Development of Shift Map for Electric Commercial Vehicle and Comparison Verification of Pneumatic 4-Speed AMT and 4-Speed Transmission with Synchronizer in Simulation

Abstract

1. Introduction

2. Vehicle Experiment and Modeling

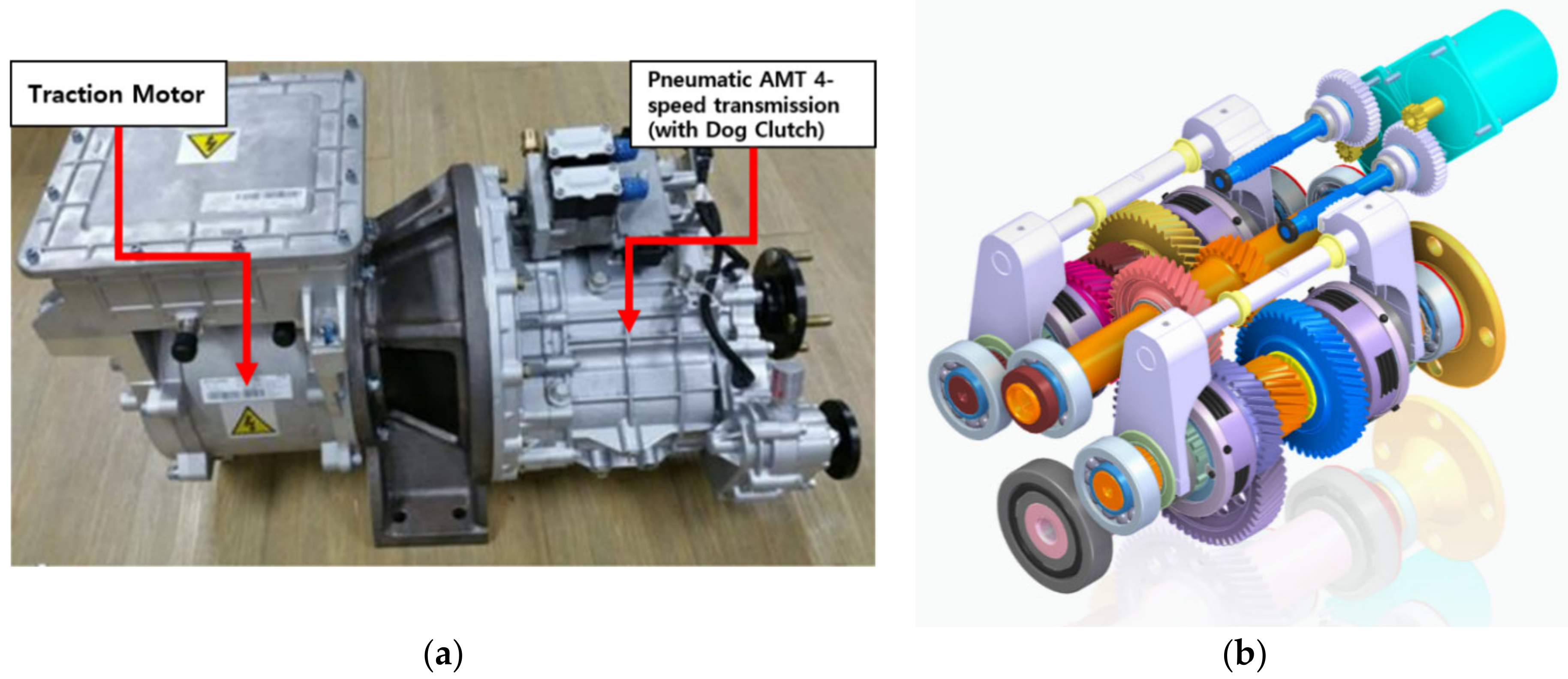

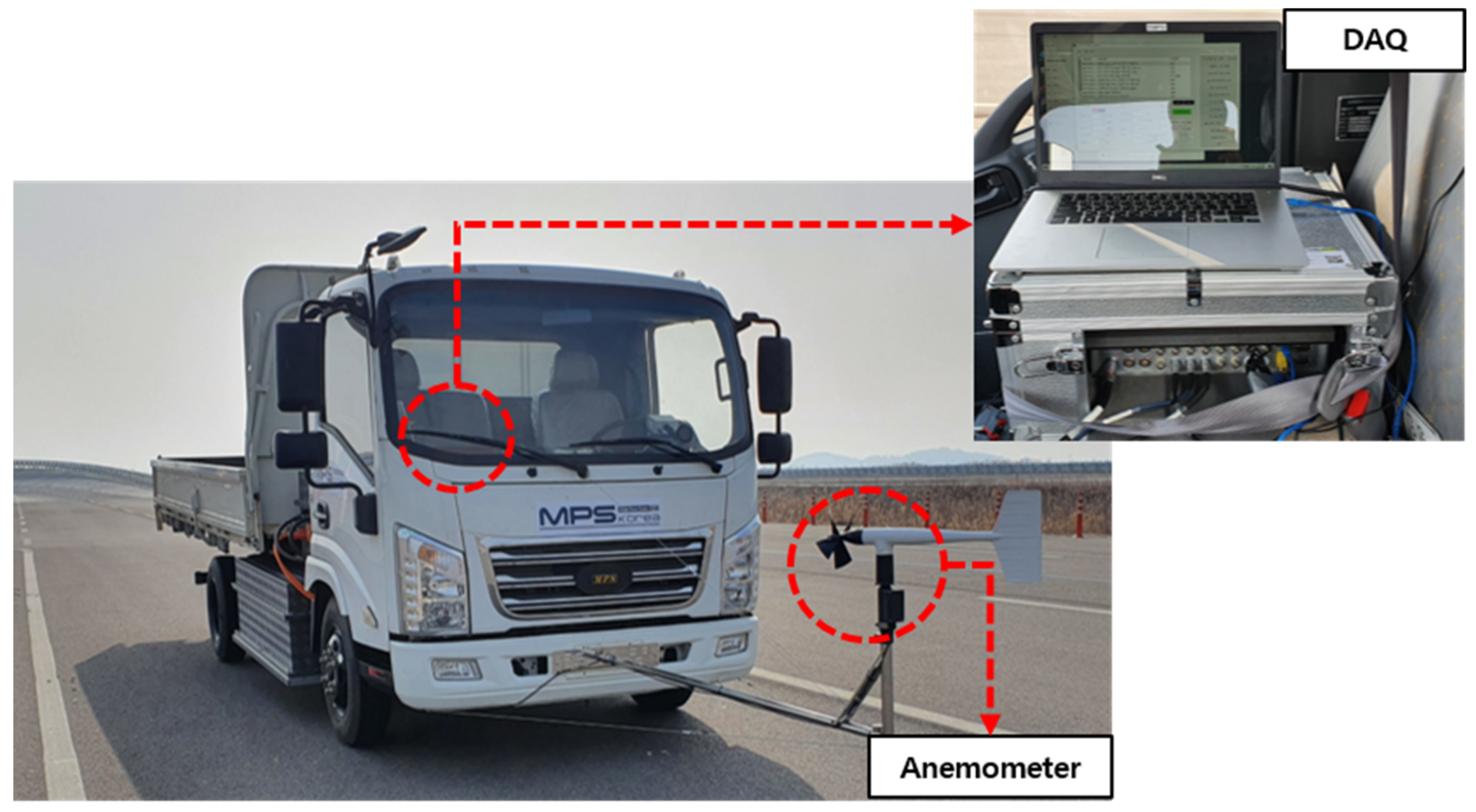

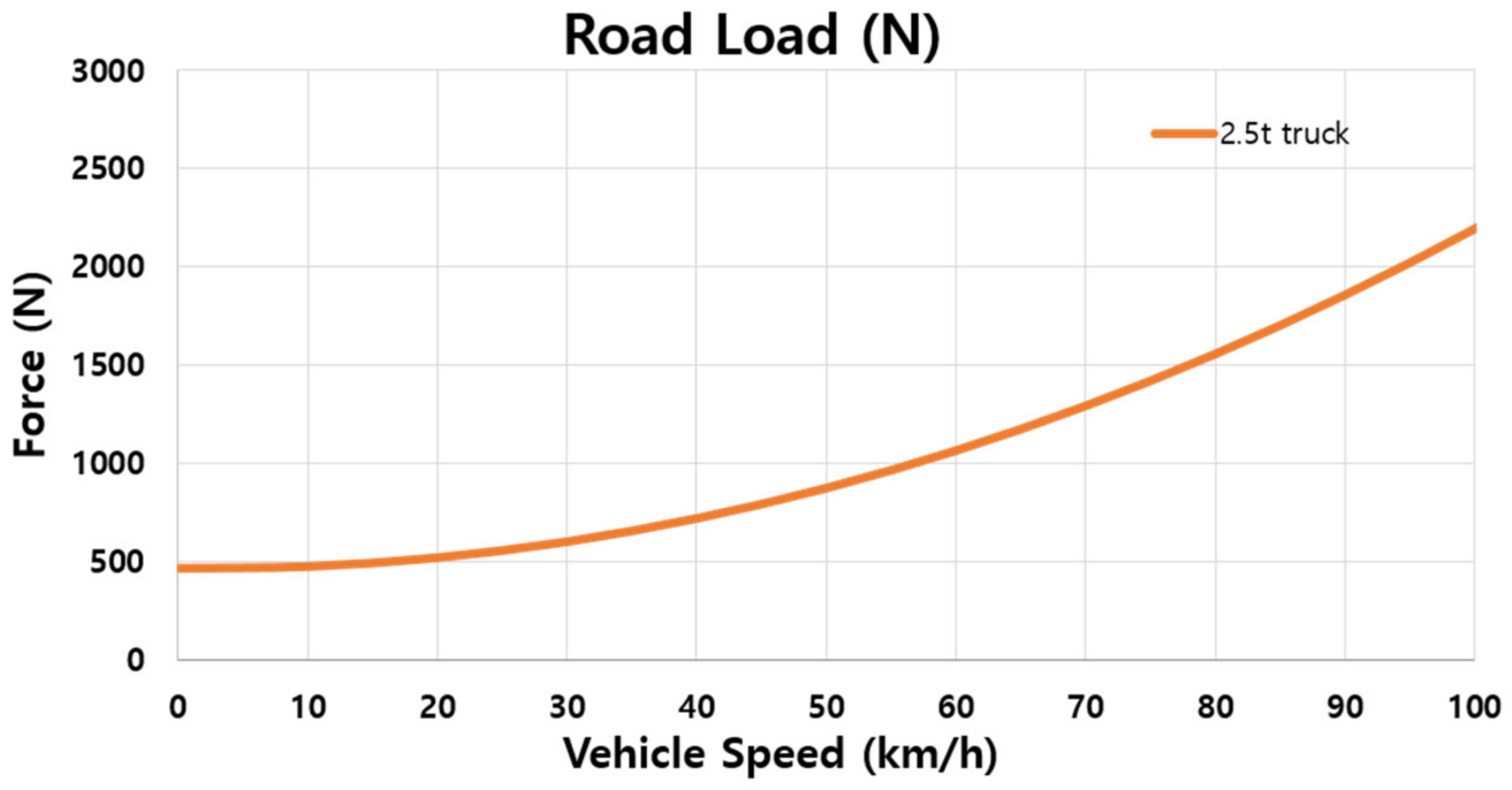

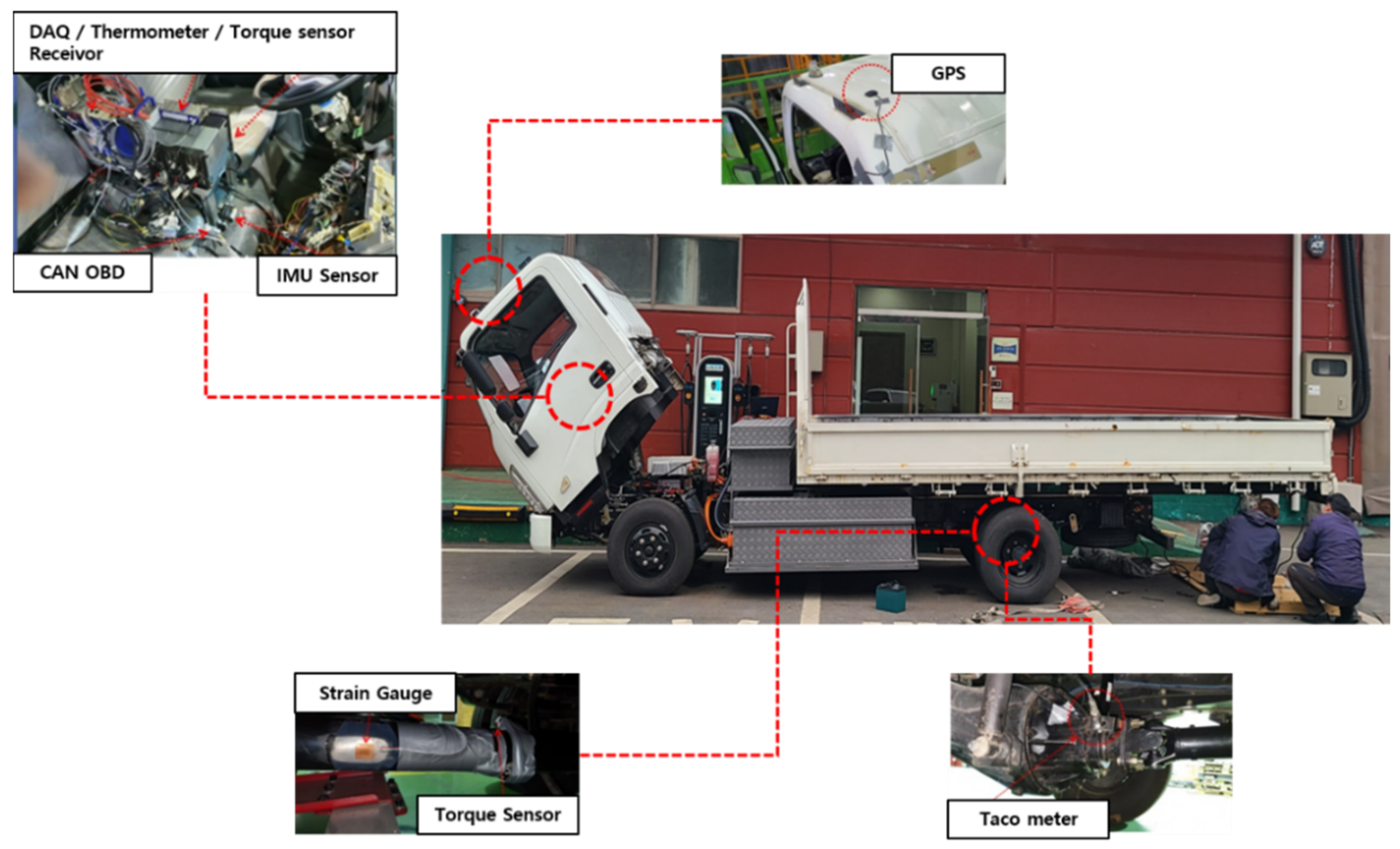

2.1. Experiments of Target Vehicle and Unit Tests

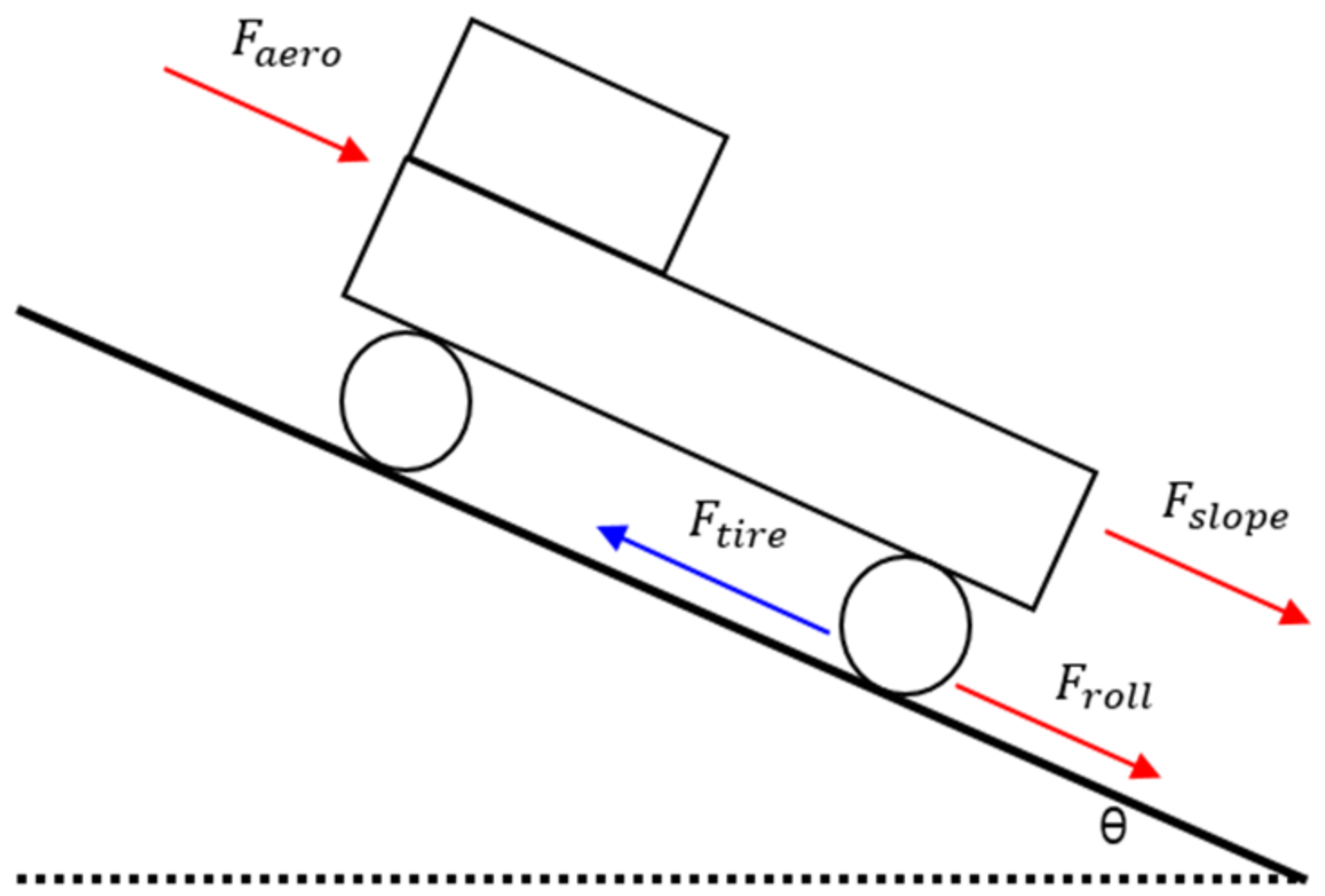

2.2. Modeling of Longitudinal Vehicle Dynamics

2.3. Modeling of Battery, Motor, VCU, and Driver Input

2.3.1. Battery

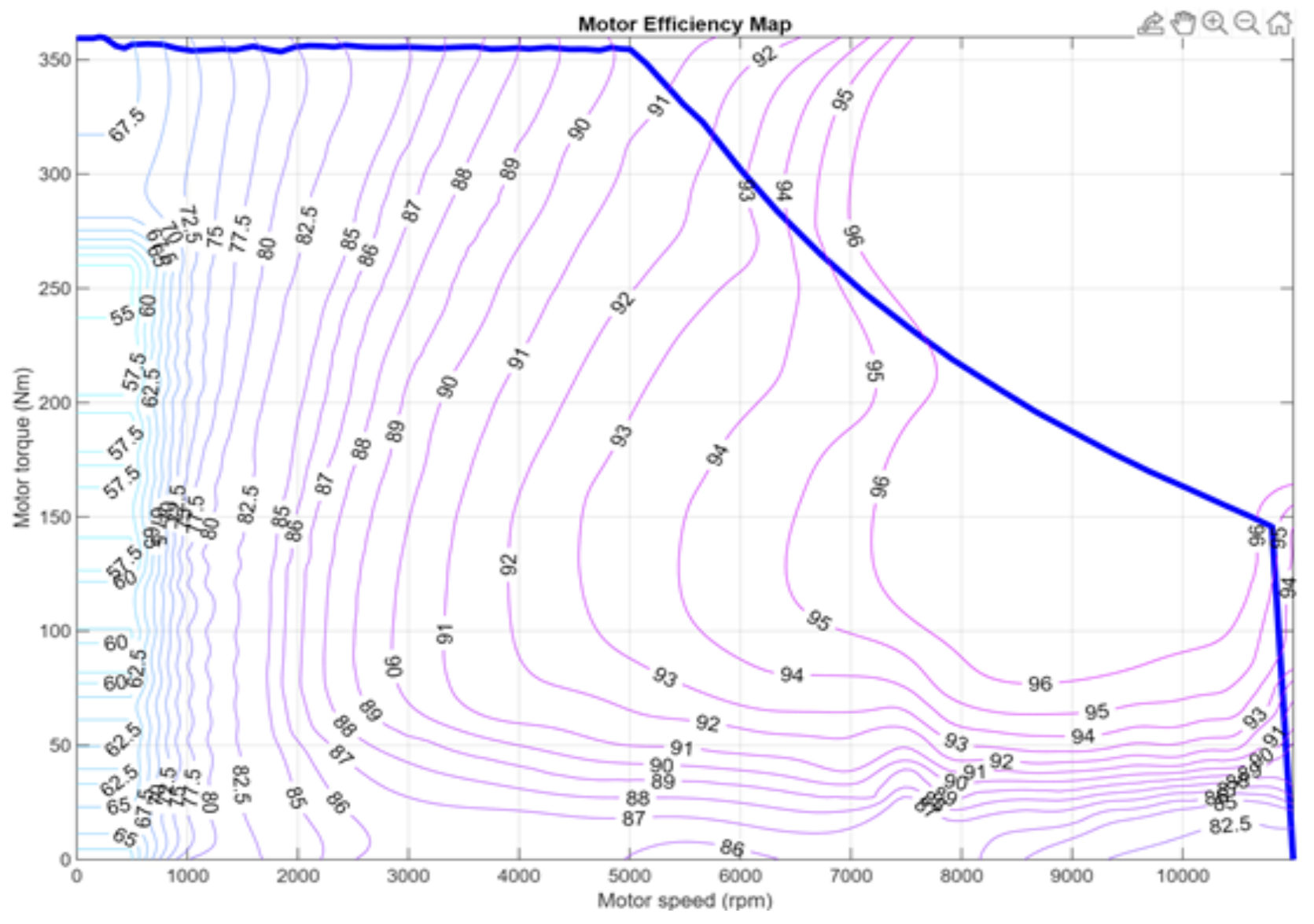

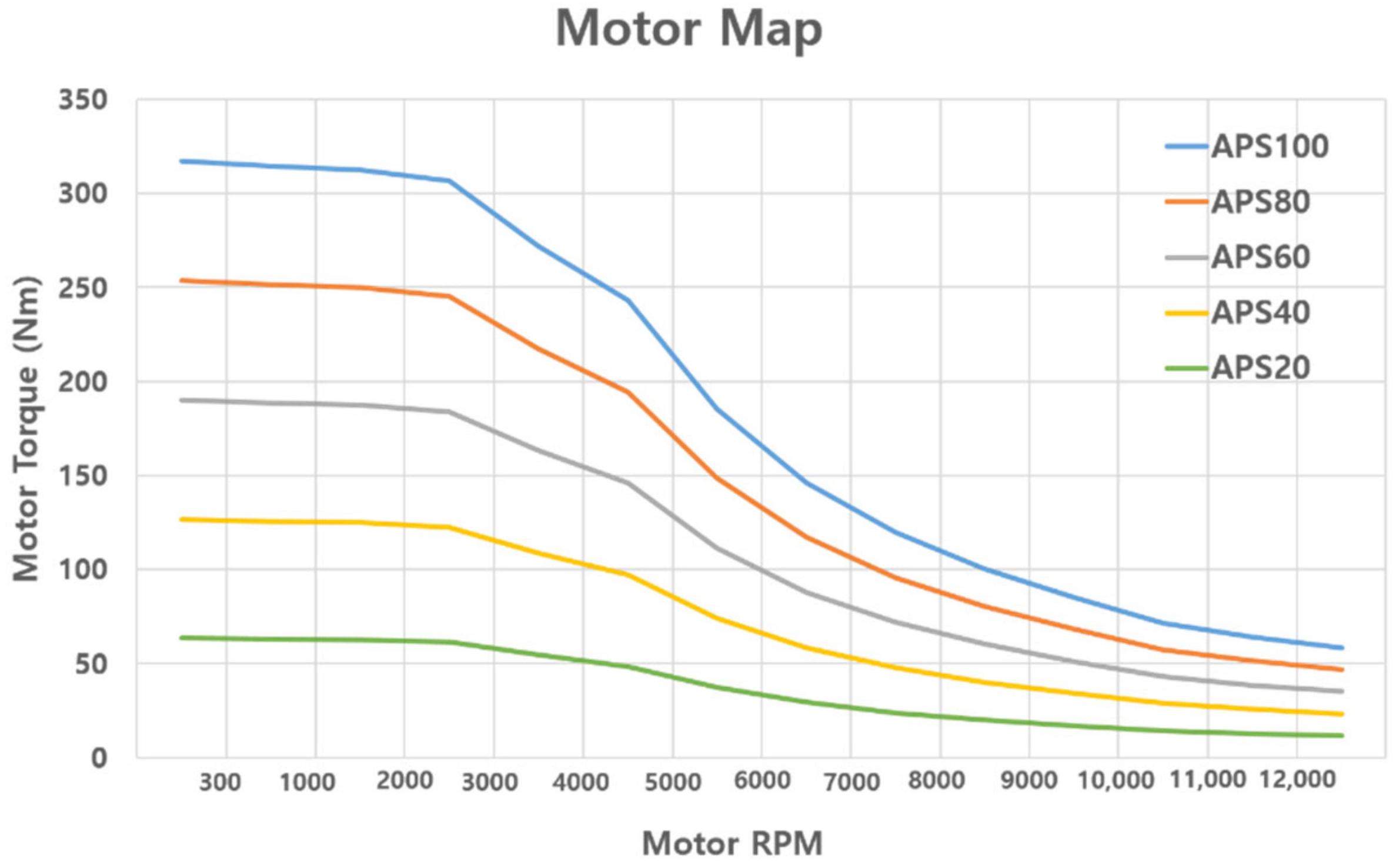

2.3.2. Motor

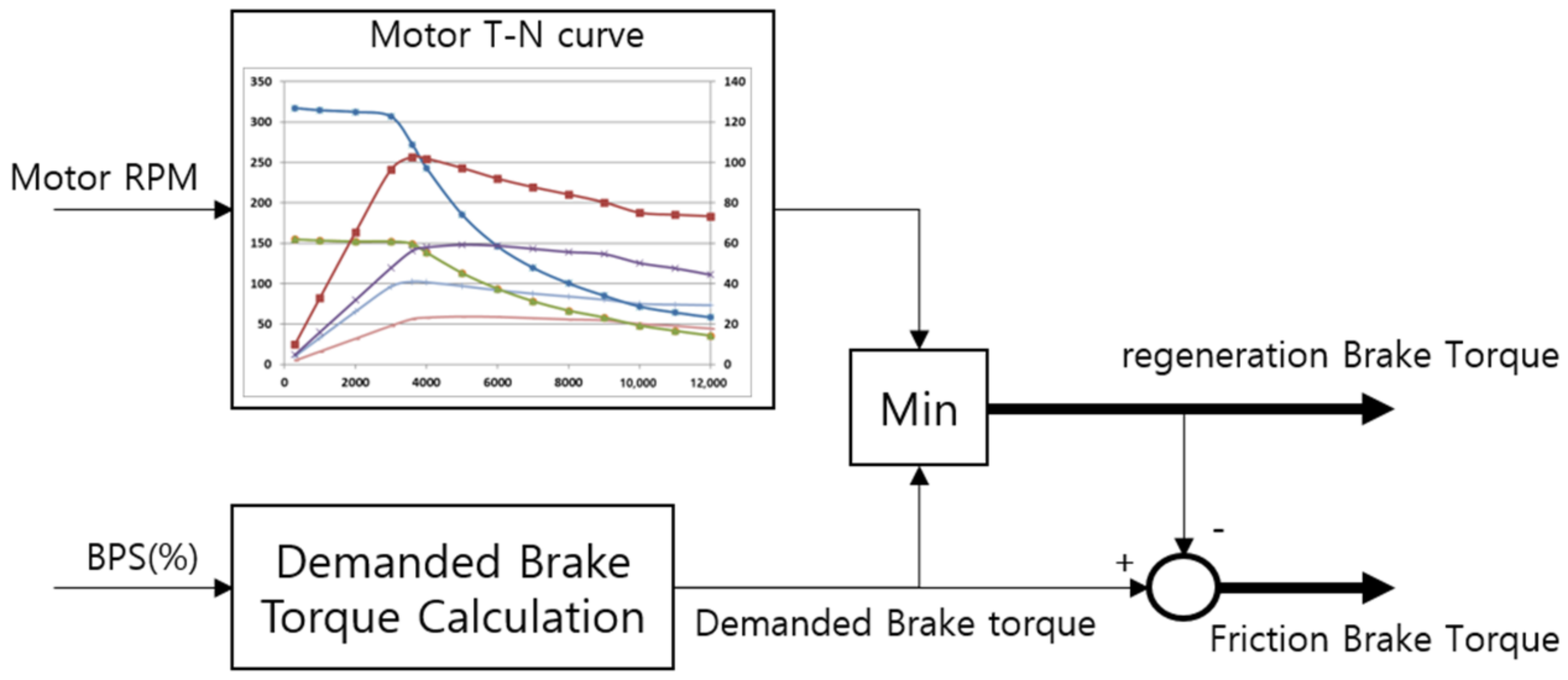

2.3.3. VCU

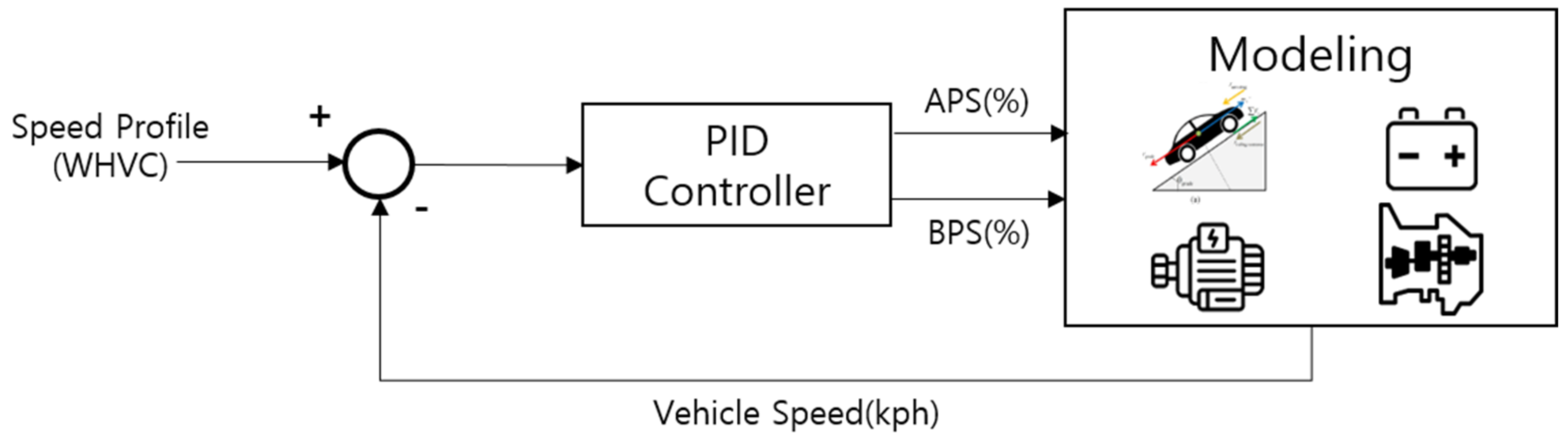

2.3.4. Driver Input

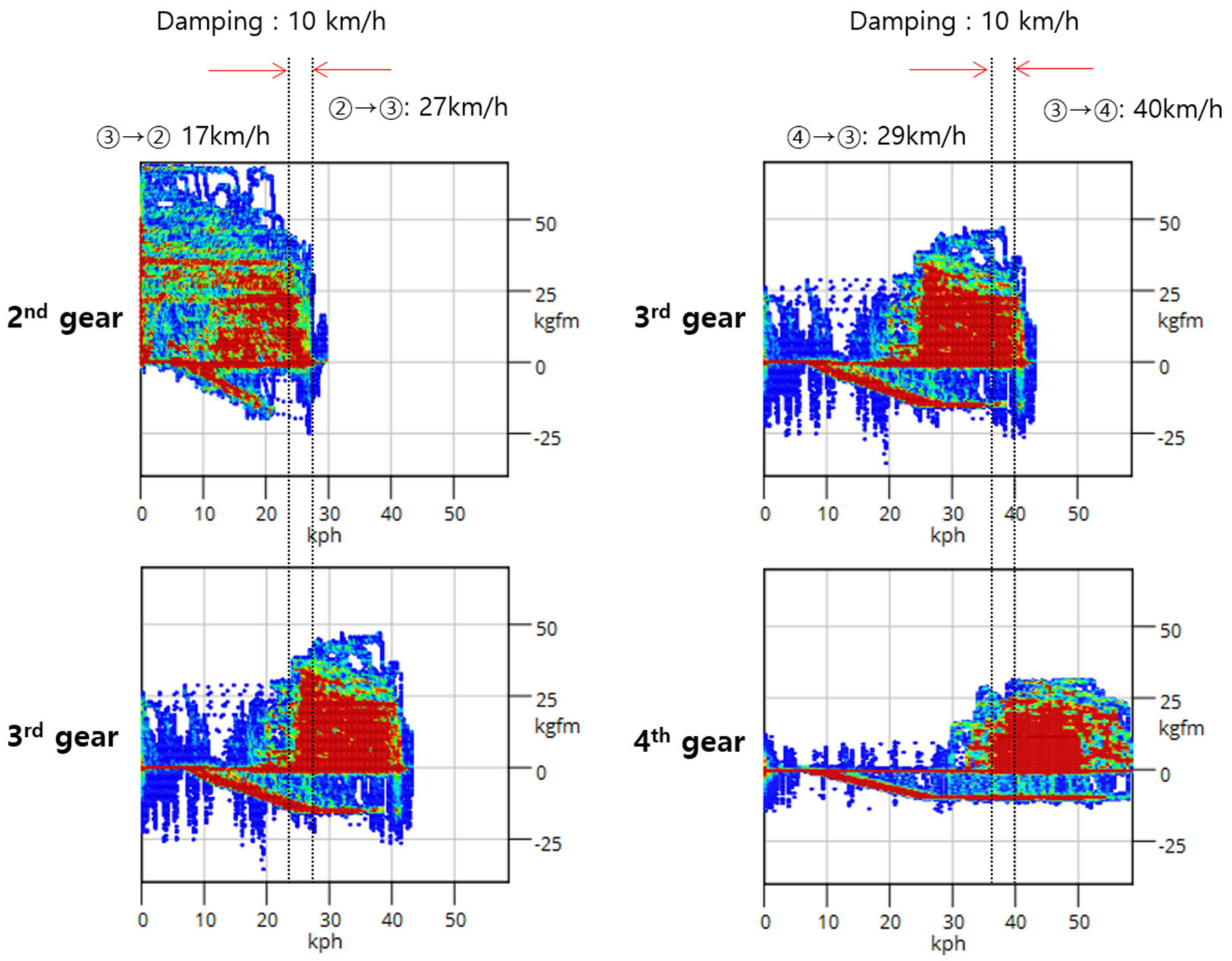

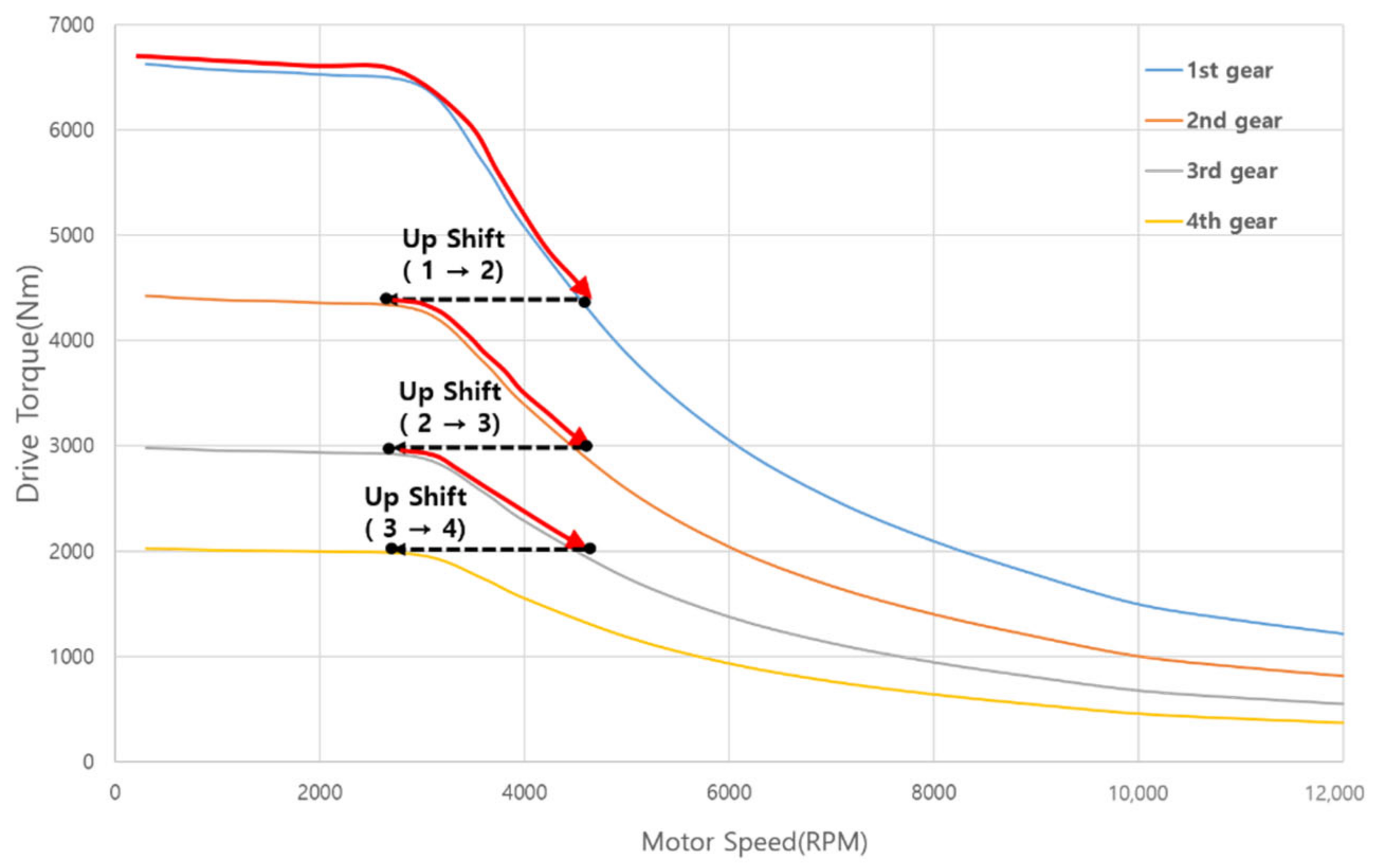

2.4. Development of Shift Map for 4-Speed Transmission with Synchronizer

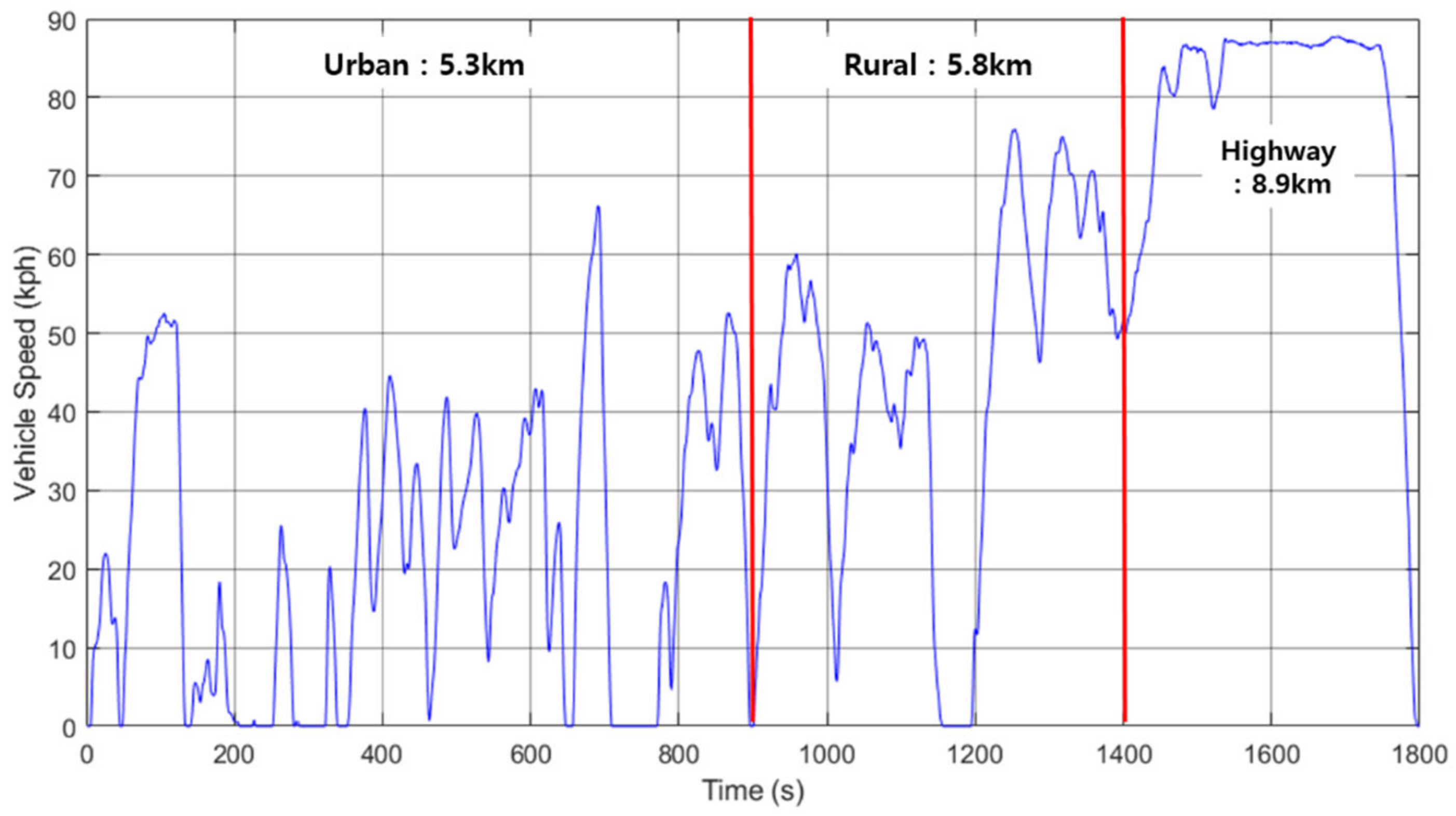

2.5. Development of Simulation Configuration

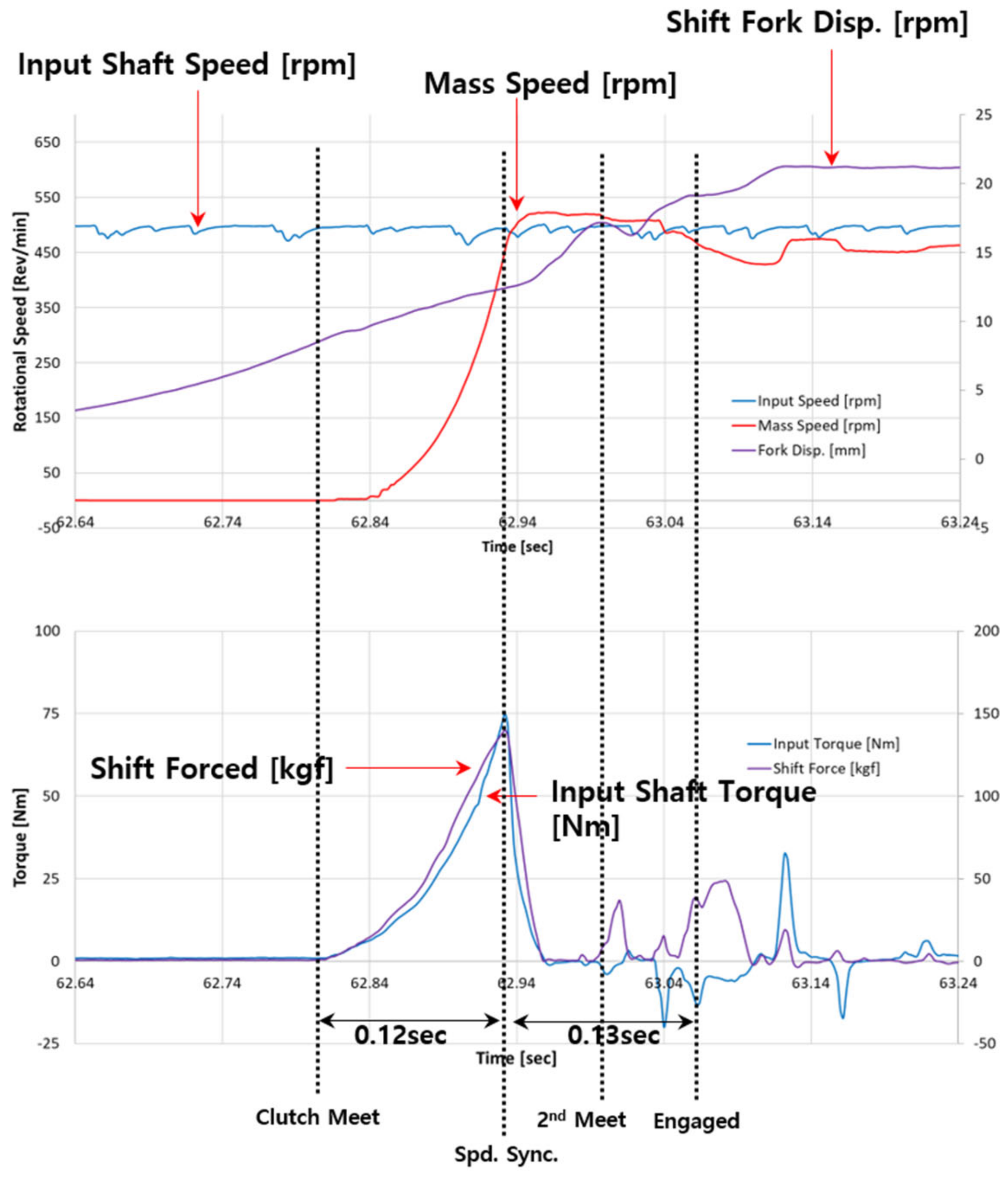

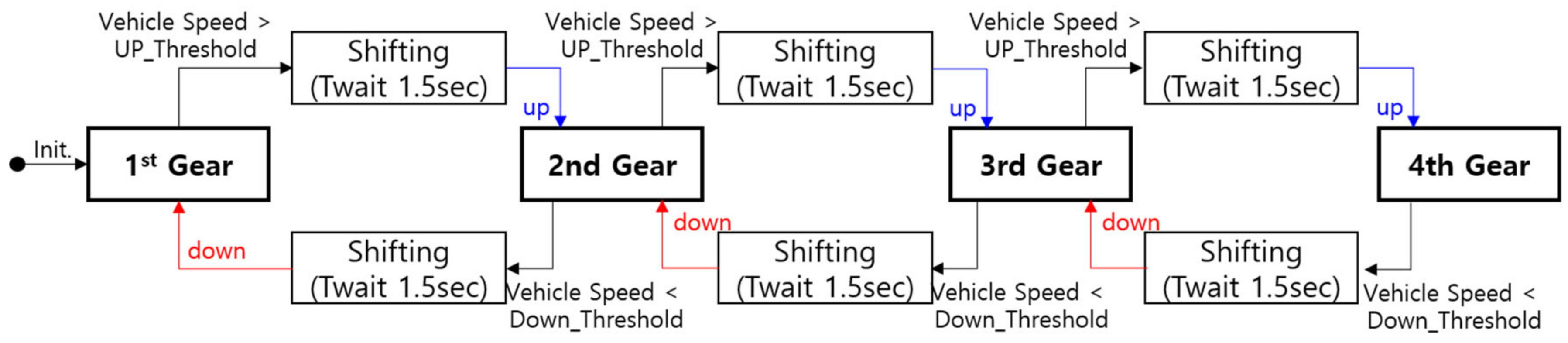

2.5.1. Pneumatic 4-Speed AMT Shift Logic Modeling

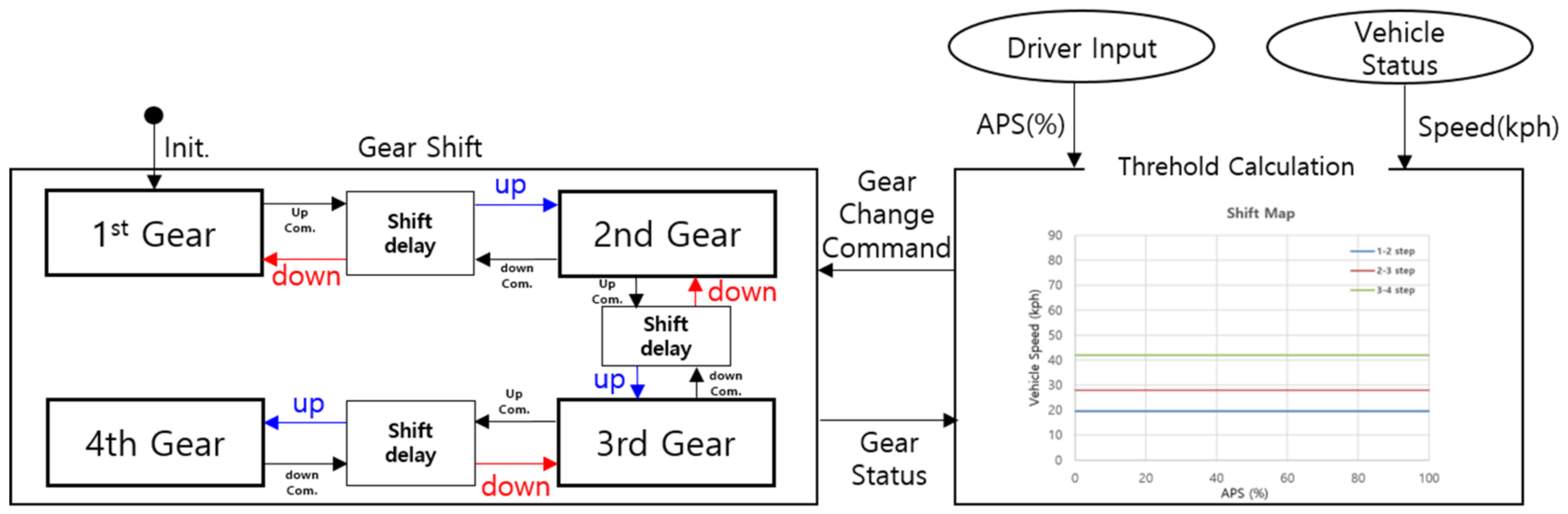

2.5.2. 4-Speed Transmission with Synchronizer Shift Logic Modeling

3. Results

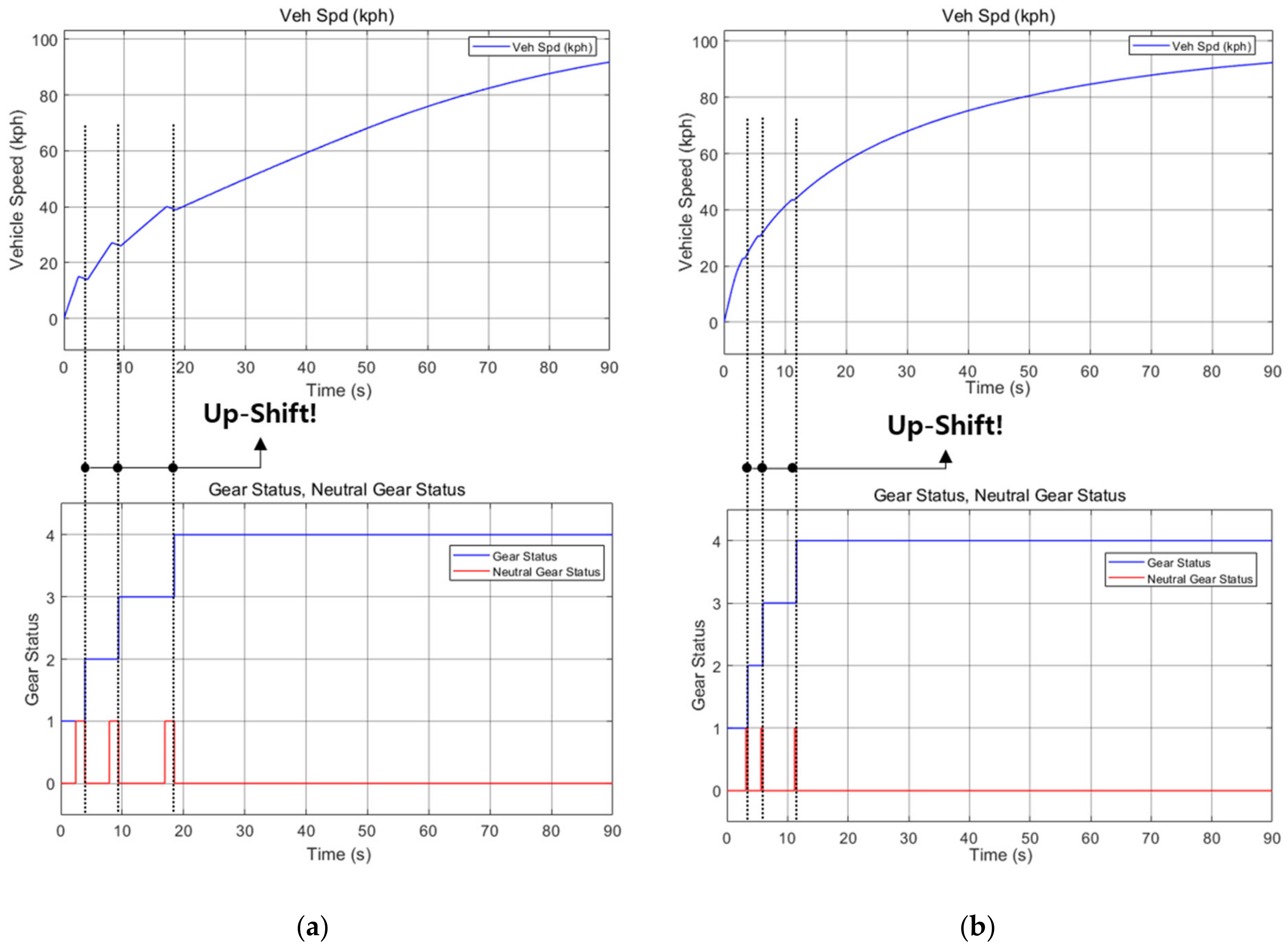

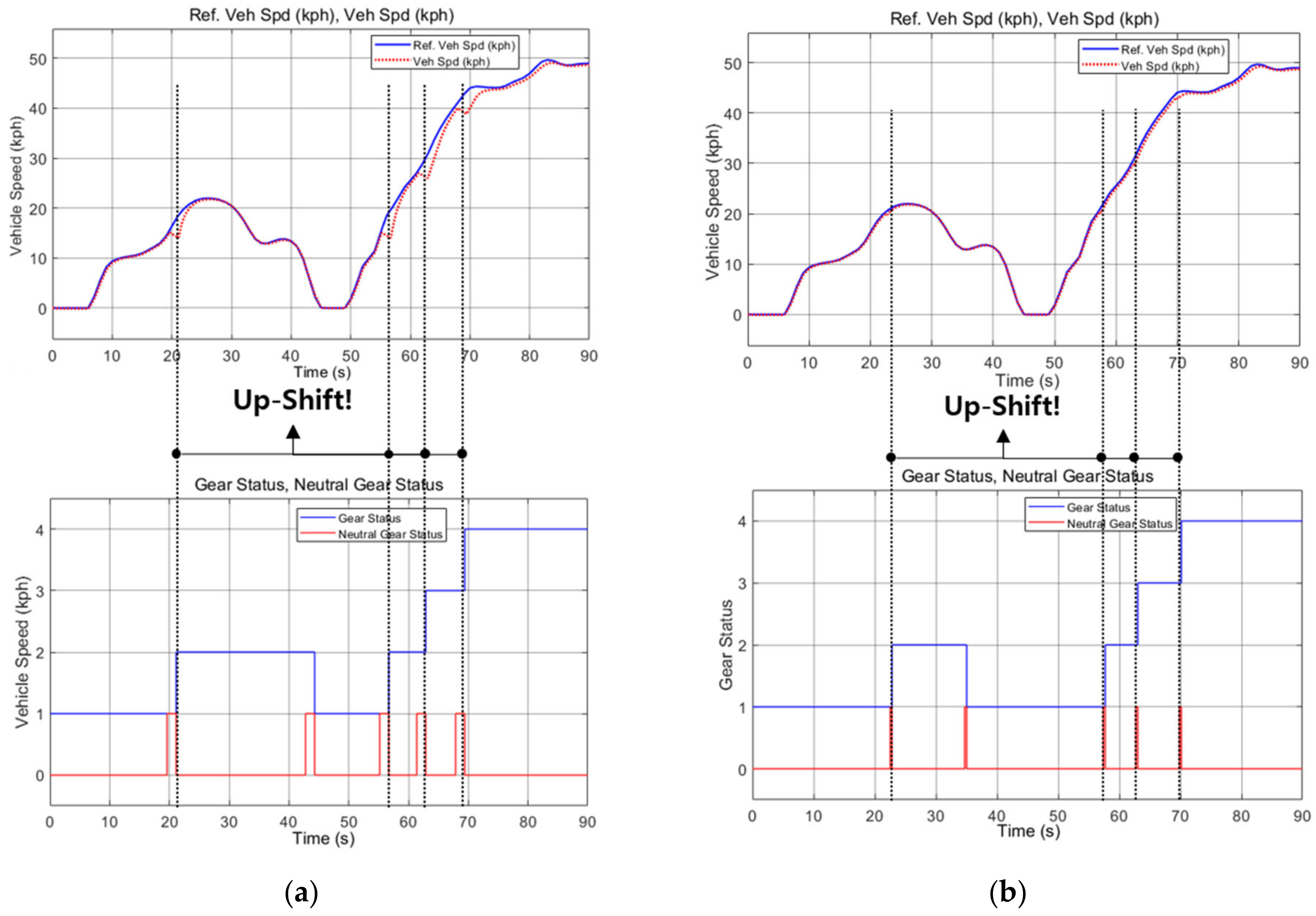

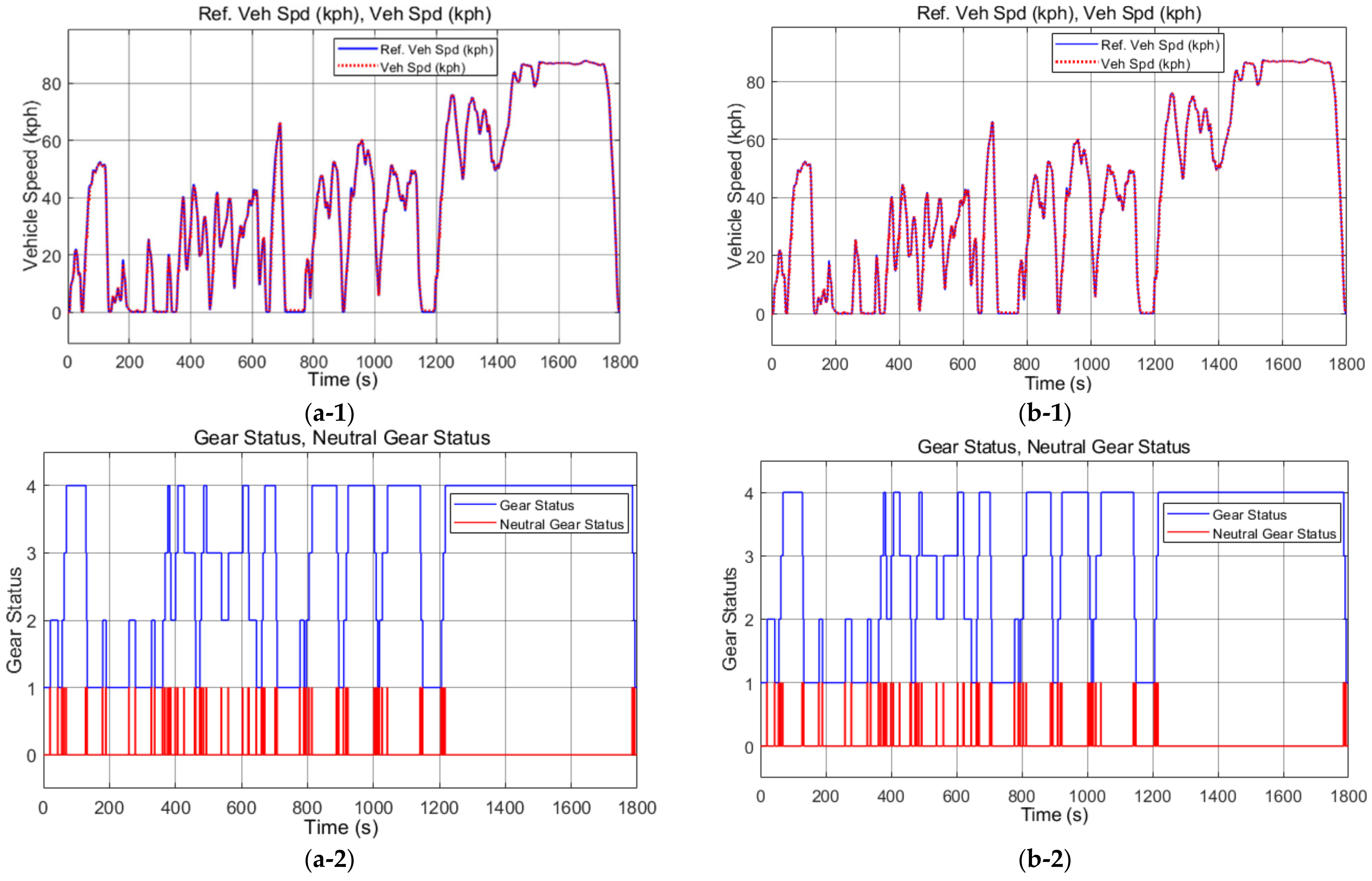

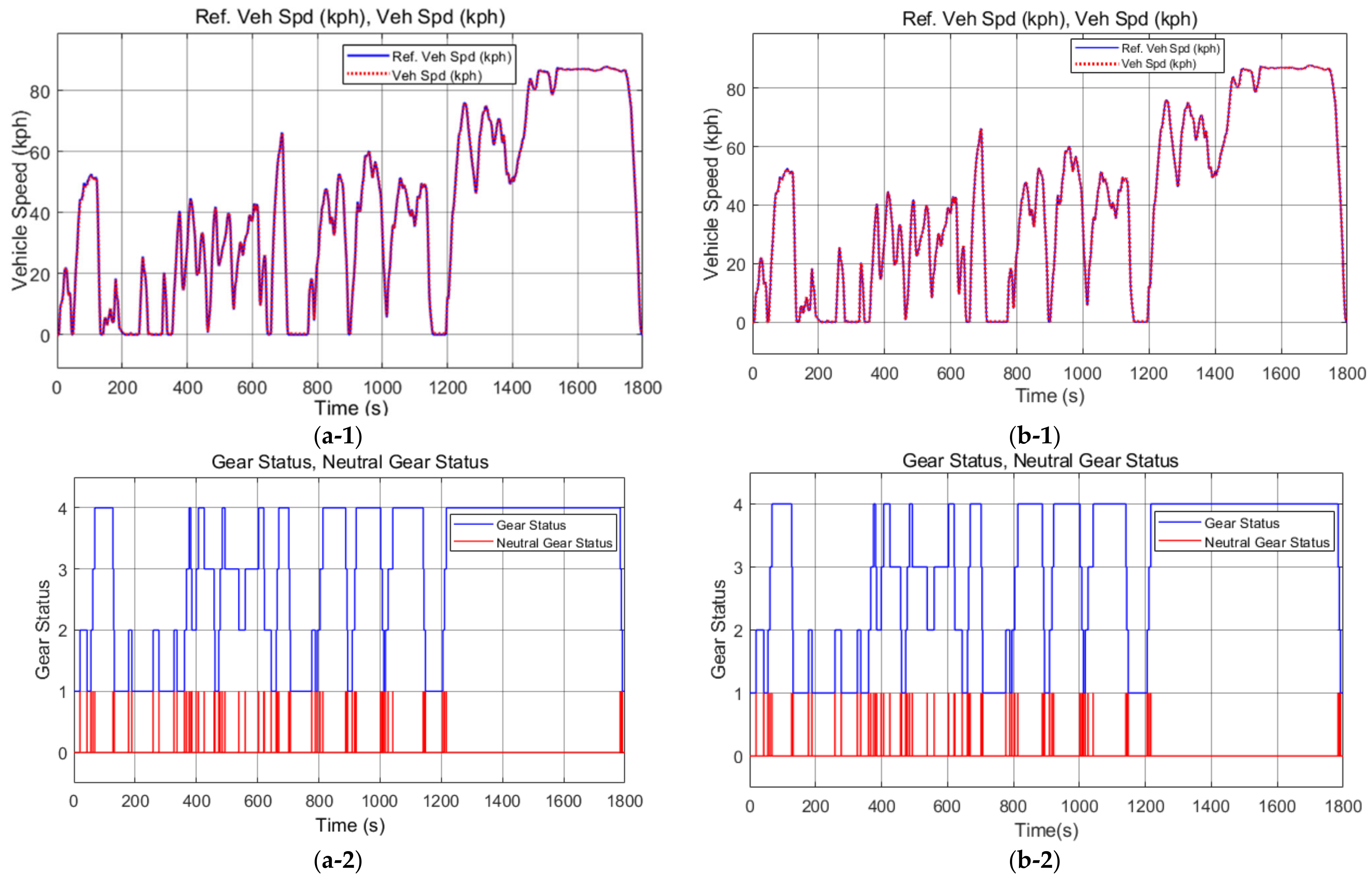

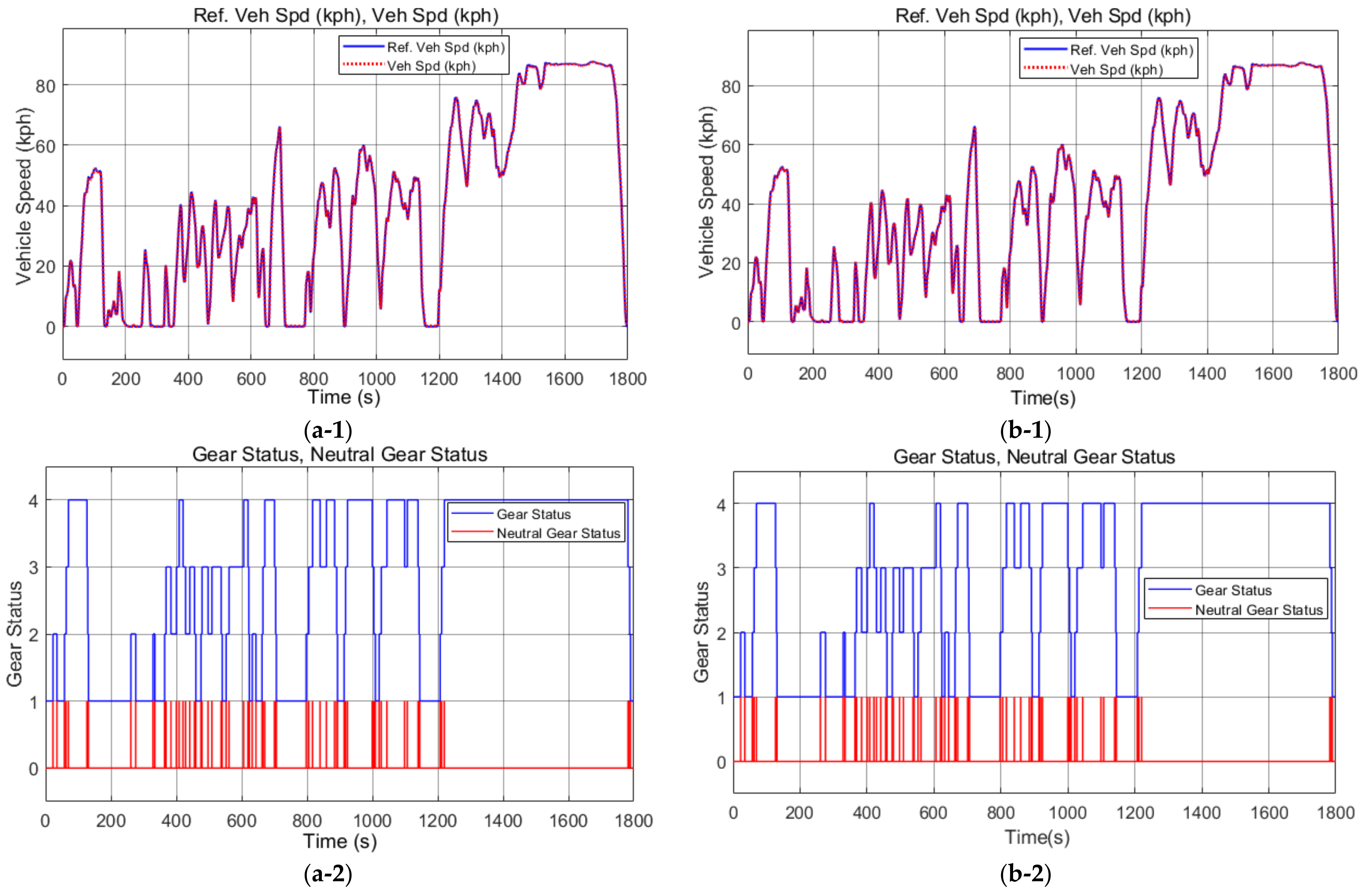

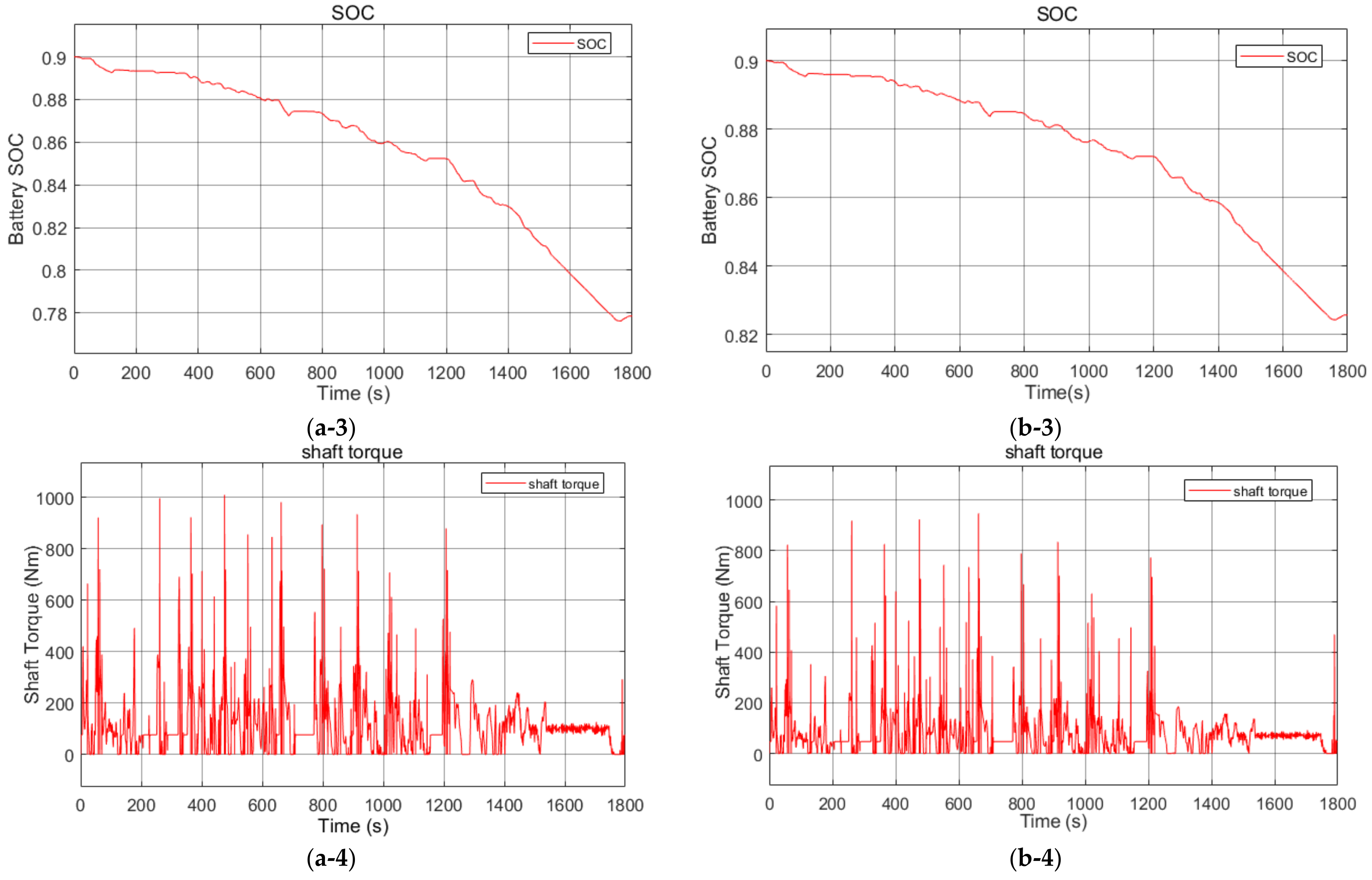

3.1. Shifting Delay Results in Simulation

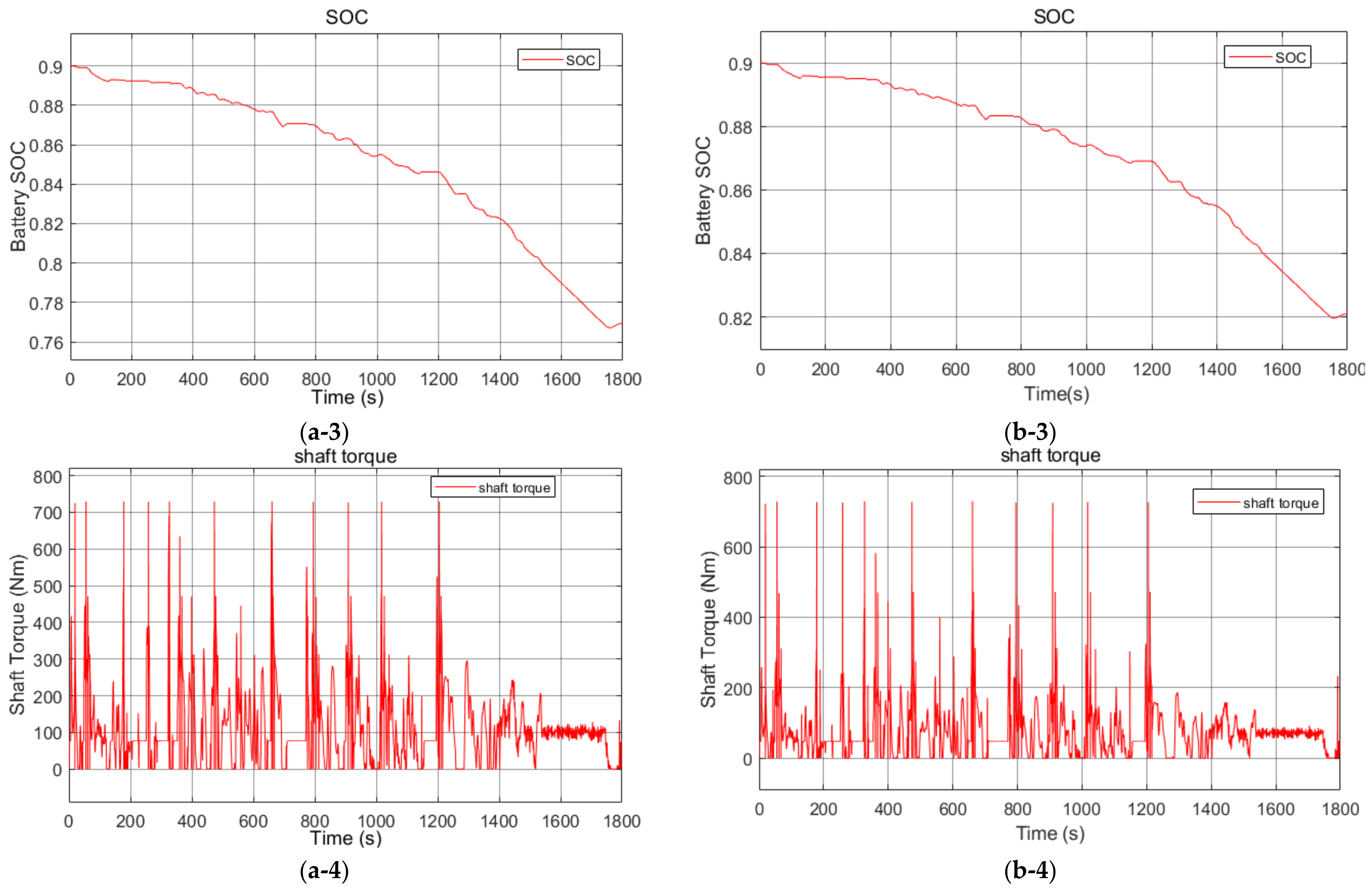

3.2. Comparison Verification of Efficiency and Performance

4. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kumar, M.S.; Revankar, S.T. Development scheme and key technology of an electric vehicle: An overview. Renew. Sustain. Energy Rev. 2017, 70, 1266–1285. [Google Scholar] [CrossRef]

- Zhang, W.; Fang, X.; Sun, C. The alternative path for fossil oil: Electric vehicles or hydrogen fuel cell vehicles? J. Environ. Manag. 2023, 341, 118019. [Google Scholar] [CrossRef]

- Nair, S.; Viri, R.; Mäkinen, J.; Pöllänen, M.; Liimatainen, H.; O’Hern, S. Effect of Policies to Accelerate the Adoption of Battery Electric Vehicles in Finland—A delphi Study. Future Transp. 2024, 4, 67–91. [Google Scholar] [CrossRef]

- Yun, S.; Yun, J.; Han, J. Development of a 470-Horsepower Fuel Cell–Battery Hybrid Xcient Dynamic Model Using SimscapeTM. Energies 2023, 16, 8092. [Google Scholar] [CrossRef]

- Martinez-Boggio, S.; Monsalve-Serrano, J.; García, A.; Curto-Risso, P. High Degree of Electrification in Heavy-Duty Vehicles. Energies 2023, 16, 3565. [Google Scholar] [CrossRef]

- Balazadeh Meresht, N.; Moghadasi, S.; Munshi, S.; Shahbakhti, M.; McTaggart-Cowan, G. Advances in Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles: A Review. Energies 2023, 16, 6809. [Google Scholar] [CrossRef]

- Xin, W.; Zhang, Y.; Fu, Y.; Yang, W.; Zheng, H. A multi-objective optimization design approach of large mining planetary gear reducer. Sci. Rep. 2023, 13, 18640. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Zha, M.; Wang, W.; Liu, K.; Xiang, C. Efficient energy management strategy for hybrid electric vehicles/plug-in hybrid electric vehicles: Review and recent advances under intelligent transportation system. IET Intell. Transp. Syst. 2020, 14, 702–711. [Google Scholar] [CrossRef]

- Konovalov, D.; Tolstorebrov, I.; Eikevik, T.M.; Kobalava, H.; Radchenko, M.; Hafner, A.; Radchenko, A. Recent Developments in Cooling Systems and Cooling Management for Electric Motors. Energies 2023, 16, 7006. [Google Scholar] [CrossRef]

- Poorfakhraei, A.; Narimani, M.; Emadi, A. A Review of Multilevel Inverter Topologies in Electric Vehicles: Current Status and Future Trends. IEEE Open J. Power Electron. 2021, 2, 155–170. [Google Scholar] [CrossRef]

- Mikhaylov, Y.; Aboelhassan, A.; Buticchi, G.; Galea, M. Considerations on the Development of High-Power Density Inverters for Highly Integrated Motor Drives. Electronics 2024, 13, 355. [Google Scholar] [CrossRef]

- Tian, S.; Wang, Y.; Wu, L. Parameters Matching and Effects of Different Powertrain on Vehicle: Performance for Pure Electric City Bus; SAE Technical Paper 2015-01-2799; SAE International: Pittsburgh, PA, USA, 2015. [Google Scholar]

- Fei, L.; Jian, S.; Shengnan, F.; Haijun, S.; Nguyen, T.S. Dynamic characteristics of a three-speed uninterrupted powertrain AMT. J. Tsinghua Univ. 2020, 61, 1–10. [Google Scholar]

- Ahssan, M.; Ektesabi, M.; Gorji, S. Electric Vehicle with Multi-Speed Transmission: A Review on Performances and Complexities. SAE Int. J. Altern. Powertrains 2018, 7, 169–181. [Google Scholar] [CrossRef]

- Vehviläinen, M.; Rahkola, P.; Keränen, J.; Pippuri-Mäkeläinen, J.; Paakkinen, M.; Pellinen, J.; Tammi, K.; Belahcen, A. Simulation-Based Comparative Assessment of a Multi-Speed Transmission for an E-Retrofitted Heavy-Duty Truck. Energies 2022, 15, 2407. [Google Scholar] [CrossRef]

- Shin, J.W.; Kim, J.O.; Choi, J.Y.; Oh, S.H. Design of 2-Speed Transmission For Electric Commercial Vehicle. IJAT 2014, 15, 145–150. [Google Scholar] [CrossRef]

- Gao, B.; Liang, Q.; Xiang, Y.; Guo, L.; Chen, H. Gear ratio optimization and shift control of 2-speed I-AMT in electric vehicle. Mech. Syst. Signal Process. 2015, 50, 615–632. [Google Scholar] [CrossRef]

- Walker, P.D.; Abdul Rahman, S.; Zhu, B.; Zhang, N. Modeling, Simulations, and Optimization of Electric Vehicle for Analysis of Transmission Ratio Selection. Sage journals. Adv. Mech. Eng. 2013, 5, 340435. [Google Scholar] [CrossRef]

- Wang, H.; Wang, B.; Pi, D.; Wang, E.; Wang, X. Two-Layer Structure Control of an Automatic Mechanical Transmission Clutch During Hill Start for Heavy-Duty Vehicles. IEEE Access 2020, 8, 49617–49628. [Google Scholar] [CrossRef]

- Mali, V.; Mache, A.; Mulik, R.; Ramdasi, S. Desing Methodology for Gear Shift Map of Automated Manual Transmission. IConAMMA 2017, 5, 23899–23907. [Google Scholar]

- Ngo, V.D.; Hofman, T.; Steinbuch, M.; Serrarens, A. Gear shift map design methodology for automotive transmission. J. Automob. Eng. 2014, 228, 50–72. [Google Scholar] [CrossRef]

- Hong, S.; Son, H.; Lee, S.; Park, J.; Kim, K.; Kim, H. Shift control of a dry-type two-speed dual-clutch transmission for an electric vehicle. J. Automob. Eng. 2016, 230, 308–321. [Google Scholar] [CrossRef]

- Han, J.H.; Jeong, H.U.; Hwang, S.H. Design of Gear Shift Map for Automatic Transmission considering Transmission Efficiency. Trans. Korean Soc. Automot. Eng. 2019, 27, 611–617. [Google Scholar] [CrossRef]

| Specification | Pneumatic 4-Speed AMT | 4-Speed Transmission with Synchronizers |

|---|---|---|

| Locking mechanism | Dog clutch | Two synchronizers |

| 1st Gear ratio | 4.01:1 | 5.655:1 |

| 2nd Gear ratio | 2.33:1 | 3.7925:1 |

| 3rd Gear ratio | 1.51:1 | 2.552:1 |

| 4th Gear ratio | 1:1 | 1.739:1 |

| Final drive ratio | 6.14:1 | |

| Vehicle Spec. | Data |

|---|---|

| C.V.W | 4000 kg |

| G.V.W | 6500 kg |

| Payload capacity | 2500 kg |

| Size | (b) 2080 mm (h) 2345 mm (L) 5370 mm |

| Test Condition | |

|---|---|

| Vehicle weight | 4100 kg (Included person and test equipment) |

| Coast down velocity | 75 kph to 15 kph |

| Test location | S.M PG (proving ground) |

| Temperature | 11.5 °C |

| Maximum wind velocity | 9.5 km/h |

| Average wind velocity | 4.1 km/h |

| Data | Result |

|---|---|

| Driving resistance equation | |

| A | 468.271 N |

| B | −0.95447 N/kph |

| C | 0.1820732 N/ |

| Test Condition | APS | Road Gradient |

|---|---|---|

| From 10 kph, full accel. | From 10 kph—100% | 0% |

| From 30 kph, full accel. | From 30 kph—100% | 0% |

| From 50 kph, full accel. | From 50 kph—100% | 0% |

| Ramp | 100% | 6% |

| Ramp | 100% | 12% |

| Real road driving | Variation | Variation |

| Sensor Type | Location | Signal |

|---|---|---|

| Torque sensor | Shaft axle | Torque of axle (Nm) |

| IMU sensor | Mass center of vehicle | XYZ Accel. (g), XYZ angular rate (rad/s) |

| Strain gauge | Shaft axle | Strain (V) |

| Tachometer | Shaft axle | Rotation speed (RPM) |

| GPS | Top of vehicle cap | Vehicle speed (m/s), vehicle position (m) |

| Constants | Description | Data |

|---|---|---|

| Vehicle mass | C.V.W: 4000 kg G.V.W: 6500 kg | |

| Final drive ratio | 6.14 | |

| Effective rolling radius | 0.368 m | |

| Drag of coefficient | 0.3 | |

| ρ | Air density | 1.16 |

| Front projection area | 3.902 | |

| Coefficient of rolling resistance | 0.02 |

| Battery Spec. | Data |

|---|---|

| Battery cell | Li-ion 21700 |

| Battery configuration | 96S 72P |

| Nominal voltage | 350 V |

| Battery capacity | 360 Ah |

| Number of cells × Li-ion cell voltage | |

| 0.5 Ω | |

| 100 kWh |

| Motor Spec. | Data |

|---|---|

| Maximum torque | 320 Nm @300 RPM |

| Nominal torque | 157 Nm @300 RPM |

| Maximum power | 100.4 kW @3600 RPM |

| Nominal power | 60 kW @12,000 RPM |

| Simulation Results | Pneumatic 4-Speed AMT (with 1.5 s Shift Delay) | Pneumatic 4-Speed AMT (with 0.3 s Shift Delay) | 4-Speed Transmission with Synchronizers |

|---|---|---|---|

| With 2500 kg payload | |||

| Average fuel efficiency (km/kWh) | 1.378 | 1.533 | 1.69 |

| Battery SOC (%) | 90% > 75.46% | 90% > 76.93% | 90% > 78.15% |

| Speed error, RMS | 0.09841 | 0.04824 | 0.03716 |

| Without payload | |||

| Average fuel efficiency (km/kWh) | 2.143 | 2.533 | 2.697 |

| Battery SOC,(%) | 90% > 80.65% | 90% > 82.09% | 90% > 82.57% |

| Speed error, RMS | 0.06918 | 0.03203 | 0.02644 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Lee, Y.; Jin, H.; Park, S.; Hwang, S.-H. Development of Shift Map for Electric Commercial Vehicle and Comparison Verification of Pneumatic 4-Speed AMT and 4-Speed Transmission with Synchronizer in Simulation. Energies 2024, 17, 1038. https://doi.org/10.3390/en17051038

Kim J, Lee Y, Jin H, Park S, Hwang S-H. Development of Shift Map for Electric Commercial Vehicle and Comparison Verification of Pneumatic 4-Speed AMT and 4-Speed Transmission with Synchronizer in Simulation. Energies. 2024; 17(5):1038. https://doi.org/10.3390/en17051038

Chicago/Turabian StyleKim, Joohyung, Yoonkwon Lee, Hyomin Jin, Seunguk Park, and Sung-Ho Hwang. 2024. "Development of Shift Map for Electric Commercial Vehicle and Comparison Verification of Pneumatic 4-Speed AMT and 4-Speed Transmission with Synchronizer in Simulation" Energies 17, no. 5: 1038. https://doi.org/10.3390/en17051038

APA StyleKim, J., Lee, Y., Jin, H., Park, S., & Hwang, S.-H. (2024). Development of Shift Map for Electric Commercial Vehicle and Comparison Verification of Pneumatic 4-Speed AMT and 4-Speed Transmission with Synchronizer in Simulation. Energies, 17(5), 1038. https://doi.org/10.3390/en17051038