Solar Organic Rankine Cycle (ORC) Systems: A Review of Technologies, Parameters, and Applications

Abstract

1. Introduction

2. Description of the Organic Rankine Cycle

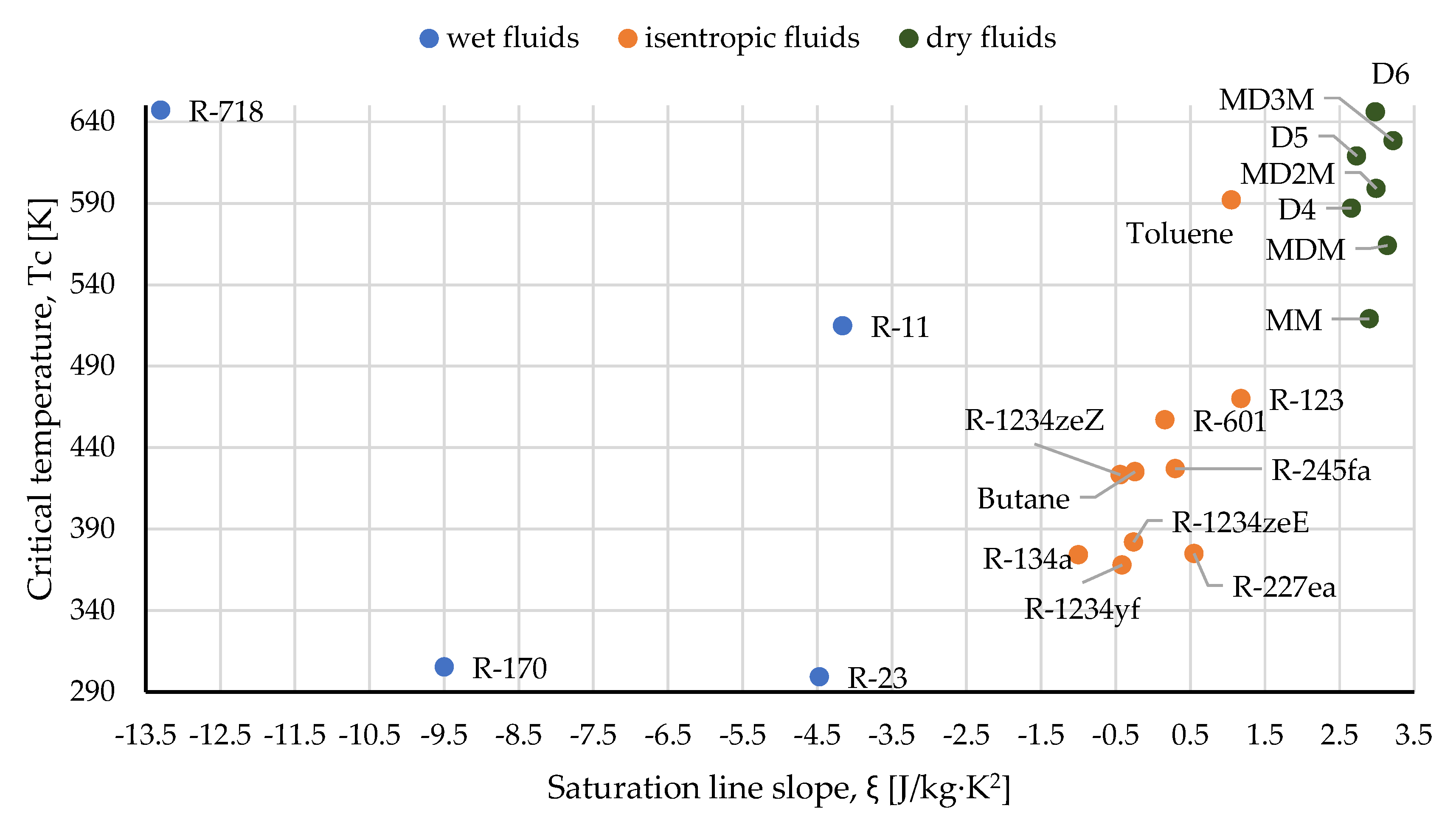

2.1. Working Fluid Selection

2.2. Modeling

- -

- represents the mass flow rate in kg/s,

- -

- h represents the specific enthalpy in kJ/kg.

- -

- TAM is the temperature of the environment,

- -

- TSUN is the temperature of the sun (and is taken as 5800 K in calculations).

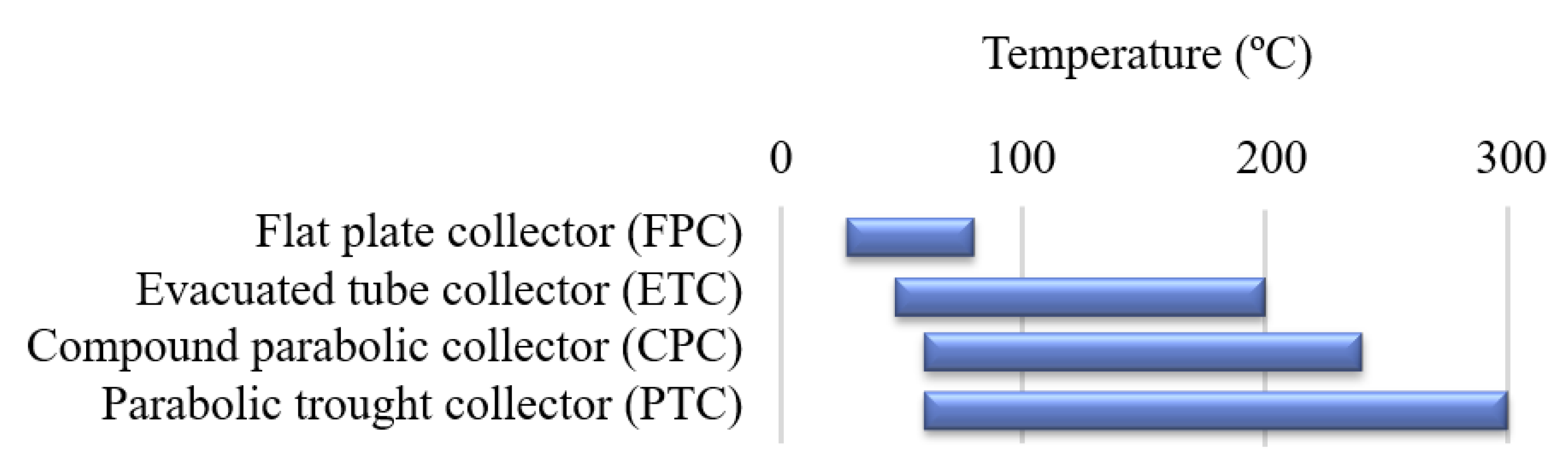

3. Solar Energy as Heat Source and Solar Collector Options for Its Conversion

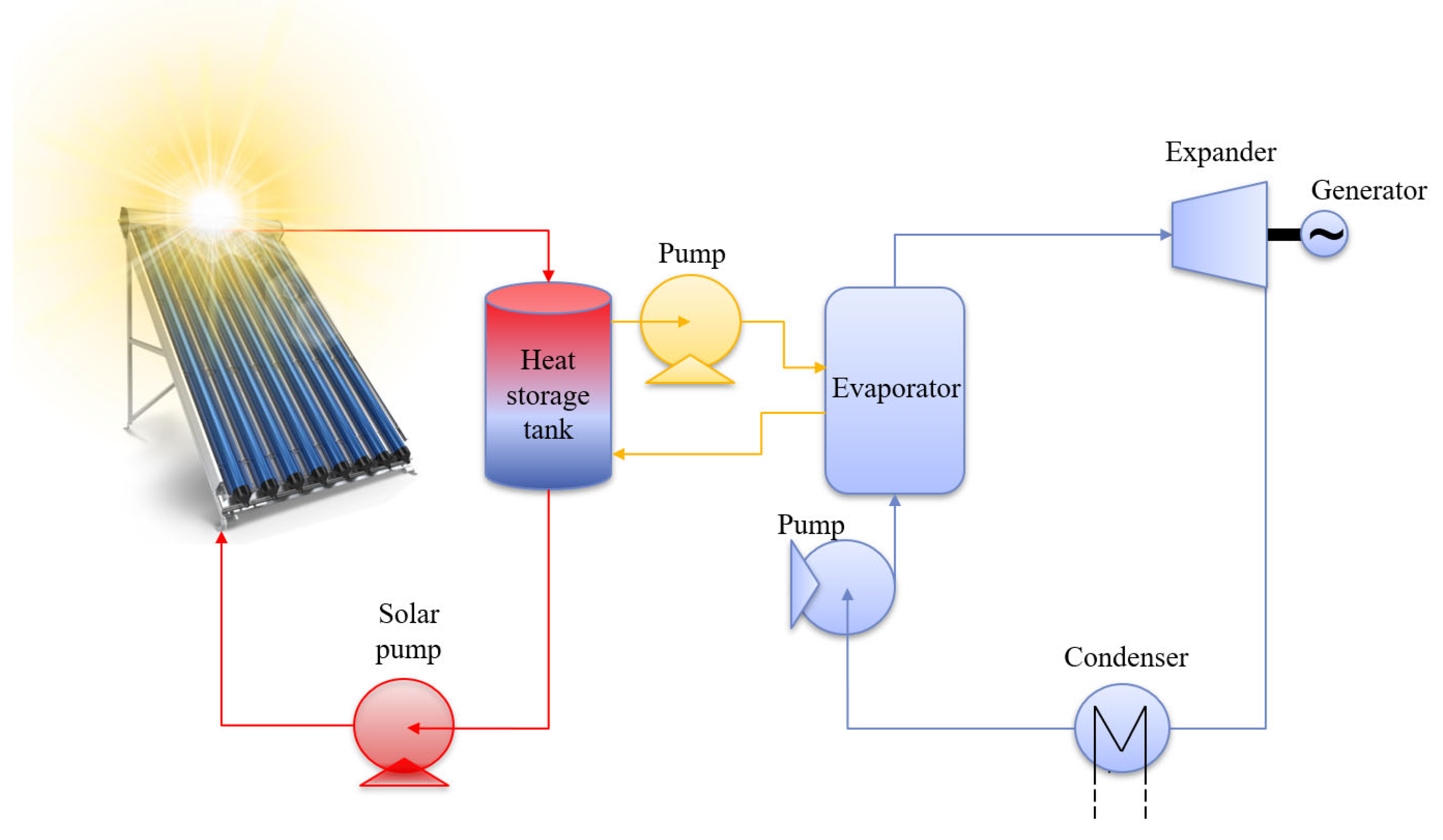

4. Solar-ORC Systems

4.1. Flat Plate Collectors (FPCs)

4.2. Evacuate Tube Collectors (ETCs)

4.3. Compound Parabolic Collectors (CPCs)

4.4. Parabolic Trough Collector (PTCs)

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CPC | compound parabolic collector |

| DVG-ORC | direct vapor generated ORC |

| ETC | evacuated tube collector |

| FPC | flat plate collector |

| HRS | heat recovery system |

| HTF | heat transfer fluid |

| LCOE | levelized cost of electricity |

| LFR | Linear Fresnel Reflectors |

| MDM | octamethyltrisiloxane |

| MM | hexamethyldisiloxane |

| ORC | Organic Rankine Cycle |

| PCM | phase change materials |

| PEC | partial evaporation ORC |

| PSO | particle swarm optimization |

| PTC | parabolic through collector |

| PTC | solar Organic Rankine Cycle |

| SNORC | subcritical nonrecuperative ORC |

| SRORC | subcritical recuperative ORC |

| TES | thermal energy storage |

| TLC | trilateral ORC |

| TNORC | transcritical nonrecuperative ORC |

| TRORC | transcritical recuperative ORC |

| WF | working fluid |

References

- Huang, W.; Zheng, D.; Chen, X.; Shi, L.; Dai, X.; Chen, Y.; Jing, X. Standard Thermodynamic Properties for the Energy Grade Evaluation of Fossil Fuels and Renewable Fuels. Renew. Energy 2020, 147, 2160–2170. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M. Development of Renewable Energy Sources in the Context of Threats Resulting from Low-Altitude Emissions in Rural Areas in Poland: A Review. Energies 2019, 12, 3558. [Google Scholar] [CrossRef]

- Dzikuć, M.; Gorączkowska, J.; Piwowar, A.; Dzikuć, M.; Smoleński, R.; Kułyk, P. The Analysis of the Innovative Potential of the Energy Sector and Low-Carbon Development: A Case Study for Poland. Energy Strategy Rev. 2021, 38, 100769. [Google Scholar] [CrossRef]

- Jullian, S.; Longaygue, X. From Conventional to More Sustainable Fuels: Trends and Needs in Research in the Thermodynamics Area. Fluid. Phase Equilib. 2014, 362, 192–195. [Google Scholar] [CrossRef]

- Ceran, B. The Concept of Use of PV/WT/FC Hybrid Power Generation System for Smoothing the Energy Profile of the Consumer. Energy 2019, 167, 853–865. [Google Scholar] [CrossRef]

- Forman, C.; Muritala, I.K.; Pardemann, R.; Meyer, B. Estimating the Global Waste Heat Potential. Renew. Sustain. Energy Rev. 2016, 57, 1568–1579. [Google Scholar] [CrossRef]

- Rahimi, M.; Straub, A.P.; Zhang, F.; Zhu, X.; Elimelech, M.; Gorski, C.A.; Logan, B.E. Emerging Electrochemical and Membrane-Based Systems to Convert Low-Grade Heat to Electricity. Energy Environ. Sci. 2018, 11, 276–285. [Google Scholar] [CrossRef]

- Shahverdi, K.; Loni, R.; Ghobadian, B.; Gohari, S.; Marofi, S.; Bellos, E. Numerical Optimization Study of Archimedes Screw Turbine (AST): A Case Study. Renew. Energy 2020, 145, 2130–2143. [Google Scholar] [CrossRef]

- Olczak, P.; Olek, M.; Kryzia, D. The Ecological Impact of Using Photothermal and Photovoltaic Installations for DHW Preparation. Energy Policy J. 2020, 23, 65–74. [Google Scholar] [CrossRef]

- Li, Z.; Lu, Y.; Huang, Y.; Qian, G.; Chen, F.; Yu, X.; Roskilly, A. Comparison Study of Trilateral Rankine Cycle, Organic Flash Cycle and Basic Organic Rankine Cycle for Low Grade Heat Recovery. Energy Procedia 2017, 142, 1441–1447. [Google Scholar] [CrossRef]

- Rijpkema, J.; Munch, K.; Andersson, S.B. Thermodynamic Potential of Twelve Working Fluids in Rankine and Flash Cycles for Waste Heat Recovery in Heavy Duty Diesel Engines. Energy 2018, 160, 996–1007. [Google Scholar] [CrossRef]

- Matuszewska, D.; Kuta, M.; Górski, J. The Environmental Impact of Renewable Energy Technologies Shown in Case of ORC-Based Geothermal Power Plant. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012142. [Google Scholar] [CrossRef]

- Iqbal, M.A.; Rana, S.; Ahmadi, M.; Date, A.; Akbarzadeh, A. Experimental Study on the Prospect of Low-Temperature Heat to Power Generation Using Trilateral Flash Cycle (TFC). Appl. Therm. Eng. 2020, 172, 115139. [Google Scholar] [CrossRef]

- Demirkaya, G.; Padilla, R.V.; Fontalvo, A.; Lake, M.; Lim, Y.Y. Thermal and Exergetic Analysis of the Goswami Cycle Integrated with Mid-Grade Heat Sources. Entropy 2017, 19, 416. [Google Scholar] [CrossRef]

- Demirkaya, G.; Padilla, R.V.; Fontalvo, A.; Bula, A.; Goswami, D.Y. Experimental and Theoretical Analysis of the Goswami Cycle Operating at Low Temperature Heat Sources. J. Energy Resour. Technol. 2018, 140, 072005. [Google Scholar] [CrossRef]

- Modi, A.; Kærn, M.R.; Andreasen, J.G.; Haglind, F. Thermoeconomic Optimization of a Kalina Cycle for a Central Receiver Concentrating Solar Power Plant. Energy Convers. Manag. 2016, 115, 276–287. [Google Scholar] [CrossRef]

- Masrur Hossain, M.; Afnan Ahmed, N.; Abid Shahriyar, M.; Monjurul Ehsan, M.; Riaz, F.; Salehin, S.; Awais Salman, C. Analysis and Optimization of a Modified Kalina Cycle System for Low-Grade Heat Utilization. Energy Convers. Manag. X 2021, 12, 100121. [Google Scholar] [CrossRef]

- Manente, G. High Performance Integrated Solar Combined Cycles with Minimum Modifications to the Combined Cycle Power Plant Design. Energy Convers. Manag. 2016, 111, 186–197. [Google Scholar] [CrossRef]

- Zaversky, F.; Les, I.; Sorbet, P.; Sánchez, M.; Valentin, B.; Brau, J.-F.; Siros, F. The Challenge of Solar Powered Combined Cycles—Providing Dispatchability and Increasing Efficiency by Integrating the Open Volumetric Air Receiver Technology. Energy 2020, 194, 116796. [Google Scholar] [CrossRef]

- Ortiz, C.; Chacartegui, R.; Valverde, J.M.; Carro, A.; Tejada, C.; Valverde, J. Increasing the Solar Share in Combined Cycles through Thermochemical Energy Storage. Energy Convers. Manag. 2021, 229, 113730. [Google Scholar] [CrossRef]

- Matuszewska, D.; Olczak, P. Evaluation of Using Gas Turbine to Increase Efficiency of the Organic Rankine Cycle (ORC). Energies 2020, 13, 1499. [Google Scholar] [CrossRef]

- Yuksel, Y.E.; Ozturk, M.; Dincer, I. Thermodynamic Performance Assessment of a Novel Environmentally-Benign Solar Energy Based Integrated System. Energy Convers. Manag. 2016, 119, 109–120. [Google Scholar] [CrossRef]

- Yılmaz, F. Thermodynamic Performance Evaluation of a Novel Solar Energy Based Multigeneration System. Appl. Therm. Eng. 2018, 143, 429–437. [Google Scholar] [CrossRef]

- Özcan, Z.; Ekici, Ö. A Novel Working Fluid Selection and Waste Heat Recovery by an Exergoeconomic Approach for a Geothermally Sourced ORC System. Geothermics 2021, 95, 102151. [Google Scholar] [CrossRef]

- Ziółkowski, P.; Hyrzyński, R.; Lemański, M.; Kraszewski, B.; Bykuć, S.; Głuch, S.; Sowiżdżał, A.; Pająk, L.; Wachowicz-Pyzik, A.; Badur, J. Different Design Aspects of an Organic Rankine Cycle Turbine for Electricity Production Using a Geothermal Binary Power Plant. Energy Convers. Manag. 2021, 246, 114672. [Google Scholar] [CrossRef]

- Lecompte, S.; Oyewunmi, O.A.; Markides, C.N.; Lazova, M.; Kaya, A.; den Broek, M.; De Paepe, M. Case Study of an Organic Rankine Cycle (ORC) for Waste Heat Recovery from an Electric Arc Furnace (EAF). Energies 2017, 10, 649. [Google Scholar] [CrossRef]

- Marchionni, M.; Fatigati, F.; Di Bartolomeo, M.; Di Battista, D.; Petrollese, M. Experimental and Numerical Dynamic Investigation of an ORC System for Waste Heat Recovery Applications in Transportation Sector. Energies 2022, 15, 9339. [Google Scholar] [CrossRef]

- Mascuch, J.; Novotny, V.; Spale, J.; Vodicka, V.; Zeleny, Z. Experience from Set-up and Pilot Operation of an in-House Developed Biomass-Fired ORC Microcogeneration Unit. Renew. Energy 2021, 165, 251–260. [Google Scholar] [CrossRef]

- Świerzewski, M.; Kalina, J.; Musiał, A. Techno-Economic Optimization of ORC System Structure, Size and Working Fluid within Biomass-Fired Municipal Cogeneration Plant Retrofitting Project. Renew. Energy 2021, 180, 281–296. [Google Scholar] [CrossRef]

- Wang, M.; Jing, R.; Zhang, H.; Meng, C.; Li, N.; Zhao, Y. An Innovative Organic Rankine Cycle (ORC) Based Ocean Thermal Energy Conversion (OTEC) System with Performance Simulation and Multi-Objective Optimization. Appl. Therm. Eng. 2018, 145, 743–754. [Google Scholar] [CrossRef]

- Hu, Z.; Fan, C.; Gao, W.; Chen, Y. Experimental Study of a Miniature Organic Rankine Cycle Unit Using Ocean Thermal Energy. Energy Convers. Manag. 2023, 293, 117494. [Google Scholar] [CrossRef]

- Mikielewicz, D.; Mikielewicz, J. Criteria for Selection of Working Fluid in Low-Temperature ORC. Chem. Process Eng. 2016, 37, 429–440. [Google Scholar] [CrossRef][Green Version]

- Thurairaja, K.; Wijewardane, A.; Jayasekara, S.; Ranasinghe, C. Working Fluid Selection and Performance Evaluation of ORC. Energy Procedia 2019, 156, 244–248. [Google Scholar] [CrossRef]

- Wang, Y.; Song, J.; Chatzopoulou, M.A.; Sunny, N.; Simpson, M.C.; Wang, J.; Markides, C.N. A Holistic Thermoeconomic Assessment of Small-Scale, Distributed Solar Organic Rankine Cycle (ORC) Systems: Comprehensive Comparison of Configurations, Component and Working Fluid Selection. Energy Convers. Manag. 2021, 248, 114618. [Google Scholar] [CrossRef]

- Jankowski, M.; Klonowicz, P.; Borsukiewicz, A. Multi-Objective Optimization of an ORC Power Plant Using One-Dimensional Design of a Radial-Inflow Turbine with Backswept Rotor Blades. Energy 2021, 237, 121506. [Google Scholar] [CrossRef]

- Jankowski, M. A New Indicator for Minimizing Size of an ORC Power Plant Based on Heat Exchanger and Turbine Design Parameters. Appl. Therm. Eng. 2022, 201, 117750. [Google Scholar] [CrossRef]

- Alvi, J.Z.; Imran, M.; Pei, G.; Li, J.; Gao, G.; Alvi, J. Thermodynamic Comparison and Dynamic Simulation of Direct and Indirect Solar Organic Rankine Cycle Systems with PCM Storage. Energy Procedia 2017, 129, 716–723. [Google Scholar] [CrossRef]

- Alvi, J.Z.; Feng, Y.; Wang, Q.; Imran, M.; Alvi, J. Modelling, simulation and comparison of phase change material storage based direct and indirect solar organic Rankine cycle systems. Appl. Therm. Eng. 2020, 170, 114780. [Google Scholar] [CrossRef]

- History of ORC. Knowledge Center for Organic Rankine Cycle. Available online: https://kcorc.org/technology/history/ (accessed on 7 July 2024).

- ORC World Map. Available online: https://orc-world-map.org/ (accessed on 7 July 2024).

- Tartière, T.; Astolfi, M. A World Overview of the Organic Rankine Cycle Market. Energy Procedia 2017, 129, 2–9. [Google Scholar] [CrossRef]

- Harinck, J.; Guardone, A.; Colonna, P. The Influence of Molecular Complexity on Expanding Flows of Ideal and Dense Gases. Phys. Fluids 2009, 21, 0036850420950130. [Google Scholar] [CrossRef]

- Bao, J.; Zhao, L. A Review of Working Fluid and Expander Selections for Organic Rankine Cycle. Renew. Sustain. Energy Rev. 2013, 24, 325–342. [Google Scholar] [CrossRef]

- Matuszewska, D.; Sztekler, K.; Gorski, J. An Influence of Low-Stability Region on Dense Gas Phenomena and Their Peculiarities in the ORC Fluids. MATEC Web Conf. 2014, 18, 03005. [Google Scholar] [CrossRef]

- Tchanche, B.F.; Papadakis, G.; Lambrinos, G.; Frangoudakis, A. Fluid Selection for a Low-Temperature Solar Organic Rankine Cycle. Appl. Therm. Eng. 2009, 29, 2468–2476. [Google Scholar] [CrossRef]

- Almehmadi, F.A.; Elattar, H.F.; Fouda, A.; Alqaed, S.; Mustafa, J.; Alharthi, M.A.; Refaey, H.A. Energy Performance Assessment of a Novel Solar Poly-Generation System Using Various ORC Working Fluids in Residential Buildings. Energies 2022, 15, 8286. [Google Scholar] [CrossRef]

- Loni, R.; Najafi, G.; Asli-Ardeh, E.A.; Ghobadian, B.; Le Roux, W.G.; Yusaf, T. Performance Investigation of Solar ORC Using Different Nanofluids. Appl. Sci. 2019, 9, 3048. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, X.; Zhang, Z.; Hao, L.; Cao, Z.; Li, S.; Guo, B.; Zheng, Y.; Dong, C.; Zhao, L. Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids. Energies 2024, 17, 3133. [Google Scholar] [CrossRef]

- Rayegan, R.; Tao, Y.X. A Procedure to Select Working Fluids for Solar Organic Rankine Cycles (ORCs). Renew. Energy 2011, 36, 659–670. [Google Scholar] [CrossRef]

- Lukawski, M.; Tester, J.; DiPippo, R. Impact of Molecular Structure of Working Fluids on Performance of Organic Rankine Cycles (ORCs). Sustain. Energy Fuels 2017, 1, 1098–1111. [Google Scholar] [CrossRef]

- Petela, R. Exergy of Undiluted Thermal Radiation. Sol. Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Siva Reddy, V.; Kaushik, S.C.; Ranjan, K.R.; Tyagi, S.K. State-of-the-Art of Solar Thermal Power Plants—A Review. Renew. Sustain. Energy Rev. 2013, 27, 258–273. [Google Scholar] [CrossRef]

- Barber, R.E. Current Costs of Solar Powered Organic Rankine Cycle Engines. Sol. Energy 1978, 20, 1–6. [Google Scholar] [CrossRef]

- Delcea, A.; Bitir-Istrate, I. Renewable Energy Sources for Industrial Consumers—A Past to Present Analysis of Technical and Financial Efficiency. IOP Conf. Ser. Earth Environ. Sci. 2021, 664, 12031. [Google Scholar] [CrossRef]

- IEA Solar Heating & Cooling Programme. SOLAR HEAT WORLD WIDE 2022; IEA: Gleisdorf, Austria, 2023. [Google Scholar]

- Karki, S.; Haapala, K.R.; Fronk, B.M. Technical and Economic Feasibility of Solar Flat-Plate Collector Thermal Energy Systems for Small and Medium Manufacturers. Appl. Energy 2019, 254, 113649. [Google Scholar] [CrossRef]

- Pluta, Z. Evacuated Tubular or Classical Flat Plate Solar Collectors? J. Power Technol. 2011, 91, 158–164. [Google Scholar]

- Sokhansefat, T.; Kasaeian, A.; Rahmani, K.; Heidari, A.H.; Aghakhani, F.; Mahian, O. Thermoeconomic and Environmental Analysis of Solar Flat Plate and Evacuated Tube Collectors in Cold Climatic Conditions. Renew. Energy 2018, 115, 501–508. [Google Scholar] [CrossRef]

- Ersöz, M.A. Effects of Different Working Fluid Use on the Energy and Exergy Performance for Evacuated Tube Solar Collector with Thermosyphon Heat Pipe. Renew. Energy 2016, 96, 244–256. [Google Scholar] [CrossRef]

- Olczak, P.; Olek, M. The Influence of Evacuated-Tube Collector Assembly on Heat Loss in Tracking Solar System with Parabolic Mirror Reflectors. Proced. Eng. 2016, 157, 317–324. [Google Scholar] [CrossRef]

- Papadimitratos, A.; Sobhansarbandi, S.; Pozdin, V.; Zakhidov, A.; Hassanipour, F. Evacuated tube solar collectors integrated with phase change materials. Sol. Energy 2016, 129, 10–19. [Google Scholar] [CrossRef]

- Zhang, D.; Diao, Y.; Wang, Z.; Pan, Y.; Sun, M.; Wang, X.; Du, P.; Zhao, Y. Thermal Performance of Two Evacuated Tube Solar Collectors with Flat Heat Pipes. Appl. Therm. Eng. 2024, 241, 122366. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A.; Mc Keever, M.; Conlon, M.; McCormack, S.J. Comparative field performance study of flat plate and heat pipe evacuated tube collectors (ETCs) for domestic water heating systems in a temperate climate. Energy 2011, 36, 3370–3378. [Google Scholar] [CrossRef]

- Olczak, P.; Porzuczek, J.; Kandefer, S. Passive Sun Tracking of a Single Evacuated Tube Collector with the Focusing Mirror. In Proceedings of the 2016 IEEE International Conference on Power and Renewable Energy, ICPRE, Shanghai, China, 21–23 October 2016. [Google Scholar]

- Akrami, M.; Alsari, H.; Javadi, A.A.; Dibaj, M.; Farmani, R.; Fath, H.E.S.; Salah, A.H.; Negm, A. Analysing the Material Suitability and Concentration Ratio of a Solar-Powered Parabolic Trough Collector (PTC) Using Computational Fluid Dynamics. Energies 2020, 13, 5479. [Google Scholar] [CrossRef]

- Chavarría-Domínguez, B.; De León-Aldaco, S.E.; Velázquez-Limón, N.; Ponce-Silva, M.; Aguilar-Jiménez, J.A.; Chavarría-Domínguez, F. A Review of the Modeling of Parabolic Trough Solar Collectors Coupled to Solar Receivers with Photovoltaic/Thermal Generation. Energies 2024, 17, 1582. [Google Scholar] [CrossRef]

- Fernandez-Garcia, A.; Zarza, E.; Valenzuela, L.; Perez, M. Parabolic-trough solar collectors and their applications. Renew. Sustain. Energy Rev. 2010, 14, 1695–1721. [Google Scholar] [CrossRef]

- Wang, M.; Wang, J.; Zhao, Y.; Zhao, P.; Dai, Y. Thermodynamic Analysis and Optimization of a Solar-Driven Regenerative Organic Rankine Cycle (ORC) Based on Flat-Plate Solar Collectors. Appl. Therm. Eng. 2013, 50, 816–825. [Google Scholar] [CrossRef]

- Valencia Ochoa, G.; Ortiz, E.V.; Forero, J.D. Thermo-Economic and Environmental Optimization Using PSO of Solar Organic Rankine Cycle with Flat Plate Solar Collector. Heliyon 2023, 9, e13697. [Google Scholar] [CrossRef]

- Ramos, A.; Chatzopoulou, M.A.; Freeman, J.; Markides, C.N. Optimisation of a High-Efficiency Solar-Driven Organic Rankine Cycle for Applications in the Built Environment. Appl. Energy 2018, 228, 755–765. [Google Scholar] [CrossRef]

- Roumpedakis, T.C.; Loumpardis, G.; Monokrousou, E.; Braimakis, K.; Charalampidis, A.; Karellas, S. Exergetic and Economic Analysis of a Solar Driven Small Scale ORC. Renew. Energy 2020, 157, 1008–1024. [Google Scholar] [CrossRef]

- Mavrou, P.; Papadopoulos, A.I.; Stijepovic, M.Z.; Seferlis, P.; Linke, P.; Voutetakis, S. Novel and Conventional Working Fluid Mixtures for Solar Rankine Cycles: Performance Assessment and Multi-Criteria Selection. Appl. Therm. Eng. 2015, 75, 384–396. [Google Scholar] [CrossRef]

- Ancona, M.A.; Bianchi, M.; Branchini, L.; De Pascale, A.; Melino, F.; Peretto, A.; Poletto, C.; Torricelli, N. Solar Driven Micro-ORC System Assessment for Residential Application. Renew. Energy 2022, 195, 167–181. [Google Scholar] [CrossRef]

- Habka, M.; Ajib, S. Performance Estimation of Mixtures in Solar Organic Rankine Cycle with Two Mini Cogeneration Options for Improvement Purpose. Sustain. Energy Technol. Assess. 2016, 16, 174–189. [Google Scholar] [CrossRef]

- Alvi, J.Z.; Jinghu, Y.; Feng, Y.; Asim, M.; Qian, W.; Pei, G. Performance Assessment of Direct Vapor Generation Solar Organic Rankine Cycle System Coupled with Heat Storage. Sustainability 2022, 14, 15296. [Google Scholar] [CrossRef]

- Rodriguez-Pastor, D.A.; Becerra, J.A.; Chacartegui, R. Adaptation of Residential Solar Systems for Domestic Hot Water (DHW) to Hybrid Organic Rankine Cycle (ORC) Distributed Generation. Energy 2023, 263, 125901. [Google Scholar] [CrossRef]

- Sonsaree, S.; Asaoka, T.; Jiajitsawat, S.; Aguirre, H.; Tanaka, K. A Small-Scale Solar Organic Rankine Cycle Power Plant in Thailand: Three Types of Non-Concentrating Solar Collectors. Sol. Energy 2018, 162, 541–560. [Google Scholar] [CrossRef]

- Kutlu, C.; Li, J.; Su, Y.; Pei, G.; Riffat, S. Off-Design Performance Modelling of a Solar Organic Rankine Cycle Integrated with Pressurized Hot Water Storage Unit for Community Level Application. Energy Convers. Manag. 2018, 166, 132–145. [Google Scholar] [CrossRef]

- Twomey, B.; Jacobs, P.A.; Gurgenci, H. Dynamic Performance Estimation of Small-Scale Solar Cogeneration with an Organic Rankine Cycle Using a Scroll Expander. Appl. Therm. Eng. 2013, 51, 1307–1316. [Google Scholar] [CrossRef]

- Piñerez, G.P.; Valencia Ochoa, G.; Duarte-Forero, J. Energy, Exergy, and Environmental Assessment of a Small-Scale Solar Organic Rankine Cycle Using Different Organic Fluids. Heliyon 2021, 7, e07947. [Google Scholar] [CrossRef]

- Gilani, H.A.; Hoseinzadeh, S.; Esmaeilion, F.; Memon, S.; Garcia, D.A.; Assad, M.E.H. A Solar Thermal Driven ORC-VFR System Employed in Subtropical Mediterranean Climatic Building. Energy 2022, 250, 123819. [Google Scholar] [CrossRef]

- Bellos, E.; Lykas, P.; Tzivanidis, C. Investigation of a Solar-Driven Organic Rankine Cycle with Reheating. Appl. Sci. 2022, 12, 2322. [Google Scholar] [CrossRef]

- Scardigno, D.; Fanelli, E.; Viggiano, A.; Braccio, G.; Magi, V. A Genetic Optimization of a Hybrid Organic Rankine Plant for Solar and Low-Grade Energy Sources. Energy 2015, 91, 807–815. [Google Scholar] [CrossRef]

- Atiz, A.; Karakilcik, H.; Erden, M.; Karakilcik, M. Assessment of Electricity and Hydrogen Production Performance of Evacuated Tube Solar Collectors. Int. J. Hydrogen Energy 2019, 44, 14137–14144. [Google Scholar] [CrossRef]

- Pei, G.; Li, J.; Ji, J. Analysis of Low Temperature Solar Thermal Electric Generation Using Regenerative Organic Rankine Cycle. Appl. Therm. Eng. 2010, 30, 998–1004. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Zhao, P.; Dai, Y. Off-Design Performance Analysis of a Solar-Powered Organic Rankine Cycle. Energy Convers. Manag. 2014, 80, 150–157. [Google Scholar] [CrossRef]

- Villarini, M.; Tascioni, R.; Arteconi, A.; Cioccolanti, L. Influence of the Incident Radiation on the Energy Performance of Two Small-Scale Solar Organic Rankine Cycle Trigenerative Systems: A Simulation Analysis. Appl. Energy 2019, 242, 1176–1188. [Google Scholar] [CrossRef]

- Bocci, E.; Villarini, M.; Vecchione, L.; Sbordone, D.; Di Carlo, A.; Dell’Era, A. Energy and Economic Analysis of a Residential Solar Organic Rankine Plant. Energy Procedia 2015, 81, 558–568. [Google Scholar] [CrossRef][Green Version]

- Cioccolanti, L.; Villarini, M.; Tascioni, R.; Bocci, E. Performance Assessment of a Solar Trigeneration System for Residential Applications by Means of a Modelling Study. Energy Procedia 2017, 126, 445–452. [Google Scholar] [CrossRef]

- Cioccolanti, L.; Tascioni, R.; Bocci, E.; Villarini, M. Parametric Analysis of a Solar Organic Rankine Cycle Trigeneration System for Residential Applications. Energy Convers. Manag. 2018, 163, 407–419. [Google Scholar] [CrossRef]

- Antonelli, M.; Baccioli, A.; Francesconi, M.; Lensi, R.; Martorano, L. Analysis of a Low Concentration Solar Plant with Compound Parabolic Collectors and a Rotary Expander for Electricity Generation. Energy Procedia 2014, 45, 170–179. [Google Scholar] [CrossRef]

- Antonelli, M.; Baccioli, A.; Francesconi, M.; Desideri, U. Dynamic Modelling of a Low-Concentration Solar Power Plant: A Control Strategy to Improve Flexibility. Renew. Energy 2016, 95, 574–585. [Google Scholar] [CrossRef]

- Li, S.; Li, W. Thermo-Economic Optimization of Solar Organic Rankine Cycle Based on Typical Solar Radiation Year. Energy Convers. Manag. 2018, 169, 78–87. [Google Scholar] [CrossRef]

- Loni, R.; Mahian, O.; Markides, C.N.; Bellos, E.; le Roux, W.G.; Kasaeian, A.; Najafi, G.; Rajaee, F. A Review of Solar-Driven Organic Rankine Cycles: Recent Challenges and Future Outlook. Renew. Sustain. Energy Rev. 2021, 150, 111410. [Google Scholar] [CrossRef]

- Roumpedakis, T.C.; Fostieris, N.; Braimakis, K.; Monokrousou, E.; Charalampidis, A.; Karellas, S. Techno-Economic Optimization of Medium Temperature Solar-Driven Subcritical Organic Rankine Cycle. Thermo 2021, 1, 77–105. [Google Scholar] [CrossRef]

- Yu, H.; Helland, H.; Yu, X.; Gundersen, T.; Sin, G. Optimal Design and Operation of an Organic Rankine Cycle (ORC) System Driven by Solar Energy with Sensible Thermal Energy Storage. Energy Convers. Manag. 2021, 244, 114494. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Investigation of a Novel CO2 Transcritical Organic Rankine Cycle Driven by Parabolic Trough Solar Collectors. Appl. Syst. Innov. 2021, 4, 53. [Google Scholar] [CrossRef]

- Casartelli, D.; Binotti, M.; Silva, P.; Macchi, E.; Roccaro, E.; Passera, T. Power Block Off-Design Control Strategies for Indirect Solar ORC Cycles. Energy Procedia 2015, 69, 1220–1230. [Google Scholar] [CrossRef]

- Chacartegui, R.; Vigna, L.; Becerra, J.A.; Verda, V. Analysis of Two Heat Storage Integrations for an Organic Rankine Cycle Parabolic Trough Solar Power Plant. Energy Convers. Manag. 2016, 125, 353–367. [Google Scholar] [CrossRef]

- Cau, G.; Cocco, D. Comparison of Medium-Size Concentrating Solar Power Plants Based on Parabolic Trough and Linear Fresnel Collectors. Energy Procedia 2014, 45, 101–110. [Google Scholar] [CrossRef]

- Manfrida, G.; Secchi, R.; Stańczyk, K. Modelling and Simulation of Phase Change Material Latent Heat Storages Applied to a Solar-Powered Organic Rankine Cycle. Appl. Energy 2016, 179, 378–388. [Google Scholar] [CrossRef]

- Patil, V.R.; Biradar, V.I.; Shreyas, R.; Garg, P.; Orosz, M.S.; Thirumalai, N.C. Techno-Economic Comparison of Solar Organic Rankine Cycle (ORC) and Photovoltaic (PV) Systems with Energy Storage. Renew. Energy 2017, 113, 1250–1260. [Google Scholar] [CrossRef]

- Eddouibi, J.; Abderafi, S.; Vaudreuil, S.; Bounahmidi, T. Dynamic Simulation of Solar-Powered ORC Using Open-Source Tools: A Case Study Combining SAM and Coolprop via Python. Energy 2022, 239, 121935. [Google Scholar] [CrossRef]

- Sigue, S.; Abderafi, S.; Vaudreuil, S.; Bounahmidi, T. Design and Steady-State Simulation of a CSP-ORC Power Plant Using an Open-Source Co-Simulation Framework Combining SAM and DWSIM. Therm. Sci. Eng. Prog. 2023, 37, 101580. [Google Scholar] [CrossRef]

- Chambers, T.; Raush, J.; Russo, B. Installation and Operation of Parabolic Trough Organic Rankine Cycle Solar Thermal Power Plant in South Louisiana. Energy Procedia 2014, 49, 1107–1116. [Google Scholar] [CrossRef]

- Khalid, F.; Dincer, I.; Rosen, M.A. Techno-Economic Assessment of a Renewable Energy Based Integrated Multigeneration System for Green Buildings. Appl. Therm. Eng. 2016, 99, 1286–1294. [Google Scholar] [CrossRef]

- Heberle, F.; Hofer, M.; Ürlings, N.; Schröder, H.; Anderlohr, T.; Brüggemann, D. Techno-Economic Analysis of a Solar Thermal Retrofit for an Air-Cooled Geothermal Organic Rankine Cycle Power Plant. Renew. Energy 2017, 113, 494–502. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Sorrentino, A.; Miliozzi, A.; Shah, N.; Markides, C.N. Solar/Biomass Hybrid Cycles with Thermal Storage and Bottoming ORC: System Integration and Economic Analysis. Energy Procedia 2017, 129, 724–731. [Google Scholar] [CrossRef]

| Country | Site Plan | Company | Capacity | Year |

|---|---|---|---|---|

| Australia | Mulka Bore | Enreco | 15 kWel | 1975 |

| Australia | Mulka Station | Enreco | 15 kWel | 1980 |

| Germany | Schleiz | GMK | 150 kWel | 2005 |

| USA | APS | ORMAT | 1000 kWel | 2006 |

| USA | Kona, Hawaii | Electratherm | 50 kWel | 2009 |

| Morocco | Ait Baha | Turboden | 2000 kWel | 2010 |

| USA | Lafayette | Electratherm | 65 kWel | 2012 |

| Spain | Heliotec | RANK | 2.5 kWel | 2012 |

| Brazil | Itajuba | ENOGIA | 10 kWel | 2013 |

| USA | Tampa | Electratherm | 65 kWel | 2014 |

| Burkina Faso | Ouagadougou | ENOGIA | 10 kWel | 2014 |

| France | Odeillo | ENOGIA | 20 kWel | 2015 |

| Italy | Palermo | RANK | 10 kWel | 2015 |

| Italy | UniKore | Zuccato | 50 kWel | 2015 |

| Greece | Xanthi | ENOGIA | 10 kWel | 2015 |

| Egypt | Cairo | ENOGIA | 10 kWel | 2015 |

| India | Rainbow | ENERTIME | 100 kWel | 2015 |

| Qatar | Gord | ENOGIA | 10 kWel | 2016 |

| Tunisia | Tunisia | Zuccato | 60 kWel | 2016 |

| Turkey | Bricker | RANK | 87 kWel | 2016 |

| China | Confidential | ENOGIA | 10 kWel | 2016 |

| France | Solho | RANK | 1.5 kWel | 2018 |

| Denmark | Bronderslev | Turboden | 3800 kWel | 2018 |

| Spain | Magtel | RANK | 11 kWel | 2019 |

| Spain | Soria | Enerbasque | 3 kWel | 2019 |

| Spain | Almeria | ENOGIA | 10 kWel | 2020 |

| Slovakia | Lehnice | ENOGIA | 10 kWel | 2022 |

| Region | Collector Area [m2] | HTF | Operating Temperature [°C] | ORC System, Working Fluid | Power Output | TES Type | Authors (Year), Ref. |

|---|---|---|---|---|---|---|---|

| China (Xi’an city) | 528 | water | range: (50–70)/(20–30) | regenerative ORC; WFs: R245fa, R123, isobutane, R134a. | output parameters | a thermal storage system | Wang et al., 2013 [68] |

| Colombia (Las Flores) | optimization variables: 150–200 | Thermal oil | 250/(40–60) | regenerative and basic ORC; WF: toluene | output parameter | thermal storage tank volume: 50 m3 | Ochoa et al., 2023 [69] |

| Greece (Athens) | 60 | a mixture of water-glycol | range (80–100)/(55–60) | basic ORC; WFs: R245fa and R1233zd | output parameters: 0.4–0.5 kW | water tank | Ramos et al., 2018 [70] |

| Greece (Athens, Thessaloniki), Turkey (Istanbul), Cyprus (Larnaca)—the South-East Mediterranean region: | optimization variable | water | 90/70 | a single stage conventional ORC; WFs: R134a, R245fa, R227ea, R152a, R236ea, R1234ze(E) | 5 kW | storage tank | Roumpedakis et al., 2020 [71] |

| Greece (Northern part) | 144 | water | output parameter/30 | simple ORC: WF: several mixtures | 1 kWe | the heat storage tank with capacity to 3960 l | Mavrou et al., 2015 [72] |

| Italy (Bologna) | 21.5, 32.25, 64.5 | water | range: (45–95)/(14–28) | recuperative ORC; WFs: R134a, R1234yf, R1234ze(E), R1243zf, R513A, R515A | output variable: 0–1800 W | two storage tanks varied from 0 to 12,000 L with a step of 3000 L | Ancona et al., 2022 [73] |

| Germany (southern part—Bayern region) | optimization of the collector area | a mixture of water-glycol | optimization: 70–90/output parameter | direct ORC system; WF: zeotropic mixtures | 1 kWe | none-direct utilization | Habka and Ajib, 2016 [74] |

| Pakistan (Lahore) | Not Available (N/A). | water | N/A | subcritical ORC, WF: R123 | 17.4–40.4 kW | the PCM tank (capacity of 90 m3) | Alvi et al., 2022 [75] |

| Spain (Sevilla) | output parameters | water | 90/20 | simple ORC, WF: R245fa | 1 kW | 0.3 m3 the storage tank with six stratification levels | Rodriguez-Pastor et al., 2022 [76] |

| Thailand (Bangkok) | 2.08 per unit, respectively; 100 to 1200 units (with 50 units increment) | water | N/A | simple ORC; WF: R245fa | 20, 40 and 60 kWe | none | Sonsaree et al., 2018 [77] |

| United Kingdom | 550 | water | (70–105)/30 | basic ORC; WF: R245fa | output parameter: ranged from 4.3 to 5.7 kW in the daytime, 9 to 11.2 kW at early night and 4.7 to 4.3 kW in night | pressurized water storage unit | Kutlu et al., 2018 [78] |

| United Kingdom (London) | 15 | Therminol VP-1 | 180/40 | six different ORC configuration; WFs: sixteen working fluids | 0.8–3 kW | two-tank configuration (high temperature, low temperature), buffer | Wang et al., 2021 [34] |

| Region | Collector Area [m2] | HTF | Operating Temperature [°C] | ORC System, Working Fluid | Power Output | TES Type | Authors (Year), Ref. |

|---|---|---|---|---|---|---|---|

| Australia (Brisbane) | 50 | water | 85–120/output data | simple ORC (with scroll expander); WF: R134a | output data: max. instantaneous power is 676 W | solar storage vessel with water (800 L) | Twomey et al., 2012 [79] |

| Colombia (cities Rancho Grande, Puerto Bolivar, Manaure, and Nazareth) | 100 | thermal oil Therminol 75 | (120–130)/20 | simple ORC WFs: Toluene, Cyclohexane, and Acetone | design output: 3–7.5 kW | a thermal storage tank: a storage tank that operates during non-radiation hours | Piñerez et al., 2021 [80] |

| Cyprus (Paralimni) | 265 | water | 95/40 | simple and internal heat exchange ORC; WF: isobutene | 3.92 kW | storage tank capacity (optimized): 48 m3 | Gilani et al., 2022 [81] |

| Greece (Athens) | 300 | thermal oil Therminol VP-1 | (80–150)/(24–45) | regenerative ORC with and without reheating; WF: cyclopentan | 25, 20, 15, 10 kW | sensible thermal storage tank (5 m3) | Bellos et al., 2022 [82] |

| Greece (Athens) | 60 | thermal oil Therminol 66 | (180–200)/(55–60) | basic ORC; WFs: R245fa and R1233zd | output parameters: 1.2–1.8 kW | water tank | Ramos et al., 2018 [70] |

| Greece (Athens, Thessaloniki), Turkey (Istanbul), Cyprus (Larnaca)—the South-East Mediterranean region: | optimization variable | water | 110/90 | a single stage conventional ORC; WFs: R134a, R245fa, R227ea, R152a, R236ea, R1234ze(E) | 5 kW | storage tank | Roumpedakis et al., 2020 [71] |

| Italy (Florence) | output parameter | water | 90/output parameter | simple ORC cycle; WFs: R32, R41, R125, R134a, R143a, R152a, R218, R227ea | output parameter | none | Scardigno et al., 2015 [83] |

| Thailand (Bangkok) | 2.37 per unit, respectively; 100 to 1200 units (with 50 units increment) | water | N/A | simple ORC; WF: R245fa | 20, 40 and 60 kWe | none | Sonsaree et al., 2018 [77] |

| Turkey (Adana) | 300 | water | 90/39 | simple ORC system; WF: isobutan | output data | none | Atiz et al., 2018 [84] |

| United Kingdom (London) | 15 | thermal oil Therminol VP-1 | 180/40 | six different ORC configuration; WFs: sixteen working fluids | 0.8–3 kW | two-tank configuration (high temperature, low temperature), buffer | Wang et al., 2021 [34] |

| Region | Collector Area [m2] | HTF | Operating Temperature [°C] | ORC System, Working Fluid | Power Output | TES Type | Authors (Year), Ref. |

|---|---|---|---|---|---|---|---|

| for locations with radiation: 600, 750, 900 W/m2 | output parameter | conduction oil | 120/20 | regenerative ORC; WF: HCFC-123 | output parameter | thermal storage with PCMs | Gang et al., 2010 [85] |

| China (Xi’an city) | output parameter | thermal oil | N/A | simple ORC; WF: R245fa | output parameter | thermal storage tank with water | Wang et al., 2014 [86] |

| Italy (Napoli) | 146 | therminol 62 | output parameters | small-scale regenerative solar ORC trigeneration plants: WF: R245fa | 3.5 kWe | oil storage tank (3 m3) | Villarini et al., 2019 [87] |

| Italy (Orte) | 50 | Therminol 62 | 150/30 | simple ORC, WF: R245fa | 1.8–3 kW | two tank storage system, 3 m3 of thermal storage | Bocci et al., 2015 [88] |

| Italy (Orte) | 50 | Therminol 62 | maximum evaporation temperature 150; minimum driving temperature difference between the evaporator and the condenser at the expander equal to 50 °C | regenerative ORC; WF: R245fa | 3.5 kWe | two TES tanks: HTT used between the solar field and the ORC; LTT—the ORC thermal output and the absorber (3000 l each) | Cioccolanti et al., 2017 [89] |

| Italy (Orte) | 50 | HTT: diathermic oil LTT: water | 100–150/15–30 | simple ORC; WF: R245fa | 3.5 kWe | two 3 m3 heat storage tanks: HTT, LTT | Cioccolanti et al., 2018 [90] |

| Italy (Pisa) | 750 | pressurized water | 100–120/output parameter | Regenerative ORC (with a modified Wankel engine); WF: R134a, R152a, R236ea, R245fa, R600a | 50 kW | none | Antonelli et al., 2014 [91] |

| Italy (Pisa) | a surface of the panels of 197 | pressurized water | 150/condensing temperature was 15 °C higher than the ambient temperature | regenerative ORC (with rotary volumetric expander); WF: R600a | 25 kW | none | Antonelli et al., 2016 [92] |

| Thailand (Bangkok) | 2.16 per unit, respectively; 100 to 1200 units (with 50 units increment) | water | N/A | simple ORC; WF: R245fa | 20, 40 and 60 kWe | none | Sonsaree et al., 2018 [77] |

| USA (Desert Rock, Nevada; Fort Peck, Montana; Pennsylvania State University, Pennsylvania; Bondville, Illinois) | output parameter: 5–565 | water | Evaporation temperature: 390–430 K | simple ORC; WF: R245fa | output parameter | capacity of TES: 20–400 L | Li and Li, 2018 [93] |

| Region | Collector Area [m2] | HTF | Operating Temperature [°C] | ORC System, Working Fluid | Power Output | TES Type | Authors (Year), Ref. |

|---|---|---|---|---|---|---|---|

| Belgium (Brussels), Greece (Athens), Spain (Madrid), Germany (Berlin) and Italy (Rome) | optimization variables: 10 ÷ 400 | Therminol VP-1 | 210/>20 | ORC system with recuperator; WFs: isohexane, acetone, hexane, cyclopentane, methanol, ethanol, heptane, cyclohexane, benzene, MDM, octane, toluene, n-nonane, p-xylene | output parameter | the thermal energy storage (TES); storage tank capacity—optimization variables: 0.2–5.0 m3 | Roumpedakis et al., 2021 [95] |

| China (Yinchuan) | from optimization | a mixture of Diphenyl Oxide and Biphenyl | independent variables in optimization: (300–400)/(50–300)—basic-ORC; (300–400)/(100–300)—recuperative ORC | basic and recuperative ORCs; WFs: toluene, cyclohexane, hexamethyldisiloxane (HMDSO), n-pentane, benzene and n-hexane | independent variables in optimization: 50—500 kW | sensible thermal energy storage system | Yu et al., 2021 [96] |

| Greece (Athens) | 227.4 | CO2 | default value: 800/25; Range: (600–1000)/(15–30) turbine inlet temp/condenser temp | recuperative ORC; WF: CO2 | 44.14 kWe | none | Bellos and Tzivanidis, 2021 [97] |

| Greece (Athens, Thessaloniki), Turkey (Istanbul), Cyprus (Larnaca)—the South-East Mediterranean region: | optimization variable | water | 110/90 | a single stage conventional ORC; WFs: R134a, R245fa, R227ea, R152a, R236ea, R1234ze(E) | 5 kW | storage tank | Roumpedakis et al., 2020 [71] |

| Spain (Sevilla) | output parameter | Therminol VP1 | output parameter/40 °C | regenerative Rankine cycle; WF: toluene | 5 MWel | none | Casartelli et al., 2015 [98] |

| Spain (Sevilla) | output parameters: for toluene varies between 38,400–77,200 | Oil Therminol VP-1 in the indirect system; molten salt Hitec XL in a direct system | 400/(30–120) | recuperative ORC; WFs: toluene, cyclohexane, siloxane D4 | 5 MWe | two different active storage systems: two tanks indirect storage system and two tanks direct storage system; output parameter: (0–10 h) | Chacartegui et al., 2016 [99] |

| India (Ahmadabad) | optimization variables: 200–5000 | glycerol | 275/161 | regenerative solar-ORC, WF: isobutane | design capacity (power output): 50 kWe | a single-tank sensible heat storage system (optimization variables: storage hours 0–20 h) | Patil et al., 2017 [102] |

| Morocco (Fes, Errachidia, Oujda, Tata, Marrakech, Ouarzazate, and Benguerir) | design point area is equal to 10,496 | Therminol VP-1 | 320/160 | recuperative ORC, WF: cyclopentane | 0–1.224 MWe under the considered weather conditions | a direct storage system (3 h) | Eddouibi et al., 2022 [103] |

| Senegal (isolated and arid rural settlement) | design outputs: 4703 | Therminol VP-1 | 400/12 | recuperative ORC; WF: cyclopentane | design outputs: 1018.41 kW | a direct storage system; storage capacity: 4 h volume of the storage tanks: 104 m3 | Sigue et al., 2022 [104] |

| USA (Crowley (Louisiana) | 1051 | water | 121/93 | WF: R245fa | 0.05 | buffer is planned | Chambers et al., 2014 [105] |

| Italy (Cagliari, Italy | 865.5 | Thermal oil | 305/204 | simple ORC; WF: a siliconic oil | 1 MW | two-tank direct thermal storage system (storage capacity 4–12 h) | Cau and Cocco, 2014 [100] |

| Italy (Pisa San Giusto) | 2583 | water | 120/70 | simple ORC, WF: R245fa | output data | latent Heat Storage (LHS) system with PCH storage tank | Manfrida et al., 2016 [101] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matuszewska, D. Solar Organic Rankine Cycle (ORC) Systems: A Review of Technologies, Parameters, and Applications. Energies 2024, 17, 5106. https://doi.org/10.3390/en17205106

Matuszewska D. Solar Organic Rankine Cycle (ORC) Systems: A Review of Technologies, Parameters, and Applications. Energies. 2024; 17(20):5106. https://doi.org/10.3390/en17205106

Chicago/Turabian StyleMatuszewska, Dominika. 2024. "Solar Organic Rankine Cycle (ORC) Systems: A Review of Technologies, Parameters, and Applications" Energies 17, no. 20: 5106. https://doi.org/10.3390/en17205106

APA StyleMatuszewska, D. (2024). Solar Organic Rankine Cycle (ORC) Systems: A Review of Technologies, Parameters, and Applications. Energies, 17(20), 5106. https://doi.org/10.3390/en17205106