‘Greening’ an Oil Exporting Country: A Hydrogen, Wind and Gas Turbine Case Study

Abstract

1. Introduction

2. Renewable Energy Decarbonisation

3. Analysis Method

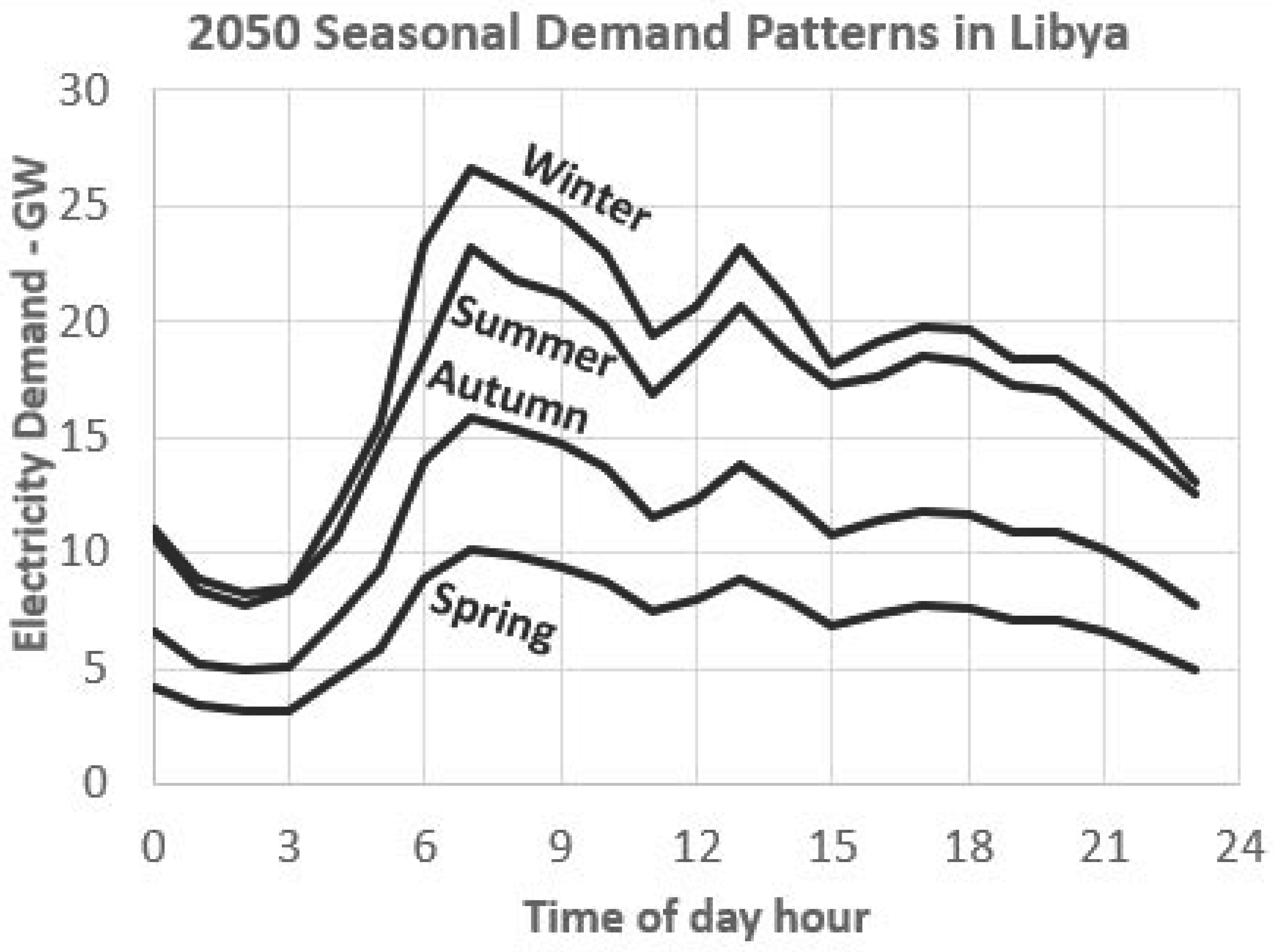

4. Energy Demand Prediction for Libya in 2050

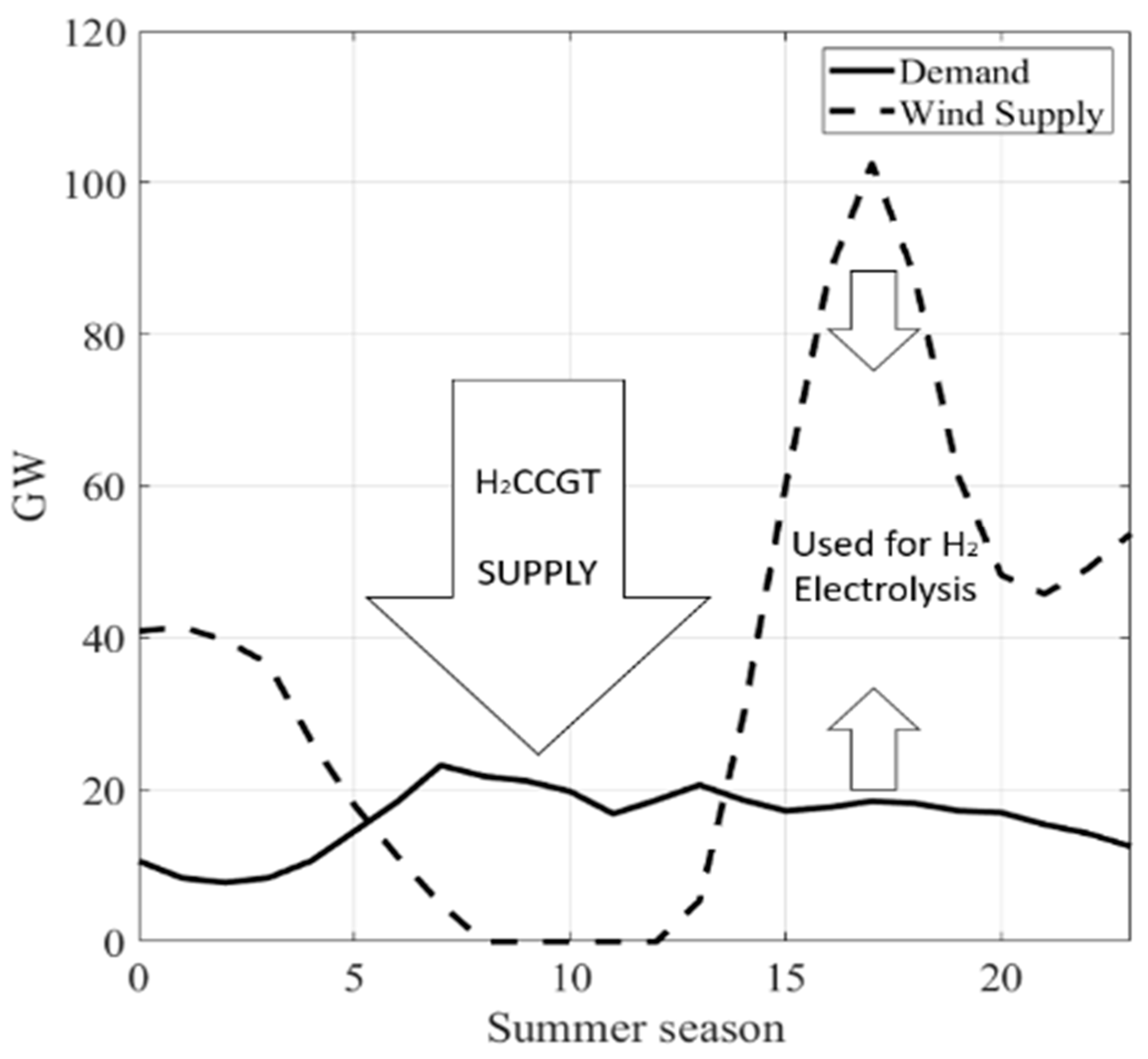

5. Energy Demands and H2CCGTs as the Balancing Mechanism

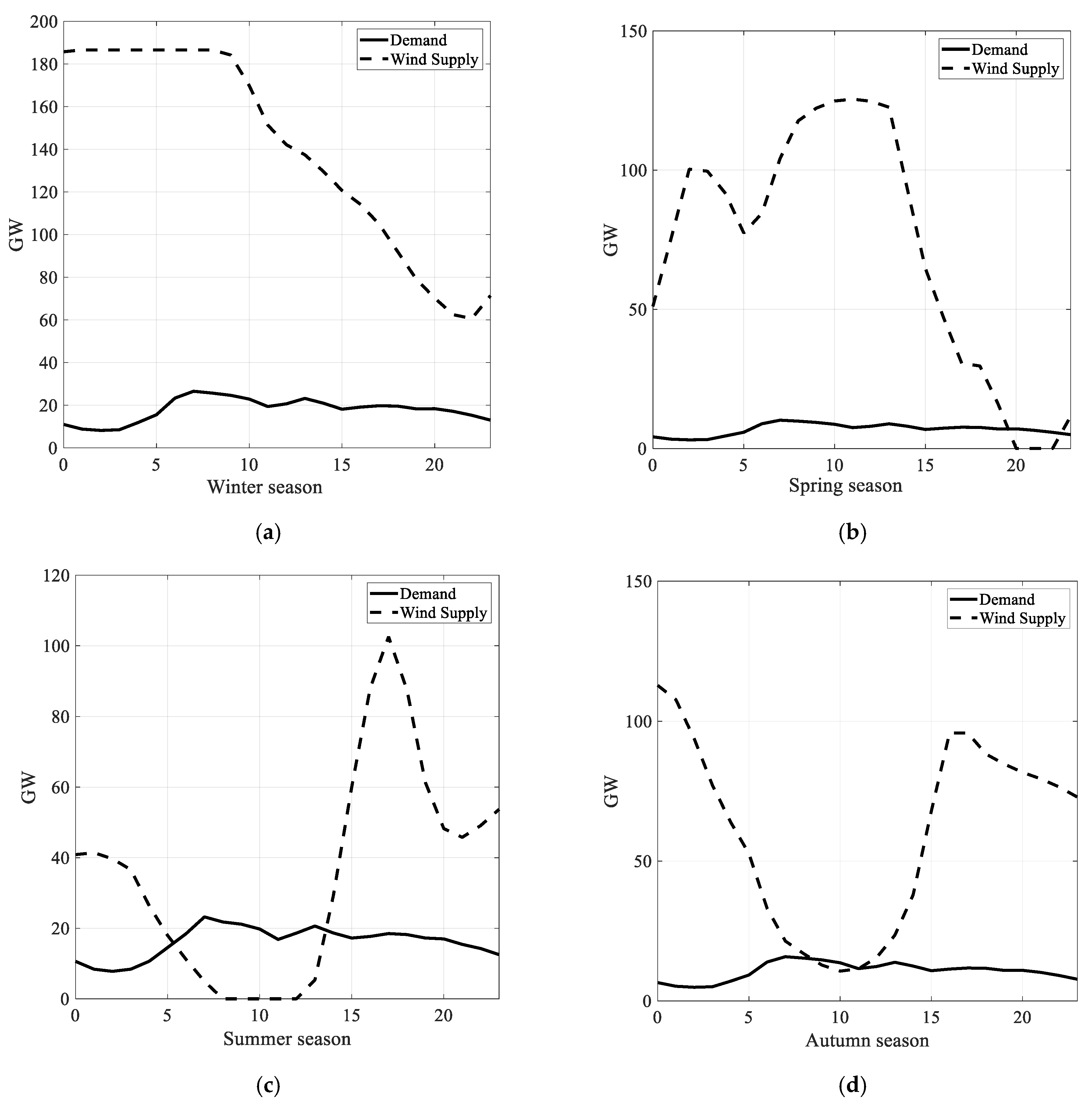

- -

- The electricity demand of 406.86 PJ in the daily patterns is shown in Table 1.

- -

- A total of 1210.7 ktonnes of hydrogen (3.32 k tonnes/day) that require 223.7 PJ annually.

- -

- Additional hydrogen for H2CCGTs for electricity when wind is not available.

- -

- A 4% H2 margin (2 weeks of operation) for the H2CCGTs’ peak and non-windy day demand duties.

6. Assessments of Requirements Based on the Summer Season

7. Winter, Spring, and Autumn Seasons

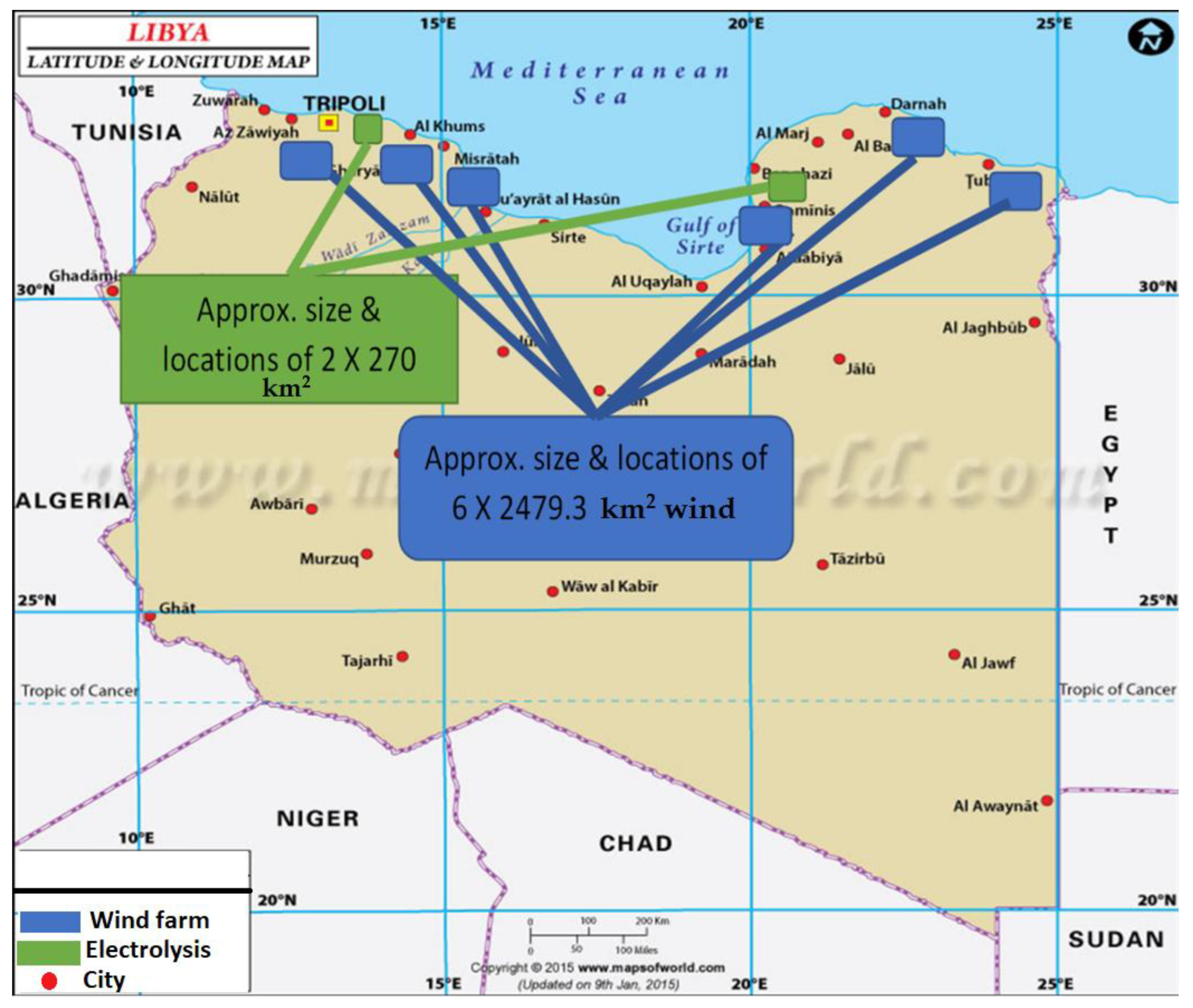

8. A View of the Whole National System

9. A Foundation Baseline for Future Policy and R&D Investments

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| wind | Fuel calorific value |

| GJ/T | Gigajoules/tonne |

| H2 | Hydrogen |

| H2GTCC | Hydrogen-fuelled gas turbine combined cycle |

| kTonne | Kilotonne = 1000 tonnes |

| MTs | Mega tonnes (million tonnes) |

| MTOE | Million-tonne oil equivalent |

| NOx | Nitrogen Oxide |

| PJs | Petajoules = 1015 Joules |

| Pw | Wind power |

| R&D | Research and Development |

| TERA | Technoeconomic Environmental Risk Analysis |

| TJ | Terajoule = 1012 Joule |

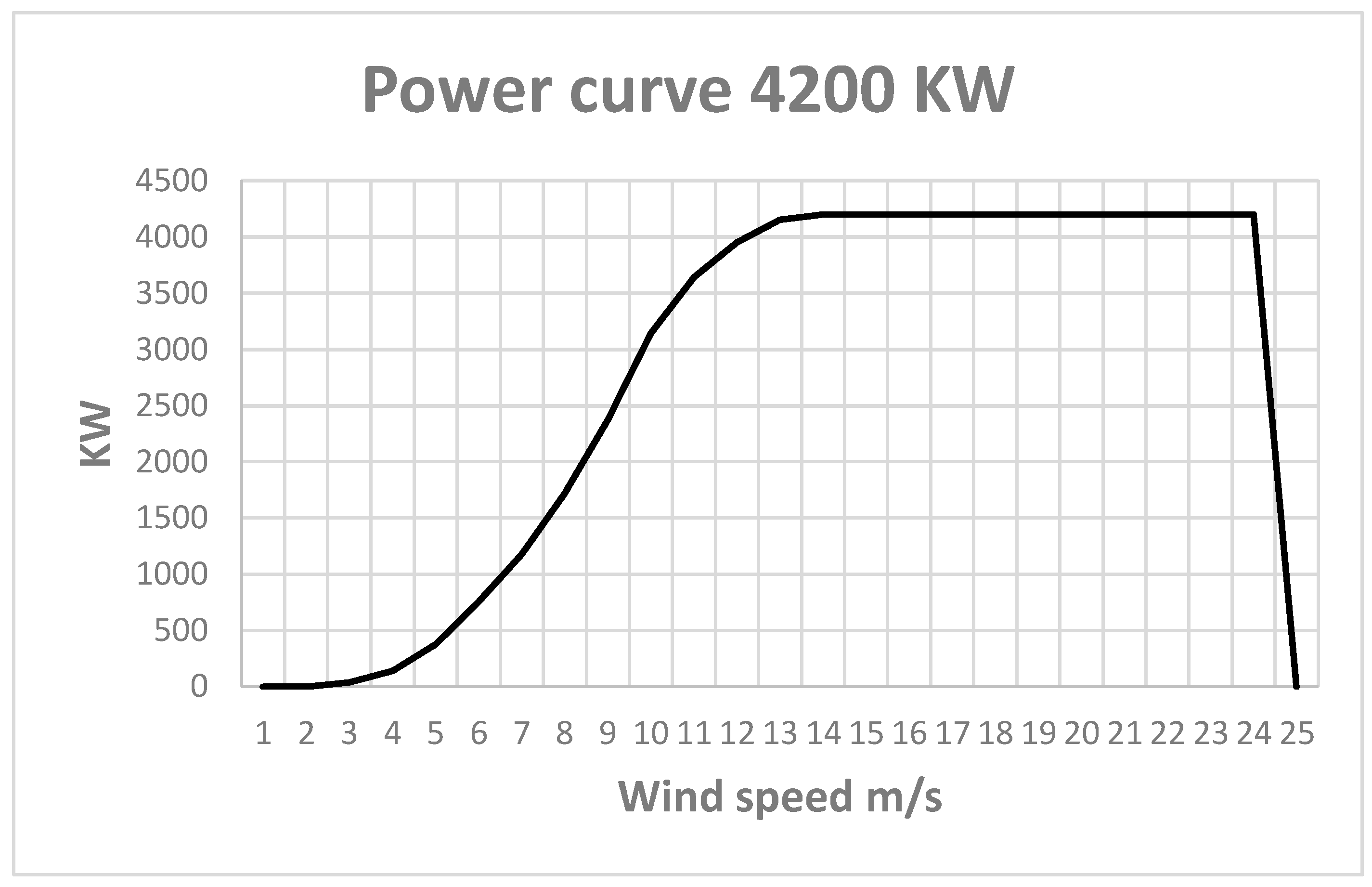

Appendix A. Evaluating Wind Power from Wind Potential

- Cut-in wind speed.

- Cut-off wind speed.

- Rated wind speed.

- Wind turbine rated power output.

- = Wind turbine final actual power output.

References

- Economist. The Economist Achieving Net-Zero Carbon Emissions Will Be Eye-Wateringly Expensive. 2021. Available online: https://www.economist.com/britain/2021/07/17/achieving-net-zero-carbon-emissions-will-be-eye-wateringly-expensive (accessed on 2 November 2023).

- Dray, L.; Schäfer, A.W.; Grobler, C.; Falter, C.; Allroggen, F.; Stettler, M.E.; Barrett, S.R. Cost and emissions pathways towards net-zero climate impacts in aviation. Nat. Clim. Chang. 2022, 12, 956–962. [Google Scholar] [CrossRef]

- Rosling, H.; Rosling Rönnlund, A.; Rosling, O. Factfulness: Ten Reasons We’re Wrong about the World—And Why Things Are Better Than You Think; Flatiron Books: New York, NY, USA, 2019. [Google Scholar]

- UNPRI. 2021. Available online: https://www.unpri.org/inevitable-policy-response/what-is-the-inevitable-policy-response/4787.article (accessed on 23 September 2021).

- Parker, R.J.; Pilidis, P. The light beyond the clouds. Aeronaut. J. 2021, 125, 1467–1468. [Google Scholar] [CrossRef]

- Nielsen. The Emerging School of Techno-Philosophy|Grand Strategy The View from Oregon. The View from Oregon’. 2012. Available online: https://geopolicraticus.wordpress.com (accessed on 18 January 2023).

- OAPECORG. Arab Energy 10th Conference, Abu Dhabi, United Arab Emirates. 2014. Available online: https://oapecorg.org/media/c48589f8-07e1-4745-b82f-a62ff4085333/558960152/Presentations/%D9%8419 (accessed on 19 March 2022).

- USEIA. Energy Information Administration. 2022. Available online: https://www.eia.gov/outlooks/ieo/ (accessed on 8 April 2022).

- Global Economy. These 5 Charts Reveal the Global Economic Outlook for 2022. Available online: https://www.worldbank.org/en/country/libya/overview (accessed on 28 January 2022).

- Country Economy. 2022. Available online: https://countryeconomy.com/energy-and-/electricity-generation/libya (accessed on 8 October 2022).

- Our World in Data. 2022. ‘Libya: Energy Country Profile’. Available online: https://ourworldindata.org/energy/country/libya (accessed on 25 February 2022).

- Rawesat, Y.; Salah, S. (Engineers at the General Electricity Company, Tripoli, Libya). Energy Demands and Daily Consumption Patterns in Libya. Private Communication, 2021. [Google Scholar]

- Sameti, M.; Syron, E. 100% renewable industrial decarbonization: Optimal integration of solar heat and photovoltaics. Smart Energy 2022, 8, 100087. [Google Scholar] [CrossRef]

- Ferrari, L.; Pasini, G.; Desideri, U. Towards a Power Production from 100% Renewables: The Italian Case Study. Energies 2023, 16, 2295. [Google Scholar] [CrossRef]

- Brick, S.; Thernstrom, S. Renewables and decarbonization: Studies of California, Wisconsin and Germany. Electr. J. 2016, 29, 6–12. [Google Scholar] [CrossRef][Green Version]

- Simonis, B.; Newborough, M. Sizing and operating power-to-gas systems to absorb excess renewable electricity. Int. J. Hydrogen Energy 2017, 42, 21635–21647. [Google Scholar] [CrossRef]

- Victor, N.; Nichols, C.; Zelek, C. The U.S. power sector decarbonization: Investigating technology options with MARKAL nine-region model. Energy Econ. 2018, 73, 410–425. [Google Scholar] [CrossRef]

- Bistline, J.E.T.; Blanford, G.J. Value of technology in the U.S. electric power sector: Impacts of full portfolios and technological change on the costs of meeting decarbonization goals. Energy Econ. 2020, 86, 104694. [Google Scholar] [CrossRef]

- Stock, J.H.; Stuart, D.N. Robust Decarbonization of the US Power Sector: Policy Options; National Bureau of Economic Research: Cambridge, MA, USA, 2021. [Google Scholar]

- Bernal-Agustín, J.L.; Dufo-López, R. Hourly energy management for grid-connected wind-hydrogen systems. Int. J. Hydrogen Energy 2008, 33, 6401–6413. [Google Scholar] [CrossRef]

- Yan, H.; Wang, R.; Zhang, C.; Xu, Z.; Hu, B.; Shao, Z. The role of heat pump in heating decarbonization for China carbon neutrality. Carbon. Neutrality 2022, 1, 40. [Google Scholar] [CrossRef]

- Wang, J.; An, Q.; Zhao, Y.; Pan, G.; Song, J.; Hu, Q.; Tan, C.W. Role of electrolytic hydrogen in smart city decarbonization in China. Appl. Energy 2023, 336, 120699. [Google Scholar] [CrossRef]

- Hjeij, D.; Bicer, Y.; Al-Sada, M.B.S.; Koç, M. Hydrogen export competitiveness index for a sustainable hydrogen economy. Energy Rep. 2023, 9, 5843–5856. [Google Scholar] [CrossRef]

- Ishaku, H.P.; Adun, H.; Jazayeri, M.; Kusaf, M. Decarbonisation Strategy for Renewable Energy Integration for Electrification of West African Nations: A Bottom-Up EnergyPLAN Modelling of West African Power Pool Targets. Sustainability 2022, 14, 15933. [Google Scholar] [CrossRef]

- Mraoui, A.; Menia, S. Renewable electrolytic hydrogen potential in Algeria. Int. J. Hydrogen Energy 2019, 44, 26863–26873. [Google Scholar] [CrossRef]

- Khouya, A. Levelized costs of energy and hydrogen of wind farms and concentrated photovoltaic thermal systems. A case study in Morocco. Int. J. Hydrogen Energy 2020, 45, 31632–31650. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Rezaei, M.; Moftakharzadeh, A.; Qolipour, M.; Salimi, M. Evaluation of hydrogen production by wind energy for agricultural and industrial sectors. Int. J. Hydrogen Energy 2019, 44, 7983–7995. [Google Scholar] [CrossRef]

- Sandaka, B.P.; Kumar, J. Alternative vehicular fuels for environmental decarbonization: A critical review of challenges in using electricity, hydrogen, and biofuels as a sustainable vehicular fuel. Chem. Eng. J. Adv. 2023, 14, 100442. [Google Scholar] [CrossRef]

- Yu, X.; LeBlanc, S.; Sandhu, N.; Wang, L.; Wang, M.; Zheng, M. Decarbonization potential of future sustainable propulsion—A review of road transportation. Energy Sci. Eng. 2023, 12, 438–455. [Google Scholar] [CrossRef]

- Raupova, O.; Kamahara, H.; Goto, N. Assessment of physical economy through economy-wide material flow analysis in developing Uzbekistan. Resour. Conserv. Recycl. 2014, 89, 76–85. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Rawesat, A.; Mohammed, M.; Impey, S.; Pilidis, P. ‘Greening’ an Oil Exporting Country: A Hydrogen, Solar and Gas Turbine Case Study. J. Energy Sources Part B Econ. Plan. Policy 2023. under review. [Google Scholar] [CrossRef]

- Decker, L. Latest Global Trend in Liquid Hydrogen Production HYPER Closing Seminar Brussels. 10 December 2019. Available online: https://www.sintef.no/globalassets/project/hyper/presentations-day-2/day2_1105_decker_liquid-hydrogen-distribution-technology_linde.pdf (accessed on 19 January 2023).

- Pantelis, I.; Huete, J.; Nalianda, D.; Jarzębowska, E.; Pilidis, P. Hydrogen Propulsion for Civil Aviation: An Introduction Scenario Pericles Pilidis. Available online: https://www.isabe.org/ (accessed on 11 February 2024).

- S&PGlobal. 2023. Available online: https://www.spglobal.com/commodityinsights/en/market-insights/latest-news/oil/072122-libyan-oil-minister-expects-crude-output-to-double-to-12-mil-bd-in-10-days (accessed on 7 April 2023).

- OPEC. Monthly Oil Market Report. 2021. Available online: https://www.opec.org/opec_web/en/21.htm (accessed on 2 November 2022).

- Ramelli, R.; Shalabiea, O.M.; Saleh, I.; Stenflo, J.O. Prospects of Renewable Energy in Libya. In Proceedings of the International Symposium on Solar Physics and Solar Eclipses (SPSE), Waw an Namos, Libya, 27–29 March 2006. [Google Scholar]

- Reksten, A.H.; Thomassen, M.S.; Møller-Holst, S.; Sundseth, K. Projecting the future cost of PEM and alkaline water electrolysers; a CAPEX model including electrolyser plant size and technology development. Int. J. Hydrogen Energy 2022, 47, 38106–38113. [Google Scholar] [CrossRef]

- Statista. Statista Libya: Age Dependency Ratio 2010–2021. 2022. Available online: https://www.statista.com/statistics/1234502/age-dependency-ratio-in-libya/ (accessed on 25 November 2022).

- Statista Libya. Available online: https://www.statista.com/topics/3885/libya/#topicOverview (accessed on 27 November 2022).

- World Bank. World Bank Data. 2023. Available online: https://data.worldbank.org/indicator/NY.GDP.MKTP.KD.ZG?locations=LY (accessed on 7 April 2023).

- Siemens. 2023. Available online: https://www.siemens-energy.com/global/en/home/products-services/product/sgt5-9000hl.html (accessed on 20 January 2023).

- Mas’ud, A.A.; Wirba, A.V.; Ardila-Rey, J.A.; Albarracín, R.; Muhammad-Sukki, F.; Jaramillo Duque, Á.; Bani, N.A.; Munir, A.B. Wind power potentials in Cameroon and Nigeria: Lessons from South Africa. Energies 2017, 10, 443. [Google Scholar] [CrossRef]

- Alkishriwi, N.A.; Sherwali, H.H. Analysis of Wind Energy Conversion Systems in Two Selected Sites in Libya Using Levelized Cost of Electricity (LCOE). In Proceedings of the International Conference on Recent Advances in Electrical Systems, Hammamet, Tunisia, 22–24 December 2017. [Google Scholar]

- El-Osta, W.; Kalifa, Y. Prospects of Wind Power Plants in Libya: A Case Study. 2003. Available online: www.elsevier.com/locate/renene (accessed on 11 December 2022).

- Planning and Prospects for Renewable Energy Disclaimer about IRENA. 2013. Available online: www.irena.org (accessed on 8 October 2022).

- ITM. ITM Power, 7. 100MW Electrolyser. 2017. Available online: https://www.youtube.com/watch?v=eku0GuSKiIc (accessed on 22 November 2022).

- H2FUTURE. H2FUTURE Project Site. 2022. Available online: https://www.h2future-project.eu/ (accessed on 7 December 2022).

- REFHYNE. REFHYNE Project Site. 2022. Available online: https://refhyne.eu/ (accessed on 13 December 2022).

- Herzog, B. Energy Systems/Moglichkeiten von Wasserstoff-Elektrolyseuren in Flexibilitatsmarkten. Technical Report Siemens AG. 2017. Available online: https://scholar.google.com/scholar?q=Herzog%20B.%20M%C3%B6glichkeiten%20von%20Wasserstoff-%20Elektrolyseuren%20in%20Flexibilit%C3%A4tsm%C3%A4rkten%2C%20Tech.%20rep.%2C%20Siemens%20AG%3B%202017.%20https%3A%2F%2Fwww.hslu.ch%2F-%2Fmedia%2Fcampus%2Fcommon%2Ffiles%2Fdokumente%2Fta%2Fenergiewende%2Fe%2Ffachtagungflexibilitaetinderelektrizitaetswirtschaft2017%2F2017051006p2gbrunoherzogv04.pdf%3Fla%3Dde-ch (accessed on 11 February 2024).

- Mohammed-Ibrahim, J.; Moussab, H. Recent advances on hydrogen production through seawater electrolysis. Mater. Sci. Energy Technol. 2020, 3, 780–807. [Google Scholar] [CrossRef]

- Mohamed, A.M.A.; Al-Habaibeh, A.; Abdo, H.; Elabar, S. Towards exporting renewable energy from MENA region to Europe: An investigation into domestic energy use and householders’ energy behaviour in Libya. Appl. Energy 2015, 146, 247–262. [Google Scholar] [CrossRef]

- Libya Crude-Oil-Exports. 2023. Available online: https://www.ceicdata.com/en/indicator/libya/crude-oil-exports (accessed on 20 January 2023).

- Alkhaledi, A.N.F.N.R.; Sampath, S.; Pilidis, P. A hydrogen fuelled LH2 tanker ship design. Ships Offshore Struct. 2022, 17, 1555–1564. [Google Scholar] [CrossRef]

- Roadnight Taylor. The Independent Specialist Grid Consultancy. 2022. Available online: https://roadnighttaylor.co.uk/ (accessed on 14 April 2023).

- BEIS. Department for Business, Education and Skills, UK. 2022. Available online: https://www.gov.uk/government/statistical-data-sets/historical-electricity-data (accessed on 10 April 2023).

- OEC. Crude Petroleum in Libya. OEC—The Observatory of Economic Complexity. 2021. Available online: https://oec.world/en/profile/country/lby (accessed on 3 April 2023).

- Abudu, K.; Igie, U.; Roumeliotis, I.; Hamilton, R. Impact of gas turbine flexibility improvements on combined cycle gas turbine performance. Appl. Therm. Eng. 2021, 189, 116703. [Google Scholar] [CrossRef]

- Igie, U.; Abbondanza, M.; Szymański, A.; Nikolaidis, T. Impact of compressed air energy storage demands on gas turbine performance. Proc. Inst. Mech. Eng. Part. A J. Power Energy 2021, 235, 850–865. [Google Scholar] [CrossRef]

- Mrehel, O.G.; Salama, A.G. Energy Generation Potential from Wind Power in the Southern Libyan Regions. In Proceedings of the 2021 IEEE 1st International Maghreb Meeting of the Conference on Sciences and Techniques of Automatic Control and Computer Engineering, MI-STA 2021—Proceedings, Tripoli, Libya, 25–27 May 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 548–553. [Google Scholar] [CrossRef]

- Kassem, Y.; Çamur, H.; Aateg, R.A.F. Exploring solar and wind energy as a power generation source for solving the electricity crisis in Libya. Energies 2020, 13, 3708. [Google Scholar] [CrossRef]

- Kunz, T.H.; Arnett, E.B.; Erickson, W.P.; Hoar, A.R.; Johnson, G.D.; Larkin, R.P.; Strickland, M.D.; Thresher, R.W.; Tuttle, M.D. Ecological impacts of wind energy development on bats: Questions, research needs, and hypotheses. Front. Ecol. Environ. 2007, 5, 315–324. [Google Scholar] [CrossRef]

- Nalianda, D.K. Impact of Environmental Taxation Policies on Civil Aviation—A Techno-Economic Environmental Risk Assessment. Ph.D. Thesis, School of Engineering, Cranfield University, Cranfield, UK, 2012. [Google Scholar]

- Gwec—Global Wind Report. Annual Market Update 2015. 2015. Available online: www.gwec.net (accessed on 30 May 2023).

- Badi, I.; Pamučar, D.; Stević, Ž.; Muhammad, L.J. Wind farm site selection using BWM-AHP-MARCOS method: A case study of Libya. Sci. Afr. 2023, 19, e01511. [Google Scholar] [CrossRef]

- Farhan, A.; Hassanpour, A.; Burns, A.; Motlagh, Y.G. Numerical study of effect of winglet planform and airfoil on a horizontal axis wind turbine performance. Renew. Energy 2019, 131, 1255–1273. [Google Scholar] [CrossRef]

- Adefarati, T.; Bansal, R.C. Reliability, economic and environmental analysis of a microgrid system in the presence of renewable energy resources. Appl. Energy 2019, 236, 1089–1114. [Google Scholar] [CrossRef]

- Ninja. Renewables Ninja. Available online: http://renewables.ninja (accessed on 30 May 2023).

| Libya Energy Panorama in 2050 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| n | Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 1 | Item | Current Energy Use PJ 2020 | 2050 Energy Demand PJ | Replacement Factors to Decarbonise | Need to Replace PJ | Replace with | Electricity PJ to Satisfy Direct Electrical Demand | Electricity for Hydrogen—PJ | H2 FCV PJ | H2 kTonne | H2 % of Use |

| Motor gasoline | 227.01 | 410.9 | 0.8 | 328.7 | Electricity | 70.44 | |||||

| 2 | 0.2 | 82.2 | H2 Gas | 58.70 | 41.09 | 342.4 | 28.28 | ||||

| Diesel for transport | 165.60 | 299.7 | 0.8 | 239.8 | Electricity | 85.64 | |||||

| 3 | 0.2 | 59.9 | H2 Gas | 71.37 | 49.96 | 416.3 | 34.38 | ||||

| Jet fuel | 24.49 | 44.3 | 0.15 | 6.6 | Electricity | 2.85 | |||||

| 4 | 0.85 | 37.7 | LH2 | 75.36 | 41.45 | 345.4 | 28.53 | ||||

| Other (marine, etc.) | 2.87 | 5.2 | 0.7 | 3.6 | Electricity | 1.56 | |||||

| 5 | 0.3 | 1.6 | H2 Gas | 2.23 | 1.56 | 13.0 | 1.07 | ||||

| 6 | Liquid fossil fuel for electricity | 9.66 | 0 | Replaced with wind power for electricity demand | |||||||

| 7 | Gas for electricity | 337.50 | 0.0 | Replaced with wind power for electricity demand | |||||||

| 8 | Gas: domestic | 21.60 | 39.1 | 1 | 39.1 | Electricity | 39.10 | ||||

| Gas: other | 20.70 | 37.5 | 0.7 | 26.2 | Electricity | 11.24 | |||||

| 9 | 0.3 | 11.2 | H2 Gas | 16.06 | 11.24 | 93.7 | 7.74 | ||||

| 10 | Wind power | 0.02 | 0.04 | 0.04 | Electricity | 0.04 | |||||

| 11 | Electricity from gas | 104.83 | 189.7 | 189.7 | Electricity | 189.75 | |||||

| 12 | Electricity from liquid fossil fuel | 3.46 | 6.3 | 6.3 | Electricity | 6.26 | |||||

| Total requirement | 809.45 | 1032.7 | 406.86 | 223.70 | 145.29 | 1210.7 | 100 | ||||

| Total electricity | 108.32 | 196 | Total 2050 | 630.56 | |||||||

| Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Summer Hour | Power Demand GW | Energy Demand for the Hour TJ | Wind Density KW/m2 | Wind Power Produced GW | Wind Energy Produced for the Hour TJ | Supply–Demand TJ | Wind Energy for H2—TJ | Electrical Power for H2—GW | H2 Energy TJ of FCV | Tonnes of H2 Produced | Tonnes of H2 in Storage | H2CCGT Fuel Energy Needed TJ | Tonnes of H2 Consumed | H2 CCGT GW | No 600 MW Single-Shaft GTs Need |

| 00:00 | 10.61 | 38.20 | 920 | 41.23 | 148.44 | 110.24 | 110.24 | 30.62 | 71.65 | 597.12 | 9647.08 | 0 | 0 | 0 | 0 |

| 01:00 | 8.39 | 30.21 | 932 | 41.77 | 150.38 | 120.17 | 120.17 | 33.38 | 78.11 | 650.93 | 10,298.01 | 0 | 0 | 0 | 0 |

| 02:00 | 7.79 | 28.03 | 893 | 40.04 | 144.14 | 116.11 | 116.11 | 32.25 | 75.47 | 628.93 | 10,926.94 | 0 | 0 | 0 | 0 |

| 03:00 | 8.40 | 30.25 | 824 | 36.93 | 132.95 | 102.70 | 102.70 | 28.53 | 66.75 | 556.29 | 11,483.22 | 0 | 0 | 0 | 0 |

| 04:00 | 10.65 | 38.35 | 594 | 26.60 | 95.77 | 57.42 | 57.42 | 15.95 | 37.32 | 311.00 | 11,794.22 | 0 | 0 | 0 | 0 |

| 05:00 | 14.54 | 52.35 | 404 | 18.11 | 65.21 | 12.86 | 12.86 | 3.57 | 8.36 | 69.67 | 11,863.89 | 0 | 0 | 0 | 0 |

| 06:00 | 18.46 | 66.45 | 252 | 11.27 | 40.58 | −25.86 | −25.86 | −7.18 | −16.81 | −140.08 | 11,723.81 | 0 | 0 | 0 | 0 |

| 07:00 | 23.22 | 83.60 | 111 | 4.98 | 17.93 | −65.67 | 0 | 0 | 0 | 0 | 10,562.71 | 139.33 | 1161.10 | 18.24 | 36.57 |

| 08:00 | 21.78 | 78.41 | 0 | 0 | 0 | −78.41 | 0 | 0 | 0 | 0 | 9473.64 | 130.69 | 1089.07 | 21.78 | 44 |

| 09:00 | 21.16 | 76.17 | 0 | 0 | 0 | −76.17 | 0 | 0 | 0 | 0 | 8415.72 | 126.95 | 1057.92 | 21.16 | 42.32 |

| 10:00 | 19.78 | 71.20 | 0 | 0 | 0 | −71.20 | 0 | 0 | 0 | 0 | 7426.86 | 118.66 | 988.87 | 19.78 | 39.55 |

| 11:00 | 16.83 | 60.59 | 0 | 0 | 0 | −60.59 | 0 | 0 | 0 | 0 | 6585.29 | 100.99 | 841.57 | 16.83 | 33.66 |

| 12:00 | 18.64 | 67.10 | 0 | 0 | 0 | −67.10 | 0 | 0 | 0 | 0 | 5653.41 | 111.83 | 931.88 | 18.64 | 37.28 |

| 13:00 | 20.63 | 74.28 | 121 | 5.41 | 19.48 | −54.79 | 0 | 0 | 0 | 0 | 4621.80 | 123.79 | 1031.61 | 15.22 | 30.53 |

| 14:00 | 18.67 | 67.20 | 658 | 29.49 | 106.16 | 38.96 | 38.96 | 10.82 | 25.33 | 211.05 | 211.05 | 0 | 0 | 0 | 0 |

| 15:00 | 17.23 | 62.01 | 1352 | 60.61 | 218.20 | 156.19 | 156.19 | 43.39 | 101.52 | 846.01 | 1057.06 | 0 | 0 | 0 | 0 |

| 16:00 | 17.68 | 63.64 | 1979 | 88.68 | 319.26 | 255.62 | 255.62 | 71.01 | 166.16 | 1384.63 | 2441.69 | 0 | 0 | 0 | 0 |

| 17:00 | 18.50 | 66.58 | 2308 | 103.44 | 372.38 | 305.79 | 305.79 | 84.94 | 198.77 | 1656.39 | 4098.07 | 0 | 0 | 0 | 0 |

| 18:00 | 18.20 | 65.54 | 1968 | 88.21 | 317.54 | 252.01 | 252.01 | 70.00 | 163.81 | 1365.05 | 5463.12 | 0 | 0 | 0 | 0 |

| 19:00 | 17.24 | 62.05 | 1379 | 61.83 | 222.59 | 160.54 | 160.54 | 44.59 | 104.35 | 869.60 | 6332.72 | 0 | 0 | 0 | 0 |

| 20:00 | 16.99 | 61.15 | 1086 | 48.67 | 175.21 | 114.07 | 114.07 | 31.69 | 74.14 | 617.86 | 6950.58 | 0 | 0 | 0 | 0 |

| 21:00 | 15.43 | 55.56 | 1030 | 46.17 | 166.23 | 110.66 | 110.66 | 30.74 | 71.93 | 599.43 | 7550.02 | 0 | 0 | 0 | 0 |

| 22:00 | 14.25 | 51.31 | 1105 | 49.53 | 178.30 | 126.99 | 126.99 | 35.27 | 82.54 | 687.84 | 8237.85 | 0 | 0 | 0 | 0 |

| 00:23 | 12.53 | 45.11 | 1209 | 54.18 | 195.04 | 149.93 | 149.93 | 41.65 | 97.45 | 812.10 | 9049.96 | 0 | 0 | 0 | 0 |

| Total | 1395.34 | 3085.80 | 2164.40 | 1406.86 | 11,723.81 | 852.24 | 7102.02 | 0 | 0 | ||||||

| H2 Produced K-tonnes | 11,723.81 | H2 for CCGT | 7102.02 | Other H2 | 3693 | H2 exports | 5 | Wind farm | 20,529 km2 |

| Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spring Hour | Power Demand GW | Energy Demand for the Hour TJ | Wind Density KW/m2 | Wind Power Produced GW | Wind Energy Produced for the Hour TJ | Supply–Demand TJ | Wind Energy for H2—TJ | Electrical Power for H2 GW | H2 Energy TJ of FCV | Tonnes of H2 Produced | Tonnes of H2 in Storage | H2CCGT Fuel Energy Needed TJ | Tonnes of H2 Consumed | H2 CCGT GW | No 600 MW Single-Shaft GTs Need |

| 00:00 | 4.21 | 15.16 | 1150 | 51 | 183.92 | 168.76 | 168.76 | 46.88 | 110 | 914.11 | 914.11 | 0 | 0 | 0 | 0 |

| 01:00 | 3.38 | 12.16 | 1697 | 75 | 271.50 | 259.35 | 259.35 | 72.04 | 169 | 1404.79 | 2318.90 | 0 | 0 | 0 | 0 |

| 02:00 | 3.13 | 11.27 | 2258 | 100 | 361.22 | 349.95 | 349.95 | 97.21 | 227 | 1895.56 | 4214.47 | 0 | 0 | 0 | 0 |

| 03:00 | 3.23 | 11.62 | 2242 | 100 | 358.63 | 347.01 | 347.01 | 96.39 | 226 | 1879.66 | 6094.13 | 0 | 0 | 0 | 0 |

| 04:00 | 4.54 | 16.34 | 2061 | 92 | 329.75 | 313.41 | 313.41 | 87.06 | 204 | 1697.63 | 7791.75 | 0 | 0 | 0 | 0 |

| 05:00 | 5.86 | 21.09 | 1742 | 77 | 278.71 | 257.62 | 257.62 | 71.56 | 167 | 1395.42 | 9187.17 | 0 | 0 | 0 | 0 |

| 06:00 | 8.91 | 32.07 | 1901 | 84 | 304.11 | 272.04 | 272.04 | 75.57 | 177 | 1473.57 | 10,660.74 | 0 | 0 | 0 | 0 |

| 07:00 | 10.20 | 36.71 | 2344 | 104 | 374.98 | 338.28 | 338.28 | 93.97 | 220 | 1832.33 | 12,493.07 | 0 | 0 | 0 | 0 |

| 08:00 | 9.85 | 35.46 | 2649 | 118 | 423.79 | 388.33 | 388.33 | 107.87 | 252 | 2103.44 | 14,596.51 | 0 | 0 | 0 | 0 |

| 09:00 | 9.38 | 33.78 | 2752 | 122 | 440.18 | 406.41 | 406.41 | 112.89 | 264 | 2201.38 | 16,797.89 | 0 | 0 | 0 | 0 |

| 10:00 | 8.72 | 31.39 | 2809 | 125 | 449.37 | 417.97 | 417.97 | 116.10 | 272 | 2264.02 | 19,061.91 | 0 | 0 | 0 | 0 |

| 11:00 | 7.52 | 27.09 | 2824 | 125 | 451.72 | 424.63 | 424.63 | 117.95 | 276 | 2300.10 | 21,362.01 | 0 | 0 | 0 | 0 |

| 12:00 | 8.01 | 28.83 | 2807 | 125 | 449.06 | 420.22 | 420.22 | 116.73 | 273 | 2276.21 | 23,638.22 | 0 | 0 | 0 | 0 |

| 13:00 | 8.89 | 32.01 | 2759 | 123 | 441.32 | 409.31 | 409.31 | 113.70 | 266 | 2217.11 | 25,855.33 | 0 | 0 | 0 | 0 |

| 14:00 | 8.03 | 28.90 | 2101 | 93 | 336.17 | 307.27 | 307.27 | 85.35 | 200 | 1664.38 | 27,519.71 | 0 | 0 | 0 | 0 |

| 15:00 | 6.86 | 24.70 | 1456 | 65 | 232.89 | 208.19 | 208.19 | 57.83 | 135 | 1127.68 | 28,647.39 | 0 | 0 | 0 | 0 |

| 16:00 | 7.33 | 26.39 | 1058 | 47 | 169.18 | 142.79 | 142.79 | 39.66 | 93 | 773.43 | 29,420.82 | 0 | 0 | 0 | 0 |

| 17:00 | 7.67 | 27.60 | 689 | 31 | 110.29 | 82.69 | 82.69 | 22.97 | 54 | 447.88 | 29,868.70 | 0 | 0 | 0 | 0 |

| 18:00 | 7.60 | 27.35 | 668 | 30 | 106.79 | 79.43 | 79.43 | 22.06 | 52 | 430.27 | 30,298.96 | 0 | 0 | 0 | 0 |

| 19:00 | 7.05 | 25.37 | 361 | 16 | 57.72 | 32.34 | 32.34 | 8.98 | 21 | 175.20 | 30,474.16 | 0 | 0 | 0 | 0 |

| 20:00 | 7.09 | 25.51 | 0 | 0 | 0 | −25.52 | −25.52 | 0 | 0 | 0 | 30,119.74 | 42.53 | 354.42 | 7.09 | 14.18 |

| 21:00 | 6.55 | 23.56 | 0 | 0 | 0 | −23.57 | −23.57 | 0 | 0 | 0 | 29,792.42 | 39.28 | 327.32 | 6.55 | 13.09 |

| 22:00 | 5.83 | 20.99 | 0 | 0 | 0 | −21.00 | −21.00 | 0 | 0 | 0 | 29,500.77 | 35.00 | 291.65 | 5.83 | 11.67 |

| 00:23 | 4.99 | 17.97 | 262 | 12 | 41.95 | 23.97 | 23.97 | 6.66 | 16 | 129.85 | 29,630.62 | 0 | 0 | 0 | 0 |

| Total | 593.36 | 6173.25 | 5649.97 | 367.48 | 30,604.02 | 117 | 973.396 | ||||||||

| H2 produced K-tonnes | 30,604.02 | H2 for CCGT | 973.396 | Other H2 | 3693 | H2 exports | 25,936.9 | Wind farm | 20,529 km2 |

| Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Winter Hour | Power Demand GW | Energy Demand for the Hour TJ | Wind Density KW/m2 | Wind Power Produced GW | Wind Energy Produced for the Hour TJ | Supply–Demand TJ | Wind Energy for H2—TJ | Electrical Power for H2 GW | H2 Energy TJ of FCV | Tonnes of H2 Produced | Tonnes of H2 in Storage | H2CCGT Fuel Energy Needed TJ | Tonnes of H2 Consumed | H2 CCGT GW | No 600 MW Single-Shaft GTs Need |

| 00:00 | 10.99 | 39.57 | 4180 | 185.74 | 668.66 | 629.10 | 629.10 | 174.75 | 408.91 | 3407.61 | 3407.61 | 0 | 0 | 0 | 0 |

| 01:00 | 8.81 | 31.72 | 4200 | 186.63 | 671.87 | 640.15 | 640.15 | 177.82 | 416.10 | 3467.49 | 6875.09 | 0 | 0 | 0 | 0 |

| 02:00 | 8.19 | 29.48 | 4200 | 186.63 | 671.87 | 642.39 | 642.39 | 178.44 | 417.55 | 3479.60 | 10,354.69 | 0 | 0 | 0 | 0 |

| 03:00 | 8.52 | 30.66 | 4200 | 186.63 | 671.87 | 641.21 | 641.21 | 178.11 | 416.78 | 3473.21 | 13,827.90 | 0 | 0 | 0 | 0 |

| 04:00 | 11.87 | 42.72 | 4200 | 186.63 | 671.87 | 629.15 | 629.15 | 174.76 | 408.95 | 3407.88 | 17,235.78 | 0 | 0 | 0 | 0 |

| 05:00 | 15.55 | 55.99 | 4200 | 186.63 | 671.87 | 615.88 | 615.88 | 171.08 | 400.32 | 3336.02 | 20,571.81 | 0 | 0 | 0 | 0 |

| 06:00 | 23.37 | 84.12 | 4200 | 186.63 | 671.87 | 587.75 | 587.75 | 163.26 | 382.04 | 3183.64 | 23,755.45 | 0 | 0 | 0 | 0 |

| 07:00 | 26.56 | 95.63 | 4200 | 186.63 | 671.87 | 576.25 | 576.25 | 160.07 | 374.56 | 3121.33 | 26,876.78 | 0 | 0 | 0 | 0 |

| 08:00 | 25.71 | 92.54 | 4200 | 186.63 | 671.87 | 579.33 | 579.33 | 160.92 | 376.56 | 3138.02 | 30,014.81 | 0 | 0 | 0 | 0 |

| 09:00 | 24.65 | 88.74 | 4146 | 184.21 | 663.16 | 574.42 | 574.42 | 159.56 | 373.37 | 3111.43 | 33,126.24 | 0 | 0 | 0 | 0 |

| 10:00 | 22.90 | 82.44 | 3823 | 169.86 | 611.51 | 529.07 | 529.07 | 146.96 | 343.89 | 2865.79 | 35,992.02 | 0 | 0 | 0 | 0 |

| 11:00 | 19.40 | 69.84 | 3407 | 151.37 | 544.95 | 475.11 | 475.11 | 131.97 | 308.82 | 2573.49 | 38,565.51 | 0 | 0 | 0 | 0 |

| 12:00 | 20.66 | 74.39 | 3199 | 142.16 | 511.78 | 437.39 | 437.39 | 121.50 | 284.30 | 2369.19 | 40,934.70 | 0 | 0 | 0 | 0 |

| 13:00 | 23.21 | 83.54 | 3093 | 137.43 | 494.73 | 411.19 | 411.19 | 114.22 | 267.27 | 2227.28 | 43,161.99 | 0 | 0 | 0 | 0 |

| 14:00 | 20.95 | 75.43 | 2916 | 129.59 | 466.53 | 391.11 | 391.11 | 108.64 | 254.22 | 2118.49 | 45,280.48 | 0 | 0 | 0 | 0 |

| 15:00 | 18.14 | 65.31 | 2717 | 120.74 | 434.68 | 369.37 | 369.37 | 102.60 | 240.09 | 2000.73 | 47,281.21 | 0 | 0 | 0 | 0 |

| 16:00 | 19.13 | 68.87 | 2569 | 114.17 | 411.01 | 342.14 | 342.14 | 95.04 | 222.39 | 1853.26 | 49,134.47 | 0 | 0 | 0 | 0 |

| 17:00 | 19.77 | 71.18 | 2361 | 104.91 | 377.67 | 306.49 | 306.49 | 85.14 | 199.22 | 1660.15 | 50,794.61 | 0 | 0 | 0 | 0 |

| 18:00 | 19.59 | 70.52 | 2071 | 92.04 | 331.35 | 260.83 | 260.83 | 72.45 | 169.54 | 1412.82 | 52,207.43 | 0 | 0 | 0 | 0 |

| 19:00 | 18.32 | 65.96 | 1782 | 79.18 | 285.03 | 219.07 | 219.07 | 60.85 | 142.40 | 1186.65 | 53,394.08 | 0 | 0 | 0 | 0 |

| 20:00 | 18.38 | 66.16 | 1580 | 70.20 | 252.73 | 186.58 | 186.58 | 51.83 | 121.27 | 1010.62 | 54,404.70 | 0 | 0 | 0 | 0 |

| 21:00 | 17.13 | 61.67 | 1405 | 62.44 | 224.78 | 163.11 | 163.11 | 45.31 | 106.02 | 883.50 | 55,288.19 | 0 | 0 | 0 | 0 |

| 22:00 | 15.30 | 55.07 | 1365 | 60.67 | 218.40 | 163.34 | 163.34 | 45.37 | 106.17 | 884.74 | 56,172.93 | 0 | 0 | 0 | 0 |

| 00:23 | 13.03 | 46.91 | 1606 | 71.35 | 256.85 | 209.94 | 209.94 | 58.32 | 136.46 | 1137.20 | 57,310 | 0 | 0 | 0 | 0 |

| Total | 1548.49 | 12,129 | 10,580 | 6877 | 57,310 | 0 | 0 | ||||||||

| H2 produced K-tonnes | 57,310 | H2 for CCGT | 0 | Other H2 | 3693 | H2 exports | 53,616.4 | Wind farm | 20,529 km2 |

| Column | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Autumn Hour | Power Demand GW | Energy Demand for the Hour TJ | Wind Density KW/m2 | Wind Power Produced GW | Wind Energy Produced for the Hour TJ | Supply–Demand TJ | Wind Energy for H2—TJ | Electrical Power for H2 GW | H2 Energy TJ of FCV | Tonnes of H2 Produced | Tonnes of H2 in Storage | H2CCGT Fuel Energy Needed TJ | Tonnes of H2 Consumed | H2 CCGT GW | No 600 MW Single-Shaft GTs Need |

| 00:00 | 6.54 | 23.56 | 2537 | 112.72 | 405.81 | 382.25 | 382.25 | 106.18 | 248.46 | 2070.53 | 2070.53 | 0 | 0 | 0 | 0 |

| 01:00 | 5.25 | 18.89 | 2421 | 107.59 | 387.33 | 368.44 | 368.44 | 102.35 | 239.49 | 1995.73 | 4066.26 | 0 | 0 | 0 | 0 |

| 02:00 | 4.88 | 17.56 | 2111 | 93.80 | 337.67 | 320.12 | 320.12 | 88.92 | 208.08 | 1733.98 | 5800.24 | 0 | 0 | 0 | 0 |

| 03:00 | 5.07 | 18.26 | 1736 | 77.13 | 277.68 | 259.42 | 259.42 | 72.06 | 168.62 | 1405.18 | 7205.42 | 0 | 0 | 0 | 0 |

| 04:00 | 7.07 | 25.44 | 1439 | 63.94 | 230.17 | 204.73 | 204.73 | 56.87 | 133.08 | 1108.97 | 8314.39 | 0 | 0 | 0 | 0 |

| 05:00 | 9.26 | 33.33 | 1185 | 52.67 | 189.63 | 156.29 | 156.29 | 43.42 | 101.59 | 846.60 | 9160.99 | 0 | 0 | 0 | 0 |

| 06:00 | 13.91 | 50.08 | 744 | 33.08 | 119.07 | 68.99 | 68.99 | 19.16 | 44.84 | 373.69 | 9534.68 | 0 | 0 | 0 | 0 |

| 07:00 | 15.81 | 56.93 | 481 | 21.39 | 77.00 | 20.07 | 20.07 | 5.57 | 13.05 | 108.71 | 9643.39 | 0 | 0 | 0 | 0 |

| 08:00 | 15.30 | 55.10 | 381 | 16.91 | 60.88 | 5.79 | 5.79 | 1.61 | 3.76 | 31.34 | 9674.73 | 0 | 0 | 0 | 0 |

| 09:00 | 14.68 | 52.84 | 288 | 12.81 | 46.12 | −6.72 | 0 | 0 | 0 | 0 | 8940.91 | 88.06 | 733.83 | 1.87 | 3.73 |

| 10:00 | 13.63 | 49.08 | 240 | 10.66 | 38.36 | −10.72 | 0 | 0 | 0 | 0 | 8259.22 | 81.80 | 681.68 | 2.98 | 5.96 |

| 11:00 | 11.55 | 41.58 | 258 | 11.48 | 41.32 | −0.25 | 0 | 0 | 0 | 0 | 7681.74 | 69.30 | 577.48 | 0.07 | 0.14 |

| 12:00 | 12.30 | 44.29 | 349 | 15.50 | 55.81 | 11.53 | 11.53 | 3.20 | 7.49 | 62.43 | 7744.17 | 0 | 0 | 0 | 0 |

| 13:00 | 13.81 | 49.73 | 529 | 23.50 | 84.61 | 34.88 | 34.88 | 9.69 | 22.67 | 188.92 | 7933.10 | 0 | 0 | 0 | 0 |

| 14:00 | 12.47 | 44.90 | 853 | 37.90 | 136.44 | 91.54 | 91.54 | 25.43 | 59.50 | 495.82 | 8428.91 | 0 | 0 | 0 | 0 |

| 15:00 | 10.80 | 38.88 | 1528 | 67.91 | 244.46 | 205.58 | 205.58 | 57.11 | 133.63 | 1113.56 | 9542.47 | 0 | 0 | 0 | 0 |

| 16:00 | 11.39 | 41.00 | 2157 | 95.83 | 344.98 | 303.97 | 303.97 | 84.44 | 197.58 | 1646.51 | 11,188.98 | 0 | 0 | 0 | 0 |

| 17:00 | 11.77 | 42.38 | 2156 | 95.80 | 344.87 | 302.49 | 302.49 | 84.02 | 196.62 | 1638.47 | 12,827.45 | 0 | 0 | 0 | 0 |

| 18:00 | 11.66 | 41.99 | 1986 | 88.25 | 317.69 | 275.70 | 275.70 | 76.58 | 179.20 | 1493.37 | 14,320.81 | 0 | 0 | 0 | 0 |

| 19:00 | 10.91 | 39.27 | 1906 | 84.68 | 304.85 | 265.58 | 265.58 | 73.77 | 172.63 | 1438.57 | 15,759.39 | 0 | 0 | 0 | 0 |

| 20:00 | 10.94 | 39.38 | 1839 | 81.73 | 294.22 | 254.84 | 254.84 | 70.79 | 165.65 | 1380.39 | 17,139.77 | 0 | 0 | 0 | 0 |

| 21:00 | 10.20 | 36.71 | 1787 | 79.41 | 285.87 | 249.15 | 249.15 | 69.21 | 161.95 | 1349.58 | 18,489.35 | 0 | 0 | 0 | 0 |

| 22:00 | 9.11 | 32.78 | 1722 | 76.53 | 275.51 | 242.73 | 242.73 | 67.42 | 157.77 | 1314.78 | 19,804.13 | 0 | 0 | 0 | 0 |

| 00:23 | 7.76 | 27.93 | 1640 | 72.89 | 262.42 | 234.49 | 234.49 | 65.14 | 152.42 | 1270.16 | 21,074.30 | 0 | 0 | 0 | 0 |

| Total | 921.89 | 5162.77 | 4258.58 | 2768.07 | 23,067.29 | 293.19 | 1992.992 | ||||||||

| H2 produced K-tonnes | 23,067.29 | H2 for CCGT | 1992.99 | Other H2 | 3693 | H2 exports | 17,381 | Wind farm | 20,529 km2 |

| Scenario | Wind Farm GW | Wind Farm km2 | 600 MW of H2 CCGTS | Electrolysis GW | Storage of H2 Tonnes | Transmission GW | Hydrogen Export PJ |

|---|---|---|---|---|---|---|---|

| Self-sufficient | 187 | 20,529 | 44 | 175 | 75,310 | 197 | 1061 |

| Export 2100 PJ of H2 | 311 | 34,199 | 44 | 303 | 101,054 | 327 | 2100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rawesat, A.; Pilidis, P. ‘Greening’ an Oil Exporting Country: A Hydrogen, Wind and Gas Turbine Case Study. Energies 2024, 17, 1032. https://doi.org/10.3390/en17051032

Rawesat A, Pilidis P. ‘Greening’ an Oil Exporting Country: A Hydrogen, Wind and Gas Turbine Case Study. Energies. 2024; 17(5):1032. https://doi.org/10.3390/en17051032

Chicago/Turabian StyleRawesat, Abdulwahab, and Pericles Pilidis. 2024. "‘Greening’ an Oil Exporting Country: A Hydrogen, Wind and Gas Turbine Case Study" Energies 17, no. 5: 1032. https://doi.org/10.3390/en17051032

APA StyleRawesat, A., & Pilidis, P. (2024). ‘Greening’ an Oil Exporting Country: A Hydrogen, Wind and Gas Turbine Case Study. Energies, 17(5), 1032. https://doi.org/10.3390/en17051032