Development of Dual Intake Port Technology in ORC-Based Power Unit Driven by Solar-Assisted Reservoir

Abstract

1. Introduction

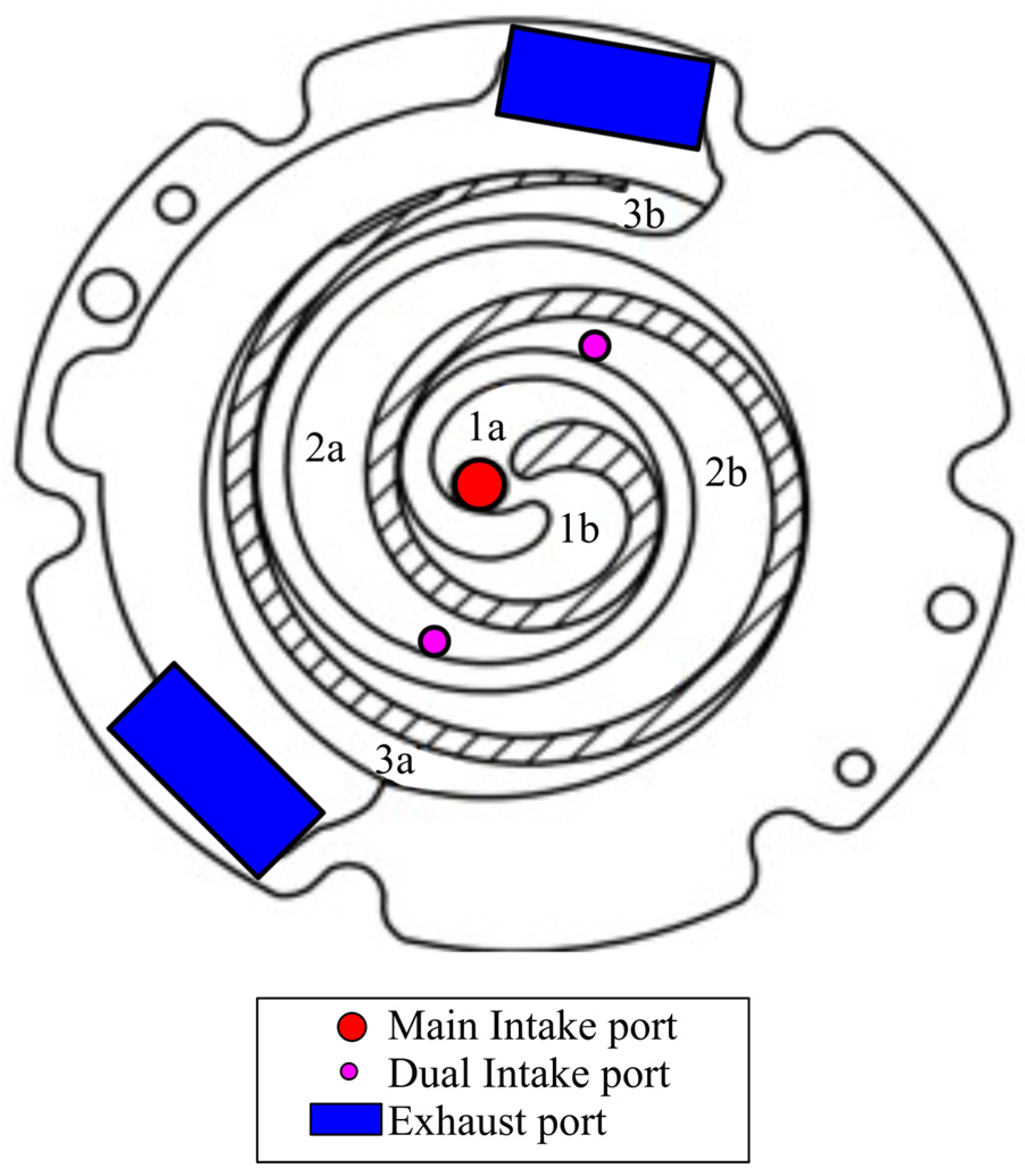

2. Materials and Methods

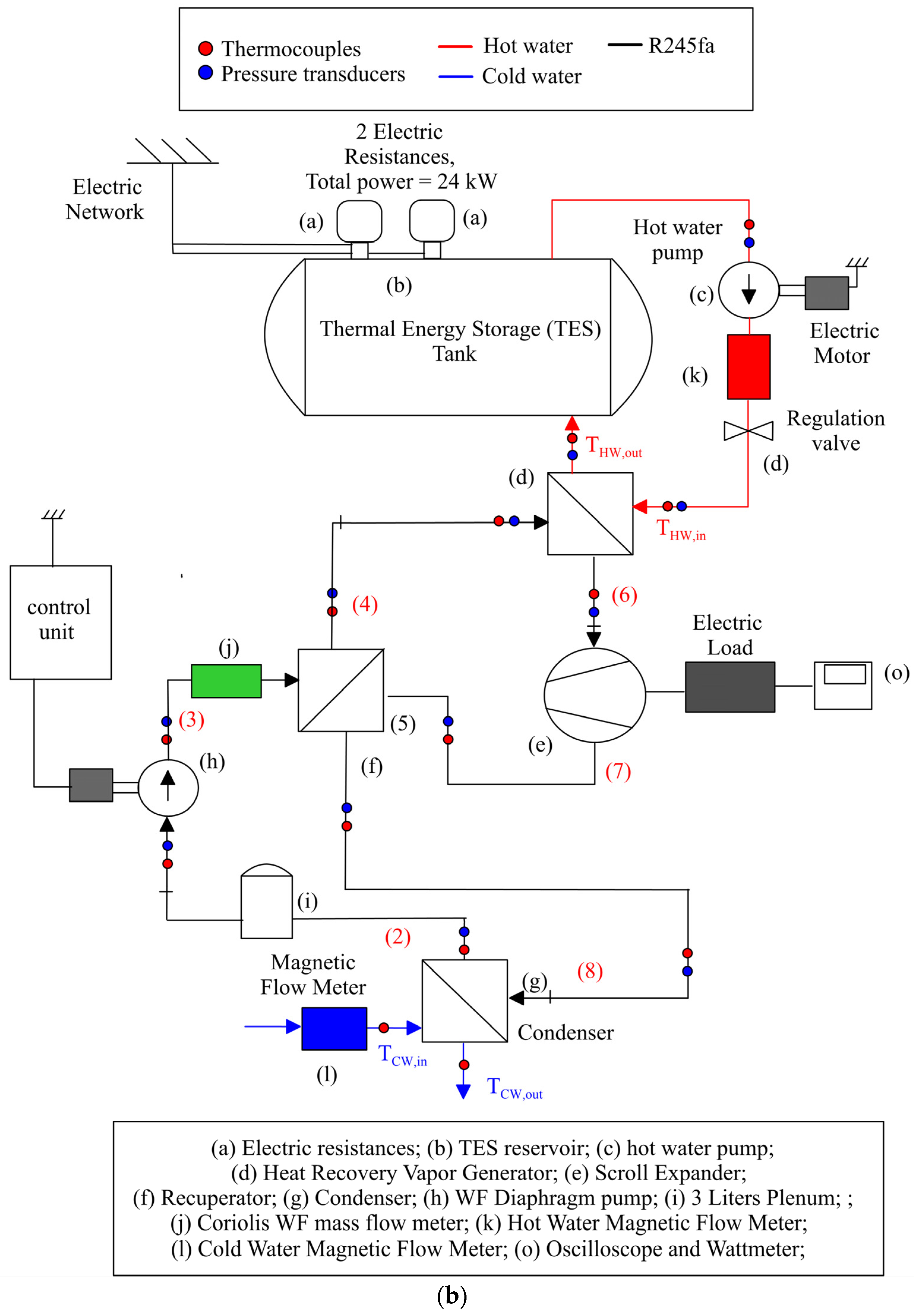

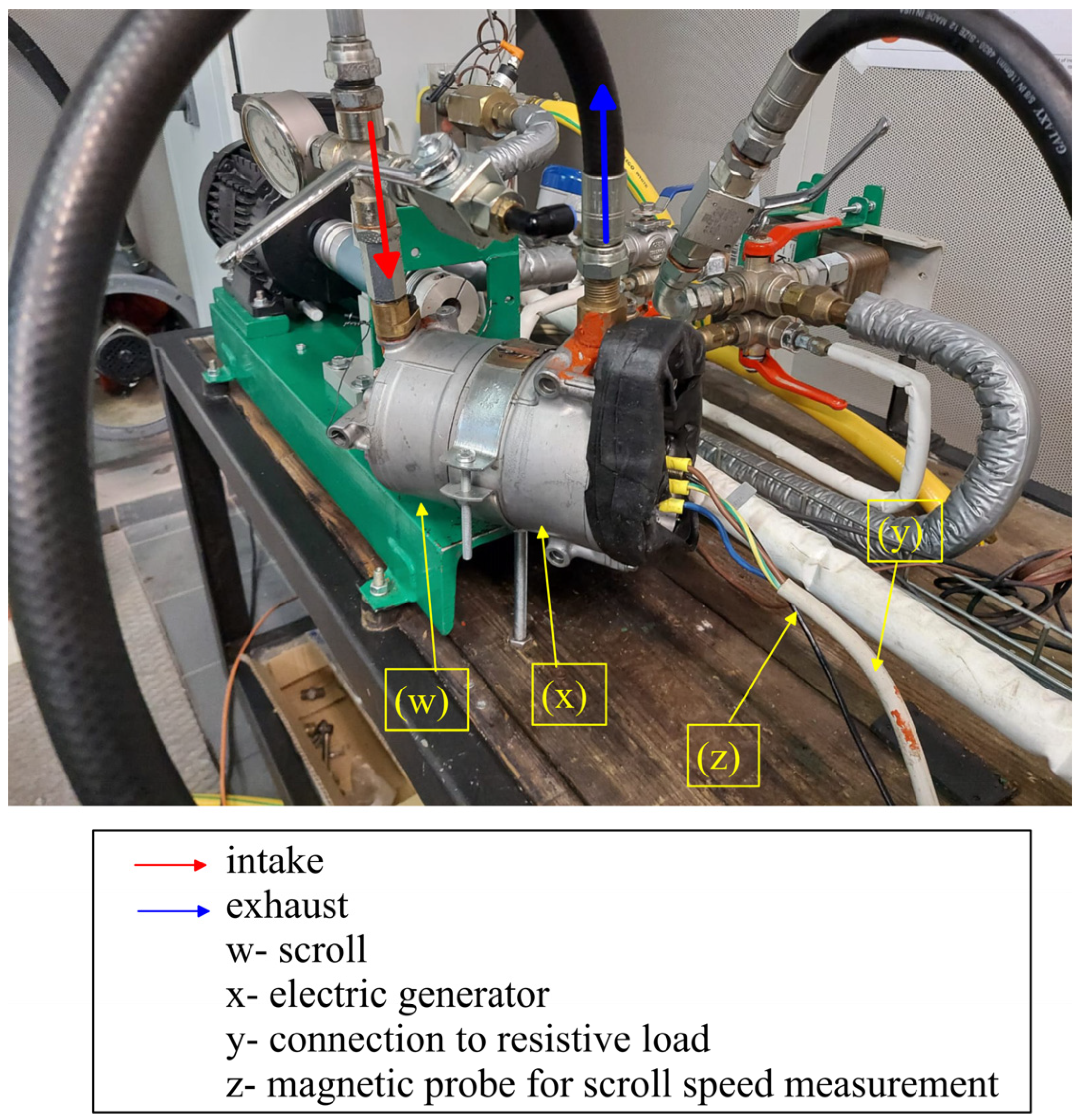

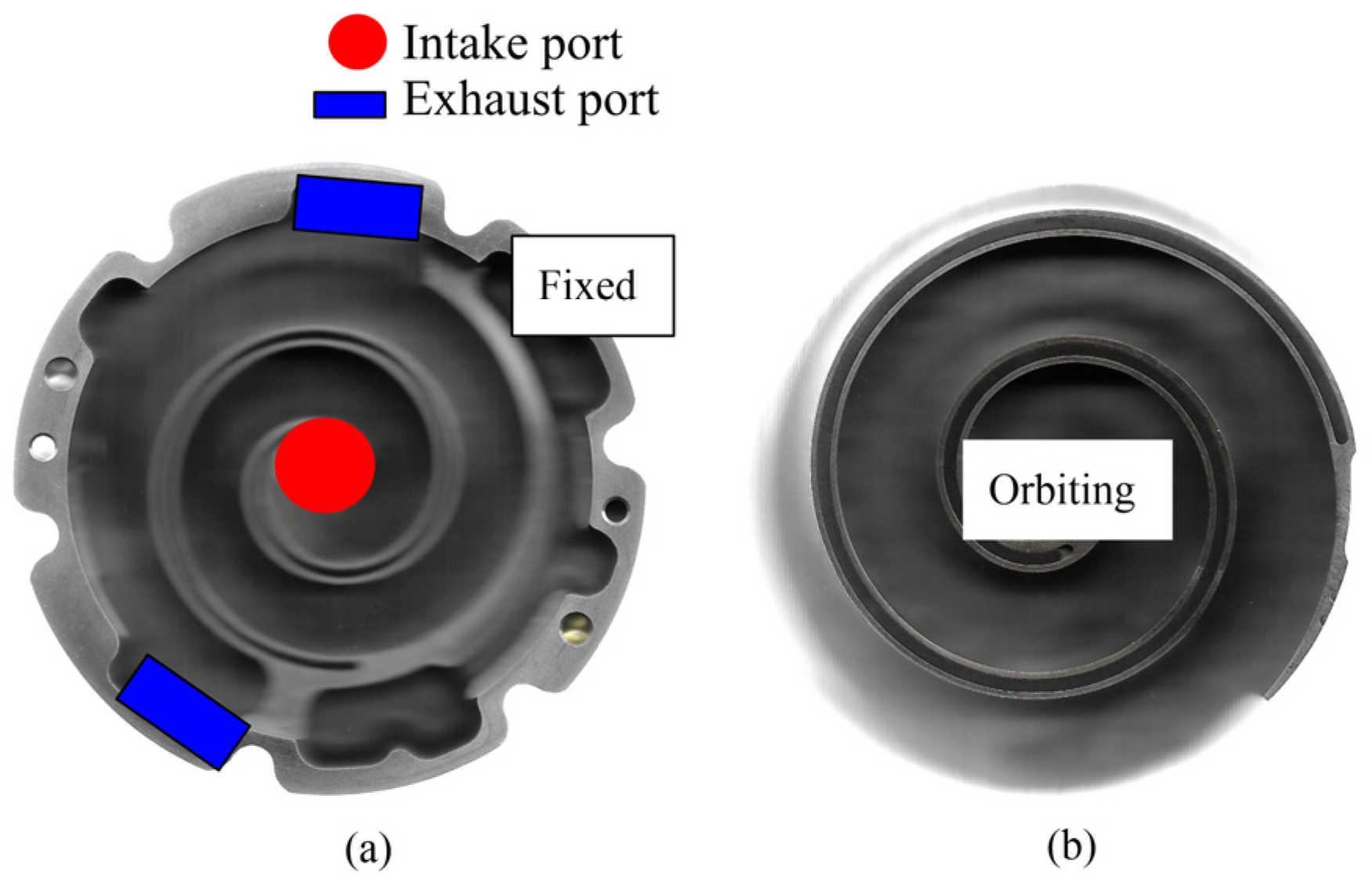

2.1. Experimental Test Bench

2.2. Theoretical Model

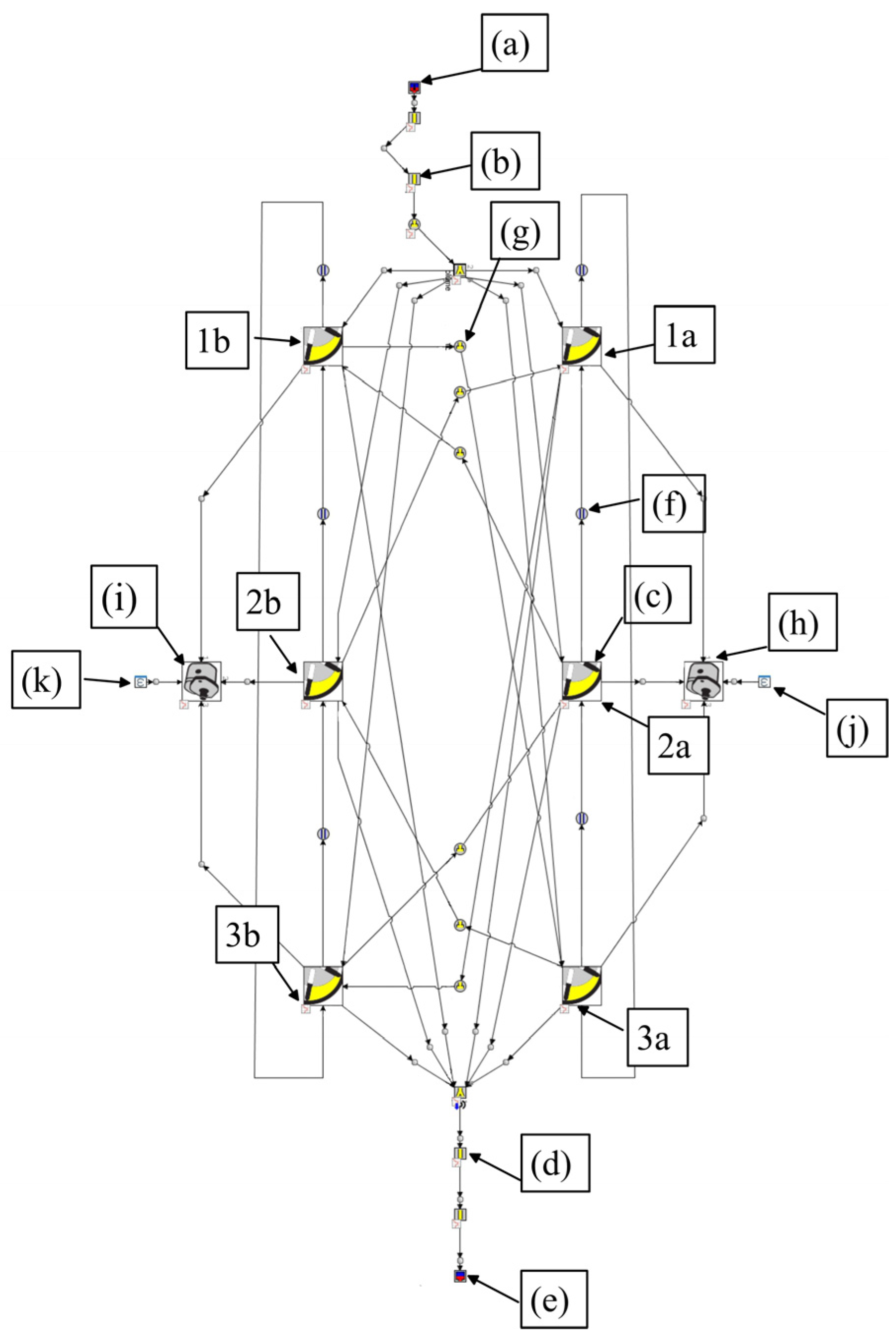

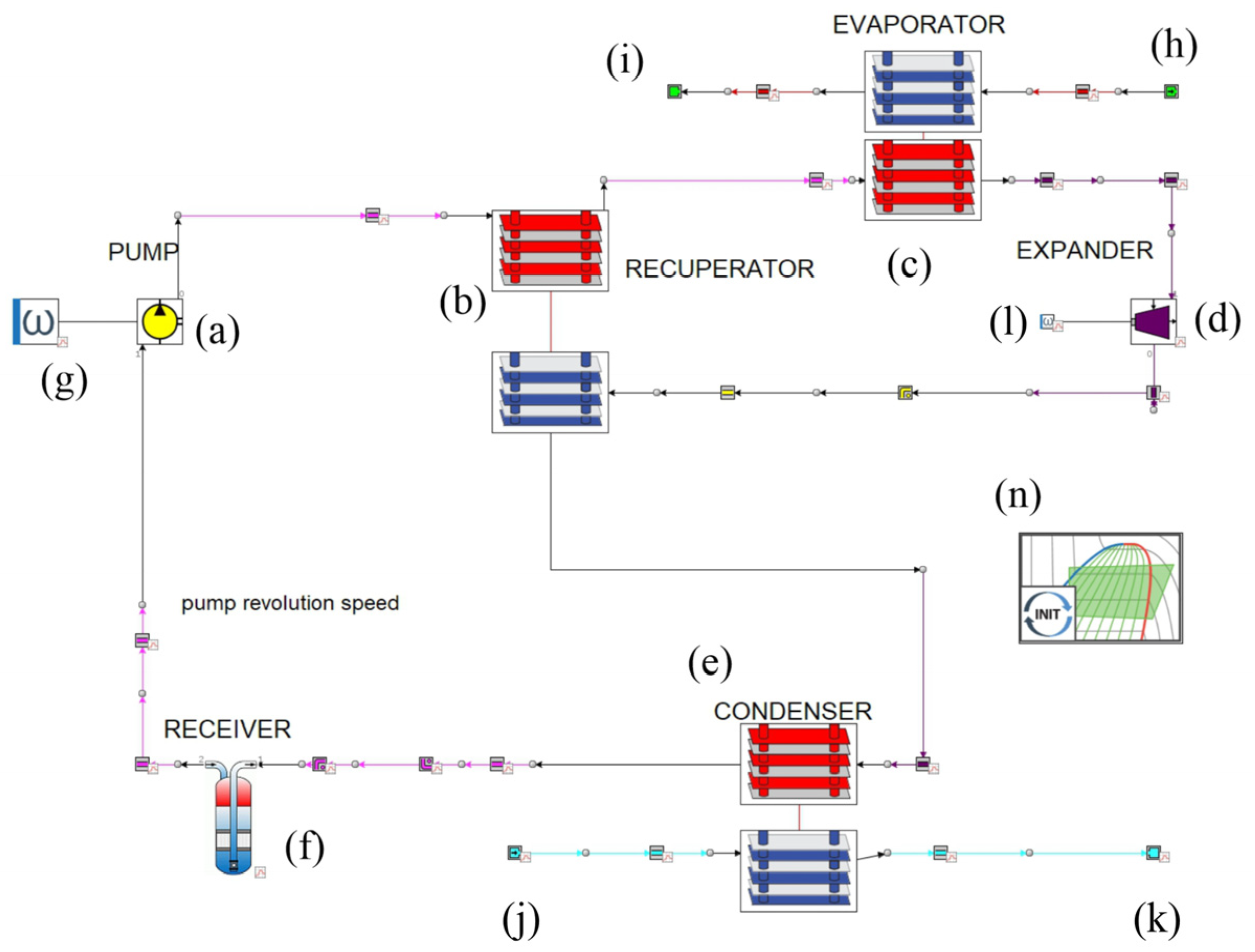

2.3. ORC-Based Power Unit Model

- −

- Pump speed. It is introduced through element (g) of Figure 7 and allows to set the desired mass flow rate with the pump being a volumetric machine.

- −

- The temperature and mass flow rate of the hot water at HRVG inlet (hot side). The data can be introduced through the element (h).

- −

- Pressure at HRVG outlet of the hot water. It can be introduced through element (i).

- −

- The temperature and the mass flow rate of the cold water at condenser inlet (cold side). The values can be introduced through element (j).

- −

- Pressure at condenser outlet (cold side). It can be set via element (k).

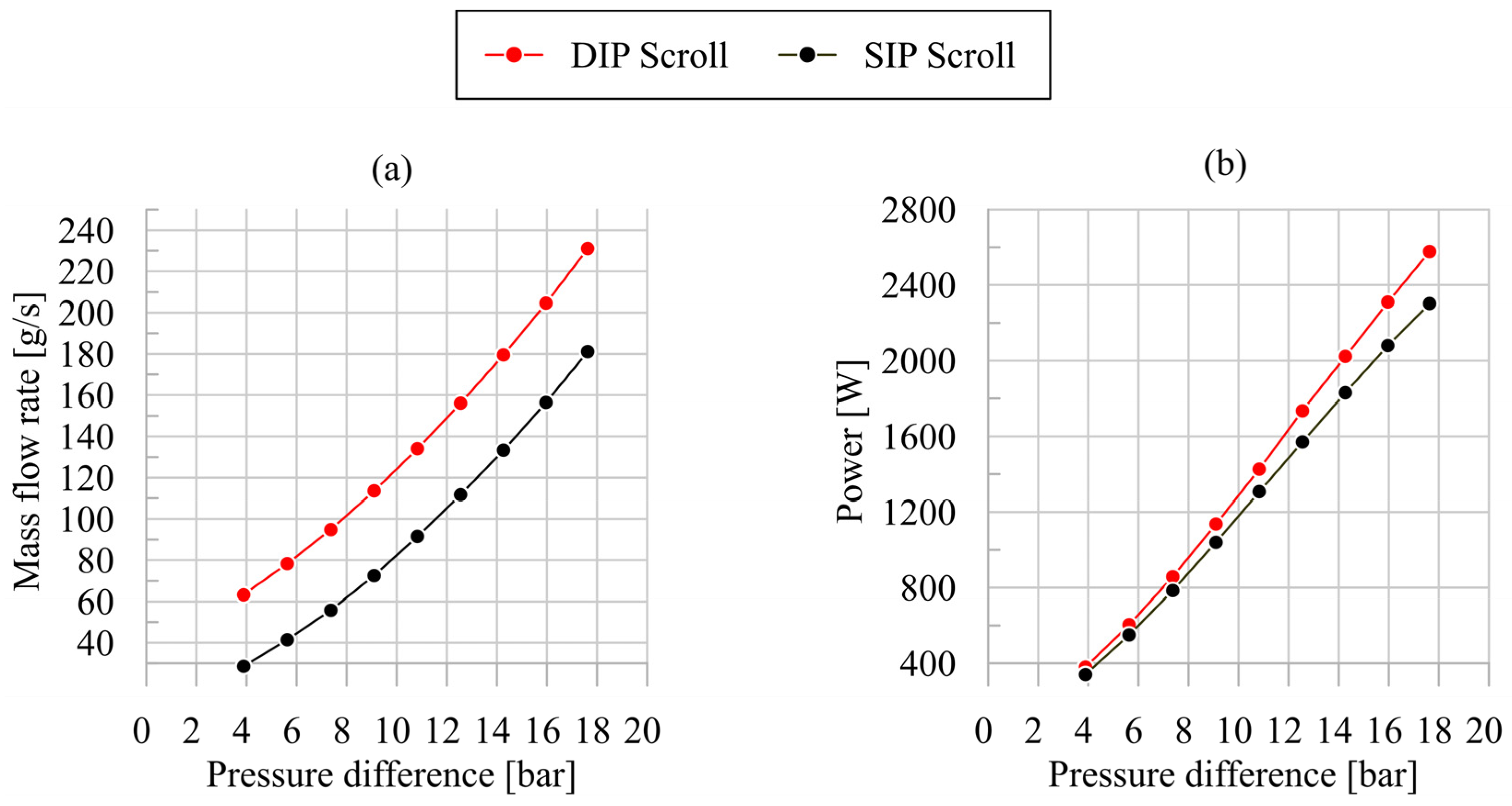

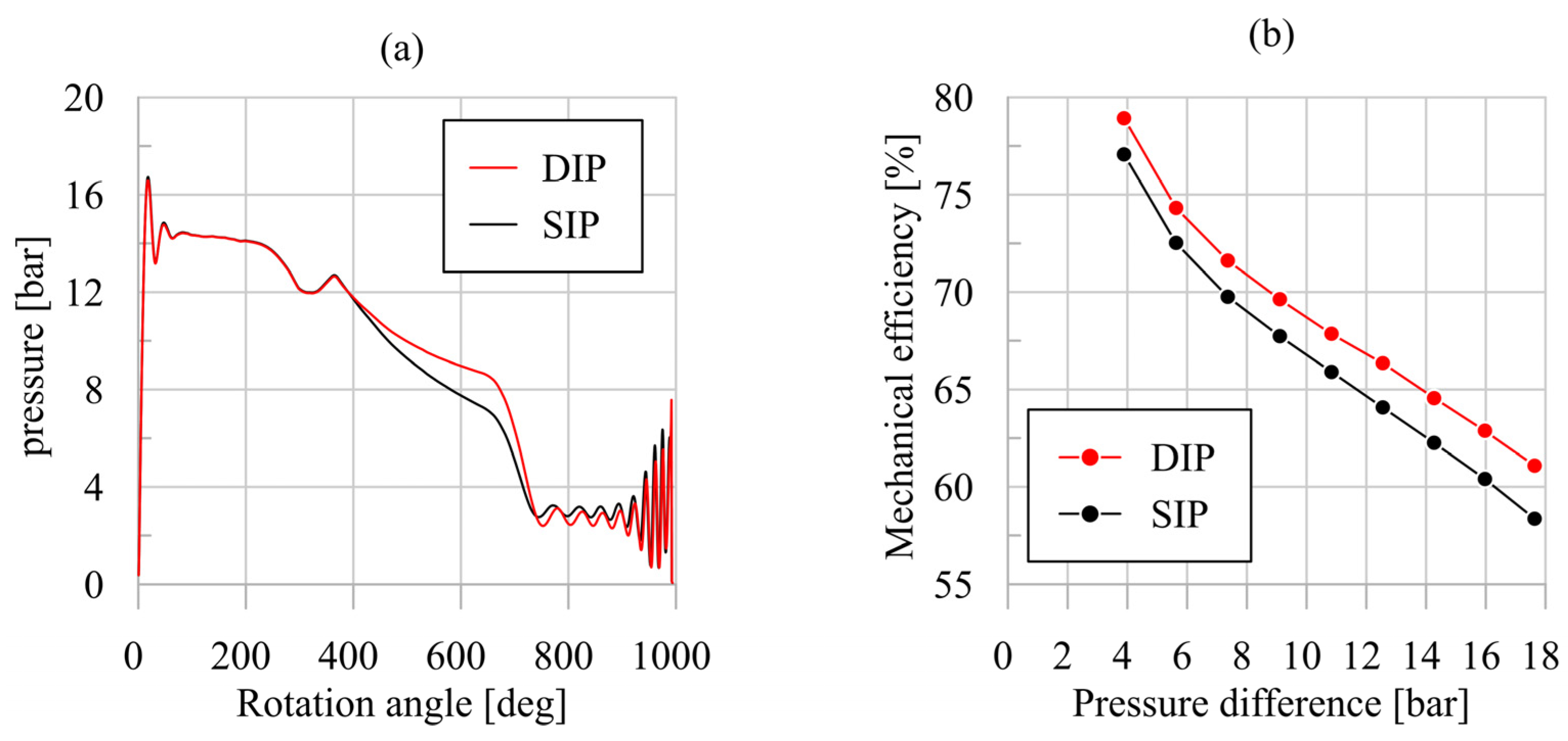

3. Results

3.1. Experimental Validation

3.2. Impact of DIP Introduction on Expander and Plant Performance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | |

| dVi | infinitesimal increase in i-chamber volume [m3] |

| ṁ | mass flow rate [kg/s] |

| P | Power [W] |

| p | pressure [Pa]-[bar] |

| T | Temperature [°C], [K] |

| tcycle | time of a complete cycle [s] |

| Greek letters | |

| α | permeability [kg/(s·MPa)] |

| Δp | pressure difference [bar] |

| η | efficiency |

| ω | expander speed [rps]-[rpm] |

| Subscripts | |

| exp | expander |

| i | internal pressure i-chamber |

| in | intake/inlet |

| ind | indicated power |

| losses | power losses |

| mech | mechanical |

| out | exhaust/outlet |

| WF | working fluid |

| Acronyms | |

| DHW | Domestic Hot Water |

| DIP | Dual Intake Port |

| ORC | Organic Rankine Cycle |

| HRVG | Heat Recovery Vapor Generator |

| RHX | Recuperative Heat Exchanger |

| SIP | Single Intake Port |

| TES | Thermal Energy Storage |

| WF | Working fluid |

References

- Chatzopoulou, M.A.; Lecompte, S.; De Paepe, M.; Markides, C.N. Off-design optimisation of organic Rankine cycle (ORC) engines with different heat exchangers and volumetric expanders in waste heat recovery applications. Appl. Energy 2019, 253, 113442. [Google Scholar] [CrossRef]

- Manfredi, M.; Spinelli, A.; Astolfi, M. Definition of a general performance map for single stage radial inflow turbines and analysis of the impact of expander performance on the optimal ORC design in on-board waste heat recovery applications. Appl. Therm. Eng. 2023, 224, 119857. [Google Scholar] [CrossRef]

- de Oliveira Neto, R.; Sotomonte, C.A.R.; Coronado, C.J.R. Off-design model of an ORC system for waste heat recovery of an internal combustion engine. Appl. Therm. Eng. 2021, 195, 117188. [Google Scholar] [CrossRef]

- Cipollone, R.; Di Battista, D.; Bettoja, F. Performances of an ORC power unit for Waste Heat Recovery on Heavy Duty Engine. Energy Procedia 2017, 129, 770–777. [Google Scholar] [CrossRef]

- Aryanfar, Y.; Mohtaram, S.; Alcaraz, J.L.G.; Sun, H. Energy and exergy assessment and a competitive study of a two-stage ORC for recovering SFGC waste heat and LNG cold energy. Energy 2023, 264, 126191. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Amat-Albuixech, M. Multi-objective optimization of a novel reversible High-Temperature Heat Pump-Organic Rankine Cycle (HTHP-ORC) for industrial low-grade waste heat recovery. Energy Convers. Manag. 2019, 197, 111908. [Google Scholar] [CrossRef]

- Rodriguez-Pastor, D.A.; Becerra, J.A.; Chacartegui, R. Adaptation of residential solar systems for domestic hot water (DHW) to hybrid organic Rankine Cycle (ORC) distributed generation. Energy 2023, 263, 125901. [Google Scholar] [CrossRef]

- Petrollese, M.; Cocco, D. A multi-scenario approach for a robust design of solar-based ORC systems. Renew. Energy 2020, 161, 1184–1194. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; De Pascale, A.; Melino, F.; Peretto, A.; Poletto, C.; Torricelli, N. Solar driven micro-ORC system assessment for residential application. Renew. Energy 2022, 195, 167–181. [Google Scholar] [CrossRef]

- Hasani, M.R.; Nedaei, N.; Assareh, E.; Alirahmi, S.M. Thermo-economic appraisal and operating fluid selection of geothermal-driven ORC configurations integrated with PEM electrolyzer. Energy 2023, 262, 125550. [Google Scholar] [CrossRef]

- Song, J.; Wang, Y.; Wang, K.; Wang, J.; Markides, C.N. Combined supercritical CO2 (SCO2) cycle and organic Rankine cycle (ORC) system for hybrid solar and geothermal power generation: Thermoeconomic assessment of various configurations. Renew. Energy 2021, 174, 1020–1035. [Google Scholar] [CrossRef]

- Braimakis, K.; Charalampidis, A.; Karellas, S. Techno-economic assessment of a small-scale biomass ORC-CHP for district heating. Energy Convers. Manag. 2021, 247, 114705. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A review of working fluid and expander selections for organic Rankine cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Dumont, O.; Parthoens, A.; Dickes, R.; Lemort, V. Experimental investigation and optimal performance assessment of four volumetric expanders (scroll, screw, piston and roots) tested in a small-scale organic Rankine cycle system. Energy 2018, 165, 1119–1127. [Google Scholar] [CrossRef]

- Lemort, V.; Quoilin, S.; Cuevas, C.; Lebrun, J. Testing and modeling a scroll expander integrated into an Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 3094–3102. [Google Scholar] [CrossRef]

- Mujic, E.; Kovacevic, A.; Stosic, N.; Smith, I. Advanced Design Environment for Screw Machines. In Proceedings of the International Compressor Engineering Conference, Purdue, IN, USA, 12–15 July 2010; p. 1971. Available online: https://docs.lib.purdue.edu/icec/1971 (accessed on 4 February 2024).

- Kovacevic, A.; Stosic, N.; Smith, I.K.; Mujic, E. Advances in Numerical Modelling of Helical Screw Machines. In Proceedings of the International Compressor Engineering Conference, Purdue, IN, USA, 12–15 July 2010; p. 1953. Available online: https://docs.lib.purdue.edu/icec/1953 (accessed on 4 February 2024).

- Leibowitz, H.; Smith, I.K.; Stosic, N. Cost Effective Small Scale ORC Systems for Power Recovery From Low Grade Heat Sources. In Proceedings of the ASME 2006 International Mechanical Engineering Congress and Exposition. Advanced Energy Systems, Chicago, IL, USA, 5–10 November 2006; pp. 521–527. [Google Scholar] [CrossRef]

- Bianchi, M.; Branchini, L.; Casari, N.; De Pascale, A.; Melino, F.; Ottaviano, S.; Pinelli, M.; Spina, P.R.; Suman, A. Experimental analysis of a micro-ORC driven by piston expander for low-grade heat recovery. Appl. Therm. Eng. 2019, 148, 1278–1291. [Google Scholar] [CrossRef]

- Mohd, M.; Tahir, N.Y.; Hoshino, T. Efficiency of compact organic Rankine cycle system with rotary-vanetype expander for low-temperature waste heat recovery. Int. J. Environ. Sci. Eng. 2010, 2, 11–16. [Google Scholar]

- Badr, O.; Naik, S.; O’Callaghan, P.W.; Probert, S.D. Expansion machine for a low power-output steam Rankine-cycle engine. Appl. Energy 1991, 39, 93–116. [Google Scholar] [CrossRef]

- Musthafah, M.T.; Yamada, N. Thermodynamic analysis of expansion profile for displacement-type expander in low-temperature Rankine cycle. J. Therm. Sci. Technol. 2010, 5, 61–74. [Google Scholar] [CrossRef]

- Vodicka, V.; Novotny, V.; Zeleny, Z.; Mascuch, J.; Kolovratnik, M. Theoretical and experimental investigations on the radial and axial leakages within a rotary vane expander. Energy 2019, 189, 116097. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Bartolomeo, M.; Cipollone, R. Dual intake rotary vane expander technology: Experimental and theoretical assessment. Energy Convers. Manag. 2019, 186, 156–167. [Google Scholar] [CrossRef]

- Fatigati, F.; Di Giovine, G.; Cipollone, R. Feasibility Assessment of a Dual Intake-Port Scroll Expander Operating in an ORC-Based Power Unit. Energies 2022, 15, 770. [Google Scholar] [CrossRef]

- Marchionni, M.; Fatigati, F.; Di Bartolomeo, M.; Di Battista, D.; Petrollese, M. Experimental and Numerical Dynamic Investigation of an ORC System for Waste Heat Recovery Applications in Transportation Sector. Energies 2022, 15, 9339. [Google Scholar] [CrossRef]

- GT-SUITE-Flow Theory Manual; T Gamma—Gamma Technologies Inc.: Westmont, IL, USA, 2020; Available online: https://www.gtisoft.com/ (accessed on 1 December 2023).

- Dittus, F.W.; Boelter, L.M. Heat transfer in automobile radiators of the tubular type. Int. Commun. Heat Mass Transf. 1985, 12, 3–22. [Google Scholar] [CrossRef]

- Yan, Y.-Y.; Lio, H.-C.; Lin, T.-F. Condensation heat transfer and pressure drop of refrigerant R-134a in a plate heat exchanger. Int. J. Heat Mass Transf. 1999, 42, 993–1006. [Google Scholar] [CrossRef]

- Kandlikar, S.G. A General Correlation for Saturated Two-Phase Flow Boiling Heat Transfer Inside Horizontal and Vertical Tubes. J. Heat Transf. 1990, 112, 219–228. [Google Scholar] [CrossRef]

- Friedel, L. Improved Friction Pressure Drop Correlation for Horizontal and Vertical Two-Phase Pipe Flow. Available online: https://www.semanticscholar.org/paper/Improved-Friction-Pressure-Drop-Correlation-for-and-Friedel/5e65d566aaeff9037a4918d6f60d742787ce0d4a (accessed on 1 December 2023).

| Variable | Sensor Type | Measurement Uncertainty |

|---|---|---|

| Temperature | Thermocouple | ±0.75 °C |

| Pressure | Pressure transducers | ±1.5% of full-scale |

| Mass flow rate (R245fa) | Coriolis Flow meter | ±0.15% measured value |

| Mass flow rate (water) | Magnetic Flowmeter | ±0.5% measured value |

| Power | Wattmeter | ±1% measured value |

| 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|

| pexp,in [bar] | 7.6 | 8.3 | 9.2 | 9.4 | 10.1 | 10.7 |

| pexp,out [bar] | 2.1 | 2.3 | 2.4 | 2.5 | 2.6 | 2.8 |

| Texp,in [°C] | 93 | 98 | 102 | 95 | 99 | 101 |

| Texp,out [°C] | 71 | 75 | 76 | 66 | 72 | 75 |

| ṁwf [g/s] | 32.0 | 36.0 | 40.7 | 45.0 | 49.0 | 54.0 |

| Pexp [W] | 398 | 447 | 499 | 486 | 525 | 545 |

| ωexp [rpm] | 4590 | 4950 | 5250 | 5100 | 5400 | 5520 |

| 1 | 2 | 3 | 4 | 5 | 6 | |

|---|---|---|---|---|---|---|

| Relative errors [%] | ||||||

| WF mass flow rate ṁwf | 7.50 | 6.06 | 7.54 | 2.90 | 3.45 | 1.09 |

| Expander intake pressure pin, exp | 0.53 | −2.91 | −0.25 | 1.62 | 2.64 | 2.01 |

| Absolute errors [°C] | ||||||

| Expander exhaust temperature Texp,out | 3.4 | 2.7 | 0.8 | −0.2 | 2.4 | 4.0 |

| Experimental Quantities | Units | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| Mass flow rate | g/s | 50.7 | 45.9 | 41.4 | 49.3 | 17.8 | 23.0 |

| ORC maximum pressure | bar | 10.4 | 9.7 | 9.0 | 10.1 | 5.0 | 5.9 |

| ORC maximum temperature | °C | 108.0 | 104.3 | 105.9 | 104.3 | 91.4 | 90.5 |

| ORC minimum pressure | bar | 1.5 | 1.5 | 1.4 | 1.5 | 1.2 | 1.3 |

| ORC minimum temperature | °C | 20 | 20.2 | 17.8 | 23 | 14.6 | 13.7 |

| Temperature at RHX inlet (hot side) | °C | 82 | 65.6 | 76.7 | 78.3 | 69.2 | 67.7 |

| Temperature at RHX outlet (hot side) | °C | 33 | 30.3 | 31.1 | 34.8 | 29 | 28.4 |

| Temperature at RHX outlet (cold side) | °C | 53.3 | 44.2 | 50.3 | 53.0 | 44.6 | 42.9 |

| Expander power | W | 583 | 565 | 546 | 563 | 271 | 347 |

| Pump power | W | 223 | 179 | 142 | 209 | 15 | 33 |

| ORC unit power | W | 360 | 386 | 404 | 354 | 256 | 314 |

| Errors | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Mass flow rate [%] | −1.0 | −0.9 | −1.3 | −0.4 | −1.6 | −1.8 |

| ORC maximum pressure [%] | −1.9 | −0.1 | −0.2 | −2.7 | −2.1 | −1.8 |

| ORC maximum temperature [°C] | −1.6 | 2.5 | 1.6 | −5.0 | 0.8 | 0.7 |

| ORC minimum pressure [%] | 1.5 | −1.2 | 0.6 | −4.9 | 9.3 | 10.5 |

| ORC minimum temperature [°C] | 5.3 | 4.5 | 6.6 | 2.1 | 8.2 | 9.6 |

| Temperature at RHX inlet (hot side) [°C] | −1.8 | 5.7 | 2.0 | −5.3 | 2.9 | 2.3 |

| Temperature at RHX outlet (hot side) [°C] | 4.2 | 4.2 | 4.5 | 0.5 | 2.5 | 3.3 |

| Temperature at RHX outlet (cold side) [°C] | 2.0 | 6.1 | 4.3 | −1.8 | 6.9 | 7.3 |

| ORC unit power [%] | −5.4 | −3.8 | −10.0 | −11.7 | −12.7 | −14.7 |

| ORC efficiency [%] | 4.4 | 2.5 | 9.2 | 11.4 | 9.0 | 10.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fatigati, F.; Cipollone, R. Development of Dual Intake Port Technology in ORC-Based Power Unit Driven by Solar-Assisted Reservoir. Energies 2024, 17, 1021. https://doi.org/10.3390/en17051021

Fatigati F, Cipollone R. Development of Dual Intake Port Technology in ORC-Based Power Unit Driven by Solar-Assisted Reservoir. Energies. 2024; 17(5):1021. https://doi.org/10.3390/en17051021

Chicago/Turabian StyleFatigati, Fabio, and Roberto Cipollone. 2024. "Development of Dual Intake Port Technology in ORC-Based Power Unit Driven by Solar-Assisted Reservoir" Energies 17, no. 5: 1021. https://doi.org/10.3390/en17051021

APA StyleFatigati, F., & Cipollone, R. (2024). Development of Dual Intake Port Technology in ORC-Based Power Unit Driven by Solar-Assisted Reservoir. Energies, 17(5), 1021. https://doi.org/10.3390/en17051021