Environmental Benefits of Hydrogen-Powered Buses: A Case Study of Coke Oven Gas

Abstract

1. Introduction

1.1. Reasoning behind the Research

1.2. World Trends in Bus Environmental Research

2. Materials and Methods

2.1. Life Cycle Assessment

2.1.1. Goal and Scope: System Boundary and Functional Unit

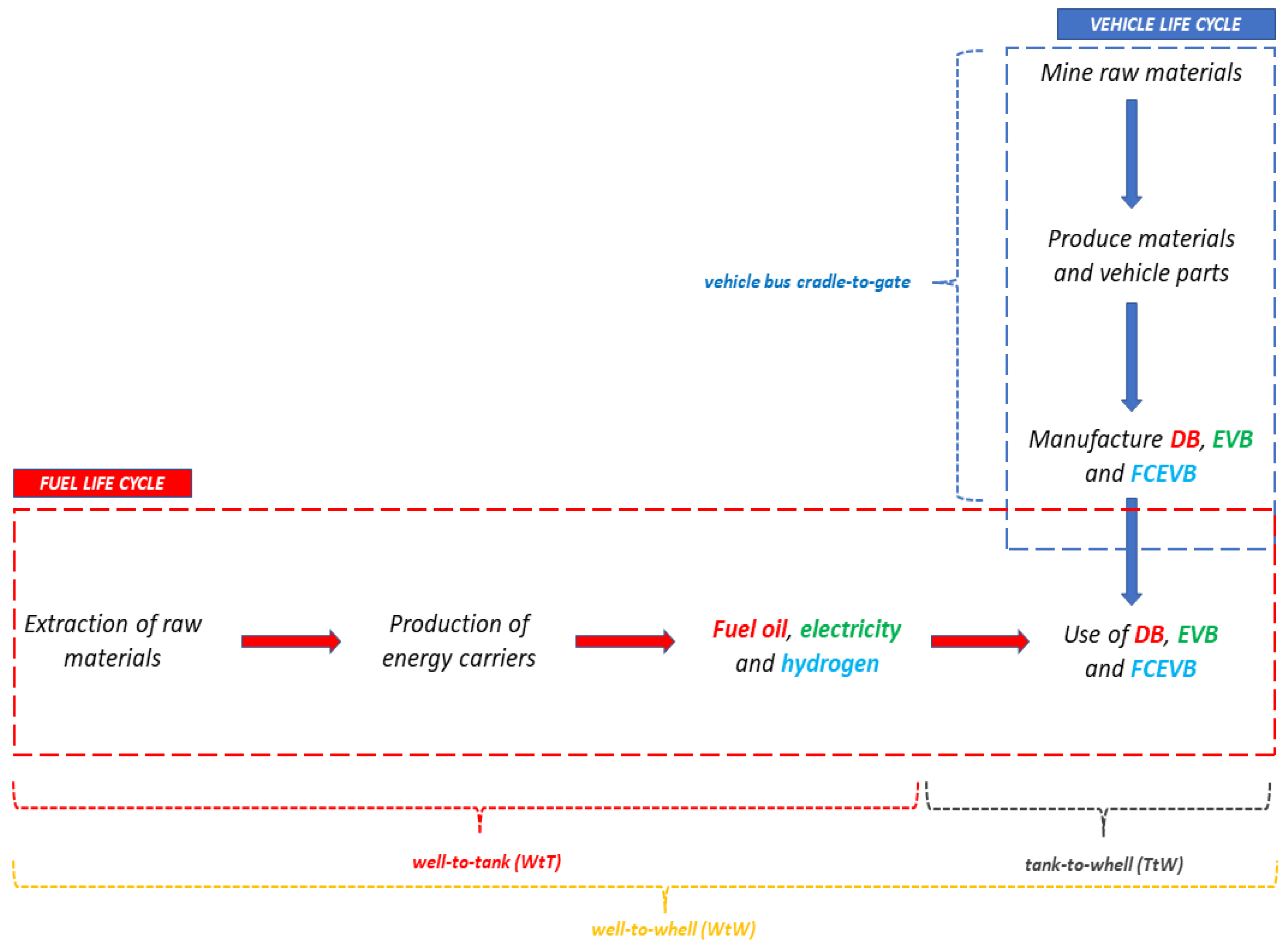

- The first part of the analysis consists of two steps: (a) an analysis concerning the energy carrier (diesel, electricity, and hydrogen), hereinafter referred to as well-to-tank (WTT), and (b) an analysis concerning the fuel usage, tank-to-wheel (TTW); hence, the first part of the analysis (the sum of steps a and b) will hereinafter be referred to as well-to-wheel (WTW);

- The second part includes a vehicle bus cradle-to-gate analysis.

2.1.2. Life Cycle Inventory—Analysis of Inputs and Outputs. Assumptions Made for the Analysis. Case Study—Silesia Region in Southern Poland in Europe

- Conventional buses fully fueled with diesel fuel (Diesel bus, DB), as the ones with the largest share in the structure of SR, are subject to possible replacement due to environmental restrictions;

- Electric vehicle bus (EVB) as the most environmentally beneficial in the literature;

- Fuel cell electric vehicle bus (FCEVB) powered by hydrogen from coke oven gas as an alternative to DB vehicles.

2.1.3. Life Cycle Impact Assessment (LCIA) Method

3. Results and Discussion

3.1. Well-to-Tank (WTT) Phase

3.2. Tank-to-Wheel (TTW) Phase

3.3. Production of Vehicle Buses: From the Cradle to the Gate

3.4. Fuel Bus Life Cycle + Vehicle Bus Life Cycle (FBLC + VBLC)

3.5. Comparison of the Life Cycle of FBLC + VBLC for DB, EVB, and FCEVB

3.6. Substitution of DB Vehicles by FCEVB: A Case Study

4. Conclusions

- The analysis of the WTT phase demonstrates that hydrogen fuel from coke oven gas is considered environmentally preferable to both conventional diesel fuel and electricity for alternative electric vehicle fuel. Hydrogen produced from coke oven gas has the lowest environmental impact among all fuels analyzed at the WTT stage. It does not exceed 20% in any LCIA category, while diesel fuel has the highest impact in most LCIA categories, contributing 100% in 8 of 11 categories;

- The analysis of the TTW phase for the modeled buses demonstrates that diesel vehicles (DB) generate the most significant environmental load during fuel use. This is due to their exhaust and non-exhaust emissions. Zero-emission vehicles (EVB and FCEVB) also emit pollutants, but only in the form of non-exhaust emissions. While they have a lower overall environmental impact compared to diesel vehicles, they still contribute to HTP (human toxicity) impacts. Key factors considered in the TTW analysis include PM10, PM2.5, soot, Cu, Pb, and PAHs. Based on these factors, zero-emission vehicles are clearly more environmentally preferable than diesel-powered vehicles;

- The analysis of the cradle-to-gate stage, examining the environmental impacts of producing each bus model showed that the DB bus had the lowest overall environmental impact. This was primarily due to its lower weight and simpler design compared to the EVB and FCEVB. The EVB, while lighter than the FCEVB, had significant environmental impacts due to the aluminum used in its construction and the large lithium-ion battery. The FCEVB had the highest environmental impact in almost all categories, primarily attributed to its heavier weight and complex design;

- Life Cycle Assessment (LCA) analysis of a DB diesel bus demonstrates that the predominant environmental impact occurs during the fuel combustion stage for most impact categories. Specifically, categories such as ADP fossil fuels, GWP100a, ODP, POCP, AP, and EP show a nearly 100% contribution from fuel combustion to the total environmental impact throughout the bus’s life cycle and operation. In-service operations like tire, battery, oil changes, and non-fuel emissions have a negligible impact on these impact categories

- Life Cycle Assessment (LCA), conducted on an electric bus, reveals that the dominant contributors to environmental impact are factors related to the lithium-ion battery and the national energy mix. These factors contribute to varying shares of environmental impact, ranging from 83.9% for EP to 41.0% for TETP. The production of the electric bus contributes to LCIA from 3.2% to 20.8%. Non-combustion emissions from the operation of the electric bus over its 15-year life cycle have a significant impact, accounting for 87.3% of the HTP category;

- LCA analysis of a hydrogen bus powered by hydrogen from coke oven gas reveals that fuel production and bus manufacturing are the primary contributors to environmental impact. The recovery of hydrogen from coke oven gas accounts for a significant portion of emissions in fossil fuel categories. Non-combustion emissions constitute the largest share of the overall environmental impact. The Li-On battery, used for energy storage, contributes substantially to the ADP structure;

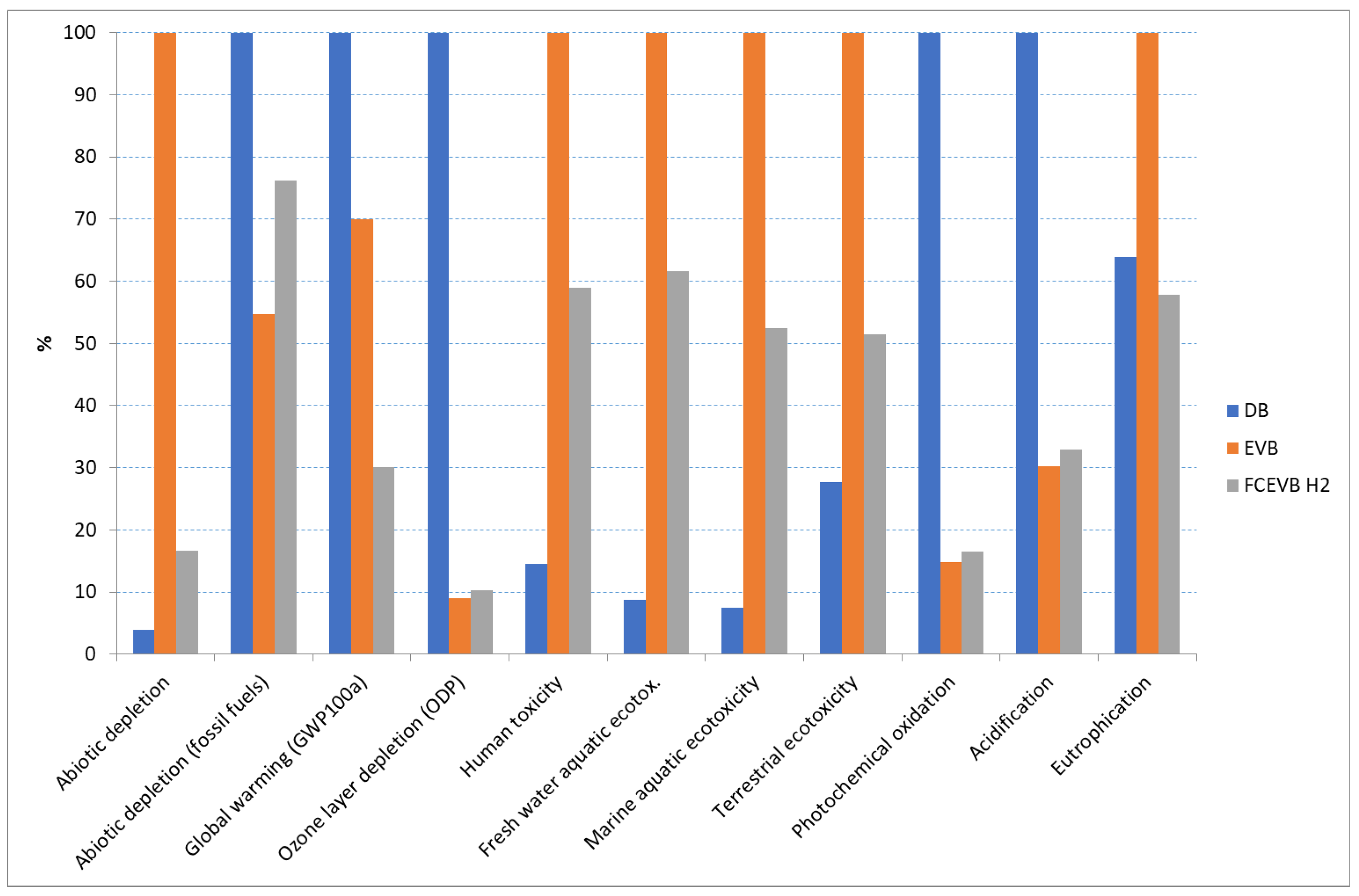

- Fuel cell electric vehicles (FCEVB H2) perform best in most of the analyzed harm categories. This means that they are the most environmentally friendly of the three types of buses compared. They achieve particularly favorable results in terms of depletion of fossil resources (fuels) and global warming;

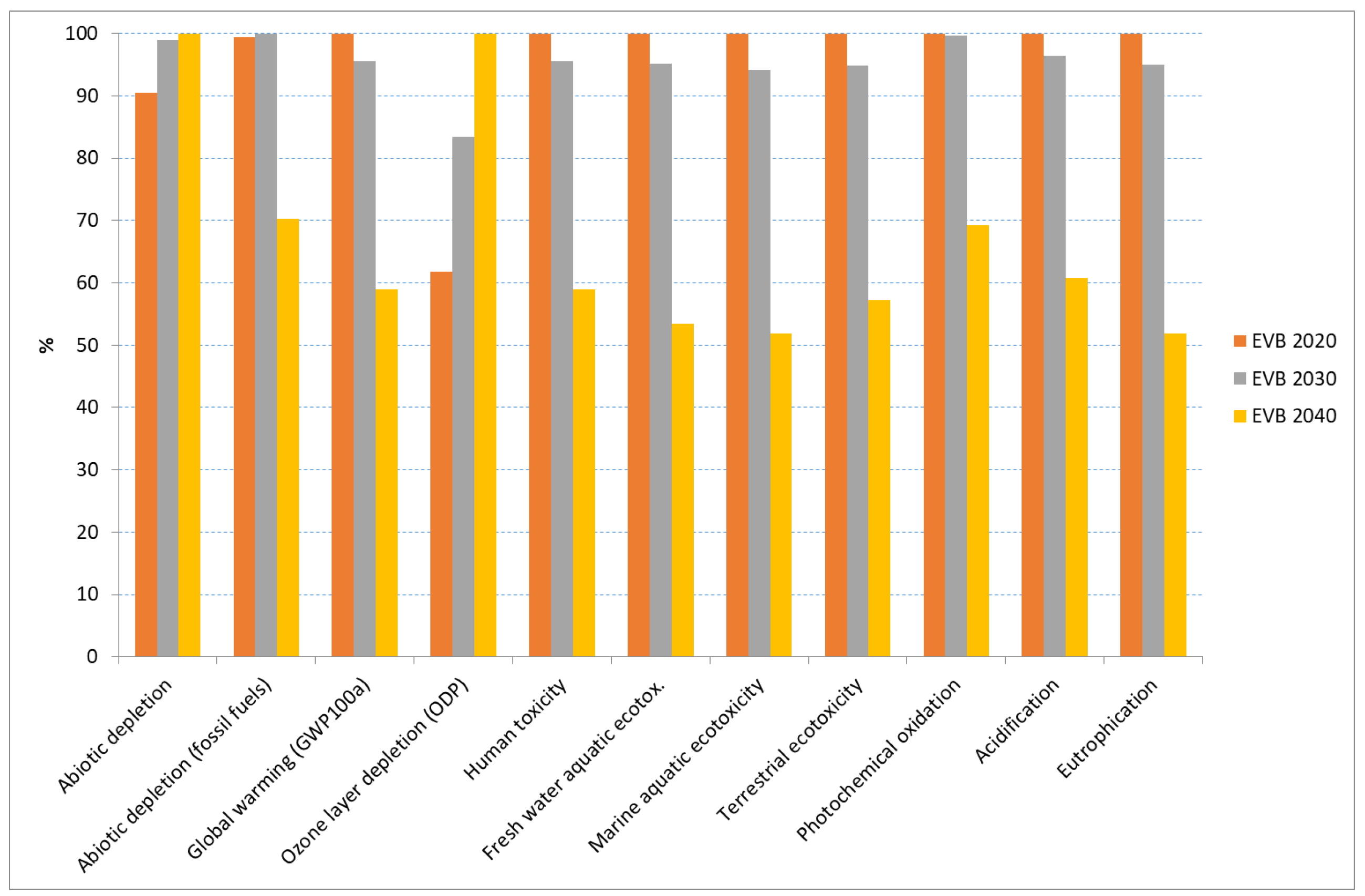

- Electric vehicles (EVB) also have a relatively low environmental impact, especially in the category of fossil resource depletion. However, their environmental impact largely depends on the source of the electricity used to power them. If the electricity comes from renewable sources, the environmental impact of EVBs is even lower;

- Diesel buses (DB) have the highest environmental impact in most of the analyzed categories. They have a particularly adverse impact on global warming, ozone layer depletion, and air pollution;

- The results suggest that replacing diesel buses with hydrogen buses can be a beneficial strategy for reducing greenhouse gas emissions and improving air quality. However, the trade-off in terms of increased mineral resource consumption should be carefully considered.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Okonkwo, E.C.; Al-Breiki, M.; Bicer, Y.; Al-Ansari, T. Sustainable hydrogen roadmap: A holistic review and decision-making methodology for production, use, and exportation using Qatar as a case study. Int. J. Hydrogen Energy 2021, 46, 35525–35549. [Google Scholar] [CrossRef]

- The Future of Hydrogen—Analysis. IEA. Available online: https://www.iea.org/reports/the-future-of-hydrogen (accessed on 12 January 2022).

- Moral, G.; Ortiz-Imedio, R.; Ortiz, A.; Gorri, D.; Ortiz, I. Recovery of hydrogen from coke oven gas. Comparative analysis of technical alternatives. Ind. Eng. Chem. Res. 2022, 61, 6106–6124. [Google Scholar] [CrossRef] [PubMed]

- Nasze Otoczenie—Raport JSW 2020. Available online: https://www.jsw.pl/raportroczny-2020/nasze-otoczenie/otoczenie-rynkowe-i-konkurencyjne#rynek_koksu-tab (accessed on 29 June 2022).

- File: Hard Coal Deliveries to Coke Ovens and Coke Oven Coke Production, EU, 2016–2020 (Million Tonnes).png. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=File:Hard_coal_deliveries_to_coke_ovens_and_coke_oven_coke_production,_EU,_2016-2020_(million_tonnes).png (accessed on 29 June 2022).

- National Bureau of Statistics of China. Available online: http://www.stats.gov.cn/english/ (accessed on 30 June 2022).

- Gallego-Schmid, A.; Rivera, X.C.S.; Stamford, L. Introduction of life cycle assessment and sustainability concepts in chemical engineering curricula. Int. J. Sustain. High. Educ. 2018, 19, 442–458. [Google Scholar] [CrossRef]

- Mazzi, A. Introduction. Life cycle thinking. In Life Cycle Sustainability Assessment for Decision-Making; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–19. [Google Scholar]

- Ahamed, A.; Vallam, P.; Iyer, N.S.; Veksha, A.; Bobacka, J.; Lisak, G. Life cycle assessment of plastic grocery bags and their alternatives in cities with confined waste management structure: A Singapore case study. J. Clean. Prod. 2021, 278, 123956. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Zastosowanie metod oceny środowiskowej na podstawie analizy cyklu życia dla branży motoryzacyjnej. Zesz. Nauk. Organ. Zarządzanie/Politech. Śląska 2017, 100, 77–85. [Google Scholar]

- Curran, S.J.; Wagner, R.M.; Graves, R.L.; Keller, M.; Green, J.B. Well-to-wheel analysis of direct and indirect use of natural gas in passenger vehicles. Energy 2014, 75, 194–203. [Google Scholar] [CrossRef]

- Torchio, M.F.; Santarelli, M.G. Energy, environmental and economic comparison of different powertrain/fuel options using a well-to-wheels assessment, energy and external costs—European market analysis. Energy 2010, 35, 4156–4171. [Google Scholar] [CrossRef]

- Albert, J.; Civancik-Uslu, D.; Contessotto, D.; Balaguera, A.; Fullana-i-Palmer, P. Does a life cycle assessment remain valid after 20 years? Scenario analysis with a bus stop study. Resour. Conserv. Recycl. 2019, 144, 169–179. [Google Scholar] [CrossRef]

- Jwa, K.; Lim, O. Comparative life cycle assessment of lithium-ion battery electric bus and diesel bus from well to wheel. Energy Procedia 2018, 145, 223–227. [Google Scholar] [CrossRef]

- Harris, A.; Soban, D.; Smyth, B.M.; Best, R. Assessing life-cycle impacts and the risk and uncertainty of alternative bus technologies. Renew. Sustain. Energy Rev. 2018, 97, 569–579. [Google Scholar] [CrossRef]

- Chang, C.-C.; Liao, Y.-T.; Chang, Y.-W. Life Cycle Assessment of Carbon Footprint in Public Transportation: A Case Study of Bus Route NO. 2 in Tainan City, Taiwan. Procedia Manuf. 2019, 30, 388–395. [Google Scholar] [CrossRef]

- Gabriel, N.R.; Martin, K.K.; Haslam, S.J.; Faile, J.C.; Kamens, R.M.; Gheewala, S.H. A comparative life cycle assessment of electric, compressed natural gas and diesel buses in Thailand. J. Clean. Prod. 2021, 314, 128013. [Google Scholar] [CrossRef]

- Iannuzzi, L.; Hilbert, J.A.; Lora, E.E.S. Life cycle assessment (LCA) for use on renewable-sourced hydrogen fuel cell buses versus diesel engines buses in the city of Rosario, Argentina. Int. J. Hydrogen Energy 2021, 46, 29694–29705. [Google Scholar] [CrossRef]

- Pederzoli, D.W.; Carnevali, C.; Genova, R.; Mazzucchelli, M.; Del Borghi, A.; Gallo, M.; Moreschi, L. Life-cycle assessment of hydrogen-powered city buses in the High V. LO-City project: Integration of vehicle operation and refuelling infrastructure. SN Appl. Sci. 2022, 4, 57. [Google Scholar] [CrossRef]

- Rinawati, D.I.; Keeley, A.R.; Takeda, S.; Managi, S. A systematic review of the life cycle assessment of hydrogen for the use in road transport. Prog. Energy 2021, 4, 012001. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2022.

- ISO 14044:2006; Environmental Management—Life Cycle Assessment—Requirements and Guidelines. ISO: Geneva, Switzerland, 2022.

- Nordelöf, A.; Messagie, M.; Tillman, A.-M.; Ljunggren Söderman, M.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid and battery electric vehicles: What can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Statystyka—Izba Gospodarcza Komunikacji Miejskiej. Available online: https://igkm.pl/statystyka/ (accessed on 24 March 2022).

- Burmistrz, P.; Czepirski, L.; Gazda-Grzywacz, M. Carbon dioxide emission in hydrogen production technology from coke oven gas with life cycle approach. E3S Web Conf. 2016, 10, 00023. [Google Scholar] [CrossRef]

- EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019—European Environment Agency. Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 14 April 2022).

- Directive 2007/46/EC of the European Parliament and of the Council of 5 September 2007 Establishing a Framework for the Approval of Motor Vehicles and Their Trailers, and of Systems, Components and Separate Technical Units Intended for Such Vehicles. Available online: https://eur-lex.europa.eu/eli/dir/2007/46/oj (accessed on 24 March 2022).

- Addition of Materials Data to the Danish Transportation LCA Model. Available online: https://ghgenius.ca/index.php/all-reports/37-addition-of-materials-data-to-the-danish-transportation-lca-model (accessed on 25 March 2022).

- Miotti, M.; Hofer, J.; Bauer, C. Integrated environmental and economic assessment of current and future fuel cell vehicles. Int. J. Life Cycle Assess. 2017, 22, 94–110. [Google Scholar] [CrossRef]

- Evangelisti, S.; Tagliaferri, C.; Brett, D.J.; Lettieri, P. Life cycle assessment of a polymer electrolyte membrane fuel cell system for passenger vehicles. J. Clean. Prod. 2017, 142, 4339–4355. [Google Scholar] [CrossRef]

- Cavalett, O.; Chagas, M.F.; Seabra, J.E.; Bonomi, A. Comparative LCA of ethanol versus gasoline in Brazil using different LCIA methods. Int. J. Life Cycle Assess. 2013, 18, 647–658. [Google Scholar] [CrossRef]

- FC-HyGuide. 2011. Available online: https://www.h2euro.org/whats-h2appening/fc-hyguide-%e2%80%93-guidance-document-for-performing-lcas-on-hydrogen-and-fuel-cells-technologies/ (accessed on 27 January 2022).

- Ding, N.; Pan, J.; Zhang, Z.; Yang, J. Life cycle assessment of car sharing models and the effect on the GWP of urban transportation: A case study of Beijing. Sci. Total Environ. 2019, 688, 1137–1144. [Google Scholar] [CrossRef] [PubMed]

- Valente, A.; Iribarren, D.; Dufour, J. Harmonising methodological choices in life-cycle assessment of hydrogen: A focus on acidification and renewable hydrogen. Int. J. Hydrogen Energy 2019, 44, 19426–19433. [Google Scholar] [CrossRef]

- Drielsma, J.A.; Russell-Vaccari, A.J.; Drnek, T.; Brady, T.; Weihed, P.; Mistry, M.; Simbor, L.P. Mineral resources in life cycle impact assessment: Defining the path forward. Int. J. Life Cycle Assess. 2016, 21, 85–105. [Google Scholar] [CrossRef]

- Khoo, H.H.; Halim, I.; Handoko, A.D. LCA of electrochemical reduction of CO2 to ethylene. J. CO2 Util. 2020, 41, 101229. [Google Scholar] [CrossRef]

- Morales-Méndez, J.D.; Silva-Rodrguez, R. Environmental assessment of ozone layer depletion due to the manufacture of plastic bags. Heliyon 2018, 4, e01020. [Google Scholar] [CrossRef]

- Harder, R.; Peters, G.M.; Svanström, M.; Khan, S.J.; Molander, S. Estimating human toxicity potential of land application of sewage sludge: The effect of modelling choices. Int. J. Life Cycle Assess. 2017, 22, 731–743. [Google Scholar] [CrossRef]

- Berthoud, A.; Maupu, P.; Huet, C.; Poupart, A. Assessing freshwater ecotoxicity of agricultural products in life cycle assessment (LCA): A case study of wheat using French agricultural practices databases and the USEtox model. Int. J. Life Cycle Assess. 2011, 16, 841–847. [Google Scholar] [CrossRef]

- Paulu, A.; Bartáček, J.; Šerešová, M.; Kočí, V. Combining Process Modelling and LCA to Assess the Environmental Impacts of Wastewater Treatment Innovations. Water 2021, 13, 1246. [Google Scholar] [CrossRef]

- Plouffe, G.; Bulle, C.; Deschênes, L. Characterisation factors for terrestrial zinc ecotoxicity, including speciation. Int. J. Life Cycle Assess. 2016, 21, 523–535. [Google Scholar] [CrossRef]

- Farinha, C.; de Brito, J.; Veiga, M.D. (Eds.) Chapter 8—Life cycle assessment. In Eco-Efficient Rendering Mortars; Woodhead Publishing: Sawston, UK, 2021; pp. 205–234. [Google Scholar] [CrossRef]

- Poland’s Energy Mix—Instrat. 2019. Available online: https://instrat.pl/pie-working-paper-06-2019/ (accessed on 14 April 2022).

| Parameter | Unit | Value |

|---|---|---|

| The amount of mine gas that flared in the CHP * plant converted to methane | mln. m3(NTP)/year | 67,520,000 |

| Technological blowdown (residual gas from the CHP plant) | mln. m3(NTP)/year | 92,691,900 |

| Average methane content in the mine gas | % vol. | 56.66 |

| Average calorific value of methane in mine gas | MJ/m3 | 35.810 |

| Amount of electricity produced from the gas of the gas of the mine | MWh/year | 183,026 |

| Amount of heat produced from the mine gas (including cooling) | GJ/year | 451,310 |

| Compressed air production | thousand m3/rok | 32,899 |

| Stream | Yield [kg] |

|---|---|

| Coke | 0.743 |

| Dry gas | 0.117 |

| Steam | 0.093 |

| Benzol | 0.011 |

| Tar | 0.036 |

| Component | % m | % v |

|---|---|---|

| H2 | 6.0 | 41.7 |

| CO | 4.6 | 2.3 |

| CH4 | 22.6 | 19.7 |

| CO2 | 3.1 | 1.0 |

| C2H6 | 5.6 | 2.6 |

| H2S | 1.4 | 0.6 |

| NH3 | 2.3 | 1.9 |

| H2O | 36.2 | 28.0 |

| Benzol | 4.3 | 0.8 |

| Tar | 14.0 | 1.5 |

| Input | Output | LHV MJ/kg | Allocation Coefficient | ||||

|---|---|---|---|---|---|---|---|

| Coal | 132.48 | kg | Hydrogen | 1 | kg | 120 | 0.04 |

| Oxygen | 3.24 | kg | CO2 from PSA | 8.34 | kg | - | - |

| Steam | 3.61 | kg | CO2 in the flue gas | 3.9 | kg | - | - |

| Water | 4.03 | kg | Coke | 96 | kg | 28.6 | 0.9 |

| Electricity | 5.79 | kWh | Tar | 3.65 | kg | 38.7 | 0.05 |

| Heat | 13.71 | MJ | Benzene | 1.22 | kg | 32.8 | 0.01 |

| Material [kg] | Notes | DB | EVB | FCEVB |

|---|---|---|---|---|

| Stell | Average | 5366 | 3766 | 5971 |

| High-Strength | 0 | 0 | 2895 | |

| Stainless | 429 | 429 | 317 | |

| Iron | Cast | 966 | 100 | |

| Aluminium | Average wrought | 966 | 1500 | 1185 |

| Average cast | 0 | 0 | 789 | |

| Copper | 80 | 80 | 856 | |

| Zinc | 80 | 80 | 40 | |

| Magnesium | 80 | 80 | 52 | |

| Powder Metals | 80 | 80 | 184 | |

| Glass | 537 | 537 | 407 | |

| Rubber | 644 | 644 | 895 | |

| Fluids and lubricants | 429 | 429 | 856 | |

| Fibre Glass | 0 | 0 | 0 | |

| Plastics | High-density polyethylene | 0 | 0 | 0 |

| Polyethylene terephthalate | 0 | 0 | 0 | |

| Polyprolylene | 0 | 0 | 0 | |

| Average | 644 | 644 | 1580 | |

| Composites | Glass Fibre Composite Plastic | 0 | 0 | 0 |

| CF For general use | 0 | 0 | 816 | |

| CF For High Pressure | 0 | 0 | 816 | |

| Lead | Average | 0 | 0 | 157 |

| Nickel | Avearge | 0 | 0 | 77 |

| Titanium | 0 | 0 | 0 | |

| Lithium battery | 0 | 3000 | 0 | |

| Other | 429 | 429 | 1315 | |

| Total | 10,301 | 11,798 | 19,200 |

| FCEVB Vehicle Bus with FC, 70 kW | Unit | Value |

|---|---|---|

| Production of tetrafluoroethylen | kg | 0.55 |

| Production of Sulfuric Acids | kg | 0.03 |

| Tetrafluoroethylen Production | kg | 0.06 |

| Fleece production | kg | 0.59 |

| Carbon fibre-reinforced plastic inj moulted glo | kg | 1.19 |

| Production of tetrafluoroethylen | kg | 0.10 |

| Carbon Black Prod | kg | 0.29 |

| Production of tetrafluoroethylen | kg | 0.09 |

| Organic Solvent Production | kg | 0.02 |

| Textile production, cotton, dying | kg | 1.19 |

| Extrusion, Plastic Film | kg | 1.46 |

| Selective coating of cooper sheet, sputering | kg | 5.39 |

| Thermoforming with calendering | kg | 4.48 |

| Polysulphide Production Sealing | kg | 3.30 |

| Injection moulding | kg | 3.30 |

| Platinum Group Metal Extr and Refinery | kg | 0.01 |

| Treatment of automobile catalyst | kg | 0.00 |

| Carbon Black Prod | kg | 0.01 |

| Production of tetrafluoroethylen | kg | 0.00 |

| Organic Solvent Production | kg | 0.12 |

| Selective coating of cooper sheet, sputering | kg | 5.39 |

| Steel Cromium Hot-Rolled | kg | 17.15 |

| Titanium dioxide production chloride | kg | 1.72 |

| Graphite production | kg | 1.72 |

| Phenolic resin production | kg | 0.24 |

| Deep draving, steel 650 kn press autom | kg | 15.83 |

| Selective coating of cooper sheet, sputering | kg | 13.20 |

| Glass fibre production | kg | Value |

| Epoxy resin prod liq | kg | 0.55 |

| Copper production primary | kg | 0.03 |

| Steel prod chromium hot-roled | kg | 0.06 |

| Polypropylen ranulate | kg | 0.59 |

| Injection moulding | kg | 1.19 |

| Metal working/average for cooper prod manu | kg | 0.10 |

| thermoforming with calendering | kg | 3.96 |

| Parameter | Unit | DB | EVB | FCEVB |

|---|---|---|---|---|

| exhaust: | 0 | 0 | ||

| CO2 | g/kg of fuel | 3140 | 0 | 0 |

| CH4 | g/kg of fuel | 0.2 | 0 | 0 |

| N2O | g/kg of fuel | 0.1 | 0 | 0 |

| NMVOC | g/kg of fuel | 8 | 0 | 0 |

| CO | g/kg of fuel | 36 | 0 | 0 |

| NO2 | g/kg of fuel | 42 | 0 | 0 |

| Particulates, Diesel Soot | g/kg of fuel | 0.94 | 0 | 0 |

| Ammonia | g/kg of fuel | 0.013 | 0 | 0 |

| Indeno(1,2,3-cd)pyrene | µg/kg fuel | 7.9 | 0 | 0 |

| bezno(k)fluoranathene | µg/kg fuel | 34.4 | 0 | 0 |

| bezno(b)fluoranathene | µg/kg fuel | 30.8 | 0 | 0 |

| benzo(a)pyrene | µg/kg fuel | 5.1 | 0 | 0 |

| Lead | µg/kg fuel | 52 | 0 | 0 |

| non-exhaust: | ||||

| PM2.5 tire wear | mg/km | 14.84 | 14.84 | 14.84 |

| PM2.5 brake | mg/km | 21.44 | 21.44 | 21.44 |

| PM2.5 road | mg/km | 20.52 | 20.52 | 20.52 |

| PM10 tire wear | mg/km | 21.2 | 21.2 | 21.2 |

| PM10 brake | mg/km | 53.6 | 53.6 | 53.6 |

| PM10 road | mg/km | 38 | 38 | 38 |

| average vehicle speed (urban) | km/h | 17 | 17 | 17 |

| average combustion/energy consumption (urban) | kg fuel oil a, kWh b, kg H2 c/100 km | 37 a | 110 b | 9 c |

| Energy Carrier | 2020 (Current) | 2030 | 2040 |

|---|---|---|---|

| EU REF | EU REF | EU REF | |

| Crude oil | 0 | 0 | 0 |

| Coal | 65 | 65 | 35 |

| Natural Gas | 8 | 15 | 20 |

| Nuclear | 0 | 0 | 19 |

| Biomass, biogas, and waste | 5 | 8 | 10 |

| Hydropower | 2 | 1 | 1 |

| Geothermal | 0 | 0 | 0 |

| Wind power | 14 | 11 | 15 |

| Solar energy | 2 | 0 | 0 |

| Tidal power | 0 | 0 | 0 |

| Other | 3 | ||

| Total | 100 | 100 | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gazda-Grzywacz, M.; Grzywacz, P.; Burmistrz, P. Environmental Benefits of Hydrogen-Powered Buses: A Case Study of Coke Oven Gas. Energies 2024, 17, 5155. https://doi.org/10.3390/en17205155

Gazda-Grzywacz M, Grzywacz P, Burmistrz P. Environmental Benefits of Hydrogen-Powered Buses: A Case Study of Coke Oven Gas. Energies. 2024; 17(20):5155. https://doi.org/10.3390/en17205155

Chicago/Turabian StyleGazda-Grzywacz, Magdalena, Przemysław Grzywacz, and Piotr Burmistrz. 2024. "Environmental Benefits of Hydrogen-Powered Buses: A Case Study of Coke Oven Gas" Energies 17, no. 20: 5155. https://doi.org/10.3390/en17205155

APA StyleGazda-Grzywacz, M., Grzywacz, P., & Burmistrz, P. (2024). Environmental Benefits of Hydrogen-Powered Buses: A Case Study of Coke Oven Gas. Energies, 17(20), 5155. https://doi.org/10.3390/en17205155