A Comparison of the Life-Cycle Impacts of the Concentrating Solar Power with the Product Environmental Footprint and ReCiPe Methods

Abstract

1. Introduction

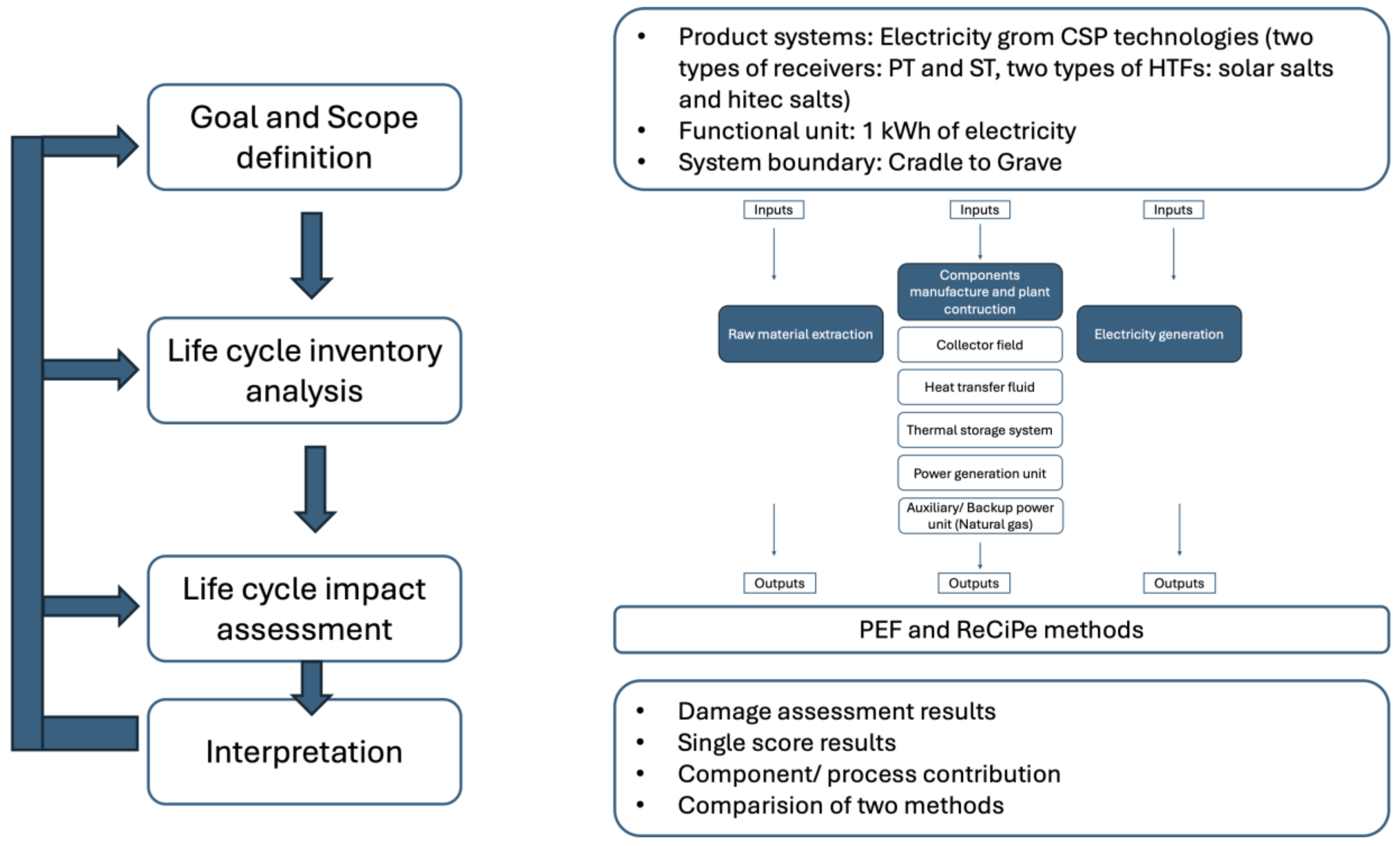

2. Materials and Methods

2.1. Goal and Scope

2.2. Technology Description

2.3. Life Cycle Inventory Data

2.4. Life-Cycle Impact Assessment Methods

3. Results and Discussion

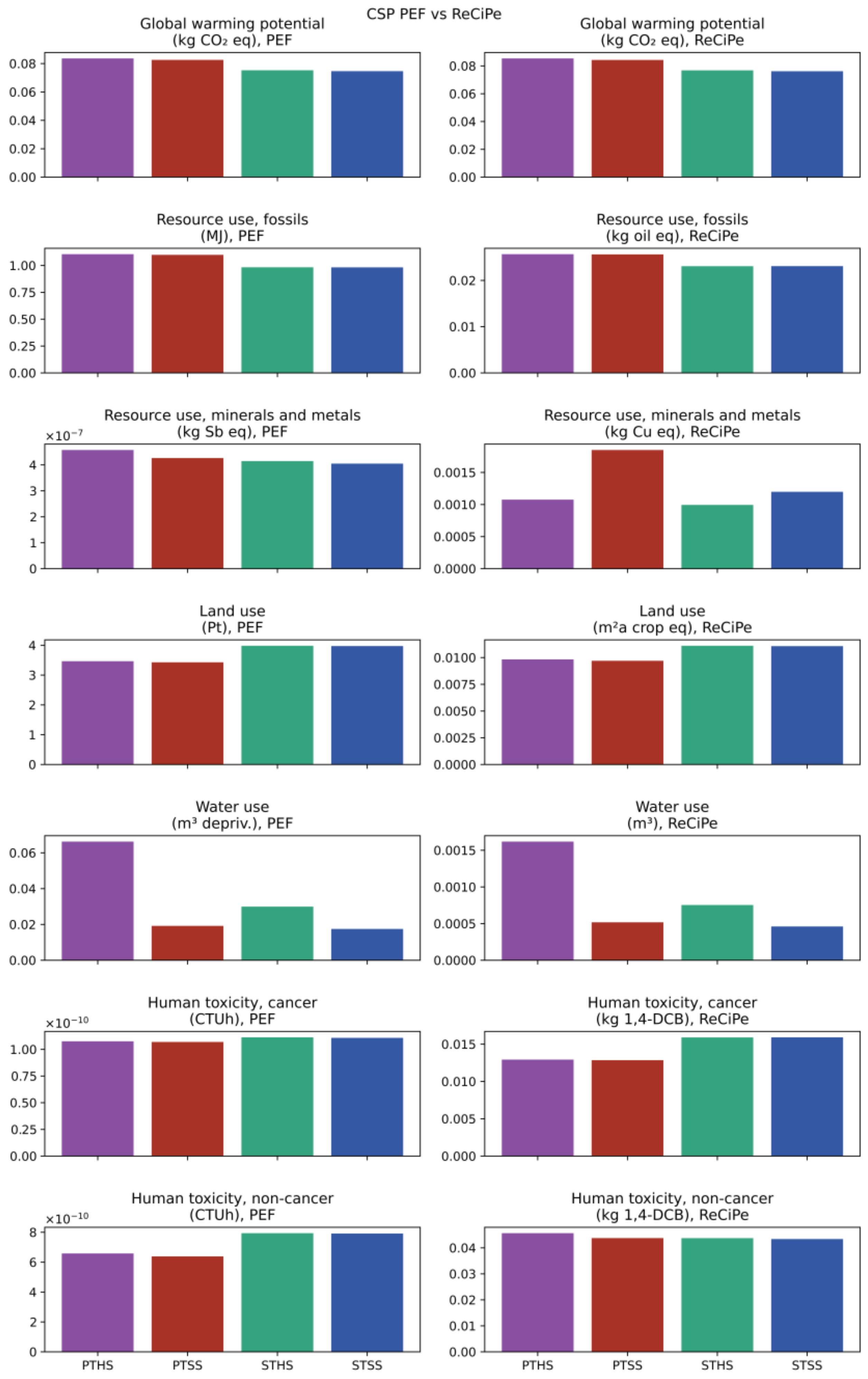

3.1. Life Cycle Environmental Impacts

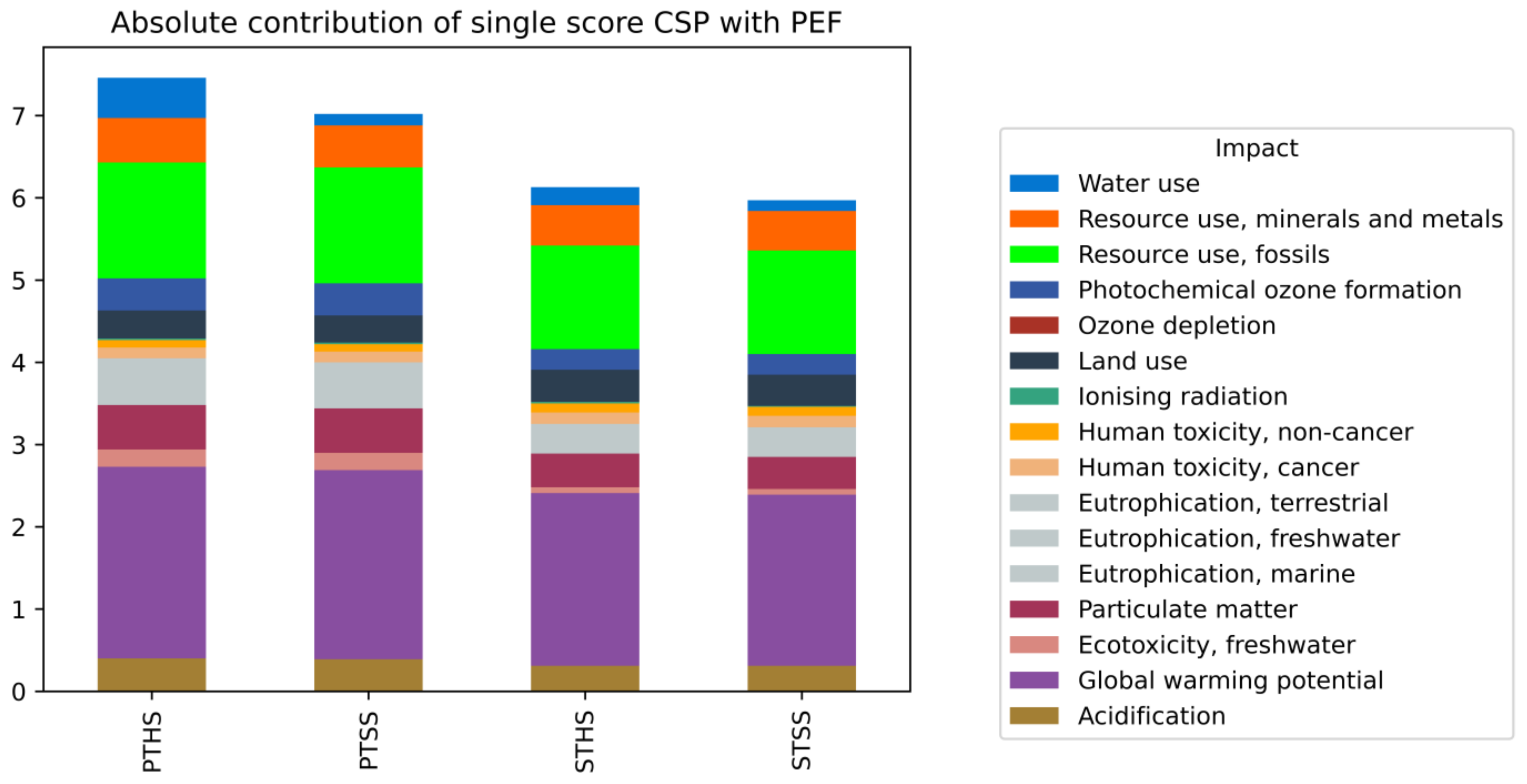

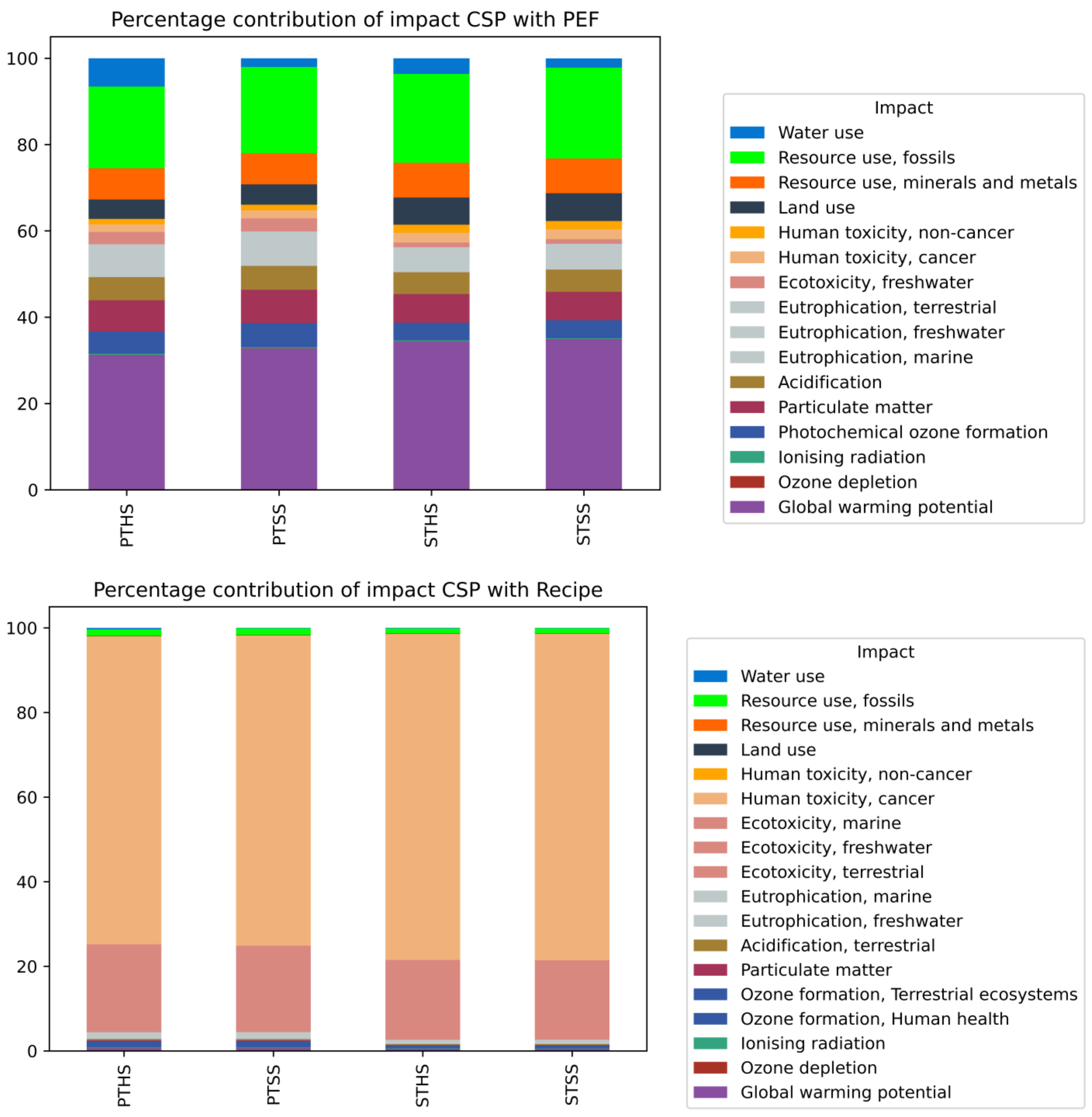

3.2. Single-Score Results

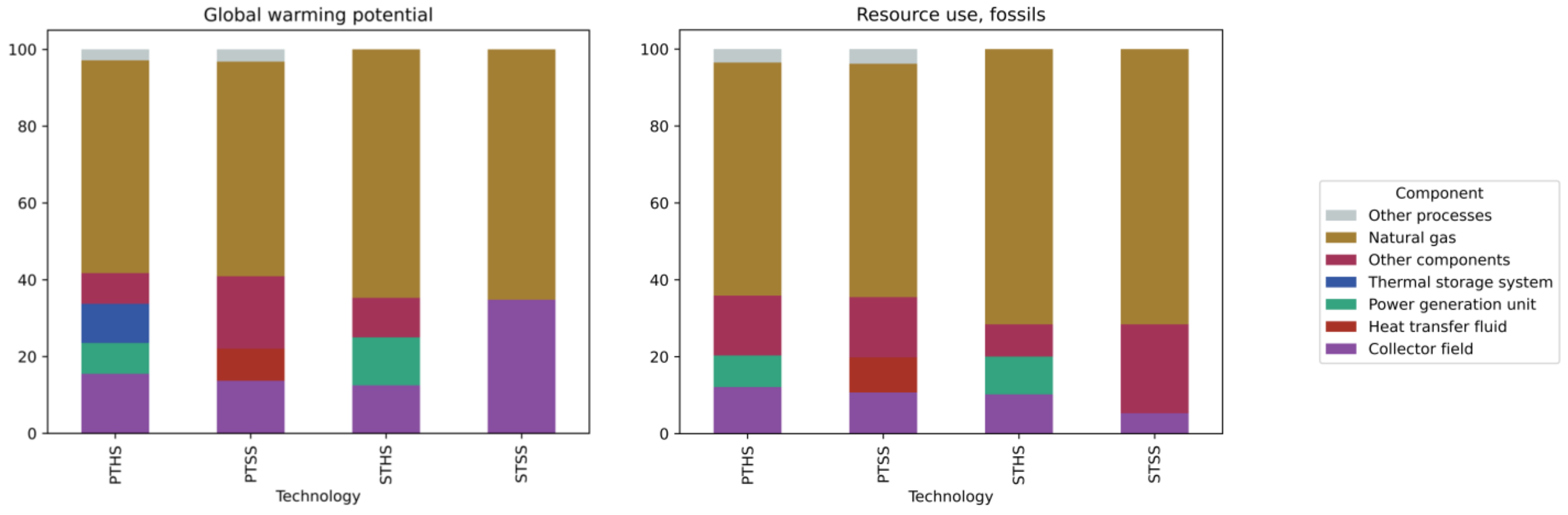

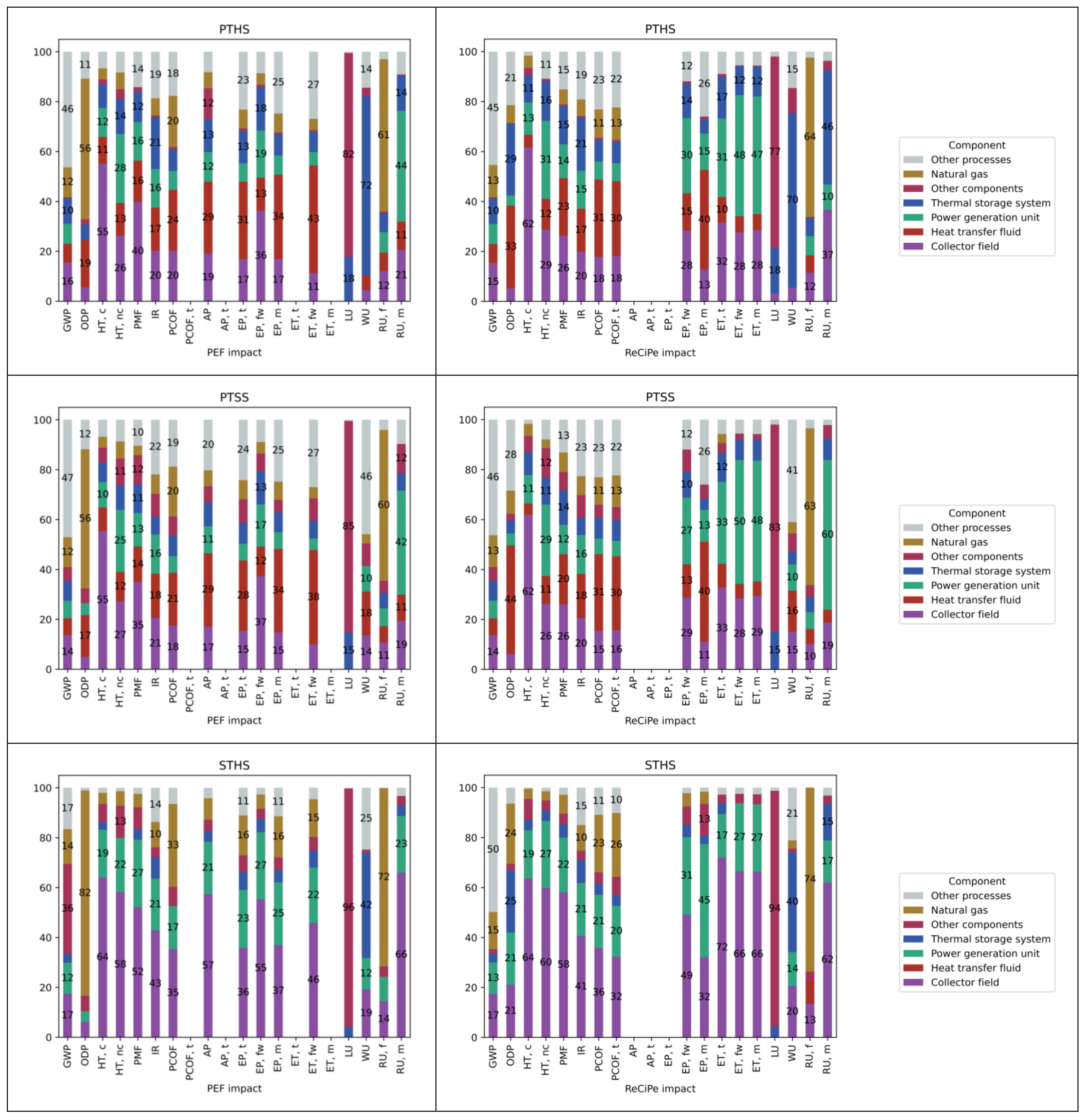

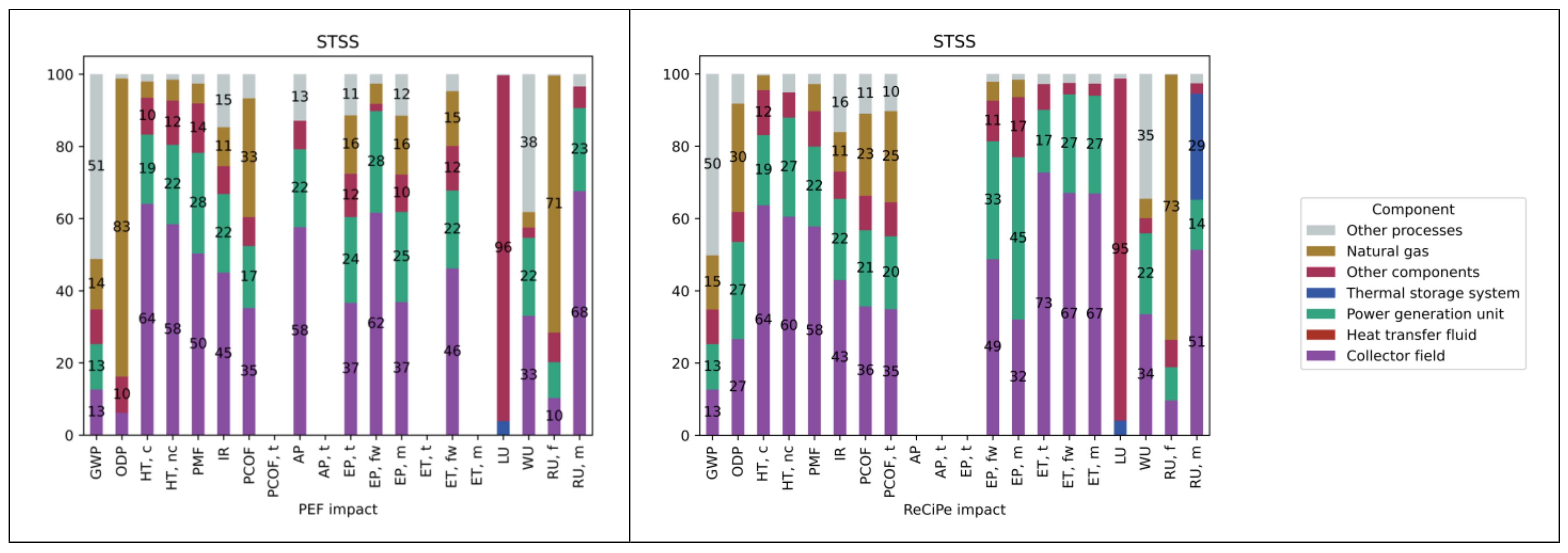

3.3. Contribution of Components to Individual Impacts

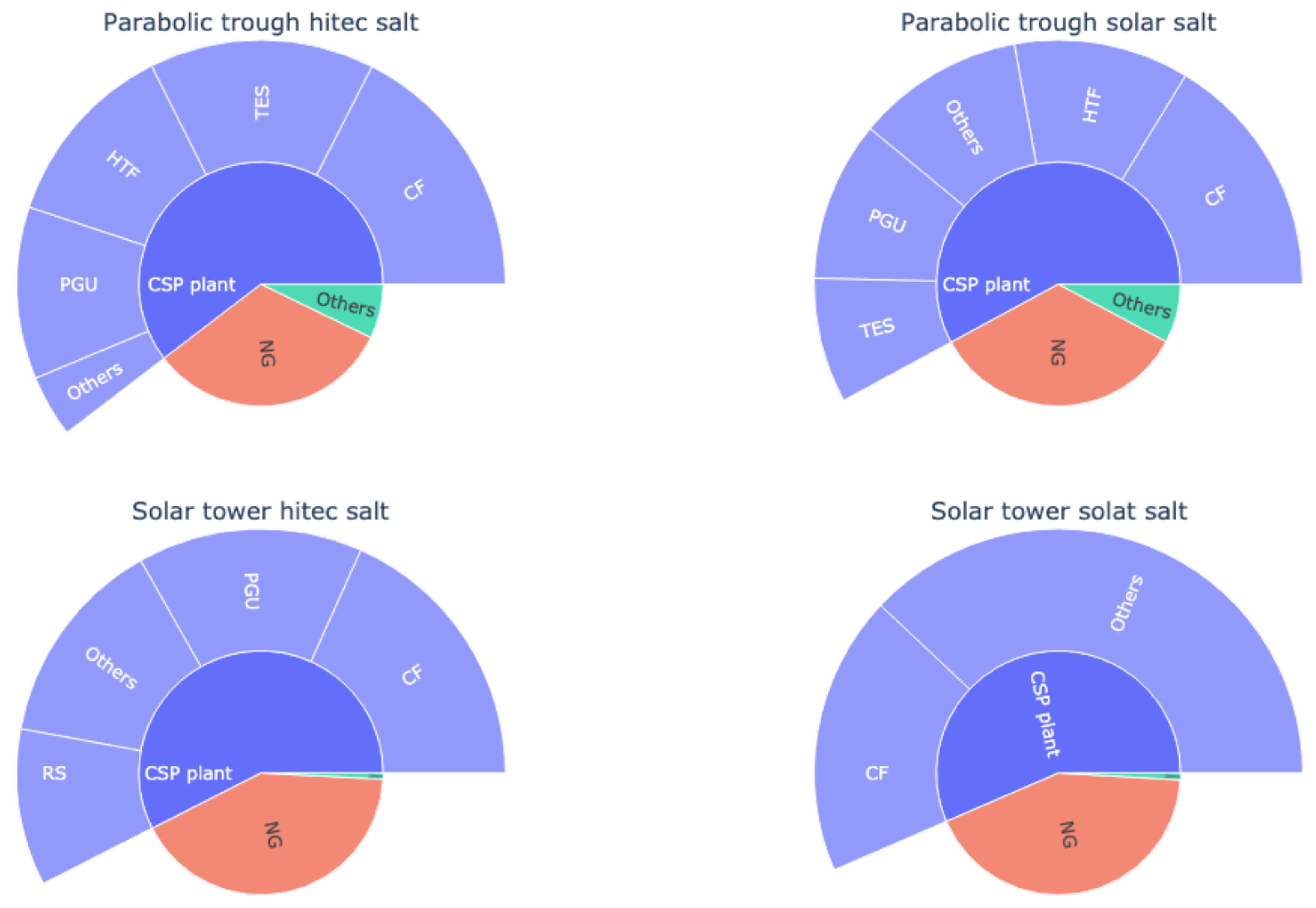

3.4. Contribution of Components to Single-Score Results

4. Conclusions and Future Paths for Eco-Design Studies

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AP | Acidification potential |

| CSP | Concentrating solar power |

| disease inc. | Disease incidence |

| EC | European Commission |

| EP | Eutrophication potential |

| ET | Ecotoxicity |

| GW | Gigawatt |

| GWP | Global warming potential |

| HS | Hitec salt |

| HT | Human toxicity |

| HTF | Heat-transfer fluid |

| IEA | International Energy Agency |

| IPCC | Intergovernmental Panel on Climate Change |

| IR | Ionising radiation |

| ISO | International Organization for Standardization |

| kg CO2 eq | Kilogram carbon dioxide equivalent |

| kWh | Kilowatt hour |

| LCA | Life-cycle assessment |

| LCIA | Life-cycle impact assessment |

| LU | Land use |

| m3 depriv. | Cubic meter-deprived |

| MJ | Megajoule |

| MW | Megawatt |

| ODP | Ozone depletion potential |

| OEF | Organization environmental footprint |

| OEFSR | Organization environmental footprint sector rules |

| PCOF | Photochemical ozone formation |

| PEF | Product environmental footprint |

| PEFCR | Product environmental footprint category rules |

| PT | Parabolic trough |

| Pt | Point |

| PV | Photovoltaics |

| RU | Resource use |

| SS | Solar salt |

| ST | Solar tower |

| TES | Thermal-energy storage system |

| UNEP | United Nation Environment Program |

| WU | Water use |

References

- IRENA. Renewable Power Generation Costs in 2019; International Renewable Energy Agency (IRENA): Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Răboacă, M.S.; Badea, G.; Enache, A.; Filote, C.; Răsoi, G.; Rata, M.; Lavric, A.; Felseghi, R.-A. Concentrating Solar Power Technologies. Energies 2019, 12, 1048. [Google Scholar] [CrossRef]

- IEA. Renewables 2020—Analysis and Forecast to 2025; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Ferruzzi, G.; Delcea, C.; Barberi, A.; Di Dio, V.; Di Somma, M.; Catrini, P.; Guarino, S.; Rossi, F.; Parisi, M.L.; Sinicropi, A.; et al. Concentrating Solar Power: The State of the Art, Research Gaps and Future Perspectives. Energies 2023, 16, 8082. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Senthilkumar, T. Five Decades of Evolution of Solar Photovoltaic Thermal (PVT) Technology—A Critical Insight on Review Articles. J. Clean. Prod. 2021, 322, 128997. [Google Scholar] [CrossRef]

- Kumar, L.; Hasanuzzaman, M.; Rahim, N.A. Global Advancement of Solar Thermal Energy Technologies for Industrial Process Heat and Its Future Prospects: A Review. Energy Convers. Manag. 2019, 195, 885–908. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Xu, Q.; Luo, Q.; Xuan, Y. MXene Reconciles Concurrent Enhancement of Thermal Conductivity and Mechanical Robustness of SiC-Based Thermal Energy Storage Composites. DeCarbon 2023, 1, 100005. [Google Scholar] [CrossRef]

- Lamnatou, C.; Notton, C.; Chemisana, D.; Cristofari, C. Storage Systems for Building-Integrated Photovoltaic (BIPV) and Building-Integrated Photovoltaic/Thermal (BIPVT) Installations: Environmental Profile and Other Aspects. Sci. Total Environ. 2020, 699, 134269. [Google Scholar] [CrossRef] [PubMed]

- Koli, P.; Kumar, R.; Dayma, Y.; Dheerata; Jonwal, M. Graphite Counter Electrode Modified Tropaeolin-O Photo-sensitized Photogalvanic Cells for Solar Power and Storage. EcoEnergy 2024, 2, 278–298. [Google Scholar] [CrossRef]

- Speranza, R.; Zaccagnini, P.; Sacco, A.; Lamberti, A. High-Voltage Energy Harvesting and Storage System for Internet of Things Indoor Application. Sol. RRL 2022, 6, 2200245. [Google Scholar] [CrossRef]

- Vignarooban, K.; Xu, X.; Arvay, A.; Hsu, K.; Kannan, A.M. Heat Transfer Fluids for Concentrating Solar Power Systems—A Review. Appl. Energy 2015, 146, 383–396. [Google Scholar] [CrossRef]

- Horne, R. Life Cycle Assessment: Origins, Principles and Context. In Life Cycle Assessment—Principles, Practice and Prospects; CSIRO Publishing: Collingwood, VIC, Australia, 2009; pp. 1–8. [Google Scholar]

- Fava, J.A. Life Cycle Initiative: A Joint UNEP/SETAC Partnership to Advance the Life-Cycle Economy. Int. J. Life Cycle Assess. 2002, 7, 196–198. [Google Scholar] [CrossRef]

- Frischknecht, R.; Heath, G.; Raugei, M.; Sinha, P.; de Wild-Scholten, M. Methodology Guidelines on Life Cycle Assessment of Photovoltaic Electricity; International Energy Agency: Paris, France, 2016. [Google Scholar]

- European Commission. Understanding Product Environmental Footprint and Organisation Environmental Footprint Methods; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar]

- ISO 14040:2006; ISO Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- Bjørn, A.; Owsianiak, M.; Molin, C.; Hauschild, M.Z. LCA History. In Life Cycle Assessment; Hauschild, M.Z., Rosenbaum, R.K., Hauschild, S.I.O., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Luu, Q.L.; Van Doan, B.; Nguyen, N.Q.; Nguyen, N.H. Life Cycle Assessment (LCA) of an Integrated Solar PV and Wind Power System in Vietnam. J. Asian Energy Stud. 2020, 4, 36–47. [Google Scholar] [CrossRef]

- Leontief, W. Chapter 11: Environmental Repercussions and the Economic Structure: An Input-Output Approach. In Input-Output Economics; Oxford University Press: New York, NY, USA, 1986. [Google Scholar]

- Gibon, T.; Wood, R.; Arvesen, A.; Bergesen, J.D.; Suh, S.; Hertwich, E.G. A Methodology for Integrated, Multiregional Life Cycle Assessment Scenarios under Large-Scale Technological Change. Environ. Sci. Technol. 2015, 49, 11218–11226. [Google Scholar] [CrossRef] [PubMed]

- Luu, L.Q.; Gibon, T.; Cellura, M.; Sanseverino, E.R.; Longo, S. Integrated Hybrid Multi-Regional Input-Output for Assessing Life Cycle Air Emissions of the Italian Power System. Energy 2024, 290, 130109. [Google Scholar] [CrossRef]

- ISO 14044:2006; ISO Environmental Management—Life Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Cellura, M.; Luu, L.Q.; Guarino, F.; Minestra, M. Life Cycle Greenhouse Gas Emissions and Relevant Impacts of Concentrating Solar Technologies. In Proceedings of the Networks, Markets and People Symposium 2024 (NMP2024), Reggio Calabria, Italy, 22–24 May 2024. [Google Scholar]

- Gobio-Thomas, L.B.; Darwish, M.; Stojceska, V. Environmental Impacts of Solar Thermal Power Plants Used in Industrial Supply Chains. Therm. Sci. Eng. Prog. 2023, 38, 101670. [Google Scholar] [CrossRef]

- NREL. SolarPACES—Concentrating Solar Power (CSP) Projects; National Renewable Energy Laboratory (NREL): Golden, CO, USA, 2022. [Google Scholar]

- EPLCA. Environmental Footprint (EF) Impact Assessment; European Platform on Life Cycle Assessment: Brussels, Belgium; Available online: https://eplca.jrc.ec.europa.eu/EFVersioning.html (accessed on 14 August 2024).

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.D.M.; Hollander, A.; Zijp, M.; van Zelm, R. ReCiPe 2016 v1.1 A Harmonized Life Cycle Impact Assessment Method at Midpoint and Endpoint Level Report I: Characterization; RIVM: Bilthoven, The Netherlands, 2016; p. 201. [Google Scholar]

- Sala, S.; Cerutti, A.; Pant, R. Development of a Weighting Approach for Environmental Footprint; Publication Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-68041-0. [Google Scholar]

- Vieira, M. The End of the PEF Pilot Phase and the Start of a Beautiful Friendship; Pre Sustainability 2018. Available online: https://pre-sustainability.com/articles/the-end-of-the-pef-pilot-phase-review-transition-phase/ (accessed on 14 August 2024).

- European Commission. Commission Recommendation of 16.12.2021 on the Use of the Environmental Footprint Methods to Measure and Communicate the Life Cycle Environmental Performance of Products and Organisations; European Commission: Brussels, Belgium, 2021. [Google Scholar]

- Cordella; Sala, S. The Environmental Footprint Methods: What, Why, How, Where; TAIEX-EIR Multi-country Flagship Workshop on best practices of use of Environmental Footprint methods on the EU market. Brussels, Belgium, 30 May 2024. Available online: https://webgate.ec.europa.eu/TMSWebRestrict/resources/js/app/#/library/detail/85542 (accessed on 14 August 2024).

- Polverini, D.; Espinosa, N.; Eynard, U.; Leccisi, E.; Ardente, F.; Mathieux, F. Assessing the Carbon Footprint of Photovoltaic Modules through the EU Ecodesign Directive. Sol. Energy 2023, 257, 1–9. [Google Scholar] [CrossRef]

- PEFCR PV Technical Secretariat Product Environmental Footprint Category Rules (PEFCR). Photovoltaic Modules Used in Photovoltaic Power Systems for Electricity Generation. 2019. Available online: https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_PV_electricity_feb2020_2.pdf (accessed on 14 August 2024).

- Beccali, M.; Cellura, M.; Longo, S. LCA and Techno-Eco Comparison between Reference and New Systems; IEA Task 53 SHC; International Energy Agency: Paris, France, 2018. [Google Scholar]

| PEF | ReCiPe | ||

|---|---|---|---|

| Impact Category | Unit of Measure | Impact Category | Unit of Measure |

| Climate change | kg CO2 eq | Climate change | kg CO2 eq |

| Ozone depletion | kg CFC-11 eq | Ozone depletion | kg CFC-11 eq |

| Human toxicity, cancer | CTUh | Human toxicity, cancer | kg 1,4 DCB |

| Human toxicity, non-cancer | CTUh | Human toxicity, non-cancer | kg 1,4 DCB |

| Particulate matter | disease incidence | Fine-particulate matter formation | kg PM2.5 eq |

| Ionizing radiation, human health | kBq U-235 eq | Ionizing radiation | kBq Co-60 eq |

| Photochemical ozone formation, human health | kg NMVOC eq | Photochemical oxidant formation: human health | kg NOx eq |

| Photochemical oxidant formation, terrestrial ecosystems | kg NOx eq | ||

| Acidification | mol H+ eq | Terrestrial acidification | kg SO2 eq |

| Eutrophication, terrestrial | mol N eq | ||

| Eutrophication, freshwater | kg P eq | Freshwater eutrophication | kg P eq |

| Eutrophication, marine | kg N eq | ||

| Terrestrial ecotoxicity | kg 1,4 DCB eq | ||

| Ecotoxicity, freshwater | CTUe | Freshwater ecotoxicity | kg 1,4 DCB eq |

| Marine ecotoxicity | kg 1,4 DCB eq | ||

| Land use | pt | Land use | m2 × yr annual cropland eq |

| Water use | m3 world eq | Water use | m3 water eq consumed |

| Resource use, minerals and metals | kg Sb eq | Mineral resource scarcity | kg Cu eq |

| Resource use, fossils | MJ | Fossil resource scarcity | kg oil eq |

| Impact Category | Normalization Factor (Unit of Measure per Person) | Weighting Factor (%) |

|---|---|---|

| Climate change | 8.10 × 103 | 21.06 |

| Ozone depletion | 5.36 × 10−2 | 6.31 |

| Human toxicity, cancer | 1.69 × 10−5 | 2.13 |

| Human toxicity, non-cancer | 2.30 × 10−4 | 1.84 |

| Particulate matter | 5.95 × 10−4 | 8.96 |

| Ionizing radiation, human health | 4.22 × 103 | 5.01 |

| Photochemical ozone formation, human health | 4.06 × 101 | 4.78 |

| Acidification | 5.56 × 101 | 6.2 |

| Eutrophication, terrestrial | 1.77 × 102 | 3.71 |

| Eutrophication, freshwater | 1.61 × 100 | 2.8 |

| Eutrophication, marine | 1.95 × 101 | 2.96 |

| Ecotoxicity, freshwater | 4.27 × 104 | 1.92 |

| Land use | 8.19 × 105 | 7.94 |

| Water use | 1.15 × 104 | 8.51 |

| Resource use, minerals and metals | 6.36 × 10−2 | 7.55 |

| Resource use, fossils | 6.50 × 104 | 8.32 |

| Impact Category | Unit | PTHS | PTSS | STHS | STSS | Difference between Technologies | Difference between HTFs |

|---|---|---|---|---|---|---|---|

| Acidification | mol H+ eq | 3.58 × 10−4 | 3.50 × 10−4 | 2.77 × 10−4 | 2.76 × 10−4 | 28% | 1% |

| Global warming potential | kg CO2 eq | 8.36 × 10−2 | 8.26 × 10−2 | 7.53 × 10−2 | 7.46 × 10−2 | 11% | 1% |

| Ecotoxicity, freshwater | CTUe | 6.29 × 10−1 | 6.28 × 10−1 | 1.96 × 10−1 | 1.94 × 10−1 | 222% | 0% |

| Particulate matter formation | disease inc. | 3.61 × 10−9 | 3.62 × 10−9 | 2.70 × 10−9 | 2.61 × 10−9 | 36% | 1% |

| Eutrophication, marine | kg N eq | 9.24 × 10−5 | 9.31 × 10−5 | 4.37 × 10−5 | 4.40 × 10−5 | 112% | −1% |

| Eutrophication, freshwater | kg P eq | 1.28 × 10−5 | 1.25 × 10−5 | 1.07 × 10−5 | 1.09 × 10−5 | 17% | 0% |

| Eutrophication, terrestrial | mol N eq | 9.97 × 10−4 | 9.61 × 10−4 | 4.89 × 10−4 | 4.79 × 10−4 | 102% | 3% |

| Human toxicity, cancer | CTUh | 1.08 × 10−10 | 1.07 × 10−10 | 1.11 × 10−10 | 1.11 × 10−10 | −3% | 0% |

| Human toxicity, non-cancer | CTUh | 6.58 × 10−10 | 6.39 × 10−10 | 7.94 × 10−10 | 7.92 × 10−10 | −18% | 2% |

| Ionizing radiation | kBq U-235 eq | 1.87 × 10−3 | 1.61 × 10−3 | 1.30 × 10−3 | 1.22 × 10−3 | 38% | 12% |

| Land use | Pt | 3.47 × 100 | 3.43 × 100 | 3.98 × 100 | 3.97 × 100 | −13% | 1% |

| Ozone depletion | kg CFC-11 eq | 3.80 × 10−9 | 3.76 × 10−9 | 2.69 × 10−9 | 2.68 × 10−9 | 41% | 1% |

| Photochemical oxidant formation | kg NMVOC eq | 3.30 × 10−4 | 3.33 × 10−4 | 2.12 × 10−4 | 2.13 × 10−4 | 56% | −1% |

| Resource use, fossils | MJ | 1.10 × 100 | 1.10 × 100 | 9.83 × 10−1 | 9.82 × 10−1 | 12% | 0% |

| Resource use, minerals and metals | kg Sb eq | 4.57 × 10−7 | 4.26 × 10−7 | 4.14 × 10−7 | 4.05 × 10−7 | 8% | 5% |

| Water use | m3 depriv. | 6.63 × 10−2 | 1.92 × 10−2 | 3.00 × 10−2 | 1.75 × 10−2 | 80% | 162% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luu, L.Q.; Cellura, M.; Longo, S.; Guarino, F. A Comparison of the Life-Cycle Impacts of the Concentrating Solar Power with the Product Environmental Footprint and ReCiPe Methods. Energies 2024, 17, 4461. https://doi.org/10.3390/en17174461

Luu LQ, Cellura M, Longo S, Guarino F. A Comparison of the Life-Cycle Impacts of the Concentrating Solar Power with the Product Environmental Footprint and ReCiPe Methods. Energies. 2024; 17(17):4461. https://doi.org/10.3390/en17174461

Chicago/Turabian StyleLuu, Le Quyen, Maurizio Cellura, Sonia Longo, and Francesco Guarino. 2024. "A Comparison of the Life-Cycle Impacts of the Concentrating Solar Power with the Product Environmental Footprint and ReCiPe Methods" Energies 17, no. 17: 4461. https://doi.org/10.3390/en17174461

APA StyleLuu, L. Q., Cellura, M., Longo, S., & Guarino, F. (2024). A Comparison of the Life-Cycle Impacts of the Concentrating Solar Power with the Product Environmental Footprint and ReCiPe Methods. Energies, 17(17), 4461. https://doi.org/10.3390/en17174461