Impact of the Regulation Strategy on the Transient Behavior of a Brayton Heat Pump

Abstract

1. Introduction

1.1. Background

1.2. Objectives and Elements of Novelty

- A thermal load alteration caused by an abrupt change in the desired heat sink temperature;

- A thermal load alteration due to a sudden variation in the sink mass flow rate. In the former scenario, the motor/compressor speed adapts to the heat sink temperature at the desired setpoint.

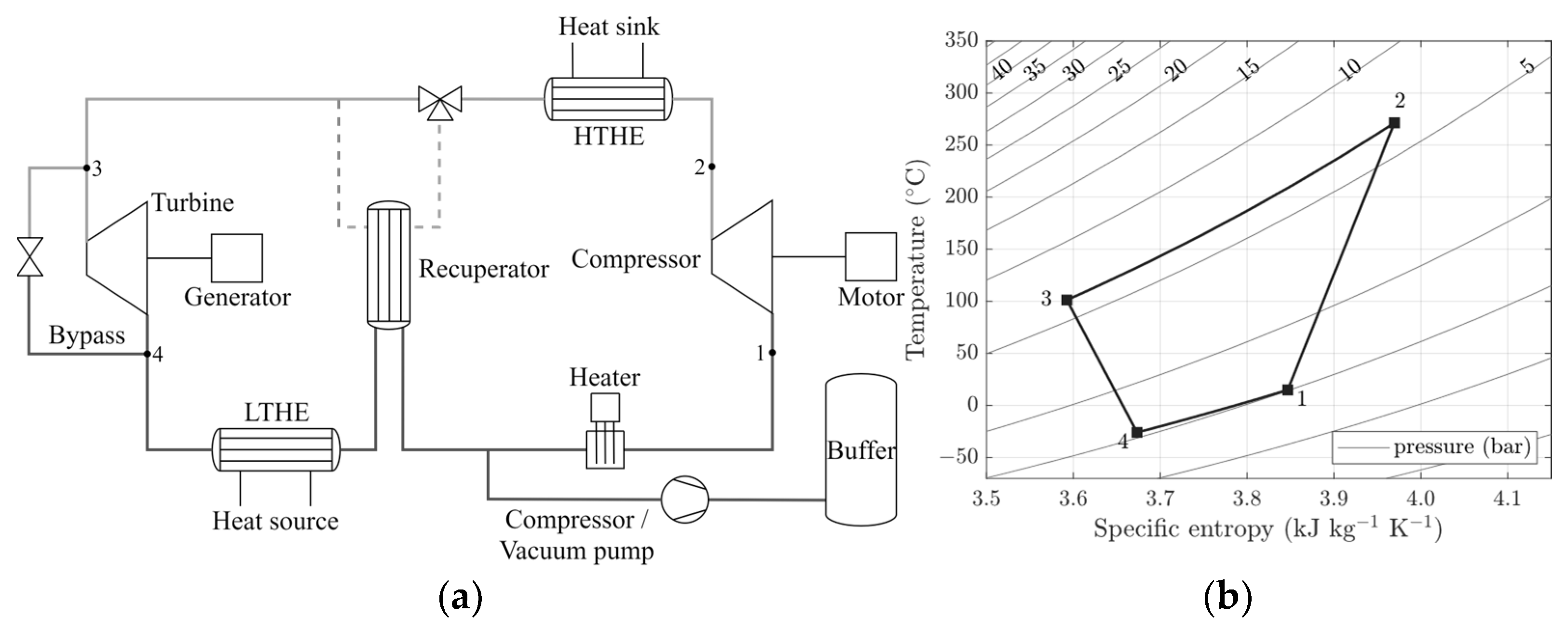

2. Case Study

3. Methods

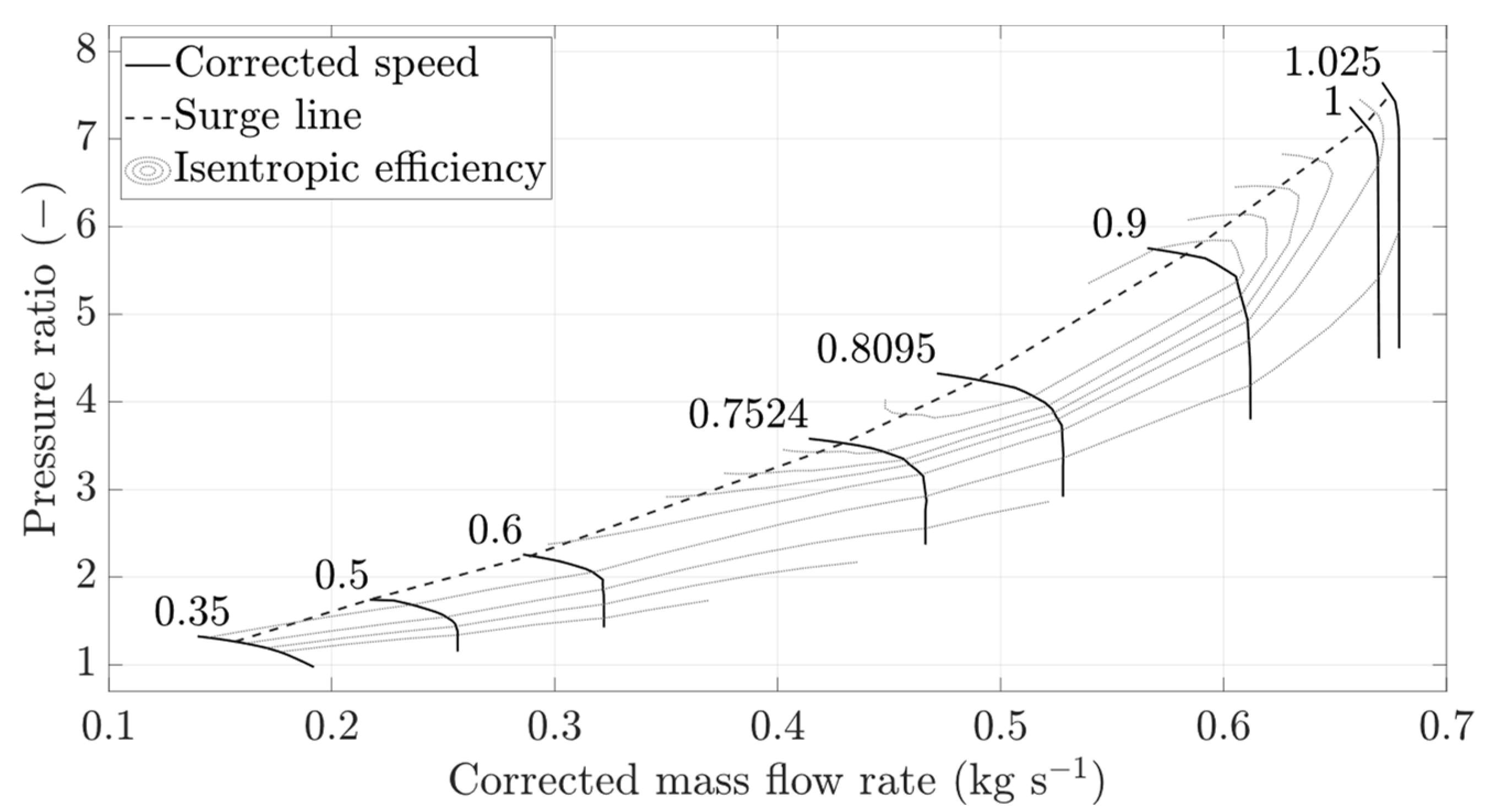

3.1. Turbomachinery

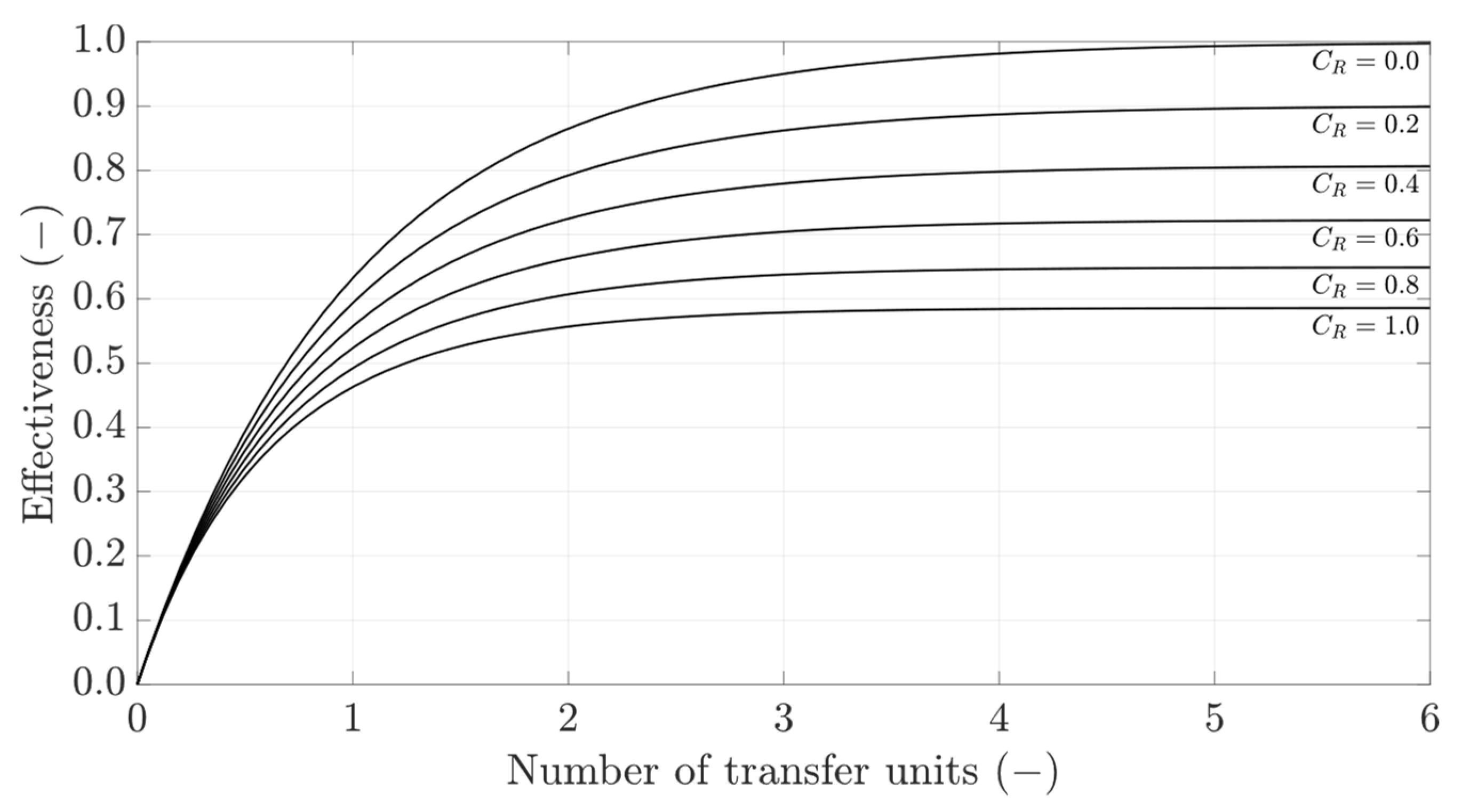

3.2. Heat Exchangers

3.3. Piping and Valves

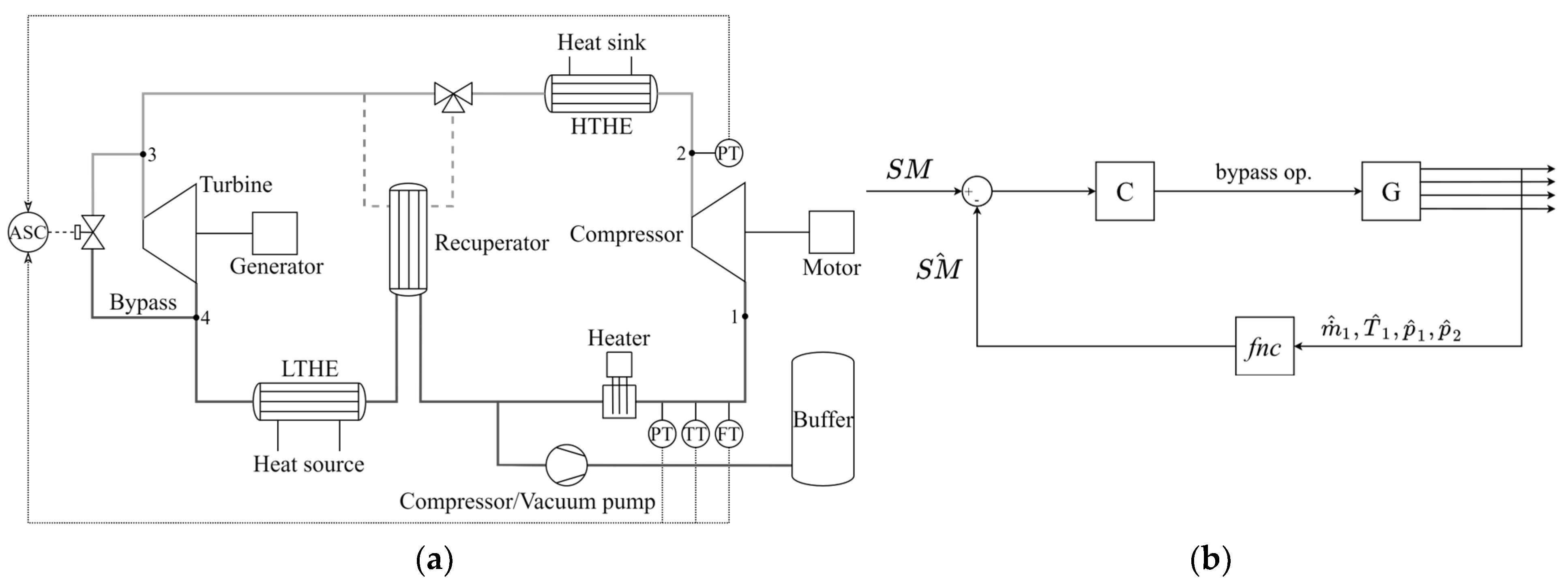

3.4. Control Systems

- Anti-surge control;

- Temperature/speed control;

- Fluid inventory control.

- Zero residual upon reaching the new steady-state condition;

- Temperature rates below 2 K/min at the compressor outlet [12].

4. Results and Discussion

4.1. Performed Analyses

- Step change of the desired sink temperature while the TC is used to adapt the thermal load supplied by the heat pump;

- Step change of the sink mass flow rate while the sink outlet temperature is maintained through the TC;

- Step change of the sink mass flow rate while the sink outlet temperature is upheld at the design value by the FIC.

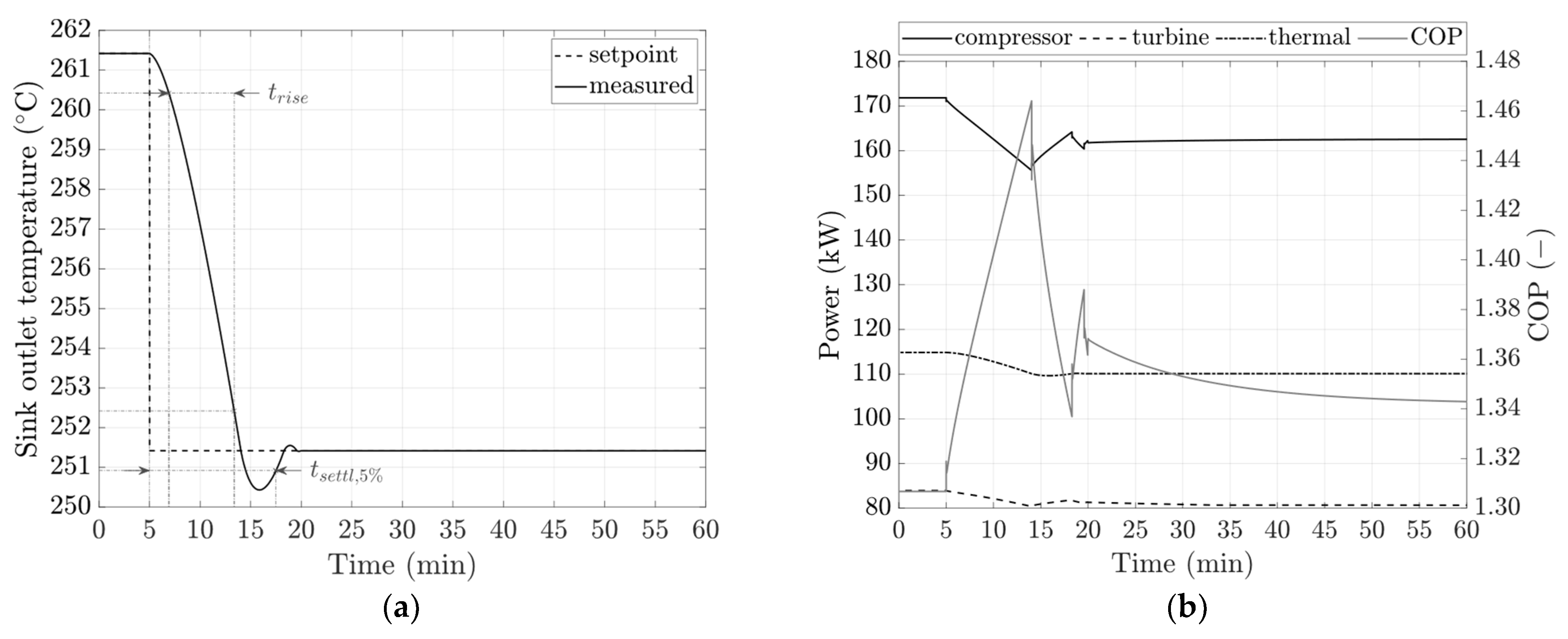

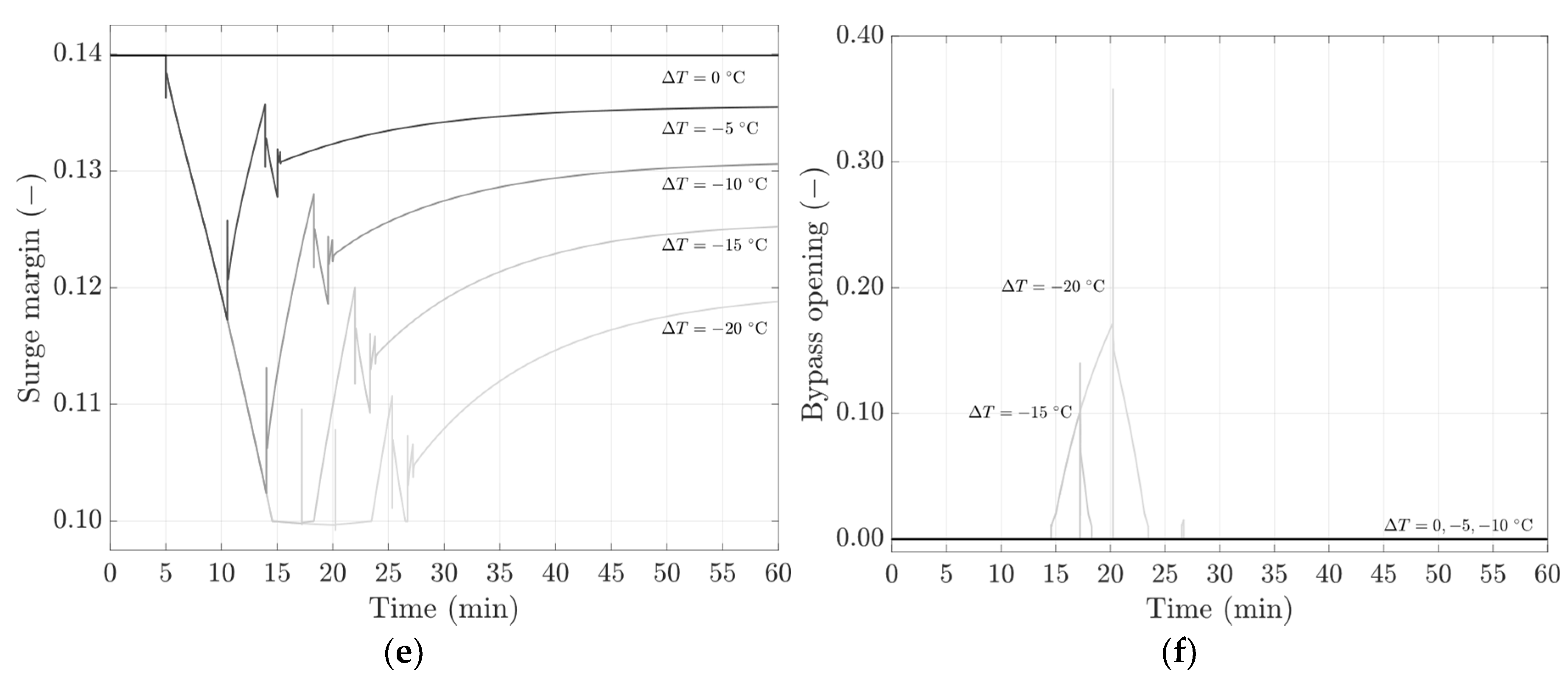

4.2. Sink Outlet Temperature Variation and Temperature/Speed Control

- Varying the compressor speed to change the sink temperature ensures a regulation time of about 8–20 min, depending on the required heat sink temperature variation;

- The system response time is limited by the maximum thermal stress that the heat exchangers can endure. The higher the allowed stress, the shorter the regulation time;

- Such a control approach causes the heat pumps to operate at higher COPs, as the net power absorbed by the system reduces more than the heat flow rate provided at the sink;

- Such a control approach can lead to compressor surge for large sink temperature variations.

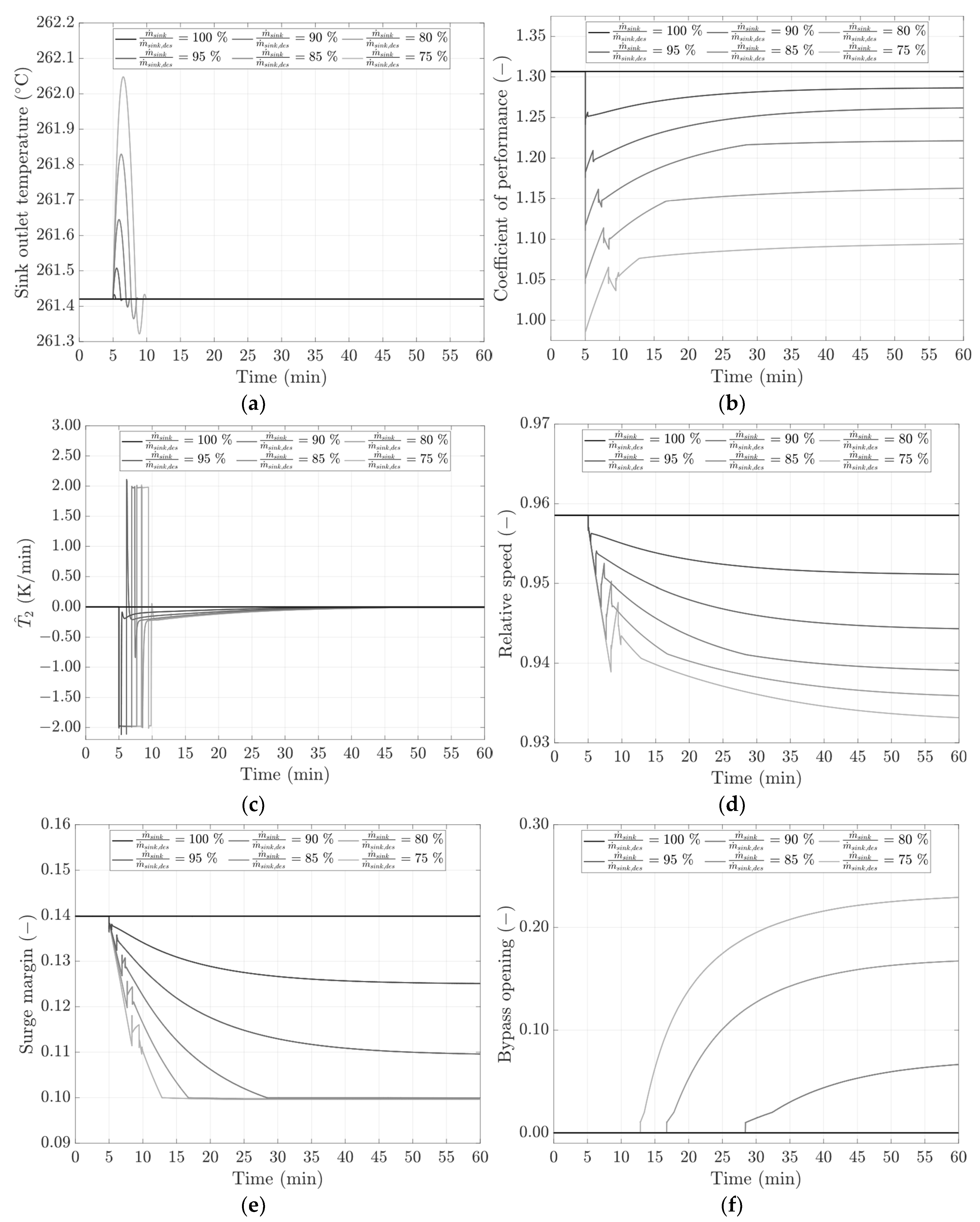

4.3. Sink Mass Flow Rate Variation and Temperature/Speed Control

- Adjusting the compressor speed enables the heat pump to keep the heat sink temperature deviation below 1 °C in response to step changes in the sink mass flow rate. The oscillations in the sink outlet temperature are dampened within 2 to 5 min, depending on the reduction in the sink mass flow rate;

- Allowing higher thermal stress at the heat exchangers may reduce the time required to stabilize the heat sink temperature;

- Employing such a control strategy approach results in the system operating at lower COPs. Notably, higher reductions in the sink mass flow lead to decreased COPs;

- Such a control approach can lead to compressor surge in case of a significant reduction in the sink mass flow rate.

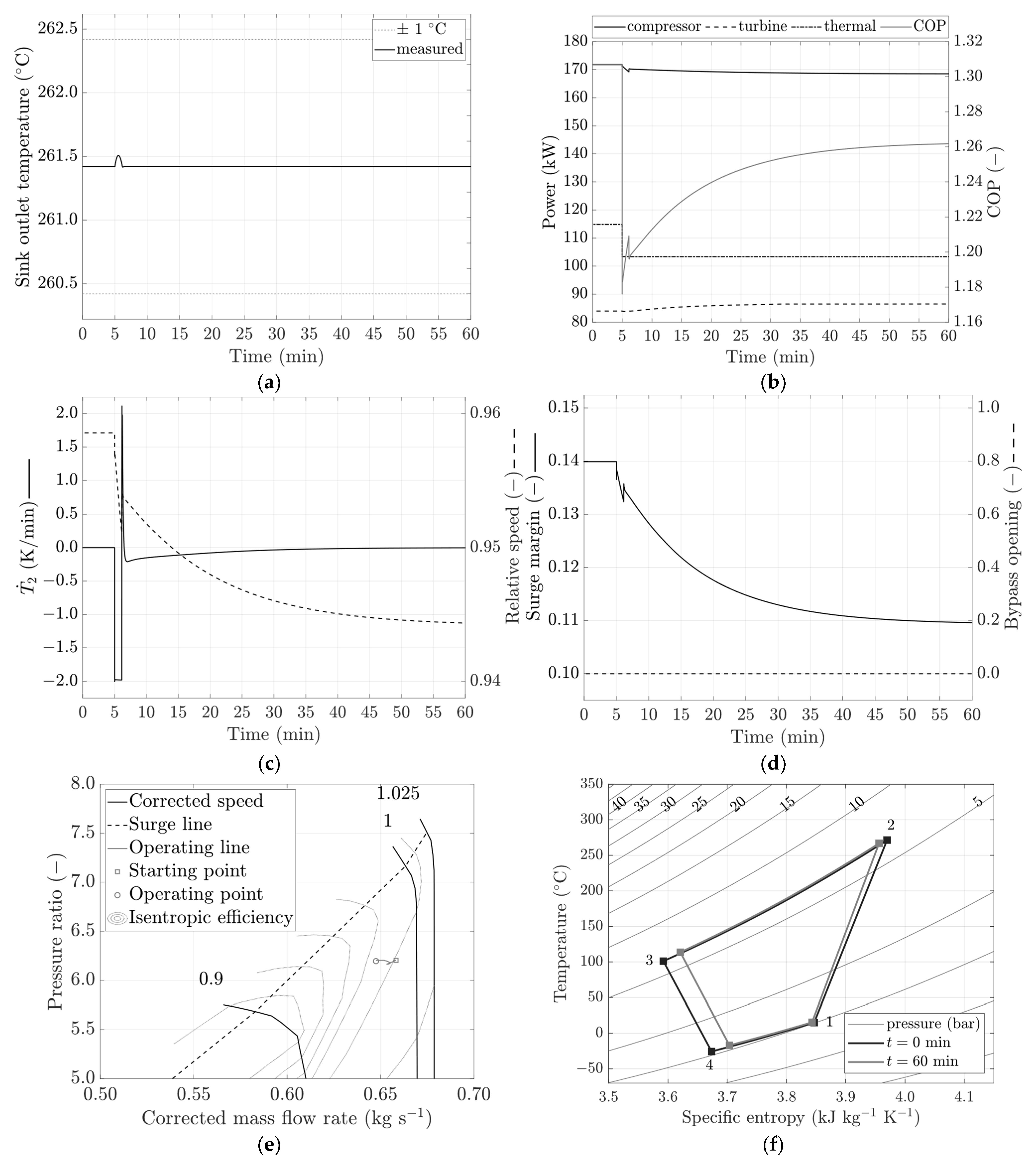

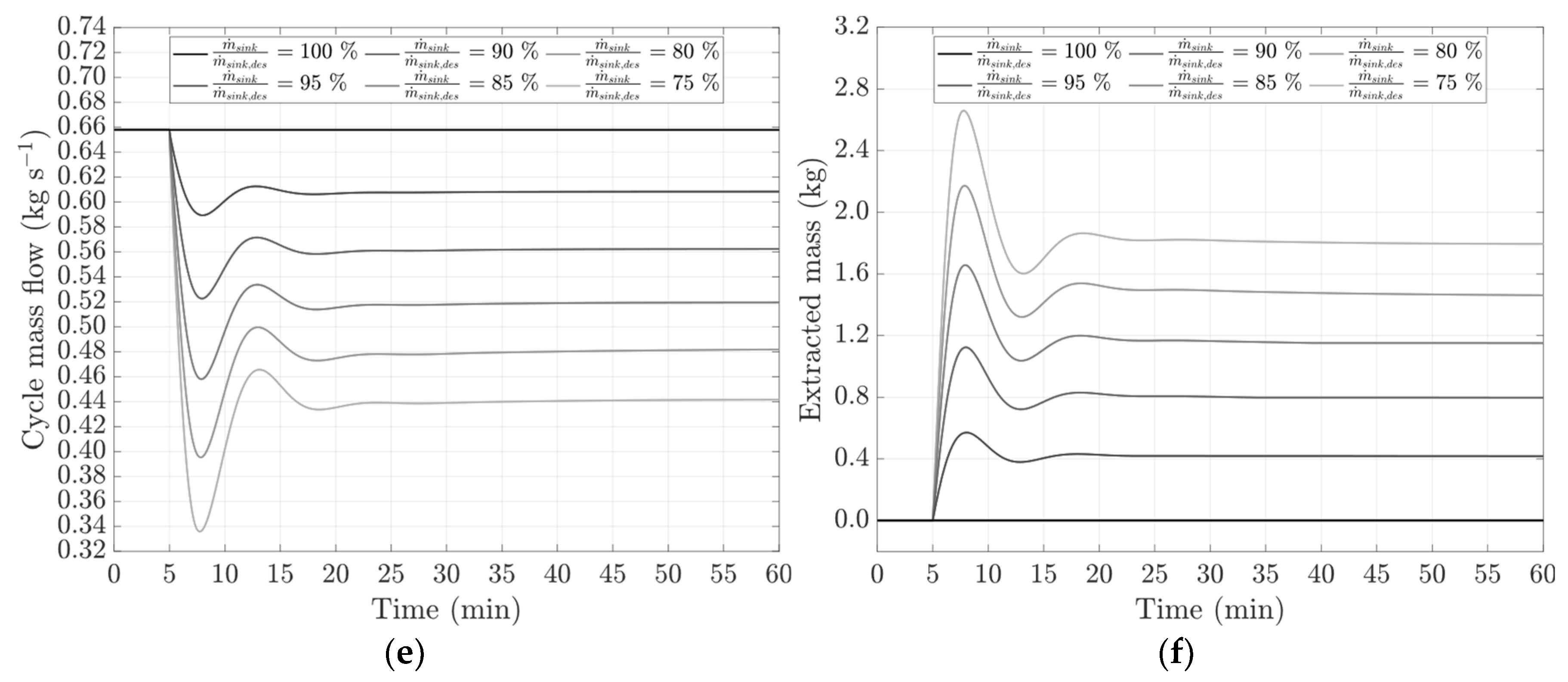

4.4. Sink Mass Flow Rate Variation through Inventory Control

- The inventory control allows the heat pump to maintain the heat sink temperature deviation below 1.5 °C in response to step variation in the sink mass flow rate. Transient oscillations subside within 15 min, and larger variations cause higher temperature residuals during the transient phase;

- This control approach can lead to sub-ambient pressure at the compressor inlet;

- The inventory control enables the system to operate at higher COPs in new steady conditions. In particular, as the sink mass flow reduction increases, so does the COP;

- The inventory control approach does not cause compressor surge, even in scenarios involving large reductions in the sink mass flow rate.

5. Conclusions

- When varying the compressor speed to regulate the heat sink temperature, the system reduces the sink temperature to new desired values according to a second-order system response, and the larger the desired sink outlet temperature reduction, the longer the response time. Additionally, the rate at which the sink outlet temperature increases is bounded by the maximum allowed temperature rate at the compressor outlet;

- When varying the compressor speed to maintain the heat sink temperature in response to a 10% reduction in the sink mass flow, the sink outlet temperature experiences only a minor oscillation, which dampens after about 5 min. The system COP reduces once the new steady-state conditions are met. Larger sink mass flow reductions cause higher heat sink temperature residuals during the transient phase (although always below ± 1 °C) and progressively lower COPs;

- When using the inventory control to maintain the sink outlet in response to a 10% reduction in the sink mass flow, the sink outlet temperature deviates by about 0.6 °C from the nominal value during the transient phase and stabilizes after nearly 15 min. The system COP increases by about 0.05 compared with nominal operating conditions. Larger sink mass flow rate reductions lead to higher heat sink temperature residuals during the transient phase (always below 1.5 °C) and progressively higher COPs;

- When comparing the considered control strategies to maintain the desired heat sink temperature in response to a sudden reduction in the sink mass flow, varying the compressor speed allows for lower sink outlet temperature perturbations (e.g., 0.1 °C vs. 0.6 °C) and faster response times (e.g., 5 min vs. 15 min). On the other hand, the fluid inventory control enables the system to operate at higher COPs (e.g., 1.35 vs. 1.26) when new operating conditions are met. Moreover, unlike the speed regulation approach, the inventory control approach ensures large surge margins, reducing the risk of compressor surge.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PTES | Pumped Thermal Electricity Storage | |

| DLR | German Aerospace Center | |

| HTHE | High-Temperature Heat Exchanger | |

| LTHE | Low-Temperature Heat Exchanger | |

| COP | Coefficient of Performance | (-) |

| NTU | Number of Transfer Units | |

| ASC | Anti-Surge Control/Regulator | |

| SM | Surge Margin | (-) |

| PR | Pressure Ratio | (-) |

| PT | Pressure Transducer | |

| TT | Temperature Transducer | |

| ST | Speed Transducer | |

| FT | Mass Flow Rate Transducer | |

| TC | Temperature Control/Regulator | |

| FIC | Fluid Inventory Control | |

| Symbols | ||

| time | (s) | |

| mass flow rate | (kg/s) | |

| total temperature | (K) | |

| total pressure | (Pa) | |

| volume | (m3) | |

| mass | (kg) | |

| specific enthalpy | (J/kg) | |

| specific internal energy | (J/kg) | |

| internal energy | (J) | |

| power | (W) | |

| rotational speed | (rad/s) | |

| moment of inertia | (kg m2) | |

| heat transfer rate | (W) | |

| thermal capacity rate | (W/K) | |

| specific heat | (J/kg/K) | |

| thermal resistance | (K/W) | |

| heat transfer area | (m2) | |

| cross-sectional area | (m2) | |

| thermal conductivity | (W/m/K) | |

| diameter | (m) | |

| L | length | (m) |

| pressure differential ratio at chocked flow | (-) | |

| flow coefficient | (m3/h) | |

| ratio of the isentropic exponent | (-) | |

| efficiency | (-) | |

| energy flow rate | (W) | |

| torque | (N m) | |

| density | (kg/m3) | |

| convective heat transfer coefficient | (W/m2/K) | |

| effectiveness | (-) | |

| Subscripts | ||

| cycle points | ||

| i | i-th element | |

| p | at constant pressure | |

| u | at constant specific internal energy | |

| T | at constant temperature | |

| V | at constant volume | |

| in | inlet | |

| out | outlet | |

| is | isentropic | |

| m | mechanical | |

| I | internal/gas volume | |

| fluid | fluid | |

| corr | corrected | |

| surge | surge | |

| op | operating conditions | |

| overall | overall | |

| tube | tube side | |

| shell | shell side | |

| mat | material | |

| wall | wall | |

| avg | average | |

| lam | laminar | |

| min | minimum | |

| max | maximum | |

| hot | hot fluid/side | |

| cold | cold fluid/side | |

| conv | convective | |

| cond | conductive | |

| ref | reference | |

References

- IEA. Heating; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/heating (accessed on 10 January 2024).

- IEA. The Future of Heat Pumps; IEA: Paris, France, 2022; Available online: https://www.iea.org/reports/the-future-of-heat-pumps (accessed on 10 January 2024).

- Wolf, S.; Blesl, M. Model-Based Quantification of the Contribution of Industrial Heat Pumps to the European Climate Change Mitigation Strategy. In ECEEE Industrial Summer Study Proceedings; ECEEE: Berlin, Germany, 2016; pp. 477–487. [Google Scholar]

- Gai, L.; Varbanov, P.S.; Walmsley, T.G.; Klemeš, J.J. Critical Analysis of Process Integration Options for Joule-Cycle and Conventional Heat Pumps. Energies 2020, 13, 635. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S.S. High Temperature Heat Pumps: Market Overview, State of the Art, Research Status, Refrigerants, and Application Potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Naegler, T.; Simon, S.; Klein, M.; Gils, H.C. Quantification of the European Industrial Heat Demand by Branch and Temperature Level: Quantification of European Industrial Heat Demand. Int. J. Energy Res. 2015, 39, 2019–2030. [Google Scholar] [CrossRef]

- Rehfeldt, M.; Fleiter, T.; Toro, F. A Bottom-up Estimation of the Heating and Cooling Demand in European Industry. Energy Effic. 2018, 11, 1057–1082. [Google Scholar] [CrossRef]

- Bless, F.; Arpagaus, C.; Bertsch, S.S.; Schiffmann, J. Theoretical Analysis of Steam Generation Methods—Energy, CO2 Emission, and Cost Analysis. Energy 2017, 129, 114–121. [Google Scholar] [CrossRef]

- Jesper, M.; Schlosser, F.; Pag, F.; Walmsley, T.G.; Schmitt, B.; Vajen, K. Large-Scale Heat Pumps: Uptake and Performance Modelling of Market-Available Devices. Renew. Sustain. Energy Rev. 2021, 137, 110646. [Google Scholar] [CrossRef]

- Zühlsdorf, B.; Bühler, F.; Bantle, M.; Elmegaard, B. Analysis of Technologies and Potentials for Heat Pump-Based Process Heat Supply above 150 °C. Energy Convers. Manag. X 2019, 2, 100011. [Google Scholar] [CrossRef]

- Smith, N.R.; Tom, B.; Rimpel, A.; Just, J.; Marshall, M.; Khawly, G.; Revak, T.; Hoopes, K. The Design of a Small-Scale Pumped Heat Energy Storage System for the Demonstration of Controls and Operability. In Volume 4: Cycle Innovations: Energy Storage; Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 4. [Google Scholar] [CrossRef]

- Oehler, J.; Tran, A.P.; Stathopoulos, P. Simulation of a Safe Start-Up Maneuver for a Brayton Heat Pump. In Volume 4: Cycle Innovations: Energy Storage; Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 4, p. V004T06A003. [Google Scholar] [CrossRef]

- Ferrari, L.; Pettinari, M.; Frate, G.F.; Tran, A.P.; Oehler, J.; Stathopoulos, P. Transient Analysis and Control of a Brayton Heat Pump During Start-Up. In Proceedings of the 36th International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems (ECOS 2023), Las Palmas De Gran Canaria, Spain, 25–30 June 2023; pp. 839–850. [Google Scholar] [CrossRef]

- Pettinari, M.; Frate, G.F.; Kyprianidis, K.; Ferrari, L. Dynamic Modelling and Part-Load Behavior of a Brayton Heat Pump. In Proceedings of the 64th International Conference of Scandinavian Simulation Society, SIMS 2023, Västerås, Sweden, 25–28 September 2023; pp. 254–261. [Google Scholar] [CrossRef]

- The MathWorks Inc. MATLAB Version: 9.13.0 (R2022b). 2022. Available online: https://www.mathworks.com (accessed on 10 January 2024).

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- The MathWorks Inc. Simscape Fluids Reference. Available online: https://it.mathworks.com/help/pdf_doc/hydro/hydro_ref.pdf (accessed on 10 January 2024).

- Holman, J.P. Heat Transfer, 9th ed.; McGraw-Hill: New York, NY, USA, 2002; ISBN 978-0-07-352936-3. [Google Scholar]

- White, F.M. Fluid Mechanics, 7th ed.; McGraw-Hill Series in Mechanical Engineering; McGraw-Hill: New York, NY, USA, 2011; ISBN 978-0-07-352934-9. [Google Scholar]

| Description | Point | T (°C) | p (bar) | (kg s−1) |

|---|---|---|---|---|

| Cycle | 1 | 15.00 | 1.013 | 0.658 |

| 2 | 271.40 | 6.282 | 0.658 | |

| 3 | 101.30 | 6.128 | 0.658 | |

| 4 | −25.85 | 1.085 | 0.658 | |

| Sink | inlet | 15.00 | 1.08 | 0.458 |

| outlet | 261.40 | 1.017 | 0.458 | |

| Source | inlet | 17.20 | 1.239 | 1.011 |

| outlet | −9.46 | 1.067 | 1.011 |

| Scenario | Description | Control Enabled | Target |

|---|---|---|---|

| 1 | 10 °C step reduction of the desired sink temperature | ASC, TC | sink temperature adjustment |

| 2 | 10% step reduction of the sink mass flow rate | ASC, TC | constant sink temperature |

| 3 | 10% step reduction of the sink mass flow rate | ASC, FIC | constant sink temperature |

| ∆T (°C) | trise (min) | tsettl,5% (min) | OV (%) |

|---|---|---|---|

| −5 | 3.93 | 8.5 | 14 |

| −10 | 6.47 | 12.52 | 9.88 |

| −15 | 8.75 | 15.82 | 7.82 |

| −20 | 10.95 | 18.73 | 6.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pettinari, M.; Frate, G.F.; Tran, A.P.; Oehler, J.; Stathopoulos, P.; Kyprianidis, K.; Ferrari, L. Impact of the Regulation Strategy on the Transient Behavior of a Brayton Heat Pump. Energies 2024, 17, 1020. https://doi.org/10.3390/en17051020

Pettinari M, Frate GF, Tran AP, Oehler J, Stathopoulos P, Kyprianidis K, Ferrari L. Impact of the Regulation Strategy on the Transient Behavior of a Brayton Heat Pump. Energies. 2024; 17(5):1020. https://doi.org/10.3390/en17051020

Chicago/Turabian StylePettinari, Matteo, Guido Francesco Frate, A. Phong Tran, Johannes Oehler, Panagiotis Stathopoulos, Konstantinos Kyprianidis, and Lorenzo Ferrari. 2024. "Impact of the Regulation Strategy on the Transient Behavior of a Brayton Heat Pump" Energies 17, no. 5: 1020. https://doi.org/10.3390/en17051020

APA StylePettinari, M., Frate, G. F., Tran, A. P., Oehler, J., Stathopoulos, P., Kyprianidis, K., & Ferrari, L. (2024). Impact of the Regulation Strategy on the Transient Behavior of a Brayton Heat Pump. Energies, 17(5), 1020. https://doi.org/10.3390/en17051020