Environmental Product Declarations as a Data Source for the Assessment of Environmental Impacts during the Use Phase of Photovoltaic Modules: Critical Issues and Potential

Abstract

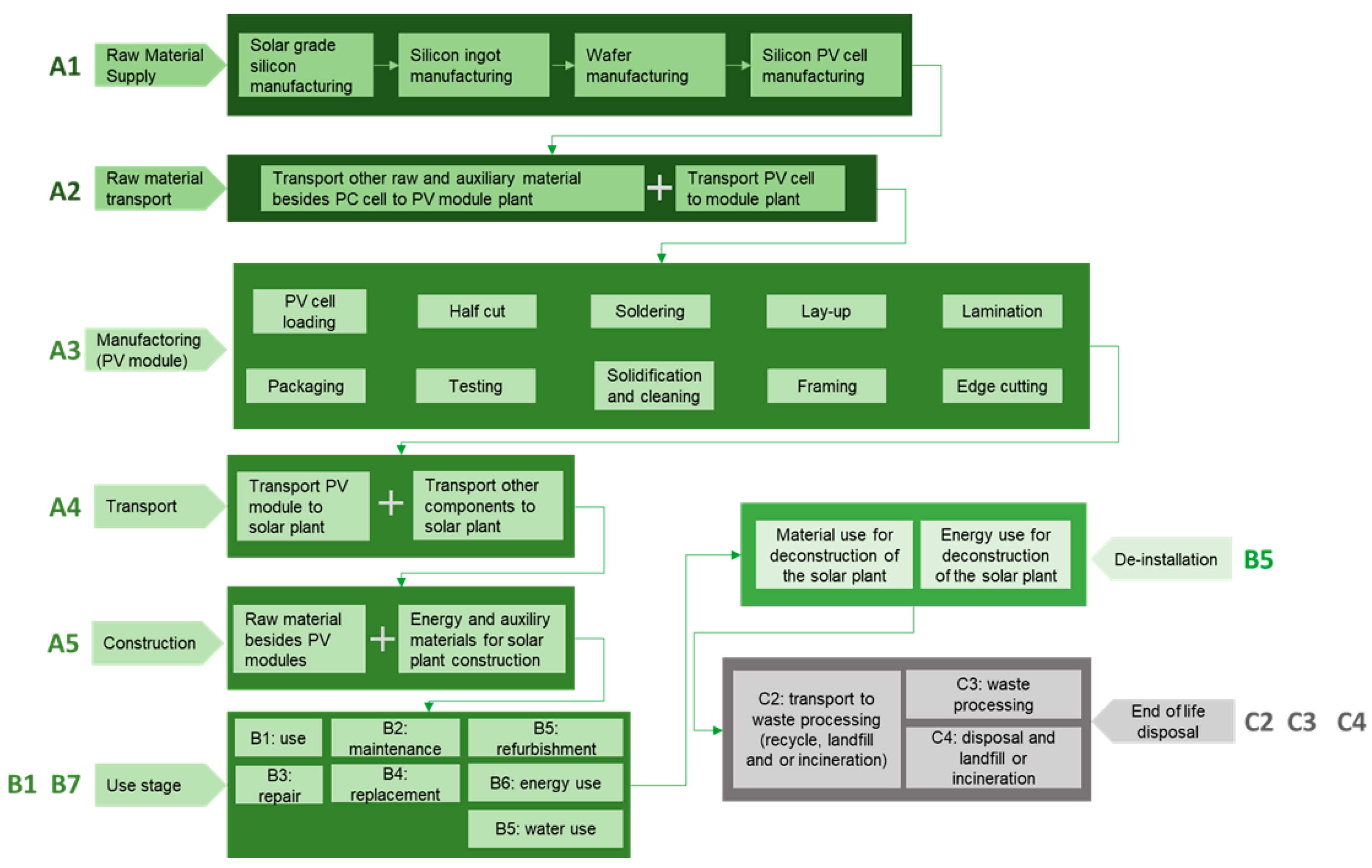

1. Introduction

2. Materials and Methods

- (a)

- Analysis of the most recurring causes of PV module malfunctions and the interventions necessary to maintain the performance defined by the project over time;

- (b)

- Analysis of the PCR of the PV modules;

- (c)

- Check the Modeling requirements of modules B1 to B7 in the use stage;

- (d)

- Review of the LCA results of modules B1 to B7 of a significant sample of EPDs;

- (e)

- Analysis of the feasibility of using EPDs as a data source for the evaluation of the environmental impacts caused by maintenance activities;

- (f)

- Estimation of the impact of maintenance activities throughout the entire life cycle.

2.1. Recurring Causes of PV Module Malfunction vs. Ordinary and Extraordinary Maintenance

- Discoloration: The so-called snail trail effect has an impact on photovoltaic module performances and energy production. Generally, snail trails indicate the presence of cell cracks [26]. Snail tracks can influence the daily energy production of PV modules by around 68% and 88% compared to undamaged PV modules. These percentages are the result of various tests, such as the indoor electroluminescence (EL) test, according to which there is a strong correlation between the appearance of the phenomenon and microcracks in photovoltaic cells and the consequent 29% reduction in energy production [27].

- Delamination involves the detachment of the central layer’s ethylene vinyl acetate (EVA) and the photovoltaic cells from the external glass or the backsheet. This results in a loss of insulation and can lead to module overheating. In cases where detachment creates internal air bubbles, moisture could penetrate the module and oxidize the photovoltaic cells. The main causes of delamination are poor workmanship quality and module wear; this phenomenon necessitates the replacement of the modules [28]. Delamination can also depend on the type of additives used in the EVA foil [29].

- Potential-induced degradation (PID) involves the degradation of the photovoltaic effect and the depowering of the cells. When there is an electron leakage dispersing towards the ground through the module’s frame, it generates leakage current. Both crystalline and thin-film cell modules are susceptible to this degradation. The performance decline, between 12.6% and 18.7% [30], can be reversible (polarization) or irreversible (electro corrosion). This issue was more widespread in PV modules produced before 2013, while currently manufactured modules incorporate integrated anti-PID solutions. These solutions, in addition to module replacement, also include repair processes involving subjecting the strings to a high positive voltage relative to the ground during the nighttime hours. This reverses the direction of parasitic leakage currents that occur during the daytime operation of the system.

2.2. Analysis of the PCR of the PV Modules

2.3. Check of the Modeling Requirements of Modules B1 to B7 for the Assessment of the Environmental Impacts

2.4. Review of the LCA Results of Modules B1 to B7 of a Significant Sample of EPDs

3. Application Case of the Methodology

3.1. EPD of Solar Monocrystalline Silicon PV Modules with Aggegated Data

3.2. EPD of Bifacial Monocrystalline Silicon Photovoltaic (PV) Modules with Disaggegated Data

4. Results/Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- IPCC 2023, AR6 Synthesis Report: Climate Change 2023. Available online: https://www.ipcc.ch/report/sixth-assessment-report-cycle/ (accessed on 15 October 2023).

- European Commission. Proposal for a Directive of the European Parliament and of the Council on the Energy Performance of Buildings (Recast) COM/2021/802 Final. 2021. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52021PC0802&qid=1641802763889 (accessed on 15 October 2023).

- ISO 21930:2017; Sustainability in Buildings and Civil Engineering Works—Core Rules for Environmental Product Declarations of Construction Products and Services. International Organization for Standardization: Geneva, Switzerland, 2017.

- EN 15804:2012+A2:2019; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. UNI: Rome, Italy, 2019. Available online: https://store.uni.com/en-15804-2012-a2-2019 (accessed on 15 October 2023).

- ISO 41001:2018; Facility Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:41001:ed-1:v1:en (accessed on 15 October 2023).

- ISO 41011: 2017; Facility Management—Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:41011:ed-1:v1:en (accessed on 15 October 2023).

- UNI 11063: 2017; Manutenzione—Definizioni di Manutenzione Ordinaria e Straordinaria. UNI: Rome, Italy, 2017. Available online: https://store.uni.com/uni-11063-2017 (accessed on 15 October 2023).

- ISO 14040:2006+A1:2020; Environmental Management. Life Cycle Assessment. Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/76121.html (accessed on 15 October 2023).

- ISO 14044:2006/Amd2:2020; Environmental Management. Life Cycle Assessment. Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2020. Available online: https://www.iso.org/standard/76122.html (accessed on 17 January 2024).

- ISO/TS 14074:2022(en); Environmental Management. Life Cycle Assessment. Principles, Requirements and Guidelines for Normalization, Weighting and Interpretation. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/standard/61117.html (accessed on 17 January 2024).

- ISO 14025:2006(en); Environmental Labels and Declarations—Type III Environmental Declarations—Principles and Procedures. International Organization for Standardization: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:14025:ed-1:v1:en (accessed on 15 October 2023).

- EN 15804:2012+A2:2019/AC:2021; Sustainability of Construction Works. Core Rules for the Product Category of Construction Products. Comite Europeen de Normalisation: Belgium, Brussels, 2021. Available online: https://infostore.saiglobal.com/en-us/standards/en-15804-2012-a2-2019-ac-2021-337631_saig_cen_cen_3041301/ (accessed on 15 October 2023).

- Del Rosario, P.; Palumbo, E.; Traverso, M. Environmental Product Declarations as Data Source for the Environmental Assessment of Buildings in the Context of Level(s) and DGNB: How Feasible Is Their Adoption? Sustainability 2021, 13, 6143. [Google Scholar] [CrossRef]

- Strazza, C.; Del Borghi, A.; Magrassi, F.; Gallo, M. Using environmental product declaration as source of data for life cycle assessment: A case study. J. Clean. Prod. 2016, 112, 333–342. [Google Scholar] [CrossRef]

- NREL National Renewable Energy Laboratory; Best Practices Working Group. Best Practices for Operation and Maintenance of Photovoltaic and Energy Storage Systems, 3rd ed.; NREL/TP-7A40-73822; National Renewable Energy Laboratory: Golden, CO, USA, 2018. Available online: https://www.nrel.gov/docs/fy19osti/73822.pdf (accessed on 15 October 2023).

- IEA. Report IEA-PVPS T13-25:2022 Task 13 Reliability and Performance of Photovoltaic Systems Guidelines for Operation and Maintenance of Photovoltaic Power Plants in Different Climates 2022. Available online: https://iea-pvps.org/wp-content/uploads/2022/11/IEA-PVPS-Report-T13-25-2022-OandM-Guidelines.pdf (accessed on 15 October 2023).

- Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.-C.; Yi, J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies 2021, 14, 4278. [Google Scholar] [CrossRef]

- Theristis, M.; Livera, A.; Micheli, L.; Jones, C.B.; Makrides, G.; Georghiou, G.E.; Stein, J.S. Nonlinear Photovoltaic Degradation Rates: Modeling and Comparison Against Conventional Methods. IEEE J. Photovolt. 2020, 10, 1112–1118. [Google Scholar] [CrossRef]

- Theristis, M.; Livera, A.; Micheli, L.; Ascencio-Vasquez, J.; Makrides, G.; Georghiou, G.E.; Stein, J.S. Comparative Analysis of Change-Point Techniques for Nonlinear Photovoltaic Performance Degradation Rate Estimations. IEEE J. Photovolt. 2021, 11, 1511–1518. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Panat, S.; Varanasi, K.K. Electrostatic dust removal using adsorbed moisture–assisted charge induction for sustainable operation of solar panels. Sci. Adv. 2022, 8, eabm0078. [Google Scholar] [CrossRef] [PubMed]

- Zahedi, R.; Ranjbaran, P.; Gharehpetian, G.B.; Mohammadi, F.; Ahmadiahangar, R. Cleaning of Floating Photovoltaic Systems: A Critical Review on Approaches from Technical and Economic Perspectives. Energies 2021, 14, 2018. [Google Scholar] [CrossRef]

- Brahma, H.; Pant, S.; Micheli, L.; Smestad, G.P.; Sarmah, N. Effect of Environmental Factors on Photovoltaic Soiling: Experimental and Statistical Analysis. Energies 2023, 16, 45. [Google Scholar] [CrossRef]

- Micheli, L. Monitoring and Modelling Photovoltaic Soiling in an Urban Environment. In Proceedings of the 2023 IEEE International Conference on Environment and Electrical Engineering and 2023 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 6–9 June 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Micheli, L.; Theristis, M.; Talavera, D.L.; Almonacid, F.; Stein, J.S.; Fernández, E.F. Photovoltaic cleaning frequency optimization under different degradation rate patterns. Renew. Energy 2020, 166, 136–146. [Google Scholar] [CrossRef]

- Meyer, S.; Richter, S.; Timmel, S.; Gläser, M.; Werner, M.; Swatek, S.; Hagendorf, C. Snail Trails: Root Cause Analysis and Test Procedures. Energy Procedia 2013, 38, 498–505. [Google Scholar] [CrossRef]

- Dolara, A.; Lazaroiu, G.C.; Leva, S.; Manzolini, G.; Votta, L. Snail Trails and Cell Microcrack Impact on PV Module Maximum Power and Energy Production. IEEE J. Photovolt. 2016, 6, 1269–1277. [Google Scholar] [CrossRef]

- Wohlgemuth, J.H.; Hacke, P.; Bosco, N.; Miller, D.C.; Kempe, M.D.; Kurtz, S.R. Assessing the Causes of Encapsulant Delamination in PV Modules. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; pp. 248–254. [Google Scholar] [CrossRef]

- Jentsch, A.; Eichhorn, K.-J.; Voit, B. Influence of typical stabilizers on the aging behavior of EVA foils for photovoltaic applications during artificial UV-weathering. Polym. Test. 2015, 44, 242–247. [Google Scholar] [CrossRef]

- Kwembur, I.M.; McCleland, J.C.; van Dyk, E.; Vorster, F.J. Detection of Potential Induced Degradation in mono and multi-crystalline silicon photovoltaic modules. Phys. B Condens. Matter 2019, 581, 411938. [Google Scholar] [CrossRef]

- ENEL. 2022 PCR for PV Panel: EPDItaly 014–rel. 1.1. Available online: https://www.epditaly.it/en/pcr_/pcr-for-pv-panel-epditaly-014/ (accessed on 15 October 2023).

- BRE Group. BRE Global Product Category Rules (PCR) For Type III EPD of Construction Products to EN 15804+A2 PN 514 Rev 3.0. 2018. Available online: https://it.scribd.com/document/692337244/PN514-BRE-EN-15804-PCR (accessed on 17 January 2024).

- Pfister, S.; Koehler, A.; Hellweg, S. Assessing the Environmental Impacts of Freshwater Consumption in LCA. Environ. Sci. Technol. 2009, 43, 4098–4104. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Liu, C.; Yu, K.; Yan, C.; Shen, Y.; An, Z.; Jing, J. Droplet cleaning method and water consumption analysis for superhydrophobic solar photovoltaic glass. Sol. Energy 2022, 235, 94–104. [Google Scholar] [CrossRef]

- PVCycle. Rapporto Annuale 2022 PV Cycle Italia. 2022. Available online: https://pvcyclegroup.it/wp-content/uploads/2023/07/PV-CYCLE-ITALIA_Rapporto-annuale-2022-1-1.pdf (accessed on 20 November 2023).

- Directive 19/EU of the European Parliament and of the Council of 4 July 2012 on Waste Electrical and Electronic Equipment (WEEE) (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32012L0019 (accessed on 20 November 2023).

- IEA. End-of-Life Management of Photovoltaic Panels: Trends in PV Module Recycling Technologies. 2018. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/End_of_Life_Management_of_Photovoltaic_Panels_Trends_in_PV_Module_Recycling_Technologies_by_task_12.pdf (accessed on 20 November 2023).

- Fiandra, V.; Sannino, L. RT/2023/5/ENEA Analysis Report on Photovoltaic waste as source of valuable materials. In Overview on the Current Material Recovery Approaches; Department of Energy Technologies and Renewable Sources Photovoltaic and Smart Devices Division Innovative Devices Laboratory Portici Research Center, ENEA: Frascati, Italy, 2023. [Google Scholar]

- EPD Italy. 2022 Mono-Crystalline Silicon PV Modules, Registration Number MR-EPDITALY0057. Available online: https://www.epditaly.it/epd/lr4-72hbd-lr5-72hbd-lr5-72hph-lr572hibd-lr5-72hih-lr5-54hph-lr5-54hih-lr5-54hib/ (accessed on 15 October 2023).

- EPD Italy. Bi-Facial Mono-Crystalline Silicon Photovoltaic (PV) Modules, Registration Number EPDITALY0341. 2022. Available online: https://www.epditaly.it/en/epd/bi-facial-mono-crystalline-silicon-photovoltaic-pv-modules/ (accessed on 15 October 2023).

- Dodd, N.; Espinosa, N. Preparatory Study for Solar Photovoltaic Modules, Inverters and Systems—Task 4 Technical Analysis Including End-of-Life; European Commission, Joint Research Centre: Belgium, Brussels, 2018; Available online: https://susproc.jrc.ec.europa.eu/product-bureau/sites/default/files/contentype/product_group_documents/1581689975/DraftReport_Task5.pdf (accessed on 15 October 2023).

- Agostinelli, S.; Cumo, F.; Marzo, R.; Muzi, F. Digital Construction Strategy for Project Management Optimization in a Building Renovation Site: Machine Learning and Big Data Analysis. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2023; Volume 306, pp. 20–35. [Google Scholar] [CrossRef]

- Muzi, F.; Marzo, R.; Nardi, F. Digital Information Management in the Built Environment: Data-Driven Approaches for Building Process Optimization. In Technological Imagination in the Green and Digital Transition; The Urban Book Series; Springer: Cham, Switzerland, 2023; pp. 123–132. [Google Scholar] [CrossRef]

| Life cycles stages according to EPD Italy PCR | UP STREAM | CORE STREAM | DOWN STREAM | Benefits and loads Beyond the system boundary | |||||||||||||

| A1-Raw material supply | A2-Transport Raw material | A3-Manufacturing | A4-Transport to site | A5-Assembly/Install | B1-Use | B2-Maintenance | B3-Repair | B4-Replacement | B5-Refurbishment | B6-Operational energy use | B7-Operational water use | C1-Deconstruction | C2-Transport waste | C3-Waste processing | C4-Disposal | D-Reuse, Recovery, Recycling potential | |

| Life cycles stages according to EN 15804 | PRODUCT STAGE | CONSTRUCTION PROCESS STAGE | USE STAGE | END OF LIFE | Benefits and loads beyond the system boundary | ||||||||||||

| Module | Modeling Requirements |

|---|---|

| B1 | The information in the module concerns consumptions and emissions during the use of the PV modules in the predetermined life cycle. In cases of emissions of dangerous substances to air, soil and water, they must be reported in module B1 as additional information, referring to current legislation and measurement standards. |

| B2 | The information in the module concerns consumption and emissions during ordinary and extraordinary maintenance activities: cleaning, replacement of the inverter, partial replacement or repair of worn, damaged or degraded parts of the photovoltaic modules during the RSL. Module B2 concerns the consumption of energy and demineralized water, the disposal of replaced photovoltaic modules, the production of replacement photovoltaic modules, the production of auxiliary materials used during installation and the consumption and emissions associated with all necessary transport. In cases of damage to the system requiring the total replacement of the PV modules, the environmental impacts shall be reported in module (B4); cases of the total replacement of the PV modules as part of a scheduled program of refurbishment for the building shall be reported in refurbishment module (B5). The environmental impacts in module (B2) are directly related to the context of the PV modules’ installation site and shall be assessed with defined assumptions through a schedule of ordinary and extraordinary maintenance. |

| B3 | The information in the module concerns consumption and emissions related to corrective, responsive or reactive repair all of the PV modules or part of them during the RSL. The module includes an assumption—directly related to the context of the PV modules installation site—of how many such repair situations will arise during the RSL. The environmental impacts include consumption and emissions caused by the production and transport of the auxiliary materials necessary to carry out repairs and by the management and transport of waste produced during repairs. |

| B4 | The information in the module concerns consumption and emissions related to the total replacement of the PV modules due to damage during the RSL. The environmental impacts include the deconstruction of the PV modules (see C1), the management of waste from replaced PV modules (see C3 and C4), the production process of the new modules (see A1 and A3), the installation of the new PV modules (see A5) and the impacts caused by all the necessary transport (see A2, A4 and C2). |

| B5 | The information in the module concerns consumption and emissions related to the total replacement of the PV modules as part of a scheduled of refurbishment for the building in which the system is installed. The environmental impacts include the deconstruction of the PV modules (see C1), the management of waste from replaced PV modules (see C3 and C4), the production process of the new modules (see A1 and A3), the installation of the new PV modules (see A5) and the impacts caused by all the necessary transport (see A2, A4 and C2). |

| B6 | The information in the module concerns energy consumption and related emissions for the operation of the PV system during the RSL. |

| B7 | The information in the module concerns water consumption for the operation of the PV system during the RSL (see B2). |

| Module | Modeling Requirements |

|---|---|

| C1 | The information in the module concerns consumption and emissions related to the disassembly of the PV modules from a building. The environmental impacts include separating the PV modules into their component parts for recycling or disposal in landfill [35]. |

| C2 | The information in the module concerns consumption and emissions related to the transport of the component parts of the PV modules. The environmental impacts include the division of materials into homogeneous fractions, i.e., towards collection and recycling centers or towards landfills [35]. |

| C3 | The information in the module concerns consumption and emissions related to the activities of reuse, recycling and recovery carried out in the waste treatment plants depending on the characteristics of the individual materials to be treated. Since there is lack of data on the recycling rate, the PV module is useful as it refers, for example, to the waste electrical and electronic equipment (WEEE) directive [36] and to the data from the IEA report on the end-of-life management of PV panels [37]. |

| C4 | The information contained in the Form concerns consumption and emissions relating to final disposal at the disposal site, including any required pre-treatments and management of the disposal plant. For the assessment of the environmental impacts associated with disposal, reference can be made, in Italy, to the ENEA report relating to the end of life of photovoltaic panels [38]. |

| Typology, Code, Factory Site | LCA Software, LCI Database(s), LCIA Methodology Version Number | System Boundaries | Key Assumptions for Use and Maintenance |

|---|---|---|---|

| 1 Monocrystalline silicon photovoltaic modules EPDITALY0501 China | LCA—Software SimaPro 9.3 LCI—Database Ecoinvent 3.8 LCIA—Methodology EN 15804 + A2:2019 (version 1.00) and Traci. Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data. For the use stage, only (B2) during the RSL period is included. Modules B3 to B7 are not included, and no activities are contained during life cycle modules (B1). | Consumption only occurs in maintenance (B2). During maintenance, water used for cleaning is assumed to be 0.3 L per module per time (source: www.polywater.com), and cleaning frequency is two times per year. And it is assumed that small, manual, handheld systems that spray water onto panels are used. No electricity consumption during the cleaning process is assumed. |

| 2 Monocrystalline, double glass, P-type, solar photovoltaic modules MR- EPDITALY0073 China/Norway | LCA—Software SimaPro v9 LCI—Database Ecoinvent v3.6 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 Wp Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data only for modules (A4) and (A5). | PV modules are considered as self-cleaning materials. No maintenance (B2), repair (B3), replacement (B4) or refurbishment (B5) are required during the PV module lifetime. Modules (B6) and (B7) do not require energy or water consumption. |

| 3 Monocrystalline, double-glass, N-type, solar photovoltaic modules MR-EPDITALY0072 China | LCA—Software SimaPro v9 LCI—Database Ecoinvent v3.6 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 Wp Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data only for modules (A4) and (A5). | PV modules are considered as self-cleaning materials. No maintenance (B2), repair (B3), replacement (B4) or refurbishment (B5) are required during the PV module lifetime. Modules (B6) and (B7) do not require energy or water consumption. |

| 4 Monocrystalline, single-glass, P-type, solar photovoltaic modules MR-EPDITALY0071 China | LCA—Software SimaPro v9 LCI—Database Ecoinvent v3.6 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 Wp Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data only for modules (A4) and (A5). | PV modules are considered as self-cleaning materials. No maintenance (B2), repair (B3), replacement (B4) or refurbishment (B5) are required during the PV module lifetime. Modules (B6) and (B7) do not require energy or water consumption. |

| 5 Monocrystalline silicon photovoltaic (PV) modules EPDITALY0470 China | LCA—Software SimaPro 9.4 LCI—Database Ecoinvent 3.8 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data for all the modules. Modules (B1), (B3) and B5 to B7 are modules Not Declared (MND). | For the use stage, only modules (B2) and (B4) are considered. The maintenance (B2) of the system consists of washing the panels once a year and replacing (B4) the inverters at the end of their life after 15 years. The assessment was carried out in relation to the production site in Taizhou (China) and the installation site in Nulvi (SS) Italy. |

| 6 N-type and P-type PV modules EPDITALY0426 China | LCA—Software SimaPro 9.4 LCI—Database Ecoinvent 3.8 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data for all the modules. | Maintenance (B2) is largely determined by cleaning assumed to be conducted once per month within 10 km driving distance. The water use is linearly associated with the dimension of the PV module. The reference PV plant applies a 0.765 L/m2 water use rate. PV modules are assumed to be replaced (B4) by 3%. The service life of the inverter is 15 years. |

| 7 Monocrystalline silicon PV, bifacial, double glass MR-EPDITALY0069 China/Vietnam | LCA—Software SimaPro 9.1 LCI—Database Ecoinvent 3.6 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2.1 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data for all the modules. | Electricity used (B6) during the PV plant operation is assumed to be powered by the plant itself. Water used (B7) for cleaning is assumed to be 0.23 L (source: www.polywater.com) per module per time and two times per year. The replacement of inverter (B2) is assumed to be one inverter/2 years during RSL. |

| 8 Monocrystalline PERC module China MR-EPDITALY006 (PCR: NPCR 029 version 1.2) | LCA—Software SimaPro 9.4 LCI—Database Ecoinvent 3.8 LCIA—Methodology NPCR 029 version 1.2 Functional Unit (FU) 1 Wp. Reference Service Life (RSL) 25 years | EPD includes all the stages with disaggregated data for all the modules. Modules (B1–B7) are modules not declared (MND). | It is assumed that there are no material or energy inputs nor emissions during use (B1) and maintenance (B2). The PV modules do not require repair (B3), replacement (B4) and refurbishment (B5) during their RSL. Also, no operational electricity consumption (B6) or water consumption (B7) is assumed. |

| 9 Monocrystalline bifacial, monofacial, double glass MR-EPDITALY0067 China | LCA—Software SimaPro 9.2 LCI—Database Ecoinvent 3.7 and IEA PVPS Task 12,2020 LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data for all the modules. Modules (B1), (B3) and (B4 to B7) are modules not declared (MND). | Consumptions and emissions only occur in module (B2). |

| 10 Monocrystalline silicon PV modules MR-EPDITALY 0057 China | LCA—Software SimaPro 9.1 LCI—Database Ecoinvent 3.6 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2.1 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data for all the modules. | For the use stage, electricity consumption (B6) during the PV plant operation is assumed to be powered by the plant itself. Water used for cleaning the PV panels (B2) is assumed to be 0.23 L (source: www.polywater.com) per module per time and two times per year. Replacement of inverter is assumed to be one inverter/2 years during RSL (30 years), but the modules in which to place this data are not specified. |

| 11 Bifacial monocrystalline silicon photovoltaic (PV) modules EPDITALY0341 China/Canada | LCA—Software SimaPro 9.2 LCI—Database Ecoinvent 3.7 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2. Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the Stages with disaggregated data for all the modules. Modules B1 to B6 are modules with zero impacts. Energy production in the first year of operation was modeled in Pvsyst software using the scenario that the power plant is installed in Rome in Italy. | For the use stage, module use (B1), maintenance (B2), repair (B3), replacement (B4), refurbishment (B5) and operational energy use (B6) are considered to be completely non-impacting, assuming that the product does not require any type of modification. Operational water (B7) to clean PV panels is 9.091 L/m2. |

| 12 Monofacial monocrystalline silicon photovoltaic (PV) modules EPDITALY0340 China/Canada | LCA—Software SimaPro 9.2 LCI—Database Ecoinvent 3.7 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2. Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data for all the modules. Modules B1 to B6 have zero impacts. Energy production in the first year of operation was modeled in Pvsyst software using the scenario that the power plant is installed in Rome in Italy. | For the use stage, module use (B1), maintenance (B2), repair (B3), replacement (B4), refurbishment (B5) and operational energy use (B6) are considered to be completely non-impacting, assuming that the product do not requires any type of modification. Operational water (B7) to clean PV panels is 9.091 L/m2. |

| 13 Monocrystalline PV module MR-EPDITALY0056 China/Norway/Phillipines/USA/Mexico | LCA—Software SimaPro v9 LCI—Database Ecoinvent v3.6 LCIA—Methodology NPCR 029 version 1.1 Functional Unit (FU) 1 Wp. Declared unit: 1 m2 of photovoltaic module = 226 Wp Reference Service Life (RSL) 25 years | EPD includes all the stages with disaggregated data. Modules B1-B7 are modules not relevant (MNR). | It is assumed that there is no consumption or emissions in any of the modules (B1 to B7) of the use phase. |

| 14 Monocrystalline silicon PV module, double glass MR-EPDITALY0051 China | LCA—Software SimaPro 9 LCI—Database Ecoinvent 3 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data. Modules (B1) and B3 to B7 are modules not relevant (MNR), with zero impacts. | For the use stage, module use (B1), repair (B3), replacement (B4), refurbishment (B5), operational energy use (B6) and water energy use (B7) are considered without impact. Electricity and water consumption for the maintenance of the PV system (B2) during RSL are calculated on the basis of the real operating data of the first year provided by the manufacturer, multiplying them by RSL. |

| 15 Monocrystalline silicon PV module, single glass MR-EPDITALY0050 China | LCA—Software SimaPro 9 LCI—Database Ecoinvent 3 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci 2 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with aggregated data. Modules (B1) and B3 to B7 are modules not relevant (MNR) with zero impacts. | This EPD analyzes high-energy-density, single-glass, monocrystalline silicon PV modules. The modules use specific technologies to achieve significantly improved performance with conversion efficiency. The LCA study contains the same key assumptions as EPD n.14. |

| 16 Monocrystalline silicon PV module MR-EPDITALY0252 China | LCA—Software SimaPro 9.1 LCI—Database Ecoinvent 3.4 with adaptation of regional energy and material data by Ecovane LCIA—Methodology EN 15804:2012 + A2:2019 Functional Unit (FU) 1 kWh Reference Service Life (RSL) 30 years | EPD includes all the stages with disaggregated data. All the modules are included. | For the use stage, module use (B1), maintenance (B2), repair (B3), refurbishment (B5) and operational energy use (B6) are considered with zero impacts. Replacement (B4) and operational water use (B7) are included. Water used for cleaning is assumed to be 0.23 L (source: www.polywater.com) per module per time and two times per year. Replacement PV modules: 20 pieces (pcs)/year(B4); inverter: 1 pcs/2 years. |

| 17 Monocrystalline silicon PV modules MR-EPDITALY0043 China | LCA—Software SimaPro 9 LCI—Database Ecoinvent 3 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci | EPD includes all the stages and all the modules with aggregated data. | For the use stage, module (B6) operational energy is assumed to be powered by the plant itself. Repair (B3), replacement (B4) and refurbishment (B5) are considered with zero impacts. Operational water (B7) used for cleaning the PV panels is assumed to be 0.23 L (source: www.polywater.com) per module per time and two times per year. Replacement of inverter (B2) is included and assumed to be one inverter/2 years during RSL. |

| 18 Monocrystalline silicon PV modules, single glass MR-EPDITALY0042 China | LCA—Software SimaPro 9 LCI—Database Ecoinvent 3 LCIA—Methodology EN 15804:2012 + A2:2019 and Traci | EPD includes all the stages and all the modules with aggregated data. | This EPD analyzes high-energy-density, single-glass, monocrystalline silicon PV modules. The modules use specific technologies to achieve significantly improved performance with conversion efficiency. The LCA developed contains the same key assumptions as EPD n.17. |

| EPD n.10 (see Table 4) [39] Monocrystalline silicon with aggregated data for all the core stream modules A3, A4, A5, B1, B2, B3, B4, B5, B6, B7, C1, C2 | ||||

| LCA results over 30 years of the modules A3, A4, A5, B1, B2, B3, B4, B5, B6, B7, C1, C2 | ||||

| Climate Change Total (CCT) * | Water Consumption | Water Depletion Potential WDP | Ozone Depletion | Acidification |

| 9.87 × 10−4 ton CO2 eq | 3.05 × 10−4 m3 | 3.05 × 10−4 m3 deprivation | 7.37 × 10−11 g CFC-11 eq | 1.60 × 10−5 mol H+ eq |

| EPD n.11 (see Table 4) [40] Bifacial monocrystalline silicon with disaggregated data for all the core stream modules A3, A4, A5, B1, B2, B3, B4, B5, B6, B7, C1, C2 | ||||

| LCA results over 30 years of the module B7 (manual cleaning of PV modules surface) | ||||

| Climate Change Total (CCT) * | Water Consumption m3 | Water Depletion Potential WDP | Ozone Depletion | Acidification |

| 3.66 × 10−7 kgCO2 eq | 1.03 × 10−6 | 4.43 × 10−5 m3 deprivation | g CFC-11 eq | mol H+ eq |

| Data | Water Consumption for Cleaning | Replacement Inverter | Replacement PV Modules | |||

|---|---|---|---|---|---|---|

| n. | Agg. | Disag. | B2 maintenance (1 PV module = 2 m2) | B7 operational water consumption | Module not specified | Module not specified |

| 1 | √ | cleaning two time per year: 0.15 L/m2 water use rate | no | no | ||

| 2 | √ | no | no | no | no | |

| 3 | √ | no | no | no | no | |

| 4 | √ | no | no | no | no | |

| 5 | √ | cleaning the panels once a year | see B2 | after 15 years | no | |

| 6 | √ | cleaning once per month within 10 km driving distance: 0.765 L/m2 water use rate | see B2 | after 15 years | PV modules are assumed to be replaced (B4) by 3% | |

| 7 | √ | see B7 | operational water uses for cleaning two time per year, 0.12 L/m2 water use rate | after 15 years | no | |

| 8 | √ | no | no | no | no | |

| 9 | √ | consumptions only occur in maintenance (B2) | - | no | no | |

| 10 | √ | cleaning two time per year: 0.12 L/m2 water use rate | see B2 | after 15 years | ||

| 11 | √ | see B7 | operational water uses for manual cleaning in Rome Italy is 9.091 L/m2 | no | no | |

| 12 | √ | see B7 | operational water use for manual cleaning in Rome Italy is 9.091 L/m2 | no | no | |

| 13 | √ | no | no | no | no | |

| 14 | √ | water consumptions are calculated based on the first-year operation real data provided by manufacturer | see B2 | no | no | |

| 15 | √ | water consumptions are calculated based on the first-year operation real data provided by manufacturer | see B2 | no | no | |

| 16 | √ | - | operational water uses for cleaning two time per year: 0.12 L/m2 water use rate | 1 piece (pcs)/2 years | replacements (B4) PV modules: 20 pieces (pcs)/year | |

| 17 | √ | - | operational water uses for cleaning two times per year: 0.12 L/m2 | 1 inverter/2 years during RSL | no | |

| 18 | √ | - | operational water uses for cleaning two time per year: 0.12 L/m2 water use rate | 1 inverter/2 years during RSL | no | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Piras, G.; Sferra, A.S. Environmental Product Declarations as a Data Source for the Assessment of Environmental Impacts during the Use Phase of Photovoltaic Modules: Critical Issues and Potential. Energies 2024, 17, 482. https://doi.org/10.3390/en17020482

Piras G, Sferra AS. Environmental Product Declarations as a Data Source for the Assessment of Environmental Impacts during the Use Phase of Photovoltaic Modules: Critical Issues and Potential. Energies. 2024; 17(2):482. https://doi.org/10.3390/en17020482

Chicago/Turabian StylePiras, Giuseppe, and Adriana Scarlet Sferra. 2024. "Environmental Product Declarations as a Data Source for the Assessment of Environmental Impacts during the Use Phase of Photovoltaic Modules: Critical Issues and Potential" Energies 17, no. 2: 482. https://doi.org/10.3390/en17020482

APA StylePiras, G., & Sferra, A. S. (2024). Environmental Product Declarations as a Data Source for the Assessment of Environmental Impacts during the Use Phase of Photovoltaic Modules: Critical Issues and Potential. Energies, 17(2), 482. https://doi.org/10.3390/en17020482