1. Introduction

The progress made in recent decades in the field of power electronics and computer technology has resulted in the induction motor (IM) being used in high-performance drives. Due to its simplicity, low cost, and reliability, the IM is preferred in industrial applications. However, its nonlinear dynamics with internal coupled states involve appropriate advanced control strategies to achieve the requirement of high performance.

The classical advanced control structure of the IM is traditionally designed in cascade topology, where the vector control principle, also called field-orientated control (FOC), is used [

1,

2,

3].

The vector control strategy is based on the dynamic dq model of the IM defined in the synchronously rotating reference frame. Usually, the inner loop is intended for dq stator currents control and the outer one is used for rotor flux and rotor mechanical speed control. Due to the nonlinear, multivariable coupled models of the two loop plants, various control techniques have been developed to solve the problems generated by complex models.

For the inner loop, model linearization and its decoupling through feedforward components are generally used. Based on the resulting decoupled linear models, the

dq stator currents are usually controlled with two proportional–integral (PI) controllers [

3,

4]. Due to the physics-based constraints generated by the limits imposed on the stator voltages and currents, PI control has been replaced with advanced techniques to solve this problem. In general, among the advanced techniques used for the inner loop, model predictive current control (MPCC) algorithms are preferred because constraints due to the physical limitations of the stator voltages and currents can be imposed in the design phase. However, in most cases, MPCC is based on the multivariable coupled nonlinear model of

dq currents, resulting in the two currents not being separately controlled, according to the FOC requirement. Thus, in [

5], two model predictive control (MPC) cascade structures based on a continuous control set and finite control set without PI controllers were analyzed, studying the advantages and difficulties. The inner loop generates the output control voltages, considering the stator voltages and current constraints, and the outer loop is the torque reference, keeping in mind the constraints of the torque/speed characteristics of the IM. The full predictive cascaded speed and current control of an IM is presented in [

6]. Here, the currents from the inner loop are controlled using a finite control set MPC algorithm, while, for speed control, a continuous control set MPC based on the explicit inversion of the mechanical model is suggested. Considering the importance of the handling of constraints for induction machines, in [

7], a cascade speed control structure with MPC controllers capable of incorporating the constraints in the objective function is proposed. The inner loop uses an MPCC controller, and the outer one uses an explicit MPC controller for speed control. The common limitations of the stator voltages and currents described as quadratic inequality in the

dq-frame are reformulated because the quadratic inequalities of the current and voltage can be represented by the linear one of the torque. The linear inequality is parameter-varying because the limited torque depends nonlinearly on the rotor speed and, to solve this problem, a multiparametric quadratic programming (mp-QP) algorithm is utilized. To replace the inner PI current controllers and the pulse width modulation (PWM) block and, thus, to obtain faster dynamics, in [

8], a finite control set predictive current control approach is proposed to control the IM. For rotor speed control, in the outer loop, a PI controller is used and, for IM stator windings protection, the electromagnetic torque current command is limited. By including the magnetic saturation and rotor-speed-dependent iron-loss resistance in the IM model, in [

9], an MPCC strategy is developed based on this model for IM control considering saturation and iron core losses, to which a control effort penalty is added to reduce the average switching frequency. The proposed strategy is based on replacing the PI current controllers in the inner loop with the proposed predictive control algorithm, while, in the outer loop, a classical PI controller is used to control the mechanical speed of the rotor. But there are also IM control structures that keep PI controllers in the inner loop. Thus, for the cascade control structure in [

10], a multivariable generalized predictive control (GPC) controller is proposed for rotor speed and flux control, while, in the inner loop, the currents are controlled with conventional PI controllers. The stator is protected against over electrical signals by the current constraints imposed on the GPC controllers in the design phase and by restricting the module of the phase stator voltage through a limiting block attached to the PI controllers.

For the outer loop, the two controlled currents of the inner loop are used as inputs so that the

d component keeps the rotor flux constant as well as the

q one to control rotor speed. The main problem of outer loop control derives from the nonlinear coupled multivariable model of the plant. In the vector control approach, with the assumption that the rotor flux is constant after reaching its reference, the speed dynamics become linear and can be controlled with PI controllers [

11]. One method to decouple the flux dynamics from the speed dynamics is to use the input–output feedback linearization method, which leads to separating the flux and speed control. But the input–output feedback linearization method cannot be applied to the IM model due to the singularity of the decoupling matrix of the feedback transformation when the flux is zero at the start-up of the motor [

4,

12]. To solve this problem, in [

11], based on an IM model which includes both electrical and mechanical dynamics, it is proposed to control the square of the rotor flux and the speed using the input–output linearization technique in conjunction with the use of an open loop controller at the start-up of the motor. As soon as the flux becomes greater than zero, the control input is switched from the open loop controller to the nonlinear-state feedback control. Starting from the same reduced fourth-order state-space model of the IM and the control objectives from [

11], in [

13], a switching strategy based on the homotopy continuation is presented that allows the application of the input–output feedback linearization approach. The strategy is based on the construction of a homotopy that combines the output of the nonlinear model of the IM with the output of an attached linear model, which is then linearized by feedback. When the conventional feedback linearization cannot be applied, the control is switched to the parameter continuation method. Starting from [

13], the authors presented in [

4] a new control approach for driving the output to zero using the combination of the state feedback linearization and the homotopy numerical continuation, which does not require switching between two computationally complex controllers. Both methods from [

4,

13] use a cascade control structure with a PI current control inner loop, but the outer loop from [

13] controls the square of the flux and the speed, while, in [

4], the deviation of the flux and speed is in relation with their references. Another method for dynamic feedback linearization control of an IM is presented in [

14], where, to avoid the impossibility of applying linearization through feedback, an integrator on the

d-axis is additionally added to the IM

dq model and, thus, the decoupling matrix of the feedback transformation is no longer singular at the start-up of the motor. The

dq currents are controlled in an inner loop using conventional PI controllers. The introduction of an integrator on the

q-axis instead of the

d-axis is also analyzed, resulting in the feedback linearization of the IM model but with the disadvantage that the feedback controller is singular when the quadrature current is zero and implicitly the motor torque is zero. A speed/position control strategy for the IM based on the exact feedback linearization with state and state-derivative feedback is presented in [

15]. This control strategy also uses PI controllers for the current loop. IM speed sensorless feedback linearization control based on a current/flux and speed tracking controller is proposed in [

16]. Using a cascade control structure, the feedback linearization controller is designed to control the inner current loop and, respectively, the speed and flux in the outer loop. To obtain speed tracking throughout the operating range, a PI controller is added. Also, using an input–output feedback linearization technique, in [

17], a sliding-mode speed controller for the IM is proposed instead of the classical PI.

The MPCC algorithms for the inner loop mentioned above, although they handle the physics constraints more easily, being designed considering the uncoupled multivariable model of the dq currents, do not fulfill the major requirement of the FOC regarding the independent control of the two currents. For the outer loop, the above methods for decoupling the flux from the rotor speed through feedback linearization require an additional loop to track the imposed references. Typically, the additional loop uses PI controllers, which do not always give good transient dynamics, especially if the homotopy variant of the feedback linearization is used.

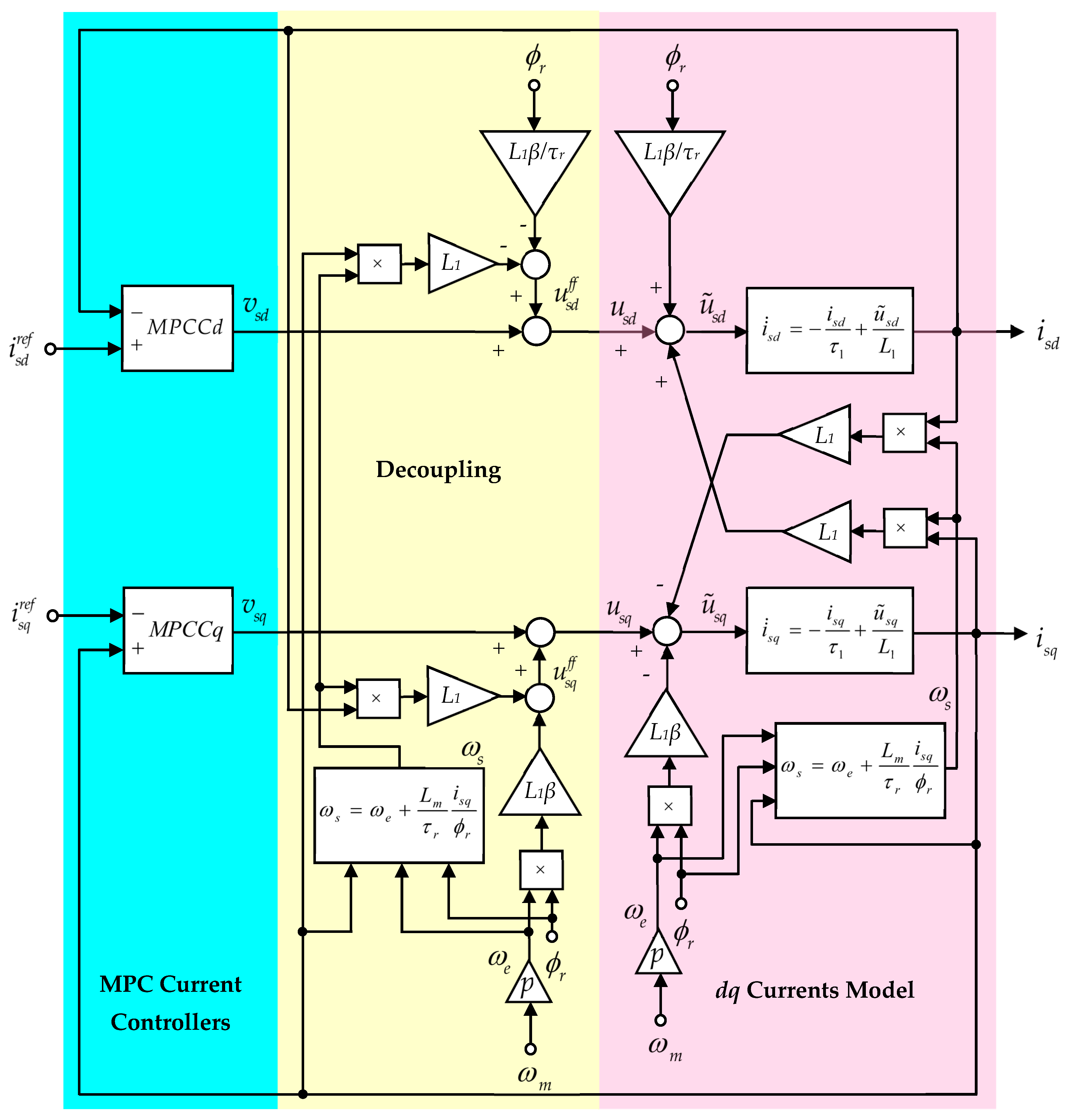

In this paper, to solve the aforementioned problems, a new cascade control structure is proposed for the speed and flux control of an IM. For

dq current control, in the inner loop, decoupling and MPCC algorithms are used. In the outer loop, its plant is firstly linearized and decoupled by feedback based on the homotopy continuation and, then, the model-free intelligent-proportional (iP) algorithms are employed so that the two controlled outputs track the related references. In the inner loop, the cross-coupling of the

dq currents and the back electromotive force (EMF) are considered disturbances that are compensated by a decoupling algorithm based on feedforward components. After decoupling, two linear single-input single-output (SISO) models result, which are used to design the MPCC algorithms, taking into account the physics constraints introduced by the limitations imposed on the stator currents and voltages. To reduce the computational effort of the constraint optimization, a boxed linear constraint [

3] was used, with the consideration of the relationships between the

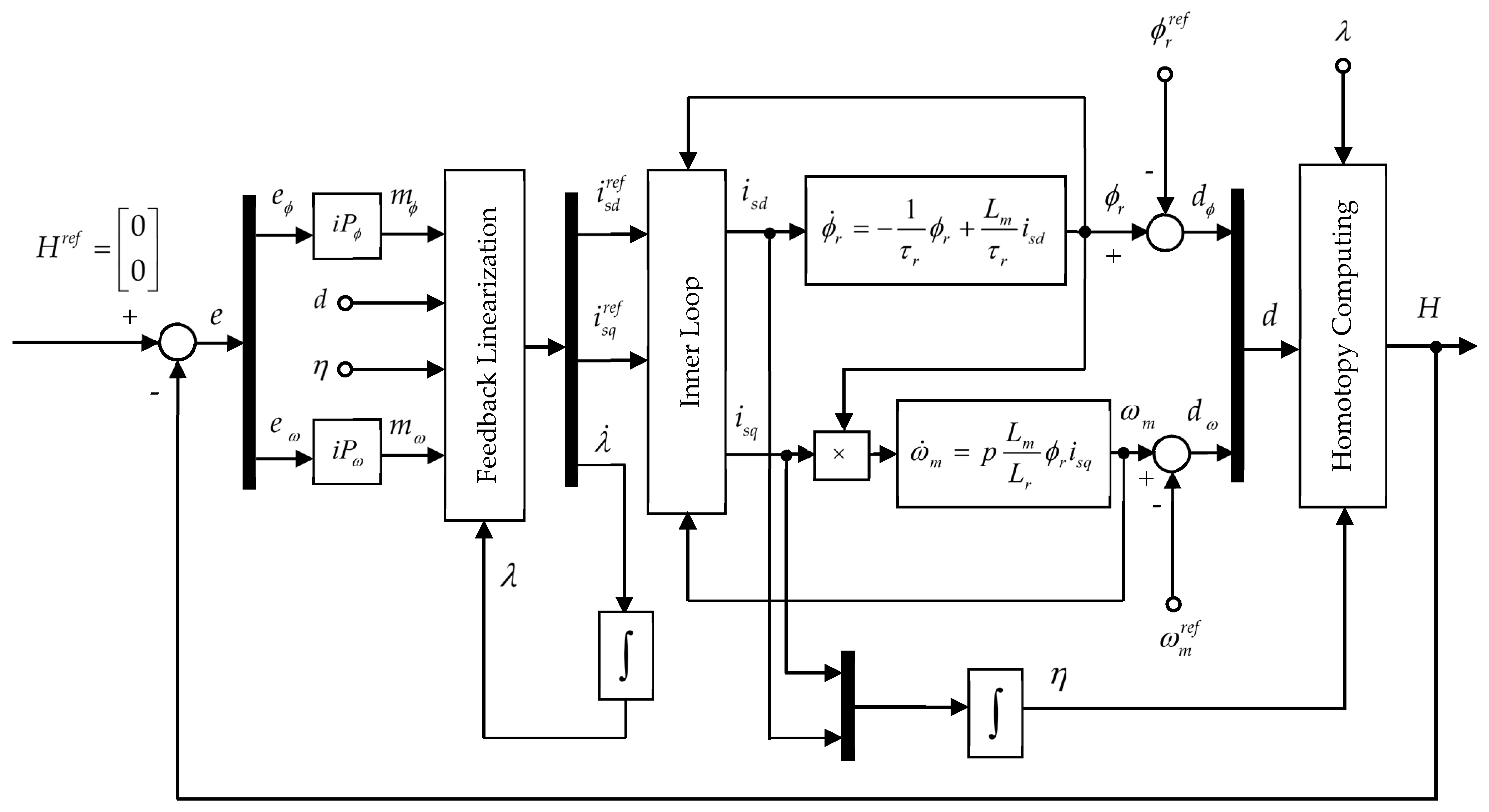

dq stator voltages generated by MPCC controllers via the decoupling algorithm. In the outer loop, to decouple the flux from the rotor speed and, thus, control them independently, the homotopy-based variant of the feedback linearization from [

4] was utilized. Since, at the beginning, when the homotopy parameter varies between zero and one, the plant model is variable, a model-free iP controller is proposed for the additional loop used to control the flux and speed of the IM due to their capabilities to manage complex dynamics from data, without requiring the knowledge of the plant model. This employment of the SISO box constrained MPCC algorithms, together with the homotopy-based variant of feedback linearization and model-free iP algorithms led to IM improved vector control compared to the use of conventional PI controllers instead of advanced algorithms. The performances of the proposed cascade control strategy were tested by simulation and compared with those obtained with conventional PI controllers, resulting in a better dynamic behavior for the predictive and model-free control. The following are the major contributions of this paper:

Incorporating MPCC and model-free advanced algorithms together with the homotopy-based feedback linearization to IM improved vector control.

To reduce the computational effort of the constrained optimization, our method uses a boxed linear constraint for considering the physics limitations of the stator currents and voltages.

To solve the limitation related to the stator voltages, we developed a method by which the limitations were correlated with the outputs of the MPCC controllers and with the feedforward components of the decoupling algorithm.

To solve the reference tracking problem in conjunction with the feedback linearization, we used a model-free algorithm due to the modeling uncertainty during the variation of the homotopy parameter from zero to one.

To demonstrate the ability to improve the vector control of the IM with the proposed cascade control structure that includes advanced algorithms, a case study was performed.

The paper is organized as follows.

Section 2 presents the

dq IM nonlinear model for the vector control strategy.

Section 3 is dedicated to the IM cascade control structure design, considering a constrained predictive current control algorithm for the inner loop and a homotopy-based variant of feedback linearization for the outer loop plant together with the model-free control algorithms for the rotor flux and speed control. An illustrative case study is given in

Section 4 that presents a comparative analysis of the results obtained for both the conventional controllers and the advanced ones. At last, in

Section 5 the main features arising from the study developed in this paper are summarized.

2. Nonlinear IM Model for Vector Control

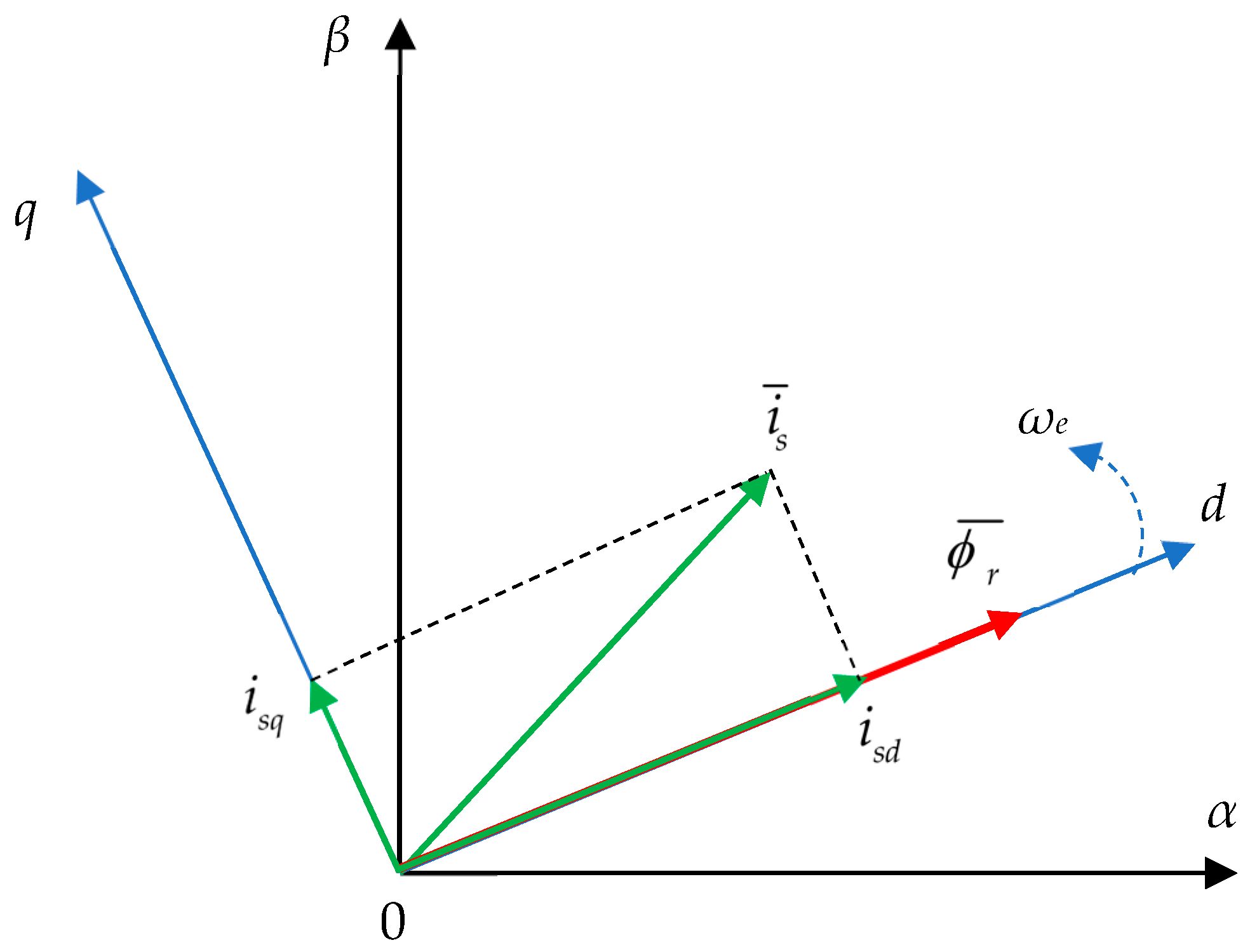

IM control is typically carried out by using the vector control strategy, which can separate the stator current components that produce the rotor flux and the electromagnetic torque, respectively. Thus, the well-known vector control strategy of the IM is usually performed in the reference frame

dq attached to the rotor flux space vector whose direct

d-axis is aligned with the rotor flux space vector

, as shown in

Figure 1.

Besides the stationary frame

αβ fixed to the stator, the stator current space vector

has the components

in the reference frame

dq attached to the rotor, which rotates at a general speed

. This alignment of the rotor flux space vector

with the

d-axis causes the

q-axis component to be zero [

11,

18], resulting in the

dq flux components:

The IM model, represented in

dq co-ordinates, includes stator current equations, rotor flux, and motion equations [

11]:

where

and

represent the components of the stator voltages and currents in the

dq reference frame,

is the rotor flux,

denotes the synchronous angular speed,

are the electrical and mechanical rotor angular speeds correlated by

, where

is the number of pole pairs,

and

are the electromagnetic and load torques, and

is the motor inertia. The parameters and the time constants related to the model described by Equations (2)–(4) are given by:

where

represent the stator and rotor resistances,

are the stator and rotor self-inductances,

is the mutual inductance,

is the equivalent resistance and

the equivalent inductance,

is the equivalent time constant,

is the rotor time constant, and

is a constant.

The synchronous angular speed

from Equation (2) is estimated using:

and the electromagnetic torque

from Equation (4) is calculated with:

Analyzing the IM model from Equations (2)–(7), it turns out that it is a strongly nonlinear coupled multivariable system.

The rotor flux-oriented vector control strategy requires the independent control of the two currents: , which produces the rotor flux, and , which generates the electromagnetic torque, respectively. The control of the two currents is performed by the stator voltages and , which are not decoupled control variables, as can be seen from Equation (2). To decouple and independently control the two stator currents , the stator voltage equations must be decoupled. The interactions between the stator currents and the nonlinearity of the current system are eliminated commonly using feedforward components. The control and decoupling of the stator currents is usually carried out in an inner loop of a cascade control structure considering the constraints generated by the physics electrical signal limits. In the outer loop, the rotor flux and the mechanical rotor angular speed are controlled based on the affine nonlinear multivariable system generated by Equations (3) and (4) and using as control variables the current references and . To obtain a linear decoupled behavior between the inputs and outputs of the outer plant model, a feedback linearization strategy can be used.

To solve the control problems mentioned above, generated by the nonlinear IM model, this paper proposes a cascade control strategy with the inner loop for the independent control of the currents and the outer loop for the independent control of the rotor flux and speed. A detailed presentation of the cascade control structure, together with its design, are given in the next section.

4. Case Study

The improvement of the IM vector control by using the proposed cascade control structure with the block diagrams of the inner and outer loops from

Figure 2 and

Figure 3, implemented using MATLAB/Simulink software version R 2023b, was tested and evaluated by simulation.

The IM specification data were taken from [

4,

11] and are given in

Table 1.

The nominal voltage and current,

and

, from

Table 1 are related on the root mean square (RMS) values, which, in practice, have a physical meaning. For the vector control, considering the power invariant

dq transformation, the nominal values of the space vector magnitude of the voltage and the current are defined as

and

.

The performance evaluation was conducted in comparison with the use of the conventional discrete-time PI controllers instead of the MPCC controllers in the inner loop and instead of the model-free iP controllers in the outer loop, respectively. The design of the PI controllers was performed with the pole placement method from [

26,

27] and it is briefly presented as follows.

The PI controllers from the inner loop described by the transfer function:

are designed based on the same plant described by the transfer function obtained from Equation (23):

Using the two transfer functions in Equations (47) and (48), the following characteristic polynomial of the closed loop control system is obtained:

Based on the required performances, the percent overshoot

, and the settling time

, the desired characteristic polynomial is constructed:

whose parameters are computed with:

where the damping ratio

and natural frequency

are calculated based on the desired performances, and

is the sampling period. The PI tuning parameters are computed solving the Diophantine equation:

In a similar way, the tuning parameters of the PI controllers from the outer loop:

are obtained considering that, now, the plant is the integrator

obtained after the homotopy-based feedback linearization. In this case, the characteristic polynomial of the closed loop control system is:

Using a similar desired characteristic polynomial developed based on performances and solving a Diophantine equation, the following tuning parameters are found:

Employing the IM motor parameters and the desired performances for the inner loop

, the following tuning parameters of the inner loop PI controllers are obtained for

Ts = 0.4 ms:

Similarly, for the outer loop, by imposing the performances

, the tuning parameters of the PI controllers are as follows:

The MPCC

j controllers from the inner loop are implemented using the MPC controller block from the MPC Simulink library [

21], which is based on the SISO model in Equation (25). Employing the IM parameters from

Table 1, the model becomes:

The constraint formulations for the MPCC

d controller are based on the first inequalities from Equations (18) and (23):

and, for the MPCC

q controller, the second inequalities:

The maximum values of the stator current and voltage of the IM are

and

, where the IM is supplied by a power inverter with the DC-bus voltage

. Knowing the nominal rotor flux from

Table 1, the nominal

d-axis current results in

, and its maximum value

. Using Equation (14), the parameter

is computed and, finally, with Equation (15), the

q-axis current maximum value

results.

In order to obtain the maximum values of the voltages from Equations (21) and (22), the parameter is firstly chosen and, then, the maximum values of the voltages are calculated using Equation (19), resulting in and . Finally, with Equation (22), the maximum values of the voltages are determined: and .

The operation of the IM is conducted by imposing the nominal value of the rotor flux as its reference, .

For the inner loop, the designed MPCC controllers have the parameters depicted in

Table 2.

The outer loop plant in Equation (34), having as outputs the deviations in rotor flux and speed from their references, with the IM parameters from

Table 1 becomes:

Since the model in Equation (61) is not feedback linearizable for

when the decoupling matrix

g(

x) is singular, the linear dynamic system in Equation (35) is associated with the outer loop plant model (61). Using the outputs

d and

of the two associated systems, a new output

H is constructed based on the continuous time-dependent parameter

, utilizing Equation (36). For the augmented system

H with the dynamics in Equation (37), the state feedback controller in Equation (40) is designed, having the parameter

, and, thus, a homotopy-based variant of feedback linearization results, which transforms the nonlinear system in Equation (39) into the linear one in Equation (41). The purpose of the state feedback controller (40) is to maintain

[

4] and, for

, the deviations defined by Equation (33) will be zero and, thus, the rotor flux and speed track their imposed references. For this reason,

is chosen. For the integrator-type linear system in Equation (41) obtained after the homotopy-based feedback linearization, two additional control loops are built with the model-free iP controllers to maintain the reference imposed to

H and, respectively,

d when

. Usually, PI controllers are used for these additional control loops [

4,

13]. In this paper, the model-free iP controllers capable of dealing with the modeling uncertainty, especially during the variation in the

parameter from 0 to 1, are proposed. The design of these controllers is made considering the connection between the iP controllers and the conventional PI given in [

24] and the following tuning parameters of the iP controller were obtained based on the parameters in Equation (57) of the PI controllers:

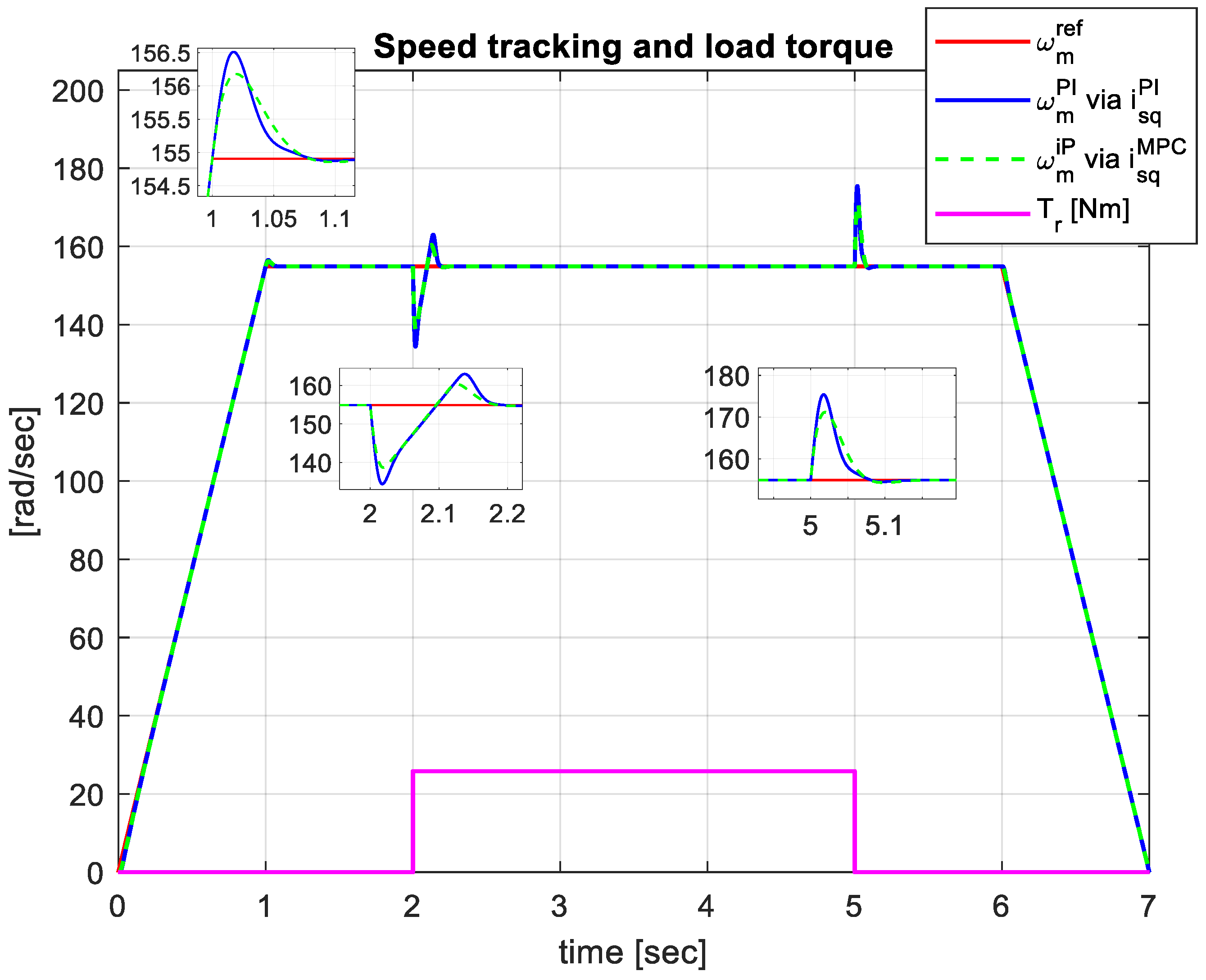

The simulation test consists of an acceleration of the angular speed to 154.9 rad/s within 1 s, keeping this value 5 s, and then deceleration to 0 in 1 s, while the rotor flux is maintained at its nominal value . A high load torque is also applied, starting with t = 2 s for 3 s. The performances obtained with the proposed cascade vector control structure, having MPCC controllers in the inner loop and the homotopy-based feedback linearization of the outer loop plant, followed by the control of the resulting linear system with model-free iP controllers, are compared with those obtained with the conventional PI controllers in the two control loops.

The evolution of the rotor angular speed in relation to its reference during the test is represented in

Figure 4 for both the cascade control structures, with advanced control algorithms MPCC and iP and with conventional PI controllers.

Reaching the nominal value of the rotor speed is performed with a slightly lower overshoot of 0.8% in the case of the cascade with the iP and MPCC algorithms compared to the PI controllers’ cascade with an overshoot of 1%. A better rejection of the load torque is also obtained for the case of the advanced algorithms compared to PI.

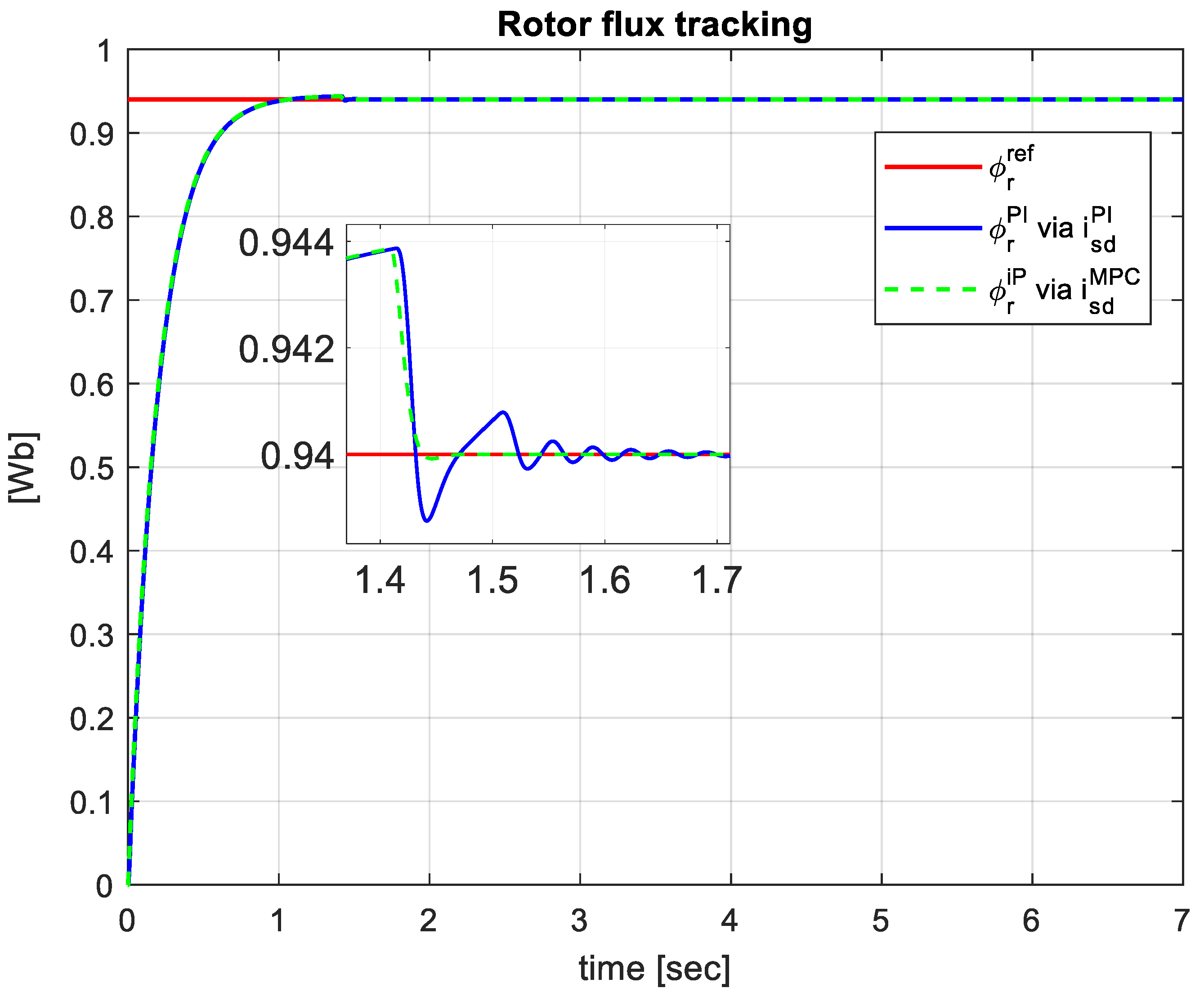

From the responses to the rotor flux reference represented in

Figure 5, it can be seen that the performances obtained with the advanced algorithms MPCC and iP are very similar to those of PI controllers, with slightly better behavior of the MPCC–iP tandem. For both cascade control structures, a small overshoot of 0.1% resulted but the return to the steady state is accomplished with damped oscillations when the PI controller is used.

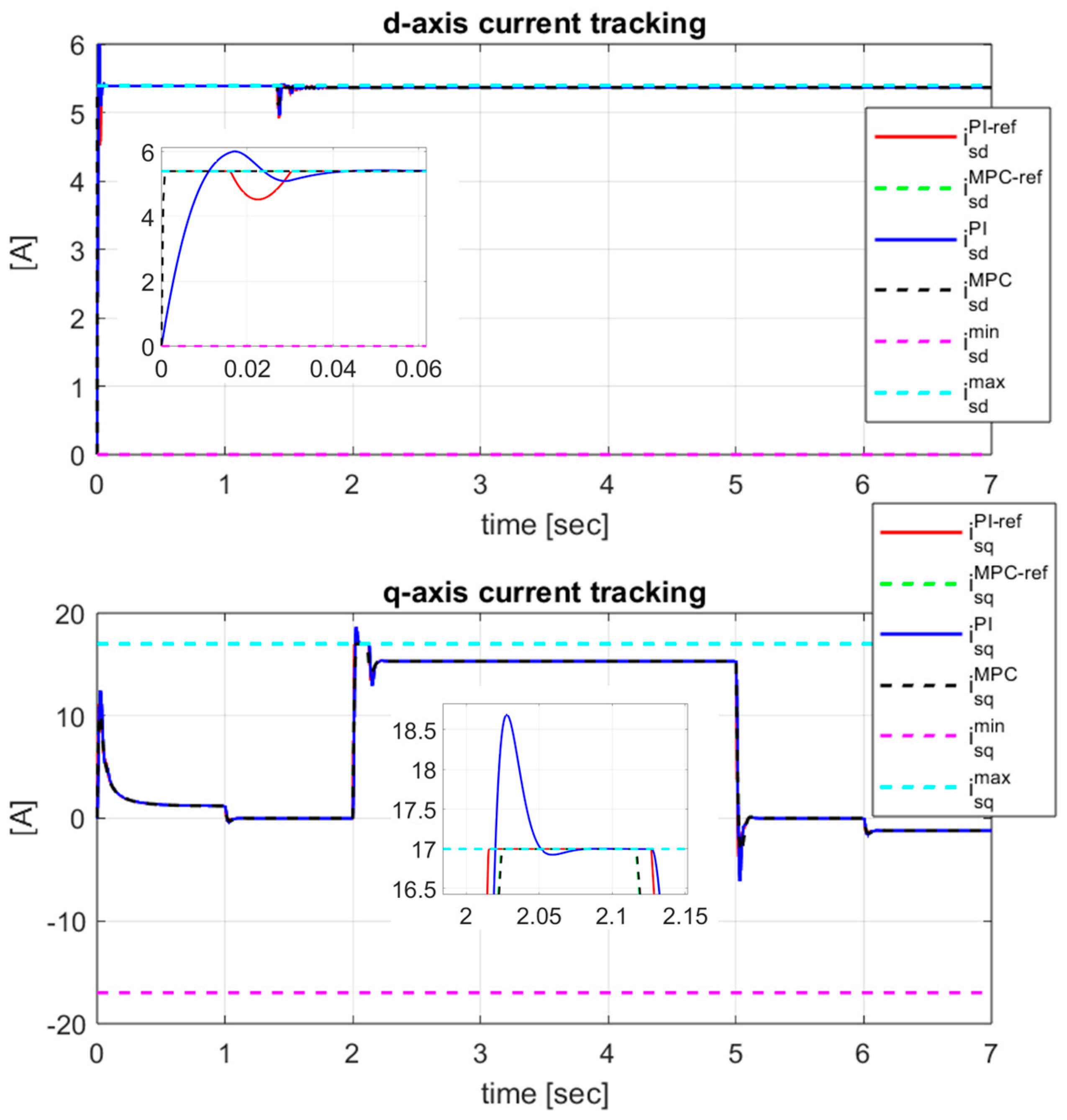

The

currents tracking their references generated by the feedback linearization block are represented in

Figure 6, upper

and lower

, for the two structures with MPCC controller and, respectively, PI. The limits imposed on the two currents are also represented in the figure. Current limiting is conducted in a different way for the two types of controllers. Thus, for the MPCC controller, by imposing the constraints in Equations (59) and (60) in the design phase, the

currents do not violate the limits. For the case of the PI controller, the limitation of the currents was conducted by limiting the references generated by the feedback linearization block. But, because, in the transient state, the currents can have overshoot and exceed the reference, the imposed limit is violated. In the upper figure, at the beginning of the transitory state, the

current obtained with the PI controller exceeds the imposed limit due to an overshoot of 10% and the steady state is reached after a settling time of 0.05 s. The performances obtained with the MPCC controller are superior, the response being without overshoot and the settling time being only 0.001 s. In the lower figure, the current

exceeds the limit imposed when the high load torque is applied due to an overshoot of 9%. The current obtained with the MPCC controller, being limited by the predictive algorithm, has no overshoot. The settling time is also much lower for MPCC compared to PI.

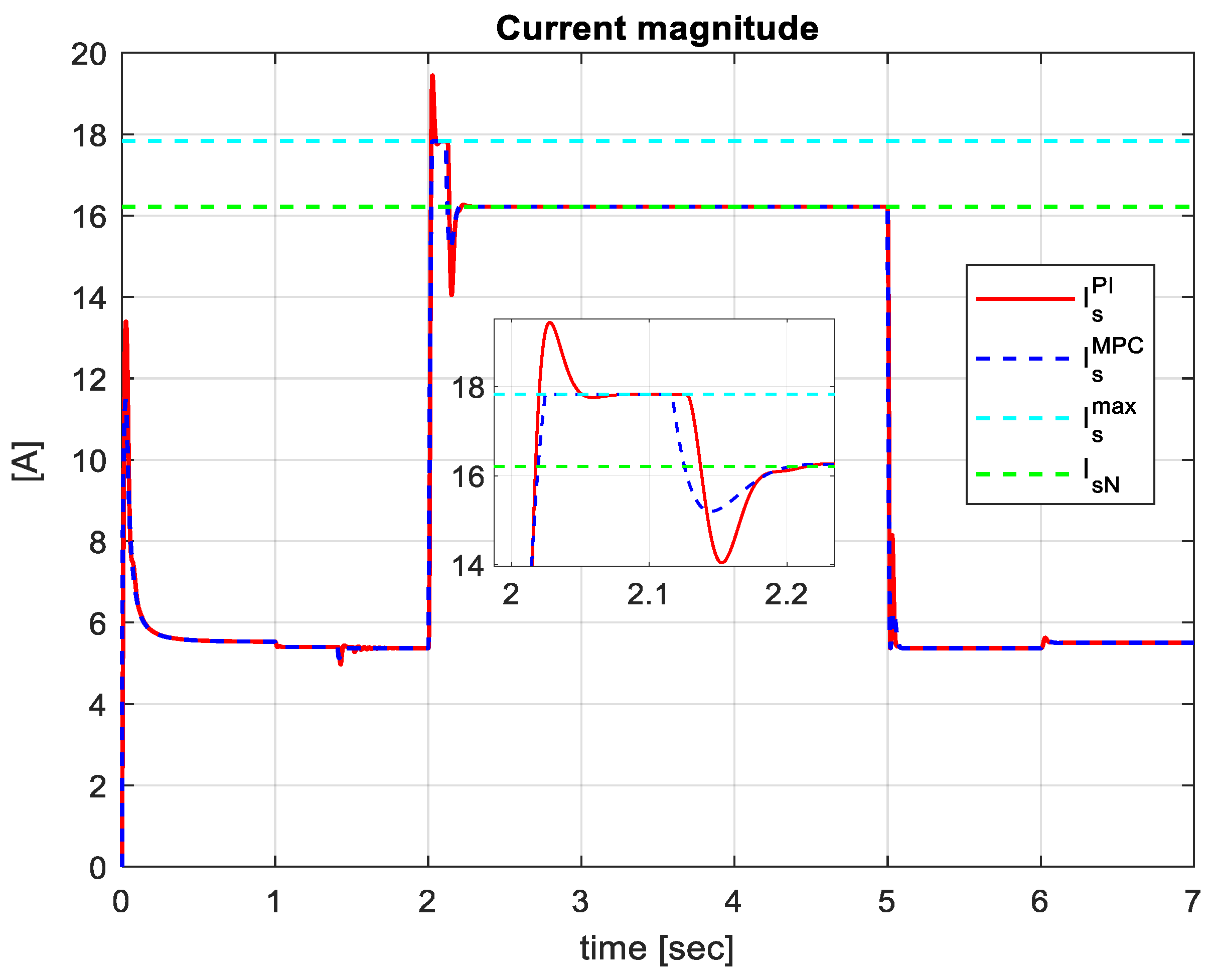

To better illustrate constraint (13) satisfaction regarding the currents,

Figure 7 shows the maximum value of the stator current

and the nominal value

IsN together with the maximum values obtained with MPCC and with PI, respectively:

From the figure, one may notice that, when high load torque is applied at the beginning only while in the steady state, both stator currents are equal to the nominal current: .

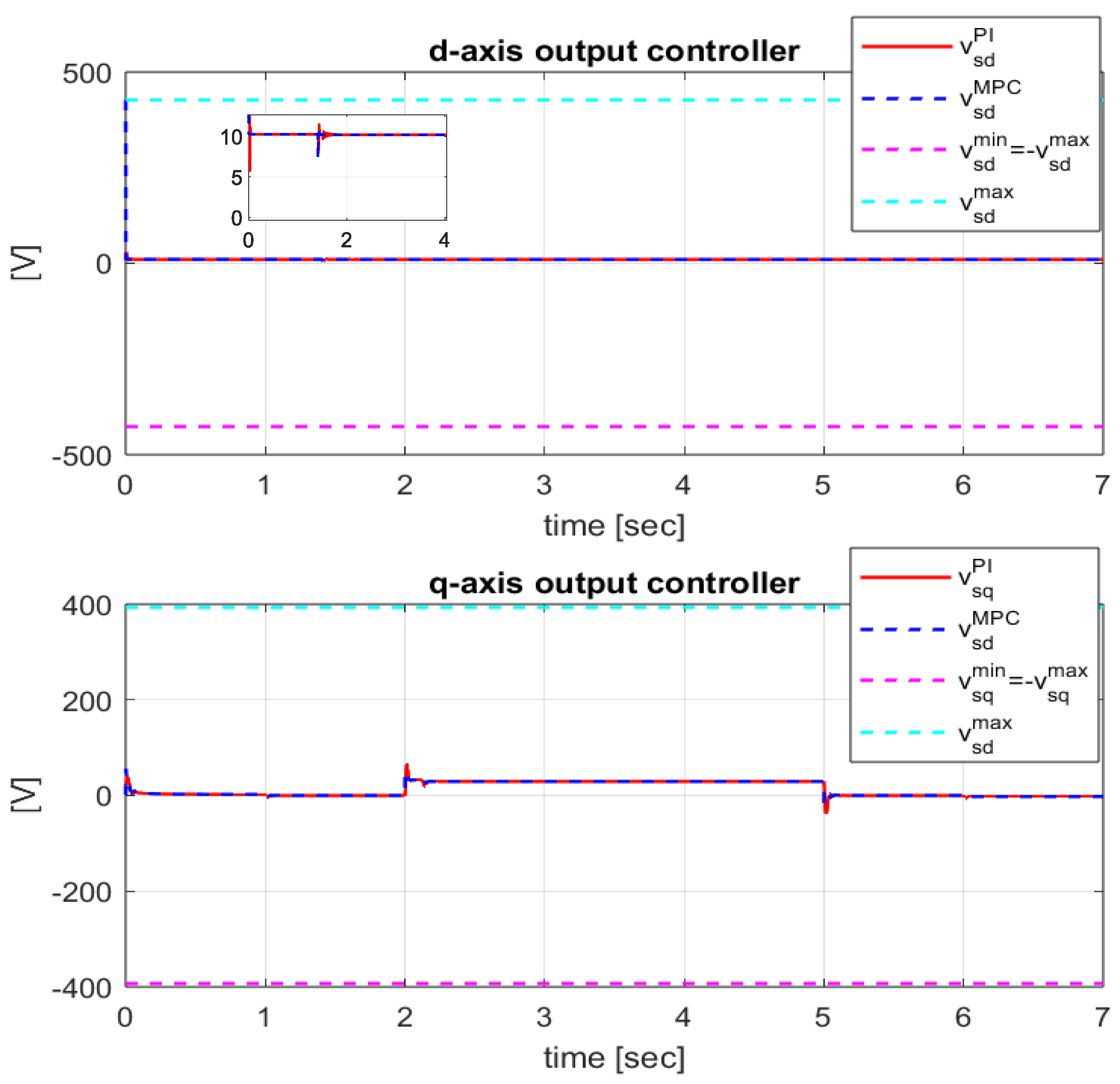

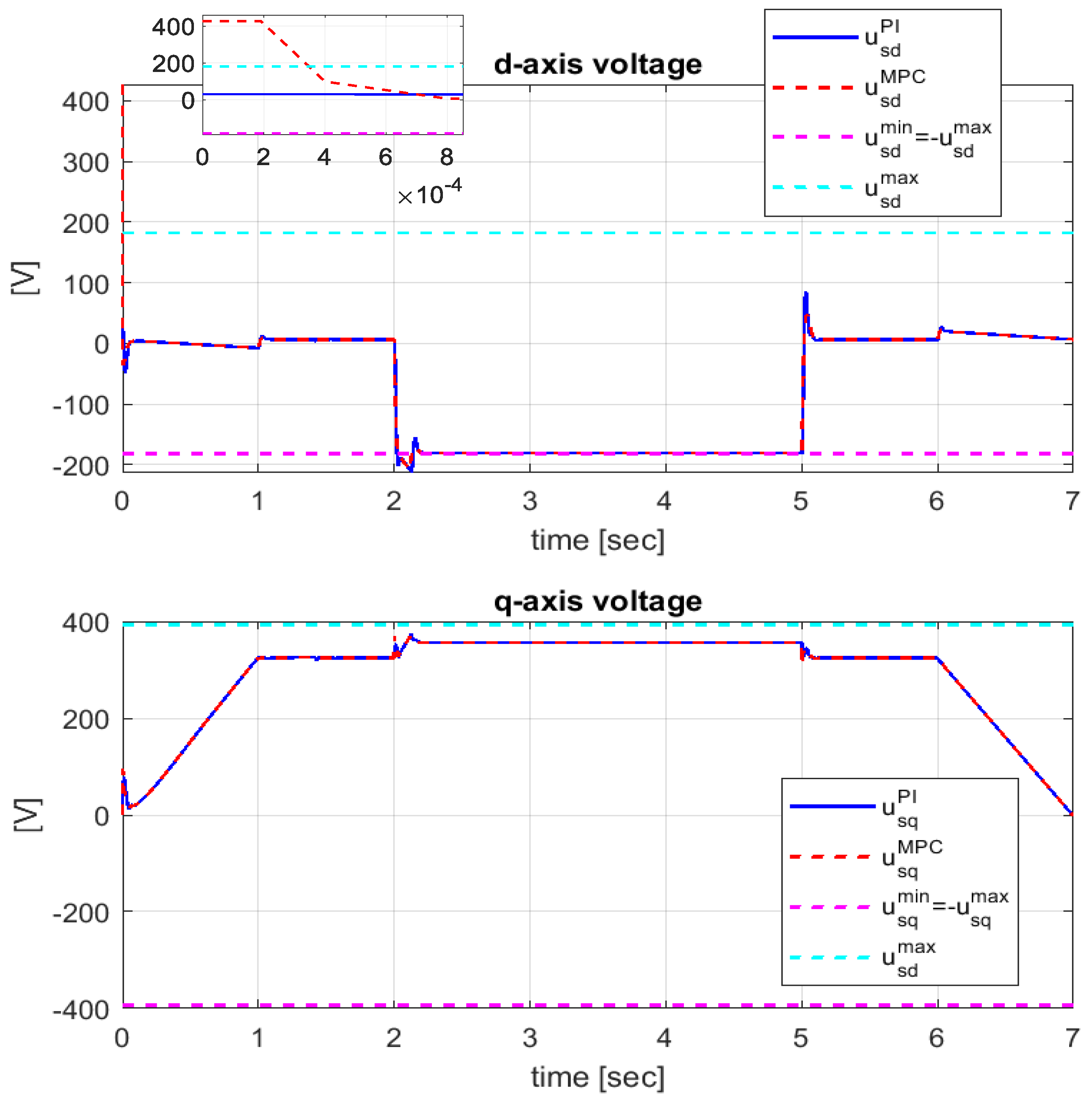

The MPCC and PI current controller outputs,

and

, together with their limits generated by constraints are depicted in

Figure 8, upper

and lower

. Due to the anticipative action of the MPCC controllers, especially on the

d-axis, the dynamics of the current on this axis and implicitly of the flux are a little bit faster as compared to PI.

At the same time, due to the MPCC controller constraints and the anti-windup mechanism of the PI controllers, the imposed limits are not violated. For IM safety, it is important to respect the limits imposed on the input voltages

and

whose dynamics are represented in

Figure 9, upper

d-axis voltage and lower

q-axis voltage. From Equation (9), it follows that the maximum values

are calculated based on the maximum values of the voltages

and of the feedforward components

, respectively. As presented in

Section 3.1.2, the maximum values of the feedforward components are dependent on the nominal value of the rotor flux

and the angular speed

. For the large variations in the flux at the start-up and, respectively, of the angular speed when the high load torque is applied, the flux and angular speed have significantly lower values than the nominal ones and the voltage

slightly exceeds the imposed limits for a short period of time. After the flux and the angular speed transitory states,

returns within the imposed limits. However, even in the transitory state generated at the start-up or when high load torque is applied, the voltage limit (13) is also fulfilled for the MPCC controller, as is seen in

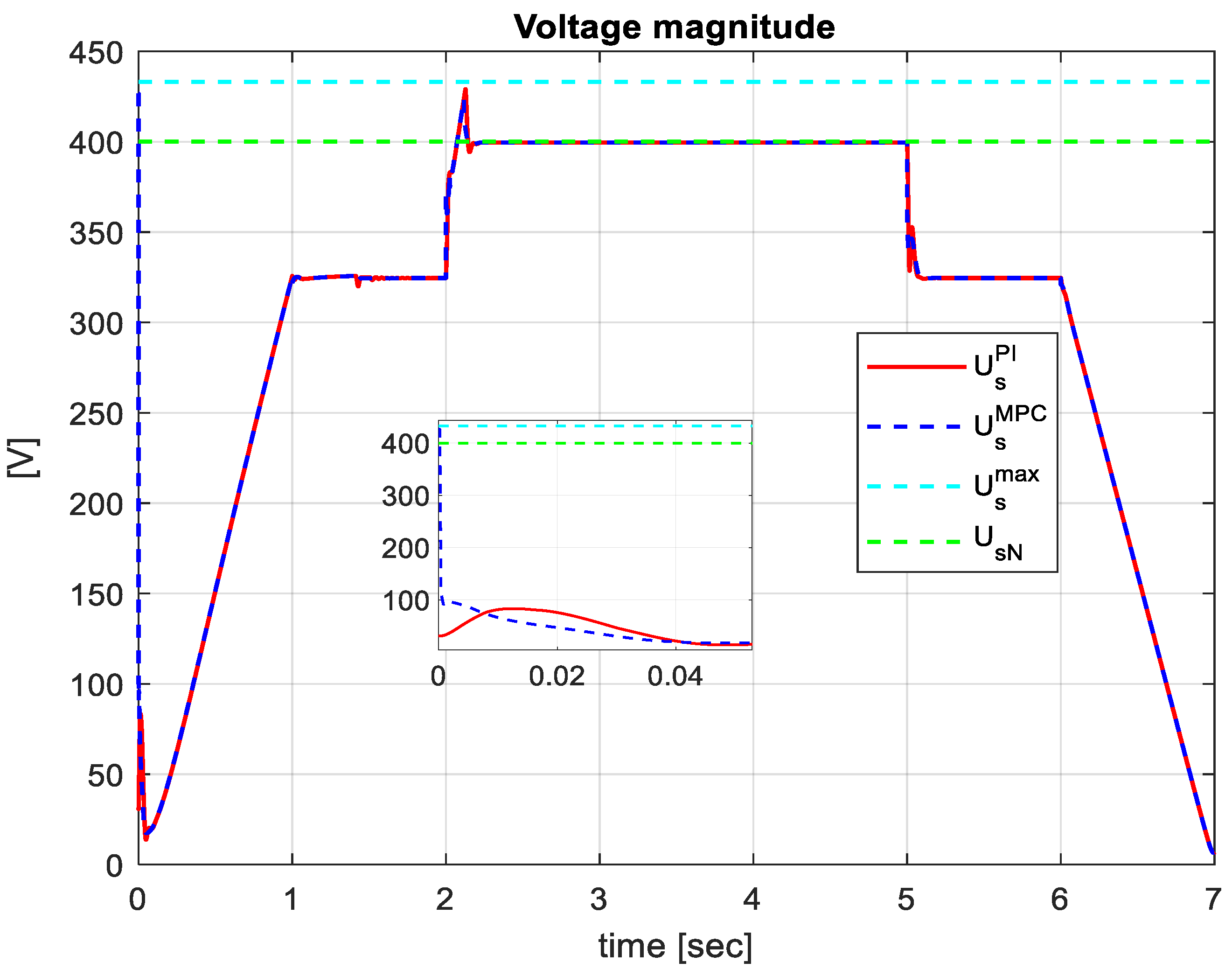

Figure 10, where the stator voltages obtained with MPCC and PI:

are represented in relation to the maximum value

and the nominal one

.

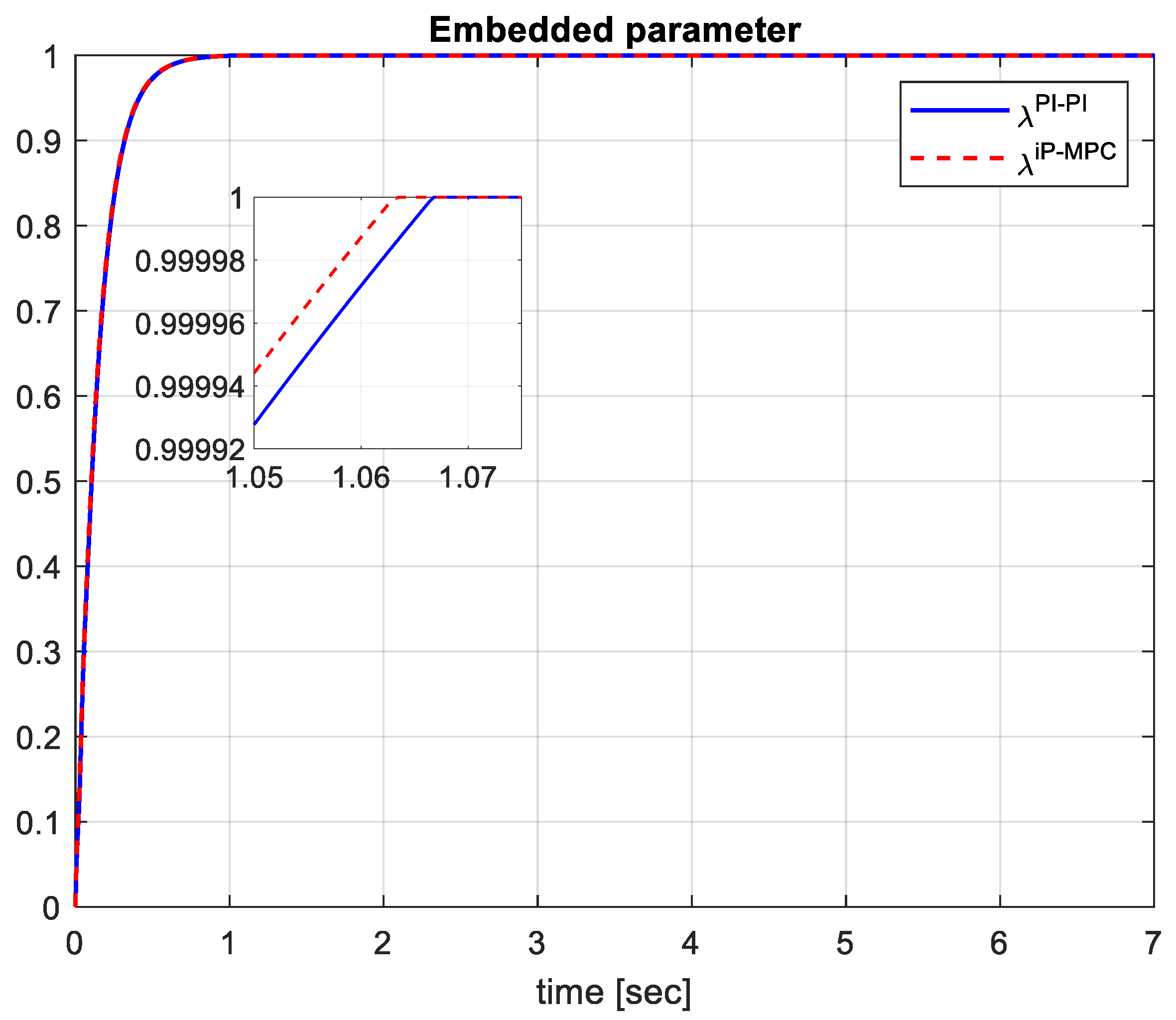

In

Figure 11, the smooth transition of the homotopy continuous time-dependent parameter from

to

is represented, with faster dynamics in the case of the cascade control structure with the advanced MPCC and iP algorithms, compared to the result obtained with conventional PI controllers.

The results obtained in the simulation test shown in

Figure 6,

Figure 7,

Figure 8,

Figure 9 and

Figure 10 highlight the superior performances of the MPCC algorithm compared to PI from the inner loop through much smaller settling times, without overshoot and satisfying the physics constraints. For the outer loop,

Figure 4 and

Figure 5 show that, with the model-free iP controllers, better performances were obtained than with PI through lower values of overshoot and settling time, both for the variation in the reference and the load torque.

To globally evaluate the reference tracking performance by the controlled outputs of the two cascade control structures with the advanced MPCC and model-free iP algorithms, respectively, with the conventional PI controllers, and using a homotopy variant of feedback linearization for the decoupling the rotor flux and speed, the following performance indices are used:

In Equation (65), s is the beginning of the evaluation time, s is the simulation time, and is the total number of samples. The performance indices and are used to evaluate the current tracking results, while the next two indices, and , provide the performance evaluation of the flux and speed responses.

The evaluation results regarding the controlled outputs tracking their references considering the performance indices in Equation (65) are presented in

Table 3.

The numerical values of the performance indices from

Table 3 show that, with the advanced algorithms in the inner and outer loops, lower values are obtained compared to those obtained with the conventional PI controllers and, thus, the improvement of vectorial control of IM with the proposed control strategy is indicated.