Impact of Process Technology on Properties of Large-Scale Wind Turbine Blade Composite Spar Cap

Abstract

1. Introduction

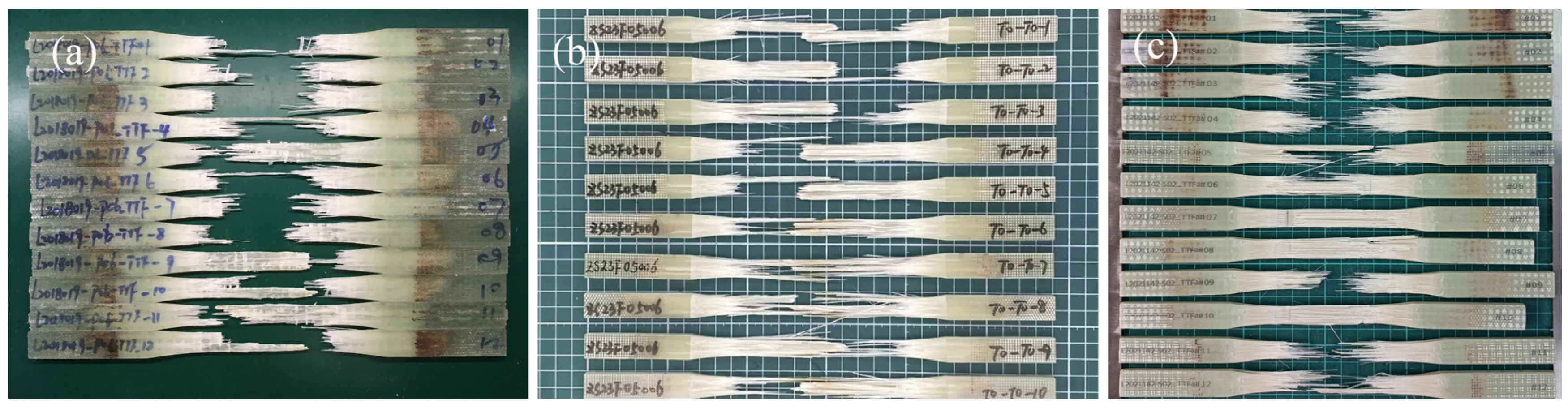

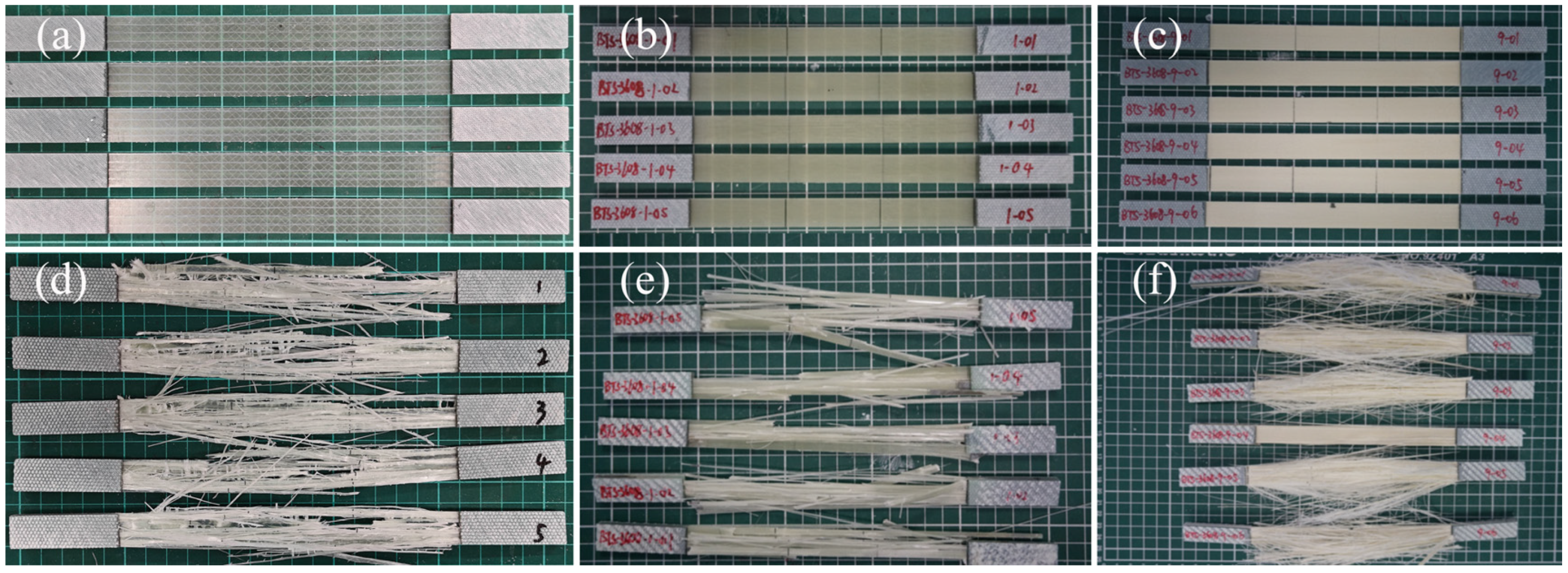

2. Experimental Section

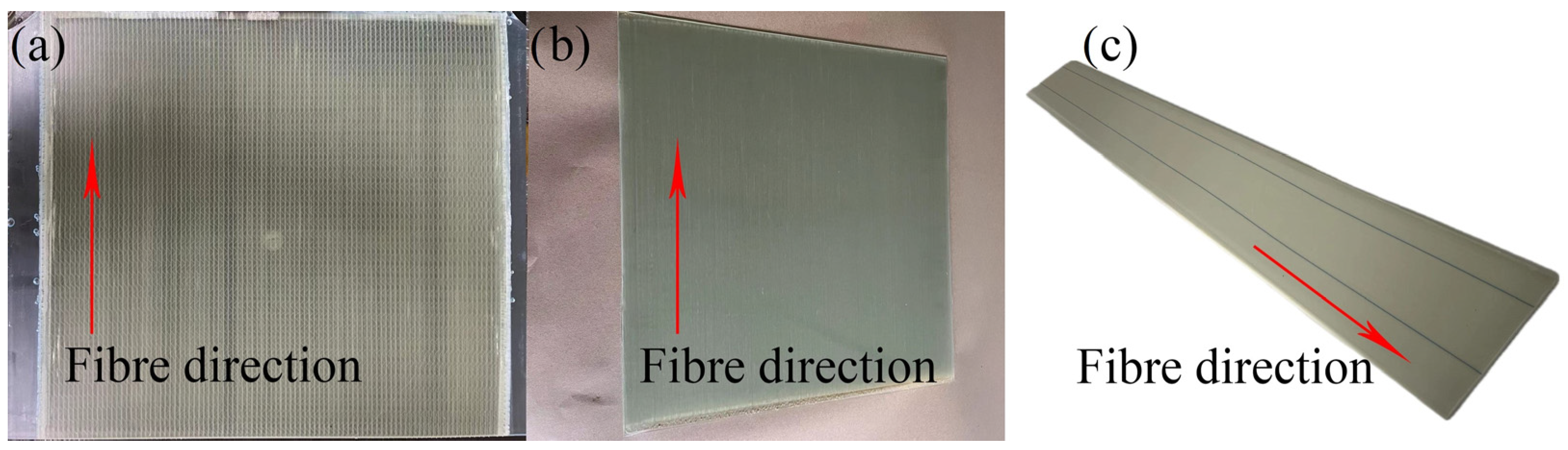

2.1. Sample Preparation

2.2. Analysis of the Cross-Section

2.3. Thermoanalysis

2.4. Mechanical Property Analysis

3. Results

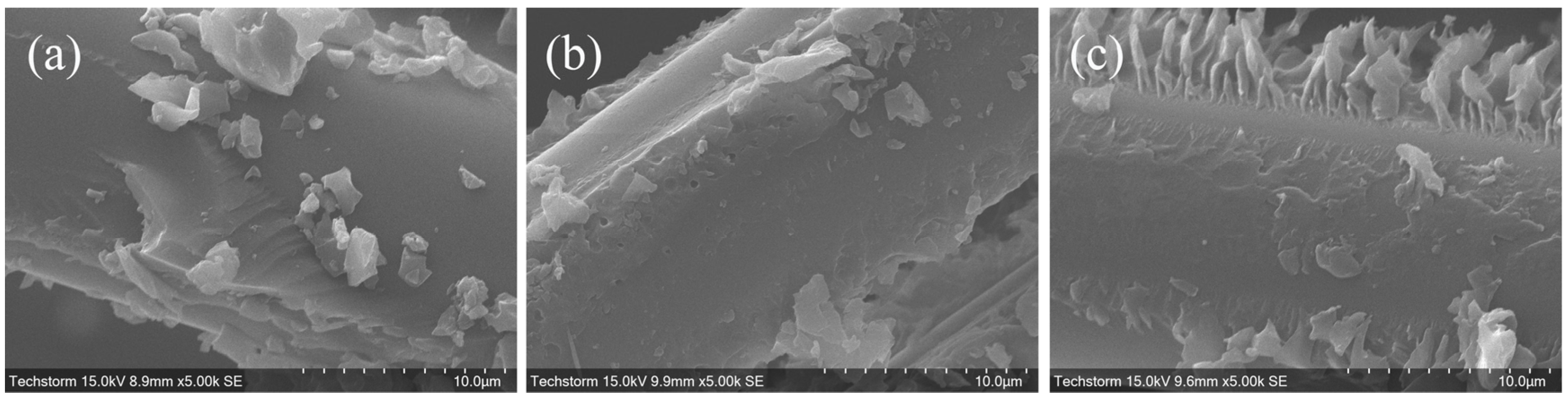

3.1. Micromorphology Analysis

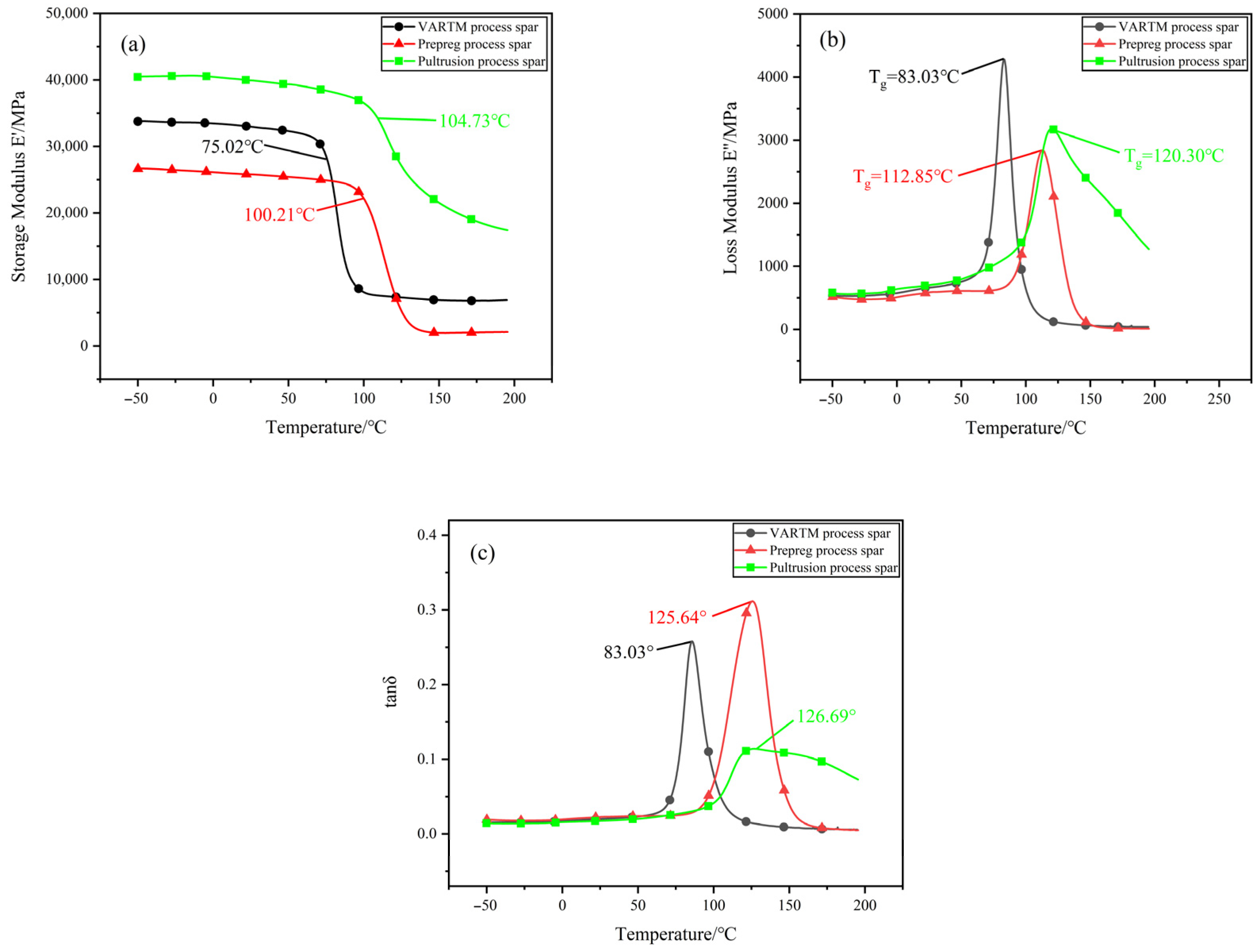

3.2. Research on Thermal Properties

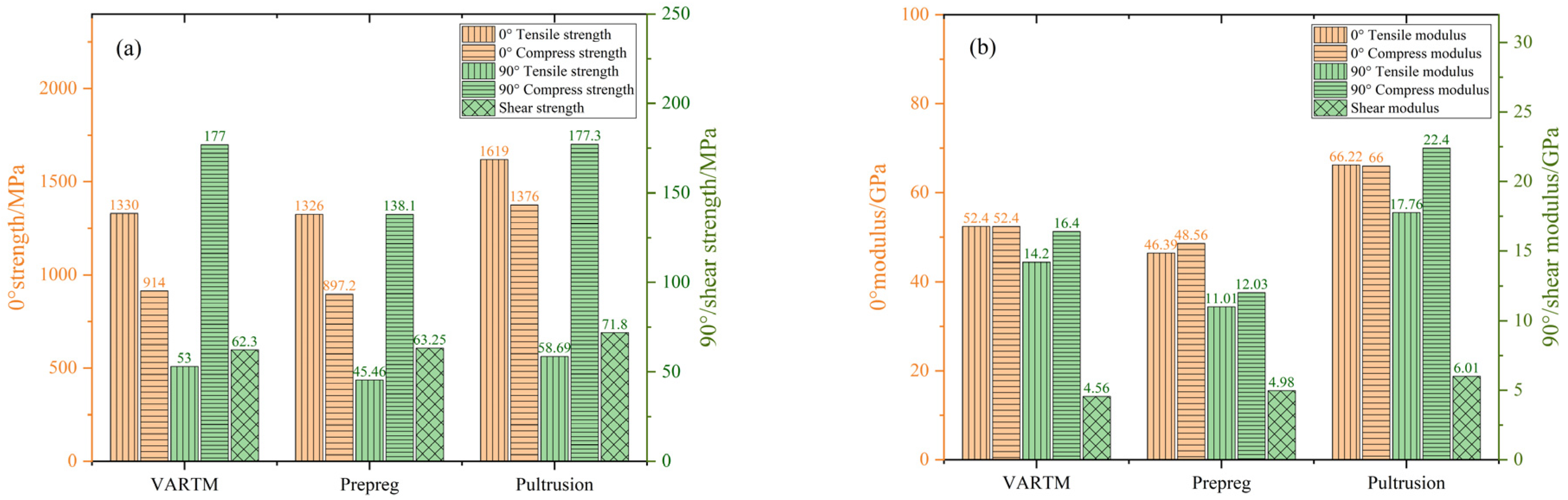

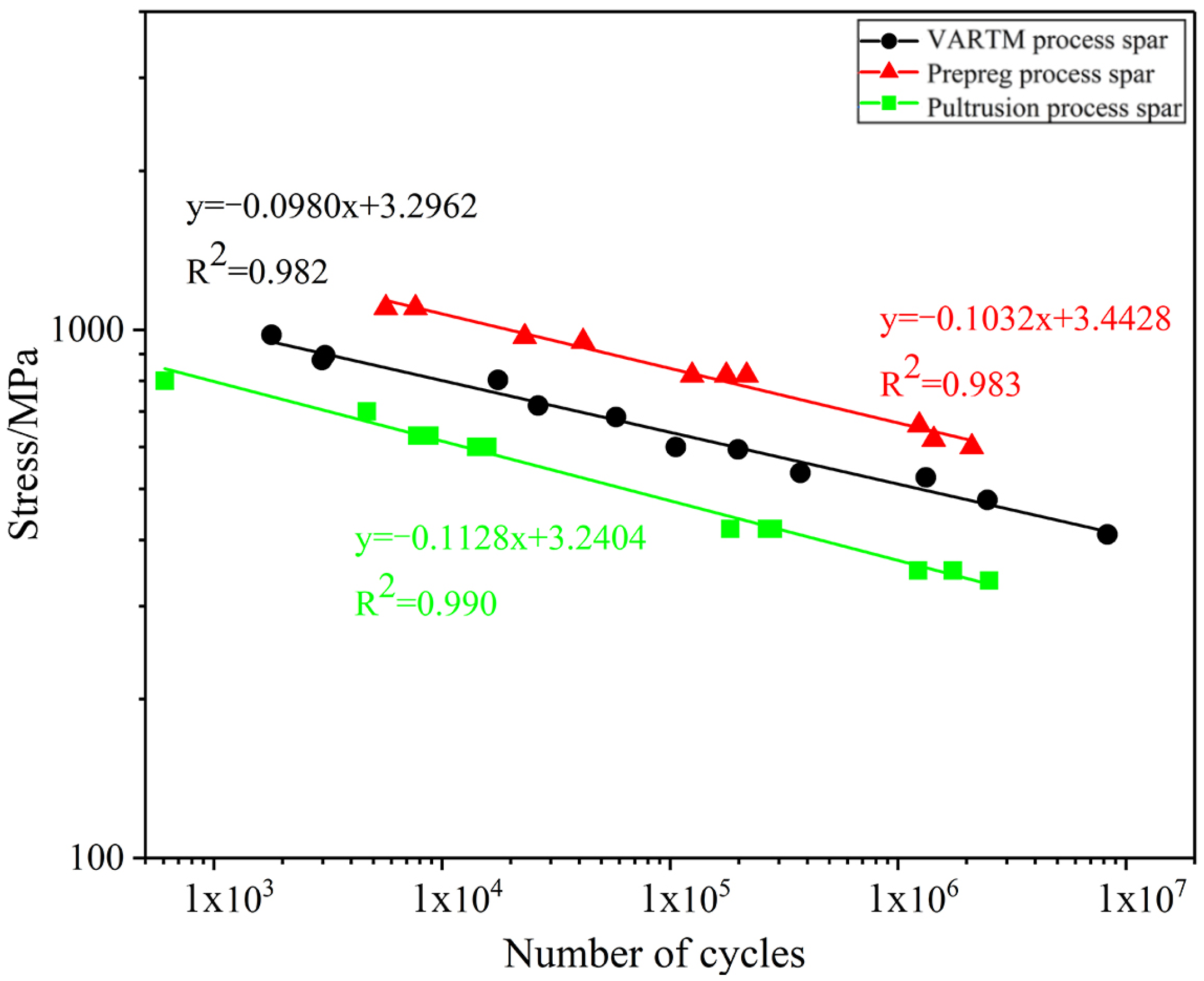

3.3. Study of Mechanical Properties

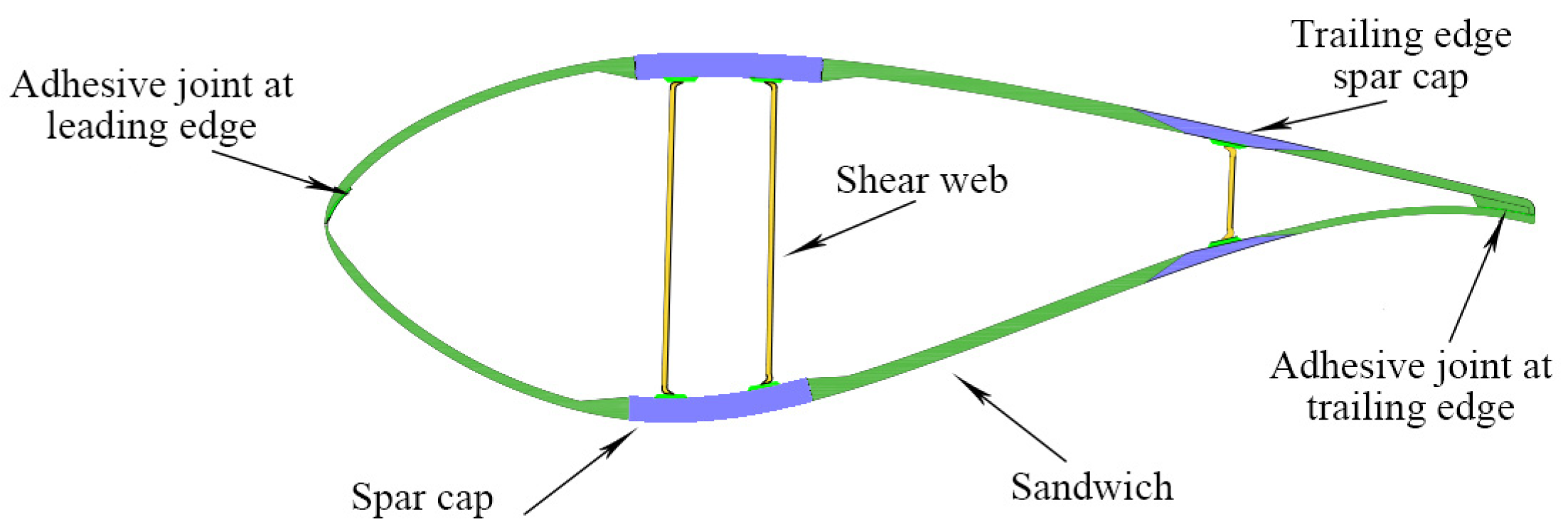

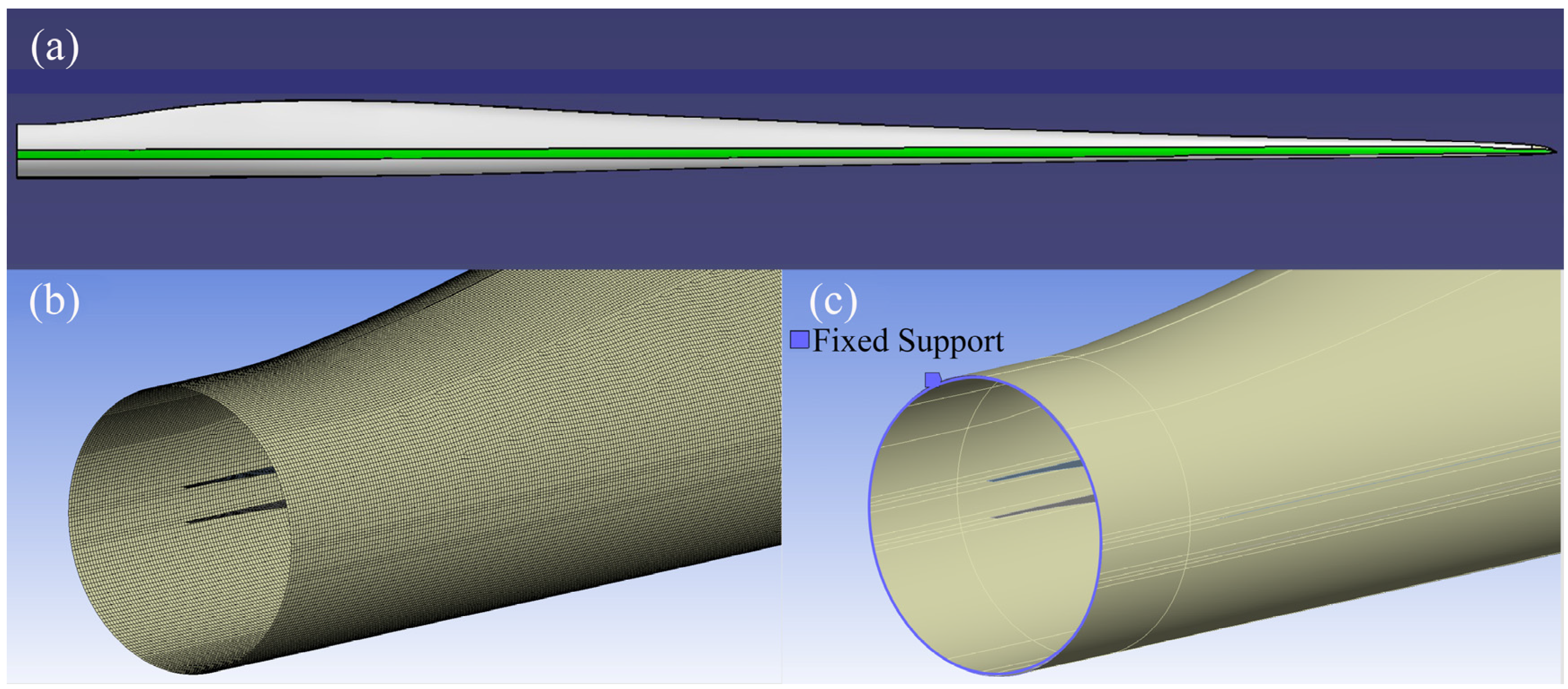

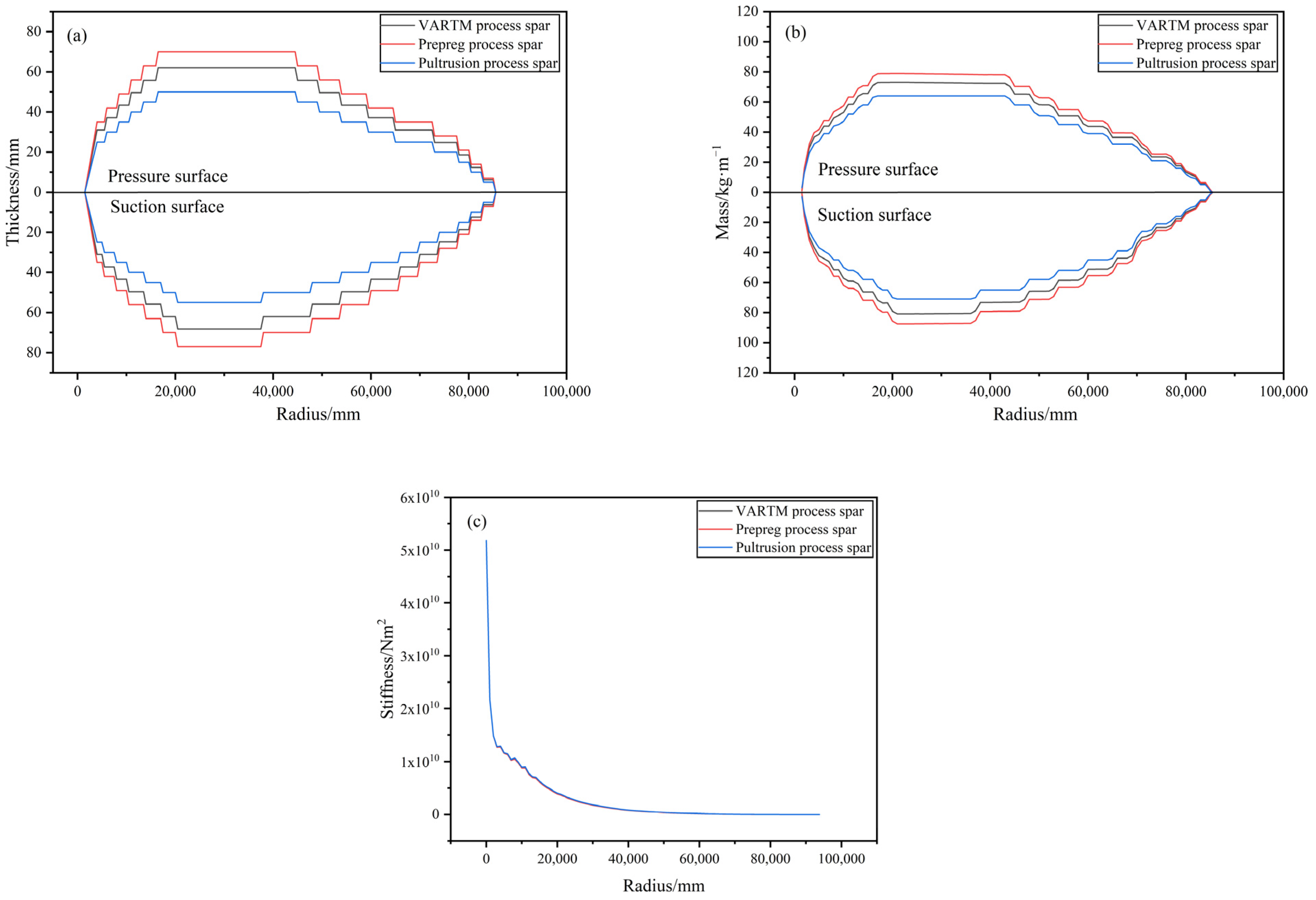

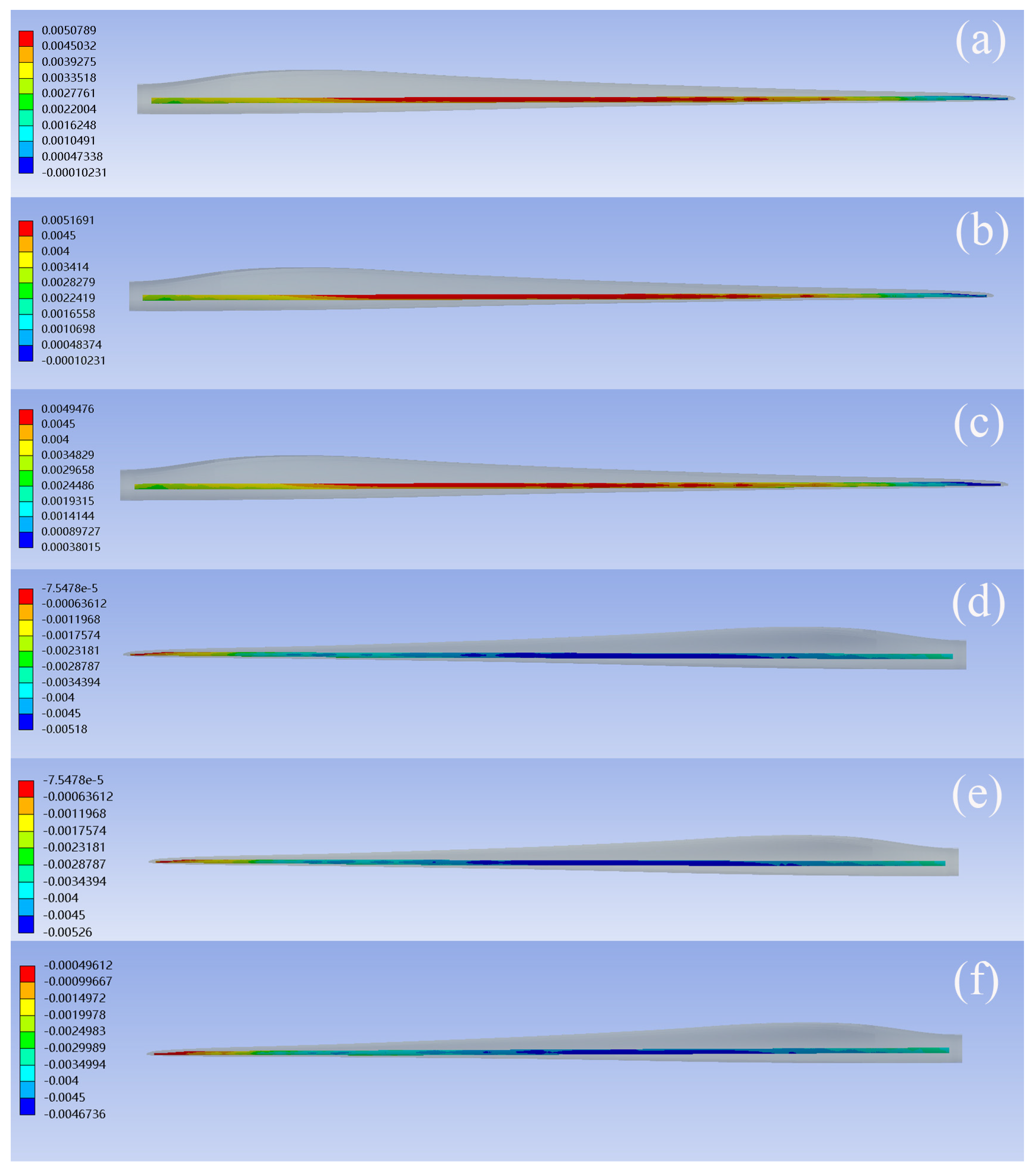

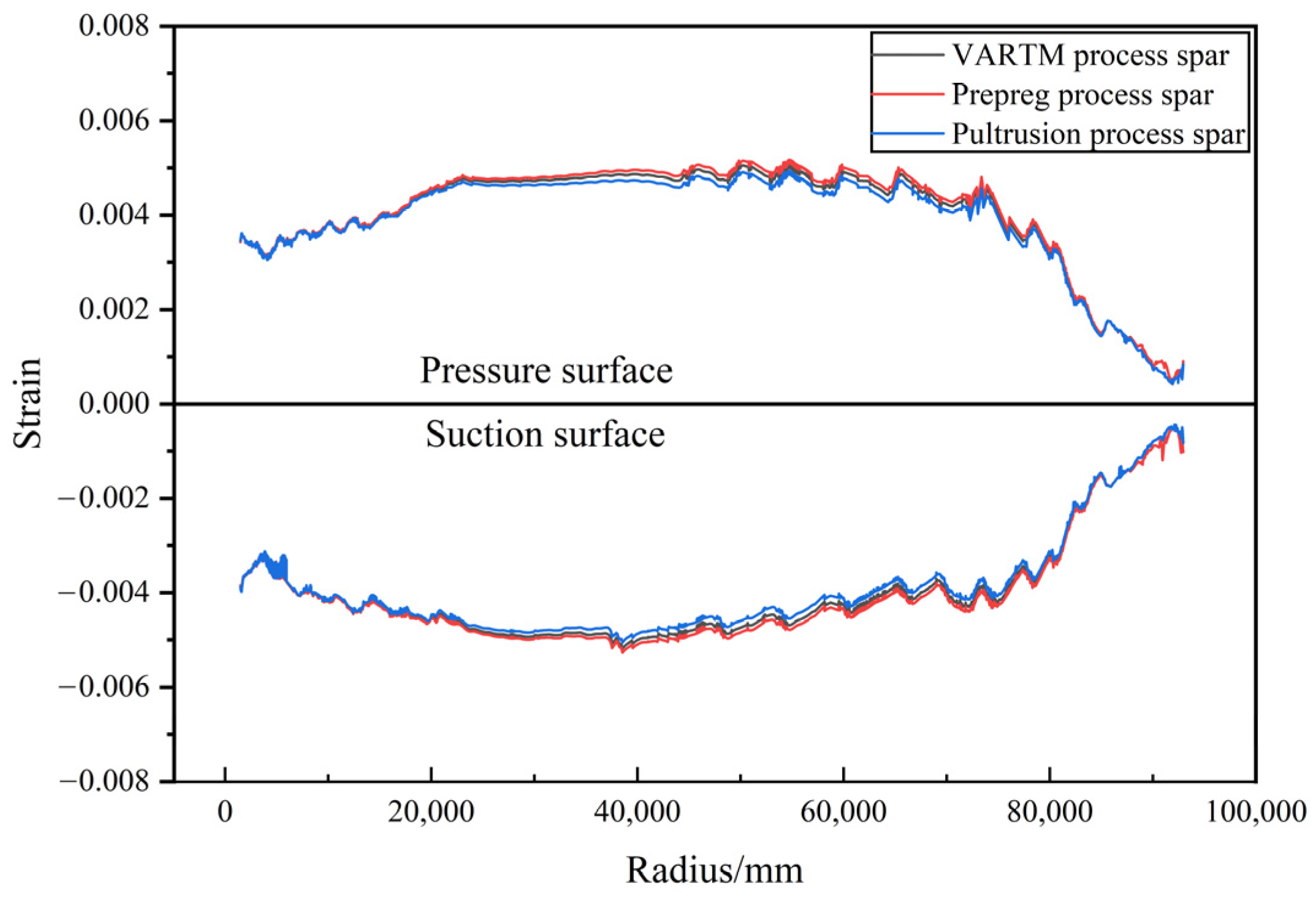

3.4. Wind Turbine Blade Design for Three Processes

4. Conclusions

- (1)

- Compared with VARTM and prepreg, the fibres of pultrusion were uniformly distributed and dense, as indicated by the SEM results. Through DSC and DMA analysis, the pultrusion process exhibits a higher Tg value and a higher energy storage modulus at high temperatures compared with those of VARTM and prepreg processes.

- (2)

- The fibre weight contents of the VARTM, prepreg, and pultrusion composites were 75.14%, 69.72%, and 84.98%, respectively. The fibre weight content of the VARTM and pultrusion composites was higher by 7.8% and 21.9%, respectively, compared with that of the prepreg samples.

- (3)

- Under the same yarn-grade S-glass conditions, the 0° tensile modulus of the VARTM, prepreg, and pultrusion composites were 52.4, 46.39, and 66.2 GPa, respectively. The 0° tensile modulus of the VARTM and pultrusion composites were higher by 13.0% and 42.7%, respectively, compared to those of the prepreg samples.

- (4)

- Under equal stiffness, the spar cap weight of a 94-m blade under the pultrusion process was 7965 kg, while those of the VARTM and prepreg processes were 9170 and 9942 kg, respectively, indicating an increase of 15.1% and 24.8%, respectively.

5. Research Limitations and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | Description |

| VARTM | Vacuum-assisted resin transfer moulding |

| HLU | Hand lay-up |

| SEM | Scanning electron microscopy |

| DMA | Dynamic mechanical analysis |

| DSC | Differential scanning calorimetry |

| TGA | Thermogravimetric analysis |

| HLU | Hand lay-up |

| Smax | The maximum stress |

| Smin | The minimum stress |

| CNC | Computer numerical control |

| ACP | Ansys Composite PrepPost |

References

- Singh, U.; Rizwan, M.; Malik, H.; García Márquez, F.P. Wind Energy Scenario, Success and Initiatives towards Renewable Energy in India—A Review. Energies 2022, 15, 2291. [Google Scholar] [CrossRef]

- Dupré la Tour, M.-A. Photovoltaic and Wind Energy Potential in Europe—A Systematic Review. Renew. Sust. Energ. Rev. 2023, 179, 113189. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Datta, R.; Kumar, M.P.; Davim, J.P.; Pramanik, S. Energy Conversion Strategies for Wind Energy System: Electrical, Mechanical and Material Aspects. Materials 2022, 15, 1232. [Google Scholar] [CrossRef] [PubMed]

- Hutchinson, M.; Zhao, F. Global Wind Report 2023; GWEC: Brussels, Belgium, 2023. [Google Scholar]

- He, Y.; Wang, Y.; Zhou, H.; Li, C.; Zhang, L.; Zhang, Y. Research on Mechanical Properties and Damage Evolution of Pultruded Sheet for Wind Turbine Blades. Materials 2022, 15, 5719. [Google Scholar] [CrossRef] [PubMed]

- Jureczko, M.; Mrówka, M. Multiobjective Optimization of Composite Wind Turbine Blade. Materials 2022, 15, 4649. [Google Scholar] [CrossRef] [PubMed]

- Adolphs, G.; Skinner, C. Non-Crimp Fabric Composites in Wind Turbines; OCV Technical Fabrics: Zele, Belgium, 2011; pp. 481–493. [Google Scholar]

- Choudhary, M.; Sharma, A.; Dwivedi, M.; Patnaik, A. A Comparative Study of the Physical, Mechanical and Thermo-mechanical Behavior of GFRP Composite Based on Fabrication Techniques. Fibers Polym. 2019, 20, 823–831. [Google Scholar] [CrossRef]

- Li, C.; Yang, C.; Ni, A.; Wang, J.; Song, Q. Application and Development of Composite Materials in Large-Scale Wind Turbine Blade. Acta Mater. Compos. Sin. 2023, 3, 1274–1284. [Google Scholar]

- Ennis, B.L.; Das, S.; Norris, R.E. Economic Competitiveness of Pultruded Fiber Composites for Wind Turbine Applications. Compos. Part B Eng. 2023, 265, 110960. [Google Scholar] [CrossRef]

- Pilawka, R.; Osiewicz-Powezka, M.; Hankus, H. Prepregs Based on Epoxy Resin as a Repair Material for Wind Turbine Blades. Przem. Chem. 2021, 4, 353–355. [Google Scholar]

- Budelmann, D.; Schmidt, C.; Meiners, D. Adhesion-Cohesion Balance of prepreg tack in thermoset automated fibre placement. Part 1: Adhesion and surface wetting. Compos. Part C Open Access 2021, 6, 100204. [Google Scholar] [CrossRef]

- Wolff-Fabris, F.; Lengsfeld, H.; Kramer, J. 2. Prepregs and their precursors. In Composite Technology, 2nd ed.; Lengsfeld, H., Lacalle, J., Neumeyer, T., Altstadt, V., Eds.; Hanser Publications: Munich, Germany, 2021; pp. 11–30. [Google Scholar]

- Song, Q.; Jia, Z.; Gao, K. Study on mechanical properties and process performance of domestic carbon fiber prepregs for wind turbine blade. J. Fiber Reinforced Plastics/Composites 2016, 2, 40–46. [Google Scholar]

- Grujicic, M.; Arakere, G.; Pandurangan, B. Multidisciplinary Design Optimization for Glass-Fiber Epoxy-Matrix Composite 5 MW Horizontal-Axis Wind-Turbine Blades. J. Mater. Eng. Perform 2010, 8, 1116–1127. [Google Scholar] [CrossRef]

- Ma, L.; Mehta, R.; Athreya, S.R.; Barpanda, D.; Shafi, A. Composite Processing Modeling for Wind Turbine Blade Applications. SAMPE J. 2017, 6, 34–44. [Google Scholar]

- Kim, S.O.; Seong, D.G.; Um, M.K.; Choi, J.H. Experimental and Phenomenological Modeling Studies on Variation of Fibre Volume Fraction During Resin Impregnation in VARTM. Compos. Res. 2015, 6, 340–347. [Google Scholar] [CrossRef][Green Version]

- Gao, Q.; Xin, H.; Zhang, Y. Experimental Investigation on Transverse Tension-Tension Fatigue Behavior of Pultruded Glass-Fibre Reinforced Polymer (GFRP) Unidirectional Lamina. Constr. Build. Mater. 2023, 399, 132527. [Google Scholar] [CrossRef]

- Vedernikov, A.; Safonov, A.; Tucci, F.; Carlone, P.; Akhatov, I. Pultruded materials and structures: A review. J. Compos. Mater. 2020, 54, 4081–4117. [Google Scholar] [CrossRef]

- ISO 527-5:2021; Plastics Determination of Tensile Properties Part 5: Test Conditions for Unidirectional Fibre-Reinforced Plastic Composites. International Organization for Standardization (ISO): Geneva, Switzerland, 2021.

- ISO 14126:2023; Fibre-Reinforced Plastic Composites Determination of Compressive Properties in the In-Plane Direction. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- ASTM D7078/D7078M-20e1; Standard Test Method for Shear Properties of Composite Materials by V-Notched Rail Shear Method. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2021.

- ISO 13003:2003; Fibre-Reinforced Plastics Determination of Fatigue Properties Under Cyclic Loading Conditions. International Organization for Standardization (ISO): Geneva, Switzerland, 2003.

- Struzziero, G.; Nardi, D.; Sinke, J.; Teuwen, J.J.E. Cure-Induced Residual Stresses for Warpage Reduction in Thermoset Laminates. J. Compos. Mater. 2020, 54, 3055–3065. [Google Scholar] [CrossRef]

- Rosemeier, M.; Lester, C.; Antoniou, A.; Fahrenson, C.; Manousides, N.; Balzani, C. Determination of As-Built Properties of Fibre Reinforced Polymers in a Wind Turbine Blade Using Scanning Electron and High-Resolution X-ray Microscopy. Compos. Part C Open Access 2022, 9, 100310. [Google Scholar] [CrossRef]

- ISO 1172:2023; Textile-Glass-Reinforced Plastics—Prepregs, Moulding Compounds and Laminates—Determination of the Textile-Glass and Mineral-Filler Content Using Calcination Methods. International Organization for Standardization (ISO): Geneva, Switzerland, 2023.

- ISO 845:2006; Cellular Plastics and Rubbers—Determination of Apparent Density. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Ghamarian, N.; Hanim, M.; Penjumras, P.; Abdul Majid, D.L.A.H. Effect of Fibre Orientation on the Mechanical Properties of Laminated Polymer Composites. In Encyclopedia of Materials: Composites; Brabazon, D., Ed.; Elsevier: Oxford, UK, 2016; pp. 746–765. [Google Scholar]

- Zheng, T.; Zhao, C.; He, J. Research on fatigue performance of offshore wind turbine blade with basalt fiber bionic plate. Structures 2023, 47, 466–481. [Google Scholar] [CrossRef]

- Beura, S.; Chakraverty, A.P.; Thatoi, D.N.; Mohanty, U.K.; Mohapatra, M. Failure Modes in GFRP Composites Assessed with the Aid of SEM Fractographs. Mater. Today Proc. 2021, 41, 172–179. [Google Scholar] [CrossRef]

| Process Technology | Fibre Mass Weight Content % | 0° Tensile Modulus | Density | |||

|---|---|---|---|---|---|---|

| Test Value % | Growth Ratio (Equivalent to Prepreg) | Test Value GPa | Growth Ratio (Equivalent to Prepreg) | Test Value g·cm−3 | Growth Ratio (Equivalent to Prepreg) | |

| Prepreg | 69.72 | 100% | 43.61 | 100% | 1.9178 | 100% |

| VARTM | 75.14 | 107.8% | 52.4 | 120% | 1.998 | 104% |

| Pultrusion | 84.98 | 121.9% | 66.2 | 152% | 2.193 | 114% |

| Fatigue Properties | Prepreg Process Composites | VARTM Process Composites | Pultrusion Process Composites |

|---|---|---|---|

| m values | 9.69 | 10.20 | 8.87 |

| 107 Limit maximum stress value/MPa | 525.29 | 407.57 | 282.36 |

| R2 value | 0.983 | 0.982 | 0.990 |

| Fabric | 0° Tensile Modulus | 90° Tensile Modulus | Shear Modulus | Poisson’s Ratio | Density |

|---|---|---|---|---|---|

| MPa | MPa | MPa | - | g·cm−3 | |

| UD | 48,000 | 13,000 | 3600 | 0.24 | 1.960 |

| BIAX | 13,500 | 13,500 | 13,800 | 0.575 | 1.960 |

| Balsa | 100 | 100 | 30 | 0.3 | 0.325 |

| Polyvinyl chloride | 80 | 80 | 20 | 0.3 | 0.227 |

| Polyethylene glycol terephthalate | 120 | 120 | 15 | 0.3 | 0.222 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Y.; Hu, C.; Li, J. Impact of Process Technology on Properties of Large-Scale Wind Turbine Blade Composite Spar Cap. Energies 2024, 17, 1149. https://doi.org/10.3390/en17051149

Sun Y, Hu C, Li J. Impact of Process Technology on Properties of Large-Scale Wind Turbine Blade Composite Spar Cap. Energies. 2024; 17(5):1149. https://doi.org/10.3390/en17051149

Chicago/Turabian StyleSun, Yuanrong, Congli Hu, and Jianbo Li. 2024. "Impact of Process Technology on Properties of Large-Scale Wind Turbine Blade Composite Spar Cap" Energies 17, no. 5: 1149. https://doi.org/10.3390/en17051149

APA StyleSun, Y., Hu, C., & Li, J. (2024). Impact of Process Technology on Properties of Large-Scale Wind Turbine Blade Composite Spar Cap. Energies, 17(5), 1149. https://doi.org/10.3390/en17051149