Assessing the Quantitative Risk of Urban Hydrogen Refueling Station in Seoul, South Korea, Using SAFETI Model

Abstract

1. Introduction

2. Methodology

2.1. Scenario

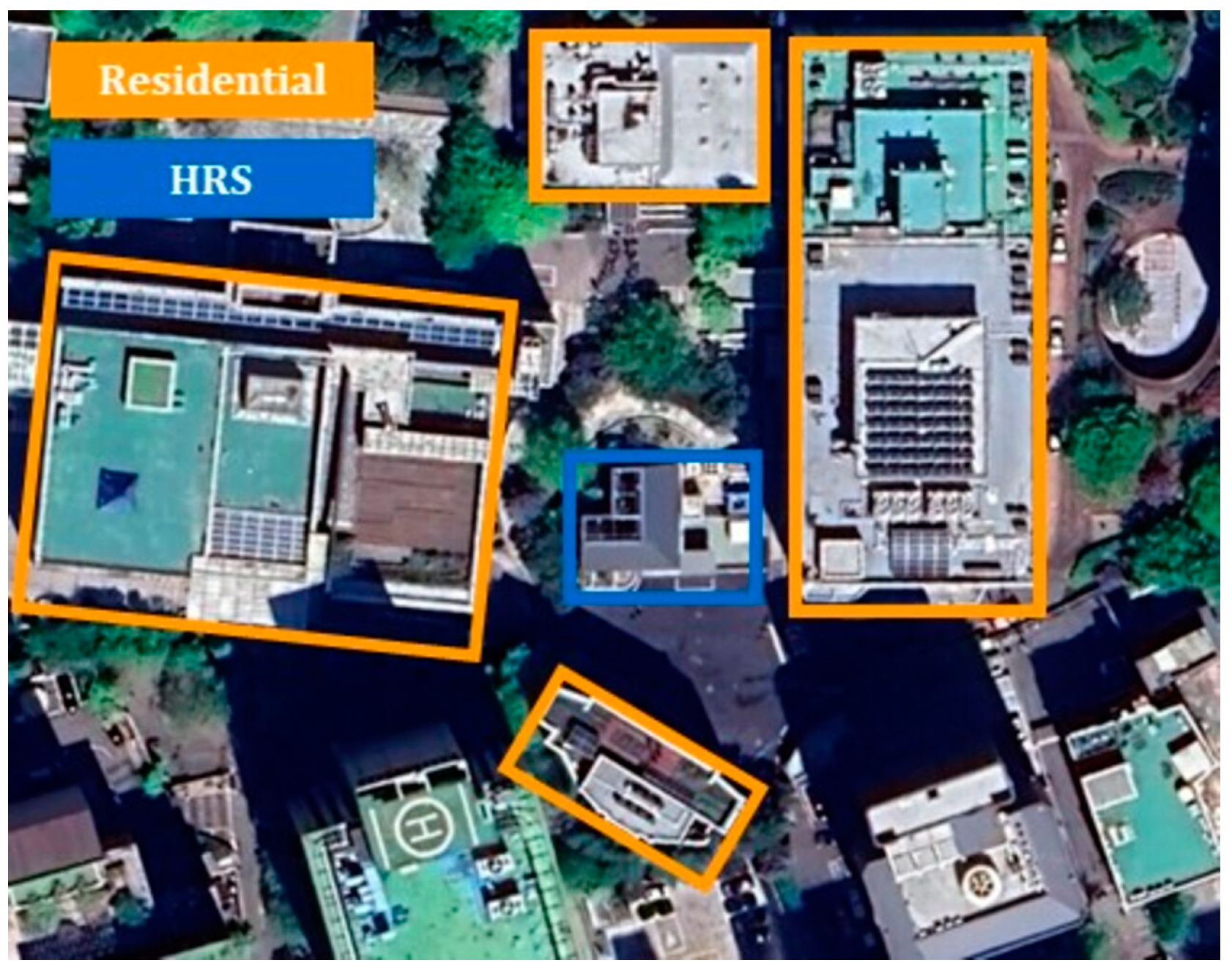

2.1.1. HRS Selection

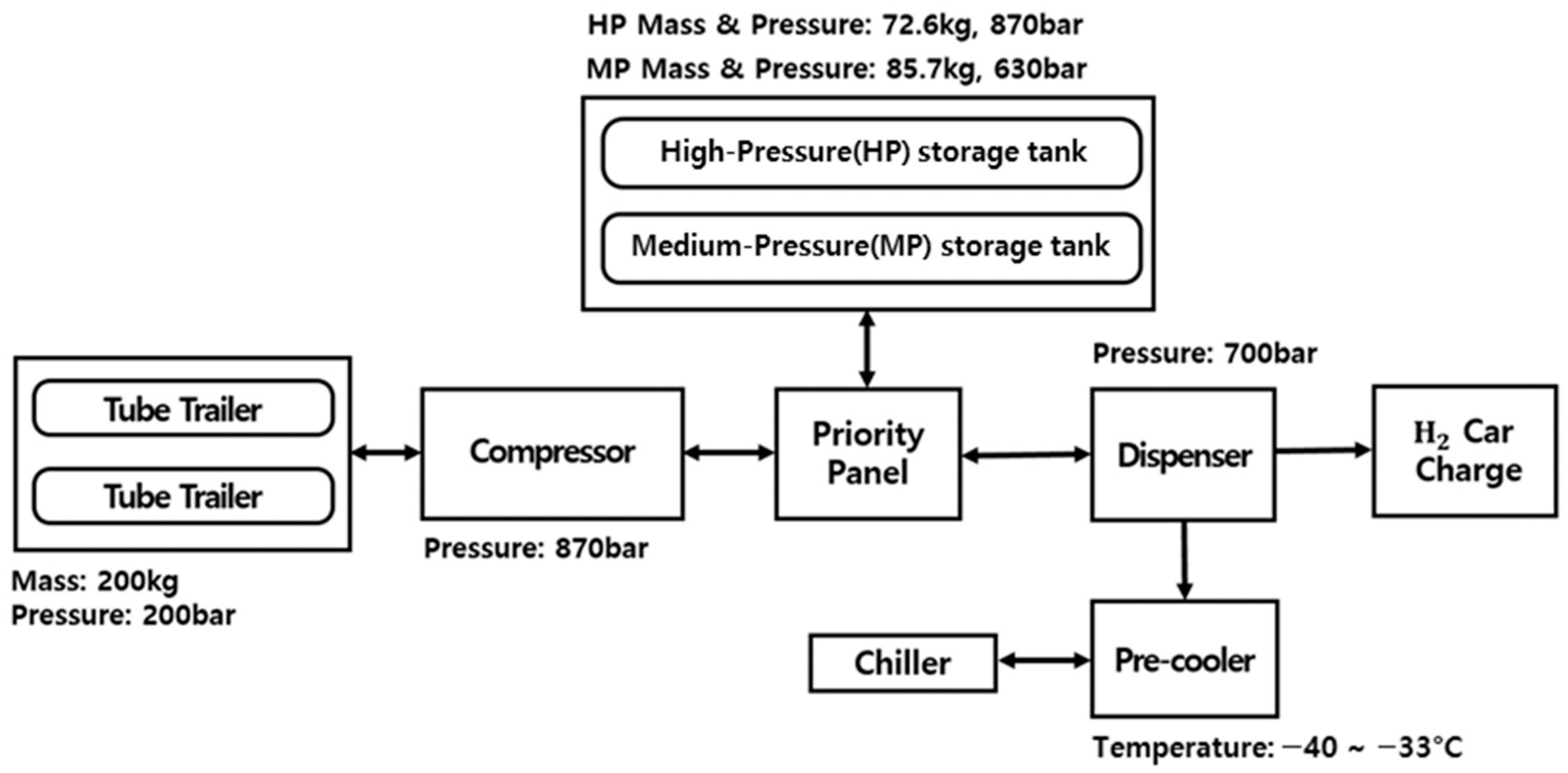

2.1.2. HRS Specification

2.1.3. Weather Condition

2.1.4. Population Density

2.1.5. Mitigation Selection

2.2. QRA Program for HRS

2.2.1. Jet Fire Model

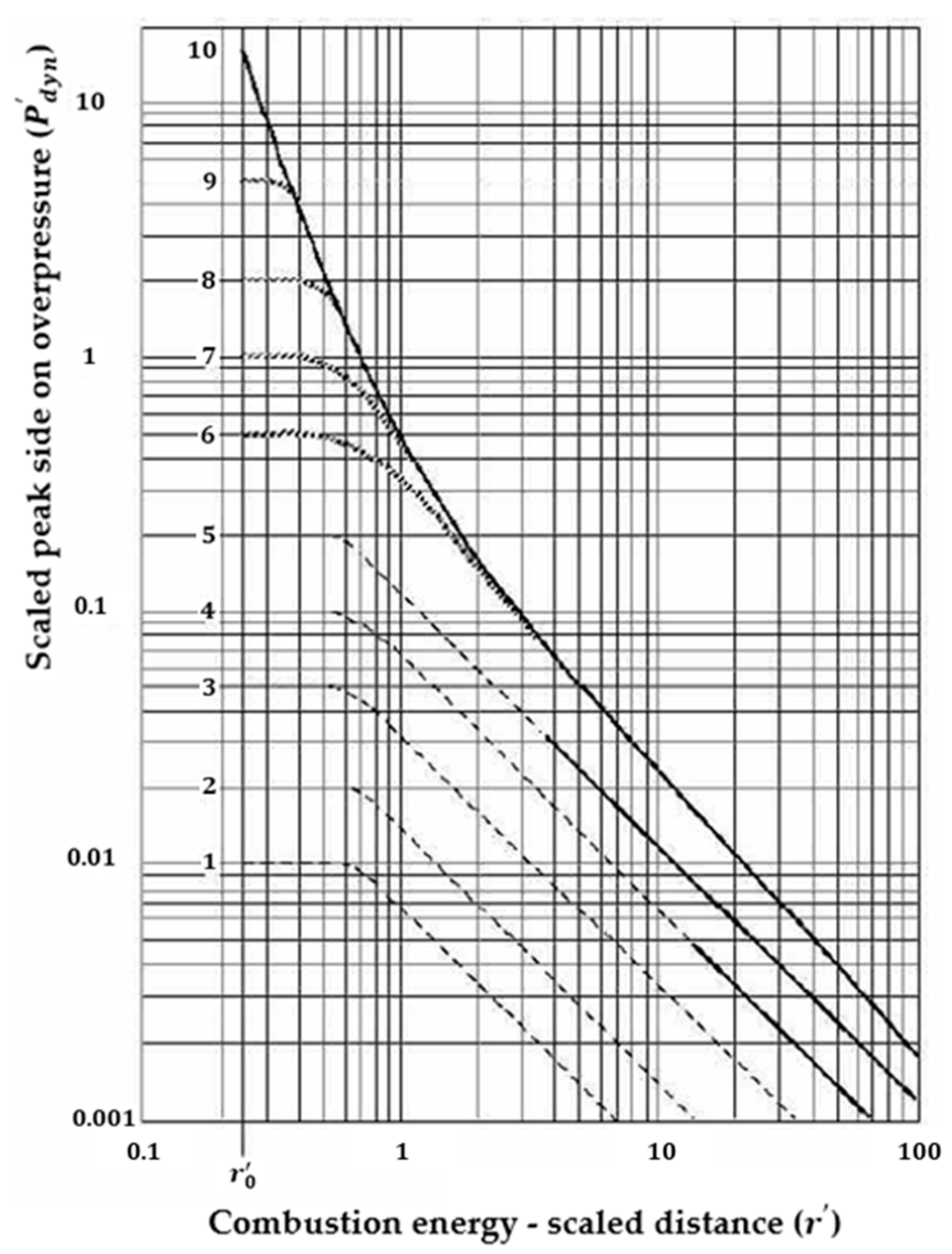

2.2.2. Explosion Model

2.2.3. Fireball Model

2.3. SR Analysis Method

2.3.1. Probit Model

2.3.2. Ignition Probability

3. Results

3.1. CA of Leak Scenario

3.1.1. Results of Jet Fire

3.1.2. Results of VCE

3.2. CA of Catastrophic Rupture Scenario

3.2.1. Results of Fireball

3.2.2. Results of VCE

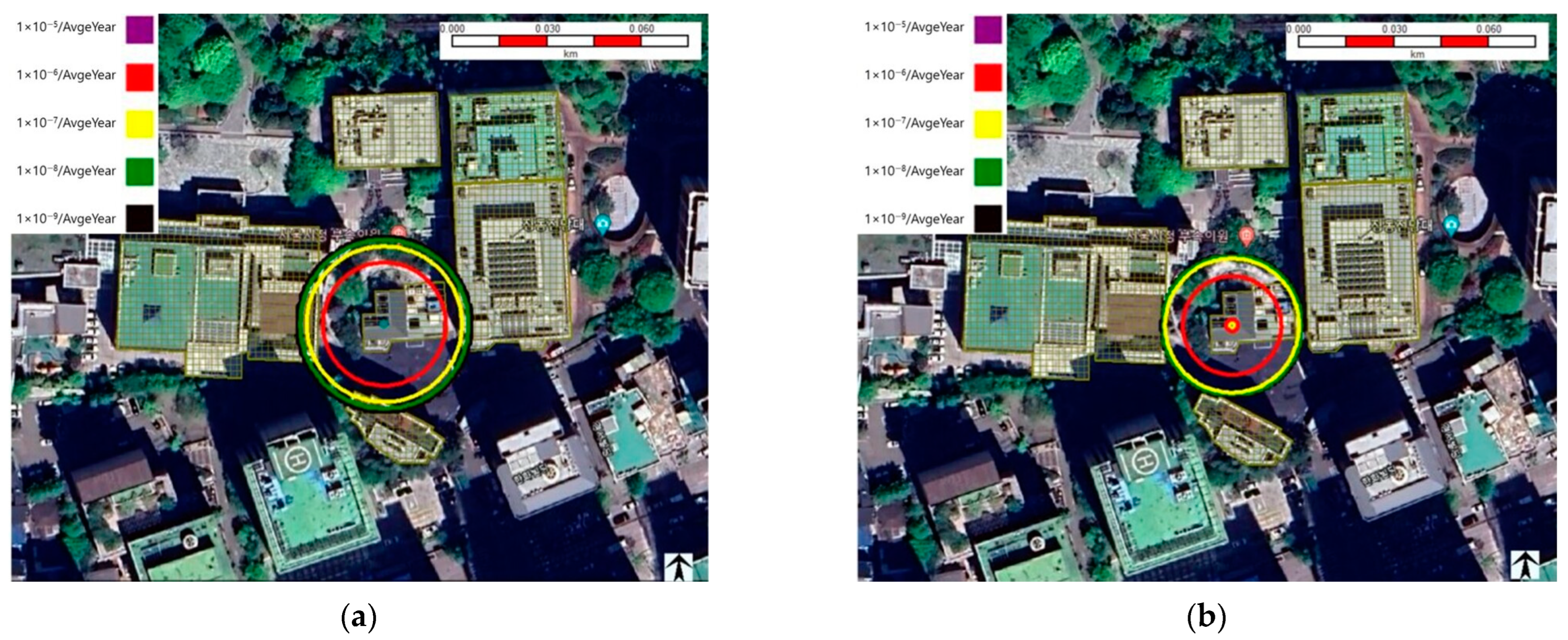

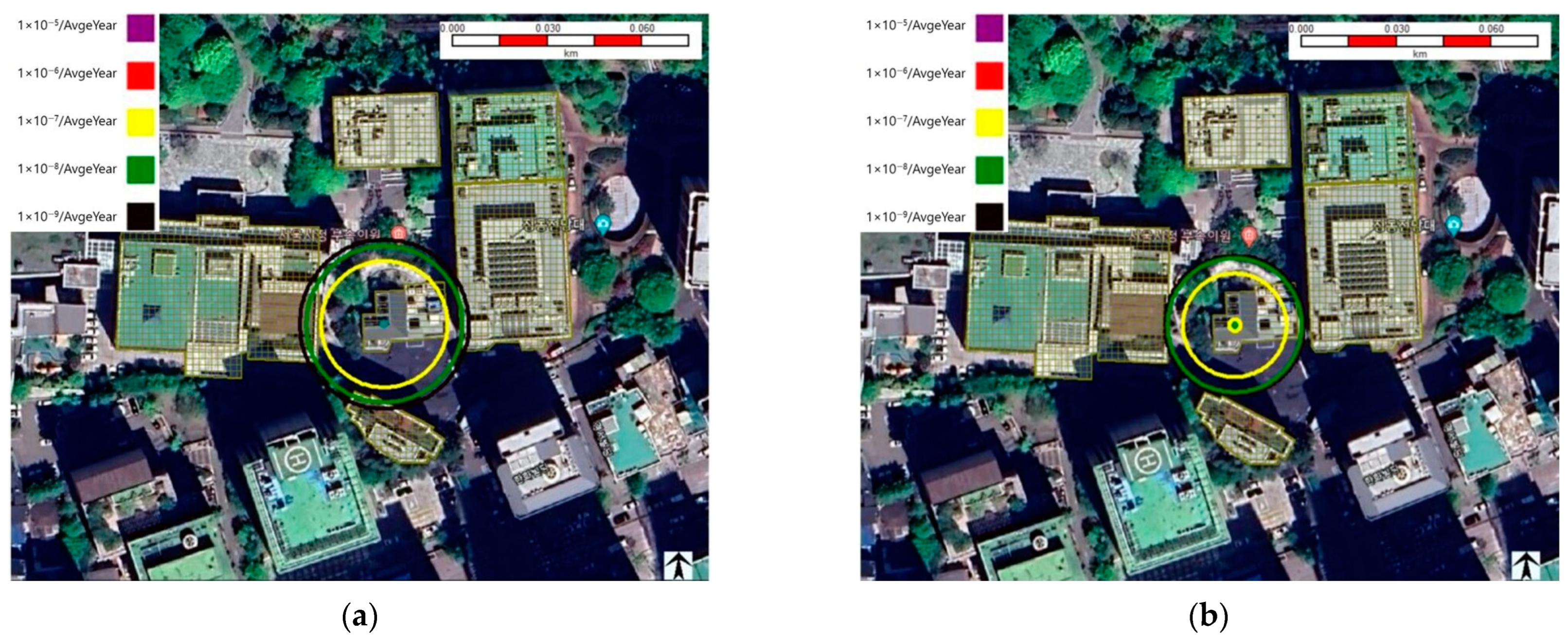

3.3. IR Analysis

3.4. SR of Each Case

4. Conclusions

- In the CA analysis results for the leakage scenarios, there was little difference in the effective range of the jet fire and VCE among the target facilities because of their similar maximum leakage rates. However, for catastrophic rupture scenarios, the effective range was proportional to the mass, with the tube trailer having the largest impact range for fireballs and VCE. In the leakage scenarios, jet fire and VCE occurred, with jet fires occurring in all leak scenarios. The flame length of jet fires was around 20.5 m, and the impact distance up to 4 kW/m2 was around 33.5 m. VCE occurred only in large- and medium-leak scenarios, with the explosion occurring downwind at a distance of 40 m in the large-leak scenario and downwind distances of 20 m and 10 m in the medium-leak scenario. The impact distance of up to 1 psi was approximately 34 m for the large-leak scenario and approximately 7.5 m for the medium-leak scenario. In the catastrophic rupture scenario, fireball and VCE occurred, with fireball diameters of 12.1 m and 12.79 m for the HP storage tank and MP storage tank, respectively, and 16.96 m for the tube trailer. The impact distances up to 4 kW/m2 were approximately 100.24 m and 105.58 m for the HP storage tank and MP storage tank, respectively, and 137.87 m for the tube trailer. VCE occurred downwind at 10 m for both the HP storage tank and MP storage tank, with impact distances of approximately 81.69 m and 86.96 m, respectively. For the tube trailer, the VCE occurred downwind at 20 m, with an impact distance of up to 113.18 m.

- In the IR analysis, regardless of the application of the shutoff valve, the tube trailer had the highest risk in all cases, contributing to over 47% of the total IR. The total IR for cases with and without a single shutoff valve system is recommended as an acceptable risk level within the HSE ALARP criteria. For the double shutoff valve system, the application effectively controlled the IR below the HSE ALARP criteria. The Total IR for the without shutoff valve case was 6.24 × 10−5, with IRs for the HP storage tank, MP storage tank, and tube trailer being 1.67 × 10−5, 1.63 × 10−5, and 2.93 × 10−5, respectively. For the single shutoff valve system case, the Total IR was 6.80 × 10−6, with IRs for the HP storage tank, MP storage tank, and tube trailer being 1.82 × 10−6, 1.78 × 10−6, and 3.20 × 10−6, respectively. In the double shutoff valve system case, the Total IR was 7.48 × 10−7, with IRs for the HP storage tank, MP storage tank, and tube trailer being 2.00 × 10−7, 1.96 × 10−7, and 3.52 × 10−7, respectively. Furthermore, the operator and public IRs were 6.16 × 10−5 and 7.91 × 10−7, respectively, for the without shutoff valve case, 6.75 × 10−6 and 5.21 × 10−8 for the single shutoff valve system case, and 7.43 × 10−7 and 5.73 × 10−9 for the double shutoff valve system case.

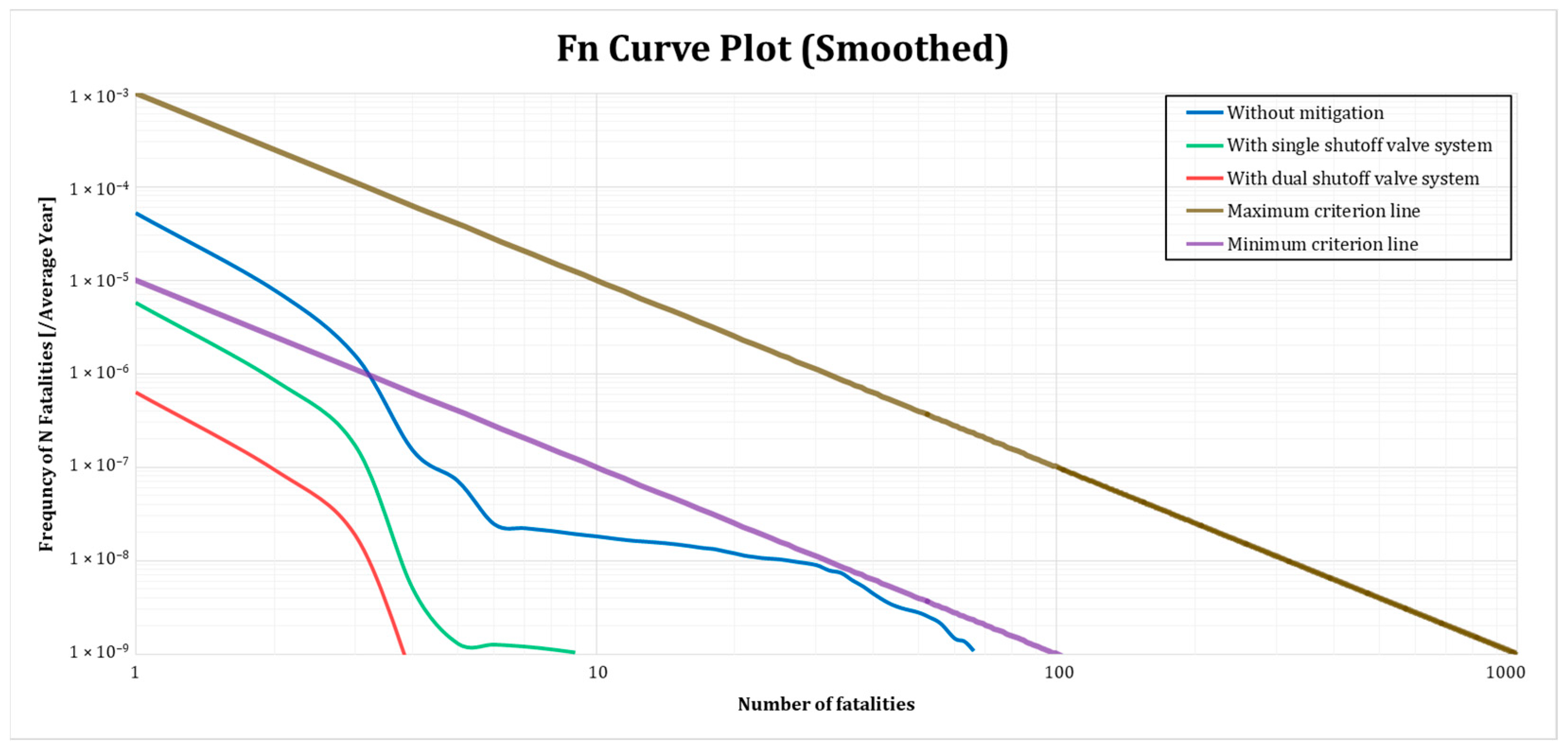

- The SR for cases with and without the shutoff valve fell within the ALARP criteria in the Netherlands. The SR of the double shutoff valve system was effectively controlled below the Netherlands ALARP criteria. This indicates that the application of the double shutoff valve system or safety devices with a mitigation value exceeding 1.21 × 10−2 can successfully manage the risk of urban HRS to a level below the broadly acceptable risk according to the Netherlands ALARP criteria.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Name | Units | Description |

|---|---|---|

| Total surface area of the flame | ||

| m | Flame momentum length | |

| J | Total combustion energy of the explosion | |

| kW/ | Surface emissive power of fireball | |

| - | Radiant heat fraction of horizontal flame | |

| Fatality probability defined by accident scenario | ||

| - | Fraction of the total available heat energy | |

| kJ/kg | Heat of combustion of gas | |

| kJ/kg | Heat of combustion of the fuel | |

| - | Total probability of fatality at a specific location | |

| - | Accident scenario | |

| m | Flame length for leak hole to flame tip | |

| m | Zero wind flame length | |

| m | Flame center line length | |

| m | Flame lift due to buoyancy | |

| kg | Mass of fuel involved in the fireball | |

| kg/s | Mass discharge rate | |

| Pa | Atmospheric pressure | |

| Pa | Dynamic overpressure | |

| - | Frequency of events defined by accident scenario | |

| Pa | Peak side on overpressure | |

| Pa | Scaled peak side on overpressure | |

| - | Richardson number | |

| m | Flame wind buoyancy section length | |

| m | Distance from center of explosion | |

| m | Scaled distance from center of explosion | |

| m | Fireball radius at elapsed time | |

| m | Maximum fireball radius | |

| seconds | Elapsed time | |

| seconds | Fireball duration of dynamic model | |

| seconds | Lift-off time of fireball | |

| kW/ | Surface emissive power of horizontal jet flame | |

| radians | Horizontal lift angle | |

| radians | Vertical lift angle | |

| radians | Angle between the vertical planes cutting the release source and jet flame, respectively, into symmetrical halves |

References

- Amin, M.; Shah, H.H.; Fareed, A.G.; Khan, W.U.; Chyng, E.; Zia, A.; Lee, C. Hydrogen production through renewable and non-renewable energy processes and their impact on climate change. Int. J. Hydrogen Energy 2002, 47, 33112–33134. [Google Scholar] [CrossRef]

- Mazloomi, K.; Gomes, C. Hydrogen as an energy carrier: Prospects and challenges. Renew. Sustain. Energy Rev. 2012, 16, 3024–3033. [Google Scholar] [CrossRef]

- Shi, J.; Chang, Y. Methodological improvements in the risk analysis of an urban hydrogen fueling station. J. Clean. Prod. 2020, 257, 120545. [Google Scholar] [CrossRef]

- Oliveira, A.M.; Beswick, R.R.; Yan, Y. A green hydrogen economy for a renewable energy society. Curr. Opin. Chem. Eng. 2021, 33, 100701. [Google Scholar] [CrossRef]

- Dincer, I. Green methods for hydrogen production. Int. J. Hydrogen Energy 2012, 37, 1954–1971. [Google Scholar] [CrossRef]

- Korea Ministry of Trade Industry and Energy. Hydrogen Economy Roadmap (2019); Korea Ministry of Trade Industry and Energy: Sejong, Republic of Korea, 2019.

- Yoo, B.H.; Wilailak, S.; Bae, S.H.; Gye, H.R.; Lee, C.J. Comparative risk assessment of liquefied and gaseous hydrogen refueling stations. Int. J. Hydrogen Energy 2021, 46, 35511–35524. [Google Scholar] [CrossRef]

- Yang, N.; Deng, J.; Wang, C.; Bai, Z.; Qu, J. High pressure hydrogen leakage diffusion: Research progress. Int. J. Hydrogen Energy 2024, 50, 1029–1046. [Google Scholar] [CrossRef]

- Jeon, B.I.; Kim, S.; Yoon, Y.S.; Jung, S. Quantitative Risk Assessment of Hydrogen Refueling Station in Cheonan City of South Korea. Energies 2023, 16, 7138. [Google Scholar] [CrossRef]

- SAND2009-0874; Analyses to Support Development of Risk-Informed Separation Distances for Hydrogen Codes and Standards. Sandia National Laboratories: Albuquerque, NM, USA, 2009.

- Korea Ministry of Trade, Industry and Energy. Enforcement Regulation of High-Pressure Gas Safety Management Act (2024); Korea Ministry of Trade, Industry and Energy: Sejong, Republic of Korea, 2022.

- American Petroleum Institute. API Pub 581-2016 Risk-Based Inspection Technology; API Standards: New York, NY, USA, 2016. [Google Scholar]

- Kwak, J.; Lee, H.; Park, S.; Park, J.; Jung, S. Risk Assessment of a Hydrogen Refueling Station in an Urban Area. Energies 2023, 16, 3963. [Google Scholar] [CrossRef]

- Sun, K.; Pan, X.; Li, Z.; Ma, J. Risk analysis on mobile hydrogen refueling stations in Shanghai. Int. J. Hydrogen Energy 2014, 39, 20411–20419. [Google Scholar] [CrossRef]

- Gye, H.R.; Seo, S.K.; Bach, Q.V.; Ha, D.; Lee, C.J. Quantitative risk assessment of an urban hydrogen refueling station. Int. J. Hydrogen Energy 2019, 44, 1288–1298. [Google Scholar] [CrossRef]

- Kikukawa, S.; Yamaga, F.; Mitsuhashi, H. Risk assessment of Hydrogen fueling stations for 70áMPa FCVs. Int. J. Hydrogen Energy 2008, 33, 7129–7136. [Google Scholar] [CrossRef]

- Suzuki, T.; Shiota, K.; Izato, Y.; Komori, M.; Sato, K.; Takai, Y.; Miyake, A. Quantitative risk assessment using a Japanese hydrogen refueling station model. Int. J. Hydrogen Energy 2021, 46, 8329–8343. [Google Scholar] [CrossRef]

- Tsunemi, K.; Kihara, T.; Kato, E.; Kawamoto, A.; Saburi, T. Quantitative risk assessment of the interior of a hydrogen refueling station considering safety barrier systems. Int. J. Hydrogen Energy 2019, 44, 23522–23531. [Google Scholar] [CrossRef]

- Park, B.; Kim, Y.; Lee, K.; Paik, S.; Kang, C. Risk assessment method combining independent protection layers (IPL) of layer of protection analysis (LOPA) and RISKCURVES software: Case study of hydrogen refueling stations in Urban Areas. Energies 2021, 14, 4043. [Google Scholar] [CrossRef]

- Li, Z.; Pan, X.; Ma, J. Quantitative risk assessment on 2010 Expo hydrogen station. Int. J. Hydrogen Energy 2011, 36, 4079–4086. [Google Scholar]

- Seoul Metropolitan City Administrative and Local Autonomy Committee. Report on the Evaluation of the Second Supplementary Shared Property Management Plan; Seoul Metropolitan City Administrative and Local Autonomy Committee: Seoul, Republic of Korea, 2021. [Google Scholar]

- Seoul Energy Corporation. 2022–2023 Seosomun Complex Hydrogen Charging Station Hydrogen Charging Facility Operation Service Task Order; Seoul Energy Corporation: Seoul, Republic of Korea, 2022. [Google Scholar]

- National Institute for Public Health and the Environment (RVIM). Guidelines for Quantitative Risk Assessment, Purple Book (CPR 18E); RVIM: Karnataka, India, 2001; pp. 42–118.

- National Institute of Chemical Safety (NICS). Chemical Accident Prevention and Management Plan Preparation Manual (BC2021-1); NICS: Cheongju, Republic of Korea, 2021; pp. 69–71. [Google Scholar]

- Statistics Korea. The Organizational Chart and Employee Work Information of Seoul City. Available online: https://data.seoul.go.kr/dataList/OA-2277/S/1/datasetView.do;jse-sionid=C5D98908B5CA75CD39E423D62EEFD3CA.new_portal-svr-21 (accessed on 13 October 2023).

- Suzuki, T.; Kawatsu, K.; Shiota, K.; Izato, Y.I.; Komori, M.; Sato, K.; Miyake, A. Quantitative risk assessment of a hydrogen refueling station by using a dynamic physical model based on multi-physics system-level modeling. Int. J. Hydrogen Energy 2021, 46, 38923–38933. [Google Scholar] [CrossRef]

- Lees, F. Lee’s Prevention in the Process Industries: Hazard Identification, Assessment and Control; Butterworth-Hrinemann: Oxford, UK, 2012. [Google Scholar]

- New Energy and Industrial Technology Development Organization (NEDO). FY 2005–2009 Results Report: Studies on Fundamental Properties of Materials for Hydrogen Service, Study of Safety Technology Related to Hydrogen Infrastructure; New Energy and Industrial Technology Development Organization: Tokyo, Japan, 2010. [Google Scholar]

- Japan Chemical Industry Association (JCIA). Guidelines for Chemical Substance Risk Assessment; Japan Chemical Industry Association (JCIA): Tokyo, Japan, 2005. [Google Scholar]

- Miller, D. New model for predicting thermal radiation from flares and high pressure jet fires for hydrogen and syngas. Process Saf. Prog. 2017, 36, 237–251. [Google Scholar] [CrossRef]

- Oke, A.O. JFSH (Jet Fire) Theory Document; DNV Report; DNV: Oslo, Norway, 2005. [Google Scholar]

- Mercx, W.P.M.; Van den Berg, A.C. Methods for the Calculation of Physical Effects (the Yellow Book); TNO: The Hague, The Netherlands, 1997. [Google Scholar]

- Martinsen, W.E.; Marx, J.D. An improved model for the prediction of radiant heat from fireballs. In Proceedings of the 1999 International Conference and Workshop on Modeling Consequences of Accidental Releases of Hazardous Materials, San Francisco, CA, USA, 28 September–1 October 1999. [Google Scholar]

- Chen, C.; Reniers, G.; Khakzad, N. A dynamic multi-agent approach for modeling the evolution of multi-hazard accident scenarios in chemical plants. Reliab. Eng. Syst. Saf. 2021, 207, 107349. [Google Scholar] [CrossRef]

- Emerson; Worthington, D.; Witlox, H.; Vatier, D. MPACT Risk Model Theory Document; DNV Report; DNV: Oslo, Norway, 1982. [Google Scholar]

- Health and Safety Executive (HSE). Methods of Approximation and Determination of Human Vulnerability for Offshore Major Accident Hazard Assessment; HSE: London, UK, 2006. [Google Scholar]

- Worthington, D.; Vatier, D. Vulnerability Model Theory Document; DNV Report; DNV: Oslo, Norway, 2004. [Google Scholar]

- World Bank. Techniques for Assessing Industrial Harzard (WTP55); World Bank: Washington, DC, USA, 1988. [Google Scholar]

- Health and Safety Executive, Fire Effects. Available online: https://www.hse.gov.uk/offshore/strategy/effects.htm (accessed on 24 July 2023).

- Centers for Disease Control and Prevention (CDC). Effects of Blast Pressure on Structures and the Human Body. Available online: https://www.cdc.gov/niosh/docket/archive/pdfs/NIOSH-125/125-ExplosionsandRefugeChambers.pdf (accessed on 24 May 2023).

- Dormohammadi, A.; Zarei, E.; Delkhosh, M.B.; Gholami, A. Risk analysis by means of a QRA approach on a LPG cylinder filling installation. Process Saf. Prog. 2014, 33, 77–84. [Google Scholar] [CrossRef]

- Ale, B.J.M.; Hartford, D.N.D.; Slater, D. ALARP and CBA all in the same game. Saf. Sci. 2015, 76, 90–100. [Google Scholar] [CrossRef]

- Melchers, R.E. On the ALARP approach to risk management. Reliab. Eng. Syst. Saf. 2001, 71, 201–208. [Google Scholar] [CrossRef]

- Health and Safety Executive (HSE). Guidance on ALARP Decisions in COMAH, Ver. 3. Available online: https://www.hse.gov.uk/foi/internalops/hid_circs/permissioning/spc_perm_37/ (accessed on 24 July 2023).

- Pasman, H.; Reniers, G. Past, present and future of Quantitative Risk Assessment (QRA) and the incentive it obtained from Land-Use Planning (LUP). J. Loss Prev. Process Ind. 2014, 28, 2–9. [Google Scholar] [CrossRef]

- Frank, W.; Jones, D. Choosing appropriate quantitative safety risk criteria: Applications from the new CCPS guidelines. Process Saf. Prog. 2010, 29, 293–298. [Google Scholar] [CrossRef]

- Parvini, M.; Kordrostami, A. Consequence modeling of explosion at Azad-Shahr CNG refueling station. J. Loss Prev. Process Ind. 2014, 30, 47–54. [Google Scholar] [CrossRef]

- DNV. SAFETI Manage Hazards for Safe and Efficient Operations, Safeti Flyer; DNV: Oslo, Norway, 2023. [Google Scholar]

| Facility | Operating Pressure (bar) | Operating Temperature (°C) | Storage Mass (kg) |

|---|---|---|---|

| High-pressure storage tank | 870 | 21 | 72.6 |

| Medium-pressure storage tank | 630 | 21 | 85.7 |

| Tube trailer | 200 | 21 | 200 |

| Facility | Accident Scenario | Leak Diameter (mm) | Leakage Frequency ) |

|---|---|---|---|

| High-pressure storage tank | Catastrophic rupture | - | 5.00 × 10−7 |

| Large leak | 7.16 | 1.02 × 10−4 | |

| Medium leak | 2.26 | 2.09 × 10−4 | |

| Small leak | 0.72 | 1.23 × 10−3 | |

| Medium-pressure storage tank | Catastrophic rupture | - | 5.00 × 10−7 |

| Large leak | 7.92 | 1.02 × 10−4 | |

| Medium leak | 2.50 | 2.09 × 10−4 | |

| Small leak | 0.79 | 1.23 × 10−3 | |

| Tube trailer | Catastrophic rupture | - | 5.00 × 10−7 |

| Large leak | 12.70 | 1.80 × 10−4 | |

| Medium leak | 4.02 | 3.21 × 10−4 | |

| Small leak | 1.27 | 4.14 × 10−4 |

| Facility | Accident Scenario | Leak Diameter (mm) | Leakage Frequency ) |

|---|---|---|---|

| Pressurized vessel | Catastrophic rupture | over 152.4 | 6.00 × 10−7 |

| Large leak | 101.6 | 2.00 × 10−6 | |

| Medium leak | 25.4 | 2.00 × 10−5 | |

| Small leak | 6.4 | 8.00 × 10−6 | |

| Atmospheric tank | Catastrophic rupture | over 152.4 | 1.00 × 10−7 |

| Large leak | 101.6 | 5.00 × 10−6 | |

| Medium leak | 25.4 | 2.50 × 10−5 | |

| Small leak | 6.4 | 7.00 × 10−5 | |

| Pipe (8 to 16 inch) | Catastrophic rupture | over 152.4 | 6.00 × 10−7 |

| Large leak | 101.6 | 2.00 × 10−6 | |

| Medium leak | 25.4 | 2.00 × 10−5 | |

| Small leak | 6.4 | 8.00 × 10−6 |

| Weather Conditions | Wind Speed | Atmospheric Temperature | Atmospheric Stability | Humidity |

|---|---|---|---|---|

| Worst case | 1.5 m/s | 25 °C | F | 50% |

| Buildings | Population Category | Day Population | Night Population | Indoor Fraction |

|---|---|---|---|---|

| Seosomun HRS | Operator | 2 (Resident) 2 (Non-resident) | 2 (Resident) | 0.9 |

| Seosomun Government Complex 2 | Public | 95 | 0 | 0.9 |

| Seosomun Annex Building 5 | 133 | 0 | 0.9 | |

| Parliamentary Hall | 86 | 0 | 0.9 | |

| Seosomun Welfare | 195 | 0 | 0.9 | |

| Seoul Museum of Art | Public | 175 (1746/10 h *) | 0 | 0.9 |

| Total | - | 688 | 2 | - |

| Time | Time Period | Fraction |

|---|---|---|

| Day | 09:00~20:00 (11 h) | 0.4583 |

| Night | 20:00~09:00 (12 h) | 0.5417 |

| Valve | Failure Probability () | Operating Time (Seconds) |

|---|---|---|

| Check valve | 0.0009 | 0 |

| Excess flow valve | 0.0009 | 0.1 |

| Shutoff valve | 0.11 | 30 |

| Radiation Heat (kW/m2) | Damage on Humans |

|---|---|

| 4 | Pain and swelling occur if not protected for more than 20 s |

| 12.5 | Fatalities occur within minutes |

| 37.5 | Instant death |

| Overpressure (psi) | Damage on Humans |

|---|---|

| 1 | Ruptured eardrum |

| 3 | Physical injury may occur |

| 5 | Risk of injury and even a possibility of death |

| Release Rate (kg/s) | Ignition Probability | |

|---|---|---|

| Immediate | Delayed | |

| <0.125 | 0.008 | 0.004 |

| 0.125−6.25 | 0.053 | 0.027 |

| >6.25 | 0.230 | 0.120 |

| Facility | Peak Release Rate (kg/s) | ||

|---|---|---|---|

| Large Leak | Medium Leak | Small Leak | |

| High-pressure storage tank | 1.63 | 0.16 | 0.02 |

| Medium-pressure storage tank | 1.50 | 0.15 | 0.02 |

| Tube trailer | 1.32 | 0.13 | 0.01 |

| Facility | Leak Size | Flame Length (m) | Distance Downwind to Radiation Heat (kW/m2) | ||

|---|---|---|---|---|---|

| 4 | 12.5 | 37.5 | |||

| High-pressure storage tank | Large | 21.07 | 34.28 | 25.95 | 21.28 |

| Medium | 7.32 | 11.19 | 8.52 | 6.81 | |

| Small | 2.53 | 3.28 | - | - | |

| Medium-pressure storage tank | Large | 20.53 | 33.57 | 25.34 | 20.74 |

| Medium | 7.14 | 10.92 | 8.30 | 6.61 | |

| Small | 2.45 | 3.16 | - | - | |

| Tube trailer | Large | 19.88 | 33.22 | 24.97 | 20.29 |

| Medium | 6.95 | 10.85 | 8.19 | 6.49 | |

| Small | 2.39 | 3.15 | - | - | |

| Facility | Leak Size | Explosion Center (m) | Diameter of Overpressure (psi) | ||

|---|---|---|---|---|---|

| 1 | 3 | 5 | |||

| High-pressure storage tank | Large | 40 | 35.55 | 15.24 | 11.05 |

| Medium | 20 | 8.03 | 3.44 | 2.50 | |

| Medium-pressure storage tank | Large | 40 | 34.99 | 15.00 | 10.88 |

| Medium | 10 | 7.50 | 3.21 | 2.33 | |

| Tube trailer | Large | 40 | 33.36 | 14.30 | 10.37 |

| Medium | 10 | 7.25 | 3.11 | 2.25 | |

| Facility | Fireball Diameter (m) | Radiation Heat | |

|---|---|---|---|

| Level (kW/m2) | Diameter (m) | ||

| High-pressure storage tank | 12.10 | 4 | 100.24 |

| 12.5 | 57.58 | ||

| 37.5 | 33.02 | ||

| Medium-pressure storage tank | 12.79 | 4 | 105.58 |

| 12.5 | 60.91 | ||

| 37.5 | 34.80 | ||

| Tube trailer | 16.96 | 4 | 137.87 |

| 12.5 | 80.37 | ||

| 37.5 | 45.48 | ||

| Facility | Explosion Center (m) | Overpressure | |

|---|---|---|---|

| Level (psi) | Diameter (m) | ||

| High-pressure storage tank | 10 | 1 | 81.69 |

| 3 | 35.20 | ||

| 5 | 25.33 | ||

| Medium-pressure storage tank | 10 | 1 | 86.96 |

| 3 | 37.24 | ||

| 5 | 29.85 | ||

| Tube trailer | 20 | 1 | 113.18 |

| 3 | 47.13 | ||

| 5 | 34.38 | ||

| Case | Facility | ) | Percentage (%) |

|---|---|---|---|

| Without shutoff valve | HP Storage tank | 1.67 × 10−5 | 26.72 |

| MP Storage tank | 1.63 × 10−5 | 26.17 | |

| Tube trailer | 2.93 × 10−5 | 47.11 | |

| Total | 6.24 × 10−5 | 100.00 | |

| With single shutoff valve | HP Storage tank | 1.82 × 10−6 | 26.77 |

| MP Storage tank | 1.78 × 10−6 | 26.13 | |

| Tube trailer | 3.20 × 10−6 | 47.10 | |

| Total | 6.80 × 10−6 | 100.00 | |

| With dual shutoff valve | HP Storage tank | 2.00 × 10−7 | 26.77 |

| MP Storage tank | 1.96 × 10−7 | 26.13 | |

| Tube trailer | 3.52 × 10−7 | 47.10 | |

| Total | 7.48 × 10−7 | 100.00 |

| Case | Group | Total Risk Integral |

|---|---|---|

| Without shutoff valve | Operator | 6.16 × 10−5 |

| Public | 7.91 × 10−7 | |

| With single shutoff valve | Operator | 6.75 × 10−6 |

| Public | 5.21 × 10−8 | |

| With dual shutoff valve | Operator | 7.43 × 10−7 |

| Public | 5.73 × 10−9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kwak, H.; Kim, M.; Min, M.; Park, B.; Jung, S. Assessing the Quantitative Risk of Urban Hydrogen Refueling Station in Seoul, South Korea, Using SAFETI Model. Energies 2024, 17, 867. https://doi.org/10.3390/en17040867

Kwak H, Kim M, Min M, Park B, Jung S. Assessing the Quantitative Risk of Urban Hydrogen Refueling Station in Seoul, South Korea, Using SAFETI Model. Energies. 2024; 17(4):867. https://doi.org/10.3390/en17040867

Chicago/Turabian StyleKwak, Hyunjun, Minji Kim, Mimi Min, Byoungjik Park, and Seungho Jung. 2024. "Assessing the Quantitative Risk of Urban Hydrogen Refueling Station in Seoul, South Korea, Using SAFETI Model" Energies 17, no. 4: 867. https://doi.org/10.3390/en17040867

APA StyleKwak, H., Kim, M., Min, M., Park, B., & Jung, S. (2024). Assessing the Quantitative Risk of Urban Hydrogen Refueling Station in Seoul, South Korea, Using SAFETI Model. Energies, 17(4), 867. https://doi.org/10.3390/en17040867