Abstract

Smart mining solutions currently suffer from inadequate big data support and insufficient AI applications. The main reason for these limitations is the absence of a comprehensive industrial internet cloud platform tailored for the coal industry, which restricts resource integration. This paper presents the development of an innovative platform designed to enhance safety, operational efficiency, and automation in fully mechanized coal mining in China. This platform integrates cloud edge computing, real-time data processing, and AI-driven analytics to improve decision-making and maintenance strategies. Several AI models have been developed for the proactive maintenance of comprehensive mining face equipment, including early warnings for periodic weighting and the detection of common faults such as those in the shearer, hydraulic support, and conveyor. The platform leverages large-scale knowledge graph models and Graph Retrieval-Augmented Generation (GraphRAG) technology to build structured knowledge graphs. This facilitates intelligent Q&A capabilities and precise fault diagnosis, thereby enhancing system responsiveness and improving the accuracy of fault resolution. The practical process of implementing such a platform primarily based on open-source components is summarized in this paper.

1. Background

China currently has thousands of coal mines, including large state-owned mines and small private mines. The advancement of the economy and social progress has brought new challenges to production safety, and the demand for unmanned and less-manned operations has increased. At the same time, with the improvement of automation in mining equipment and the increase in the amount of equipment in the mechanized mining faces, the maintenance pressure on underground equipment has also increased. Modern industrial internet big data platforms, integrating cloud computing, big data, and artificial intelligence technologies, provide solutions to improving production efficiency and achieving unmanned operations in coal mines. These systems typically include integrated control platforms for coal mines, intelligent operation and maintenance platforms for equipment, and underground safety production platforms. Compared to other energy sectors in China, such as oil and electricity, the coal industry faces significant challenges in leveraging industrial internet platforms to build advanced IoT, big data, and AI platforms.

There have recently been rapid advancements in software technology, particularly the rapid development of open-source components, including IoT platforms based on Huawei’s HarmonyOS, relation databases like openGauss and PostgreSQL, time-series databases like IoTDB [1], and big data platforms like Doris, StarRocks [2], Clickhouse, and Huawei’s FusionInsight [3,4], as well as the continuous emergence of new applications for AI large models. By developing a fully integrated system based on cloud-native technology and low-code aPaaS platforms, these components can be continuously optimized to create a complete high-performance industrial internet platform, thereby improving the efficiency and automation of safe mining production and enhancing the efficiency of coal mine equipment operation and maintenance.

If, in communication software, the central concern is protocol algorithms and control/data planes, then the core issue of the software architecture revolves around orchestration. Specifically, there are three types of orchestration: device orchestration, service orchestration, and business logic implementation (orchestration). This research seeks to explore whether these three-layer orchestration architectures can be optimized to enhance system efficiency. Additionally, can such a system fully support advanced applications, such as big data and AI? While there are many valuable studies on industrial internet-based platforms [5] and architecture overviews [6,7,8], some papers focus solely on IoT device orchestration [6], while others emphasize service layer orchestration [7]. A comprehensive architecture overview by Li (2020) [9] not only presents the structure of a fully functional industrial internet-based platform but also highlights the significance of big data and advanced AI applications, particularly in the coal mining industry. However, compared to previous research [10,11,12], this study not only provides an architectural methodology integrated with advanced applications but also offers tools and open-source modules to build a fully functional platform.

2. Overview of the Industrial Mining Internet-Based Platform

In the design of the industrial mining internet-based platform, the following five technologies play important roles. The cloud-native platform serves as the carrier for application services, participating in the entire lifecycle management of these application services from development to deployment and practical application. It ensures interface communication and a high availability of services after the applications are deployed. The IoT platform’s information perception layer is responsible for data collection and edge computing operations [12]. The big data platform and data lake are responsible for data governance, real-time data analysis, and large-scale storage. The intelligent analysis layer, based on the big data platform, manages AI models and machine learning (ML) mechanism models to complete specific analysis tasks on cleaned data [13,14]. The front-end presentation layer realizes data display and human–computer interactions for mobile technology service applications.

Cloud-Native Platform: The main functions and uses of the cloud-native platform in the system include improving the deployment speed and operation and maintenance efficiency of applications, ensuring the portability and flexibility of the applications through containerization and microservice architecture. It supports automated scaling and resource management to adapt to continuously changing load demands while achieving high availability and fault tolerance.

IoT Platform: In this layer, various sensors are responsible for collecting the operating data of on-site equipment and managing them through the industrial internet-based platform’s cloud–edge integrated IoT platform [15] (integrated and compatible with Huawei HarmonyOS [16]). The data are uploaded to the data collection system through wireless or wired terminals, organized, and then used by the on-site decision-making system. The high-efficiency data processing capability of the cloud–edge integrated IoT platform ensures high-quality and high-availability data, providing reliable data support for production control, safety monitoring, and predictive maintenance strategies.

Big Data Platform: The big data platform can efficiently process and analyze large amounts of data collected in real time from the coal mining face, such as the equipment operating status, environmental monitoring, and employee information. This enables managers to monitor the production process in real time, promptly identify issues, and take measures. By combining with algorithm models and analyzing historical and real-time data, the big data platform can predict equipment failures, thereby implementing predictive maintenance, reducing unexpected downtime, and extending the equipment lifespan.

Intelligent Analysis Layer: In this layer, on-site equipment data are uploaded to the big data platform and AI platform [15,17] for in-depth intelligent analysis and data mining [13,14]. These analysis results are used to generate new predictive models and maintenance strategies, which are then downloaded and updated to the on-site decision-making system through the network. The intelligent analysis layer is also responsible for adjusting equipment operating parameters based on data feedback to optimize equipment performance and extend equipment lifespan. Additionally, it includes a large AI model that can interact with a knowledge base to provide human-like responses, such as a “chatBot” service for maintenance applications.

Front-end Presentation Layer: The front-end presentation layer is the interface where users interact with the application, which is responsible for displaying data and receiving user inputs. Utilizing front-end frameworks like Vue, a widely used framework in China, intuitive monitoring dashboards can be efficiently developed. These dashboards display mining data, equipment status, and safety warnings in real time, enhancing operational convenience and production efficiency while improving real-time safety management and decision support.

The infrastructure consists of the IaaS platform and data center hardware. Together, they create a complete data flow from IoT data collection to transmission, governance, storage, and analysis, supporting PaaS applications and the front-end display.

3. System Design

3.1. Architecture Design

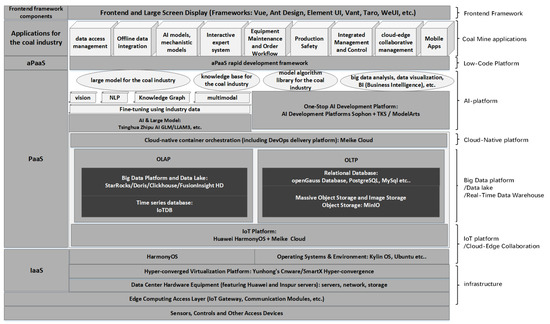

The overall architecture of the platform is shown in Figure 1. The software layer includes the five major systems mentioned previously: IoT edge computing, a cloud-native platform, a big data platform, an AI platform, and a low-code development component to accelerate application development speed. The front-end application layer is implemented using the Vue framework.

Figure 1.

Overall architecture of the intelligent operation and maintenance platform.

The data collected by the IoT platform are transmitted to the big data platform through the IoT gateway and cloud–edge collaboration mechanism, where data governance, including cleaning and processing, is performed. The data are transformed into the required form for the algorithm models and applications to call. The final processed data are stored in a structured database, making them accessible for the application logic programs and presentation layer.

To implement this comprehensive industrial internet-based architecture, it is essential to ensure high performance in device and service orchestration as well as the rapid implementation of business logic to form a complete framework. A low-code platform is used for fast business logic deployment, a cloud-native platform manages service orchestration, and an IoT platform orchestrates devices on underground mining faces, particularly when cloud–edge communication is established over the internet.

The platform consists primarily of open-source components, covering data collection, big data processing, back-end business logic, and the front-end display. The component names in the architecture diagram are the names of open-source projects and can be searched for and accessed on the internet. To lower the development effort and shorten the software development lifecycle, a commercial AI platform, Sophon, is used and will be introduced in detail later. It provides visualization and drag-and-drop tools for managing datasets and AI models, which are useful when managing a large number of AI models and datasets. However, such an AI platform can also be built from scratch using alternative open-source components such as OpenStack, MLflow, Kubeflow, etc.

3.2. Core Component Construction

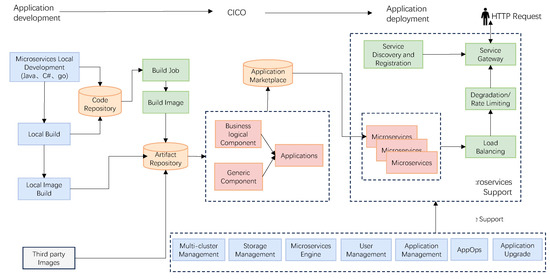

3.2.1. Cloud-Native Platform

The cloud-native platform connects and integrates all the components and applications across the entire platform while managing application services. Cloud-native is a method for software development, deployment, and online application management. It leverages cloud computing features such as elasticity, scalability, automation, and distributed architectures to improve software quality, efficiency, and security. The core principles of cloud-native include containerization, microservices, continuous integration and continuous delivery (CI/CD), declarative APIs, and infrastructure as code (IaC). The Meike Cloud platform [17], a cloud-native solution developed using open-source projects, supports multi-language microservice architectures and continuous integration and deployment (DevOps), as well as resource management, deployment, load balancing, dependencies, routing, fault tolerance, containerized cluster deployment, elastic scaling, high availability, and observability of cloud-native applications. Figure 2 illustrates the cloud-native platform’s architecture.

Figure 2.

Cloud-native platform architecture design.

This solution uses the Meike Cloud platform [17] as the foundational software layer for upper-layer applications. Comparable high-performance cloud-native platforms include Alibaba Cloud Container Service (ACK), Digital China Cloud-Native Platform, Zhongke Cloud-Native Platform, Yunzhihui Cloud-Native Platform, Yonyou Cloud-Native Platform, and Chinasoft Cloud-Native Platform. Meike Cloud supports numerous applications in the coal industry and complies with the industry’s standard system.

3.2.2. Coal Mine IoT Platform and Cloud–Edge Collaboration for Data Collection, Transmission, and Remote Application Deployment

- (1)

- IoT platform

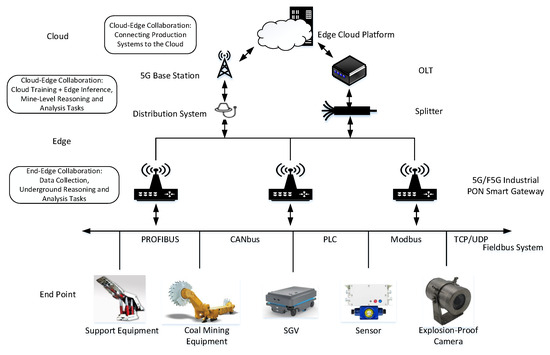

This system uses the Meike Cloud platform [17,18] as the foundation to provide PaaS capabilities and cloud–edge collaboration capabilities, utilizing HarmonyOS for edge data collection capabilities. HarmonyOS, developed by Huawei, is a multi-device distributed operating system designed to support various types of devices and platforms. The HarmonyOS cloud–edge integrated IoT platform, with its “distributed OS architecture” and “distributed soft bus technology,” reduces the difficulty of implementing the underlying technology of corresponding distributed applications, making it more developer-friendly. Huawei’s HarmonyOS microkernel is not open-source, but its data synchronization mechanism is based on key-value pairs, similar to ETCD, a distributed key-value store for data consistency. The HarmonyOS edge-side solution [19] is shown in Figure 3 below.

Figure 3.

HarmonyOS cloud–edge composition.

The cloud–edge collaboration solution of HarmonyOS leverages the distributed capabilities of HarmonyOS, offering the following advantages [19]: The system enhances efficiency and intelligence by integrating cloud computing resources with edge computing nodes. The IoT edge provides a terminal computing engine, enabling developers to manage Harmony gateway applications and AI algorithms through automatic deployment and updates. Using the IoT edge SDK, developers can create and manage plugins, monitor their status, and ensure connectivity with the Harmony gateway.

After the data collection process, IoT data can be stored in the IoTDB time-series database [1]. IoTDB, an Apache incubator project led by Tsinghua University, is specifically designed for IoT time-series data, providing functions for data collection, storage, and analysis. IoTDB offers an end-to-cloud integrated solution, delivering high-performance data read-and-write operations and rich query capabilities in the cloud. It customizes efficient directory organization structures for IoT scenarios and seamlessly connects with big data systems like Apache Hadoop, Spark, and Flink. On the edge side, it provides lightweight TsFile management capabilities, allowing data to be written to a local TsFile and offering basic query functions while supporting TsFile data synchronization to the cloud.

- (2)

- Cloud–edge collaboration

Equipment at a coal mining face generates a large amount of data. Uploading all the data to the cloud for processing can, firstly, put pressure on the transmission links and the coal mine data center (cloud), and secondly, it cannot meet the requirements of latency-sensitive scenarios. To reduce latency and alleviate the pressure on the cloud, edge computing nodes can handle lightweight data storage and computation within a certain range. Meanwhile, the cloud performs business analysis and mining, algorithm model training, and optimization. The generated algorithm models are pushed to the edge, forming a data learning and application closed loop.

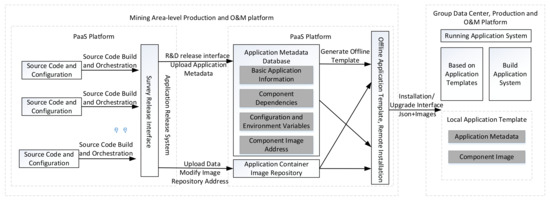

Additionally, applications developed in the cloud development environment can also be deployed to the edge for operation, allowing for the remote monitoring and maintenance of applications. After the application is updated, it can be updated to the edge with one click. Figure 4 below illustrates the remote data flow of cloud–edge collaboration.

Figure 4.

Cloud–edge collaboration—application remote synchronization.

Mine-level edge cloud nodes connect external source code to build and configure components, arrange multiple components into a complete application system, and upload application metadata and images to the application market through the release interface provided by the application market. The applications are then remotely delivered to the coal mine intelligent integrated control platform for deployment and operation, and in subsequent upgrades, remote one-click upgrades can be achieved.

- (3)

- Cloud edge collaboration—data synchronization

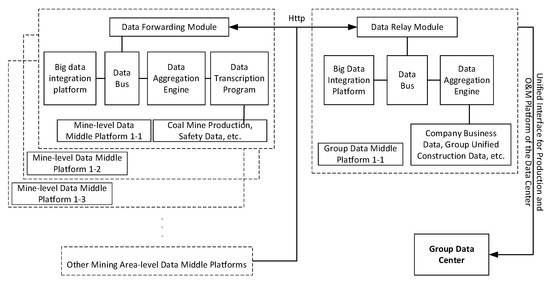

The data synchronization process is shown in Figure 5; it provides bidirectional synchronization capabilities for mine-level, mine-area-level, and enterprise-group-level data.

Figure 5.

Cloud–edge collaboration—data synchronization.

Data flow process:

- (1)

- Coal mine production and safety data are written into the local mine-end data aggregation engine through data transcription programs. The data aggregation engine then writes the data into the local data bus. The data-forwarding module processes the data in the data bus in real time, synchronizing them to the mine-area-level data-forwarding module.

- (2)

- The mine-area-level data-forwarding module, after receiving the data pushed by the subordinate mine-level middle data platform, persists a copy locally and pushes the copy to the group data center according to the group’s unified interface.

- (3)

- The mine-area-level data-forwarding module pulls business management and master data from the group data center, processes a copy locally, and forwards the relevant data to the mine-level middle data platform.

- (4)

- The middle data platform’s data-forwarding module processes the data locally when it receives data from the mine area-level.

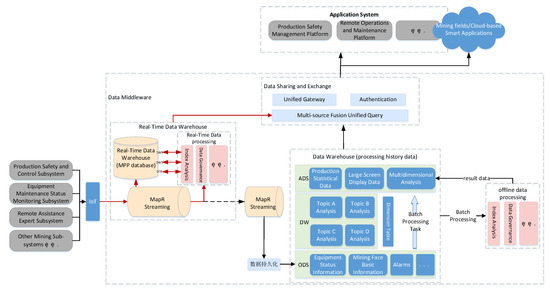

3.2.3. High-Concurrency Distributed Real-Time Data Warehouse

Figure 6, shown below, describes the data flow architecture of the intelligent operation and maintenance platform for the mining production equipment. The collected data are transmitted to the real-time data warehouse through the IoT platform and then modeled and layered into ADS, DW, and ODS to generate the data required by the business platform and to construct the dataset [14]. The real-time data warehouse also has multiple open-source big data components to choose from. For example, StarRocks is a new-generation ultra-fast all-scenario MPP (Massively Parallel Processing) database [2,3].

Figure 6.

Data flow diagram of the intelligent operation and maintenance platform for mining.

Big data utilize data synchronization as well as the sharding and replication methods, which can distribute data to multiple nodes according to certain rules. Each node contains only part of the data, while each node can have multiple replicas, each of which contains all the data completely. This enables horizontal scaling and a high availability of data, improving query performance and fault tolerance.

The platform design uses the open-source big data and distributed computing engine StarRocks [2] (an open-source project) to build a real-time data warehouse that processes underground working condition data with high latency requirements. The data collected through the IoT platform are stored in the Apache IoTDB time-series database, and the full historical data and the cleaned data are stored in the real-time data warehouse of StarRocks. The StarRocks big data platform is an ultra-fast all-scenario MPP (Massively Parallel Processing) database. Similar platforms also include Doris, Clickhouse, Aliyun Feitian Big Data, Huawei FusionInsight Intelligent Data Lake, etc. Many big data and distributed computing engines originate from open-source projects and focus more on efficiency optimization at the application level, making products like StarRocks’ large-scale parallel real-time data warehouse MPP perform better than industry benchmarks like Clickhouse in multi-table queries and real-time data warehouse associative queries.

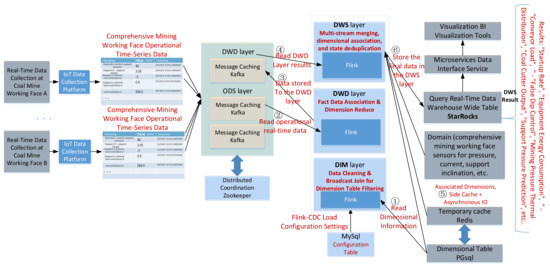

A data warehouse is a technical architecture for data storage that includes the Operational Data Store (ODS) layer, Data Warehouse Detail (DWD) layer, and Data Warehouse Summary (DWS) layer, aiming to effectively manage and analyze large amounts of data. The real-time data warehouse completes the result analysis through stream processing during the data flow conversion process. Figure 7 shows the design architecture of the big data real-time mining data warehouse.

Figure 7.

Real-time data warehouse data flow for mining.

After the data are collected, they are transmitted to the message queue, and then the real-time data warehouse stream processing begins.

- (1)

- Firstly, dimensional information is read from the dimension table.

- (2)

- Then, the working condition data in the message queue are read from Kafka, cleaned (e.g., data filling, time alignment, data quality checks), and joined with the dimension table through a broadcast join, forming fact table business results stored in Kafka.

- (3)

- Through fact table data association and dimension degradation processing, the DWD-layer data of the real-time data warehouse is constructed.

- (4)

- The required DWS-layer data are constructed through multi-stream merging, dimension association, and state de-duplication.

- (5)

- The final DWS-layer result is constructed by associating with the dimensional information in the bypass cache.

- (6)

- The result is written back to the real-time data warehouse StarRocks database through stream processing.

Steps (2) and (3) construct the DWD-layer data, while steps (4) and (5) construct the DWS-layer data. At this point, the DWS data of the real-time data warehouse have become the statistical result data that can be called by applications, including the mining face startup rate, equipment energy consumption, conveyor load, false slope control, etc., or predictive data, such as the coal mine periodic pressure. Different dimension tables and wide tables can be constructed according to different needs. The advantage of the real-time data warehouse is that it can timely calculate massive real-time data during production and synchronously obtain the required results, facilitating timely decision-making and adjustment of production tasks.

3.2.4. aPaaS Low-Code Platform

The production and intelligent operation and maintenance platform integrates a large number of front-end Vue component libraries for coal industry applications, including the SCADA configuration library for mining face equipment, combined with some common public components, such as reports, file systems, user permission management, workflow management, etc. Based on the Meike Cloud, an aPaaS low-code platform was developed by our own development team. Mining application production control and alarm systems require high real-time data and system reliability, while most applications do not have such high real-time requirements but encounter complex business scenarios, working condition processes, and rapidly changing business needs, posing challenges to application development. The low-code platform is reasonably used in the implementation of the upper-layer applications to improve the platform’s response speed to needs and increase development efficiency. Similar aPaaS low-code platforms to refer to include Budibase/Appsmith/Joget/Saltcorne, etc., and other high-performance, functionally comprehensive platforms. The visual development environment of the low-code platform greatly reduces the technical threshold for application development, allowing non-technical personnel to build applications through simple drag-and-drop operations. Currently, low-code platforms are widely used in core business management, mobile application data collection, API interface data writing, and dashboard construction, among other scenarios.

The advantages of using a low-code platform lie in its efficient development speed and cost reduction and efficiency improvement capabilities. Statistics show that using low-code development can increase application development efficiency by approximately 67%, significantly shortening project delivery cycles. Low-code platforms also have strong enterprise-level foundational capabilities that can support the needs of most mining industry applications. Additionally, ease-of-use and maintainability are also its standout features.

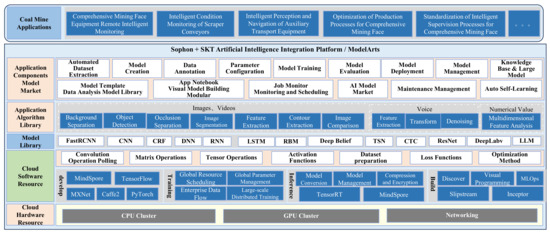

3.2.5. Intelligent Analysis and Decision Support

The production and intelligent operation and maintenance platform utilizes the high-performance AI management platform Sophon [20,21], which has numerous practical applications. The Sophon platform includes a complete AI process management system, capable of performing dataset preprocessing, labeling, data augmentation, data access maintenance, and other operations. Sophon also includes big data components like Slipstream, which serves the same function as Flink, and Inceptor, which serves the same function as Kafka. These big data components can process and manage data sources and can also connect to other types of databases through extended drivers. The architecture of the Sophon AI platform is shown in Figure 8 below.

Figure 8.

Application architecture of AI computing frameworks.

The AI platform foundation provides a large number of operator libraries, supporting multi-frameworks such as TensorFlow, MxNet, and Caffe. It enables users to quickly and efficiently complete full data modeling tasks through graphical drag-and-drop modeling. Model sharing improves teamwork efficiency; API services and workflow scheduling promote the integration of models with business systems and foster intelligent applications. The coal production and intelligent operation and maintenance platform uses Sophon as the foundational framework for its AI platform, greatly simplifying the design of the industrial internet-based platform while fully utilizing AI capability components to quickly implement business applications.

Using Sophon [20,21], AI models can be constructed quickly with simple clicks and mouse drag-and-drop actions. For example, a pressure prediction model for a coal mine comprehensive mining face or a coal mining machine health status model can be trained and deployed online in a short time. These models assess the health status of equipment based on various sensor parameters during coal operation, predicting the likelihood of faults in a timely manner. Due to the differences in each coal mining face, models need to be trained specifically for each mine, matching each model to its respective mining face. The model management capabilities of the Sophon platform allow for targeted model training, deployment management, and version control of application models for numerous mining faces. The application of these AI models and algorithms in fully mechanized mining faces significantly enhances the automation and intelligence level of mining operations.

The TKS knowledge middle platform [22], as an external component of the Sophon platform [20,21], provides support for large models and has been applied in various industry projects for knowledge queries and recommendations, supporting industry knowledge queries, recommendations, and remote intelligent fault diagnosis [21,23]. TKS offers two modes of intelligent Q&A: knowledge Q&A and searching based on large vectorized document models and large knowledge graph models. In knowledge search applications, large vectorized document models can improve the accuracy and relevance of search algorithms and enhance deep semantic understanding. Large knowledge graph models store information in a structured form, including entities (such as people, places, and events) and their relationships, providing clear answers to questions [20,22,24]. Through logical relationships in the graph, these models can perform complex reasoning to solve more intricate problems, typically used for inference-heavy factual questions, such as fault diagnosis of mining faces and decision support.

“Retrieval-Augmented Generation” (RAG) technology [25] is applied in this process, aiming to enhance the quality and accuracy of answer generation by combining retrieval and generation mechanisms, thus enhancing the capabilities of language models [24,25], especially when dealing with complex queries requiring extensive background knowledge or specific information. Depending on the characteristics of the knowledge Q&A system’s needs, different architectures can be chosen to enhance the language model capabilities. For scenarios requiring deep semantic understanding and efficient retrieval, such as open-domain Q&A or content recommendation, a combination of large vector models and RAG may be more suitable. For scenarios where the application needs to focus on precise facts and logical reasoning support, such as professional domain Q&A, complex data analysis, or decision support, a combination of large knowledge graph models and RAG may be more optimal. This technology (knowledge-graph-based) has been well applied in remote operation and maintenance processes for interactive intelligent fault diagnosis, intelligent work orders, and “chatBot” intelligent robots [26].

GraphRAG technology combines graph-based knowledge representation with Retrieval-Augmented Generation (RAG) to enhance AI capabilities in information retrieval and natural language generation [25]. By integrating a graph database that captures complex relationships between data points, GraphRAG enables more accurate and context-aware information retrieval. This method has been used to automatically generate knowledge graphs and has been compared to traditional methods, offering improvements in accuracy and performance. This field is still rapidly evolving, and research will continue to advance with technological progress.

Building industry-specific large models based on large general models suitable for their own industry attributes is a future trend in current development. Although there are many AI platform foundations like Sophon+TKS, Huawei ModelArts, etc., there are still few applications of industry-specific large models suitable for the coal industry. This research into the coal production and intelligent operation and maintenance platform is the first step in the successful practice of AI and industry-specific large model technology, which will greatly enhance the intelligence of coal production and operation and leave huge opportunities for the leading companies in coal industry application software and equipment manufacturing.

4. Practical Application Cases

4.1. Efficient Platform Application Development Environment

The combination of the aPaaS low-code platform and Meike Cloud’s cloud-native DevOps development platform provides coal mine enterprises with an efficient, flexible, and easy-to-manage development environment. The advantages of this integration are mainly reflected in the following aspects [17,18]:

- Rapid Development and Deployment: The visual design and drag-and-drop features of the low-code platform make application building quick and intuitive. Combined with the automated pipelines of cloud-native DevOps, it enables rapid iteration from development to deployment.

- Lowering Technical Barriers: Non-technical personnel can participate in application development through the low-code platform, significantly reducing the enterprise’s dependence on professional developers and improving cross-departmental collaboration efficiency.

- Resource Optimization: The containerization and microservices architecture provided by the cloud-native platform make resource utilization more efficient. The modular design of the low-code platform further enhances code reusability.

- Elasticity and Scalability: The automatic scaling capability of the cloud-native platform ensures the stability of the application system during load changes. The flexible configuration of the low-code platform allows applications to quickly adapt to changing business needs.

- Cost-Effectiveness: By reducing manual coding, development costs are lowered.

- Quick Implementation: This enables the rapid implementation of business logic and data presentation.

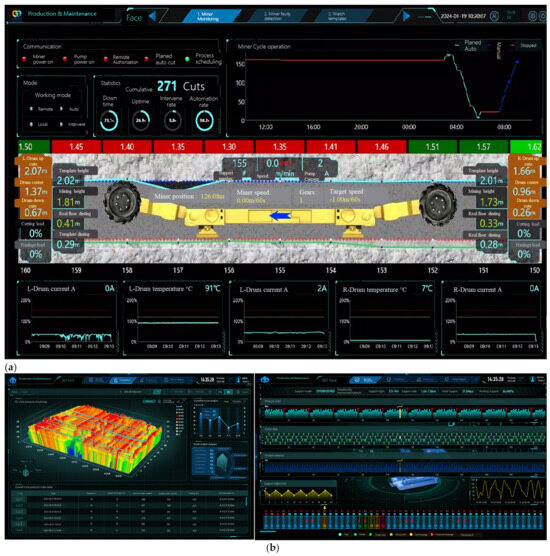

Figure 9a shows a big data analysis of miner working statistics and coal cutting planning analysis in a fully mechanized mining face. In the top left section, miner working statistics are displayed, such as the cutting number and working status, including the communication status, power status, and coal cutting planning status. The top right section shows the various stages of the coal mining cut. The light blue line represents the auto-planning coal cut stage, the blue line indicates the remote manual control stage, and the red line marks the pause stage. The x-axis represents the timeline, while the y-axis shows the miner positions. In the middle section, the real-time position and working status of the miner are shown. The bottom section displays the real-time measurements of the electric current (A) and temperature (°C) for the left and right cutting drums, respectively. These values can be used for AI analysis to enable proactive miner health prediction [27].

Figure 9.

(a) Big data analysis of miner work statistics and guidance for coal cutting planning. (b) Big data analysis and visualization of mining hydraulic supports.

The left section of Figure 9b presents the big data analysis of the 3D dynamic visualization, while the right section shows the mining pressure analysis for individual hydraulic supports across the entire mining face. In the right section of the figure, the setting load, mean load, and end load pressures for each hydraulic support working cycle are analyzed using real-time big data processing. The results are sent to the AI platform for predicting coal mine periodic weighting [28].

4.2. Intelligent, Interactive Remote Operation and Maintenance

The coal industrial internet-based platform can inspect and predict faults in fully mechanized mining faces through the Sophon platform [20] and the TKS (Transwarp Knowledge Studio) platform. When the fully mechanized mining face system encounters an abnormality, general faults can be automatically analyzed by AI models, and root-cause analysis can be performed using large AI models [20,24]. This allows for the final solutions and timely suggestions to be pushed to the end user [21]. Several AI models have been developed for the proactive maintenance of comprehensive mining face equipment, including early warnings for periodic weighting and the detection of common issues such as shearer, hydraulic support, and conveyor faults. For example, the system can predict mining pressure cycles across one to five cutting operations, allowing operators to anticipate and perform pressure relief operations or slow down advancing processes [28]. Another example is the AI model for detecting coal machine faults [26,27], which can analyze data such as the drum working current and motor temperature to help identify issues with components like the shearer arm gearbox, cutting motor, screw drum, haulage motor, haulage gearbox, and haulage block faults, etc.. Additionally, the AI video analysis can perform safety checks, generate alarms in unsafe areas, and regulate the behavior of underground coal miners to ensure compliance with safety protocols. This significantly enhances the safety of coal mining operations.

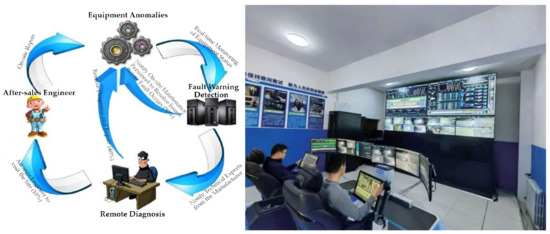

For complex faults, the system’s chatBot, along with experts, project leaders, and service engineers, conducts online consultations to locate the problems and provide solutions [20,24]. The workflow is shown in Figure 10.

Figure 10.

Interactive equipment AI fault diagnosis expert system.

The services that can be provided include the following:

- (1)

- Remote operation and maintenance guidance

In the traditional mode, after-sales service personnel need to go on-site to inspect the customer’s equipment issues and contact technical personnel for confirmation and subsequent problem handling. In the intelligent after-sales service mode, after-sales issues are first handled by an AI robot. The system provides fault location, possible causes, and handling methods through big data analysis. It then provides accurate and comprehensive recommendations through the knowledge base and large models to guide remote users in locating and solving the problem. Service applications with AR (augmented reality) functionality can be developed to initiate audio and video connections directly for new product applications or complex problems, involving service engineers and technical and R&D personnel together. This improves the response speed and quality of on-site service issues.

- (2)

- Customized services

In the intelligent remote operation and maintenance service platform, different intelligent after-sales service solutions can be customized according to application needs. High-value customers can receive premium full-service support through WeChat (a popular mobile application), phone, and dedicated after-sales service personnel, enhancing customer experience and loyalty. General projects can enjoy a certain degree of intelligent after-sales service, providing better and more convenient professional services to customers, gradually establishing long-term, stable, and win–win cooperation relationships. An example includes intelligent work order services using “work orders” to track and manage each customer service request through views, processing, settings, pending work orders, assigned work orders, pending visits, and follow-ups. The operation and maintenance knowledge base is combined with work orders to extract and validate confirmed work order data entities and relationships. The “chatBot” intelligent robot can also provide more accurate interactive AI services in order dispatching and remote assistance.

4.3. Application of Cloud-Native Technology and Big Data Platform

Using Meike Cloud’s cloud-native technology [17] and big data platform to achieve a 1 + N intelligent platform architecture can enable one intelligent monitoring and control platform and N intelligent applications, including a centralized production monitoring center, a safety integration monitoring and early warning center, decision-making dispatch command, and precise IT operation and maintenance control, etc., [18].

Based on the coal industrial internet-based big data platform, the real-time and historical data analysis of fully mechanized mining faces has already been applied in a normalized manner at the Baode 81309 Coal Mine face, the Shangwan 12403 Coal Mine face, and other locations in China. This showcases a comprehensive dynamic overview of the equipment status on the fully mechanized mining face, including the real-time monitoring of the shearer and the hydraulic support equipment, shearer cutting pick count analysis, hydraulic support process stage analysis, production statistics analysis, equipment status analysis, report statistics analysis, and periodic mining pressure prediction, among other functionalities. Through the platform’s mobile app, system monitoring, video follow-up monitoring, and alarm messages can be realized.

A mine work face needs to handle about 50 GB of data on a monthly basis, such as the Baode 81202 mining face in China’s Shanxi province. These data are often sent to the data center in one batch at an uncertain time each month for processing. Previously, it took more than a day to complete the calculation of a mechanistic model index using the ML.NET package. Now, using the developed platform, the mechanistic model calculation task can be completed in about 81 s in a three-node big data processing environment. The real-time processing data generated on-site can be analyzed in seconds. Previously, only historical report statistical tasks could be performed, but now they can be completed in real time, greatly enhancing on-site intelligent decision-making capabilities.

The system has also been trialed at the Ulan Mulun Coal Mine and Cuncaota Two Coal Mine in the Inner Mongolia province of China and in other fully mechanized mining faces with significant results. It has reduced investment costs, with supporting costs being reduced by more than 10%, improved installation and commissioning cycles to one hour, and significantly enhanced maintenance efficiency. The use of the platform system has helped these coal mines improve their level of intelligence and promote intelligent construction.

5. Conclusions

This paper presents the development of an innovative platform designed to enhance safety, operational efficiency, and automation in fully mechanized coal mining in China. This platform integrates cloud–edge computing, real-time data processing, and AI-driven analytics to improve decision-making and maintenance strategies. The platform leverages AI models for interactive technical support and Data Streaming operations, thus advancing the transition toward fully automated and unmanned mining processes.

This paper presents a highly practical approach to building an advanced industrial internet-based platform. This study emphasizes the importance of managing device orchestration, service orchestration, and rapid business logic implementation when applying the framework in practice. Performance analysis of these orchestration layers will provide a deeper understanding of the platform’s architecture. Future system optimization and theoretical work may follow this direction, while practical efforts to enhance underground mining intelligence and safety will depend on advancements and innovations in key modular components, such as big data and AI platforms.

The successful development of the platform has narrowed the gap with industrial internet-based applications in other energy sectors. The future development prospects of the industrial internet-based platform for the coal industry are broad. The future development of the platform will focus more on safety, intelligence, and modular design, continuously optimizing production processes to adapt to rapidly changing market demands. Furthermore, the deep integration of cloud computing, AI modeling, and IoT technology will further enhance the platform’s performance, providing strong support for the innovation and development of industrial internet-based platforms in the coal industry.

Author Contributions

Conceptualization, Y.F. and Y.W.; methodology, Y.W.; software, Y.W., B.W. and Y.G.; validation, Y.F. and C.X.; formal analysis, B.T.; investigation, Y.W. and Y.G.; resources, C.X. and B.T.; data curation, Y.W. and B.W.; writing—original draft preparation, Y.W.; writing—review and editing, Y.F. and Y.W.; visualization, Y.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author/s.

Conflicts of Interest

Authors Yongtao Wang, Yinhui Feng, Chengfeng Xi, Bochao Wang, Bo Tang and Yanzhao Geng were employed by the company, Beijing Tianma Intelligent Control Technology Co., Ltd.

References

- Lu, C.; Li, X.; Sun, J. Data Cleaning and Upgrading Method for Aero-Engine Test Data Based on IoTDB. Gas Turbine Exp. Res. 2023, 36, 38–42. [Google Scholar]

- Gao, H.; Ye, C. Design of Real-Time Data Warehouse Based on StarRocks. Comput. Era 2023, 2, 46–50+60. [Google Scholar] [CrossRef]

- Guo, Y.; Zhou, R. Non-functional Evaluation Index and Efficiency Testing Methods for MPP Database. Ind. Technol. Innov. 2018, 5, 30–34. [Google Scholar] [CrossRef]

- Cai, L.; Hebert, J.; Jagtiani, K.; Lin, S.; Ghazal, A. Fusion insight librA: Huawei’s enterprise cloud data analytics platform. In Proceedings of the VLDB Endowment, Rio de Janeiro, Brazil, 6 February 2018; Volume 11, pp. 1822–1834. [Google Scholar]

- Agarwal, N.; Brem, A. Strategic business transformation through technology convergence: Implications from General Electric's industrial internet initiative. Int. J. Technol. Manag. 2015, 67, 196–214. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Zhou, J.; Liang, Y. Discussion on industrial internet platform construction based on power internet of things. J. Phys. Conf. Ser. 2021, 1939, 012077. [Google Scholar] [CrossRef]

- Li, J.; Qiu, J.J.; Zhou, Y.; Wen, S.; Dou, K.Q.; Li, Q. Study on the reference architecture and assessment framework of industrial internet platform. IEEE Access 2020, 8, 164950–164971. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Li, Z.; Zhang, Y. Strengthen or weaken? How industrial internet platform affects the core competitiveness of manufacturing companies. Oper. Manag. Res. 2024, 17, 220–232. [Google Scholar] [CrossRef]

- Li, S. The Industrial Internet of Coal and Its Key Technologies. Coal Sci. Technol. 2020, 48, 98–108. [Google Scholar]

- Nepsha, F.; Varnavskiy, K.; Voronin, V.; Ermakov, A.; Kostomarov, R. Employing the digital platform for control system development in a coal mining enterprise. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 012012. [Google Scholar] [CrossRef]

- Liu, R.; Xie, X. Improve the industrial digital transformation through Industrial Internet platforms. Front. Eng. Manag. 2024, 11, 167–174. [Google Scholar] [CrossRef]

- Arshi, O.; Rai, A.; Gupta, G.; Pandey, J.K.; Mondal, S. IoT in energy: A comprehensive review of technologies, applications, and future directions. Peer-to-Peer Netw. Appl. 2024, 17, 2830–2869. [Google Scholar] [CrossRef]

- Demirkan, D.C.; Duzgun, H.S.; Juganda, A.; Brune, J.; Bogin, G. Real-Time Methane Prediction in Underground Longwall Coal Mining Using AI. Energies 2022, 15, 6486. [Google Scholar] [CrossRef]

- Drissi Elbouzidi, A.; Ait El Cadi, A.; Pellerin, R.; Lamouri, S.; Tobon Valencia, E.; Bélanger, M.J. The role of AI in warehouse digital twins: Literature review. Appl. Sci. 2023, 13, 6746. [Google Scholar] [CrossRef]

- Ki, I.; Song, H.; Ryu, J.; Jeong, J. Production improvement rate with time series data on standard time at manufacturing sites. Appl. Sci. 2023, 13, 10937. [Google Scholar] [CrossRef]

- Yuan, A. Application of Mine HarmonyOS in the Monitoring Station of Shearer Roadway. Coal Mine Mach. 2022, 43, 146–148. [Google Scholar] [CrossRef]

- Zhang, X. “Meike Cloud” Mine Intelligent Integrated Management and Control Platform. Intell. Mine 2022, 3, 132–135. [Google Scholar]

- Wang, L.; Fang, Q.; Zhang, X.; Su, S.; Shi, Z.; Wang, Y. Data Warehouse Modeling Method for Intelligent Coal Mines. Ind. Min. Autom. 2022, 48, 5–13. (In Chinese) [Google Scholar] [CrossRef]

- Xue, Y.; Ding, P.; Shen, Y.; Duan, H.; Zhang, X.; Song, Y. Flexible Intelligent Manufacturing Technology Solution Based on 5G Edge-Cloud Collaboration. Mob. Commun. 2021, 45, 18–23. [Google Scholar]

- Xin, C. Design and Implementation of the Sharing System on Transwarp Sophon Platform. Master’s Thesis, Nanjing University, Nanjing, China, 2019. [Google Scholar]

- Cai, A.; Zhang, Y.; Ren, Z. Construction of Knowledge Graph for Comprehensive Coal Mining Equipment Failures. Ind. Min. Autom. 2023, 49, 46–51. [Google Scholar] [CrossRef]

- Zeng, K.; Ye, J.; Cui, X.; Pang, W.; Li, Y.; Ni, P.; Feng, J. Exploration and Challenges of Key Technologies of Generative Large Language Models in the Field of Civil Aviation Maintenance. Aviat. Maint. Eng. 2024, 1, 20–24. [Google Scholar] [CrossRef]

- Feng, J.; Chang, Y.; Lu, J.; Tang, H.; Lv, Z.; Qiu, Y. Construction and Application of Water Project Scheduling Knowledge Graph Based on Large Language Model. Comput. Sci. Explor. 2024, 6, 1637–1647. [Google Scholar]

- Liu, S.; Wen, T.; Pattamatta, A.S.L.; Srolovitz, D.J. A Prompt-Engineered Large Language Model, Deep Learning Workflow for Materials Classification. arXiv 2024, arXiv:2401.17788. [Google Scholar] [CrossRef]

- Edge, D.; Trinh, H.; Cheng, N.; Bradley, J.; Chao, A.; Mody, A.; Truitt, S.; Larson, J. From local to global: A graph rag approach to query-focused summarization. arXiv 2024, arXiv:2404.16130. [Google Scholar]

- Zhang, L.; Fu, S.; Yu, S. Research on Knowledge Graph System for Maintenance of Coal Mine Mechanical and Electrical Equipment. Equip. Manag. Maint. 2023, 18, 47–48. [Google Scholar] [CrossRef]

- Feng, Y.H.; Song, Y.; Li, W.J.; Wu, Y.X.; Qin, Z.Y. Abnormal Detection of Shearer Based on Autoencoder Twin Neural Network. Coal Eng. 2022, 54, 136–141. [Google Scholar]

- Feng, Y.H.; Song, Y.; Li, W.J.; Wu, Y.X.; Qin, Z.Y. Research on Working Face Pressure Prediction Model Based on Optimized Support Data. Coal Eng. 2023, 55, 101–107. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).