Productivity Model for Multi-Fractured Horizontal Wells with Complex Fracture Networks in Shale Oil Reservoirs Considering Fluid Desorption and Two-Phase Behavior

Abstract

1. Introduction

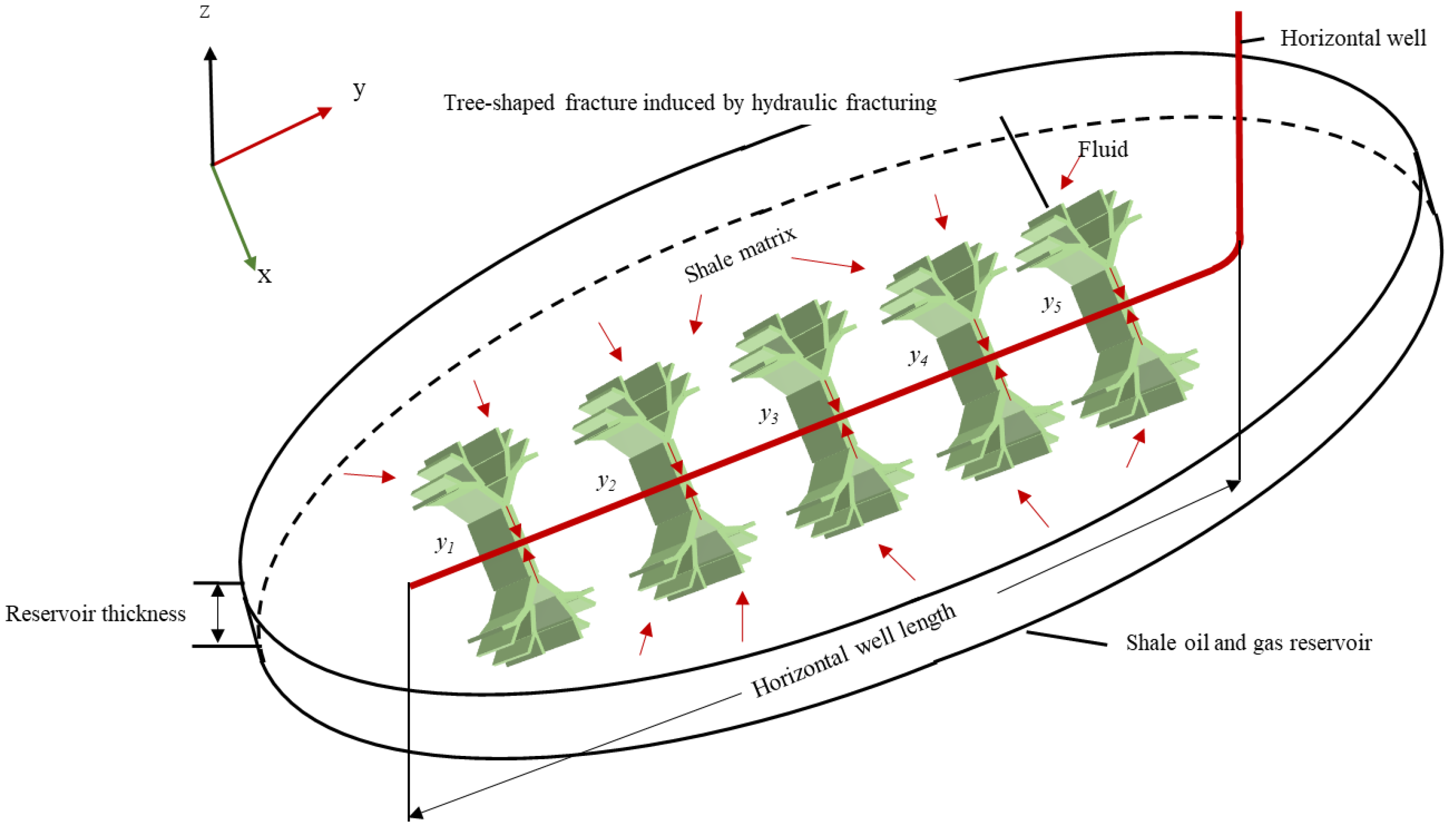

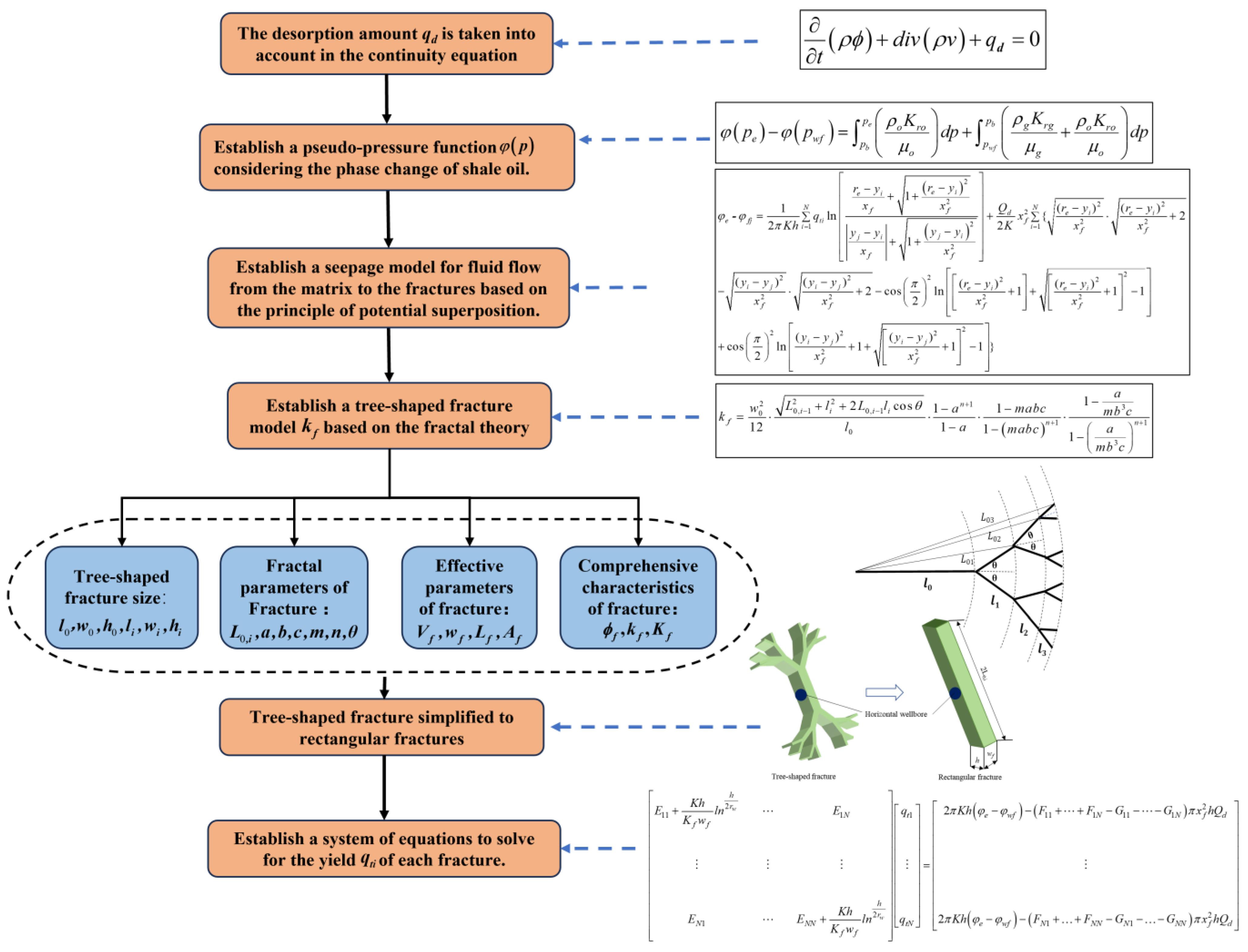

2. Mathematical Models

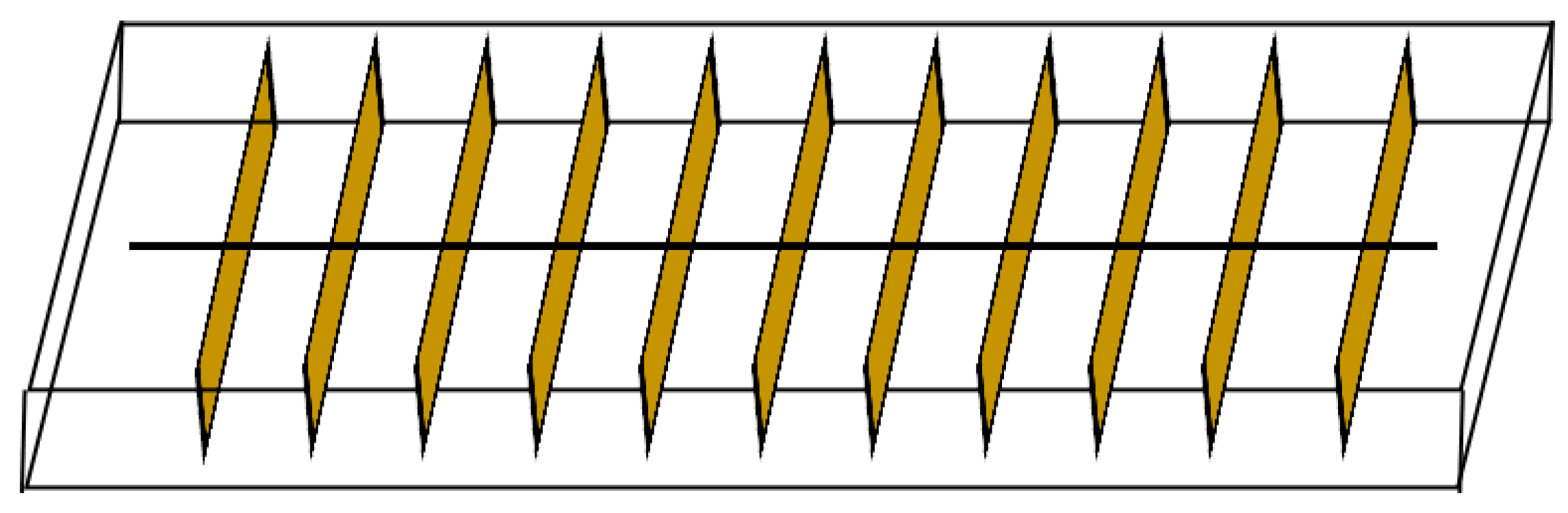

2.1. Model Assumptions

- (1)

- The shale oil reservoir is a finite, vertically sealed formation with a thickness of , and the reservoir exhibits homogeneity and isotropy.

- (2)

- The horizontal well, with a length of , is centrally situated within the reservoir and runs parallel to both the upper and lower boundaries of the reservoir.

- (3)

- The hydraulic fractures, each with a half-length of , fully penetrate the reservoir while maintaining uniform spacing between them.

- (4)

- The fluid flows from the formation into the fracture, and then it flows from the fracture into the wellbore. The production of the MFHW is the sum of the production from each fracture.

- (5)

- The fluid flow in shale oil reservoirs is considered to be isothermal two-phase flow, governed by Darcy’s law.

2.2. Seepage Model for Oil and Gas Flows in Shale Matrix

2.2.1. Model Establishment

2.2.2. Model Solution

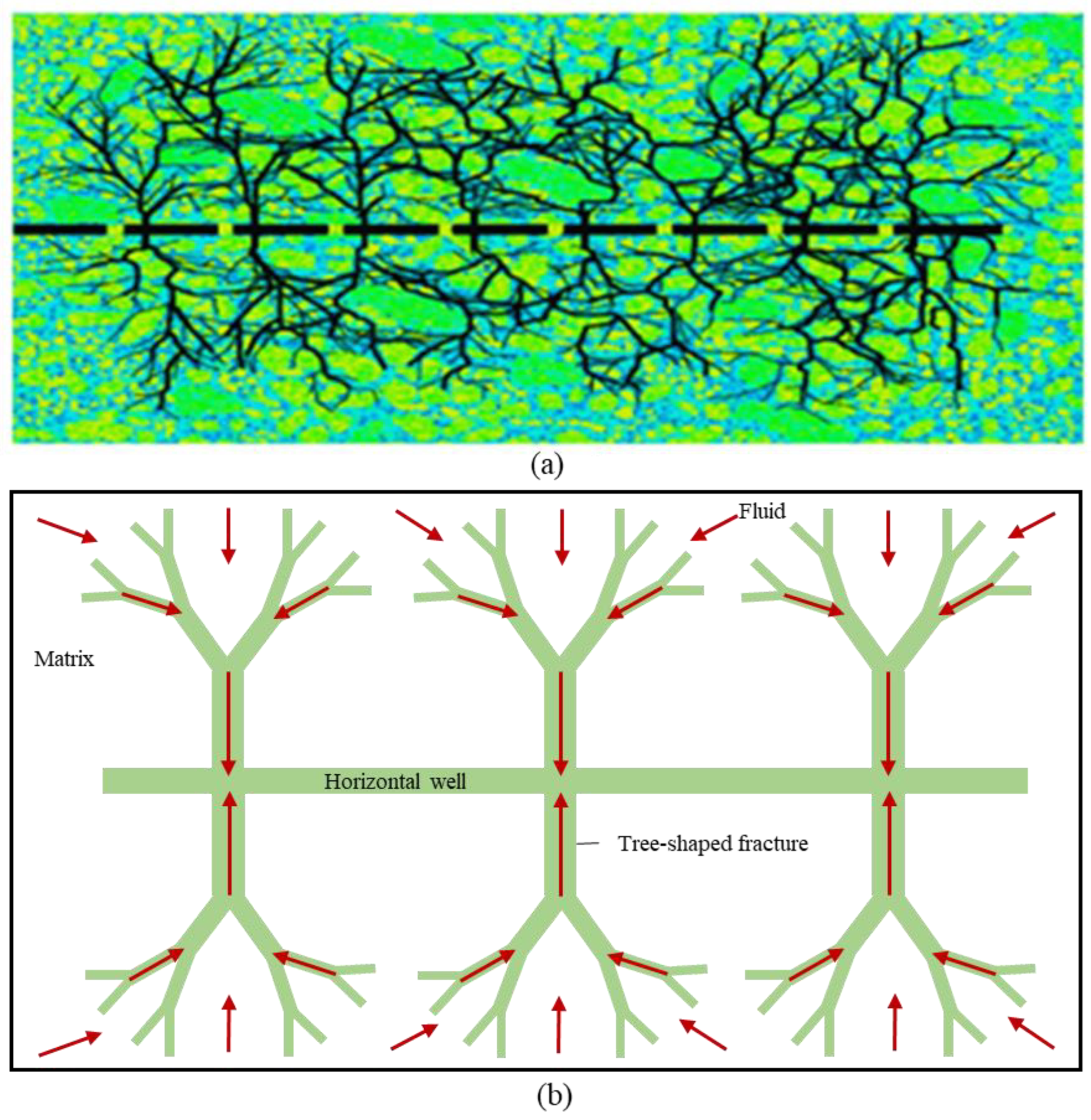

2.3. Seepage Model for Oil and Gas Flows in Tree-Shaped Fractures

2.3.1. Characteristic Parameters of Tree-Shaped Fractures

2.3.2. Tree-Shaped Fracture Permeability

2.3.3. Oil–Gas Two-Phase Seepage Model

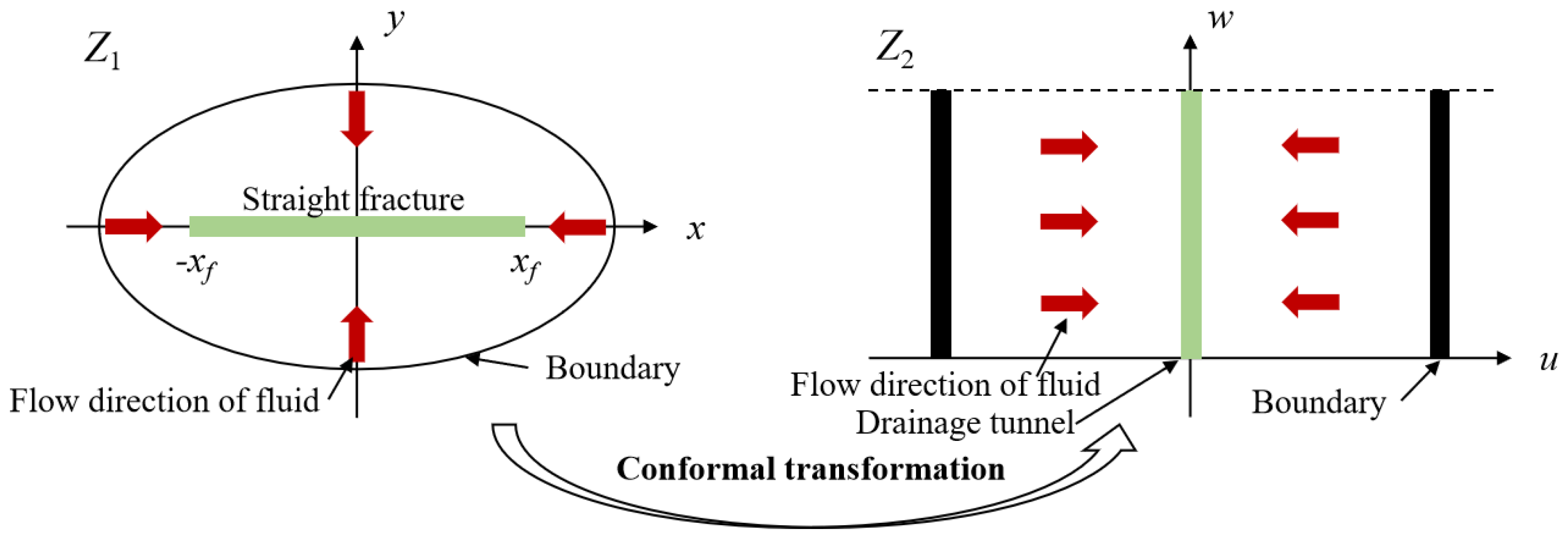

2.4. Productivity Model for MFHWs

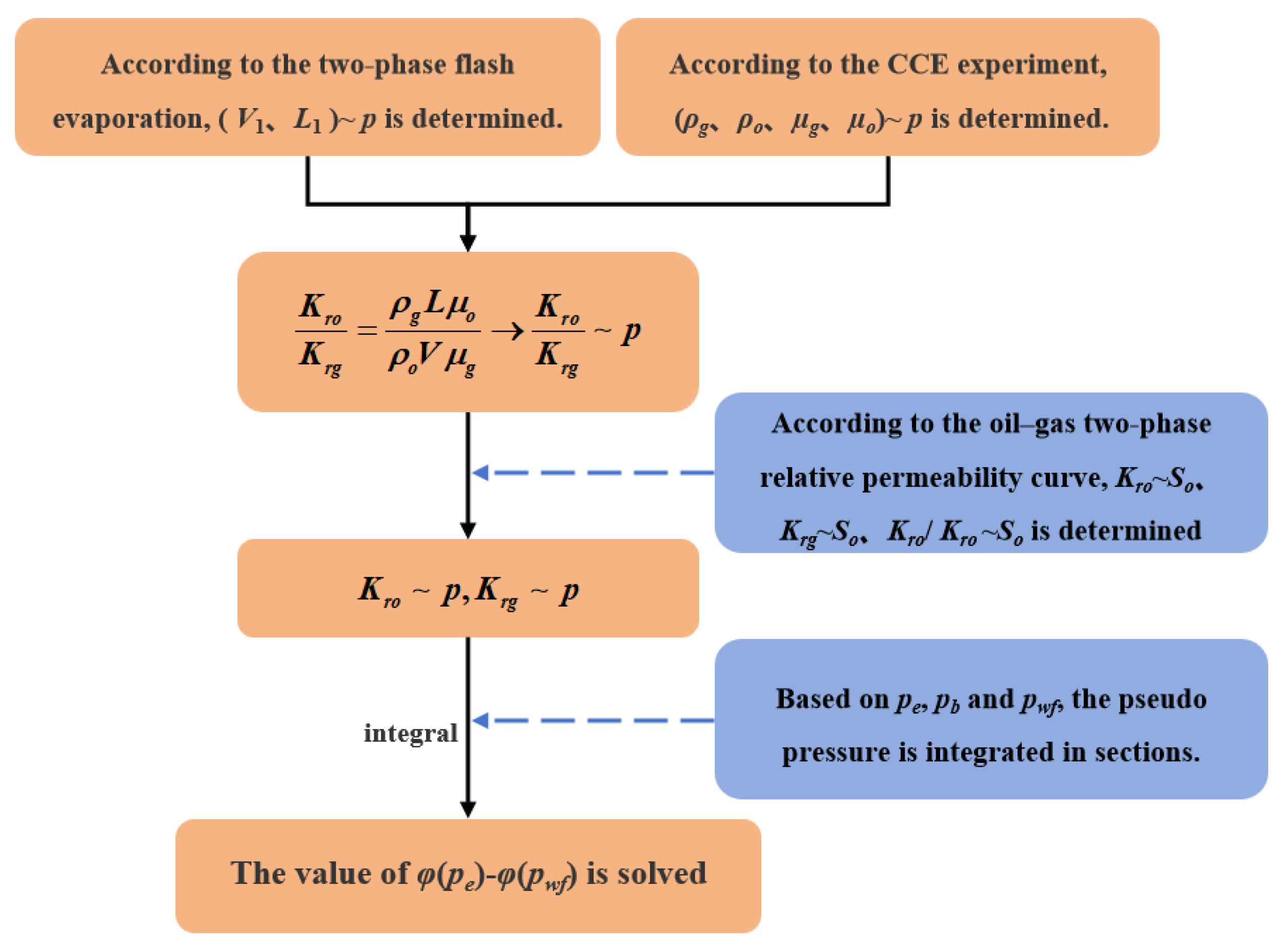

2.5. Solution for Two-Phase Pseudo-Pressure

2.6. Solution for Productivity Model

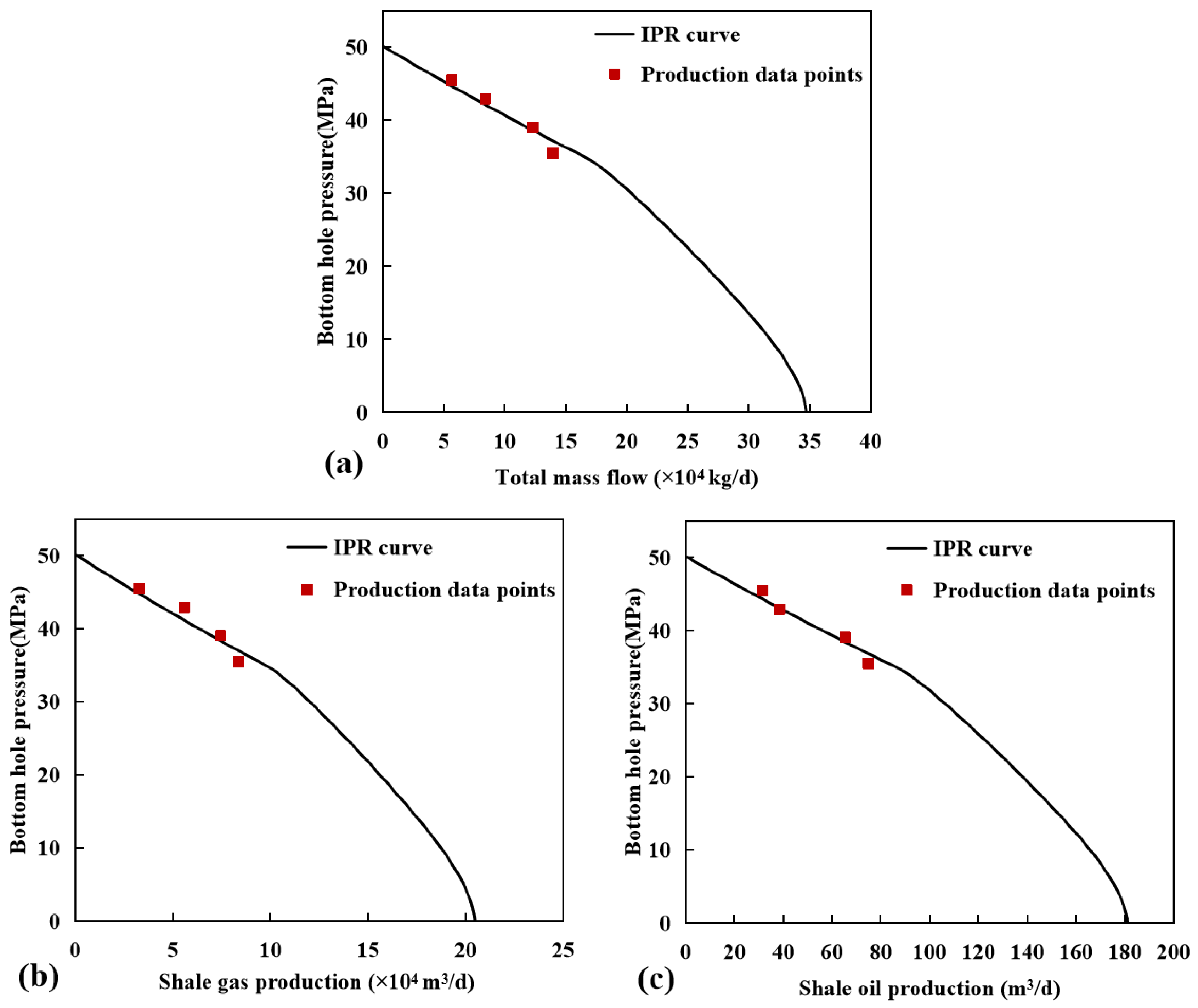

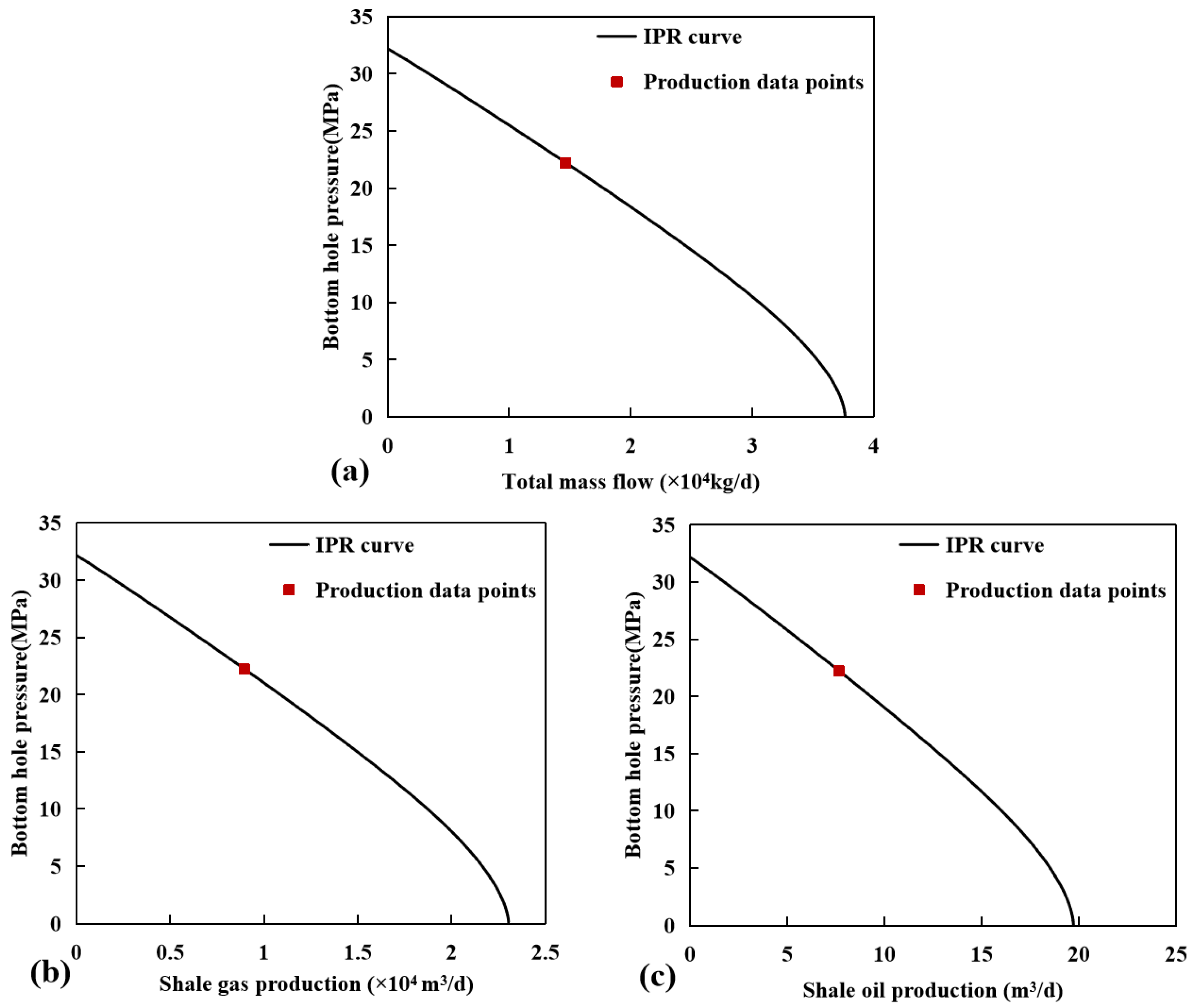

3. Model Verification

3.1. PVT Fitting

3.2. Productivity Calculation

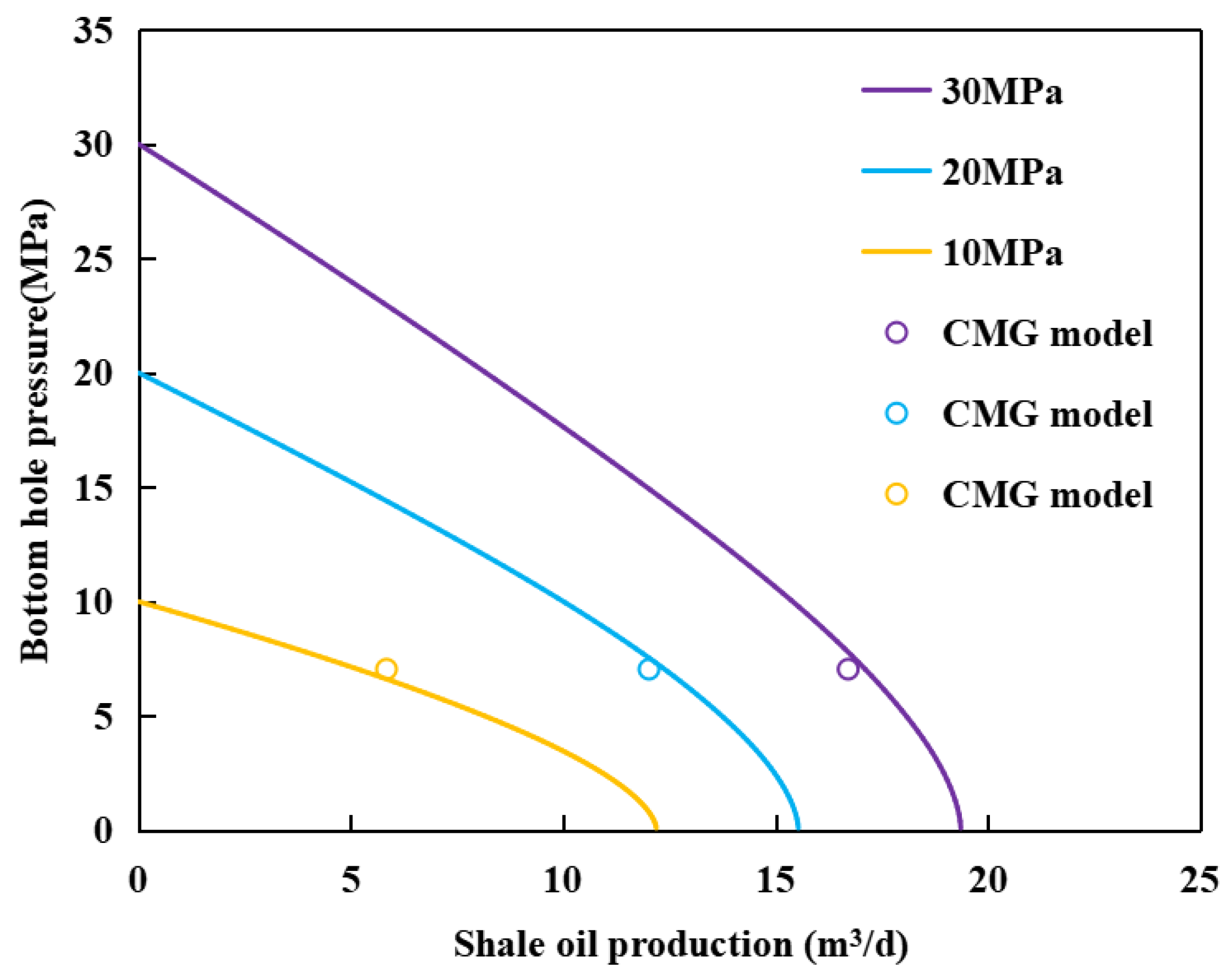

3.3. Numerical Simulation Verification

4. Results and Analyses

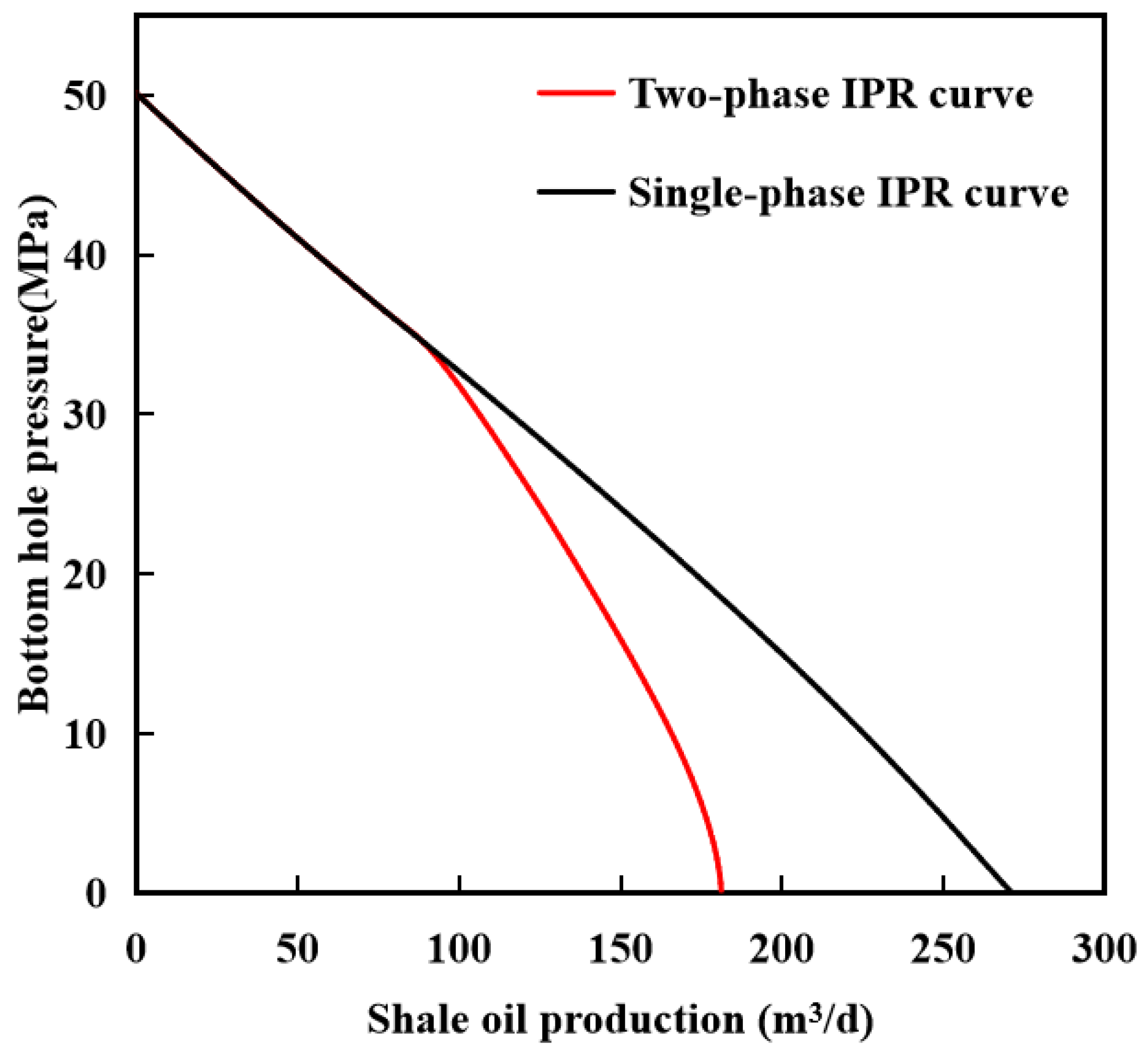

4.1. The Impact of Shale Oil Phase Behavior on Well Productivity

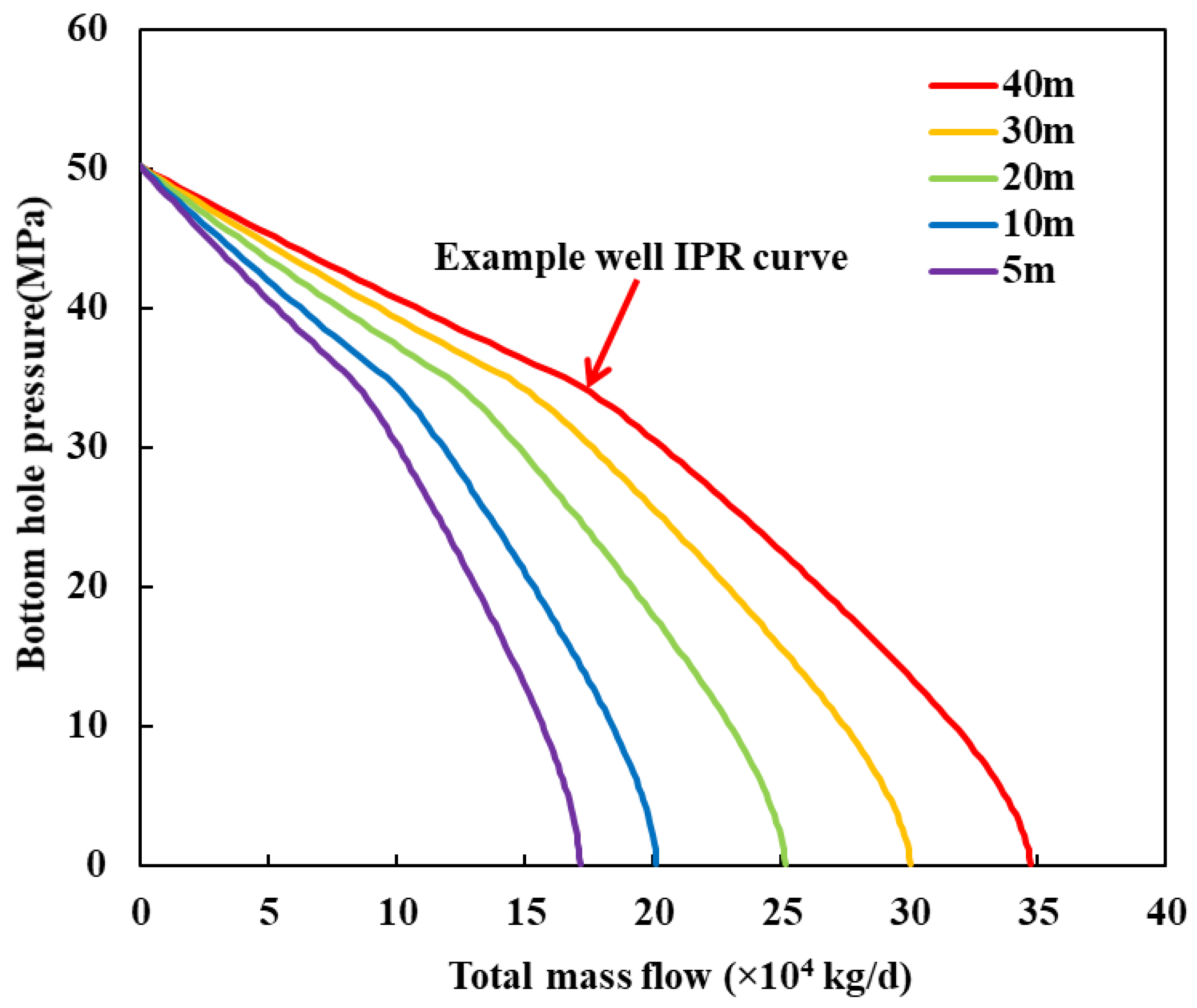

4.2. The Impact of Fracture Spacing on Well Productivity

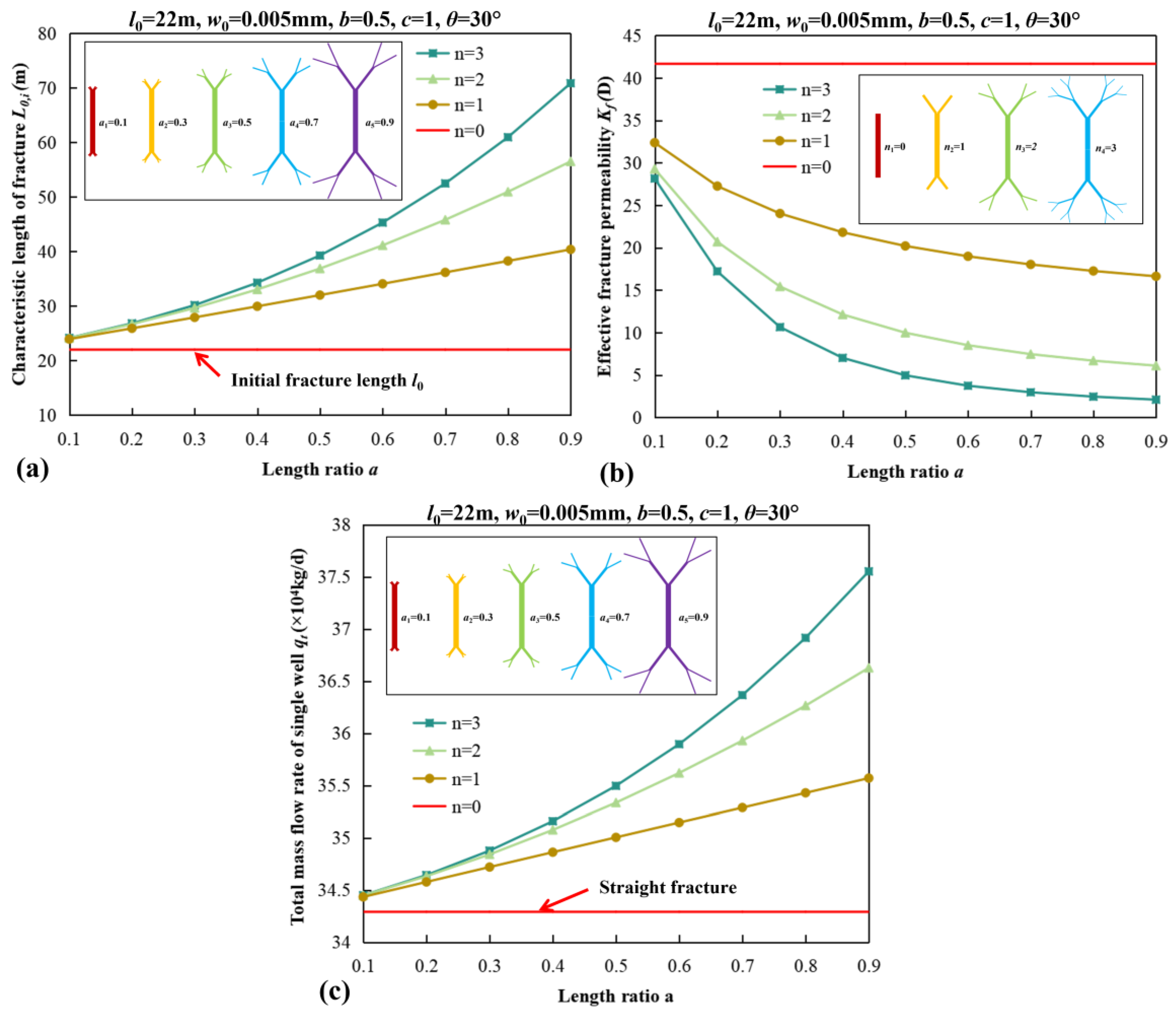

4.3. The Impact of Tree-Shaped Fracture Characteristics on Well Productivity

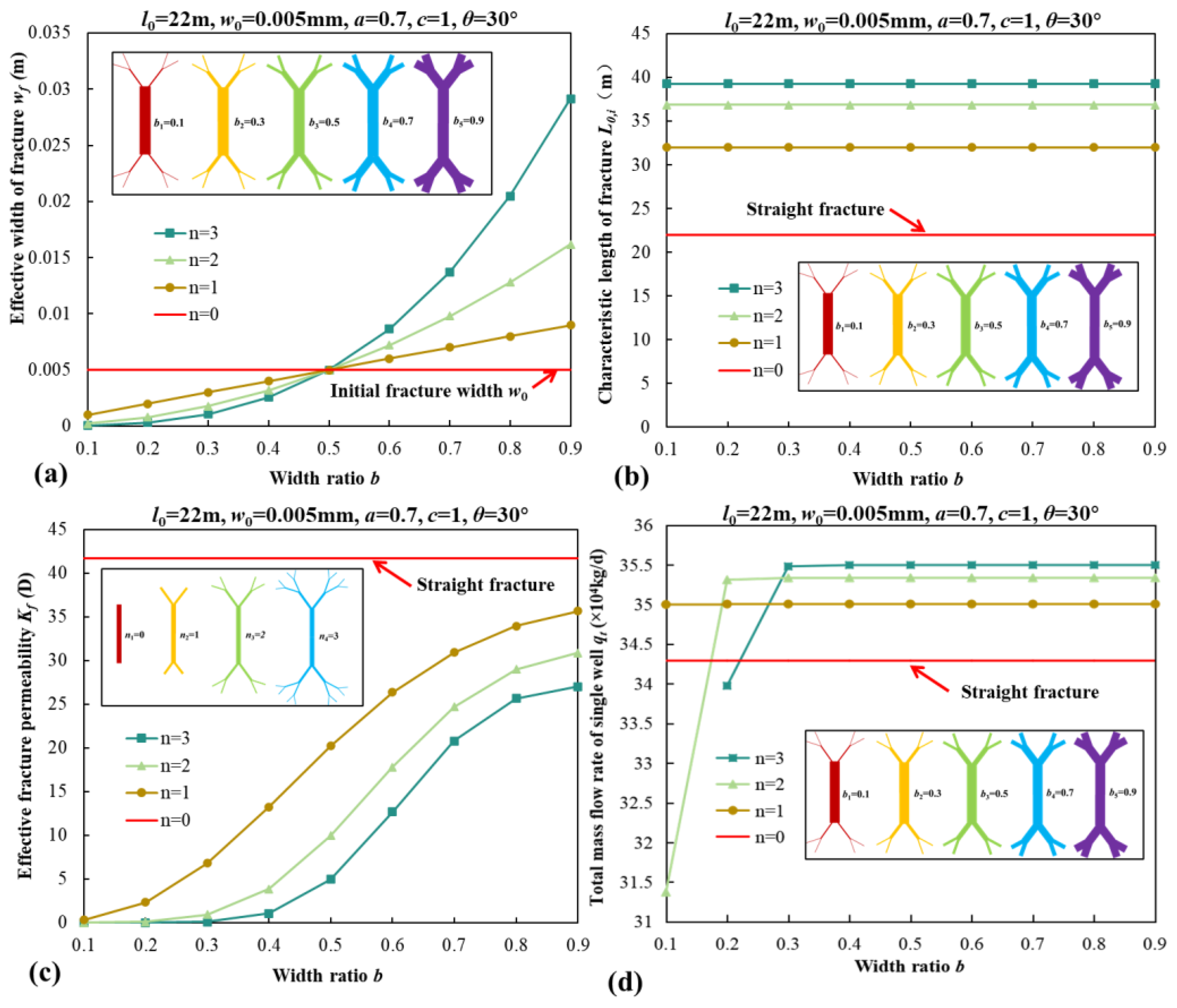

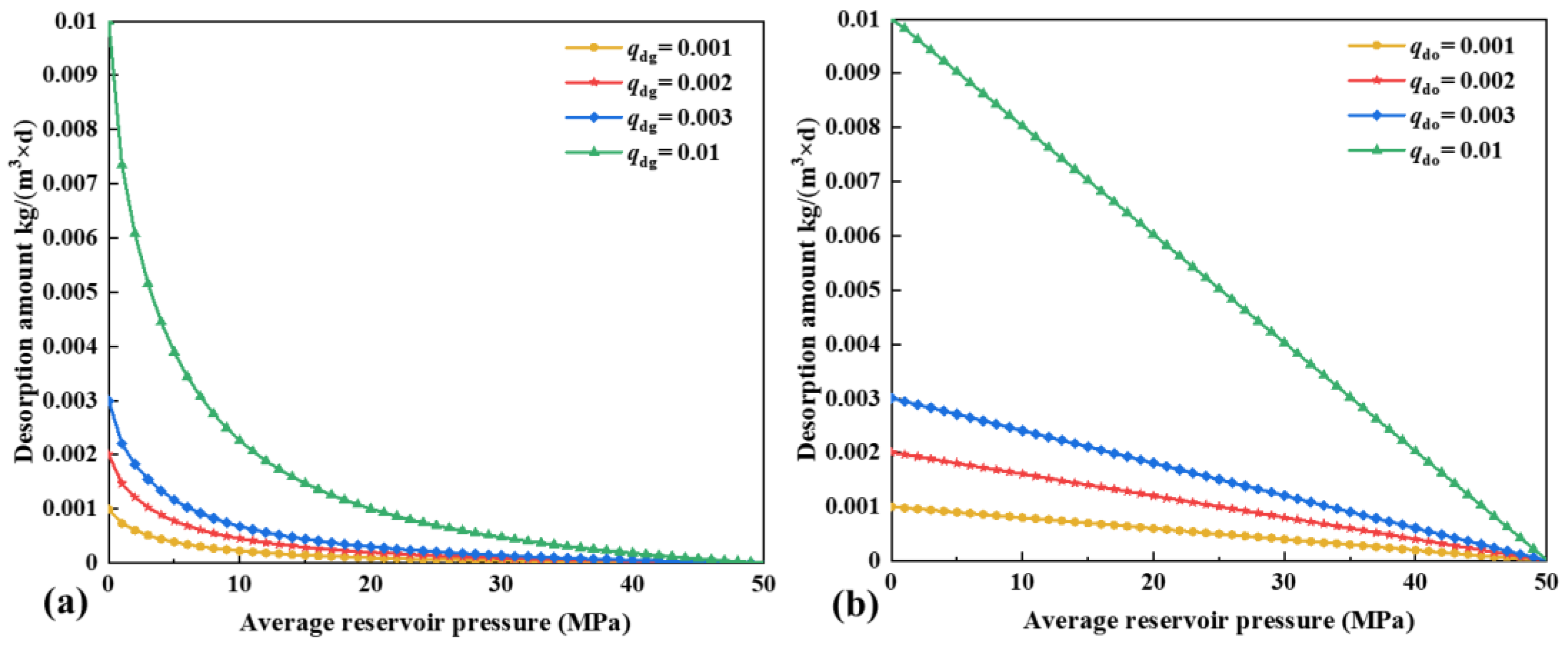

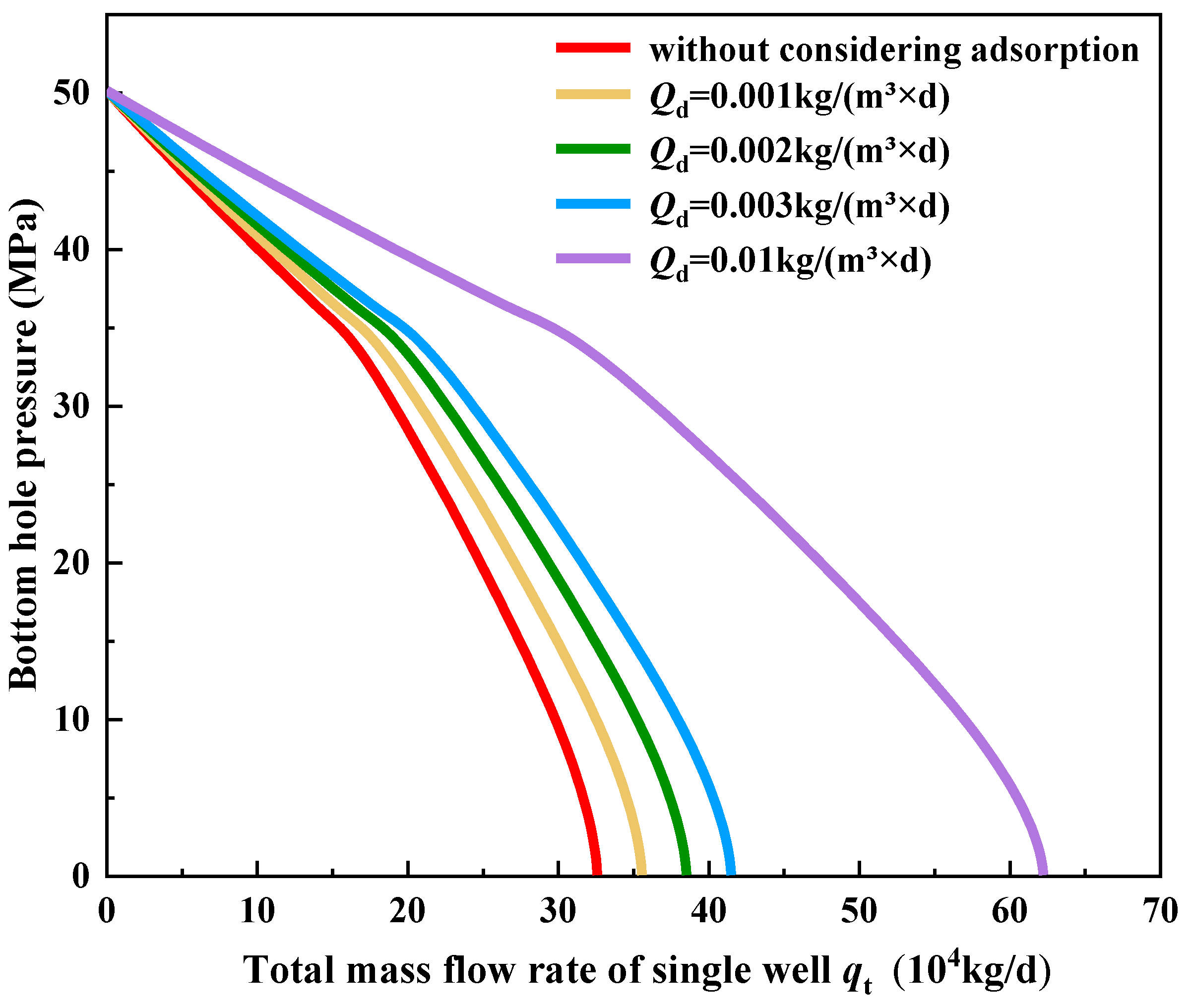

4.4. The Impact of Oil and Gas Desorption on Well Productivity

5. Conclusions

- (1)

- Compared to previous productivity models, this model considers the effects of fluid desorption, hydraulic fracture networks, and oil–gas phase behavior, which is more consistent with the actual development of shale oil reservoirs. The predicted results of the proposed model show strong agreement with the field data from an actual shale oil well, confirming the reliability of the proposed model.

- (2)

- As the pressure decreases, the oil phase undergoes a phase change into a two-phase mixture of oil and gas, leading to an increase in flow resistance. Consequently, this phase behavior of oil and gas results in a significant decrease in well production. As the fracture spacing decreases, the interference between hydraulic fractures becomes stronger, leading to a reduction in well productivity.

- (3)

- The characteristic parameters of hydraulic fracture networks have a substantial influence on well productivity. The increase in length ratio , the decline in branch angle , and the increase in branch level result in an increase in well productivity. As the width ratio increases, the well productivity gradually increases and reaches a stable value.

- (4)

- As the pressure decreases, the desorption amount of oil exhibits a linear increase, whereas the desorption amount of gas demonstrates an initial slow increase followed by a rapid escalation. As the maximum desorption amount increases, there is a significant enhancement in well productivity, highlighting the crucial role of fluid desorption in improving well performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zou, C.N.; Yang, Z.; Cui, J.W.; Zhu, R.K.; Hou, L.H.; Tao, S.Z.; Yuan, X.J.; Wu, S.T.; Lin, S.H.; Wang, L. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 15–27. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Salviato, M.; Chau, V.T.; Viswanathan, H.; Zubelewicz, A. Why fracking works. J. Appl. Mech. 2014, 81, 101010. [Google Scholar] [CrossRef]

- Peplow, M. The great gas gold rush. Nature 2017, 550, 26–28. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Hughes, J.D. A reality check on the shale revolution. Nature 2013, 494, 307–308. [Google Scholar] [CrossRef] [PubMed]

- Li, J.H.; Li, Y.J.; Sang, Q.; Gong, H.J.; Xu, L.; Zhang, H.Y.; Arif, M.; Dong, M.Z.; Cui, C.Z. Quantification of seepage characteristics in shale oil reservoirs: A triple medium model-driven approach. Geoenergy Sci. Eng. 2024, 242, 213225. [Google Scholar] [CrossRef]

- Qu, J.; Tang, Z.; Lei, G.; Wu, Q.; Liao, Q.; Ning, F. A novel threshold pressure gradient model and its influence on production simulation for shale oil reservoirs. Energy Fuels 2024, 38, 11644–11661. [Google Scholar] [CrossRef]

- Zou, C.; Zhao, Q.; Dong, D.; Yang, Z.; Qiu, Z.; Liang, F.; Wang, N.; Huang, Y.; Duan, A.; Zhang, Q.; et al. Geological characteristics, main challenges and future prospect of shale gas. Nat. Gas Geosci. 2017, 2, 273–288. [Google Scholar] [CrossRef]

- Lei, Q.; Xu, Y.; Cai, B.; Guan, B.; Wang, X.; Bi, G.Q.; Li, H.; Li, S.; Ding, B.; Fu, H.F.; et al. Progress and prospects of horizontal well fracturing technology for shale oil and gas reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, L.; Zhao, Y.; Guo, J. A composite model to analyze the decline performance of a multiple fractured horizontal well in shale reservoirs. J. Nat. Gas Sci. Eng. 2015, 26, 999–1010. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.P.; Li, H.; Wei, Q.; Bai, R.T. A new method to calculate the productivity of fractured horizontal gas wells considering non-Darcy flow in the fractures. J. Nat. Gas Sci. Eng. 2015, 26, 981–991. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Y.; Yang, H. New method of productivity equation for multibranch horizontal well in three-dimensional anisotropic oil reservoirs. J. Energy Resour. Technol. 2012, 134, 032801. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Y.; Yang, H. A new analytical solution of the productivity equation for a vertical fractured well in 3D anisotropic oil reservoirs. Pet. Sci. Technol. 2014, 32, 433–441. [Google Scholar] [CrossRef]

- Chen, Z.M.; Liao, X.W.; Zhao, X.L.; Lyu, S.B.; Zhu, L.T. A comprehensive productivity equation for multiple fractured vertical wells with non-linear effects under steady-state flow. J. Pet. Sci. Eng. 2017, 149, 9–24. [Google Scholar] [CrossRef]

- Wei, B.C.; Nie, X.R.; Zhang, Z.H.; Ding, J.C.; Shayireatehan, R.Y.Z.; Ning, P.Z.; Deng, D.T.; Cao, Y. Productivity equation of fractured vertical well with gas–water co-production in high-water-cut tight sandstone gas reservoir. Processes 2023, 11, 3123. [Google Scholar] [CrossRef]

- Soleimani, R.; Jahanpeyma, Y.; Salehian, M. Analysis of horizontal well productivity in tight gas formations and its sensitivity to reservoir properties. J. Pet. Explor. Prod. Technol. 2019, 9, 1237–1244. [Google Scholar] [CrossRef]

- Lou, Y.; Song, H.Q.; Yang, J.S.; Huang, X.H.; Dong, H. Productivity equation of fractured well in CBM reservoirs. J. Nat. Gas Sci. Eng. 2013, 11, 39–45. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Williams-Kovacs, J.D. Modeling two-phase flowback of multifractured horizontal wells completed in shale. SPE J. 2013, 18, 795–812. [Google Scholar] [CrossRef]

- Song, H.Q.; Liu, Q.P.; Yang, D.W.; Yu, M.X.; Lou, Y.; Zhu, W.Y. Productivity equation of fractured horizontal well in a water-bearing tight gas reservoir with low-velocity non-Darcy flow. J. Nat. Gas Sci. Eng. 2014, 18, 467–473. [Google Scholar] [CrossRef]

- Qi, Q.; Zhu, W.Y. The three-zone composite productivity model for a multi-fractured horizontal shale gas well. IOP Conf. Ser. Earth Environ. Sci. 2018, 121, 052051. [Google Scholar] [CrossRef]

- Jiang, B.M.; Mu, L.F.; Yan, Y.Q.; Li, Q.; Wu, Z.B.; Chen, J.Y.; Zhang, Q.S. Calculation method of productivity for shale oil in volumetric fractured horizontal wells. ACS Omega 2022, 7, 20495–20504. [Google Scholar] [CrossRef]

- Wang, Q.; Wan, J.; Mu, L.; Shen, R.; Jurado, M.J.; Ye, Y. An analytical solution for transient productivity prediction of multi-fractured horizontal wells in tight gas reservoirs considering nonlinear porous flow mechanisms. Energies 2020, 13, 1066. [Google Scholar] [CrossRef]

- Yao, S.S.; Wang, X.Z.; Yuan, Q.W.; Guo, Z.X.; Zeng, F. Production analysis of multifractured horizontal wells with composite models: Influence of complex heterogeneity. J. Hydrol. 2020, 583, 124542. [Google Scholar] [CrossRef]

- Zhang, H.; Sheng, J.J. Complex fracture network simulation and optimization in naturally fractured shale reservoir based on modified neural network algorithm. J. Nat. Gas Sci. Eng. 2021, 95, 104232. [Google Scholar] [CrossRef]

- Lu, M.J.; Qian, Q.; Zhong, A.H.; Yang, F.; He, W.J.; Li, M. High-precision flow numerical simulation and productivity evaluation of shale oil considering stress sensitivity. Fluid Dyn. Mater. Process. 2024, 20, 2281–2300. [Google Scholar] [CrossRef]

- Guan, Q.S.; Chen, C.W.; Pu, X.G.; Wan, Y.G.; Xu, J.; Zeng, H.W.; Jia, C.; Gao, H.H.; Yang, W.; Peng, Z.S. Production performance analysis of a continental shale oil reservoir in Bohai Bay basin. Petroleum 2024, 10, 294–305. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, F.; Liu, Y.; Wang, P. A coupled matrix-fracture productivity calculation model considering low-velocity non-Darcy flow in shale reservoirs. Fuel 2024, 357, 129845. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, W.D.; Su, Y.L.; Chen, W.; Lei, Z.D.; Li, L.; Hao, Y.M. A semi-analytical model for coupled flow in stress-sensitive multi-scale shale reservoirs with fractal characteristics. Pet. Sci. 2024, 21, 327–342. [Google Scholar] [CrossRef]

- Wang, Z.P.; Zhu, W.Y.; Yue, M.; Gao, Y.; Zhao, G.J.; Wang, H.Q. A method to predict the production of fractured horizontal wells in low/ultra-low permeability reservoirs. Chin. J. Eng. 2012, 34, 750–754. [Google Scholar]

- Li, Q.; Li, Q.C.; Wang, F.L.; Wu, J.J.; Wang, Y.L. The carrying behavior of water-based fracturing fluid in shale reservoir fractures and molecular dynamics of sand-carrying mechanism. Processes 2024, 12, 2051. [Google Scholar] [CrossRef]

- Li, Q.C.; Li, Q.; Han, Y. A numerical investigation on kick control with the displacement kill method during a well test in a deep-water gas reservoir: A case study. Processes 2024, 12, 2090. [Google Scholar] [CrossRef]

- Wang, J.G.; Hu, B.W.; Wu, D.; Dou, F.K.; Wang, X.L. A multiscale fractal transport model with multilayer sorption and effective porosity effects. Transp. Porous Media 2019, 129, 25–51. [Google Scholar] [CrossRef]

- Lane, H.S.; Lancaster, D.E.; Watson, A.T. Characterizing the role of desorption in gas production from Devonian shales. Energy Sources 1991, 13, 337–359. [Google Scholar] [CrossRef]

- Bumb, A.C.; McKee, C.R. Gas-well testing in the presence of desorption for coalbed methane and Devonian shale. SPE Form. Eval. 1988, 3, 179–185. [Google Scholar] [CrossRef]

- Jenkins, C.D.; Boyer, C.M. Coalbed- and shale-gas reservoirs. J. Pet. Technol. 2008, 60, 92–99. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.; Wu, K. Study on gas flow through nano pores of shale gas reservoirs. Fuel 2015, 143, 107–117. [Google Scholar] [CrossRef]

- Xiong, H.; Devegowda, D.; Huang, L.L. Water bridges in clay nanopores: Mechanisms of formation and impact on hydrocarbon transport. Langmuir 2020, 36, 723–733. [Google Scholar] [CrossRef]

- Singh, H.; Javadpour, F.; Ettehadtavakkol, A.; Darabi, H. Nonempirical apparent permeability of shale. SPE Reserv. Eval. Eng. 2014, 17, 414–424. [Google Scholar] [CrossRef]

- Li, M.; Su, Y.L.; Dong, M.Z.; Zhou, L.H.; Li, Y.J.; Pu, X.G.; Li, S.; Han, W.Z.; Wang, W.D. A numerical study of fluids desorption and phase behavior in shale oil reservoir using a chemical reaction model. J. Pet. Sci. Eng. 2021, 196, 108050. [Google Scholar] [CrossRef]

- Mo, C.P.; Zhang, G.D.; Zhang, Z.W.; Yuan, Y.H.; Yang, S. Productivity calculation model for fractured horizontal wells considering phase variation. J. Pet. Sci. Eng. 2022, 209, 109811. [Google Scholar] [CrossRef]

- Liu, X.Y.; Zhang, D.X. A review of phase behavior simulation of hydrocarbons in confined space: Implications for shale oil and shale gas. J. Nat. Gas Sci. Eng. 2019, 68, 102901. [Google Scholar] [CrossRef]

- Liu, X.Y.; Li, X.; Zhang, D.X. A statistical thermodynamics-based equation of state and phase equilibrium calculation for confined hydrocarbons in shale reservoirs. J. Nat. Gas Sci. Eng. 2022, 102, 104579. [Google Scholar] [CrossRef]

- Alharthy, N.; Teklu, T.; Kazemi, H.; Graves, R.; Hawthorne, S.; Braunberger, J.; Kurtoglu, B. Enhanced oil recovery in liquid–rich shale reservoirs: Laboratory to field. SPE Reserv. Eval. Eng. 2018, 21, 137–159. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, Y.M.; Ma, S.; Ju, Y.; Guo, Y.C.; Yu, Y. Crack propagation induced by hydraulic fracturing in low permeability rocks using CT technology. J. Min. Saf. Eng. 2013, 30, 739–743. [Google Scholar]

- Chen, M. Re-orientation and propagation of hydraulic fractures in shale gas reservoir. J. China Univ. Pet. 2013, 37, 88–94. [Google Scholar]

- Deng, J.; Zhu, W.Y.; Liu, J.X.; Zhang, Z.; Ma, Q.; Zhang, M.; Deng, K.; Ma, L. Productivity prediction model of shale gas considering stress sensitivity. Nat. Gas Geosci. 2013, 24, 456–460. [Google Scholar]

- Zhu, W.Y.; Yue, M.; Song, H.Q.; Yang, J.S.; Wang, Y.B.; Yu, M.X. Productivity model of gas flow in CBM fractured reservoirs considering desorption and diffusion. J. Basic Sci. Eng. 2013, 21, 953–960. [Google Scholar]

- Xu, P.; Yu, B.M.; Yun, M.J.; Zou, M.Q. Heat conduction in fractal tree-like branched networks. Int. J. Heat Mass Transf. 2006, 49, 3746–3751. [Google Scholar] [CrossRef]

| Characteristic Parameter | Symbol | Characteristic Parameter | Symbol |

|---|---|---|---|

| Fracture characteristic length at i-level | Branch angle of crack | ||

| Fracture length at i-level | Length ratio of adjacent cracks | ||

| Fracture width at i-level | Width ratio of adjacent cracks | ||

| Fracture height at i-level | Height ratio of adjacent cracks | ||

| Initial fracture length | Fracture branch grade | ||

| Initial fracture width | Fracture branch number | ||

| Initial fracture height | Rectangular fracture permeability | ||

| Effective width of tree-shaped crack | Fracture effective porosity | ||

| Total volume of tree-shaped crack | Tree-shaped fracture permeability | ||

| Total length of tree-shaped crack | Correctional fracture permeability | ||

| Equivalent area of tree-shaped crack |

| Component | Molar Composition, % | Molecular Weight, g/mol |

|---|---|---|

| CO2 | 0.112 | 44.01 |

| N2 | 0.280 | 28.01 |

| C1 | 56.798 | 16.04 |

| C2 | 16.716 | 30.07 |

| C3 | 5.765 | 44.1 |

| iC4 | 1.415 | 58.12 |

| nC4 | 1.571 | 58.12 |

| iC5 | 0.942 | 72.15 |

| nC5 | 0.468 | 72.15 |

| C6 | 0.403 | 86.18 |

| C7 | 1.304 | 100.2 |

| C8 | 1.959 | 114.23 |

| C9 | 1.420 | 128.26 |

| C10 | 1.175 | 142.29 |

| C11+ | 9.672 | 248.18 |

| Parameter | PA-1 | YY-1 | Parameter | PA-1 | YY-1 |

|---|---|---|---|---|---|

| Fracture number, | 21 | 31 | Bubble point pressure, , MPa | 36.17 | 36.17 |

| Horizontal well length, , m | 817 | 1400 | Reservoir pressure, , MPa | 50.14 | 32.19 |

| Control radius, , m | 500 | 750 | Matrix permeability, , mD | 0.025 | 0.016 |

| Well radius, , m | 0.06985 | 0.06985 | Reservoir thickness, , m | 63.5 | 20 |

| 0-level fracture length, , m | 22 | 28 | Oil density, , kg/m3 | 786.2 | 786.2 |

| 0-level fracture width, , mm | 0.005 | 0.005 | Gas density, , kg/m3 | 0.9608 | 0.9608 |

| Length ratio, | 0.5 | 0.5 | Reservoir temperature, , °C | 66.5 | 66.5 |

| Width ratio, | 0.5 | 0.5 | Langmuir volume, , m3/kg | 5.82 × 10−3 | 5.82 × 10−3 |

| Height ratio, | 1 | 1 | Langmuir pressure, , MPa | 4.45 | 4.45 |

| Branch angle, | 30° | 30° | |||

| Branch number, | 2 | 2 | |||

| Fracture branch level, | 3 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Guo, P.; Ren, J.; Wang, Z.; Tu, H. Productivity Model for Multi-Fractured Horizontal Wells with Complex Fracture Networks in Shale Oil Reservoirs Considering Fluid Desorption and Two-Phase Behavior. Energies 2024, 17, 6012. https://doi.org/10.3390/en17236012

Liu X, Guo P, Ren J, Wang Z, Tu H. Productivity Model for Multi-Fractured Horizontal Wells with Complex Fracture Networks in Shale Oil Reservoirs Considering Fluid Desorption and Two-Phase Behavior. Energies. 2024; 17(23):6012. https://doi.org/10.3390/en17236012

Chicago/Turabian StyleLiu, Xin, Ping Guo, Junjie Ren, Zhouhua Wang, and Hanmin Tu. 2024. "Productivity Model for Multi-Fractured Horizontal Wells with Complex Fracture Networks in Shale Oil Reservoirs Considering Fluid Desorption and Two-Phase Behavior" Energies 17, no. 23: 6012. https://doi.org/10.3390/en17236012

APA StyleLiu, X., Guo, P., Ren, J., Wang, Z., & Tu, H. (2024). Productivity Model for Multi-Fractured Horizontal Wells with Complex Fracture Networks in Shale Oil Reservoirs Considering Fluid Desorption and Two-Phase Behavior. Energies, 17(23), 6012. https://doi.org/10.3390/en17236012