Research on Energy-Saving Control Strategies for Single-Effect Absorption Refrigeration Systems

Abstract

1. Introduction

1.1. Traditional Control

1.2. Feedback Control

1.3. Intelligent and Optimized Control

1.4. Current Research

2. System Description

2.1. Overview of an Absorption Refrigeration System

2.2. Working Fluid Pair in Absorption Refrigeration

2.3. Thermodynamic Analysis of the Absorption Refrigeration Cycle

- The generator, condenser, evaporator, and absorber were modeled using the lumped parameter method. The working medium inside the heat exchanger was in a dynamic-phase equilibrium state, with uniform temperature, pressure, and solution concentration at each point;

- The condensation pressure was equal to the occurrence pressure, and the evaporation pressure was equal to the absorption pressure;

- We neglected the heat exchange between the unit and the surrounding environment;

- We neglected the decrease in pipe pressure caused by pipeline length and resistance;

- The power of the solution pump was very small and could be ignored;

- The inlet cooling water temperature of the condenser was equal to the outlet cooling water temperature of the absorber;

- The refrigerant water at the outlet of the condenser was in a saturated liquid state, while the refrigerant water at the outlet of the evaporator was in a saturated gaseous state;

- There was an isothermal adiabatic throttling process;

- The heat exchange efficiency of the solution heat exchanger was a constant value.

2.4. Performance and Requirements of Absorption Refrigeration Units

- The boiling point difference between the two components of the solution should be as large as possible;

- The refrigerant should have a high latent heat of vaporization and be easily soluble in the absorbent;

- The physical properties affecting heat and mass transfer, such as fluid viscosity, thermal conductivity, and diffusion coefficient, should be within acceptable ranges;

- Both the refrigerant and absorbent must be noncorrosive, environmentally friendly, inexpensive, and readily available.

2.5. Dynamic Modeling of Absorption Refrigeration Units

- A thermodynamic analysis was conducted based on the operating characteristics of the single-effect lithium bromide absorption refrigeration cycle to determine the main working medium’s flow and the relationship of the heat transfer equipment.

- Under the simulation assumptions, each component of the unit was mathematically modeled. Components with rapidly changing parameters, such as the solution pump and throttle valve, were modeled by considering only their nonlinear characteristics, and empirical formulas were used instead of dynamic characteristics. The solution heat exchanger, having simple dynamic characteristics, was modeled using a steady-state method. For the generator, condenser, evaporator, and absorber, which have complex dynamic characteristics and slow parameter changes but significantly impact system performance, dynamic mathematical models were established based on the mass, energy, and component conservation equations.

- Through a review of the literature, a calculation equation for the physical properties of the lithium bromide solution suitable for the operating range of the single-effect absorption refrigeration unit was selected. Polynomial equations for the physical properties of refrigerant water were fitted using data from Refprop9.0, an authoritative international refrigerant property calculation software developed by the National Institute of Standards and Technology (NIST) in the United States.

- Based on the boundary conditions and the input–output relationships between the unit components, the component models were combined to form an initial overall model of the unit. Considering the model’s complexity and numerous parameters, a sixth-order nonlinear multivariable state–space model of the unit was obtained by integrating and reducing the state variables based on assumptions and the overall analysis of the unit.

2.6. Analysis of the Open-Loop Characteristics of Absorption Refrigeration Systems

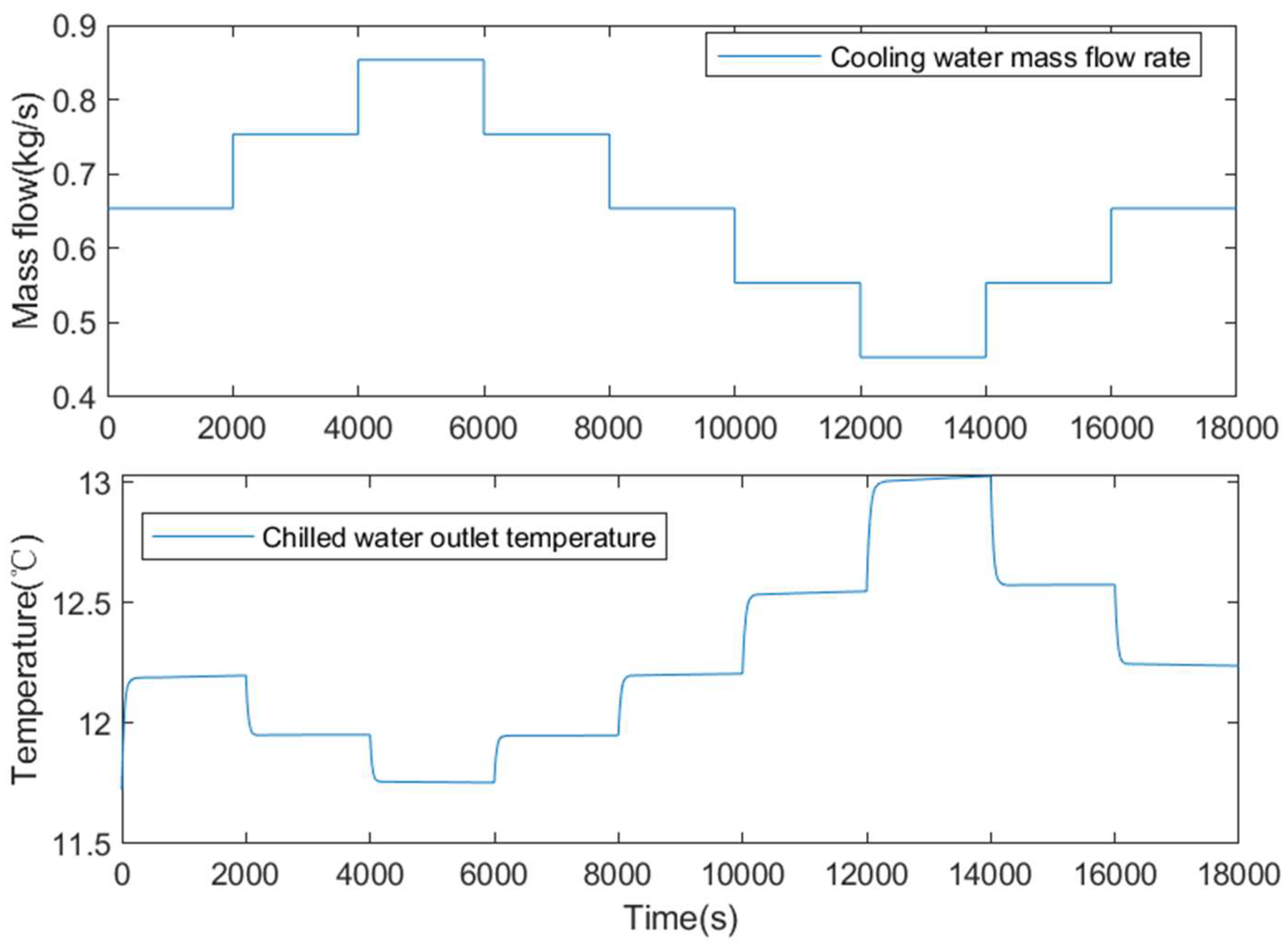

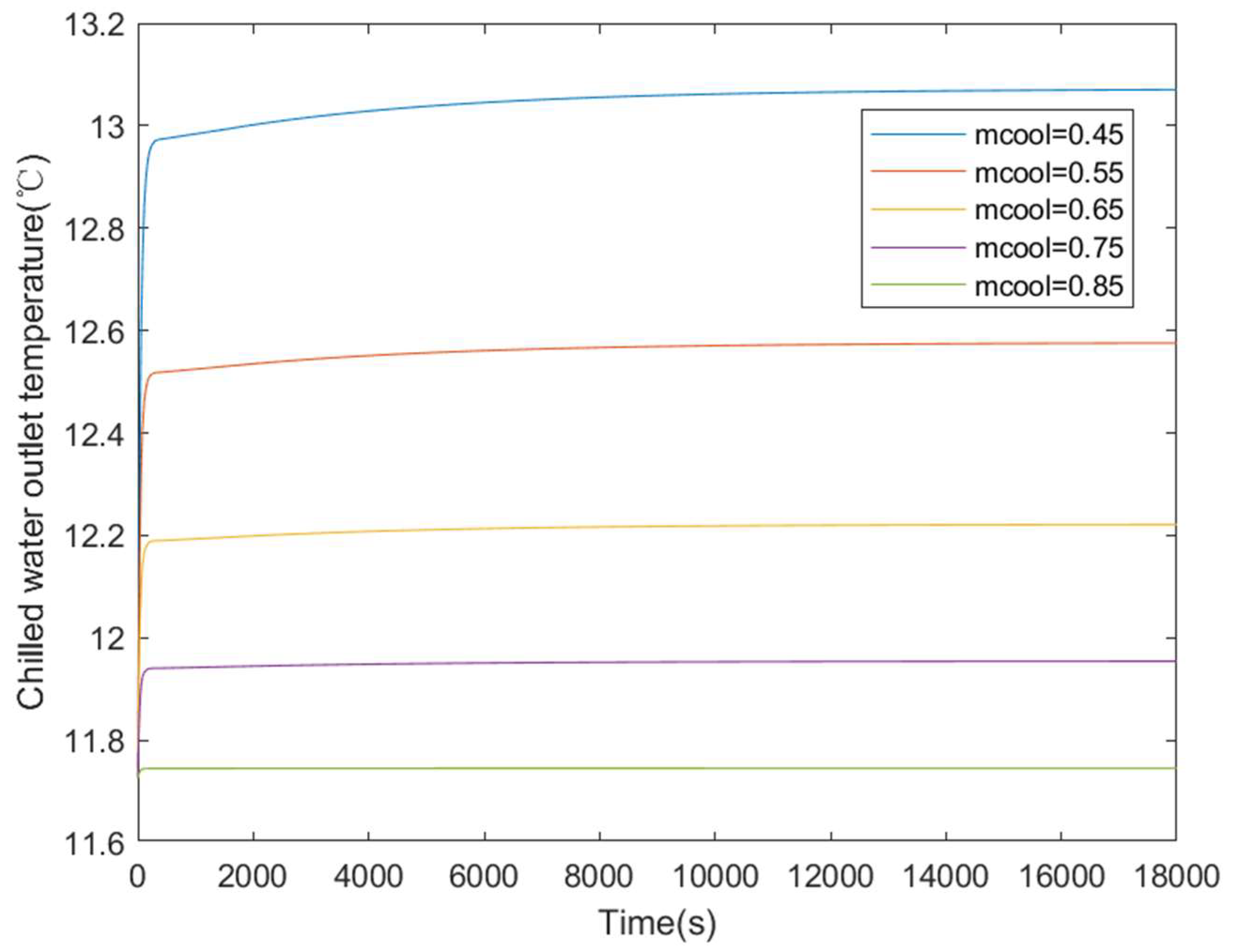

2.7. Influence of Cooling Water Flow Rate on Chilled Water Outlet Temperature

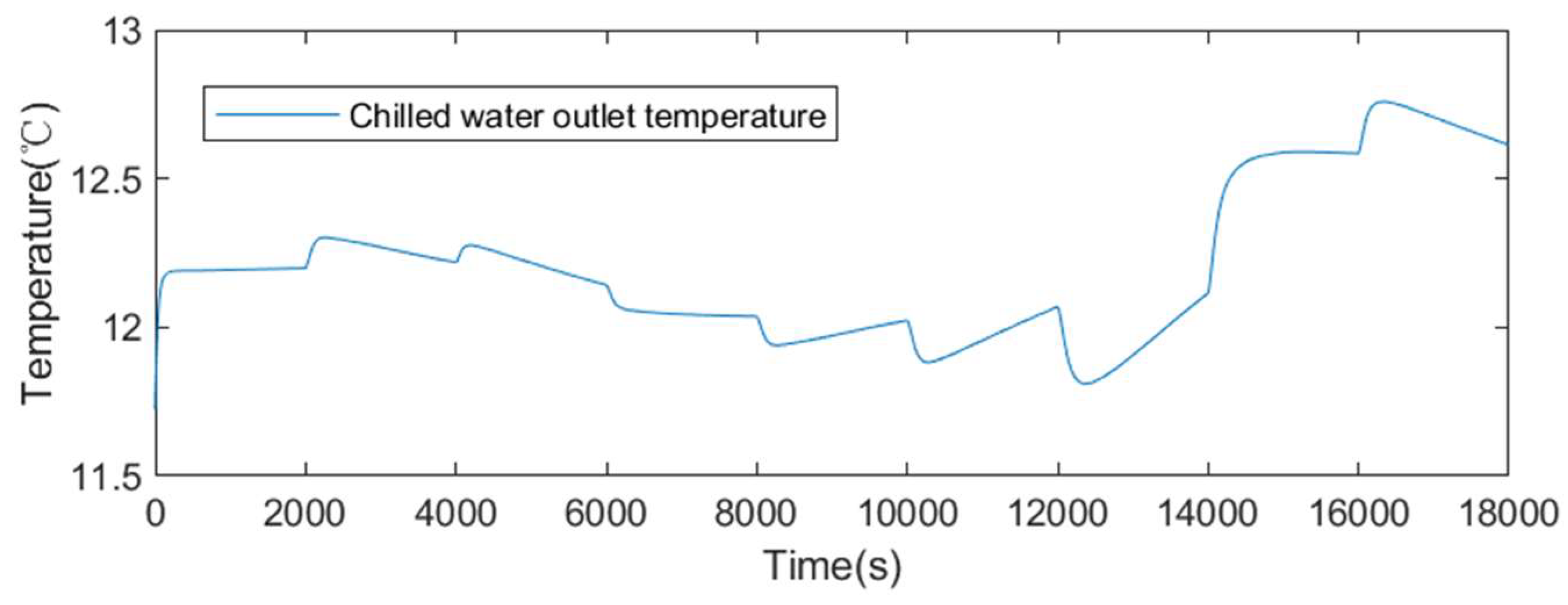

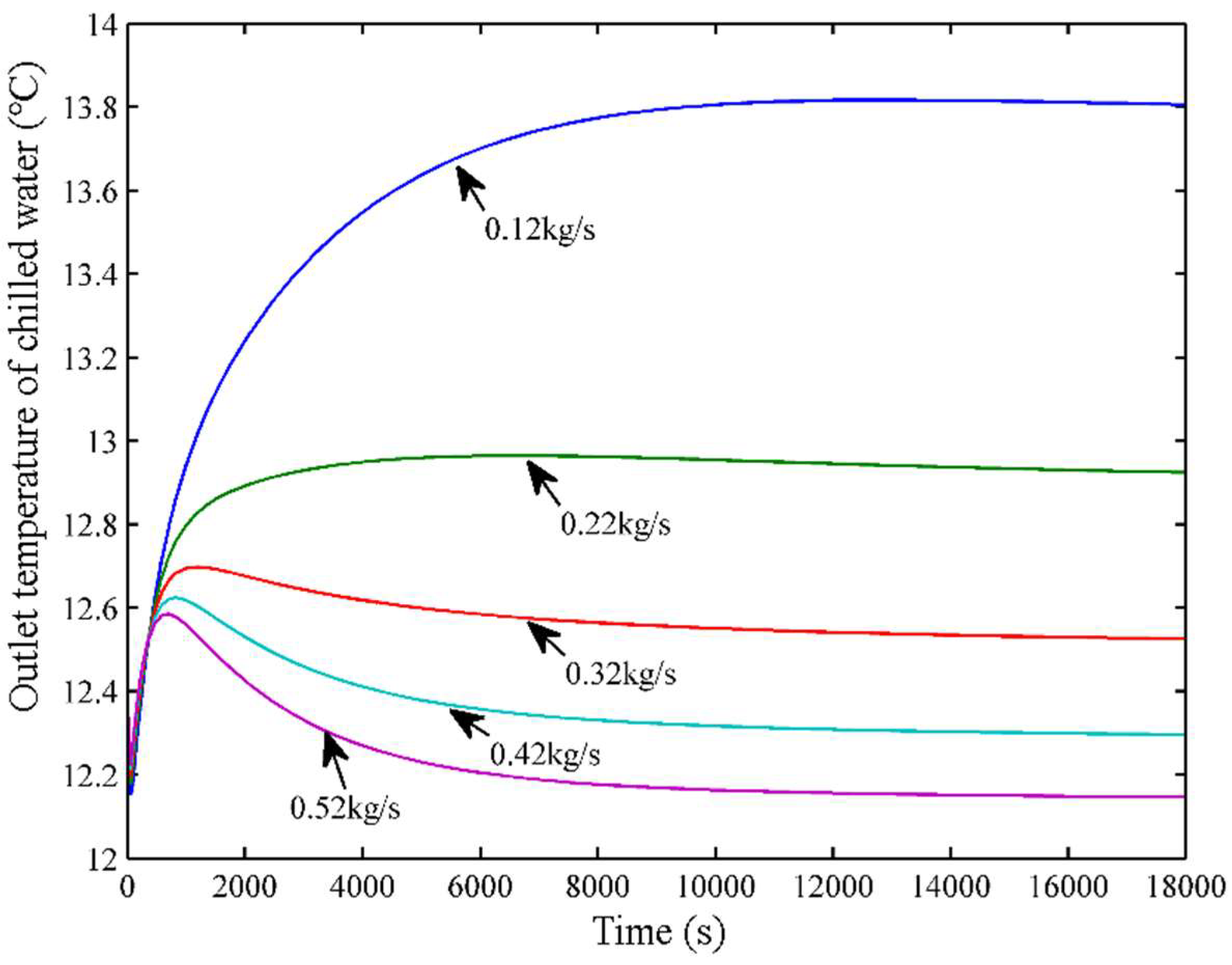

2.8. Influence of Heat Source Water Flow Rate on Chilled Water Outlet Temperature

3. Control Strategy

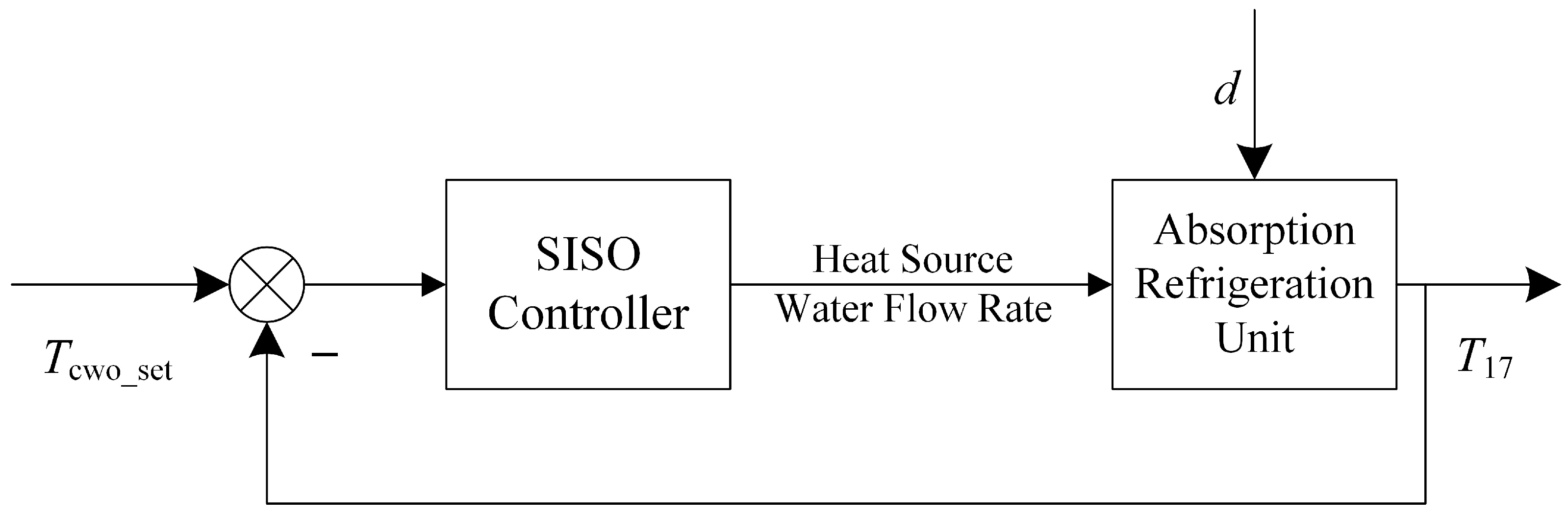

3.1. Single-Loop Control of Absorption Refrigeration Systems

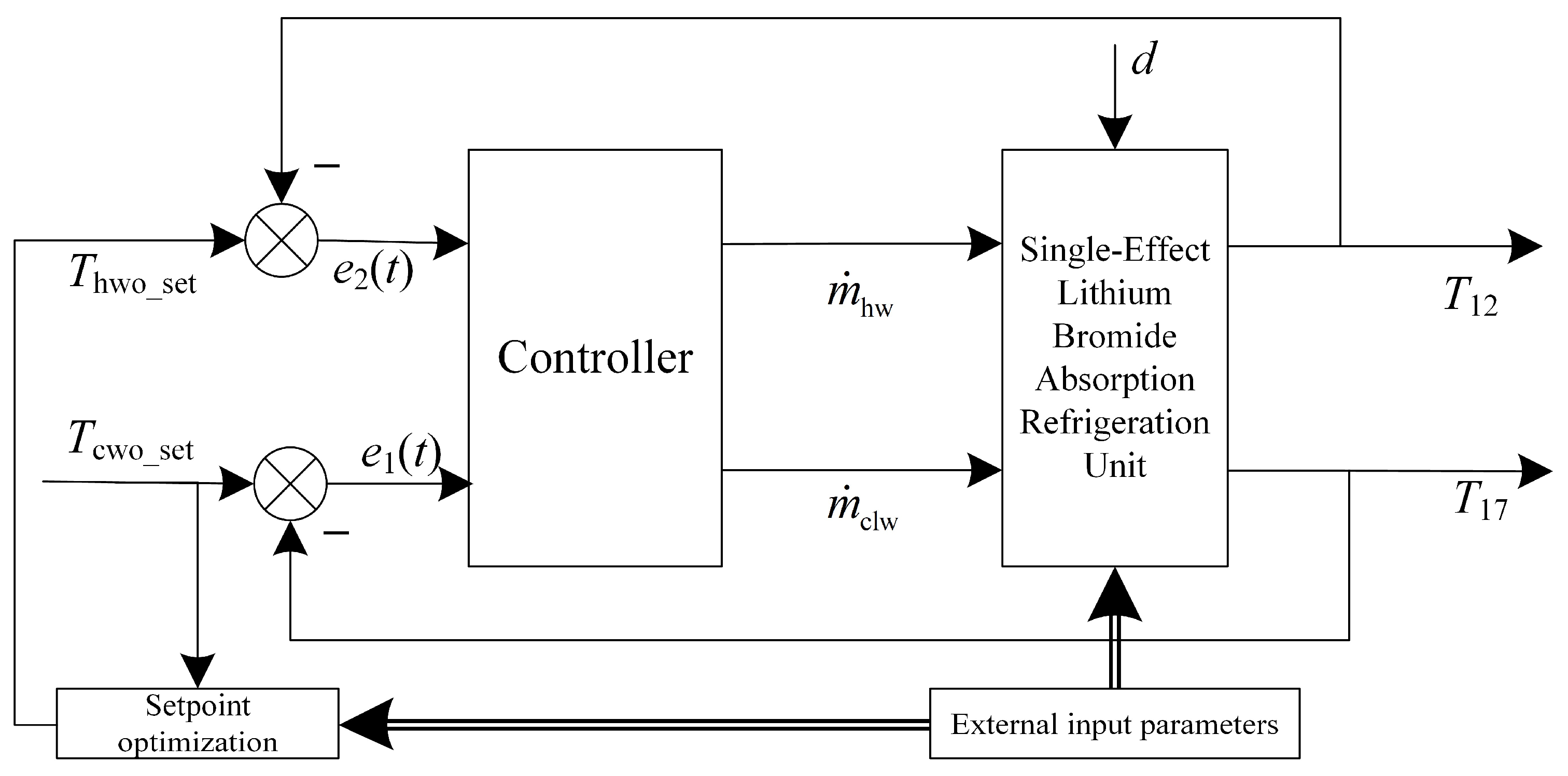

3.2. Double-Closed-Loop Energy Control for Absorption Refrigeration Systems

4. Simulation Experiment and Results

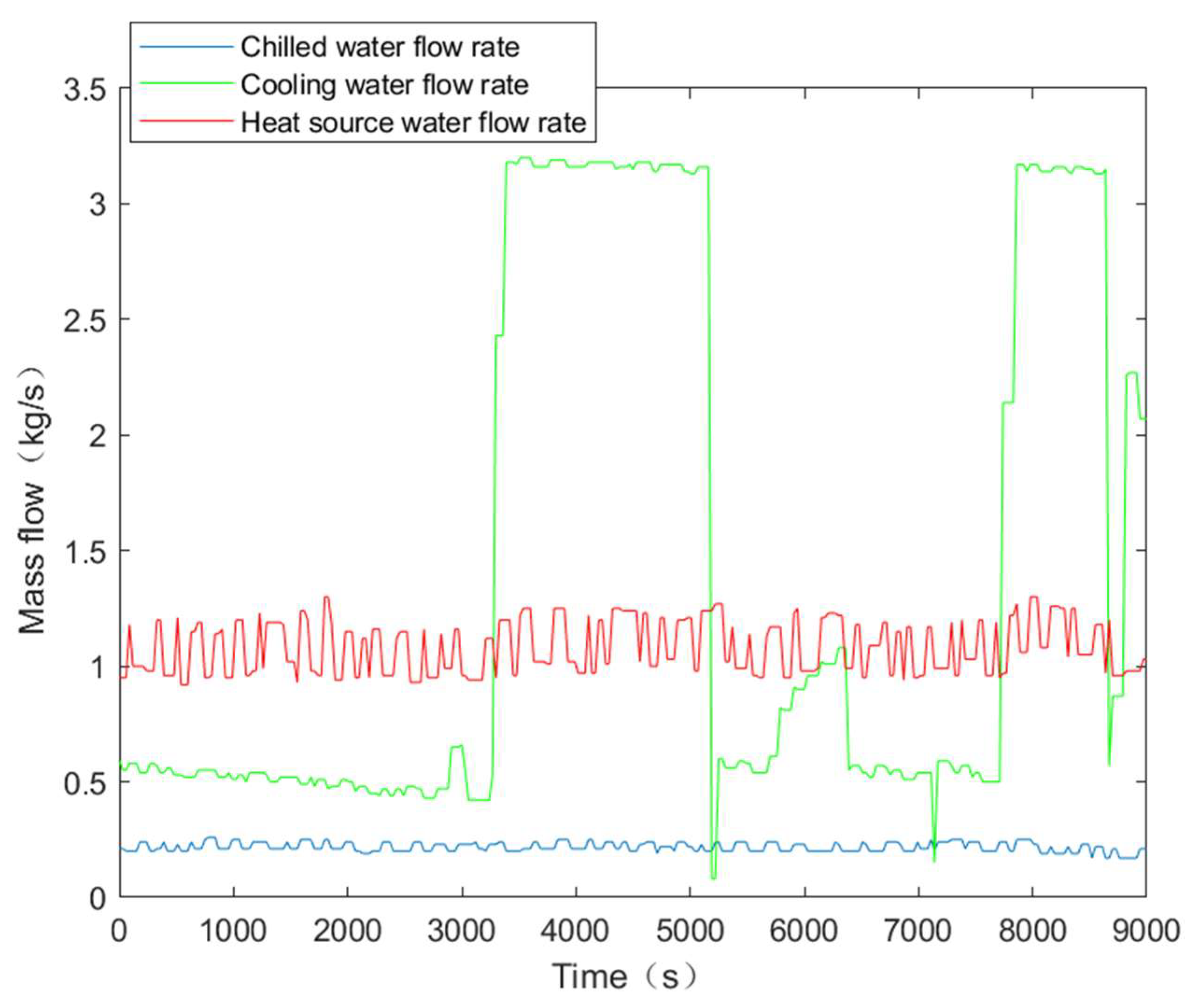

4.1. Simulation Study of Single-Loop Energy-Saving Control

4.2. Simulation Study of Dual-Loop Energy-Saving Control

4.3. Experimental Study of the Model-Free Control of Absorption Refrigeration Systems

5. Conclusions

- Based on the dynamic model of absorption refrigeration systems, an open-loop response characteristic analysis was conducted, identifying the control structure of these systems with the heat source and cooling water flow rates as the operating variables.

- Considering the complexity and modeling difficulties of absorption refrigeration system mechanisms, advanced control algorithms highly dependent on models cannot be applied. PID-like controllers, although commonly used, also struggle to achieve satisfactory control effects for multivariable, strongly coupled, and highly time-delayed and nonlinear absorption refrigeration systems. Model-free control algorithms, which do not require quantitative knowledge of the controlled object but rely solely on input–output data, exhibit good robustness. Therefore, a model-free control algorithm was selected for the control strategy design of absorption refrigeration systems.

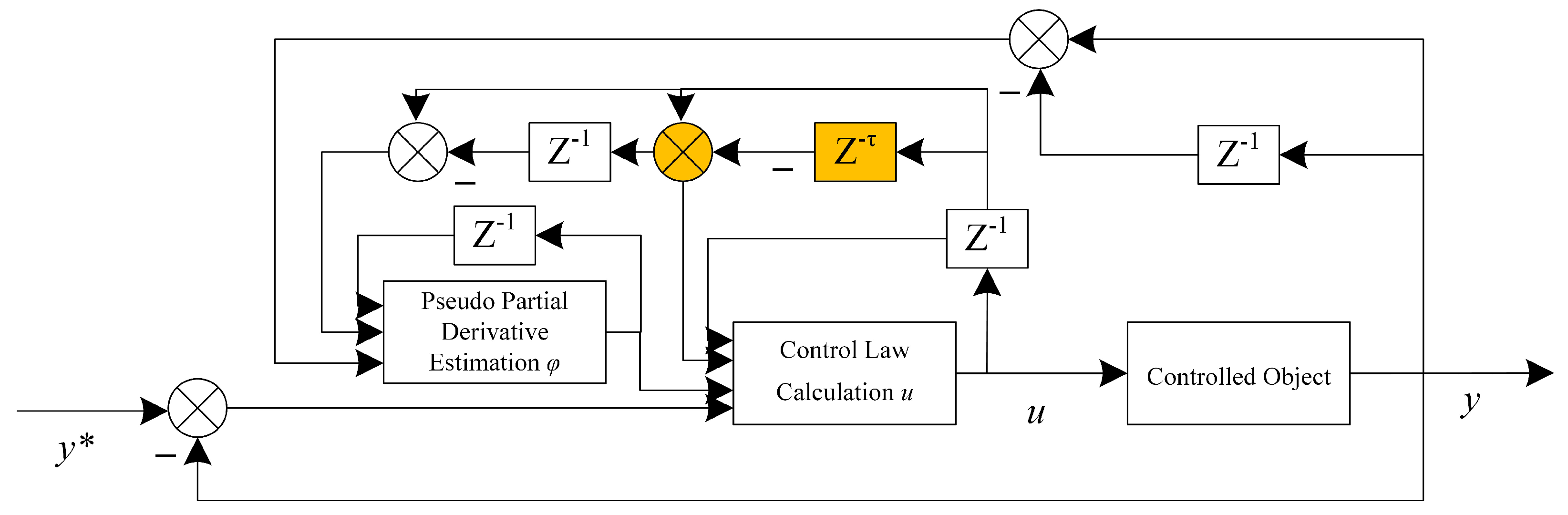

- Addressing the large time-delay characteristics of absorption refrigeration systems, a model-free control algorithm with time delay was derived based on classical model-free controllers.

- Recognizing that single-loop control can only ensure the cooling capacity of the unit without guaranteeing its energy efficiency, an energy-saving dual-loop control scheme for absorption refrigeration systems was proposed based on setpoint ensemble optimization. A model-free MIMO control algorithm with time delay was derived accordingly.

- Applying the model-free control algorithm to absorption refrigeration system control, simulations were conducted on single- and dual-loop energy-saving control strategies. The heat consumption was cut by approximately 20%, from 3.276 kW to 2.621 kW, under the dual-loop control strategy, which saved 0.655 kW compared to the other approach. Similarly, electricity consumption was reduced by about 10%, from 0.683 kW to 0.615 kW. These changes resulted in a 16.6% boost in the unit’s COP, from 0.360 to 0.418, and an overall improvement in the system’s SCOP of approximately 19.3%, from 0.330 to 0.387, showcasing the efficacy of the dual-loop energy-efficient control scheme.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Sulaiman, F.A. Performance assessment of a solar powered ammonia–water absorption refrigeration system with storage units. Energy Convers. Manag. 2016, 126, 316–328. [Google Scholar]

- Determan, M.D.; Garimella, S. Design, fabrication, and experimental demonstration of a microscale monolithic modular absorption heat pump. Appl. Therm. Eng. 2012, 47, 119–125. [Google Scholar] [CrossRef]

- Verma, A.; Kaushık, S.C.; Tyagı, S.K. Performance enhancement of absorption refrigeration systems: An overview. J. Therm. Eng. 2023, 9, 1100–1113. [Google Scholar] [CrossRef]

- Modi, B.; Mudgal, A.; Raja, B.D.; Patel, V. Low grade thermal energy driven-small scale absorption refrigeration system (SSARS): Design, fabrication and cost estimation. Sustain. Energy Technol. Assess. 2022, 50, 101787. [Google Scholar] [CrossRef]

- Ahmad, T.; Azhar; Sinha, M.; Meraj; Mahbubul, I.M.; Ahmad, A. Energy analysis of lithium bromide-water and lithium chloride-water based single effect vapour absorption refrigeration system: A comparison study. Clean. Eng. Technol. 2022, 7, 100432. [Google Scholar] [CrossRef]

- Chun, A.; Donatelli, J.L.M.; Santos, J.J.C.S.; Zabeu, C.B.; Carvalho, M. Superstructure optimization of absorption chillers integrated with a large internal combustion engine for waste heat recovery and repowering applications: Thermodynamic and economic assessments. Energy 2023, 263, 125970. [Google Scholar] [CrossRef]

- Ham, J.; Yong, J.; Kwon, O.; Bae, K.; Cho, H. Experimental investigation on heat transfer and pressure drop of brazed plate heat exchanger using LiBr solution. Appl. Therm. Eng. 2023, 225, 120161. [Google Scholar] [CrossRef]

- Zendehnam, A.; Pourfayaz, F. Sensitivity analysis of avoidable and unavoidable exergy destructions in a parallel double-effect LiBr–water absorption cooling system. Energy Sci. Eng. 2023, 11, 527–546. [Google Scholar] [CrossRef]

- Vega, M.; Venegas, M.; García-Hernando, N. Modeling and performance analysis of an absorption chiller with a microchannel membrane-based absorber using LiBr-H2O, LiCl-H2O, and LiNO3-NH3. Int. J. Energy Res. 2018, 42, 3544–3558. [Google Scholar] [CrossRef]

- Amaris, C.; Bourouis, M.; Vallès, M.; Salavera, D.; Coronas, A. Thermophysical properties and heat and mass transfer of new working fluids in plate heat exchangers for absorption refrigeration systems. Heat Transf. Eng. 2015, 36, 388–395. [Google Scholar] [CrossRef]

- Didion, D.; Radermacher, R. Part-load performance characteristics of residential absorption chillers and heat pump. Int. J. Refrig. 1984, 7, 393–398. [Google Scholar] [CrossRef]

- Alvares, S.G.; Trepp, C. Simulation of a solar driven aqua-ammonia absorption refrigeration system Part 1: Mathematical description and system optimization. Int. J. Refrig. 1987, 10, 40–48. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, T.; Sun, F.; Wu, C. Irreversible four-temperature-level absorption refrigerator. Solar Energy 2006, 80, 347–360. [Google Scholar] [CrossRef]

- Cézar, K.L.; Caldas, A.G.A.; Caldas, A.M.A.; Cordeiro, M.C.L.; Dos Santos, C.A.C.; Ochoa, A.A.V.; Michima, P.S.A. Development of a novel flow control system with arduino microcontroller embedded in double effect absorption chillers using the LiBr/H2O pair. Int. J. Refrig. 2020, 111, 124–135. [Google Scholar] [CrossRef]

- Staudt, S.; Unterberger, V.; Muschick, D.; Gölles, M.; Horn, M.; Wernhart, M.; Rieberer, R. MIMO state feedback control for redundantly-actuated LiBr/H2O absorption heat pumping devices and experimental validation. Control Eng. Pract. 2023, 140, 105661. [Google Scholar] [CrossRef]

- Labus, J.; Hernández, J.; Bruno, J.; Coronas, A. Inverse neural network based control strategy for absorption chillers. Renew. Energy 2012, 39, 471–482. [Google Scholar] [CrossRef]

- Alcântara, S.C.S.; Ochoa, A.A.V.; da Costa, J.Â.P.; de Menezes, F.D.; Leite, G.D.N.P.; Michima, P.S.A.; da Silva Marques, A. Development of a method for predicting the transient behavior of an absorption chiller using artificial intelligence methods. Appl. Therm. Eng. 2023, 231, 120978. [Google Scholar] [CrossRef]

- Tang, C.; Li, N.; Bao, L. Predictive Control Modeling of Regional Cooling Systems Incorporating Ice Storage Technology. Buildings 2024, 14, 2488. [Google Scholar] [CrossRef]

- Homod, R.Z.; Mohammed, H.I.; Ben Hamida, M.B.; Albahri, A.; Alhasnawi, B.N.; Albahri, O.; Alamoodi, A.; Mahdi, J.M.; Albadr, M.A.A.; Yaseen, Z.M. Optimal shifting of peak load in smart buildings using multiagent deep clustering reinforcement learning in multi-tank chilled water systems. J. Energy Storage 2024, 92, 112140. [Google Scholar] [CrossRef]

- Faruque, W.; Khan, Y.; Nabil, M.H.; Ehsan, M.M. Parametric analysis and optimization of a novel cascade compression-absorption refrigeration system integrated with a flash tank and a reheater. Results Eng. 2023, 17, 101008. [Google Scholar] [CrossRef]

- Altiokka, A.B.G.; Arslan, O. Design and optimization of absorption cooling system operating under low solar radiation for residential use. J. Build. Eng. 2023, 73, 106697. [Google Scholar] [CrossRef]

- Sharifi, S.; Heravi, F.N.; Shirmohammadi, R.; Ghasempour, R.; Petrakopoulou, F.; Romeo, L. Comprehensive thermodynamic and operational optimization of a solar-assisted LiBr/water absorption refrigeration system. Energy Rep. 2020, 6, 2309–2323. [Google Scholar] [CrossRef]

- Mohammadi, K.; Jiang, Y.; Borjian, S.; Powell, K. Thermo-economic assessment and optimization of a hybrid triple effect absorption chiller and compressor. Sustain. Energy Technol. Assess. 2020, 38, 100652. [Google Scholar] [CrossRef]

- Marcos, J.D.; Izquierdo, M.; Palacios, E. New method for COP optimization in water- and air-cooled single and double effect LiBr–water absorption machines. Int. J. Refrig. 2011, 34, 1348–1359. [Google Scholar] [CrossRef]

- Der, O.; Alqahtani, A.A.; Marengo, M.; Bertola, V. Characterization of polypropylene pulsating heat stripes: Effects of orientation, heat transfer fluid, and loop geometry. Appl. Therm. Eng. 2021, 184, 116304. [Google Scholar] [CrossRef]

- Nikolayev, V.S. Physical principles and state-of-the-art of modeling of the pulsating heat pipe: A review. Appl. Therm. Eng. 2021, 195, 117111. [Google Scholar] [CrossRef]

- Srikhirin, P.; Aphornratana, S.; Chungpaibulpatana, S. A review of absorption refrigeration technologies. Renew. Sustain. Energy Rev. 2001, 5, 343–372. [Google Scholar] [CrossRef]

- Mendiburu, A.Z.; Roberts, J.J.; Rodrigues, L.J.; Verma, S.K. Thermodynamic modelling for absorption refrigeration cycles powered by solar energy and a case study for Porto Alegre, Brazil. Energy 2023, 266, 126457. [Google Scholar] [CrossRef]

- Kaushik, S.C.; Arora, A. Energy and exergy analysis of single effect and series flow double effect water–lithium bromide absorption refrigeration systems. Int. J. Refrig. 2009, 32, 1247–1258. [Google Scholar] [CrossRef]

- Bouaziz, N.; Lounissi, D. Energy and exergy investigation of a novel double effect hybrid absorption refrigeration system for solar cooling. Int. J. Hydrogen Energy 2015, 40, 13849–13856. [Google Scholar] [CrossRef]

- Cui, P.; Yu, M.; Liu, Z.; Zhu, Z.; Yang, S. Energy, exergy, and economic (3E) analyses and multi-objective optimization of a cascade absorption refrigeration system for low-grade waste heat recovery. Energy Convers. Manag. 2019, 184, 249–261. [Google Scholar] [CrossRef]

- Talbi, M.M.; Agnew, B. Exergy analysis: An absorption refrigerator using lithium bromide and water as the working fluids. Appl. Therm. Eng. 2000, 20, 619–630. [Google Scholar] [CrossRef]

- Wen, H.; Wu, A.; Liu, Z.; Shang, Y. A state-space model for dynamic simulation of a single-effect LiBr/H2O absorption chiller. IEEE Access 2019, 7, 57251–57258. [Google Scholar] [CrossRef]

- Rêgo, A.; Hanriot, S.; Oliveira, A.; Brito, P.; Rêgo, T. Automotive exhaust gas flow control for an ammonia–water absorption refrigeration system. Appl. Therm. Eng. 2014, 64, 101–107. [Google Scholar] [CrossRef]

- Zhonsheng, H.; Jin, S. Model Free Adaptive Control Theory and Application; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Jin, S.; Hou, Z. An improved model-free adaptive control for a class of nonlinear large-lag systems. Control Theory Appl. 2008, 25, 623–626. [Google Scholar]

| Symbols | Meanings | Symbols | Meanings |

|---|---|---|---|

| Mass of lithium bromide solution in the generator (kg) | Fluid mass flow rate of solution pump (kg/s) | ||

| Mass fraction of generator fluid | Fluid mass flow rate of condenser (kg/s) | ||

| Generator solution temperature (°C) | Saturated liquid mass flow rate (kg/s) | ||

| Mass of liquid refrigerant water inside the condenser (kg) | Saturated gas mass flow rate (kg/s) | ||

| Absorber fluid mass fraction | Mass flow rate of refrigerant water vapor (kg/s) | ||

| Absorber solution temperature (°C) | Generator inlet dilute solution enthalpy value (kJ/kg) | ||

| Generator heat transfer rate (kJ/kg) | Enthalpy value of concentrated solution at the inlet of the absorber (kJ/kg) | ||

| Absorber heat transfer rate (kJ/s) | Generator solution enthalpy value (kJ/kg) | ||

| Molar mass of lithium bromide (g/mol) | Absorber solution enthalpy value (kJ/kg) | ||

| Molar mass of water (g/mol) | Generator outlet refrigerant steam enthalpy value (kJ/kg) | ||

| Heat capacity (g/mol) | Evaporator outlet refrigerant steam enthalpy value (kJ/kg) |

| Heat Source Water Inlet Temperature | Cooling Water Inlet Temperature | Chilled Water Inlet Temperature | Cooling Water Flow Rate | Chilled Water Flow Rate | Solution Pump Frequency |

|---|---|---|---|---|---|

| 95 °C | 30 °C | 15 °C | 0.65 kg/s | 0.26 kg/s | 30 Hz |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Wu, A.; Wen, H. Research on Energy-Saving Control Strategies for Single-Effect Absorption Refrigeration Systems. Energies 2024, 17, 4658. https://doi.org/10.3390/en17184658

Liu Z, Wu A, Wen H. Research on Energy-Saving Control Strategies for Single-Effect Absorption Refrigeration Systems. Energies. 2024; 17(18):4658. https://doi.org/10.3390/en17184658

Chicago/Turabian StyleLiu, Zhenchang, Aiguo Wu, and Haitang Wen. 2024. "Research on Energy-Saving Control Strategies for Single-Effect Absorption Refrigeration Systems" Energies 17, no. 18: 4658. https://doi.org/10.3390/en17184658

APA StyleLiu, Z., Wu, A., & Wen, H. (2024). Research on Energy-Saving Control Strategies for Single-Effect Absorption Refrigeration Systems. Energies, 17(18), 4658. https://doi.org/10.3390/en17184658