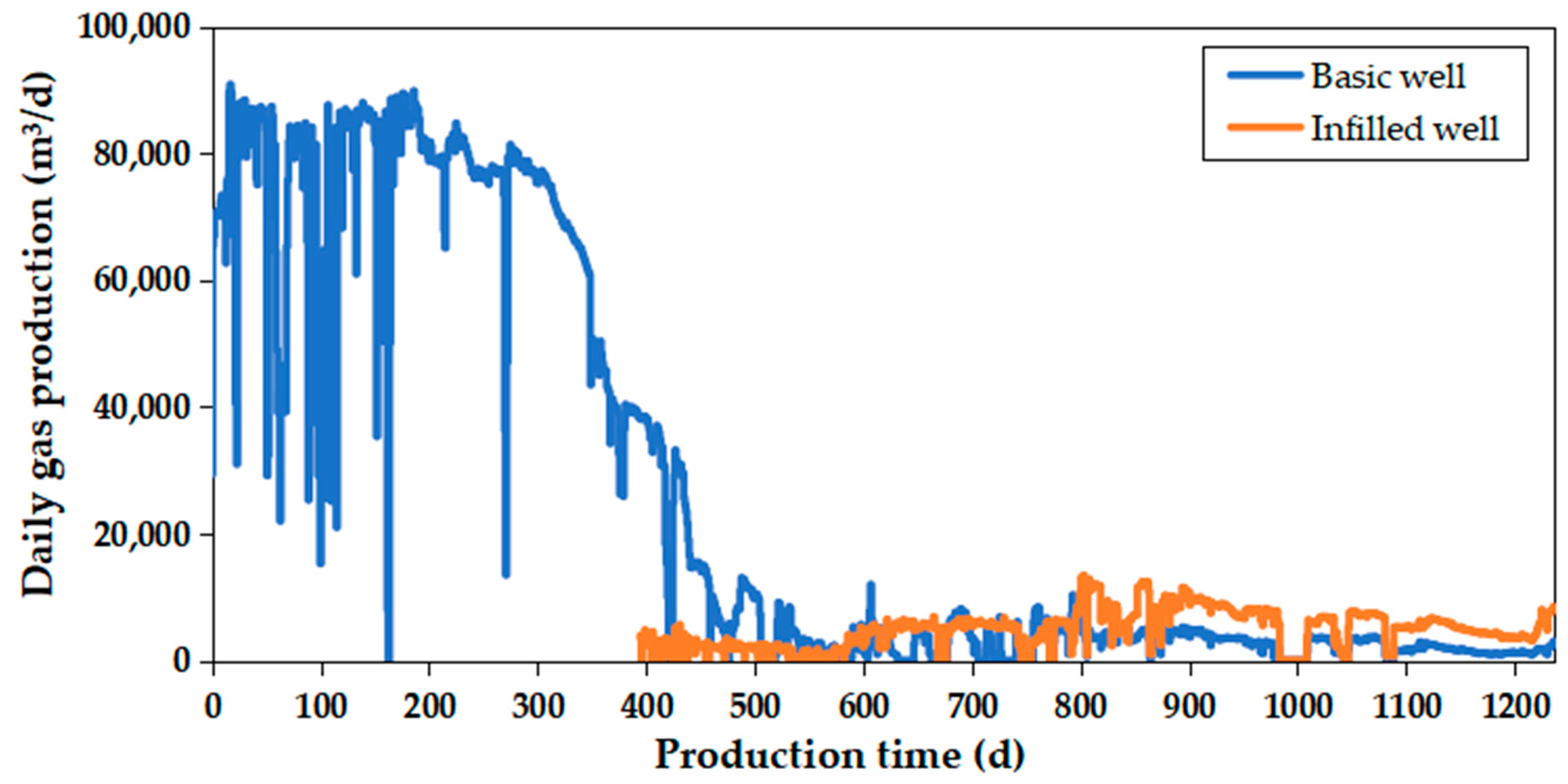

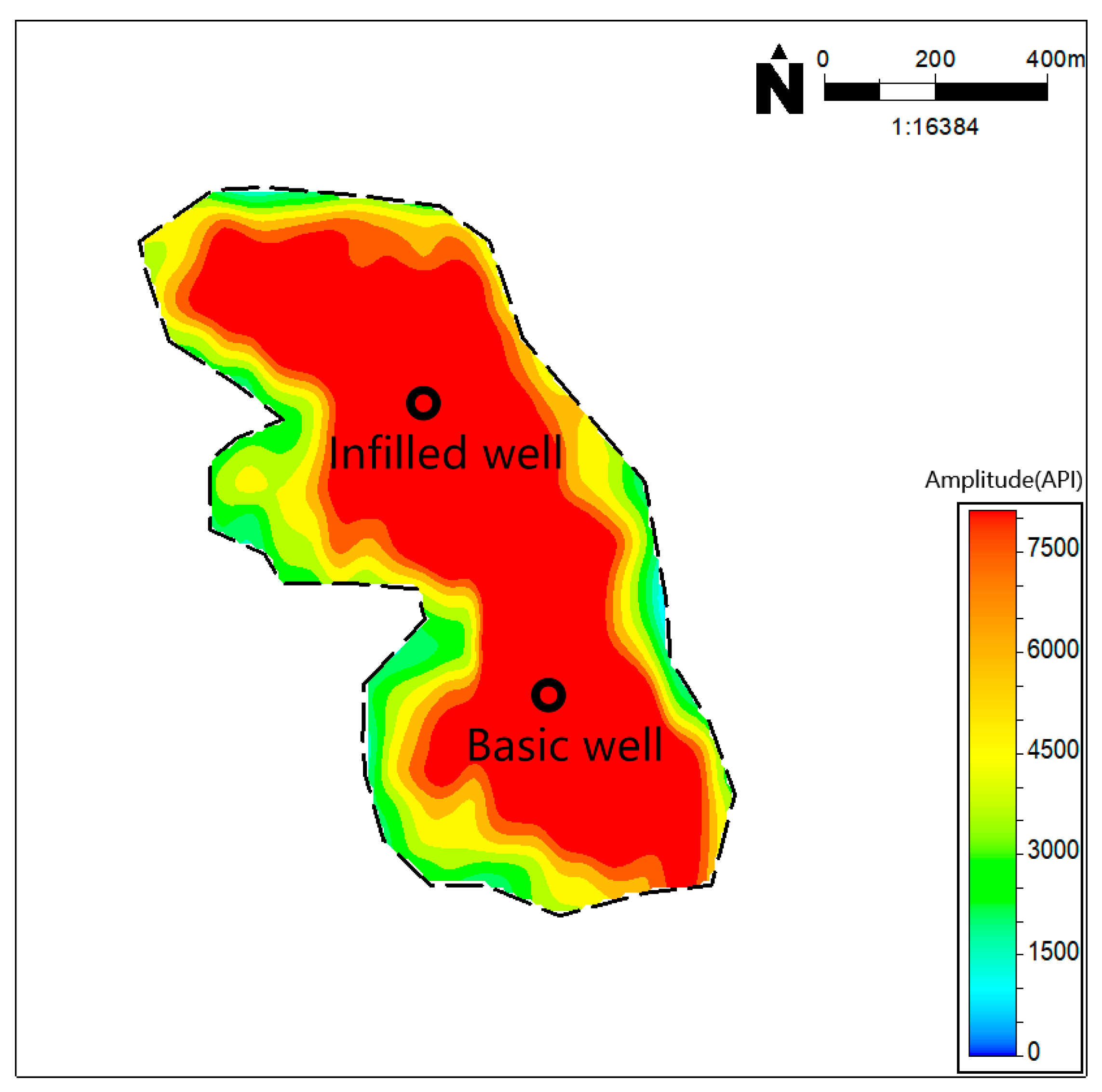

4.1. Analysis of Economic Well Pattern Density and Infilling Time—Taking the X-62 Well Site as an Example

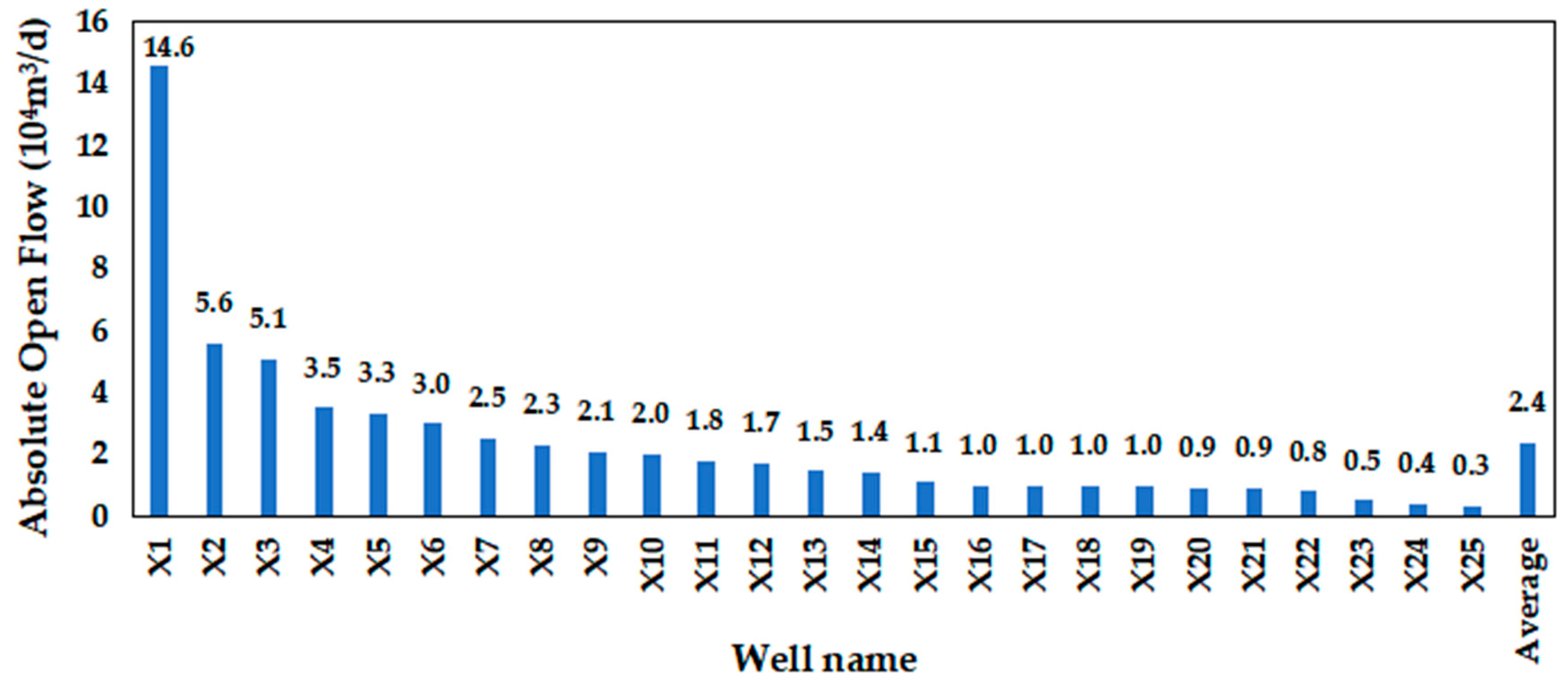

4.2. Application in the Linxing–Shenfu Gas Field

4.3. Discussion

5. Conclusions

- (1)

- In consideration of construction investment, gas prices, and associated taxes, we formulated evaluation standards encompassing the average single well EUR, production interference ratio, and production increment of the infilled well. For the first time, we introduced the evaluation index “infilling time” to provide a quantitative characterization of the maximum recovery that aligns with the production increment standard of the infilled well.

- (2)

- A relationship chart depicting economic well pattern density, reserve abundance, and permeability was developed, based on the fine characterization of the sand body. This chart presents a novel method for promptly determining economic well pattern density when both the reserve abundance and permeability of the sand body are provided.

- (3)

- A relationship chart depicting infilling time, reserve abundance, and permeability was developed, based on the fine characterization of the sand body. This chart presents a novel method for promptly determining infilling time when both the reserve abundance and permeability of the sand body are provided.

- (4)

- The application of the new method for determining economic well pattern density and infilling time has been successfully implemented in the Linxing–Shenfu gas field. As a consequence of applying this method, a total of 47 infilled wells have been drilled, with a projected cumulative production capacity of 1.24 × 108 m3 a year. Out of these, 25 infilled wells have been brought into production, boasting an average AOF of 2.4 × 104 m3/d. These results affirm the effectiveness and suitability of the new method for the conditions prevailing in the Linxing–Shenfu gas field.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, L. Development of natural gas industry in China: Review and prospect. Nat. Gas Ind. B 2022, 9, 187–196. [Google Scholar] [CrossRef]

- Sun, L.; Zou, C.; Jia, A.; Wei, Y.; Zhu, R.; Wu, S.; Guo, Z. Development characteristics and orientation of tight oil and gas in China. Pet. Explor. Dev. 2019, 46, 1073–1087. [Google Scholar] [CrossRef]

- Dai, J.; Ni, Y.; Wu, X. Tight gas in China and its significance in exploration and exploitation. Pet. Explor. Dev. 2012, 39, 277–284. [Google Scholar] [CrossRef]

- Jia, A.; Wei, Y.; Guo, Z.; Wang, G.; Meng, D.; Huang, S. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. B 2022, 9, 467–476. [Google Scholar] [CrossRef]

- Gao, H.; Li, H.A. Engineering, Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones. J. Nat. Gas Sci. Eng. 2016, 28, 536–547. [Google Scholar] [CrossRef]

- Li, Y.; Xiao, F.; Xu, W.; Wang, J. Performance evaluation on water-producing gas wells based on gas & water relative permeability curves: A case study of tight sandstone gas reservoirs in the Sulige gas field, Ordos Basin. Nat. Gas Ind. B 2016, 3, 52–58. [Google Scholar]

- Wu, Z.; Jiang, Q.; Zhou, Y.; He, Y.; Sun, Y.; Tian, W.; Zhou, C.; An, W. Key technologies and orientation of EGR for the Sulige tight sandstone gas field in the Ordos Basin. Nat. Gas Ind. B 2023, 10, 591–601. [Google Scholar] [CrossRef]

- Farouk, S.; Sen, S.; Saada, S.A.; Eldosouky, A.M.; Elsayed, R.; Kassem, A.A.; Al-Kahtany, K.; Abdeldaim, A. Characterization of Upper Cretaceous Matulla and Wata Clastic Reservoirs from October field, Central Gulf of Suez, Egypt. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 106. [Google Scholar] [CrossRef]

- Lotfy, N.M.; Farouk, S.; Hakimi, M.H.; Ahmad, F.; El Shennawy, T.; El Nady, M.M.; Salama, A.; Shehata, A.M. Biomarker and isotopic characteristics of Miocene condensates and natural gases, West Delta deep marine concession, Eastern Mediterranean, Egypt. Sci. Rep. 2024, 14, 235. [Google Scholar] [CrossRef]

- McCain, W.D.; Voneiff, G.W.; Hunt, E.R.; Semmelbeck, M.E. A tight gas field study: Carthage (Cotton Valley) Field. In Proceedings of the SPE Unconventional Resources Conference/Gas Technology Symposium, Calgary, AB, Canada, 28 June 1993. [Google Scholar]

- Voneiff, G.; Cipolla, C. A new approach to large-scale infill evaluations applied to the OZONA (Canyon) gas sands. In Proceedings of the SPE Permian Basin Oil and Gas Recovery Conference, Midland, TX, USA, 27–29 March 1996. [Google Scholar]

- Fu, N.; Tang, H.; Liu, Q. Technologies for fine adjustment in the middle-later development stage of low permeability tight sandstone gas reservoirs. J. Southwest Univ. (Sci. Technol. Ed.) 2018, 40, 136. [Google Scholar]

- Jia, A.; Wang, G.; Meng, D.; Guo, Z.; Ji, G.; Cheng, L. Well pattern infilling strategy to enhance oil recovery of giant low-permeability tight gasfield: A case study of Sulige gasfield, Ordos Basin. Acta Pet. Sin. 2018, 39, 802. [Google Scholar]

- Lu, T.; Liu, Y.; Wu, L.; Wang, X. Challenges to and countermeasures for the production stabilization of tight sandstone gas reservoirs of the Sulige Gasfield, Ordos Basin. Nat. Gas Ind. B 2015, 2, 323–333. [Google Scholar] [CrossRef]

- Li, Y.; Xu, W.; Xiao, F.; Liu, L.; Liu, S.; Zhang, W. Optimization of a development well pattern based on production performance: A case study of the strongly heterogeneous Sulige tight sandstone gas field, Ordos Basin. Nat. Gas Ind. B 2015, 2, 95–100. [Google Scholar] [CrossRef][Green Version]

- Gao, S.; Liu, H.; Ye, L.; Wen, Z.; Zhu, W.; Zhang, C. A new method for well pattern density optimization and recovery efficiency evaluation of tight sandstone gas reservoirs. Nat. Gas Ind. B 2020, 7, 133–140. [Google Scholar] [CrossRef]

- Li, Q.; Gao, S.-S.; Liu, H.-X.; Ye, L.-Y.; Wu, H.-H.; Zhu, W.-Q.; Zhang, J.; Yang, Y.; Yang, M.-H. Well network densification and recovery evaluation of tight sandstone gas reservoirs. Nat. Gas Geosci. 2020, 31, 865–876. [Google Scholar]

- Guo, Z.; Wang, G.; Xia, Y.; Yang, B.; Han, J. Technical countermeasure of well pattern optimization in multi-layer lenticular tight sandstone gas field. Nat. Gas Geosci. 2022, 33, 1883–1894. [Google Scholar]

- Cheng, M.; Xue, W.; Guo, Z.; Hou, M.; Wang, C. Development of Large-Scale Tight Gas Sandstone Reservoirs and Recommendations for Stable Production—The Example of the Sulige Gas Field in the Ordos Basin. Sustainability 2023, 15, 9933. [Google Scholar] [CrossRef]

- Ji, G.; Jia, A.; Meng, D.; Guo, Z.; Wang, G.; Cheng, L.; Zhao, X. Technical strategies for effective development and gas recovery enhancement of a large tight gas field: A case study of Sulige gas field, Ordos Basin, NW China. Pet. Explor. Dev. 2019, 46, 629–641. [Google Scholar] [CrossRef]

- Xie, S.; Lan, Y.; Jiao, Y.; Liu, H.; Wu, Y. Research of Dynamic Reserves Estimation Methods for Complex Gas Wells in Low Permeability and Tight Gas Reservoir. IOP Conf. Ser. Earth Environ. Sci. 2019, 237, 042002. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Gao, S.; Liu, H.; Ye, L.; Wu, H.; Zhu, W.; An, W. Well network optimization and recovery evaluation of tight sandstone gas reservoirs. J. Pet. Sci. Eng. 2020, 196, 107705. [Google Scholar] [CrossRef]

- Guo, Z.; Jia, A.; Ji, G.; Ning, B.; Wang, G.; Meng, D. Reserve classification and well pattern infilling method of tight sandstone gasfield: A case study of Sulige gasfield. Acta Pet. Sin. 2017, 38, 1299. [Google Scholar]

- Sarhan, M.A. Technology, Gas-generative potential for the post-Messinian megasequence of Nile Delta Basin: A case study of Tao Field, North Sinai Concession, Egypt. J. Pet. Explor. Prod. Technol. 2022, 12, 925–947. [Google Scholar] [CrossRef]

- Farouk, S.; Sen, S.; Ahmad, F.; Al-Kahtany, K.; Benmamar, S.; Abdeldaim, A. Assessment of pore pressure in the Oligocene–Pleistocene stratigraphy of the West Delta Deep Marine, offshore Nile Delta, Egypt. Mar. Geophys. Res. 2024, 45, 6. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, Z.; Cheng, H.; Qin, Q.; Wang, M. Research of tight gas reservoir simulation technology. IOP Conf. Ser. Earth Environ. Sci. 2021, 804, 022046. [Google Scholar] [CrossRef]

- Zhang, H.; Bai, Y.; Xu, B.; Du, X.; Gai, S. Numerical Simulation and Sensitivity Analysis of Hydraulic Fracturing in Multilayered Thin Tight Sandstone Gas Reservoir. Geofluids 2023, 2023, 8310206. [Google Scholar] [CrossRef]

| Size (m) | Area (km2) | Thickness (m) | Porosity (%) | Gas Saturation (%) | Initial Pressure (MPa) |

|---|---|---|---|---|---|

| 1430 × 700 | 1.0 | 13.0 | 11.0 | 55.0 | 15.0 |

| Logging permeability (mD) | 0.4 | 0.6 | 0.8 | 1.0 | 1.2 | 1.5 | 2.0 |

| Effective permeability (mD) | 0.15 | 0.19 | 0.24 | 0.29 | 0.36 | 0.50 | 0.86 |

| Lithology | Top Depth (m) | Bottom Depth (m) | Thickness (m) | Sg (%) | Poro (%) | Perm (mD) |

|---|---|---|---|---|---|---|

| Mudstone | 1453.1 | 1470.1 | 17.0 | 0 | 0 | 0.01 |

| Gas sandstone | 1470.1 | 1480.5 | 10.4 | 63.6 | 15.7 | 2.00 |

| Mudstone | 1480.5 | 1498.4 | 17.9 | 0 | 0 | 0.01 |

| Sand body properties | ||||

| Area (km2) | Reserve (108 m3) | Reserve abundance (108 m3/km2) | Well pattern density (wells/km2) | Permeability (mD) |

| 0.64 | 0.83 | 1.3 | 1.6 | 2.0 |

| Well production data | ||||

| Well | Recovery before infilling (%) | Cumulative gas production before infilling (104 m3) | Predicting EUR before infilling (104 m3) | Predicting EUR after infilling (104 m3) |

| Basic well | 34 | 2772 | 4250 | 3436 |

| Infilled well | \ | \ | \ | 771 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Fang, M.; Li, H.; Cao, G.; Fan, W.; Wang, B. A New Method for Determining Economic Well Pattern Density and Infilling Time of Tight Gas Reservoirs. Energies 2024, 17, 1223. https://doi.org/10.3390/en17051223

Wang D, Fang M, Li H, Cao G, Fan W, Wang B. A New Method for Determining Economic Well Pattern Density and Infilling Time of Tight Gas Reservoirs. Energies. 2024; 17(5):1223. https://doi.org/10.3390/en17051223

Chicago/Turabian StyleWang, Daye, Maojun Fang, Hao Li, Guangsheng Cao, Weipeng Fan, and Bo Wang. 2024. "A New Method for Determining Economic Well Pattern Density and Infilling Time of Tight Gas Reservoirs" Energies 17, no. 5: 1223. https://doi.org/10.3390/en17051223

APA StyleWang, D., Fang, M., Li, H., Cao, G., Fan, W., & Wang, B. (2024). A New Method for Determining Economic Well Pattern Density and Infilling Time of Tight Gas Reservoirs. Energies, 17(5), 1223. https://doi.org/10.3390/en17051223