Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review

Abstract

1. Introduction

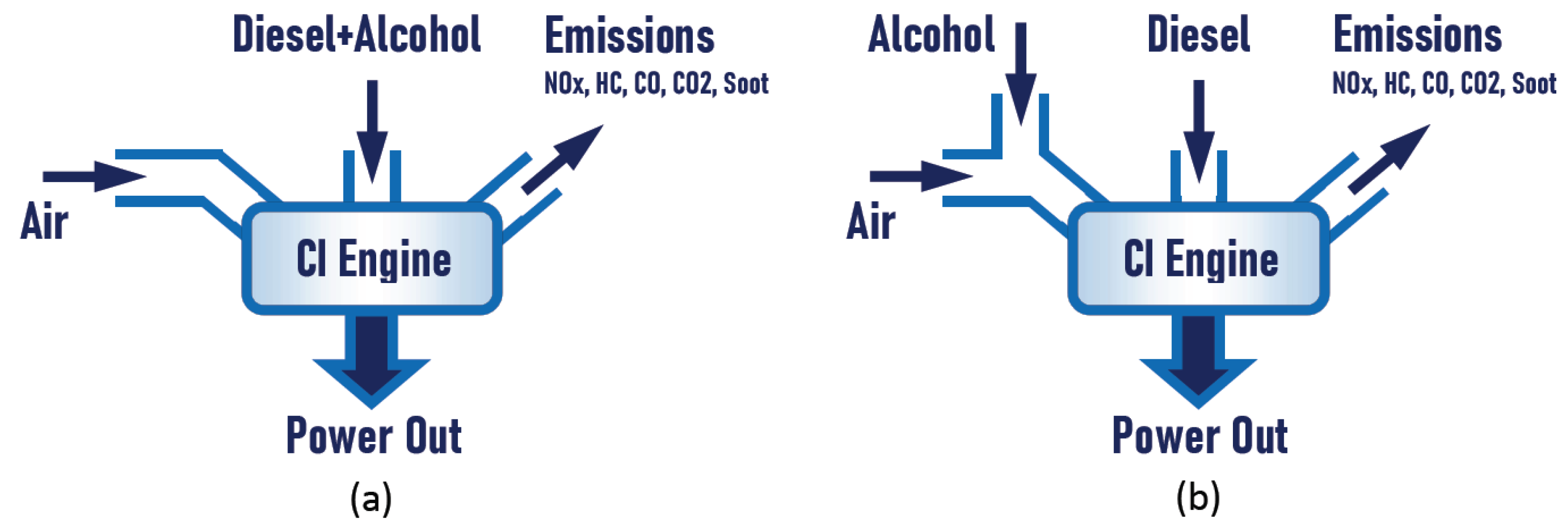

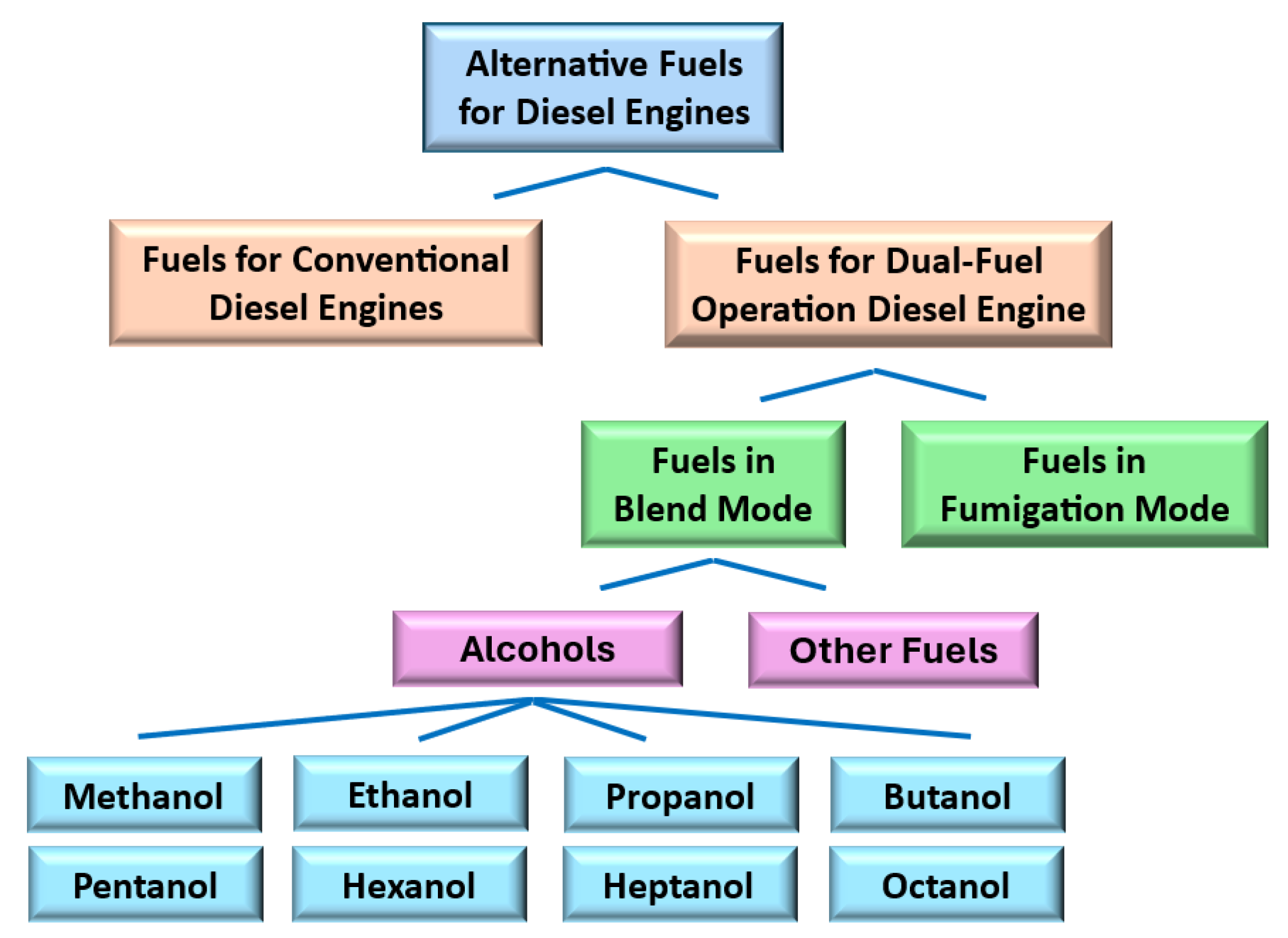

2. Blend and Fumigation as Dual-Fuel Operation in Diesel Engine

- -

- efficiency and specific fuel consumption: these are of primary concern to engine users, as higher efficiency results in lower operating costs;

- -

- combustion process parameters: this aspect is mainly of interest to researchers working on similar topics, as controlling the combustion process is crucial for achieving high engine efficiency, which leads to lower fuel consumption;

- -

- engine stability: this is particularly important for engines powering electric generators that are connected to the power grid;

- -

- exhaust emissions: nowadays, this is arguably the most critical aspect of engine performance evaluation, particularly in terms of assessing GHG emissions.

3. Characteristics of Alcohol Fuels

4. Methodology

- efficiency and specific fuel consumption, which are of primary interest to engine users, as higher efficiency translates to lower operating costs;

- combustion process parameters; this issue is mainly relevant to researchers dealing with similar topics, as controlling the combustion process determines high engine efficiency, i.e., low fuel consumption;

- engine stability; this is a crucial issue, especially for engines powering electricity generators that operate in conjunction with the power grid;

- emissions; nowadays, this is perhaps the most important aspect of evaluating not only piston engine performance but also the assessment of GHG emissions.

5. Effect of Blended Diesel/Alcohol on Combustion, Performance, Stability, and Emissions of a CI Engine

- Diesel/methanol blends

- Diesel/ethanol blends

- Diesel/propanol blends

- Diesel/butanol blends

- Diesel/pentanol blends

- Diesel/hexanol blends

- Diesel/heptanol blends

- Diesel/octanol blends

5.1. Combustion

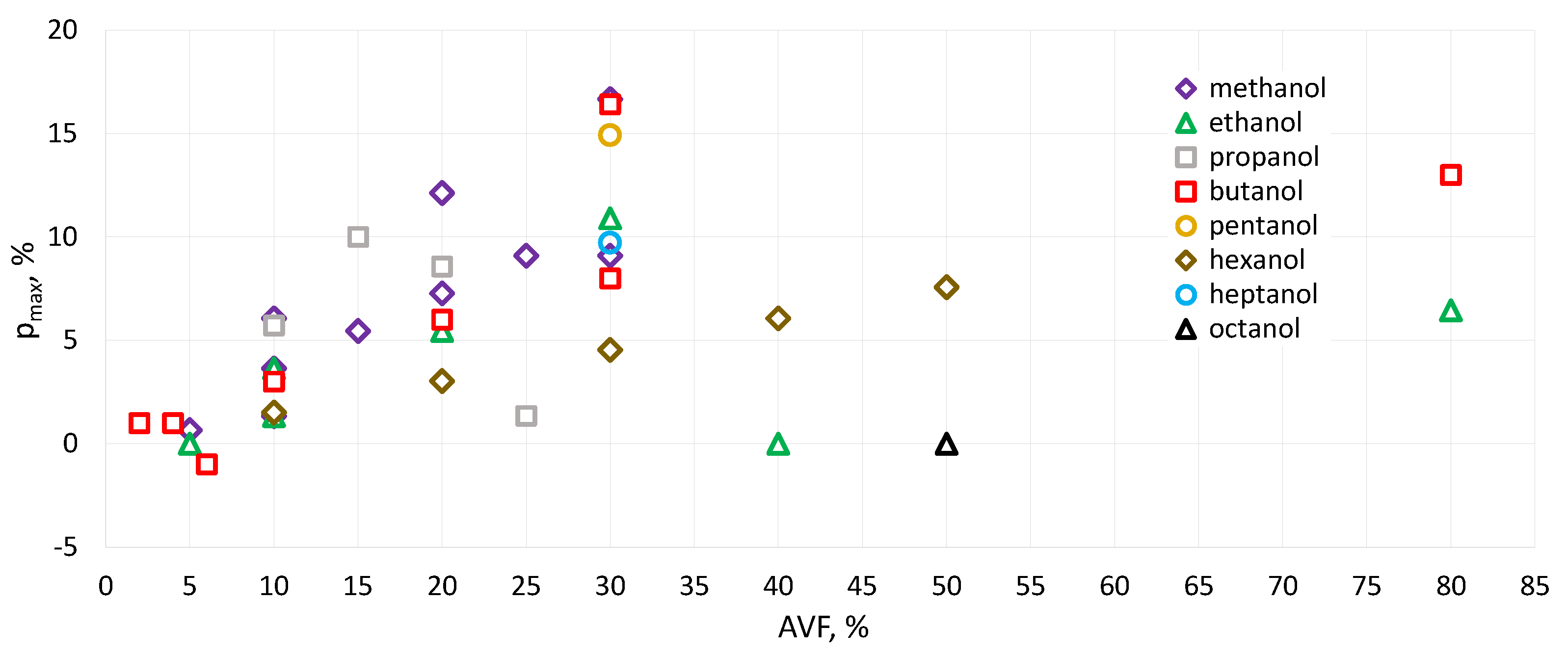

5.1.1. Maximum In-Cylinder Pressure (pmax)

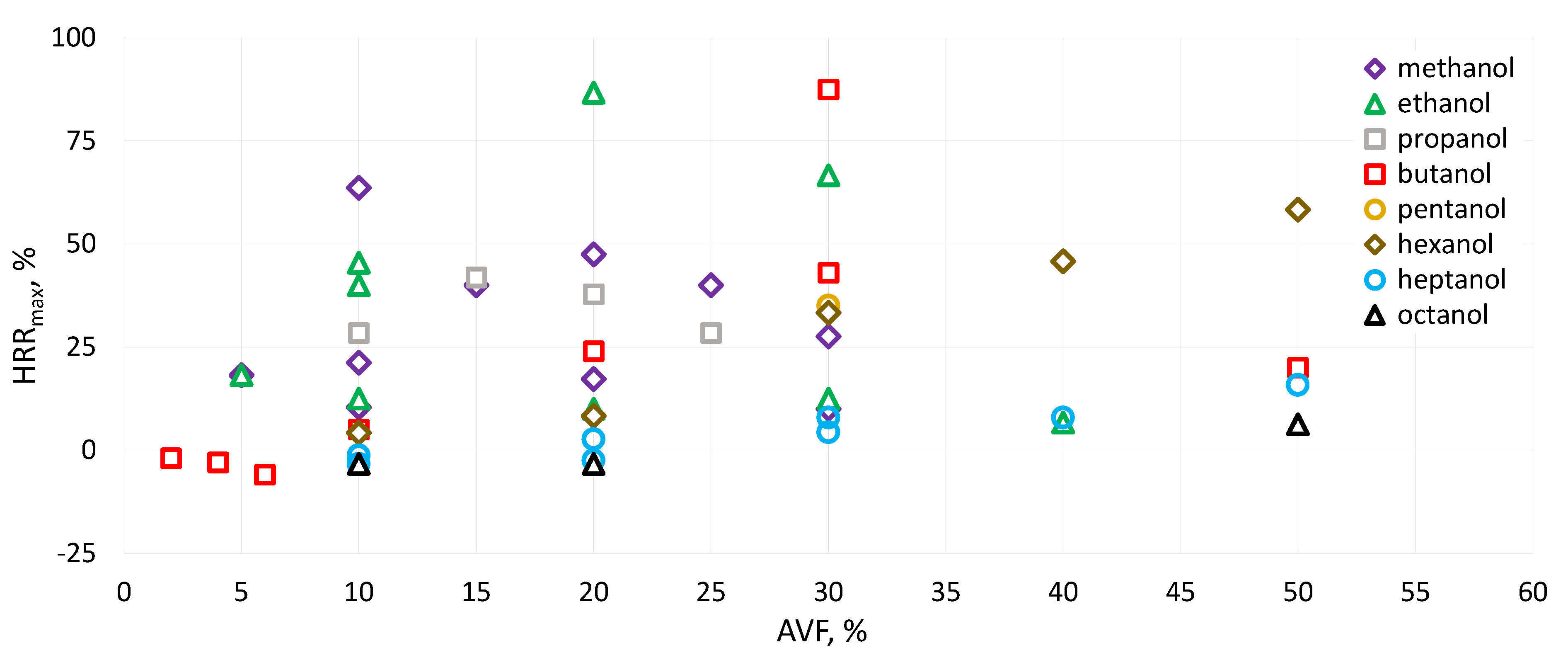

5.1.2. Maximum Heat Release Rate (HRRmax)

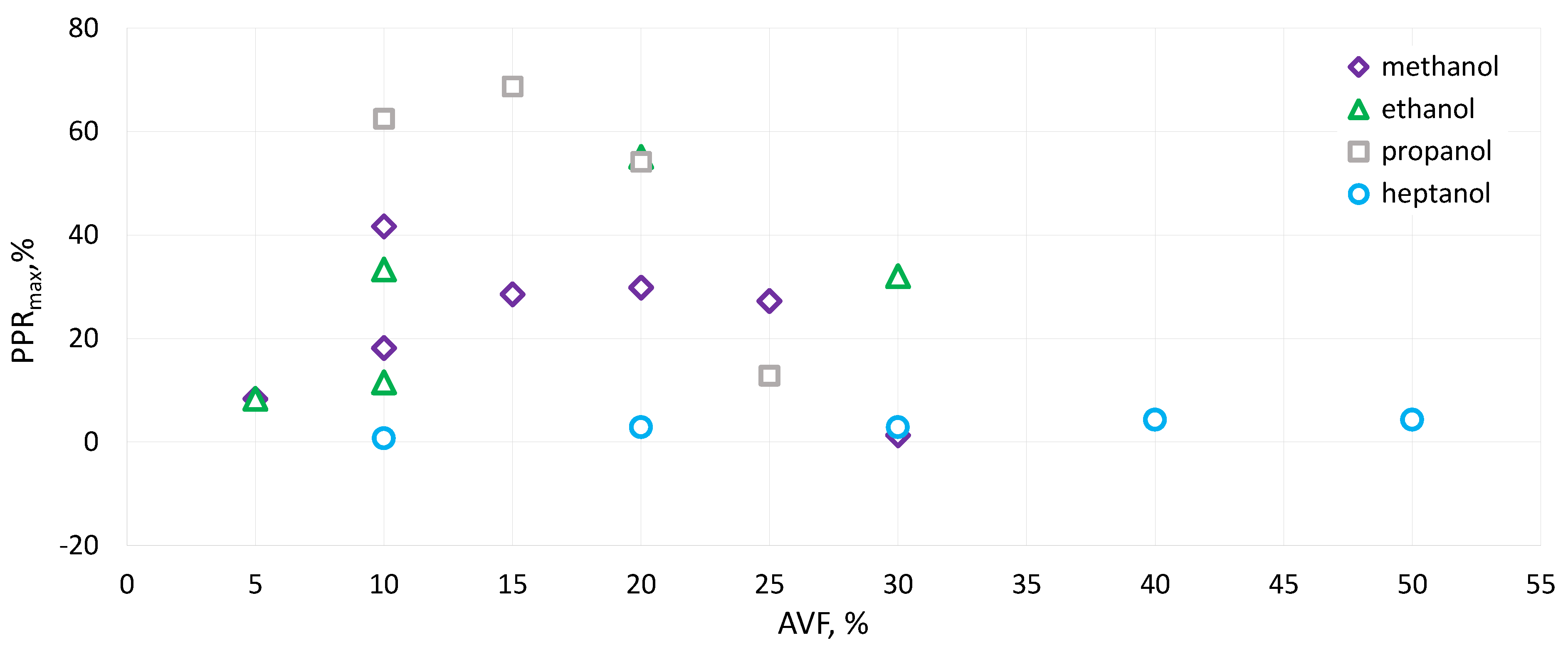

5.1.3. Maximum Peak Pressure Rise (PPRmax)

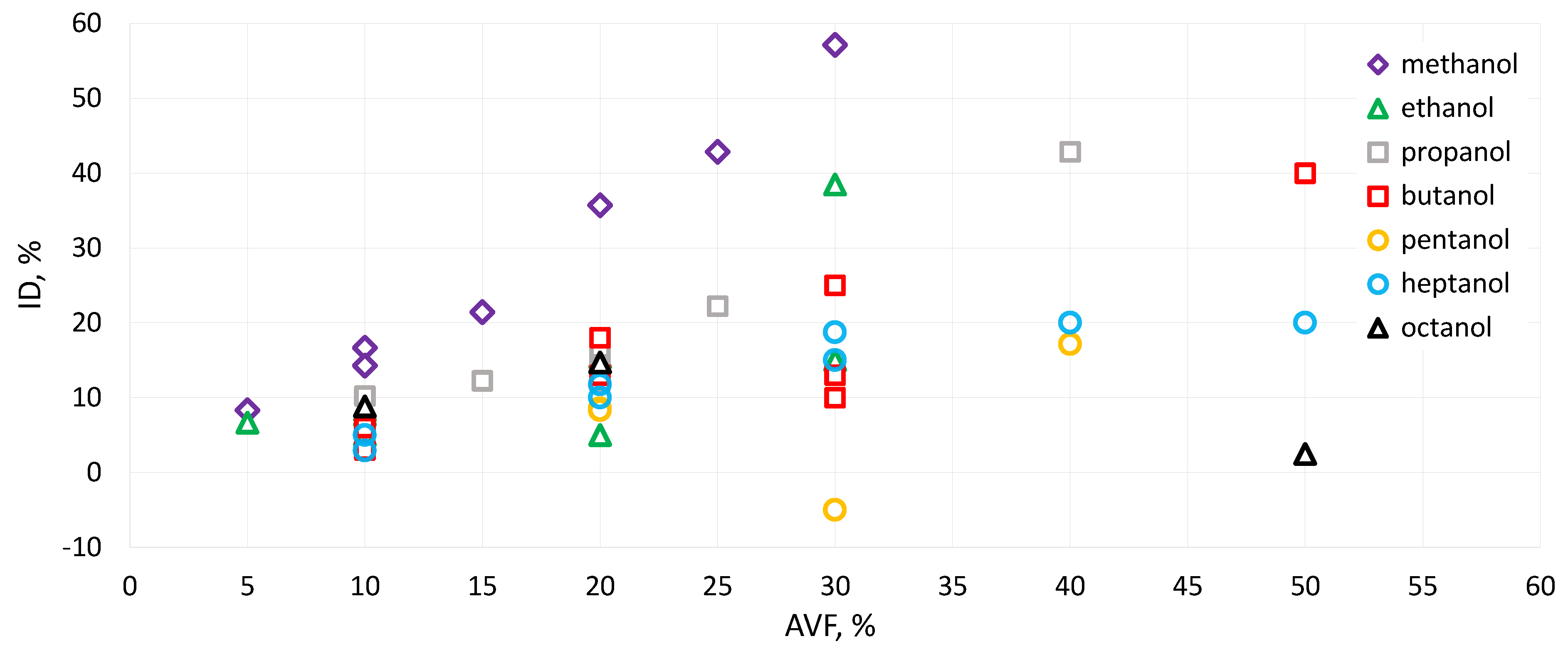

5.1.4. Ignition Delay (ID)

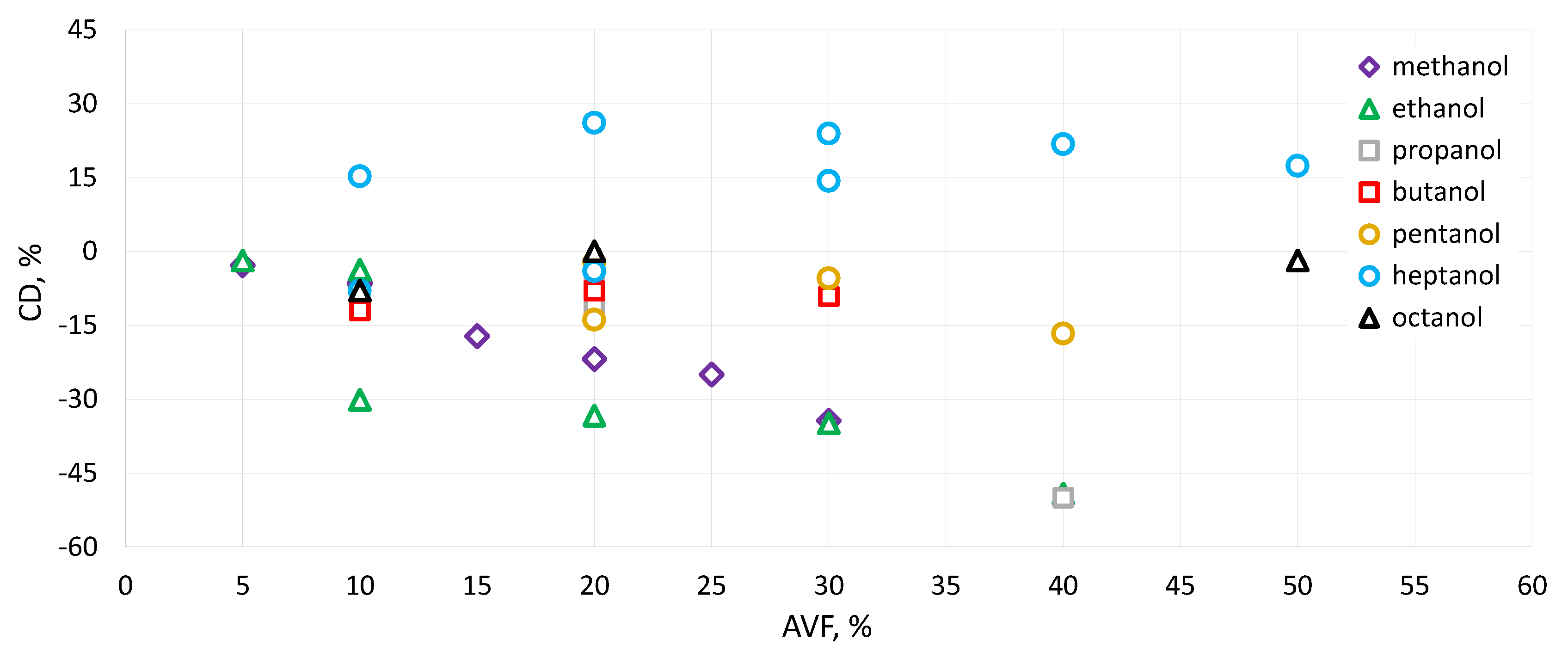

5.1.5. Combustion Duration (CD)

5.2. Performance

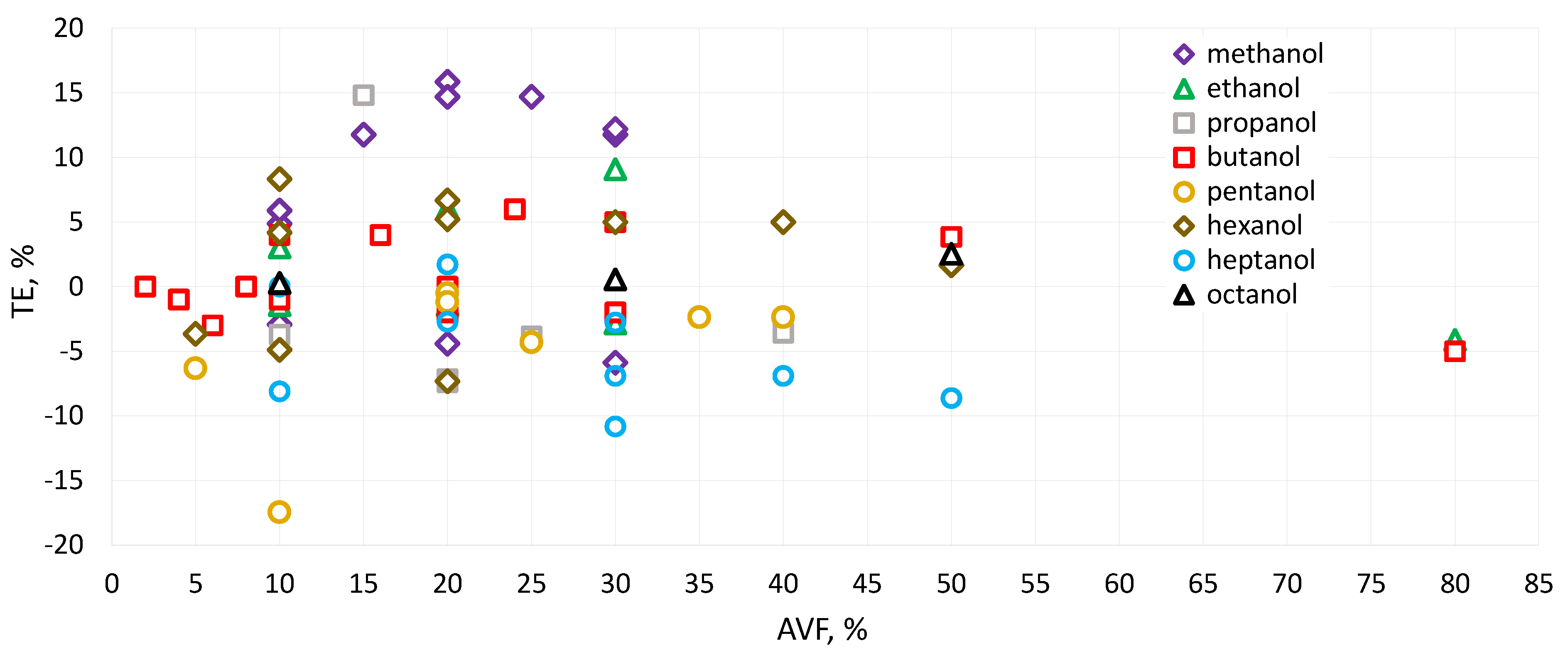

5.2.1. Thermal Efficiency (TE)

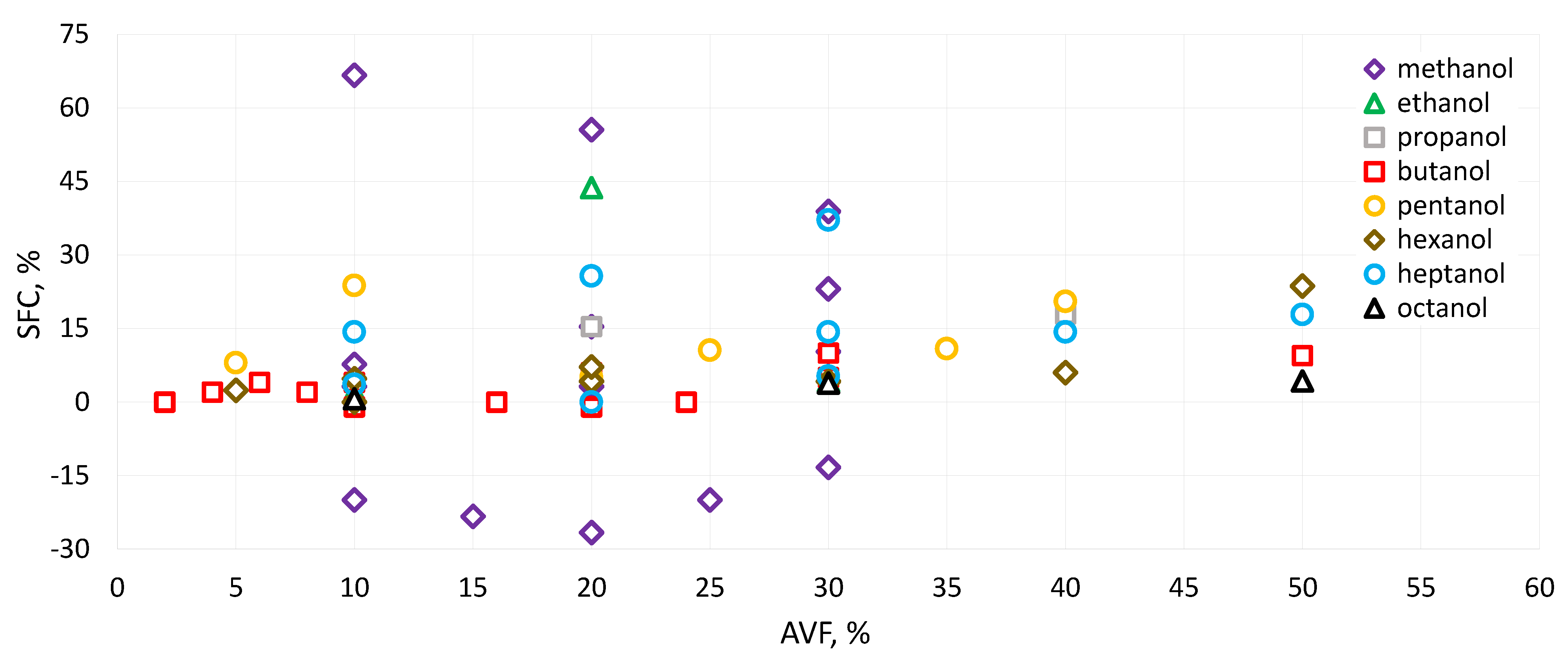

5.2.2. Specific Fuel Consumption (SFC)

5.3. Stability

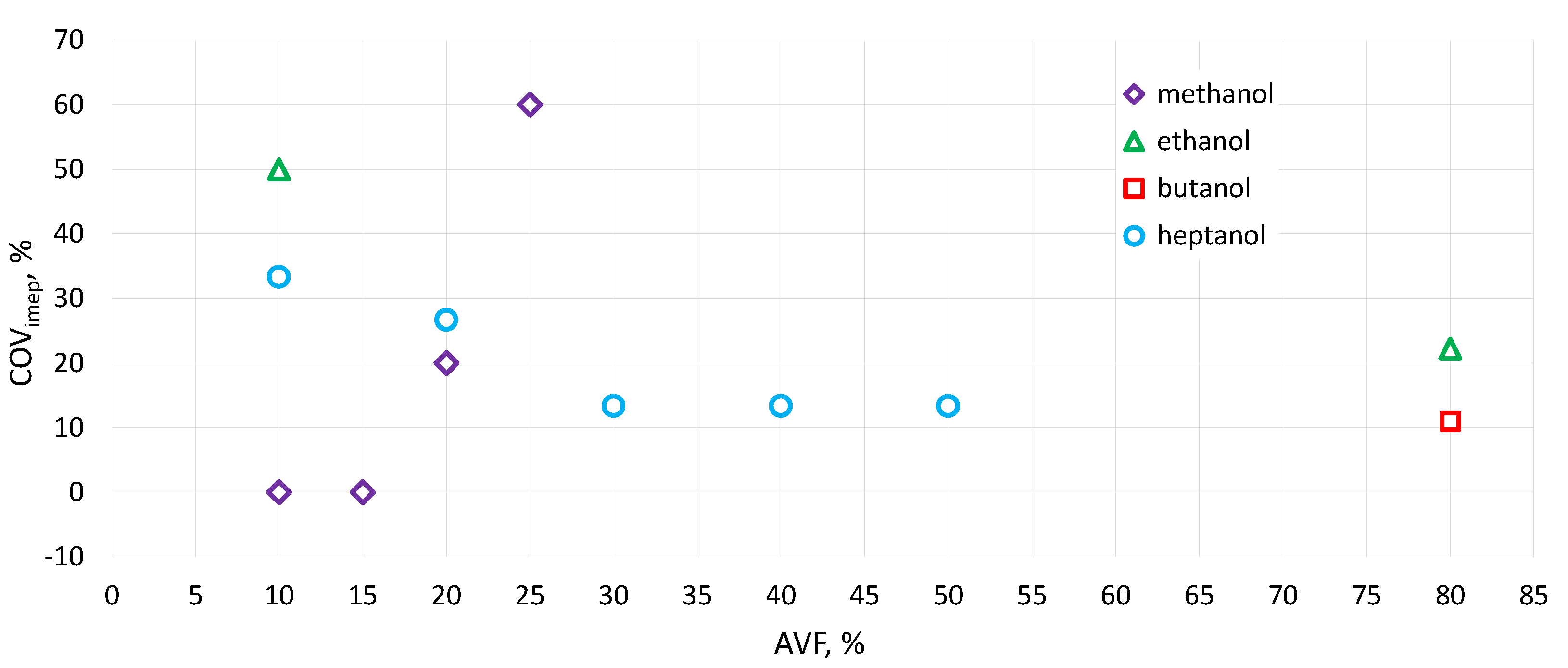

Coefficient of Variation of Indicated Mean Effective Pressure (COVimep)

5.4. Emissions

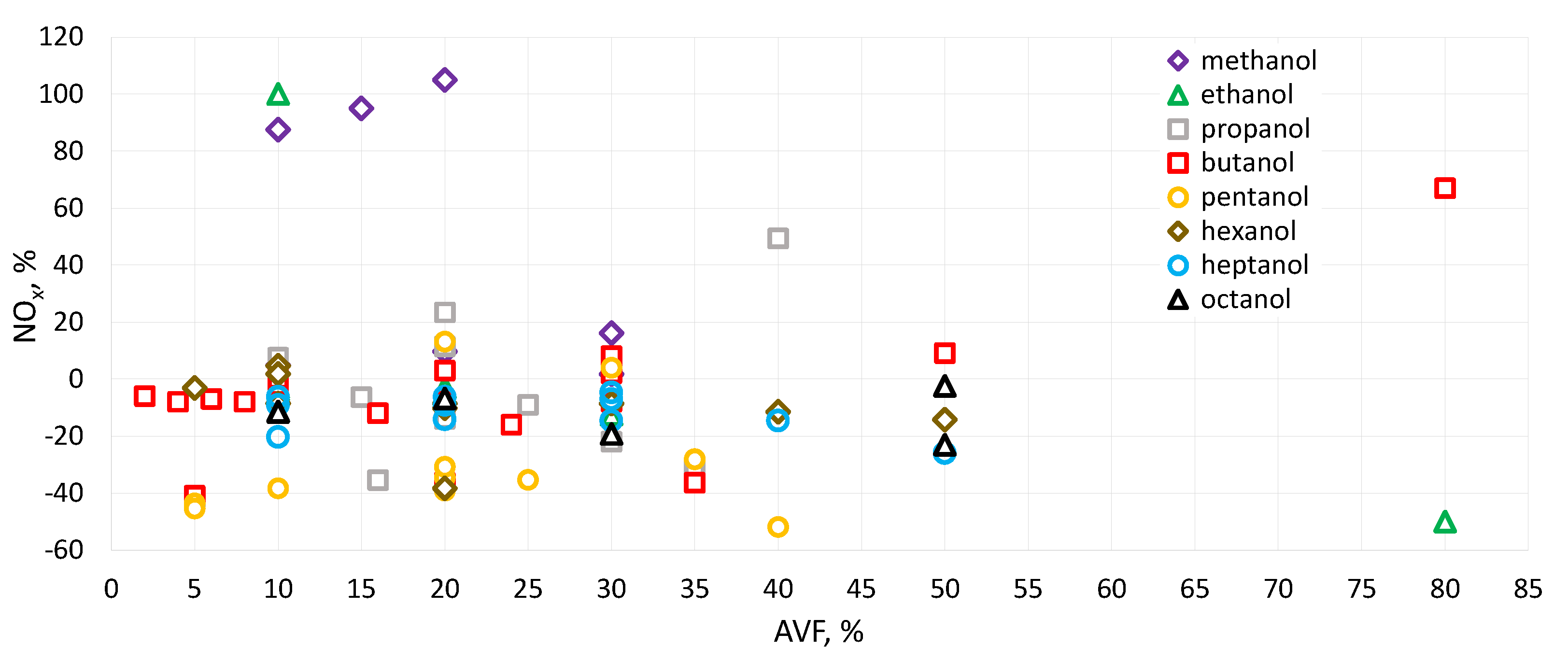

5.4.1. NOx Emissions

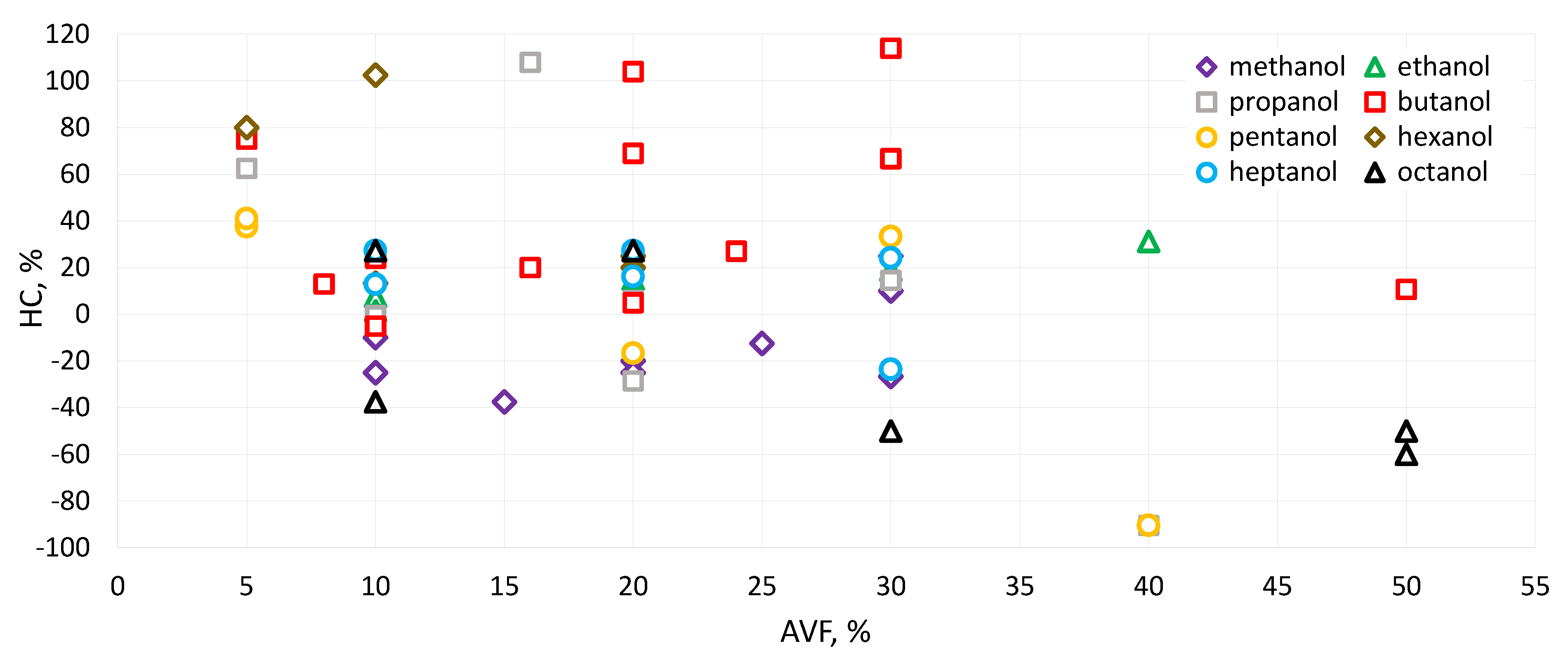

5.4.2. HC Emissions

5.4.3. CO Emissions

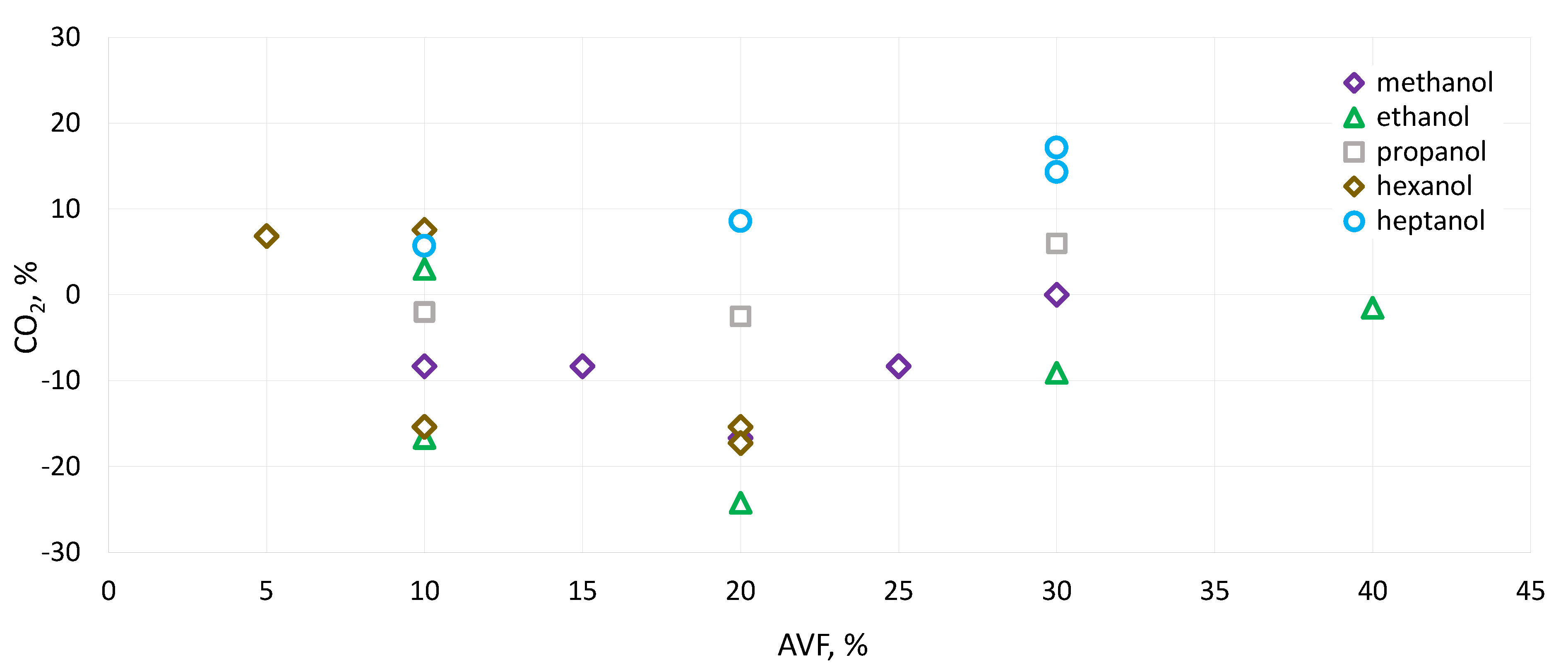

5.4.4. CO2 Emissions

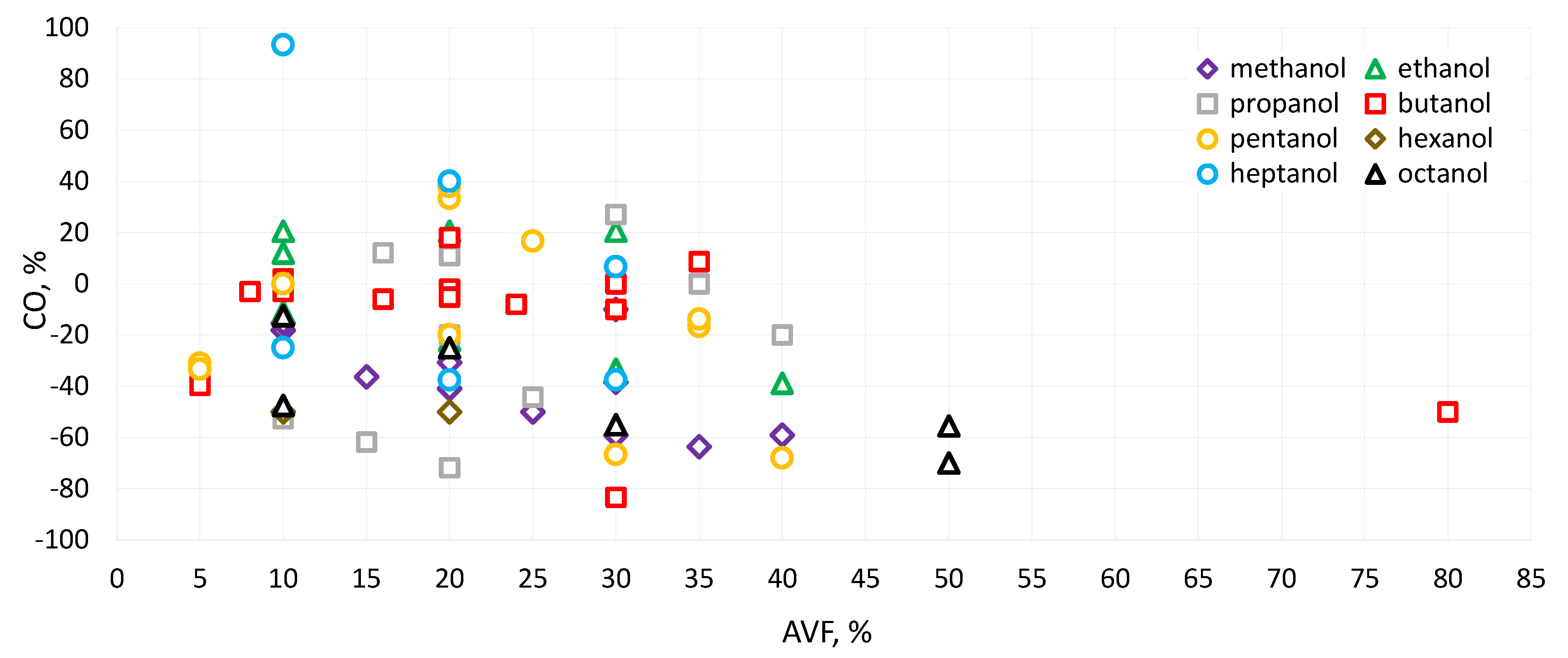

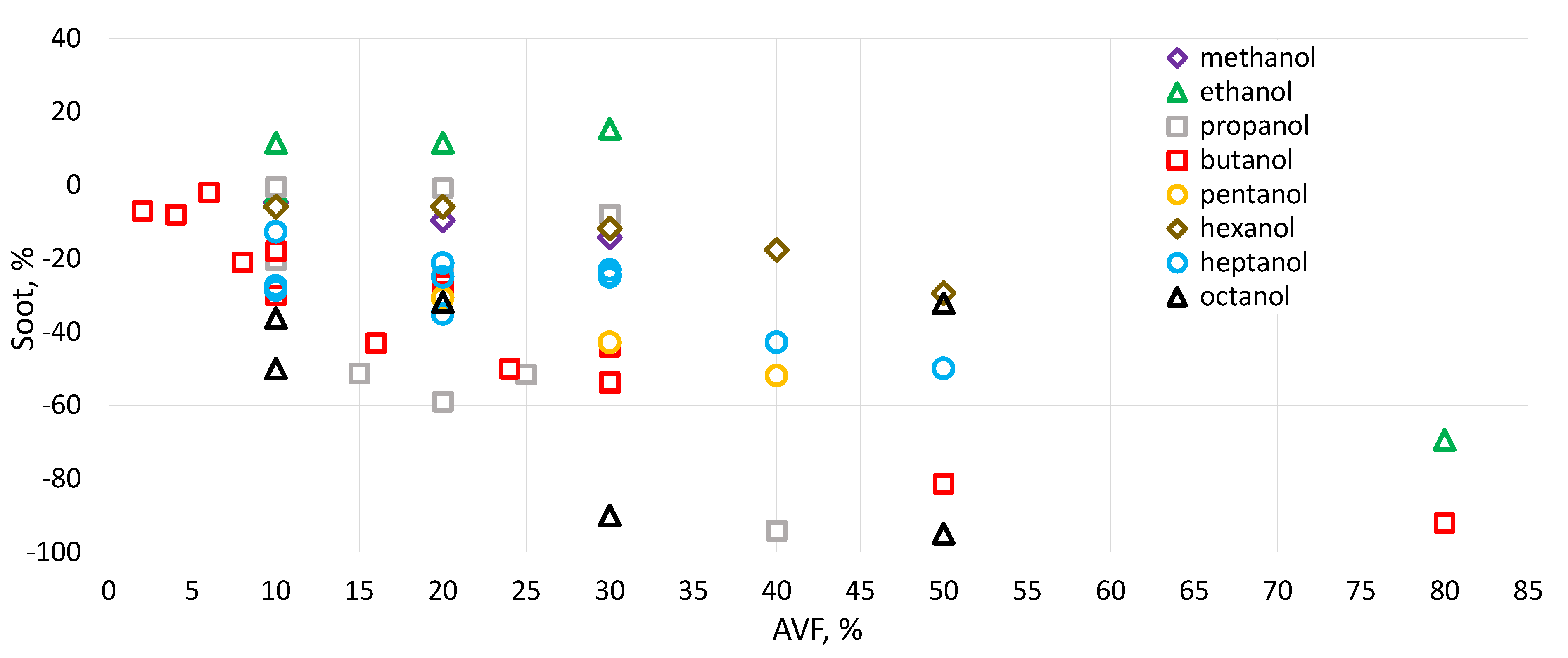

5.4.5. Soot Emissions

6. Discussion

7. Conclusions and Recommendations

- the addition of alcohol fuel to diesel in CI engines increases ignition delay, with a greater increase corresponding to a higher volumetric share of alcohol. The highest ignition delay was observed with the diesel/methanol blend (57%);

- combustion of a blend containing alcohol generally resulted in an increase in pmax compared to pure diesel combustion (by approximately 15–20%). Higher volumetric shares of alcohol resulted in progressively higher pmax values. The highest pmax was achieved with short- and medium-chain alcohols, such as methanol, propanol, butanol, and pentanol;

- an increase in the volumetric share of alcohol in the diesel blend, up to 30%, is associated with an increase in PPRmax, with the highest pressure rise rates observed with diesel and propanol blends (approximately 70%). Unfortunately, the increase in pmax and PPRmax also leads to higher mechanical loads on the engine, which may reduce its durability;

- higher alcohol content leads to an increase in HRRmax. Diesel combustion with the addition of methanol, ethanol, and butanol up to 30% showed the highest HRRmax values, even up to approximately 80% higher compared to diesel alone;

- the effect of alcohol fuel on the combustion duration of diesel/alcohol blends in CI engines is not straightforward. Most studies indicate a reduction in combustion duration with an increase in alcohol volumetric share, with the shortest CD observed in diesel with methanol and ethanol (approximately 50%). Increased heat release rates and shorter combustion durations may lead to higher instantaneous thermal loads on the engine cylinder, potentially worsening the lubricating properties of the engine oil;

- the addition of alcohol to diesel in CI engines can either improve or worsen thermal efficiency. For simple, short-chain alcohols, thermal efficiency (TE) increased, with the highest TE for the diesel/methanol blend (approximately 15%). For complex alcohols, TE decreased (by approximately 10%). This inconsistency in results may be due to the lack of optimization of the engine’s thermal cycle (CA50), which should be conducted for each adapted engine;

- the addition of alcohol to diesel slightly deteriorates the stability of CI engine operation, as defined by the COVimep coefficient (approximately 60%);

- most studies indicate a positive impact of alcohol fuel addition to diesel on NOx emissions in CI engines, with the greatest reductions in emissions reaching approximately 50%;

- based on the literature review, it is not possible to definitively determine the impact of alcohol fuel addition on HC emissions from CI engines. The largest increase in hydrocarbon emissions was observed with propanol, butanol, and hexanol (approximately 100%). However, diesel blends with methanol and octanol resulted in the greatest reduction in HC emissions (approximately 60%);

- the reviewed studies do not conclusively answer how alcohol fuels co-combusted with diesel affect CO and CO2 concentrations in CI engine exhaust. Unburned hydrocarbon and CO emissions are closely related to the so-called gap effect, which is a consequence of engine design. The literature does not specify the volumetric share of gaps relative to the combustion chamber volume, which could provide insight into emission evaluation;

- the addition of alcohol fuel to diesel contributes to a reduction in soot emissions from CI engines. For all analyzed alcohols (except ethanol), increasing the volumetric share of alcohol in the diesel blend resulted in a greater reduction in soot emissions (up to approximately 90%). Authors often limit their evaluation to soot emissions, but a comprehensive assessment should also include PM emissions divided into different fractions.

- optimization of alcohol blends for optimal engine performance: due to the variety of research setups, results are inconsistent, making it difficult to definitively determine the most beneficial ratio of individual alcohols in diesel blends for engine performance. Research should focus on identifying the optimal blend and exploring the potential for additives that enhance and stabilize these mixtures;

- engine design aspects: adaptation of engines to operate on alcohol blends involves modifications to injection systems and engine control strategies. Research should investigate the best practices for integrating these adaptations to improve engine performance and reliability;

- durability testing: there appears to be the most work needed in this area. The literature reveals a gap in studies on the long-term effects of high alcohol content on engine durability, particularly for naturally aspirated and turbocharged engines under various loads;

- exhaust emissions: development work is recommended on exhaust cleaning systems, particularly for NOx and particulate matter (PM). Research should focus on advancing these systems to meet emission standards effectively;

- economic analysis (LCA—Life Cycle Assessment): a comprehensive approach is proposed, including an economic analysis covering the entire life cycle of alcohol fuels. This should include the production process, the economic impact of engine operation, exhaust emissions, recycling of engine components, and the economics of fuel distribution. Additionally, the feasibility of producing alcohols from agricultural waste and lignocellulosic biomass should be evaluated.

Funding

Conflicts of Interest

Nomenclature

| AVF | alcohol volume fraction |

| TE | thermal efficiency |

| SFC | specific fuel consumption |

| HRR | heat release rate |

| PPR | peak pressure rise |

| COVimep | coefficient of variation of indicated mean effective pressure |

| LHV | lower heating value |

| CI | compression ignition |

| SI | spark ignition |

| ID | ignition delay |

| CD | combustion duration |

| p | pressure |

| n | engine speed |

| TDC | top dead center |

| CH3OH | methanol |

| C2H5OH | ethanol |

| C3H7OH | propanol |

| C4H9OH | butanol |

| C5H11OH | pentanol |

| C6H13OH | hexanol |

| C7H15OH | heptanol |

| C8H17OH | octanol |

| O2 | oxygen |

| H2 | hydrogen |

| C | carbon |

| NOx | nitrogen oxides |

| NO | nitrogen monoxide |

| HC | hydrocarbons |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| GHG | greenhouse gas |

References

- Kumar, S.; Cho, J.H.; Park, J.; Moon, I. Advances in diesel–alcohol blends and their effects on the performance and emissions of diesel engines. Renew. Sustain. Energy Rev. 2013, 22, 46–72. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W. A study of performance and emissions of SI engine with two-stage combustion system. Chem. Process Eng. 2011, 32, 453–471. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Co-combustion of hydrogen with diesel and biodiesel (RME) in a dual-fuel compression-ignition engine. Energies 2023, 16, 4892. [Google Scholar] [CrossRef]

- Onorati, A.; Payri, R.; Vaglieco, B.; Agarwal, A.; Bae, C.; Bruneaux, G.; Canakci, M.; Gavaises, M.; Günthner, M.; Hasse, C.; et al. The role of hydrogen for future internal combustion engines. Int. J. Engine Res. 2022, 23, 529–540. [Google Scholar] [CrossRef]

- Tornatore, C.; Marchitto, L.; Sabia, P.; De Joannon, M. Ammonia as Green Fuel in Internal Combustion Engines: State-of-the-Art and Future Perspectives. Front. Mech. Eng. 2022, 8, 944201. [Google Scholar] [CrossRef]

- Pedersen, K.A.; Lewandowski, M.T.; Schulze-Netzer, C.; Pasternak, M.; Løvås, T. Ammonia in Dual-Fueled Internal Combustion Engines: Impact on NOx, N2O, and Soot Formation. Energy Fuels 2023, 37, 17585–17604. [Google Scholar] [CrossRef]

- Ashfaque, A.; Naidu, S.R.M.; Kumar, M.; Yadav, R.K.; Sohal, J.K.; Shariff, S.H.; Yadav, A.S.; Sharma, A. Impact of biodiesel on engine performance and emission. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.B.; Radhakrishnan, S.; Mahalingam, A.; Nagappan, B. Experimental testing and evaluation of neat biodiesel and heptanol blends in diesel engine. J. Test. Eval. 2019, 47, 987–997. [Google Scholar] [CrossRef]

- Damyanov, A.; Hofmann, P. Utilisation of sustainable Ethanol in a Dual-Fuel Diesel Engine. Mech. Agric. Conserv. Resour. Int. Sci. J. 2021, 1, 28–37. Available online: http://hdl.handle.net/20.500.12708/137819 (accessed on 8 August 2024).

- Gawale, G.R.; Srinivasulu, G.N. Experimental investigation of ethanol/diesel and ethanol/biodiesel on dual fuel mode HCCI engine for different engine load conditions. Fuel 2020, 263, 116725. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Grab-Rogaliński, K. Combustion stability, performance and emission characteristics of a CI engine fueled with diesel/n-butanol blends. Energies 2021, 14, 2817. [Google Scholar] [CrossRef]

- Prak, D.L.; Cowart, J. Physical properties and diesel engine combustion of blends of alcohols with military jet fuel JP-5. Fuel 2024, 371 Pt B, 132070. [Google Scholar] [CrossRef]

- Zhang, Z.; Tian, J.; Xie, G.; Li, J.; Xu, W.; Jiang, F.; Huang, Y.; Tan, D. Investigation on the combustion and emission characteristics of diesel engine fueled with diesel/methanol/n-butanol blends. Fuel 2022, 314, 123088. [Google Scholar] [CrossRef]

- Ardebili, S.M.S.; Solmaz, H.; Ipci, D.; Calam, A.; Mostafaei, M. A review on higher alcohol of fuel oil as a renewable fuel for internal combustion engines: Applications, challenges, and global potential. Fuel 2020, 279, 118516. [Google Scholar] [CrossRef]

- Olson, A.L.; Tunér, M.; Verhelst, S. A Review of Isobutanol as a Fuel for Internal Combustion Engines. Energies 2023, 16, 7470. [Google Scholar] [CrossRef]

- Balat, M.; Balat, H. Recent trends in global production and utilization of bio-ethanol fuel. Appl. Energy 2009, 86, 2273–2282. [Google Scholar] [CrossRef]

- Koh, L.P.; Ghazoul, J. Biofuels, biodiversity, and people: Understanding the conflicts and finding opportunities. Biol. Conserv. 2008, 141, 2450–2460. [Google Scholar] [CrossRef]

- Çelebi, Y.; Aydın, H. An overview on the light alcohol fuels in diesel engines. Fuel 2019, 236, 890–911. [Google Scholar] [CrossRef]

- O’Connor, C.T.; Forrester, R.D.; Scurrell, M.S. Cetane number determination of synthetic diesel fuels. Fuel 1992, 71, 1323–1327. [Google Scholar] [CrossRef]

- Hernández, J.J.; Cova-Bonillo, A.; Wu, H.; Barba, J.; Rodríguez-Fernández, J. Low temperature autoignition of diesel fuel under dual operation with hydrogen and hydrogen-carriers. Energy Convers. Manag. 2022, 258, 115516. [Google Scholar] [CrossRef]

- Boehm, R.; Yang, Z.; Bell, D.; Feldhausen, J.; Heyne, J. Lower heating value of jet fuel from hydrocarbon class concentration data and thermo-chemical reference data: An uncertainty quantification. Fuel 2022, 311, 122542. [Google Scholar] [CrossRef]

- Krishnamoorthi, M.; Malayalamurthi, R.; He, Z.; Kandasamy, S. A review on low temperature combustion engines: Performance, combustion and emission characteristics. Renew. Sustain. Energy Rev. 2019, 116, 109404. [Google Scholar] [CrossRef]

- Soni, D.K.; Gupta, R. Application of nano emulsion method in a methanol powered diesel engine. Energy 2017, 126, 638–648. [Google Scholar] [CrossRef]

- Muthaiyan, P.; Gomathinayagam, S. Combustion Characteristics of a Diesel Engine Using Propanol Diesel Fuel Blends. J. Inst. Eng. (India) Ser. C 2016, 97, 323–329. [Google Scholar] [CrossRef]

- Turkcan, A.; Canakci, M.E. Combustion Characteristics of an Indirect Injection (IDI) Diesel Engine Fueled with Ethanol/Diesel and Methanol/Diesel Blends at Different Injection Timings. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar]

- Yusaf, T.F.; Hamawand, I.; Baker, P.; Najafi, G. The Effect of Methanol-Diesel Blended Ratio on CI Engine Performance. Int. J. Automot. Mech. Eng. 2013, 8, 1385–1395. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Pyrc, M.; Sobiepański, M. Experimental investigations on combustion, performance and emission characteristics of stationary CI engine fuelled with diesel-methanol and biodiesel-methanol blends. Environ. Prog. Sustain. Energy 2017, 36, 1151–1163. [Google Scholar] [CrossRef]

- Kumar, B.R.; Saravanan, S.; Rana, D.; Nagendran, A. A comparative analysis on combustion and emissions of some next generation higher-alcohol/diesel blends in a direct-injection diesel engine. Energy Convers. Manag. 2016, 119, 246–256. [Google Scholar] [CrossRef]

- Dogan, B.; Cakmak, A.; Yesilyurt, M.K.; Erol, D. Investigation on 1-heptanol as an oxygenated additive with diesel fuel for compression-ignition engine applications: An approach in terms of energy, exergy, exergoeconomic, enviroeconomic, and sustainability analyses. Fuel 2020, 275, 117973. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gnatowska, R.; Nowak, Ł. Comparative analysis of the combustion stability of diesel-methanol and diesel-ethanol in a dual fuel engine. Energies 2019, 12, 971. [Google Scholar] [CrossRef]

- Jamrozik, A. The effect of the alcohol content in the fuel mixture on the performance and emissions of a direct injection diesel engine fueled with diesel-methanol and diesel-ethanol blends. Energy Convers. Manag. 2017, 148, 461–476. [Google Scholar] [CrossRef]

- Rakopoulos, D.; Rakopoulos, C.; Giakoumis, E.; Dimaratos, A.; Kyritsis, D. Kyritsis, Effects of butanol–diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Sundar, R.C.; Saravanan, G. Influence of hexanol-diesel blends on constant speed diesel engine. Therm. Sci. 2011, 15, 1215–1222. [Google Scholar] [CrossRef]

- Şahin, Z.; Durgun, O.; Aksu, O.N. Experimental investigation of n-butanol/diesel fuel blends and n-butanol fumigation—Evaluation of engine performance, exhaust emissions, heat release and flammability analysis. Energy Convers. Manag. 2015, 103, 778–789. [Google Scholar] [CrossRef]

- Laza, T.; Bereczky, A. Basic fuel properties of rapeseed oil-higher alcohols blends. Fuel 2011, 90, 803–810. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Grab-Rogaliński, K. Effects of propanol on the performance and emissions of a dual-fuel industrial diesel engine. Appl. Sci. 2022, 12, 5674. [Google Scholar] [CrossRef]

- Karabektas, M.; Yilancilar, M.S. Investigation of the effects of high-carbon alcohol addition to camelina oil methyl ester on the performance parameters and soot emission of a diesel engine. Int. J. Low-Carbon Technol. 2022, 17, 206–213. [Google Scholar] [CrossRef]

- Santhosh, K.; Kumar, G.N. Impact of 1-hexanol/diesel blends on combustion, performance and emission characteristics of CRDI CI mini truck engine under the influence of EGR. Energy Convers. Manag. 2020, 217, 113003. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M. A comparative study of co-combustion process of diesel-ethanol and biodiesel-ethanol blends in the direct injection diesel engine. Appl. Therm. Eng. 2017, 117, 155–163. [Google Scholar] [CrossRef]

- Zhao, W.; Yan, J.; Gao, S.; Lee, T.H.; Li, X. The combustion and emission characteristics of a common-rail diesel engine fueled with diesel, propanol, and pentanol blends under low intake pressures. Fuel 2022, 307, 121692. [Google Scholar] [CrossRef]

- Yilmaz, N.; Atmanli, A.; Vigil, F.M.; Donaldson, B. Comparative assessment of polycyclic aromatic hydrocarbons and toxicity in a diesel engine powered by diesel and biodiesel blends with high concentrations of alcohols. Energies 2022, 15, 8523. [Google Scholar] [CrossRef]

- Shitu, A.; Nair, N.; Li, Y.; Hu, J. Water-containing i-propanol-n-butanol-ethanol (IBE) as a next-generation biofuel of n-butanol for diesel engine. Int. J. Mater. Mech. Eng. 2021, 28, 223–233. [Google Scholar] [CrossRef]

- Hassan, Q.H.; Ridha, G.S.A.; Hafedh, K.A.H.; Alalwan, H.A. The impact of methanol-diesel compound on the performance of a four-stroke CI engine. Mater. Today Proc. 2021, 42, 1993–1999. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.A.; Nada, S.A. Combustion, performance and emission analysis of diesel engine fuelled by higher alcohols (butanol, octanol and heptanol)/diesel blends. Energy Convers. Manag. 2019, 185, 313–329. [Google Scholar] [CrossRef]

- Han, J.; He, W.; Somers, L.M.T. Experimental investigation of performance and emissions of ethanol and n-butanol fuel blends in a heavy-duty diesel engine. Front. Mech. Eng. 2020, 6, 1–16. [Google Scholar] [CrossRef]

- Tosun, Z.; Aydin, H. Combustion, performance and emission analysis of propanol addition on safflower oil biodiesel in a diesel engine. Clean. Chem. Eng. 2022, 3, 100041. [Google Scholar] [CrossRef]

- Bhumula, K.B.; Kumar, G.N. Using CRITIC-TOPSIS and python to examine the effect of 1-Hepatnol on the performance and emission characteristics of CRDI CI engine with split injection. Heliyon 2024, 10, e31484. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Saravanan, B.; Patel, D.; Sudarshan, B.; Ramasamy, R.A. An assessment on the effects of 1-pentanol and 1-butanol as additives with Calophyllum Inophyllum biodiesel. Energy Convers. Manag. 2018, 158, 70–80. [Google Scholar] [CrossRef]

- Nour, M.; Nada, S.; Li, X. Experimental study on the combustion performance of a stationary CIDI engine fueled with 1-heptanol-diesel mixtures. Fuel 2022, 312, 122902. [Google Scholar] [CrossRef]

- Zhou, X.; Qian, W.; Pan, M.; Huang, R.; Xu, L.; Yin, J. Potential of n-butanol/diesel blends for CI engines under post injection strategy and different EGR rates conditions. Energy Convers. Manag. 2020, 204, 112329. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Grab-Rogaliński, K. Evaluation of combustion stability and exhaust emissions of a stationary compression ignition engine powered by diesel/n-butanol and RME biodiesel/n-butanol blends. Energies 2023, 16, 1717. [Google Scholar] [CrossRef]

- Rajasekar, V. Experimental investigations to study the effect of butanol and pentanol addition in a jatropha oil methyl ester fuelled compression ignition engine. J. Chem. Pharm. Sci. 2016, 9, 665–668. [Google Scholar]

- Anandavelu, A.; Rajkumar, S.; Thangarasu, V. Dual fuel combustion of 1-hexanol with diesel and biodiesel fuels in a diesel engine: An experimental investigation and multi crTEria optimization using artificial neural network and TOPSIS algorithm. Fuel 2023, 338, 127318. [Google Scholar] [CrossRef]

- Ahn, J.; Jang, K.; Yang, J.; Kim, B.; Kwon, J. Impact of using n-octanol/diesel blends on the performance and emissions of a direct-injection diesel engine. Energies 2024, 17, 2691. [Google Scholar] [CrossRef]

- Balki, M.K. Determination of optimum operating parameters in a non-road diesel engine fueled with 1-heptanol/biodiesel at different injection pressures and advances. Energies 2024, 17, 1588. [Google Scholar] [CrossRef]

- Pan, M.; Tong, C.; Qian, W.; Lu, F.; Yin, J.; Huang, H. The effect of butanol isomers on diesel engine performance, emission and combustion characteristics under different load conditions. Fuel 2020, 277, 118188. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Gruca, M.; Pyrc, M. Performance, emission and combustion characteristics of CI dual fuel engine powered by diesel/ethanol and diesel/gasoline fuels. J. Mech. Sci. Technol. 2018, 32, 2947–2957. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Pyrc, M.; Gruca, M.; Kočiško, M. Study on co-combustion of diesel fuel with oxygenated alcohols in a compression ignition dual-fuel engine. Fuel 2018, 221, 329–345. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; Pyrc, M.; Grab-Rogaliński, K. Experimental study on ammonia-diesel co-combustion in a dual-fuel compression ignition engine. J. Energy Inst. 2024, 115, 101711. [Google Scholar] [CrossRef]

- Gounkaou, Y.W.; Daho, T.; Diane, A.; Vaitilingom, G.; Piriou, B.; Valette, J.; Sanogo, O.; Béré, A. Experimental Study on Performance and Combustion Analysis of a Diesel Engine Fueled with Diesel and Jatropha Oil Blended with Heptane. Energy Power Eng. 2021, 13, 1–16. [Google Scholar] [CrossRef]

- Ngo, V.T.; Nguyen, T.G. Comparison of the combustion characteristics of gasoline and gasoline–ethanol blend under gasoline compression ignition mode. Cogent Eng. 2022, 9, 2031684. [Google Scholar] [CrossRef]

- Pinzi, S.; Redel-Macías, M.D.; Leiva-Candia, D.E.; Soriano, J.A.; Dorado, M.P. Influence of ethanol/diesel fuel and propanol/diesel fuel blends over exhaust and noise emissions. Energy Procedia 2017, 142, 849–854. [Google Scholar] [CrossRef]

- Cheng, X.; Li, S.; Yang, J.; Liu, B. Investigation into partially premixed combustion fueled with N-butanol-diesel blends. Renew. Energy 2016, 86, 723–732. [Google Scholar] [CrossRef]

- Bhumula, K.B.; Kumar, G.N. Evaluation of performance, combustion, and emission parameters of crdi ci engine with 1-heptanol using critic-topsis and fuel injection strategies. SSRN 2024, 1–50. [Google Scholar] [CrossRef]

- Duraisamy, S.; Kasirajan, L.; Kasinathan, S.; Kadasari, R.; Rajagopal, C.T. Performance test and emission characteristics of diesel fuel blended with n-hexanol. Therm. Sci. 2020, 24, 557–564. [Google Scholar] [CrossRef]

- Guo, Z.; Li, T.; Dong, J.; Chen, R.; Xue, P.; Wei, X. Combustion and emission characteristics of blends of diesel fuel and methanol-to-diesel. Fuel 2011, 90, 1305–1308. [Google Scholar] [CrossRef]

- Atmanli, A.; Yilmaz, N. Comparative assessment of different diesel engines fueled with 1-pentanol and diesel blends. Environ. Prog. Sustain. Energy 2021, 40, ep13663. [Google Scholar] [CrossRef]

- Yilmaz, N.; Vigil, F.M.; Atmanli, A.; Donaldson, B. Detailed analysis of PAH formation, toxicity and regulated pollutants in a diesel engine running on diesel blends with n-propanol, n-butanol and n-pentanol. Energies 2022, 15, 6487. [Google Scholar] [CrossRef]

- Chen, H.; Zhou, Z.; He, J.; Zhang, P.; Zhao, X. Effect of isopropanol and n-pentanol addition in diesel on the combustion and emission of a common rail diesel engine under pilot plus main injection strategy. Energy Rep. 2020, 6, 1734–1747. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Lus, T.; Klyus, O. Mažeika M. Combustion and performance parameters of a diesel engine operating on ethanol-diesel fuel blends. Sci. J. Marit. Univ. Szczec. 2013, 36, 102–109. [Google Scholar]

- Tutak, W.; Jamrozik, A.; Gnatowska, R. Combustion of different reactivity fuel mixture in a dual fuel engine. Therm. Sci. 2018, 22, 1191–1203. [Google Scholar] [CrossRef]

- Nanthagopal, A.K.; Anand Ashok, V.; Aravind, K.M.; Jeevanantham, A.K.; Balusamy, S. Effects of n-octanol as a fuel blend with biodiesel on diesel engine characteristics. Fuel 2019, 235, 363–373. [Google Scholar] [CrossRef]

- Graziano, B.; Schönfeld, S.; Heuser, B.; Pelerin, D. 1-Octanol as CO2-neutral Fuel for Commercial Vehicle Applications. ATZ Heavy Duty Worldw. 2020, 13, 36–41. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Rorimpandey, P.; Zhai, G.; Kook, S.; Hawkes, E.R.; Chan, Q.N. Effects of energy-share and ambient oxygen concentration on hydrogen-diesel dual-fuel direct-injection (H2DDI) combustion in compression-ignition conditions. Int. J. Hydrogen Energy 2024, 49, 1346–1361. [Google Scholar] [CrossRef]

- Dhole, A.; Lata, D.B.; Yarasu, R.B. Effect of hydrogen and producer gas as secondary fuels on combustion parameters of a dual fuel diesel engine. Appl. Therm. Eng. 2016, 108, 764–773. [Google Scholar] [CrossRef]

- Hong, C.; Ji, C.H.; Wang, S.; Xin, G.; Qiang, Y.; Yang, J. Evaluation of hydrogen injection and oxygen enrichment strategies in an ammonia-hydrogen dual-fuel engine under high compression ratio. Fuel 2023, 354, 129244. [Google Scholar] [CrossRef]

- Deheri, C.; Acharya, S.K.; Thatoi, D.N.; Mohanty, A.P. A review on performance of biogas and hydrogen on diesel engine in dual fuel mode. Fuel 2020, 260, 116337. [Google Scholar] [CrossRef]

- Wang, B.; Pamminger, M.; Wallner, T. Impact of fuel and engine operating conditions on efficiency of a heavy duty truck engine running compression ignition mode using energy and exergy analysis. Appl. Energy 2019, 254, 113645. [Google Scholar] [CrossRef]

- Ceviz, M.A.; Çavuşoğlu, B.; Kaya, F.; Öner, I.V. Determination of cycle number for real in-cylinder pressure cycle analysis in internal combustion engines. Energy 2011, 36, 2465–2472. [Google Scholar] [CrossRef]

- Olalekan, W.S.; Rashid, A.A.; Baharom, M. Cycle-by-cycle variations in a direct injection hydrogen enriched compressed natural gas engine employing EGR at relative air-fuel ratios. MATEC Web Conf. 2014, 13, 02009. [Google Scholar] [CrossRef]

- O’Driscoll, R.; Stettler, M.E.J.; Molden, N.; Oxley, T.; ApSimon, H.M. Real world CO2 and NOx emissions from 149 Euro 5 and 6 diesel, gasoline and hybrid passenger cars. Sci. Total Environ. 2018, 621, 282–290. [Google Scholar] [CrossRef]

- Thakur, D.; Ganguly, R. Chapter 15—Occurrence and fate of micropollutants in air. In Advances in Pollution Research, Environmental Micropollutants; Hashmi, M.Z., Wang, S., Ahmed, Z., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 305–313. [Google Scholar] [CrossRef]

- Ahmed, A.K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427. [Google Scholar] [CrossRef]

- Xi, J.; Zhong, B.J. Soot in Diesel Combustion Systems. Chem. Eng. Technol. 2006, 29, 665–673. [Google Scholar] [CrossRef]

- Vishal Patil, Paramvir Singh, Sudarshan Kumar, Reliability of renewable oxygenated fuels in engines: A comprehensive review of long-term testing. Fuel 2024, 367, 131451. [CrossRef]

- Brandão, M. Indirect Effects Negate Global Climate Change Mitigation Potential of Substituting Gasoline With Corn Ethanol as a Transportation Fuel in the, U.S.A. Front. Clim. 2022, 4, 814052. [Google Scholar] [CrossRef]

| Fuel | Diesel | Methanol | Ethanol | Propanol | ||||

|---|---|---|---|---|---|---|---|---|

| Molecular Formula | CnH1.8n (C8–C20) | CH3OH | C2H5OH | C3H7OH | ||||

| Molar mass (g/mol) | 190–220 142 | [23] [24] | 32 32.04 | [23,25,26] [25,27,28,29,30] | 46 46.07 | [25,26,31,32,33] [24,29,34] | 60.1 60.065 | [24,29,35] [36] |

| Density at 1 bar, 20 °C (kg/m3) | 840 830 | [23,26,27,30] [25] | 790 796 | [23,25] [27,30] | 780 790 | [24] [33] | 785 815 | [35] [36] |

| Viscosity at 40 °C (mm/s2) | 2.6 2.86 | [32] [37] | 0.58 0.65 | [28,37,38] [30] | 1.2 1.1 | [32,34] [39] | 1.74 2.497 | [37,38,40,41,42] [35] |

| Cetane number | 40–55 52 | [23] [24,28,40] | 2 5 | [29,37] [28,38,43] | 5–8 11 | [25] [29] | <15 12 | [24] [29,36,37,38,40,41,42] |

| Autoignition temperature (°C) | 180–240 254–300 | [26] [28,40,44] | 470 463 | [23,25] [27,28] | 360 425 | [26] [31] | 350 399 | [29,36,37,38,40] [42] |

| Stoichiometric A/F ratio | 15 14.3 | [32] [42] | 6.4 6.47 | [26] [28] | 9 8.97 | [32] [45] | 10.35 10.4 | [36] [42] |

| Lower heating value (MJ/kg) | 44.5 42.49 | [24,26] [28,40] | 19.5 22.7 | [27] [43] | 23.8 29.8 | [26] [24] | 33.6 29.82 | [24,37] [40] |

| Latent heat of evaporation (kJ/kg) | 250–290 270–37 | [23] [28,40] | 1178 1100 | [23,24] [26,27] | 840 923 | [31,32] [24] | 790 727.88 | [24] [29,37,38,40] |

| Hydrogen content (wt%) | 14 13 | [23] [27] | 12.6 12.48 | [24] [29,44] | 13 13.02 | [31] [28,29] | 13.4 13.31 | [24,36] [29,40] |

| Carbon content (wt%) | 86 84–87 | [23] [24] | 37.5 37.48 | [23,27,40] [28,29] | 52.2 52.14 | [24,31] [28,29] | 60 59.96 | [24,36] [29] |

| Oxygen content (wt%) | 0 | [23,27,40] | 50 49.9 | [23,27,30] [24] | 34.8 34.7 | [31,32,33] [24,29] | 26.6 26.62 | [24,36,42] [29,40,46] |

| Fuel | Butanol | Pentanol | Hexanol | Heptanol | Octanol | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Molecular Formula | C4H9OH | C5H11OH | C6H13OH | C7H15OH | C8H17OH | |||||

| Molar mass (g/mol) | 74 74.123 | [32] [34] | 88.15 | [32,38,40,47,48] | 102.18 | [28,29,33,38,47] | 116.2 | [29,44,47,49] | 130.23 | [28,29,44,47] |

| Density at 1 bar, 20 °C (kg/m3) | 794 810 | [34] [37,50,51] | 814.8 815 | [37,40,48] [41,52] | 821.8 | [28,29,38,47,53] | 818 824 | [29,44,47,49] [42] | 827 820 | [28,29,38] [54] |

| Viscosity at 40 °C (mm/s2) | 2.28 3.64 | [44] [34] | 2.89 | [28,37,40,41] [48] | 4.64 3.32 | [28] [53] | 5.75 6.9 | [44,49] [42] | 7.59 10.2 | [44] [54] |

| Cetane number | <15 17–25 | [28] [51] | 18.2–20 20 | [38,40] [28] | 23 42 | [28,29,38,47,53] [33] | 39 23 | [42,55] [38] | 37 39.1 | [28,54] [44] |

| Autoignition temperature (°C) | 415 343 | [28] [51,56] | 300 | [29,37,40,44,47] | 285 | [28,29,38,47,53] | 275 270 | [29,44,47] [38] | 270 253 | [28,29,44,47] [54] |

| Stoichiometric A/F ratio | 14.2 11.13 | [44] [45] | 11.76 | [28] | 12.15 | [28] | 14.41 12.47 | [44] [49] | 14.45 12.7 | [47] [54] |

| Lower heating value (MJ/kg) | 33.64 33.08 | [28] [45] | 32.16 35.06 | [29,47] [48] | 36.4 39.1 | [28] [29,33,38,47,53] | 39.92 34.65 | [29,44,47] [55] | 37.53 52.94 | [28] [29,38,47] |

| Latent heat of evaporation (kJ/kg) | 684 581.4 | [28] [34] | 647.1 305 | [28] [52] | 603 486 | [28,53] [29,33,38,47] | 575 408 | [49] [42] | 315.1 550 | [44] [54] |

| Hydrogen content (wt%) | 13.49 13.64 | [28,29,47] [44] | 13.61 | [28,29,40,47] | 13.70 | [28,29,47] | 13.71 13.88 | [29,44,47,49] [42] | 13.8 13.91 | [28] [44] |

| Carbon content (wt%) | 64.82 64.8 | [28,29,44,47] [34,51] | 68.13 | [28,29,47] | 70.52 70.53 | [28,29] [47] | 72.16 73.80 | [29,44,47,49] [42] | 73.72 73.73 | [28,29] [47] |

| Oxygen content (wt%) | 19.54 21.62 | [44] [50] | 18.15 | [28,29,40,47] [52] | 15.7 | [28,29,33,47] | 14.13 12.32 | [44] [42] | 12.29 12.41 | [28,29,47] [44] |

| Fuel | Diesel | Methanol | Ethanol | Propanol | Butanol | Pentanol | Hexanol | Heptanol | Octanol |

|---|---|---|---|---|---|---|---|---|---|

| Molecular Formula | CnH1.8n (C8–C20) | CH3OH | C2H5OH | C3H7OH | C4H9OH | C5H11OH | C6H13OH | C7H15OH | C8H17OH |

| Density at 1 bar, 20 °C (kg/m3) | 820–845 (EN) | 792 (ISO) 791–793 (ASTM) | 790–793 (EN) 790 (ASTM) | 803 (EN) (ISO) (ASTM) | 810 (EN) (ISO) (ASTM) | 810 (EN) (ISO) (ASTM) | 825 (EN) (ISO) (ASTM) | 827 (EN) (ISO) (ASTM) | 826 (EN) (ISO) (ASTM)) |

| Viscosity at 40 °C (mm/s2) | 2.0–4.5 (EN) 1.9–4.1 (ASTM) | - | - | - | - | - | - | - | - |

| Cetane number | 51 (EN) 40 (ASTM) | - | - | - | - | - | - | - | - |

| Autoignition temperature (°C) | 220–290 (EN) 210–290 (ASTM) | - | - | - | - | - | - | - | - |

| Lower heating value (MJ/kg) | 42.8 (EN) 42.8–43 (ASTM) | 19.7 (EN) (ASTM) | 23.5 (EN) (ASTM) | 27.6 (EN) (ASTM) | 28.9 (EN) (ASTM) | 29.7 (EN) (ASTM) | 29.8 (EN) (ASTM) | 30.5 (EN) (ASTM) | 31.1 (EN) (ASTM) |

| Ref. | Engine Type | Fuels | Combustion | Performance | Stability | Emissions |

|---|---|---|---|---|---|---|

| [27] Jamrozik et al. | One-cylinder, naturally aspirated, air-cooled, CR–17, speed of 1500 rpm, full load | diesel/methanol blends (0–40% vol. alcohol) | increased: ID, pmax, HRRmax, and PPRmax; decreased: CD | increased: TE; decreased: SFC | increased: COVimep | increased: NOx; reduced: HC, CO, CO2 |

| [28] Kumar et al. | One -cylinder, naturally aspirated, air-cooled, speed of 1500 rpm, CR–17.5, high load (5.3 bar bmep) | diesel/iso-butanol (DB) blends, diesel/pentanol (DP) blends, diesel/n-octanol (DO) blends (30% vol. alcohol) | increased: ID, pmax, HRRmax, and PPRmax; decreased: CD | - | - | for DB and DP, increased: HC; reduced: NOx, CO, and soot; for DO, reduced: NOx, HC, CO, and soot |

| [44] Nour et al. | One -cylinder, naturally aspirated, air-cooled, CR –17, speed of 1500 rpm, high load (18 bar IMEP) | diesel/butanol blends, diesel/heptanol blends, diesel/octanol blends, (10, 20% vol. alcohol) | increased: ID; degreased: CD | decreased: SFC; increased: TE | - | reduced: NOx, soot, and CO; increased: HC |

| [31] Jamrozik | One -cylinder, naturally aspirated, air-cooled, CR–17, speed of 1500 rpm, full load | diesel/ethanol blends (10, 20, 30, 40%, vol. alcohol) | increased: ID, pmax, HRRmax, and PPRmax; decreased: CD | increased: TE | increased: COVimep | increased: HC, NOx; reduced: CO, CO2 |

| [40] Zhao et al. | One -cylinder, naturally aspirated, liquid-cooled, CR–17.1, speed of 4500 rpm, high load (55 MPa IMEP) | diesel/propanol blends, diesel/pentanol blends (20, 40% vol alcohol) | increased: ID; degreased: CD | increased: SFC; degreased: TE | - | increased: NOx; reduced: soot, CO, and HC |

| [49] Nour et al. | One -cylinder, naturally aspirated, air-cooled, CR–17, speed of 1500 rpm, 100% load | diesel/1-heptanol blends (10, 20, 30, 40, and 50% vol. alcohol) | increased: ID, CD, HRRmax, PPRmax | decreased: TE; increased: SFC | increased: COVimep | reduced: soot and NOx |

| [54] Ahn et al. | One -cylinder, naturally aspirated, air-cooled, CR–21, speed of 1700 rpm, partial load (0.49 MPa bmep) | diesel/n-octanol blends (10, 30, and 50% vol. alcohol) | - | increased: TE, SFC | - | reduced: CO, soot, HC, and NOx |

| [32] Rakopoulos et al. | One -cylinder, naturally aspirated, liquid-cooled, CR–19.8, speed of 2000 rpm, high load (5.37 bar bmep) | diesel/n-butanol blends (8, 16, and 24% vol. alcohol) | - | constant: TE | - | reduced: soot, NOx, CO; increased: HC |

| [29] Dogan et al. | One -cylinder, naturally aspirated, liquid-cooled, CR–17.5, speed of 1500 rpm, 100% load | diesel/1-hexanol blends (5, 10, 20% vol. alcohol) | - | decreased: TE; increased: SFC | - | reduced: CO2 and NOx; increased: HC |

| [64] Bhumula and Kumar | One -cylinder, naturally aspirated, liquid-cooled, CR–18, speed of 1500 rpm, 100% load | diesel/1-heptanol blends (30% vol. alcohol) | increased: ID, CD, pmax, HRRmax | decreased: TE; increased: SFC | - | reduced: CO, soot, HC, and NOx; increased: CO2 |

| [47] Bhumula end Kumar | One cylinder, naturally aspirated, liquid-cooled, CR–18, speed od 1500 rpm, high load (4.44 kW) | diesel/1-heptanol blends (10, 20, and 30% vol. alcohol) | - | decreased: TE; increased: SFC | - | reduced: soot and NOx; increased: HC, CO, and CO2 |

| [65] Duraisamy et al. | One -cylinder, liquid-cooled, CR–17.5, speed of 1500 rpm, high load (4.44 kW) | diesel/n-hexanol blends (10 and 20% vol. alcohol) | - | increased: TE; | reduced: CO, CO2, NOx; increased: HC | |

| [23] Soni and Gupta | One -cylinder, liquid cooled, CR–17.5, speed of 1500 rpm, 100% load | diesel/methanol blends (10, 20, 30%, vol. alcohol) | increased: pmax, HRRmax | increased: SFC; decreased: TE | - | reduced: soot, HC, and CO; increased: NOx |

| [66] Guo et al. | One -cylinder, liquid-cooled, speed of 2000 rpm, full load | diesel/methanol blends (10, 20, 30%, vol. alcohol) | - | increased: SFC | - | increased: NOx and HC; reduced: CO |

| [24] Muthaiyan and Gomathinayagam | One -cylinder, liquid-cooled, CR—16.5, speed of 1500 rpm; full load | diesel/1-propanol blends (10, 15, 20%, 25% vol. alcohol) | increased: HRRmax, pmax, and ID | degreased: TE | reduced: NOx, CO, and soot | |

| [33] Sundar and Saravanan | One -cylinder, liquid-cooled, CR—17.5, speed of 1500 rpm, peak load (5.2 kW) | diesel/hexanol blends (10, 20, 30, 40, and 50% vol. alcohol) | increased: pmax, HRRmax | increased: SFC, TE | - | reduced: NOx, soot |

| [67] Atmanli and Yilmaz | Four-cylinder, naturally aspirated, air-cooled, CR—19, speed of 1800 rpm, high load (9 kW) | diesel/1-pentanol blends, (5, 10, 20, 30, 35% vol. alcohol) | - | decreased: TE; increased: SFC | - | reduced: NOx; increased: HC and CO |

| [25] Turkcan and Çanakçı | Four-cylinder, naturally aspirated, liquid cooled, CR—21.47, speed of 1400 rpm, partial load (40 Nm) | diesel/methanol blends, diesel/ethanol blends (5, 10% vol. alcohol) | increased: ID, pmax, HRRmax, and PPRmax; decreased: CD | - | - | - |

| [68] Yilmaz et al. | Four-cylinder, naturally aspirated, liquid-cooled, CR—19, speed of 1800 rpm 75% max load (9 kW), | diesel/ n-propanol blends, diesel/n-propanol (5, 20, 35% vol. alcohol) | - | - | - | reduced: NOx, CO; increased: HC |

| [62] Pinzi et al. | Four-cylinder, turbocharged, liquid-cooled, CR—18, speed of 2400 rpm, high load (110 Nm) | diesel/ethanol blends, diesel/1-propanol blends (10, 20, 30% vol. alcohol) | - | - | - | reduced: NOx and soot; increased: CO and THC |

| [69] Chen et al. | Four-cylinder, turbocharged, liquid-cooled, CR—18, speed of 2200 rpm, high load (350 Nm) | diesel/iso-propanol and diesel/n-pentanol blends (20% vol. alcohol) | increased: ID; degreased: CD | - | - | increased: NOx |

| [63] Cheng et al. | Four-cylinder, turbocharged, liquid-cooled, CR—17.5, speed of 1500 rpm, medium load (0.86 MPa bmep) | diesel/n-butanol blends (10 and 30% vol. alcohol) | increased: ID | increased: TE, SFC | - | reduced: soot; increased: NOx |

| [45] Han et al. | Six-cylinder, turbocharged, liquid-cooled, CR—15.85, high load (18 bar IMEP) | diesel/n-butanol (DB) blends, diesel/ethanol (DE) blends (80% vol. alcohol) | increased: pmax, HRRmax, PPRmax | decreased: TE | increased: COVimep | for DB, reduced: CO and soot; increased: HC and NOx; for DE, reduced: NOx and soot; increased: HC and CO |

| [34] Sahin et al. | Four-cylinder, turbocharged, liquid-cooled, CR—18.25, speed of 2000 rpm, high load (145 Nm) | diesel/n-butanol blends (2, 4, 6% vol. alcohol) | decreased: HRRmax | decreased: TE; increased: IMEP, SFC | - | reduced: NOx and soot |

| [50] Zhou et al. | Four-cylinder, turbocharged, liquid-cooled, CR—16.5, speed of 1400 rpm, load (0.8 MPa) | diesel/n-butanol blends (10, 20, 30% vol. alcohol) | increased: ID, pmax, HRRmax | decreased: TE; increased: IMEP, SFC | - | reduced: CO and soot; increased: HC and NOx |

| [56] Pan et al. | Four-cylinder, turbocharged, liquid-cooled, CR—16.5, speed of 1400 rpm, high load (1.2 MPa bmep) | diesel/n-butanol blends (50% vol. alcohol) | increased: ID, HRRmax | increased: TE, SFC | - | reduced: soot; increased: HC and NOx |

| [26] Yusaf et al. | Four-cylinder, air-cooled, CR—15.5, speed of 2000 rpm, full load | diesel/methanol blends, diesel/ethanol blends (10, 20, 30% vol. alcohol) | - | increased: TE and SFC | - | - |

| [70] Labeckas et al. | Four-cylinder, liquid-cooled, CR—16, speed of 2200 rpm speed, full load | diesel/ethanol blends (5, 10, 15% vol. alcohol) | increased: ID, HRRmax | increased: SEC; decreased: TE | - | increased: CO and soot; reduced: NOx |

| % vol. | 5 | 10 | 10 | 10 | 10 | 10 | 15 | 20 | 20 | 20 | 20 | 25 | 30 | 30 | 30 | 30 | 35 | 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | 8 | 17 | 14 | 21 | 36 | 43 | 57 | 79 | 79 | |||||||||

| pmax | 1 | 1 | 4 | 6 | 5 | 12 | 7 | 9 | 17 | 9 | −20 | −38 | ||||||

| HRRmax | 18 | 64 | 21 | 10 | 40 | 17 | 48 | 40 | 28 | 10 | −43 | −75 | ||||||

| PPRmax | 8 | 42 | 18 | 29 | 30 | 27 | 1 | −74 | −87 | |||||||||

| CD | −3 | −7 | −6 | −17 | −22 | −25 | −34 | −44 | −50 | |||||||||

| TE | 5 | 6 | −3 | 12 | −4 | 16 | 15 | 15 | −6 | 12 | 12 | −6 | ||||||

| SFC | 67 | 3 | −20 | 8 | −23 | 15 | 56 | −27 | 3 | −20 | 23 | −13 | 39 | 10 | 0 | 60 | ||

| COVimep | 0 | 0 | 20 | 60 | 900 | 990 | ||||||||||||

| NOx | 88 | 5 | 95 | 10 | 105 | 16 | 2 | 105 | 88 | |||||||||

| HC | −25 | −10 | −38 | −20 | −25 | −13 | −27 | 25 | 10 | |||||||||

| CO | −18 | −15 | −36 | −31 | −41 | −50 | −38 | −59 | −10 | −64 | −59 | |||||||

| CO2 | −8 | −8 | −17 | −8 | 0 | 50 | ||||||||||||

| Soot | −5 | −10 | −14 | |||||||||||||||

| [23] | Soni and Gupta | |||||||||||||||||

| [25] | Turkcan and Çanakçı | |||||||||||||||||

| [26] | Yusaf et al. | |||||||||||||||||

| [27] | Jamrozik et al. | |||||||||||||||||

| [66] | Guo et al. | |||||||||||||||||

| % vol. | 5 | 10 | 10 | 10 | 20 | 20 | 30 | 30 | 40 | 80 |

|---|---|---|---|---|---|---|---|---|---|---|

| ID | 7 | 5 | 8 | 8 | 15 | 5 | 38 | 15 | 69 | |

| pmax | 0 | 4 | 1 | 5 | 11 | 6 | ||||

| HRRmax | 18 | 13 | 40 | 45 | 87 | 10 | 67 | 13 | 7 | |

| PPRmax | 8 | 12 | 33 | 55 | 32 | −49 | ||||

| CD | −2 | −30 | −4 | −33 | −35 | −49 | ||||

| TE | −1 | 3 | 6 | −1 | 9 | −3 | −4 | |||

| SFC | 2 | 44 | 4 | |||||||

| COVimep | 50 | 900 | 22 | |||||||

| NOx | −3 | 100 | −4 | −3 | −13 | −50 | ||||

| HC | 7 | 1.5 | 15 | 19 | 31 | |||||

| CO | 21 | −11 | 12 | −22 | 21 | −33 | 21 | −39 | ||

| CO2 | −17 | 3 | −24 | −9 | −2 | |||||

| Soot | 12 | −2 | 12 | 15 | −69 | |||||

| [25] | Turkcan and Çanakçı | |||||||||

| [31] | Jamrozik | |||||||||

| [45] | Han et al. | |||||||||

| [62] | Pinzi et al. | |||||||||

| [70] | Labeckas et al. | |||||||||

| % vol. | 5 | 10 | 10 | 15 | 16 | 20 | 20 | 20 | 20 | 25 | 30 | 35 | 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | 10 | 12 | 17 | 12 | 14 | 22 | 43 | ||||||

| pmax | 6 | 10 | 9 | 1 | |||||||||

| HRRmax | 28 | 42 | 38 | 28 | |||||||||

| PPRmax | 63 | 69 | 54 | 13 | |||||||||

| CD | −5 | −11 | −50 | ||||||||||

| TE | −4 | 15 | −7 | −7 | −4 | −4 | |||||||

| SFC | 15 | 18 | |||||||||||

| NOx | −42 | −6 | 7.5 | −6 | −35 | 11 | −14 | −8 | 23 | −9 | −22 | −32 | 49 |

| HC | 63 | −1 | 108 | 6 | −29 | 15 | −90 | ||||||

| CO | −34 | −53 | −2 | −62 | 12 | 11 | −72 | −20 | −44 | 27 | 0 | −20 | |

| CO2 | −2 | −3 | 6 | ||||||||||

| Soot | −21 | −1 | −51 | −1 | −59 | −25 | −52 | −8 | −94 | ||||

| [24] | Muthaiyan and Gomathinayagam | ||||||||||||

| [40] | Zhao et al. | ||||||||||||

| [62] | Pinzi et al. | ||||||||||||

| [68] | Yilmaz et al. | ||||||||||||

| [69] | Chen et al. | ||||||||||||

| % vol. | 2 | 4 | 5 | 6 | 8 | 10 | 10 | 16 | 20 | 20 | 20 | 24 | 30 | 30 | 30 | 35 | 50 | 80 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | 6 | 3 | 18 | 13 | 13 | 25 | 10 | 40 | ||||||||||

| pmax | 1 | 1 | −1 | 3 | 6 | 8 | 16 | 13 | ||||||||||

| HRRmax | −2 | −3 | −6 | 5 | 24 | 43 | 88 | 20 | ||||||||||

| CD | −12 | −8 | −9 | |||||||||||||||

| TE | 0 | −1 | −3 | 0 | 4 | −1 | 4 | 0 | −2 | 6 | 5 | −2 | 4 | −5 | ||||

| SFC | 0 | 2 | 4 | 2 | −1 | 4 | 0 | −1 | 6 | 0 | 5 | 10 | 9 | |||||

| COVimep | 11 | |||||||||||||||||

| NOx | −6 | −8 | −41 | −7 | −8 | −2 | 0 | −12 | −8 | 3 | −36 | −16 | 2 | 8 | −8 | −36 | 9 | 67 |

| HC | 75 | 13 | −5 | 24 | 20 | 5 | 69 | 104 | 27 | 114 | 67 | 11 | ||||||

| CO | −40 | −3 | −3 | 2 | −6 | 18 | −2 | −5 | −8 | 0 | −10 | −83 | 9 | −50 | ||||

| Soot | −7 | −8 | −2 | −21 | −30 | −18 | −43 | −27 | −29 | −50 | −44 | −54 | −54 | −81 | −92 | |||

| [28] | Kumar et al. | |||||||||||||||||

| [32] | Rakopoulos et al. | |||||||||||||||||

| [34] | Sahin et al. | |||||||||||||||||

| [44] | Nour et al. | |||||||||||||||||

| [45] | Han et al. | |||||||||||||||||

| [50] | Zhou et al. | |||||||||||||||||

| [56] | Pan et al. | |||||||||||||||||

| [63] | Cheng et al. | |||||||||||||||||

| [68] | Yilmaz et al. | |||||||||||||||||

| % vol. | 5 | 5 | 10 | 20 | 20 | 20 | 20 | 25 | 30 | 35 | 35 | 40 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | 9 | 8 | −5 | 17 | ||||||||

| pmax | 15 | |||||||||||

| HRRmax | 35 | |||||||||||

| CD | −14 | −2 | −5 | −17 | ||||||||

| TE | −6 | −17 | −1 | −1 | −4 | −2 | −2 | |||||

| SFC | 8 | 24 | 5 | 5 | 11 | 11 | 21 | |||||

| NOx | −44 | −45 | −38 | −39 | −35 | −31 | 13 | −35 | 4 | −28 | −28 | −52 |

| HC | 38 | 41 | −17 | 33 | −90 | |||||||

| CO | −31 | −33 | 0 | 33 | 38 | −20 | 17 | −67 | −17 | −14 | −68 | |

| Soot | −31 | −43 | −52 | |||||||||

| [28] | Kumar et al. | |||||||||||

| [40] | Zhao et al. | |||||||||||

| [67] | Atmanli and Yilmaz | |||||||||||

| [68] | Yilmaz et al. | |||||||||||

| [69] | Chen et al. | |||||||||||

| % vol. | 5 | 10 | 10 | 10 | 20 | 20 | 20 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|---|---|---|---|

| pmax | 2 | 3 | 5 | 6 | 8 | |||||

| HRRmax | 4 | 8 | 33 | 46 | 58 | |||||

| TE | −4 | 8 | −5 | 4 | 7 | 5 | −7 | 5 | 5 | 2 |

| SFC | 2 | 0 | 5 | 4 | 7 | 4 | 6 | 24 | ||

| NOx | −3 | −9 | 5 | 2 | −9 | −10 | −38 | −9 | −11 | −14 |

| HC | 80 | 103 | 13 | 20 | 25 | |||||

| CO | −50 | −50 | ||||||||

| CO2 | 7 | 8 | −15 | −15 | −17 | |||||

| Soot | −6 | −6 | −12 | −18 | −29 | |||||

| [29] | Dogan et al. | |||||||||

| [33] | Sundar and Saravanan | |||||||||

| [65] | Duraisamy et al. | |||||||||

| % vol. | 10 | 10 | 10 | 20 | 20 | 20 | 30 | 30 | 30 | 40 | 50 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | 3 | 5 | 12 | 10 | 15 | 19 | 20 | 20 | |||

| CD | −8 | 15 | −4 | 26 | 24 | 14 | 22 | 17 | |||

| pmax | 10 | ||||||||||

| HRRmax | −3 | −1 | −3 | 3 | 8 | 4 | 8 | 16 | |||

| PPRmax | 1 | 3 | 3 | 4 | 4 | ||||||

| TE | −8 | 0 | 2 | −3 | −7 | −3 | −11 | −7 | −9 | ||

| SFC | 14 | 4 | 0 | 26 | 14 | 5 | 37 | 14 | 18 | ||

| COVimep | 33 | 27 | 13 | 13 | 13 | ||||||

| NOx | −9 | −20 | −6 | −9 | −6 | −14 | −15 | −5 | −7 | −15 | −26 |

| HC | 27 | 13 | 27 | 16 | −24 | 24 | |||||

| CO | −25 | 93 | −38 | 40 | −38 | 7 | |||||

| CO2 | 6 | 9 | 17 | 14 | |||||||

| Soot | −27 | −13 | −29 | −35 | −25 | −21 | −25 | −23 | −24 | −43 | −50 |

| [44] | Nour et al. | ||||||||||

| [47] | Bhumula and Kumar | ||||||||||

| [49] | Nour et al. | ||||||||||

| [64] | Bhumula and Kumar | ||||||||||

| % vol. | 10 | 10 | 20 | 30 | 50 | 50 |

|---|---|---|---|---|---|---|

| ID | 9 | 15 | 3 | |||

| pmax | 0 | |||||

| HRRmax | −3 | −3 | 6 | |||

| CD | −8 | 0 | −2 | |||

| TE | 0 | 1 | 3 | |||

| SFC | 1 | 4 | 4 | |||

| NOx | −11 | −12 | −7 | −19 | −2 | −23 |

| HC | 27 | −38 | 27 | −50 | −50 | −60 |

| CO | −13 | −48 | −25 | −55 | −56 | −70 |

| Soot | −36 | −50 | −32 | −90 | −32 | −98 |

| [28] | Kumar et al. | |||||

| [44] | Nour et al. | |||||

| [54] | Ahn et al. | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jamrozik, A.; Tutak, W. Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review. Energies 2024, 17, 4516. https://doi.org/10.3390/en17174516

Jamrozik A, Tutak W. Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review. Energies. 2024; 17(17):4516. https://doi.org/10.3390/en17174516

Chicago/Turabian StyleJamrozik, Arkadiusz, and Wojciech Tutak. 2024. "Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review" Energies 17, no. 17: 4516. https://doi.org/10.3390/en17174516

APA StyleJamrozik, A., & Tutak, W. (2024). Alcohols as Biofuel for a Diesel Engine with Blend Mode—A Review. Energies, 17(17), 4516. https://doi.org/10.3390/en17174516