Technology Progress in High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil and Its Prospects in Low-Carbon Situations

Abstract

1. Introduction

2. Progress of High-Frequency Electromagnetic In Situ Thermal Recovery and Its Prospects in Low-Carbon Situations

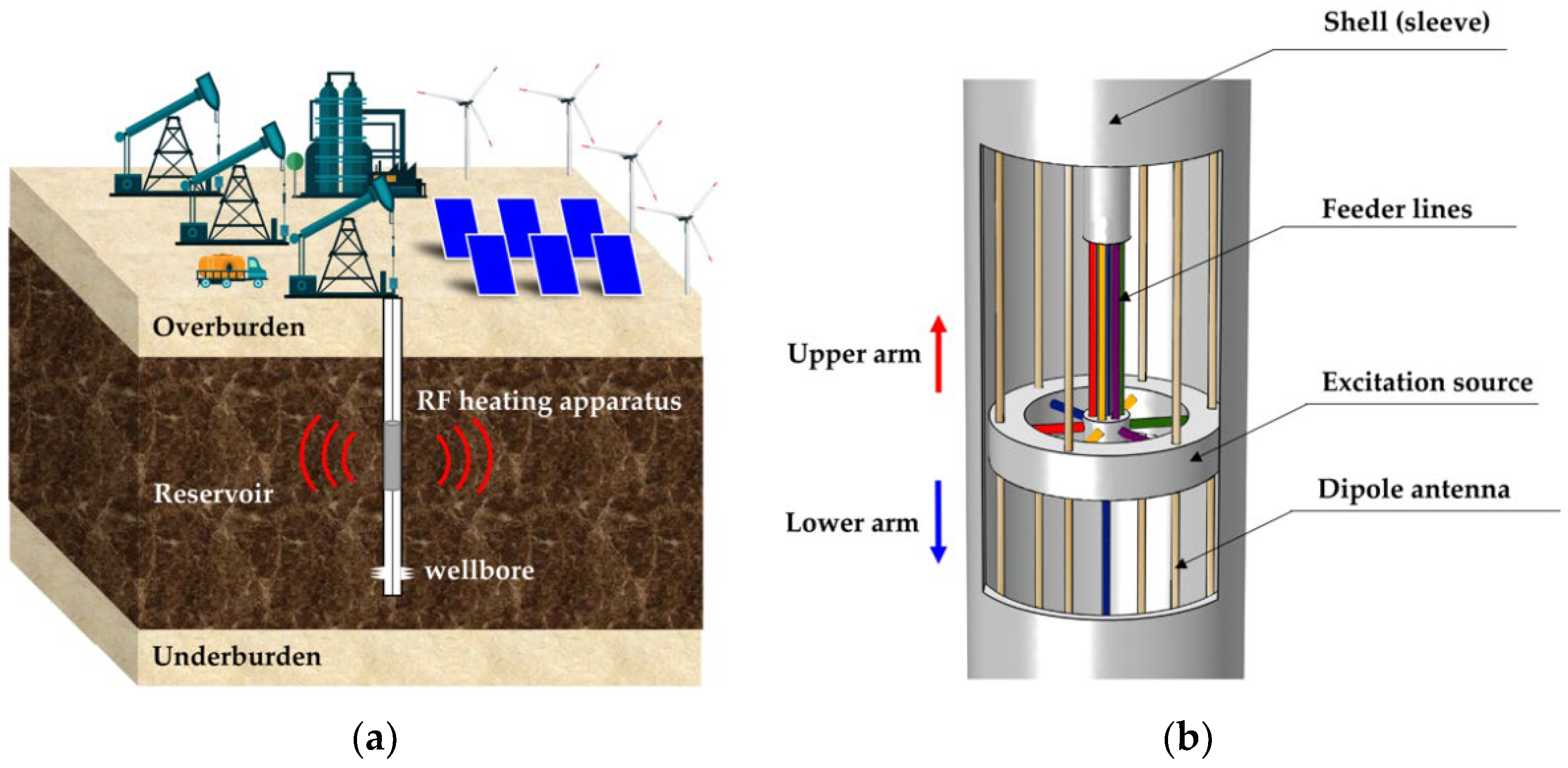

2.1. The Development History of High-Frequency Electromagnetic In Situ Thermal Methods for Heavy Oil

2.2. Research Progress on the Coupled Heat and Mass Transfer Mechanisms of High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil

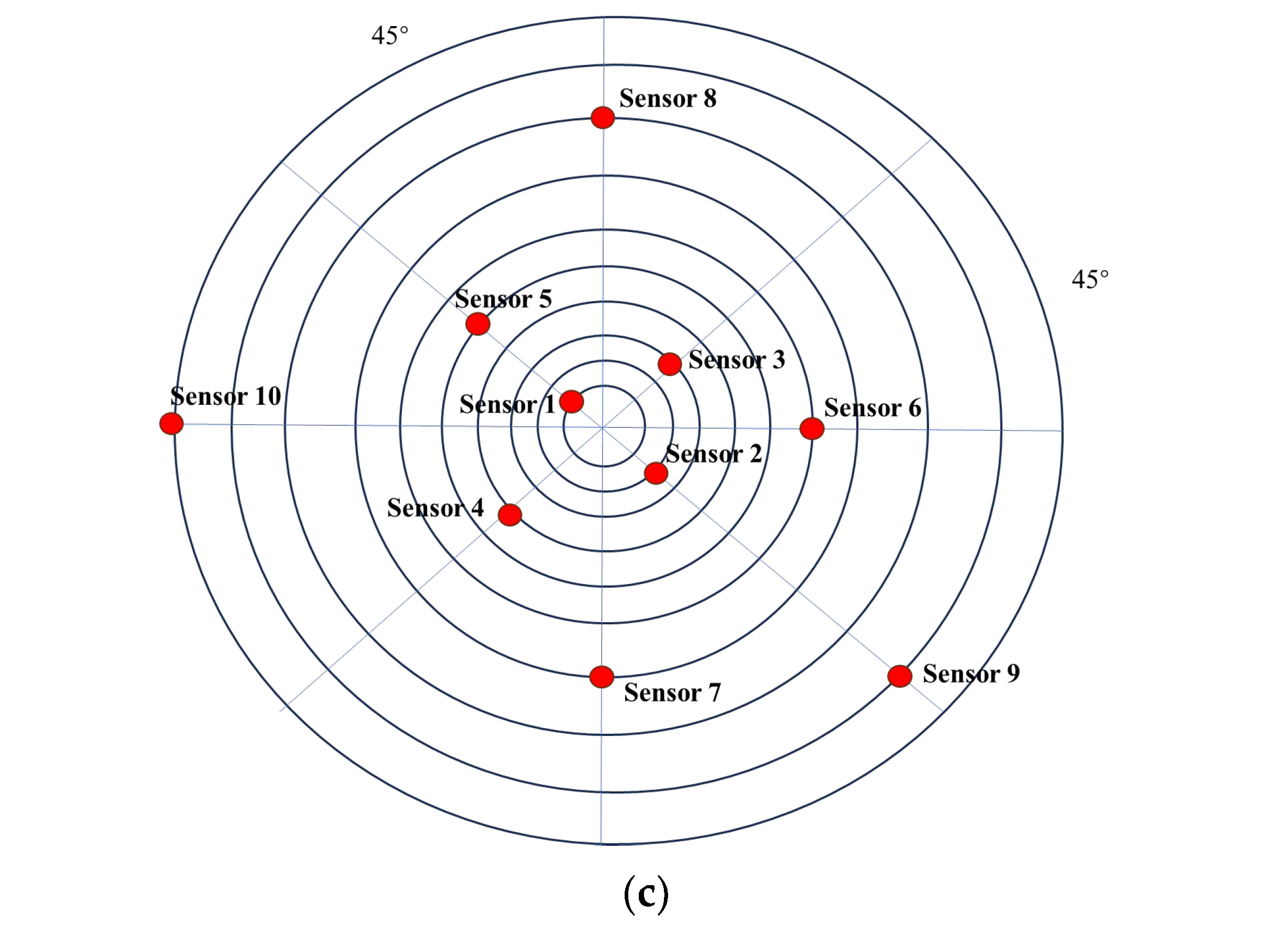

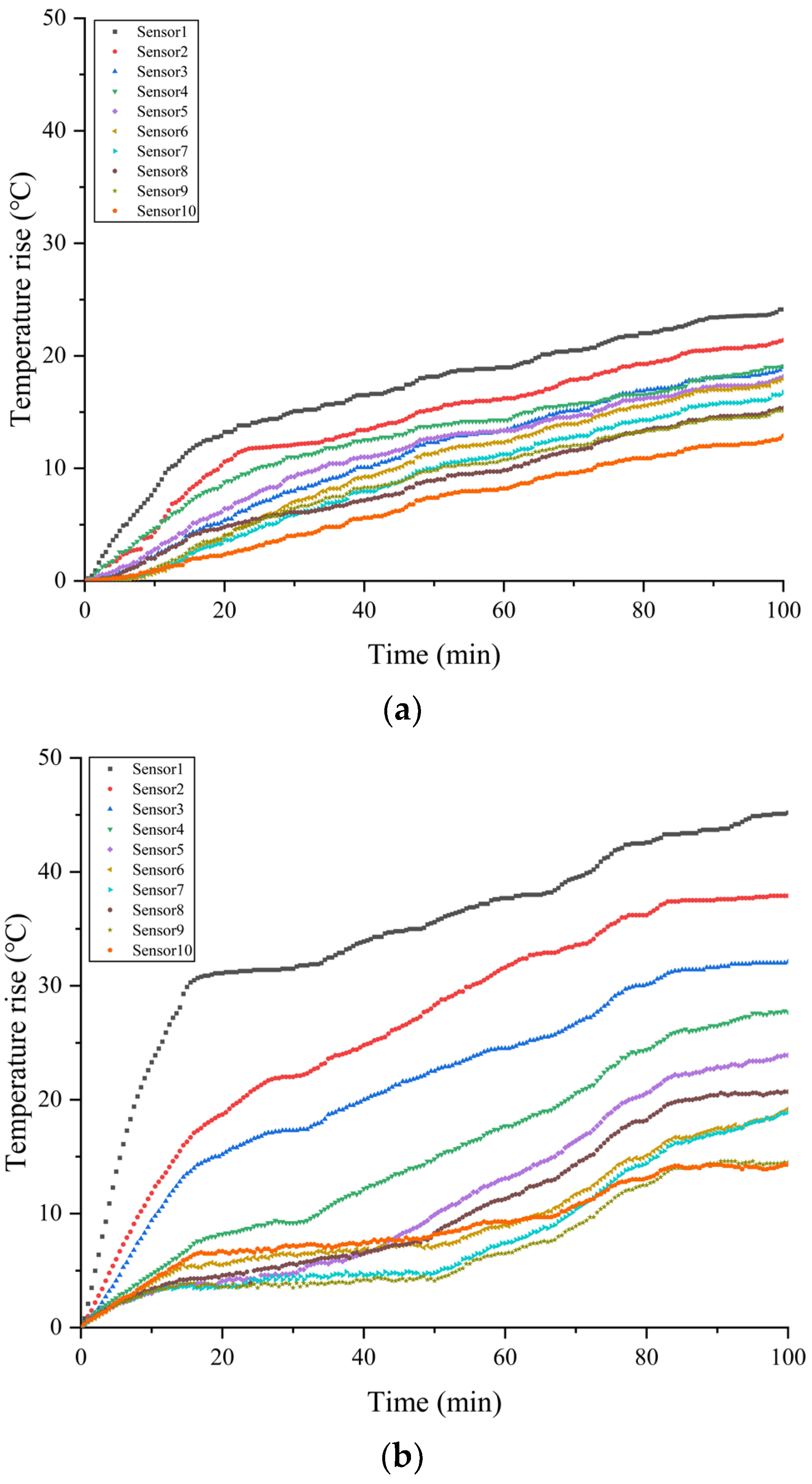

2.2.1. Physical Experimental Research Methods

2.2.2. Mathematical Modeling Research Methods

2.3. Research Progress on the Mechanism of Enhancing Heavy Oil Recovery by CO2/N2 Injection in Thermal Recovery Processes

2.4. Research Prospects in Low-Carbon Situations and Challenges

2.4.1. Research Prospects in Low-Carbon Situations

2.4.2. Research Challenges

- (a)

- The process of CO2-N2-enhanced heavy oil electromagnetic in situ thermal recovery is a complex heat and mass transfer process under multi-physics coupling [52]. It primarily involves the dissipation of high-frequency electromagnetism in the reservoir (electromagnetic field), the heat generation from electromagnetic dissipation and heat transfer in the reservoir (temperature field), changes in the non-Darcy seepage capacity of heavy oil and multiphase flow (seepage field), phase change of fluids and diffusion of CO2, N2, and volatile light components in multiphase fluids (composition field), as well as the complex interactions between these physical fields, as illustrated in Figure 9. These physical fields and their high-temperature and high-pressure property characteristics can be influenced by other fields or even by changes within their own fields. For instance, the dielectric properties [28,29,30,31] of formation water, heavy oil, and rock samples (such as permittivity and electrical conductivity), thermal properties (specific heat, thermal conductivity), can vary with temperature or electromagnetic frequency; the viscosity, yield stress, and threshold pressure gradient of non-Darcy seepage flow of heavy oil can change with temperature, CO2, N2, or concentration of light components in heavy oil; changes in heavy oil composition are related to the electromagnetic non-thermal effects [10]; temperature changes can affect the porosity and permeability of rocks; the CO2-N2-heavy oil-water mixture can undergo phase changes with variations in temperature and pressure; the diffusion coefficients [47] of CO2, N2, etc., in heavy oil are influenced by temperature and pressure. Accurate measurement of the property characteristics and coupling relationships of multiple physical fields during the process of CO2-N2-enhanced heavy oil electromagnetic in situ thermal recovery is a fundamental prerequisite for establishing a multi-physics coupled theoretical model for this process, which is essential to solve on-site engineering and technical problems.

- (b)

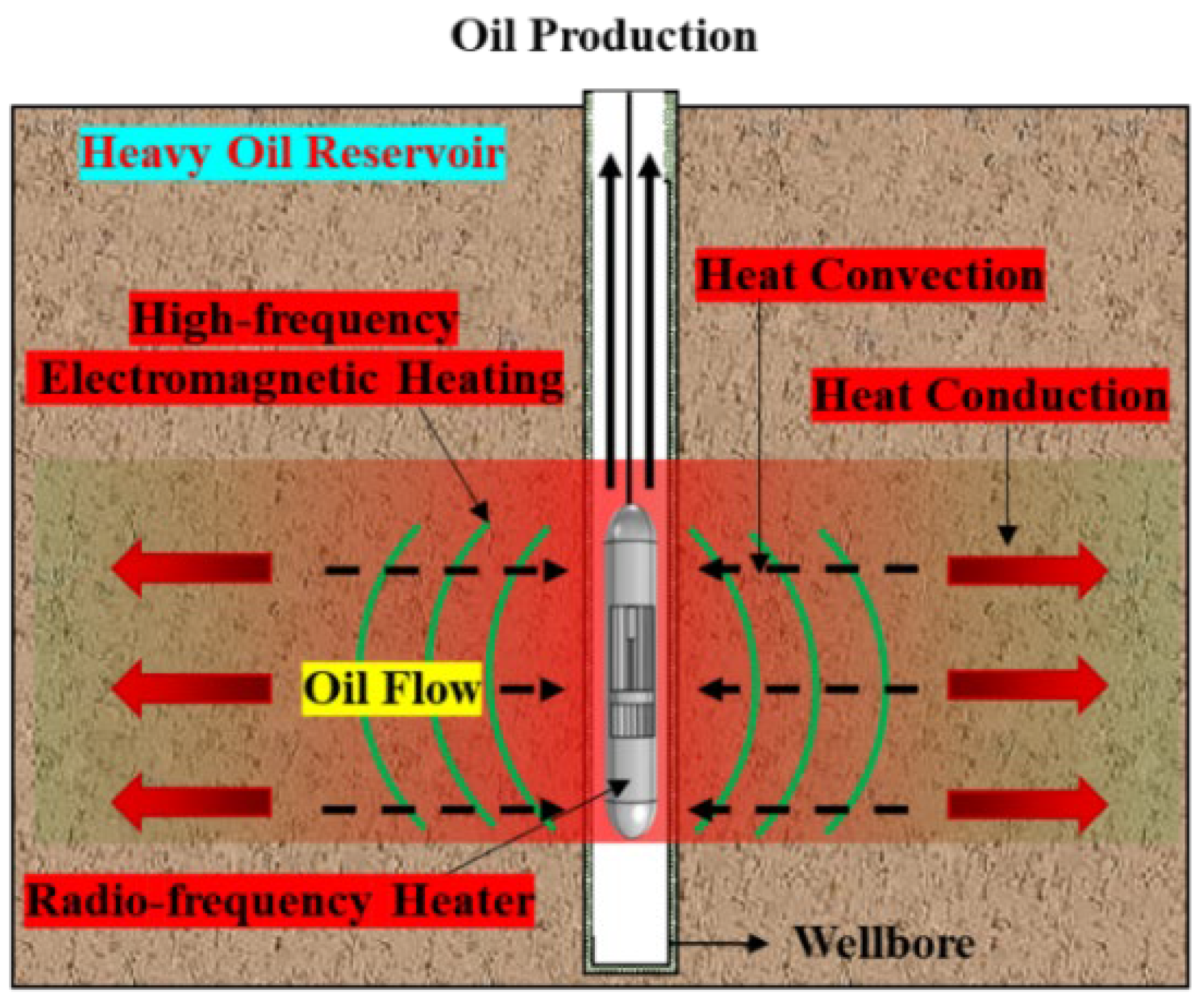

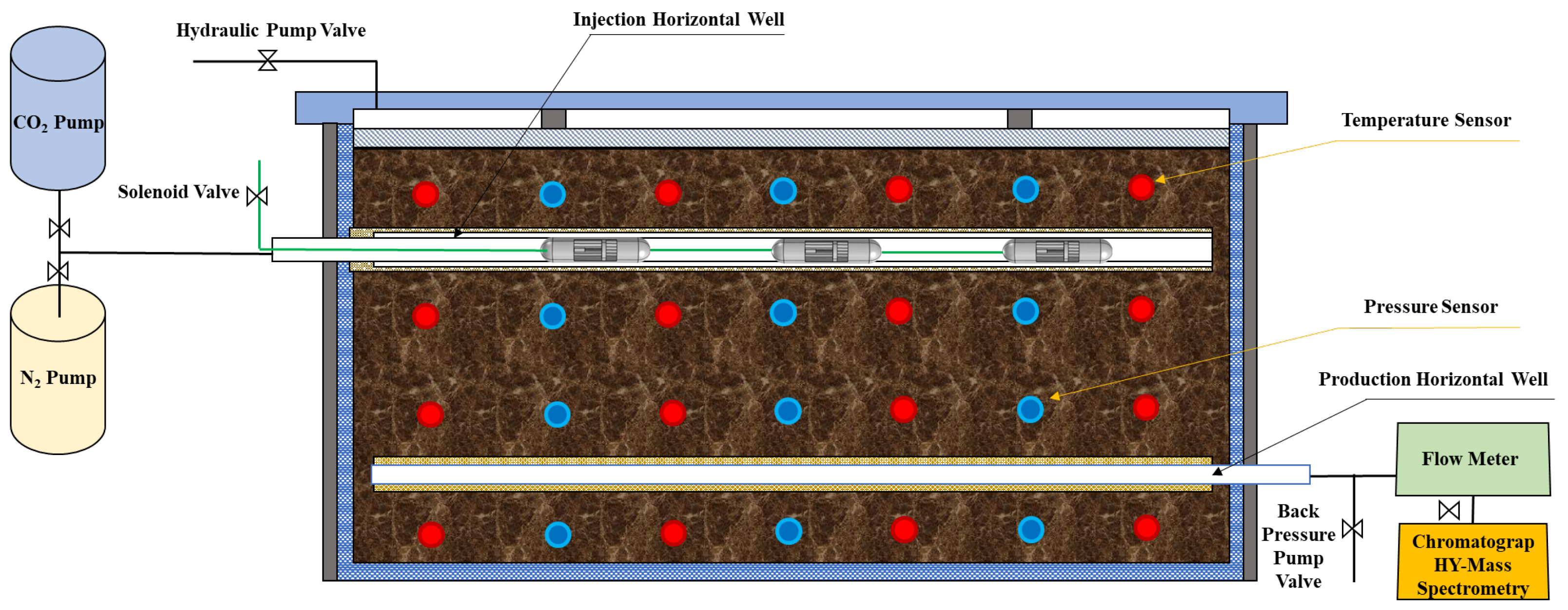

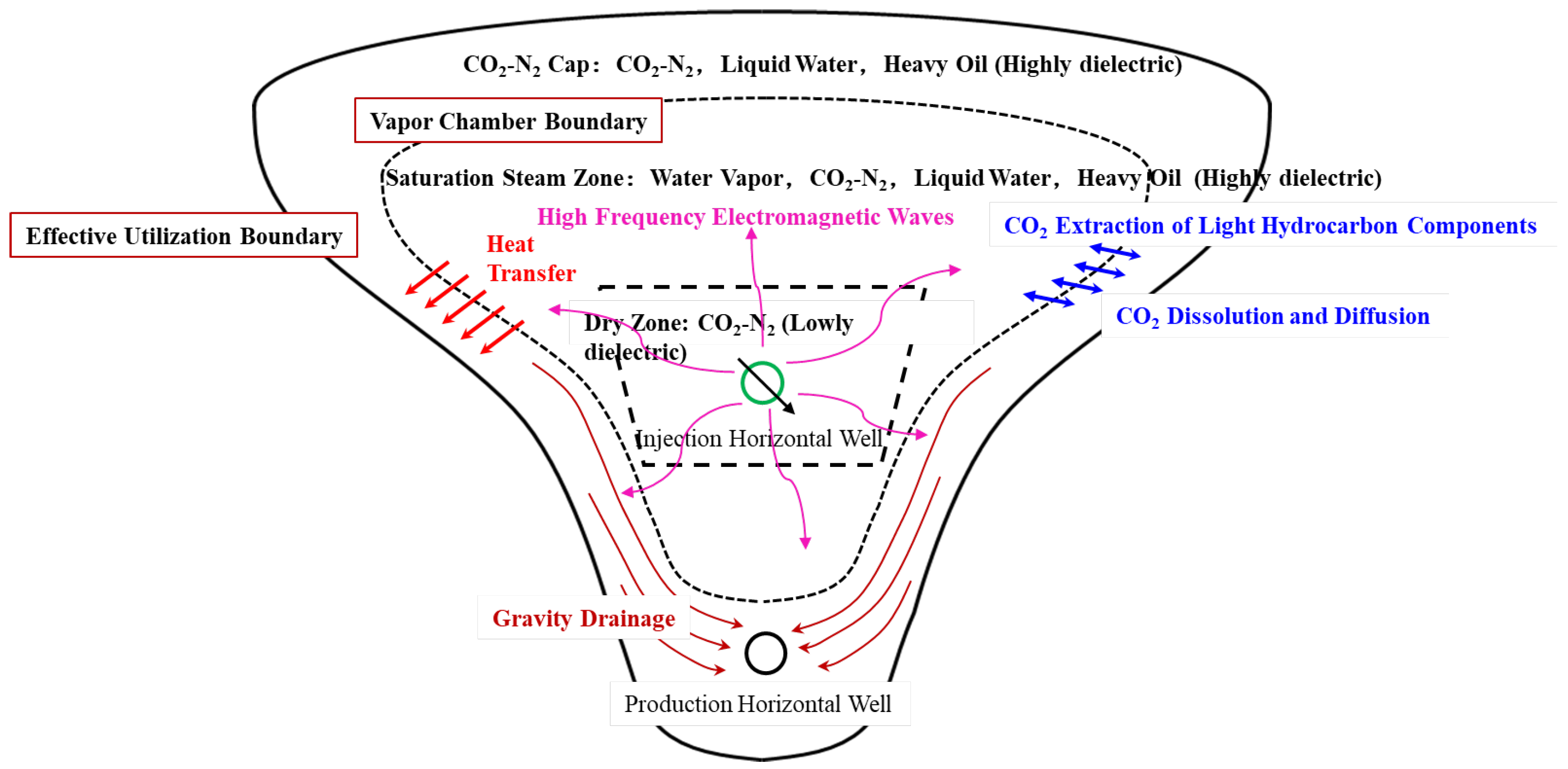

- The high-temperature and high-pressure physical simulation experiments for CO2-N2-enhanced electromagnetic in situ thermal recovery of heavy oil involve several key heat and mass transfer mechanisms [53,54,55]. An experimental apparatus for physical simulation of the SAGD-inspired thermal recovery mode with dual horizontal wells, one for injection and one for production, is shown in Figure 10. Taking a vertical reservoir cross-section of a dual horizontal well configuration analogous to SAGD as an example (see Figure 11), these mechanisms include the volume heating of the heavy oil reservoir in situ by high-frequency electromagnetic waves emitted from a dipole antenna installed in a wellbore, which increases the mobility and elastic energy of the heavy oil and affects the porosity and permeability of the reservoir. Injecting CO2-N2 into the wellbore equipped with the antenna not only replenishes the reservoir’s energy and boosts production but also creates a high-temperature and high-pressure gas cavity around the wellbore. Within this cavity, a low-dielectric dry zone [33] composed of CO2 and N2 reduces the dielectric loss near the wellbore, enhances the heated reservoir range of the electromagnetic waves, and prevents local overheating that could compromise the stability of the wellbore. The gas cavity dynamically expands into the deeper heavy oil reservoir with concurrent heat and mass transfer. Therefore, the stability of the developed gas cavity is helpful for improving the effect of high-frequency electromagnetic in situ thermal recovery. Unexpected complications during field operations may be an underdeveloped gas cavity or instability in the developed gas cavity. At the boundary of the gas cavity, the dissolution and diffusion of CO2 into the deeper heavy oil enhances its mobility and elastic energy [41]. CO2 also extracts the lighter components of the heavy oil; it can reduce the gas–liquid mobility ratio and interfacial tension of multiphase fluids, and inhibit gas breakthrough. The superimposed gas cavity heats the underlying heavy oil reservoir, initiating a gravity drainage mechanism, while the insulating effect of the CO2-N2-filled cavity above prevents heat loss. CO2 also dissolves and diffuses in the formation water. There are multiple component multiphase flows, non-Darcy flow of non-Newtonian heavy oil, and other complexities. These mechanisms are interrelated, and collectively control the efficiency of heavy oil extraction and thermal energy utilization. Based on mathematical models, similarity rules [56] can be derived to design and conduct high-temperature and high-pressure physical simulation experiments. These experiments aim to elucidate the coupled heat and mass transfer mechanisms of CO2-N2-enhanced electromagnetic in situ thermal recovery of heavy oil across multiple physical fields. By identifying the controlling factors for heavy oil production capacity, recovery rate, energy utilization efficiency, and CO2 storage efficiency, these experiments provide a critical theoretical foundation for the optimization of new thermal recovery technologies and the evaluation of their performance.

- (c)

- A multi-physics coupled mathematical model for CO2-N2-enhanced heavy oil electromagnetic in situ thermal recovery involves complex heat and mass transfer processes under the influence of multiple physical fields interacting with each other. The electromagnetic field heats the reservoir volume in situ, where the electromagnetic frequency influences the reservoir’s dielectric properties, thereby affecting the heating efficiency. Heat is then transferred via convection and conduction, impacting the temperature field. The electromagnetic “non-thermal effects” [10] and the increase in temperature reduce the viscosity, density, and threshold pressure gradient of the non-Newtonian heavy oil non-Darcy seepage flow. However, increased temperatures simultaneously decrease the solubility of gaseous CO2, N2, and light components in the heavy oil and formation water, affecting diffusion rates; it will lead to increased viscosity and density of the heavy oil, changes in capillary forces at multiphase fluid interfaces, and thus cause alterations in reservoir pressure, fluid phases, and fluid saturation. Increased temperatures also affect the porosity, permeability, dielectric, and thermal properties of the reservoir, influencing the multiphase flow field, composition field, and electromagnetic field. Changes in fluid saturation lead to modifications in the reservoir’s dielectric and thermal properties, which affect the in situ heating efficiency of the electromagnetic waves and the heat dissipation process; thereby, the electromagnetic and temperature fields are affected (as depicted in Figure 9). The dynamic changes in reservoir properties can be tested experimentally, and their mathematical formula can be applied into the mathematical modeling. Therefore, integrating theories from electromagnetics, heat and mass transfer, fluid mechanics, and thermodynamics, a comprehensive multi-component multiphase mathematical model that describes the dynamic coupling of the electromagnetic field, temperature field, seepage flow field, and composition field can be established. Coupled with an efficient numerical simulation method for heat and mass transfer under multi-physics conditions, such a model can provide an essential engineering tool for optimizing and evaluating the effectiveness of new thermal recovery technologies for heavy oil. It is worth mentioning that applying artificial intelligence techniques in combination of physical constraints [57] can be used to improve the accuracy and efficiency of numerical simulation of the complicated multi-physics field coupling for the high-frequency electromagnetic in situ thermal recovery technology for heavy oil. The model can be validated against the real-world data through the comparison of the numerical simulation results with the actual data obtained from heavy oil fields. Numerical stability of the numerical simulation method should be guaranteed so as to ensure robustness across different reservoir conditions.

- (d)

- Engineering methods for CO2-N2-enhanced electromagnetic in situ thermal recovery of heavy oil can be elucidated through field-scale numerical simulations, aiming to establish methodologies for thermal recovery process optimization and reservoir suitability assessment. Initially, field-scale numerical simulations for CO2-N2-enhanced heavy oil electromagnetic in situ thermal recovery are conducted. These simulations reconstruct the spatiotemporal distributions of the electromagnetic field, temperature field, seepage flow field, and composition field. Analysis of the simulations reveals the temporal and spatial evolution patterns of the steam chamber, the dry zone within the chamber, and the effective mobilization area, which significantly impact thermal recovery efficiency. These patterns are further investigated under various influencing factors such as thermal recovery modes (e.g., huff and puff [58] of vertical well, huff and puff of horizontal well, dual horizontal wells mimicking SAGD [59] with one well injection and one well production, and multilateral wells for injection and production, see Figure 12), production regimes, well placement, and inter-well spacing, to understand the multi-physics regulation mechanisms. Subsequently, orthogonal numerical simulation experiments can be designed with objectives such as production capacity, recovery factor, energy utilization efficiency, CO2 storage efficiency, and economic benefits. These numerical simulation experiments, combined with the understanding of multi-physics heat and mass transfer coupling mechanisms and regulation strategies, facilitate studies on optimization of thermal recovery modes, injection-production regimes, well placement, and inter-well spacing. Process scheme optimizations for CO2-N2-enhanced electromagnetic in situ thermal recovery of heavy oil under different reservoir conditions are carried out. Reservoir conditions include dielectric and thermal characteristics of the reservoir (including over-burden and under-burden layers), multiphase and multicomponent flow and diffusion characteristics, reservoir thickness and heterogeneity, reservoir geometry, and external boundary conditions (such as the presence of edge or bottom water). Comparisons with traditional thermal recovery methods (like steam flooding and cyclic steam stimulation) are made regarding the optimization goals to comprehensively evaluate the reservoir suitability of the CO2-N2-enhanced electromagnetic in situ thermal recovery process.

3. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, S.; Wang, Q. New progress and prospect of oilfields development technologies in China, Petrol. Explor. Dev. 2018, 45, 698–711. [Google Scholar] [CrossRef]

- Guan, W.; Jiang, Y.; Guo, E.; Wang, B. Heavy oil development strategy under the “Carbon Peaking and Carbon Neutrality” target. Acta Pet. Sin. 2023, 44, 826–840. [Google Scholar]

- Xiong, R.; Guo, J.; Kiyingi, W.; Gao, C.; Wang, L.; Luo, J.; Song, H.; Wang, X. Technical transformation of heavy/ultra-heavy oil production in China driven by low carbon goals: A review. J. Clean. Prod. 2024, 458, 142531. [Google Scholar] [CrossRef]

- Xu, Z.; Ding, Y.; Tao, L.; Hu, Z.; Zhang, X.; Bai, J.; Shi, W.; Li, J.; Li, S. Low-carbon development strategy to achieve heat conversion in heavy oil reservoirs: In-situ combustion. Geoenergy Sci. Eng. 2024, 240, 213055. [Google Scholar] [CrossRef]

- Wang, L.; Guo, J.; Li, C.; Xiong, R.; Chen, X.; Zhang, X. Advancements and future prospects in in-situ catalytic technology for heavy oil reservoirs in China: A review. Fuel 2024, 374, 132376. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, W.; Taleghani, A.D. Numerical study on non-Newtonian Bingham fluid flow in development of heavy oil reservoirs using radiofrequency heating method. Energy 2022, 239, 122385. [Google Scholar] [CrossRef]

- Hu, L.; Li, H.; Babadagli, T.; Xie, X.; Deng, H. Thermal stimulation of shale formations by electromagnetic heating: A clean technique for enhancing oil and gas recovery. J. Clean. Prod. 2020, 277, 123197. [Google Scholar] [CrossRef]

- Sivakumar, P.; Krishna, S.; Hari, S.; Vij, R.K. Electromagnetic heating, an eco-friendly method to enhance heavy oil production: A review of recent advancements. Environ. Technol. Innov. 2020, 20, 101100. [Google Scholar] [CrossRef]

- Bera, A.; Babadagli, T. Status of electromagnetic heating for enhanced heavy oil/bitumen recovery and future prospects: A review. Appl. Energ. 2015, 151, 206–226. [Google Scholar] [CrossRef]

- Zhang, H.; Feng, B.; Jiang, H.; Wei, A. Mathematic model of the effect of microwave on heavy oil. Spec. Oil Gas Reserv. 2006, 05, 100–110. [Google Scholar]

- Ritchey, H.W. Radiation heating. USA Patent Application Serial No. 2,757,738, 1956. [Google Scholar]

- Cesar, O.; Pedro, V.; Gunther, H.; James, D.; Ronald, B.; Lee, D.; Michal, O. Materials. Well Designs and Numerical Simulations for the Construction of a Low Loss Zone for Radiofrequency Downhole Heating. In Proceedings of the SPE Canada Heavy Oil Conference, Virtual, 28 September–2 October 2020. SPE-199946. [Google Scholar]

- Xiao, J.; Wang, Z.; Dong, X. Simulation experiments of radio frequency heating of heavy oil assisted by additives and related influencing factors. Pet. Geol. Oilfield Dev. Daqing 2023, in press.

- Santoso, R.K.; Rachmat, S.; Resha, A.H.; Putra, W.D.K.; Hartowo, H.; Setiawati, O. An Investigation of Fe2O3 Nanoparticles Diffusion into Oil for Heat Transfer Optimisation on Electromagnetic Heating for Well Stimulation and EOR. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016. SPE-182152. [Google Scholar]

- Santoso, R.K.; Rachmat, S.; Putra, W.D.K.; Resha, A.H.; Hartowo, H. Numerical modeling of nanoparticles transport in porous media for optimisation in well stimulation and EOR using electromagnetic heating. In Proceedings of the SPE Asia Pacific Oil & Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016. SPE-182182. [Google Scholar]

- Vakhin, A.V.; Khelkhal, M.A.; Mukhamatdinov, I.I.; Mukhamatdinova, R.E.; Tajik, A.; Slavkina, O.V.; Malaniy, S.Y.; Gafurov, M.R.; Nasybullin, A.R.; Morozov, O.G. Changes in Heavy Oil Saturates and Aromatics in the Presence of Microwave Radiation and Iron-Based Nanoparticles. Catalysts 2022, 12, 514. [Google Scholar] [CrossRef]

- Trautman, M.; Ehresman, D.; Edmunds, N.; Taylor, G.; Cimolai, M. Effective Solvent Extraction System Incorporating Electromagnetic Heating. USA Patent Application Serial No. 8,776,877 B2, 17 November 2010. p. 086569. [Google Scholar]

- Hu, L.; Li, H.A.; Babadagli, T.; Ahmadloo, M. Experimental investigation of combined electromagnetic heating and solvent-assisted gravity drainage for heavy oil recovery. J. Petrol. Sci. Eng. 2017, 154, 589–601. [Google Scholar] [CrossRef]

- Jamaloei, B.Y. Electromagnetic Heating for Heavy- Oil and Bitumen Recovery: Experimental, Numerical, and Pilot Studies. SPE Res. Eval. Eng. 2022, 25, 433–454. [Google Scholar] [CrossRef]

- Hu, Y.; Jha, K.N.; Chakma, A. Heavy-oil recovery from thin pay zones by electromagnetic heating. Energy Sources 1999, 21, 63–73. [Google Scholar]

- Greff, J.H.; Babadagli, T. Use of nano-metal particles as catalyst under electromagnetic heating for viscosity reduction of heavy oil. In Proceedings of the International Petroleum Technology Conference, Bangkok, Thailand, 15–17 November 2011. [Google Scholar]

- Hu, L.; Andy Li, H.; Babadagli, T.; Ahmadloo, M. Experimental Investigation of Combined Electromagnetic Heating and Solvent Assisted Gravity Drainage for Heavy Oil Recovery. SPE 2016, SPE-180747. [Google Scholar]

- Liao, H.; Morte, M.; Hascakir, B. Effect of Crude Oil Composition on Microwave Absorption of Heavy Oils. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 23–26 April 2019. SPE-190089. [Google Scholar]

- Wang, Z. Basic Research on the Downhole Radio Frequency Heating Technology. Ph.D. Thesis, China University of Petroleum, Beijing, China, 2020. [Google Scholar]

- Gharibshahi, R.; Omidkhah, M.; Jafari, A.; Mehrooz, N. Parametric optimization of in-situ heavy oil upgrading using simultaneous microwave radiation and magnetic nanohybrids via Taguchi approach. Fuel 2022, 325, 124717. [Google Scholar] [CrossRef]

- Abernethy, E.R. Production increase of heavy oils by electromagnetic heating. J. Can. Petrol. Technol. 1976, 15, 91–97. [Google Scholar] [CrossRef]

- Dong, X.; Duan, Z.; Nie, T.; Gao, D. An analytical model for reservoir temperature during electromagnetic heating based on power transmission. Appl. Therm. Eng. 2023, 219, 119441. [Google Scholar] [CrossRef]

- Bogdanov, I.; Cambon, S.; Mujica, M.; Brisset, A. Heavy Oil Recovery via Combination of Radio-Frequency Heating with Solvent Injection. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 7–9 June 2016. SPE-180709. [Google Scholar]

- Davletbaev, A.; Kovaleva, L.; Zainulin, A.; Kireev, V.; Babadagli, T.; Minnigalimov, R. Modeling heavy-oil recovery using electromagnetic radiation/hydraulic fracturing considering adiabatic effect and thermal expansion. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 6–8 December 2016. SPE-184161. [Google Scholar]

- Wang, Z.; Gao, D.; Fang, J. Numerical simulation of RF heating heavy oil reservoir based on the coupling between electromagnetic and temperature field. Fuel 2018, 220, 14–24. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Q.; Zhao, Q.; Jiang, H.; Li, B.; Zhang, J.; Zhao, L.; Men, M.; Wang, G.; Ye, C.; et al. Performance evaluation of combined radio frequency heating and conductive medium injection for heavy oil recovery. J. Petrol. Sci. Eng. 2021, 201, 108535. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D.; Diao, B.; Tan, L.; Zhang, W.; Liu, K. Comparative performance of electric heater vs. RF heating for heavy oil recovery. Appl. Therm. Eng. 2019, 160, 114105. [Google Scholar] [CrossRef]

- Hu, L.; Andy Li, H.; Babadagli, T.; Ahmadloo, M. A semianalytical model for simulating combined electromagnetic heating and solvent-assisted gravity drainage. SPE J. 2018, 23, 1248–1270. [Google Scholar] [CrossRef]

- Ji, D.; Harding, T.; Chen, Z.; Dong, M.; Liu, H. Modelling of Electromagnetic Heating Process and its Applications in Oil Sands Reservoirs. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019. SPE-193905. [Google Scholar]

- Kong, X. Advanced Porous Flow Mechanics, 3rd ed.; University of Science and Technology of China Press: Hefei, China, 2020. [Google Scholar]

- Wan, Y.; Wu, N.; Chen, Q.; Li, W.; Hu, G.; Huang, L.; Ouyang, W. Coupled thermal-hydrodynamic-mechanical–chemical numerical simulation for gas production from hydrate-bearing sediments based on hybrid finite volume and finite element method. Comput. Geotech. 2022, 145, 104692. [Google Scholar] [CrossRef]

- Zhao, J.; He, Y.; Wang, J.; Peng, M.; Yang, J.; Zeng, F. Effect of in-situ emulsification on CO2/N2-based cyclic solvent injection process for enhancing heavy oil recovery and CO2 storage. Chem. Eng. Sci. 2024, 295, 120185. [Google Scholar] [CrossRef]

- Wang, Z.; Du, H.; Li, S.; Li, S. Experimental study on gas-assisted cyclic steam stimulation under heavy-oil sandstone reservoir conditions: Effect of N2/CO2 ratio and foaming agent. Geoenergy Sci. Eng. 2023, 228, 211976. [Google Scholar] [CrossRef]

- Lin, Z.; Lu, X.; Wang, X.; Chang, Y.; Kang, K.; Zeng, F. Effect of N2 impurity on CO2-based cyclic solvent injection process in enhancing heavy oil recovery and CO2 storage. Energy 2024, 290, 130227. [Google Scholar] [CrossRef]

- Lun, Z.; Wang, H.; Zhang, C.; Li, B.; Liu, Y.; Li, Z. Mechanism of CO2 and Chemical Additive Synergetic Enhanced Steam Flooding in Heavy Oil Reservoirs. J. China Univ. Pet. 2023, 47, 72–79. [Google Scholar]

- Hao, H.; Hou, J.; Huang, H.; Zhao, F.; Liu, H. Feasibility of CO2/N2 Hybrid Gas Huff and Puff for Enhancing Recovery in Shallow Heavy Oil Reservoirs of Jidong Area. Oilfield Chem. 2020, 37, 80–85. [Google Scholar]

- Hamdi, Z.; Foo, F.K. Cold CO2 and steam injection for heavy oil recovery. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar]

- Zhou, X.; Jiang, Q.; Yuan, Q.; Zhang, L.; Feng, J.; Chu, B.; Zeng, F.; Zhu, G. Determining CO2 diffusion coefficient in heavy oil in bulk phase and in porous media using experimental and mathematical modeling methods. Fuel 2020, 263, 116205. [Google Scholar] [CrossRef]

- Jang, H.W.; Yang, D. Determination of the concentration-dependent effective diffusivity of CO2 in unconsolidated porous media saturated with heavy oil by considering the swelling effect. Int. J. Heat. Mass. Tran. 2023, 201, 123552. [Google Scholar] [CrossRef]

- Xi, C.; Qi, Z.; Zhang, Y.; Liu, T.; Shen, D.; Mu, H.; Dong, H.; Li, X.; Jiang, Y.; Wang, H. CO2-Assisted Steam Injection Technology for Late Stage of Steam Flooding in Heavy Oil Reservoirs. Petrol. Explor. Dev. 2019, 46, 1169–1177. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Zhang, J.; Cheng, H.; Ji, H.; Wang, W.; Li, H.; Liang, C.; Li, C.; Zhang, L. EOR mechanisms of CO2 huff and puff process for heavy oil recovery. J. China Univ. Pet. 2021, 45, 102–111. [Google Scholar]

- Yang, D.; Li, Y.; Huang, D. Quantification of Phase Behaviour and Physical Properties of Alkane Solvents/CO2/ Water/Heavy Oil Systems under Equilibrium and Nonequilibrium Conditions. In Proceedings of the Canadian Energy Technology Conference, Calgary, AB, Canada, 16–17 March 2022. SPE-208968. [Google Scholar]

- Chen, Z.; Huan, G.; Ma, Y. Computational Methods for Multiphase Flows in Porous Media; SIAM: Philadelphia, PA, USA, 2006. [Google Scholar]

- Liu, L.J.; Yao, J.; Sun, H.; Huang, Z.Q.; Yan, X.; Li, L.L. Compositional modeling of shale condensate gas flow with multiple transport mechanisms. J. Petrol. Sci. Eng. 2019, 172, 1186–1201. [Google Scholar]

- Xia, Z.; Zhao, J.; Liu, F.; Qin, E.; Cai, B.; Wang, Q. Evaluation of Gas Injection Huff-and-Puff Suitability in Heavy Oil Reservoirs of Turpan-Hami Exploration Area. Xinjiang Pet. Geol. 2023, 44, 341–346. [Google Scholar]

- Nath, F.; Mahmood, M.N.; Yousuf, N. Recent advances in CCUS: A critical review on technologies, regulatory aspects and economics. Geoenergy Sci. Eng. 2024, 238, 212726. [Google Scholar] [CrossRef]

- Li, G.; Guan, X.; Wang, H.; Du, S.; Wu, D.; Chen, J. Simulation of Radio Frequency Heating of Heavy Oil Reservoir Using Multi-Physics Coupling of Reservoir Simulation with Electromagnetic Solver. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 10–11 April 2019. SPE-193836. [Google Scholar]

- Bogdanov, I.; Torres, J.A.; Corre, B. Numerical simulation of electromagnetic driven heavy oil recovery. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. SPE-154140. [Google Scholar]

- Bapat, S.; Akhter, N. Optimization of heavy oil recovery by radio frequency heating: A theoretical approach with experimental modeling. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Xu, Z.; Zhou, L.; Ma, S.; Qin, J.; Huang, X.; Han, B.; Yang, L.; Luo, Y.; Liu, P. Study on CO2 Huff-n-Puff Development Rule of Horizontal Wells in Heavy Oil Reservoir by Taking Liuguanzhuang Oilfield in Dagang as an Example. Energies 2023, 16, 4258. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, T.; Liu, T.; Sha, J.; Ren, H. Numerical simulation and experimental verification of the steady-state heat transfer similarity theory based on dimensional analysis. Case. Stud. Therm. Eng. 2024, 60, 104714. [Google Scholar] [CrossRef]

- Zhou, L.; Sun, H.; Fan, D.; Zhang, L.; Imani, G.; Fu, S.; Yang, Y.; Zhang, K.; Yao, J. Flow prediction of heterogeneous nanoporous media based on physical information neural network. Gas Sci. Eng. 2024, 125, 205307. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, H.; Zhao, C.; Zhu, E. Investigating phase dynamics of reservoir fluids in CO2 huff-n-puff enhanced oil recovery. Geoenergy Sci. Eng. 2024, 238, 212925. [Google Scholar] [CrossRef]

- Liu, M.; Zhao, G. A performance comparison study of electromagnetic heating and SAGD process. In Proceedings of the SPE Heavy Oil Conference-Canada, Calgary, AB, Canada, 11–13 June 2013. SPE-165547. [Google Scholar]

| Auxiliary Enhancement Measures | Nanometal Oxide Injection | Hydrocarbon Solvent Injection | N2 Injection | CO2-N2 Mixture Injection | |

|---|---|---|---|---|---|

| Heavy Oil Thermal Recovery Methods | |||||

| Electromagnetic In Situ Heating | Improves heating effect but causes environmental metal pollution. | Significantly improves heating effect but has high economic cost. | Helps to improve thermal recovery effectiveness, but pure nitrogen is prone to breakthrough. | Research gap. | |

| Traditional Steam Injection | Not applicable. | Significantly improves recovery effect. | Helps to improve thermal recovery effectiveness, but pure nitrogen is prone to breakthrough. | Significantly enhances thermal recovery efficiency, facilitates carbon dioxide geological sequestration, yet is prone to corroding pipelines and incurs high costs. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Y.; Liu, W.; Yu, J.; Liu, C.; Cao, Y.; Sun, M.; Li, M.; Meng, Z.; Yan, X. Technology Progress in High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil and Its Prospects in Low-Carbon Situations. Energies 2024, 17, 4715. https://doi.org/10.3390/en17184715

Yang Y, Liu W, Yu J, Liu C, Cao Y, Sun M, Li M, Meng Z, Yan X. Technology Progress in High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil and Its Prospects in Low-Carbon Situations. Energies. 2024; 17(18):4715. https://doi.org/10.3390/en17184715

Chicago/Turabian StyleYang, Yang, Wenchao Liu, Jifei Yu, Chen Liu, Yanfeng Cao, Mingkai Sun, Menglong Li, Zicheng Meng, and Xinjiang Yan. 2024. "Technology Progress in High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil and Its Prospects in Low-Carbon Situations" Energies 17, no. 18: 4715. https://doi.org/10.3390/en17184715

APA StyleYang, Y., Liu, W., Yu, J., Liu, C., Cao, Y., Sun, M., Li, M., Meng, Z., & Yan, X. (2024). Technology Progress in High-Frequency Electromagnetic In Situ Thermal Recovery of Heavy Oil and Its Prospects in Low-Carbon Situations. Energies, 17(18), 4715. https://doi.org/10.3390/en17184715