Effect of the Arc Extinguishing and Insulation Properties of C4F7N/CO2 Mixtures with Oxygen Addition: Experimental Investigations and Comparative Analysis

Abstract

1. Introduction

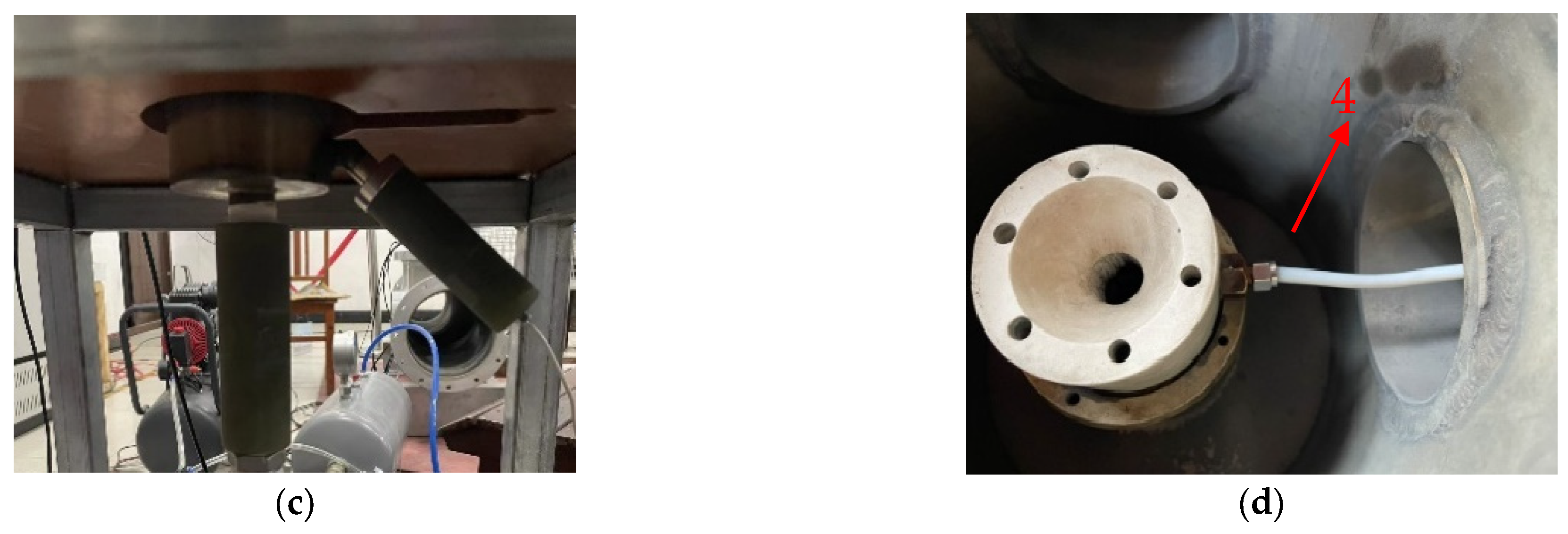

2. Experimental Methods

- (1)

- Rogowski coil: CWT150 (precision 0.1%, sensitivity 0.2 mV/A, conversion rate 40 kA/µs), utilized for measuring the arc current;

- (2)

- Differential probe: HT8100 (precision 2%, rise time 3.5 ns) used for measuring arc voltage;

- (3)

- Displacement sensor: Hermit (precision 0.1 mm) employed for tracking the trajectory of the upper electrode;

- (4)

- Pressure probe: 8530b–500 (precision 0.5%) for measuring dynamic pressure in the nozzle throat and gas storage chamber.

3. Results and Discussion

3.1. Study on Pressure Characteristics

3.2. Study on Arc Voltage and Current Characteristics

3.3. Thermal Interrupting Capability Assessment

3.4. Solid Product Analysis

4. Conclusions

- The arc in the C4F7N/CO2/O2 mixtures increases the pressure at the nozzle throat more than in the C4F7N/CO2 mixtures, suggesting that in practical circuit breakers, the arc in the C4F7N/CO2/O2 mixtures can more effectively block the nozzle throat, enhancing the blasting strength. Additionally, the flow rate of the C4F7N mixtures is higher than that of SF6, which in practical circuit breakers may lead to a rapid drop in the pressure of the interrupter chamber during the interrupting process, potentially failing to maintain sufficient blasting strength to assist in arc extinguishing at the current zero moment;

- Comparing the arc extinguishing voltage peaks and critical RRRV between C4F7N/CO2 and C4F7N/CO2/O2 mixtures reveals that there is no significant difference in the extinguishing voltage peaks, with the critical RRRV differing by only 0.02 kV/μs. This suggests that the addition of a small amount of oxygen has a minimal impact on the thermal recovery characteristics of the C4F7N/CO2 mixtures;

- After conducting breaking experiments in three different gases, a comparison of the solid residues inside the vessels reveals that the color of the product in the C4F7N/CO2/O2 mixtures is significantly lighter than that in the C4F7N/CO2 mixture. This indicates that oxygen effectively inhibits the deposition of carbon under the influence of an electric arc in fluorocarbon gases, thereby enhancing their insulation properties. Therefore, using the C4F7N/CO2/O2 mixtures as the filling medium for circuit breakers appears to be the better choice;

- To provide more comprehensive support for the design and optimization of new environmentally friendly circuit breaker structures and to more thoroughly evaluate the application prospects of the C4F7N mixtures, we plan to conduct experiments in our future work to measure the arc temperatures in different C4F7N mixtures and perform a more detailed analysis of the composition of solid products after the arc-firing tests.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schneider Electric. SF6 Properties and Use in MV and HV Switchgear. Cahiers Techniques. Available online: https://www.studiecd.dk/cahiers_techniques/SF6_properties.pdf (accessed on 15 August 2024).

- Gui, Z.W.; Li, Y. Challenges and proposals on SF6 emission reduction approaches. Sci. Total Environ. 2024, 906, 167347. [Google Scholar]

- Simmonds, P.G.; Rigby, M.; Manning, A.J.; Park, S.; Stanley, K.M.; McCulloch, A.; Henne, S.; Graziosi, F.; Maione, M.; Arduini, J.; et al. The increasing atmospheric burden of the greenhouse gas SF6. Atmos. Chem. Phys. 2020, 20, 7271–7290. [Google Scholar] [CrossRef]

- Beroual, A.; Haddad, A. Recent advances in the quest for a new insulation gas with a low impact on the environment to replace SF6 gas in high-voltage power network applications. Energies 2017, 8, 1216. [Google Scholar] [CrossRef]

- Reilly, J.; Prinn, R.; Harnisch, J. Multi-gas assessment of the Kyoto Protocol. Nature 1999, 401, 549–555. [Google Scholar] [CrossRef]

- Iwata, H.; Okada, K. Greenhouse gas emissions and the role of the Kyoto Protocol. Environ. Econ. Policy Stud. 2014, 16, 325–352. [Google Scholar] [CrossRef]

- Tian, S.; Liu, W.; Ding, J.; Liu, J.; Xu, Z.; Yuan, Z.; Zhang, W.; Rao, X.; Wan, Q.; Li, Y.; et al. Study on subacute inhalation toxicity and offspring teratogenicity of C4F7N: An environmentally friendly insulating gas to replace SF6. J. Clean. Prod. 2023, 387, 135799. [Google Scholar] [CrossRef]

- Li, X.; Liu, L.; Wang, W.; Geng, Z. Analysis of Breaking Characteristics of C4F7N/CO2 Mixture Gas in Circuit Breaker. Energies 2024, 17, 2638. [Google Scholar] [CrossRef]

- Ahmed, R.; Abd-Rahman, R.; Ullah, Z.; Ullah, R.; Sami, I.; Yousof, M.F. The Insulation Performance of Novel Refrigerant Gas as an Alternative to SF6 for Medium Voltage Switchgear. IEEE Access 2024, 12, 47068–47079. [Google Scholar] [CrossRef]

- Tian, S.; Yuan, Z.; Zhang, X.; Wang, Y.; Luo, W.; Liu, Y. Adsorption properties of envirormentally friendly insulating medium C4F7N and its common decomposition products in NaA, NaZSM-5, and NaX molecular sieves. High Volt. 2022, 8, 611–621. [Google Scholar] [CrossRef]

- Seeger, M.; Smeets, R.; Yan, J.; Ito, H.; Claessens, M.; Dullni, E.; Falkingham, L.; Franck, C.M.; Gentils, F.; Hartmann, W.; et al. Recent trends in development of high voltage circuit breakers with SF6 alternative gases. Plasma Phys. Technol. 2017, 4, 8–12. [Google Scholar] [CrossRef]

- Rabie, M.; Franck, C.M. An assessment of eco-friendly gases for electrical insulation to replace the most potent industrial greenhouse gas SF6. Environ. Sci. Technol. 2017, 52, 369–380. [Google Scholar] [CrossRef] [PubMed]

- Nechmi, H.E.; Beroual, A.; Girodet, A.; Vinson, P. Fluoronitriles/CO2 gas mixture as promising substitute to SF6 for insulation in high volt-age applications. IEEE Trans. Dielectr. Electr. Insul. 2016, 5, 2587–2593. [Google Scholar] [CrossRef]

- Kieffel, Y.; Biquez, F. SF6 alternative development for high voltage switchgears. In Proceedings of the 2015 IEEE Electrical Insulation Conference, Seattle, WA, USA, 7–10 June 2015. [Google Scholar]

- Kieffel, Y.; Irwin, T.; Ponchon, P.; Owens, J. Greengas to replace SF6 in electrical grids. IEEE Power Energy Mag. 2016, 14, 32–39. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Uzelac, H.; Cao, Y. Fluoronitrile/CO2 mixtures as an eco-friendly alternative to SF6 for medium voltage switchgears. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1340–1350. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, J.; Xu, J.; Zhong, J.; Song, Y.; Zhang, Y. Dynamic dielectric strength of C3F7CN/CO2 and C3F7CN/N2 gas mixtures in high voltage circuit breakers. IEEE Trans. Power Deliv. 2022, 37, 4032–4041. [Google Scholar] [CrossRef]

- Meyer, F.; Huguenot, F.; Kieffel, Y. Application of Fluoronitrile/CO2/O2 Mixtures in High Voltage Products to Lower the Environmental Footprint; CIGRE Reports; CIGRE: Paris, France, 2018. [Google Scholar]

- Na, J.Y.; Hwang, R.; Cho, S.J.; Song, T.H.; Lee, B.W. Breakdown Characteristics of a Fluoronitrile Mixture Gas According to Mixing Ratio and Oxygen Content for High-Voltage Power Equipment Application. IEEE Access 2024, 12, 16117–16126. [Google Scholar] [CrossRef]

- Yang, Y.; Gao, K.L.; Yuan, S.; Yan, X.L.; Bi, J.G. Study on the power frequency breakdown characteristics of C4F7N/CO2/O2 mixed gas under typical electric field. Trans. China Electrotech. Soc. 2022, 37, 4032–4041. [Google Scholar]

- Yang, Y.; Gao, K.L.; Wang, B.S.; Yan, X.L.; Cao, R.J.; Zhang, S.L. Decomposition characteristics of C4F7N/CO2/O2 mixtures by AC corona discharge. High Volt. Technol. 2023, 49, 955–961. [Google Scholar]

- Zhang, B.Y.; Zhou, R.; Hao, M.; Yang, T.; Li, X.W.; Jiang, X.; Zhu, K.; Deng, Y.K. Research on the application of C4F7N mixtures in 40.5 kV circuit breakers (Part 2): Arc extinguishing performance experiment and post-arc decomposition characteristics. Chin. Soc. Electr. Eng. 2022, 42, 9147–9159. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, D.; Li, X.; Wang, W.; Geng, Z. Effect of the Arc Extinguishing and Insulation Properties of C4F7N/CO2 Mixtures with Oxygen Addition: Experimental Investigations and Comparative Analysis. Energies 2024, 17, 4202. https://doi.org/10.3390/en17174202

Guo D, Li X, Wang W, Geng Z. Effect of the Arc Extinguishing and Insulation Properties of C4F7N/CO2 Mixtures with Oxygen Addition: Experimental Investigations and Comparative Analysis. Energies. 2024; 17(17):4202. https://doi.org/10.3390/en17174202

Chicago/Turabian StyleGuo, Dongyu, Xiaolong Li, Wen Wang, and Zhenxin Geng. 2024. "Effect of the Arc Extinguishing and Insulation Properties of C4F7N/CO2 Mixtures with Oxygen Addition: Experimental Investigations and Comparative Analysis" Energies 17, no. 17: 4202. https://doi.org/10.3390/en17174202

APA StyleGuo, D., Li, X., Wang, W., & Geng, Z. (2024). Effect of the Arc Extinguishing and Insulation Properties of C4F7N/CO2 Mixtures with Oxygen Addition: Experimental Investigations and Comparative Analysis. Energies, 17(17), 4202. https://doi.org/10.3390/en17174202