Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Moisture Content

2.3. Determination of Bulk Density

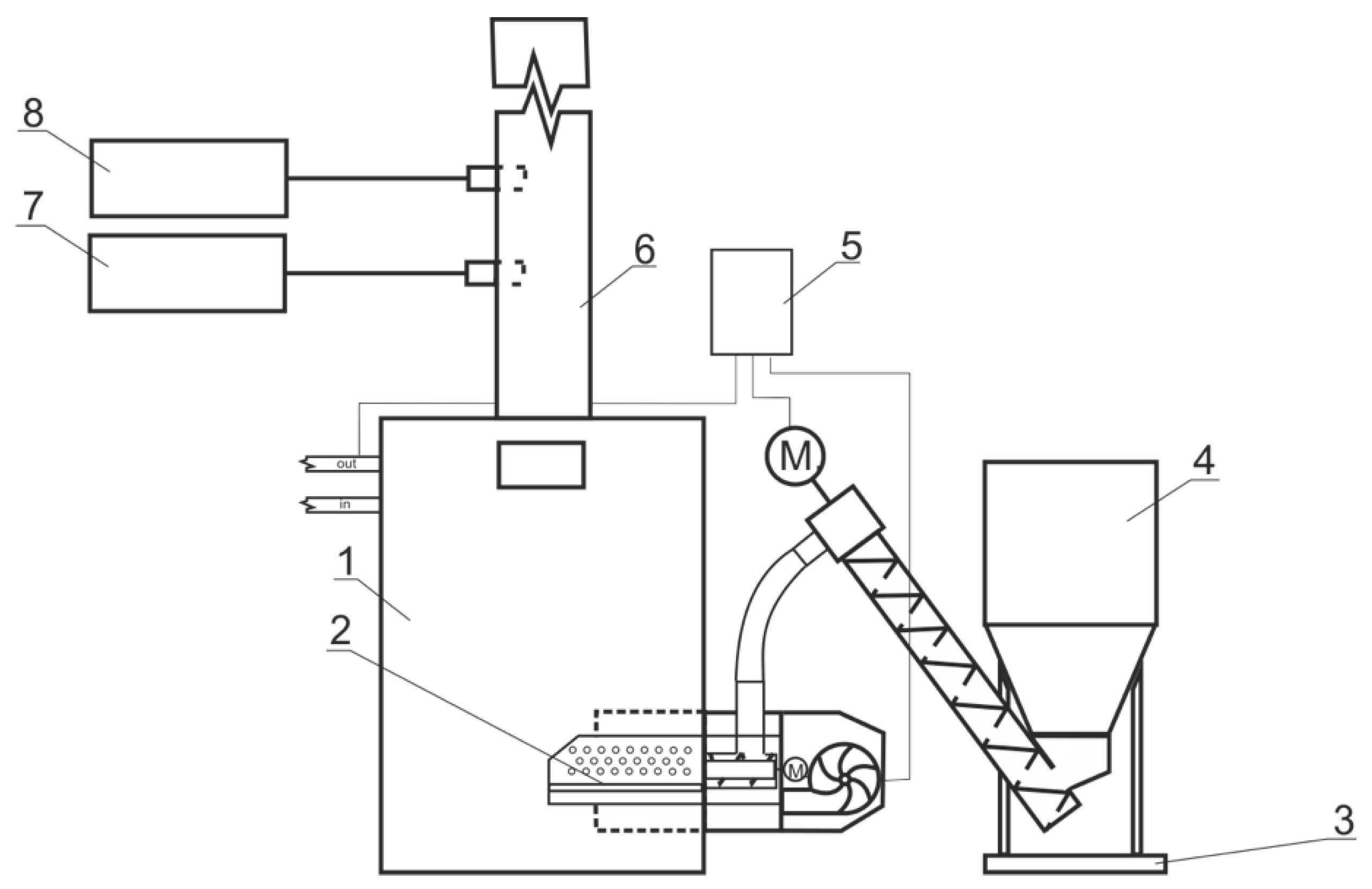

2.4. Determination of Particle Size Distribution

2.5. Elemental Composition Analysis

2.6. Heavy Metals Analysis

2.7. Determination of Calorific Value and Heat of Combustion

- LHV—calorific value (Lower Heating Value) [MJ·kg−1];

- HHV—heat of combustion (Higher Heating Value) [MJ·kg−1];

- w—moisture content of the sample [%];

- Ha—hydrogen content of the sample [%];

- 24.43—coefficient accounting for the heat of water vaporization at 25 °C in pellets with a 1% water content;

- 8.94—coefficient accounting for the stoichiometry of the hydrogen combustion reaction (quantitative changes).

2.8. Investigations of the Compaction Process under Laboratory Conditions

- wm = 14—mixture humidity [%];

- do = 12—diameter of holes in the matrix [mm];

- Qm = 50—mass flow rate of the mixture [kg·h−1];

- nr = 170—rotational speed of the compaction roller system [rpm];

- hr = 0.4—gap between the rollers and the matrix [mm].

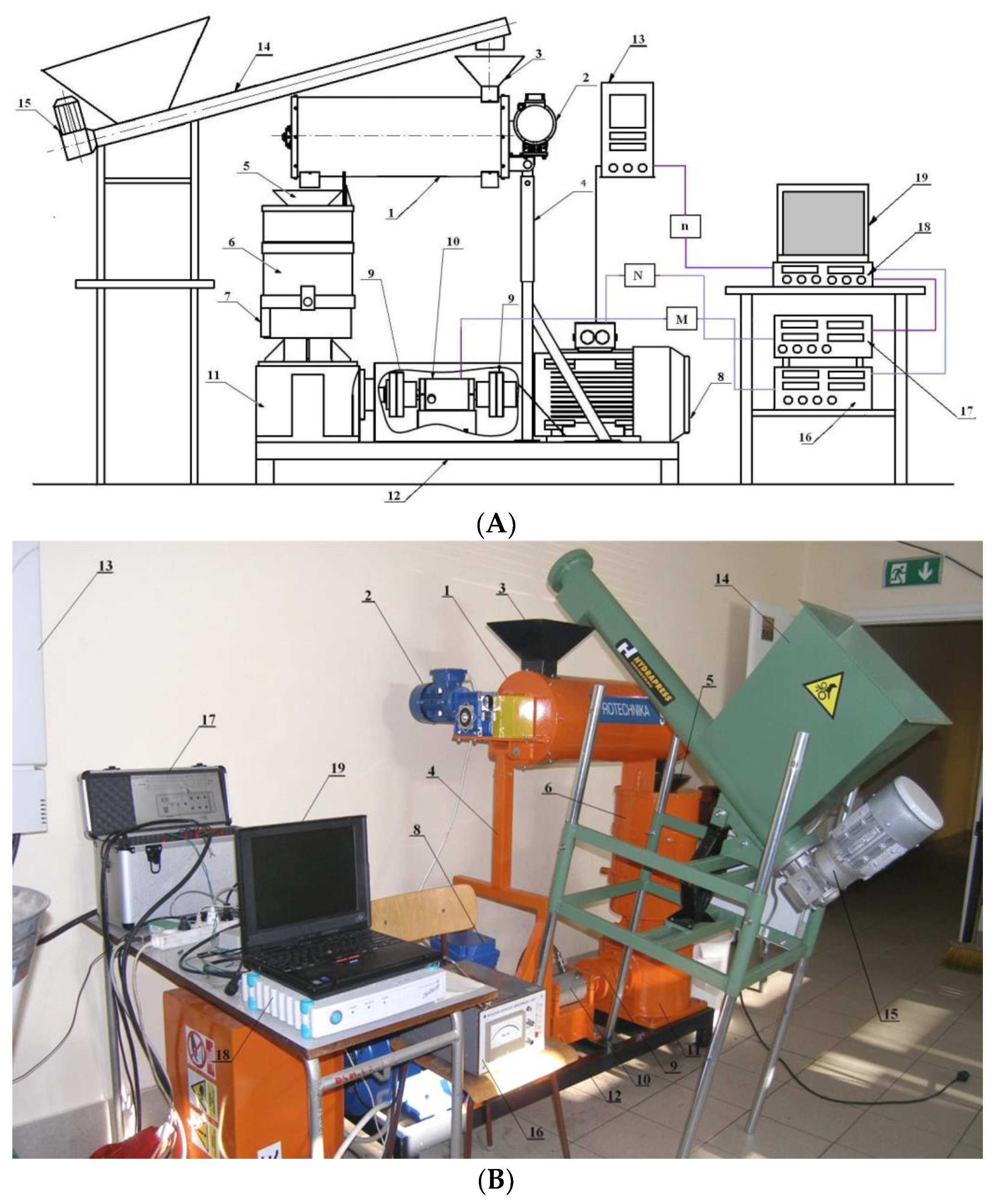

2.9. Investigations of the Compaction Process under Industrial Conditions

- do = 6—diameter of the holes in the matrix of the pelletizer [mm],

- Q = 350—raw material mass flow rate [kg·h−1],

- nr = 170—rotational speed of the compaction roller system [rpm],

- hr = 0.2—gap between the rollers and the matrix [mm].

- power demand of the pelletizer Ng,

- strength of the obtained pellets Pdx,

- density of the obtained pellets ρg,

- bulk density of the obtained pellets ρug.

2.10. Density and Bulk Density of Pellets

2.11. Kinetic Durability of Pellets

- Pdx—kinetic durability of the pellets [%];

- m1—mass delivered before the test [kg];

- m2—mass delivered after the test [kg].

2.12. Energy Indicators of Pellet Production under Industrial Conditions

- EY—energy yield of pellets [Wh·kg−1],

- LHV—Lower Heating Value (calorific value) [Wh·kg−1],

- ECU—Energy Consumption Unit [Wh·kg−1].

- EE—energy efficiency [%],

- IE—Initial Energy Content of Biomass [Wh·kg−1],

- ECU—Energy Consumption Unit [Wh·kg−1].

- ED—energy density [GJ·m−3],

- BD—bulk density [kg·m−3].

- LHV—Lower Heating Value (calorific value) [GJ·kg−1].

2.13. Thermogravimetric Analysis

2.13.1. Analysis of the Content of Analytical Moisture, Volatile Matter, Fixed Carbon, and Ash in Biomass

- FC—fixed carbon content [%],

- MC—analytical moisture value [%],

- VM—volatile matter value [%],

- AC—ash content [%].

2.13.2. Ignition Characteristics

- (dX·dt−1)max—maximum combustion rate (%·min−1),

- (dX·dt−1)mean—average combustion rate (%·min−1),

- Ti—ignition temperature (K),

- Tf—burn-out temperature (K).

- β—heating rate [K·min−1],

- AI—sample residue during ignition [%],

- AF—sample residue during firing [%].

2.14. Emissions from Pellet Combustion

- Zs1—the actual content of a chemical compound in exhaust gases [%, mg·m−3];

- Zs2—the content of a chemical compound in exhaust gases for a given oxygen content [%, mg·m−3];

- —the assumed oxygen content in exhaust gases [%];

- —the actual oxygen content in exhaust gases [%].

3. Results

3.1. Moisture of the Tested Raw Materials

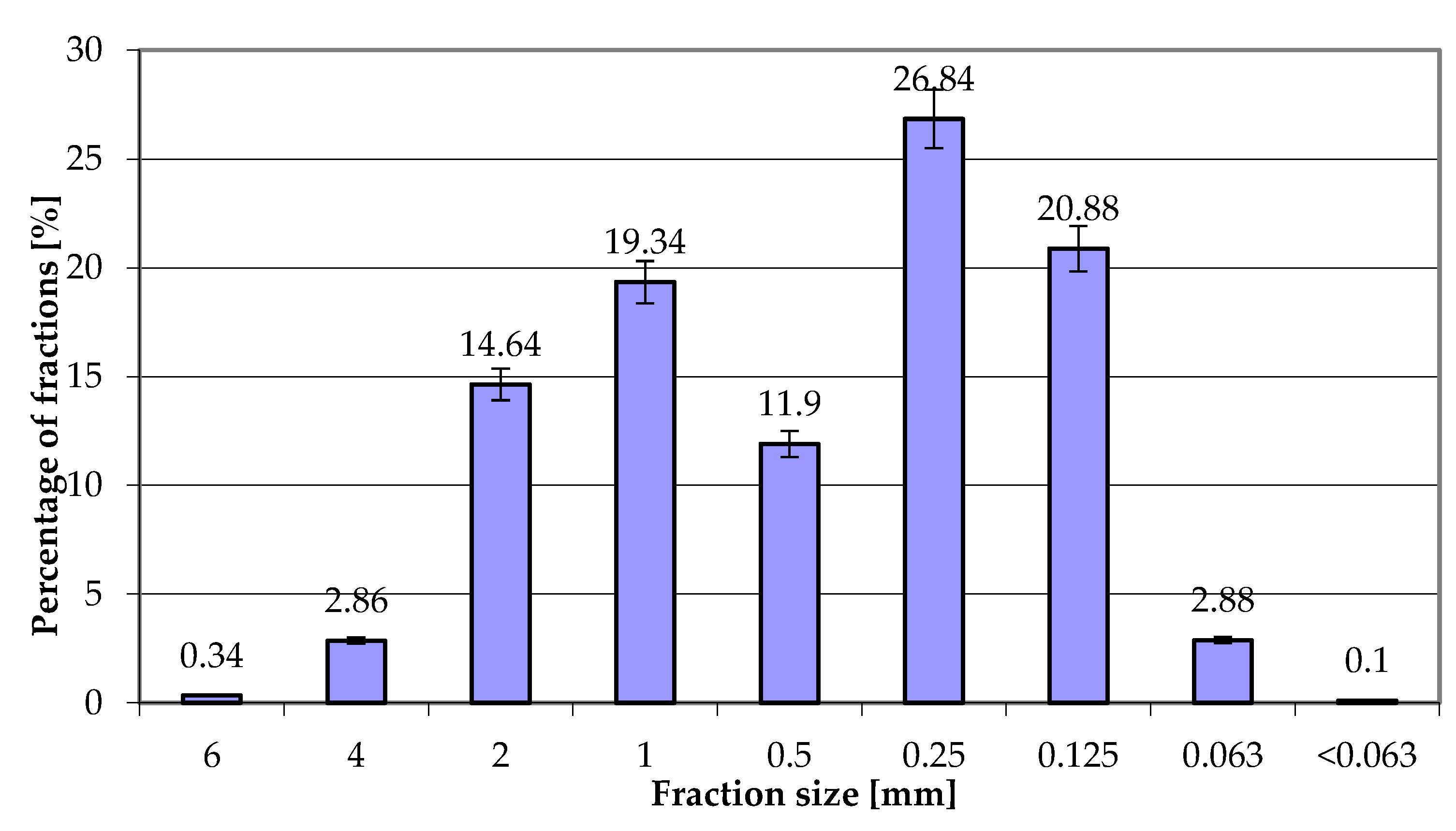

3.2. Granulometric Distribution of Tested Raw Materials

3.3. Bulk Density of the Tested Raw Materials

3.4. Elemental Composition of Tested Raw Materials

3.5. Heavy Metal Content

3.6. Calorific Value and Heat of Combustion

- HHV—heat of combustion [MJ·kg−1],

- zp—potato pulp content [%].

- LHV—calorific value [MJ·kg−1],

- zp—potato pulp content [%].

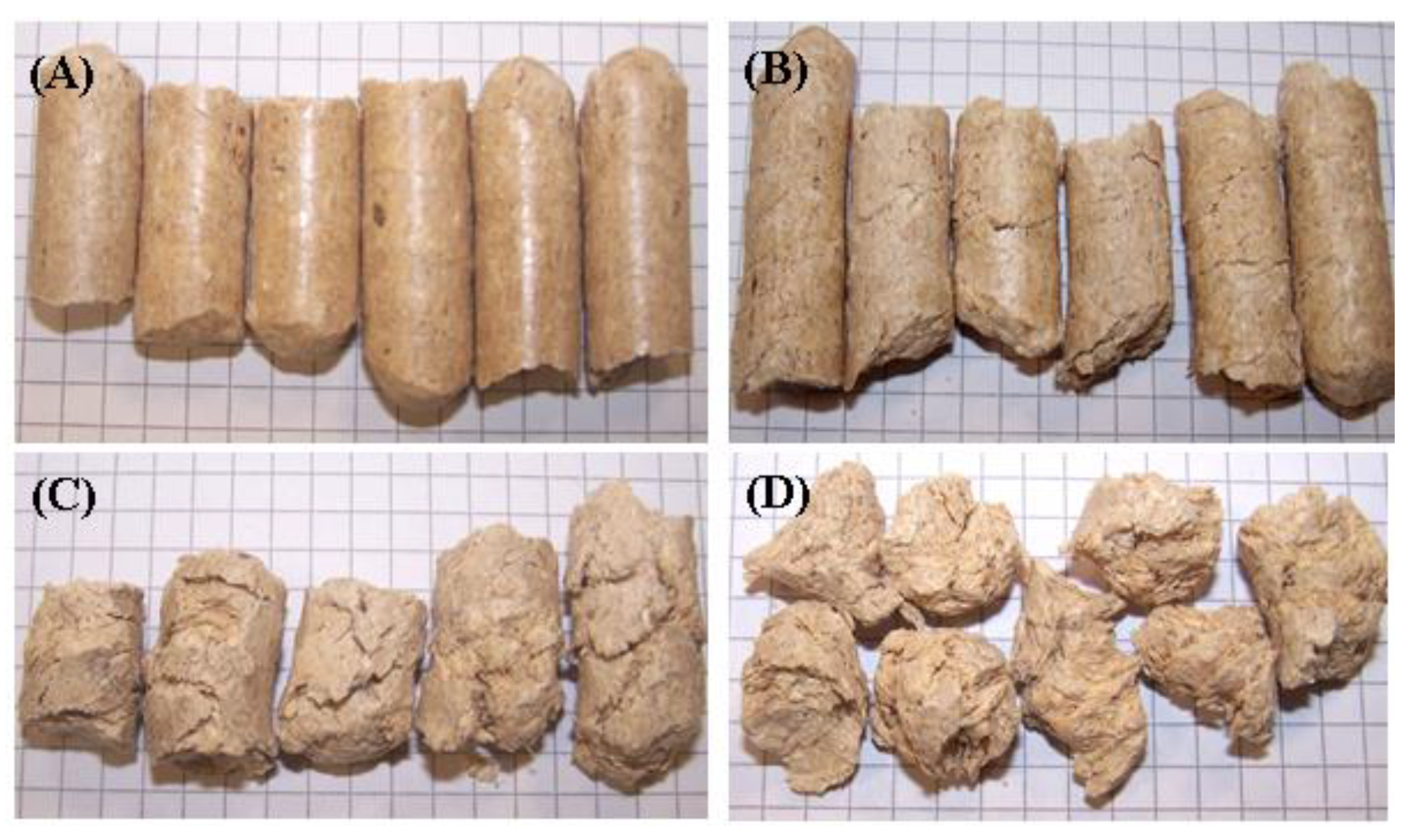

3.7. Pelleting Process under Laboratory Conditions and Pellet Characteristics

- zp—potato pulp content [%];

- Ng—power demand of the pelletizer [kW].

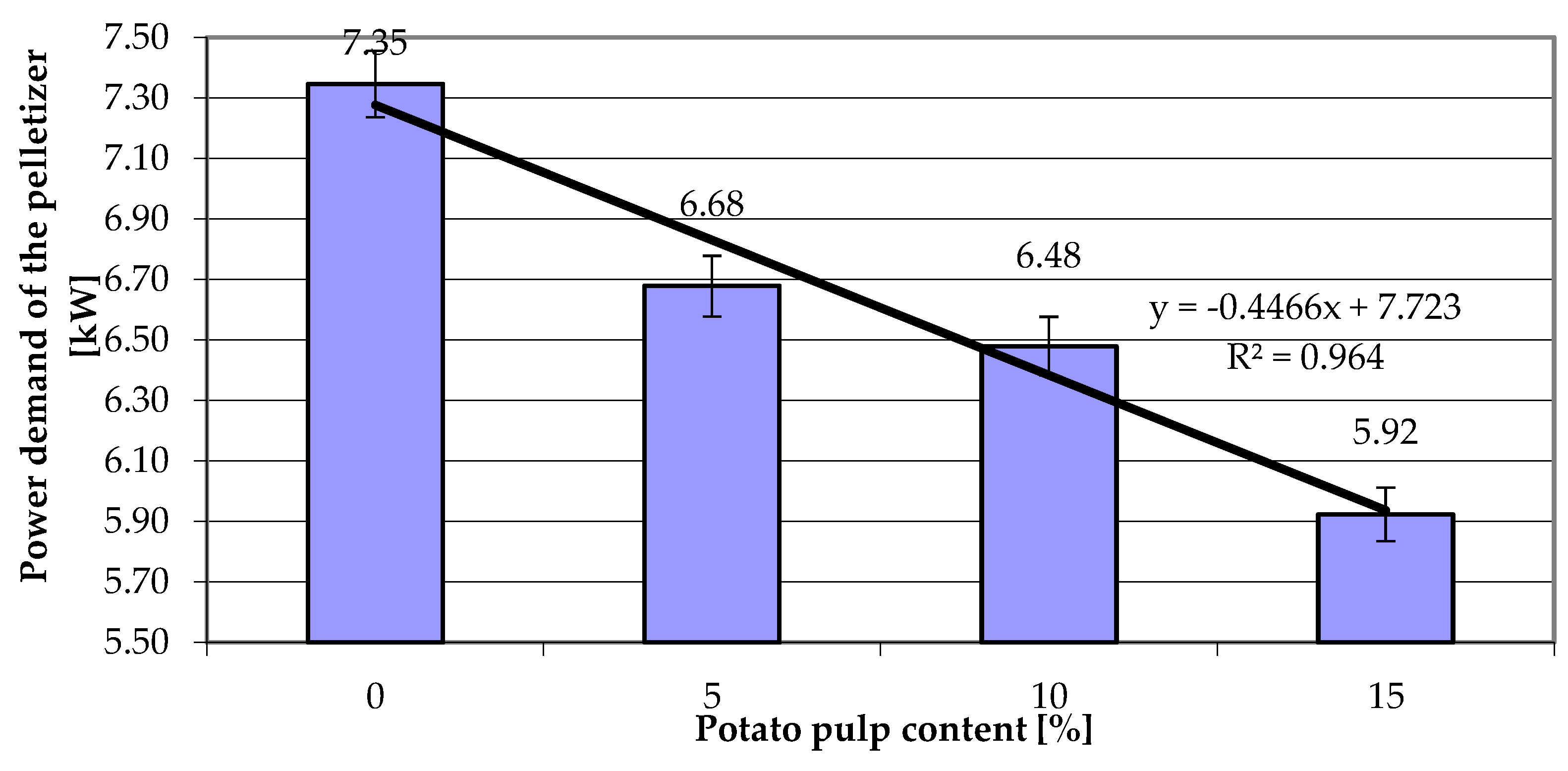

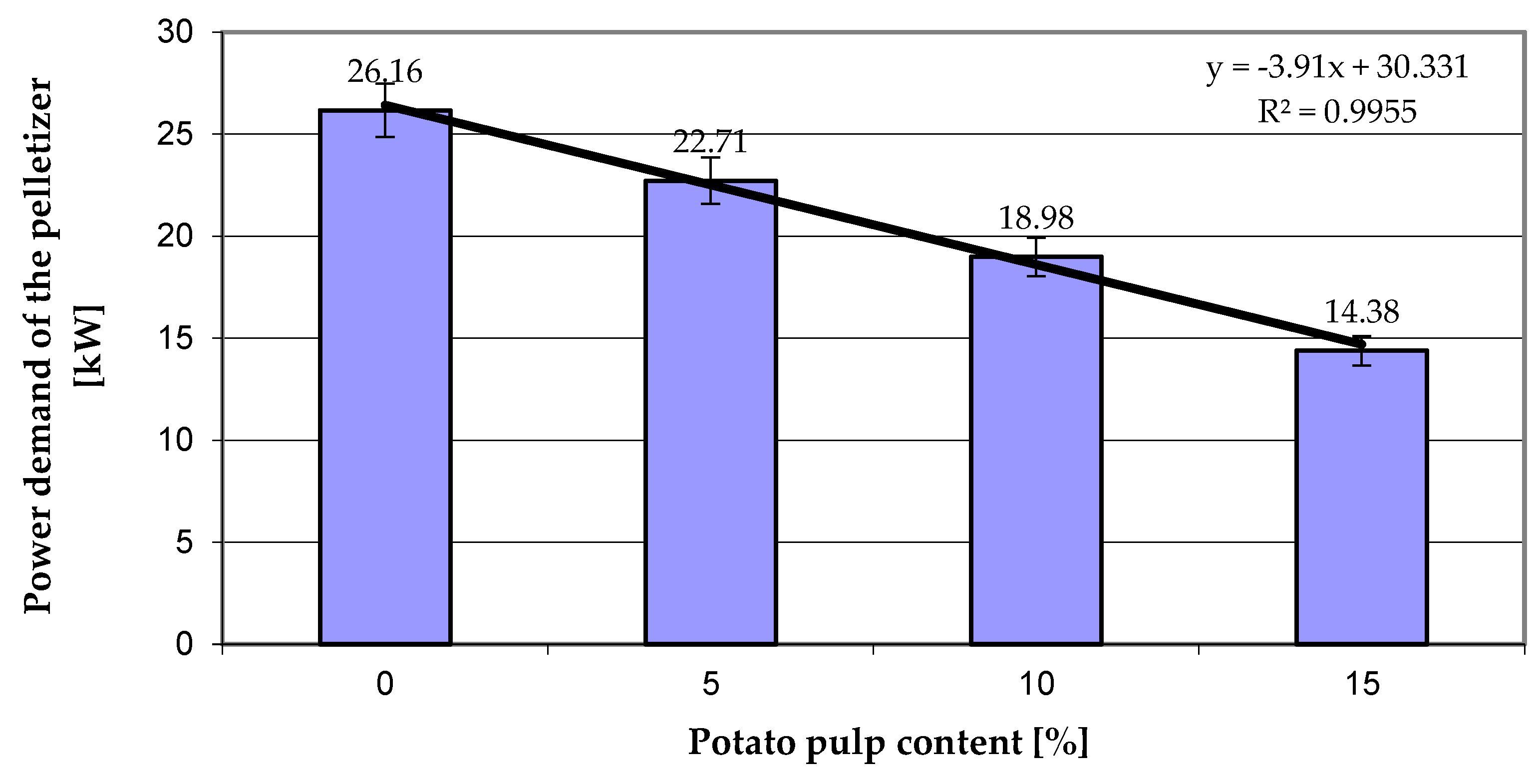

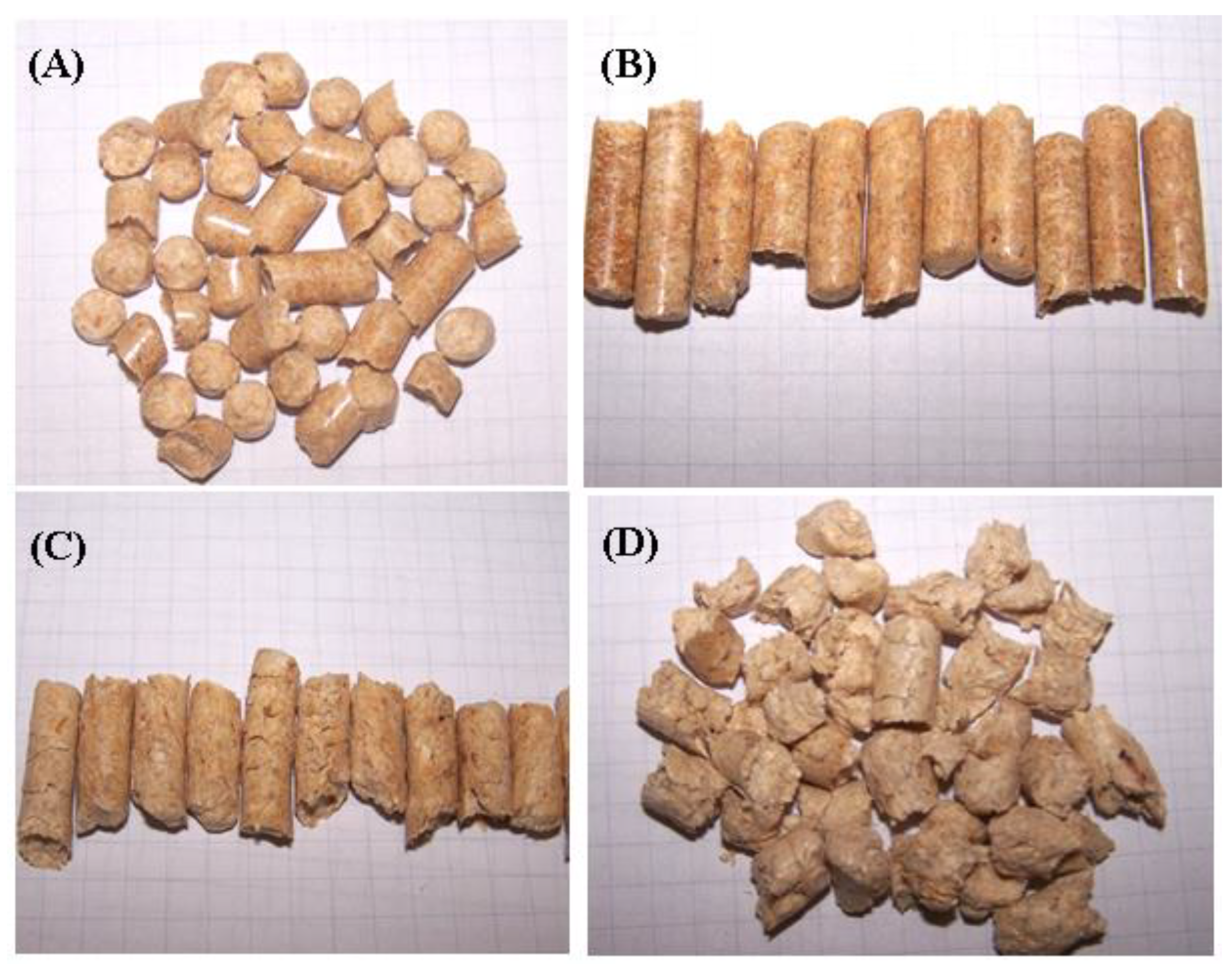

3.8. Pelleting Process under Industrial Conditions and Pellet Characteristics

- zp—potato pulp moisture [%],

- Ng—power demand of the pelletizer [kW].

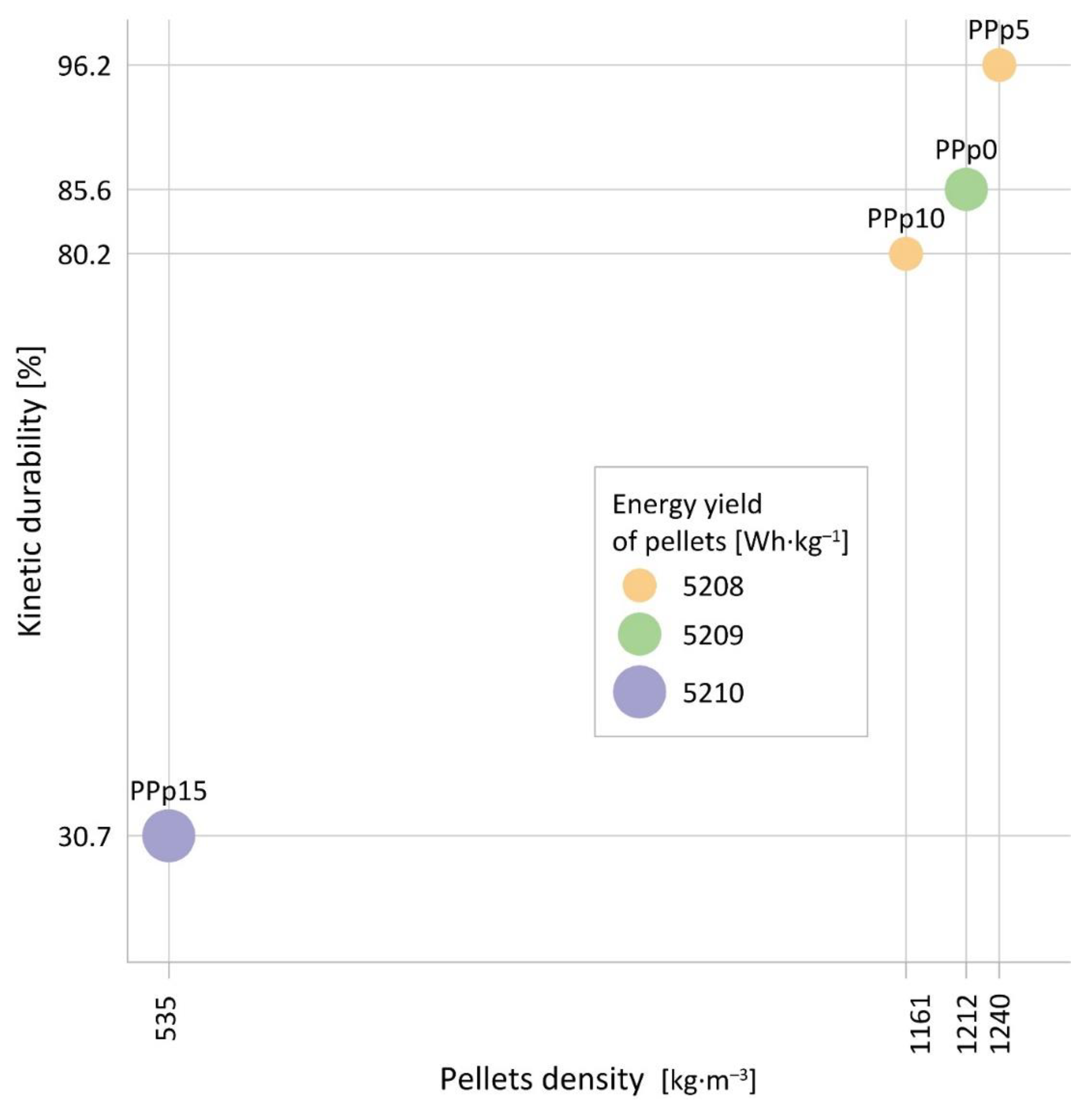

3.9. Physical Properties of the Produced Pellets

- zp—potato pulp content [%],

- Pdxg—kinetic strength of pellets [%].

- zp—potato pulp content [%],

- Pdxg—kinetic strength of pellets [%].

- zp—potato pulp content [%],

- ρg—pellet density [kg·m−3],

- ρug—bulk density of pellets [kg·m−3].

- zp—potato pulp content [%],

- ρg—pellet density [kg·m−3],

- ρug—bulk density of pellets [kg·m−3].

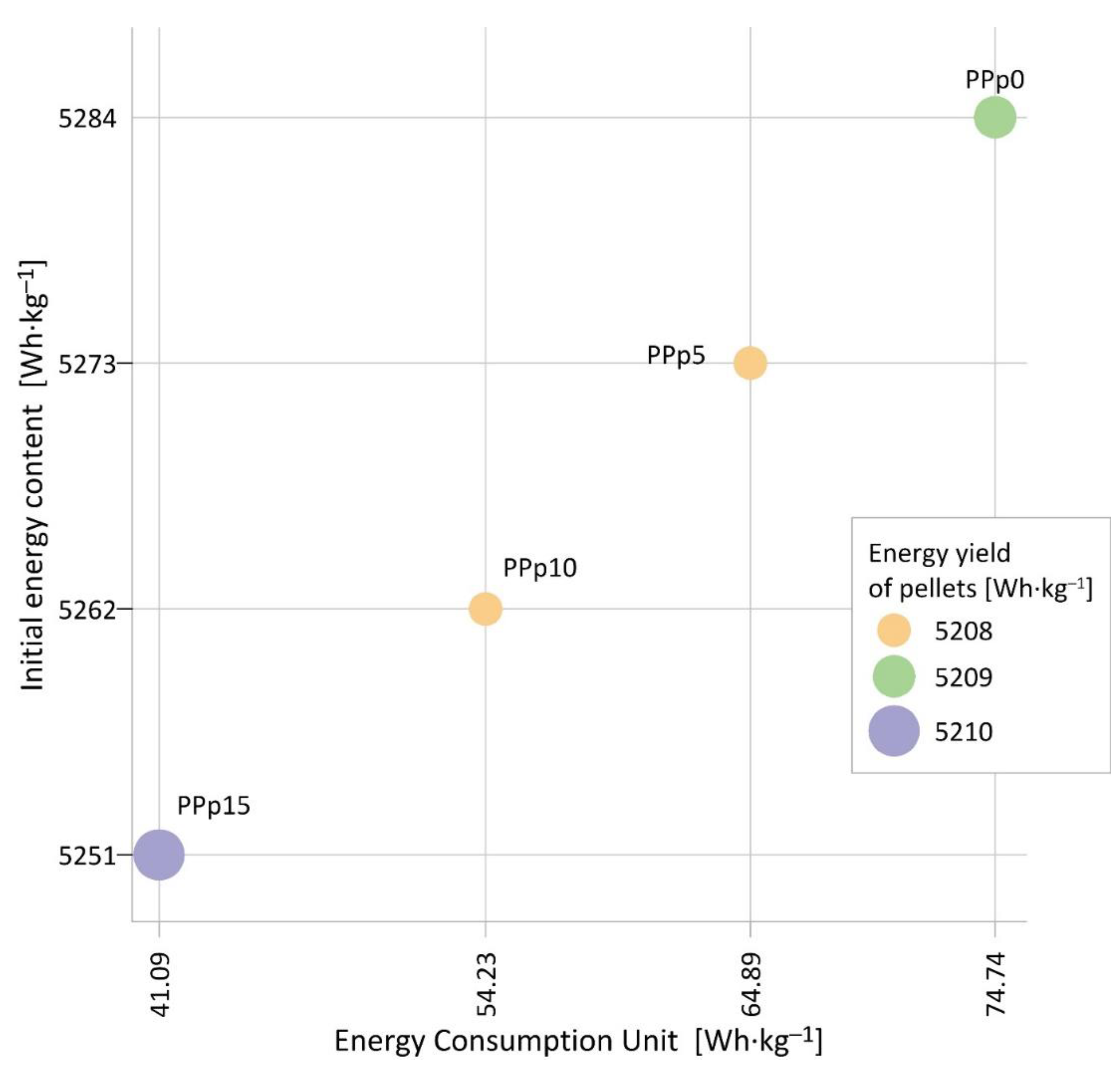

3.10. Energy Indicators of Pellet Production

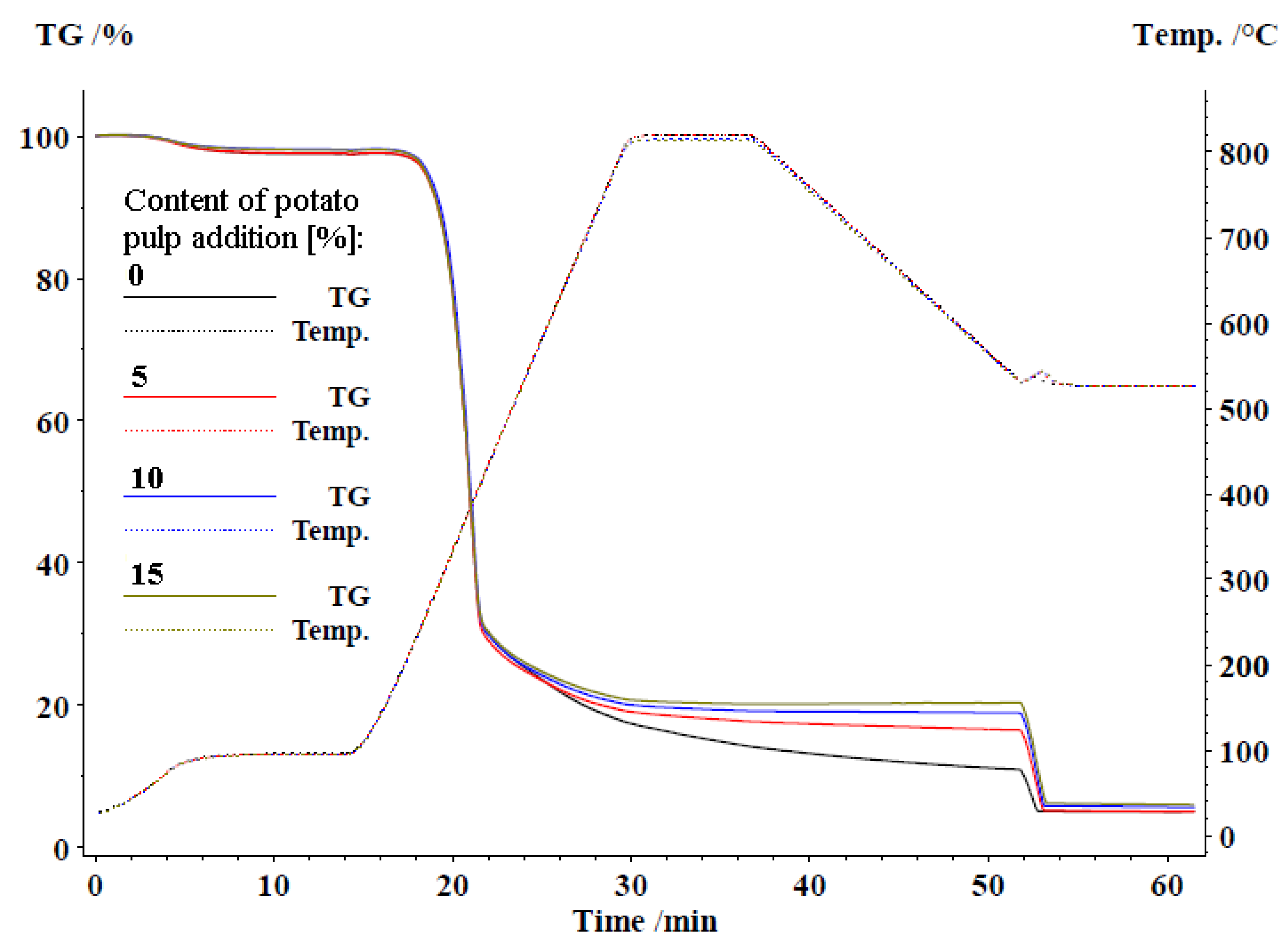

3.11. Thermogravimetric Analysis

3.12. Exhaust Composition during Combustion

4. Conclusions

- The use of potato pulp as an additive to wood sawdust, characterized by a granulometric composition with fine fractions below 0.5 mm and a mass fraction exceeding 50%, improves the conditions for the pelletization process. This reduces its energy demand by causing partial pressureless pelletization of the dusty fraction. It also reduces the risk of spontaneous combustion of this fraction.

- The addition of potato pulp has a very beneficial effect on reducing the power demand of the pelletizer during the pelleting, which is significantly lower than the demand in the case of pelleting sawdust alone. Increasing the potato pulp content in the sawdust mixture from 10 to 25% reduces the power demand of the pelletizer by approx. 20% (from 7.35 kW to 5.92 kW).

- The density values of pellets produced from a mixture of sawdust and potato pulp (over 1000 kg·m−3) with a 10% potato pulp content indicate that these pellets are of good market quality and represent a high-quality solid fuel. However, increasing the potato pulp content from 10% to 15% results in a decrease in pellet density from 1191.03 kg·m−3 (with a bulk density of 567.79 kg·m−3) to 428.08 kg·m−3 (with a bulk density of 275.95 kg·m−3).

- Increasing the potato pulp content in the sawdust mixture from 10 to 25% causes a significant decrease in the kinetic strength of the pellets, from 98.01% to approx. 24% for a potato pulp content of 25%.

- Increasing the potato pulp content from 0 to 25% causes a slight decrease in the heat of combustion (HHV), from 20.45 to 20.32 MJ·kg−1 (for the dry mass of sawdust and for the mixture, respectively), and the calorific value (LHV), from 19.02 to 18.83 MJ·kg−1 (for the dry mass of sawdust and for the mixture, respectively). This allows for the pellets to be used as an additive to sawdust in the production of fuel pellets.

- During the tests, a high content of volatile matter was found, i.e., above 77%. Fuels containing significant amounts of volatile matter (>60%) produce a long flame during combustion and require additional amounts of air for completely smokeless combustion.

- Thermogravimetric analysis showed a positive effect of potato pulp on the quality of the pellets, reducing their ignition temperature from 249.4 °C to 244.3 °C and the combustion temperature from 325.2 °C to 316.7 °C. The addition of potato pulp also resulted in an increase in the comprehensive combustion index by 0.14 × 10−5.

- The study on the combustion of pine sawdust pellets with the addition of potato pulp showed that an addition of up to 10% of potato pulp did not increase CO, CO2, and NOx. During the combustion of pellets containing 5 and 10% potato pulp, PM emissions also decreased; however, the increased emissions of this compound were identified during the combustion of pellets containing 15% potato pulp. This is directly related to the low kinetic durability of such pellets and their overall high ash content. A beneficial feature of the tested pellets is also low sulfur content, which translated into low SO2 emissions, below the detection level of the device.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GUS Central Statistical Office Energy from Renewable Sources in 2022. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/energia-ze-zrodel-odnawialnych-w-2022-roku,10,6.html (accessed on 9 July 2024).

- Križan, P.; Matú, M.; Šooš, Ľ.; Beniak, J. Behavior of Beech Sawdust during Densification into a Solid Biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef]

- Gilbert, P.; Ryu, C.; Sharifi, V.; Swithenbank, J. Effect of Process Parameters on Pelletisation of Herbaceous Crops. Fuel 2009, 88, 1491–1497. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent Developments in Biomass Pelletization-a Review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Azargohar, R.; Nanda, S.; Dalai, A.K. Densification of Agricultural Wastes and Forest Residues: A Review on Influential Parameters and Treatments. In Recent Advancements in Biofuels and Bioenergy Utilization; Sarangi, P.K., Nanda, S., Mohanty, P., Eds.; Springer: Singapore, 2018; pp. 27–51. ISBN 9789811313066. [Google Scholar]

- Peng, J.; Bi, X.T.; Lim, C.J.; Peng, H.; Kim, C.S.; Jia, D.; Zuo, H. Sawdust as an Effective Binder for Making Torrefied Pellets. Appl. Energy 2015, 157, 491–498. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S. Effect of used cooking oil additive on sewage sludge combustion. Przem. Chem. 2017, 96, 1848–1851. [Google Scholar]

- Obidziński, S.; Dołżyńska, M. Study of the Grain Waste Thickening Process. Przemysł Chem. 2017, 96, 1000–1003. [Google Scholar]

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Piekut, J.; Czerniawski, S.; Sobczak, P. Investigation of Pelleting Process of Hemp Waste with Potato Pulp. Carpathian J. Food Sci. Technol. 2018, 10, 53–64. [Google Scholar]

- Yub Harun, N.; Parvez, A.M.; Afzal, M.T. Process and Energy Analysis of Pelleting Agricultural and Woody Biomass Blends. Sustainability 2018, 10, 1770. [Google Scholar] [CrossRef]

- Gheorghe, D.; Neacsu, A. The Influence of Additives Upon the Energetic Parameters and Physicochemical Properties of Environmentally Friendly Biomass Pellets. J. Mex. Chem. Soc. 2024, 68, 438–454. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Abdulsalam, I.A.; Ola, F.A.; Akande, F.B.; Orisaleye, J.I. Effects of Binders and Die Geometry on Quality of Densified Rice Bran Using a Screw-Type Laboratory Scale Pelleting Machine. Energy Nexus 2024, 13, 100275. [Google Scholar] [CrossRef]

- Kumar, P.; Fiori, L.; Subbarao, P.M.V.; Vijay, V.K. Development of an Efficient Method to Blend Forest Biomass with Agricultural Residue to Produce Fuel Pellets with Improved Mechanical Properties. Biofuels 2024, 1–12. [Google Scholar] [CrossRef]

- Kamga, P.L.W.; Vitoussia, T.; Bissoue, A.N.; Nguimbous, E.N.; Dieudjio, D.N.; Bot, B.V.; Njeugna, E. Physical and Energetic Characteristics of Pellets Produced from Movingui Sawdust, Corn Spathes, and Coconut Shells. Energy Rep. 2024, 11, 1291–1301. [Google Scholar] [CrossRef]

- Nie, Y.; Song, X.; Shan, M.; Yang, X. Effect of Pelletization on Biomass Thermal Degradation in Combustion: A Case Study of Peanut Shell and Wood Sawdust Using Macro-TGA. Energy Built Environ. 2024; in press. [Google Scholar] [CrossRef]

- Woo, D.-G.; Kim, S.H.; Kim, T.H. Solid Fuel Characteristics of Pellets Comprising Spent Coffee Grounds and Wood Powder. Energies 2021, 14, 371. [Google Scholar] [CrossRef]

- Abedi, A.; Cheng, H.; Dalai, A.K. Effects of Natural Additives on the Properties of Sawdust Fuel Pellets. Energy Fuels 2018, 32, 1863–1873. [Google Scholar] [CrossRef]

- Stulpinaite, U.; Tilvikiene, V.; Zvicevicius, E. Co-Pelletization of Hemp Residues and Agricultural Biomass: Effect on Pellet Quality and Stability. Energies 2023, 16, 5900. [Google Scholar] [CrossRef]

- Elniski, A.; Dongre, P.; Bujanovic, B.M. Lignin Use in Enhancing the Properties of Willow Pellets. Forests 2023, 14, 2041. [Google Scholar] [CrossRef]

- Sykorova, V.; Jezerska, L.; Sassmanova, V.; Honus, S.; Peikertova, P.; Kielar, J.; Zidek, M. Biomass Pellets with Organic Binders-before and after Torrefaction. Renew. Energy 2024, 221, 119771. [Google Scholar] [CrossRef]

- Kulig, R. The Effect of Pressure on Compaction Process Parameters of Milk Thistle Straw with Binder. J. Res. Appl. Agric. Eng. 2023, 68, 33–39. [Google Scholar] [CrossRef]

- Mack, R.; Schön, C.; Kuptz, D.; Hartmann, H.; Brunner, T.; Obernberger, I.; Behr, H.M. Influence of Wood Species and Additives on Emission Behavior of Wood Pellets in a Residential Pellet Stove and a Boiler. Biomass Conv. Bioref. 2023, 1–20. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of Briquette Binders and Briquetting Mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Dobrowolska, E. Properties of Pellets Made of Agglomerated Pine and Spruce Sawdust with the Addition of Wheat Bran. Ann. Wars. Univ. Life Sci.-SGGW. For. Wood Technol. 2023, 124, 5–15. [Google Scholar]

- Lykidis, C.; Kamperidou, V.; Mantanis, G.I. The Use of Black Pine Bark for Improving the Properties of Wood Pellets. Forests 2023, 14, 1069. [Google Scholar] [CrossRef]

- Obidziński, S. Evaluation of the energy properties of potato pulp. Postępy Tech. Przetwórstwa Spożywczego. 2010, 1, 58–62. [Google Scholar]

- Gumul, D.; Ziobro, R.; Korus, J.; Surma, M. Pulp from Colored Potatoes (Solanum tuberosum L.) as an Ingredient Enriching Dessert Cookies. Foods 2023, 12, 3735. [Google Scholar] [CrossRef] [PubMed]

- Trabert, A.; Schmid, V.; Keller, J.; Emin, M.A.; Bunzel, M. Chemical Composition and Technofunctional Properties of Carrot (Daucus carota L.) Pomace and Potato (Solanum tuberosum L.) Pulp as Affected by Thermomechanical Treatment. Eur. Food Res. Technol. 2022, 248, 2451–2470. [Google Scholar] [CrossRef]

- Sip, A.; Thanh-Blicharz, L.; Siergiej, K.; Lesiecki, M.; Lewandowicz, G. The Influence of the Addition of Used Cooking Oil on the Effects of Sewage Sludge Combustion. Postępy Nauk. Technol. Przemysłu Rolno-Spożywczego 2016, 71, 65–80. [Google Scholar]

- Muter, O.; Pogulis, A.; Grube, M.; Gavare, M.; Berzins, A.; Strikauska, S.; Hansons, U.; Hansons, A. Potato Pulp as a Composting Substrate. Zemdirb.-Agric. 2014, 101, 57–66. [Google Scholar] [CrossRef][Green Version]

- Priyanga, K.; Reji, A.; Bhagat, J.K.; Anbuselvi, S. Production of Organic Manure from Potato Peel Waste. Int. J. Chem. Tech. Res. 2016, 9, 845–847. [Google Scholar]

- Maske, N.S.; Satyanarayan, S. Effect of Special Fish Feed Prepared Using Potato Peels on Fresh Water Fish Labeo Rohita. J. Indus. Pollut. Control 2012, 29, 33–38. [Google Scholar]

- Ncobela, C.N.; Kanengoni, A.T.; Hlatini, V.A.; Thomas, R.S.; Chimonyo, M. A Review of the Utility of Potato by-Products as a Feed Resource for Smallholder Pig Production. Anim. Feed Sci. Technol. 2017, 227, 107–117. [Google Scholar] [CrossRef]

- Bengtsson, H.; Montelius, C.; Tornberg, E. Heat-Treated and Homogenised Potato Pulp Suspensions as Additives in Low-Fat Sausages. Meat Sci. 2011, 88, 75–81. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Zhang, M.; Dong, S.; Guo, P.; Li, H. Impact of Potato Pulp on the Processing Characteristics and Gluten Structures of Wheat Flour Dough. J. Food Process Preserv. 2020, 44, e14473. [Google Scholar] [CrossRef]

- Kurnik, K.; Treder, K.; Twarużek, M.; Grajewski, J.; Tretyn, A.; Tyburski, J. Potato Pulp as the Peroxidase Source for 2,4-Dichlorophenol Removal. Waste Biomass Valor. 2018, 9, 1061–1071. [Google Scholar] [CrossRef]

- Patelski, P.; Berłowska, J.; Balcerek, M.; Dziekońska-Kubczak, U.; Pielech-Przybylska, K.; Dygas, D.; Jędrasik, J. Conversion of Potato Industry Waste into Fodder Yeast Biomass. Processes 2020, 8, 453. [Google Scholar] [CrossRef]

- Chen, D.; Lawton, D.; Thompson, M.R.; Liu, Q. Biocomposites Reinforced with Cellulose Nanocrystals Derived from Potato Peel Waste. Carbohydr. Polym. 2012, 90, 709–716. [Google Scholar] [CrossRef] [PubMed]

- Righetti, M.C.; Cinelli, P.; Mallegni, N.; Massa, C.A.; Aliotta, L.; Lazzeri, A. Thermal, Mechanical, Viscoelastic and Morphological Properties of Poly (Lactic Acid) Based Biocomposites with Potato Pulp Powder Treated with Waxes. Materials 2019, 12, 990. [Google Scholar] [CrossRef] [PubMed]

- Raigond, P.; Raigond, B.; Kochhar, T.; Sood, A.; Singh, B. Conversion of Potato Starch and Peel Waste to High Value Nanocrystals. Potato Res. 2018, 61, 341–351. [Google Scholar] [CrossRef]

- Olad, A.; Doustdar, F.; Gharekhani, H. Fabrication and Characterization of a Starch-Based Superabsorbent Hydrogel Composite Reinforced with Cellulose Nanocrystals from Potato Peel Waste. Colloids Surf. A Physicochem. Eng. Asp. 2020, 601, 124962. [Google Scholar] [CrossRef]

- Liang, S.; McDonald, A.G.; Coats, E.R. Lactic Acid Production with Undefined Mixed Culture Fermentation of Potato Peel Waste. Waste Manag. 2014, 34, 2022–2027. [Google Scholar] [CrossRef]

- Cheng, L.; Hu, X.; Gu, Z.; Hong, Y.; Li, Z.; Li, C. Characterization of Physicochemical Properties of Cellulose from Potato Pulp and Their Effects on Enzymatic Hydrolysis by Cellulase. Int. J. Biol. Macromol. 2019, 131, 564–571. [Google Scholar] [CrossRef] [PubMed]

- Mayer, F. Potato Pulp: Agricultural Waste with Technical Potential. Net. J. Agric. Sci. 2016, 4, 56–57. [Google Scholar]

- Sheikh, A.Y.; Sandeep, N.M. Sustainable Low-Thermal Pretreatment Enhances Substrate Solubilization and Biogas Production: A Case Study with Potato Peel Waste. Int. J. Innov. Eng. Technol. 2019, 12, 31–38. [Google Scholar]

- Chen, M.; Liu, S.; Yuan, X.; Li, Q.X.; Wang, F.; Xin, F.; Wen, B. Methane Production and Characteristics of the Microbial Community in the Co-Digestion of Potato Pulp Waste and Dairy Manure Amended with Biochar. Renew. Energy 2021, 163, 357–367. [Google Scholar] [CrossRef]

- Awogbemi, O.; Kallon, D.V.V.; Owoputi, A.O. Biofuel Generation from Potato Peel Waste: Current State and Prospects. Recycling 2022, 7, 23. [Google Scholar] [CrossRef]

- Galhano dos Santos, R.; Ventura, P.; Bordado, J.C.; Mateus, M.M. Direct and Efficient Liquefaction of Potato Peel into Bio-Oil. Environ. Chem. Lett. 2017, 15, 453–458. [Google Scholar] [CrossRef]

- Atitallah, I.B.; Antonopoulou, G.; Ntaikou, I.; Alexandropoulou, M.; Nasri, M.; Mechichi, T.; Lyberatos, G. On the Evaluation of Different Saccharification Schemes for Enhanced Bioethanol Production from Potato Peels Waste via a Newly Isolated Yeast Strain of Wickerhamomyces Anomalus. Bioresour. Technol. 2019, 289, 121614. [Google Scholar] [CrossRef]

- Soltaninejad, A.; Jazini, M.; Karimi, K. Sustainable Bioconversion of Potato Peel Wastes into Ethanol and Biogas Using Organosolv Pretreatment. Chemosphere 2022, 291, 133003. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Mei, X.; Liang, Q.; Wu, D.; Ren, N.; Xing, D. Biological Degradation of Potato Pulp Waste and Microbial Community Structure in Microbial Fuel Cells. RSC Adv. 2017, 7, 8376–8380. [Google Scholar] [CrossRef]

- Obidziñski, S. Pelletization of Biomass Waste with Potato Pulp Content. Int. Agrophysics 2014, 28, 85–91. [Google Scholar] [CrossRef][Green Version]

- PN-EN ISO 18134-1:2015-11; Solid Biofuels—Determination of Moisture Content—Drying Method—Part 1: Total Mois-Ture—Reference Method. ISO: Geneva, Switzerland, 2015.

- PN-EN ISO 17828:2016-02; Solid Biofuels—Determination of Bulk Density. ISO: Geneva, Switzerland, 2016.

- PN–R–64798:2009; Feed—Determination of Fineness. Polski Komitet Normalizacyjny: Warsaw, Poland, 2009.

- PN-EN ISO 16948:2015-07; Solid Biofuels—Determination of Total Carbon, Hydrogen and Nitrogen Content. ISO: Geneva, Switzerland, 2015.

- PN-EN ISO 16994:2016-10; Solid Biofuels—Determination of Total Sulfur and Chlorine Content. ISO: Geneva, Switzerland, 2016.

- Obidziński, S.; Dołżyńska, M.; Kowczyk-Sadowy, M.; Jadwisieńczak, K.; Sobczak, P. Densification and Fuel Properties of Onion Husks. Energies 2019, 12, 4687. [Google Scholar] [CrossRef]

- PN-EN ISO 17225-1:2021-11; Solid Biofuels—Fuel Specifications and Grades—Part 1: General Requirements. ISO: Geneva, Switzerland, 2021.

- PN-EN ISO 1928:2002; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method, and Calculation of Net Calorific Value. ISO: Geneva, Switzerland, 2002.

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Sienkiewicz, A.; Krasowska, M.; Szyszlak-Bargłowicz, J.; Zając, G.; Kryński, R. Effect of the Addition of Elderberry Waste to Sawdust on the Process of Pelletization and the Quality of Fuel Pellets. Energies 2024, 17, 1508. [Google Scholar] [CrossRef]

- PN-EN ISO 17831-1:2016-02; Solid Biofuels—Determination of Mechanical Durability of Pellets and Briquettes. ISO: Geneva, Switzerland, 2016.

- PN-EN ISO 18134-3:2023-12; Solid Biofuels—Determination of Moisture Content—Part 3: Moisture in the Sample for General Analysis. ISO: Geneva, Switzerland, 2023.

- PN-EN ISO 18123:2023-10; Solid Biofuels—Determination of Volatile Parts. ISO: Geneva, Switzerland, 2023.

- PN-EN ISO 18122:2023-05; Solid Biofuels—Determination of Ash Content. ISO: Geneva, Switzerland, 2023.

- Jia, G. Combustion Characteristics and Kinetic Analysis of Biomass Pellet Fuel Using Thermogravimetric Analysis. Processes 2021, 9, 868. [Google Scholar] [CrossRef]

- Jezerska, L.; Zajonc, O.; Rozbroj, J.; Vyletělek, J.; Zegzulka, J. Research on Effect of Spruce Sawdust with Added Starch on Flowability and Pelletization of the Material. IERI Procedia 2014, 8, 154–163. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Stasiełuk, W. Production of Fuel Pellets from a Mixture of Sawdust and Rye Bran. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012073. [Google Scholar] [CrossRef]

- Dawood, S.; Sen, T.K.; Phan, C. Synthesis and Characterisation of Novel-Activated Carbon from Waste Biomass Pine Cone and Its Application in the Removal of Congo Red Dye from Aqueous Solution by Adsorption. Water Air Soil. Pollut. 2013, 225, 1818. [Google Scholar] [CrossRef]

- Ward, J.; Rasul, M.G.; Bhuiya, M.M.K. Energy Recovery from Biomass by Fast Pyrolysis. Procedia Eng. 2014, 90, 669–674. [Google Scholar] [CrossRef]

- Dąbrowska, W.; Gargol, M.; Gil-Kowalczyk, M.; Nowicki, P. The Influence of Oxidation and Nitrogenation on the Physicochemical Properties and Sorption Capacity of Activated Biocarbons Prepared from the Elderberry Inflorescence. Molecules 2023, 28, 5508. [Google Scholar] [CrossRef]

- Zhang, J.; Zeng, G.; Chen, Y.; Yu, M.; Yu, Z.; Li, H.; Yu, Y.; Huang, H. Effects of Physico-Chemical Parameters on the Bacterial and Fungal Communities during Agricultural Waste Composting. Bioresour. Technol. 2011, 102, 2950–2956. [Google Scholar] [CrossRef]

- Butler, E.; Devlin, G.; Meier, D.; McDonnell, K. Characterisation of Spruce, Salix, Miscanthus and Wheat Straw for Pyrolysis Applications. Bioresour. Technol. 2013, 131, 202–209. [Google Scholar] [CrossRef]

- Kumar, N.S.; Asif, M.; Al-Hazzaa, M.I. Adsorptive Removal of Phenolic Compounds from Aqueous Solutions Using Pine Cone Biomass: Kinetics and Equilibrium Studies. Environ. Sci. Pollut. Res. 2018, 25, 21949–21960. [Google Scholar] [CrossRef] [PubMed]

- Khalili, S.; Khoshandam, B.; Jahanshahi, M. A Comparative Study of CO2 and CH4 Adsorption Using Activated Carbon Prepared from Pine Cone by Phosphoric Acid Activation. Korean J. Chem. Eng. 2016, 33, 2943–2952. [Google Scholar] [CrossRef]

- Kot, A.M.; Pobiega, K.; Piwowarek, K.; Kieliszek, M.; Błażejak, S.; Gniewosz, M.; Lipińska, E. Biotechnological Methods of Management and Utilization of Potato Industry Waste—A Review. Potato Res. 2020, 63, 431–447. [Google Scholar] [CrossRef]

- Grzybek, A. Biomasa Jako Źródło Energii. W: Wierzba Energetyczna–Uprawa Technol. Przetwarz. 2004, 35, 10–19. [Google Scholar]

- Kraszkiewicz, A.; Stryjecka, M.; Nowosad, N.; Kocira, S. The Influence of the Addition of Used Cooking Oil on the Effects of Sewage Sludge Combustion. Rocz. Ochr. Sr. 2018, 20, 1269–1285. [Google Scholar]

- Mediavilla, I.; Esteban, L.S.; Fernández, M.J. Optimisation of Pelletisation Conditions for Poplar Energy Crop. Fuel Process. Technol. 2012, 104, 7–15. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Núñez-Retana, V.D.; Rosales-Serna, R.; Prieto-Ruíz, J.Á.; Wehenkel, C.; Carrillo-Parra, A. Improving the Physical, Mechanical and Energetic Properties of Quercus Spp. Wood Pellets by Adding Pine Sawdust. PeerJ 2020, 8, e9766. [Google Scholar] [CrossRef] [PubMed]

- Souček, J.; Jasinskas, A. Assessment of the Use of Potatoes as a Binder in Flax Heating Pellets. Sustainability 2020, 12, 10481. [Google Scholar] [CrossRef]

- Cui, X.; Yang, J.; Shi, X.; Lei, W.; Huang, T.; Bai, C. Experimental Investigation on the Energy Consumption, Physical, and Thermal Properties of a Novel Pellet Fuel Made from Wood Residues with Microalgae as a Binder. Energies 2019, 12, 3425. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G.; Vieira, F.H.A.; de Paula Protásio, T. Assessment of Plant Biomass for Pellet Production Using Multivariate Statistics (PCA and HCA). Renew. Energy 2019, 139, 796–805. [Google Scholar] [CrossRef]

- Obidziński, S.; Szyszlak-Bargłowicz, J.; Zając, G.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Cwalina, P.; Faszczewski, D.; Wasilewski, J. The Effect of Bakery Waste Addition on Pine Sawdust Pelletization and Pellet Quality. Energies 2024, 17, 523. [Google Scholar] [CrossRef]

- Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Krasowska, M.; Sienkiewicz, A.; Faszczewski, D.; Szyszlak-Bargłowicz, J. The Use of Bread Bakery Waste as a Binder Additive in the Production of Fuel Pellets from Straw. Energies 2023, 16, 7313. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Słowik, T.; Zając, G.; Blicharz-Kania, A.; Zdybel, B.; Andrejko, D.; Obidziński, S. Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process. Energies 2021, 14, 4167. [Google Scholar] [CrossRef]

- Da Silva, S.B.; Arantes, M.D.C.; de Andrade, J.K.B.; Andrade, C.R.; Carneiro, A.d.C.O.; de Paula Protásio, T. Influence of Physical and Chemical Compositions on the Properties and Energy Use of Lignocellulosic Biomass Pellets in Brazil. Renew. Energy 2020, 147, 1870–1879. [Google Scholar] [CrossRef]

- Liu, Z.; Mi, B.; Jiang, Z.; Fei, B.; Cai, Z. Improved Bulk Density of Bamboo Pellets as Biomass for Energy Production. Renew. Energy 2016, 86, 1–7. [Google Scholar] [CrossRef]

- Kocabaş-Ataklı, Z.Ö.; Okyay-Öner, F.; Yürüm, Y. Combustion Characteristics of Turkish Hazelnut Shell Biomass, Lignite Coal, and Their Respective Blends via Thermogravimetric Analysis. J. Therm. Anal. Calorim. 2015, 119, 1723–1729. [Google Scholar] [CrossRef]

- Nath, B.; Chen, G.; Bowtell, L.; Graham, E. An Investigation of Thermal Decomposition Behavior and Combustion Parameter of Pellets from Wheat Straw and Additive Blends by Thermogravimetric Analysis. Int. J. Thermofluids 2024, 22, 100660. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.; Cai, H.; Gao, F. Study of Combustion Characteristics and Kinetics of Agriculture Briquette Using Thermogravimetric Analysis. ACS Omega 2021, 6, 15827–15833. [Google Scholar] [CrossRef]

- Guo, F.; He, Y.; Hassanpour, A.; Gardy, J.; Zhong, Z. Thermogravimetric Analysis on the Co-Combustion of Biomass Pellets with Lignite and Bituminous Coal. Energy 2020, 197, 117147. [Google Scholar] [CrossRef]

- Sippula, O.; Hytönen, K.; Tissari, J.; Raunemaa, T.; Jokiniemi, J. Effect of Wood Fuel on the Emissions from a Top-Feed Pellet Stove. Energy Fuels 2007, 21, 1151–1160. [Google Scholar] [CrossRef]

- Kordylewski, W.; Bulewicz, E.M.; Dyjakon, A.; Hardy, T.; Słupek, S.; Miller, R.; Wanik, A. Spalanie i Paliwa; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2008; ISBN 83-7493-378-X. [Google Scholar]

- Juszczak, M. Ecological Burning Waste Wood; Industrial research limit of carbon monoxide and nitrogen oxide; Poznań Wyd. Pol. Poznańskiej: Poznań, Poland, 2002. [Google Scholar]

- Schmidt, G.; Trouvé, G.; Leyssens, G.; Schönnenbeck, C.; Genevray, P.; Cazier, F.; Dewaele, D.; Vandenbilcke, C.; Faivre, E.; Denance, Y. Wood Washing: Influence on Gaseous and Particulate Emissions during Wood Combustion in a Domestic Pellet Stove. Fuel Process. Technol. 2018, 174, 104–117. [Google Scholar] [CrossRef]

- Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T. Testing the Emission of Selected Gas Pollutants during the Combustion of Agro Biomass Pellets in a Low Power Boiler. Rocz. Ochr. Sr. 2017, 19, 715–730. [Google Scholar]

- Zajac, G.; Szyszlak-Barglowicz, J.; Slowik, T.; Wasilewski, J.; Kuranc, A. Emission Characteristics of Biomass Combustion in a Domestic Heating Boiler Fed with Wood and Virginia Mallow Pellets. Fresenius Environ. Bull. 2017, 26, 4663–4670. [Google Scholar]

- Szyszlak-Bargłowicz, J.; Wasilewski, J.; Zając, G.; Kuranc, A.; Koniuszy, A.; Hawrot-Paw, M. Evaluation of Particulate Matter (PM) Emissions from Combustion of Selected Types of Rapeseed Biofuels. Energies 2022, 16, 239. [Google Scholar] [CrossRef]

- Wasilewski, J.; Zając, G.; Szyszlak-Bargłowicz, J.; Kuranc, A. Evaluation of Greenhouse Gas Emission Levels during the Combustion of Selected Types of Agricultural Biomass. Energies 2022, 15, 7335. [Google Scholar] [CrossRef]

- Perez-Jimenez, J.A. Gaseous Emissions from the Combustion of Biomass Pellets. Biomass Pelletization Stand. Prod. 2015, 2, 85. [Google Scholar]

- Lamberg, H.; Tissari, J.; Jokiniemi, J.; Sippula, O. Fine Particle and Gaseous Emissions from a Small-Scale Boiler Fueled by Pellets of Various Raw Materials. Energy Fuels 2013, 27, 7044–7053. [Google Scholar] [CrossRef]

| Raw Material | Moisture ± SD [%] |

|---|---|

| Potato pulp | 85.08 ± 0.34 |

| Pine sawdust | 6.88 ± 0.22 |

| Potato Pulp Content [%] | Moisture Content of the Mixture [%] |

|---|---|

| 10 | 11.72 ± 0.20 |

| 15 | 17.90 ± 0.22 |

| 20 | 21.72 ± 0.18 |

| 25 | 26.54 ± 0.24 |

| Raw Materials | Medium Bulk Density ± SD [kg·m−3] |

|---|---|

| Pine sawdust | 105.17 ± 1.39 |

| Potato pulp | 534.92 ± 4.27 |

| Raw Material | C ± SD [%] | H ± SD [%] | N ± SD [%] | S ± SD [%] | Cl ± SD [%] |

|---|---|---|---|---|---|

| Pine sawdust | 47.54 ± 0.13 | 6.85 ± 0.04 | 0.11 ± 0.01 | 0.01 ± 0.001 | 0.0039 ± 0.0004 |

| Potato pulp | 40.82 ± 0.109 | 5.27 ± 0.03 | 0.12 ± 0.02 | 0.42 ± 0.001 | 0.0191 ± 0.0002 |

| Material | Content of Heavy Metals ± SD [mg∙kgd.m.−1] | ||||||

|---|---|---|---|---|---|---|---|

| Cr | Ni | Cu | Zn | As | Cd | Pb | |

| Pine sawdust | 2.45 ± 0.18 | 2.99 ± 0.04 | 5.42 ± 0.38 | 39.71 ± 1.40 | 0.11 ± 0.03 | x ≤ 0.05 | x ≤ 0.05 |

| Potato pulp | 0.00 | 1.33 ± 0.11 | 8.96 ± 0.32 | 28.57 ± 1.02 | 0.16 ± 0.04 | 1.08 ± 0.02 | 8.21 ± 0.44 |

| Pellets containing 10% Potato pulp | 2.21 ± 0.12 | 2.82 ± 0.12 | 5.77 ± 0.39 | 38.60 ± 1.19 | 0.12 ± 0.02 | 0.15 ± 0.01 | 0.87 ± 0.11 |

| Pellets containing 15% Potato pulp | 2.08 ± 0.11 | 2.74 ± 0.09 | 5.95 ± 0.33 | 38.04 ± 1.23 | 0.12 ± 0.03 | 0.20 ± 0.02 | 1.27 ± 0.06 |

| Pellets containing 20% Potato pulp | 1.96 ± 0.14 | 2.66 ± 0.10 | 6.13 ± 0.41 | 37.48 ± 1.28 | 0.12 ± 0.03 | 0.26 ± 0.02 | 1.68 ± 0.07 |

| Pellets containing 25% Potato pulp | 1.84 ± 0.13 | 2.58 ± 0.11 | 6.31 ± 0.38 | 36.93 ± 1.15 | 0.12 ± 0.03 | 0.31 ± 0.03 | 2.09 ± 0.05 |

| Content of Potato Pulp [%] | Moisture Content of Mixture before Combustion [%] | HHVar ± SD | HHVdry ± SD | LHVar ± SD | LHVdry ± SD |

|---|---|---|---|---|---|

| [MJ·kg−1] | |||||

| 0 | 4.78 | 19.471 ± 0.05 | 20.449 ± 0.04 | 17.919 ± 0.05 | 19.022 ± 0.04 |

| 25 | 9.46 | 18.398 ± 0.06 | 20.320 ± 0.03 | 16.813 ± 0.07 | 18.825 ± 0.08 |

| Content of Potato Pulp [%] | HHV [MJ·kg−1] | LHV [MJ∙kg−1] |

|---|---|---|

| For Dry Matter | For Dry Matter | |

| 0 | 20.449 | 19.022 |

| 5 | 20.424 | 18.983 |

| 10 | 20.398 | 18.943 |

| 15 | 20.373 | 18.904 |

| 20 | 20.347 | 18.864 |

| 25 | 20.320 | 18.825 |

| Potato Pulp Content [%] | Pellet Density [kg·m−3] | Bulk Density [kg·m−3] | Kinetic Strength [%] | |||

|---|---|---|---|---|---|---|

| Laboratory Conditions | Industrial Conditions | Laboratory Conditions | Industrial Conditions | Laboratory Conditions | Industrial Conditions | |

| 0 | - | 1212.24 | - | 709.12 | - | 85.62 |

| 5 | - | 1240.73 | - | 724.75 | - | 96.20 |

| 10 | 1191.03 | 1161.72 | 567.79 | 523.09 | 98.01 | 80.17 |

| 15 | 1109.63 | 535.04 | 501.28 | 329.00 | 93.28 | 30.74 |

| 20 | 627.03 | - | 339.52 | - | 34.50 | - |

| 25 | 428.08 | - | 275.95 | - | 24.29 | - |

| Indicator | Unit | Pellets Containing 0% Potato Pulp | Pellets Containing 5% Potato Pulp | Pellets Containing 10% Potato Pulp | Pellets Containing 15% Potato Pulp |

|---|---|---|---|---|---|

| HHV | [Wh·kg−1] | 5680 | 5673 | 5666 | 5659 |

| LHV | [Wh·kg−1] | 5284 | 5273 | 5262 | 5251 |

| Energy Consumption Unit (EU) | [Wh·kg−1] | 74.74 | 64.89 | 54.23 | 41.09 |

| Energy Yield of Pellets (EY) | [Wh·kg−1] | 5209 | 5208 | 5208 | 5210 |

| Energy Efficiency (EE) | [%] | 98.68 | 98.86 | 99.04 | 99.27 |

| Energy Density (ED) | [GJ·m−3] | 13.49 | 13.76 | 9.91 | 6.22 |

| Potato Pulp Content [%] | Analytical Moisture Content MC [%] | Volatile Matter Content VM [%] | Fixed Carbon Content FC [%] | Ash Content AC [%] |

|---|---|---|---|---|

| 0 | 2.57 | 80.2 | 12.2 | 5.03 |

| 5 | 2.45 | 79.8 | 12.71 | 5.04 |

| 10 | 1.95 | 78.86 | 13.55 | 5.64 |

| 15 | 2.02 | 77.83 | 14.17 | 5.98 |

| Combustion Characteristics | Pellets Containing 0% Potato Pulp | Pellets Containing 5% Potato Pulp | Pellets Containing 10% Potato Pulp | Pellets Containing 15% Potato Pulp |

|---|---|---|---|---|

| Ignition point Ti (°C) | 249.40 | 249.20 | 244.70 | 244.30 |

| Combustion temperature Tf (°C) | 325.20 | 319.20 | 317.70 | 316.70 |

| Maximum combustion rate (%·min−1) | 92.74 | 92.00 | 94.1 | 94.46 |

| Average combustion rate (%·min−1) | 24.32 | 26.43 | 25.31 | 25.41 |

| Comprehensive combustion index S (10−5) | 1.38 | 1.50 | 1.50 | 1.52 |

| Potato Pulp Content [%] | CO [mg·m−3] | NO [mg·m−3] | CO2 [%] | λ [-] | O₂ [%] | TS [°C] | PM [mg·m−3] |

|---|---|---|---|---|---|---|---|

| 0 | 311.86 | 86.55 | 5.71 | 3.34 | 15.06 | 108.1 | 17.5 |

| 5 | 298.47 | 66.76 | 4.94 | 3.81 | 15.85 | 112.2 | 16.7 |

| 10 | 282.49 | 69.82 | 4.69 | 3.99 | 16.11 | 112.4 | 16.8 |

| 15 | 273.95 | 66.92 | 4.14 | 4.46 | 16.68 | 112.2 | 19.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obidziński, S.; Cwalina, P.; Kowczyk-Sadowy, M.; Sienkiewicz, A.; Krasowska, M.; Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T.; Mazur, J.; Jankowski, M. Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition. Energies 2024, 17, 3960. https://doi.org/10.3390/en17163960

Obidziński S, Cwalina P, Kowczyk-Sadowy M, Sienkiewicz A, Krasowska M, Szyszlak-Bargłowicz J, Zając G, Słowik T, Mazur J, Jankowski M. Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition. Energies. 2024; 17(16):3960. https://doi.org/10.3390/en17163960

Chicago/Turabian StyleObidziński, Sławomir, Paweł Cwalina, Małgorzata Kowczyk-Sadowy, Aneta Sienkiewicz, Małgorzata Krasowska, Joanna Szyszlak-Bargłowicz, Grzegorz Zając, Tomasz Słowik, Jacek Mazur, and Marek Jankowski. 2024. "Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition" Energies 17, no. 16: 3960. https://doi.org/10.3390/en17163960

APA StyleObidziński, S., Cwalina, P., Kowczyk-Sadowy, M., Sienkiewicz, A., Krasowska, M., Szyszlak-Bargłowicz, J., Zając, G., Słowik, T., Mazur, J., & Jankowski, M. (2024). Physical and Energy Properties of Fuel Pellets Produced from Sawdust with Potato Pulp Addition. Energies, 17(16), 3960. https://doi.org/10.3390/en17163960