1. Introduction

In order to amplify the output torque of the driving motor, a reduction gear is always used in the electric vehicle (EV) [

1,

2]. Compared with mechanical gears that require contact between the input and output rotors, which will cause vibrations and noise problems [

3], magnetic gears (MGs) are quieter and require less maintenance. Furthermore, MGs are capable of inherent overload protection due to the physical isolation between the input and output rotors, which is a key characteristic increasing the reliability of the transmission system [

4]. These aforementioned features make MGs promising for EV applications [

5,

6,

7].

The original structure and working principle of a coaxial MG based on the flux modulation effect was first proposed in [

8]; its experimental investigation was reported in [

9]. The proposed MG employs permanent magnets (PMs) on the surface of both the low-speed and high-speed rotors. Based on this structure, quite a few new MG topologies have been proposed in recent years. In [

10], an MG that uses a spoke-type high-speed rotor and a surface-mounted PM (SPM) low-speed rotor was reported. The mechanical strength of the MG proposed in [

10] is significantly improved because of the spoke-type configuration and, it is demonstrated that this MG can achieve a comparable torque density to mechanical gears. In [

11], a high-torque-density spoke-type MG was proposed, and a parameter optimization was performed to obtain the highest torque density. The hybrid utilization of PM materials was investigated in terms of the volumetric torque density (VTD), specific torque, and manufacturing cost of the MG. Finally, it was demonstrated that spoke-type MGs can achieve a high torque density with a lower utilization of rare-earth PMs such as NdFeB. Based on the spoke-type configuration, another flux-focusing MG (FFMG) with a 1:4.25 gear ratio was introduced in [

12], and a comparative study was conducted when the proposed FFMG employed ferrite, NdFeB, and hybrid magnets. It was demonstrated that the proposed FFMG can achieve a torque density of over 200 kNm/m

3 by scaling up the total volume [

13]. Another topological refinement was conducted in [

14], which employed a slotted outer rotor yoke with a flux-focusing arrangement of PMs to reduce the overall weight of the MG by slotting the iron yoke of the low-speed rotor and improve the gravimetric torque density of the MG. To further improve the performance of MGs, the Halbach configuration was proposed in [

15]. The results showed that the implementation of the Halbach array in MGs leads to a higher torque density, a lower torque ripple and less iron loss. Moreover, the effect of modulation ring support on the Halbach MG was investigated in [

16], which illustrated that the implementation of circular rod supports can significantly reduce the manufacturing intricacy of the MG and maintain an acceptable VTD for EV propulsion. To achieve a high gear ratio, multi-stage MG was used in [

17,

18]. Nonetheless, this structure suffered from a low transmission efficiency due to the multi-stage configuration.

In addition to exploring novel technologies, design optimization is another effective way to improve the performance of MGs, such as selecting the best pole pair combination, maximizing the torque density and efficiency, and minimizing the torque ripple and cost [

19,

20]. Since electromagnetic devices such as electric machines and MGs have a multi-physics performance, the abovementioned single-objective optimizations are not enough to improve the overall operation of such devices. In this regard, multi-objective optimization algorithms such as the genetic algorithm (GA) [

21] and the non-dominated sorting genetic algorithm (NSGA) [

22], and its improved version, NSGA II [

23], have been employed by researchers in recent years. In order to evaluate the different objectives during the optimization process, an FEA-based model can be implemented. Although the FEA-based models possess high accuracy, the time-consuming search procedure using these models can be costly, especially for cases that require 3D-FEA due to the axial geometry of the device [

24,

25]. Hence, surrogate models can be adopted to replace the FEA-based model with an approximate model to establish a connection between the variables and objectives in the optimization process [

26]. The accuracy of the surrogate model is a controversial problem, especially in the high-dimensional optimizations. As a consequence, various fitting approaches, such as response surface methodology (RSM) [

27], or Kriging method [

28], have recently been developed to create an approximate model with reasonable accuracy in terms of data prediction. In addition to the modern fitting approaches, the proper sampling of data can significantly reduce the potential inaccuracies in the resultant surrogate model. One of the most effective sampling approaches is the Latin-Hypercube Sampling (LHS) method, which creates initial samples, leading to a precise surrogate model [

29].

This paper aims to optimize a novel coaxial MG topology that combines the flux-focusing and Halbach configurations to achieve a high torque density. A multi-objective NSGA-II optimization based on a surrogate model using the Kriging fitting approach and LHS method is conducted to maximize the VTD, TPMV, and efficiency, and to minimize the torque ripple of the proposed FFH-CMG. The paper is organized as follows: in

Section 2, the structure and working principle of the proposed FFH-CMG are introduced. In

Section 3, the adopted surrogate-based multi-objective optimization is described and used to optimize the specified characteristics of the MG. The performance of the optimized FFH-CMG is investigated through 2D-FEA in

Section 4, and, finally, the conclusion of this paper is presented in

Section 5.

2. Structure and Working Principle

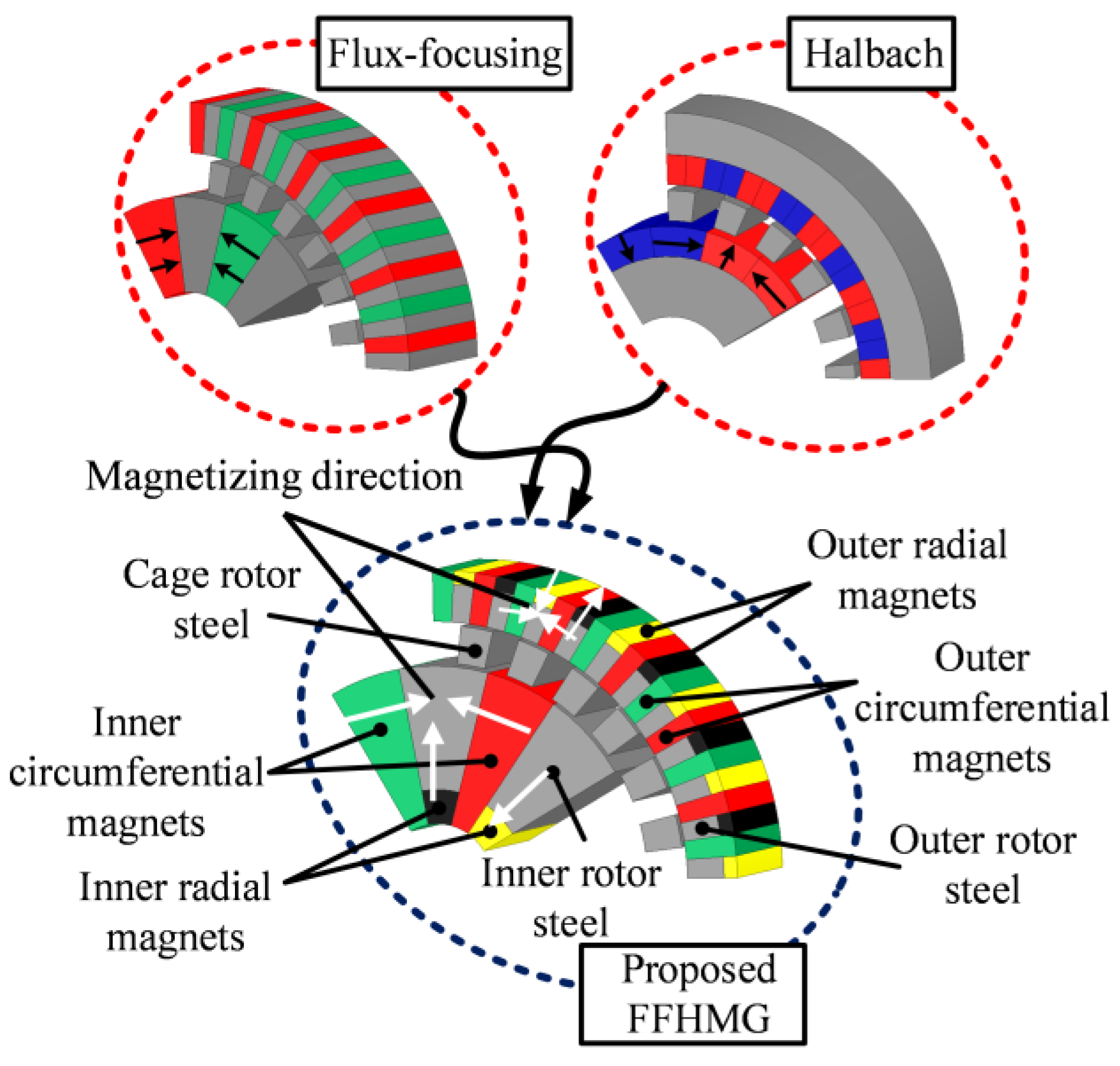

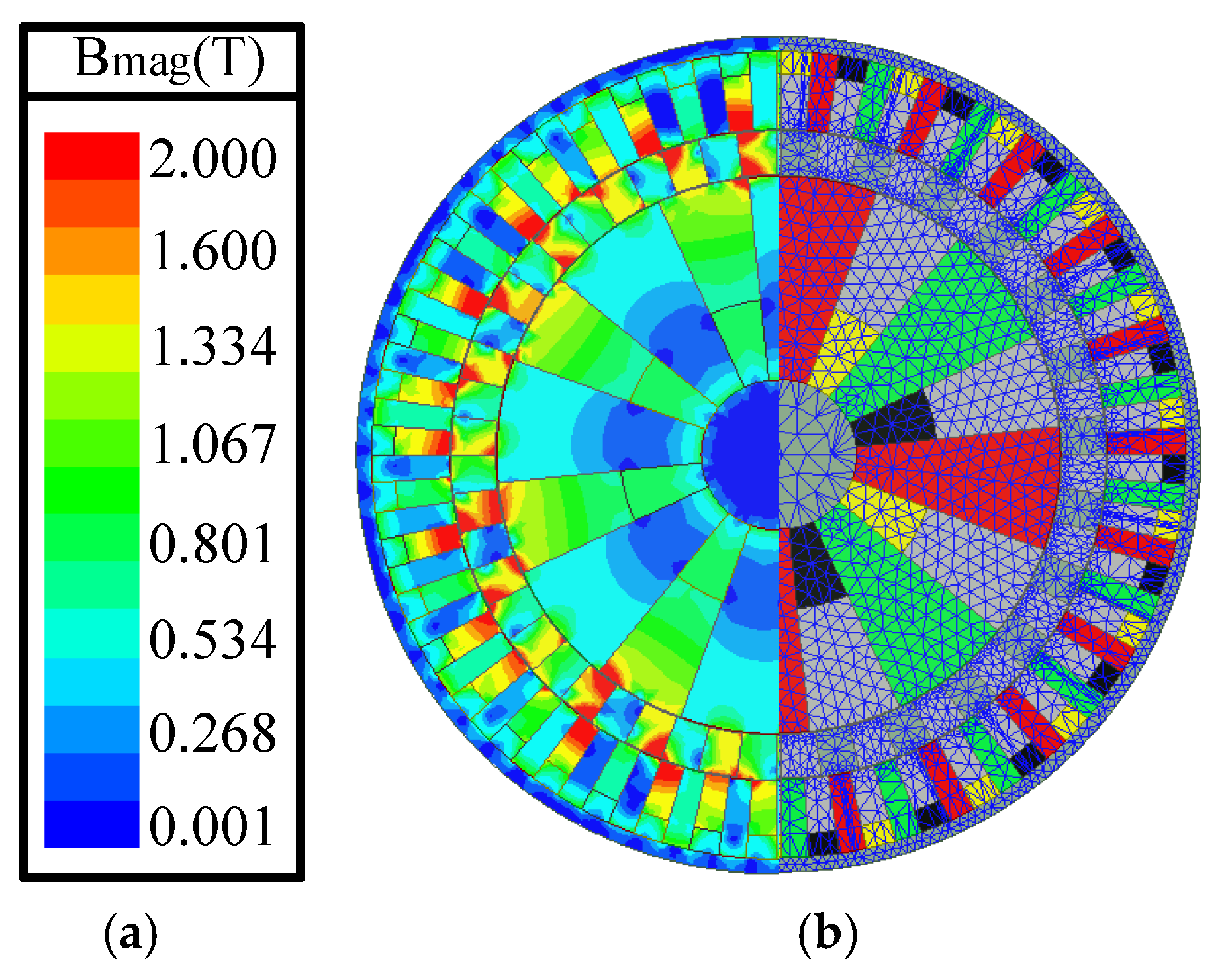

Figure 1 illustrates the structure of the proposed FFH-CMG that consists of PMs on the inner rotor, ferromagnetic pole pieces on the cage rotor, and PMs on the outer rotor. The modulation effect of the cage rotor enables effective magnetic coupling between the inner and outer rotors. As is shown, the red, green, black, and yellow magnets are producing flux lines in positive circumferential, negative circumferential, positive radial, and negative radial directions, respectively. The proposed FFH-CMG can be considered as a combination of flux-focusing and Halbach MGs, as shown in

Figure 1, in which the flux-focusing PM arrangement transmits the major torque. The Halbach array contributes to the torque transmission as well; moreover, it reduces the leakage flux of the flux-focusing structure and increases the VTD of the MG accordingly. Therefore, the total output torque of the proposed FFH-CMG is larger than the sum of the output torque of flux-focusing and Halbach MGs, and a high VTD can be achieved.

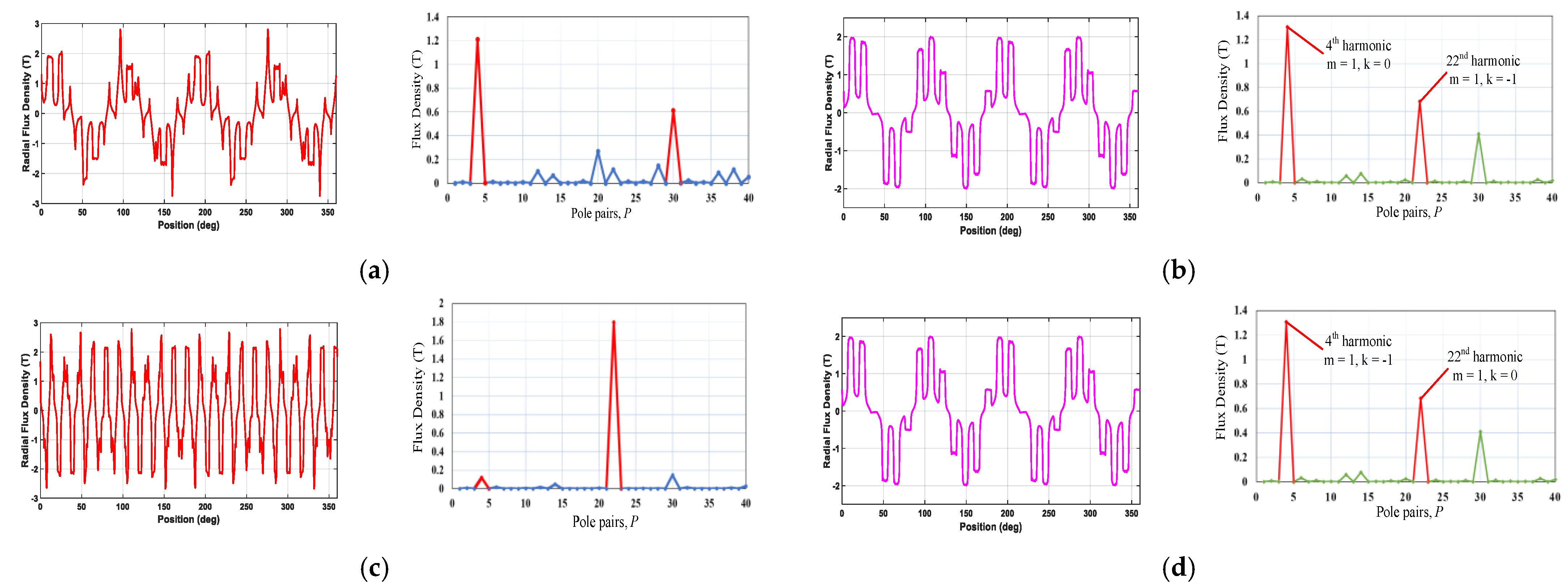

The radial component of the air-gap flux density after flux modulation can be expressed as follows [

30]:

where

p and

ns are the number of pole pairs on the PM rotor and the number of ferromagnetic pole pieces;

Ωr and

Ωs are the rotational velocities of the PM rotor and ferromagnetic pole pieces;

m, and

j are the corresponding numbers of Fourier components for the flux density and the modulating function;

λj and bm are the Fourier coefficients of modulation permeance and flux density distribution of PMs;

t and

θ are the time and position of the PM rotor, respectively. According to (1), the radial flux density in the inner airgap consists of a series of spatial harmonics, as follows:

The corresponding angular velocity of each spatial harmonic can be obtained by:

To achieve the maximum torque,

m = 1 and

k = −1, should be met in the above equation [

31]. Consequently, by holding different parts of the MG in a fixed position, different gear ratios can established. In this paper, the outer rotor of the FFH-CMG is fixed, and the cage rotor and inner rotor are considered as low-speed and high-speed rotors, respectively. Therefore, substituting

Ω3 = 0, the gear ratio of the proposed FFH-CMG can be calculated as follows:

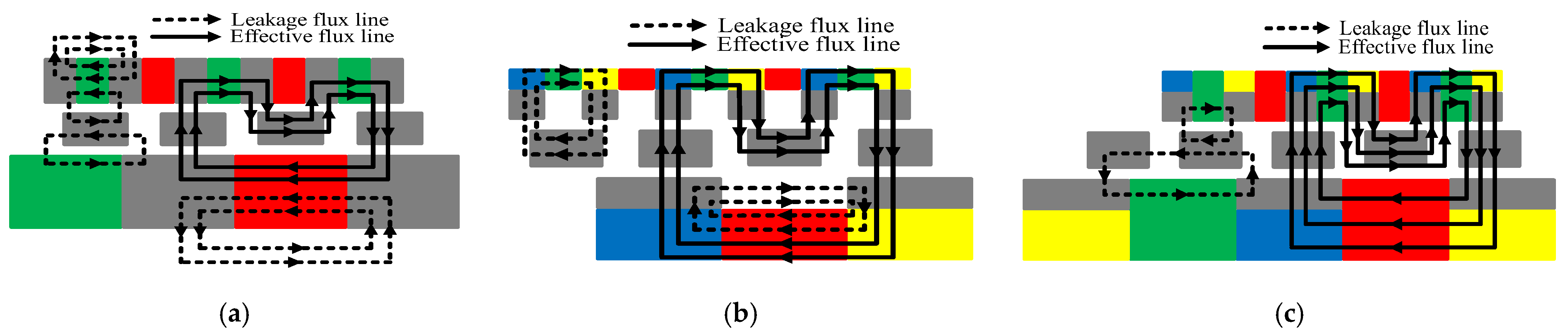

Figure 2a shows the flux lines of the flux-focusing MG. The leakage and effective flux lines are distinguished with dotted and solid lines, respectively. It is obvious that a significant portion of the interior flux lines end their path by the inner side of the high-speed rotor. This means that there will be lower flux density in the air gap and approximately half of the magnets’ fluxes do not contribute to the torque transmission. Moreover, there are some leakage fluxes that circulate between the rotors and ferromagnetic pole pieces, which have a deteriorating effect on the torque transmission and increase the core loss in the cage rotor. Implementing the Halbach array in the interior side of the high-speed rotor and the exterior side of the low-speed rotor blocks the path of leakage fluxes that were subjected to the flux-focusing structure, as illustrated in

Figure 2b. However, another leakage flux pattern is revealed in this structure, which closes their route through the vacant space between the rotor’s steel segments. The above-mentioned problems can be addressed by integrating the Halbach array into the flux-focusing design, as depicted in

Figure 2c. With the addition of the Halbach PM arrays, all the flux lines in the rotor cross the air gap, which will increase the torque density of the proposed FFH-CMG. The same works for the outer rotor, where all the flux lines of the outer rotor PMs are forced to pass the air gap with the help of the Halbach arrays on the outer rotor. In comparison with the basic flux-focusing topology, the deteriorating leakage fluxes in the proposed FFH-CMG are significantly reduced; nonetheless, the leakage fluxes in the cage rotor continue to exist, in spite of the fact that their effect is trivial.

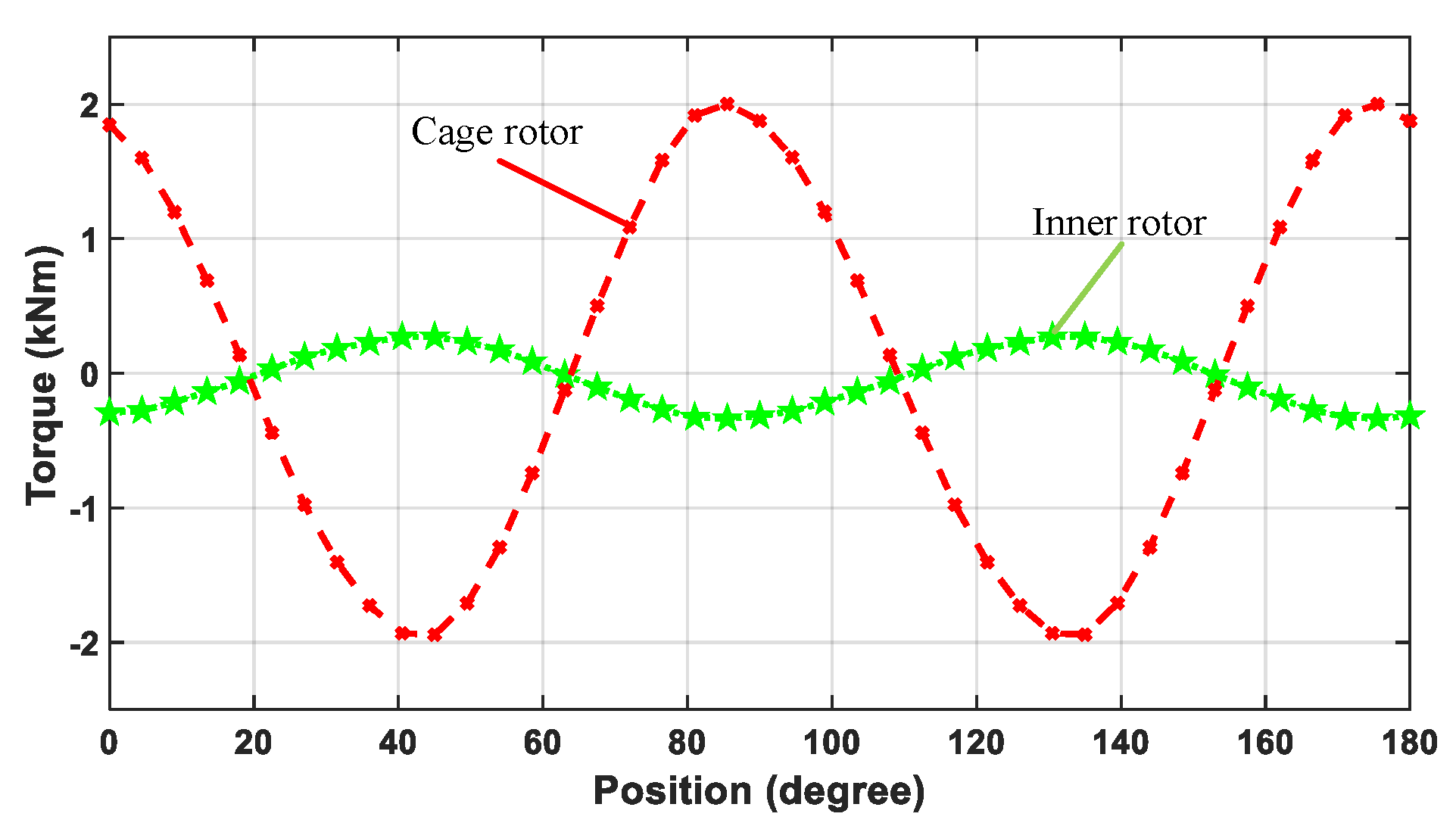

The proposed FFH-CMG is a combination of flux-focusing MG and Halbach MG, and both of them can transmit torque independently.

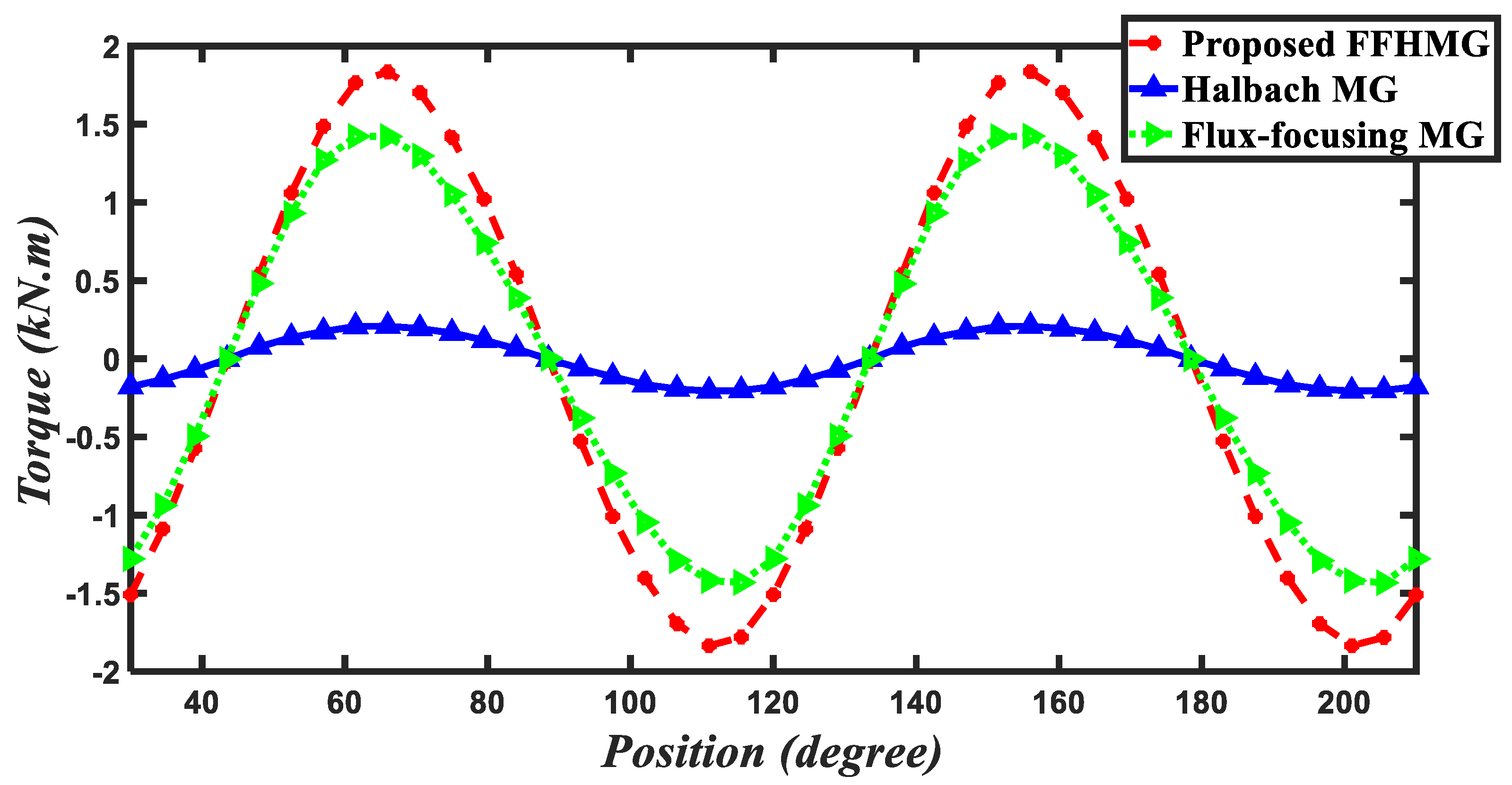

Figure 3 shows the stand-still torque of the cage rotor of the flux-focusing MG, Halbach MG, and the proposed FFH-CMG. One can see that the maximum output torque of the flux-focusing MG, Halbach MG, and the proposed FFH-CMG are 1.4, 0.23, and 1.74 kNm, respectively. The output torque of the proposed FFH-CMG is larger than the sum of output torque of the flux-focusing MG and Halbach MG, because Halbach magnets help to reduce the leakage flux of the flux-focusing MG and increase its output accordingly.

3. Multi-Objective Design Optimization of the Proposed FFH-CMG

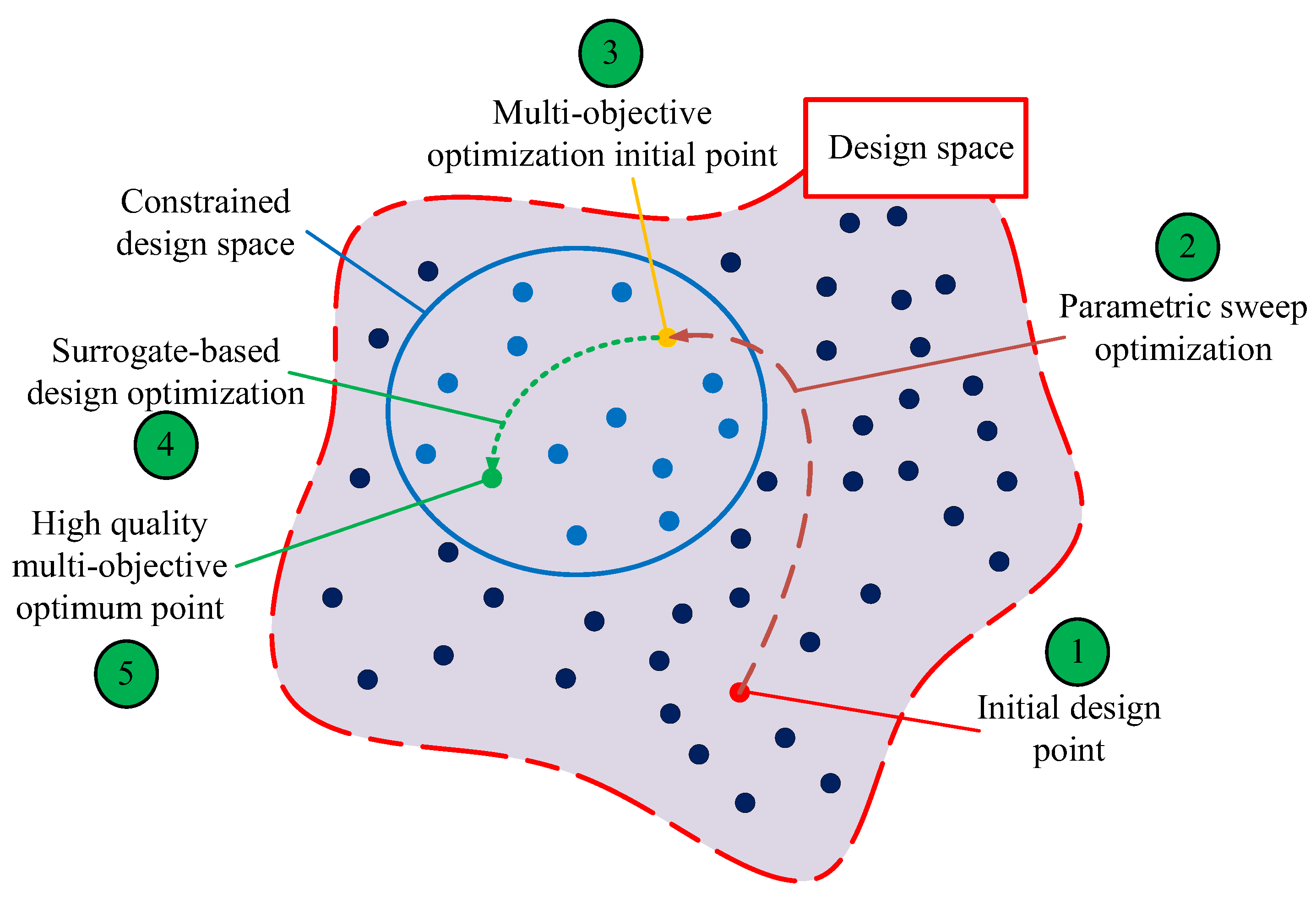

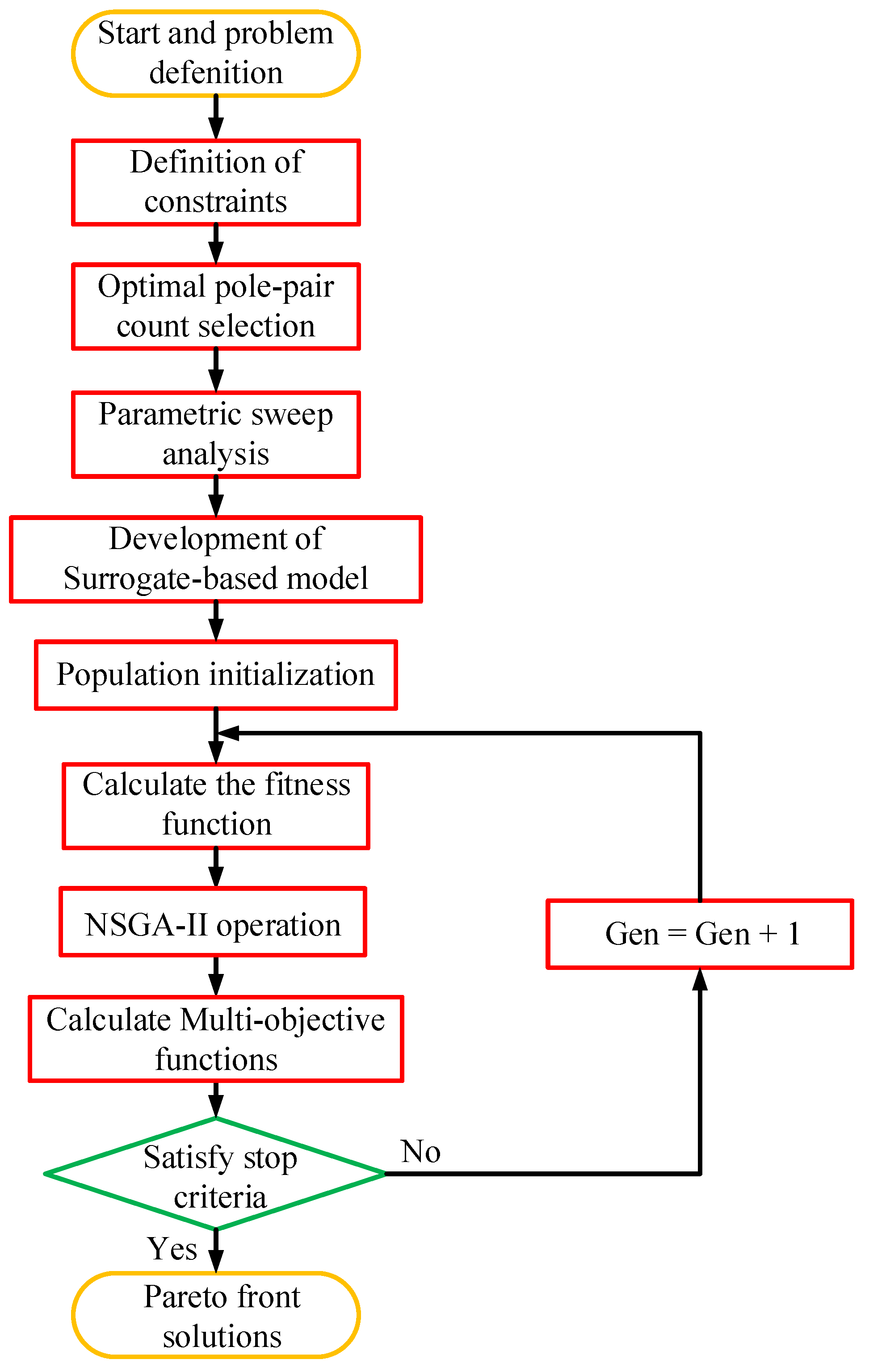

Due to their high-dimensional and multi-level geometry, the design optimization of electromagnetic devices such as MGs is not a straightforward procedure. Consequently, the traditional optimization approaches are not powerful enough to be adopted for the multi-objective optimization of MGs. In this regard, modern intelligent algorithms, coupled with FEA, can be a suitable alternative for such purposes. Nevertheless, the convergence process of the FEA-coupled approaches is quite time-consuming due to the iterative function of these algorithms, in which many sampling data are required for each iteration. Surrogate-based models, also called approximate models, can be used to replace the FEA to predict the required sampling data with an acceptable accuracy and fast speed. In this section, a surrogate-based multi-objective optimization is conducted to extract the optimal design of the FFH-CMG in terms of VTD, TPMV, efficiency, and torque ripple. The procedure of the proposed optimization algorithm is as follows: (a) the design constraints of the MG are defined according to the desired application; (b) the best pole pair combination for the proposed FFH-CMG is obtained based on a tree diagram analysis of the feasible combinations; (c) a parametric sweep optimization is then conducted to shift the initial design point to the constrained design space and obtain the suitable initial point for the subsequent intelligent optimization algorithm, as illustrated in

Figure 4; (d) eventually, the surrogate model based on Kriging fitting method and LHS approach is established to predict the objective functions of the required sampling data with an acceptable exactness, and the NSGA II intelligent optimization method is implemented to obtain Pareto-front optimal solutions for the MG design. The step-by-step progress of the proposed optimization method is summarized in the brief flowchart depicted in

Figure 5.

3.1. Design Constraints

In an optimization case, a set of constraints is usually defined to confine the searching space to the feasible and desirable solutions. From the perspective of the desired application and the fabrication complexity, the optimization constraints of the proposed FFH-CMG are summarized as follows:

6 ≤ Gr ≤ 7: In order to generate enough torque to propel the EV, the gear ratio is normally between 6 and 10 in EV applications. Since a large gear ratio will increase the leakage flux, a gear ratio between 6 and 7 is targeted in our design.

η ≥ 90%: The proposed FFH-CMG will be axially coupled with an electric motor (EM). A minimum efficiency of 90% is set as another constraint in our design to guarantee the high overall efficiency of the electric drive system.

wpm ≥ 3 mm: A very small size of magnets increases the complexity of the device and the magnetizing process. Consequently, the PM width (wpm) is set to be larger than 3 mm in our design.

Ro ≤ 135 mm, and Ri ≥ 25 mm: Due to the limited space in an EV, the maximum radius of MG is set to be Ro = 135 mm. Meanwhile, a common shaft is adopted to axially couple the inner rotor of the MG with the motor rotor. Hence, a minimum inner radius of Ri = 25 mm is considered for the shaft installation.

3.2. Optimal Pole Pair Combination

According to the required torque-speed levels of the considered application for the proposed FFH-CMG, a gear ratio of around 6 could be a suitable choice. To ensure the minimum torque ripple and noise, a non-integer gear ratio should be selected [

32]. Furthermore, the number of ferromagnetic pole pieces in the cage rotor should be even to avoid detrimental, unbalanced radial forces being found in the modulation ring [

33]. Since the topology of the proposed FFH-CMG is mainly based on the flux-concentrating structure, the number of pole pairs in the high-speed rotor must be more than

ph = 2, to guarantee the conduction of flux lines to the air gap.

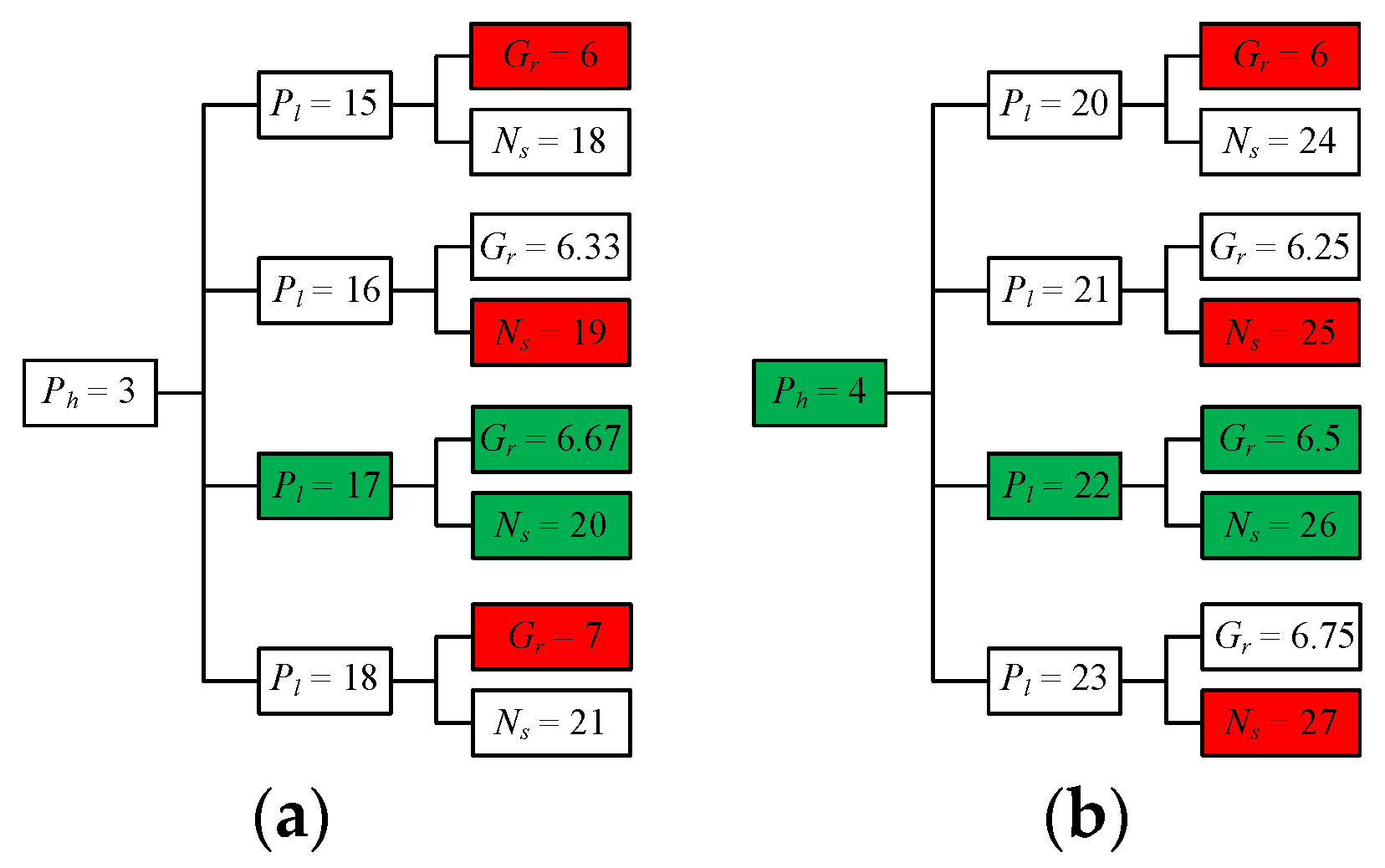

Consequently, a pole-pair-count selection analysis was conducted using a tree diagram, as demonstrated in

Figure 6. The evaluation of more than four pole pairs in the high-speed rotor is avoided in the suggested tree diagram due to the high manufactural complexity that will result from the high number of pole pairs in the low-speed rotor. As illustrated, two potential optimal solutions can be employed with

ph = 3, and

ph = 4 pole pair numbers of high-speed rotors, which led to

Gr = 6.67, and

Gr = 6.5 gear ratios, respectively. In order to select the best pole pair combination for the reported optimal solutions, a 2D-FEA was conducted to evaluate the maximum torque and torque ripple of the proposed FFH-CMG in each feasible combination. The obtained results are summarized in

Table 1. According to the acquired data, in the case of

ph = 4, a larger stall torque and a lower output torque ripple is achieved. Hence, the best pole pair combination of the proposed FFH-CMG was selected to be

ph = 4,

pl = 22, and

ns = 26.

3.3. Parametric Sweep Optimization

To achieve the highest TPMV and select the best initial design for the multi-objective optimization of the proposed FFH-CMG, a single-objective optimization, based on the parametric sweep method, was performed. In

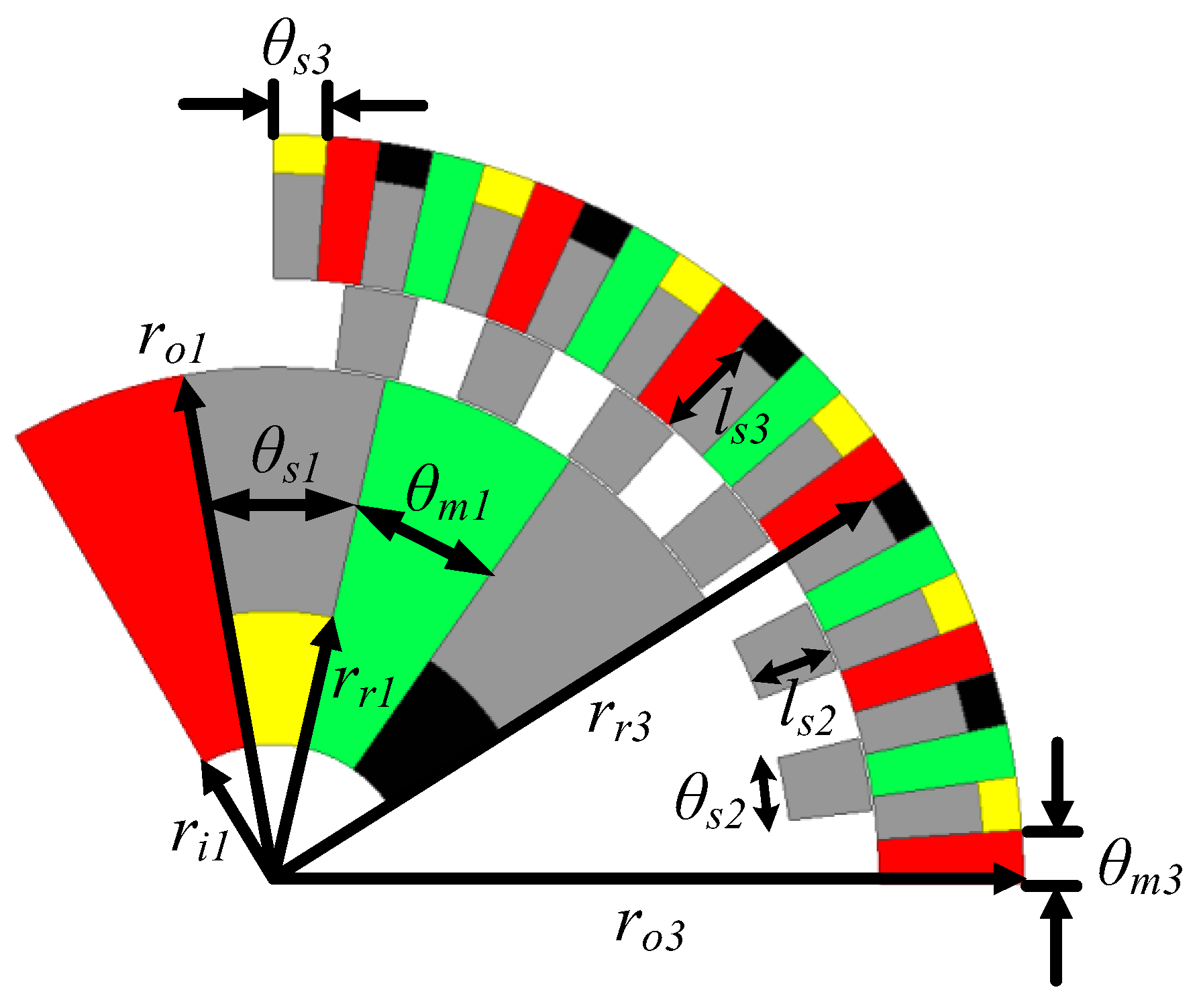

Figure 7, the geometric parameters of the proposed MG are depicted. As shown,

θs1,

θm1,

θs3, and

θm3 are the spans of the inner rotor steel, inner rotor magnet, outer rotor steel, and outer rotor magnets, respectively. The inner radius of the high-speed rotor (

ri1 = 25 mm) and the outer radius of the low-speed rotor (

ro3 = 135 mm) are fixed during the optimization to ensure that the total volume of the FFH-CMG remains constant.

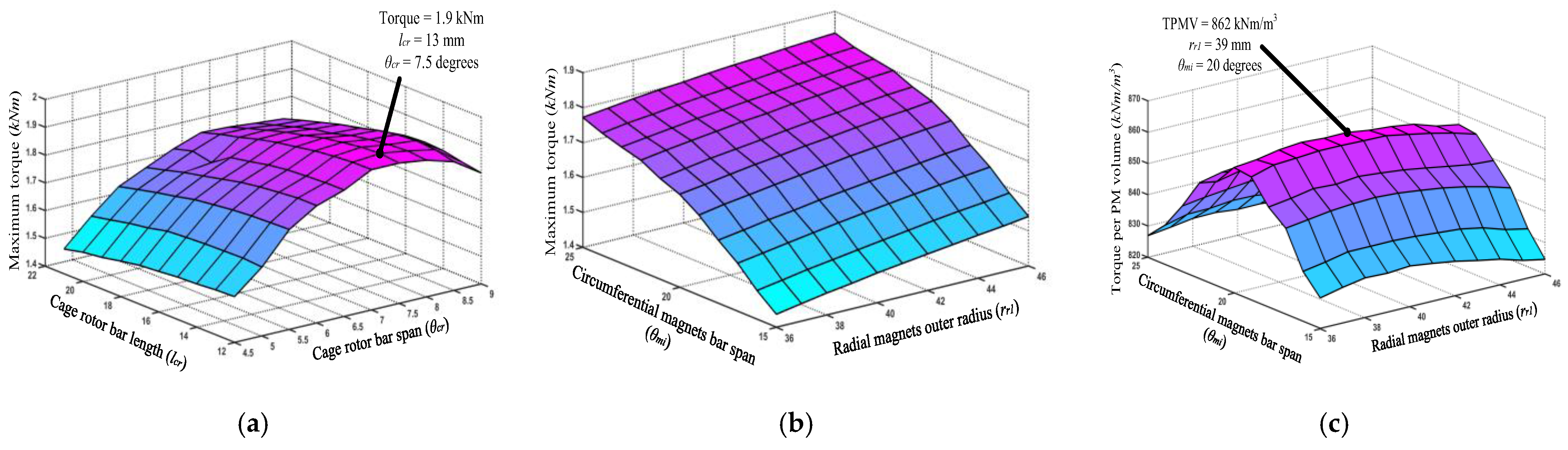

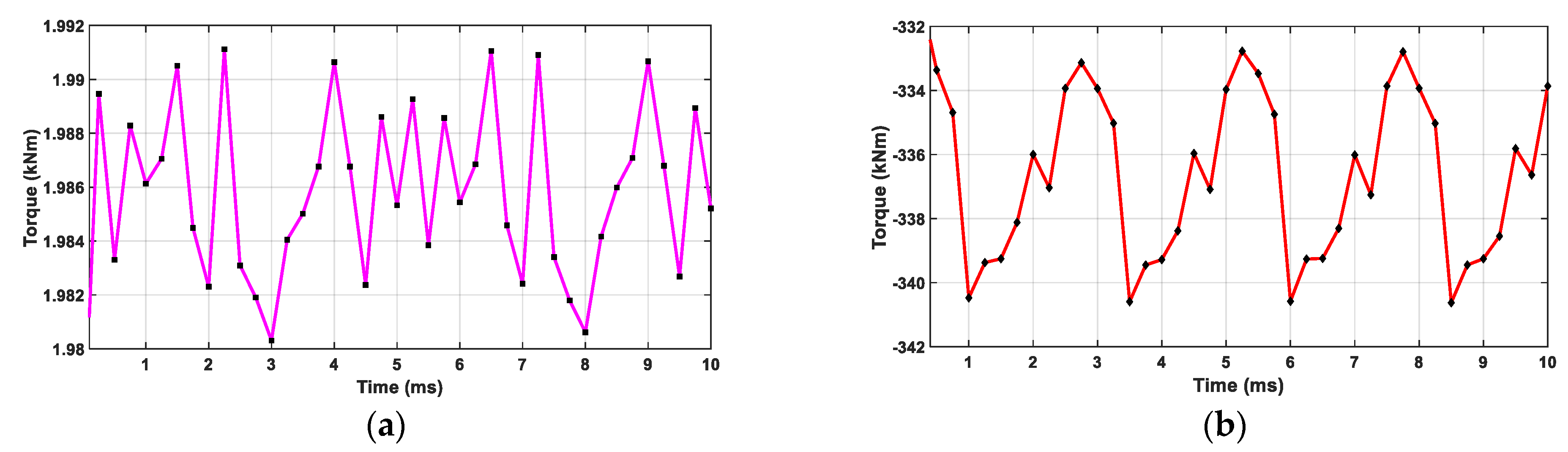

Initially, a parametric sweep was performed for the length (ls2) and bar span (θs2) of the cage rotor. During the parametric sweep, the total volume and the air-gap length of the FFH-CMG were fixed. In other words, with the increase in ls2, the values of ro1, and ls3 are decreased in the same proportion to keep the volume constant.

In

Figure 8a, the obtained results of the parametric sweep using 2D-FEA are illustrated. It can be noticed that a maximum stall torque of 1.9 kNm can be achieved when

θs2 and

ls2 are 7.5 degrees and 13 mm, respectively. Another parametric sweep is provided to select the most optimal thickness values of interior radial magnets (

rr1) and the bar span of the circumferential magnets (

θm1). In

Figure 8b, the stall torque values of the FFH-CMG are depicted for the different values of

rr1 and

θm1. It can be observed that the maximum torque of the FFH-CMG increases with the increase in of

rr1 and

θm1 values because of the increase in PM volumes. However, this will increase the total cost of the FFH-CMG. Hence, the optimal values of

rr1 and

θm1 are obtained when they lead to the highest TPMV.

Figure 8c demonstrates the influence of the magnet thickness and circumferential span on the TPMV. A maximum TPMV of 862 kNm/m

3 is obtained when

rr1 and

θm1 are 39 mm and 20 degrees, respectively. The final geometric parameters of the proposed FFH-CMG are summarized in

Table 2. The obtained values will be used as the initial design for the surrogate-based multi-objective optimization in the following.

3.4. Surrogate-Based Multi-Objective Design Optimization

By finishing the parametric sweep optimization, a proper value was obtained for each of the design variables. However, it is necessary to conduct a local compressive search around the obtained point to ensure the reliability of the optimization process. To achieve this goal, a non-dominated sorting genetic algorithm (NSGAII), coupled with a surrogate modeling technique, was adopted to efficiently search the constrained design space. The Kriging modeling method was utilized as the surrogate-model construction tool due to its high accuracy and low training cost compared to conventional methods such as response surface methodology (RSM) or artificial-intelligence-based methods such as artificial neural networks (ANNs) [

34,

35]. The Kriging surrogate model is defined as follows:

where

can be the linear of the quadratic polynomial and

is the random error term. A detailed mathematical definition of the Kriging model can be found in [

36].

To train an accurate surrogate model for each optimization objective, it is necessary to create a reliable training dataset. The number of samples and their distribution in the design space are two major factors that can significantly affect the accuracy and required computational cost.

The LHS method has proven to be an efficient sampling technique that can provide uniformly distributed samples in the design space. In this way, it is possible to increase the accuracy of the models based on a fixed number of samples. In this study, the number of input variables for the optimization process is equal to six (see

Table 3). Therefore, 270 (2.5423 levels for each input variable) samples were generated to properly cover the design space. By using the developed training dataset, a surrogate model of each optimization objective was constructed. The R-squared (

) accuracy metric was used to measure the accuracy of the constructed surrogate models, and the measured values demonstrate an acceptable match between the FEA results and the values predicted by the surrogate models.

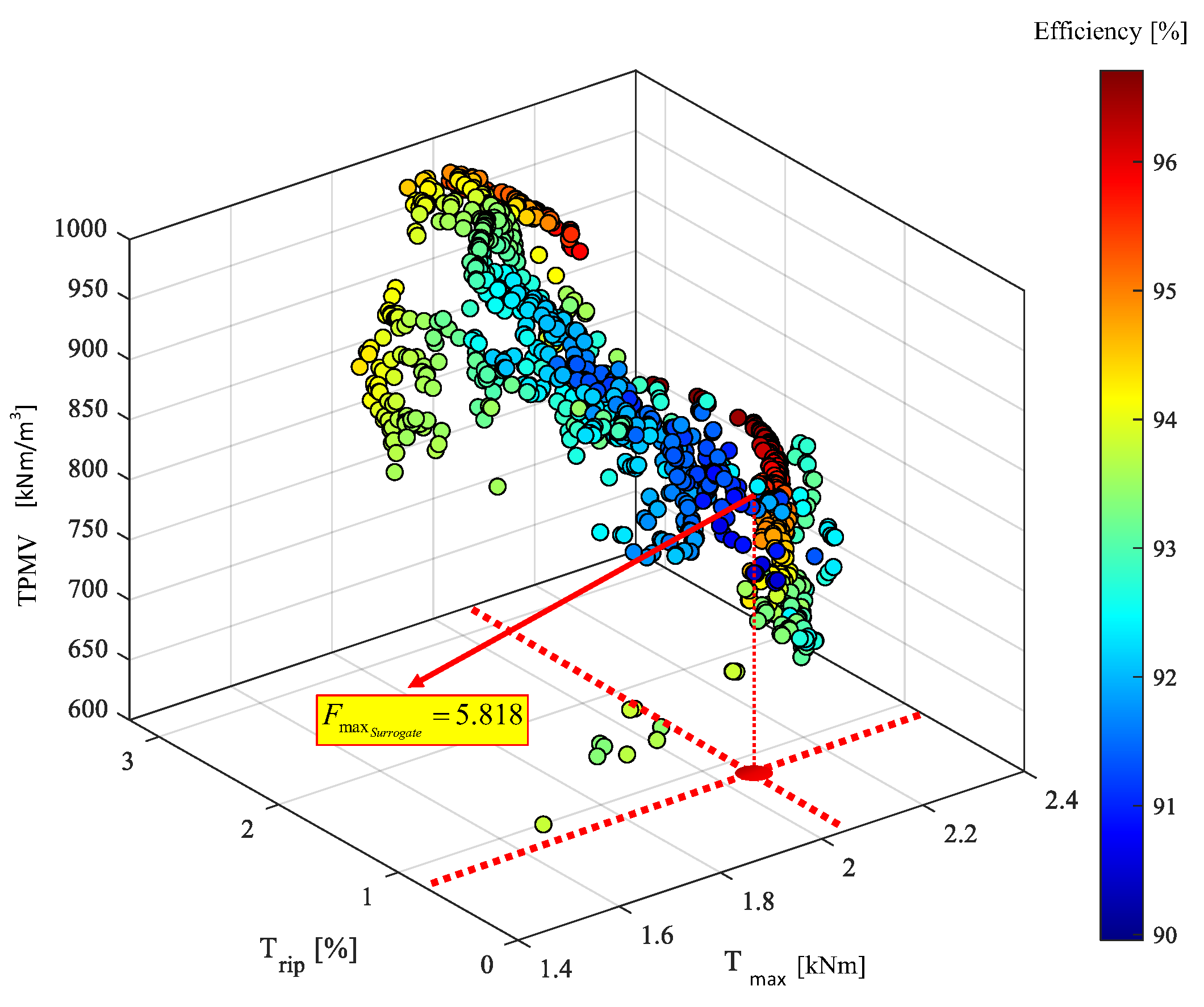

By adopting the NSGAII, 10,000 samples (100 population size and 100 generations) were evaluated during the multi-objective optimization process. From the evaluated designs, 2057 Pareto-optimum solutions were achieved that cannot be dominated by any other design.

Figure 9 illustrates the obtained Pareto front with respect to all four objective functions. While

varies within a small range, the remaining three objectives, including

Tmax,

TPMV, and

η, considerably change between the obtained Pareto solutions.

Figure 10 also shows the normalized distribution of the design parameters according to the Pareto solutions. While parameters such as

ls2 and

rr3 generate the optimum design with the values near to their upper bound (near to one in normalized plots), the

θm3 provides most of the optimum designs with the values near to its lower and upper bound.

The diversity of the Pareto-optimum solutions demonstrates that a successful multi-objective optimization was achieved. However, a solution must be chosen as the final product of the process. To select the final solution, a decision-making function considering all the optimization objectives was defined as follows:

where the aim is to find the maximized value among the obtained Pareto solutions.

Figure 9 illustrates the position of the selected optimum design corresponding to the objectives, and the optimized parameters are presented in

Table 3. Note that the predicted performance is only a surrogate-based solution. Therefore, its performance must be re-evaluated using the FEA method. The performance evaluation and comparison results are presented in the next section.

3.5. Effectiveness of the Proposed Optimization Approach

Unlike the conventional surrogate-based optimization algorithms that were employed by researchers in previous works, the proposed approach benefits from two main advantages: (1) the number of samples that are required to establish a precise surrogate model is reduced, and (2) the output results of the proposed optimization method are more reliable, and can be considered as the global optimum point. In the following, each advantage of the proposed technique is elaborated.

3.5.1. Sampling Efficiency

The initial design space of an MG, as well as other electromagnetic devices, is always a large enough to cover all possible design schemes. However, the optimal solution is only located in a small subspace. If this aspect is disregarded, a significant number of samples that lie outside the relevant subspace will undergo evaluation during the optimization process, leading to an unnecessary waste of computational resources. A sequential parametric sweep optimization was developed in this paper to confine the design space to an interesting subspace. This technique empowers designers to attain a precise surrogate model using the lowest possible number of sampled data points.

After the construction of approximate models, the accuracy and effectiveness of the constructed models should be verified with some new samples. The verification method implemented in this paper is the coefficient of determination

R2, defined as:

where

Ne is the number of new samples {

xi};

yi is their true responses;

, and

are the fitting approximate responses and their average value. This is a numerical value that represents the degree of compatibility between the data and a particular model, which is often represented by a line or curve. This value serves as one of the metrics used to assess the accuracy of approximate models. A higher accuracy is indicated when the

R2 value approaches 1.

Using the defined accuracy metric, a comparison between two optimization cases is conducted to demonstrate the effectiveness of the proposed surrogate model, coupled with the parametric weep technique. In both cases, the same number of samples was utilized to establish the approximate model. In the proposed approach, 200 samples were employed to find a suitable initial point for the subsequent multi-objective optimization, and then 300 samples were employed, using the LHS method, to establish the surrogate model. A total of 500 samples was utilized in the proposed method. For the second case, 500 samples, using the LHS method, were employed to establish the conventional surrogate model in the initial design space.

Table 4 illustrates the calculated

R2 values for each method. One can see that the accuracy of the proposed optimization approach is much better than that of the conventional surrogate-based optimization methods. This characteristic is more noteworthy when the objectives of the optimization problem are very sensitive to the optimization parameters, like the torque ripple in this case. The obtained results demonstrate the superiority of the proposed approach as compared to conventional surrogate-based optimization methods. More than 1000 samples with true responses are required for the conventional surrogate-based method to achieve an approximate model as accurate as the one established by the proposed approach. For the proposed FFH-CMG, each 2D-FEA takes an average time of 2 min. This means that for an approximate model using conventional surrogate-based optimization to achieve the same accuracy as the proposed optimization method, 1000 min (16.7 h) more time is needed to extract the required samples. This time duration could be even more considerable for topologies that require 3D-FEA.

3.5.2. Optimization Reliability

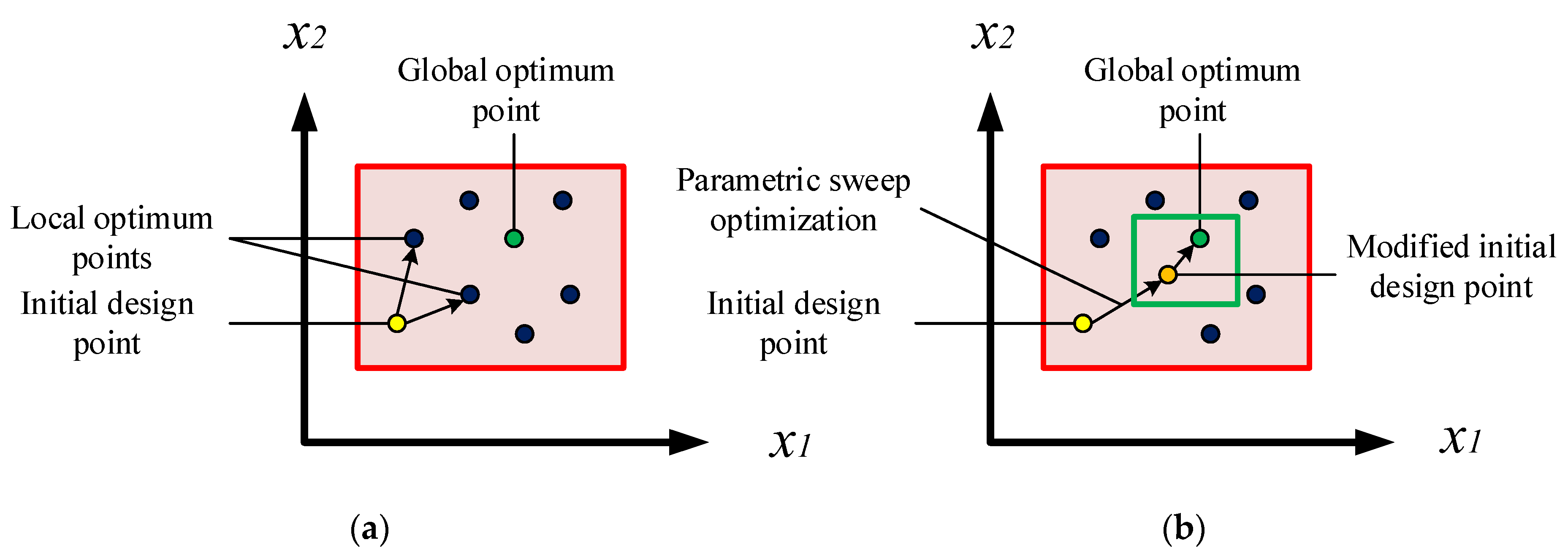

In the initial design space of an MG, there could be several local optimum points. Therefore, there is always a risk of convergence to the local optimum points rather than the global points during the optimization process, as illustrated in

Figure 11a. The proper selection of the initial sampling point is the key element when avoiding this problem. Thanks to the pre-conducted parametric sweep optimization that was used to select the suitable initial point for the subsequent multi-objective optimization, the probability of local optimum results being achieved was significantly reduced and the obtained results can be considered the global optimum design points, as illustrated in

Figure 11b.