Review of Experimental Activities and Recent Developments of Spouted Bed Reactors at Different Operational Scales

Abstract

1. Introduction

2. SBR Description and Different Configurations

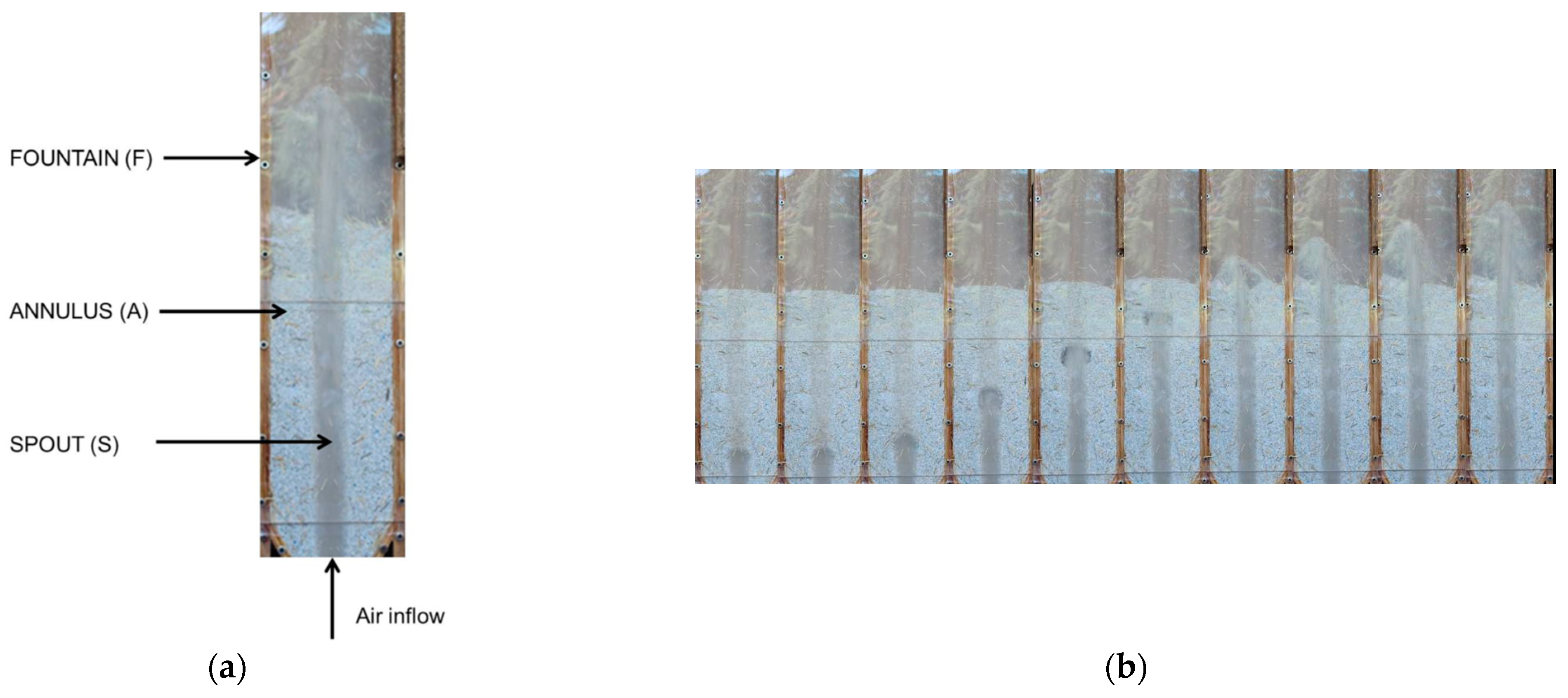

- Cylindrical spouted beds. They were first proposed by Mathur and Gishler [10]. They have a cylindrical bed shape and can be easily constructed. Their main disadvantage, the appearance of dead zones at the bed corners where particles do not take part in the circulation of solids, and the maximum bed height that can be processed, limit their application in a wide range of processes.

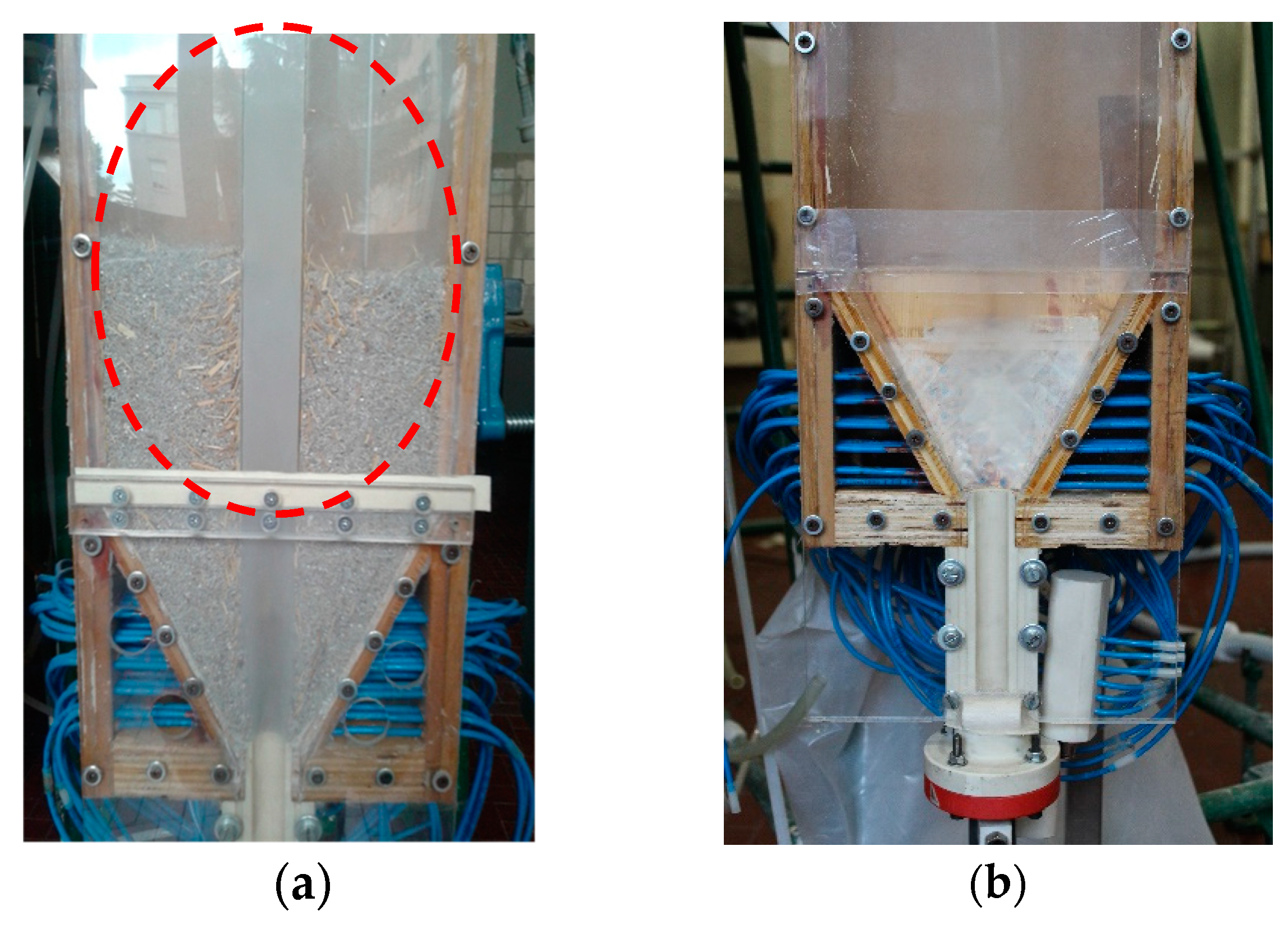

- Conical spouted beds. First proposed by Mujumdar [11], they consist of a conical bottom and a cylindrical top. Their main characteristic is the minimisation of dead zones, in contrast with cylindrical reactors. Thanks to its geometry, conical bed shapes highly promote the mixing of solids and gas–solid contact greatly increasing process efficiencies. However, these types of reactors are more sensitive to geometric and operational parameters, making the delimitation of the stable conditions more difficult [12].

- Rectangular/square spouted beds. It represents the most interesting technology for a further industrial scale-up as the width of the rectangular base can be easily increased using equivalent fluid dynamic correlations [13]. Also, stagnant or dead zones in the annulus are greatly minimised improving solids mixing and mass and transfer rates.

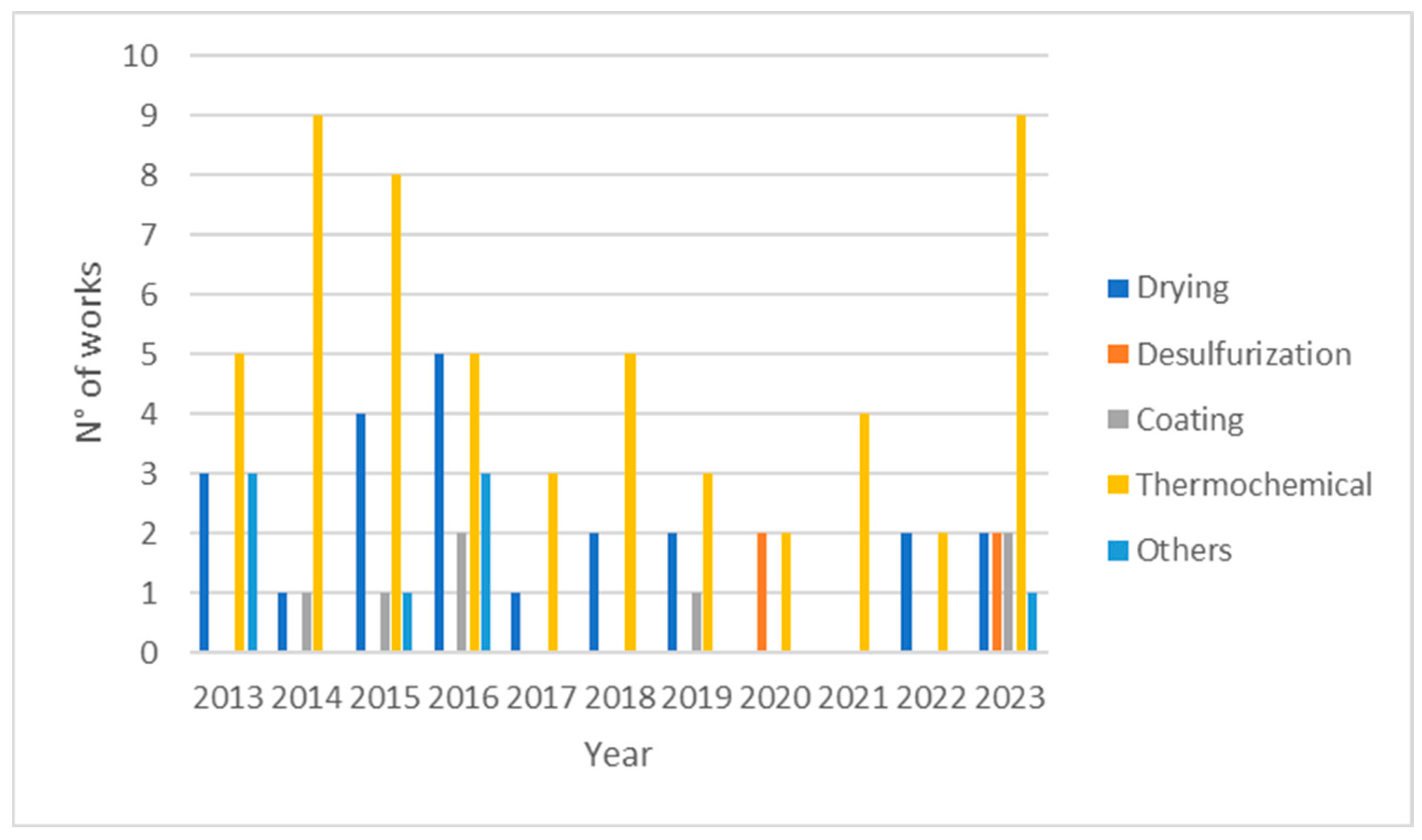

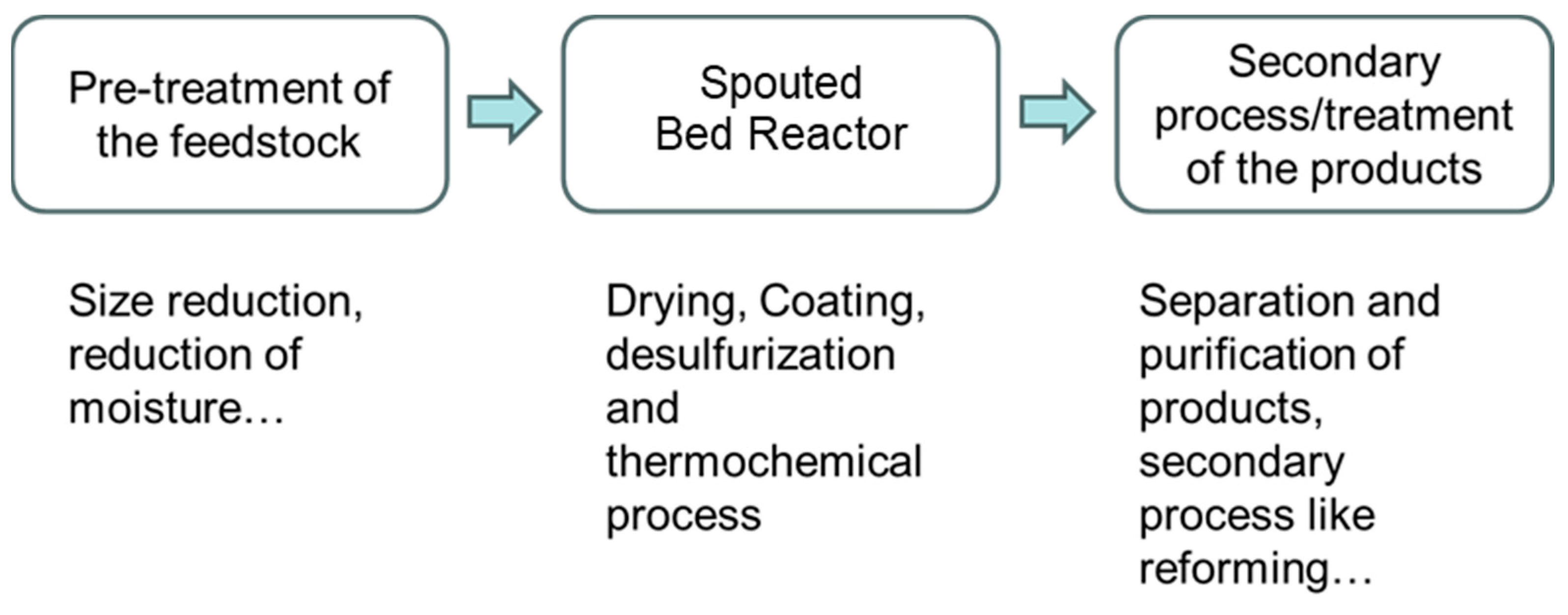

3. Experimental Applications

- The so-called “cold-flow tests”, normally at room temperature, aimed at studying the geometric parameters of the reactors and their different possible configurations. This fluid dynamic characterisation is essential to establish adequate operational parameters (spouting velocity, use of auxiliary devices, …) to ensure a stable spouting regime.

- Study of the process variables in the different applications (quantity of materials, temperature, pressure, …) to optimise process efficiencies.

3.1. Lab-Scale Reactors

3.1.1. Drying

3.1.2. Coating

3.1.3. Desulphurisation

3.1.4. Thermo-Chemical Processes

- ⮚

- Pyrolysis

- Biomass

- Sludge

- Plastics

- Other feedstocks

| Feedstock | Type of Reactor | Temperature | Yield of Main Target Products | Reference |

|---|---|---|---|---|

| Pinecones | Conical | 500 °C | 32 wt% biochar | [47] |

| Rice husk | Conical | 450 °C | 70 wt% bio-oil | [50] |

| Eucalyptus waste | Conical | 500 °C | 75 wt% bio-oil | [52] |

| Sludge | Conical | 500 °C | 77 wt% bio-oil | [58] |

| Polystyrene | Conical | 500 °C | 71 wt% styrene | [63] |

| Waste tyres | Conical | 450 °C | 67 wt% bio-oil | [67] |

- ⮚

- Combustion

- Biomass

- Sludge

- ⮚

- Gasification

- Biomass

- Plastic

| Feedstock | Type of Reactor | Temperature | Yield of H2 | Reference |

|---|---|---|---|---|

| Pinewood sawdust | Conical | 600 °C | 11.2 wt% | [84] |

| Pine sawdust | Conical | 600 °C | 10.5 wt% | [85] |

| Pinewood sawdust | Conical | 600 °C | 8.3 wt% | [86] |

| HDPE | Conical | 900 °C | 61.6% vol | [91] |

| HDPE | Conical | 700 °C | 36 wt% | [93] |

| HDPE | Conical | 700 °C | 29.1 wt% | [94] |

- Other feedstocks

3.1.5. Other Processes

3.2. Demonstration/Industrial Scale Development

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Epstein, N.; Grace, J.R. Spouted and Spout-Fluid Beds: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Marchelli, F.; Moliner, C.; Curti, M.; Bosio, B.; Arato, E. CFD-DEM simulations of a continuous square-based spouted bed and evaluation of the solids residence time distribution. Powder Technol. 2020, 366, 840–858. [Google Scholar] [CrossRef]

- Du, J.; Wu, F.; Ma, X. Progress in research of process intensification of spouted beds: A comprehensive review. Chin. J. Chem. Eng. 2023, 62, 238–260. [Google Scholar] [CrossRef]

- Olazar, M.; Alvarez, S.; Aguado, R.; José, M.S. Spouted bed reactors. Chem. Eng. Technol. 2003, 26, 845–852. [Google Scholar] [CrossRef]

- Marchelli, F.; Curti, M.; Tognin, M.; Rovero, G.; Moliner, C.; Arato, E.; Bosio, B. Experimental study on the solids residence time distribution in multiple square-based spouted beds. Energies 2020, 13, 4694. [Google Scholar] [CrossRef]

- Moliner, C.; Marchelli, F.; Curti, M.; Bosio, B.; Rovero, G.; Arato, E. Spouting behaviour of binary mixtures in square-based spouted beds. Particuology 2019, 43, 193–201. [Google Scholar] [CrossRef]

- Moliner, C.; Marchelli, F.; Bosio, B.; Arato, E. Modelling of spouted and spout-fluid beds: Key for their successful scale up. Energies 2017, 10, 1729. [Google Scholar] [CrossRef]

- Hoorijani, H.; Esgandari, B.; Zarghami, R.; Sotudeh-Gharebagh, R.; Mostoufi, N. CFD-DEM simulation of heat transfer in spout-fluid beds. Chem. Eng. Res. Des. 2023, 200, 95–106. [Google Scholar] [CrossRef]

- Al-Juwaya, T.; Ali, N.; Al-Dahhan, M. Experimental validation of the mechanistic scale-up methodology of gas–solid spouted beds using radioactive particle tracking (RPT). Ann. Nucl. Energy 2023, 181, 109559. [Google Scholar] [CrossRef]

- Mathur, K.B.; Gishler, P.E. A technique for contacting gases with coarse solid particles. AIChE J. 1955, 1, 157–164. [Google Scholar] [CrossRef]

- He, A.; Lim, C.J.; Grace, J.R.; Qin, S. Spout diameters in full and half spouted beds. Can. J. Chem. Eng. 1998, 76, 702–706. [Google Scholar] [CrossRef]

- Olazar, M.; José, M.J.S.; Aguayo, A.T.; Arandes, J.M.; Bilbao, J. Design Factors of Conical Spouted Beds and Jet Spouted Beds. 1993. Available online: https://pubs.acs.org/sharingguidelines (accessed on 20 February 2024).

- Pailahueque, N.; Reyes, A.; Henríquez-Vargas, L.; Gil, M.; Castro, P.; Bubnovich, V. Fluid dynamic analysis and residence time distribution determination for rectangular based spouted beds. Powder Technol. 2021, 380, 385–393. [Google Scholar] [CrossRef]

- Tellabide, M.; Estiati, I.; Pablos, A.; Altzibar, H.; Aguado, R.; Olazar, M. New operation regimes in fountain confined conical spouted beds. Chem. Eng. Sci. 2020, 211, 115255. [Google Scholar] [CrossRef]

- Che, X.; Wu, F.; Jing, W.; Ma, X. Numerical study of multi-jet structure impact on flue gas desulfurization process in 3D spouted beds. Chem. Eng. J. 2023, 457, 141259. [Google Scholar] [CrossRef]

- Fujita, A.; Borges, K.; Correia, R.; Franco, B.D.G.d.M.; Genovese, M.I. Impact of spouted bed drying on bioactive compounds, antimicrobial and antioxidant activities of commercial frozen pulp of camu-camu (Myrciaria dubia Mc. Vaugh). Food Res. Int. 2013, 54, 495–500. [Google Scholar] [CrossRef]

- Jindarat, W.; Sungsoontorn, S.; Rattanadecho, P. Analysis of energy consumption in a combined microwave-hot air spouted bed drying of biomaterial: Coffee beans. Exp. Heat Transf. 2015, 28, 107–124. [Google Scholar] [CrossRef]

- Costa, R.G.; Andreola, K.; Mattietto, R.d.A.; de Faria, L.J.G.; Taranto, O.P. Effect of operating conditions on the yield and quality of açai (Euterpe oleracea Mart.) powder produced in spouted bed. LWT 2015, 64, 1196–1203. [Google Scholar] [CrossRef]

- Araújo, A.D.A.; Coelho, R.M.; Fontes, C.P.M.; Silva, A.R.A.; da Costa, J.M.C.; Rodrigues, S. Production and spouted bed drying of acerola juice containing oligosaccharides. Food Bioprod. Process. 2015, 94, 565–571. [Google Scholar] [CrossRef]

- Mussi, L.P.; Guimarães, A.O.; Ferreira, K.S.; Pereira, N.R. Spouted bed drying of jambolão (Syzygium cumini) residue: Drying kinetics and effect on the antioxidant activity, anthocyanins and nutrients contents. LWT 2015, 61, 80–88. [Google Scholar] [CrossRef]

- Chielle, D.P.; Bertuol, D.A.; Meili, L.; Tanabe, E.H.; Dotto, G.L. Spouted bed drying of papaya seeds for oil production. LWT 2016, 65, 852–860. [Google Scholar] [CrossRef]

- Alves, N.N.; Ben Messaoud, G.; Desobry, S.; Costa, J.M.C.; Rodrigues, S. Effect of drying technique and feed flow rate on bacterial survival and physicochemical properties of a non-dairy fermented probiotic juice powder. J. Food Eng. 2016, 189, 45–54. [Google Scholar] [CrossRef]

- Nagaraju, V.; Ramalakshmi, K.; Sridhar, B. Cryo assisted spouted bed roasting of coffee beans. Innov. Food Sci. Emerg. Technol. 2016, 37, 138–144. [Google Scholar] [CrossRef]

- Serowik, M.; Figiel, A.; Nejman, M.; Pudlo, A.; Chorazyk, D.; Kopec, W. Drying characteristics and some properties of spouted bed dried semi-refined carrageenan. J. Food Eng. 2017, 194, 46–57. [Google Scholar] [CrossRef]

- Huang, D.; Huang, W.; Huang, S.; Zhou, F.; Gong, G.; Li, L.; Sunden, B. Applications of spouted bed technology in the drying of food products. LWT 2023, 182, 114880. [Google Scholar] [CrossRef]

- Butzge, J.J.; de Godoi, F.C.; Rocha, S.C.d.S. Spouted bed drying efficiency of bovine hydrolyzed collagen. Braz. J. Food Technol. 2016, 19, e2015010. [Google Scholar] [CrossRef][Green Version]

- Brito, R.; Sousa, R.; Béttega, R.; Freire, F.; Freire, J. Analysis of the energy performance of a modified mechanically spouted bed applied in the drying of alumina and skimmed milk. Chem. Eng. Process.-Process Intensif. 2018, 130, 1–10. [Google Scholar] [CrossRef]

- Sousa, R.C.; Ferreira, M.C.; Altzibar, H.; Freire, F.B.; Freire, J.T. Drying of pasty and granular materials in mechanically and conventional spouted beds. Particuology 2019, 42, 176–183. [Google Scholar] [CrossRef]

- Sahin, S.; Sumnu, G.; Tunaboyu, F. Usage of solar-assisted spouted bed drier in drying of pea. Food Bioprod. Process. 2013, 91, 271–278. [Google Scholar] [CrossRef]

- Reyes, A.; Gatica, E.; Henríquez-Vargas, L.; Pailahueque, N. Modeling of sawdust drying in spouted beds using solar energy and phase change materials. J. Energy Storage 2022, 51, 104441. [Google Scholar] [CrossRef]

- Berghel, J.; Renström, R. Superheated steam drying of sawdust in continuous feed spouted beds—A design perspective. Biomass-Bioenergy 2014, 71, 228–234. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Sun, S.; Xu, L.; Yang, W. Investigation of wetting and drying process in a spout-fluid bed using acoustic sensor and electrical capacitance tomography. Chem. Eng. Sci. 2023, 281, 119160. [Google Scholar] [CrossRef]

- Runha, F.; Cordeiro, D.; Pereira, C.; Vilegas, J.; Oliveira, W. Production of dry extracts of medicinal brazilian plants by spouted bed process: Development of the process and evaluation of thermal degradation during the drying operation. Food Bioprod. Process. Trans. Inst. Chem. Eng. 2001, 79, 160–168. [Google Scholar] [CrossRef]

- Benelli, L.; Souza, C.R.F.; Oliveira, W.P. Spouted bed performance on drying of an aromatic plant extract. Powder Technol. 2013, 239, 59–71. [Google Scholar] [CrossRef]

- Beigi, S.; Charkhi, A.; Sobati, M.A. An experimental investigation on the drying of thorium oxalate in a batch spouted bed dryer. Prog. Nucl. Energy 2018, 106, 465–473. [Google Scholar] [CrossRef]

- Zhao, S.; Wu, F.; Ma, X.; Zhou, W. Effect of novel intensification structure on drying of particulate materials in spouted beds. J. Ind. Eng. Chem. 2022, 114, 263–275. [Google Scholar] [CrossRef]

- Pietsch, S.; Peter, A.; Wahl, P.; Khinast, J.; Heinrich, S. Measurement of granule layer thickness in a spouted bed coating process via optical coherence tomography. Powder Technol. 2019, 356, 139–147. [Google Scholar] [CrossRef]

- Guo, L.; Wang, G.; Zhang, F.; Wang, P.; Zhu, Z.; Lin, J. Effect of temperature on the minimum spouting velocity of heavy particles in conical spouted bed used for nuclear fuel coating. Exp. Therm. Fluid Sci. 2023, 144, 110876. [Google Scholar] [CrossRef]

- Chen, W.; Kuo, H. Surface Coating of Group B Iron Powders in a Spouted Bed. Procedia Eng. 2015, 102, 1144–1149. [Google Scholar] [CrossRef]

- Kolan, S.R.; Wang, R.; Hoffmann, T.; Tsotsas, E. Mixing sub-micron particles in a ProCell type spouted bed. Powder Technol. 2023, 428, 118828. [Google Scholar] [CrossRef]

- Wu, F.; Yue, K.; Gao, W.; Gong, M.; Ma, X.; Zhou, W. Numerical simulation of semi-dry flue gas desulfurization process in the powder-particle spouted bed. Adv. Powder Technol. 2020, 31, 323–331. [Google Scholar] [CrossRef]

- Wu, F.; Bai, J.; Yue, K.; Gong, M.; Ma, X.; Zhou, W. Eulerian–Eulerian Numerical Study of the Flue Gas Desulfurization Process in a Semidry Spouted Bed Reactor. ACS Omega 2020, 5, 3282–3293. [Google Scholar] [CrossRef]

- Che, X.; Wu, F.; Wang, J. Multiple field synergy mechanism of the desulfurization process in the intensified spouted beds. Chem. Eng. J. 2023, 467, 143521. [Google Scholar] [CrossRef]

- Du, J.; Wu, F.; Ma, X.; Wang, J. Effect of swirling spouting intensification structure on semi-dry desulfurization process in 3D spouted beds. Chem. Eng. Sci. 2023, 269, 118452. [Google Scholar] [CrossRef]

- Cortazar, M.; Alvarez, J.; Lopez, G.; Amutio, M.; Artetxe, M.; Bilbao, J.; Olazar, M. Syngas production by bio-oil steam gasification in a fountain confined conical spouted bed reactor. Fuel 2023, 345, 128228. [Google Scholar] [CrossRef]

- Curti, M.; Giansetti, M. Valorizzazione di scarti industriali tessili mediante gassificazione e pirolisi. Chim. Ind.-Riv. Soc. Chim. Ital. 2022, 4, 49–53. [Google Scholar] [CrossRef]

- Maaoui, A.; Trabelsi, A.B.H.; Ben Abdallah, A.; Chagtmi, R.; Lopez, G.; Cortazar, M.; Olazar, M. Assessment of pine wood biomass wastes valorization by pyrolysis with focus on fast pyrolysis biochar production. J. Energy Inst. 2023, 108, 101242. [Google Scholar] [CrossRef]

- Czernik, S.; Bridgwater, A.V. Overview of applications of biomass fast pyrolysis oil. Energy Fuels 2004, 18, 590–598. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Bio-oil production from rice husk fast pyrolysis in a conical spouted bed reactor. Fuel 2014, 128, 162–169. [Google Scholar] [CrossRef]

- Alvarez, J.; Hooshdaran, B.; Cortazar, M.; Amutio, M.; Lopez, G.; Freire, F.B.; Haghshenasfard, M.; Hosseini, S.H.; Olazar, M. Valorization of citrus wastes by fast pyrolysis in a conical spouted bed reactor. Fuel 2018, 224, 111–120. [Google Scholar] [CrossRef]

- Hu, D.; Zeng, X.; Wang, F.; Han, Z.; Ding, F.; Yue, J.; Xu, G. Release behavior and generation kinetics of gas product during rice husk pyrolysis in a micro spouted bed reactor. Fuel 2021, 287, 119417. [Google Scholar] [CrossRef]

- Amutio, M.; Lopez, G.; Alvarez, J.; Olazar, M.; Bilbao, J. Fast pyrolysis of eucalyptus waste in a conical spouted bed reactor. Bioresour. Technol. 2015, 194, 225–232. [Google Scholar] [CrossRef]

- Du, S.; Sun, Y.; Gamliel, D.P.; Valla, J.A.; Bollas, G.M. Catalytic pyrolysis of miscanthus × giganteus in a spouted bed reactor. Bioresour. Technol. 2014, 169, 188–197. [Google Scholar] [CrossRef]

- Azizi, K.; Moraveji, M.K.; Arregi, A.; Amutio, M.; Lopez, G.; Olazar, M. On the pyrolysis of different microalgae species in a conical spouted bed reactor: Bio-fuel yields and characterization. Bioresour. Technol. 2020, 311, 123561. [Google Scholar] [CrossRef]

- Barcelos, K.; Almeida, P.; Araujo, M.; Xavier, T.; Santos, K.; Bacelos, M.; Lira, T. Particle segregation in spouted bed pyrolysis reactor: Sand-coconut shell and sand-cocoa shell mixtures. Biomass-Bioenergy 2020, 138, 105592. [Google Scholar] [CrossRef]

- Wang, Z.; Lim, C.J.; Grace, J.R. A comprehensive study of sawdust torrefaction in a dual-compartment slot-rectangular spouted bed reactor. Energy 2019, 189, 116306. [Google Scholar] [CrossRef]

- Alvarez, J.; Amutio, M.; Lopez, G.; Bilbao, J.; Olazar, M. Fast co-pyrolysis of sewage sludge and lignocellulosic biomass in a conical spouted bed reactor. Fuel 2015, 159, 810–818. [Google Scholar] [CrossRef]

- Alvarez, J.; Amutio, M.; Lopez, G.; Barbarias, I.; Bilbao, J.; Olazar, M. Sewage sludge valorization by flash pyrolysis in a conical spouted bed reactor. Chem. Eng. J. 2015, 273, 173–183. [Google Scholar] [CrossRef]

- Alvarez, J.; Lopez, G.; Amutio, M.; Artetxe, M.; Barbarias, I.; Arregi, A.; Bilbao, J.; Olazar, M. Characterization of the bio-oil obtained by fast pyrolysis of sewage sludge in a conical spouted bed reactor. Fuel Process. Technol. 2016, 149, 169–175. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; García, I.; Peñas, F.J. Conical spouted bed combustor for clean valorization of sludge wastes from paper industry to generate energy. Chem. Eng. Res. Des. 2014, 92, 672–678. [Google Scholar] [CrossRef]

- Ibáñez, M.; Artetxe, M.; Lopez, G.; Elordi, G.; Bilbao, J.; Olazar, M.; Castaño, P. Identification of the coke deposited on an HZSM-5 zeolite catalyst during the sequenced pyrolysis–cracking of HDPE. Appl. Catal. B Environ. 2014, 148–149, 436–445. [Google Scholar] [CrossRef]

- Borsella, E.; Aguado, R.; De Stefanis, A.; Olazar, M. Comparison of catalytic performance of an iron-alumina pillared montmorillonite and HZSM-5 zeolite on a spouted bed reactor. J. Anal. Appl. Pyrolysis 2018, 130, 320–331. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Barbarias, I.; Arregi, A.; Aguado, R.; Bilbao, J.; Olazar, M. Styrene recovery from polystyrene by flash pyrolysis in a conical spouted bed reactor. Waste Manag. 2015, 45, 126–133. [Google Scholar] [CrossRef]

- Orozco, S.; Alvarez, J.; Lopez, G.; Artetxe, M.; Bilbao, J.; Olazar, M. Pyrolysis of plastic wastes in a fountain confined conical spouted bed reactor: Determination of stable operating conditions. Energy Convers. Manag. 2021, 229, 113768. [Google Scholar] [CrossRef]

- Artetxe, M.; Lopez, G.; Amutio, M.; Elordi, G.; Bilbao, J.; Olazar, M. Cracking of high density polyethylene pyrolysis waxes on HZSM-5 catalysts of different acidity. Ind. Eng. Chem. Res. 2013, 52, 10637–10645. [Google Scholar] [CrossRef]

- Barbarias, I.; Artetxe, M.; Arregi, A.; Alvarez, J.; Lopez, G.; Amutio, M.; Olazar, M. Catalytic cracking of HDPE pyrolysis volatiles over a spent FCC catalyst. Chem. Eng. Trans. 2015, 43, 2029–2034. [Google Scholar] [CrossRef]

- Hwang, J.G.; Lee, B.K.; Choi, M.K.; Park, H.C.; Choi, H.S. Optimal production of waste tire pyrolysis oil and recovery of high value-added D-limonene in a conical spouted bed reactor. Energy 2023, 262, 125519. [Google Scholar] [CrossRef]

- Moliner, C.; Bove, D.; Arato, E. Co-incineration of rice straw-wood pellets: A sustainable strategy for the valorisation of rice waste. Energies 2020, 13, 5750. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; López, R. Conical spouted bed combustor to obtain clean energy from avocado waste. Fuel Process. Technol. 2023, 239, 107543. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; García, I.; Peñas, F.J. A novel conical combustor for thermal exploitation of vineyard pruning wastes. Fuel 2013, 110, 178–184. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; Peñas, F.J.; García, I. Thermal exploitation of fruit tree pruning wastes in a novel conical spouted bed combustor. Chem. Eng. J. 2014, 238, 227–233. [Google Scholar] [CrossRef]

- José, M.J.S.; Alvarez, S.; López, R. Catalytic combustion of vineyard pruning waste in a conical spouted bed combustor. Catal. Today 2018, 305, 13–18. [Google Scholar] [CrossRef]

- Remón, J.; Broust, F.; Valette, J.; Chhiti, Y.; Alava, I.; Fernandez-Akarregi, A.; Arauzo, J.; Garcia, L. Production of a hydrogen-rich gas from fast pyrolysis bio-oils: Comparison between homogeneous and catalytic steam reforming routes. Int. J. Hydrogen Energy 2014, 39, 171–182. [Google Scholar] [CrossRef]

- Voutetakis, S.; Kechagiopoulos, P.N.; Voutetakis, S.S.; Lemonidou, A.A.; Vasalos, I.A. Sustainable Hydrogen Production via Reforming of Bio-Oil Model Compounds Using a Novel Sustainable Hydrogen Production via Reforming of Bio-Oil Model Compounds Using a Novel Spoute Sustainable Hydrogen Production via Reforming of Bio-Oil Model Compounds Using a Novel Spouted Bed Reactor Proceedings of European Congress of Chemical Engineering (ECCE-6) Sustainable Hydrogen Production via Reforming of Bio-Oil Model Compounds Using a Novel Spouted Bed Reactor. Available online: https://www.researchgate.net/publication/268341601 (accessed on 20 February 2024).

- Sangaré, D.; Belandria, V.; Bostyn, S.; Moscosa-Santillan, M.; Gökalp, I. Pyro-gasification of lignocellulosic biomass: Online quantification of gas evolution with temperature, effects of heating rate, and stoichiometric ratio. Biomass-Convers. Biorefinery 2022, 1–13. [Google Scholar] [CrossRef]

- Erkiaga, A.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Influence of operating conditions on the steam gasification of biomass in a conical spouted bed reactor. Chem. Eng. J. 2014, 237, 259–267. [Google Scholar] [CrossRef]

- Erkiaga, A.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Steam gasification of biomass in a conical spouted bed reactor with olivine and γ-alumina as primary catalysts. Fuel Process. Technol. 2013, 116, 292–299. [Google Scholar] [CrossRef]

- Lopez, G.; Erkiaga, A.; Amutio, M.; Bilbao, J.; Olazar, M. Effect of polyethylene co-feeding in the steam gasification of biomass in a conical spouted bed reactor. Fuel 2015, 153, 393–401. [Google Scholar] [CrossRef]

- Fernandez, E.; Santamaria, L.; Amutio, M.; Artetxe, M.; Arregi, A.; Lopez, G.; Bilbao, J.; Olazar, M. Role of temperature in the biomass steam pyrolysis in a conical spouted bed reactor. Energy 2022, 238, 122053. [Google Scholar] [CrossRef]

- Cortazar, M.; Alvarez, J.; Lopez, G.; Amutio, M.; Santamaria, L.; Bilbao, J.; Olazar, M. Role of temperature on gasification performance and tar composition in a fountain enhanced conical spouted bed reactor. Energy Convers. Manag. 2018, 171, 1589–1597. [Google Scholar] [CrossRef]

- Cortazar, M.; Santamaria, L.; Lopez, G.; Alvarez, J.; Amutio, M.; Bilbao, J.; Olazar, M. Fe/olivine as primary catalyst in the biomass steam gasification in a fountain confined spouted bed reactor. J. Ind. Eng. Chem. 2021, 99, 364–379. [Google Scholar] [CrossRef]

- Arregi, A.; Barbarias, I.; Alvarez, J.; Erkiaga, A.; Artetxe, M.; Amutio, M.; Olazar, M. Hydrogen production from biomass pyrolysis and in-line catalytic steam reforming. Chem. Eng. Trans. 2015, 43, 547–552. [Google Scholar] [CrossRef]

- Arregi, A.; Amutio, M.; Lopez, G.; Artetxe, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Hydrogen-rich gas production by continuous pyrolysis and in-line catalytic reforming of pine wood waste and HDPE mixtures. Energy Convers. Manag. 2017, 136, 192–201. [Google Scholar] [CrossRef]

- Arregi, A.; Santamaria, L.; Lopez, G.; Olazar, M.; Bilbao, J.; Artetxe, M.; Amutio, M. Appraisal of agroforestry biomass wastes for hydrogen production by an integrated process of fast pyrolysis and in line steam reforming. J. Environ. Manag. 2023, 347, 119071. [Google Scholar] [CrossRef]

- Fernandez, E.; Santamaria, L.; García, I.; Amutio, M.; Artetxe, M.; Lopez, G.; Bilbao, J.; Olazar, M. Elucidating coke formation and evolution in the catalytic steam reforming of biomass pyrolysis volatiles at different fixed bed locations. Chin. J. Catal. 2023, 48, 101–116. [Google Scholar] [CrossRef]

- Garcia, I.; Santamaria, L.; Lopez, G.; Bilbao, J.; Olazar, M.; Amutio, M.; Artetxe, M. Steps to understand the role played by the main operating conditions in the oxidative steam reforming of biomass fast pyrolysis volatiles. Chem. Eng. J. 2023, 475, 146223. [Google Scholar] [CrossRef]

- Boujjat, H.; Rodat, S.; Chuayboon, S.; Abanades, S. Experimental and numerical study of a directly irradiated hybrid solar/combustion spouted bed reactor for continuous steam gasification of biomass. Energy 2019, 189, 116118. [Google Scholar] [CrossRef]

- Li, X.; Yan, P.; Ma, C.; Wang, J. Structural design and optimization of a solar spouted bed reactor of biomass gasification. Appl. Therm. Eng. 2021, 194, 117058. [Google Scholar] [CrossRef]

- Alghurabie, I.K.; Hasan, B.O.; Jackson, B.; Kosminski, A.; Ashman, P.J. Fluidized bed gasification of Kingston coal and marine microalgae in a spouted bed reactor. Chem. Eng. Res. Des. 2013, 91, 1614–1624. [Google Scholar] [CrossRef]

- Orozco, S.; Santamaria, L.; Artetxe, M.; Alvarez, J.; Bilbao, J.; Olazar, M.; Lopez, G. Influence of oxidative conditions on the deactivation of an equilibrium FCC catalyst in the fast pyrolysis of HDPE in a conical spouted bed reactor. Chem. Eng. J. 2023, 472, 144947. [Google Scholar] [CrossRef]

- Barbarias, I.; Lopez, G.; Alvarez, J.; Artetxe, M.; Arregi, A.; Bilbao, J.; Olazar, M. A sequential process for hydrogen production based on continuous HDPE fast pyrolysis and in-line steam reforming. Chem. Eng. J. 2016, 296, 191–198. [Google Scholar] [CrossRef]

- Erkiaga, A.; Lopez, G.; Amutio, M.; Bilbao, J.; Olazar, M. Syngas from steam gasification of polyethylene in a conical spouted bed reactor. Fuel 2013, 109, 461–469. [Google Scholar] [CrossRef]

- Lopez, G.; Erkiaga, A.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. Hydrogen Production by High Density Polyethylene Steam Gasification and In-Line Volatile Reforming. Ind. Eng. Chem. Res. 2015, 54, 9536–9544. [Google Scholar] [CrossRef]

- Barbarias, I.; Lopez, G.; Artetxe, M.; Arregi, A.; Santamaria, L.; Bilbao, J.; Olazar, M. Pyrolysis and in-line catalytic steam reforming of polystyrene through a two-step reaction system. J. Anal. Appl. Pyrolysis 2016, 122, 502–510. [Google Scholar] [CrossRef]

- Yasin, S.; Curti, M.; Rovero, G.; Behary, N.; Perwuelz, A.; Giraud, S.; Migliavacca, G.; Chen, G.; Guan, J.S. Flame retardant end of life. BioResources 2017, 12, 5196–5211. [Google Scholar]

- da Silva, A.S.V.; Weinschutz, R.; Yamamoto, C.I.; Luz, L.F. Catalytic cracking of light gas oil using microwaves as energy source. Fuel 2013, 106, 632–638. [Google Scholar] [CrossRef]

- Taham, T.; Silva, D.O.; Barrozo, M.A. Improvement of bixin extraction from annatto seeds using a screen-topped spouted bed. Sep. Purif. Technol. 2016, 158, 313–321. [Google Scholar] [CrossRef]

- Liu, D.; Roberts, E.; Martin, A.; Holmes, S.; Brown, N.; Campen, A.; Heras, N.d.L. Electrochemical regeneration of a graphite adsorbent loaded with Acid Violet 17 in a spouted bed reactor. Chem. Eng. J. 2016, 304, 1–9. [Google Scholar] [CrossRef]

- Fernandez-Akarregi, A.; Makibar, J.; Lopez, G.; Amutio, M.; Altzibar, H.; Olazar, M. Development of a dual conical spouted bed system for heat integration purposes. Powder Technol. 2014, 268, 261–268. [Google Scholar] [CrossRef]

- Zhou, G.; Zhong, W.; Yu, A.; Xie, J. Simulation of coal pressurized pyrolysis process in an industrial-scale spout-fluid bed reactor. Adv. Powder Technol. 2019, 30, 3135–3145. [Google Scholar] [CrossRef]

- Fernandez-Akarregi, A.R.; Makibar, J.; Lopez, G.; Amutio, M.; Olazar, M. Design and operation of a conical spouted bed reactor pilot plant (25 kg/h) for biomass fast pyrolysis. Fuel Process. Technol. 2013, 112, 48–56. [Google Scholar] [CrossRef]

- Makibar, J.; Fernandez-Akarregi, A.R.; Amutio, M.; Lopez, G.; Olazar, M. Performance of a conical spouted bed pilot plant for bio-oil production by poplar flash pyrolysis. Fuel Process. Technol. 2015, 137, 283–289. [Google Scholar] [CrossRef]

- Bove, D.; Moliner, C.; Curti, M.; Baratieri, M.; Bosio, B.; Rovero, G.; Arato, E. Preliminary tests for the thermo-chemical conversion of biomass in a spouted bed pilot plant. Can. J. Chem. Eng. 2019, 97, 59–66. [Google Scholar] [CrossRef]

| Years | Lab Scale | Demonstration | Plant/Industrial-Scale |

|---|---|---|---|

| 2013 | 10 | - | 1 |

| 2014 | 10 | 1 | - |

| 2015 | 12 | - | 1 |

| 2016 | 14 | - | - |

| 2017 | 4 | - | - |

| 2018 | 7 | - | - |

| 2019 | 5 | - | 1 |

| 2020 | 3 | 1 | - |

| 2021 | 3 | 1 | - |

| 2022 | 2 | 1 | 1 |

| 2023 | 13 | 5 | - |

| TOTAL | 83 | 9 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carozzo, V.; Arato, E.; Moliner, C. Review of Experimental Activities and Recent Developments of Spouted Bed Reactors at Different Operational Scales. Energies 2024, 17, 1046. https://doi.org/10.3390/en17051046

Carozzo V, Arato E, Moliner C. Review of Experimental Activities and Recent Developments of Spouted Bed Reactors at Different Operational Scales. Energies. 2024; 17(5):1046. https://doi.org/10.3390/en17051046

Chicago/Turabian StyleCarozzo, Valerio, Elisabetta Arato, and Cristina Moliner. 2024. "Review of Experimental Activities and Recent Developments of Spouted Bed Reactors at Different Operational Scales" Energies 17, no. 5: 1046. https://doi.org/10.3390/en17051046

APA StyleCarozzo, V., Arato, E., & Moliner, C. (2024). Review of Experimental Activities and Recent Developments of Spouted Bed Reactors at Different Operational Scales. Energies, 17(5), 1046. https://doi.org/10.3390/en17051046