1. Introduction

As the world increasingly shifts towards sustainable energy practices, the need for energy efficiency and environmental sustainability has become more pressing than ever before. The building construction sector accounts for 30% of total global final energy consumption and 27% of total emissions of the energy sector. It also represents about 8% of direct CO

2 emissions related to energy by final consumers [

1]. Without the application of any energy-efficient solution, the global energy demand could increase by 50% in 2050 with connected environmental impacts [

2]. For this reason, there is a growing demand for effective methods to evaluate buildings’ energy performance and identify strategies for energy efficiency and environmental sustainability according to the targets set by the European “Fit for 55” package [

3]. Retail is an energy-intensive sector that is responsible for a significant share of greenhouse gas emissions, especially for the large-scale retail trade building sector. The food industry produces high energy consumption and greenhouse gas emissions [

4]. According to the 2022 Global Status Report for Buildings and Construction, the global contribution of residential and commercial buildings to energy consumption increased by about 4% from 2020 to 2022, which is the largest increase in the last decade [

5]. In the food industry, energy consumption is particularly high due to the constant need for refrigeration of the whole cold chain (about 30% up to 60% of the final energy use), lighting (less than 30%), heating, ventilation, and air-conditioning (HVAC), and secondary processes, e.g., food preparation, storage, transportation, etc. [

6]. The high level of energy consumption in the retail sector highlights the need for energy efficiency measures. In this panorama, the knowledge acquired in recent years enables the development of autonomous buildings capable not only of producing enough energy to feed themselves but also of yielding it to others [

7]. Moreover, environmental sustainability policies are the core of any high-level company [

8]. However, this concept is not always obvious when it comes to retail and especially warehouses [

9]. The latter are often designed without considering the optimization of systems and performance that would allow them to be much more efficient than they are [

10].

The correct management, control, and regulation of HVAC systems, plant subsystems and equipment, optimal thermal insulation of buildings, and the application of eco-sustainable solutions are fundamental for refurbishment and retrofitting projects in the context of energy transition, green economy, and environmental and energy sustainability. It was found that 58% of warehouse buildings’ performance is based on design sustainability [

11]. Several studies show some strategies that can optimize building energy efficiency in this sector and, thus, decrease energy consumption. For instance, Paride Gullo et al. [

12] showed that by replacing the coolant in HVAC systems, the power consumption of all systems can be greatly reduced. Maria Kolokotroni et al. [

6] showed that low-energy ventilation strategies—such as improving the air tightness of the casing, exploiting natural ventilation, reducing the specific fan power, and implementing new refrigeration systems—that combine CO

2 with ventilation heat recovery, can provide significant energy savings with a reasonable return on investment. Another proposed strategy concerns using advanced technology materials and passive systems to provide long-term benefits, including measures such as naturally ventilated double skin facades [

13] and green vertical systems [

14].

In the present scenario, experimental building prototypes have gained popularity for testing and comparing the efficacy of systems and materials in real operating conditions. These prototypes allow researchers to isolate and test specific variables by cutting the costs occurring when experimenting on real buildings. Revel et al. [

14] studied the effectiveness of cool-colored ceramic tiles, bituminous membranes, and acrylic paints when applied to the envelope of different building prototypes in Madrid (Spain). Similarly, Mandilaras et al. [

15] carried out a comparative analysis of the thermal resistance and general performance of different thermal insulation materials in a two-story prototype building in Athens (Greece). In Wijethunga et al. [

16], a novel leak-detection framework is proposed to design refrigeration systems in supermarket prototypes. The building–plant system, especially in large commercial systems, is complex and needs robust and effective methods to identify solutions for green energy transition and energy–environmental sustainability. This is particularly important when the building–plant system is existing and not newly designed. Moreover, these building types can be very different in terms of construction typology, built form, activity, and occupancy. It may be difficult to identify a reduced number of buildings that may represent most of them. The alternative approach proposed is the development of a series of archetypal buildings that are representative (from a physical construction and energy point of view) of the typical forms of retail trade construction. Therefore, usually, form and geometry, construction, and activity features that affect building energy performance are parameterized. Nevertheless, they can remain customizable to represent individual buildings. This type of approach is widespread in the literature when working with a huge number of buildings since it provides a standardized and replicable representation and modeling of buildings [

17,

18,

19].

The representative models are usually digitally processed by BIM (Building Information Modeling), allowing the representation of these buildings in detail both from the architectural point of view [

20,

21] and the energy and plant engineering perspective [

22,

23]. This detailed and integrated modeling method coupled with dynamic simulation modeling allows for carrying out more analyses than simpler models [

24]. These models must be verified by dynamic energy modeling validation [

25,

26,

27,

28], which is unavoidable to ensure the reliability of the models. Accurate forecasts improve power management, grid stability, and load regulation, yielding benefits for both energy producers and consumers [

29]. In addition, literature studies compare the buildings analyzed with the requirements due to regulations on energy performance [

30] to verify the status of the buildings analyzed vs. the current minimum standards [

31] or to evaluate the effect of implementing the European Energy Performance Directives [

32].

Furthermore, to have an exhaustive knowledge of the operating costs of the building, these models are coupled with information on the amount of their energy consumption and connected operating costs. This information also highlights the main problems and criticalities to be addressed. Following the guidelines of energy and environmental certification protocols, e.g., LEED (Leadership in Energy and Environmental Design) [

33], it is possible to give buildings scores for the different categories analyzed such as water use, energy use, waste management, and air quality. This certification protocol is increasingly used to design efficient and sustainable buildings. Alongside reducing energy use with sustainable strategies, the goal is often to supply the building–plant system with renewable energy, and if possible, without external sources. The crucial objective now is to identify the least impactful solution that maximizes clean energy use with the lowest environmental impact. For instance, improvements can be achieved through advanced technologies, energy recovery, waste energy utilization, better energy conversion efficiency, and optimized operational practices [

34]. In the literature, there are many solutions to optimize the use of energy [

35] according to different types of needs and possibilities. Therefore, it is necessary to identify the solutions most economically advantageous, less impactful, and more compatible with the analyzed building. Among the solutions described above, energy management process optimization is fundamental. This process depends on many features of the building that can vary quickly during the day and all year round. Therefore, the operating parameters of the whole building–plant system must be controlled by means of interconnected network systems (e.g., Konnex protocol, KNX). Many literature studies show a wide use of sensors via the Internet of Things (IoT), which are able to communicate recorded information through the internet [

36]. There are many examples of smart HVAC and indoor environment control systems [

37] or IoT-driven building environment control for predicting electric energy consumption [

38], which allows for optimizing the operation of the building when properly defined.

Finally, to verify the effective optimization of the buildings in terms of energy consumption, costs, and environmental impact, specific indices are used to express the conditions and performance of the building. These are selected according to the type of intervention implemented and the type of monitoring that is intended to be carried out. In the literature, many examples of these indices are widely used to provide structured knowledge about buildings and their energy performance [

39]. Several studies analyze different types of indices derived from the information collected by the building itself. For example, Liu et al. [

40] developed an index called “Energy saving of building envelopes” that comprises the building energy consumption baseline that is decreased due to the optimized design of building envelopes. Abu Bakar et al. [

41] revised the Energy Efficiency Index (EEI) as a more comprehensive indicator used to track the energy consumption performance in a building. Last but not least, Gonzáles et al. [

42] proposed an index that evaluates the energy efficiency of buildings by relating their energy consumption to a reference consumption. Many of these studies mentioned are based on evaluating energy efficiency without considering the possibilities of CO

2 emission reductions.

The above-listed methods and tools, summarized in

Table 1, are all well acknowledged and used in the scientific literature. They are usually implemented singularly or coupled, but they can also be combined and integrated in a comprehensive and multi-step process of analysis. Accordingly, the novelty of the methodological approach proposed in this study lies in the construction of an interactive connection network among the above-mentioned crucial elements. This approach allows for a quantitative and systemic assessment of the potential for intervention and operational development aimed at the energy transition and environmental sustainability in large-scale food retail trade buildings, which have been poorly addressed in the scientific literature from a comprehensive perspective. Therefore, this study presents a method for evaluating energy efficiency and sustainability in large-scale food retail trade buildings, demonstrated through a detailed representative case study of food retail in central Italy. This method employs dynamic simulation of the Building Energy Model (BEM) to assess the impact of various retrofit solutions in a sector that significantly impacts overall energy consumption and greenhouse gas emissions.

2. Materials and Methods

Drawing from this background, this study aims to define a method for evaluating the rational use of energy and efficiency in large-scale food retail trade buildings. The approach is designed to achieve environmental, urban, and social regeneration while supporting energy transition and sustainable development.

The proposed method entails a comprehensive analysis and evaluation of all the data and information concerning building energy systems in the commercial sector. The approach is dynamic and adaptable to different contexts and complex situations—in relation to the size of the studied system and the availability of real digital information—but always pursues the same objectives. Comparative analyses are used to identify representative prototype cases on which experimental measurements and transient simulations are developed to test the approach.

The method is used to assess energy efficiency retrofit strategies for existing large-scale food retail trade buildings. By starting from an energy diagnosis, it seeks to understand the building–plant system energy consumption, which is crucial for defining and measuring the benefits of energy-saving strategies. Dynamic simulations support energy analysis, employing BEM to develop realistic models and assess different retrofit scenarios. Integrated energy efficiency scenarios are then built to evaluate the impact of solutions on the energy performance of the building–plant system.

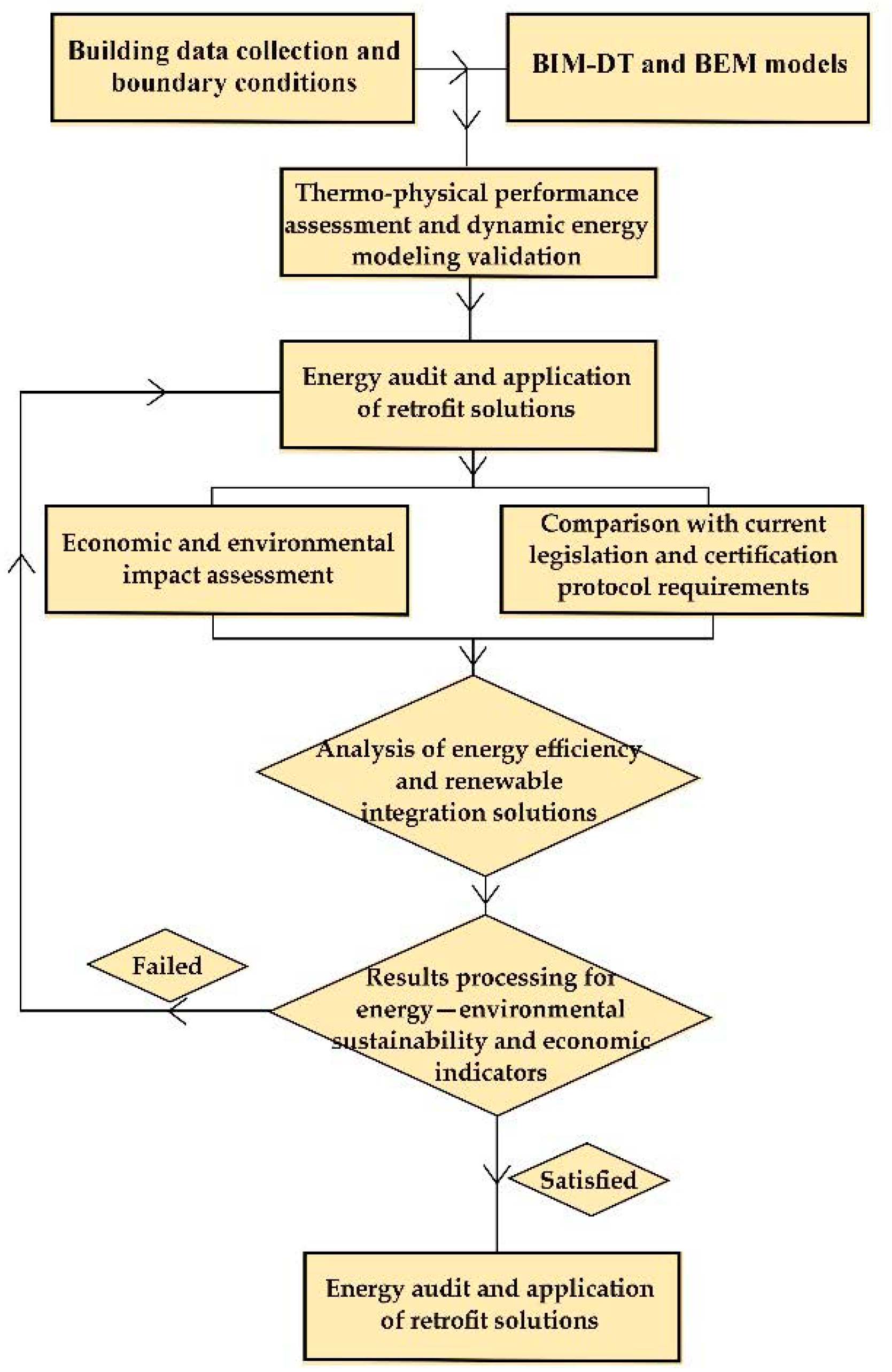

The proposed method involves different operative phases detailed in the following sub-sections and summarized in

Figure 1.

The novel assessment framework proposed begins with a building energy diagnosis using a BIM-MEP (Building Information Modeling and Mechanical, Electrical, and Plumbing) model that concerns the 3D building and plant modeling connected to a Digital Twin (DT) and BEM-based approach to survey and document the technology, structure, and facilities of the existing building. By leveraging technology, sustainable requalification was made possible through the simultaneous management of key parameters (

Figure 1).

2.1. Building Data Collection and Boundary Conditions

This phase encompasses the collection and analysis of data on the building and its boundary conditions. In this phase, it is important to analyze different data and information, such as the building’s architectural layout (including spatial and functional organization, as well as outdoor areas), envelope structure, energy systems, energy consumption, and weather data.

The data collection process is important to construct an energy consumption model and identify climate zone conditions, building geometry, occupational schedules, and other specific boundary conditions. Food retail trade buildings exhibit different zones for various purposes, such as product storage (both general and cold storage), sales areas, office zones, and technical areas.

In this phase, all the data on plants and building construction characteristics are collected, thanks to the existing as-built project accessibility. When such data are unavailable, literature evidence is used. The final step entails the compilation of information necessary for evaluating the energy performance of the existing building. This involves data regarding energy consumption across various domains such as the cold chain, HVAC systems, lighting, food preparation, and occupancy and operational schedules, supplemented by comprehensive weather data. Energy consumption data are usually provided by monthly energy bills and hourly data monitored through building-integrated energy meters, encompassing HVAC, refrigeration, lighting, food preparation, ventilation, and secondary (e.g., food preparation and washing) processes.

Representative buildings are typical buildings that exemplify a broader range of building types within a sector, e.g., the food retail trade sector. The use of representative buildings allows for a standardized and replicable evaluation of the energy performance of retrofit strategies across diverse building types managed by Distribution System Operators (DSOs). By focusing on such representative models, the findings can be generalized and applied to a wider array of similar buildings, enhancing the relevance and applicability of the proposed energy efficiency and sustainability strategies.

2.2. The BIM-DT and BEM Models

The use of representative case studies provides a comprehensive picture of buildings and their potential improvement on a large scale. To this aim, BIM-DT models of building–plant systems were developed. A digital model of the building allows us to carry out accurate simulations to foster the development of solutions tailored to the system studied, ensuring maximum compatibility.

BIM-DT and BEM modeling uses different inputs, e.g., the HVAC system, the lighting system, the presence of a maximum and minimum number of people within the different zones, the characteristics of the cold cycle machines for food storage, the characteristics of the casings, etc.

BIM is a widely recognized tool for creating and managing digital representations of the physical and functional characteristics of buildings. In the context of food retail trade buildings, BIM-DT represents a fusion of BIM with the DT concept, creating a real-time dynamic model that mirrors the performance of the building in the physical world [

22,

23].

BEM tools, such as EnergyPlus, allow the simulation of the energy flows within the building and its energy consumption, including heating, cooling, lighting, and appliance use. In the context of food retail trade buildings, BEM can be particularly useful for understanding the energy performance of complex refrigeration systems and other systems and potential retrofit solutions. In particular, the existing behavior of the building can be modeled via dynamic energy simulation, and the impact of the proposed interventions can be evaluated in terms of energy performance. As a dynamic simulation tool, this method foresees the use of the open-source EnergyPlus simulation engine. This simulation tool allows heat and moisture balance calculation, including thermal comfort, interior surface convection, daylighting and artificial lighting systems and controls, refrigeration equipment, HVAC systems, and equipment features. The EnergyPlus detailed energy modeling provides an environment to simulate all the main energy uses that characterize large-scale commercial buildings and to test different technical solutions that can be adopted to improve building performance. These models are used to build integrated energy efficiency scenarios that allow assessing the influence of different solutions on the thermal-energy behavior of the building and its surroundings.

Given that newly constructed or retrofitted buildings usually remain operational for many years, it is crucial to evaluate the performance of the proposed retrofit strategies not only at the time of implementation but also considering the changing scenario of future climate. This long-term perspective ensures that the retrofits would be effective under evolving environmental conditions, ultimately enhancing the building’s resilience and efficiency over its lifespan. By considering future climate scenarios, the building’s performance can be optimized throughout its operational life.

2.3. Thermo-Physical Performance Assessment and Dynamic Energy Modeling Validation

The third step concerns dynamic analyses of the thermo-physical and energy performance of the building–plant system according to the European standard for energy audits EN 16247-1:2022 [

44]. Referring to energy and mass flow balance, specific consumption patterns and the identification of critical issues and necessary interventions can be evaluated. The analysis includes a detailed evaluation of building thermo-physical performance and system efficiency, considering the building orientation, envelope performance, lighting system, and HVAC system, including heating and cooling energy production plants. The energy diagnosis also enables the economic evaluation of building energy consumption.

The model used for transient simulation is calibrated according to the procedure in [

45,

46]. Therefore, the calibration indices Normalized Mean Bias Error (

NMBE) [%] and Coefficient of Variation of the Root Mean Square Error (

CV (RMSE)) [%] are calculated. The

NMBE index is defined in Equation (1) [

45,

46] and the

CV (RMSE) index is defined in Equation (2) [

45,

46], where M

i is monitored data, S

i is the simulation outcome, N is the number of data, and M

mean is the mean of the measured values.

A Digital Twin (DT) is a virtual representation of a system or object during its life cycle. It uses machine learning and reasoning to help decision-making based on updated real-time data. In other words, a DT is a virtual model of a physical object that accurately reflects its behavior. Simple numerical simulations provide insights into a specific condition in time. DTs are a source for assessing and understanding any conflicts and clashes in real time. In the proposed approach, a DT model focused on the simulation of energy efficiency and GHG emissions is developed to control the Building Energy Model.

2.4. Comparison with Current Legislation and Certification Protocol Requirements

This phase concerns the comparison of the thermo-physical characteristics and energy simulation results of the building–plant system with the requirements of the current legislation and standards and acknowledged certification protocols, e.g., LEED (Leadership in Energy and Environmental Design).

The LEED criteria are considered as a reference for the identification of improvement strategies. Using existing validated technologies, LEED evaluates the environmental performance of a building during part of its life cycle, i.e., from the design phase and during the construction and operation [

33]. To directly compare the building energy performance according to the LEED protocol guidelines, different analysis scenarios are proposed. Analysis scenarios are generated referring to the type of building construction, size, and location.

Our proposed method is implemented without strict allegiance to a singular legal framework by juxtaposing simulation outcomes with mandated norms and certification protocols while scrutinizing prevailing regulations alongside simulation results. Instead, it holds the flexibility to be tailored to varying legislative contexts. This potential bears the capacity to unveil inventive strategies or techniques that could lend support to forthcoming international regulations or environmental certifications.

2.5. Economic and Environmental Impact Assessment

Environmental and economic analyses play a crucial role in determining the most effective strategies and their integration possibilities, which cannot be selected by only referring to energy performance. This phase is essential for identifying project proposals. During this phase, the initial costs of the implemented solutions and the energy costs of the building–plant system working conditions are evaluated, considering the fluctuating energy market and associated environmental factors. To conduct energy and environmental assessment, the analysis of building energy requirements throughout the year, the availability of resources, the cost, and the environmental impact resulting from their transformation and utilization are necessary. The objective is to identify energy solutions that are both economically viable and environmentally sustainable through energy analysis and diagnosing techniques applied to the building–plant system.

To assess economic feasibility, the net present value (

NPV) analysis is selected. This is a calculation method used to determine whether a project generates value within a reasonable timeframe for its economic return [

47]. The

NPV methodology calculates the discounted cash flow (

CF) after the initial investment and assesses the

CF at the moment of the initial investment. According to the

NPV calculation method, a project’s net present value is the sum of the present values of all its cash flows, including inflows and outflows, discounted at a rate that reflects the risk of the project [

48]. The expression of

NPV is reported in Equation (3) [

48]:

where

CF(

t) is the cash flow in period

t (expressed in Equation (4) [

48]),

i is the discount rate, and n is the life of the investment project. Equation (4) is as follows:

where

EBIT is Earnings Before Interest and Taxes.

In this paper, the annual euro savings was evaluated for NPV calculation. The cost of the current average energy (0.20 EUR/kWh) and the Statistics Report of

Banca d’Italia for the current discount interest rate (3%) for buildings in the retail sector were taken into account in calculating the annual euro savings [

49]. The index values utilized in the economic and energy analysis are those specifically corresponding to the same years of the available building energy consumption.

To evaluate building environmental performance, the proposed method studies different criteria: carbon footprint and social cost of carbon. In this study, the greenhouse gas emissions due to energy consumption of buildings were used to obtain science-based information about the environmental impact of the case study building, in terms of GHG emissions (kgCO

2eq), according to the standard EN 15978:2011 [

50]. GHG emissions were evaluated on the Kyoto basket gases weighted by their global warming potential (GWP) and aggregated to determine total GHG in terms of CO

2eq [

51].

2.6. Analysis of Energy Efficiency and Renewable Integration Solutions

Several factors, such as building architecture, energy demand, boundary conditions, and available resources, are considered to identify the most suitable energy efficiency and, thereafter, renewable energy integration solutions for the building. The solutions developed are designed to meet the building-specific needs and to ensure maximum compatibility with existing building systems, components, and boundaries.

The assessment of renewable energy system integration is the main aim of this phase to decrease final energy consumption and, consequently, carbon footprint and social costs of carbon. Especially, solar, wind, and geothermal energy are studied for their possible effective integration into the building. The goal is to identify the most effective and integrable renewable energy solutions in the commercial sector. In particular, the proposed method will propose different solutions for PV plants to maximize energy production and increase the self-consumption share. To maximize PV efficiency in food retail trade buildings, three different strategies are proposed: downsizing the plant system to cover the summer energy demand; designing a plant of optimum size for maximizing the self-production of energy during the whole year; and designing a plant of medium size for producing a well-defined amount of the energy required by the building (from 40% to 60%). Other improvement solutions propose commercial buildings as promoters of renewable energy communities, which are mostly optimized when different building end-uses are involved, as suggested in [

30].

2.7. Results Processing for Energy–Environmental Sustainability Indicator Identification

In this phase, fundamental sustainability indicators are identified and evaluated. These indicators are required for objectively assessing the energy, environmental, economic, and social impacts of the different solutions and comparing the proposed scenarios from a holistic point of view.

The selection of the indicators is carried out by considering several factors, e.g., energy consumption and environmental impact of the solutions adopted during their life span. The goal of the above-mentioned proposed approach is to support a reliable and useful analysis of the energy performance of commercial buildings for the food retail trade, to identify areas/sectors for improvement, and to develop energy-efficient and economically, socially, and environmentally sustainable solutions.

The identified indicators are as follows:

3. The Case Study

In this study, a representative building is selected that typifies the characteristics and energy consumption patterns of large-scale food retail trade buildings. This building serves as a case study for the application of the method described in

Section 2, providing a detailed analysis of energy-saving measures and their impact on the building–plant system’s performance. The selected case study is a retail building that exemplifies a representative supermarket building of a widespread company in Italy. It incorporates prevalent design features and functional elements observed in a significant majority of similar structures through a comprehensive typological analysis. At first, it was characterized according to the first step of the proposed approach.

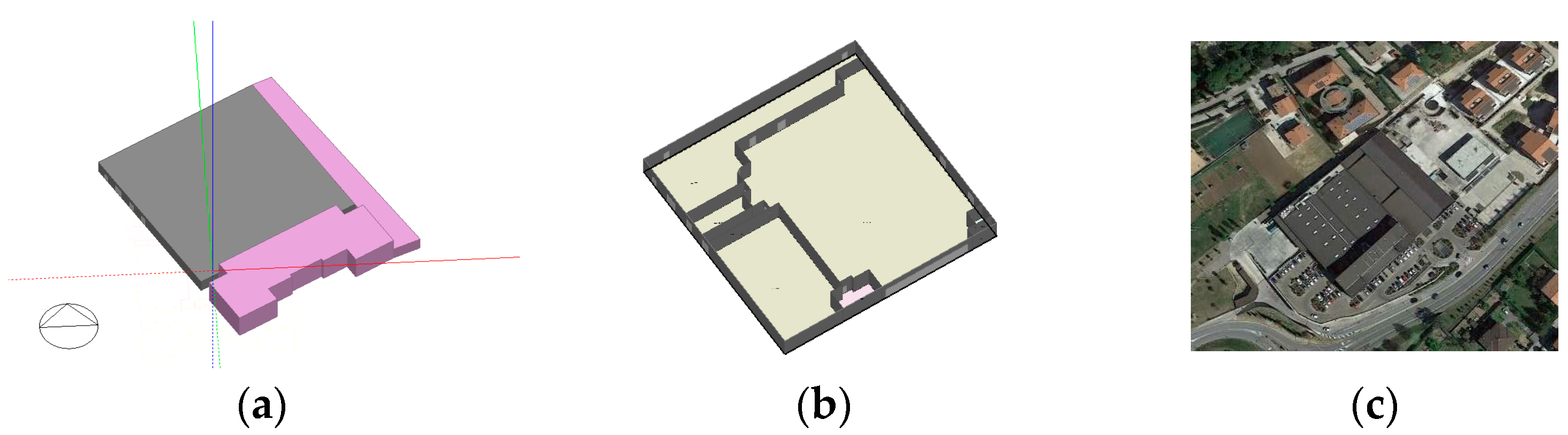

The case study is a food retail building (

Figure 2c) located in Assisi (N 43.03, E 12.34, 218 m above sea level), Italy, in the climate zone E according to the Italian climate classification introduced by the DPR 412/93 [

52] and Law 10/91 [

53]. Climate zone E includes areas characterized by Heating Degree Days (HDDs) between 2101 and 3000. The value for Assisi is 2470 HDDs. It is characterized by a Mediterranean climate, with quite cold winters (22 October–7 April) and hot summers (5 June–5 September).

The case study building was built in 2012. It has a single floor, with a supporting structure in prefabricated pillars of reinforced concrete and prefabricated concrete panels. The building envelope has a thermal insulation level compliant with the national regulation at the time of construction [

54]. Existing external walls have a thermal transmittance (U-value) of 0.302 W/m

2 K. The double-pitched roof is made of a wooden structure covered with prefabricated insulating panels. The U-value is 0.331 W/m

2 K. The existing windows have PVC frames, shock-proof fixed elements, and reflective double glass (3-16-3 mm).

The building is equipped with two different HVAC systems. The first system works for the sales area and has five air handling units (AHUs) and five heat pumps. The characteristics of each heat pump are 5340 m3/h air flow rate, COP equal to 3.05, EER equal to 3.01, total heating capacity equal to 27 kW, and total cooling capacity equal to 25 kW. The second system serves the warehouses, the office, and the locker room. This system has one AHU and a heat pump. The characteristics of the heat pump are a 10,260 m3/h air flow rate, COP equal to 4.38, EER equal to 4.31, total heating capacity equal to 22.4 kW, and total cooling capacity equal to 25 kW. Regarding the lighting system, the building is equipped with fluorescent lamps.

The supermarket is located inside a small shopping center and borders on the perimeter with a gallery in which other commercial activities are included. The surfaces that delimit the heated volume adjoin adjacent shops, the gallery, the warehouse, and the outdoors on the northwest and southwest orientations. The building includes the sales area, two warehouses, the office, the locker room with the toilet, and the technical room, for a total surface of about 1852 m2. Among all these square meters, 1807 m2 are conditioned and 45 m2 are not conditioned, leading to an air-conditioned gross volume of 9036 m3. The window-to-wall ratio is very low since the window area is equal to 40 m2.

The building is generally operating every day of the year and is open to the public from 8:30 a.m. to 8:30 p.m., while the locker room is open from 6:00 a.m. to 9:00 p.m.

The monthly consumption of electricity recorded in the bills for the year 2022 was collected and is considered for the purpose of this study. These data show that in 2022 the building had an electricity consumption rate of 822 MWh per year.

3.1. Dynamic Energy Simulation Model and Calibration

As the second step of the proposed method, the BEM model of the case study building was developed to evaluate the potential benefits achievable through energy retrofit interventions.

Figure 2 depicts the BEM model of the case study building used for the analyses (

Figure 2a), including the aerial view of the building within its surroundings (

Figure 2c) and the internal thermal zones (

Figure 2b).

In this study, dynamic numerical simulations were carried out. The BEM is the basis for the improvement and implementation of a DT building–plant system. The BEM applied for dynamic simulations of the case study building provides a detailed representation of the physical structure and energy systems, allowing for a realistic prediction of energy consumption, thermal comfort, and overall operational efficiency. Indeed, it allows for the realistic analysis and combination of refrigeration (cold storage rooms, freezers, and refrigerated display cabinets), HVAC system, lighting, and occupancy patterns, and, therefore, the digital simulation of the effect of potential retrofit strategies (before they are actually implemented).

The BEM model was calibrated with the monthly electricity consumption data for the year 2022 (including HVAC, refrigeration, lighting, food preparation, ventilation, and secondary processes) to achieve a realistic prediction. The real weather data from the local weather station of the year 2022 were used as boundary conditions for the calibration. The calibration is verified based on the indices described in

Section 2.3, i.e., NMBE and CV (RMSE). To calibrate the BEM model, different modifications to the initial model are necessary. As a result, the model was calibrated through iterative modifications. In particular, the input data of the energy systems were dynamically updated in terms of the power of machinery and the schedules of system operation.

The calculated NMBE and CV (RMSE) indices for the calibrated model, reported in

Table 2, are widely included in the tolerance range according to the reference ASHRAE standard [

55]. Indeed, when monthly values are considered, the model is considered calibrated when CV (RMSE) < 15% and −5% < NMBE > 5%.

3.2. Retrofit Scenarios

Many factors, e.g., building architecture, boundary conditions, etc., are considered to identify the most suitable energy efficiency and, thereafter, renewable energy integration solutions for the building. To evaluate the performance of retrofit scenarios, the proposed method explores different criteria, as previously detailed: energy consumption reduction, CO2 emission reduction, and economic savings.

In this study, the proposed retrofit scenarios are energy efficiency strategies that are reversible, easily installable, and also reduce maintenance costs. Investment costs are derived from the sum of the calculation of the costs of materials and intervention based on standard market costs. Consequently, they are deemed suitable for various buildings. Specifically, this study examines and analyses six retrofit scenarios outlined as follows:

Scenario (A): Additional insulation of the building envelope by means of environmentally friendly materials. In particular, the existing external walls currently have a thermal transmittance (U-value) of 0.302 W/m

2 K, thermal resistance (R-value) of 3.313 m

2 K/W, periodic thermal transmittance (Yie) of 0.072 W/m

2 K, phase displacement (φ) of 9.83 h, and damping (fd) of 0.255, i.e., higher than the current regulatory limit value. In the retrofit scenario, an EPS thermal insulation layer with graphite (λ = 0.031 W/m K) with a thickness of 10 cm is added to the external walls. Therefore, the new U-value is equal to 0.152 W/m

2 K, the R-value is equal to 6.579 W/m

2 K, Yie is equal to 0.003 W/m

2 K, φ is equal to 13,45 h, and fd is equal to 0.017, i.e., compliant with the current requirements for buildings [

56]. Similarly, the existing roof has a U-value of 0.331 W/m

2 K. In the retrofit scenario, a 10 cm layer of the same EPS is also added to the roof. The new U-value is equal to 0.181 W/m

2 K according to [

57]. The predicted investment cost for scenario A, i.e., the opaque envelope retrofit, is equal to about EUR 50,000, including the materials and the intervention costs.

Scenario (B): Additional insulation of the building envelope by means of environmentally friendly materials and PV panel integration. In detail, this scenario involves the same solutions for the building envelope implemented in scenario A and adds 585 m2 of PV panels to guarantee a peak power equal to 117 kWp obtainable by exploiting the roof with favorable exposure. For scenario B, the calculation of the initial investment was carried out based on a deep market investigation that led to the estimation of the cost of 1100 EUR/kWp. Therefore, the total initial investment (I0) was EUR 128,700 + the cost of the building envelope insulation of about EUR 50,000. The total investment cost for scenario B is equal to about EUR 178,700.

Scenario (C): Integration of PV panels in the building roof and suitable external areas involving pedestrian paths, shelters, and car parks. Therefore, 881 m2 of PV panels are integrated to guarantee a peak power equal to 180 kWp, obtainable by exploiting the roof with favorable exposure and pedestrian paths, shelters, and car parks in the building outdoors. The cost for scenario C was predicted based on the same cost estimation of scenario B of 1100 EUR/kWp. Therefore, the total initial investment (I0) was EUR 170,800.

Scenario (D): Replacement of the existing lighting systems with LED technology for both internal and external lighting. The predicted investment cost for scenario D is equal to EUR 54,800.

Scenario (E): Low-temperature waste heat recovery from the refrigeration cycle to be used for heating. The recovered waste heat is mainly used to reduce the HVAC system energy consumption in winter. The predicted investment cost for scenario E is equal to EUR 30,000.

Initially, the implementation of a green roof was also considered as a potential solution to be studied. However, it is not suitable for this specific building application because it would require the remaking of the entire roof due to load-bearing limits, which would be much more expensive than the potential energy and economic benefits achievable through this solution. Therefore, this strategy was excluded.

3.3. Current and Future Climate Scenarios

Weather data are obtained through historical records from regional weather stations installed in proximity to the building. If such data are unavailable, a monitoring campaign based on a dedicated experimental set-up must be carried out.

These data and weather data are used for the calibration of the BEM. Moreover, the Typical Meteorological Year (TMY) was obtained via the database of climate.onebuilding.org [

56] to evaluate the energy performance of the analyzed building in statistically representative weather conditions. Therefore, weather data were input into the BEM to assess the energy consumption and environmental performance accurately. Thereafter, the TMY climate file was used to generate projected climate files for the future years 2050 and 2070. The future weather files were generated using the software Meteonorm v8.0 [

58]. The applied morphing technique utilizes historical climate data, incorporating representative meteorological measurements, alongside projected global climate change patterns obtained through numerical computer modeling [

59]. This combination generates a new set of future projected climate scenarios. By leveraging recorded climate data as a foundation for future projections, this approach ensures temporal continuity and spatial downscaling.

This study considers the A1B climate change scenario [

60], which runs on the assumption that there will be an increase in air temperature of a maximum of 4.4 °C until the end of the 21st century.

The heating and cooling conditions were analyzed based on the climate station of the National Weather Service for scenario A1B. The following Equations (5) and (6) [

55,

61,

62] were used to calculate the heating degree days (HDDs) and cooling degree days (CDDs), respectively [

55,

61,

62]:

where

z is the number of heating days,

Tht is the heating threshold,

Tct is the cooling threshold, and

Ta is the mean air temperature of a heating or cooling day, respectively.

Table 3 shows the different HDDs and CDDs in the years studied. The predicted rise in temperatures is evident in the two future weather scenarios.

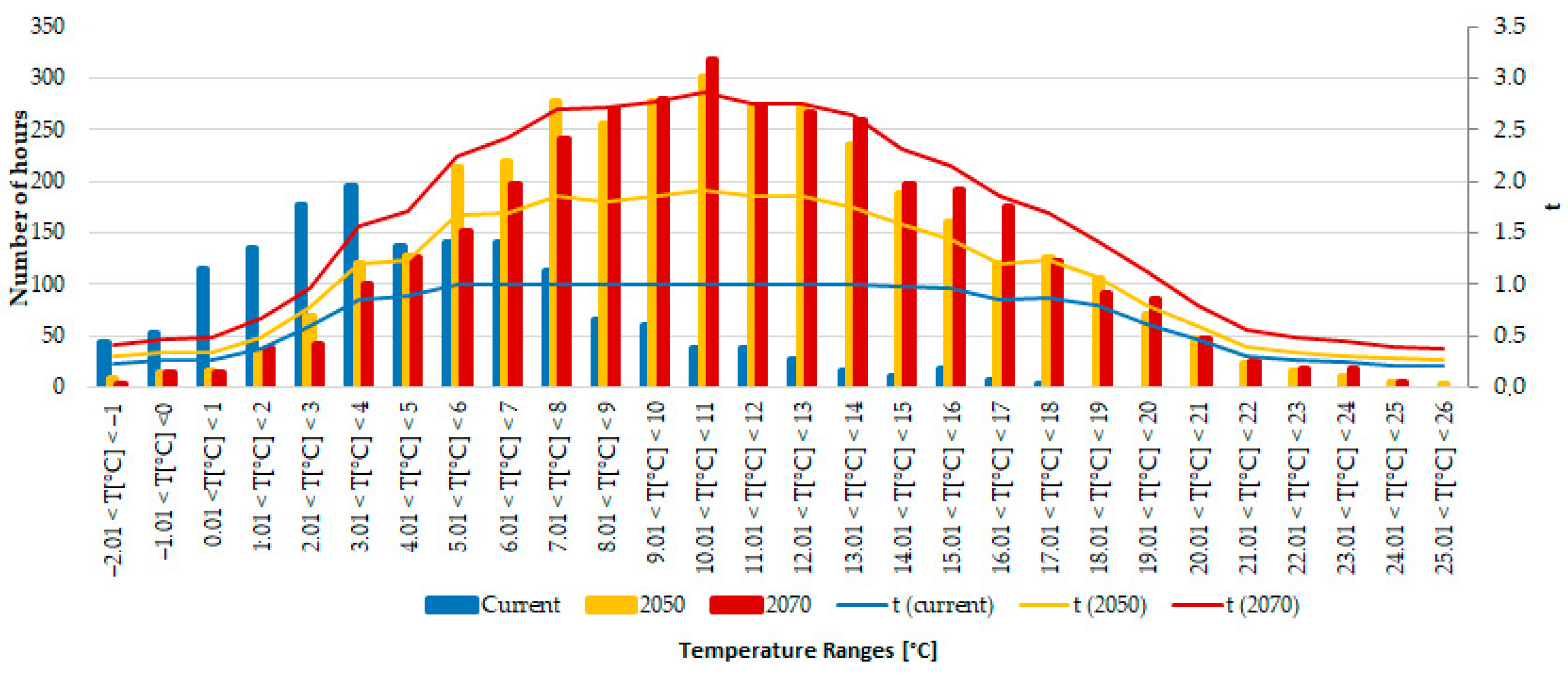

In

Figure 3, the t value is a Gaussian distribution expressed through Equation (7) [

63]:

where

H is the total hours of heating,

σ is the standard deviation calculated according to Equation (8) [

63],

Tp is the temperature project,

Te is the external temperature in °C, and

Tm is the average external temperature over the heating degree days expressed by Equation (9).

Figure 3 illustrates the distribution of hours during the heating period across various temperature intervals for the current year, 2050, and 2070. There is a notable shift in the distribution of hours towards higher temperature intervals as we move from 2022 to 2070. This indicates an expected overall increase in temperatures over time.

In the current year, the distribution is more concentrated in the lower temperature intervals, peaking around the 10–12 °C range. There are relatively fewer hours in the higher temperature ranges, with a sharp drop after 20–22 °C. In 2050, the peak shifts towards the right, centering around the 12–14 °C and 14–16 °C ranges. There is about a 30% increase in the number of hours in the higher temperature ranges (e.g., 16–18 °C and above) compared to the current conditions. In 2070, the peak continues to shift further right, around the 14–16 °C and 16–18 °C ranges. There is an approximately +31% increase in hours in even higher temperature intervals (20 °C and above). Furthermore, in 2070, the lower temperature intervals (below 7 °C) see a dramatic reduction (about −42%) in the number of hours. The shift towards higher temperatures over the decades signifies a clear warming trend, which is consistent with projections of global climate models under scenarios of continued greenhouse gas emissions.

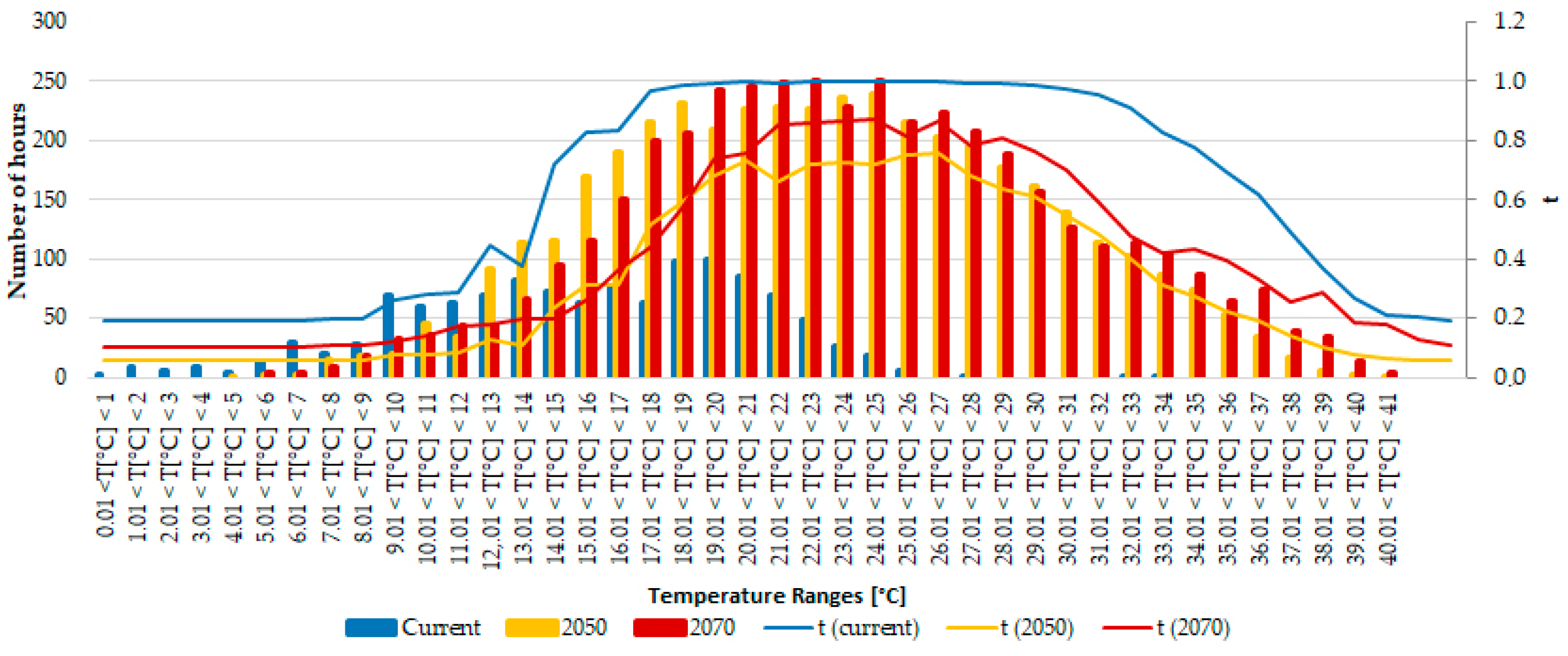

Figure 4 illustrates the distribution of hours during the non-heating period across various temperature intervals for the current year, 2050, and 2070.

In the current year, the distribution is more concentrated in the 18–22 °C range. There is a notable shift in the distribution of hours towards higher temperature intervals as we move from 2022 to 2070. This indicates an expected overall increase in temperatures over time.

In the current year, the distribution is more concentrated in the lower temperature intervals, peaking around the 10–12 °C range. In 2050 and in 2070, the peak shifts towards the right, centering around the 24–25 °C and 28–29 °C ranges. In 2070, the peak continues to shift further right, around the 14–16 °C and 16–18 °C ranges.

4. Results and Discussion

In this section, the results obtained for the case study building in each scenario concerning energy consumption, environmental impact, and economic costs are shown and discussed compared to the existing building scenario (Baseline case) in the current and future climate contexts.

4.1. Energy Consumption of the Existing Building–Plant System

The present section delves into the actual energy consumption profile (Baseline case) of the selected representative large-scale food retail building, highlighting key contributors such as refrigeration, lighting, the HVAC system, and other equipment. The potential energy consumption without any intervention was analyzed using the output of BEM dynamic simulations in the current climate scenario and in 2050 and 2070.

Table 4 summarizes the monthly total electricity consumption (including the HVAC system, refrigeration, local artificial lighting, bench lighting, and the equipment for food preparation) in the different climate scenarios.

Table 4 shows, as expected, that future scenarios, characterized by rising outdoor air temperatures, will lead to a significant increase in energy consumption, particularly during summer (June–August). Projections for 2070 show a potential increase in energy consumption of approximately 30% in June and 50% in July and August for the HVAC, and 4% in June and 6% in July and August for refrigeration. Overall, in the analyzed case study, there is an estimated increase in total energy consumption of 5% by 2050 and 6% by 2070 compared to the current situation. These trends underscore the critical need for effective retrofit strategies to generally improve building energy performance by paying attention to mitigating the impacts of climate change, in particular for large-scale food retail buildings.

4.2. Energy Consumption in Retrofit Scenarios

Table 5 shows the annual total electricity consumption in the retrofit scenarios vs. the actual scenario (Baseline case) in the current and future climate contexts.

The results show the higher potential of scenario A in the 2050 and 2070 future climates due to the more relevant role of envelope periodic thermal transmittance (Yie) in the hot season. In the current scenario, the proposed strategy has low energy savings detected (0.6% equal to 5 MWh/year), while in 2050 and 2070, the potential savings could be up to 2.9% (26 MWh/year) and 3.8% (34 MWh/year), respectively. Scenarios B and C show considerable impacts on energy consumption reduction with a similar percentage contribution—about 21% for scenario B and 28% for scenario C—in the three climate scenarios since it is primarily due to the production and self-use of electricity from renewable sources. Indeed, this shift allows for a decreased reliance on energy purchased from the grid. In detail, in the current scenario, the more effective scenario C allows a saving of 238 MWh/year, while in 2050 and 2070 the potential savings could be 246 MWh/year and 249 MWh/year, respectively.

Another noteworthy scenario is D, which focuses on replacing conventional lighting fixtures with more energy-efficient technologies. This strategy yields a significant reduction in energy consumption, estimated at around 11–12% in all of the scenarios, corresponding to about 100 MWh/year. Such improvements in lighting technology play a pivotal role in overall energy conservation efforts in the large-scale food retail trade sector, where lighting has a relevant role and a corresponding non-negligible impact on total energy consumption.

Furthermore, strategy E targets reducing energy consumption associated with heat recovery from the refrigeration cycle to be used for heating, especially during the winter season. Although this strategy results in a noteworthy reduction in heating-related energy consumption (about 20%), it translates to a modest overall consumption decrease of 0.6% (5 MWh/year) in the current climate, due to the minor contribution of heating on the total building electricity consumption in food retail buildings. However, in 2050 and 2070, strategy E could be able to reduce the consumption for space heating by about 40%, achieving a total reduction in electricity consumption of about 2–3%, which is 20–25 MWh/year.

Thereafter, since the proposed strategies can be combined, different combined scenarios were assessed. In scenarios C + D and A + C + D + E, the decrease in electricity consumption is greater than in other scenarios. These scenarios consistently provide the highest energy savings across all timeframes, achieving around 40% and more than 40% savings, respectively, for all the years.

Table 6 shows a comparative analysis of energy consumption under the different scenarios by analyzing the different energy consumption categories: HVAC, lighting, refrigeration, and PV energy production. It includes both current and future projections (2050 and 2070), for the Baseline case and the most effective scenarios, C + D and A + C + D + E.

For the Baseline scenario in the current climate, the HVAC consumption is 144 MWh/year. It increases to 177 MWh/year in 2050 (+19%) and 187 MWh/year in 2070 (+30%). In 2050, scenario C + D reaches 166 MWh/year equal to −6% compared to the Baseline case. In 2070, the same scenario saves about −8% compared to the Baseline case for HVAC energy consumption.

In scenario A + C + D + E, the HVAC consumption decreases to 128 MWh/year (−11%) in the current climate, reaching 148 MWh/year in 2050 (+3%) and 153 MWh/year in 2070 (+6%). However, in 2050, scenario A + C + D + E saves about −16% energy consumption for HVAC compared to the Baseline case, and, in 2070, about −18%.

Regarding the lighting, for the Baseline case, the energy consumption remains constant at 161 MWh/year in all climate scenarios since it does not depend on climate variation but on indoor artificial lighting needs. In scenario C + D and scenario A + C + D + E, the energy consumption for lighting decreases to 64 MWh/year in all scenarios, with energy savings of −60% compared to the Baseline case.

Furthermore, for the Baseline case, the energy consumption for refrigeration is 541 MWh/year in the current climate. It increases to 546 MWh/year in 2050 (+1%) and 549 MWh/year in 2070 (+2%). However, in scenario C + D, the energy consumption for refrigeration decreases to 534 MWh/year (−1%) in the current climate, reaching 536 MWh/year, which is equal to −2% compared to the Baseline case in 2050. In 2070, scenario C + D shows a slight increase to 541 MWh/year, which is equal to −1% compared to the Baseline case.

It can be deduced that the Baseline scenario shows an increase in HVAC and refrigeration energy consumption over time. The most effective scenario, especially considering the current timeframe, is A + C + D + E due to an important reduction in the HVAC energy consumption, with minimal increases projected over time. Both intervention scenarios show a substantial reduction in lighting energy consumption (about −60%) compared to the Baseline case.

4.3. Energy and Environmental Impact

In addition, the environmental impact of the proposed strategies is analyzed in terms of operative CO

2 emission reduction.

Figure 5 shows monthly operative CO

2 emissions in tons for the various building scenarios in the current climate, 2050, and 2070, including the actual condition and the different retrofit scenarios. Operative CO

2 emissions are emissions arising from operational energy consumption. The calculation of this environmental impact takes into account the energy transition that by 2050 will involve the use of energy sources derived exclusively from renewable energy sources. In this study, the useful life of the energy systems is not considered and their environmental efficiency is assumed to be constant.

The energy and environmental performance of the case study building was assessed through a detailed analysis of percentage energy savings and percentage operational CO

2 savings over time, as represented in

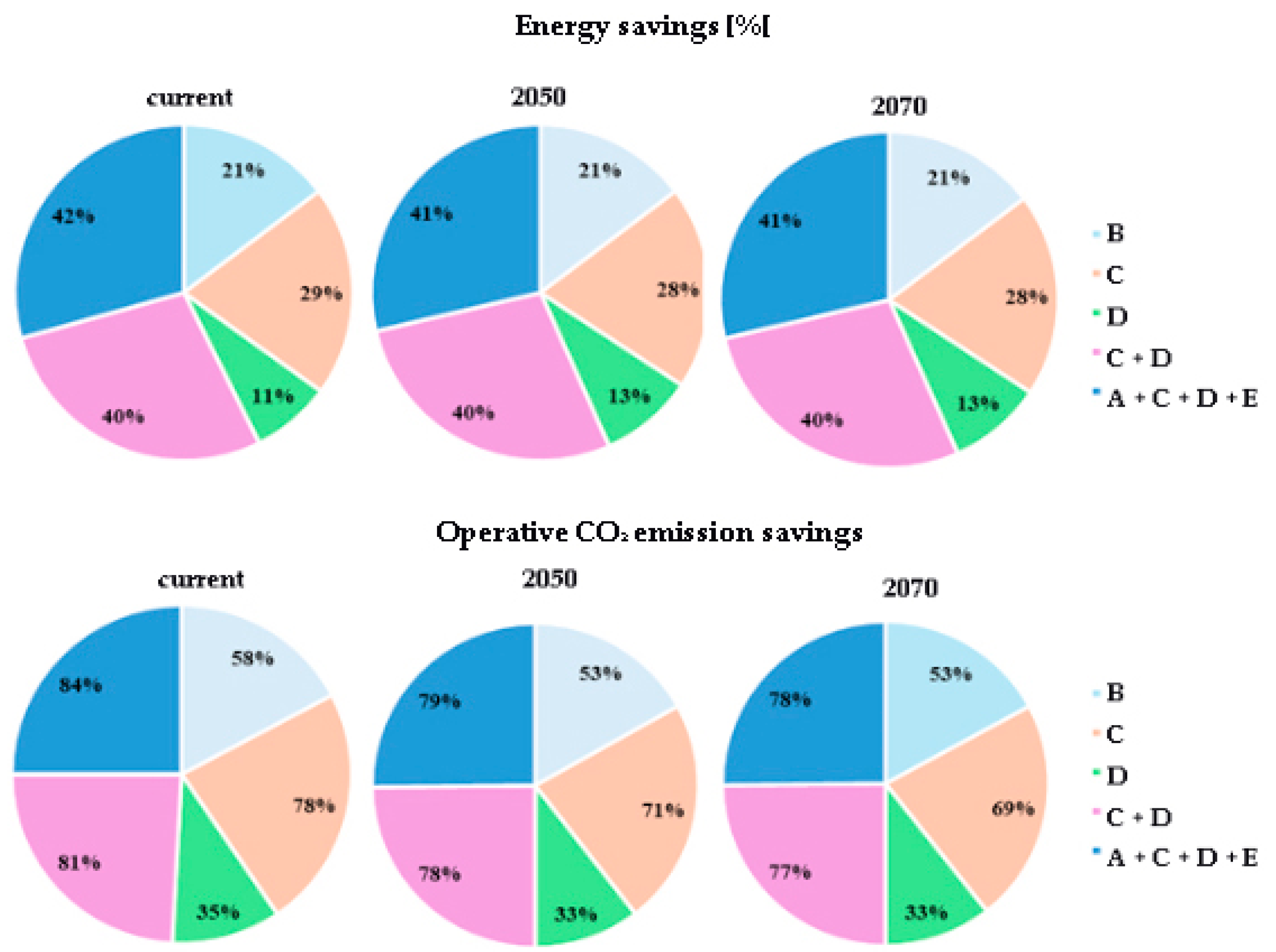

Figure 5.

Figure 5 shows energy savings (%) and CO

2 emission savings for the current period, 2050, and 2070. The pie charts display the contributions of different factors (B, C, D, C + D, A + C + D + E) to energy efficiency and CO

2 emission reductions over time. The charts highlight how the distribution of energy savings evolves across different future scenarios. In 2050, the energy savings distribution is projected to shift slightly. Scenario A + C + D + E continues to dominate with 41%, while scenario C contributes 28%, and scenario D shows a slight increase to 13%. Scenario C + D remains at 40%, and scenario B remains constant at 21%.

In 2070, the percentage of energy savings is similar to 2050, with scenario A + C + D + E holding steady at 41%.

The second part of

Figure 5 shows the percentage of operative CO

2 saving across the same scenarios for the current year, 2050, and 2070.

In the current year, scenario A + C + D + E achieves the highest operative CO2 savings at 84%, followed by scenario C + D at 81%. Scenario D contributes 78%, scenario B contributes 58%, and scenario C accounts for 35% of the CO2 savings.

By 2050, the distribution will shift slightly. Scenario A + C + D + Estill leads with 79%, while scenario C + D decreases slightly to 78%. Scenario D provides 71% of the savings, scenario B increases to 53%, and scenario C remains steady at 33%.

In 2070, scenario A + C + D + E continues to provide the highest savings at 78%, with scenario C + D at 77%. Scenario D is projected to save 69%, scenario B 53%, and scenario C remains at 33%.

Overall, the combination of measures represented by scenario A + C + D + E consistently achieves the highest energy and CO2 savings across all time steps. While individual measures also contribute significantly, their relative impact remains consistent over time. This analysis underscores the importance of an integrated approach combining multiple strategies to maximize both energy savings and environmental benefits in the long term.

4.4. Economic Analysis

According to the proposed method and as explained in

Section 2,

Table 7 provides techno-economic data for the different investment scenarios, including initial investment, annual savings (in EUR), payback period, and Net Present Value (NPV).

According to the acknowledged procedure, the cost of the current average energy (0.20 EUR/kWh) and the Statistics Report for the year 2022 of

Banca d’Italia for the current discount interest rate (3%) were taken into account for the analysis [

49].

Although scenario C involves one of the highest initial investment costs, it stands out as the most financially attractive option among all the scenarios considered. Indeed, the significant expected annual savings of EUR 30,940 result in a short payback period of 7 years. Furthermore, an NPV of about EUR 198k indicates a high level of profitability, reflecting the substantial net gains over the investment period. The combination of a high NPV and a manageable payback period makes scenario C the best solution from the economic point of view. In addition, as previously shown, scenario C is one of the best solutions to reduce energy consumption from the grid and the associated CO2 emissions.

Scenario D is also a strong option in terms of energy consumption reduction, CO2 emission reduction, and payback period. It has the shortest payback period of 5 years, meaning an investment return in a little over 5 years through annual savings of about EUR 14k. The NPV of about EUR 112k is substantial, indicating a good level of profitability. In addition, the relatively lower initial investment compared to scenario C makes it more accessible, while still providing significant financial benefits.

On the contrary, although Scenario B is technically profitable, it has a long payback period of 11 years, which is a significant drawback. Scenario B is not financially viable, even if it was shown to be a proper scenario to reduce energy consumption and CO2 emissions.

Scenarios A and E are not financially viable and do not produce a substantial reduction in energy costs and CO2 emissions. The lack of a calculated payback period suggests that the savings generated are too low to justify the initial investments within a reasonable timeframe.

Although scenario A + C + D + E was demonstrated to be among the optimal solutions to reduce energy consumption and CO2 emissions, the higher initial investment compared to the cost savings achievable during the operation phase makes it not economically viable. On the contrary, scenario C + D presents a very similar performance in terms of energy and CO2 emission savings, but with a much lower payback period of about 4 years and an NPV of about EUR 589k. Therefore, when carrying out a holistic evaluation that considers energy, environmental, and economic benefits, the result is reversed and the most suitable retrofit scenario for the case study food retail trade building appears to be scenario C + D.

4.5. Limitations

The proposed approach, based on a novel assessment framework, relies on projected climate data that may vary depending on the model and scenario utilized. It is important to note that future climate conditions are inherently uncertain, and actual results may deviate from the projections used in this analysis. As a result, the economic analysis is subject to a fundamental limitation due to the fluctuations and trends in the energy, financial, and monetary markets. These critical factors have the potential to impact results by fluctuating over time and across different locations.

The results of the energy simulations and retrofitting scenarios are specific to the food retail trade building analyzed in this study. While these findings are valuable for similar buildings and comparable geographical locations, the generalizability of the results to other types of buildings or geographical locations may be limited. However, the proposed approach can be replicated for various types of buildings, geographical and climatic locations, and application contexts.

In conclusion, it is essential to consider the uncertainties inherent in projected climate data and the potential impact of market fluctuations on the economic analysis. While the findings of this study are valuable for specific contexts, further research is needed to assess the applicability of the proposed approach to a broader range of buildings and locations.

5. Conclusions and Future Developments

This research introduces an integrated method for assessing building–plant systems’ energy efficiency and environmental sustainability. The approach combines BEM with DT and dynamic energy simulations, linked to energy cost and environmental impact analyses. This method helps identify effective retrofit strategies by comparing different solutions in terms of energy use, sustainability, and cost under different current and future climate conditions. The goal is to reach an effective and efficient building–plant refurbishment and retrofitting with lower energy use, environmental impact, and waste production reduction through passive, active, and advanced integrated management/control systems. The method involves creating virtual models of representative buildings based on real data and implementing integrated simulations of energy, environmental, and economic performance.

In this work, the proposed approach was applied to a food retail trade building in central Italy. The results of the application on the case study building indicate that the combination of various passive and active retrofit solutions, such as high thermal insulation of the building envelope to achieve Nearly Zero Energy Building requirements, PV panels, LED technology, and refrigeration waste heat recovery for heating, can maximize the reduction in energy consumption and CO2 emissions.

Future climate projections show an increasing trend in energy demand due to rising outdoor air temperatures, emphasizing the necessity for retrofit solutions but, above all, the fact that it is a “must” to orient the design of buildings and energy systems with a view to the mitigation and adaptation to climate change and the green energy transition. Future climate projections show an increase in energy demand by up to 6% by 2070—as opposed to the European goal to reduce greenhouse gas emissions—emphasizing the necessity of proactive energy-saving measures. Properly selected retrofit strategies could mitigate these impacts, with some scenarios achieving energy savings of up to 29%. The results confirm that retrofitting the food retail building with a combination of PV panels, LED lighting, and enhanced refrigeration systems (scenario C + D) can result in substantial energy savings of up to 40%. Moreover, this scenario proved to be the most cost-effective, with a payback period of 4 years and a net present value (NPV) of EUR 589,000. The environmental benefits are equally noteworthy, with CO2 reductions reaching about 81%. Overall, targeted retrofitting not only aids in significant cost reductions but also supports environmental sustainability objectives, aligning with European climate goals.

This approach aligns with both national and international energy efficiency targets and broader environmental goals, contributing to a more sustainable commercial building sector. Future developments also involve the application of the proposed method to different virtual models, which can be adapted to different contexts. Large-scale implementation could significantly reduce global energy consumption and greenhouse gas emissions in the retail sector, supporting global sustainability targets, including the European “Fit for 55” package [

3]. This study aims to offer practical blueprints, energy-saving strategies, and advanced technologies for the food retail trade sector. Focusing on renewable energy and management strategies helps stakeholders achieve energy sustainability and green transition goals, benefiting both the environment and urban communities.