LCA of Recycled (NdDy)FeB Permanent Magnets through Hydrogen Decrepitation

Abstract

1. Introduction

2. Materials and Methods

2.1. Goal and Scope

- To assess the potential environmental impacts of a novel magnet-to-magnet recycling process based on hydrogen decrepitation.

- To compare the environmental impacts of a recycled (NdDy)FeB magnet with those of a (NdDy)FeB magnet entirely produced from virgin materials.

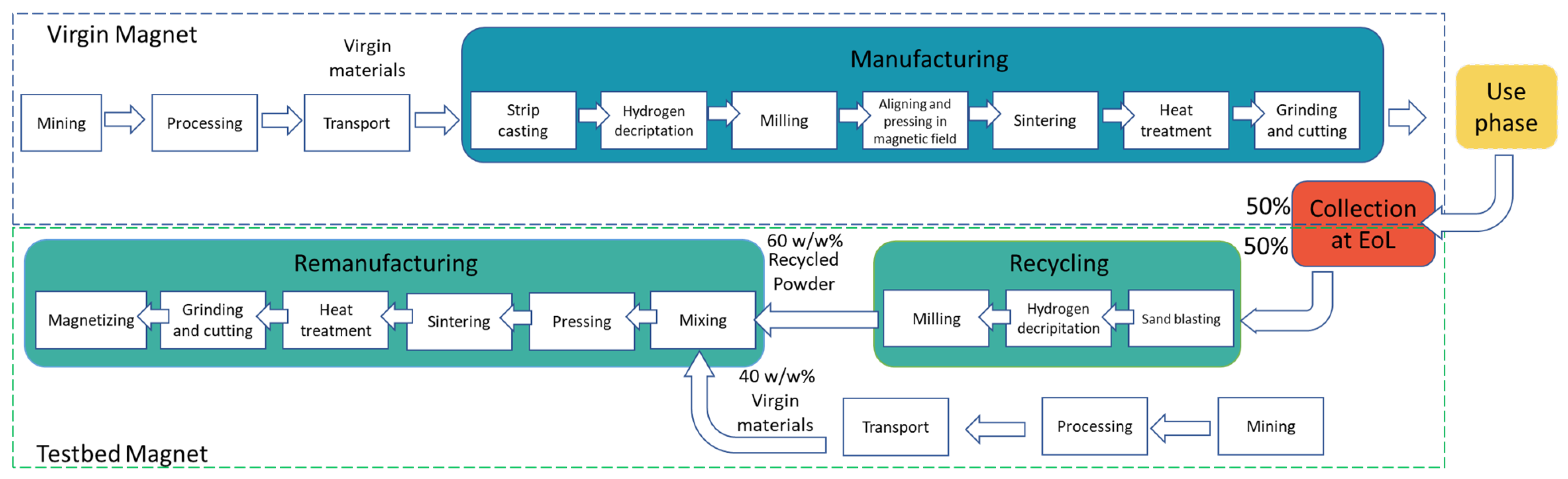

2.1.1. Product Systems under Study

2.1.2. Functional Unit

2.1.3. System Boundary

- Raw material acquisition and preprocessing;

- Manufacturing;

- Collection at EoL;

- Recycling of used magnets;

- Remanufacturing.

2.1.4. Allocation and Multifunctionality

2.1.5. Impact Assessment Method

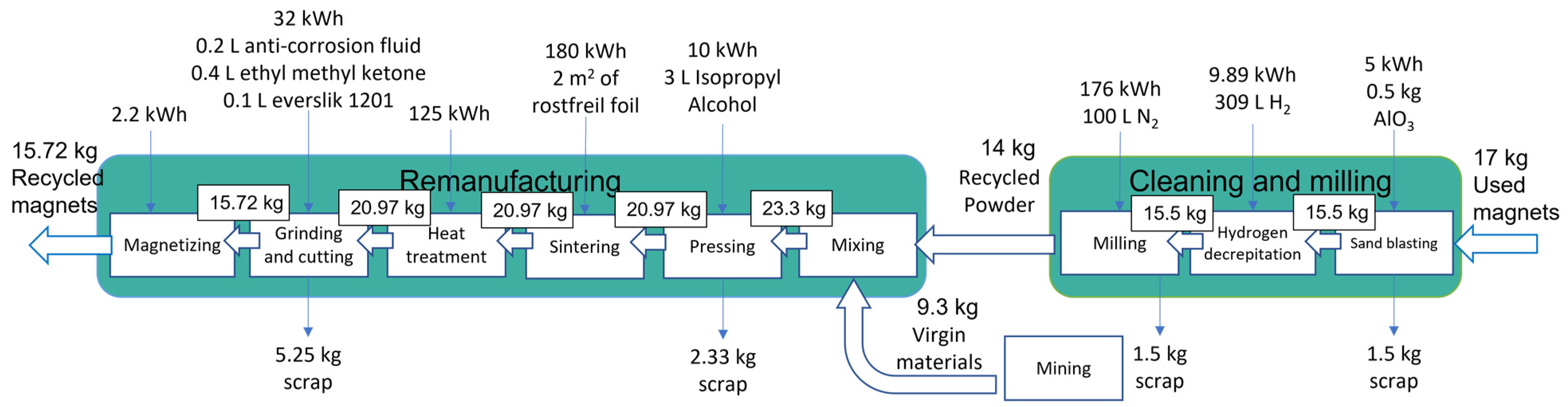

2.2. Life Cycle Inventories

2.2.1. Virgin Magnet Manufacturing Process

2.2.2. Testbed Magnet and Novel Recycling Process

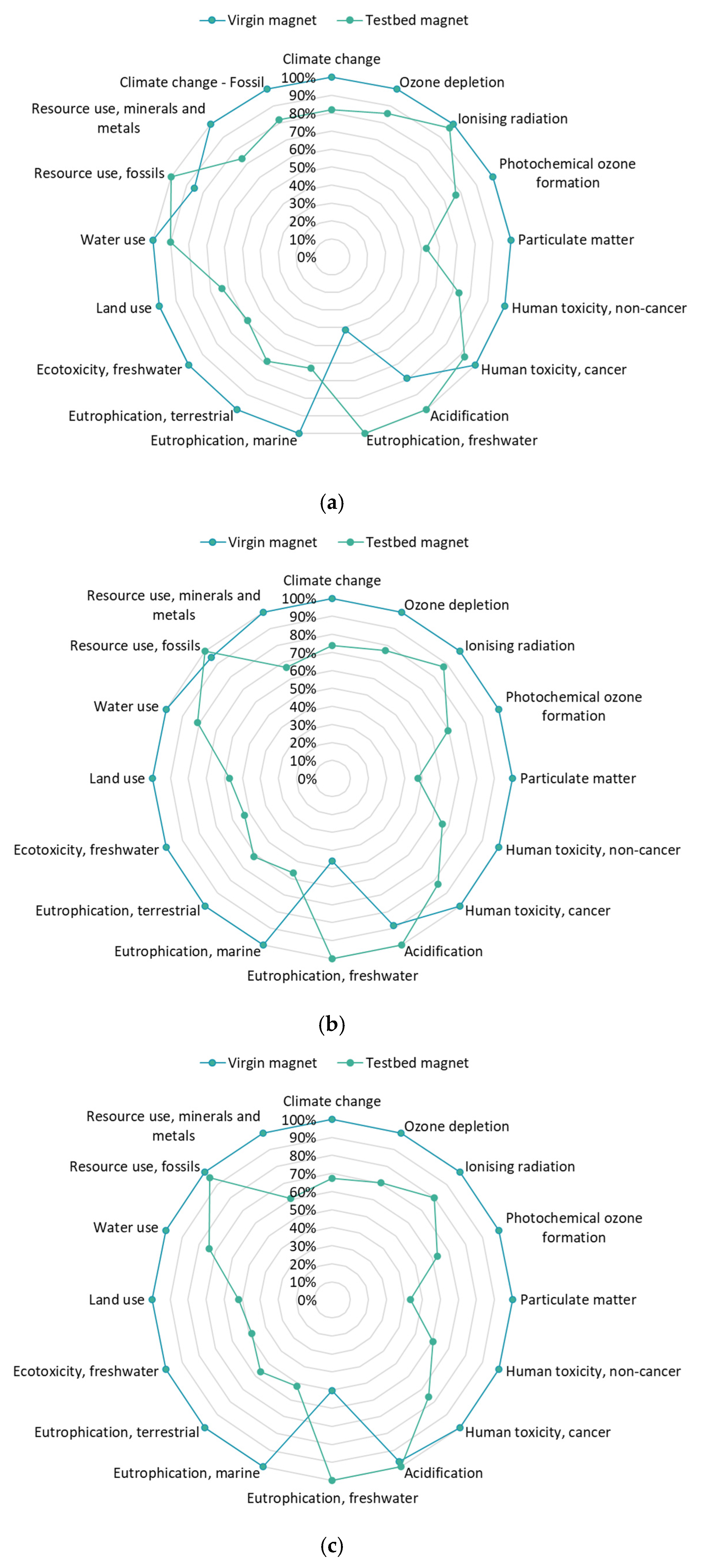

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

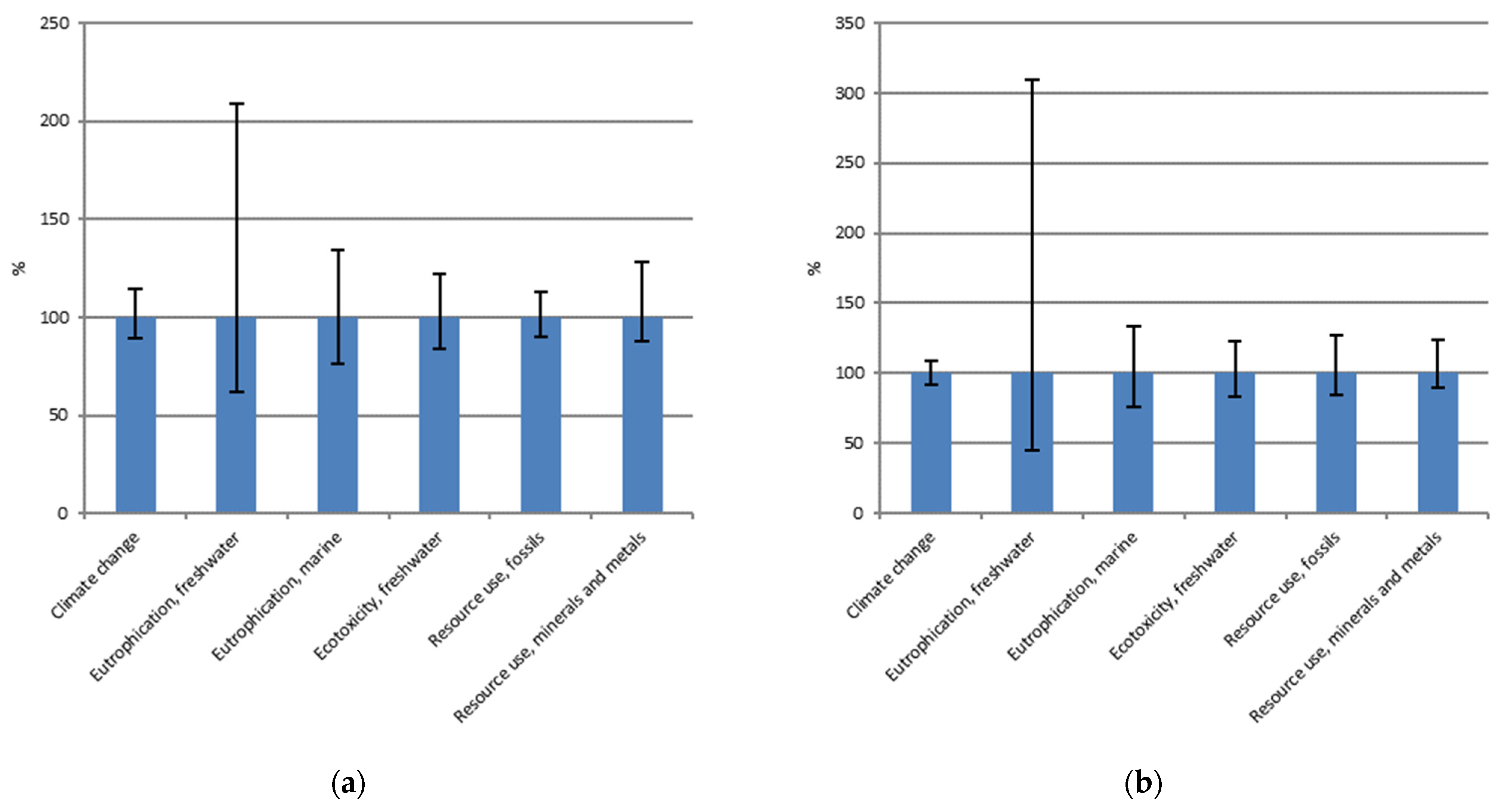

Appendix A. Uncertainty Assessment through Monte Carlo Analysis

| Deterministic LCA | Monte Carlo Analysis | |

|---|---|---|

| Impact Category | Does the Testbed Magnet Have a Lower Impact than the Virgin Magnet? | Percentage of Runs in Which the Testbed Magnet Has a Lower Impact than the Virgin One |

| Climate change | Y | 99.5% |

| Resource use, fossils | N | - |

| Eutrophication, freshwater | N | - |

| Ecotoxicity, freshwater | Y | 99.9% |

| Eutrophication, marine | Y | 98.8% |

| Resource use, minerals, and metals | Y | 98.6% |

References

- Climate Change: What the EU Is Doing. Available online: https://www.consilium.europa.eu/en/policies/climate-change/ (accessed on 23 January 2024).

- The Paris Agreement|UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement (accessed on 23 January 2024).

- Gauß, R.; Burkhardt, C.; Carencotte, F.; Gasparon, M.; Gutfleisch, O.; Higgins, I.; Karajić, M.; Klossek, A.; Mäkinen, M.; Schäfer, B.; et al. Rare Earth Magnets and Motors: A European Call for Action; A Report by the Rare Earth Magnets and Motors Cluster of the European Raw Materials Alliance; European Raw Materials Alliance: Berlin, Germany, 2021. [Google Scholar]

- Yang, Y.; Walton, A.; Sheridan, R.; Güth, K.; Gauß, R.; Gutfleisch, O.; Buchert, M.; Steenari, B.-M.; Van Gerven, T.; Jones, P.T.; et al. REE Recovery from End-of-Life NdFeB Permanent Magnet Scrap: A Critical Review. J. Sustain. Metall. 2017, 3, 122–149. [Google Scholar] [CrossRef]

- Arshi, P.S.; Vahidi, E.; Zhao, F. Behind the scenes of clean energy—The environmental footprint of rare earth products. ACS Sustain. Chem. Eng. 2018, 6, 3311–3320. [Google Scholar] [CrossRef]

- Becci, A.; Beolchini, F.; Amato, A. Sustainable Strategies for the Exploitation of End-of-Life Permanent Magnets. Processes 2021, 9, 857. [Google Scholar] [CrossRef]

- USEPA. Rare Earth Elements: A Review of Production, Processing, Recycling, and Associated Environmental Issues; USEPA: Washington, DC, USA, 2012. [Google Scholar]

- Zakotnik, M.; Tudor, C.O. Commercial-scale recycling of NdFeB-type magnets with grain boundary modification yields products with ‘designer properties’ that exceed those of starting materials. Waste Manag. 2015, 44, 48–54. [Google Scholar] [CrossRef] [PubMed]

- Koltun, P.; Tharumarajah, A. Life Cycle Impact of Rare Earth Elements. ISRN Metall. 2014, 2014, 907536. [Google Scholar] [CrossRef]

- Bailey, G.; Joyce, P.J.; Schrijvers, D.; Schulze, R.; Sylvestre, A.M.; Sprecher, B.; Vahidi, E.; Dewulf, W.; Van Acker, K. Review and new life cycle assessment for rare earth production from bastnäsite, ion adsorption clays and lateritic monazite. Resour. Conserv. Recycl. 2020, 155, 104675. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, B.; Gao, F.; Chen, W.; Nie, Z. Life cycle assessment of regeneration technology routes for sintered NdFeB magnets. Int. J. Life Cycle Assess. 2022, 27, 1044–1057. [Google Scholar] [CrossRef]

- Bailey, G.; Mancheri, N.; Van Acker, K. Sustainability of Permanent Rare Earth Magnet Motors in (H)EV Industry. J. Sustain. Metall. 2017, 3, 611–626. [Google Scholar] [CrossRef]

- Heim, M.; Wirth, F.; Boschert, L.; Fleischer, J. An Approach for the Disassembly of Permanent Magnet Synchronous Rotors to Recover Rare Earth Materials. Procedia CIRP 2023, 116, 71–76. [Google Scholar] [CrossRef]

- Bobba, S.; Eynard, U.; Maury, T.; Ardente, F.; Blengini, G.A.; Mathieux, F. Circular Input Rate: Novel indicator to assess circularity performances of materials in a sector—Application to rare earth elements in e-vehicles motors. Resour. Conserv. Recycl. 2023, 197, 107037. [Google Scholar] [CrossRef]

- Alonso, E.; Sherman, A.M.; Wallington, T.J.; Everson, M.P.; Field, F.R.; Roth, R.; Kirchain, R.E. Evaluating Rare Earth Element Availability: A Case with Revolutionary Demand from Clean Technologies. Environ. Sci. Technol. 2012, 46, 3406–3414. [Google Scholar] [CrossRef]

- Jin, H.; Frost, K.; Sousa, I.; Ghaderi, H.; Bevan, A.; Zakotnik, M.; Handwerker, C. Life cycle assessment of emerging technologies on value recovery from hard disk drives. Resour. Conserv. Recycl. 2020, 157, 104781. [Google Scholar] [CrossRef]

- Eldosouky, A.; Škulj, I. Recycling of SmCo 5 magnets by HD process. J. Magn. Magn. Mater. 2018, 454, 249–253. [Google Scholar] [CrossRef]

- Coelho, F.; Abrahami, S.; Yang, Y.; Sprecher, B.; Li, Z.; Menad, N.-E.; Bru, K.; Marcon, T.; Rado, C.; Saje, B.; et al. Upscaling of Permanent Magnet Dismantling and Recycling through VALOMAG Project. Mater. Proc. 2021, 5, 74. [Google Scholar] [CrossRef]

- Eldosouky, A.; Ikram, A.; Mehmood, M.F.; Xu, X.; Šturm, S.; Žužek Rožman, K.; Škulj, I. Hydrogen Decrepitation and Spark Plasma Sintering to Produce Recycled SmCo5 Magnets with High Coercivity. IEEE Magn. Lett. 2018, 9, 5503504. [Google Scholar] [CrossRef]

- Walton, A.; Yi, H.; Rowson, N.A.; Speight, J.D.; Mann, V.S.J.; Sheridan, R.S.; Bradshaw, A.; Harris, I.R.; Williams, A.J. The use of hydrogen to separate and recycle neodymium–iron–boron-type magnets from electronic waste. J. Clean. Prod. 2015, 104, 236–241. [Google Scholar] [CrossRef]

- Zakotnik, M.; Harris, I.R.; Williams, A.J. Multiple recycling of NdFeB-type sintered magnets. J. Alloys Compd. 2009, 469, 314–321. [Google Scholar] [CrossRef]

- Wulf, C.; Zapp, P.; Schreiber, A.; Marx, J.; Schlör, H. Lessons Learned from a Life Cycle Sustainability Assessment of Rare Earth Permanent Magnets. J. Ind. Ecol. 2017, 21, 1578–1590. [Google Scholar] [CrossRef]

- Bailey, G.; Orefice, M.; Sprecher, B.; Önal, M.A.R.; Herraiz, E.; Dewulf, W.; Van Acker, K. Life cycle inventory of samarium-cobalt permanent magnets, compared to neodymium-iron-boron as used in electric vehicles. J. Clean. Prod. 2021, 286, 125294. [Google Scholar] [CrossRef]

- Sprecher, B.; Xiao, Y.; Walton, A.; Speight, J.; Harris, R.; Kleijn, R.; Visser, G.; Kramer, G.J. Life Cycle Inventory of the Production of Rare Earths and the Subsequent Production of NdFeB Rare Earth Permanent Magnets. Environ. Sci. Technol. 2014, 48, 3951–3958. [Google Scholar] [CrossRef] [PubMed]

- Schulze, R.; Abbasalizadeh, A.; Bulach, W.; Schebek, L.; Buchert, M. An Ex-ante LCA Study of Rare Earth Extraction from NdFeB Magnet Scrap Using Molten Salt Electrolysis. J. Sustain. Metall. 2018, 4, 493–505. [Google Scholar] [CrossRef]

- Tabosa da Silva, A.L. Ex-Ante LCA of a Hydrometallurgical Route using Weak Acid for Recycling of REEs from EOL HDD’s NdFeB Permanent Magnet. Master’s Thesis, Leiden University, Leiden, The Netherlands, 2021. [Google Scholar]

- Nordelöf, A.; Alatalo, M. A Scalable Life Cycle Inventory of an Automotive Power Electronic Inverter Unit; Chalmers University of Technology: Gothenburg, Sweden, 2018. [Google Scholar]

- Chowdhury, N.A.; Deng, S.; Jin, H.; Prodius, D.; Sutherland, J.W.; Nlebedim, I.C. Sustainable Recycling of Rare-Earth Elements from NdFeB Magnet Swarf: Techno-Economic and Environmental Perspectives. ACS Sustain. Chem. Eng. 2021, 9, 15915–15924. [Google Scholar] [CrossRef]

- Buchert, M.; Sutter, J.; Merz, C. Ökobilanz der Recyclingverfahren; Öko-Institut e.V.: Darmstadt, Germany, 2014. [Google Scholar]

- Bast, U.; Blank, R.; Buchert, M.; Elwert, T.; Finstelwarder, F.; Hornig, G.; Klier, T.; Langkau, S.; Marscheider-Weidemann, S.; Muller, J.O.; et al. Recycling von Komponenten und Strategischen Metallen aus Elektrischen Fahrantrieben; MORE (Motor Recycling): Munchen, Germany, 2014. [Google Scholar]

- ISO 14040:2006; Environmental Management. Life Cycle Assessment. Principles and Framework. ISO: Geneva, Switzerland, 2006; ISBN 978-0-580-48992-1.

- ISO 14044:2006; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. ISO: Geneva, Switzerland, 2018; ISBN 978-0-539-00856-2.

- Joint Research Centre. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment: Detailed Guidance; Publications Office: Luxembourg, 2010. [Google Scholar]

- Joint Research Centre. International Reference Life Cycle Data System (ILCD) Handbook—Framework and Requirements for Life Cycle Impact Assessment Models and Indicators; EUR 24586 EN; Publications Office of the European Union: Luxembourg, 2010. [Google Scholar]

- Vittorio, N.D.; Accardo, A.; Spessa, E.; Viscido, L.; Tam, E. LCA and LCC of a Li-Ion Battery Pack for Automotive Application; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Zakotnik, M.; Tudor, C.O.; Peiró, L.T.; Afiuny, P.; Skomski, R.; Hatch, G.P. Analysis of energy usage in Nd–Fe–B magnet to magnet recycling. Environ. Technol. Innov. 2016, 5, 117–126. [Google Scholar] [CrossRef]

- Adibi, N.; Lafhaj, Z.; Payet, J. New resource assessment characterization factors for rare earth elements: Applied in NdFeB permanent magnet case study. Int. J. Life Cycle Assess. 2019, 24, 712–724. [Google Scholar] [CrossRef]

- Global Battery Alliance. Greenhouse Gas Rulebook; Global Battery Alliance: Brussels, Brussels, 2023. [Google Scholar]

- European Commission; DG Climate Action. Determining the Environmental Impacts of Conventional and Alternatively Fuelled Vehicles through LCA; Publications Office: Luxemburg, 2020. [Google Scholar]

- Accardo, A.; Dotelli, G.; Miretti, F.; Spessa, E. End-of-Life Impact on the Cradle-to-Grave LCA of Light-Duty Commercial Vehicles in Europe. Appl. Sci. 2023, 13, 1494. [Google Scholar] [CrossRef]

- Allacker, K.; Mathieux, F.; Pennington, D.; Pant, R. The search for an appropriate end-of-life formula for the purpose of the European Commission Environmental Footprint initiative. Int. J. Life Cycle Assess. 2017, 22, 1441–1458. [Google Scholar] [CrossRef]

- Zampori, L.; Pant, R. Suggestions for Updating the Product Environmental Footprint (PEF) Method; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Nordelöf, A.; Tillman, A.-M. A scalable life cycle inventory of an electrical automotive traction machine—Part II: Manufacturing processes. Int. J. Life Cycle Assess. 2018, 23, 295–313. [Google Scholar] [CrossRef]

- Jin, H.; Afiuny, P.; McIntyre, T.; Yih, Y.; Sutherland, J.W. Comparative Life Cycle Assessment of NdFeB Magnets: Virgin Production versus Magnet-to-Magnet Recycling. Procedia CIRP 2016, 48, 45–50. [Google Scholar] [CrossRef]

| Virgin | Testbed | |

|---|---|---|

| Magnetization coercivity Hc (kA/m) | 830 | 922.5 |

| Remanence Br (T) | 1076 | 1190 |

| Maximum energy product BHmax (KJ/m3) | 224 | 273 |

| Polarization coercivity Hj (kA/m) | 2375 | 1265 |

| Permeability µr | 1.03 | 1,03 |

| Curie temperature Tc (°C) | 340 | 340 |

| Oxygen amount (%) | 0.11 | 0.32 |

| Virgin | Testbed | |

|---|---|---|

| Neodymium | 16.64% | 21.37% |

| Iron | 67.34% | 66.33% |

| Boron | 0.91% | 0.92% |

| Cobalt | 1.09% | 1.95% |

| Dysprosium | 7.05% | 4.63% |

| Praseodymium | 5.86% | 3.93% |

| Aluminum | 0.46% | 0.42% |

| Gallium | 0.65% | 0.45% |

| Parameter | Functional Unit |

|---|---|

| Magnetization coercivity | 1 kA/m of magnetization coercivity of a (NdDy)FeB magnet used for EV applications |

| Maximum energy product | 1 kJ/m3 of maximum energy product of a (NdDy)FeB magnet used for EV applications |

| Mass | 1 kg of a (NdDy)FeB magnet used for EV applications |

| Impact Category | Units |

|---|---|

| Acidification | Mole H+ eq. |

| Climate Change—total | kg CO2 eq. |

| Ecotoxicity, freshwater—total | CTUe |

| Eutrophication—freshwater, marine | kg P eq., kg N eq. |

| Eutrophication—terrestrial | Mole N eq. |

| Human toxicity, cancer—total | CTUh |

| Human toxicity, non-cancer—total | CTUh |

| Ionizing radiation, human health | kBq U235 |

| Land Use | Pt |

| Ozone depletion | kg CFC-11 eq. |

| Particulate matter | Disease incidences |

| Photochemical ozone formation, human health | kg NMVOC eq. |

| Resource use, fossils | MJ |

| Resource use, minerals, and metals | kg Sb eq. |

| Water Use | m3 |

| Functional Unit | Virgin Magnet | Testbed Magnet |

|---|---|---|

| Mass | 4.66 × 101 | 3.82 × 101 |

| Magnetization coercivity | 8.54 × 10−4 | 6.29 × 10−4 |

| Maximum energy product | 3.16 × 10−3 | 2.13 × 10−3 |

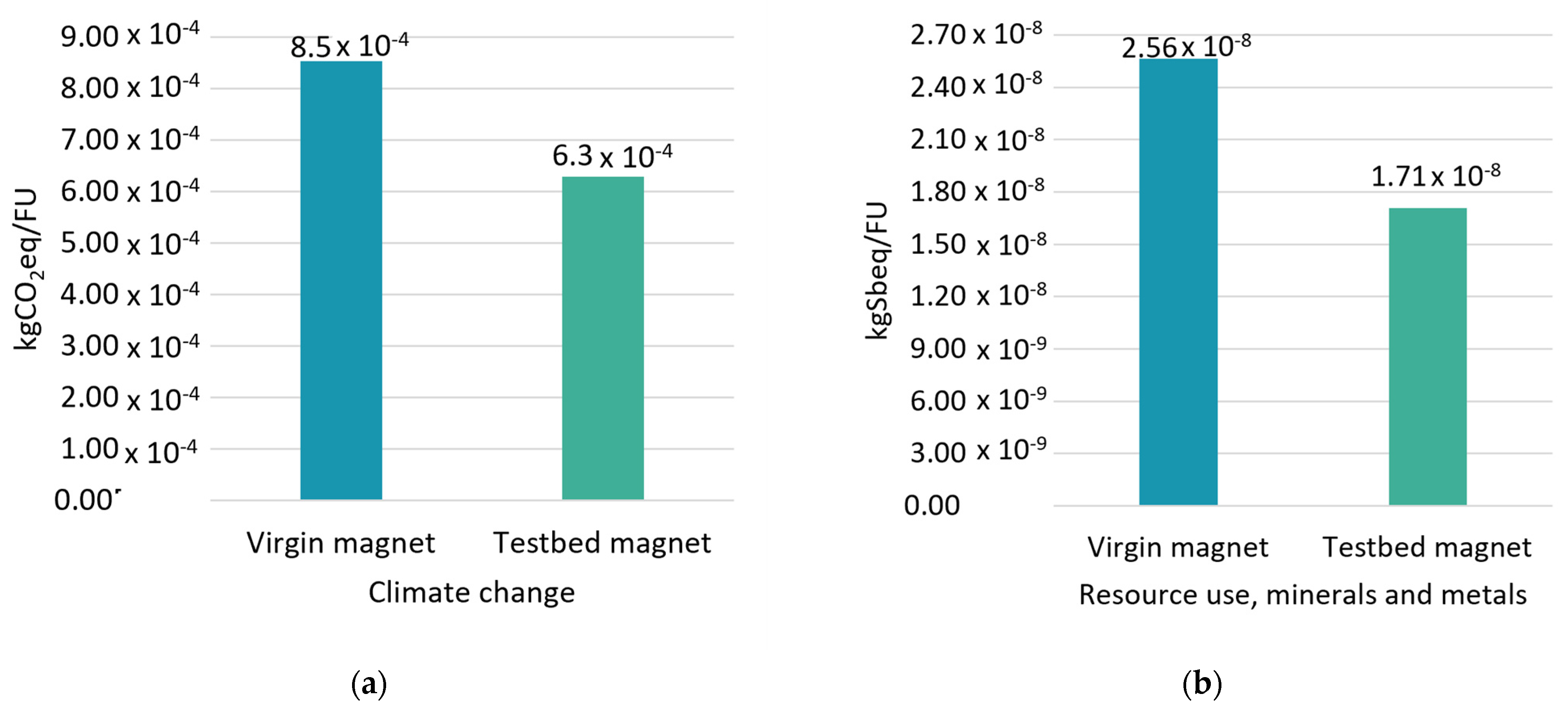

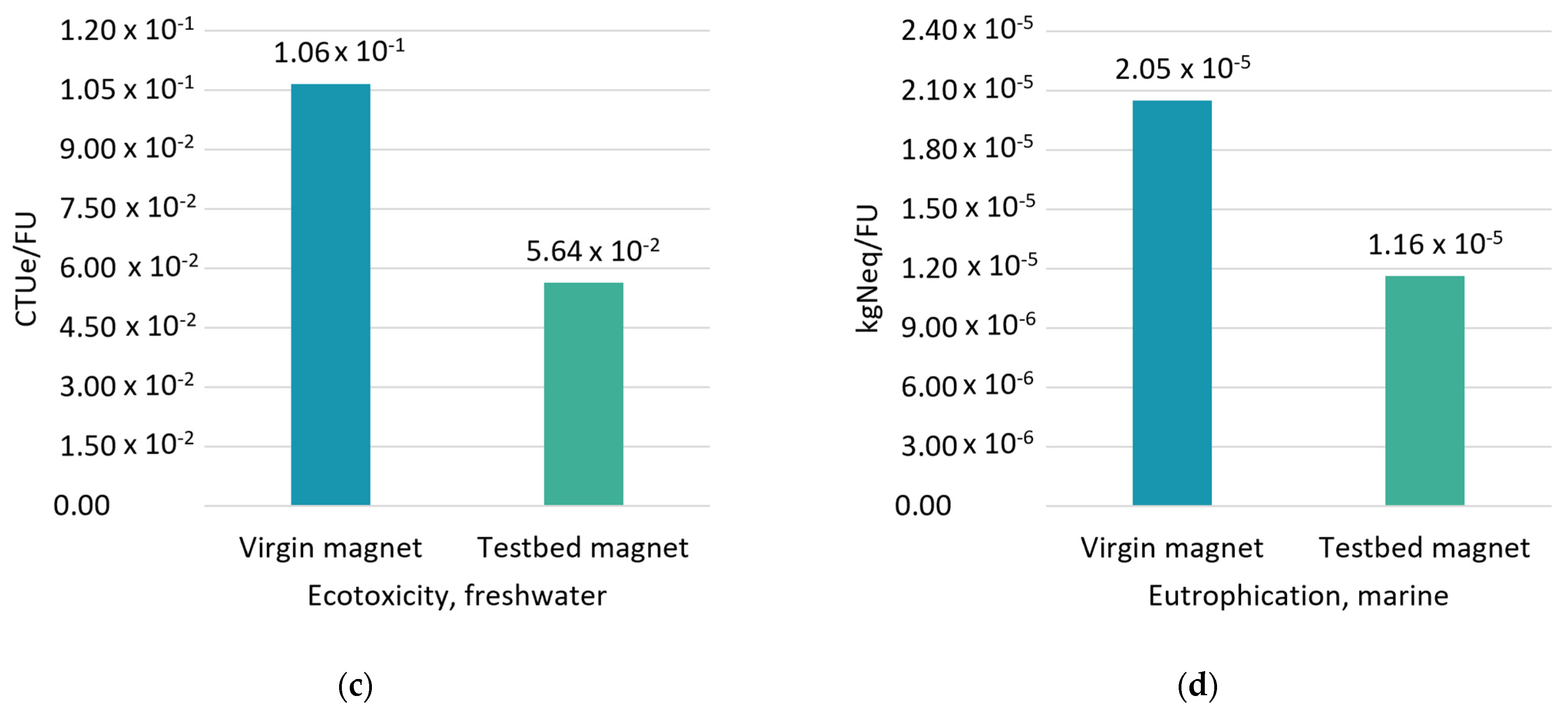

| Impact Category | Virgin Magnet | Testbed Magnet |

|---|---|---|

| Climate change | 8.54 × 10−4 | 6.29 × 10−4 |

| Resource use, fossils | 9.33 × 10−3 | 9.81 × 10−3 |

| Eutrophication, freshwater | 2.56 × 10−7 | 5.57 × 10−7 |

| Ecotoxicity, freshwater | 1.06 × 10−1 | 5.64 × 10−2 |

| Eutrophication, marine | 2.05 × 10−5 | 1.16 × 10−5 |

| Resource use, minerals, and metals | 2.56 × 10−8 | 1.71 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Accardo, A.; Costantino, T.; Spessa, E. LCA of Recycled (NdDy)FeB Permanent Magnets through Hydrogen Decrepitation. Energies 2024, 17, 908. https://doi.org/10.3390/en17040908

Accardo A, Costantino T, Spessa E. LCA of Recycled (NdDy)FeB Permanent Magnets through Hydrogen Decrepitation. Energies. 2024; 17(4):908. https://doi.org/10.3390/en17040908

Chicago/Turabian StyleAccardo, Antonella, Trentalessandro Costantino, and Ezio Spessa. 2024. "LCA of Recycled (NdDy)FeB Permanent Magnets through Hydrogen Decrepitation" Energies 17, no. 4: 908. https://doi.org/10.3390/en17040908

APA StyleAccardo, A., Costantino, T., & Spessa, E. (2024). LCA of Recycled (NdDy)FeB Permanent Magnets through Hydrogen Decrepitation. Energies, 17(4), 908. https://doi.org/10.3390/en17040908