Fault Detection and Prediction for Power Transformers Using Fuzzy Logic and Neural Networks

Abstract

1. Introduction

2. Overview of Power Transformer Failures

2.1. Power Transformers

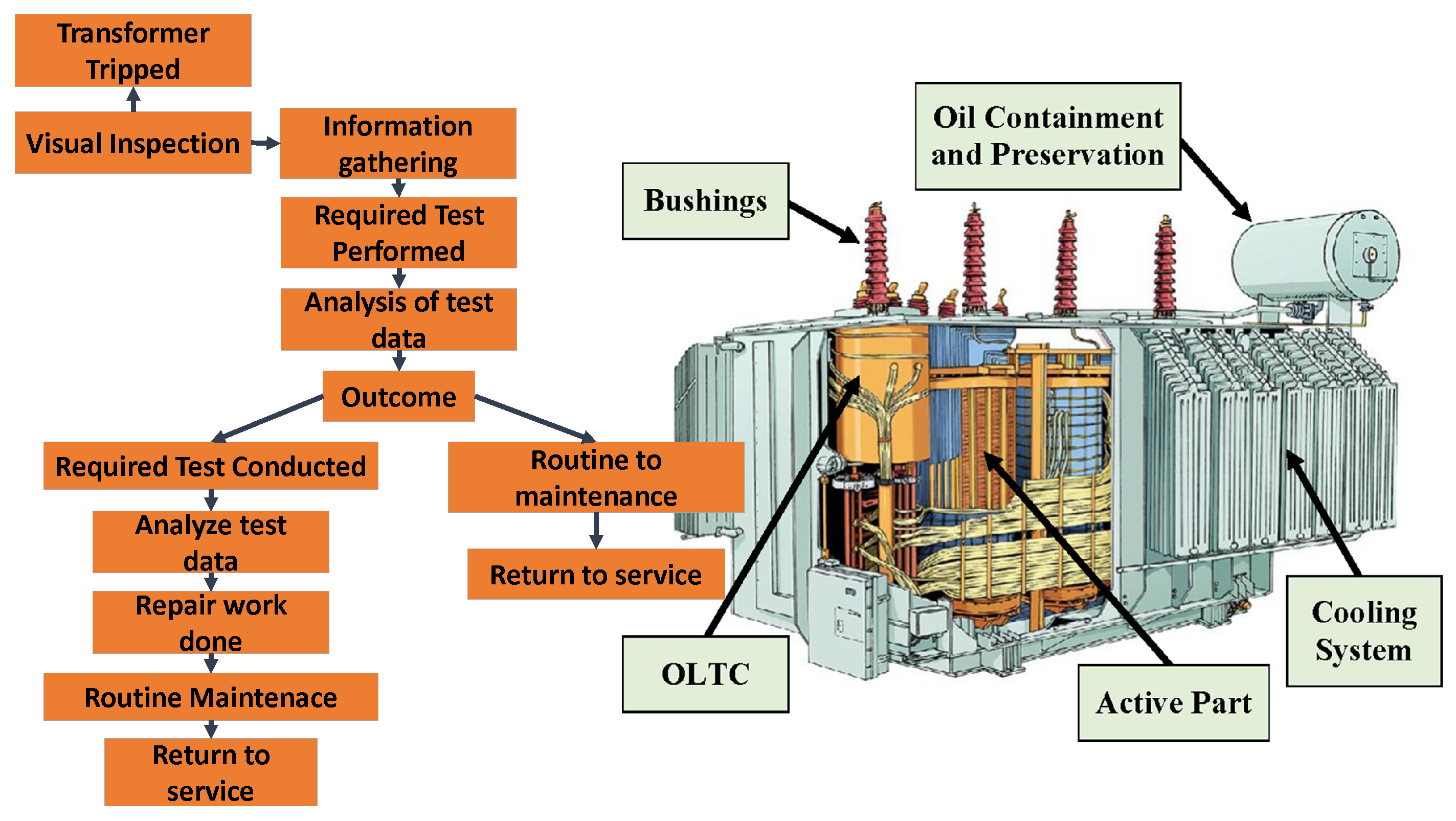

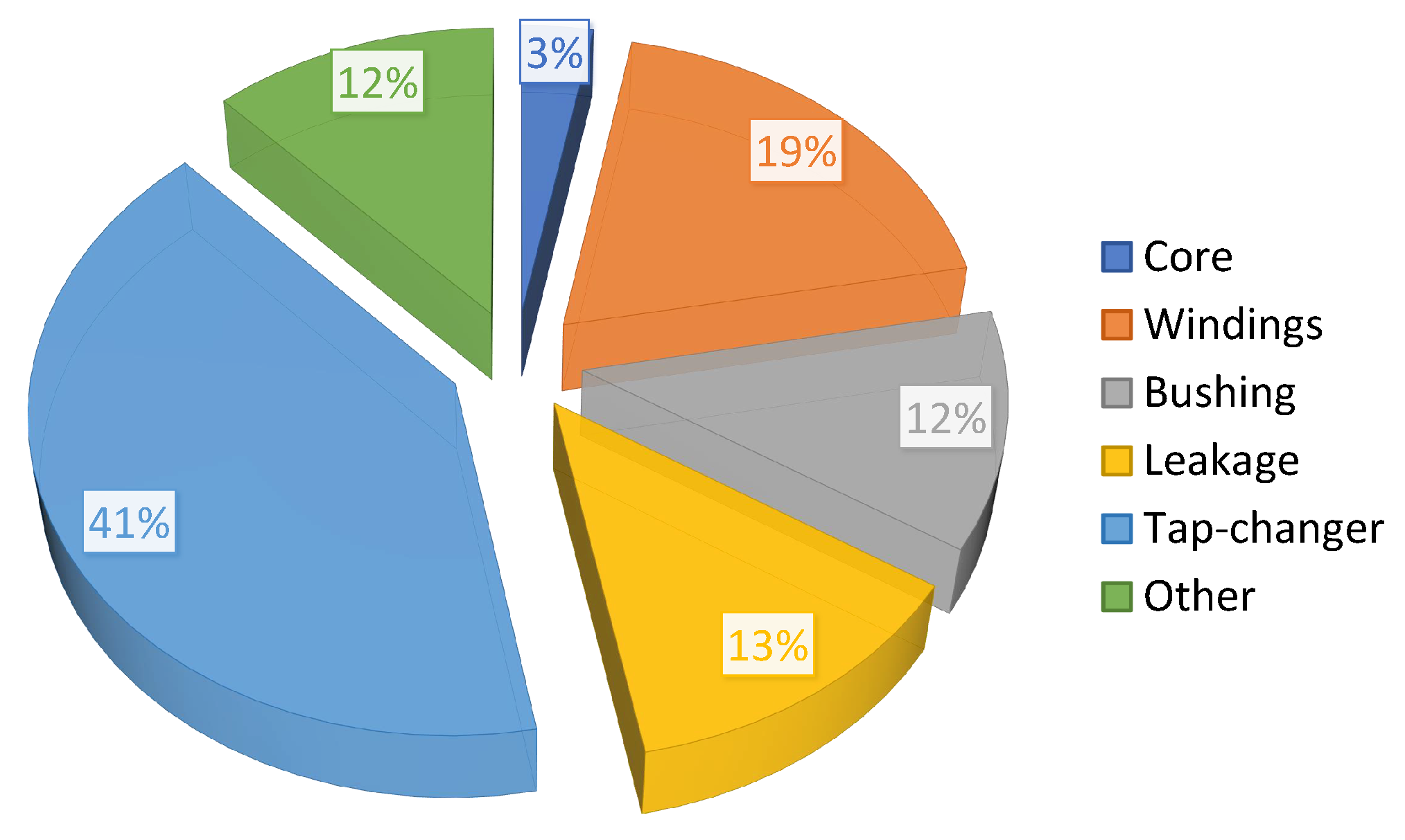

2.2. Typical Failures and Maintenance Methods

3. Literature Review

3.1. Methodology for Literature Review

3.2. Related Work

4. Background and Methods

4.1. Fuzzy Logic

4.2. Artificial Neural Networks

4.3. Method IEC 60599

5. Experiments and Results

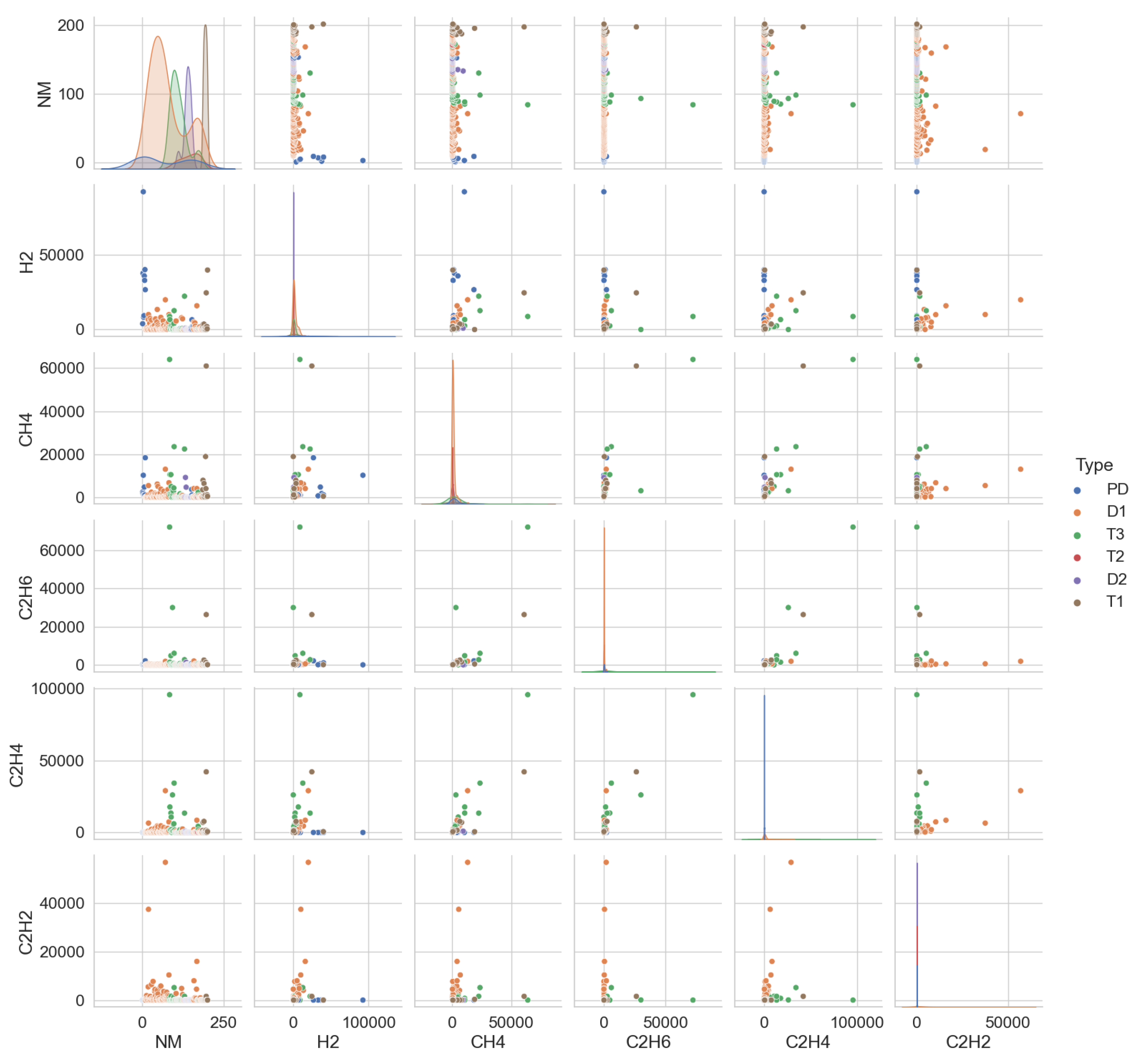

5.1. Dataset

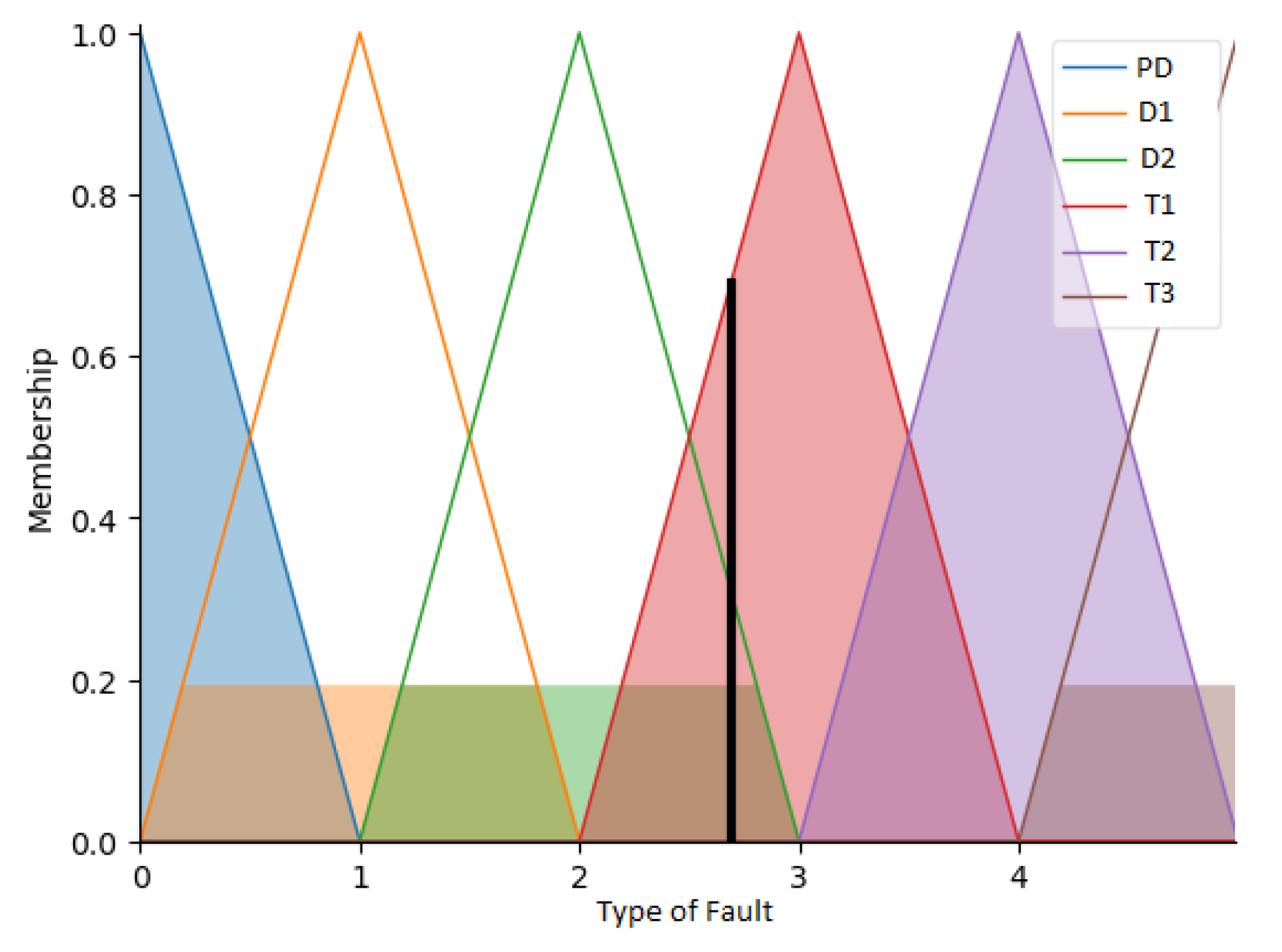

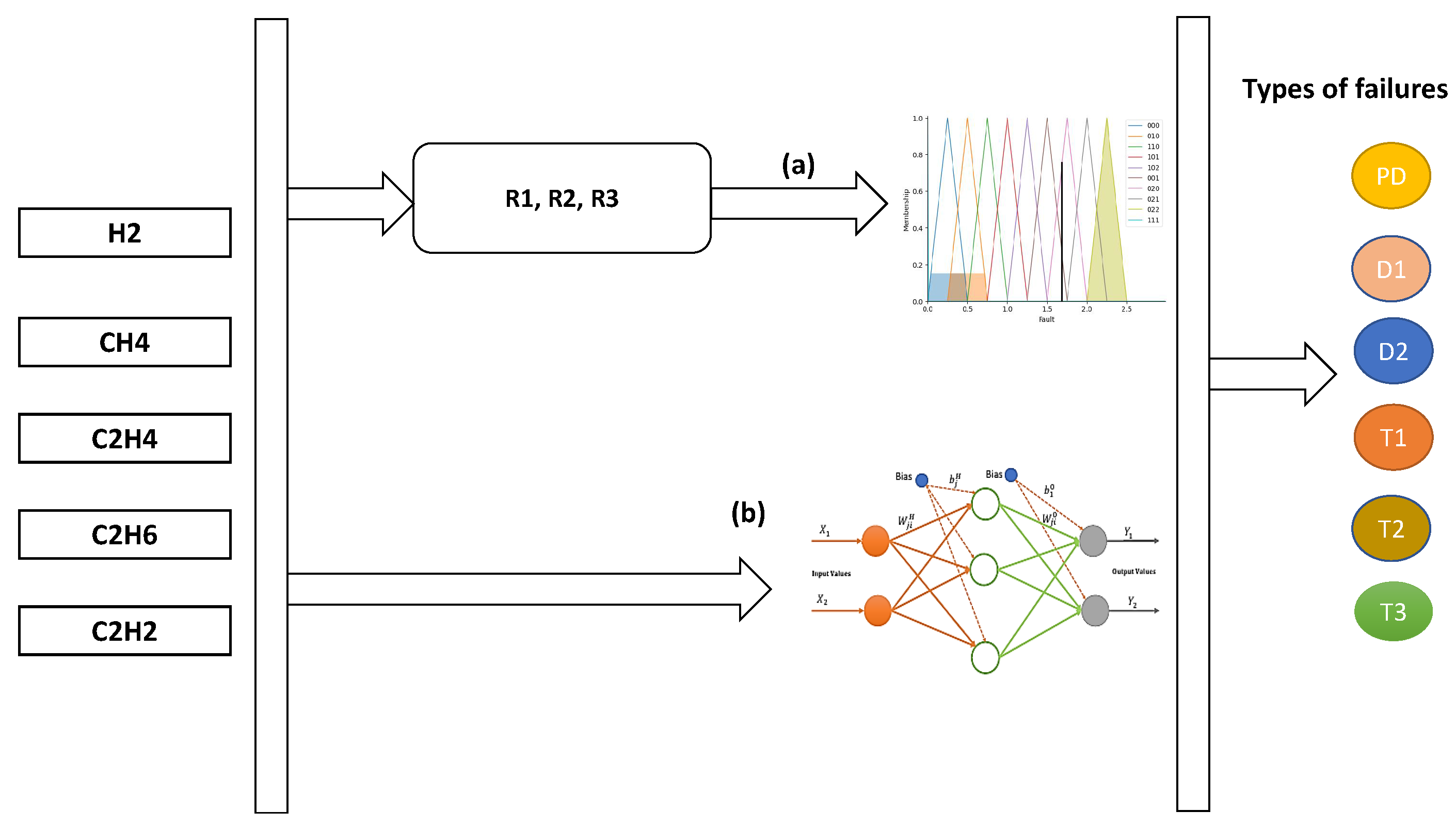

5.2. Fault Detection with Fuzzy Logic

5.3. Fault Detection with Artificial Neural Networks

5.4. Algorithm Used—Ensemble of Fuzzy Logic and Neural Network

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial Neural Network |

| FCM | Fuzzy C-Means |

| FL | Fuzzy Logic |

| DGA | Dissolved Gas Analysis |

| GNN | Generalized Neural Network |

| IEC | International Electrotechnical Commission |

| IEEE | Institute of Electrical and Electronics Engineers |

| MLP | Multilayer Perceptron |

References

- Zhang, Y.; Ding, X.; Liu, Y.; Griffin, P. An artificial neural network approach to transformer fault diagnosis. IEEE Trans. Power Deliv. 1996, 11, 1836–1841. [Google Scholar] [CrossRef]

- Liang, Z.; Parlikad, A. A Markovian model for power transformer maintenance. Int. J. Electr. Power Energy Syst. 2018, 99, 175–182. [Google Scholar] [CrossRef]

- Hazra, J.; Sinha, A.K. Identification of Catastrophic Failures in Power System Using Pattern Recognition and Fuzzy Estimation. IEEE Trans. Power Syst. 2009, 24, 378–387. [Google Scholar] [CrossRef]

- Huang, Y.C.; Sun, H.C. Dissolved gas analysis of mineral oil for power transformer fault diagnosis using fuzzy logic. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 974–981. [Google Scholar] [CrossRef]

- Christina, A.; Salam, M.A.; Rahman, Q.M.; Wen, F.; Ang, S.P.; Voon, W. Causes of transformer failures and diagnostic methods—A review. Renew. Sustain. Energy Rev. 2018, 82, 1442–1456. [Google Scholar] [CrossRef]

- Bangalore, P.; Tjernberg, L.B. An Artificial Neural Network Approach for Early Fault Detection of Gearbox Bearings. IEEE Trans. Smart Grid 2015, 6, 980–987. [Google Scholar] [CrossRef]

- Yang, W.; Tavner, P.J.; Crabtree, C.J.; Feng, Y.; Qiu, Y. Wind turbine condition monitoring: Technical and commercial challenges. Wind Energy 2014, 17, 673–693. [Google Scholar] [CrossRef]

- Zhen, D.; Li, D.; Feng, G.; Zhang, H.; Gu, F. Rolling bearing fault diagnosis based on VMD reconstruction and DCS demodulation. Int. J. Hydromechatronics 2022, 5, 205–225. [Google Scholar] [CrossRef]

- Levy, D.; Chillarege, R. Early warning of failures through alarm analysis a case study in telecom voice mail systems. In Proceedings of the 14th International Symposium on Software Reliability Engineering, Denver, CO, USA, 17–20 November 2003; pp. 271–280. [Google Scholar] [CrossRef]

- Kori, A.K.; Sharma, A.; Bhadoriya, A. Neuro Fuzzy System Based Condition Monitoring of Power Transformer. Int. J. Comput. Sci. Issues (IJCSI) 2012, 9, 495. [Google Scholar]

- Mehta, D.M.; Kundu, P.; Chowdhury, A.; Lakhiani, V.K.; Jhala, A.S. A review of critical evaluation of natural ester vis-a-vis mineral oil insulating liquid for use in transformers: Part II. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 1705–1712. [Google Scholar] [CrossRef]

- Norma, A. ASTM D3612-02; Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating oil by Gas Chromatography. ASTM: West Conshohocken, PA, USA, 2007.

- Fofana, I. Decay products in the liquid insulation of power transformers. IET Electr. Power Appl. 2010, 4, 177–184. [Google Scholar] [CrossRef]

- Khalil, M. Qualitative and Quantitative FMECA on 220 kV Power Transformers. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Dong, X.; Liu, Y.; LoPinto, F.; Scheibe, K.; Sheetz, S. Information model for power equipment diagnosis and maintenance. In Proceedings of the 2002 IEEE Power Engineering Society Winter Meeting, (Cat. No. 02CH37309), New York, NY, USA, 27–31 January 2002; Volume 1, pp. 701–706. [Google Scholar] [CrossRef]

- Rodrigues, J.A.; Farinha, J.T.; Mendes, M.; Mateus, R.J.G.; Cardoso, A.J.M. Comparison of Different Features and Neural Networks for Predicting Industrial Paper Press Condition. Energies 2022, 15, 6308. [Google Scholar] [CrossRef]

- de Almeida Pais, J.E.; Raposo, H.D.N.; Farinha, J.T.; Cardoso, A.J.M.; Marques, P.A. Optimizing the Life Cycle of Physical Assets through an Integrated Life Cycle Assessment Method. Energies 2021, 14, 6128. [Google Scholar] [CrossRef]

- Daurenbayeva, N.; Nurlanuly, A.; Atymtayeva, L.; Mendes, M. Survey of Applications of Machine Learning for Fault Detection, Diagnosis and Prediction in Microclimate Control Systems. Energies 2023, 16, 3508. [Google Scholar] [CrossRef]

- Martins, A.; Mateus, B.; Fonseca, I.; Farinha, J.T.; Rodrigues, J.; Mendes, M.; Cardoso, A.M. Predicting the Health Status of a Pulp Press Based on Deep Neural Networks and Hidden Markov Models. Energies 2023, 16, 2651. [Google Scholar] [CrossRef]

- Martins, A.; Fonseca, I.; Farinha, J.T.; Reis, J.; Cardoso, A.J.M. Online Monitoring of Sensor Calibration Status to Support Condition-Based Maintenance. Sensors 2023, 23, 2402. [Google Scholar] [CrossRef]

- Arena, F.; Collotta, M.; Luca, L.; Ruggieri, M.; Termine, F.G. Predictive Maintenance in the Automotive Sector: A Literature Review. Math. Comput. Appl. 2022, 27, 2. [Google Scholar] [CrossRef]

- Shamayleh, A.; Awad, M.; Farhat, J. IoT based predictive maintenance management of medical equipment. J. Med. Syst. 2020, 44, 1–12. [Google Scholar] [CrossRef]

- Jahromi, A.; Piercy, R.; Cress, S.; Service, J.; Fan, W. An approach to power transformer asset management using health index. IEEE Electr. Insul. Mag. 2009, 25, 20–34. [Google Scholar] [CrossRef]

- Saha, T. Review of modern diagnostic techniques for assessing insulation condition in aged transformers. IEEE Trans. Dielectr. Electr. Insul. 2003, 10, 903–917. [Google Scholar] [CrossRef]

- Emsley, A. Degradation of cellulosic insulation in power transformers. Part 2: Formation of furan products in insulating oil. IEEE Proc.-Sci. Meas. Technol. 2000, 147, 110–114. [Google Scholar] [CrossRef]

- Subburaj, S.K.; Rengaraj, M.; Mariappan, R. Evaluating critical characteristics of vegetable oil as a biodegradable insulating oil for transformer. Int. J. Emerg. Electr. Power Syst. 2020, 21, 20200128. [Google Scholar] [CrossRef]

- Singh, J.; Sood, Y.R.; Verma, P. The influence of service aging on transformer insulating oil parameters. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 421–426. [Google Scholar] [CrossRef]

- Malik, H.; Jarial, R.; Azeem, A.; Yadav, A.K. Application of Modern Technology for Fault Diagnosis in Power Transformers Energy Management. In Proceedings of the 2011 International Conference on Communication Systems and Network Technologies, Katra, India, 3–5 June 2011; pp. 376–381. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, S.K.; Husain, Z. Root Cause Analysis Of Transformer Failure Scenario At Power Substation. In Advances in Environmental and Agriculture Science; University of Naples Federico II: Naples, Italy, 2013. [Google Scholar]

- Hamed Samimi, M.; Dadashi Ilkhechi, H. Survey of different sensors employed for the power transformer monitoring. IET Sci. Meas. Technol. 2020, 14, 1–8. [Google Scholar] [CrossRef]

- Wang, M.; Vandermaar, A.; Srivastava, K. Review of condition assessment of power transformers in service. IEEE Electr. Insul. Mag. 2002, 18, 12–25. [Google Scholar] [CrossRef]

- Hjartarson, T.; Otal, S. Predicting Future Asset Condition Based on Current Health Index and Maintenance Level. In Proceedings of the ESMO 2006–2006 IEEE 11th International Conference on Transmission & Distribution Construction, Operation and Live-Line Maintenance, Albuquerque, NM, USA, 15–19 October 2006. [Google Scholar] [CrossRef]

- Höhlein, I.; Kachler, A.; Tenbohlen, S.; Leibfried, T. Transformer life management German experience with condition assessment. Contrib. CIGRE SC12 A 2003, 2, 1–13. [Google Scholar]

- Muthanna, K.; Sarkar, A.; Das, K.; Waldner, K. Transformer insulation life assessment. IEEE Trans. Power Deliv. 2006, 21, 150–156. [Google Scholar] [CrossRef]

- Chatterjee, A.; Bhattacharjee, P.; Roy, N.; Kumbhakar, P. Usage of nanotechnology based gas sensor for health assessment and maintenance of transformers by DGA method. Int. J. Electr. Power Energy Syst. 2013, 45, 137–141. [Google Scholar] [CrossRef]

- Pandey, A.; Sonwane, P.M. Implementation of Reliability Centred Maintenance for transformer. In Proceedings of the 2016 International Conference on Automatic Control and Dynamic Optimization Techniques (ICACDOT), Pune, India, 9–10 September 2016; pp. 578–581. [Google Scholar] [CrossRef]

- Tang, W.H.; Goulermas, J.Y.; Wu, Q.H.; Richardson, Z.J.; Fitch, J. A Probabilistic Classifier for Transformer Dissolved Gas Analysis With a Particle Swarm Optimizer. IEEE Trans. Power Deliv. 2008, 23, 751–759. [Google Scholar] [CrossRef]

- Sun, H.C.; Huang, Y.C.; Huang, C.M. A Review of Dissolved Gas Analysis in Power Transformers. Energy Procedia 2012, 14, 1220–1225. [Google Scholar] [CrossRef]

- Liao, R.; Zheng, H.; Grzybowski, S.; Yang, L. Particle swarm optimization-least squares support vector regression based forecasting model on dissolved gases in oil-filled power transformers. Electric Power Syst. Res. 2011, 81, 2074–2080. [Google Scholar] [CrossRef]

- Dong, L.; Xiao, D.; Liang, Y.; Liu, Y. Rough set and fuzzy wavelet neural network integrated with least square weighted fusion algorithm based fault diagnosis research for power transformers. Electric Power Syst. Res. 2008, 78, 129–136. [Google Scholar] [CrossRef]

- Hung, C.P.; Wang, M.H. Diagnosis of incipient faults in power transformers using CMAC neural network approach. Electr. Power Syst. Res. 2004, 71, 235–244. [Google Scholar] [CrossRef]

- Bakar, N.A.; Abu-Siada, A.; Islam, S. A review of dissolved gas analysis measurement and interpretation techniques. IEEE Electr. Insul. Mag. 2014, 30, 39–49. [Google Scholar] [CrossRef]

- Golarz, J. Understanding Dissolved Gas Analysis (DGA) techniques and interpretations. In Proceedings of the 2016 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016; pp. 1–5. [Google Scholar] [CrossRef]

- Bustamante, S.; Manana, M.; Arroyo, A.; Castro, P.; Laso, A.; Martinez, R. Dissolved Gas Analysis Equipment for Online Monitoring of Transformer Oil: A Review. Sensors 2019, 19, 4057. [Google Scholar] [CrossRef]

- Buchholz, M. The Buchholz protection system and its application in practice. ETZ 1928, 49, 1257–1262. [Google Scholar]

- Howe, V.H. The Identity and Significance of Gases Collected in Buchholz Protectors; Metropolitan-Vickers Electrical Company: Manchester, UK, 1956. [Google Scholar]

- Farhan Naeem, M.; Hashmi, K.; Rahman Kashif, S.A.; Khan, M.M.; Alghaythi, M.L.; Aymen, F.; Ali, S.G.; AboRas, K.M.; Ben Dhaou, I. A novel method for life estimation of power transformers using fuzzy logic systems: An intelligent predictive maintenance approach. Front. Energy Res. 2022, 10, 977665. [Google Scholar] [CrossRef]

- Da Silva Noronha, T.; De Oliveira, T.F.; Da Silveira, A.M.; Da Silva, R.R.; Saraiva, A.C.F. Knowledge acquisition of vibrations in high-power transformers using statistical analyses and fuzzy approaches—A case study. Electr. Power Syst. Res. 2013, 104, 110–115. [Google Scholar] [CrossRef]

- Souahlia, S.; Bacha, K.; Chaari, A. MLP neural network-based decision for power transformers fault diagnosis using an improved combination of Rogers and Doernenburg ratios DGA. Int. J. Electr. Power Energy Syst. 2012, 43, 1346–1353. [Google Scholar] [CrossRef]

- Soni, R.; Mehta, B. Diagnosis and prognosis of incipient faults and insulation status for asset management of power transformer using fuzzy logic controller & fuzzy clustering means. Electr. Power Syst. Res. 2023, 220, 109256. [Google Scholar] [CrossRef]

- Fu, X.; Yang, K.; Liu, M.; Xing, T.; Wu, C. LightFD: Real-Time Fault Diagnosis with Edge Intelligence for Power Transformers. Sensors 2022, 22, 5296. [Google Scholar] [CrossRef] [PubMed]

- Mofizul Islam, S.; Wu, T.; Ledwich, G. A novel fuzzy logic approach to transformer fault diagnosis. IEEE Trans. Dielectr. Electr. Insul. 2000, 7, 177–186. [Google Scholar] [CrossRef]

- Dukarm, J. Transformer oil diagnosis using fuzzy logic and neural networks. In Proceedings of the Canadian Conference on Electrical and Computer Engineering, Vancouver, AW, Canada, 14–17 September 1993; pp. 329–332. [Google Scholar] [CrossRef]

- McNeill, F.M.; Thro, E. Fuzzy Logic: A Practical Approach; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Lin, Z.M.; Chang, C.H.; Chou, N.K.; Lin, Y.H. Bluetooth Low Energy (BLE) based blood pressure monitoring system. In Proceedings of the 2014 International Conference on Intelligent Green Building and Smart Grid (IGBSG), Taipei, Taiwan, 23–25 April 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Fwa, T.; Shanmugam, R. Fuzzy logic technique for pavement condition rating and maintenance-needs assessment. In Proceedings of the Fourth International Conference on managing pavements. Citeseer, Durban, South Africa, 17–21 May 1998; Volume 1. [Google Scholar]

- Vashishtha, S.; Gupta, V.; Mittal, M. Sentiment analysis using fuzzy logic: A comprehensive literature review. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2023, 13, e1509. [Google Scholar] [CrossRef]

- Huang, Y.; Kangas, L.J.; Rasco, B.A. Applications of Artificial Neural Networks (ANNs) in Food Science. Crit. Rev. Food Sci. Nutr. 2007, 47, 113–126. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Wang, H.; Wang, G.; Kumar, A.; Sun, W.; Xiang, J. Semi-Supervised Multiscale Permutation Entropy-Enhanced Contrastive Learning for Fault Diagnosis of Rotating Machinery. IEEE Trans. Instrum. Meas. 2023, 72, 1–10. [Google Scholar] [CrossRef]

- Chaturvedi, D.; Sinha, A.; Malik, O. Short term load forecast using fuzzy logic and wavelet transform integrated generalized neural network. Int. J. Electr. Power Energy Syst. 2015, 67, 230–237. [Google Scholar] [CrossRef]

- Munir, H.S.; Ren, S.; Mustafa, M.; Siddique, C.N.; Qayyum, S. Attention based GRU-LSTM for software defect prediction. PLoS ONE 2021, 16, e0247444. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Tang, G.; Xue, X.; Saeed, A.; Hu, X. Short-Term Wind Speed Interval Prediction Based on Ensemble GRU Model. IEEE Trans. Sustain. Energy 2020, 11, 1370–1380. [Google Scholar] [CrossRef]

- Ghalkhani, M.; Fofana, I.; Bouaïcha, A.; Hemmatjou, H. Influence of aging byproducts on the gassing tendency of transformer oils. In Proceedings of the 2012 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Montreal, QC, Canada, 14–17 October 2012; pp. 870–873. [Google Scholar] [CrossRef]

- Rogers, R.R. IEEE and IEC Codes to Interpret Incipient Faults in Transformers, Using Gas in Oil Analysis. IEEE Trans. Electr. Insul. 1978, EI-13, 349–354. [Google Scholar] [CrossRef]

- Miranda, V.; Castro, A. Improving the IEC table for transformer failure diagnosis with knowledge extraction from neural networks. IEEE Trans. Power Deliv. 2005, 20, 2509–2516. [Google Scholar] [CrossRef]

| Scopus | # WOS | # Science Direct | # b-on | |

|---|---|---|---|---|

| Keywords | “Predictive Maintenance” AND “Power Transformer” | |||

| Total of documents | 91 | 16 | 126 | 36.724 |

| Keywords | “Predictive Maintenance” AND “Power Transformer” AND “Fuzzy” | |||

| Total of documents | 2 | 0 | 58 | 16.320 |

| Keywords | “Predictive maintenance” AND “Power transformer” AND | |||

| “Fuzzy” AND “Artificial Neural Network” | ||||

| Total of documents | 0 | 0 | 1 | 61 |

| Case | Characteristic Fault | R1 | R2 | R3 |

|---|---|---|---|---|

| PD | Partial discharge | NS | <0.1 | <0.2 |

| D1 | Discharges of low energy | <1 | 0.1–0.5 | >1 |

| D2 | Discharges of high energy | 0.6–2.5 | 0.1–1 | >2 |

| T1 | Thermal fault T < 300 °C | NS | >1 but NS | <1 |

| T2 | Thermal fault 300 °C < T < 700 °C | <0.1 | >1 | 1–4 |

| T3 | Thermal fault T > 700 °C | <0.2 | >1 | >4 |

| Fault Type | Type of Failure | Samples | Train | Test |

|---|---|---|---|---|

| 1 | PD | 16 | 11 | 5 |

| 2 | D1 | 103 | 72 | 31 |

| 3 | D2 | 19 | 13 | 6 |

| 4 | T1 | 16 | 11 | 5 |

| 5 | T2 | 9 | 6 | 3 |

| 6 | T3 | 38 | 27 | 11 |

| Total | 201 | 140 | 61 |

| Fault Type | Failures | MLPClassifier | FUzzy Logic | Join |

|---|---|---|---|---|

| 1 | 5 | 5.0 | 0.0 | 5.0 |

| 2 | 31 | 28 | 6.0 | 28 |

| 3 | 6 | 1.0 | 0.0 | 1.0 |

| 4 | 5 | 2.0 | 0.0 | 2.0 |

| 5 | 3 | 0.0 | 0.0 | 0.0 |

| 6 | 11 | 11 | 12 | 11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mateus, B.C.; Farinha, J.T.; Mendes, M. Fault Detection and Prediction for Power Transformers Using Fuzzy Logic and Neural Networks. Energies 2024, 17, 296. https://doi.org/10.3390/en17020296

Mateus BC, Farinha JT, Mendes M. Fault Detection and Prediction for Power Transformers Using Fuzzy Logic and Neural Networks. Energies. 2024; 17(2):296. https://doi.org/10.3390/en17020296

Chicago/Turabian StyleMateus, Balduíno César, José Torres Farinha, and Mateus Mendes. 2024. "Fault Detection and Prediction for Power Transformers Using Fuzzy Logic and Neural Networks" Energies 17, no. 2: 296. https://doi.org/10.3390/en17020296

APA StyleMateus, B. C., Farinha, J. T., & Mendes, M. (2024). Fault Detection and Prediction for Power Transformers Using Fuzzy Logic and Neural Networks. Energies, 17(2), 296. https://doi.org/10.3390/en17020296