Effects of Mechanical Stress on the Life and Insulation Performance of DC-Link Capacitors

Abstract

1. Introduction

2. Mechanical Stress of a DCLC

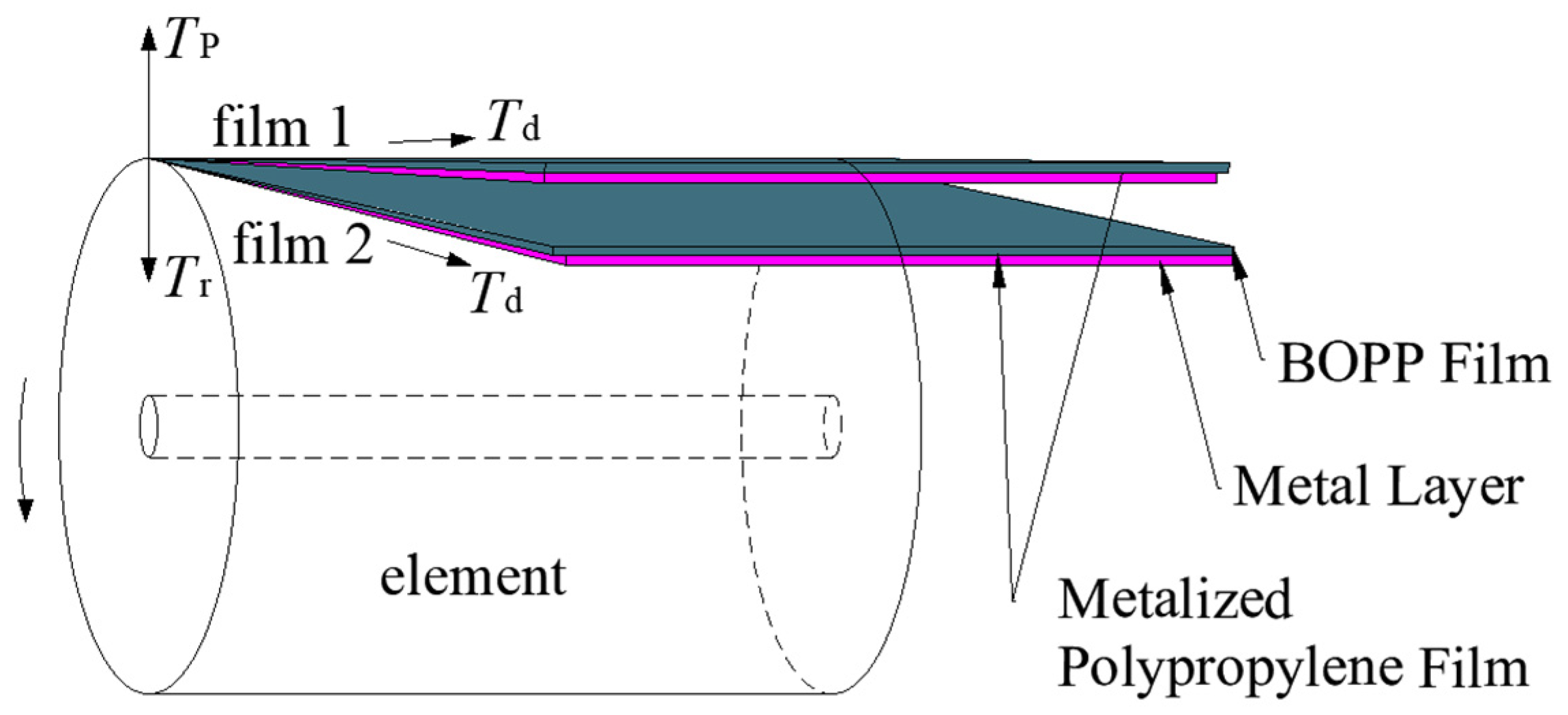

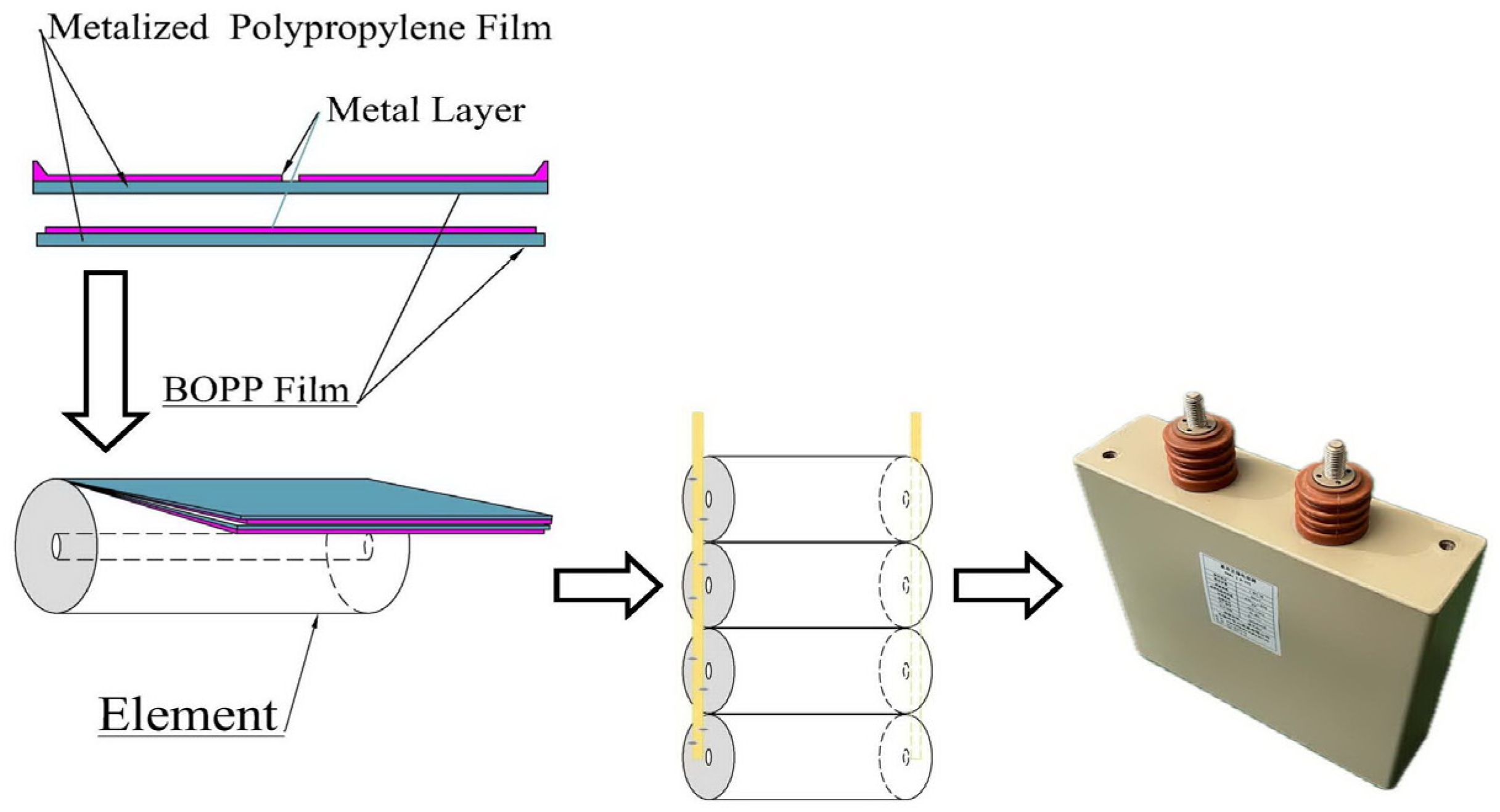

2.1. Elements of a DCLC

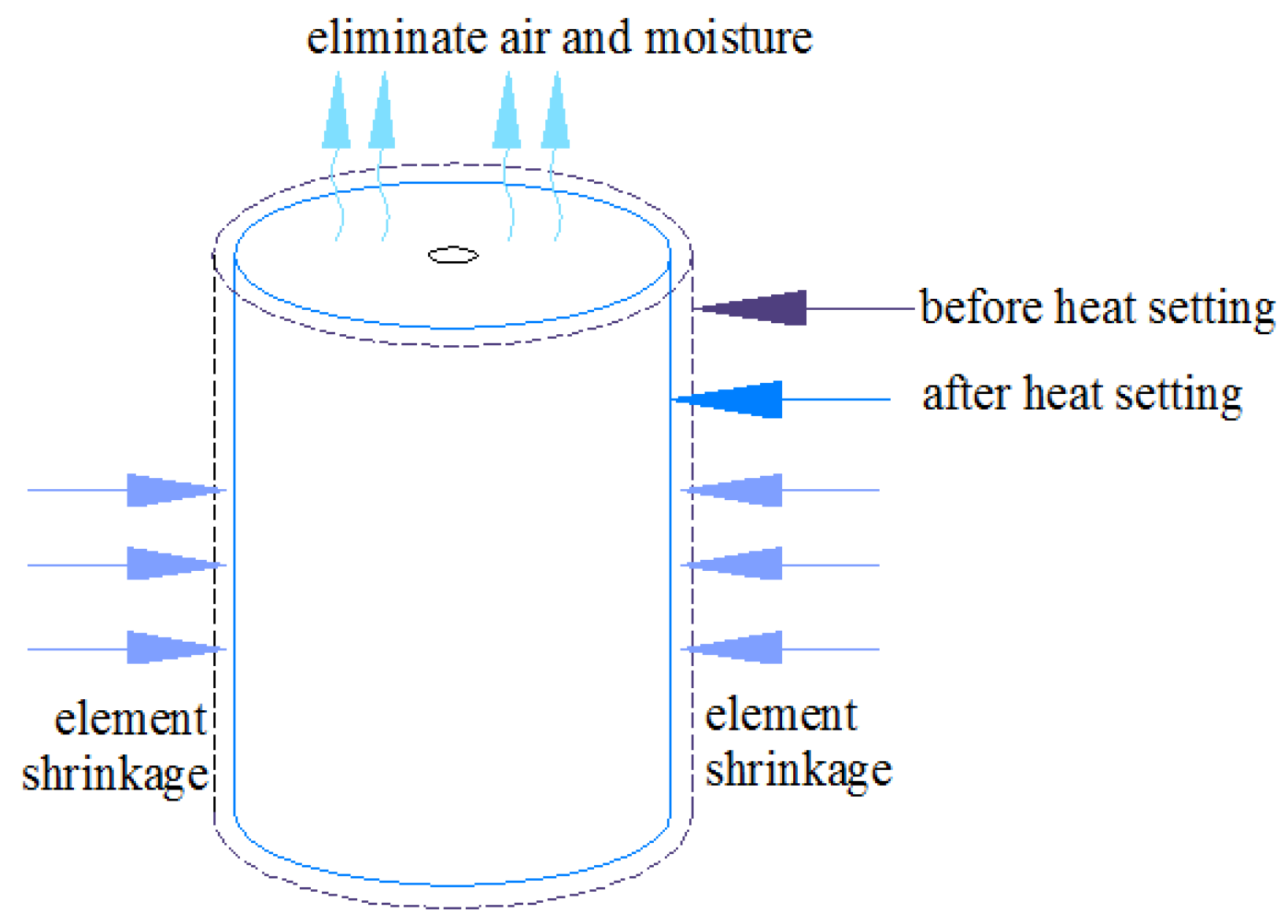

2.2. Heat Setting of the DCLC

2.3. Mechanical Stress of the DCLC

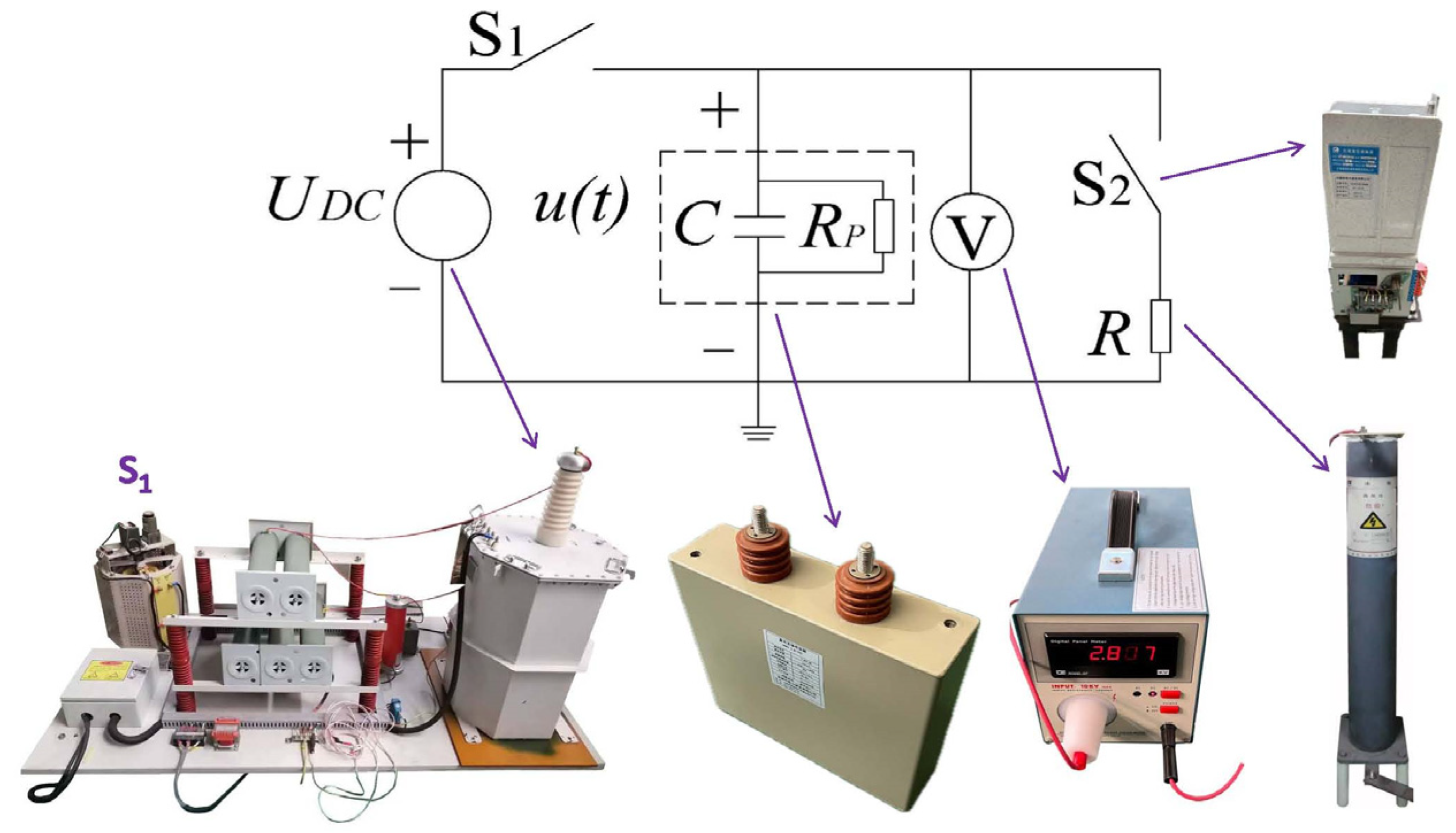

3. Experimental Method

3.1. DCLC Sample Preparation

3.2. Life Aging Test

3.3. Insulation Resistance Measurement

3.4. Withstand Voltage Test

4. Experimental Results and Discussion

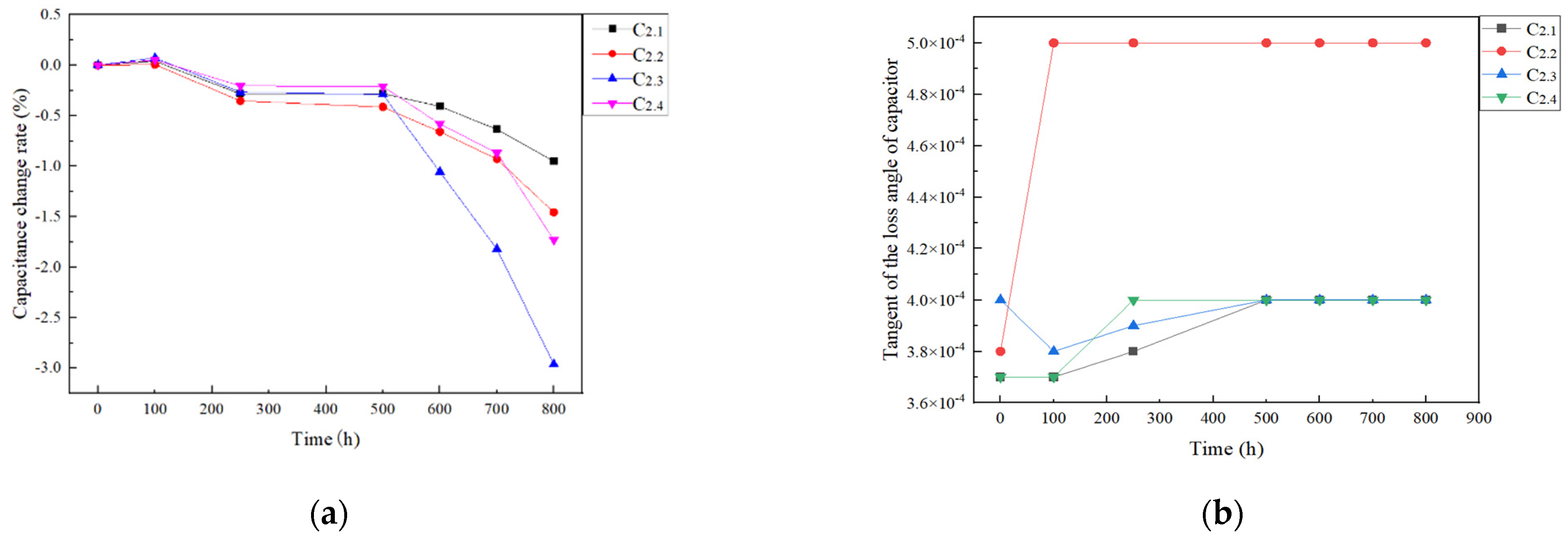

4.1. Life Aging Test

- (1)

- The HST is capable of improving the service life of the understudy DCLCs, the temperature increases by 5 °C, and the capacitance changes of all four winding tensions exhibited an increase of 73.8%, 80.8%, 5.3%, and 7% after 800 h of the aging test. This issue is essentially attributed to the fact that during hot polymerization, the polypropylene homopolymer chain is reoriented through high temperatures. Additionally, secondary crystallization occurs after the crystalline molecular chain acquires a certain energy, which alters the crystallinity and the crystalline shape of the film, and the crystallinity linearly enhances with the temperature growth [24]. As the crystallinity increases, it would be difficult for ions to move in the polypropylene film, the conductivity decreases, and the insulation resistance becomes 3–5 times larger [25], which noticeably improves the ability to store charge and maintain voltage [26]. The plotted results indicate that the appropriate increase in HST is capable of growing the crystallinity of the medium, enhancing the insulation performance, and prolonging the service life of the capacitor.

- (2)

- With the increase in the HST from 105 °C to 110 °C, the tangent of the loss angle of the DCLC for four WTCs exhibits a descending trend after 800 h of testing.

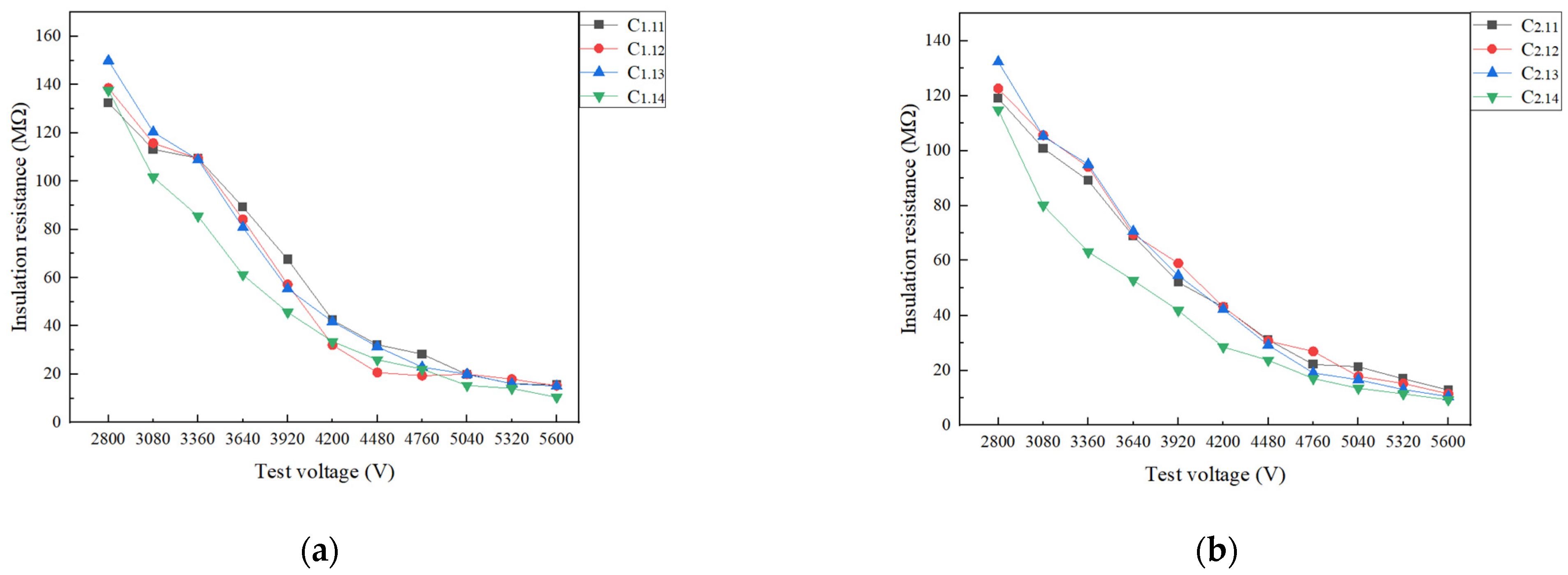

4.2. Measurement of the Insulation Resistance

- (1)

- In the cases of HST = 105 °C or 110 °C, the insulation resistance values of the samples rapidly decrease with the growth of the initial discharge voltage values. When the initial discharge voltage reaches 4480 V (i.e., 1.6 UNDC), the process of decreasing insulation resistance values slows down. This is essentially due to the fact that for high levels of the initial discharge voltage, some weak self-healing occurs in the sample and the leakage current increases. However, in the case of occurring self-healing, the insulation resistance value of the sample gradually decreases.

- (2)

- Concerning the case of HST = 105 °C, when the initial discharge voltage value is the rated operating voltage, the insulation resistance of the samples with WTC = 1.6 exhibited the largest level, and the insulation resistance of the samples with WTC = 1.4 exhibited the smallest level.

- (3)

- Concerning the case of HST = 110 °C, when the initial discharge voltage is set as the nominal operating voltage, the insulation resistance value of the samples with WTC = 1.6 exhibits the largest value, and the insulation resistance value of the samples with WTC = 1.7 reaches its smallest level.

- (4)

- As the HST of the samples rises from 105 °C to 110 °C, the insulation resistance values of the samples lessen for all considered WTCs.

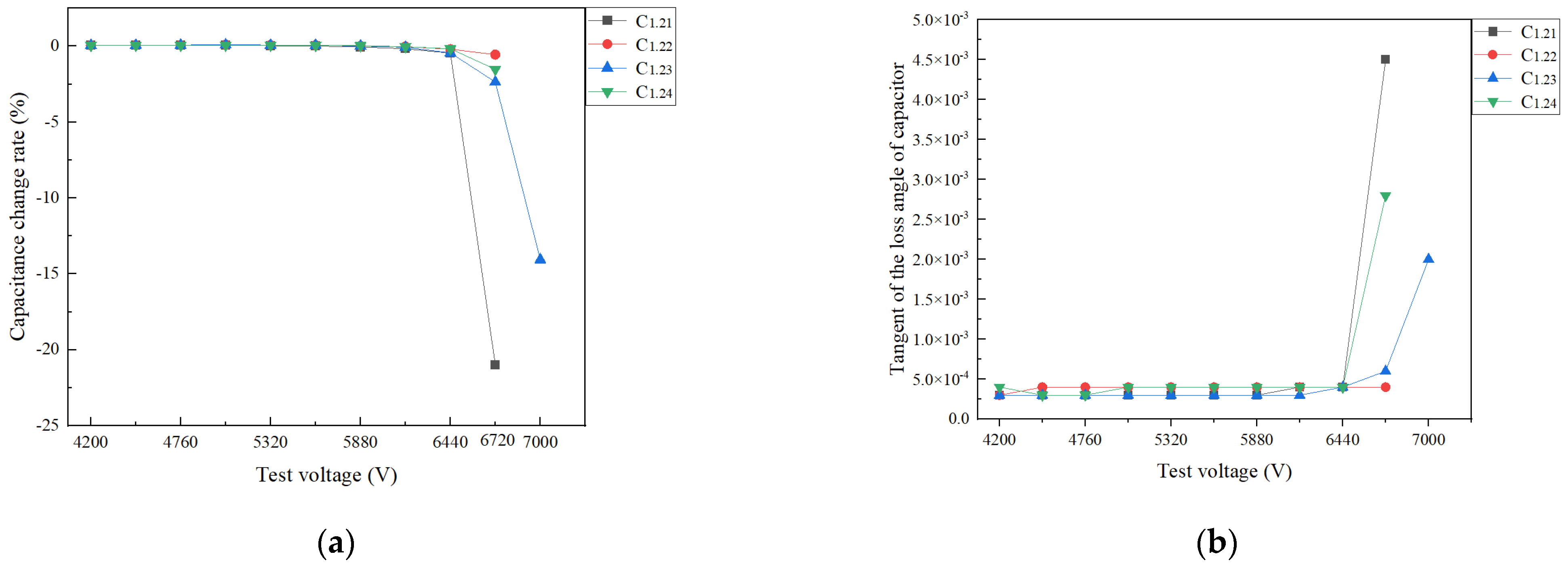

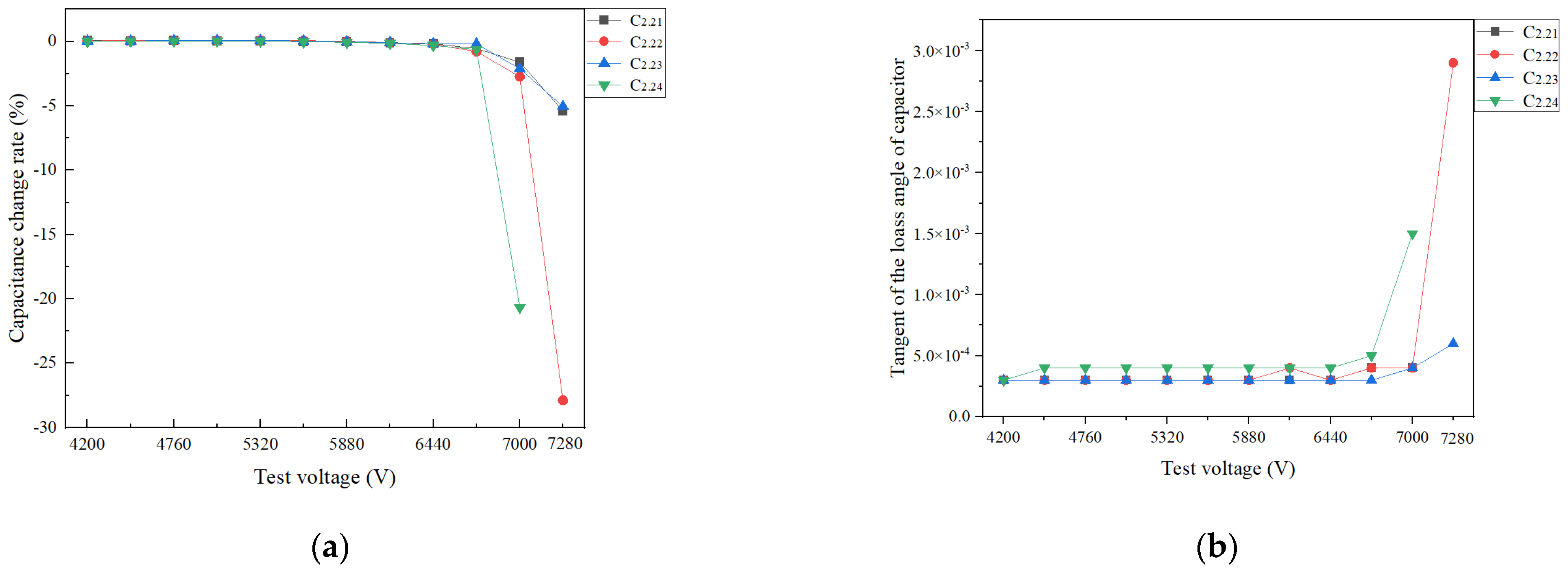

4.3. Withstand Voltage Test

5. Conclusions

- (1)

- The capacitance of the samples with four WTCs at the HSTs of 105 °C and 110 °C increased and then decreased with time.

- (2)

- Shrinkage tension during heat setting affected the service life of the samples such that their life improved with raising of the temperature. When the HST increased from 105 °C to 110 °C, the capacitance changes of all four winding tensions (tension coefficients) exhibited a descending trend accordingly after 800 h of the life aging test.

- (3)

- The winding tension influenced the life of the samples such that those with the highest tension (tension coefficient) exhibited the longest life at HST = 105 °C, whereas the samples with the lowest tension exhibited the longest life at HST = 110 °C. In the case of HST = 105 °C, the samples with WTC = 1.7 exhibited the lowest capacitance change (−1.985%) after 800 h of the aging test. In the case of HST = 110 °C, the samples with WTC = 1.4 had the lowest capacitance change rate (−0.915%) after 800 h of the life aging test.

- (4)

- Shrinkage tension during heat setting affected the tangent of the loss angle of DCLCs. When the HST was raised from 105 °C to 110 °C, all tangent values of the loss angle of the samples with four types of WTCs were reduced compared to before the test after 800 h of the life aging test.

- (5)

- When the temperature of the heat setting increased from 105 °C to 110 °C, all the insulation resistance values of the samples with four kinds of WTCs were reduced. When the initial discharge voltage was set at the rated operating voltage, the insulation resistances of the samples with WTC = 1.6 had the largest value.

- (6)

- The samples with WTC = 1.6 exhibited the best ability to withstand voltage, and the breakdown voltage of the samples was obtained as 7000 V at HST = 105 °C or 7280 V at HST = 110 °C.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rytöluoto, I.; Niittymäki, M.; Seri, P.; Naderiallaf, H.; Lahti, K.; Saarimäki, E.; Flyktman, T.; Paajanen, M. Biaxially oriented silica–polypropylene nanocomposites for HVDC film capacitors: Morphology-dielectric property relationships, and critical evaluation of the current progress and limitations. J. Mater. Chem. A 2022, 10, 3025–3043. [Google Scholar] [CrossRef]

- Makdessi, M.; Sari, A.; Venet, P. Metallized polymer film capacitors ageing law based on capacitance degradation. Microelectron. Reliab. 2014, 54, 1823–1827. [Google Scholar] [CrossRef]

- Rabuffi, M.; Picci, G. Status quo and future prospects for metallized polypropylene energy storage capacitors. IEEE Trans. Plasma Sci. 2002, 30, 1939–1942. [Google Scholar] [CrossRef]

- Sarjeant, W.J.; Zirnheld, J.; MacDougall, F.W.; Bowers, J.; Clark, N.; Clelland, I.; Price, R.; Hudis, M.; Kohlberg, I.; McDuff, G. Capacitors—Past, present, and future. In Handbook of Low and High Dielectric Constant Materials and Their Applications; Elsevier: Amsterdam, The Netherlands, 1999; pp. 423–491. [Google Scholar]

- Wang, H.; Blaabjerg, F. Reliability of capacitors for DC-link applications in power electronic converters—An overview. IEEE Trans. Ind. Appl. 2014, 50, 3569–3578. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J.; Zhang, Y.; Yin, J.; Cao, R.; Li, Y.; Liu, X. A method to characterize the shrinking of safe operation area of metallized film capacitor considering electrothermal coupling and aging in power electronics applications. IEEE Trans. Ind. Electron. 2022, 70, 1993–2002. [Google Scholar] [CrossRef]

- Du, B. Polymer Insulation Applied for HVDC Transmission; Springer Nature: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Xing, Z.; Gu, Z.; Zhang, C.; Guo, S.; Cui, H.; Lei, Q.; Li, G. Influence of space charge on dielectric property and breakdown strength of polypropylene dielectrics under strong electric field. Energies 2022, 15, 4412. [Google Scholar] [CrossRef]

- Tai, Y.; Chen, P.; Jian, Y.; Fang, Q.; Xu, D.; Cheng, J. Failure mechanism and life estimate of metallized film capacitor under high temperature and humidity. Microelectron. Reliab. 2022, 137, 114755. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Qiu, T.; Lin, F.; Wang, Y. Reliability criterion of film capacitor based on moisture diffusion in encapsulation. High Volt. 2023, 8, 1242–1252. [Google Scholar] [CrossRef]

- Wang, H.; Nielsen, D.A.; Blaabjerg, F. Degradation testing and failure analysis of DC film capacitors under high humidity conditions. Microelectron. Reliab. 2015, 55, 2007–2011. [Google Scholar] [CrossRef]

- Hu, Y.; Ye, X.; Zheng, B.; Zhao, Z.; Zhai, G. Degradation mechanisms-based reliability modeling for metallized film capacitors under temperature and voltage stresses. Microelectron. Reliab. 2022, 138, 114609. [Google Scholar] [CrossRef]

- Cheng, L.; Li, Z.; Wang, J.; Xu, Z.; Liu, W.; Li, S. Degradation behavior and mechanism of metalized film capacitor under ultrahigh field. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 509–517. [Google Scholar] [CrossRef]

- Petersson, L.; Wei, K.; Paulsson, G.; Strömsten, D.; Ekh, J. Mechanical stress distribution inside Dry capacitor elements. In Proceedings of the Nordic Insulation Symposium, Trondheim, Norway, 9–12 June 2013. [Google Scholar]

- Peng, B.; Lin, F.; Li, H.; Chen, Y.; Zhang, M.; Lv, F. Calculation and measurement of metalized film capacitor’s inner pressure and its influence on self-healing characteristics. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1612–1618. [Google Scholar] [CrossRef]

- Tandon, S. Modeling of Stresses in Cylindrically Wound Capacitors: Characterization and the Influence of Stress on Dielectric Breakdown of Polymeric Film; University of Massachusetts Amherst: Amherst, MA, USA, 1997. [Google Scholar]

- Tandon, S.; Farris, R.J. Metalized polypropylene film in capacitors: Characterization and the effect of interfacial pressure on the dielectric srength. MRS Online Proc. Libr. 1997, 476, 147. [Google Scholar] [CrossRef]

- Rytöluoto, I.; Lahti, K. Effect of inter-layer pressure on dielectric breakdown characteristics of metallized polymer films for capacitor applications. In Proceedings of the 2013 IEEE International Conference on Solid Dielectrics (ICSD), Bologna, Italy, 30 June 2013–4 July 2013; pp. 682–687. [Google Scholar]

- Wang, Z.; Qi, C.; Yan, F.; Ma, Y. Study on DC surface flashover at the clear edge of metallized polypropylene films. IEEE Trans. Plasma Sci. 2022, 50, 3139–3147. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, S.; Yan, F.; Yang, Y.; Ma, Y. Design of current gate width in AC segment metalized film capacitors based on self-healing characteristics. IEEE Trans. Plasma Sci. 2023, 51, 2688–2696. [Google Scholar] [CrossRef]

- Cui, H.; Xing, Z.; Zhang, C.; Guo, S.; Su, Y.; Zhang, H. Characteristic evaluation of BOPP capacitor after winding process with mechanical stress. In Proceedings of the 2023 IEEE 4th International Conference on Electrical Materials and Power Equipment (ICEMPE), Shanghai, China, 7–10 May 2023; pp. 1–4. [Google Scholar]

- Wang, W.; Li, H.; Li, Z.; Tong, Y.; Lin, F. Life time improvement of metalized film capacitors by inner pressure strengthening. High Power Laser Part. Beams 2014, 26, 045015. [Google Scholar] [CrossRef]

- IEC 61071:2017; Capacitors for Power Electronics. IEC: London, UK, 2017.

- Ran, Z.; Du, B.; Xiao, M.; Li, J. Crystallization morphology-dependent breakdown strength of polypropylene films for converter valve capacitor. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 964–971. [Google Scholar] [CrossRef]

- Du, B.; Ran, Z.; Liu, H.; Xiao, M. Research progress ofdielectric properties and improvement methods of polypropylene filmfor dry-type capacitor. Trans. China Electrotech. Soc. 2023, 38, 1363–1374. [Google Scholar]

- Wang, Y.; Li, H.; Wang, Z.; Lin, F. Voltage maintaining performance of metallized film capacitors based on crystallinity regulation. High Volt. Eng. 2022, 48, 3643–3650. [Google Scholar]

- Liu, H.; Du, B.; Xiao, M.; Tanaka, T. High-temperature performance of dielectric breakdown in BOPP capacitor film based on surface grafting. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1264–1272. [Google Scholar] [CrossRef]

| Samples | C1.1 | C1.2 | C1.3 | C1.4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time (h) | 100 | 500 | 800 | 100 | 500 | 800 | 100 | 500 | 800 | 100 | 500 | 800 |

| Capacitance change rate (%) | 0.022 | −1.458 | −3.440 | −0.011 | −1.692 | −7.245 | 0.044 | −0.608 | −2.239 | 0.056 | −0.502 | −1.985 |

| Samples | C2.1 | C2.2 | C2.3 | C2.4 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Time (h) | 100 | 500 | 800 | 100 | 500 | 800 | 100 | 500 | 800 | 100 | 500 | 800 |

| Capacitance change rate (%) | 0.040 | −0.281 | −0.915 | −0.006 | −0.414 | −1.391 | 0.071 | −0.290 | −2.120 | 0.052 | −0.209 | −1.693 |

| Samples | C1.11 | C1.12 | C1.13 | C1.14 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage (V) | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 |

| Insulation resistance (MΩ) | 132.44 | 32.27 | 15.52 | 138.59 | 20.72 | 15.23 | 149.95 | 31.46 | 15.13 | 137.62 | 26.02 | 10.49 |

| Samples | C2.11 | C2.12 | C2.13 | C2.24 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage (V) | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 | 2800 | 4480 | 5600 |

| Insulation resistance (MΩ) | 119.01 | 31.11 | 12.85 | 122.64 | 30.70 | 11.45 | 132.34 | 16.94 | 10.50 | 114.82 | 23.67 | 9.29 |

| Samples | C1.21 | C1.22 | C1.23 | C1.24 | |

|---|---|---|---|---|---|

| Voltage (V) | 6720 | 6720 | 6720 | 7000 | 6720 |

| Capacitance change rate (%) | −20.99 | −0.554 | −2.357 | −14.06 | −1.517 |

| Samples | C2.21 | C2.22 | C2.23 | C2.24 | |||

|---|---|---|---|---|---|---|---|

| Voltage (V) | 7000 | 7280 | 7000 | 7280 | 7000 | 7280 | 7000 |

| Capacitance change rate (%) | −1.6 | −5.386 | −2.73 | −27.88 | −2.11 | −5.04 | −20.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; Qiao, Y.; Li, Y.; Guo, X.; Cao, C. Effects of Mechanical Stress on the Life and Insulation Performance of DC-Link Capacitors. Energies 2024, 17, 699. https://doi.org/10.3390/en17030699

Sun X, Qiao Y, Li Y, Guo X, Cao C. Effects of Mechanical Stress on the Life and Insulation Performance of DC-Link Capacitors. Energies. 2024; 17(3):699. https://doi.org/10.3390/en17030699

Chicago/Turabian StyleSun, Xiaowu, Ying Qiao, Yinda Li, Xiangming Guo, and Chongfeng Cao. 2024. "Effects of Mechanical Stress on the Life and Insulation Performance of DC-Link Capacitors" Energies 17, no. 3: 699. https://doi.org/10.3390/en17030699

APA StyleSun, X., Qiao, Y., Li, Y., Guo, X., & Cao, C. (2024). Effects of Mechanical Stress on the Life and Insulation Performance of DC-Link Capacitors. Energies, 17(3), 699. https://doi.org/10.3390/en17030699