Abstract

Emissions of pollutants and their consequences for the atmosphere have received special attention from international organizations in recent years due to the climate crisis predicted in the next decades. In this regard, the Carbon Dioxide (CO2) produced in industrial sectors is one of the most concerning compounds because of its impact on global warming and climate change. This study developed a systematic review of Carbon Dioxide Emissions from manufacturing industries considering one decade of research documents focused on addressing this problem. For this, different assessments such as the trend of published articles, top-cited studies, the network evaluation of journals, and keywords network evaluation were conducted. After a careful data-driven analysis, research trends were identified. Findings revealed the increased urgency of finding and assessing information regarding the climate crisis due to CO2 emissions as well as revealing which main sectors and research areas have been involved in its investigation. Furthermore, the most influential contributions and clusters of words obtained demonstrate interrelationships among research trends that are focused on finding new paths to generate more sustainable processes in every manufacturing industry. This study aims to generate valuable insights into the role played by manufacturing industries in the context of the environmental situation, revealing trends and key points among the scientific community.

1. Introduction

The environmental crisis has become the greatest concern for the international scientific community in recent years, demonstrated by the increasing frequency, intensity, and impacts of extreme weather events. This phenomenon is mainly caused by pollutants known as Green House Gases (GHG). Contaminants in this group possess the capacity of trapping heat in the atmosphere, and they can remain in the atmosphere for a prolonged time that can range from a couple of years to even thousands of years. The presence of GHG in the atmosphere leads to a warming or cooling effect on climate, changing the Earth’s energy balance. It is calculated that the total warming effect from GHG gases added by humans increased by 45 percent in the last 20 years [1]. According to international organizations, Carbon Dioxide (CO2), Methane (CH4), Nitrous Oxide (N2), and Fluorinated Gases are the chemical compounds of greatest concern. CO2 emissions are considered to be one of the main components responsible for climate change since the pre-industrial period. This pollutant is emitted from different sources. CO2 is a result of the combustion of fossil fuels such as coal, oil, and natural gas, which are mainly employed in industrial processes including the energy, transportation, waste, and manufacturing sectors [2]. However, studies focusing on the years 1850 to 2012 reveal that the main contributor in this period is represented by Land Use, Land-Use Change, and Forestry (LULUCF). In the same way, industrial processes significantly contributed to the emission of CO2. Production of this compound within industries is a consequence of two main sources: fossil fuel consumption for energy and electricity generation; and chemical reactions to produce goods such as cement and iron and steel.

Emissions have deeply varied across regions and generations. This is a result of the variation in urbanization and industrialization. As a result, highly uneven production levels of CO2 have been registered across the years and in different regions. In fact, countries like the United States have emitted eleven times more energy-related CO2 in comparison with an average African country. Therefore, despite the fact that the importance of global efforts to cut emissions has been communicated to every nation, lack of effective participation from certain countries represents a barrier to meeting stated targets. Such disparity is demonstrated by the statistic revealing that 10% of global emitters were responsible for almost half of all energy-related CO2 emissions in 2021 [3].

The CO2 emissions problematic has become a major concern for international organizations, as current trends indicate potentially irreversible damage to the atmosphere. Since the Paris Agreement adopted by 196 parties in 2015, where the stated goal was to limit the increase in the global average temperature to 1.5 °C above pre-industrial levels, the efforts to tackle this challenge have intensified, with regulations continually being updated to create effective policies aimed at mitigating the catastrophic impacts of climate change. The most recent significant policy framework emerged from the United Nations Climate Change Conference (COP28) held in December 2023, where nearly 200 parties gathered in Dubai to complete the first global stock-take of climate action under the Paris Agreement. However, the conference revealed that progress has been insufficient across all sectors and governments. Consequently, new plans and initiatives were proposed to accelerate efforts to meet the targets established for 2030 [4].

Driven by the results and policies released by the UNCC, studies have focused on finding and calculating the impacts of the sectors responsible for the worsening climate situation all over the world and to determine actual trends in the research community to find viable solutions and paths to meet the emission targets from international organizations. To mention some of the research conducted under this phenomena, CO2 emissions derived from fossil fuel combustion for the transportation sector have been reviewed and analyzed to find current patterns and to provide crucial insights about emission causes from the top seven carbon emitter economies: the United States, China, India, Canada, Russia, and Brazil [5]. Likewise, the drivers of CO2 emissions inside the industrial sector have been investigated through the utilization of a decomposition analysis to evaluate the existing relationship between economic and industrial expansion and CO2 emissions in European Union countries; the study concluded that a viable solution to develop a completely sustainable industrial development has not been found yet [6]. Innumerable studies have been conducted providing key information about the global situation; hence, developing a bibliometric review is indispensable to accurately discern what are the most important sectors to analyze, as doing so will underline the key aspects of this problem for current and future research.

The proposed study aims to provide valuable information by generating an overview of the main sectors responsible for aggravating the climate change problem, through the generation of a bibliometric literature review. For this, 196 papers were selected according to their impact and relevance registered in scientific databases. In this way, timely analyses were performed to encounter trends and key insights from the problematic under review. Thus, the overall goals of this study are the following:

- To effectively discern the actual research areas of main interest for the scientific community based on their impact and contributions to climate change.

- To point out the main consequences of each sector that plays a crucial role in the phenomena of climate change.

- To generate an understanding of the relevance of available research, authors, and analyses conducted based on bibliometric measurements.

The outputs of the proposed study may be considered relevant information for the scientific community to focus efforts on research areas with revealed gaps needing complementary analysis. Some of the contributions of this research are as follows:

- The gaps in research areas are identified and highlighted based on the contributions from studies published in these fields.

- The crucial sectors impacting climate change are pointed out based on efforts made from the scientific community reflected in published articles.

The remainder of this paper is organized as follows. The methodology followed in this study is presented in Section 2. The subsequent section outlines the results derived from the development of different approaches based on the data gathered for analysis. Finally, in Section 4, the conclusions, limitations, and future research directions are highlighted.

2. Methodology

2.1. Data Collection

To conduct this study, research was mainly sourced from the Web of Science in July 2024. This database is known for its extensive collection of high-impact studies. As of 2024, the Web of Science indexes approximately 35,000 journals and books [7]. While several databases, including Google Scholar, Crossref, and DataCite, offer valuable data with various strengths and weaknesses in information management and presentation since the early 1990s, recent comprehensive analyses indicate that the Web of Science and Scopus have demonstrated superior performance compared to these alternatives [8].

To ensure the relevance and currency of the data, initial search filters were applied using keywords such as “CO2 emissions”, “industries”, “climate change”, and “embodied carbon emissions”. Climate change policies and regulations have consistently been informed by the findings from the United Nations Climate Change Conferences. The 2015 Paris Agreement, in particular, marked a major milestone, providing a framework that significantly shifted the research community’s focus and objectives.

Given the transformative impact of the Paris Agreement, this research was refined to include studies published between 2013 and 2024, allowing for the retention of only the most current and significant information related to climate change. This filtering process reduced the initial pool of 2220 articles to approximately 1000 studies.

Recognizing that this issue spans multiple disciplines and requires diverse expertise, the filters were not restricted to any specific area of engineering. To focus on the most influential research, an additional filter based on citation count was implemented, establishing a threshold (λ) of 50 citations. This criterion allowed for a concentration on studies that have received significant attention within the research community.

As a result, only recent studies that have made substantial contributions to understanding CO2 proliferation in the atmosphere, specifically those exceeding the established citation threshold (λ), were included. Thus, from the 1000 studies filtered based on the year of publication, only 196 studies were included for the final bibliometric analysis. Specifics on the search method and strategy followed are presented in the following section.

2.2. Research Method

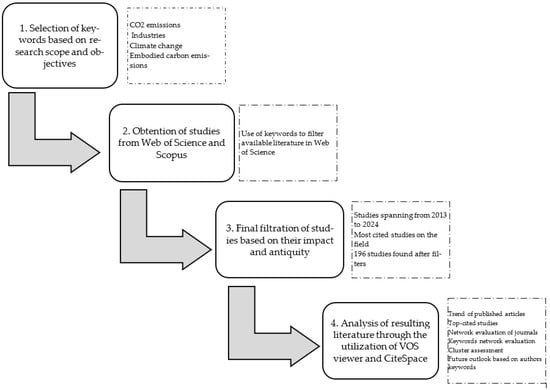

This study aims to recompile, analyze, and obtain conclusions from the most relevant literature aligned with the problematic that is under review based on a structured and objective-oriented process. In this case, finding relevant information through a bibliometric analysis about the role that manufacturing industries represent for the global climate situation will help stakeholders and decision-makers in the following ways: to synthetize hundreds of studies into the most representative keywords and trends, to find research gaps that need to be assessed, and to discover which manufacturing areas represent the biggest concern for the research community given the amount of studies conducted. In this study, the examination of the literature is conducted by the utilization of VOS Viewer version 1.6.20 and CiteSpace version 6.4.R1 software. The process followed can be recapitulated into the following 4 steps:

- Selection of keywords and their combinations based on the research scope

- Initial data filtration and obtention of studies from the Web of Science

- Final filtration of studies based on their impact and date of publication

- Assessment of filtered literature

Figure 1 depicts the process followed in this research. Although a wide diversity of analyses can be derived from the literature filtered, one of the main scopes of this contribution is to discover the trends and main contributors to climate change. Thus, the assessment of the information is going to be centered on analyzing the main industrial sectors and their impacts on the problematic.

Figure 1.

Framework for bibliometric analysis.

3. Results and Discussion

3.1. Studies’ Distribution and Trends

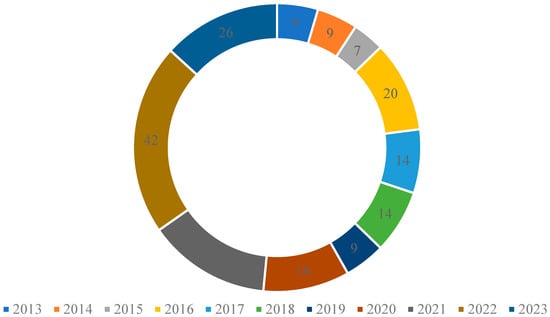

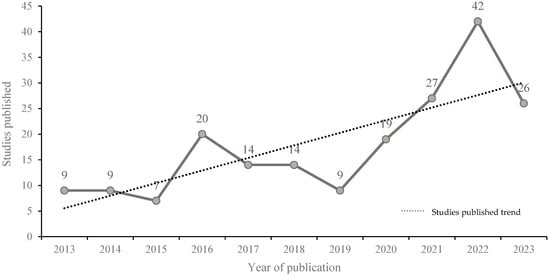

Interest in evaluating CO2 emissions from manufacturing industries has increased among the scientific community in recent years; evidence of this is the increment of studies published per year. As demonstrated in Figure 2, 2022 has been the year with the greatest number of articles published (42) within this research field. Furthermore, according to the distribution displayed, it can be observed that there has been a remarkable augmentation of available research since 2016, when the number of published articles more than doubled in comparison with the previous year (from 7 to 20). In the same way, Figure 3 displays a graphical trend of the number of documents published per year. The trend is clear as 58.16% of all documents have been published from 2020 to 2023. The behavior of this graph may be related to two main factors. First, the summary of the goals set by international organizations is as follows: the cut of CO2 emissions by 2030 and the completion of net-zero emission targets by 2050; the development of the carbon credits market; and the awareness of the increasing frequency of extreme weather events affecting civilizations worldwide. As new technologies and programs aimed at addressing these issues are introduced more frequently, researchers will have more opportunities to draw significant conclusions on the topic. The second key factor driving this remarkable growth is the ongoing evolution in the administration, display, and publication of information by databases. Specifically, the way abstract keywords and information are handled in the Web of Science Core Collection has significantly improved since the early 2000s. This advancement directly influences how data are measured and analyzed over time [9].

Figure 2.

Studies published per year.

Figure 3.

Graphical trend of studies published per year.

3.2. Network Evaluation of Journals

Developing a network analysis of journals allows us to obtain relevant information for future research and studies. This evaluation permits us to discover which journals have represented the most important source of information on the problematic under review. Three key metrics are considered to determine the order: (1) the number of studies published, (2) the number of citations, and (3) the total link strength. The first metric refers to the total number of documents (meeting the filters previously selected) that have been published by the journal assessed. The second metric indicates the total number of citations identified from studies published in the journal. The last metric denotes the correlation between journals by comparing the number of studies cited between them. In this case, with the objective of only considering the most representative journals recovered from the Web of Science, the threshold has been established to be 350 citations. Table 1 demonstrates the results obtained. An important gap is observed between the top three journals and the remaining ones in terms of the contributions generated. Furthermore, the relevance of the Journal of Cleaner Production is pointed out as there exists a difference of almost 300% on the number of studies published with respect to Applied Energy. It is important to note that this table does not account for the impact and novelty of each study published by the journals. These factors are crucial for determining which journals are the most reliable sources for obtaining qualitative information on the current status of CO2 emissions and potential solutions.

Table 1.

Journal ranking and evaluation.

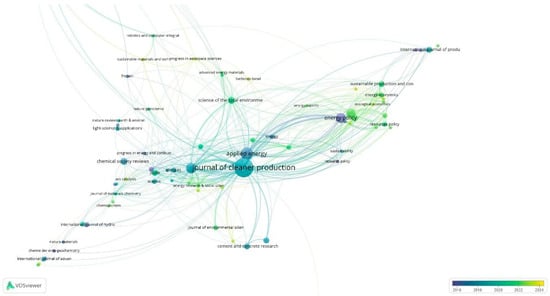

Additionally, Figure 4 depicts an insight into cross-citations between journals, derived from the metric of link strength previously presented. It is clearly demonstrated that across the years, the Journal of Cleaner Production has represented one of the backbones of the analysis of Carbon Dioxide Emissions from manufacturing industries as many additional articles have been derived from this journal.

Figure 4.

Cross-citation map from the most relevant journals.

3.3. Analysis of Influential Studies

The bibliometric analysis conducted included a further evaluation of the most relevant studies. The selected influential research was chosen based on citation count and publication year. Only recent studies with substantial contributions to understanding CO2 proliferation in the atmosphere were included. Considering the brief description and group of keywords denoted in Table 2, it is possible to deduct that studies calling for the attention of the research community fell into two main clusters: the first one comprises those studies seeking to find alternatives for industrial processes to become more sustainable; and the second one comprises the studies aiming to generate a reliable prediction of some of the key features regarding the Cement and the Iron and Steel industries. This underscores the critical role these materials have played in society over the past few decades. As economies continue to grow, these sectors are expected to maintain their significant relevance. It is important to recognize that, beyond energy production, industries such as iron and steel (I&S) and cement manufacturing are crucial to CO2 emissions and atmospheric concentration due to their high energy intensity. Consequently, research aimed at understanding their current status and future behavior has become increasingly important over time.

Some of the options analyzed from the first cluster primarily focused on improving the efficiency of current processes by implementing systemic approaches, such as adopting a circular economy in manufacturing sectors. This is particularly relevant as the world transitions to Industry 4.0. A review of the available literature revealed various strategies for fostering a regenerative economy and preserving the natural environment, aiming to prevent increases in CO2 emissions that are proportional to the demands of ever-growing societies and civilizations [10].

Additionally, innovative alternatives were evaluated, including the development and use of more sustainable carbon materials, which seek to make a significant impact on energy industries. These carbon-based structures aim to reduce the energy intensity of construction resources, thereby alleviating pressure on manufacturing sectors like cement and iron and steel. By providing reliable and environmentally friendly alternatives, these innovations could play a crucial role in meeting emissions reduction goals in the near future [11].

Moreover, research has been conducted to explore the potential implementation of emerging technologies, particularly Carbon Capture, Utilization, and Storage (CCUS), as effective solutions for reducing emissions in hard-to-abate industries. In many cases, lowering the carbon intensity in materials is either not feasible or prohibitively expensive. These studies primarily focus on the implications of adopting such technologies within the manufacturing and energy sectors, highlighting the need for increased government involvement. Policymakers must create incentives and regulations that facilitate the transition of these innovative technologies into economically viable solutions [12].

Table 2.

Studies with the greatest influence on the CO2 emissions research area.

Table 2.

Studies with the greatest influence on the CO2 emissions research area.

| Reference | Country | Description/Objective | Keywords | Sector |

|---|---|---|---|---|

| [13] | Indonesia | Generate forecasts in Cement Manufacturing Industry through the utilization of the ANN, ARIMA, and MA models. | Time series forecasting, Artificial neural network, Arima, Demand, Supply chain | Cement industry |

| [14] | Indonesia | Forecast cement demand through the employment of the ANN model. | Artificial Neural Network (ANN), Determinant of cement demand, MSE, Cement industry, Predicting, Forecasting, Linear–Nonlinear, Time series | Cement industry |

| [11] | Global | Investigate possible paths to create more sustainable variants of classic carbon materials. The applications of this research are focused on the energy and chemical industries. | Sustainable, Energy, Manufacturing, Carbon materials, Industry | Energy industries |

| [15] | Global | Predict power load in iron and steel enterprise employing PSO, DDSFF, SDDS, BPNN, and SVM methods. | Data-driven subspace, Particle swarm optimization, Power load prediction | Iron and Steel industry |

| [10] | Global | Analyze the impacts of developing a circular economy around manufacturing industries. Benefits and limitations of such models are evaluated to find practical implementation strategies. | Circular economy, Framework implementation, Resource scarcity, Environmental impact, Economic benefits | General manufacturing industries |

| [16] | Global | Generate projections of energy use and CO2 emissions from the global steel and cement industries by using linear regression and nonlinear models. | Cement, Iron and Steel, Energy and Emissions, Scenarios | Cement industry |

| [17] | India | Forecast energy consumption and GHG emission for a pig iron manufacturing organization in India through the utilization of the ARIMA model. | Environmentally conscious manufacturing, Programs, ARIMA, Forecasting, Energy consumption, GHG emission, Pig iron manufacturing | Iron and Steel industry |

| [18] | Global | Forecast cement demand based on AR, ARMA, Holt Method and Holt–Winters’ models. | Simulation, Supply chain, Demand, Forecasting, Cement industry, Efficiency | Cement industry |

| [19] | China | Generate a prediction of three major industries and residential consumption CO2 emissions in China through the utilization of LSSVM, BPNN, and GM. | CO2 emissions forecasting, Least squares support vector machine, Granger causality test, Classification and prediction, Three major industries, Residential consumption | Cement industry |

| [20] | China | Forecast Chinese steel production from 2010 to 2030 employing the IPAT method. | Modified IPAT model, Steel production, Steel scrap, Scrap ratio | Iron and Steel industry |

| [21] | United Kingdom | Evaluate the impact of tribology on the main sectors that produce CO2 emissions: transportation, manufacturing, power generation, and residential. | Friction, Wear, Energy saving, Emission reduction | Energy industries |

| [22] | Thailand | Forecast GHG emission in the manufacturing sectors of Thailand with the ARIMAX model. | Manufacturing sectors, Environmental cost, Energy consumption, GHG emission, Multiplier | Iron and Steel industry |

| [23] | Global | Explore alternatives to reduce CO2 emissions produced through the generation of electricity and materials such as cement and iron and steel. Some sources of energy are investigated and evaluated. Furthermore, options to increase production efficiency are discussed. | Energy, CO2 emissions, Innovation, Electricity, Industrial processes, Steel, Cement, Manufacturing | Energy industries |

| [24] | China | Predict energy-related carbon emissions from the cement industry using BP Neural Network and Particle Swarm Optimization models. | Carbon emissions peak, Cement industry, Scenario analysis, Back propagation neural network, Particle swarm optimization, The second generation of new dry cement technology systems | Cement industry |

| [25] | China | Forecast CO2 emissions in Hebei, China, based on the PSO and ELM methods. | Carbon dioxide emissions prediction, Extreme Learning machine, Moth–flame optimization, Random forest | Iron and Steel industry |

| [26] | Turkey | Forecast domestic shipping demand of cement based on the SARIMAX, ANN, and hybrid SARIMAX–ANN models. | Seasonal Autoregressive Integrated Moving Average with exogenous variable (SARIMAX), Hybrid model, Artificial Neural Network, Domestic shipping | Cement industry |

| [27] | Iran | Predict Iran’s CO2 emissions in 2030 with the MLR and MPR models. | Regression, Paris agreement, CO2 emission, Energy, Scenario | Iron and Steel industry |

| [28] | Global | Investigate the alternatives to increase sustainability on daily industrial operations that are going to be generated by industry 4.0. | Industry 4.0, Smart manufacturing, Digitization, Sustainability, Environmentalism, Industrial internet | General manufacturing industries |

| [29] | China | Forecast CO2 emissions of the cement industry through the utilization of the hybrid Verhulst–GM model. | CO2 emission, Cement industry, Emissions’ technical conversion, China, Grey forecasting model, Uncertainty | Cement industry |

| [30] | China | Study the relationship between carbon emissions and the economic growth of China’s iron and steel (IS) industry employing the Grey Verhulst model. | Carbon emissions, China’s Iron and Steel industry, Tapio decoupling model, Grey Verhulst model | Iron and Steel industry |

| [31] | China | Forecast carbon emission with Fast Learning Network, Extreme Learning Machine, and Chicken Swarm Optimization models. | Carbon emission peaking, Carbon neutrality, Chicken Swarm Optimization (CSO), Fast Learning Network (FLN), Scenario analysis | Cement industry |

| [32] | Bangladesh | Find the relationship of CO2 emissions, gross domestic products, and energy usages based on Convolution Neural Network, Convolution Neural Network long short-term memory, Dense Neural Network, and Long-Short term Memory models. | CO2 emissions, Forecasting, Deep learning, FMOLS, CNN-LSTM | Cement industry |

| [33] | India | Predict India’s CO2 emissions for the next 10 years based on univariate time-series data from 1980 to 2019 using ARIMA, SARIMAX, LSTM, and Holt–Winters methods. | Time-series forecasting, Linear Regression, Random forest regressor, Air pollution, CO2 emissions, Holt–Winters, LSTM | Iron and Steel industry |

| [34] | China | Project the carbon emission reduction pathways of China’s iron and steel industry during 2020–2050 based on the ELM and BA models. | Iron and steel industry, China, Driving factors, Emissions reduction pathway, Carbon neutrality, Extreme learning machine | Iron and Steel industry |

| [35] | Global | Predict total CO2 emissions for the future according to the SARIMAX model. | Artificial Intelligence, Machine learning, CO2 emission, Global warming, Atmosphere monitoring, Atmosphere maintenance | Cement industry |

| [12] | Global | Find the policy framework as well as stakeholder perceptions of CCUS as indicators for societal support. | Social acceptance, Stakeholder perceptions, Regional development, Carbon capture, utilization, and storage, Policy framework | Manufacturing industries |

| [36] | Portugal | Forecast CO2 emissions from fossil fuel combustion and cement production with the ARFIMA model. | CO2 emissions, IPCC emission Targets, Long memory, ARFIMA, Portugal | Cement industry |

| [37] | Poland | Develop a short-term forecast of steel production to determine the heat and energy consumption of the Polish steel industry up to 2025 with the Simple Moving Average approach. | Industry 4.0, Steel industry, Electricity, Heat, Steel production, Electric Arc Furnace, Basic Oxygen Furnace | Iron and Steel industry |

| [38] | China | Estimate carbon emissions based on electricity data in cement production implementing Linear Regression, Polynomial Regression, Artificial Neural Network, Least Absolute Shrinkage and Selection Operator Regression, Ridge Regression, and K-nearest Neighbor Classification models. | Carbon–electricity coupling, Carbon emissions, Cement industry | Cement industry |

| [39] | China | Predict the carbon emissions of cement enterprises in Hubei Province based on the WOA and BPNN models. | Carbon emissions, Whale optimization algorithm, BP neural network, cement industry | Cement industry |

Studies in the second group have conducted analyses to predict energy consumption and CO2 emissions from the most important contributors such as India, the United States, and China. The available literature has focused on finding reliable predicting models [17,33]. Most of the recent research has focused on calculating current and future CO2 concentrations in the atmosphere from the most concerning countries due to their potential to release hazardous pollutants. Among the studies scrutinized, the most commonly used machine learning algorithms to predict future values are the Grey Verhulst model and the PSO, ELM, and BA models to forecast carbon emissions from Iron and Steel industries, considering the dependency existing with exogenous conditions such as the impact generated by industrialization and urbanization [24,30,34]. Additionally, recent research has employed machine learning algorithms such as SARIMAX to develop models capable of forecasting CO2 emissions from cement industries [35]. Similarly, predictions for relevant regions have been conducted through the utilization of algorithms such as BPNN and linear regression models to estimate emissions from cement industries in countries like China and India [38,39].

Based on the studies reviewed, it is clear that most efforts have focused on assessing the status and contributions of Eastern countries, primarily due to their significant emissions over the past decade. These countries have experienced exponential growth in their emissions, with China’s total CO2 emissions in 2020 exceeding those of all advanced economies combined. Similarly, India became the third-largest emitter of global emissions in 2023, surpassing the European Union [40].

However, it is crucial not to overlook the significant role played by countries in the Americas. Major contributors such as the United States and Canada are substantial sources of greenhouse gas emissions, as highlighted by the Intergovernmental Panel on Climate Change (IPCC). For example, in the cement industry, the United States and Canada rank among the top ten global emitters, with emissions totaling 6001 MtCO2 and 736 MtCO2, respectively. They are also among the leading CO2 producers from emissions associated with the iron and steel sector [41]. This underscores the need to enhance efforts through comprehensive approaches that consider emissions from all regions, including North America.

While the papers analyzed in Table 2 were selected for their impact and contributions, it is crucial to recognize that climate change encompasses a wide range of scientific disciplines, each of which warrants its own thorough and detailed analysis.

3.4. Keywords Network Evaluation

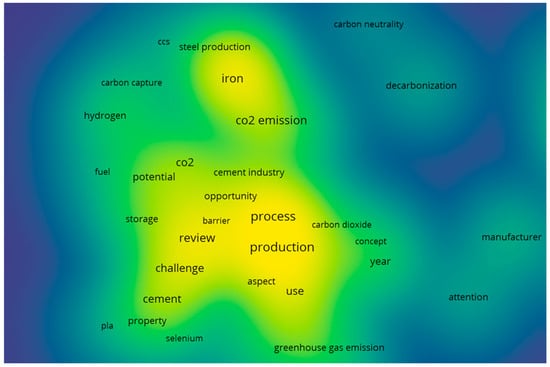

The co-occurrence of keywords is probably the insight that provides the most valuable information from the bibliometric analysis conducted. This evaluation reveals what aspects and areas have been commonly reviewed inside the research community. Therefore, conclusions regarding the most concerning areas for international organizations as well as gaps existing in the available literature may be obtained. Additionally, research trends can be deducted as an output from this assessment. Table 3 depicts the most frequently utilized keywords in CO2 emissions studies. Furthermore, Figure 5 displays a graphical representation of the most employed terms through density mapping.

Table 3.

The most employed keywords in the CO2 emissions research area.

Figure 5.

Density visualization of keyword utilization in the CO2 emissions research area.

To generate a sharper focus on most important keywords inside the area of interest, a threshold of eight was chosen for the number of occurrences in the studies reviewed. The most employed keywords are CO2 Emissions, Impact, Performance, Efficiency, Industry, China, Economic Growth, Carbon Emissions, Reduction, Consumption, Emissions, Energy Efficiency, Growth, Sustainability, Energy, Energy Consumption, Iron and Steel Industry, Life-Cycle Assessment, Additive Manufacturing, Cement Industry, and Technologies. From this group of terms, initial discussions can be formulated. Clearly, the energy sector represents the area of greatest concern due to emissions associated with its daily operations and requirements. Likewise, the next two industries under focus are the Iron and Steel and the Cement industries as demonstrated in Figure 5; a deeper analysis of these manufacturing sectors should be conducted considering the vitality of these materials in constantly growing civilizations. Additionally, it must be pointed out that the greatest research efforts are concentrated on China due to the aforementioned exponential growth in Carbon Dioxide emissions from Chinese manufacturing industries.

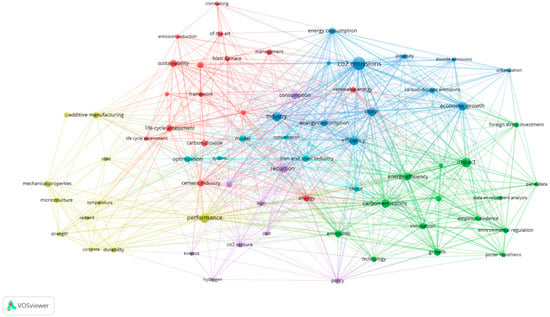

Accordingly, based on the nature of the keywords used by the authors, VOS Viewer has cataloged these terms into four main clusters. Table 4 synthesizes the groups of keywords as well as their nature and research focus. The logical relationship existing between all the groups created must be highlighted; a visual representation of the links existing is depicted in Figure 6. The interdependency existing between the terms demonstrates a cause–effect relationship between them, which leads to a further analysis of a diversity of areas, such as, for example, the following: how manufacturing industries are contributing to the emissions of Carbon Dioxide, what are the main challenges that these industries are going to face to meet emission reduction targets, what will be the roles that new technologies such as Carbon Capture will play, what is the actual trend in emissions coming from the manufacturing industries, and what can be expected for upcoming years, among others. Furthermore, some gaps can be recompiled based on the clusters obtained from the analysis conducted. Despite considering the keywords regarding emissions from the Cement and the Iron and Steel industries, the only country that is commonly mentioned in the literature examined is China, revealing the necessity of expanding such an analysis to other countries that also are key players in solving the climate change situation.

Table 4.

Four groups of authors keywords.

Figure 6.

Network relation analysis from clusters of authors’ keywords.

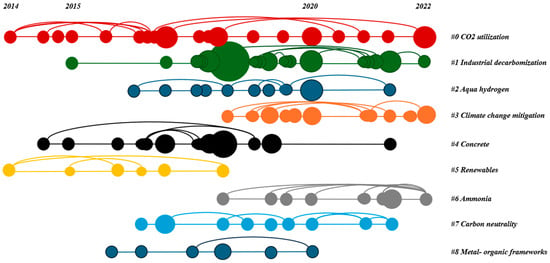

3.5. Future Outlook Based on Authors’ Keywords

This is example 1 of how a utilization of keywords is a crucial insight that reveals the main contributions and objectives from a study. Hence, analyzing how the employment of concepts and terms have varied across the years is indispensable to understanding current and future research directions. To find out what will be some of the main points of discussion inside the field of Carbon Dioxide emissions produced by manufacturing industries, CiteSpace was utilized to complement the analysis obtained in the previous sections by means of VOS Viewer. Similarly, this software generates several groups of keywords based on their nature and how they are employed in every study. In this case, nine different clusters were automatically generated and constituted as follows:

- Group 0, CO2 utilization: carbon capture, partial oxy-combustion, carbon dioxide, oxygen-based conversion, direct air capture, Co2 capture, Co2 sequestration, process intensification, carbon dioxide biofixation.

- Group 1, Industrial decarbonization: carbon dioxide removal, sustainable biomass, ship carbon emission reduction, fossil fuel.

- Group 2, Aqua hydrogen: life-cycle analysis, deep decarbonization, greenhouse gas, cost analysis, steel industry, aqua hydrogen, green hydrogen.

- Group 3, Climate change mitigation: carbon capture, industrial decarbonization, climate policy, carbon capture utilization, gas separation.

- Group 4, Concrete: life-cycle analysis, deep decarbonization, greenhouse gas, energy consumption, cost analysis.

- Group 5, Renewables: fossil fuels, renewables, Co2 mitigation, energy demand.

- Group 6, Ammonia: nitrogen fertilizers, net-zero emissions, food security, climate solutions, energy–food nexus.

- Group 7, Carbon neutrality: industrial decarbonization, sociotechnical system, energy policy, climate mitigation, climate change.

- Group 8, Metal–organic frameworks: geothermal energy, energy storage, pre-combustion, oxyfuel combustion, post-combustion.

It should be noted that the clusters obtained through this software are similar to the groups discussed in the previous sections, where concepts and definitions of new technologies oriented toward the reduction of emissions act as one of the backbones of the current studies’ objectives. Furthermore, Figure 7 corroborates the link existing between groups of keywords, validating the interrelationships previously discussed.

Figure 7.

Usage of keyword groups over time, categorized by concept type.

The frequency of the employment of keywords is represented by the size of the node depicted in the figure; this means that the dimensions of every node are proportional to the utilization of any of the keywords allocated in the cluster. Furthermore, all these nodes are arranged chronologically, from 2014 to 2022, to illustrate how the usage of the group of words has evolved over the years. Thus, considering the size of the circles located in the right part of the graph (between 2020 and 2022), it is possible to deduce that groups 0, 1, 3, and 6 represent the current and future main points of interest for the research community. In addition to the commonly expected concepts such as climate change mitigation or industrial decarbonization, the presence of terms related to Carbon Capture, Utilization, and Storage (CCUS), such as CO2 utilization and ammonia, should be noted. Such information is vital to highlight the relevance that new studies and investigations related to the employment of this technology in manufacturing industries such as the Cement and the Iron and Steel industries will have for the near future. This reflects recent technological advancements by the research community, where capturing and utilizing Carbon Dioxide has emerged as a highly viable strategy to combat climate change and move closer to achieving international emission targets.

4. Conclusions

Bibliometric analysis is a powerful alternative for the obtention of valuable data. It does not only help to initiate new research on gaps found in the available literature, but also to identify significant contributions such as the trends and key points found. The assessment conducted in this work focused on studies regarding the problematic of Carbon Dioxide emissions from manufacturing industries around the world and its consequences on the environment. Accordingly, to obtain key insights, the literature trends, contributions from journals, authors’ keywords, and most significant studies in the field were evaluated. To accomplish this, some filters were applied to the data initially recompiled. We only considered studies spanning the last ten years (from 2013 to 2024). Thus, just 196 publications from 2220 available on the Web of Science database were employed for data analysis. This study addresses gaps identified in previous research by utilizing complementary approaches applied to the same dataset. While valuable insights were gained, including trends and recent significant contributions in the field of CO2 emissions and climate change, the study also highlights existing research gaps and identifies missing information. These findings aim to enhance existing studies and contribute significantly to the field.

Results obtained throughout this study reveal that the environmental crisis has caught the attention of international organizations in recent years, as shown by the remarkable growth in published studies since 2016. Furthermore, most cited publications demonstrate interrelationships as they focused on finding new paths to generate more sustainable processes in every manufacturing industry, adapting simultaneously to civilizations’ demands that are moving towards Industry 4.0. Amongst 196 studies considered, almost 20% of them were published in the Journal of Cleaner Production and in Applied Energy, revealing an important difference in contributions generated with respect to the remaining journals. Likewise, the clusters of words gathered demonstrate a cause–effect relationship. Groups 1 and 3 represent the main sources of Carbon Dioxide emissions and some of the key aspects of the worsening climate situation; on the other hand, groups 2 and 4 mainly list alternatives to smoothly reduce the impacts of this pollutant on the atmosphere and some other potential solutions that can be adopted by industries in upcoming years. Additionally, the analysis reveals that a significant portion of the research has concentrated on Eastern countries, particularly on China and India. This focus may partly stem from the initial selection criteria used for the literature review, which could introduce some bias. Nevertheless, this observation underscores the need to broaden the research scope to include other major contributors of CO2 emissions, such as the United States. Section 3.4 supports this, showing that China is frequently mentioned in recent studies, highlighting the necessity of exploring the current and future state of CO2 emissions and the development of new solutions and technologies in other key countries. Once again, although this may be due to the filters used in data collection, it should serve as a call to continue exploring the status, potential contributions, and solutions from Western countries.

It is important to acknowledge that this study has certain limitations. Firstly, some of the keywords considered for data filtering were selected according to the interest of this study; however, if these inputs are changed, some of the results might vary. Secondly, with the objective of analyzing just state-of-the-art information, the number of publications analyzed were limited to the last decade; however, if a larger sample is considered, trends on publications may slightly change. Similarly, the databases used as a basis for the obtention of information (Web of Science and Scopus) present some limitations: (1)—The search functions are inflexible as they present some complications in handling complex queries. (2)—The results highly vary depending on the search terms and filters utilized, which leads to potentially missing important and valuable information. For further research, the results obtained in this work can be employed to conduct complementary studies on the gaps encountered. In the same way, additional contributions can be made in research areas that have received special attention in recent years. Specifically, as previously revealed, manufacturing sectors are of special interest to the research community due to their impact on climate change and because of the undeniable necessity of the goods obtained through their processes. Furthermore, the examination of new technologies oriented to the reduction of emissions and the requirements involved in their implementation in every industry will represent some of the main discussions for upcoming years.

Author Contributions

Conceptualization, Á.F.G.R. and G.K.; methodology, Á.F.G.R. and G.K.; software, Á.F.G.R.; validation, Á.F.G.R. and G.K.; formal analysis, Á.F.G.R.; investigation, Á.F.G.R.; resources, G.K.; data curation, Á.F.G.R.; writing—original draft preparation, Á.F.G.R.; writing—review and editing, G.K.; visualization, Á.F.G.R. and G.K.; supervision, G.K.; project administration, G.K.; funding acquisition, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

The second author acknowledges the financial support through President’s Research Seed Grant of the University of Regina.

Data Availability Statement

Data will be made available upon request.

Acknowledgments

The authors acknowledge the financial support through the Mitacs Fellowship program as well as University of Regina and Faculty of Graduate Studies Research funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- United States Environmental Protection Agency. Climate Change Indicators: Greenhouse Gases. 2024. Available online: https://www.epa.gov/climate-indicators/greenhouse-gases (accessed on 4 April 2024).

- Jones, M.; Peters, G.; Gasser, T.; Andrew, R.; Schwingshackl, C.; Gütschow, J.; Houghton, R.; Friedlingstein, P.; Pongratz, J.; Quéré, C. National contributions to climate change due to historical emissions of carbon dioxide, methane, and nitrous oxide since 1850. Sci. Data 2023, 29, 155. [Google Scholar] [CrossRef] [PubMed]

- Cozzi, L.; Chen, O.; Kim, H. The World’s Top 1% of Emitters Produce over 1000 Times More CO2 than the Bottom 1%; International Energy Agency: Paris, France, 2023; Available online: https://www.iea.org/commentaries/the-world-s-top-1-of-emitters-produce-over-1000-times-more-co2-than-the-bottom-1 (accessed on 12 April 2024).

- United Nations Climate Change. COP28 Agreement Signals “Beginning of the End” of the Fossil Fuel Era. 2023. Available online: https://unfccc.int/news/cop28-agreement-signals-beginning-of-the-end-of-the-fossil-fuel-era (accessed on 4 April 2024).

- Solaymani, S. CO2 emissions patterns in 7 top carbon emitter economies: The case of transport sector. Energy 2019, 168, 989–1001. [Google Scholar] [CrossRef]

- Kopidou, D.; Tsakanikas, A.; Diakoulaki, D. Common trends and drivers of CO2 emissions and employment: A decomposition analysis in the industrial sector of selected European Union countries. J. Clean. Prod. 2016, 112, 4159–4172. [Google Scholar] [CrossRef]

- Clarivate. Web of Science Coverage Details. 2024. Available online: https://clarivate.libguides.com/librarianresources/coverage (accessed on 4 July 2024).

- Gerasimov, I.; KC, B.; Mehrabian, A.; Acker, J.; Mcguire, M. Comparison of datasets citation coverage in Google Scholar, Web of Science, Scopus, Crossref, and DataCite. Scientometrics 2023, 129, 3681–3704. [Google Scholar] [CrossRef]

- Liu, F. Retrieval strategy and possible explanations for the abnormal growth of research publications: Re-evaluating a bibliometric analysis of climate change. Scientometrics 2023, 128, 853–859. [Google Scholar] [CrossRef]

- Lieder, M.; Rashid, A. Towards circular economy implementation: A comprehensive review in context of manufacturing industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Titirici, M.; White, R.; Brun, N.; Budarin, V.; Sheng, D.; Del Monte, F.; Clark, J.; MacLahlan, M. Sustainable carbon materials. Chem. Soc. Rev. 2015, 44, 250–290. [Google Scholar] [CrossRef]

- Wesche, J.; Germán, S.; Gonçalves, L.; Jödicke, I.; Lopez, S.; Prades, A.; Preub, S.; Oltra, C.; Dütschke, E. CCUS or no CCUS? Societal support for policy frameworks and stakeholder perceptions in France, Spain, and Poland.ghg greenhouse gases science and technology. Sci. Technol. 2022, 13, 48–66. [Google Scholar] [CrossRef]

- Fradinata, E.; Suthummanon, S.; Sirivongpaisal, N.; Suntiamorntuthq, W. ANN, ARIMA and MA timeseries model for forecasting in cement manufacturing industry: Case study at lafarge cement Indonesia—Aceh. In Proceedings of the 2014 International Conference of Advanced Informatics: Concept, Theory and Application (ICAICTA), Bandung, Indonesia, 20–21 August 2014; pp. 39–44. [Google Scholar]

- Fradinata, E.; Suthummanon, S.; Suntiamorntut, W. Forecasting determinant of cement demand in Indonesia with artificial neural network. J. Asian Sci. Res. 2015, 5, 373. [Google Scholar] [CrossRef]

- Huixin, T.; Jiaxin, Y. A novel improved data-driven subspace algorithm for power load forecasting in iron and steel enterprise. In Proceedings of the 27th Chinese Control and Decision Conference 2015, 2015 CCDC, Qingdao, China, 23–25 May 2015; pp. 6421–6426. [Google Scholar]

- Ruijven, B.; van Vuuren, D.P.; Neelis, M.L.; Saygin, D.; Patel, M.K. Long-term model-based projections of energy use and CO2 emissions from the global steel and cement industries. Resour. Conserv. Recycl. 2016, 112, 15–36. [Google Scholar] [CrossRef]

- Sen, P.; Roy, M.; Pal, P. Application of ARIMA for forecasting energy consumption and GHG emission: A case study of an Indian pig iron manufacturing organization. Energy 2016, 116, 1031–1038. [Google Scholar] [CrossRef]

- Uzzaman, I.; Rahman, M.; Alam, M.S.; Alam, S. Simulation of cement manufacturing process and demand forecasting of cement industry. Glob. J. Res. Eng. G Ind. Eng. 2016, 16, 2. [Google Scholar]

- Wei, S.; Mohan, L. Prediction and analysis of the three major industries and residential consumption CO2 emissions based on least squares support vector machine in China. J. Clean. Prod. 2016, 122, 144–153. [Google Scholar] [CrossRef]

- Xuan, Y.; Yue, Q. Forecast of steel demand and the availability of depreciated steel scrap in China. Resour. Conserv. Recycl. 2016, 109, 1–12. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. Influence of tribology on global energy consumption, costs and emissions. Friction 2017, 5, 263–284. [Google Scholar] [CrossRef]

- Sutthichaimethee, P.; Ariyasajjakorn, D. Forecasting model of GHG emission in manufacturing sectors of Thailand. J. Ecol. Eng. 2017, 18, 18–24. [Google Scholar] [CrossRef][Green Version]

- Davis, S.; Lewis, N.; Shaner, M.; Aggarwal, S.; Arent, D.; Azevedo, I.; Benson, S.; Bradley, T.; Brouwer, J.; Chiang, Y.; et al. Net-Zero Emissions Energy Systems. 2018. Available online: https://www.osti.gov/servlets/purl/1460617 (accessed on 4 April 2024).

- Wei, L.; Shubin, G. Prospective on energy related carbon emissions peak integrating optimized intelligent algorithm with dry process technique application for China’s cement industry. Energy 2018, 165, 33–54. [Google Scholar] [CrossRef]

- Wei, S.; Yuwei, W.; Chongchong, Z. Forecasting CO2 emissions in Hebei, China, through moth-flame optimization based on the random forest and extreme learning machine. Environ. Sci. Pollut. Res. 2018, 25, 28985–28997. [Google Scholar] [CrossRef]

- Fışkın, C.; Güldem, A. Forecasting Domestic Shipping Demand of Cement: Comparison of SARIMAX, ANN and Hybrid SARIMAX-ANN. In Proceedings of the 2019 4th International Conference on Computer Science and Engineering (UBMK), Samsun, Turkey, 11–15 September 2014; pp. 68–72. [Google Scholar] [CrossRef]

- Hosseini, S.; Saifoddin, A.; Shirmohammadi, R.; Aslani, A. Forecasting of CO2 emissions in Iran based on time series and regression analysis. Energy Rep. 2019, 5, 619–631. [Google Scholar] [CrossRef]

- Ghobakhloo, M. Industry 4.0, digitization, and opportunities for sustainability. J. Clean. Prod. 2020, 252, 119869. [Google Scholar] [CrossRef]

- Ofosu-Adarkwa, J.; Xie, N.; Javed, S. Forecasting CO2 emissions of China’s cement industry using a hybrid Verhulst-GM(1,N) model and emissions’ technical conversion. Renew. Sustain. Energy Rev. 2020, 130, 109945. [Google Scholar] [CrossRef]

- Wang, X.; Wei, Y.; Shao, Q. Decomposing the decoupling of CO2 emissions and economic growth in China’s iron and steel industry. Resour. Conserv. Recycl. 2020, 152, 104509. [Google Scholar] [CrossRef]

- Feng, R.; Dinghong, L. Carbon emission forecasting and scenario analysis in Guangdong Province based on optimized Fast Learning Network. J. Clean. Prod. 2021, 317, 128408. [Google Scholar] [CrossRef]

- Faruque, M.; Rabby, M.; Hossain, M.; Islam, M.; Rashid, M.; Muyeen, S. A comparative analysis to forecast carbon dioxide emissions. Energy Rep. 2022, 8, 8046–8060. [Google Scholar] [CrossRef]

- Kumari, S.; Singh, S. Machine learning-based time series models for effective CO2 emission prediction in India. Environ. Sci. Pollut. Res. 2023, 30, 116601–116616. [Google Scholar] [CrossRef]

- Li, W.; Zhang, S.; Lu, C. Research on the driving factors and carbon emission reduction pathways of China’s iron and steel industry under the vision of carbon neutrality. J. Clean. Prod. 2022, 361, 132237. [Google Scholar] [CrossRef]

- Meng, Y.; Noman, H. Predicting CO2 Emission Footprint Using AI through Machine Learning. Atmosphere 2022, 13, 1871. [Google Scholar] [CrossRef]

- Belbute, J.; Pereira, A. Reference forecasts for CO2 emissions from fossil-fuel combustion and cement production in Portugal. Energy Policy 2020, 144, 111642. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W. Electricity and heat demand in steel industry technological processes in Industry 4.0 conditions. Energies 2023, 16, 787. [Google Scholar] [CrossRef]

- Zhou, C.; Xuan, D.; Miao, Y.; Luo, X.; Liu, W.; Zhang, Y. Accounting CO2 Emissions of the Cement Industry: Based on an Electricity–Carbon Coupling Analysis. Energies 2023, 16, 4453. [Google Scholar] [CrossRef]

- Zhu, L.; Li, W.; Ma, L.; Wang, L.; Cai, Y.; Zhu, L.; Chen, W. A Carbon Emission Model in Cement Industry Based on IWOA-BP Neural Network. In Proceedings of the 2022 First International Conference on Cyber-Energy Systems and Intelligent Energy (ICCSIE), Beijing, China, 15–16 October 2023; pp. 1–6. [Google Scholar]

- International Energy Agency. The Changing Landscape of Global Emissions. 2023. Available online: https://www.iea.org/reports/co2-emissions-in-2023/the-changing-landscape-of-global-emissions (accessed on 23 May 2024).

- Ge, M.; Friedrich, J.; Vigna, L. 4 Charts Explain Greenhouse Gas Emissions by Countries and Sectors. 2020. World Resources Institute. Available online: https://www.wri.org/insights/4-charts-explain-greenhouse-gas-emissions-countries-and-sectors (accessed on 4 June 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).