Recovering Low-Grade Heat from Flue Gas in a Coal-Fired Thermal Power Unit

Abstract

1. Introduction

2. System Introduction

2.1. The Introduction of Power Plant

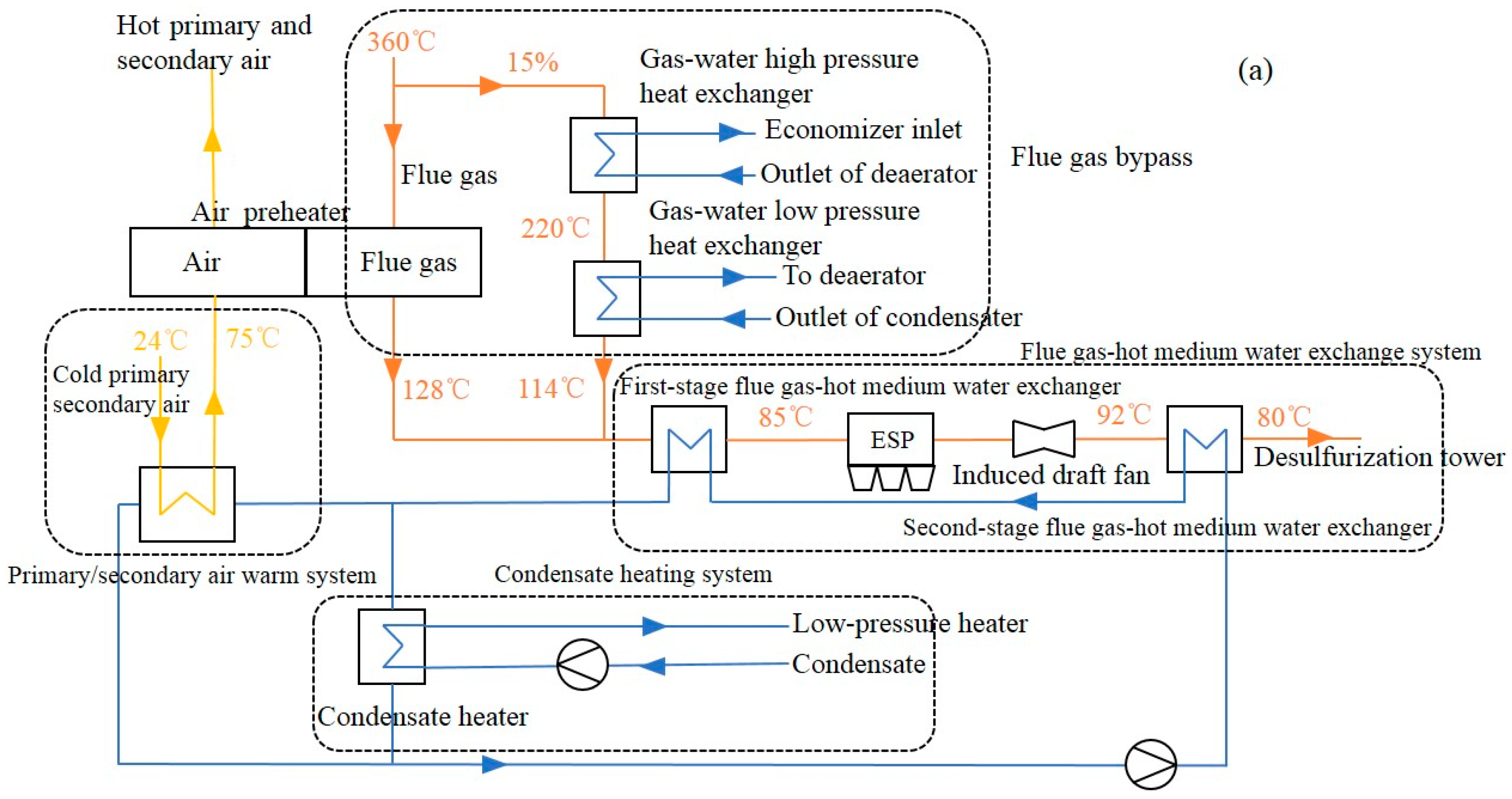

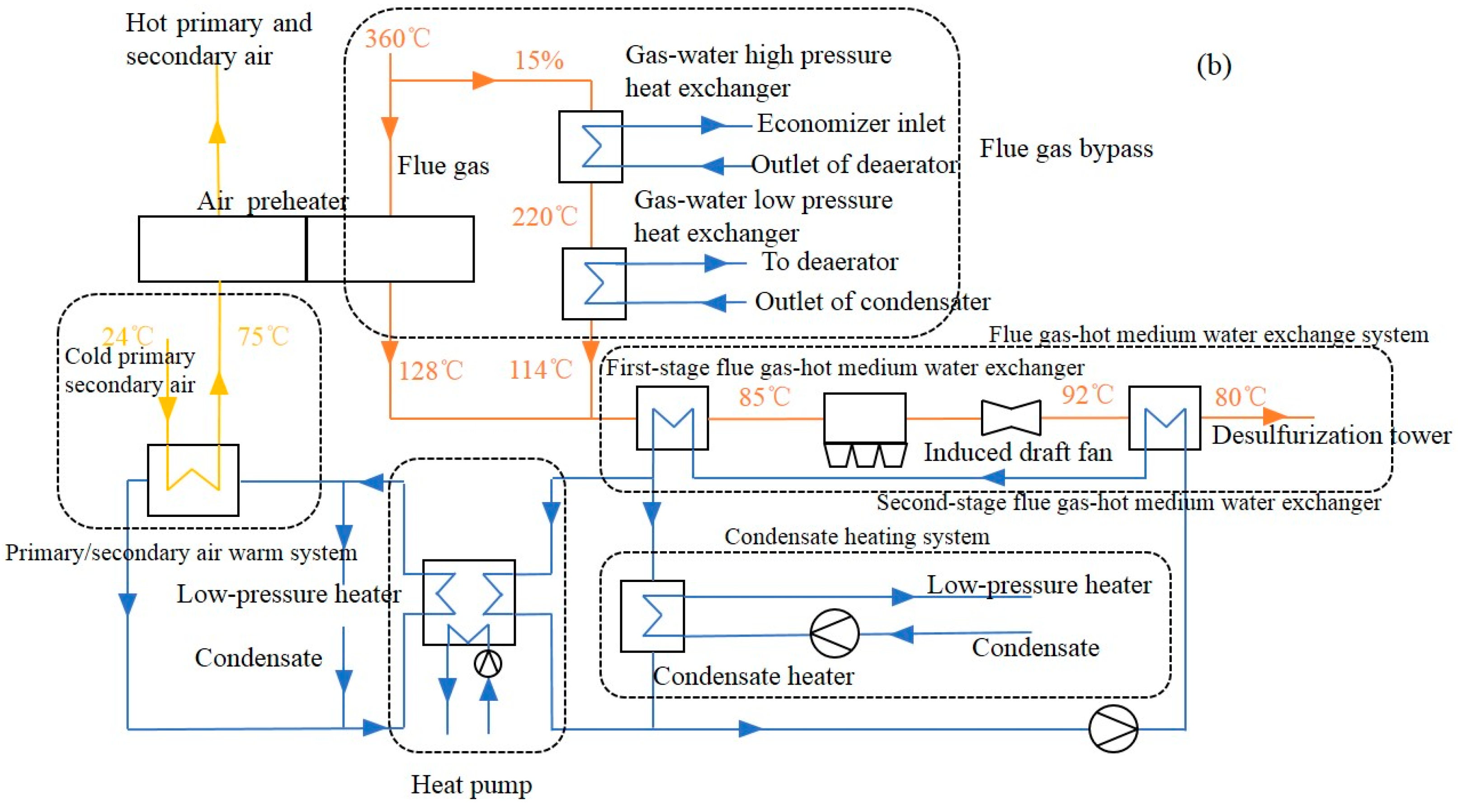

2.2. Waste Heat Recovery System

2.3. Evaluation Method

3. Result and Discussion

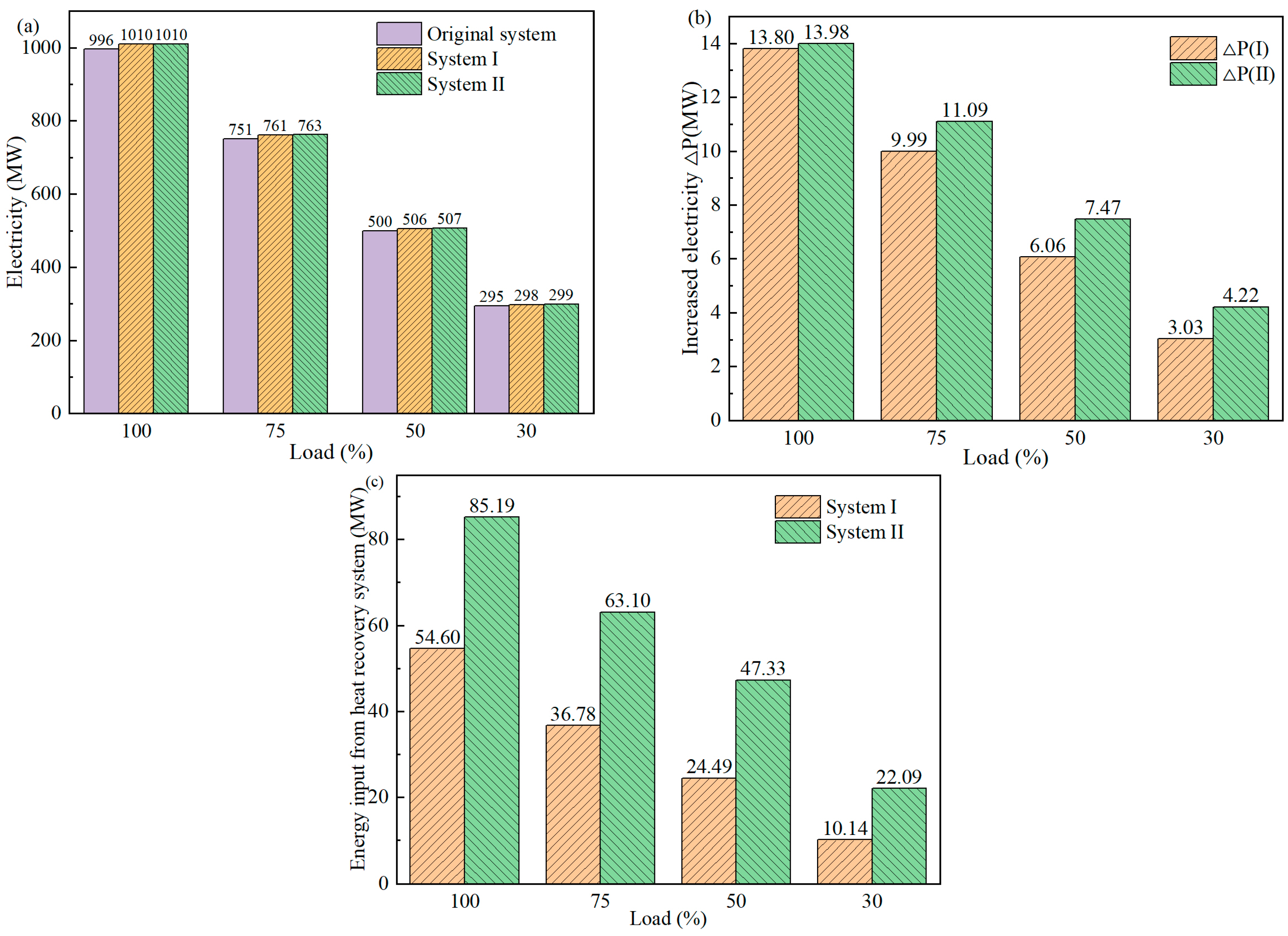

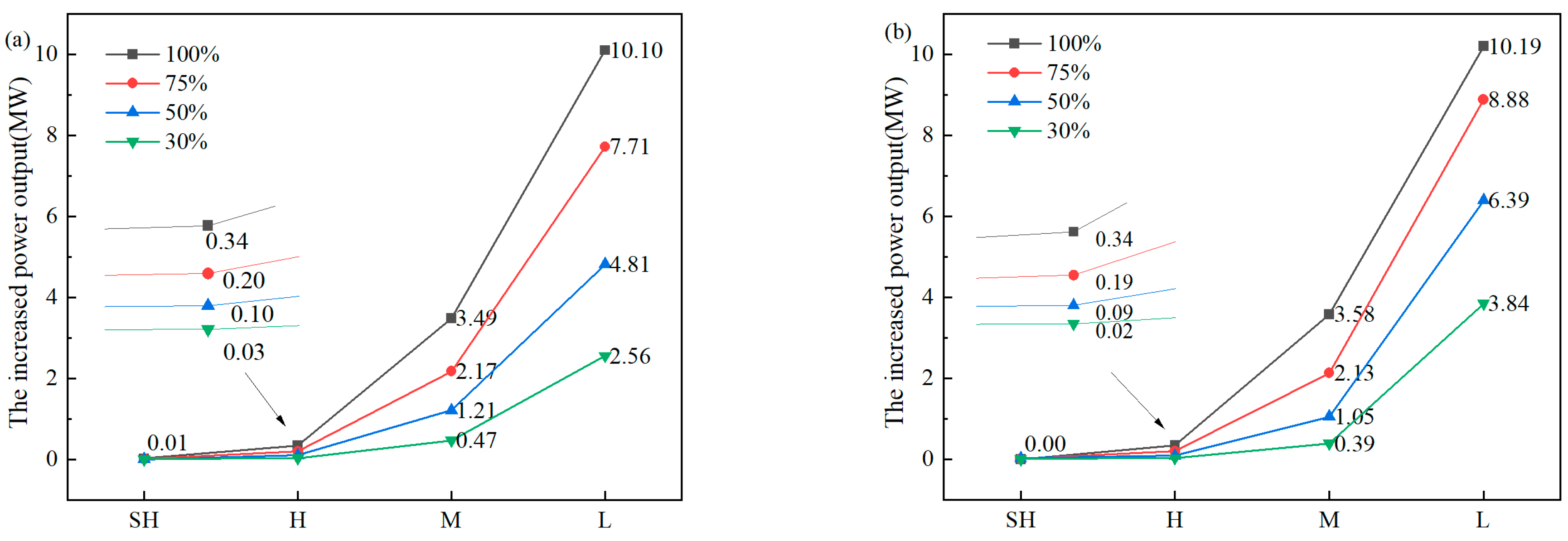

3.1. Coal Consumption Rate Analysis

3.2. Exergy Analysis

4. Conclusions

- (1)

- Both waste heat recovery systems can increase the output of the unit, reduce coal consumption, and improve the energy utilization efficiency of the equipment by recovering waste heat. System II can boost power output by up to 13.98 MW while reducing the coal consumption rate by up to 3.36 g/(kW·h), showcasing significant energy-saving benefits.

- (2)

- The increase in power output due to the waste heat recovery systems decreases as the unit load reduces. Additionally, the increased power output is mainly distributed in the medium- and low-pressure cylinder sections, with minimal impact on supercritical and high-pressure cylinders.

- (3)

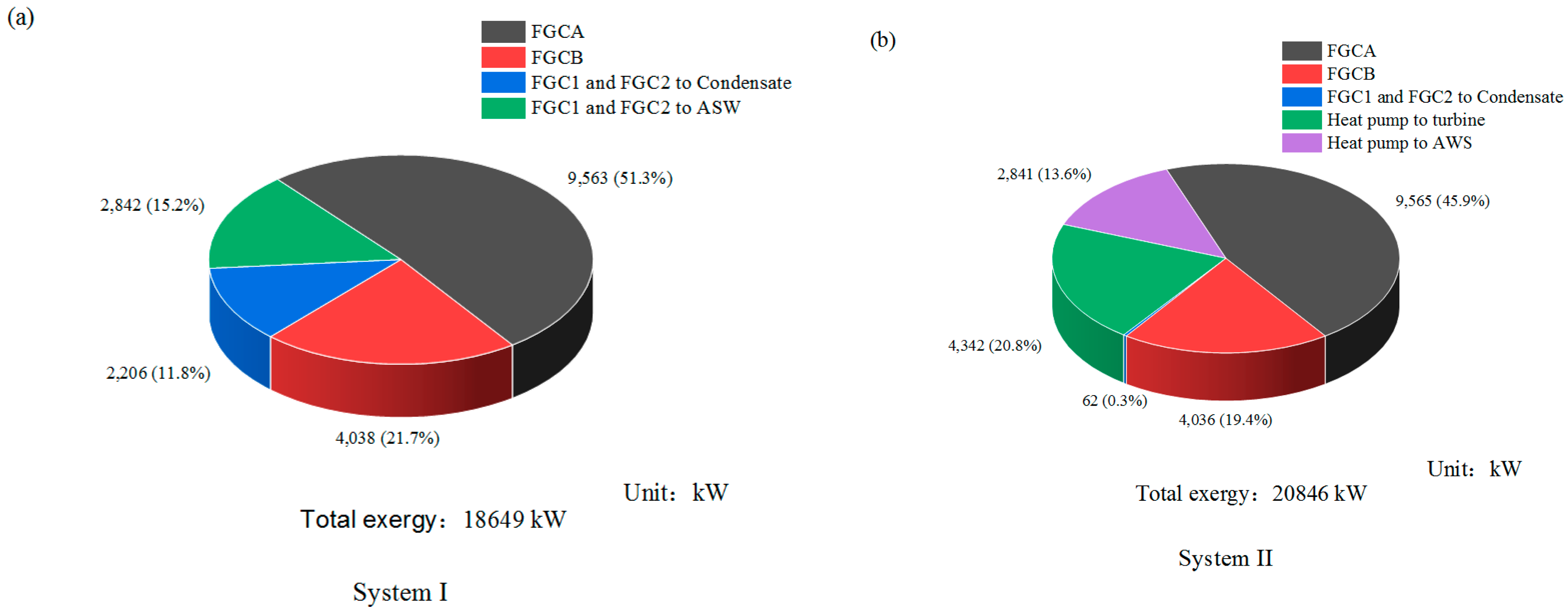

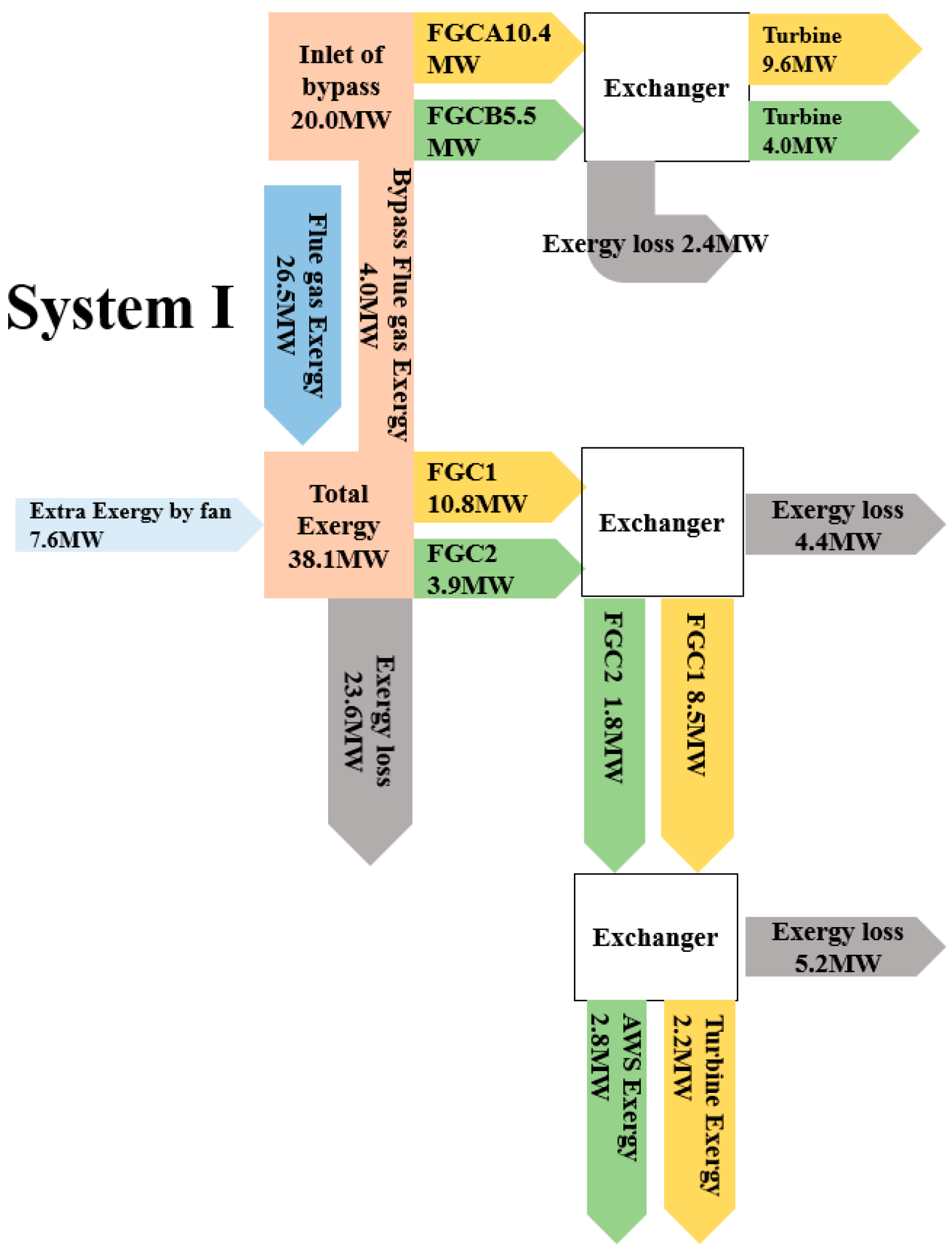

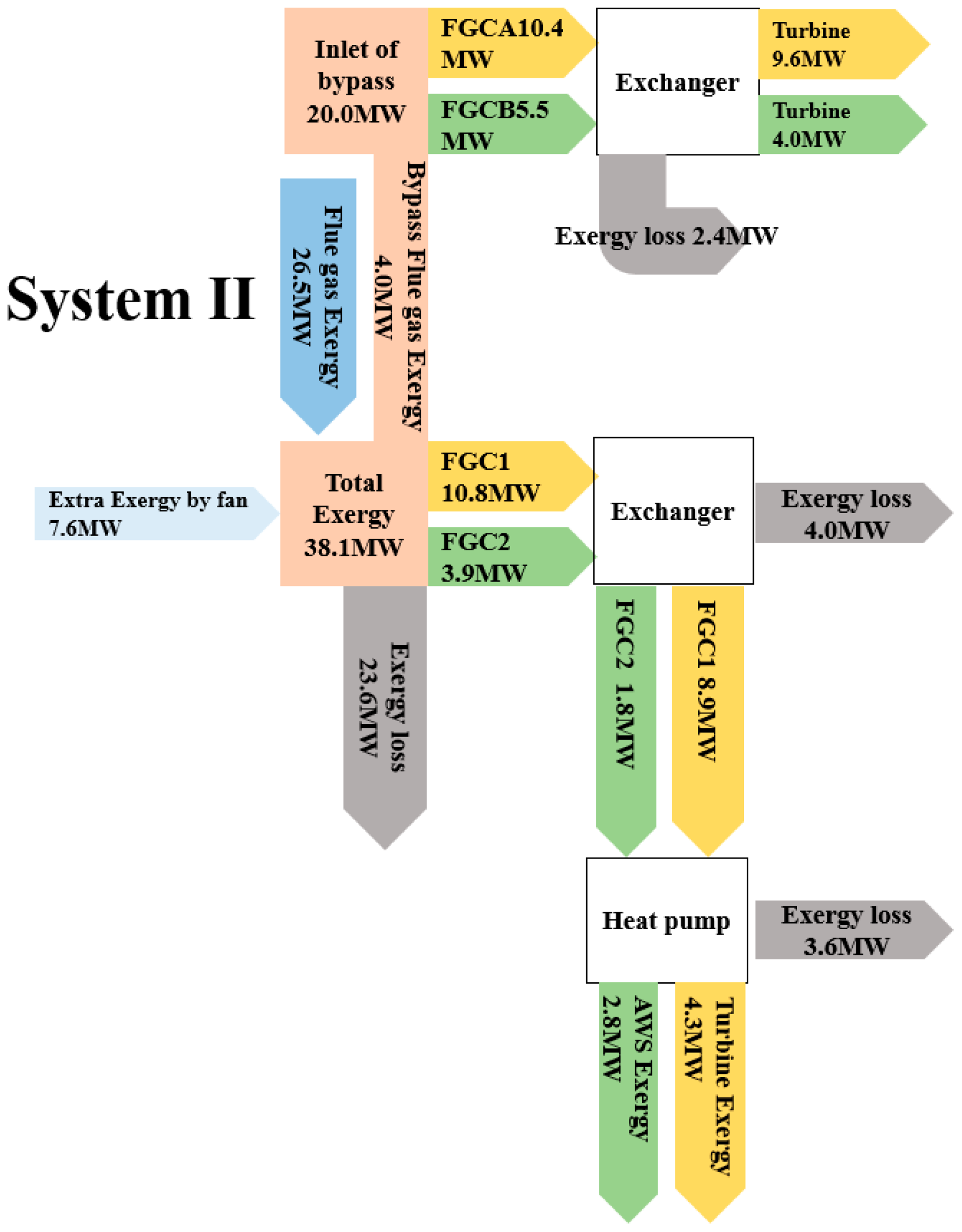

- From the perspective of energy utilization efficiency, System II has a better exergy utilization efficiency, achieving an exergy efficiency of 44% with a recovery amount of 20,845 kW. The primary thermal loss in the waste heat recovery system stems from flue gas heat loss. However, due to corrosion issues caused by flue gas temperatures reaching the acid dew point, further utilization of low-temperature heat is challenging. The heat pump system can reduce thermal losses. Corrosion problems arising from flu-gas temperatures hitting the acid dew point complicate the further use of low-temperature heat. Implementing a heat pump system can help minimize these thermal losses.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FGCA | gas–water high-pressure heat exchanger |

| FGCB | gas–water low-pressure heat exchanger |

| FGC1 | first-stage flue gas-hot medium water exchanger |

| FGC2 | second-stage flue gas-hot medium water exchanger |

| CHS | condensate heat system |

| AWS | air warm system |

| HP | heat pump |

| Symbols | |

| B | coal consumption rate |

| P | turbine power (kW) |

| Qt | energy in steam adsorbed in the furnace (J/s) |

| ηb | boiler efficiency |

| qnet | heating value of standard coal (kJ/kg) |

| design value of air temperature at air preheater inlet | |

| measured flue gas temperature at air preheater inlet | |

| measured flue gas temperature at air preheater outlet | |

| measured air temperature at air preheater inlet | |

| exergy efficiency | |

| exergy value of heated fluid existing system | |

| exergy value of heated fluid entering system | |

| exergy value of heating fluid existing system | |

| exergy value of heating fluid entering system | |

References

- Fu, C.; Anantharaman, R.; Jordal, K.; Gundersen, T. Thermal efficiency of coal-fired power plants: From theoretical to practical assessments. Energy Convers. Manag. 2015, 105, 530–544. [Google Scholar] [CrossRef]

- Chao, L.; Ke, L.; Yongzhen, W.; Zhitong, M.; Yulie, G. The Effect Analysis of Thermal Efficiency and Optimal Design for Boiler System. Energy Procedia 2017, 105, 3045–3050. [Google Scholar] [CrossRef]

- Xiao, P.; Zhang, Y.; Wang, Y.; Wang, J. Analysis of an improved economizer system for active control of the coal-fired boiler flue gas temperature. Energy 2019, 170, 185–198. [Google Scholar] [CrossRef]

- Xu, G.; Xu, C.; Yang, Y.; Fang, Y.; Li, Y.; Song, X. A novel flue gas waste heat recovery system for coal-fired ultra-supercritical power plants. Appl. Therm. Eng. 2014, 67, 240–249. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, C.; Xu, G.; Han, Y.; Fang, Y.; Zhang, D. A new conceptual cold-end design of boilers for coal-fired power plants with waste heat recovery. Energy Convers. Manag. 2015, 89, 137–146. [Google Scholar] [CrossRef]

- Wang, X.; Zhuo, J.; Liu, J.; Li, S. Synergetic process of condensing heat exchanger and absorption heat pump for waste heat and water recovery from flue gas. Appl. Energy 2020, 261, 114401. [Google Scholar] [CrossRef]

- Wei, M.; Zhao, X.; Fu, L.; Zhang, S. Performance study and application of new coal-fired boiler flue gas heat recovery system. Appl. Energy 2017, 188, 121–129. [Google Scholar] [CrossRef]

- Xu, G.; Huang, S.; Yang, Y.; Wu, Y.; Zhang, K.; Xu, C. Techno-economic analysis and optimization of the heat recovery of utility boiler flue gas. Appl. Energy 2013, 112, 907–917. [Google Scholar] [CrossRef]

- Wang, C.; He, B.; Sun, S.; Wu, Y.; Yan, N.; Yan, L.; Pei, X. Application of a low pressure economizer for waste heat recovery from the exhaust flue gas in a 600 MW power plant. Energy 2012, 48, 196–202. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, S.; Sun, B.; Liu, J.; Yan, J. Design on a novel waste heat recovery system integrated with the bypass flue and outside primary air preheater for bitumite-fired power plants. Energy 2024, 291, 130341. [Google Scholar] [CrossRef]

- Stevanovic, V.D.; Petrovic, M.M.; Wala, T.; Milivojevic, S.; Ilic, M.; Muszynski, S. Efficiency and power upgrade at the aged lignite-fired power plant by flue gas waste heat utilization: High pressure versus low pressure economizer installation. Energy 2019, 187, 115980. [Google Scholar] [CrossRef]

- Yang, B.; Yuan, W.; Fu, L.; Zhang, S.; Wei, M.; Guo, D. Techno-economic study of full-open absorption heat pump applied to flue gas total heat recovery. Energy 2020, 190, 116429. [Google Scholar] [CrossRef]

- Han, Y.; Xu, G.; Zheng, Q.; Xu, C.; Hu, Y.; Yang, Y.; Lei, J. New heat integration system with bypass flue based on the rational utilization of low-grade extraction steam in a coal-fired power plant. Appl. Therm. Eng. 2017, 113, 460–471. [Google Scholar] [CrossRef]

- Yan, M.; Zhang, L.; Shi, Y.; Zhang, L.; Li, Y.; Ma, C. A novel boiler cold-end optimisation system based on bypass flue in coal-fired power plants: Heat recovery from wet flue gas. Energy 2018, 152, 84–94. [Google Scholar] [CrossRef]

- Faraji, H.; Faraji, M.; El Alami, M. Numerical Survey of the Melting Driven Natural Convection Using Generation Heat Source: Application to the Passive Cooling of Electronics Using Nano-Enhanced Phase Change Material. J. Therm. Sci. Eng. Appl. 2019, 12, 1–17. [Google Scholar] [CrossRef]

- Yang, M.; Zhou, Y.; Yang, J.; Bao, J.; Wang, D.; Yu, Q. Performance analysis of an efficient waste heat utilization system in an ultra-supercritical coal-fired power plant. Energy Rep. 2022, 8, 5871–5882. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Yang, Y.; Wang, L.-M.; Wang, D.-D. Performance Analysis and Optimization of Flue Gas Waste Heat Recovery System of a 600MW Coal-Fired Power Plant. In Proceedings of the ASME 2020 Power Conference Collocated with the 2020 International Conference on Nuclear Engineering, ASME 2020 Power Conference, Virtual, 4–5 August 2020. [Google Scholar]

- Du, X.; Bai, R.; Sang, P.; Fang, L.; Shi, Y. Experimental and simulation study on optimal operation of flue gas waste heat utilization system of coal-fired unit. J. China Coal Soc. 2023, 48, 2682–2690. [Google Scholar]

- Zhang, H.; Dong, Y.; Lai, Y.; Zhang, H.; Zhang, X. Waste heat recovery from coal-fired boiler flue gas: Performance optimization of a new open absorption heat pump. Appl. Therm. Eng. 2021, 183, 116111. [Google Scholar] [CrossRef]

- Kashif Shahzad, M.; Ding, Y.; Xuan, Y.; Gao, N.; Chen, G. Performance analysis of a novel double stage multifunctional open absorption heat pump system: An industrial moist flue gas heat recovery application. Energy Convers. Manag. 2022, 254, 115224. [Google Scholar] [CrossRef]

- Yong, L.; Yanhong, W.; Beingwen, Z. Correction of boiler thermal efficiency and standard coal consumption rate based on different standards. J. Chin. Soc. Power Eng. 2012, 32, 273–281. [Google Scholar]

- GB/T 10184—2015; Performance Test Code for Utility Boiler. China Standards Press: Beijing, China, 2015.

- Juan, Y.; Jianfeng, L.; Juan, W.; Ziyuan, Z.; Guitao, P.; Ma, Q.; Chu, J. Research on Retrofit Scheme of Ultra-high Heating Load of Coal-fired Units. J. Electr. Power 2022, 37, 287–297. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Chen, G.; Xu, X.; Tan, R.; Gao, X.; Zhang, H.; Yu, J. Recovering Low-Grade Heat from Flue Gas in a Coal-Fired Thermal Power Unit. Energies 2024, 17, 5204. https://doi.org/10.3390/en17205204

Huang L, Chen G, Xu X, Tan R, Gao X, Zhang H, Yu J. Recovering Low-Grade Heat from Flue Gas in a Coal-Fired Thermal Power Unit. Energies. 2024; 17(20):5204. https://doi.org/10.3390/en17205204

Chicago/Turabian StyleHuang, Linbin, Guoqing Chen, Xiang Xu, Rui Tan, Xinglong Gao, Haifeng Zhang, and Jie Yu. 2024. "Recovering Low-Grade Heat from Flue Gas in a Coal-Fired Thermal Power Unit" Energies 17, no. 20: 5204. https://doi.org/10.3390/en17205204

APA StyleHuang, L., Chen, G., Xu, X., Tan, R., Gao, X., Zhang, H., & Yu, J. (2024). Recovering Low-Grade Heat from Flue Gas in a Coal-Fired Thermal Power Unit. Energies, 17(20), 5204. https://doi.org/10.3390/en17205204