The Impact of Fractures on Shale Oil and Gas Enrichment and Mobility: A Case Study of the Qingshankou Formation in the Gulong Depression of the Songliao Basin, NE China

Abstract

1. Introduction

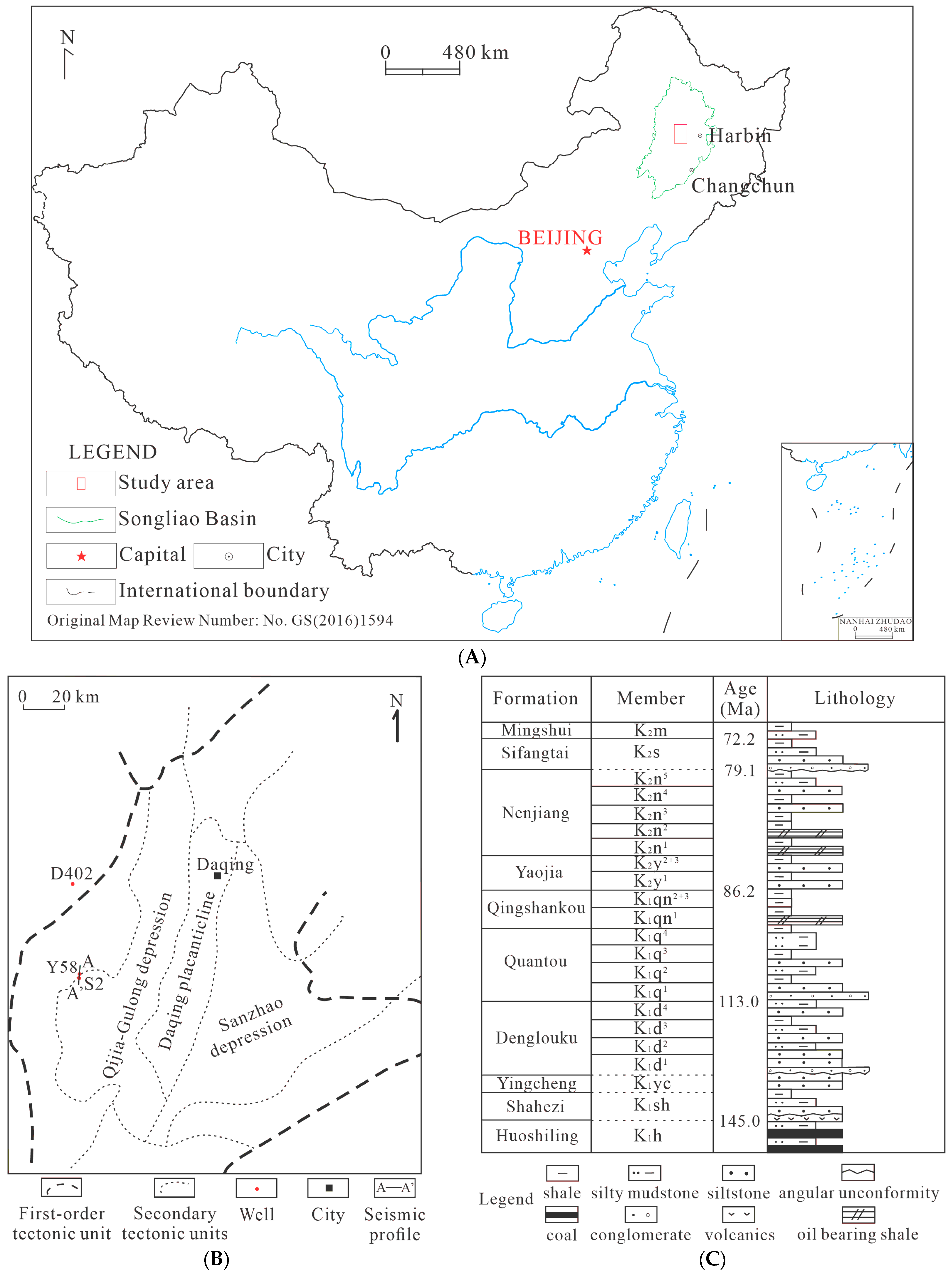

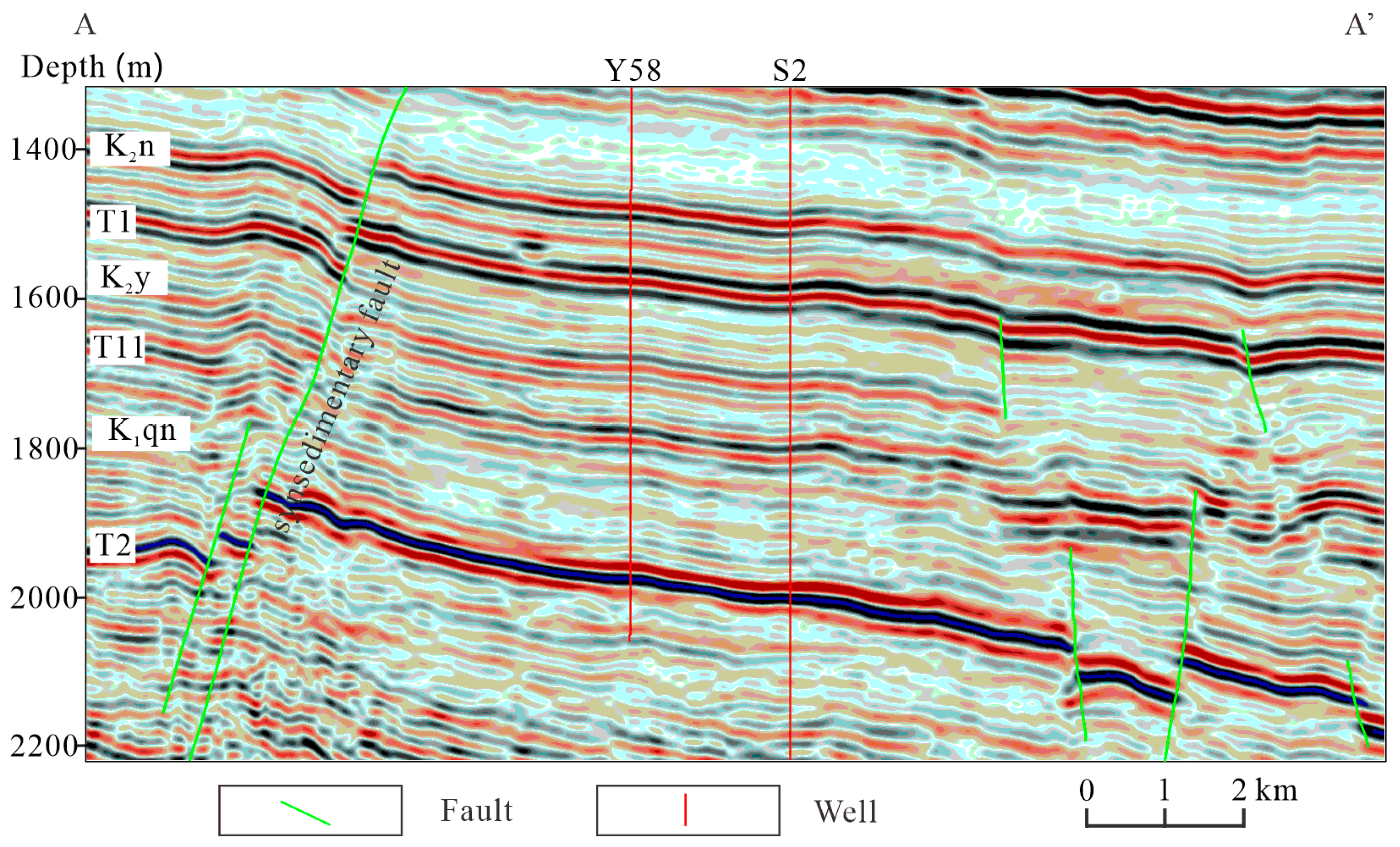

2. Geological Setting

3. Samples and Experiments

3.1. Samples Information

3.2. Experiments

3.2.1. Organic Carbon and Pyrolysis of Rocks

3.2.2. XRD Bulk Mineral Analysis

3.2.3. Chloroform Asphalt “A” and Its Group Components

3.2.4. Saturated Hydrocarbon Gas Chromatography

4. Results

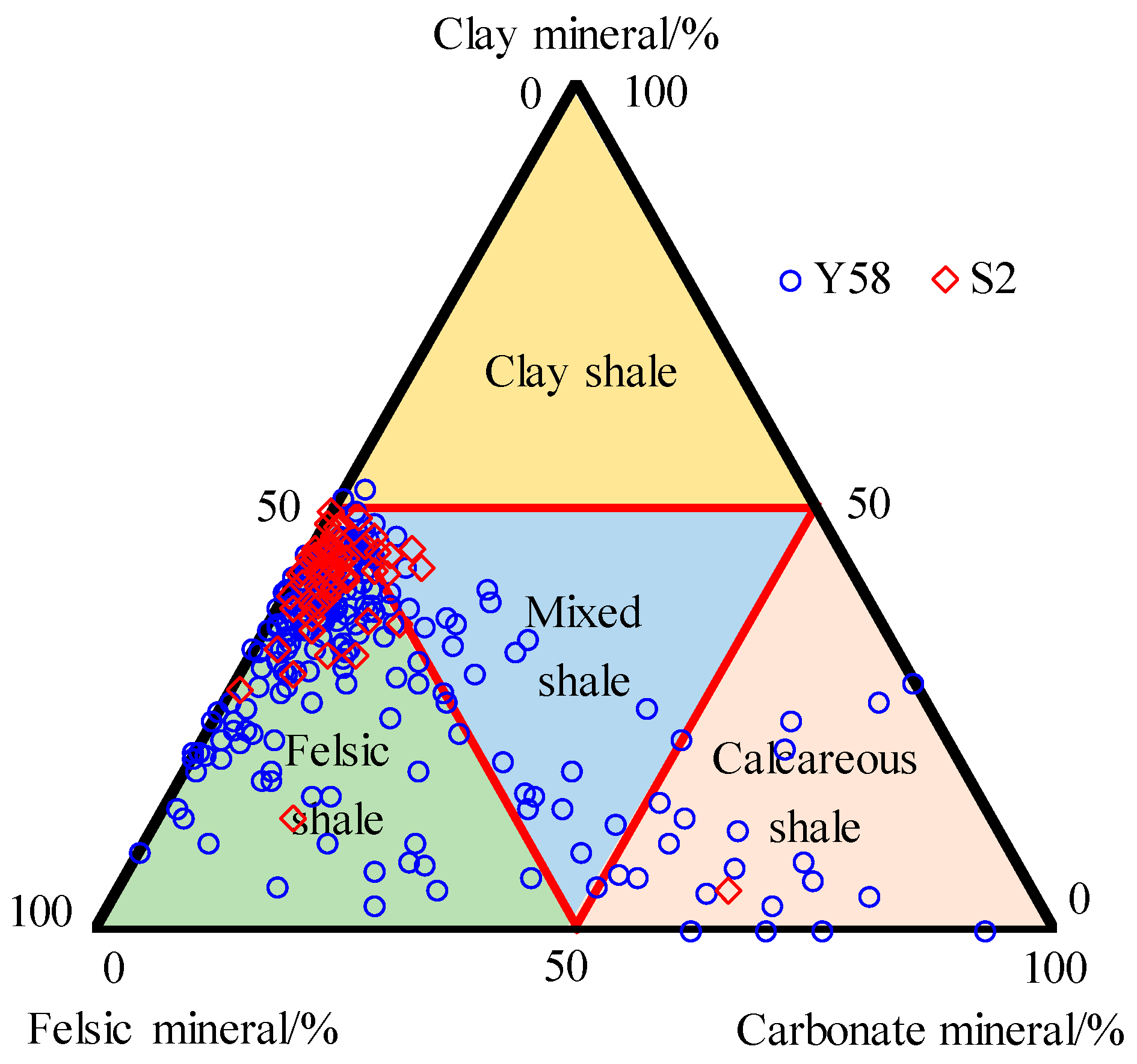

4.1. Mineral Composition Characteristics

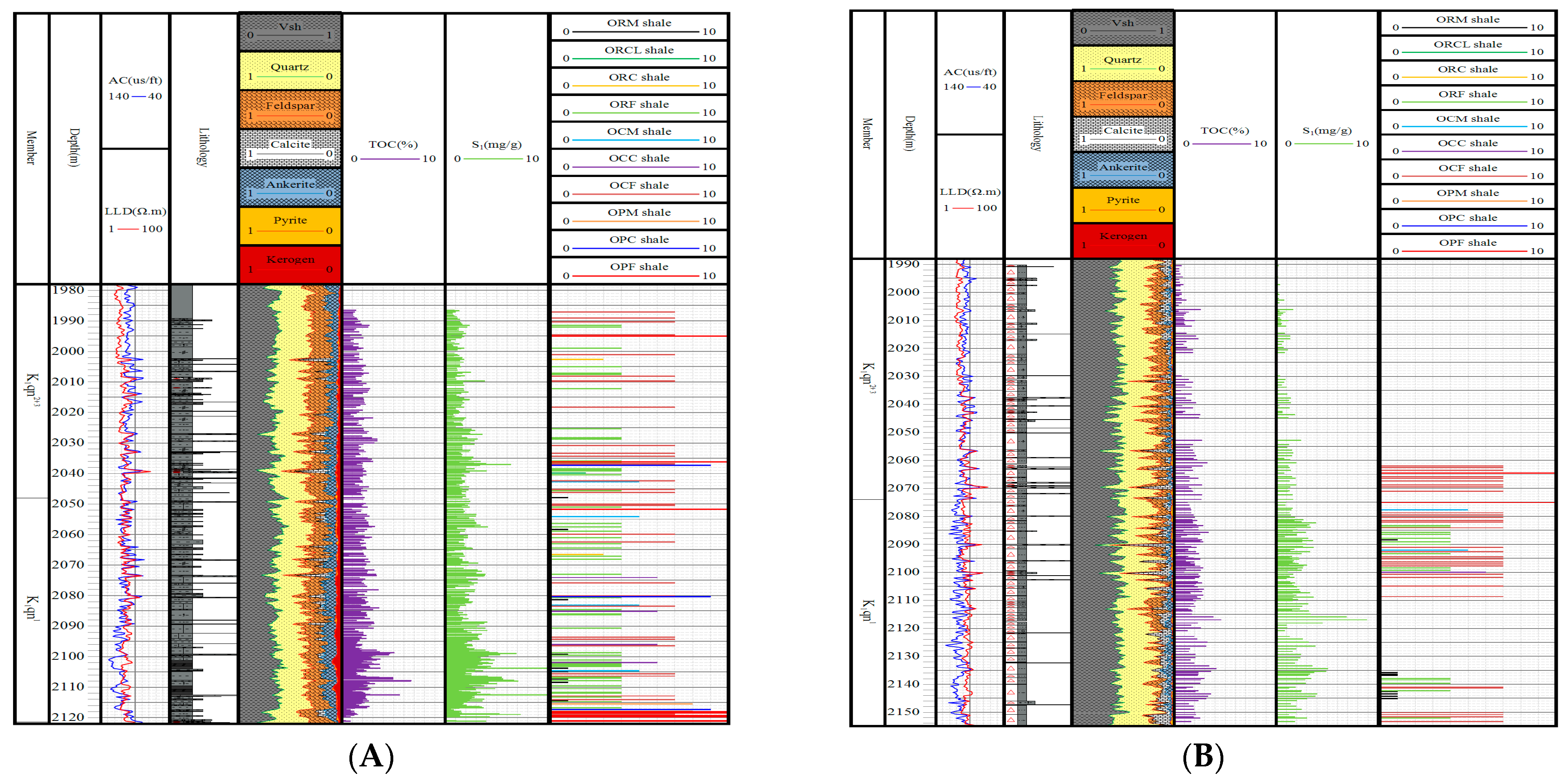

4.2. Characteristics of Organic Matter Content

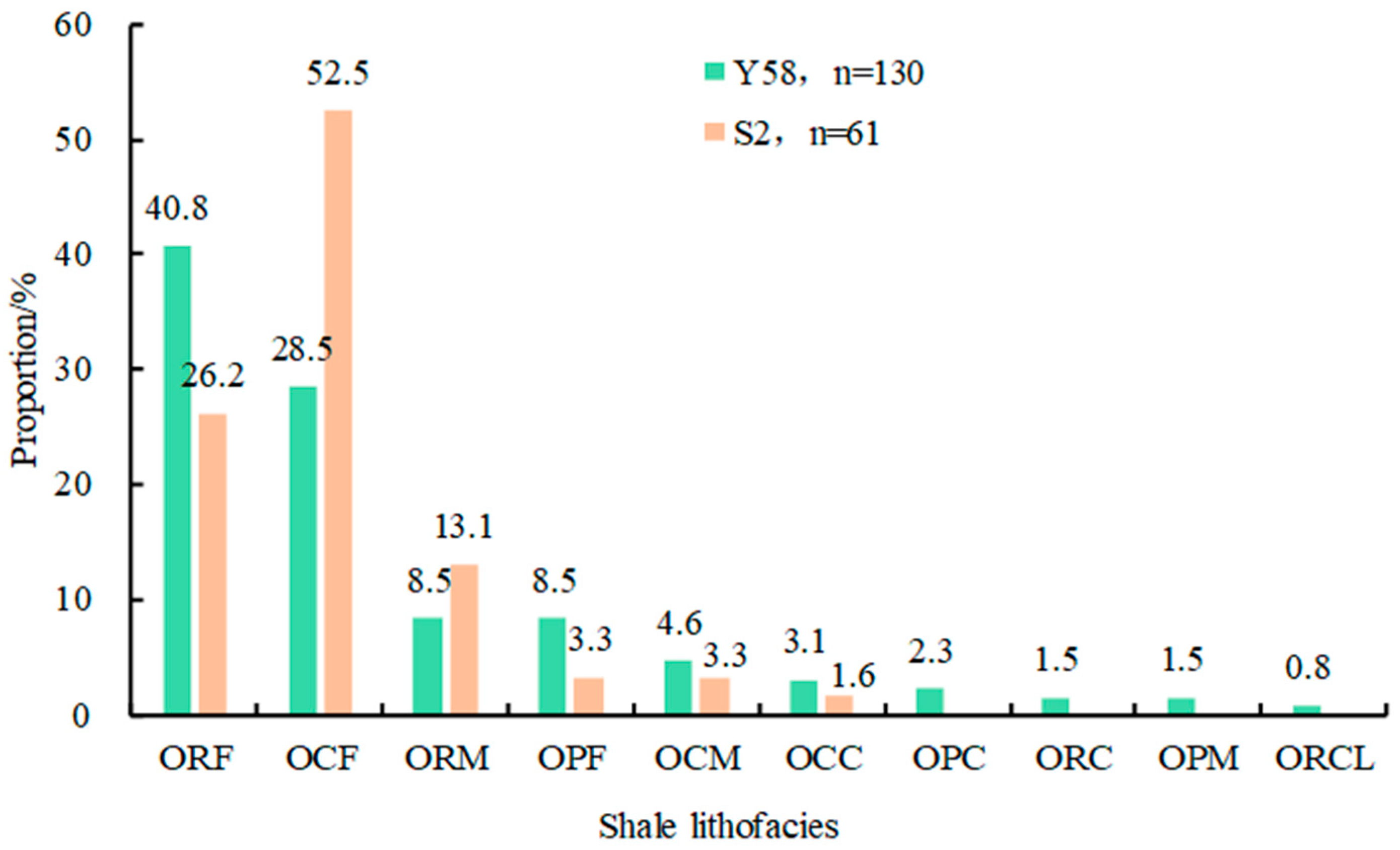

4.3. Shale Lithofacies Classification

5. Discussions

5.1. Evaluation of Shale Oil Generation and Expulsion Quantity

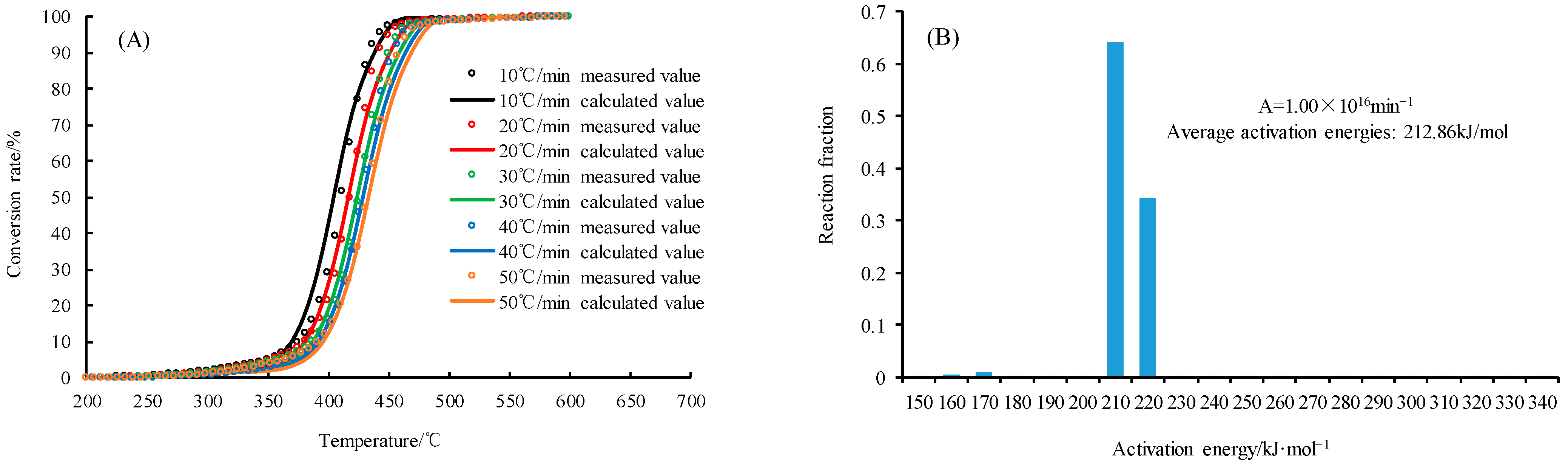

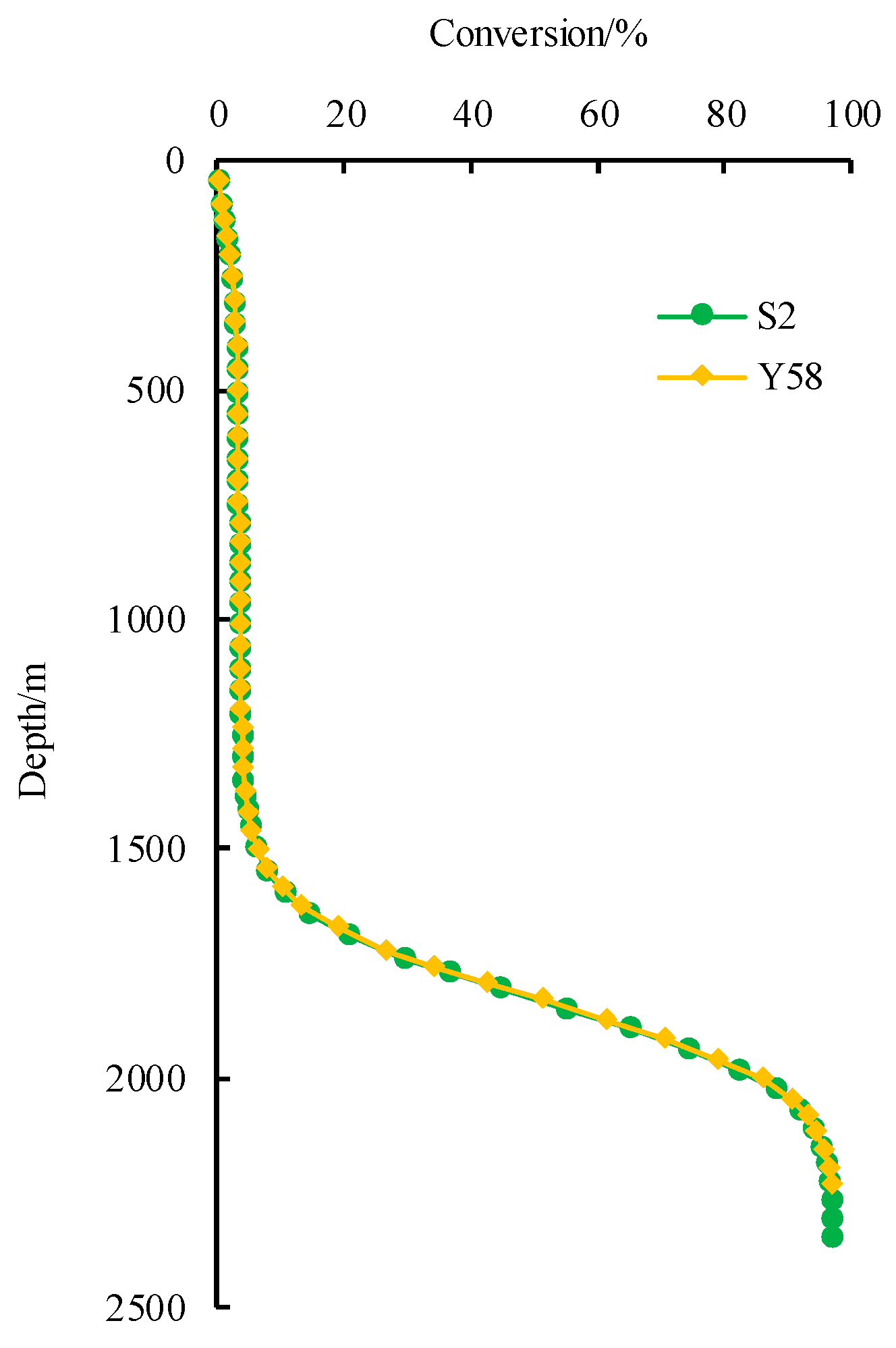

5.1.1. Oil Generation Quantity Evaluation

- Mr represents the current mass of a certain volume of source rock, kg.

- mc is the mass of the corresponding organic carbon, kg.

- ΔIH represents the recovery amount of hydrocarbon generation potential, mg/g TOC.

- Qo is the oil generation quantity, mg/g.

- K1 is the proportion of organic matter oil generation, %.

- K2 is the organic matter oil generation conversion rate, %.

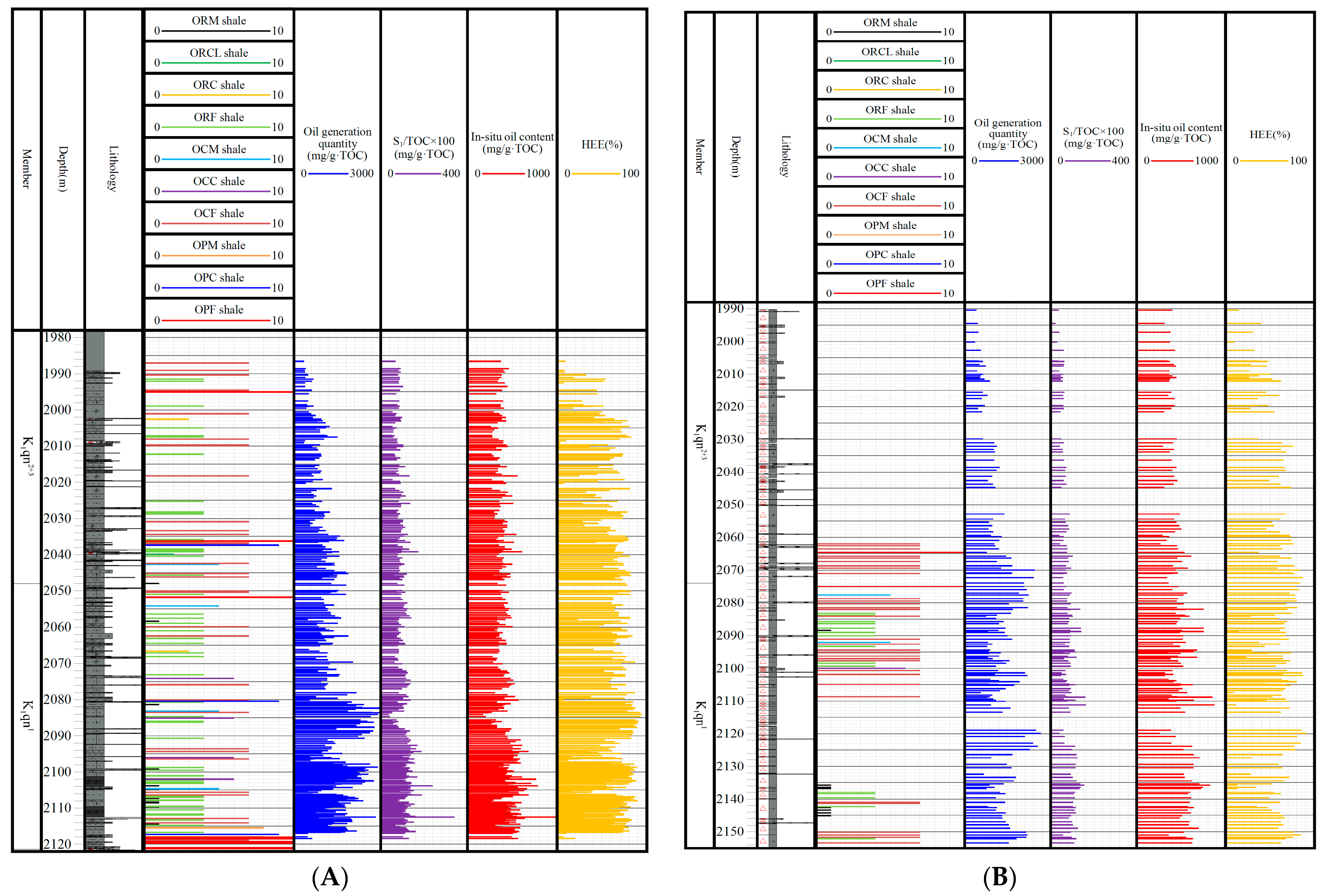

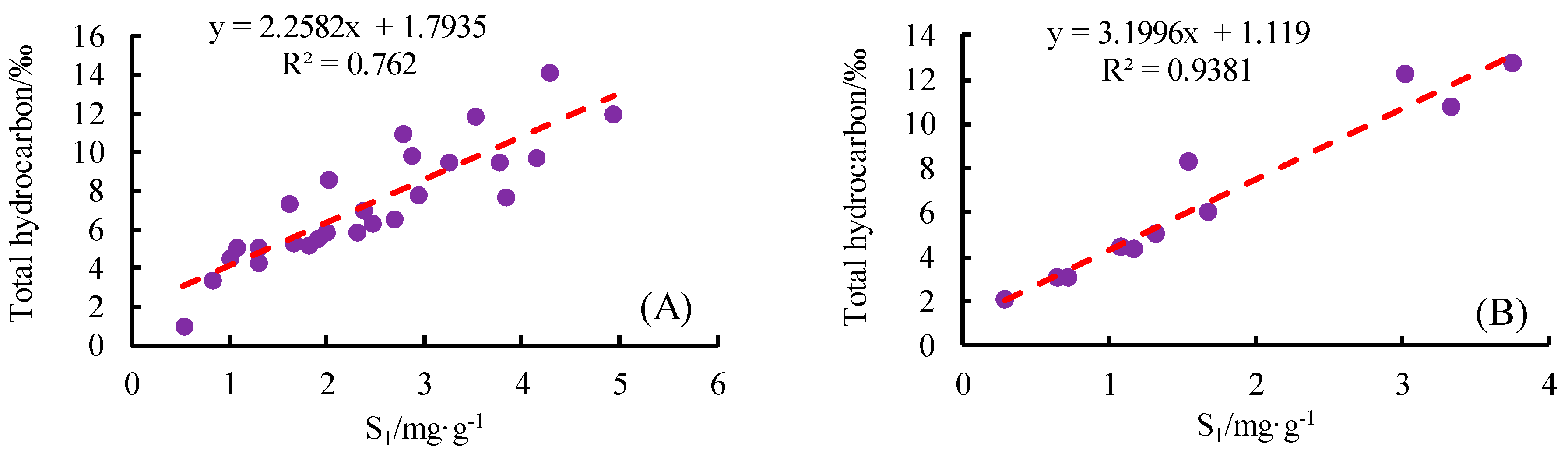

5.1.2. Oil Content Evaluation

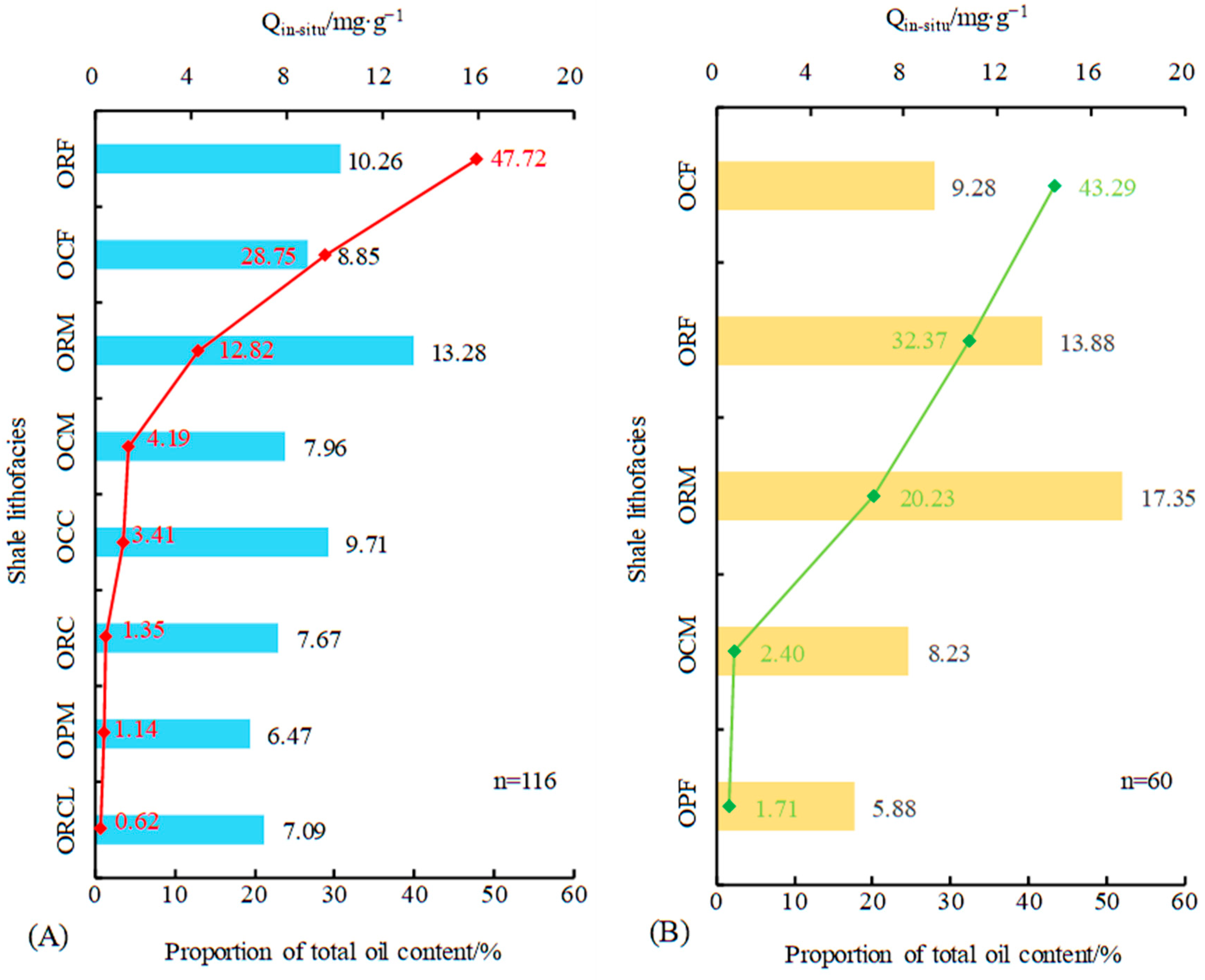

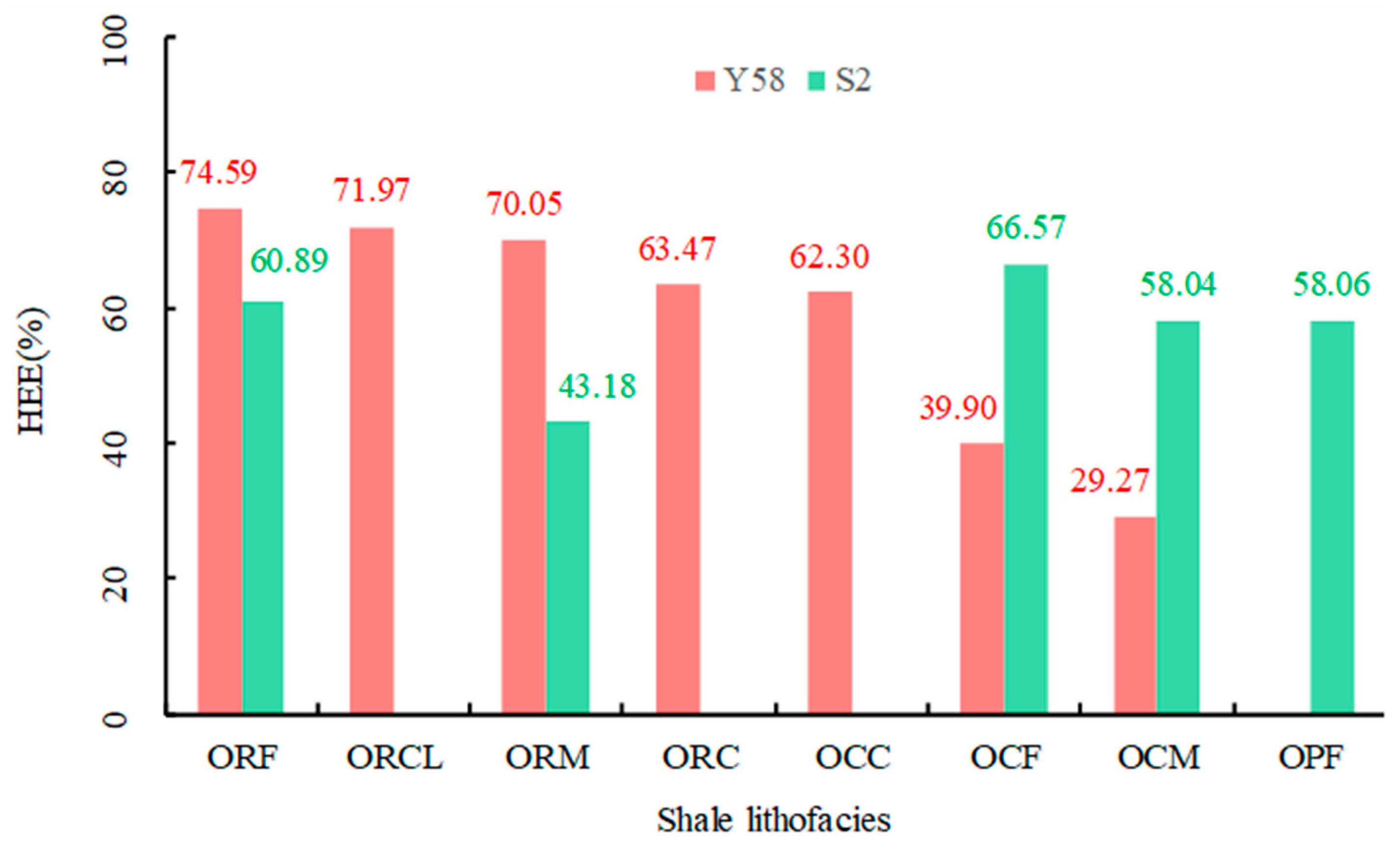

5.1.3. Hydrocarbon Expulsion Efficiency (HEE)

5.2. The Impact of Fractures on Shale Oil Mobility

5.2.1. Shale Oil Group Components

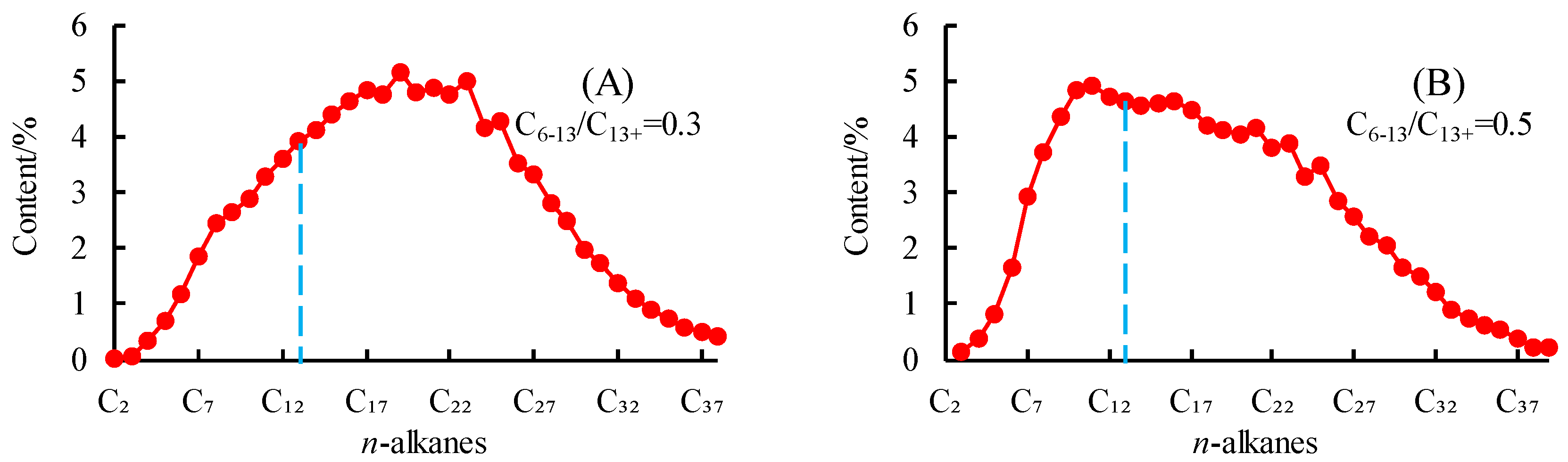

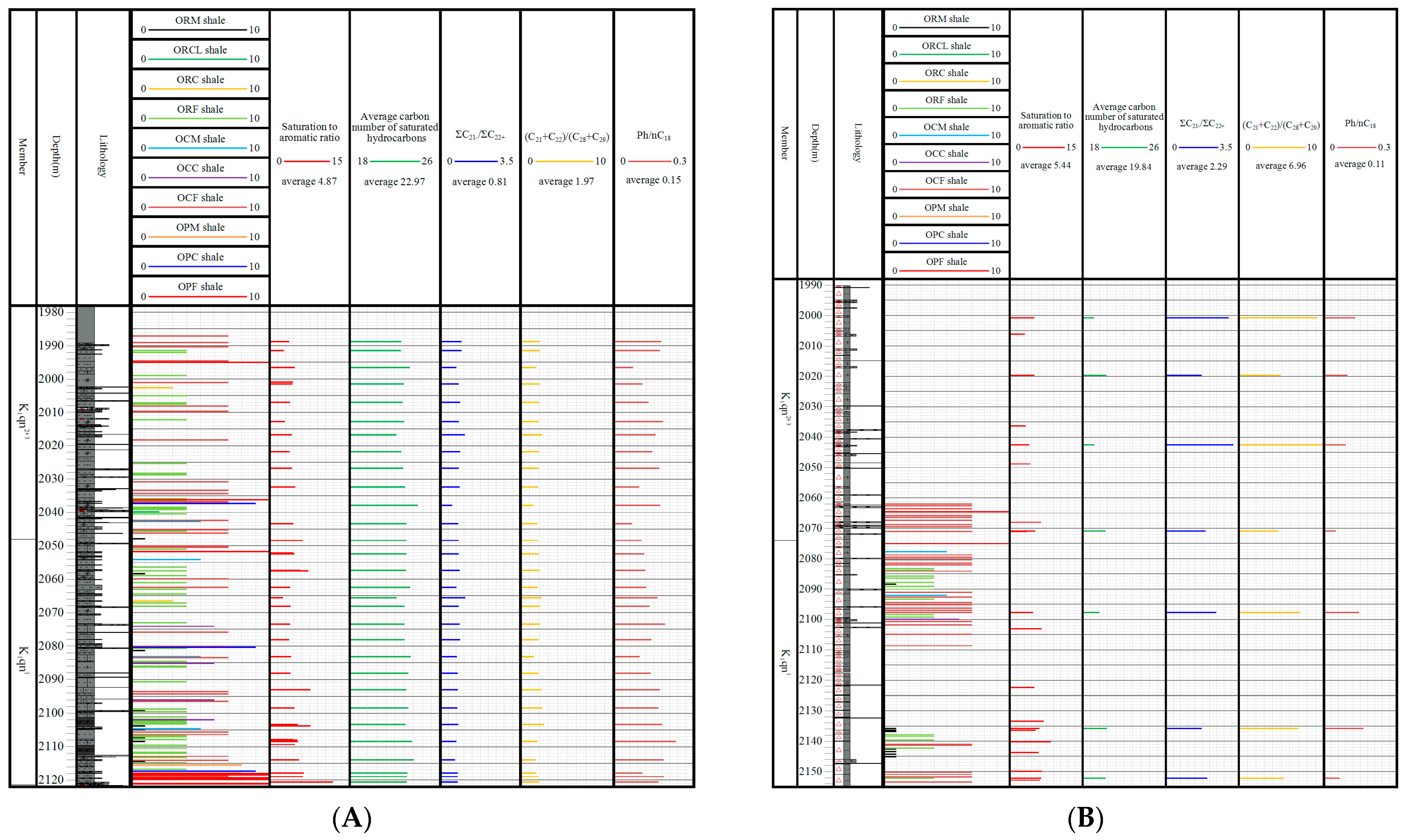

5.2.2. Molecular Composition

5.3. Inspiration

- (1)

- In the process of shale oil exploration and development, the impact of faults on HEE should be considered, which can lead to a decrease in shale oil content and shale oil mobility. Therefore, the target well location should not be too close to the fault.

- (2)

- There is a coupling relationship between shale oil content and shale oil mobility. Reservoirs with good preservation conditions have high oil content and good shale oil mobility.

6. Conclusions

- (1)

- The research area has developed 10 types of shale, with a large scale of ORF shale and OCF shale, accounting for over 65%. The average in situ oil content of both wells is relatively high, reaching over 8.8 mg/g in both wells. At the same time, the development scale of these two types of shale is large, making it the highest resource contribution. However, in areas close to the fault, ORF shale has a higher HEE, which will reduce the mobility of shale oil. At this time, OCF shale has a lower HEE, which combines high resource reserves and good shale oil mobility. On the contrary, in places far from the fault, OCF shale has a higher HEE and slightly lower shale oil mobility.

- (2)

- Light hydrocarbons account for over 30% of heavy hydrocarbons (C6–13/C13+) in crude oil, and light hydrocarbons are prone to loss. By recovering light and heavy hydrocarbons from pyrolysis S1, the in situ oil content of shale can be accurately and quantitatively characterized, clarifying that the fracture system has a significant control effect on shale oil enrichment. Research has found that although the oil generation quantity of well Y58, which is close to the fault, is higher than that of well S2, its migration effect is stronger than that of well S2, which means that the HEE is higher, resulting in a significantly lower in situ oil content and OSI of the shale in well Y58 compared to well S2.

- (3)

- The development of faults leads to enhanced migration, manifested as increased HEE, which leads to differentiation of shale oil components and affects their mobility. Specifically, with the enhancement of migration, the ratio of saturated aromatics is reduced, the average carbon number of saturated hydrocarbons is increased, the ratios of ΣC21−/ΣC22+ and (C21 + C22)/(C28 + C29) are reduced, and the ratio of Ph/nC18 is increased; that is, a large number of easily migrated components with small polarity and light weight in shale oil are discharged, which reduces the mobility of in situ shale oil.

- (4)

- When exploring and developing shale oil, it is necessary to consider the impact of faults on shale oil content and shale oil mobility and to try to avoid faults as much as possible.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, M.; Wang, M.; Zhang, J.Y.; Zhang, Y.C.; Liu, Z.; Luo, B.; Bian, C.S.; Li, J.B.; Wang, X.; Zhao, X.B.; et al. Evaluation of the compositions of lacustrine shale oil in China’s typical basins and its implications. Oil Gas Geol. 2023, 44, 1479–1498. [Google Scholar]

- Zhi, D.M.; Tang, Y.; Yang, Z.F.; Guo, X.G.; Zheng, M.L.; Wan, M.; Huang, L.L. Geological characteristics and accumulation mechanism of continental shale oil in Jimusaer sag, Junggar Basin. Oil Gas Geol. 2019, 40, 524–534. [Google Scholar]

- Jin, Z.J.; Zhu, R.K.; Liang, X.P.; Shen, Y.Q. Several issues worthy of attention in current lacustrine shale oil exploration and development. Pet. Explor. Dev. 2021, 48, 1276–1287. [Google Scholar] [CrossRef]

- Liu, B.; Sun, J.H.; Zang, Y.Q.; He, J.L.; Fu, X.F.; Yang, L.; Xing, J.L.; Zhao, X.Q. Reservoir space and enrichment model of shale oil in the first member of Cretaceous Qingshankou Formation in the Changling Sag, southern Songliao Basin, NE China. Pet. Explor. Dev. 2021, 48, 521–535. [Google Scholar] [CrossRef]

- He, W.Y.; Liu, B.; Zhang, J.Y.; Bai, L.H.; Tian, S.S.; Chi, Y.A. Geological Characteristics and Key Scientific and Technological Problems of Gulong Shale Oil in Songliao Basin. Earth Sci. 2023, 48, 49–62. [Google Scholar]

- Tian, H.; He, K.; Huangfu, Y.H.; Liao, F.R.; Wang, X.M.; Zhang, S.C. Oil content and mobility in a shale reservoir in Songliao Basin, Northeast China: Insights from combined solvent extraction and NMR methods. Fuel 2024, 357, 129678. [Google Scholar] [CrossRef]

- Liu, H.M.; Bao, Y.S.; Li, M.W.; Li, Z.; Wu, L.B.; Zhu, R.F.; Wang, D.Y.; Wang, X. Geochemical parameters for evaluating shale oil enrichment and mobility: A case study of shales inthe Bakken Formation, Williston Basin and the Shahejie Formation, Jiyang Depression. Oil Gas Geol. 2024, 45, 622–636. [Google Scholar]

- Liu, B.; Bai, L.H.; Chi, Y.A.; Jia, R.; Fu, X.F.; Yang, L. Geochemical characterization and quantitative evaluation of shale oil reservoir by two-dimensional nuclear magnetic resonance and quantitative grain fluorescence on extract: A case study from the Qingshankou Formation in Southern Songliao Basin, northeast China. Mar. Pet. Geol. 2019, 109, 561–573. [Google Scholar]

- Sun, L.D.; Wang, X.J.; Feng, Z.H.; Shao, H.M.; Zeng, H.S.; Gao, B.; Jiang, H. Formation mechanisms of nano-scale pores/fissures and shale oil enrichment characteristics for Gulong shale, Songliao Basin. Oil Gas Geol. 2023, 44, 1350–1365. [Google Scholar]

- Zhao, X.Z.; Zhou, L.H.; Pu, X.G.; Jin, F.M.; Shi, Z.N.; Han, W.Z.; Jiang, W.Y.; Han, G.M.; Zhang, W.; Wang, H.; et al. Formation conditions and enrichment model of retained petroleum in lacustrine shale: A case study of the Paleogene in Huanghua depression, Bohai Bay Basin, China. Pet. Explor. Dev. 2020, 47, 856–869. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Q.M.; Lyu, Q.; Xue, Z.J.; Cao, X.P.; Liu, Z.P. Evaluation technology and practice of continental shale oil development in China. Pet. Explor. Dev. 2022, 49, 955–964. [Google Scholar] [CrossRef]

- Yang, Y. Shale oil development techniques and application based on ternary-element storage and flow concept in Jiyang Depression, Bohai Bay Basin, East China. Pet. Explor. Dev. 2024, 51, 337–347. [Google Scholar] [CrossRef]

- Jin, X.; Li, G.X.; Meng, S.W.; Wang, X.Q.; Liu, C.; Tao, J.P.; Liu, H. Microscale comprehensive evaluation of continental shale oil recoverability. Pet. Explor. Dev. 2021, 48, 222–232. [Google Scholar] [CrossRef]

- Han, Y.J.; Horsfield, B.; Lareau, H.; Mahlstedt, N. Intraformational migration of petroleum: Insights into the development of sweet spot in the Cretaceous Niobrara shale-oil system, Denver Basin. Mar. Pet. Geol. 2019, 107, 301–309. [Google Scholar] [CrossRef]

- Hu, S.Z.; Li, S.F.; Xia, L.W.; Lyu, Q.; Cao, J. On the internal oil migration in shale systems and implications for shale oil accumulation: A combined petrological and geochemical investigation in the Eocene Nanxiang Basin, China. J. Pet. Sci. Eng. 2020, 184 Pt 2, 106493. [Google Scholar] [CrossRef]

- Jin, Z.J.; Wang, G.P.; Liu, G.X.; Gao, B.; Liu, Q.Y.; Wang, H.L.; Liang, X.P.; Wang, R.Y. Research progress and key scientific issues of continental shale oil in China. Acta Pet. Sin. 2021, 42, 821–835. [Google Scholar]

- Jiang, F.J.; Jia, C.Z.; Pang, X.Q.; Jiang, L.; Zhang, C.L.; Ma, X.Z.; Qi, Z.G.; Chen, J.Q.; Pang, H.; Hu, T.; et al. Upper Paleozoic total petroleum system and geological model of natural gas enrichment in Ordos Basin, NW China. Pet. Explor. Dev. 2023, 50, 281–292. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Zhang, L.B.; Wang, Q.B.; Wang, X.; Li, X.Q.; Deng, Z.X.; Dong, S.D. Understanding pore space and oil content of liquid-rich shale in the southern Bohai Sea, China. Geoenergy Sci. Eng. 2024, 223, 212552. [Google Scholar] [CrossRef]

- Ma, W.J.; Li, J.B.; Wang, M. Determination of in situ hydrocarbon contents in shale oil plays: Part 3: Quantification of light hydrocarbon evaporative loss in old cores based on preserved shales. Mar. Pet. Geol. 2024, 160, 106574. [Google Scholar] [CrossRef]

- Liang, C.; Cao, Y.C.; Liu, K.Y.; Jiang, Z.X.; Wu, J.; Hao, F. Diagenetic variation at the lamina scale in lacustrine organic-rich shales: Implications for hydrocarbon migration and accumulation. Geochim. Cosmochim. Acta 2018, 229, 112–128. [Google Scholar] [CrossRef]

- Han, Y.J.; Horsfield, B.; Mahlstedt, N.; Lareau, H.; Curry, D.J. Compositional fractionation of petroleum from reservoir to wellhead in the Niobrara shale oil play. Int. J. Coal Geol. 2018, 198, 156–166. [Google Scholar] [CrossRef]

- Han, Y.J.; Poetz, S.; Mahlstedt, N.; Karger, C.; Horsfield, B. Fractionation of Pyrrolic Nitrogen Compounds Compounds during Primary Migration of Petroleum within the Barnett Shale Sequence of Marathon 1 Mesquite Well, Texas. Energy Fuels 2018, 32, 4638–4650. [Google Scholar] [CrossRef]

- Han, Y.J.; Horsfield, B.; Mahlstedt, N.; Noah, M. Chemostatistic allocation of shale oil production using acidic heterocompounds. AAPG Bull. 2021, 105, 2207–2219. [Google Scholar] [CrossRef]

- Han, Y.J.; Mahlstedt, N.; Horsfield, B. The Barnett Shale: Compositional fractionation associated with intraformational petroleum migration, retention, and expulsion. AAPG Bull. 2015, 99, 2173–2202. [Google Scholar] [CrossRef]

- Pan, S.Q.; Zou, C.N.; Li, J.; Yang, Z.; Liu, E.T.; Han, Y.J. Unconventional shale systems: A comparative study of the “in-source sweet spot” developed in the lacustrine Chang 7 Shale and the marine Barnett Shale. Mar. Pet. Geol. 2019, 100, 540–550. [Google Scholar] [CrossRef]

- Feng, L.Y.; Zhang, J.G.; Jiang, Z.X.; Li, C.S.; Bai, Y.F. High-precision sedimentary cycle framework and organic matter enrichment response of Qingshankou Formation in Songliao Basin. Acta Pet. Sin. 2023, 44, 299–311. [Google Scholar]

- Wang, Y.C.; Li, P.P.; Feng, Z.H.; Shao, H.M.; Jia, Z.W.; Xia, Y.Q.; Li, J.; Wang, Z. Geochemical characteristics of shales from the first mem ber of Qingshankou Formation in Gulong Sag, Songliao Basin, China: Implication for mechanism of organic matter enrichment. Mar. Pet. Geol. 2023, 150, 106142. [Google Scholar] [CrossRef]

- Hang, Q.H.; Wu, H.C.; Wan, X.Q.; He, H.Y.; Deng, C.L. New progress of integrated chronostratigraphy of the cretaceous in Songliao Basin. J. Stratigr. 2011, 35, 250–257. [Google Scholar]

- Liu, B.; Wang, H.L.; Fu, X.F.; Bai, Y.F.; Bai, L.H.; Jia, M.C.; He, B. Lithofacies and depositional setting of a highly prospective lacustrine shale oil succession from the Upper Cretaceous Qingshankou Formation in the Gulong sag, northern Songliao Basin, northeast China. AAPG Bull. 2019, 103, 405–432. [Google Scholar] [CrossRef]

- Sun, L.D.; Liu, H.; He, W.Y.; Li, G.X.; Zhang, S.C.; Zhu, R.K.; Jin, X.; Meng, S.W.; Jiang, H. An analysis of major scientific problems and research paths of Gulong shale oil in Daqing Oilfield, NE China. Pet. Explor. Dev. 2021, 48, 453–463. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Y.Q.; Cai, M.; Meng, S.W.; Tao, J.P. Practice and development suggestions of hydraulic fracturing technology in the Gulong shale oil reservoirs of Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 603–612. [Google Scholar] [CrossRef]

- Liu, B.; Shi, J.X.; Fu, X.F.; Lyu, Y.F.; Sun, X.D.; Gong, L.; Bai, Y.F. Petrological characteristics and shale oil enrichment of lacustrine fine-grained sedimentary system: A case study of organic-rich shale in first member of Cretaceous Qingshankou Formation in Gulong Sag, Songliao Basin, NE China. Pet. Explor. Dev. 2018, 45, 828–838. [Google Scholar] [CrossRef]

- Sun, L.D.; Cui, B.W.; Zhu, R.K.; Wang, R.; Feng, Z.H.; Li, B.H.; Zhang, J.Y.; Gao, B.; Wang, Q.Z.; Zeng, H.S.; et al. Shale oil enrichment evaluation and production law in Gulong Sag, Songliao Basin, NE China. Pet. Explor. Dev. 2023, 50, 441–454. [Google Scholar] [CrossRef]

- Liu, Z.J.; Liu, R.; Sun, P.C.; Meng, Q.T.; Hu, F. Oil Shale Characteristics and Distribution in Typical Basins of China. J. Jilin Univ. Earth Sci. Ed. 2020, 50, 313–325. [Google Scholar]

- Behar, F.; Beaumont, V.; Penteado, H.L.D.B. Rock-Eval 6 Technology: Performances and Developments. Oil Gas Sci. Technol. 2001, 56, 111–134. [Google Scholar] [CrossRef]

- SY/T 5163-2018; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction. Petroleum Industry Press: Beijing, China, 2019.

- SY/T 5118-2021; Determination of the Extract Content of Rock. Petroleum Industry Press: Beijing, China, 2022.

- Zheng, D.Z.; Miska, S.; Ozbayoglu, E.; Zhang, J.G. Combined experimental and well log study of anisotropic strength of shale. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 16–18 October 2023. [Google Scholar]

- Zheng, D.Z.; Miska, S.; Ziaja, M.; Zhang, J.G. Study of anisotropic strength properties of shale. AGH Drill. Oil Gas 2019, 36, 93–112. [Google Scholar] [CrossRef]

- Li, J.J.; Wang, W.M.; Cao, Q.; Shi, Y.L.; Yan, X.T.; Tian, S.S. Impact of hydrocarbon expulsion efficiency of continental shale upon shale oil accumulations in eastern China. Mar. Pet. Geol. 2015, 59, 467–479. [Google Scholar]

- Lu, S.F. Theory and Application of Organic Matter Hydrocarbon Generation Dynamics; Petroleum Industry Press: Beijing, China, 1996; pp. 1–94. [Google Scholar]

- Liu, Y.; He, K.; Li, X.Q.; Xu, H.W.; Zhang, J.Z.; Hu, S.L.; Wang, G.; Fan, Z.W. Hydrocarbon generation kinetics and the efficiency of petroleum expulsion of lacustrine source rocks: Taking the Qingshankou Formation in the Songliao Basin as an example. Geoscience 2016, 30, 627–634. [Google Scholar]

- Chen, Z.H.; Zha, M. Simulation experiment of geochromatographic effect during hydrocarbon expulsion. Geochimica 2006, 35, 157–166. [Google Scholar]

- Lyu, X.X.; Yang, H.J.; Wang, X.; Han, J.F.; Bai, Z.K. Application of geochemical parameters in hydrocarbon migration studies: Taking Tazhong area of the Tarim Basin as an example. Oil Gas Geol. 2010, 31, 838–846. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Li, J.; Liu, W.; Li, J.; Fu, X.; Su, Y.; Zheng, Q.; Lu, S.; Zeng, X.; You, H.; et al. The Impact of Fractures on Shale Oil and Gas Enrichment and Mobility: A Case Study of the Qingshankou Formation in the Gulong Depression of the Songliao Basin, NE China. Energies 2024, 17, 4517. https://doi.org/10.3390/en17174517

Bai X, Li J, Liu W, Li J, Fu X, Su Y, Zheng Q, Lu S, Zeng X, You H, et al. The Impact of Fractures on Shale Oil and Gas Enrichment and Mobility: A Case Study of the Qingshankou Formation in the Gulong Depression of the Songliao Basin, NE China. Energies. 2024; 17(17):4517. https://doi.org/10.3390/en17174517

Chicago/Turabian StyleBai, Xuefeng, Junhui Li, Wei Liu, Jijun Li, Xiuli Fu, Yangxin Su, Qiang Zheng, Shuangfang Lu, Xu Zeng, Hang You, and et al. 2024. "The Impact of Fractures on Shale Oil and Gas Enrichment and Mobility: A Case Study of the Qingshankou Formation in the Gulong Depression of the Songliao Basin, NE China" Energies 17, no. 17: 4517. https://doi.org/10.3390/en17174517

APA StyleBai, X., Li, J., Liu, W., Li, J., Fu, X., Su, Y., Zheng, Q., Lu, S., Zeng, X., You, H., & Xu, Y. (2024). The Impact of Fractures on Shale Oil and Gas Enrichment and Mobility: A Case Study of the Qingshankou Formation in the Gulong Depression of the Songliao Basin, NE China. Energies, 17(17), 4517. https://doi.org/10.3390/en17174517