Factors Influencing Differences Between Computed and Measured Ground Resistance Values for Horizontal Tape Electrodes

Abstract

1. Introduction

2. Materials and Methods

2.1. Soil Resistivity Measurement

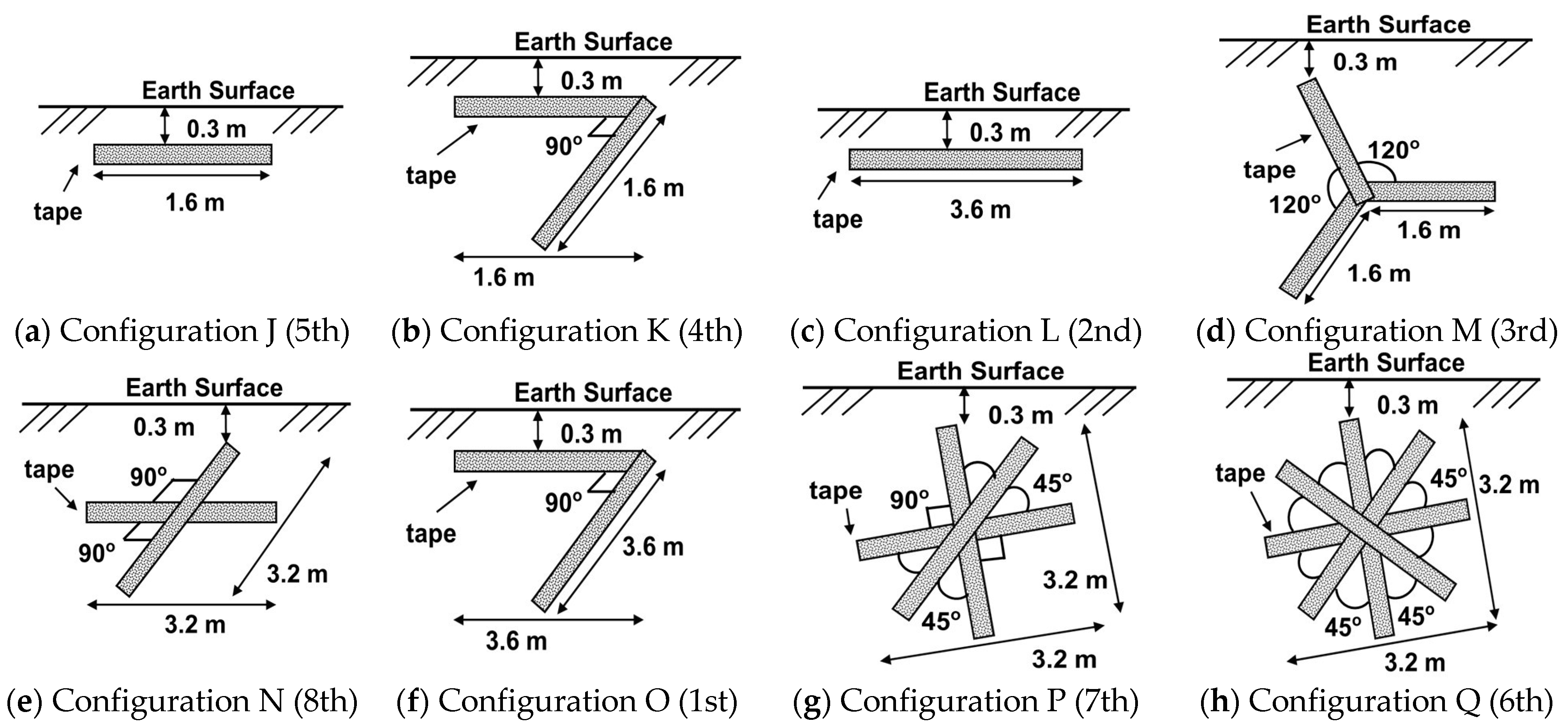

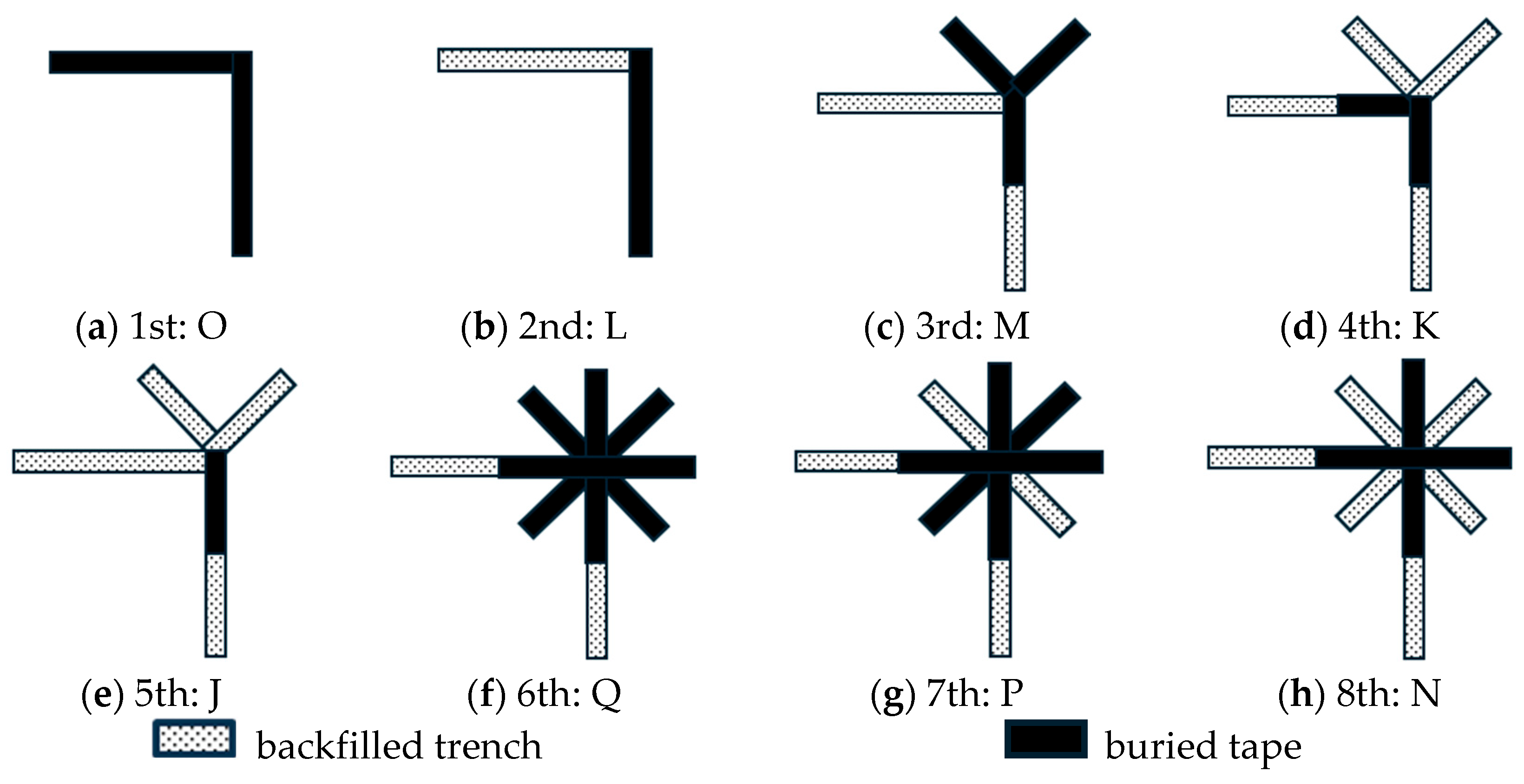

2.2. Grounding System Configurations

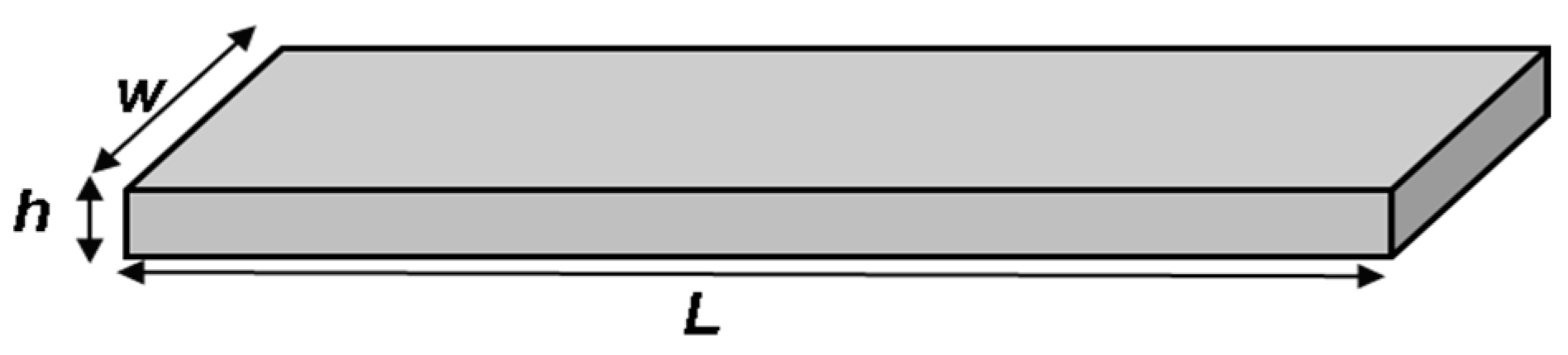

2.3. Grounding System Size

2.4. Field Measurement

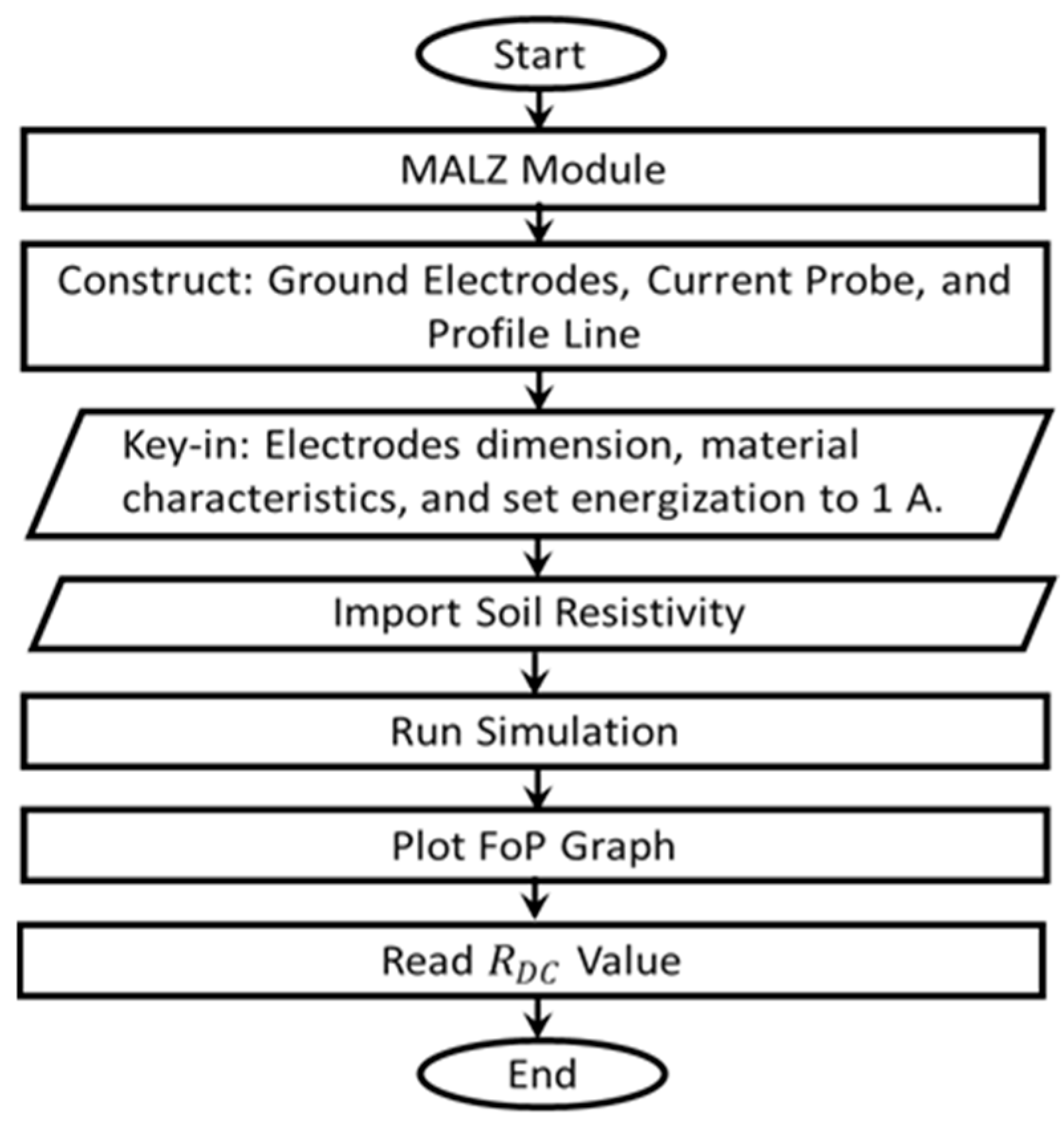

2.5. Computational Method

3. Results

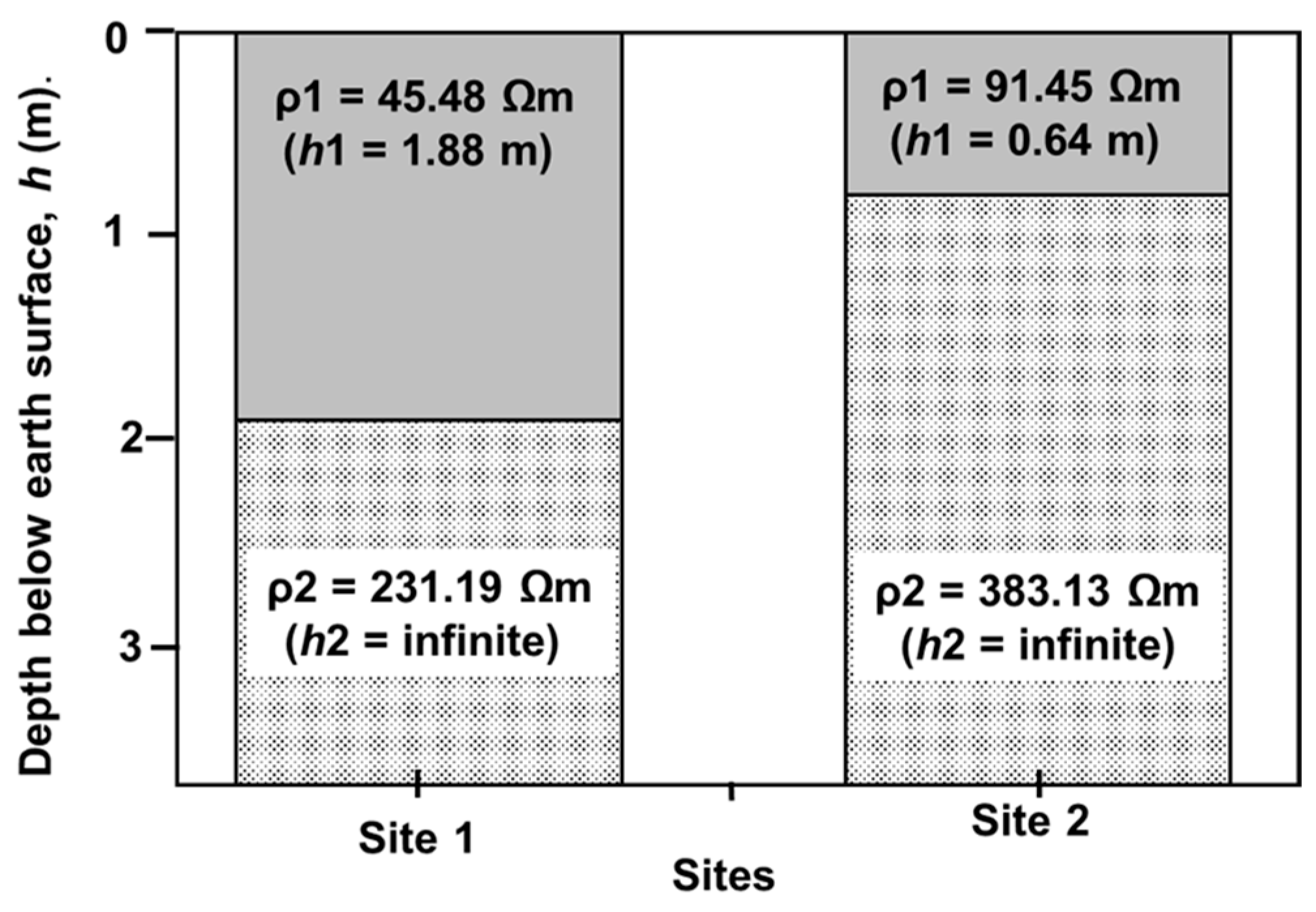

3.1. Soil Resistivity

3.2. Grounding Resistance (RDC)

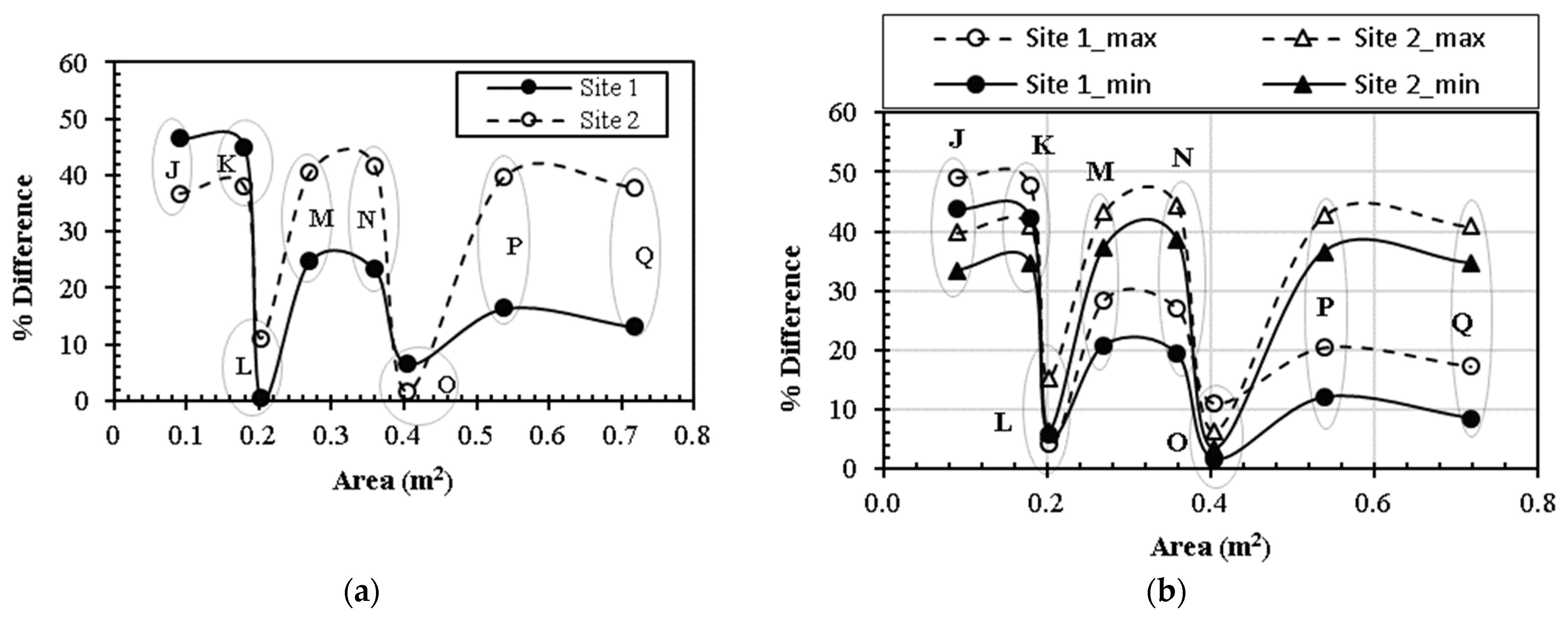

3.3. Effect of Ground Electrode Size

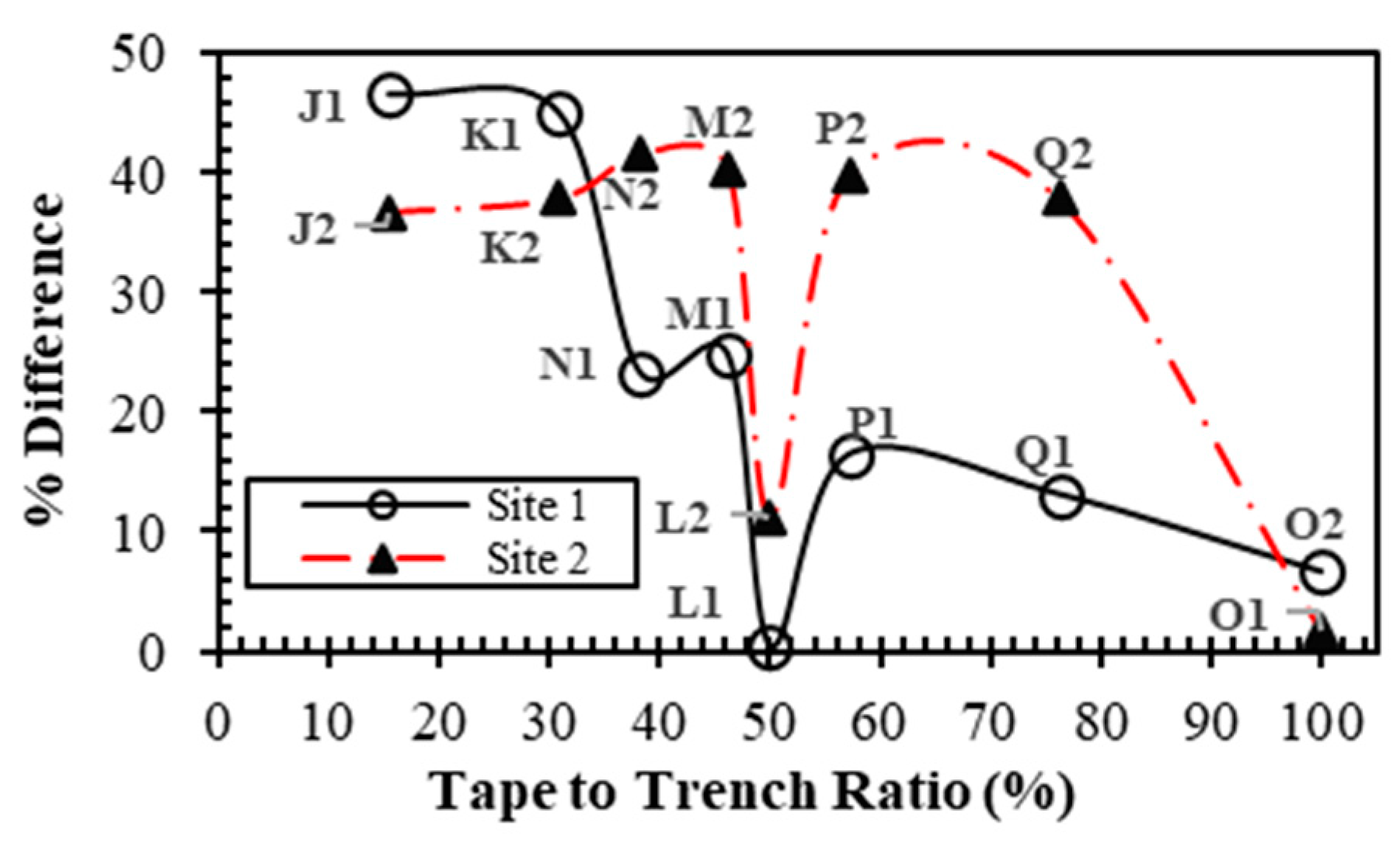

3.4. Effect of Soil Disturbance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Barker, P. Overvoltage considerations in applying distributed resources on power systems. In Proceedings of the IEEE Power Engineering Society Summer Meeting, Chicago, IL, USA, 21–25 July 2002; Volume 1, pp. 109–114. [Google Scholar] [CrossRef]

- Saleh, S.A.; Jewett, D.; Al-Durra, A.; Kanukollu, S. Experimental assessment of grounding system impacts on ground currents and transient overvoltage. IEEE Trans. Ind. Appl. 2022, 58, 5987–6001. [Google Scholar] [CrossRef]

- Obi, P.I.; Okoro, C.K.; Okonkwo, I.I. Electrocution, accidents and electrical injuries in Nigerian homes and work sites—Causes, Effects and Remedies. IOSR J. Elect. Electron. Eng. 2020, 15, 53–61. [Google Scholar]

- Muhammad, U.; Aman, F.; Mohamad Nor, N.; Abdullah, S. Determination of safety distances from ground electrodes subjected to impulse conditions. Adv. Elect. Electron. Eng. 2024, 22, 17–24. [Google Scholar] [CrossRef]

- Mousa, S.; Griffiths, H.; Harid, N.; Haddad, A. Current distribution under high frequency and transient conditions in earth electrode systems. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012; pp. 150–153. [Google Scholar] [CrossRef]

- Mousa, S.; Harid, N.; Griffiths, H.; Haddad, A. Experimental investigation of high frequency and transient performance of earth rod systems. Electr. Power Syst. Res. 2014, 113, 196–203. [Google Scholar] [CrossRef]

- Clark, D.; Mousa, S.; Harid, N.; Griffiths, H.; Haddad, A. Lightning current performance of conventional and enhanced rod ground electrodes. IEEE Trans. Electromagn. Compat. 2021, 63, 1179–1188. [Google Scholar] [CrossRef]

- Mousa, S.; Harid, N.; Griffiths, H.; Haddad, M. Distribution of impulse current in earth grid electrodes. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Turin, Italy, 1–4 September 2020; pp. 1–4. [Google Scholar] [CrossRef]

- Dawalibi, F.; Mukhedkar, D. Influence of ground rods on grounding grids. IEEE Trans. Power Appl. Syst. 1979, PAS-98, 2089–2098. [Google Scholar] [CrossRef]

- Permal, N.; Osman, M.; Ariffin, A.M.; Kadir, M.Z.A.A. The impact of substation grounding grid design parameters in non-homogenous soil to the grid safety threshold parameters. IEEE Access 2021, 9, 37497–37509. [Google Scholar] [CrossRef]

- IEEE Std 80-2013; IEEE Guide for Safety in AC Substation Grounding. IEEE: Piscataway, NJ, USA, 2013.

- IEC 62305-3:2024; Protection Against Lightning-Part 3: Physical Damage to Structures and Life Hazard. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2024.

- BS 7430:2011+A1:2015; Code of Practice for Protective Earthing of Electrical Installations. BSI: London, UK, 2015.

- Hizamul-din, H.H.; Mohamad Nor, N.; Ahmad, N.N.; Idris, N.F.; Mahmud, A. Investigations on the performance of various horizontal ground electrodes. Energies 2021, 14, 1036. [Google Scholar] [CrossRef]

- Mohamad Nor, N.; Trlep, M.; Abdullah, S.; Rajab, R. Investigations of earthing systems under steady-state and transients with FEM and experimental work. Int. J. Electr. Power Energy Syst. 2013, 44, 758–763. [Google Scholar] [CrossRef]

- Cvetković, N.N.; Jovanović, D.B.; Ristić, A.T.; Stojanović, M.S.; Krstić, D.D. Comparison of different models for determining the grounding rod resistance. Electrotech. Electron. E+E 2015, 50, 35–39. [Google Scholar]

- Abdullah, S.; Mohamad Nor, N.; Rajab, R.; Trlep, M. Analysis of 4 mesh grid grounding systems by FEM simulations and field tests. Appl. Mech. Mater. 2015, 793, 159–163. [Google Scholar] [CrossRef]

- Harid, N.; Griffiths, H.; Haddad, A. Effect of ground return path on impulse characteristics of earth electrodes. In Proceedings of the 2011 7th Asia-Pacific International Conference on Lightning, Chengdu, China, 1–4 November 2011; pp. 686–689. [Google Scholar] [CrossRef]

- Aman, F.; Mohamad Nor, N.; Ahmad, N.N. Impulse characteristics of ground electrodes over time (10 months). In Proceedings of the 2022 57th International Universities Power Engineering Conference (UPEC), Istanbul, Turkey, 30 August–2 September 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Jovanović, D.B.; Cvetković, N.N.; Ristić, A.T.; Stanković, V.B. Different calculation methods and experimental validation for various ground electrode types. In Proceedings of the 2015 9th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 7–9 May 2015; pp. 337–342. [Google Scholar] [CrossRef]

- Reffin, M.S.; Mohamad Nor, N.; Ahmad, N.N.; Abdullah, S. Performance of practical grounding systems under high impulse conditions. Energies 2018, 11, 3187. [Google Scholar] [CrossRef]

- Muhammad, U.; Aman, F.; Mohamad Nor, N. Effect of localised soil on the measured and calculated resistance values. In Proceedings of the 2023 4th International Conference on High Voltage Engineering and Power Systems (ICHVEPS), Denpasar Bali, Indonesia, 6–10 August 2023; pp. 604–608. [Google Scholar] [CrossRef]

- Muhammad, U.; Ahmad, N.N.; Mohamad Nor, N.; Aman, F. Measured and computed resistance values for vertical ground rods. In Proceedings of the 2024 Multimedia University Engineering Conference (MECON 2024), Cyberjaya, Malaysia, 23–25 July 2024. [Google Scholar]

- SafEngServices & Technologies Ltd. Current Distribution, Electromagnetic Fields, Grounding and Soil Structure Analysis (CDEGS); SafEngServices & Technologies Ltd.: Laval, QC, Canada, 1995; Available online: https://www.sestech.com/en/Product/Package/CDEGS (accessed on 10 January 2024).

- IEEE Std. 81-2012; Guide for Measuring Earth Resistivity, Ground Impedance, and Earth Surface Potentials of a Grounding System. IEEE: Piscataway, NJ, USA, 2012.

- Muhammad, U.; Zaid, H.; Ahmad, N.N.; Mohamad Nor, N.; Aman, F. Evaluation of steady-state ground resistance by field measurement and CDEGS computation. Bull. Electr. Eng. Inform. 2024, 13, 3033–3042. [Google Scholar] [CrossRef]

- de Melo, L.B.B.; Silva, B.M.; Peixoto, D.S.; Chiarini, T.P.A.; de Oliveira, G.C.; Curi, N. Effect of compaction on the relationship between electrical resistivity and soil water content in Oxisol. Soil Tillage Res. 2021, 208, 104876. [Google Scholar] [CrossRef]

- Hassan, A.A. Influence of compaction on electrical resistivity characteristics of fine-grained soil East of Baghdad City, Iraq. Earth Sci. Res. J. 2023, 27, 169–182. [Google Scholar] [CrossRef]

- Seladji, S.; Cosenza, P.; Tabbagh, A.; Ranger, J.; Richard, G. The effect of compaction on soil electrical resistivity: A laboratory investigation. Eur. J. Soil Sci. 2010, 61, 1043–1055. [Google Scholar] [CrossRef]

| Configuration | Grounding System | Tape Length (m) | Total Area (m2) |

|---|---|---|---|

| J | horizontal | 1.6 | 0.0898 |

| K | L-shape | 3.2 | 0.1795 |

| L | horizontal | 3.6 | 0.2018 |

| M | 3-star | 4.8 | 0.2693 |

| N | 4-star | 6.4 | 0.3590 |

| O | L-shape | 7.2 | 0.4035 |

| P | 6-star | 9.6 | 0.5385 |

| Q | 8-star | 12.8 | 0.7180 |

| Site | Soil Resistivity Profile | |||

|---|---|---|---|---|

| ρ1 (Ωm) | ρ2 (Ωm) | h1 (m) | h2 (m) | |

| 1 | 45.48 | 231.19 | 1.88 | infinite |

| 2 | 91.45 | 383.13 | 0.64 | infinite |

| Conf. | Grounding System | Site 1 | Site 2 | ||||

|---|---|---|---|---|---|---|---|

| RDC (Ω) | % Diff. | RDC (Ω) | % Diff. | ||||

| Measured ± 5% = [min., max.] | CDEGS | Measured ± 5% = [min., max.] | CDEGS | ||||

| J | horizontal | 61.30 ± 3.065 = [58.24, 64.37] | 32.77 | 46.54 | 125.90 ± 6.295 = [119.61, 132.20] | 79.60 | 36.78 |

| K | L-shape | 39.20 ± 1.960 = [37.24, 41.16] | 21.54 | 45.05 | 88.60 ± 4.430 = [84.17, 93.03] | 55.00 | 37.92 |

| L | horizontal | 19.90 ± 0.995 = [18.91, 20.90] | 19.99 | −0.45 | 57.60 ± 2.880 = [54.72, 60.48] | 51.20 | 11.11 |

| M | 3-star | 22.90 ± 1.145 = [21.76, 24.05] | 17.22 | 24.80 | 75.20 ± 3.760 = [71.44, 78.96] | 44.80 | 40.43 |

| N | 4-star | 20.30 ± 1.015 = [19.29, 21.32] | 15.56 | 23.35 | 70.90 ± 3.545 = [67.36, 74.45] | 41.40 | 41.61 |

| O | L-shape | 14.30 ± 0.715 = [13.59, 15.02] | 13.35 | 6.64 | 35.60 ± 1.780 = [33.82, 37.38] | 35.00 | 1.69 |

| P | 6-star | 17.00 ± 0.850 = [16.15, 17.85] | 14.20 | 16.47 | 64.10 ± 3.205 = [60.90, 67.31] | 38.60 | 39.78 |

| Q | 8-star | 15.40 ± 0.770 = [14.63, 16.17] | 13.38 | 13.12 | 59.40 ± 2.970 = [56.43, 62.37] | 36.90 | 37.88 |

| Conf. | Installation Sequence | Total Length (m) | Tape-to-Trench Ratio (%) | % Difference | ||

|---|---|---|---|---|---|---|

| Tape | Trench | Site 1 | Site 2 | |||

| J | 5th | 1.60 | 10.40 | 15.38 | 46.54 | 36.78 |

| K | 4th | 3.20 | 10.40 | 30.77 | 45.05 | 37.92 |

| L | 2nd | 3.60 | 7.20 | 50.00 | 0.45 | 11.11 |

| M | 3rd | 4.80 | 10.40 | 46.15 | 24.80 | 40.43 |

| N | 8th | 6.40 | 16.80 | 38.10 | 23.35 | 41.61 |

| O | 1st | 7.20 | 7.20 | 100.00 | 6.64 | 1.69 |

| P | 7th | 9.60 | 16.80 | 57.14 | 16.47 | 39.78 |

| Q | 6th | 12.80 | 16.80 | 76.19 | 13.12 | 37.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muhammad, U.; Ahmad, N.N.; Mohamad Nor, N.; Aman, F. Factors Influencing Differences Between Computed and Measured Ground Resistance Values for Horizontal Tape Electrodes. Energies 2024, 17, 5845. https://doi.org/10.3390/en17235845

Muhammad U, Ahmad NN, Mohamad Nor N, Aman F. Factors Influencing Differences Between Computed and Measured Ground Resistance Values for Horizontal Tape Electrodes. Energies. 2024; 17(23):5845. https://doi.org/10.3390/en17235845

Chicago/Turabian StyleMuhammad, Usman, Nurul Nadia Ahmad, Normiza Mohamad Nor, and Fazlul Aman. 2024. "Factors Influencing Differences Between Computed and Measured Ground Resistance Values for Horizontal Tape Electrodes" Energies 17, no. 23: 5845. https://doi.org/10.3390/en17235845

APA StyleMuhammad, U., Ahmad, N. N., Mohamad Nor, N., & Aman, F. (2024). Factors Influencing Differences Between Computed and Measured Ground Resistance Values for Horizontal Tape Electrodes. Energies, 17(23), 5845. https://doi.org/10.3390/en17235845