Abstract

Increasingly stringent pollutant emission regulations and a customer demand for a high-fuel economy drive the modern automotive industry to hurriedly solve the problem of decarbonization and powertrain efficiency, leading R&D towards alternative powertrain solutions and fuels. Electrification, today, plays the biggest role in the topic, with Mild Hybrid Electrified Vehicles (MHEVs) being the most cost-effective architectures, displaying dominance in smaller markets such as Brazil. One of the biggest challenges for HEVs’ development is the complexity of the hybrid control system, knowing when to actuate the electric machine, and the optimum power delivery, plus the gearshift schedule becomes a hard optimization problem that plays a key role in powertrain efficiency and cost savings for the customer. This paper proposes the implementation of a genetic algorithm (GA) as a machine learning-based control strategy to determine the torque split and the gear engaged for each driving condition of an MHEV operation, aiming to optimize fuel consumption. A quasi-static model of the vehicle was developed in Matlab/Simulink version 2022b, the virtual vehicle was then tested following the FTP75 and HWFET driving cycles. Simulation results indicate that the control decisions taken by the GA are qualitatively coherent for all operation conditions, and even quantitatively coherent in some cases, and that the software has the potential to be used as a control strategy outside the simulation environment, in future steps of development.

1. Introduction

Amid the 19th century, Internal Combustion Engines (ICEs) revolutionized the mobility industry, introducing to modern society a new concept of transportation—the automobile. Today, the global automotive fleet has exceeded 1.5 billion vehicles [1], making it one of the largest sectors in the global economy. Nevertheless, undesired byproducts from this advancement have led to negative environmental impacts and health issues, due to the emission of greenhouse gases [2]. Additionally, the continual rise in fossil fuel prices presents another challenge.

Consequently, achieving carbon neutrality [3] and enhancing fuel economy has become paramount for the automotive industry, pushed by strict emission legislations and consumer preference for economical vehicles, leading R&D towards many solutions including hardware and software enhancements, alternative fuels, and electrification.

1.1. The Electrification Path

An electrified vehicle consists of adding one or more electric machines to support the ICE or to completely supply the propulsion power demand from the driver. When properly controlled, such powertrains can actuate the electric machines in ways to avoid engine operation in regions of lower efficiency or when not needed and can even provide energy recovery during deceleration events (Regenerative Braking). The electrification level is categorized by the power electronics’ operation voltage, battery energy storage, and power, which when combined, determines the capability of the electric path and constrain energy-saving features. Table 1 makes a capability comparison between the six main EVs architectures, as follows: micro Hybrid (mHEV), mild Hybrid (MHEV), full/strong Hybrid (fHEV), Plug-in Hybrid (PHEV), Range-Extended Electric Vehicle (REEV), Battery Electric Vehicle (BEV) [4], and the state-of-the-art Fuel Cell Hybrid Electrified Vehicles (FCHEVs) [5].

Table 1.

xEVs’ capabilities comparison based on electrification level.

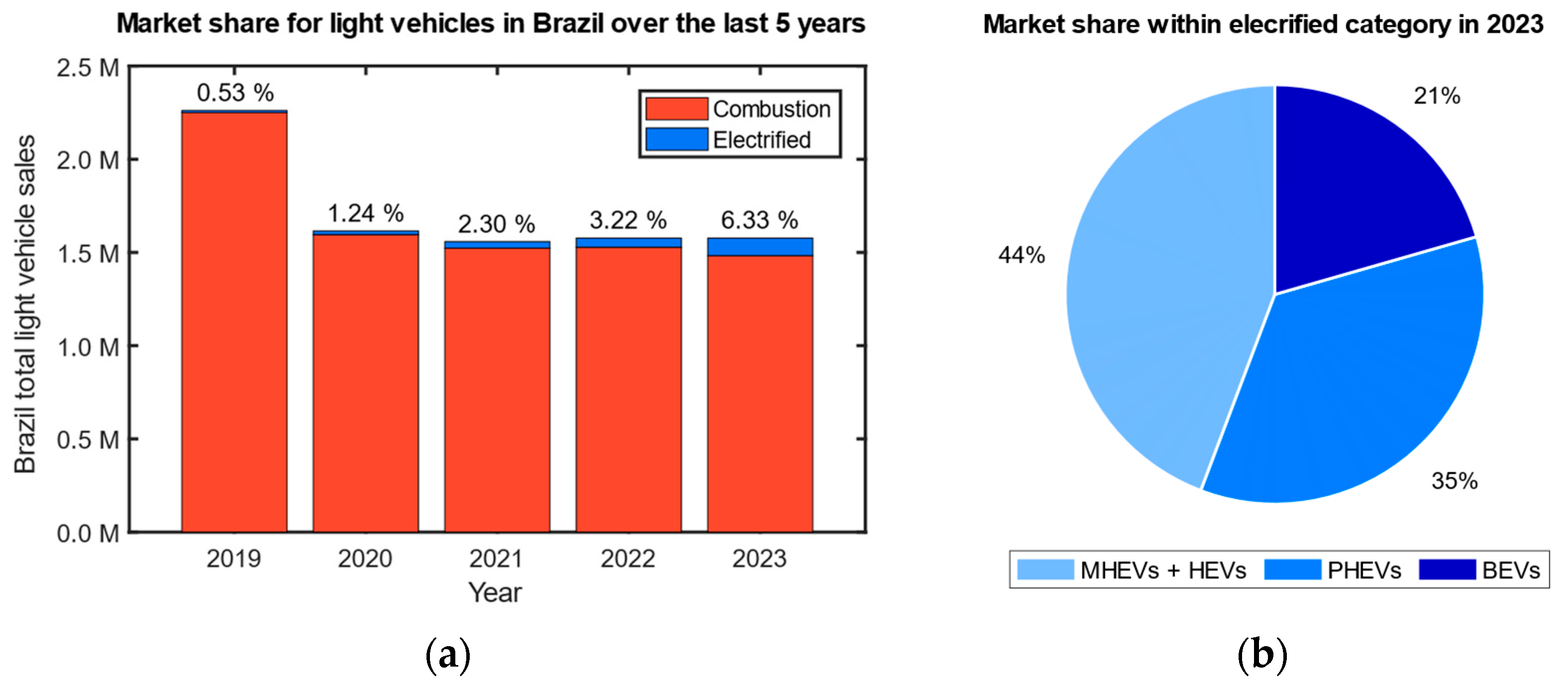

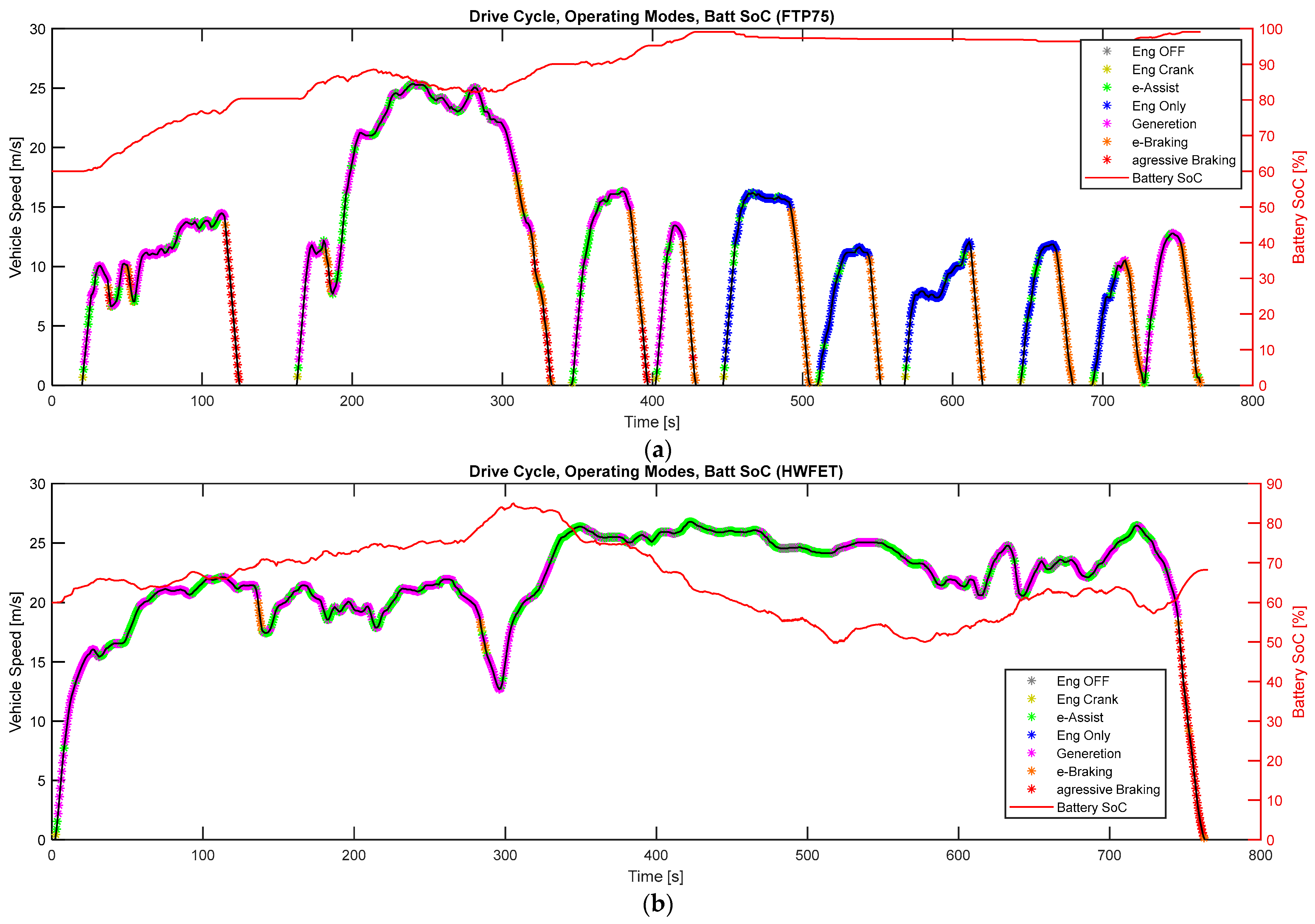

In Brazil the electrified market is very promising and, although the current adhesion is still incipient, an exponent-like growth in market share has been taking place over the last five years, as shown in Figure 1a (created using data from [6] (p. 14) and [7]). Amongst the electrified category, xHEV architecture (micro, mild, and full HEVs) holds the biggest market share, followed by PHEVs and BEVs, as shown in Figure 1b (created using data from [7]).

Figure 1.

(a) Market share for light vehicles in Brazil over the last 5 years; (b) market share within electrified category in Brazil 2023, 44% slice includes micro, mild, and full HEVs.

There are strong prospects for electrified vehicles, in general, and with Ethanol Hybrid technology (hybrid powertrain where engine is fueled by ethanol) as the main solution to achieve carbon neutrality and legislation compliance, this can be evidenced by substantial recent investments from global leading automakers to develop the technology [8,9]. Ethanol Hybrid technology is not a novel concept [10]; however, just recently, with stringent emission legislation and government subsides, it became feasible and profitable.

1.2. Challenges in the Control Strategy

On electrified powertrains, the hardware architecture has the ultimate influence over the control strategy complexity. The addition of more actuators besides the ICE [4], unlock new degrees of freedom to be controlled and optimized, enabling a better dynamic response and a higher powertrain efficiency, at the cost of a more complex hardware and software. In other words, knowing when the electric machines should help the ICE, the amount of power to be delivered at each driving condition to have optimal fuel consumption, and the gear shift schedule for vehicles equipped with computer actuated transmissions [11] are all complex optimization problems [5].

Currently, the automotive industry relies mostly on rule-based control strategies, such as in [12], and a great effort has been made by Calibration Engineers to tune controllers’ parameters. The problem with this method is that it requires a huge amount of manual effort, due to the iteration process, especially when the system is complex.

1.3. Purpose of This Research

A promising approach to shorten development time and improve robustness of calibration data is to employ computers on the iteration process, this can be carried out by associating the following two concepts:

- Virtualization: Data-based hardware (engine and e-motors) modeling and model-based control development, through acquisition of experimental hardware data.

- Tuning Automation: The use of optimization algorithms to iterate and tune the controller parameters. (e.g., GA and other optimization algorithms) [13].

This paper presents a simplified virtualization of an MHEV and the development of a genetic algorithm (GA) to act as Automatic Tuner and calibrate the torque split (ratio between the torque delivered by the Internal Combustion Engine (ICE) and the Belt Starter Generator (BSG)) and gear engaged, aiming for optimal fuel consumption.

1.4. State-of-the-Art

Currently, the automotive industry mostly relies on rule-based control strategies and great efforts from Calibration Engineers to tune controllers’ parameters. The concept of automated tune and the use of machine learning techniques and other optimization algorithms for the purpose of automatic tuning is still mainly research material.

Table 2 summarizes advances in research related to this manuscript’s content and the use of genetic algorithms and other techniques to perform similar tasks to those being proposed.

Table 2.

Literature review about GA-based control strategies and other control methods for HEVs.

The proposed paper introduces a novel approach to streamline the development process of controller tuning and enhance the robustness of calibration data for hybrid vehicles, which differs from the previous bibliographic review in the following key aspects:

- Integration of Virtualization and Tuning Automation: While the literature review primarily focuses on discussing existing energy management strategies and optimization techniques, this proposal combines the following two concepts: virtualization and tuning automation. Virtualization involves data-based hardware modeling and model-based control development, while tuning automation utilizes optimization algorithms to iterate and tune controller parameters.

- Development of a genetic algorithm for Automatic Tuning: This paper introduces the development of a genetic algorithm (GA) to serve as an automatic tuner for calibrating the torque split and gear engagement in the MHEV. Unlike the literature review, which discussed the application of GAs in optimizing energy management strategies, this proposal specifically focuses on using a GA to fine-tune controller parameters for optimal fuel consumption. Additionally, this paper mentions referencing other optimization algorithms used for similar purposes, indicating a broader exploration of optimization techniques beyond GAs.

2. System Description and Modeling

2.1. Powertrain Architecture

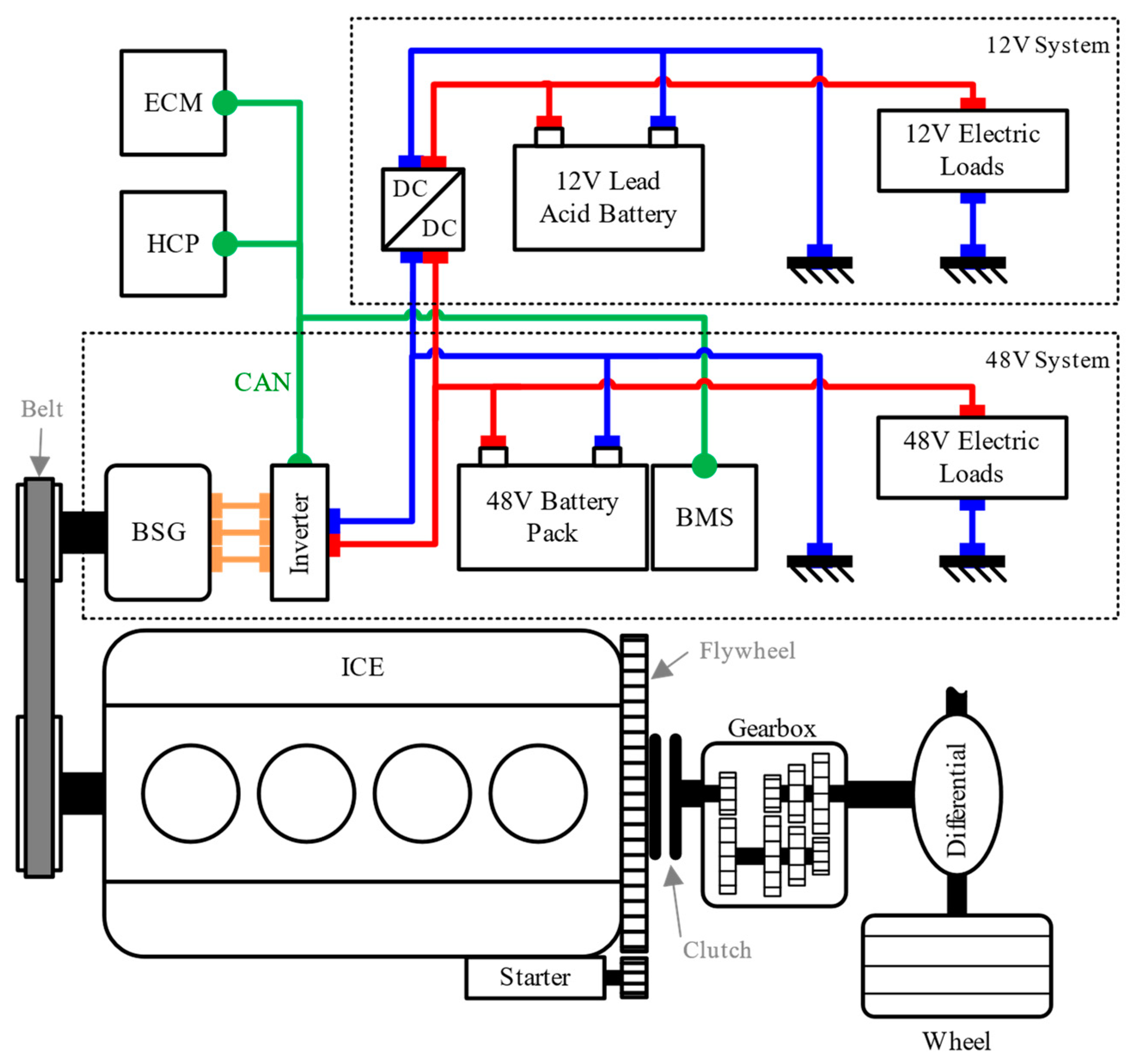

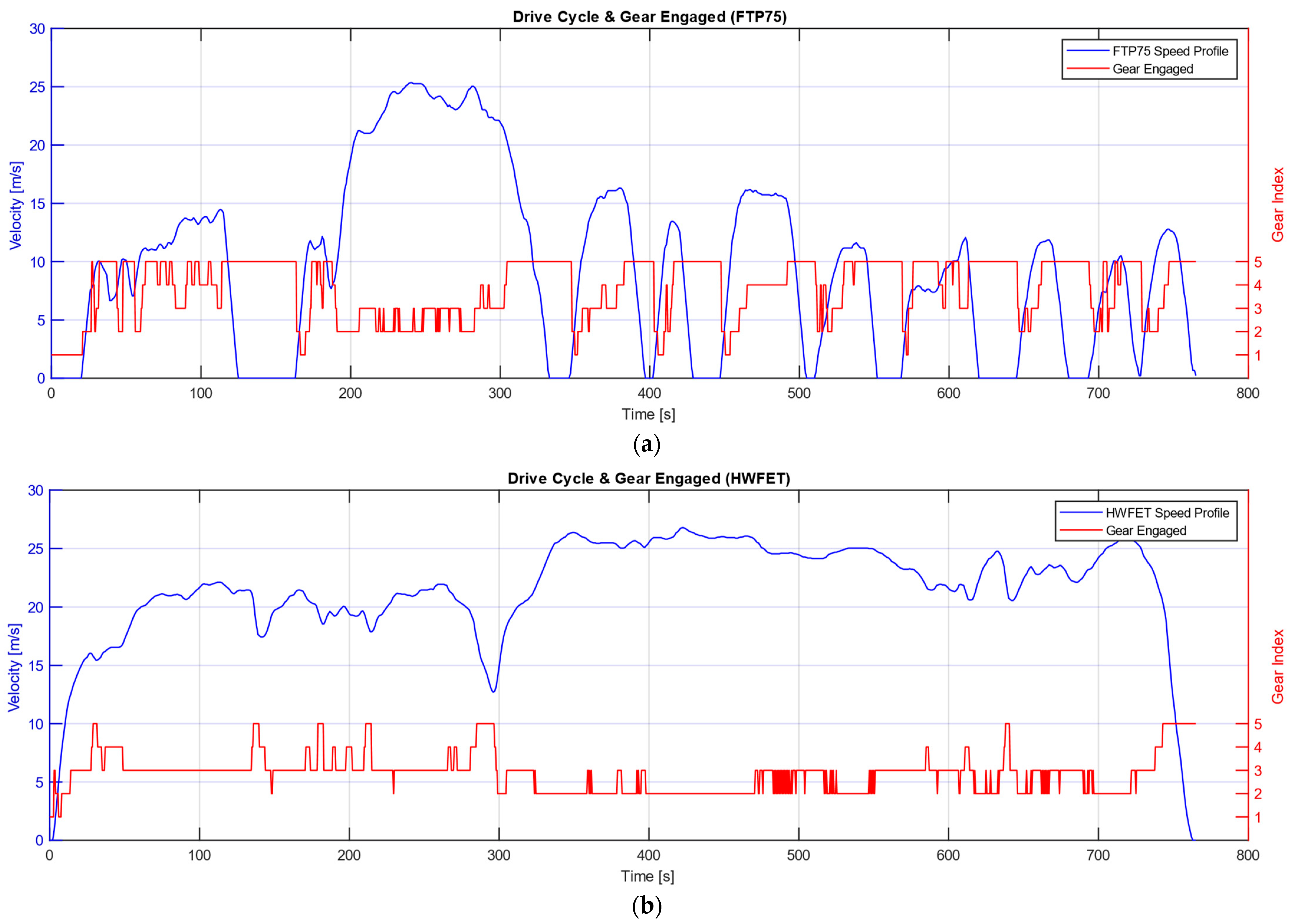

The focus of this work is an MHEV powertrain architecture, such as that in Figure 2, composed of an ICE and a 48 V Belt Starter Generator (BSG) [22]; in such a system, the presence of a Starter Motor that is much less powerful than the BSG is also very common, with the sole purpose of cranking the ICE at key crank (first crank of the drive cycle) or in any condition that the BSG is not capable of doing so, for example if the 48 V battery reaches a very low State of Charge (SoC).

Figure 2.

MHEV powertrain (ICE + 48 V BSG + Starter Motor), architecture schematic, and operating modes.

Such a system can operate at the following states:

- (1)

- Engine OFF: Vehicle is at standby, both ICE and BSG are OFF.

- (2)

- Engine Stop and Start (ESS): When the powertrain controller identifies enabling conditions adequate for an engine stop, for example in a traffic jam or when waiting for a traffic light, the engine is stalled (with -BSG help) and cranked again (with +BSG help), once a driver request or vehicle request (including critically low battery levels, system failure, etc.) is detected by the powertrain controllers.

- (3)

- e-Assist: When the torque requested by the driver is provided by both ICE and BSG (+ICE, +BSG).

- (4)

- ICE only: When the torque requested by the driver is provided only by the ICE (+ICE).

- (5)

- Generator mode: When the torque requested by the driver is fully provided by the ICE and, in addition to that, some torque is consumed by the BSG, which is working as a generator to charge the vehicle batteries (+ICE, -BSG).

- (6)

- e-Braking: When the braking torque requested by the driver is fully provided by the BSG, which is acting as a generator (-BSG).

- (7)

- Aggressive Braking: When the BSG is not capable of provide the total amount of braking torque being requested by the driver and the mechanical brakes are also engaged.

2.2. Vehicle Specification

The specifications for the MHEV are set out in Table 3, but can be changed by the user.

Table 3.

Vehicle specifications.

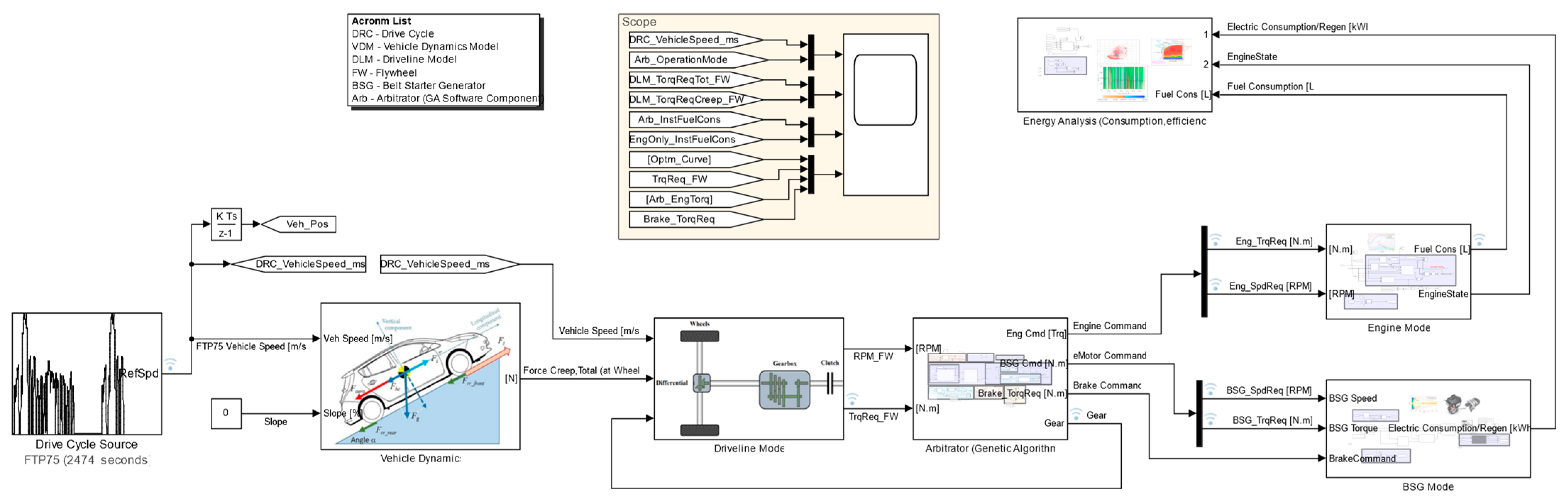

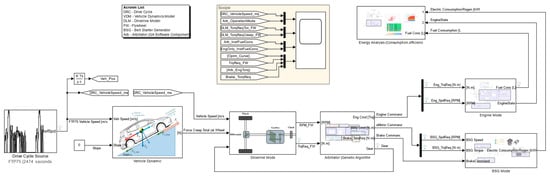

2.3. Simulink Model: Architecture and Software Components

A QuasiStatic, gray-box (equation- and data-driven), inverted simulation model of the vehicle was developed, as shown in Figure 3, following a similar approach to QSS-Toolbox 2.0.1 [23]. The intention of such an approach is to obtain the RPM and Torque demands at the flywheel from the drive cycle data and vehicle specifications only; with a data-driven model of the Engine and BSG, it is possible to make accurate estimations of the instantaneous fuel and electric energy consumption of the vehicle, throughout the drive cycle.

Figure 3.

Simulink model (cover).

The Model is composed of the following software components:

- (1)

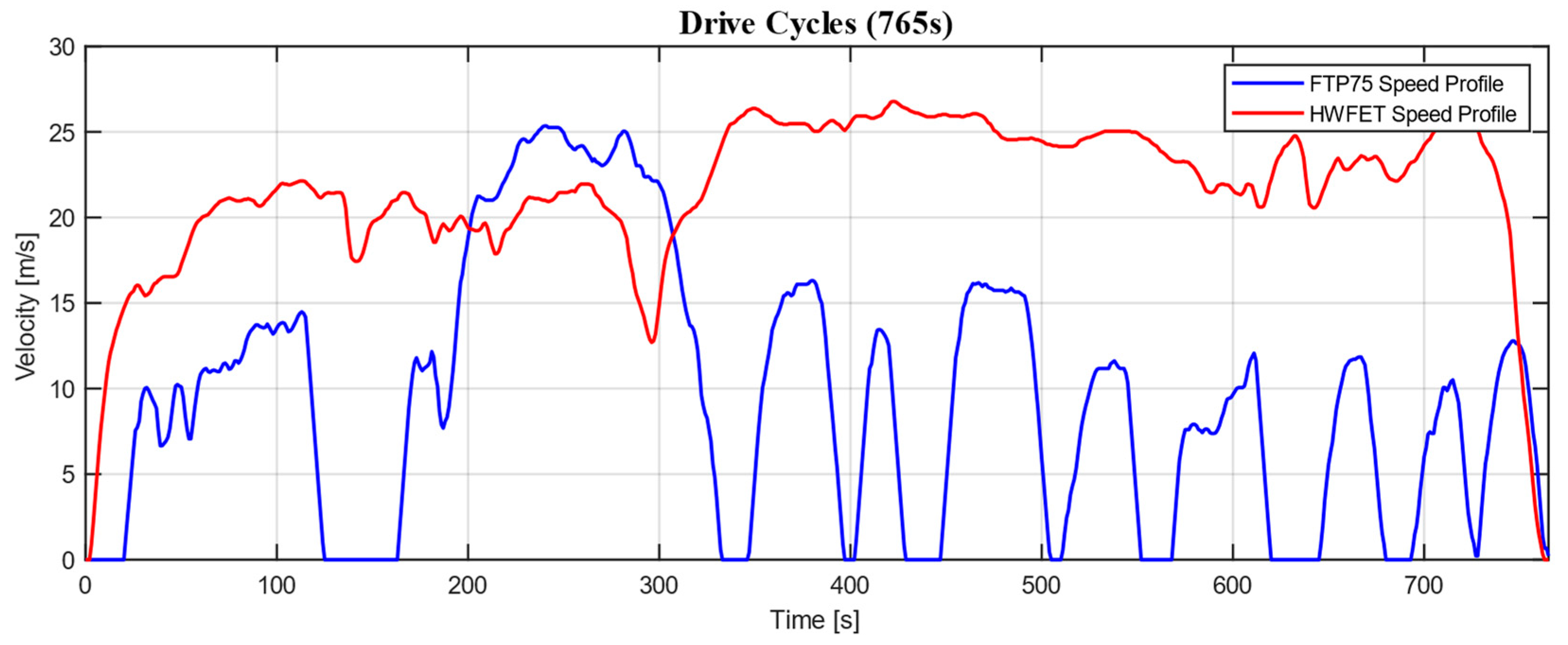

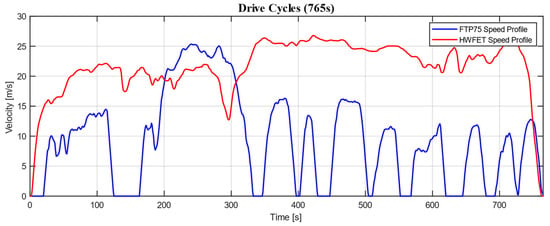

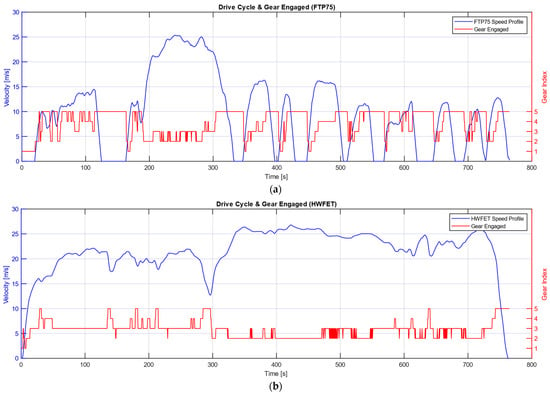

- Drive Cycle Source: Provides the Speed profile. For this work, the HWFET (Highway Fuel Economy Test) and the first 765 s of FTP-75 (Federal Test Procedure at 75° F) were used, both of which are used for validation on light-duty vehicles with the purpose of simulating Highway (HWFET) and City (FTP-75) conditions, as in Figure 4.

Figure 4. Speed profile for both driving cycles used in this work—FTP-75 and HWFET.

Figure 4. Speed profile for both driving cycles used in this work—FTP-75 and HWFET.

- (2)

- Vehicle Dynamics model: Calculates the force demand at wheel domain (1) to maintain the speed profile from the drive cycle. The calculation is based on Aerodynamic Drag (2), Road Slope (3), Rolling Resistance (4), and Inertial (5) forces.

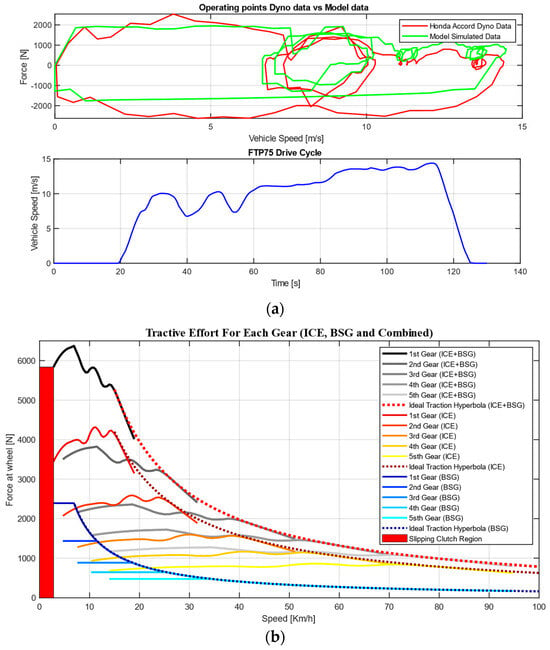

- (3)

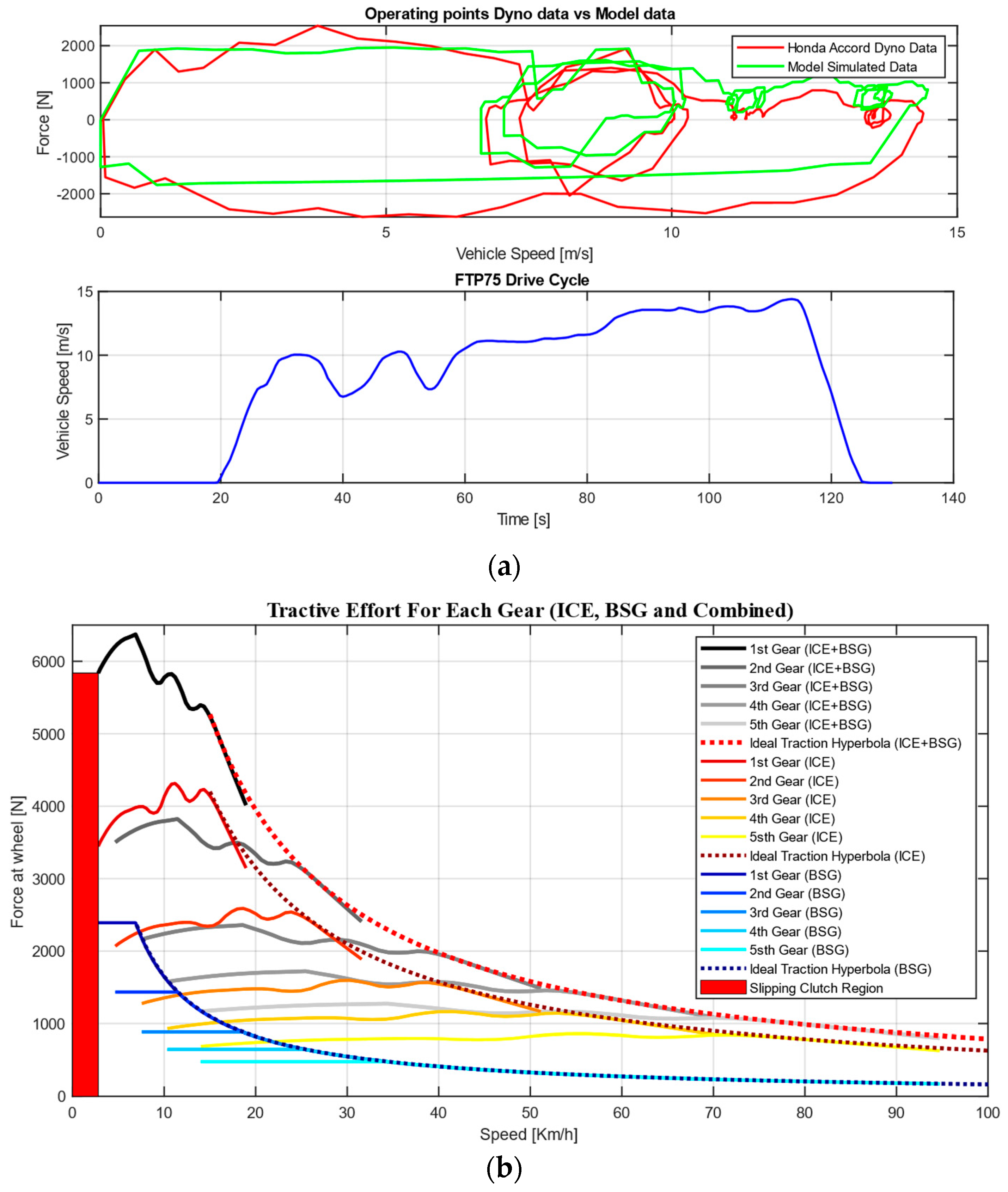

- Driveline Model: Converts the force demand at the wheel domain to the flywheel domain, based on the following transmission characteristics: gear ratios, transmission efficiency, and clutch operation. The purpose of Figure 5a is to validate the Simulink model of the vehicle by comparing the operating point graph (Veh. Speed × Force) with dynamometer data acquired from a vehicle with similar architecture and characteristics, by obtaining a close match between the two curves, whereby it is possible to say if the virtualized vehicle model in fact reflects the vehicle which it is trying to represent. The dynamometer data are from the Honda Accord, acquired from [24].

Figure 5. Tractive effort curves for the transmission simulated in this work. (a) Operating points from dynamometer data vs model data. (b) Tractive Effort curves for each gear, for both combined and individual power delivery.

Figure 5. Tractive effort curves for the transmission simulated in this work. (a) Operating points from dynamometer data vs model data. (b) Tractive Effort curves for each gear, for both combined and individual power delivery.

- (4)

- Arbitrator: This software component uses a genetic algorithm (GA) to perform the following three most important functions of the model, aiming to minimize fuel consumption:

- Torque Split Ratio Determination: Receive the total torque demand at the flywheel from the driveline model and calculate, using a genetic algorithm (GA), the Torque Split Ratio (how the torque demand at the flywheel is delivered between ICE and BSG) at every timestep of the drive cycle.

- Gear Selection: Select the gear engaged.

- Brake Actuation Split: Calculates how the braking actuation should be delivered between mechanical brakes and BSG (alternator mode).

- (5)

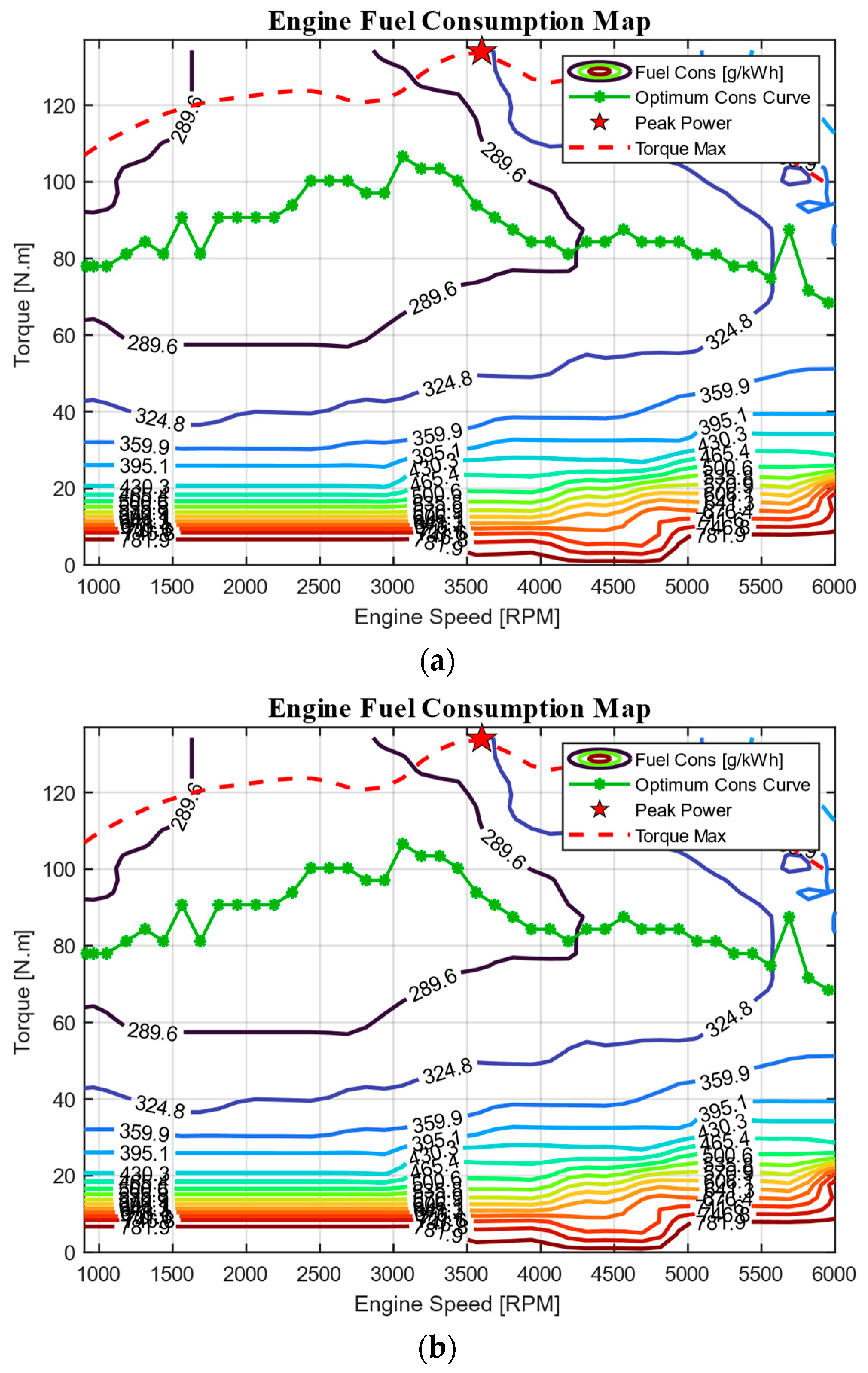

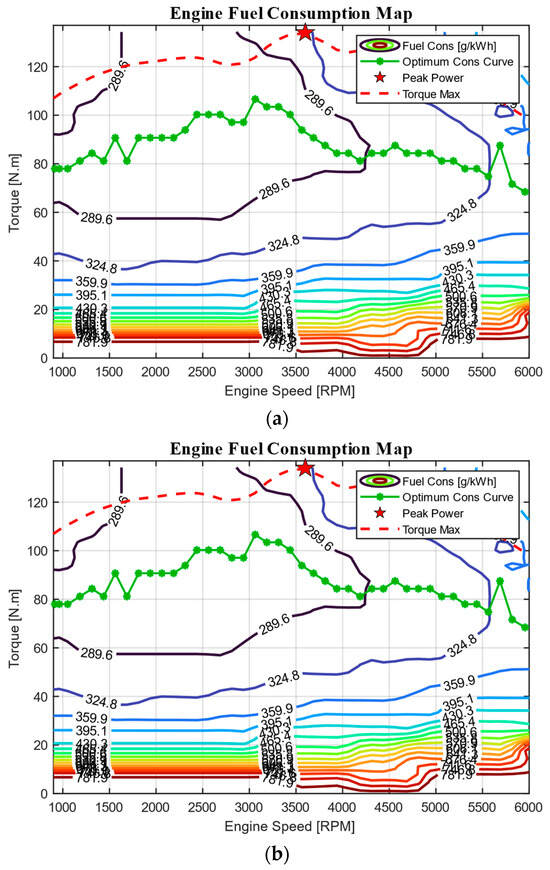

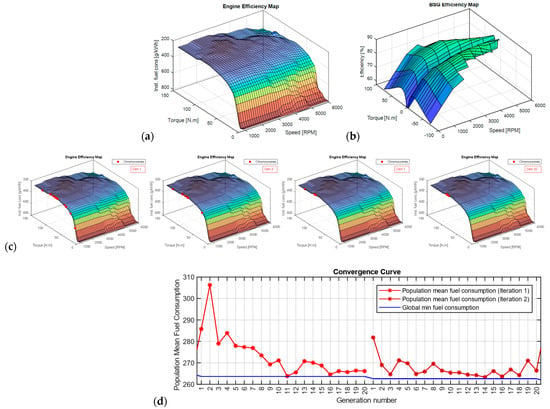

- Engine and BSG Model: Figure 6 displays the efficiency maps for both ICE and BSG. These are data-based models of the actuators (virtualization concept) and represent what kind of response, in terms of energy consumption (Fuel or Electrical), the actuator would deliver for a given (Torque and Speed) request.

Figure 6. (a) Engine fuel consumption map; and (b) BSG efficiency map.

Figure 6. (a) Engine fuel consumption map; and (b) BSG efficiency map.- Figure 6a displays the engine map, which is a contour plot (2D visualization of a surface) for the fuel consumption, with some other valuable additions such as the Torque Max (red dashed line), which shows the engine torque constrain at each speed. The Optimum Cons Curve (green solid line with dots) displays the place of lowest consumption in the contour map.

- Similarly, Figure 6b displays the equivalent information for the BSG, the efficiency (in %, since it is an electric machine), and the Torque Max curve to display the torque constrains for BSG.

3. The Genetic Algorithm

A genetic algorithm (GA) is a search heuristic evolutionary algorithm [25], inspired by the process of natural selection and genetics. It is commonly used in optimization and machine learning to find approximate solutions to optimize and search problems. The basic idea is to model the process of natural selection, where the fittest individuals (in other words, the solution which produces the best outcome) in a population are more likely to survive and reproduce, passing their genetic information to the next generation [26,27,28].

3.1. Role of GAs as Optimization Algorithms

The point of using a GA is that it is a very robust method. The GA is almost never the best optimization method for any particular problem, but it works consistently well across a range of problems or situations, which is a crucial feature for the calibration of an unknown powertrain. There are some characteristics that make the GA a unique solution for search and optimization problems [29,30,31], as follows:

- It does not require smoothness of the objective function, being capable of handling continuous or discrete functions, and even a mix of both. In fact, it does not necessarily need to know the objective function, if the application can provide the outputs only for the inputs being iterated at a given moment, the algorithm would still work, e.g., an instrumented car in a dynamometer.

- It can handle unsteadiness and noise.

- It is particularly good in escaping from local minima, the ergodicity of the evolutionary operators makes it very effective at performing global search, whenever applied to a multi-peak objective function.

- It can be applied even when the search space is unknown.

- It has a remarkable balance between exploration and exploitation of the search space.

- It has great flexibility to be hybridized with domain-dependent heuristics to make a more effective implementation for a specific problem.

3.2. GA Implementation: Working Principles and Parameters

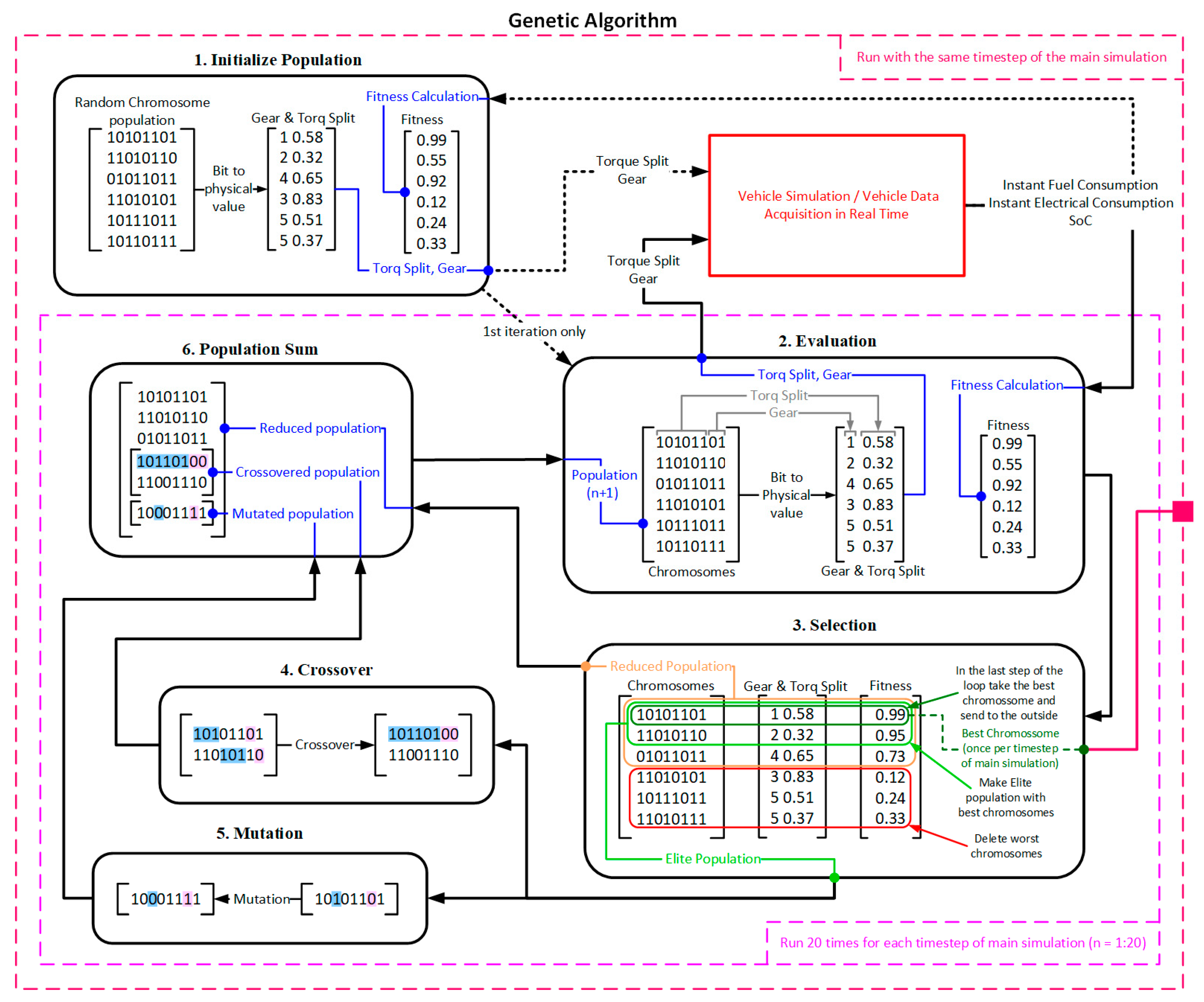

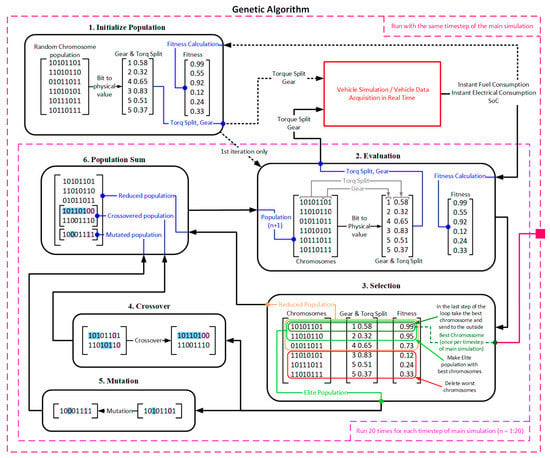

The optimization method described in this paper utilizes a GA with the objective of optimizing fuel consumption by adjusting the Torque Split Ratio and Gear Selection. The process is described below (cf. Figure 7) and the parameters used subsequently defined in Table 4:

Figure 7.

Schematic diagram of the software architecture for the genetic algorithm implemented in this paper.

Table 4.

Genetic algorithm Parameters.

- (1)

- Population Initialization: The algorithm generates a certain amount of random binary vectors called chromosomes. Each chromosome contains all the information regarding the physical values to be optimized; in this paper, the following two parameters are contained within a single chromosome: the torque split and the gear. The first 6 bits from the chromosome carry the information related to the torque split and the last 2 bits carry the information related to the gear.

- (2)

- Evaluation: The chromosomes are converted into the physical values using a built-in MATLAB function, which converts binary to decimal. The physical value is then sent as an input to the objective function, which, in this case, is the vehicle model; however, it could be an instrumented vehicle running in a dynamometer. The objective function is responsible for providing the solutions, i.e., the instantaneous fuel and electrical consumption, as well as the battery pack SoC. With this information, the GA can calculate the fitness (represents how well the chromosome is related to the optimization goals), which is a normalized weight average of fuel consumption, instantaneous efficiency, and battery SoC.

- (3)

- Selection: There are mainly three selections, which are fixed percentages of the population, and are made based on fitness, as follows:

- The worst chromosomes on the population are deleted.

- The best chromosomes are allocated on the elite population array.

- Only at the last iteration of the loop, the very best chromosome is selected and sent as the output for that timestep of the main simulation.

- (4)

- Crossover: Randomly selects two chromosomes from the elite population, they are cut at one point and the halves are spliced, creating two offspring; the process repeats for a calibratable number of chromosome pairs.

- (5)

- Mutation: Takes a certain number of chromosomes from the elite population and reverses the bit (0 to 1 or vice versa), as on Figure 7 both for Torque Split and gear bits.

- (6)

- Population Sum: Replace the deleted chromosomes from the population for the new ones from Crossover and Mutation operations.

3.3. GA Visualization

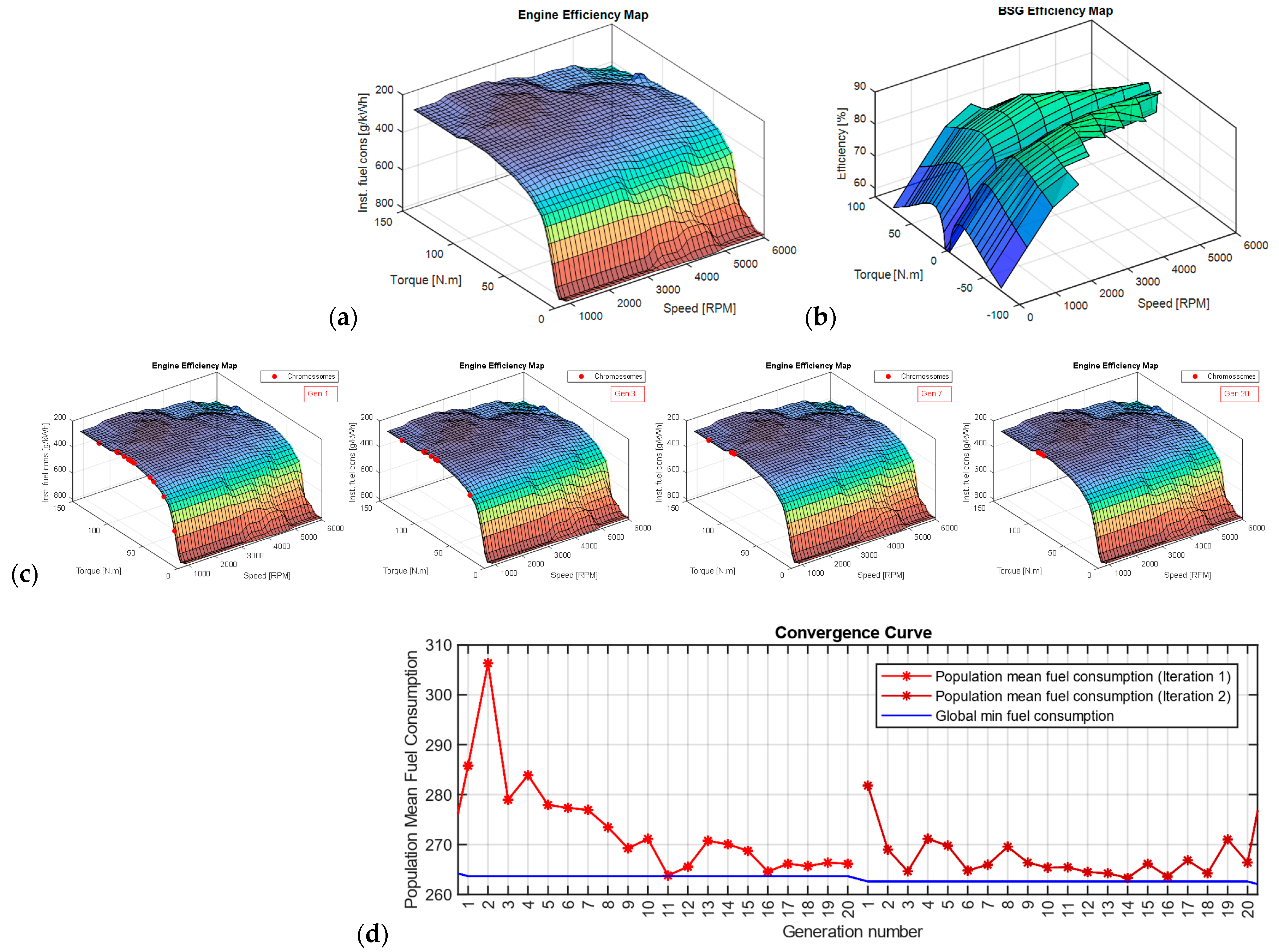

Figure 8 displays, in a simplified manner, the GA operation and general characteristics.

Figure 8.

GA algorithm: (a,b) objective functions; (c) iteration process; and (d) convergence curve.

The GA developed in this paper is multi-objective, meaning that it has more than one objective function, in this case it has two, as follows:

- (1)

- The fuel consumption map of the engine Figure 8a, which provides the instantaneous fuel consumption for any given ordered pair in the search space (Torque, Speed) within the constrain limits of the hardware (speed and torque limitations).

- (2)

- The efficiency map of the BSG Figure 8b, which provides the instantaneous efficiency for any given ordered pair in the search space (Torque, Speed) within the constrain limits of the hardware (speed and torque limitations).

Figure 8c shows how the GA iterates until it finds the lowest fuel consumption for the particular speed being requested by the driver. For each step of the main simulation, the GA completes one full cycle, composed of a population of 18 chromosomes in an loop of 20 generations. At the end of each cycle, the GA outputs the winner ordered pair (Torque, Speed), as well as its respective instantaneous fuel consumption. This same process is conducted simultaneously on the BSG efficiency map, outputting the winner ordered pair (Torque, Speed), as well as its respective efficiency. In Figure 8d, it is shown how the Mean Average Fuel Consumption of the chromosome population converges towards the global minimum as generations advance. The figure only presents the results for two iteration cycles; nevertheless, in the 765 s of simulation, 1530 iteration cycles occur, resulting in 30,600 generations and a total of 260,100 chromosomes tested.

4. Results and Discussion

This section intends to evaluate the quality of the control performed by the GA. The following subsections will present the main simulation results with a brief comment for each one of them.

4.1. Efficiency Maps with Operating Points

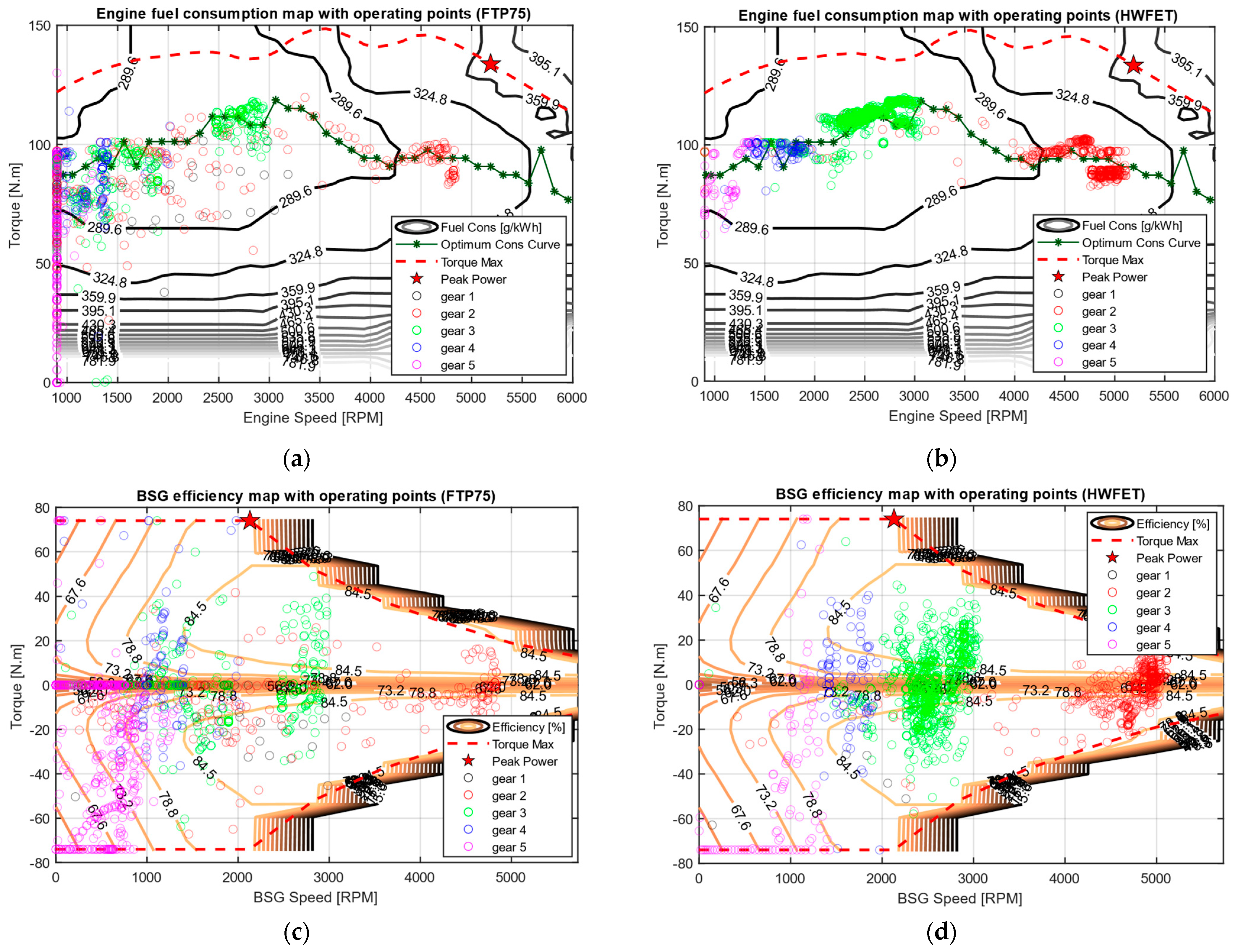

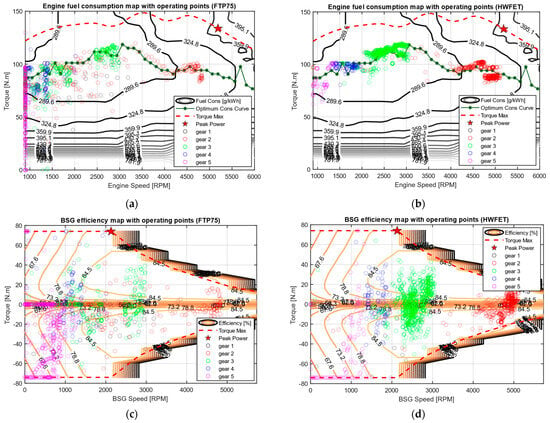

Figure 9 presents the efficiency maps for ICE and BSG, with the operation points (ordered pair (Speed, Torque)) requested throughout the driving cycle; note that each operation point is colored to also indicate the gear engaged.

Figure 9.

(a) Engine fuel consumption map with operation points for FTP75; and (b) HWFET. (c) BSG efficiency map with operating points for FTP75; and (d) HWFET.

The expectation is that the point cloud on ICE maps (Figure 9a,b) should be as close as possible to the “Optimum Cons Curve”. This behavior indicates that, in fact, the control strategy is actuating the engine to output a torque value that will result in the optimal fuel consumption for that given RPM. It is important to mention that the GA does not receive the “Optimum Cons Curve” as an input; it is plotted here for comparison purposes only.

In contrast, a much bigger dispersion on the point cloud is expected on the BSG maps (Figure 9c,d), since the main purpose of the BSG for a non-performance passenger vehicle is to optimize fuel consumption and the way to achieve this is to avoid ICE operation in inefficient zones and disable the engine when no torque is requested (aka. Start and Stop, refer to Section 2.1). Thus, the controller should always actuate the BSG to complement for the delta between Driver Torque Request and ICE Torque Output.

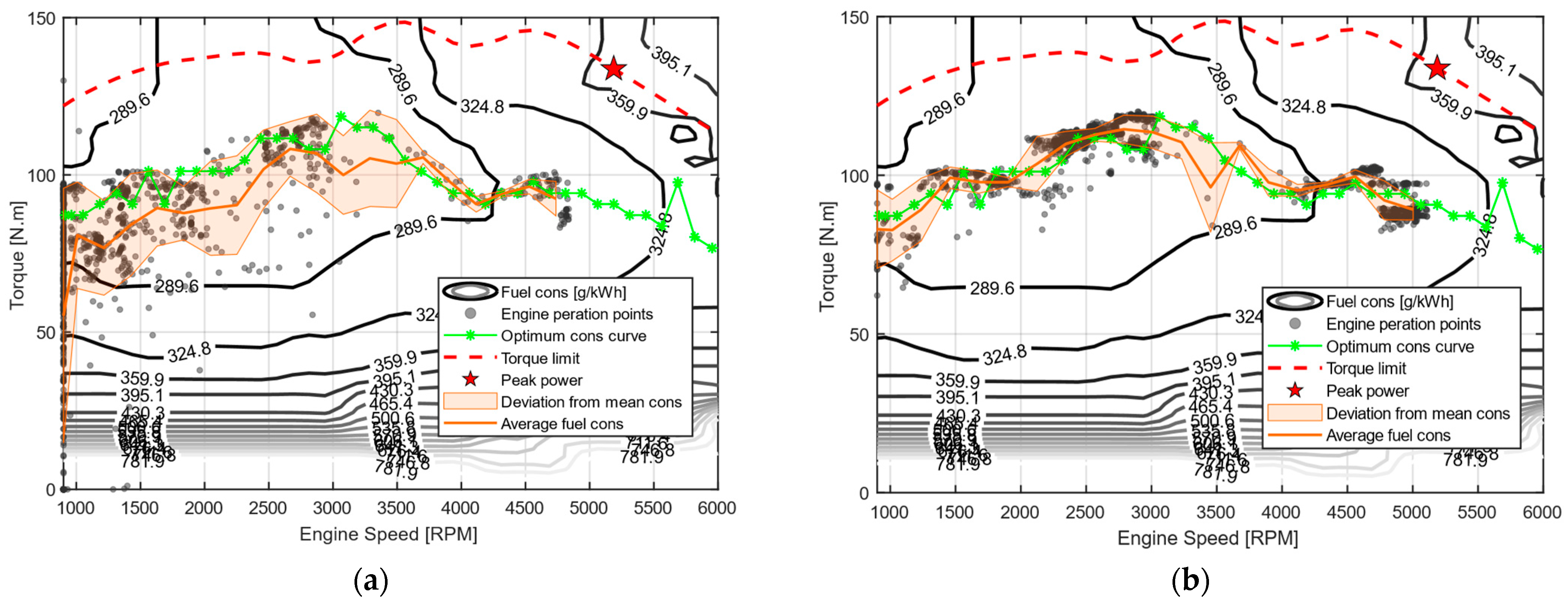

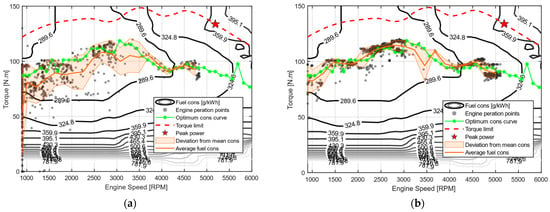

Figure 10a,b present a better overview on the point cloud deviation, which is an important metric to evaluate the quality of the control made by the GA. The expected ideal scenario would be a perfect match between the point cloud mean (orange line) and the optimum consumption curve (green line), with as little deviation as possible (orange shade).

Figure 10.

(a) Engine fuel consumption map with operating point cloud mean and deviation for FTP75; and (b) HWFET.

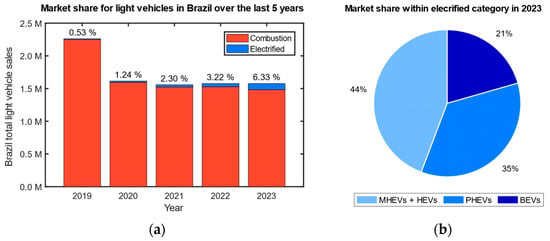

The point cloud displayed in Figure 10a, related to FTP75, undershoots the optimum curve in the low–medium speed range (1000 to 3500 RPM), this is attributed to the time window between 450 and 700 s of simulation. When the SoC reaches full capacity (Figure 11a, at about 430 s), the powertrain’s ability to enter generator mode is disabled and, subsequently, when the driver makes low torque requests, they are honored by the ICE alone, rather than by ICE and BSG in generator mode, as it would normally, to avoid engine operation in a lower efficiency zone. Alternatively, the torque request could also be honored by the BSG alone; however, they were slightly higher than BSG’s torque limit. This is a very good takeaway on why charge sustaining is so important in HEVs, especially for P1 architectures (ICE + BSG) where the electric motor does not usually have the capability to enter in fully electric mode and discharge the extra SoC, preventing Generator mode engagement.

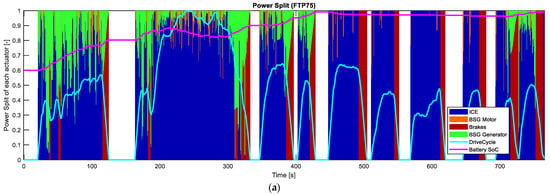

Figure 11.

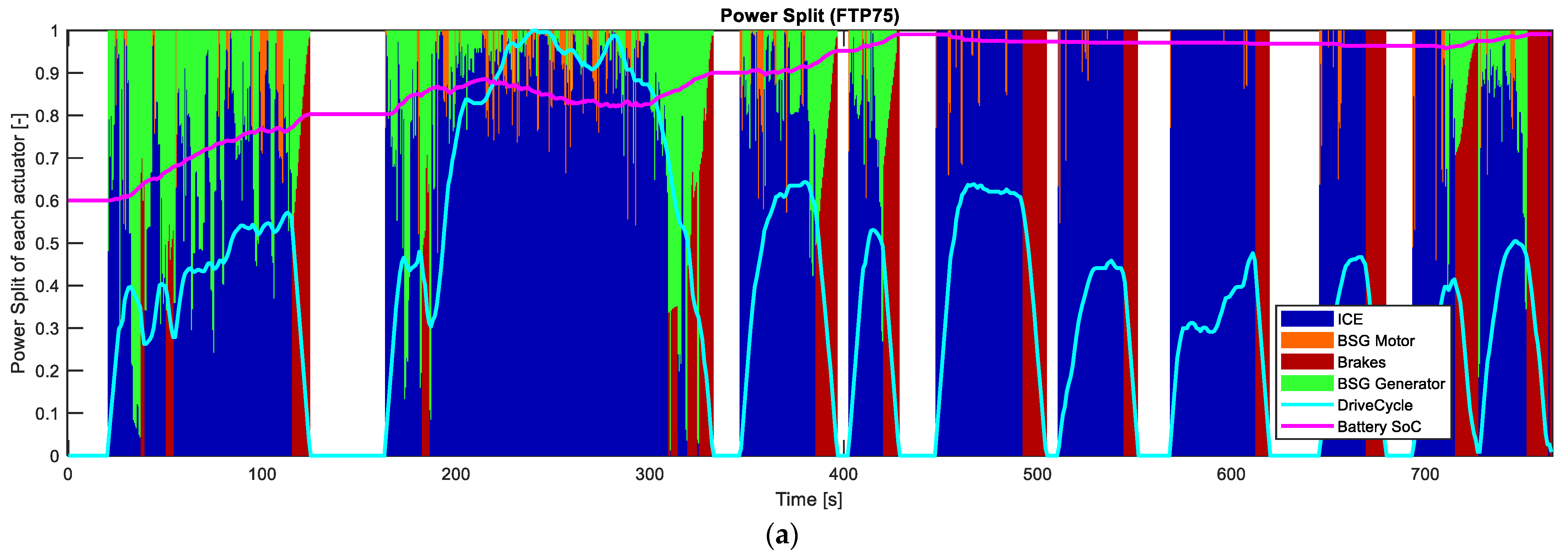

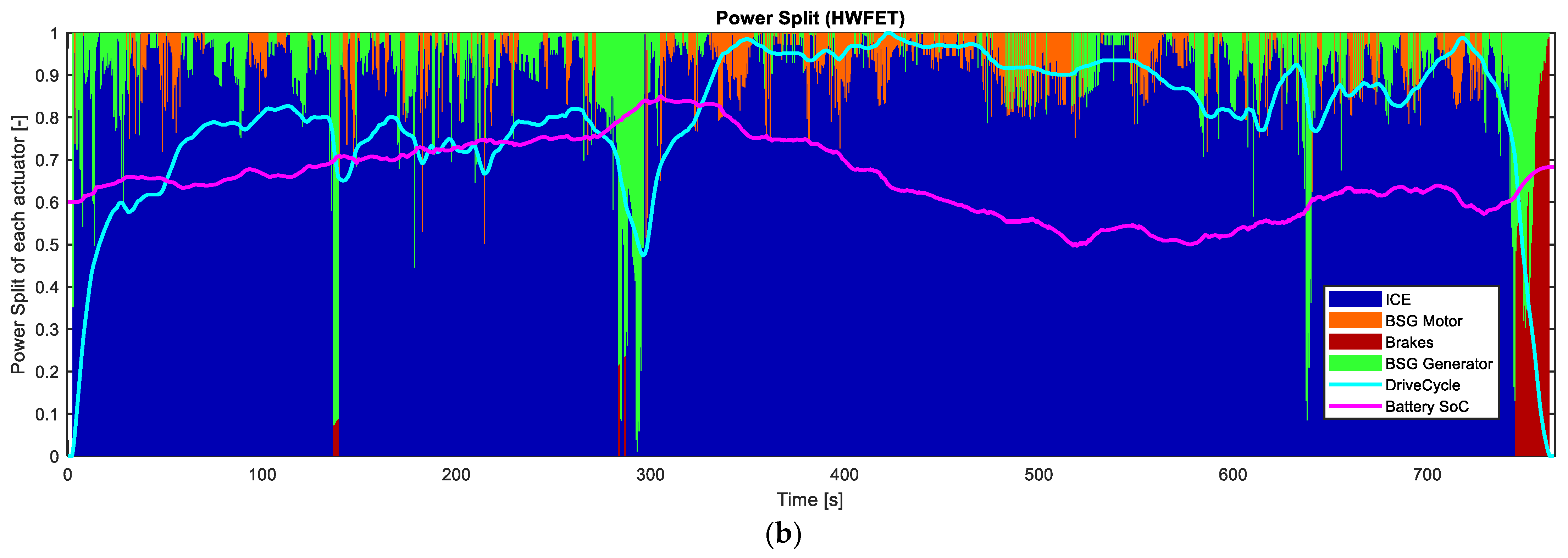

(a) Power Split for FTP75; and (b) HWFET.

Conversely, Figure 10b depicts a significantly better power split control with the average fuel consumption from the point cloud almost perfectly fitting the optimum consumption curve and an overall smaller deviation.

4.2. Power/Torque Split

Figure 11 presents the Power Split, which is the power contribution of each individual torque actuator (ICE, BSG, Brakes) for the total power request. Based on the result, the following cases can be observed:

- Positive torque/power request:

- ○

- e-Assist mode: A combination of ICE and BSG (as motor) supplies the torque/power demand.

- ○

- Generator mode: The ICE supplies all the power required for moving the vehicle and more to actuate the BSG (as generator), recharging the batteries.

- Negative torque/power request: A combination of BSG (as generator) and Brakes supplies the torque/power demand.

The bar plot (representing the Power Split) is stacked, which means that the sum of all bars in any given time is equal to 1, which is the total Power request; for example, the very first bar can be read as a roughly 50–50 split between ICE and BSG (as generator).

4.3. Drive Cycle and Operating Modes

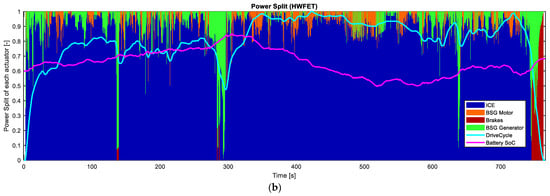

Figure 12 presents the operating modes throughout the driving cycle, recalling, from Section 2.1, the seven different operating modes in a mild Hybrid (ICE + BSG) powertrain architecture. The expectation, here, is that the control can balance between the fuel consumption optimization and SoC control, properly managing the e-Assist and Generator mode, so that the engine can operate efficiently with BSG help and the SoC can be maintained relatively close to its target throughout the driving cycle. That being said, it is safe to say that the results below are really satisfactory, at least for a static simulation, such as in this work.

Figure 12.

(a) Drive cycle with operating modes FTP75; and (b) HWFET.

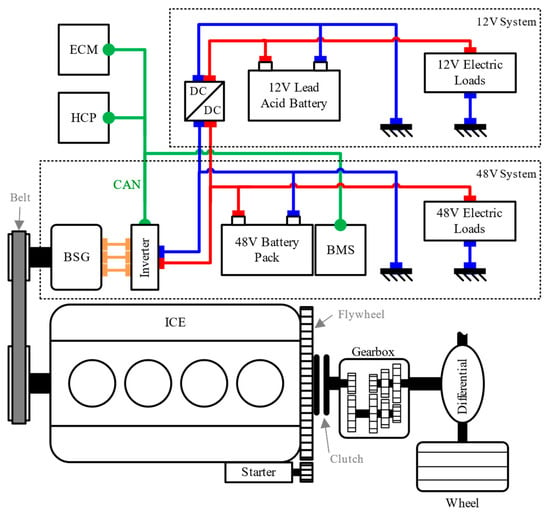

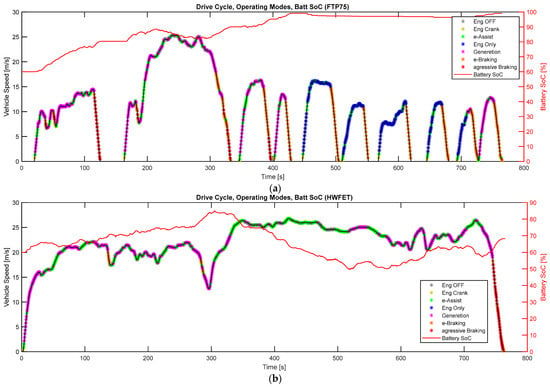

4.4. Drive Cycle and Shift Schedule

Figure 13 presents the gear engaged throughout the driving cycle. It may not seem an ideal shift schedule for a real application, and this would, in fact, be an accurate observation, as, currently, the fitness calculation for gear selection programmed into the GA only takes the fuel consumption into account and some important phenomena are not implemented, such as the following:

Figure 13.

(a) Gear shift schedule for FTP75; and (b) HWFET.

- Gear shift cost (transient fuel consumption during gear shift event).

- Hardware durability.

- Gear shift delay.

- Other transient behaviors intrinsic to the Gear Shift process, more on which can be found in [32,33].

Besides all the considerations, is safe to say that, in a qualitive way, the GA does a good job at selecting gears and, more importantly, has the potential (if programmed to take the behaviors above into account) to actually be a viable control strategy for gear selection of any computer controlled transmission—Automatic Transmission (AT), Automated Manual Transmission (AMT), and Continuously Variable Transmission (CVT).

4.5. Other Considerations

Table 5 presents important results from the simulations, among which the “number of chromosomes tested over the entire simulation” stands out as being particularly significant. There are mainly two paths to conduct automated calibration, as follows: the “in-vehicle” approach, where calibration maps are generated in real-time, while the instrumented vehicle on a dynamometer act as the objective function, providing results for any input in the search space; and the virtualization approach, where data-based hardware models are created from experimental acquisitions, essentially defining the objective function.

Table 5.

Comparative results for FTP75 and HWFET.

The in-vehicle approach incurs significant computational costs; hence, computation-heavy optimization algorithms like the genetic algorithm (GA) are not the most suitable and, instead, methods like the Pattern Search Algorithm or Surrogate Optimization would be more appropriate. On the other hand, the virtualization approach has a near-zero calculation cost, allowing the use of computation-heavy methods like the GA.

5. Conclusions

In this article, a genetic algorithm was developed to act as an automatic control strategy, actuating torque split and gear selection in a virtualized model of a mild Hybrid vehicle, aiming to optimize fuel economy.

The virtualization of the vehicle was conducted through data-based modeling of the Engine and BSG, which were integrated in a model-based system of the vehicle, running a quasi-static inverted simulation developed in Simulink and validated using real data from a dynamometer test acquisition of a similar vehicle.

The genetic algorithm (GA) was developed and integrated as an automatic control method and was tested for FTP75 and HWFET driving cycles. The control decisions from the proposed GA were plotted and the analysis indicates that the software has shown to be a useful tool when applied as a Hybrid Vehicle Simulator. Additionally, the control decisions made by the GA are coherent for all operation conditions. However, at the current stage of development, it is not feasible to use it as an automatic calibration tool for a real application, due to the lack of experimental data and comparison studies with currently used methods. Nevertheless, it has the potential to be used as an automatic calibration tool.

Future Development

Future work includes a complete virtualization of the hardware (data-based powertrain and vehicle dynamics model) and a comparison study between the proposed solution and the current approach adopted by the industry. Additionally, the development of a Graphical User Interface (GUI) for a better software user experience could be carried out in future work.

Author Contributions

Conceptualization, R.H.Q.F., R.P.M.R. and R.B.F.; Methodology, R.P.M.R. and E.d.M.F.; Software, R.H.Q.F.; Validation, R.H.Q.F.; Formal analysis, R.H.Q.F. and E.d.M.F.; Investigation, R.H.Q.F.; Resources, R.H.Q.F., R.P.M.R., E.d.M.F. and R.B.F.; Data curation, R.H.Q.F.; Writing—original draft, R.H.Q.F.; Writing—review & editing, R.P.M.R. and E.d.M.F.; Visualization, R.H.Q.F., E.d.M.F. and F.C.P.; Supervision, R.P.M.R., E.d.M.F. and R.B.F.; Project administration, E.d.M.F.; Funding acquisition, E.d.M.F. All authors have read and agreed to the published version of the manuscript.

Funding

This project is supported by Robert Bosch Ltd. and the Laboratory of Electronic Instrumentation and Control (LIEC) of the Federal University of Campina Grande (UFCG).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors R.H.Q.F., R.P.M.R. and R.B.F. were employed by the company Robert Bosch GmbH. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Davis, S.C.; Boundy, R.G. Transportation Energy Data Book, 39th ed.; No. ORNL/TM-2020/1770; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2021. [Google Scholar]

- Herzog, T. World greenhouse gas emissions in 2005. World Resour. Inst. 2009, 7, 2009. [Google Scholar]

- Chen, J.M. Carbon neutrality: Toward a sustainable future. Innovation 2021, 2, 100127. [Google Scholar] [CrossRef] [PubMed]

- Wu, G.; Zhang, X.; Dong, Z. Powertrain architectures of electrified vehicles: Review, classification and comparison. J. Frankl. Inst.-Eng. Appl. Math. 2015, 352, 425–448. [Google Scholar] [CrossRef]

- Eckert, J.J.; Barbosa, T.P.; da Silva, S.F.; Silva, F.L.; Silva, L.C.; Dedini, F.G. Electric hydraulic hybrid vehicle powertrain design and optimization-based power distribution control to extend driving range and battery life cycle. Energy Convers. Manag. 2022, 252, 115094. [Google Scholar] [CrossRef]

- Fenabrave. Anuário Fenabrave 2022: O Desempenho da Distribuição Automotiva No Brasil. 2022. Available online: https://online.fliphtml5.com/ordey/nucm/#p=1 (accessed on 7 February 2024).

- Associação Brasileira do Veículo Elétrico–ABVE. Eletrificados Iniciam 2024 Com Recorde de Vendas. 2023. Available online: https://abve.org.br/eletrificados-leves-iniciam-2024-com-novo-recorde-de-vendas-em-janeiro/ (accessed on 7 February 2024).

- Stellantis. Stellantis Announces €5.6 Billion Investment in South America, Marking the Largest Investment in the Region’s Automotive Industry [Press Release]. Available online: https://www.stellantis.com/en/news/press-releases/2024/march/stellantis-announces-5-6-billion-investment-in-south-america-marking-the-largest-investment-in-the-region-s-automotive-industry (accessed on 6 March 2024).

- Volkswagen. Volkswagen Brand Invests one Billion Euros for Growth in South America [Press Release]. Available online: https://www.volkswagen-newsroom.com/en/press-releases/volkswagen-brand-invests-one-billion-euros-for-growth-in-south-america-17431 (accessed on 7 February 2024).

- Júnior, A.N. Developing the EV Market in Brazil. Brazilian Electric Vehicle Association–ABVE. 2007. Available online: http://www.inee.org.br/down_loads/veh/developingtheevmarketinbrazil.pdf (accessed on 7 February 2024).

- Zhou, S.; Walker, P.; Wu, J.; Zhang, N. Power on gear shift control strategy design for a parallel hydraulic hybrid vehicle. Mech. Syst. Signal Process. 2021, 159, 107798. [Google Scholar] [CrossRef]

- Saiteja, P.; Ashok, B. Critical review on structural architecture, energy control strategies and development process towards optimal energy management in hybrid vehicles. Renew. Sustain. Energy Rev. 2022, 157, 112038. [Google Scholar] [CrossRef]

- Wahab, A.; Nadhir, M.; Nefti-Meziani, S.; Atyabi, A. A comprehensive review of swarm optimization algorithms. PLoS ONE 2015, 10, e0122827. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Kong, Y.; Chu, L.; Ju, H.; Yang, Z.; Xu, Z.; Xu, Z. Towards a smarter energy management system for hybrid vehicles: A comprehensive review of control strategies. Appl. Sci. 2019, 9, 2026. [Google Scholar] [CrossRef]

- Jalil, N.; Kheir, N.A.; Salman, M. A rule-based energy management strategy for a series hybrid vehicle. In Proceedings of the 1997 American Control Conference (Cat. No. 97CH36041), Albuquerque, NM, USA, 4–6 June 1997; IEEE: Piscattway, NJ, USA, 1997; Volume 1. [Google Scholar]

- Lü, X.; Wu, Y.; Lian, J.; Zhang, Y.; Chen, C.; Wang, P.; Meng, L. Energy management of hybrid electric vehicles: A review of energy optimization of fuel cell hybrid power system based on genetic algorithm. Energy Convers. Manag. 2020, 205, 112474. [Google Scholar] [CrossRef]

- Denis, N.; Dubois, M.R.; Trovao, J.P.F.; Desrochers, A. Power split strategy optimization of a plug-in parallel hybrid electric vehicle. IEEE Trans. Veh. Technol. 2017, 67, 315–326. [Google Scholar] [CrossRef]

- Chen, Z.; Mi, C.C.; Xiong, R.; Xu, J.; You, C. Energy management of a power-split plug-in hybrid electric vehicle based on genetic algorithm and quadratic programming. J. Power Sources 2014, 248, 416–426. [Google Scholar] [CrossRef]

- Ahmadi, S.; Bathaee, S.M.T. Multi-objective genetic optimization of the fuel cell hybrid vehicle supervisory system: Fuzzy logic and operating mode control strategies. Int. J. Hydrogen Energy 2015, 40, 12512–12521. [Google Scholar] [CrossRef]

- Li, M.; Li, M.; Han, G.; Liu, N.; Zhang, Q.; Wang, Y. Optimization analysis of the energy management strategy of the new energy hybrid 100% low-floor tramcar using a genetic algorithm. Appl. Sci. 2018, 8, 1144. [Google Scholar] [CrossRef]

- Saini, V.; Singh, S.; Nv, S.; Jain, H. Genetic algorithm-based gear shift optimization for electric vehicles. SAE Int. J. Altern. Powertrains 2016, 5, 348–356. [Google Scholar] [CrossRef]

- Chen, S.; Lequesne, B.; Henry, R.; Xue, Y.; Ronning, J. Design and testing of a belt-driven induction starter-generator. IEEE Trans. Ind. Appl. 2002, 38, 1525–1533. [Google Scholar] [CrossRef]

- Guzzella, L.; Amstutz, A. The QSS Toolbox Manual, Institute for Dynamic Systems and Control, Department of Mechanical and Process Engineering; ETH Zrich: Zrich, Switzerland, 2005; Available online: http://www.idsc.ethz.ch/research-guzzella-onder/downloads.html (accessed on 12 June 2015).

- Argonne National Laboratory. Downloadable Dynamometer Database (D3). 2024. Available online: https://www.anl.gov/taps/hybrid-electric-vehicle-testing (accessed on 3 April 2024).

- Voß, S.; Martello, S.; Osman, I.H.; Roucairol, C. (Eds.) Meta-Heuristics: Advances and Trends in Local Search Paradigms for Optimization; ACM: New York, NY, USA, 2012. [Google Scholar]

- Mirjalili, S. Genetic algorithm. In Evolutionary Algorithms and Neural Networks: Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2019; pp. 43–55. [Google Scholar]

- Mitchell, M. Handbook of Genetic Algorithms (LD Davis). Artif. Intell. 1998, 100, 325–330. [Google Scholar] [CrossRef]

- Sivanandam, S.N.; Deepa, S.N.; Sivanandam, S.N.; Deepa, S.N. Genetic Algorithms; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Kramer, O.; Kramer, O. Genetic Algorithms; Springer International Publishing: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Holland, J.H. Genetic algorithms. Sci. Am. 1992, 267, 66–73. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A review on genetic algorithm: Past, present, and future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef] [PubMed]

- Haj-Fraj, A.; Pfeiffer, F. Optimal control of gear shift operations in automatic transmissions. J. Frankl. Inst. 2001, 338, 371–390. [Google Scholar] [CrossRef]

- Schönknecht, A.; Babik, A.; Rill, V. Electric powertrain system design of BEV and HEV applying a multi objective optimization methodology. Transp. Res. Procedia 2016, 14, 3611–3620. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).