Investigation into the Effect of Permeable Boundary Sealing on the Behavior of Hydrate Exploitation via Depressurization Combined with Heat Injection

Abstract

1. Introduction

2. Numerical Model and Schemes

2.1. Geological Background

2.2. Model Establishment

2.3. Numerical Code and Initial Conditions

2.4. Simulation Scenarios

3. Results and Discussion

3.1. Physical Parameters Distribution

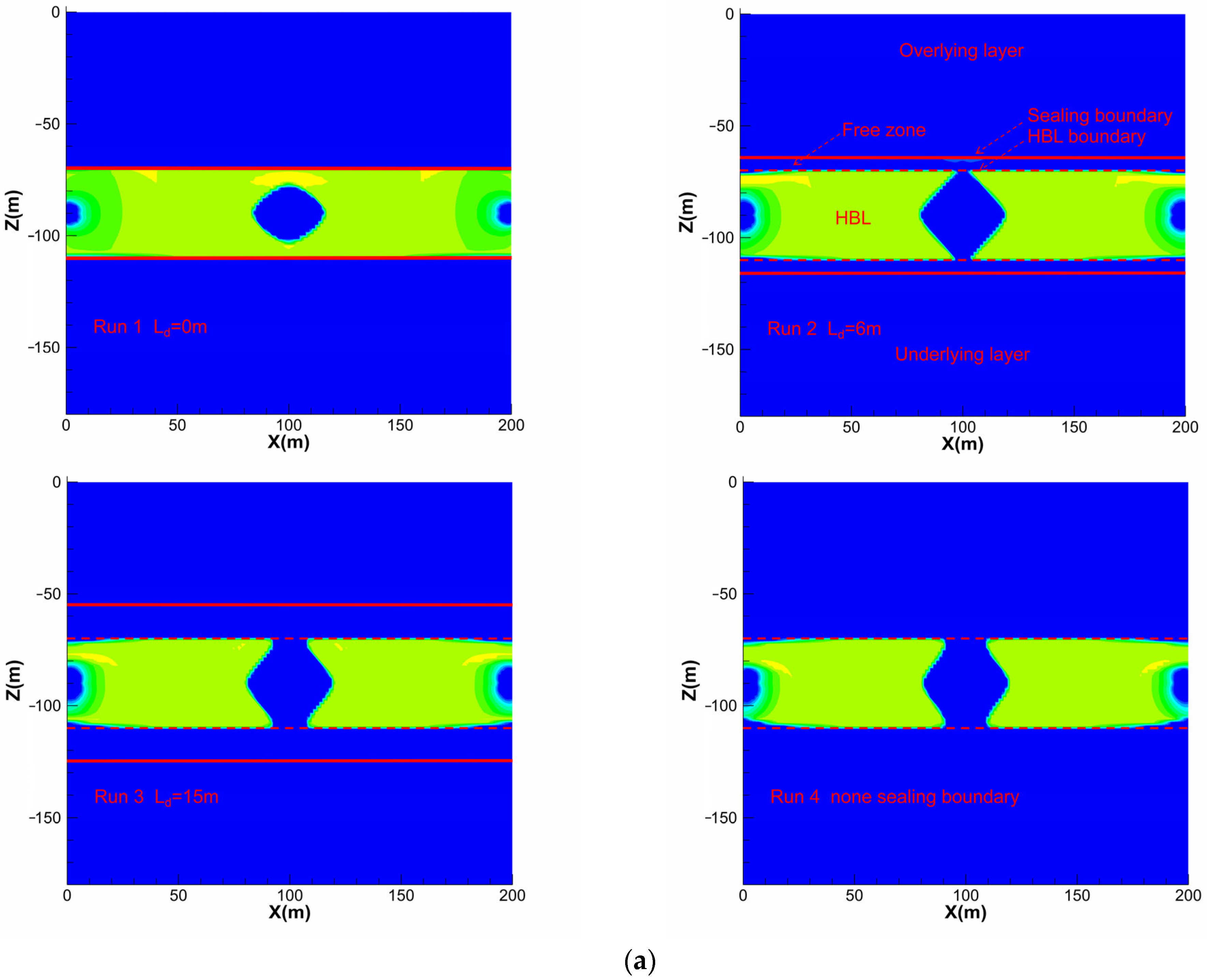

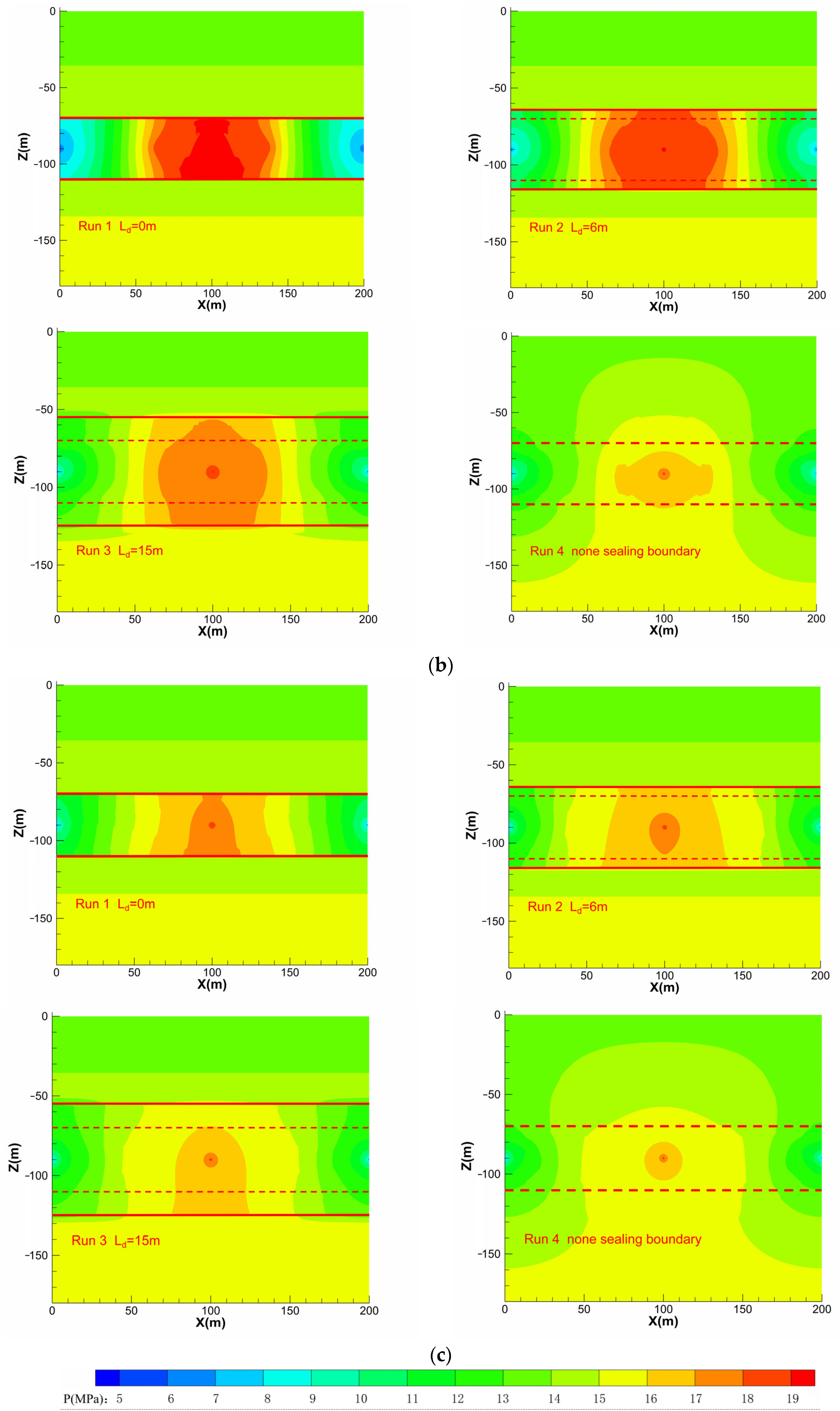

3.1.1. NGH Saturation Distribution

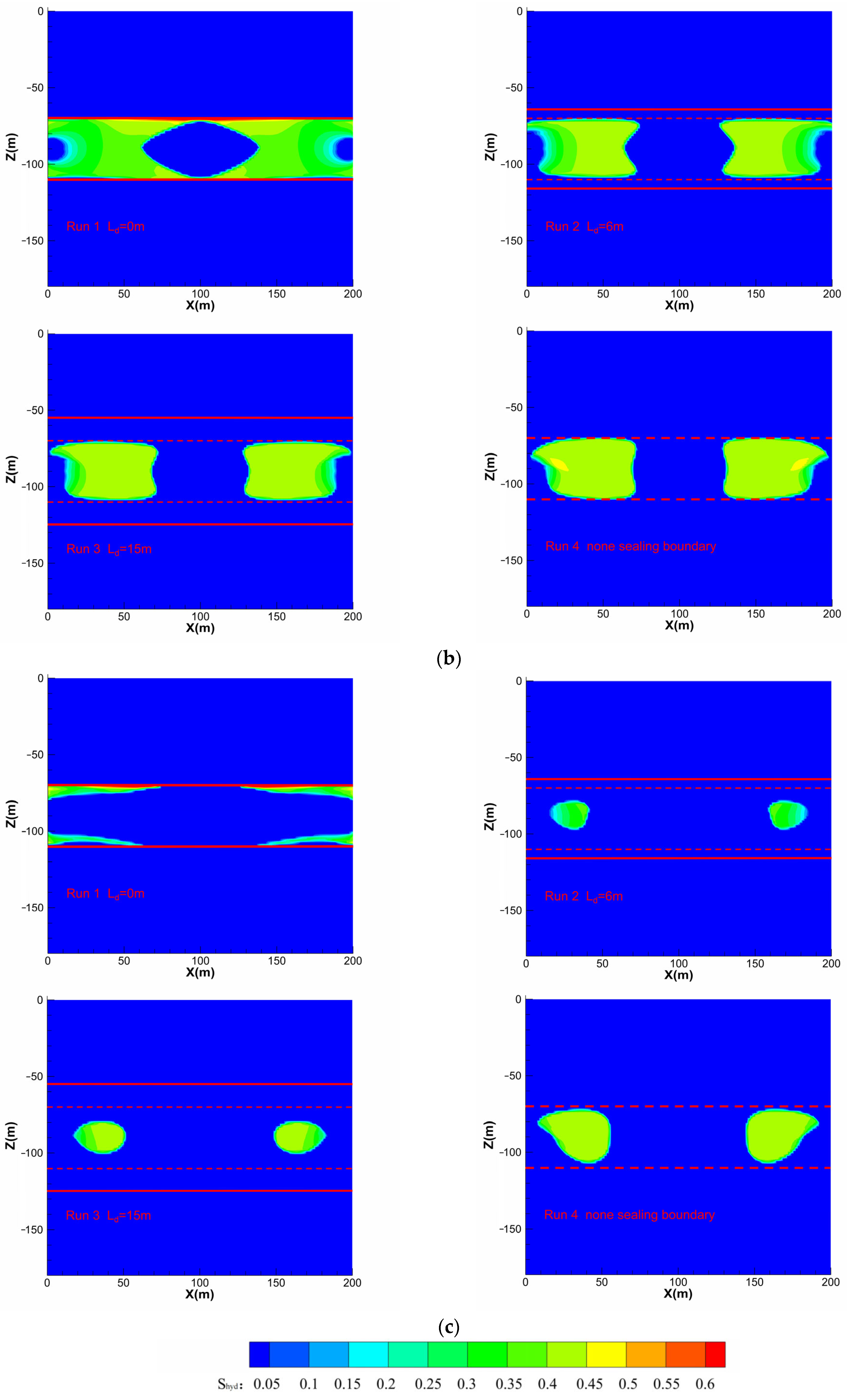

3.1.2. NGH Reservoir Temperature Distribution

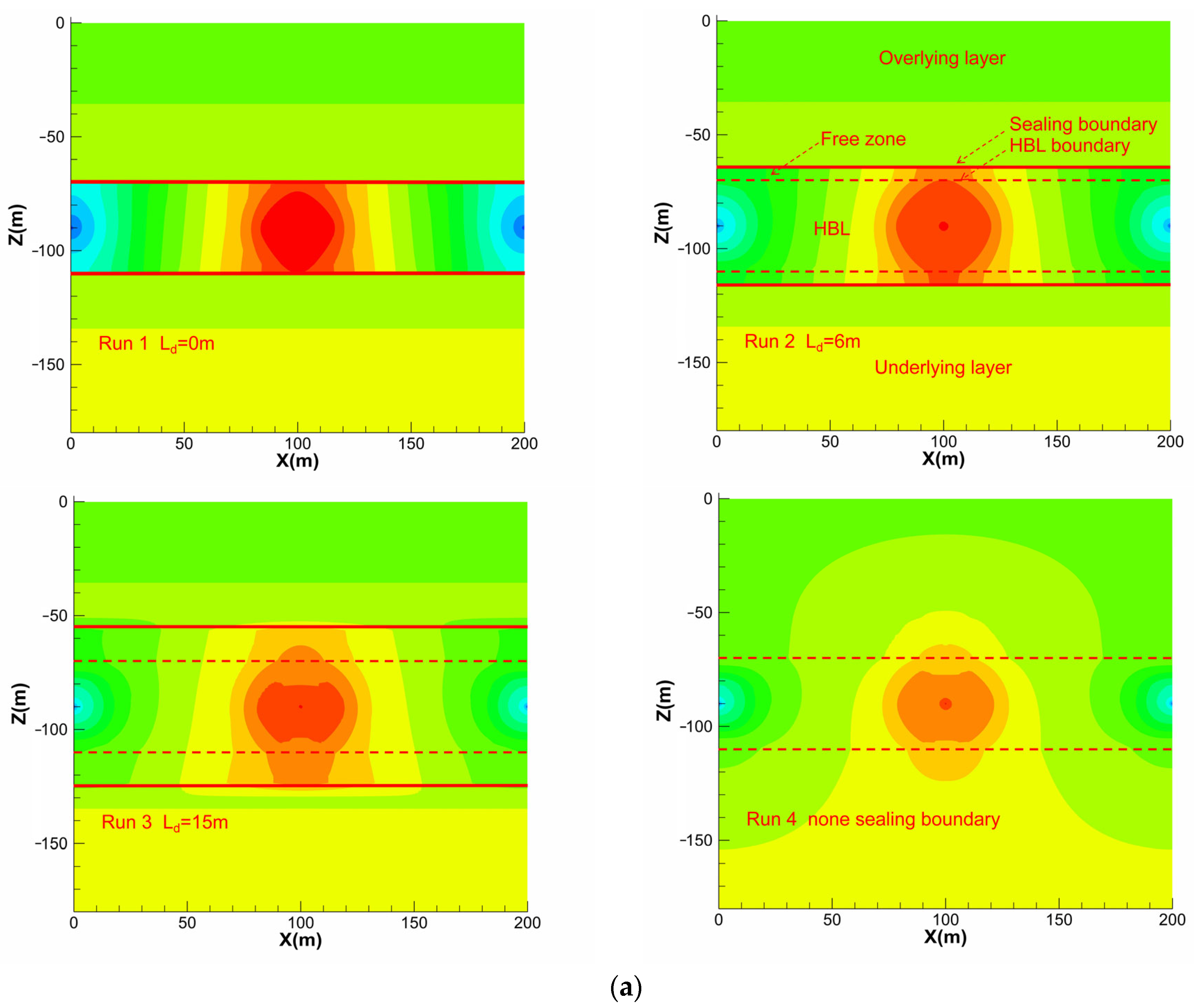

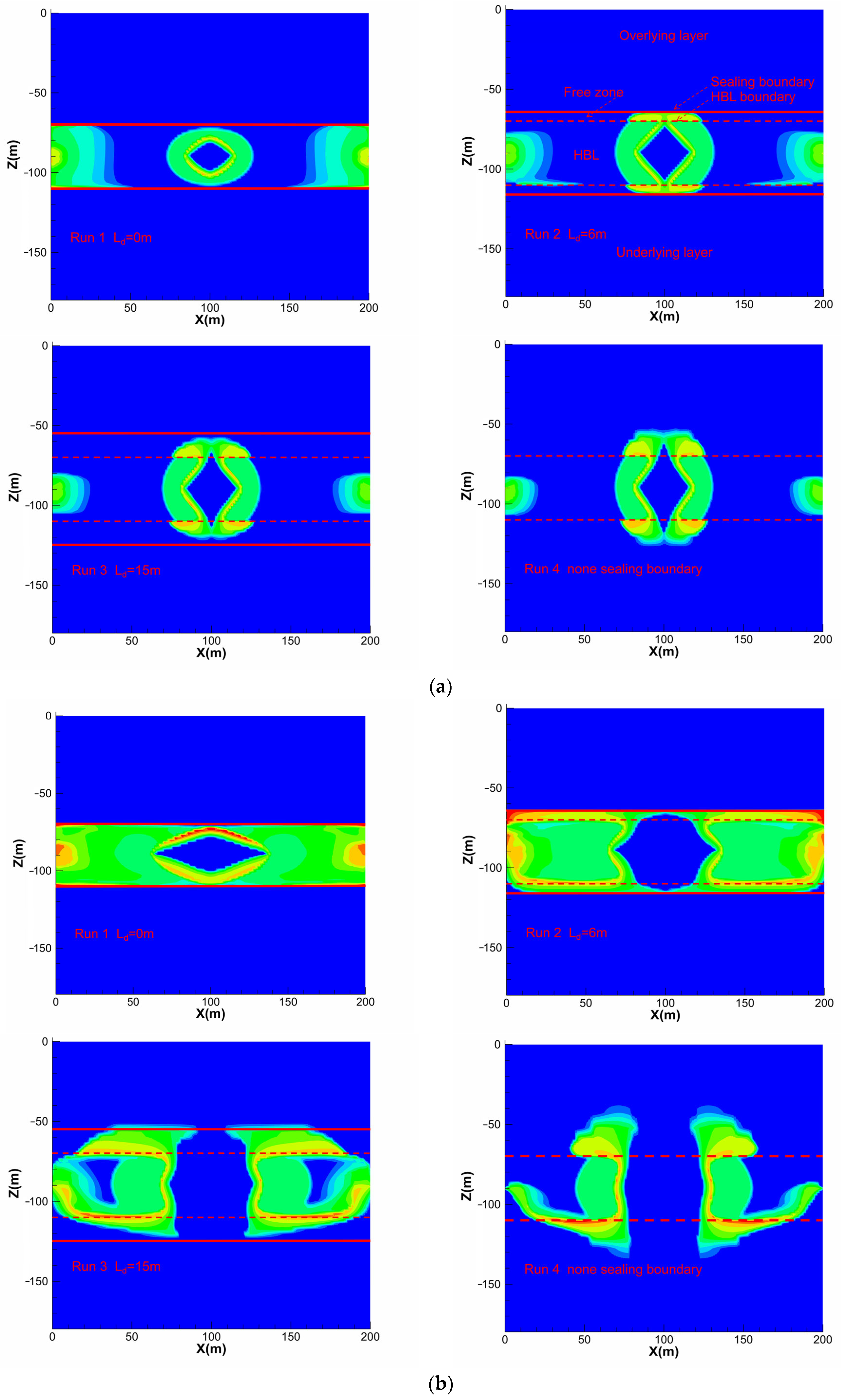

3.1.3. NGH Reservoir Pressure Distribution

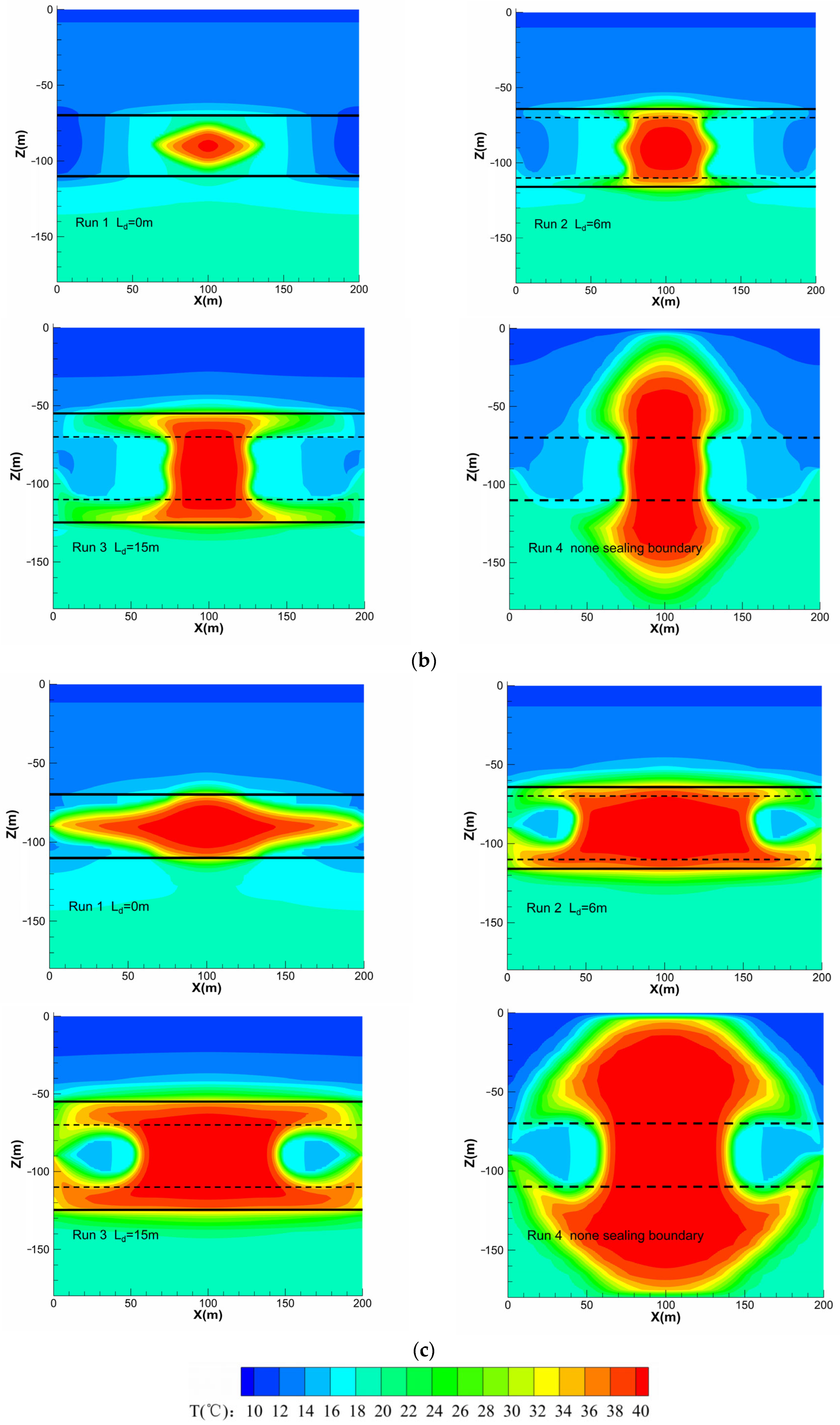

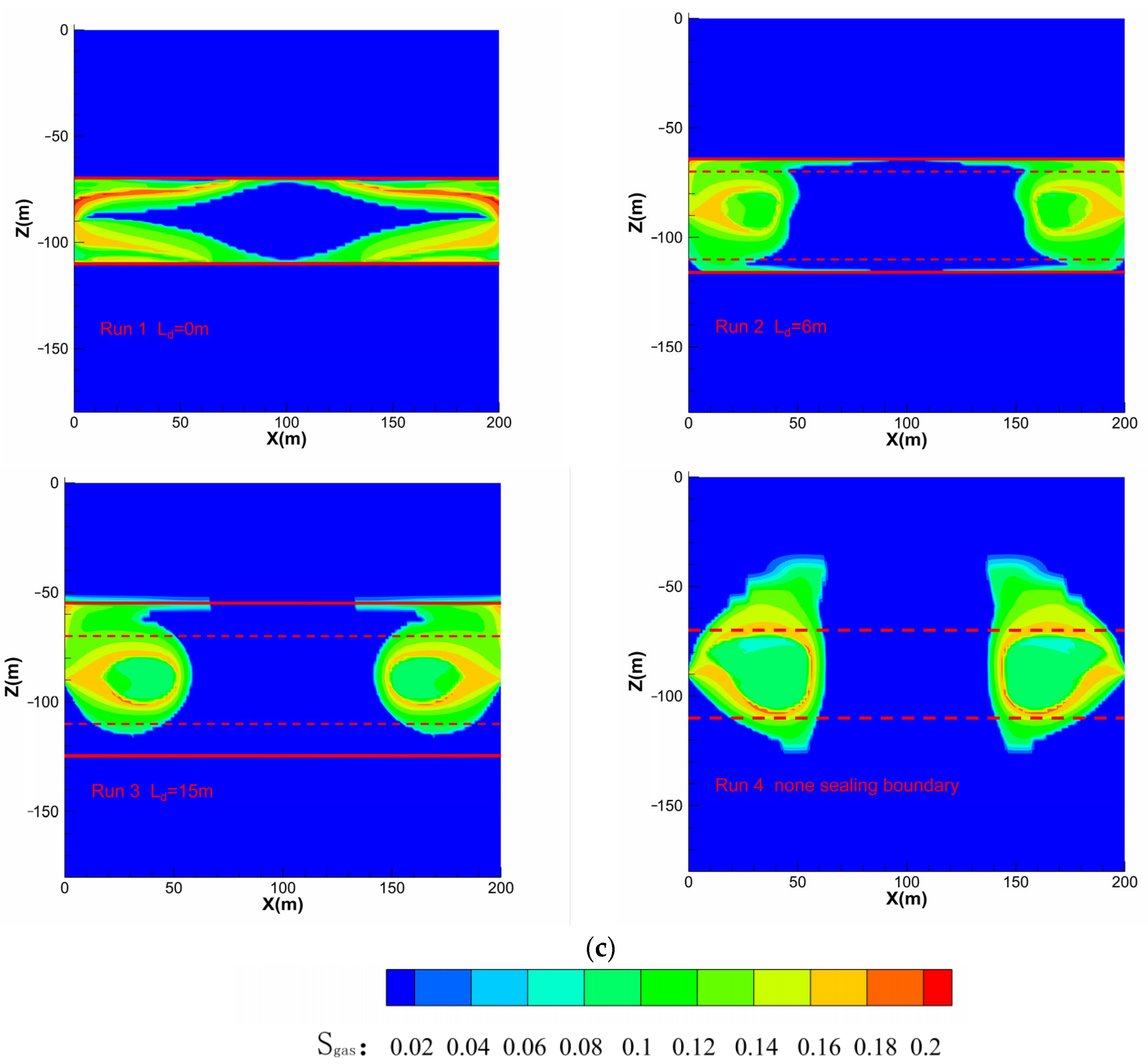

3.1.4. CH4 Saturation Distribution

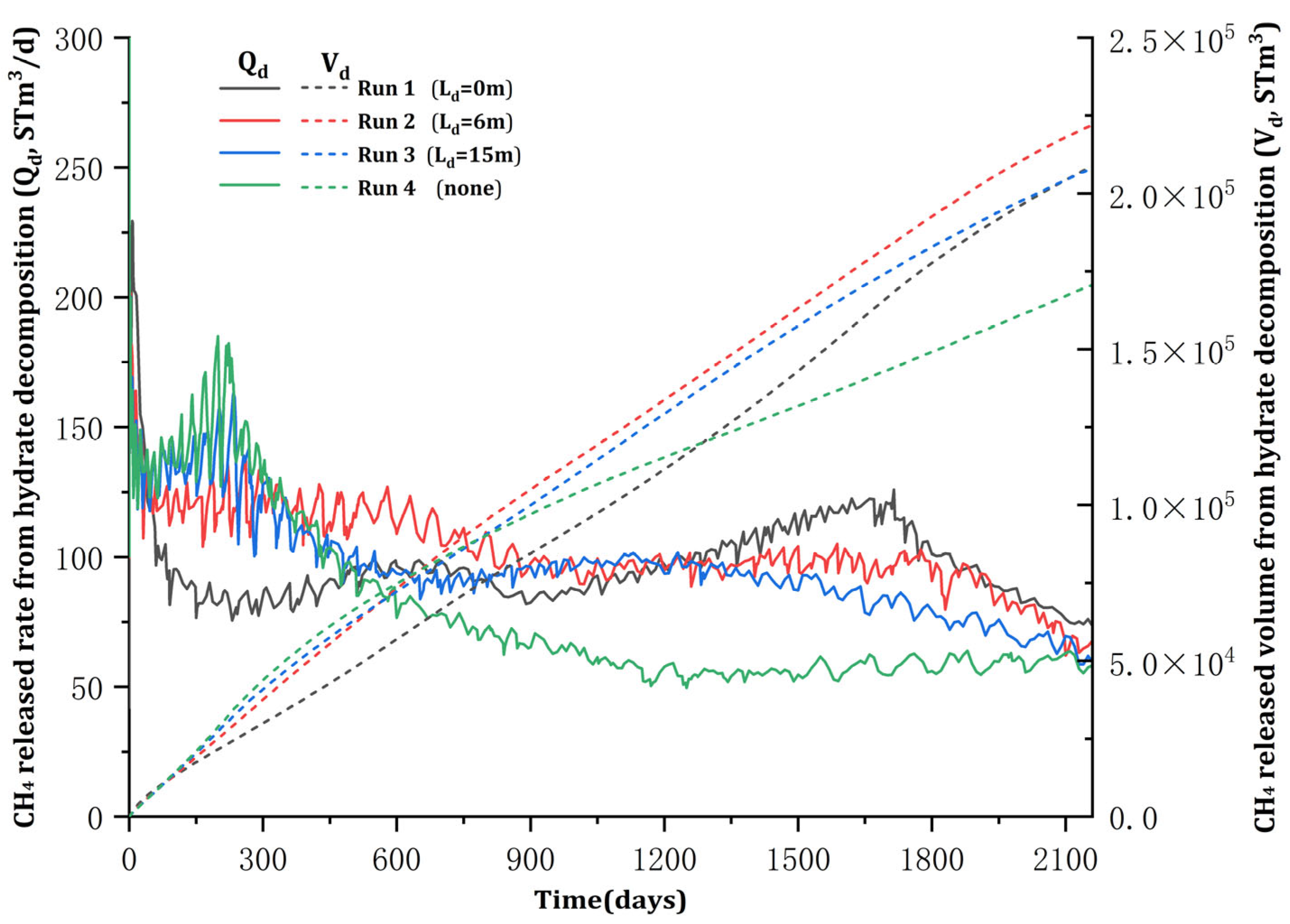

3.2. NGH Decomposition Behavior

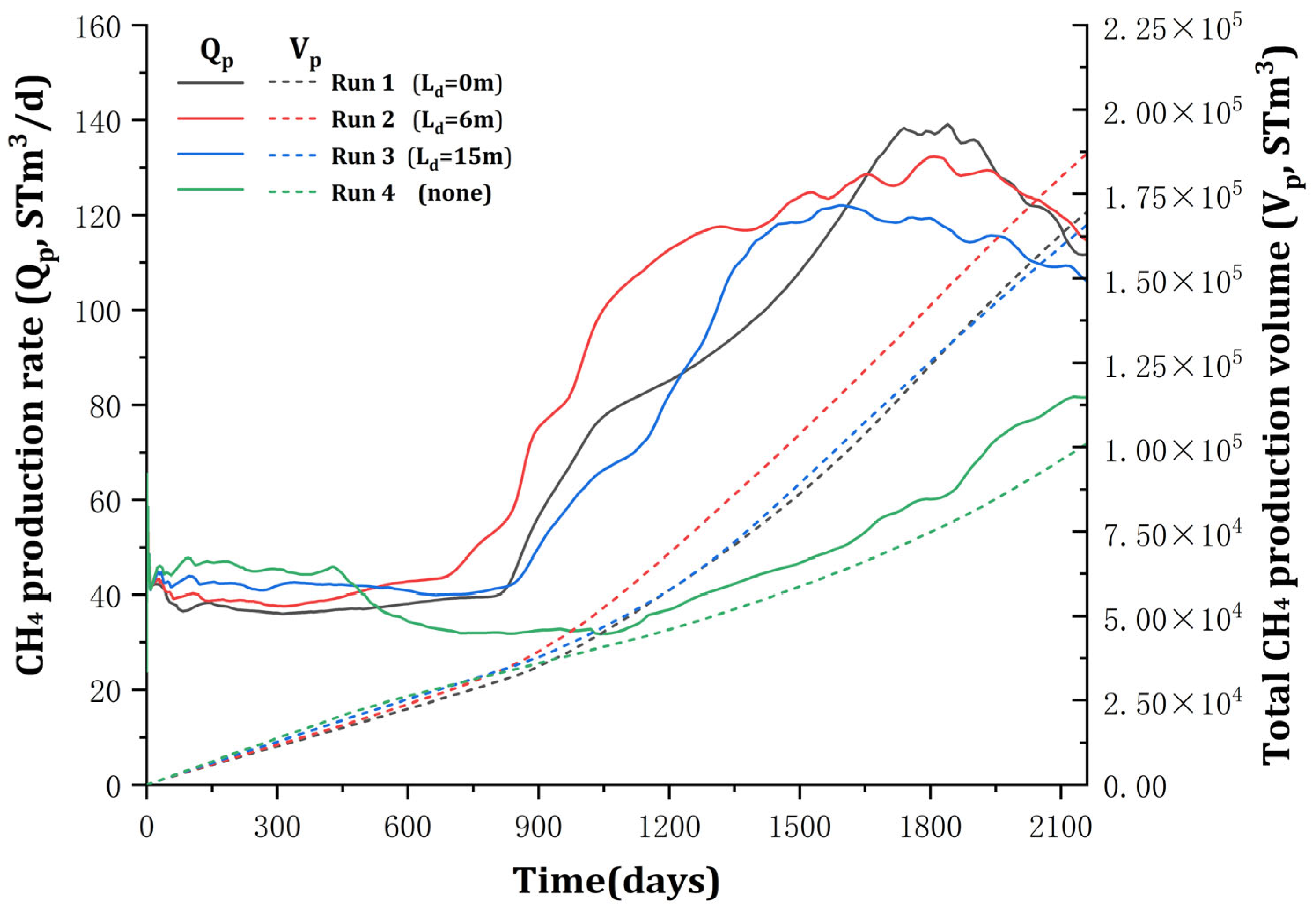

3.3. CH4 Production Behavior

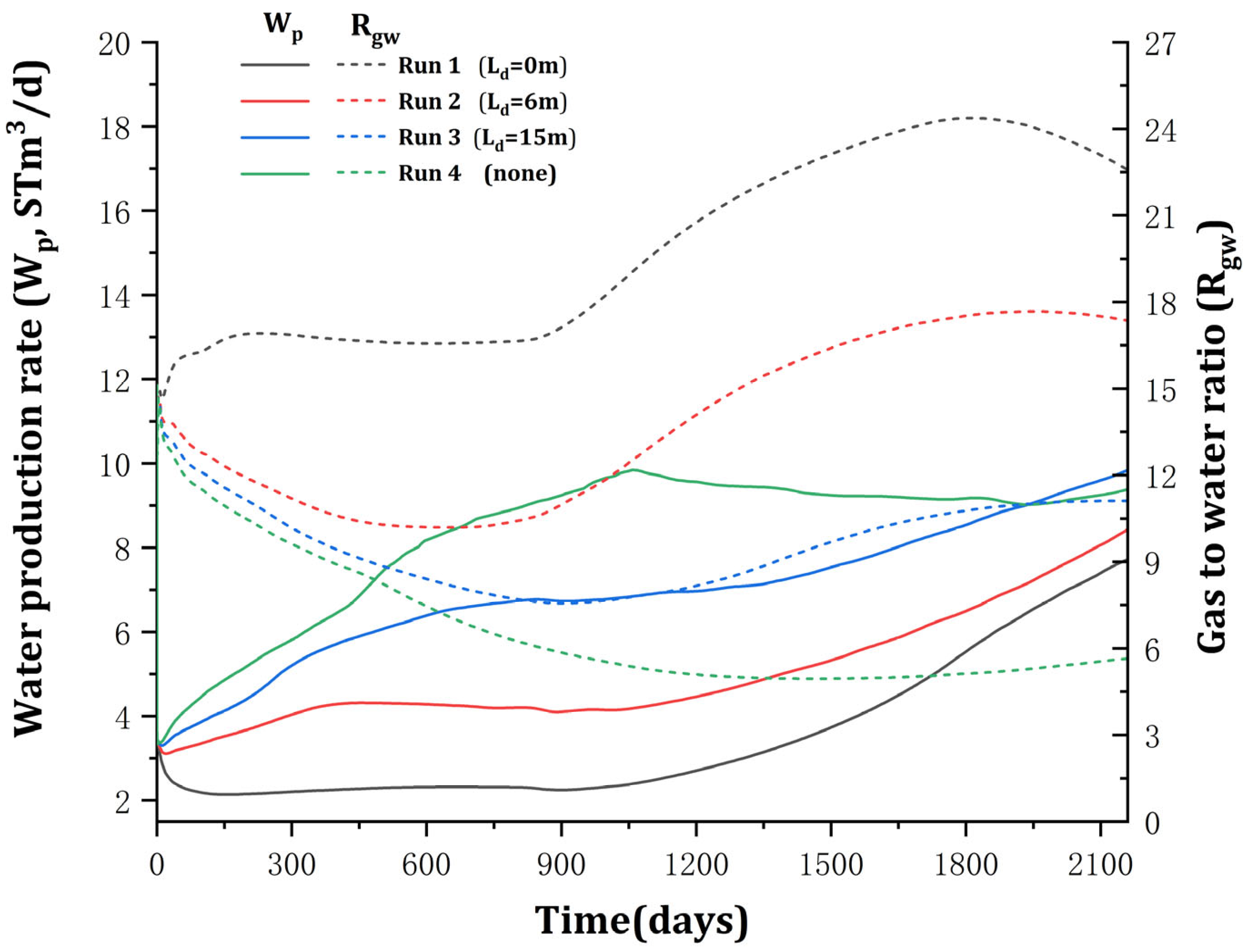

3.4. Water Production Behavior

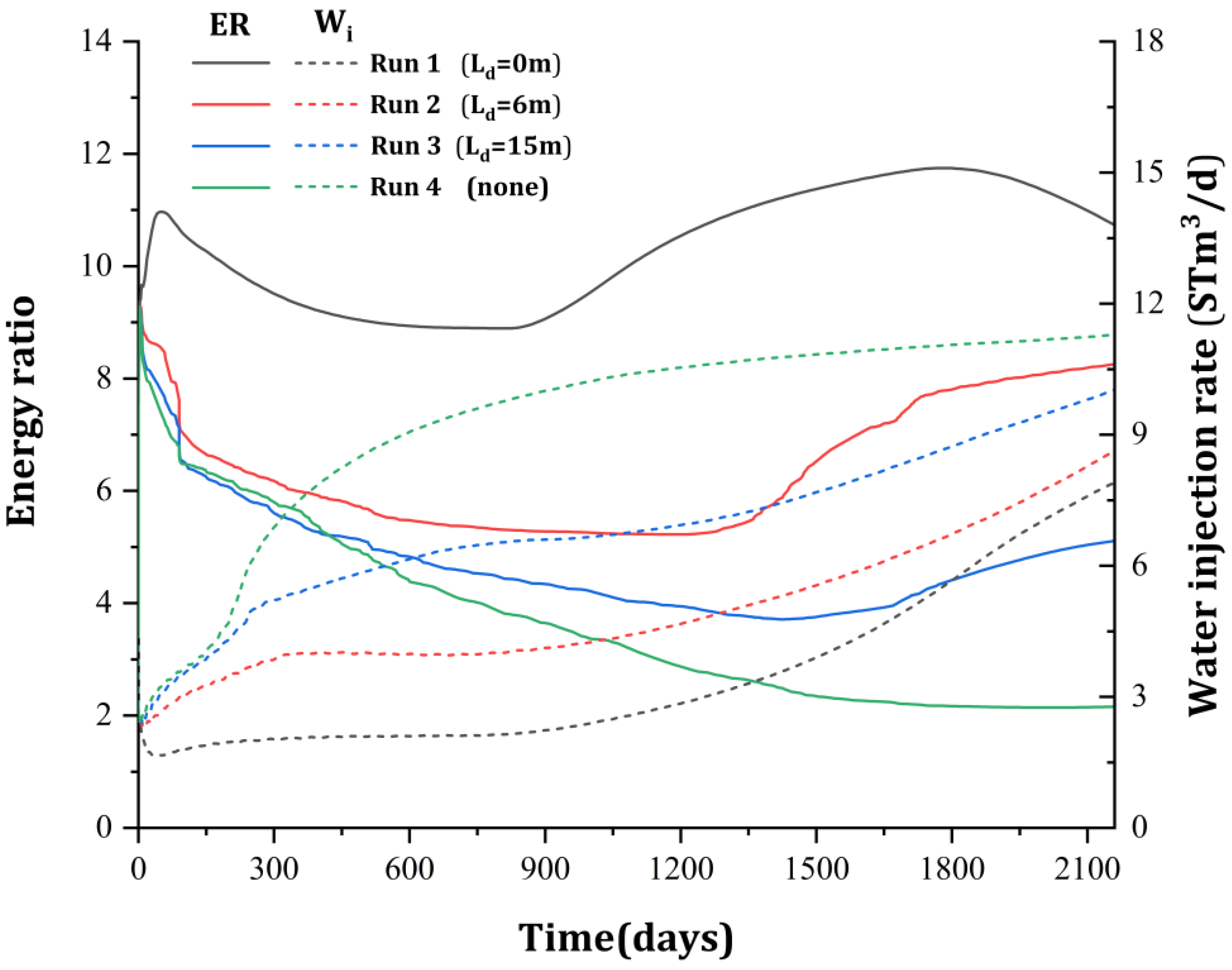

3.5. Energy Efficiency

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sloan, E.D.; Koh, C.A. Clathrate Hydrates of Natural Gases, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Boswell, R.; Shipp, C.; Reichel, T.; Shelander, D.; Saeki, T.; Frye, M.; Shedd, W.; Collett, T.S.; McConnell, D.R. Prospecting for marine gas hydrate resources. Interpretation 2016, 4, SA13–SA24. [Google Scholar] [CrossRef]

- Konno, Y.; Fujii, T.; Sato, A.; Akamine, K.; Naiki, M.; Masuda, Y.; Yamamoto, K.; Nagao, J. Key findings of the world’s first offshore methane hydrate production test off the coast of Japan: Toward future commercial production. Energy Fuels 2017, 31, 2607–2616. [Google Scholar] [CrossRef]

- Klymenko, V.; Ovetskyi, S.; Martynenko, V.; Vytiaz, O.; Uhrynovskyi, A. An alternative method of methane production from deposits of subaquatic gas hydrates. Min. Miner. Depos. 2022, 16, 11–17. [Google Scholar] [CrossRef]

- Bazaluk, O.; Sai, K.; Lozynskyi, V.; Petlovanyi, M.; Saik, P. Research into Dissociation Zones of Gas Hydrate Deposits with a Heterogeneous Structure in the Black Sea. Energies 2021, 14, 1345. [Google Scholar] [CrossRef]

- Chong, Z.R.; Yang, S.H.B.; Babu, P.; Linga, P.; Li, X.S. Review of natural gas hydrates as an energy resource: Prospects and challenges. Appl. Energy 2016, 162, 1633–1652. [Google Scholar] [CrossRef]

- Zhou, S.; Zhao, J.; Li, Q.; Chen, W.; Zhou, J.; Wei, N.; Guo, P.; Sun, W. Optimal design of the engineering parameters for the first global trial production of marine natural gas hydrates through solid fluidization. Nat. Gas. Ind. B 2018, 5, 118–131. [Google Scholar] [CrossRef]

- Wang, L.; Wang, G. Experimental and Theoretical Study on the Critical Breaking Velocity of Marine Natural Gas Hydrate Sediments Breaking by Water Jet. Energies 2020, 13, 1725. [Google Scholar] [CrossRef]

- Sun, T.; Chen, F.; Zhong, L.; Liu, W.; Wang, Y. GIS-based mineral prospectivity mapping using machine learning methods: A case study from Tongling ore district, eastern China. Ore Geol. Rev 2019, 109, 26–49. [Google Scholar] [CrossRef]

- Jin, G.; Peng, Y.; Liu, L.; Su, Z.; Liu, J.; Li, T.; Wu, D. Enhancement of gas production from low-permeability hydrate by radially branched horizontal well: Shenhu Area, South China Sea. Energy 2022, 253, 124129. [Google Scholar] [CrossRef]

- Moridis, G.J.; Reagan, M.T.; Boyle, K.L.; Zhang, K. Evaluation of the gas production potential of some particularly challenging types of oceanic hydrate deposits. Transp. Porous Media 2011, 90, 269–299. [Google Scholar] [CrossRef]

- Chibura, P.E.; Zhang, W.; Luo, A.; Wang, J. A review on gas hydrate production feasibility for permafrost and marine hydrates. J. Nat. Gas Sci. Eng. 2022, 100, 104441. [Google Scholar] [CrossRef]

- Ning, F.; Chen, Q.; Sun, J.; Wu, X.; Cui, G.; Mao, P.; Li, Y.; Liu, T.; Jiang, G.; Wu, N. Enhanced gas production of silty clay hydrate reservoirs using multilateral wells and reservoir reformation techniques: Numerical simulations. Energy 2022, 254, 124220. [Google Scholar] [CrossRef]

- Makogon, Y.; Omelchenko, R. Commercial gas production from Messoyakha deposit in hydrate conditions. J. Nat. Gas Sci. Eng. 2013, 11, 1–6. [Google Scholar] [CrossRef]

- Jin, G.; Xu, T.; Wei, M.; Liu, C. Numerical evaluation of the methane production from unconfined gas hydrate-bearing sediment by thermal stimulation and depressurization in Shenhu area, South China Sea. J. Nat. Gas. Sci. Eng. 2016, 33, 497–508. [Google Scholar] [CrossRef]

- Feng, J.C.; Wang, Y.; Li, X.S.; Li, G.; Chen, Z.Y. Production behaviors and heat transfer characteristics of methane hydrate dissociation by depressurization in conjunction with warm water stimulation with dual horizontal wells. Energy 2015, 79, 315–324. [Google Scholar] [CrossRef]

- Feng, J.C.; Li, G.; Li, X.S.; Li, B.; Chen, Z.Y. Evolution of hydrate dissociation by warm brine stimulation combined depressurization in the South China Sea. Energies 2013, 6, 5402–5425. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.; Ma, B.; Qiu, H.; Liang, J.; Lu, J.; Kuang, Z.; Lu, C.; et al. Main progress of the second gas hydrate trial production in the South China Sea. China Geol. 2020, 47, 57–68. [Google Scholar]

- Ma, X.; Sun, Y.; Guo, W.; Jia, R.; Li, B. Numerical simulation of horizontal well hydraulic fracturing technology for gas production from hydrate reservoir. Appl. Ocean Res. 2021, 112, 102674. [Google Scholar] [CrossRef]

- Yu, T.; Guan, G.; Wang, D.; Song, Y.; Abudula, A. Gas production enhancement from a Multilayered hydrate reservoir in the South China sea by hydraulic fracturing. Energy Fuels 2021, 35, 1210418. [Google Scholar] [CrossRef]

- Yang, L.; Ye, J.; Qin, X.; Liang, Q.; Wu, X. Effects of the seepage capability of overlying and underlying strata of marine hydrate system on depressurization-induced hydrate production behaviors by horizontal well. Mar. Pet. Geol. 2021, 128, 105019. [Google Scholar] [CrossRef]

- Su, Z.; He, Y.; Wu, N.; Zhang, K.; Moridis, G.J. Evaluation on gas production potential from laminar hydrate deposits in Shenhu Area of South China Sea through depressurization using vertical wells. J. Pet. Sci. Eng. 2012, 86, 87–98. [Google Scholar] [CrossRef]

- Zhong, X.; Pan, D.; Zhai, L.; Zhu, Y.; Zhang, H.; Zhang, Y.; Wang, Y.; Li, X.; Chen, C. Evaluation of the gas production enhancement effect of hydraulic fracturing on combining depressurization with thermal stimulation from challenging ocean hydrate reservoirs. J. Nat. Gas Sci. Eng. 2020, 83, 103621. [Google Scholar] [CrossRef]

- Boswell, R.; Myshakin, E.; Moridis, G.; Konno, Y.; Collett, T.S.; Reagan, M.; Ajayi, T.; Seol, Y. India National Gas Hydrate Program Expedition 02 summary of scientific results: Numerical simulation of reservoir response to depressurization. Mar. Pet. Geol. 2019, 108, 154–166. [Google Scholar] [CrossRef]

- Fujii, T.; Suzuki, K.; Takayama, T.; Tamaki, M.; Komatsu, Y.; Konno, Y.; Yoneda, J.; Yamamoto, K.; Nagao, J. Geological setting and characterization of a methane hydrate reservoir distributed at the first offshore production test site on the Daini-Atsumi Knoll in the eastern Nankai Trough, Japan. Mar. Pet. Geol. 2015, 66, 310–322. [Google Scholar] [CrossRef]

- Wei, J.; Yang, L.; Liang, Q.; Liang, J.; Lu, J.; Zhang, W.; Zhang, X.; Lu, X. Geomechanical properties of gas hydrate-bearing sediments in Shenhu Area of the South China Sea. Energy Rep. 2021, 7, 8013–8020. [Google Scholar] [CrossRef]

- Ma, X.; Sun, Y.; Liu, B.; Guo, W.; Jia, R.; Li, B.; Li, S. Numerical study of depressurization and hot water injection for gas hydrate production in China’s first offshore test site. J. Nat. Gas Sci. Eng. 2020, 83, 103530. [Google Scholar] [CrossRef]

- Zhong, X.; Pan, D.; Zhu, Y.; Wang, Y.; Tu, G.; Nie, S.; Ma, Y.; Liu, K.; Chen, C. Commercial production potential evaluation of injection-production mode for CH-Bk hydrate reservoir and investigation of its stimulated potential by fracture network. Energy 2022, 239, 122113. [Google Scholar] [CrossRef]

- Chen, C.; Meng, Y.; Zhong, X.; Nie, S.; Ma, Y.; Pan, D.; Liu, K.; Li, X.; Gao, S. Research on the Influence of Injection–Production Parameters on Challenging Natural Gas Hydrate Exploitation Using Depressurization Combined with Thermal Injection Stimulated by Hydraulic Fracturing. Energy Fuels 2021, 35, 15589–15606. [Google Scholar] [CrossRef]

- Li, S.; Wu, D.; Wang, X.; Hao, Y. Enhanced gas production from marine hydrate reservoirs by hydraulic fracturing assisted with sealing burdens. Energy 2021, 232, 120889. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, J.; Wei, J.; Su, P.; Lin, L.; Huang, W.; Guo, Y.; Deng, W.; Yang, X.; Wan, Z. Geological and geophysical features of and controls on occurrence and accumulation of gas hydrates in the first offshore gas-hydrate production test region in the Shenhu area, Northern South China Sea. Mar. Pet. Geol. 2020, 114, 104191. [Google Scholar] [CrossRef]

- Su, M.; Wang, H.; Sha, Z.; Liang, J.; Wu, N.; Qiao, S.; Cong, X.; Yang, R. Gas hydrates distribution in the Shenhu Area, northern South China Sea: Comparisons between the eight drilling sites with gas-hydrate petroleum system. Geol. Acta Int. Earth Sci. J. 2016, 14, 79–100. [Google Scholar]

- Li, G. Evaluation of the gas production potential of marine hydrate deposits in the Shenhu Area of the South China Sea. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 3 May 2010. [Google Scholar]

- Wu, N.; Yang, S.; Zhang, H.; Liang, J.; Wang, H.; Lu, J.A. Gas hydrate system of Shenhu area, northern South China Sea: Geochemical results. J. Geol. Res. 2011, 2011, 370298. [Google Scholar] [CrossRef]

- Moridis, G. Numerical studies of gas production from Class 2 and Class 3 hydrate accumulations at the Mallik Site, Mackenzie Delta, Canada. SPE Reserv. Eval. Eng. 2004, 7, 175–183. [Google Scholar] [CrossRef]

- Moridis, G.; Kowalsky, M.; Pruess, K. TOUGH+ Hydrate v1.0 User’s Manual: A Code for the Simulation of System Behaviour in Hydrate-Bearing Porous Media; Report LBNL-149E; Lawrence Berkeley National Laboratory: Berkeley, CA, USA, 2008. [Google Scholar]

- Moridis, G.J.; Reagan, M.T.; Queiruga, A.F.; Boswell, R. Evaluation of the performance of the oceanic hydrate accumulation at site NGHP-02-09 in the Krishna-Godavari Basin during a production test and during single and multi-well production scenarios. Mar. Pet. Geol. 2019, 108, 660–696. [Google Scholar] [CrossRef]

- Qin, X.; Liang, Q.; Ye, J.; Yang, L.; Qiu, H.; Liang, J.; Lu, C.; Lu, H.; Ma, B.; Kuang, Z. The response of temperature and pressure of hydrate reservoirs in the first gas hydrate production test in South China Sea. Appl. Energy 2020, 278, 115649. [Google Scholar] [CrossRef]

- Yin, Z.; Moridis, G.; Chong, Z.R.; Tan, H.K.; Linga, P. Numerical analysis of experimental studies of methane hydrate dissociation induced by depressurization in a sandy porous medium. Appl. Energy 2018, 230, 444–459. [Google Scholar] [CrossRef]

- Zhang, K.; Moridis, G.J.; Wu, N.; Li, X.; Reagan, M.T. Evaluation of alternative horizontal well designs for gas production from hydrate deposits in the Shenhu Area, South China Sea. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8 June 2010. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils. Soil. Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef]

- Boswell, R. Japan completes first offshore methane hydrate production test—Methane successfully produced from deepwater hydrate layers. Cent. Nat. Gas Oil 2013, 412, 386–7614. [Google Scholar]

| References | Exploitation Method | Exploitation Duration | Average CH4 Production Rate (m3/day/unit Production Well Length) | Type of Results |

|---|---|---|---|---|

| Second trial area of China [18] | Depressurization | 30 day | 106 | Trial results |

| Ma et al. [19] | Depressurization | 10 year | 10.3 | Simulation results |

| Yu et al. [20] | Depressurization | 15 year | 5.23 | Simulation results |

| Yang et al. [21] | Depressurization | 5 year | 21.9 | Simulation results |

| Su et al. [22] | Depressurization | 3.5 year | 35.2 | Simulation results |

| Ning et al. [13] | Depressurization | 5 year | 22.7 | Simulation results |

| Jin et al. [15] | Depressurization combined heat injection | 15 year | 37.5 | Simulation results |

| Feng et al. [17] | Depressurization combined heat injection | 30 year | 61.5 | Simulation results |

| Zhong et al. [23] | Depressurization combined heat injection | 3.5 year | 42.3 | Simulation results |

| Parameters | Unit | Value |

|---|---|---|

| Intrinsic porosity (Overburden and underburden, GHL) [33,34] | Dimensionless | 0.38 |

| Intrinsic permeability (Overburden and underburden, GHL) [26,33] | mD | 20 |

| Intrinsic permeability (sealing boundaries) | mD | 0 |

| The thickness of overburden | m | 70 |

| The thickness of GHL [33,34] | m | 40 |

| The thickness of underburden | m | 70 |

| Gas hydrate saturation of GHL [26,33,34] | Dimensionless | 0.44 |

| Water salinity (mass fraction) [26,40] | 0.03 | |

| Water saturation (overburden and underburden) [26,33,34] | Dimensionless | 1.00 |

| Geothermal gradient [34] | °C/100 m | 5 |

| Pressure gradient | MPa/m | 0.01 |

| GHL center temperature [26,34] | °C | 15.29 |

| CHL center pressure [26,34] | MPa | 14.55 |

| Rock density [34,40] | kg/m3 | 2600 |

| Capillary pressure model [41] | ||

| Entry capillary pressure () [23,40] | 1.0 × 105 | |

| Pore structure index (λ) [23,40] | 0.45 | |

| Relative permeability model [36] | ||

| Irreducible aqueous saturation () [23,40] | 0.30 | |

| Irreducible gas saturation () [23,40] | 0.03 | |

| Aqueous phase index () [23] | 3.5 | |

| Gas phase index () [23,40] | 3.5 |

| Runs | Vertical Distance of Sealing Boundaries/m | Ti/°C | Pi/MPa | Pp/MPa |

|---|---|---|---|---|

| 1 | 0 | 40 | 20 | 4.5 |

| 2 | 6 | |||

| 3 | 15 | |||

| 4 | none |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Zeng, Y.; Zhong, X.; Pan, D.; Chen, C. Investigation into the Effect of Permeable Boundary Sealing on the Behavior of Hydrate Exploitation via Depressurization Combined with Heat Injection. Energies 2024, 17, 5172. https://doi.org/10.3390/en17205172

Wang Y, Zeng Y, Zhong X, Pan D, Chen C. Investigation into the Effect of Permeable Boundary Sealing on the Behavior of Hydrate Exploitation via Depressurization Combined with Heat Injection. Energies. 2024; 17(20):5172. https://doi.org/10.3390/en17205172

Chicago/Turabian StyleWang, Yihan, Yunshuang Zeng, Xiuping Zhong, Dongbin Pan, and Chen Chen. 2024. "Investigation into the Effect of Permeable Boundary Sealing on the Behavior of Hydrate Exploitation via Depressurization Combined with Heat Injection" Energies 17, no. 20: 5172. https://doi.org/10.3390/en17205172

APA StyleWang, Y., Zeng, Y., Zhong, X., Pan, D., & Chen, C. (2024). Investigation into the Effect of Permeable Boundary Sealing on the Behavior of Hydrate Exploitation via Depressurization Combined with Heat Injection. Energies, 17(20), 5172. https://doi.org/10.3390/en17205172