An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines †

Abstract

1. Introduction

2. Methodology

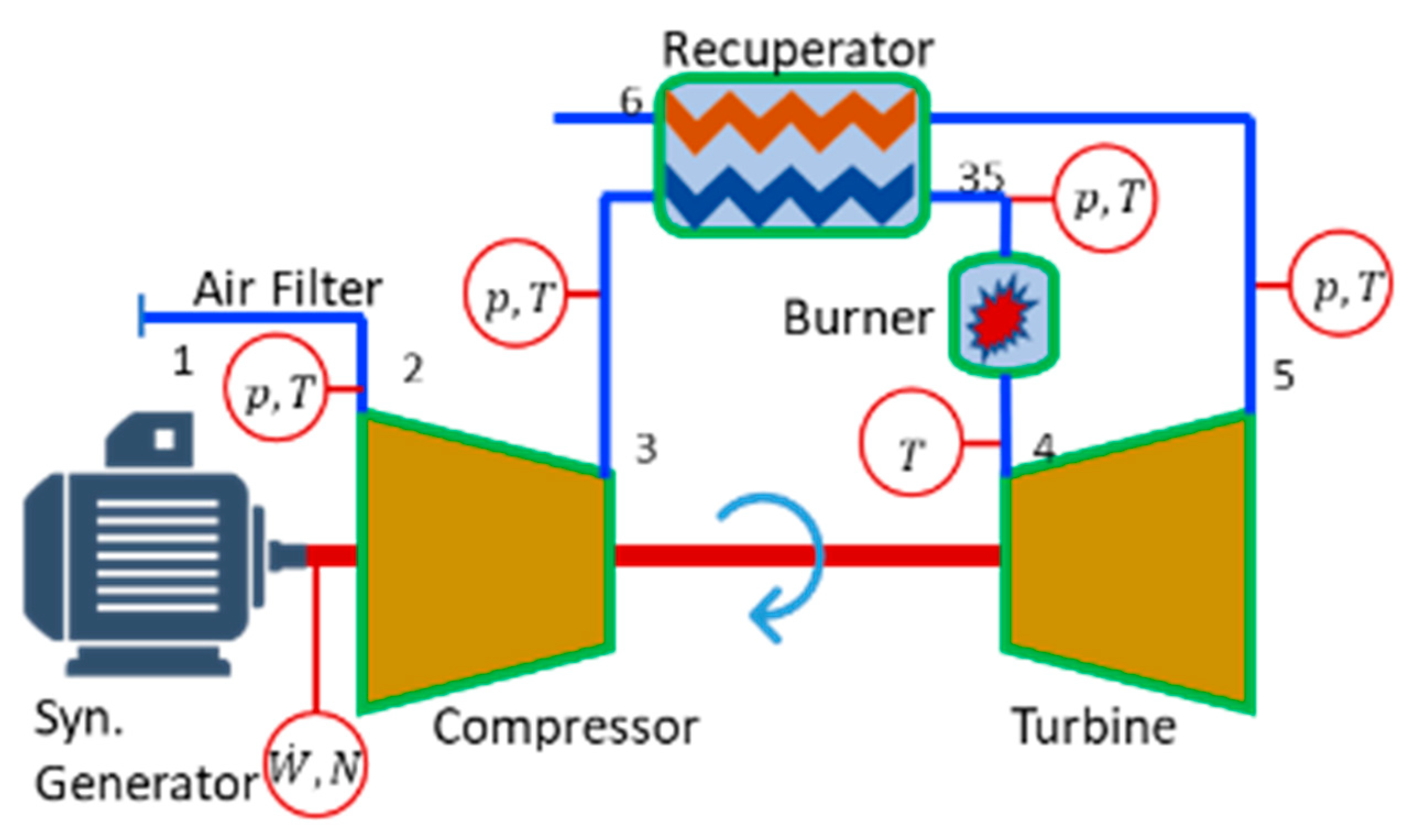

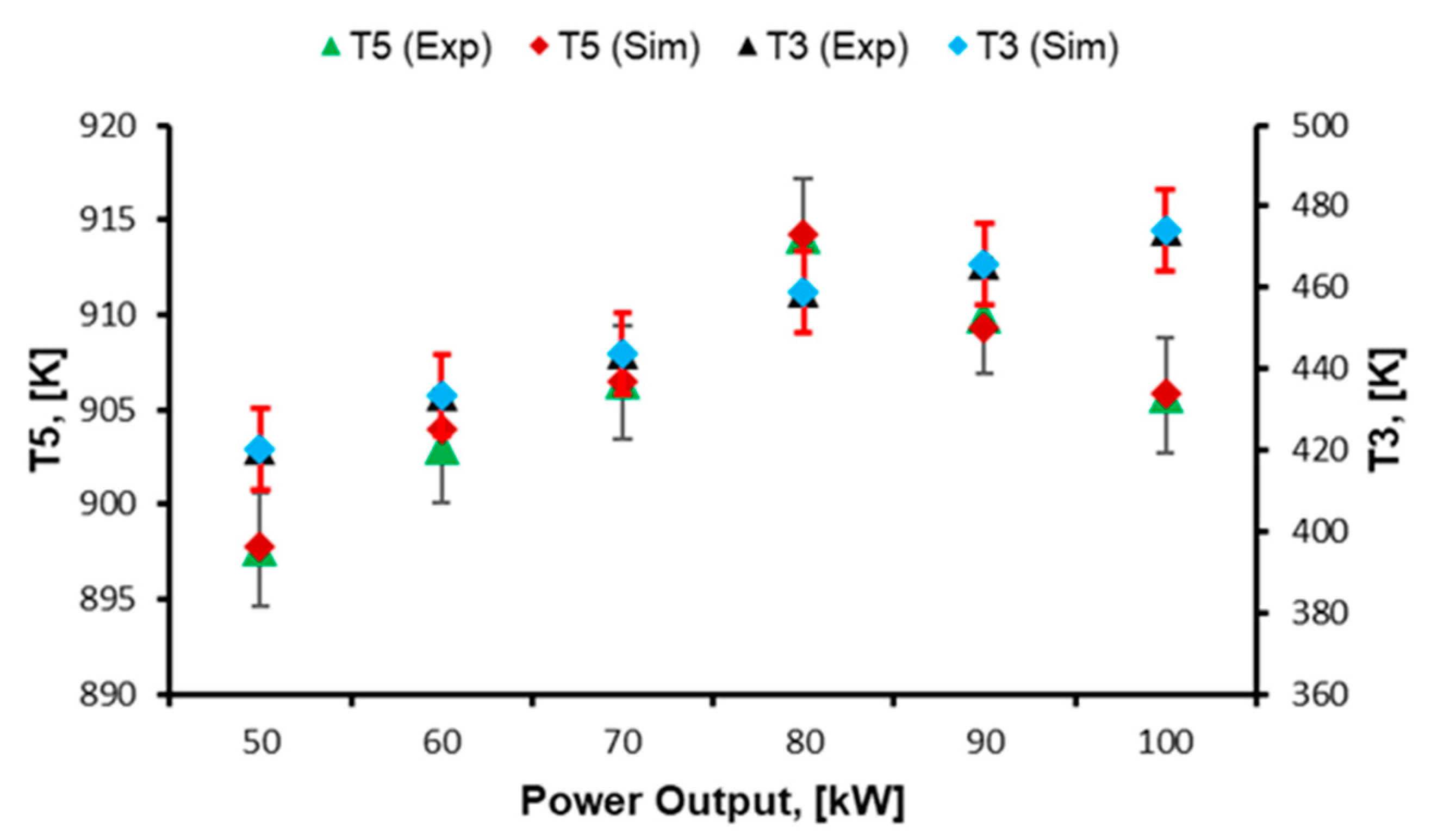

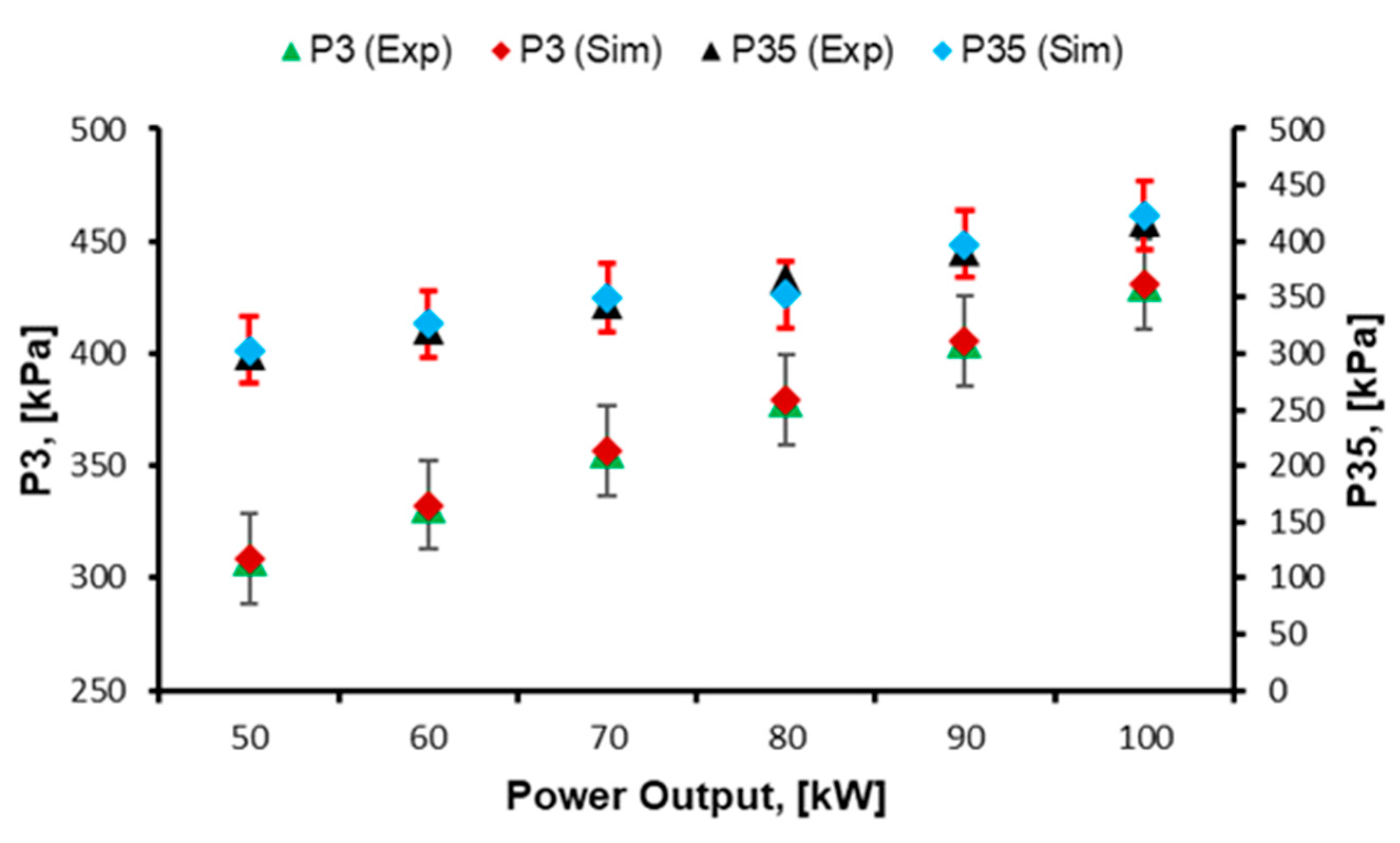

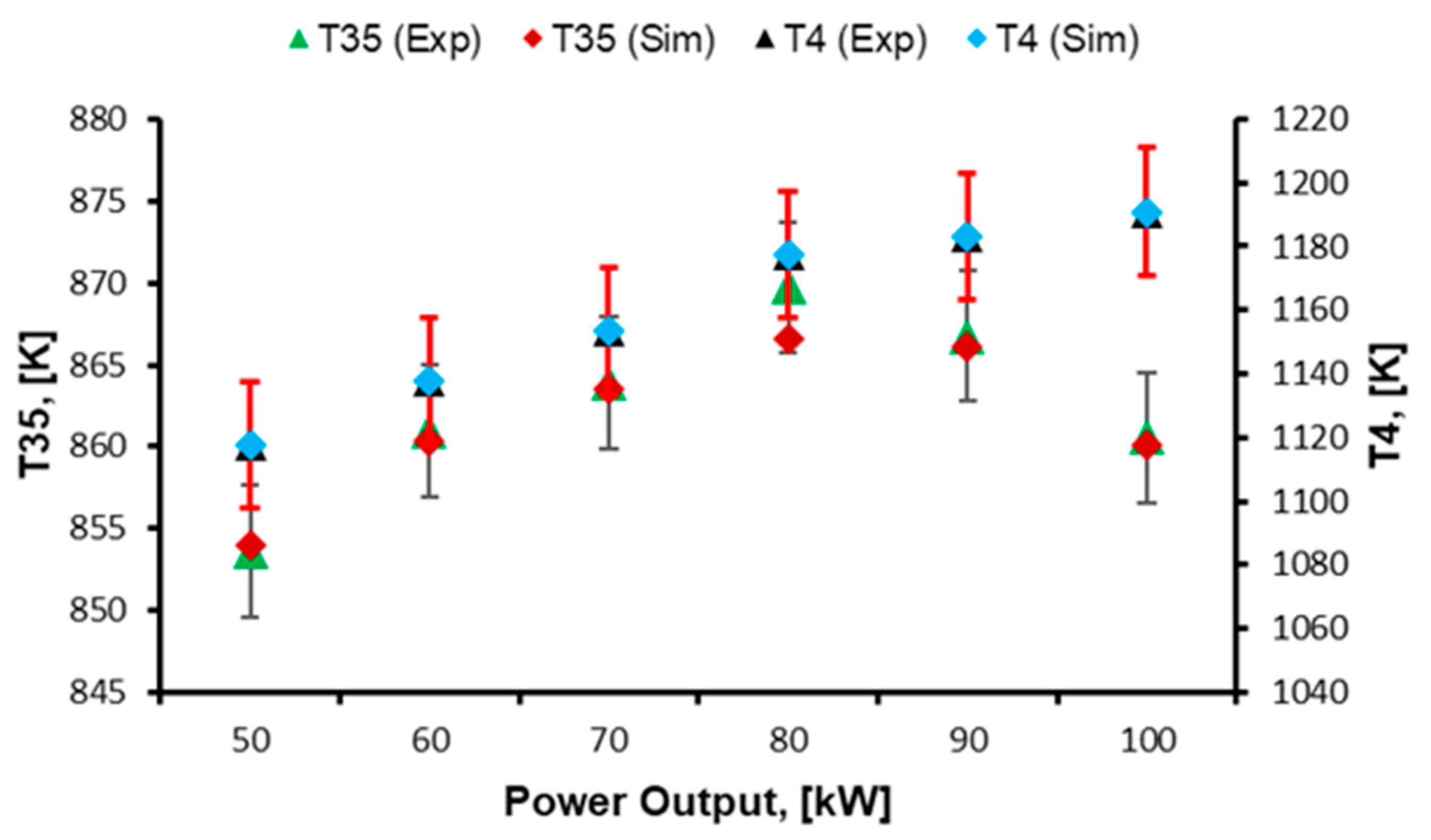

2.1. Baseline Performance Model

2.2. Component-Level Degradation

2.3. Fault Diagnosis

2.3.1. Data Processing

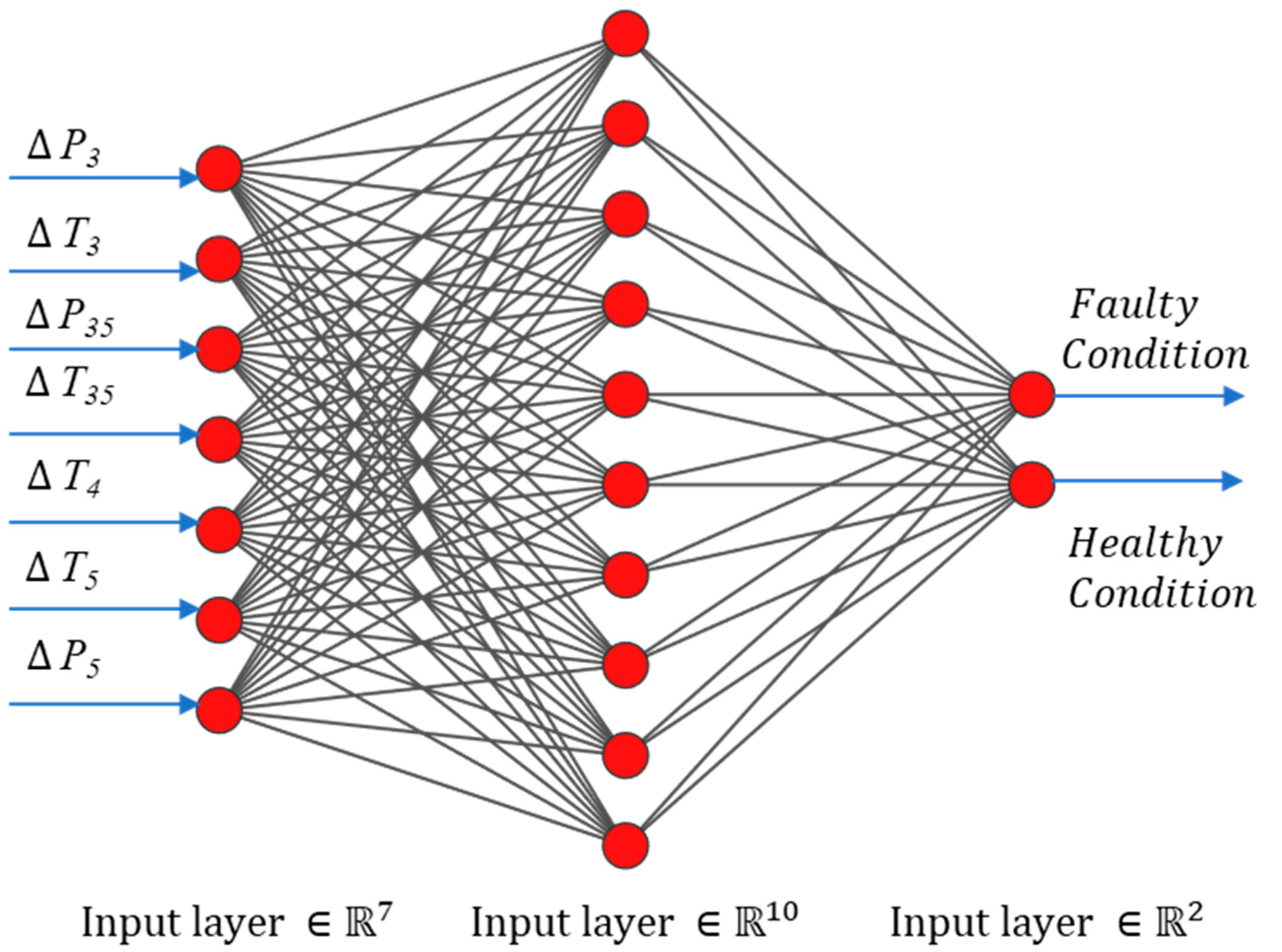

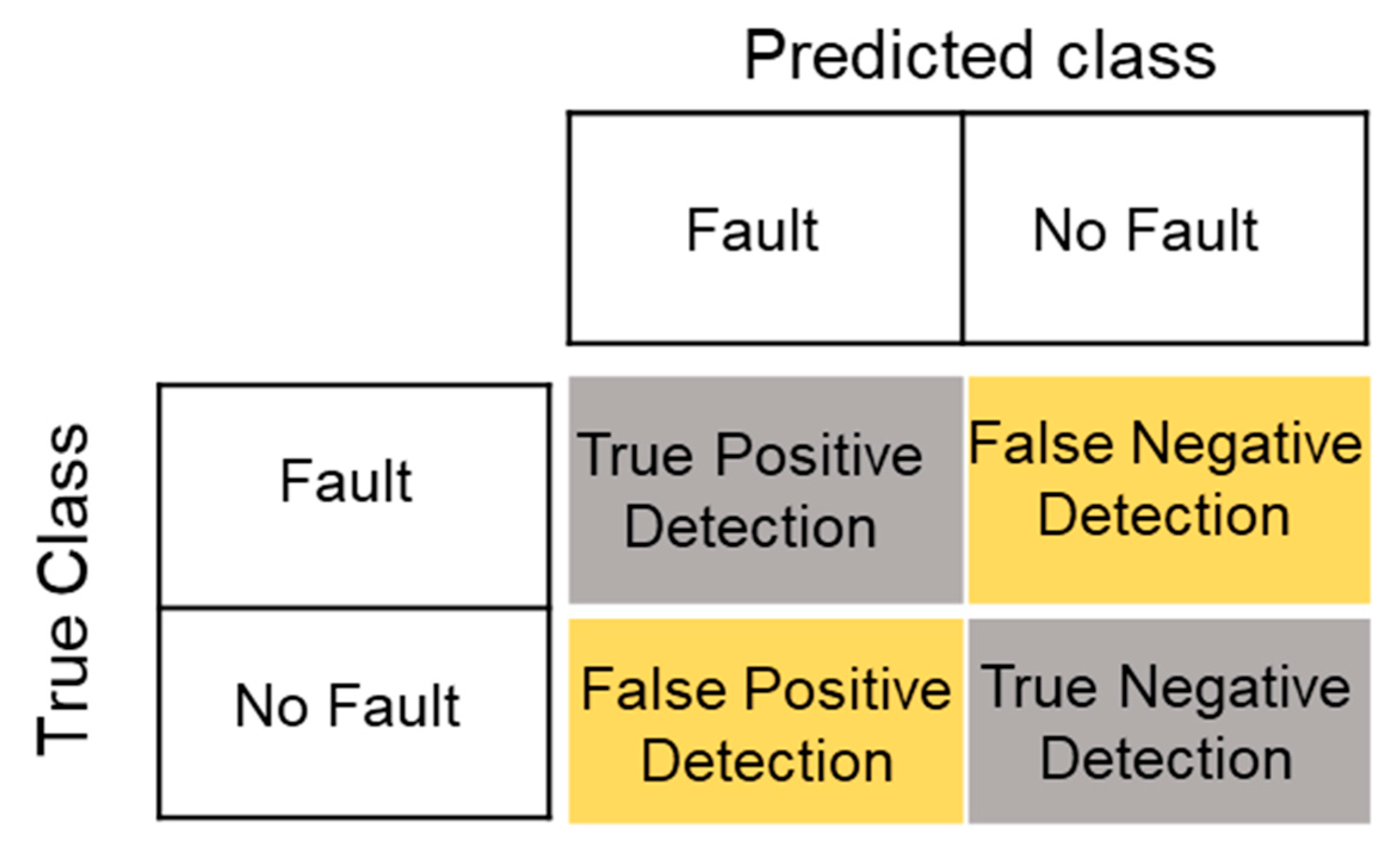

2.3.2. ANN-Based Classification (Fault Detection and Isolation)

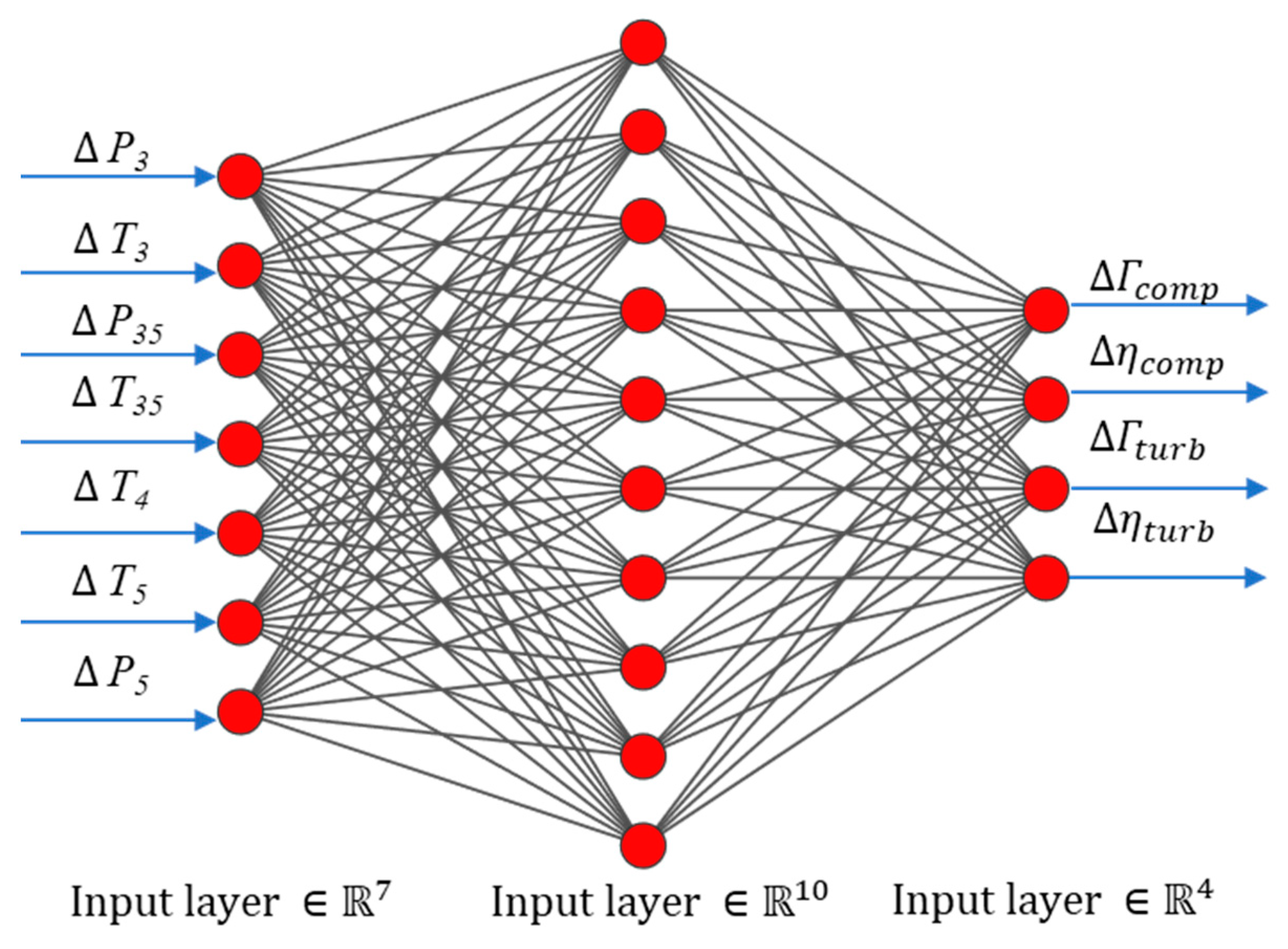

2.3.3. ANN-Based Fault Identification

2.3.4. Explainable AI for Interpretation

3. Results and Discussion

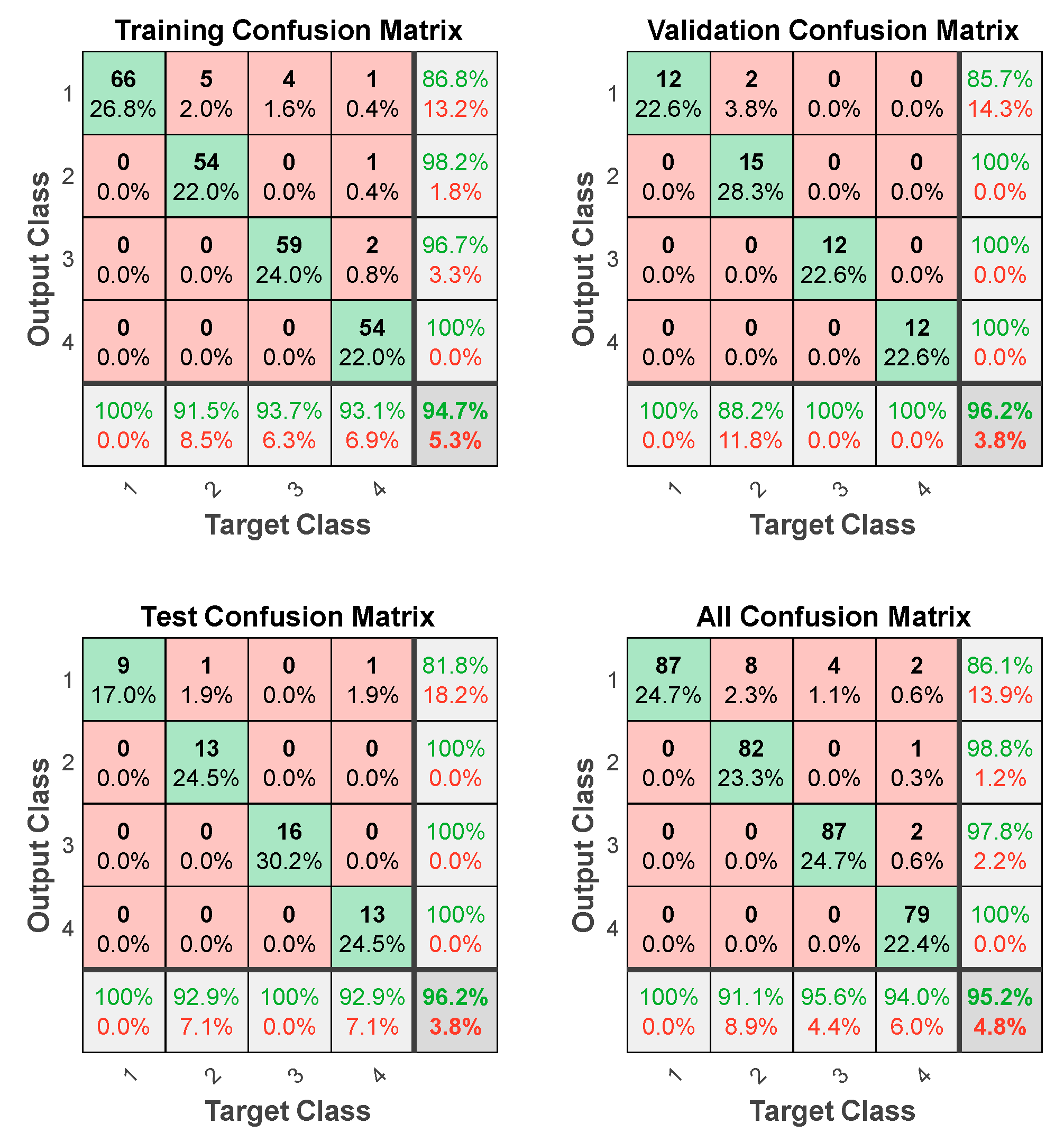

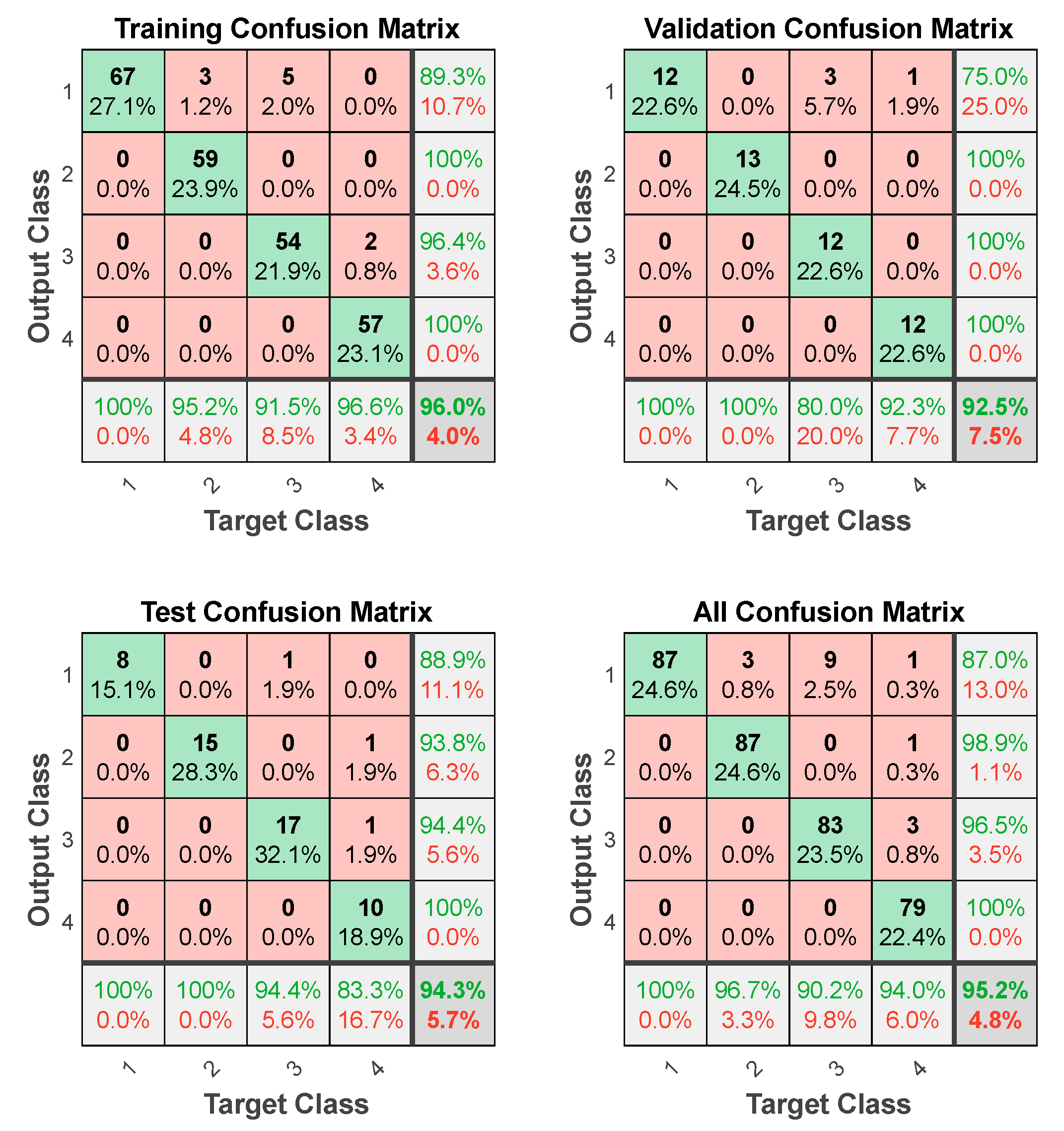

3.1. Fault Detection and Isolation

3.2. Sensitivity Analysis for Fault Detection and Isolation

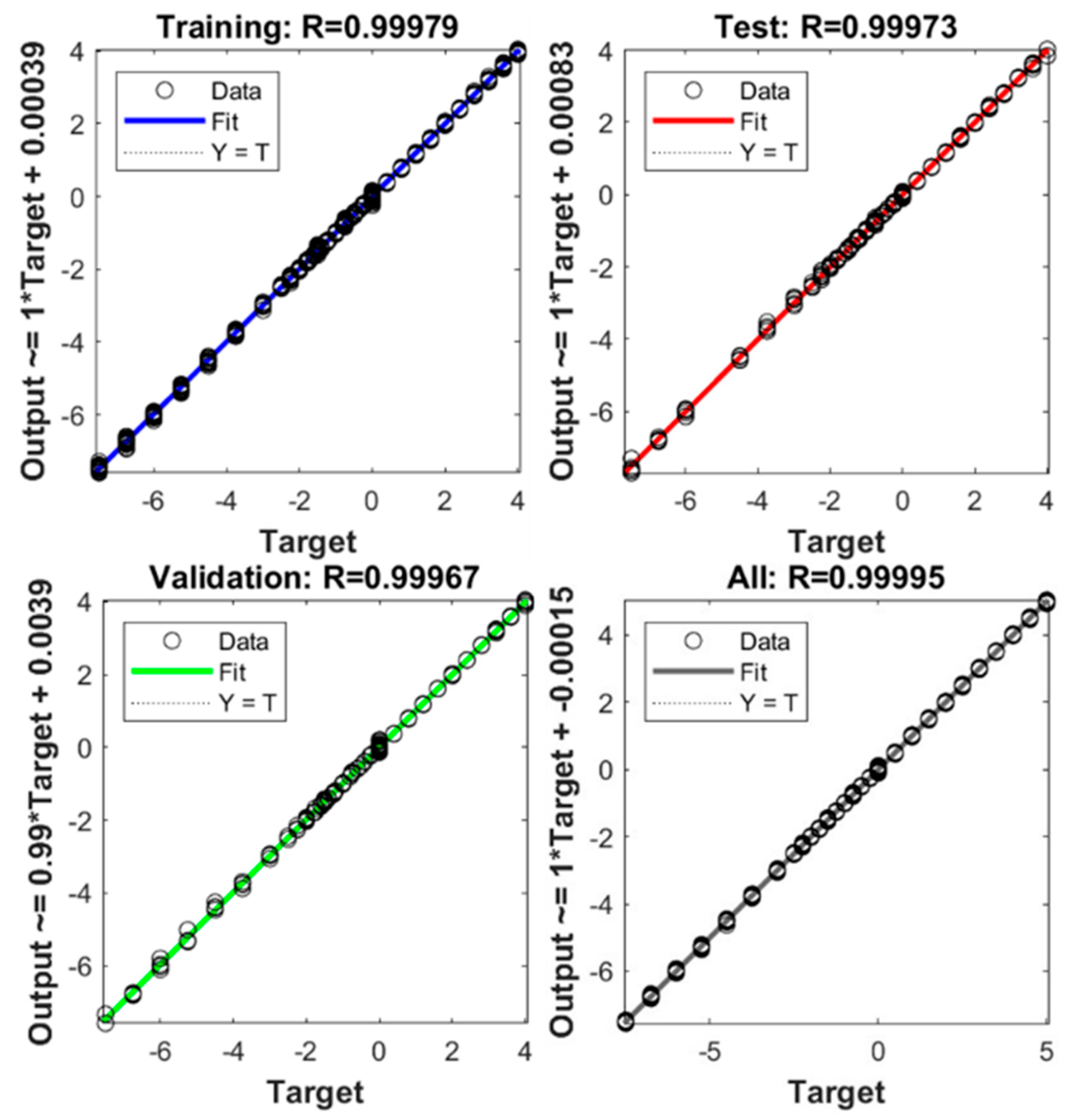

3.3. Fault Identification

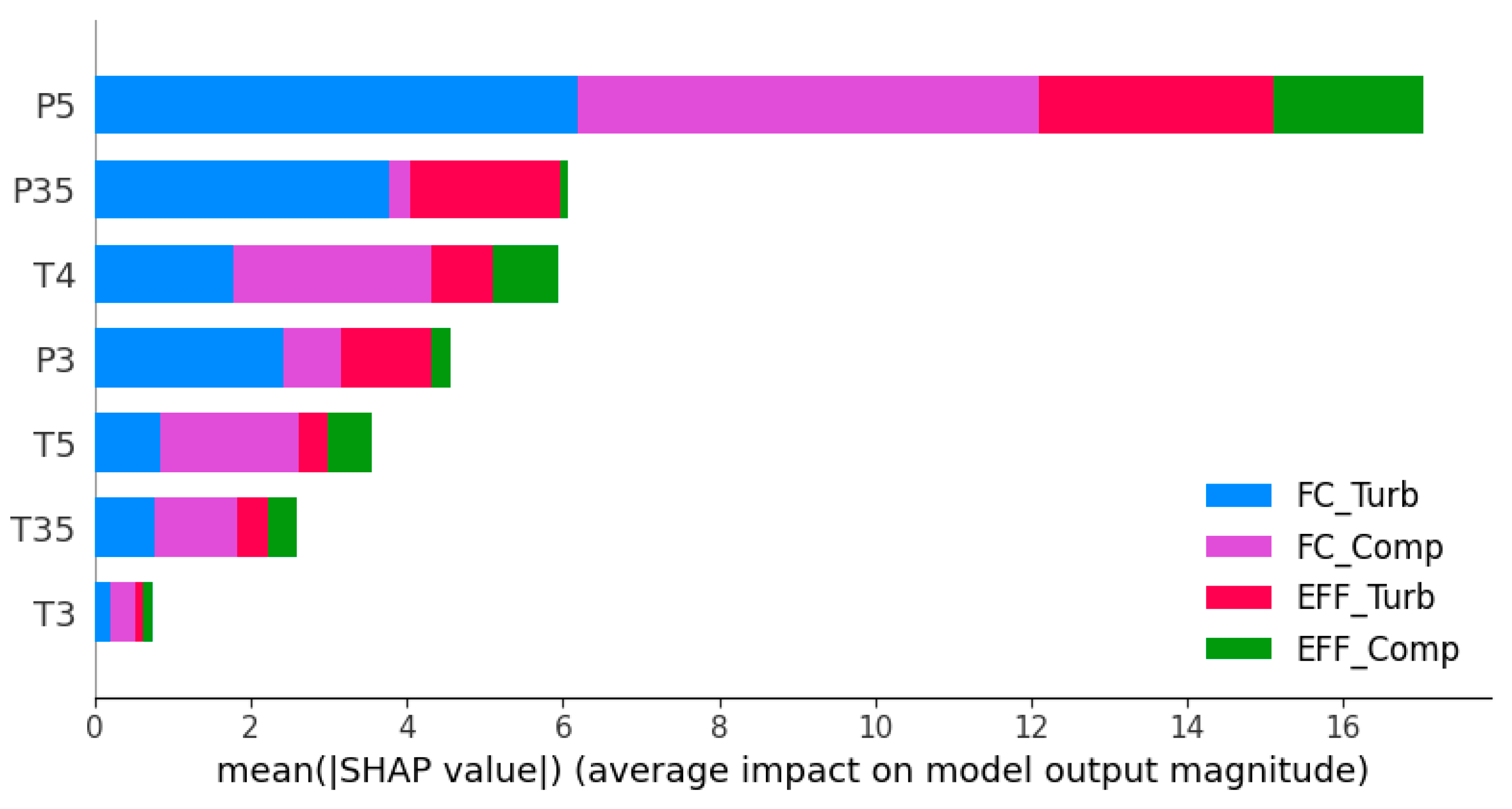

3.4. Physics-Based Insights from the ANN Model

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EDGAR; JRC. Global Carbon Dioxide Emissions from 1970 to 2021, by Sector (in Billion Metric Tons of Carbon Dioxide); Statista: Hamburg, Germany, 2022. [Google Scholar]

- ETN Global. Zero-carbon gas turbine. In Hydrogen Gas Turbines; ETN Global: Brussels, Belgium, 2020. [Google Scholar]

- Noble, D.; Wu, D.; Emerson, B.; Sheppard, S.; Lieuwen, T.; Angello, L. Assessment of current capabilities and near-term availability of hydrogen-fired gas turbines considering a low-carbon future. J. Eng. Gas Turbines Power 2021, 143, 041002. [Google Scholar] [CrossRef]

- Siemens Energy; Centrax. HYFLEXPOWER Consortium Successfully Operates a Gas Turbine with 100 Percent Renewable Hydrogen, a World First; Siemens Energy: Munich, Germany, 2023. [Google Scholar]

- Gazzani, M.; Chiesa, P.; Martelli, E.; Sigali, S.; Brunetti, I. Using hydrogen as gas turbine fuel: Premixed versus diffusive flame combustors. J. Eng. Gas Turbines Power 2014, 136, 051504. [Google Scholar] [CrossRef]

- Marinai, L.; Probert, D.; Singh, R. Prospects for aero gas-turbine diagnostics: A review. Appl. Energy 2004, 79, 109–126. [Google Scholar] [CrossRef]

- Urban, L.A. Parameter selection for multiple fault diagnostics of gas turbine engines. J. Eng. Power 1975, 97, 225–230. [Google Scholar] [CrossRef]

- Urban, L.A.; Volponi, A.J. Mathematical methods of relative engine performance diagnostics. SAE Trans. 1992, 101, 2025–2050. [Google Scholar]

- Fentaye, A.D.; Baheta, A.T.; Gilani, S.I.; Kyprianidis, K.G. A review on gas turbine gas-path diagnostics: State-of-the-art methods, challenges and opportunities. Aerospace 2019, 6, 83. [Google Scholar] [CrossRef]

- Minghui, H.; Ya, H.; Xinzhi, L.; Ziyuan, L.; Jiang, Z.; Bo, M. Digital twin model of gas turbine and its application in warning of performance fault. Chin. J. Aeronaut. 2022, 36, 449–470. [Google Scholar]

- Chen, Y.-Z.; Zhao, X.-D.; Xiang, H.-C.; Tsoutsanis, E. A sequential model-based approach for gas turbine performance diagnostics. Energy 2021, 220, 119657. [Google Scholar] [CrossRef]

- Kim, S.; Im, J.H.; Kim, M.; Kim, J.; Kim, Y.I. Diagnostics using a physics-based engine model in aero gas turbine engine verification tests. Aerosp. Sci. Technol. 2023, 133, 108102. [Google Scholar] [CrossRef]

- Ying, Y.; Li, J. An improved performance diagnostic method for industrial gas turbines with consideration of intake and exhaust system. Appl. Therm. Eng. 2023, 222, 119907. [Google Scholar] [CrossRef]

- He, Y.; Jiang, Z.; Hu, M.; Li, Y. Local maximum synchrosqueezing chirplet transform: An effective tool for strongly nonstationary signals of gas turbine. IEEE Trans. Instrum. Meas. 2021, 70, 1–14. [Google Scholar] [CrossRef]

- Chen, Y.-Z.; Tsoutsanis, E.; Wang, C.; Gou, L.-F. A time-series turbofan engine successive fault diagnosis under both steady-state and dynamic conditions. Energy 2023, 263, 125848. [Google Scholar] [CrossRef]

- Zhou, H.; Ying, Y.; Li, J.; Jin, Y. Long-short term memory and gas path analysis based gas turbine fault diagnosis and prognosis. Adv. Mech. Eng. 2021, 13, 16878140211037767. [Google Scholar] [CrossRef]

- Yang, X.; Bai, M.; Liu, J.; Liu, J.; Yu, D. Gas path fault diagnosis for gas turbine group based on deep transfer learning. Measurement 2021, 181, 109631. [Google Scholar] [CrossRef]

- Zhou, D.; Yao, Q.; Wu, H.; Ma, S.; Zhang, H. Fault diagnosis of gas turbine based on partly interpretable convolutional neural networks. Energy 2020, 200, 117467. [Google Scholar] [CrossRef]

- Shen, Y.; Khorasani, K. Hybrid multi-mode machine learning-based fault diagnosis strategies with application to aircraft gas turbine engines. Neural Netw. 2020, 130, 126–142. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Liu, J.; Ma, Y.; Zhao, X.; Long, Z.; Yu, D. Long short-term memory network-based normal pattern group for fault detection of three-shaft marine gas turbine. Energies 2020, 14, 13. [Google Scholar] [CrossRef]

- Montazeri-Gh, M.; Yazdani, S. Application of interval type-2 fuzzy logic systems to gas turbine fault diagnosis. Appl. Soft Comput. 2020, 96, 106703. [Google Scholar] [CrossRef]

- Zhu, L.; Liu, J.; Ma, Y.; Zhou, W.; Yu, D. A coupling diagnosis method for sensor faults detection, isolation and estimation of gas turbine engines. Energies 2020, 13, 4976. [Google Scholar] [CrossRef]

- Cao, Y.; Luan, J.; Han, G.; Lv, X.; Li, S. A marine gas turbine fault diagnosis method based on endogenous irreversible loss. Energies 2019, 12, 4677. [Google Scholar] [CrossRef]

- Li, J.; Ying, Y. Gas turbine gas path diagnosis under transient operating conditions: A steady state performance model based local optimization approach. Appl. Therm. Eng. 2020, 170, 115025. [Google Scholar] [CrossRef]

- Sun, R.; Shi, L.; Yang, X.; Wang, Y.; Zhao, Q. A coupling diagnosis method of sensors faults in gas turbine control system. Energy 2020, 205, 117999. [Google Scholar] [CrossRef]

- Zhong, S.-S.; Fu, S.; Lin, L. A novel gas turbine fault diagnosis method based on transfer learning with CNN. Measurement 2019, 137, 435–453. [Google Scholar] [CrossRef]

- Gomes, E.; McCaffrey, D.; Garces, M.; Polizakis, A.; Pilidis, P. Comparative analysis of microturbines performance deterioration and diagnostics. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2006; pp. 269–276. [Google Scholar]

- Yoon, J.E.; Lee, J.J.; Kim, T.S.; Sohn, J.L. Analysis of performance deterioration of a micro gas turbine and the use of neural network for predicting deteriorated component characteristics. J. Mech. Sci. Technol. 2008, 22, 2516. [Google Scholar] [CrossRef]

- Talebi, S.; Tousi, A. The effects of compressor blade roughness on the steady state performance of micro-turbines. Appl. Therm. Eng. 2017, 115, 517–527. [Google Scholar] [CrossRef]

- Bauwens, P. Gas Path Analysis for the MTT Micro Turbine; TU Delft: Delft, The Netherlands, 2015. [Google Scholar]

- Hashmi, M.B.; Mansouri, M.; Breuhaus, P.; Lemma, T.A. Effect of hot gas path component corrosion on the performance of hydrogen fueled micro gas turbines. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Boston, MA, USA, 26–30 June 2023; p. V009T018A016. [Google Scholar]

- Talebi, S.; Madadi, A.; Tousi, A.; Kiaee, M. Micro Gas Turbine fault detection and isolation with a combination of Artificial Neural Network and off-design performance analysis. Eng. Appl. Artif. Intell. 2022, 113, 104900. [Google Scholar] [CrossRef]

- Zornek, T.; Monz, T.; Aigner, M. Performance analysis of the micro gas turbine Turbec T100 with a new FLOX-combustion system for low calorific fuels. Appl. Energy 2015, 159, 276–284. [Google Scholar] [CrossRef]

- Kurzke, J. GasTurb 12: A Program to Calculate Design and Off-Design Performance of Gas Turbines: User’s Manual; GasTurb: Aachen, Germany, 2012. [Google Scholar]

- Turbec, S. Technical Description Microturbine Turbec T100: Stand. 2017. Available online: https://manualzz.com/doc/33686173/t100-microturbine-system-technical-description-t100-natur (accessed on 1 January 2024).

- Tahan, M.; Tsoutsanis, E.; Muhammad, M.; Karim, Z.A. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: A review. Appl. Energy 2017, 198, 122–144. [Google Scholar] [CrossRef]

- Oluyede, E.O.; Phillips, J.N. Fundamental impact of firing syngas in gas turbines. In Proceedings of the Turbo Expo: Power for Land, Sea, and Air, Barcelona, Spain, 8–11 May 2007; pp. 175–182. [Google Scholar]

- Zwebek, A.; Pilidis, P. Degradation effects on combined cycle power plant performance—Part III: Gas and steam turbine component degradation effects. J. Eng. Gas Turbines Power 2004, 126, 306–315. [Google Scholar] [CrossRef]

- Zwebek, A.; Pilidis, P. Degradation Effects on Combined Cycle Power Plant Performance—Part II: Steam Turbine Cycle Component Degradation Effects. J. Eng. Gas Turbines Power 2003, 125, 658–663. [Google Scholar] [CrossRef]

- Qingcai, Y.; Li, S.; Cao, Y.; Zhao, N. Full and part-load performance deterioration analysis of industrial three-shaft gas turbine based on genetic algorithm. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Republic of Korea, 13–17 June 2016; p. V006T005A016. [Google Scholar]

- Mohammadi, E.; Montazeri, G.M. Simulation of full and part-load performance deterioration of industrial two-shaft gas turbine. J. Eng. Gas Turbines Power 2014, 136, 092602. [Google Scholar] [CrossRef]

- Escher, P. Pythia: An Object-Orientated Gas Path Analysis Computer Program for General Applications; Cranfield University: Cranfield, UK, 1995. [Google Scholar]

- Ogaji, S.O.; Singh, R. Advanced engine diagnostics using artificial neural networks. Appl. Soft Comput. 2003, 3, 259–271. [Google Scholar] [CrossRef]

- Singh, R. Advances and opportunities in gas path diagnostics. In Proceedings of the 15th ISABE, Bangalore, India, 17–20 September 2003. Paper no. ISABE-2003-1008. [Google Scholar]

- Simon, D.L. Propulsion Diagnostic Method Evaluation Strategy (ProDiMES) User’s Guide; NASA: Washington, DC, USA, 2010.

| Ref. | Engine Type | Faults/Degraded Components | Diagnosis Phase | Approach | Specific Method |

|---|---|---|---|---|---|

| [15] | Turbofan engine | Fan, compressor, and turbine | FDI | Model-based | Newton–Raphson |

| [11] | Three-shaft IGT | Fouling and erosion in both compressors and turbines | FDI | Improved nonlinear GPA | Sequential diagnostics |

| [16] | Single-shaft heavy-duty gas turbine | Fouling, erosion, corrosion, and blade rubbing; thermal distortion and local object damage in the compressor and turbine | FD | Hybrid | LSTM and GPA |

| [17] | Single-shaft IGT | Fouling and erosion in the compressor and turbine | FDII | Data-driven | CNN, DNN, and SVM |

| [18] | MGT | Sensor fault and fouling in the compressor | FD | Physics-based model + data-driven | CNN + Extreme gradient boosting (XGBoost) |

| [19] | Twin-shaft aeroengine | Degradation in the HPC, HPT, LPC, and LPT | FDI | Hybrid machine-learning | RNN |

| [20] | Three-shaft marine GT | Fouling, and foreign object damage in the compressor and turbine | FD | Data-driven | LSTM |

| [21] | Twin-shaft IGT | Fouling and erosion in the compressor and turbine | FDI | Physics-based model + data-driven | Interval type-two fuzzy logic systems |

| [22] | Twin-shaft gas turbine | Sensor faults | FDII | Hybrid model-based and unsupervised learning | SRCKF + DBSCAN |

| [23] | Three-shaft marine GT | Exergy loss in the compressor and turbine | FD | Model-based | EIL |

| [24] | Single-shaft IGT | Fouling, erosion, corrosion, and blade rubbing; thermal distortion and object damage in the compressor and turbines | FD | Model-based | Kalman filter and Newton–Raphson algorithm |

| [25] | IGT | Sensor faults | FDI | Data-driven | Wavelet energy entropy and SVR |

| [26] | Turbofan engine | Exhaust gas temperature-indication fault and HPT blade-burnt fault in the turbine | FDII | Data-driven | CNN and SVM |

| Parameter | OEM Data [35] | Present Study | % Error |

|---|---|---|---|

| Power output [kW] | 100 (±3) | 100.1 | 0.09 |

| Electrical efficiency [%] | 30 (±1) | 29.99 | 0.03 |

| Pressure ratio [−] | 4.5 | 4.5 | 0 |

| Exhaust mass flow | 0.8 | 0.799 | 0.12 |

| Exhaust gas temperature [K] | 543 | 556.83 | 2.5 |

| Fault | FC (X) | Eff. (Y) | Ratios (X:Y) | Ranges | Ref. |

|---|---|---|---|---|---|

| Natural gas case | |||||

| CF | ↓ | ↓ | ~3:1 | [0, −7.5] [0, −2.5] | [40,41] |

| TC | ↑ | ↓ | ~2:1 | [0, 4] [0, −2] | [42] |

| Hydrogen case | |||||

| CF | ↓ | ↓ | ~3:1 | [0, −7.5] [0, −2.5] | [40,41] |

| TC | ↑ | ↓ | ~2:1 | [0, 5] [0, −2.5] | [27,39] |

| Criteria | Indicators |

|---|---|

| Total hidden layers | 1 |

| Neurons in hidden layers | 10 |

| Feeding approach | Backpropagation |

| Target limit of epochs | 1000 |

| Performance accuracy target | 0 |

| Performance gradient target | 1.00 × 10−7 |

| Activation function | Sigmoid |

| Training algorithm | Levenberg–Marquardt |

| Performance indicator | Mean square error |

| Label | Designated Physical Condition |

|---|---|

| 1 | No fault |

| 2 | CF: Compressor fouling |

| 3 | TC: Turbine corrosion |

| 4 | CF + TC: Simultaneous |

| Sensitivity | Measurement Sensors Dropped | Testing Accuracy (%)—H2 | Testing Accuracy (%)—NG |

|---|---|---|---|

| S1 | T4 | 94.3 | 94.3 |

| S2 | T4, T3 | 62.3 | 96.2 |

| S3 | T3 | 94.3 | 92.5 |

| S4 | T35 | 92.5 | 96.2 |

| S5 | T3, T35 | 94.3 | 96.2 |

| S6 | P3 | 96.2 | 92.5 |

| S7 | P35 | 92.5 | 90.6 |

| S8 | P5 | 50.9 | 60.7 |

| S9 | P3, P35, P5 | 47.2 | 54.7 |

| S10 | T3, T35, T4, T5 | 56.6 | 62.3 |

| MSE NG | MSE Hydrogen | RMSE NG | RMSE Hydrogen | |

|---|---|---|---|---|

| Training | 5.92 × 10−4 | 0.0018 | 0.0243 | 0.0424 |

| Testing | 6.41 × 10−4 | 0.0022 | 0.0253 | 0.04694 |

| Validation | 7.40 × 10−4 | 0.0032 | 0.0271 | 0.0565 |

| Ref. | System | Methodology | FD Accuracy (%) |

|---|---|---|---|

| Current study | MGT | ANN | 96.2 |

| [32] | MGT | ANN | 97.6 |

| [16] | Heavy-duty gas turbine | LSTM | |

| [18] | MGT | CNN | 95.5 |

| [19] | aeroengine | RNN | 89 |

| [21] | IGT | Fuzzy logic | 99 |

| [26] | Turbofan engine | Transfer learning-based CNN and SVM | 93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashmi, M.B.; Mansouri, M.; Fentaye, A.D.; Ahsan, S.; Kyprianidis, K. An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines. Energies 2024, 17, 719. https://doi.org/10.3390/en17030719

Hashmi MB, Mansouri M, Fentaye AD, Ahsan S, Kyprianidis K. An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines. Energies. 2024; 17(3):719. https://doi.org/10.3390/en17030719

Chicago/Turabian StyleHashmi, Muhammad Baqir, Mohammad Mansouri, Amare Desalegn Fentaye, Shazaib Ahsan, and Konstantinos Kyprianidis. 2024. "An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines" Energies 17, no. 3: 719. https://doi.org/10.3390/en17030719

APA StyleHashmi, M. B., Mansouri, M., Fentaye, A. D., Ahsan, S., & Kyprianidis, K. (2024). An Artificial Neural Network-Based Fault Diagnostics Approach for Hydrogen-Fueled Micro Gas Turbines. Energies, 17(3), 719. https://doi.org/10.3390/en17030719