Technical Evaluation of a Stand-Alone Photovoltaic Heat Pump Dryer without Batteries

Abstract

1. Introduction

- The control algorithm developed at the IES-UPM allows for the management of the PV power fluctuations due to cloud-passing (characterized by very abrupt fluctuations of the solar irradiance) without external support. This way, all the energy required for the drying process is provided by the PV generator, allowing for energetic independence and reducing the investment and operational costs.

- The HP unit installed does not work with the standard inverter technology (where the target is a certain temperature of the air), but with an advanced algorithm that reaches the dew point of the air to condense its humidity [35]. This way, the HP unit generates very dry air, with a high capacity of absorbing the humidity from the alfalfa, potentially reducing the drying time and energy consumption.

- Contrary to the traditional diesel-powered dryers, where the humid air is released into the ambient, this prototype recirculates the air in a closed loop: once it has absorbed the humidity from the alfalfa, it is reintroduced into the HP unit. The HP dries it by condensation, and the water extracted can be reused for several applications, such as irrigation, or even human consumption. This leads to a more efficient use of the solar resource, enabling the drying of the alfalfa and the simultaneous production of water.

2. Nomenclature

3. Methodology

3.1. System Description

- -

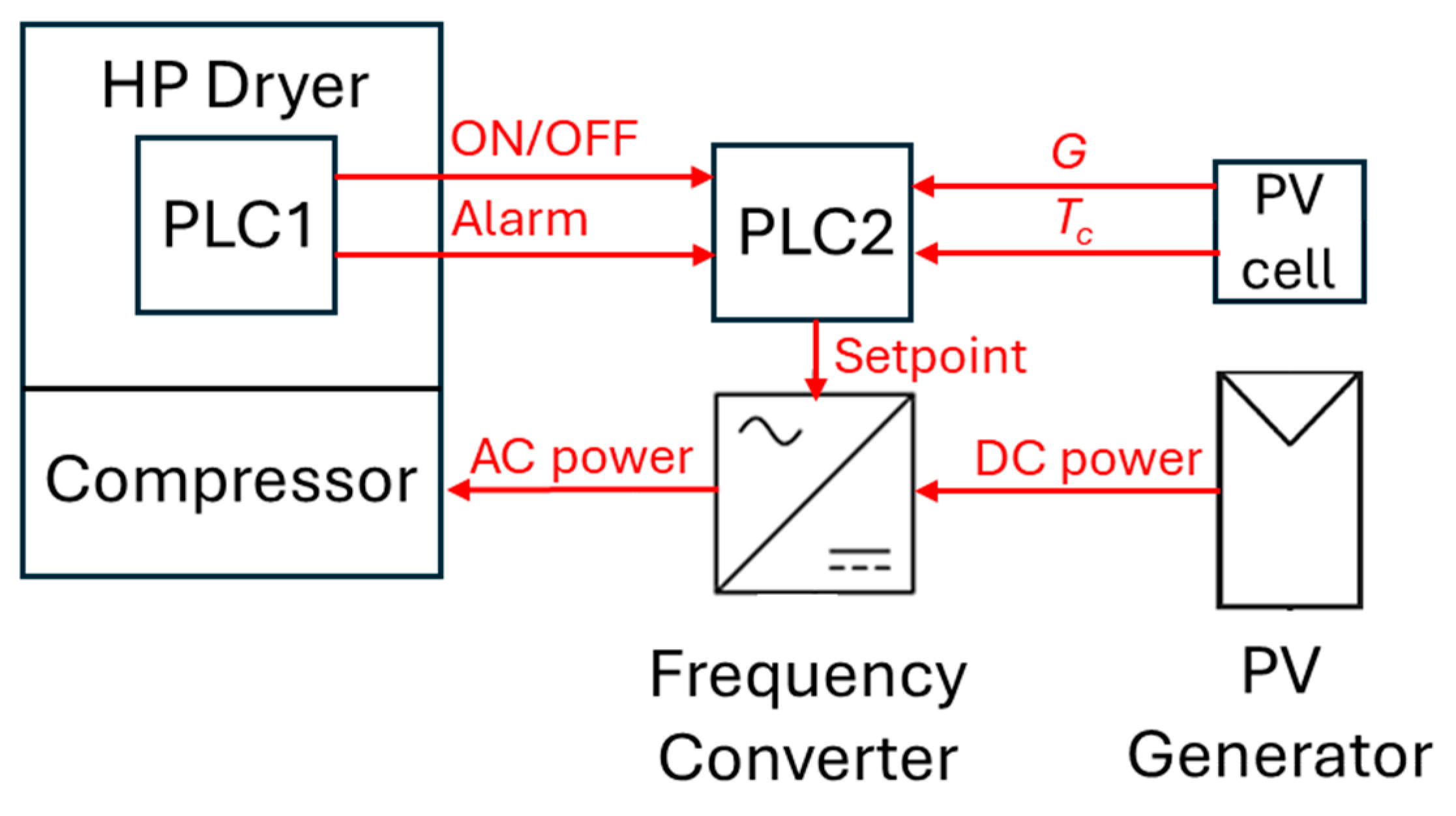

- HP dryer with an internal PLC1, which indicates an external PLC2 if there is any alarm in the HP unit, and when the user wants to start/stop drying. PLC1 monitors several pressures and temperatures in different points of the refrigerant circuit for regulating the evaporator and condenser fans and the expansion valve.

- -

- An external PLC2 that reads the PV operating conditions—global irradiance on the plane of the generator (G) and cell temperature (TC)—from a PV calibrated cell. If the PLC1 allows it, the PLC2 calculates the DC voltage at the Maximum Power Point (VMPP) and sends it to the Frequency Converter (FC). This setpoint is calculated as follows:

- -

- The FC converts the DC power delivered by the PC generator (operating at the setpoint given by PLC2) into AC power for controlling the compressor of the HP dryer.

3.2. Validation of the PV System and Control System

- -

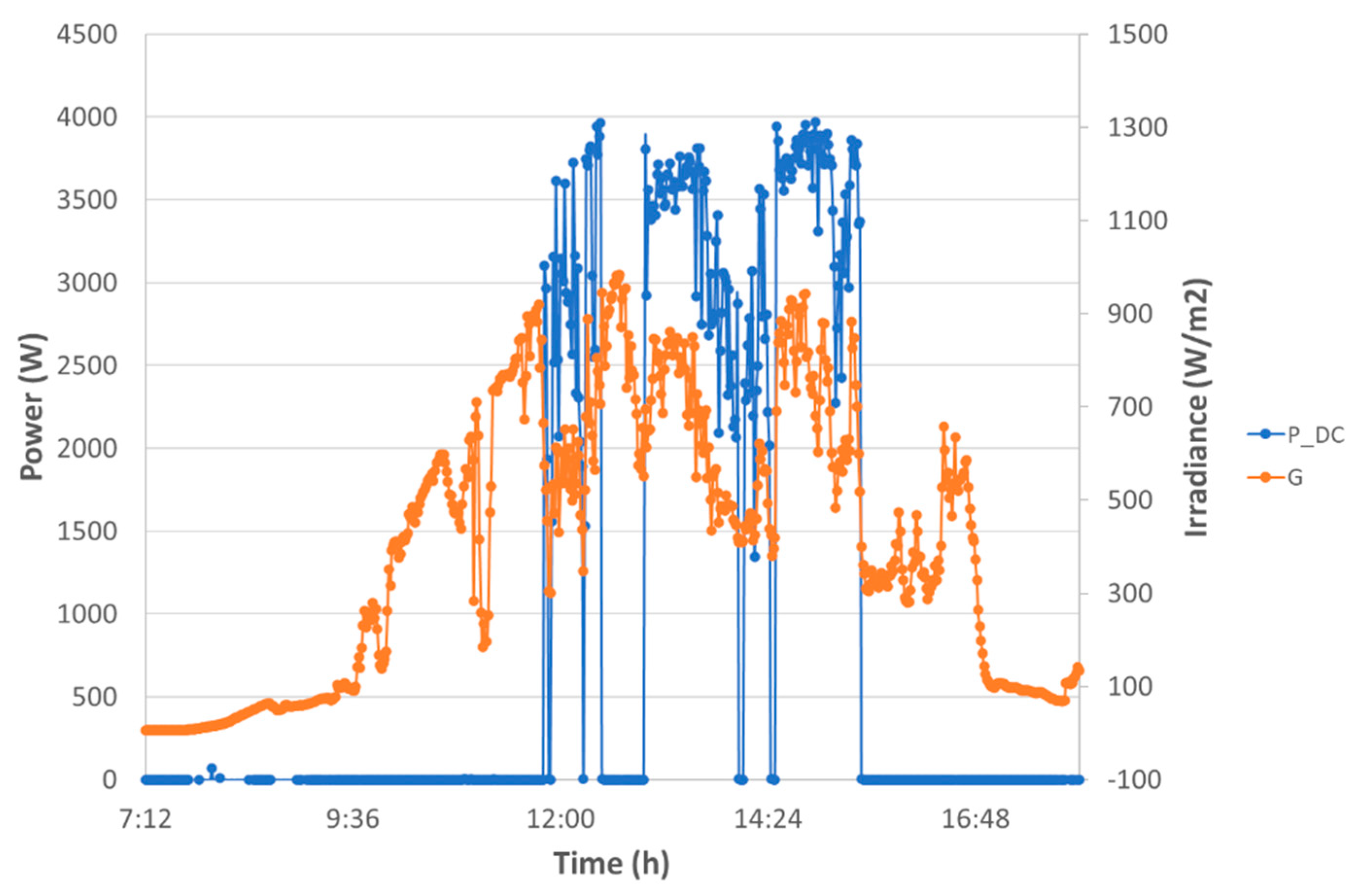

- If the DC voltage drops below a minimum value, there is an undervoltage alarm at the FC and the system stops abruptly. Abrupt stops are undesirable because they reduce the lifetime of the system components, mainly the FC and the compressor. If the operating voltage of the PV generator approaches the minimum value, the PLC orders a controlled (i.e., slow) stop of the FC.

- -

- When the DC voltage drops, so does the frequency of the compressor; if it operates below the minimum value specified by the manufacturer for more than 3 s, the PLC orders a controlled stop. Otherwise, there is risk of overheating in the compressor and of damage in the refrigerant circuit due to excessive vibrations.

3.3. Characterization of the Drying Process

4. Results and Discussion

4.1. Validation of the PV System and Control System

4.2. Characterization of the Drying Process

- -

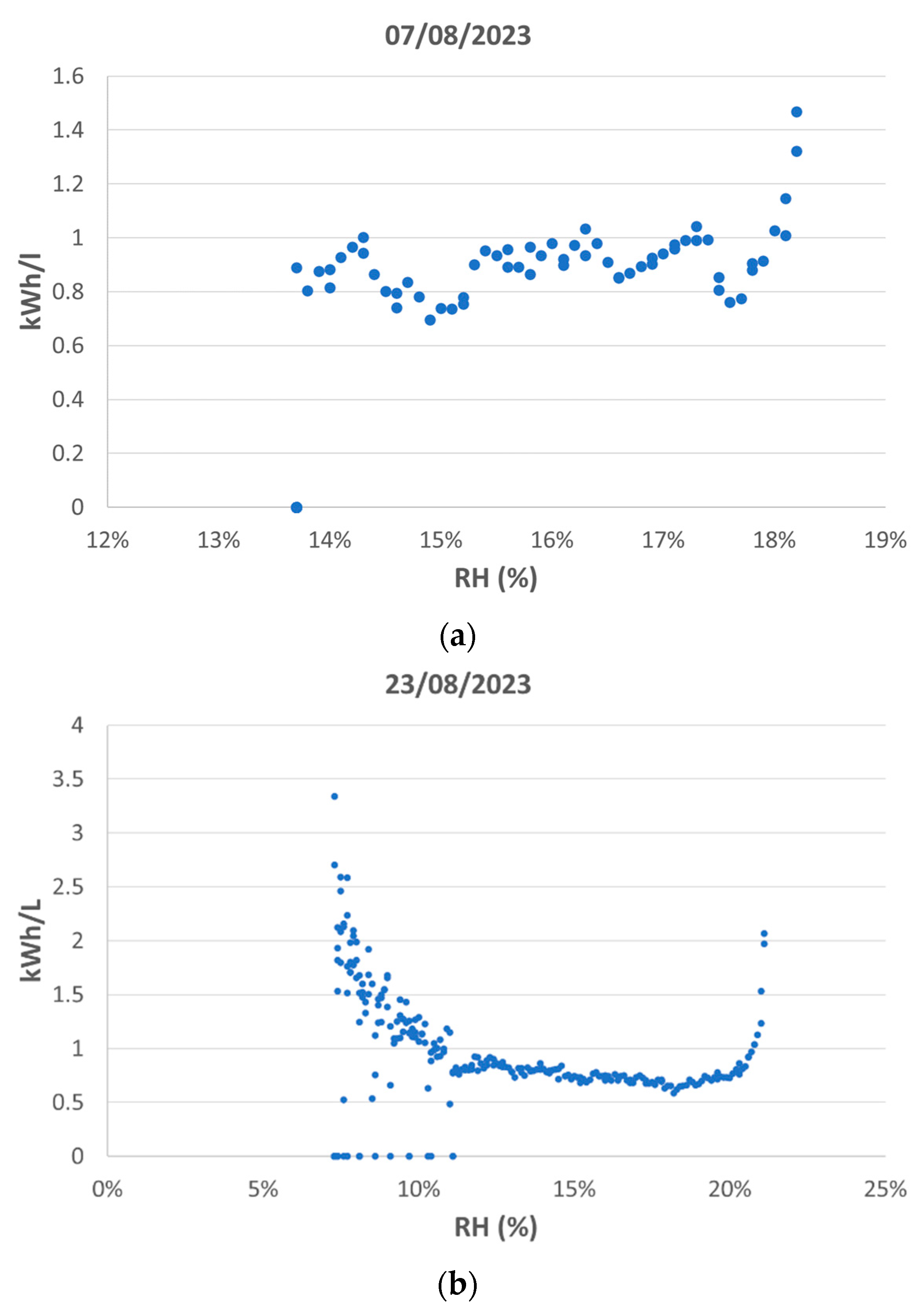

- At the beginning of the drying test (i.e., when the RH is higher), the energy consumption is very high but decreases drastically after reducing the RH by approximately 1%. This behavior is observed over the three days. The reason is that, when the HP unit is turned on, the refrigerant temperatures at the evaporator and condenser require a few minutes to stabilize and reach the optimum values for drying the air. During this time, the PVHP dryer does not extract the water efficiently, so the energy consumption increases.

- -

- In Figure 5b,c, after the energy consumption reaches a minimum, it increases again, slowly at first, and then quite abruptly. This abrupt increase occurs at different RH levels and has different causes. In Figure 5b, the RH reaches lower values than 10%, so, at the end of the experiment, the alfalfa was very dry. In this situation, the air flow absorbs little water during each recirculation (mainly because there is little water to extract), which increases the specific energy consumption. In Figure 5b, on the other hand, the increase in energy consumption occurs at RH levels higher than 20%, and the target value of 16% is never reached. In this case, the reason is an incorrect fit of the alfalfa bale inside of the drying box, which left open spaces for the air to pass through, instead of flowing through the alfalfa. These spaces increase when the alfalfa losses water and, consequently, the volume, which explains the increase in the specific energy consumption at the end of the experiment. Finally, Figure 5a does not present this abrupt increase at the end because the experiment stopped at a medium RH level, and there was a proper fit inside the drying box.

- -

- This allows us to identify the main sources of the variability observed in the energy consumption per liter of water extracted, which are as follows:

- -

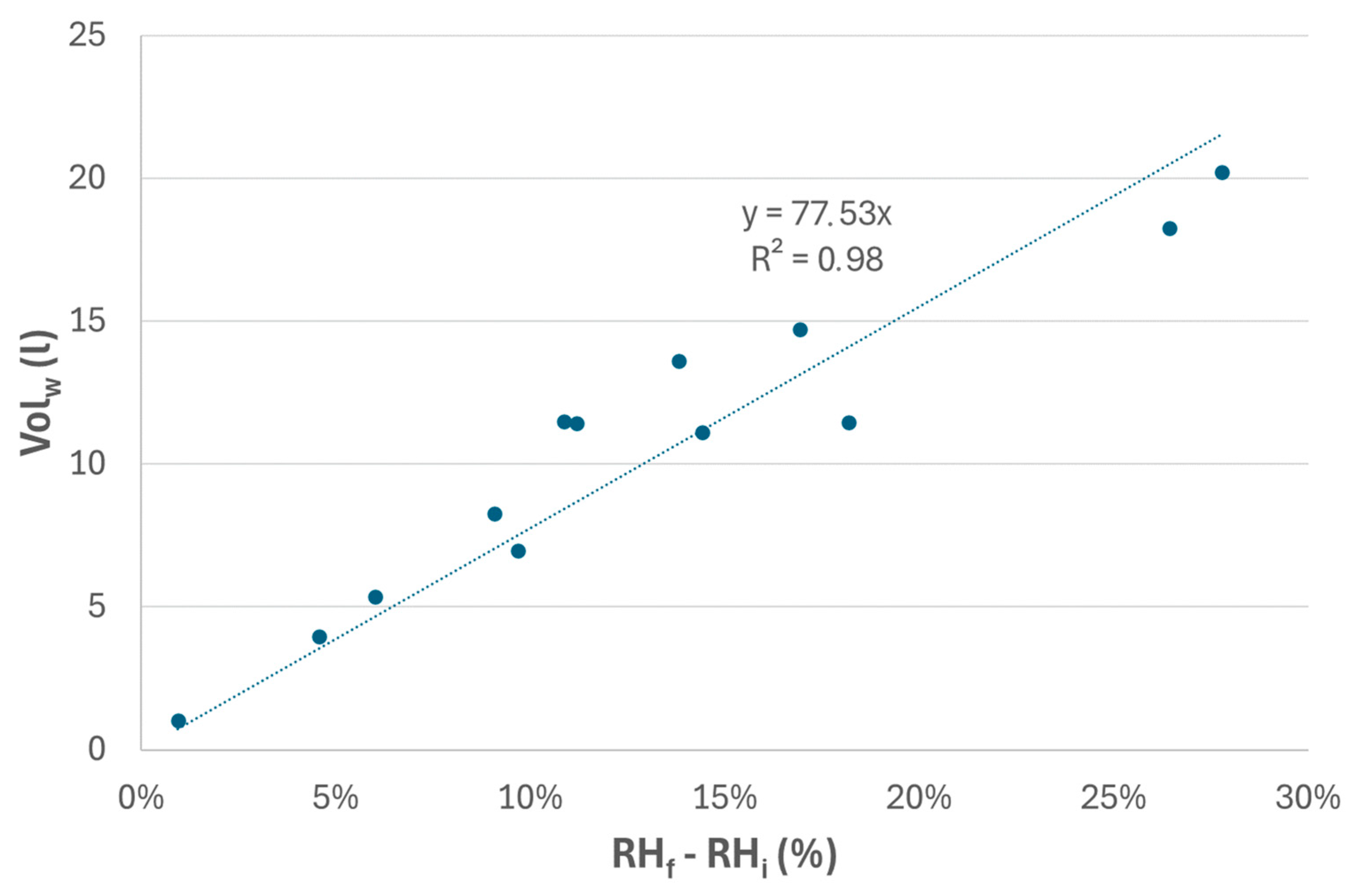

- The RH levels during the drying process, specially the RHf. There are two possibilities for reducing this uncertainty: by using a more accurate monitoring system for the humidity and temperature of the air flow, which allows us to know the RH at any moment, or by directly measuring the volume of water condensed inside the HP unit. If the RHi is well known, it is possible to know how many liters of water must be extracted for reaching the optimum 16% (as seen in Figure 4).

- -

- The correct or incorrect fit of the alfalfa bale inside of the drying box conditions the efficiency of the air flow to absorb water. This could be mitigated with an advanced design of the drying infrastructure, by changing the orientation of the box so that the weight of the alfalfa ensures a good fit by gravity.

5. Conclusions and Future Work

- -

- An accurate monitoring system for the humidity and temperature of the air flow, which allows for the determination of the RH at any moment. If this is not possible due to the heterogeneity of the air flow, a simpler solution would be to directly measure the volume of water condensed inside of the HP unit. This would allow for determining the optimum RHi and RHf to reduce the energy consumption.

- -

- Designing a drying box that ensures a better fit of the alfalfa bale, forcing the air flow through the core and reducing both energy consumption and drying times. For this, a better understanding of the fluid dynamic inside of the box would be needed, in order to evaluate the pressure and temperature gradients.

- -

- Integrating an AI-based control system for minimizing the number of stops per hour during cloudy days, reducing the URPVHP losses by improving the use of the solar resource and extending the lifetime of the compressor.

- -

- The solution proposed should be validated in different seasons and climatic conditions to generalize the results. Specially, the cloud-passing control algorithm could need different tuning, depending on the local cloud-patterns. There are already two previous works by the IES-UPM that validated the cloud-passing control algorithm for long term operation in PV irrigation systems [32] and a stand-alone PVHP system for cooling applications [33].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agricultural Dryer Market by Type (Stationary Dryer and Mobile Dryer), by Application (Residential and Commercial) and by Region-Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023–2030. Zion Market Research (Report Code ZMR-7940). January 2024. Available online: https://www.zionmarketresearch.com/report/agricultural-dryer-market (accessed on 28 June 2024).

- Global Agricultural Dryer Market Report by Type (Stationary Dryer, Mobile Dryer), by Application (Residential, Commercial) and by Regions-Industry Trends, Size, Share, Growth, Estimation and Forecast, 2023–2032. Value Market Research (Report Code ID:VMR112113505. January 2024. Available online: https://www.valuemarketresearch.com/report/agricultural-dryer-market (accessed on 28 June 2024).

- Agricultural Dryer Market Research Report 2024. Verified Market Reports (Report Code 867422). 2024. Available online: https://www.verifiedmarketreports.com/product/agricultural-dryer-market/ (accessed on 28 June 2024).

- 1214-Swedes, Mangolds, Fodder Roots, Hay, Alfalfa, Clover, Sainfoin, Forage Kale, Lupines, Vetches and Similar Forage Products, Whether or Not in the Form of Pellets. March 2024. Available online: https://www.uktradeinfo.com/commodities/1214 (accessed on 15 June 2024).

- Controlado el Incendio de 4.000 Toneladas de Alfalfa en Torres de Berrellén (Zaragoza), in Heraldo de Zaragoza. Spain. 2023. Available online: https://www.heraldo.es/noticias/aragon/zaragoza/2023/12/20/incendio-zaragoza-alfalfa-torres-berellen-1698871.html (accessed on 28 June 2024).

- Ferias, Mercados y Matederos. Precio Para la Alfalfa Deshidratada en Pacas, Lonja del Ebro. Available online: https://www.feriasymercados.net/index.php/producto/demo/1644 (accessed on 15 June 2024).

- de Muslera, P.E.; Clemente, R.G. Praderas y Forrajes, Producción y Aprovechamiento; Mundi-Prensa: Madrid, Spain, 1984. [Google Scholar]

- Parker, B.F.; White, G.M.; Lindley, M.R.; Gates, R.S.; Collins, M.; Lowry, S.; Bridges, T.C. Forced-air drying of baled alfalfa hay. Trans. Am. Soc. Agric. Eng. 1992, 35, 607–615. [Google Scholar] [CrossRef]

- Holt, G.A.; Hooker, J.D. Gaseous emissions from burning diesel, crude and prime bleachable summer yellow cottonseed oil in a burner for drying seedcotton. Bioresour. Technol. 2004, 92, 261–267. [Google Scholar] [CrossRef] [PubMed]

- Chinook Hay Systems. Available online: https://chinookhay.com/ (accessed on 30 June 2024).

- Agricompact Technologies. Available online: https://www.agricompact-technologies.com/ (accessed on 30 June 2024).

- Historical Diesel Fuel Prices. Available online: https://agtransport.usda.gov/Fuel/Historical-Diesel-Fuel-Prices/u2kh-s8ke (accessed on 28 June 2024).

- Ortiz-Rodríguez, N.M.; Condorí, M.; Durán, G.; García-Valladares, O. Solar drying Technologies: A review and future research directions with a focus on agroindustrial applications in medium and large scale. Appl. Therm. Eng. 2022, 215, 118993. [Google Scholar] [CrossRef]

- Lingayat, A.; Balijepalli, R.; Chandramohan, V.P. Applications of solar energy based drying technologies in various industries—A review. Sol. Energy 2021, 229, 52–68. [Google Scholar] [CrossRef]

- Ahmad, A.; Prakash, O.; Kumar, A.; Chatterjee, R.; Sharma, S.; Kumar, V.; Kulshreshtha, K.; Li, C.; Eldin, E.M.T. A Comprehensive State-of-the-Art Review on the Recent Developments in Greenhouse Drying. Energies 2022, 15, 9493. [Google Scholar] [CrossRef]

- Hassan, A.; Nikbakht, A.M.; Fawzia, S.; Yarlagadda, P.; Karim, A. A Comprehensive Review of the Thermohydraulic Improvement Potentials in Solar Air Heaters through an Energy and Exergy Analysis. Energies 2024, 17, 1526. [Google Scholar] [CrossRef]

- Lingayat, A.; Zachariah, R.; Modi, A. Current status and prospect of integrating solar air heating systems for drying in various sectors and industries. Sustain. Energ. Technol. Assess. 2022, 52, 102274. [Google Scholar] [CrossRef]

- Karami, H.; Kaveh, M.; Golpour, I.; Khalife, E.; Rusinek, R.; Dobrzański, B., Jr.; Gancarz, M. Thermodynamic evaluation of the forced convective hybrid-solar dryer during drying process of rosemary (Rosmarinus officinalis L.) leaves. Energies 2021, 14, 5835. [Google Scholar] [CrossRef]

- Gonçalves, L.M.; Mendoza-Martinez, C.; Rocha, E.P.A.; de Paula, E.C.; Cardoso, M. Solar Drying of Sludge from a Steel-Wire-Drawing Industry. Energies 2023, 16, 6314. [Google Scholar] [CrossRef]

- Solar (Photovoltaic) Panel Prices. Available online: https://ourworldindata.org/grapher/solar-pv-prices (accessed on 28 June 2024).

- Bennamoun, L. Integration of Photovoltaic Cells in Solar Drying Systems. Dry. Technol. 2013, 31, 1284–1296. [Google Scholar] [CrossRef]

- Barışık, D.; Colak, N.; Tavman, S. A comprehensive review of solar photovoltaic hybrid food drying systems. Crit. Rev. Food Sci. Nutr. 2021, 62, 4152–4168. [Google Scholar] [CrossRef] [PubMed]

- Rezvani, Z.; Mortezapour, H.; Ameri, M.; Akhavan, H.-R.; Arslan, S. Energy and exergy analysis of a water bed-infrared dryer coupled with a photovoltaic-thermal collector. J. Food Process Eng. 2022, 45, e14058. [Google Scholar] [CrossRef]

- Ismail, M.I.; Yunus, N.A.; Hashim, H. Integration of solar heating systems for low-temperature heat demand in food processing industry—A review. Renew. Sustain. Energy Rev. 2021, 147, 111192. [Google Scholar] [CrossRef]

- Farjana, S.H.; Huda, N.; Mahmud, M.A.P.; Saidur, R. Solar process heat in industrial systems—A global review. Renew. Sustain. Energy Rev. 2018, 82, 2270–2286. [Google Scholar] [CrossRef]

- Hao, W.; Liu, S.; Lai, Y.; Wang, M.; Liu, S. Research on drying Lentinus edodes in a direct expansion heat pump assisted solar drying system and performance of different operating modes. Renew. Energy 2022, 196, 638–647. [Google Scholar] [CrossRef]

- Aguilar, F.J.; Aledo, S.; Quiles, P.V. Experimental analysis of an air conditioner powered by photovoltaic energy and supported by the grid. Appl. Therm. Eng. 2017, 123, 486–497. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, B.Y.; Zhao, Z.G.; Taylor, R.A.; Wang, R.Z. Performance study of a grid-connected photovoltaic powered central air conditioner in the South China climate. Renew. Energy 2018, 126, 1113–1125. [Google Scholar] [CrossRef]

- Candan, D.; Oktay, Z.; Coskun, C. Design and an instantaneous experimental analysis of photovoltaic-assisted heat pump dryer for agricultural applications using banana chips. J. Food Process Eng. 2021, 44, e13832. [Google Scholar] [CrossRef]

- Khouya, A. Energy analysis of a combined solar wood drying system. Sol. Energy 2022, 231, 270–282. [Google Scholar] [CrossRef]

- Fernández-Ramos, J.; Narvarte, L.; López-Soria, R.; Almeida, R.H.; Carrêlo, I.B. An assessment of the proportional-integral control tuning rules applied to Photovoltaic Irrigation Systems based on Standard Frequency Converters. Sol. Energy 2019, 191, 468–480. [Google Scholar] [CrossRef]

- Herraiz, J.I.; Fernández-Ramos, J.; Almeida, R.H.; Báguena, E.M.; Castillo-Cagigal, M.; Narvarte, L. On the tuning and performance of Stand-Alone Large-Power PV irrigation systems. Energy Convers. Manag. X 2022, 13, 100175. [Google Scholar] [CrossRef]

- Lorenzo, C.; Narvarte, L.; Almeida, R.H.; Cristóbal, A.B. Technical evaluation of a stand-alone photovoltaic heat pump system without batteries for cooling applications. Sol. Energy 2020, 206, 92–105. [Google Scholar] [CrossRef]

- Quijano, A.; Lorenzo, C.; Narvarte, L. Economic Assessment of a PV-HP System for Drying Alfalfa in The North of Spain. Energies 2023, 16, 3347. [Google Scholar] [CrossRef]

- Ficha Técnica de GENAQ Nimbus N500, Datos de Fabricante. Available online: https://genaq.com/solutions/#industrial (accessed on 28 June 2024).

- Lorenzo, C.; Narvarte, L. Performance indicators of photovoltaic heat-pumps. Heliyon 2019, 5, e02691. [Google Scholar] [CrossRef]

- Jahn, U.; Nasse, W. Performance analysis and reliability of grid-connected PV systems in IEA countries. In Proceedings of the 3rd World Conference on Photovoltaic Energy Conversion 2003, Osaka, Japan, 11–18 May 2003; Volume 3, pp. 2148–2151. [Google Scholar]

- Purohit, I.; Purohit, P. Performance assessment of grid-interactive solar photovoltaic projects under India’s national solar mission. Appl. Energy 2018, 222, 25–41. [Google Scholar] [CrossRef]

| Heat pump dryer | |

| Manufacturer | GENAQ |

| Model | Nimbus N500-4.2 |

| Nominal Power | 4.1 |

| Moto compressor | |

| Manufacturer | Frascold |

| Model | D4-18.1Y |

| Nominal AC power (kW) | 3 |

| PV generator | |

| Orientation | 0° (South oriented) |

| Inclination | 30° |

| Nominal DC power, PMPP (kW) | 6.6 |

| Modules in series per string | 14 |

| Strings in parallel | 1 |

| Module manufacturer | Solarwatt |

| Module model | Panel Classic P1.0 pure |

| Frequency converter | |

| Manufacturer | ABB |

| Model | ACS310-03E-17A2-4 |

| Nominal AC power (kW) | 7.5 |

| This is the PR considering only losses strictly associated with the PV system itself, i.e., actual versus nominal peak power, dirtiness, thermal and DC/AC conversion losses. It is intrinsic to the technical quality of the PV components and its maintenance. is the irradiance effectively used by the system, considering only the periods of time when the compressor is functioning. | |

| This is the ratio of the total irradiation, which is the integration of the irradiance along a period of time throughout the drying period (Dp), to the total annual irradiation. It is intrinsic to a given crop. Note that it can only be applied to the annual period. | |

| This is the ratio of the irradiation necessary to deliver the power required by the compressor to the total irradiation throughout the Dp. It is intrinsic to the drying system design; specifically, it depends on the power range of the operation of the compressor, the ratio between the PV peak power and the PV power demanded by the HP, and the maximum number of starts per hour recommended by the compressor’s manufacturer. is the irradiance considered during the periods of time when the PV power is within the power range of operation of the compressor. | |

| This is the ratio of the irradiation required by the compressor during the drying schedule to the irradiation necessary to deliver the power required by the HP. It is intrinsic to both the availability of product to be dried and to the end user’s behavior. |

| Date | PR | PRPV | URPVHP | UREF | PRPV,STC | Gd (kWh/m2) | Tc (°C) |

|---|---|---|---|---|---|---|---|

| 09/07/2022 | 0.69 | 0.81 | 0.88 | 0.96 | 0.98 | 5.37 | 68.51 |

| 10/07/2022 | 0.51 | 0.77 | 0.70 | 0.94 | 0.92 | 5.67 | 66.88 |

| 11/07/2022 | 0.40 | 0.82 | 0.49 | 1.00 | 0.98 | 3.67 | 69.24 |

| 20/07/2022 | 0.65 | 0.82 | 0.80 | 1.00 | 0.97 | 2.53 | 64.37 |

| 21/07/2022 | 0.54 | 0.80 | 0.69 | 0.99 | 0.93 | 5.17 | 60.24 |

| 26/07/2022 | 0.38 | 0.87 | 0.71 | 0.61 | 0.98 | 3.98 | 49.83 |

| 28/07/2022 | 0.64 | 0.81 | 0.85 | 0.93 | 0.96 | 5.66 | 43.22 |

| 29/07/2022 | 0.28 | 0.85 | 0.84 | 0.39 | 0.98 | 6.29 | 41.37 |

| 01/08/2022 | 0.26 | 0.80 | 0.92 | 0.35 | 0.97 | 4.70 | 68.32 |

| 02/08/2022 | 0.53 | 0.82 | 0.95 | 0.68 | 0.96 | 5.54 | 62.76 |

| 17/08/2022 | 0.32 | 0.89 | 0.55 | 0.66 | 0.99 | 3.90 | 37.41 |

| 04/10/2022 | 0.60 | 0.81 | 0.86 | 0.86 | 0.96 | 4.30 | 46.10 |

| 05/10/2022 | 0.61 | 0.87 | 0.81 | 0.86 | 0.96 | 4.90 | 35.54 |

| Total 2022 | 0.49 | 0.82 | 0.81 | 0.74 | 0.96 | 61.68 | 54.91 |

| 07/08/2023 | 0.37 | 0.84 | 0.79 | 0.56 | 0.91 | 1.76 | 37.09 |

| 10/08/2023 | 0.26 | 0.84 | 0.80 | 0.38 | 0.93 | 5.58 | 60.96 |

| 23/08/2023 | 0.63 | 0.81 | 0.91 | 0.86 | 0.94 | 3.85 | 65.26 |

| 24/08/2023 | 0.25 | 0.87 | 0.85 | 0.34 | 0.96 | 5.61 | 56.23 |

| 25/08/2023 | 0.49 | 0.85 | 0.84 | 0.68 | 0.94 | 4.37 | 51.19 |

| 07/09/2023 | 0.08 | 0.85 | 0.78 | 0.12 | 0.93 | 5.21 | 41.58 |

| 08/09/2023 | 0.56 | 0.87 | 0.70 | 0.92 | 0.95 | 5.18 | 42.49 |

| 09/09/2023 | 0.63 | 0.85 | 0.79 | 0.94 | 0.93 | 5.46 | 41.22 |

| 10/09/2023 | 0.58 | 0.83 | 0.82 | 0.86 | 0.96 | 6.08 | 44.53 |

| 27/09/2023 | 0.36 | 0.85 | 0.45 | 0.94 | 0.92 | 4.35 | 35.31 |

| 28/09/2023 | 0.41 | 0.82 | 0.74 | 0.68 | 0.94 | 5.80 | 45.47 |

| 11/10/2023 | 0.30 | 0.84 | 0.89 | 0.40 | 0.94 | 5.71 | 42.87 |

| 13/10/2023 | 0.34 | 0.87 | 0.45 | 0.87 | 0.95 | 2.60 | 29.38 |

| Total 2023 | 0.40 | 0.85 | 0.75 | 0.64 | 0.94 | 61.58 | 45.66 |

| PRPV | PRPV,STC | |

|---|---|---|

| Mean | 0.84 | 0.95 |

| Standard deviation (%) | 2.68 | 2.15 |

| Sample | Date | RHi (%) | RHf (%) | Drying Time (h) | VolW (L) | AC Consumption (kWh/L) |

|---|---|---|---|---|---|---|

| 1 | 07/08/2023 | 18.3% | 13.7% | 1.0 | 3.96 | 0.90 |

| 2 | 10/08/2023 | 21.1% | 6.7% | 2.1 | 11.12 | 0.70 |

| 3 | 23/08/2023 | 21.1% | 7.3% | 3.8 | 13.60 | 0.96 |

| 4 | 24/08/2023 | 28.5% | 19.4% | 2.3 | 8.28 | 0.92 |

| 5 | 25/08/2023 | 27.1% | 10.2% | 3.3 | 14.73 | 0.79 |

| 6 | 07/09/2023 | 28.2% | 27.2% | 0.7 | 1.03 | 2.41 |

| 6 | 08/09/2023 | 27.2% | 16.0% | 4.6 | 11.44 | 1.46 |

| 7 | 09/09/2023 | 29.6% | 1.8% | 5.1 | 20.22 | 0.99 |

| 8 | 10/09/2023 | 27.4% | 1.0% | 5.3 | 18.26 | 1.11 |

| 9 | 27/09/2023 | 20.1% | 10.4% | 3.0 | 6.97 | 1.34 |

| 10 | 28/09/2023 | 18.6% | 0.4% | 3.5 | 11.48 | 1.16 |

| 11 | 11/10/2023 | 25.4% | 14.5% | 2.9 | 11.50 | 0.83 |

| 12 | 13/10/2023 | 17.9% | 11.9% | 1.7 | 5.37 | 1.03 |

| Dp | Drying period |

| EAC | AC energy delivered by the PV generator [Wh] |

| FC | Frequency Converter |

| G(t) | Global solar irradiance on the plane of the generator at a given moment [W/m2] |

| G* | Global solar irradiance on the plane of the generator at Standard Test Conditions [W/m2] |

| Gused | G, considering only the periods of time when the compressor is functioning [W/m2] |

| Guseful | G considering only the periods of time when the PV power is within the power range of operation of the compressor [W/m2] |

| Gd | Total daily irradiation received on the plane of the PV generator [Wh/m2] |

| HP | Heat Pump |

| MPP | Maximum Power Point of the PV generator |

| PDC | DC power delivered by the PV generator [kW] |

| PMPP | DC power of the PV generator at the MPP [kW] |

| PMPP* | DC power of the PV generator at the MPP at STC [kW] |

| PLC | Programable Logic Controller |

| PR | Performance Ratio [Wh/Wh] |

| PRPV | PR considering only losses strictly associated to the PV generator itself (i.e., actual versus nominal peak power, dirtiness, thermal and DC/AC conversion losses) [Wh/Wh] |

| PRPV,STC | PRPV corrected to Standard Test Conditions [Wh/Wh] |

| PV | Photovoltaic |

| RH | relative humidity [%] |

| RHi | Initial relative humidity (before drying) [%] |

| RHf | Final relative humidity (after drying) [%] |

| STCs | Standard Test Conditions (G* = 1000 W/m2, TC = 25 °C) |

| TC | Cell temperature of the PV generator [°C] |

| TC* | Cell temperature of the PV generator at STC [°C] |

| UR | Utilization Ratio of the PV system [Wh/Wh] |

| URDp | UR that reflects the energy losses associated to the Dp [Wh/Wh] |

| URPVHP | UR that reflects the energy losses intrinsic to the design of the drying system (such as the operating power range of the compressor) [Wh/Wh] |

| UREF | UR that reflects the energy losses associated with external factors (such as the availability of product to dry) [Wh/Wh] |

| VMPP | DC voltage of the PV generator at the MPP [V] |

| VMPP* | DC voltage of the PV generator at the MPP at STCs [V] |

| VolW | Volume of water extracted during the drying test [L] |

| β | Coefficient of variation of the open circuit voltage of the PV module with [V/°C] |

| γ | Coefficient of variation of the maximum power of the PV module with [W/°C] |

| η(G) | Efficiency of the PV generator at the given G [W/W] |

| η* | Efficiency of the PV generator at STCs [W/W] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quijano, A.; Lorenzo, C.; Berlanga, A.; Narvarte, L. Technical Evaluation of a Stand-Alone Photovoltaic Heat Pump Dryer without Batteries. Energies 2024, 17, 4612. https://doi.org/10.3390/en17184612

Quijano A, Lorenzo C, Berlanga A, Narvarte L. Technical Evaluation of a Stand-Alone Photovoltaic Heat Pump Dryer without Batteries. Energies. 2024; 17(18):4612. https://doi.org/10.3390/en17184612

Chicago/Turabian StyleQuijano, Antonio, Celena Lorenzo, Antonio Berlanga, and Luis Narvarte. 2024. "Technical Evaluation of a Stand-Alone Photovoltaic Heat Pump Dryer without Batteries" Energies 17, no. 18: 4612. https://doi.org/10.3390/en17184612

APA StyleQuijano, A., Lorenzo, C., Berlanga, A., & Narvarte, L. (2024). Technical Evaluation of a Stand-Alone Photovoltaic Heat Pump Dryer without Batteries. Energies, 17(18), 4612. https://doi.org/10.3390/en17184612