Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play—Technical Review and Machine Learning Study †

Abstract

1. Introduction

2. Technical Review of EOR Surveillance in the Bakken

2.1. Overview of EOR Pilot Tests

2.2. Case Study 1: CO2 Injectivity Test

- The BHP during continuous injection ranged from 9400 to 9470 psi.

- The maximum BHP was 9480 psi, which reactived natural fractures around the wellbore.

- The BHT ranged from 251° to 257 °F.

- The CO2 injection rate was stabilized between 6 and 12 gpm.

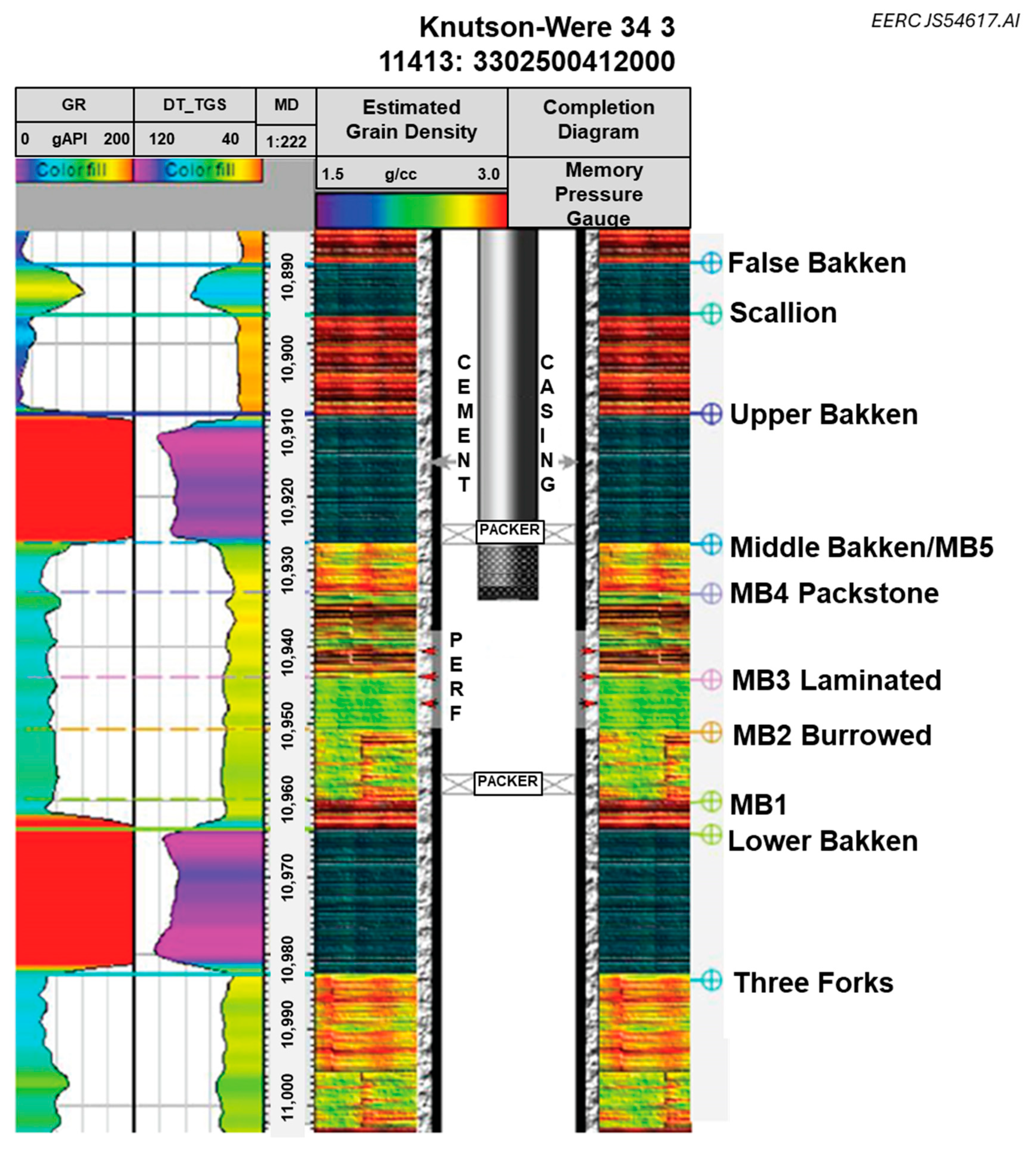

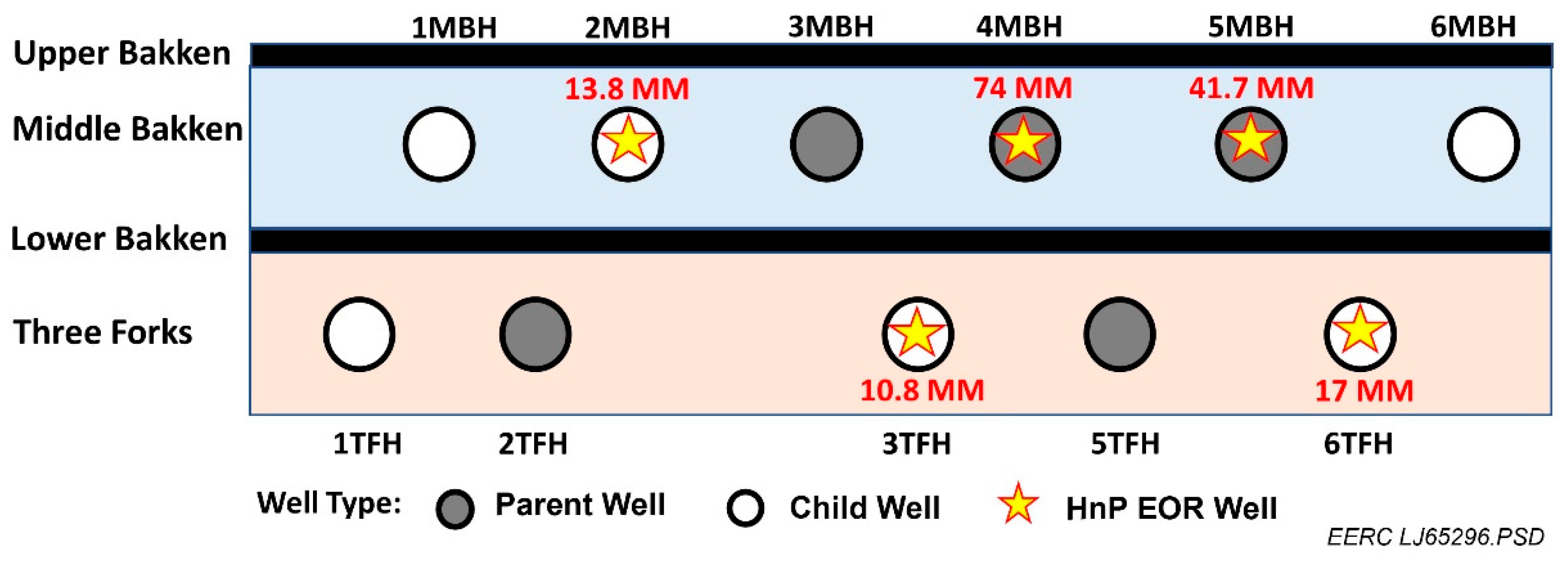

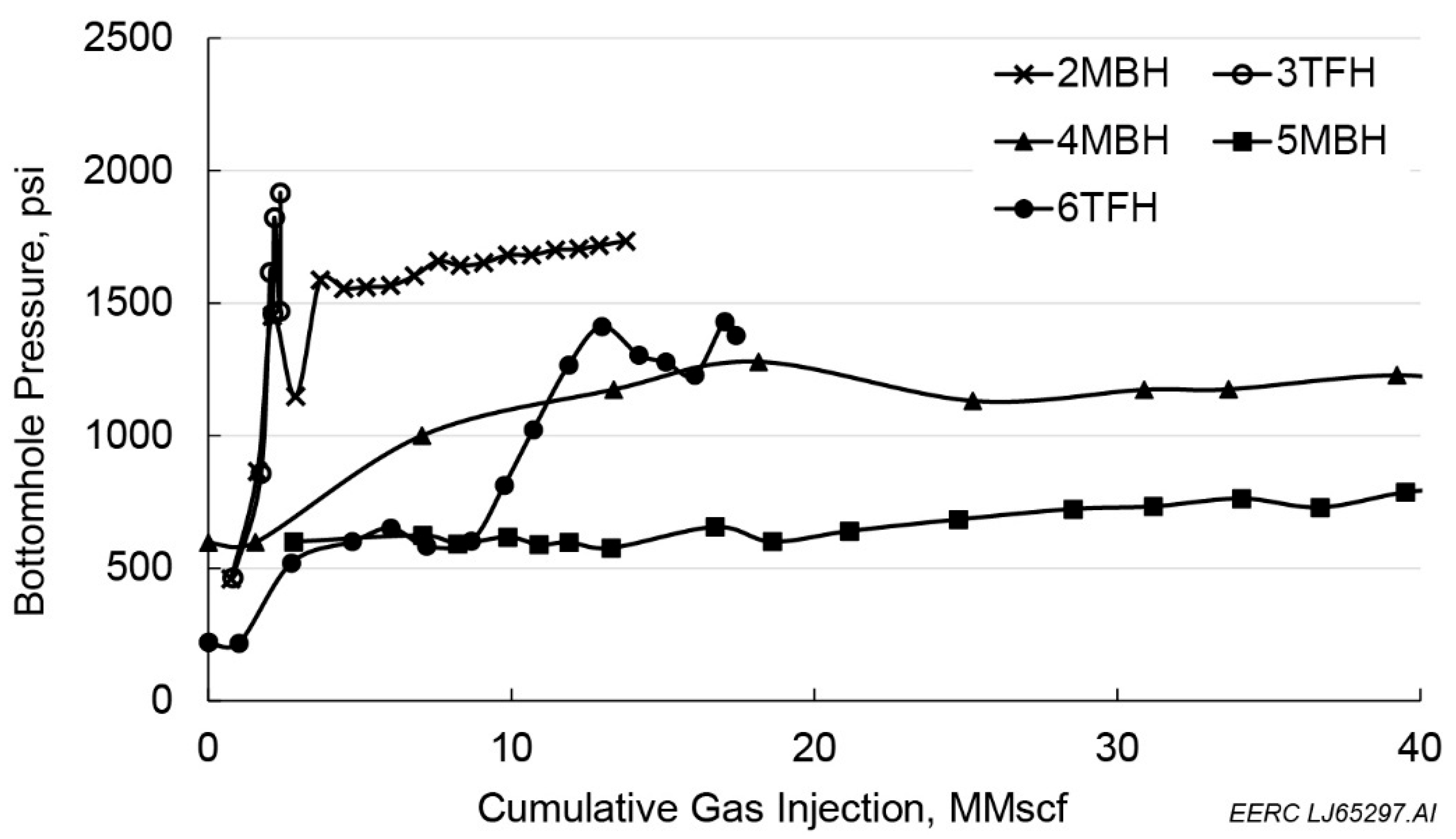

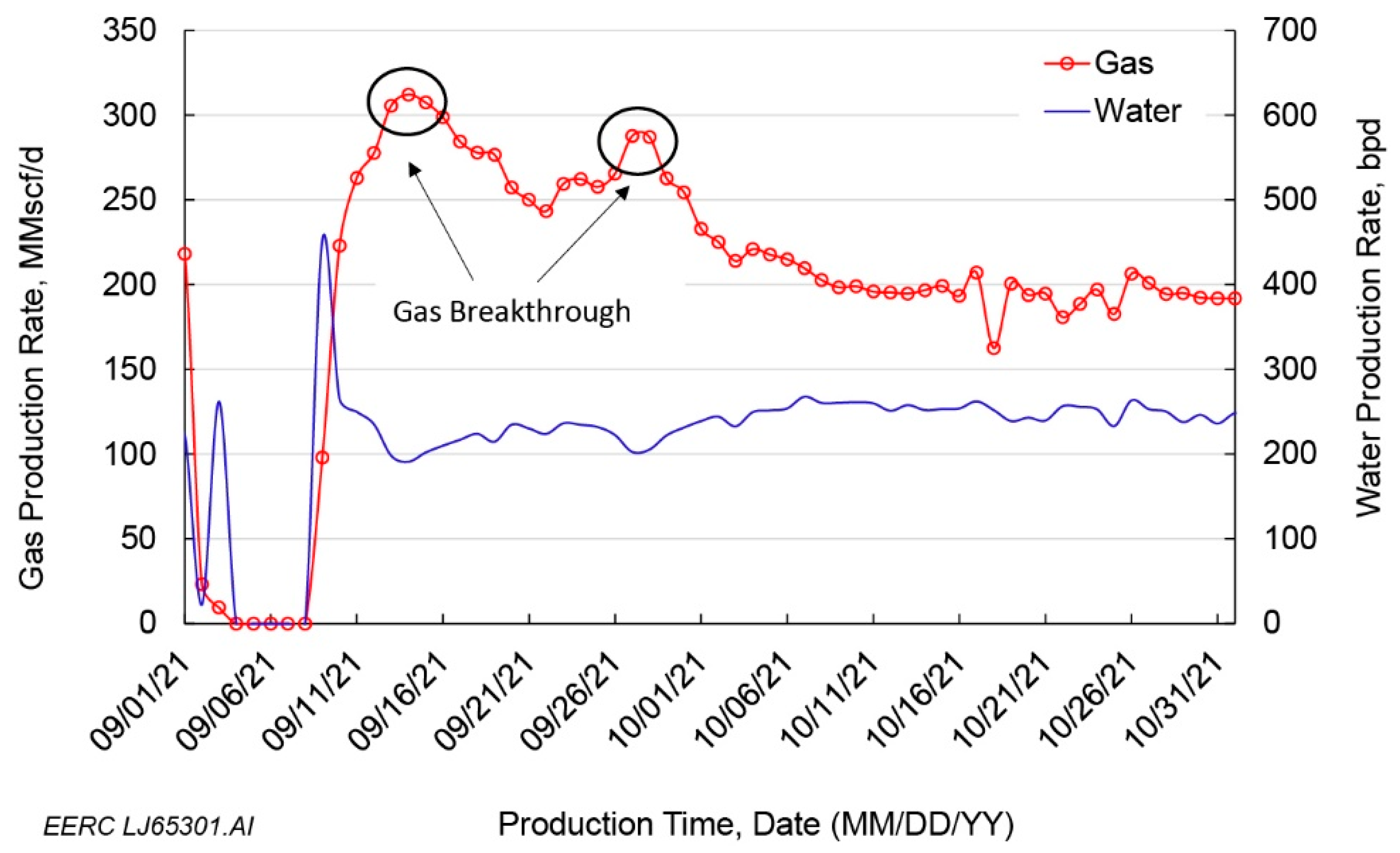

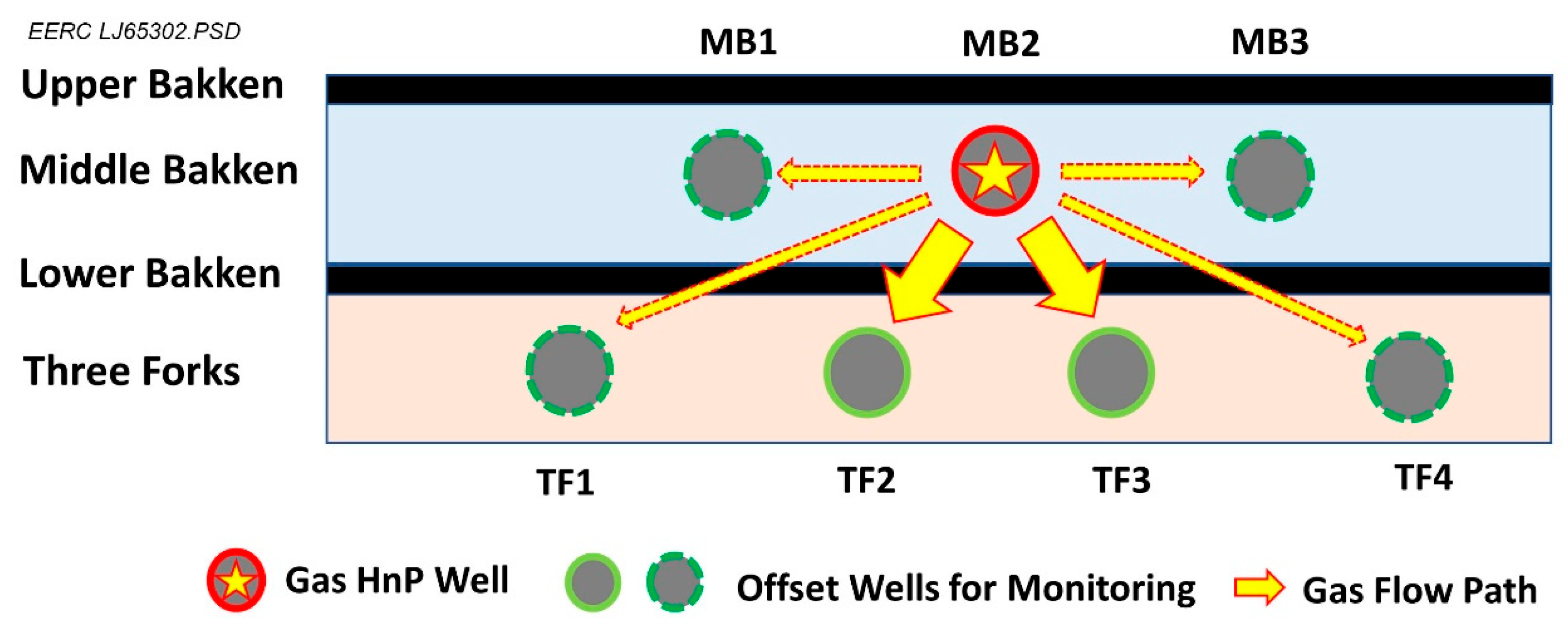

2.3. Case Study 2: Rich Gas HnP Test

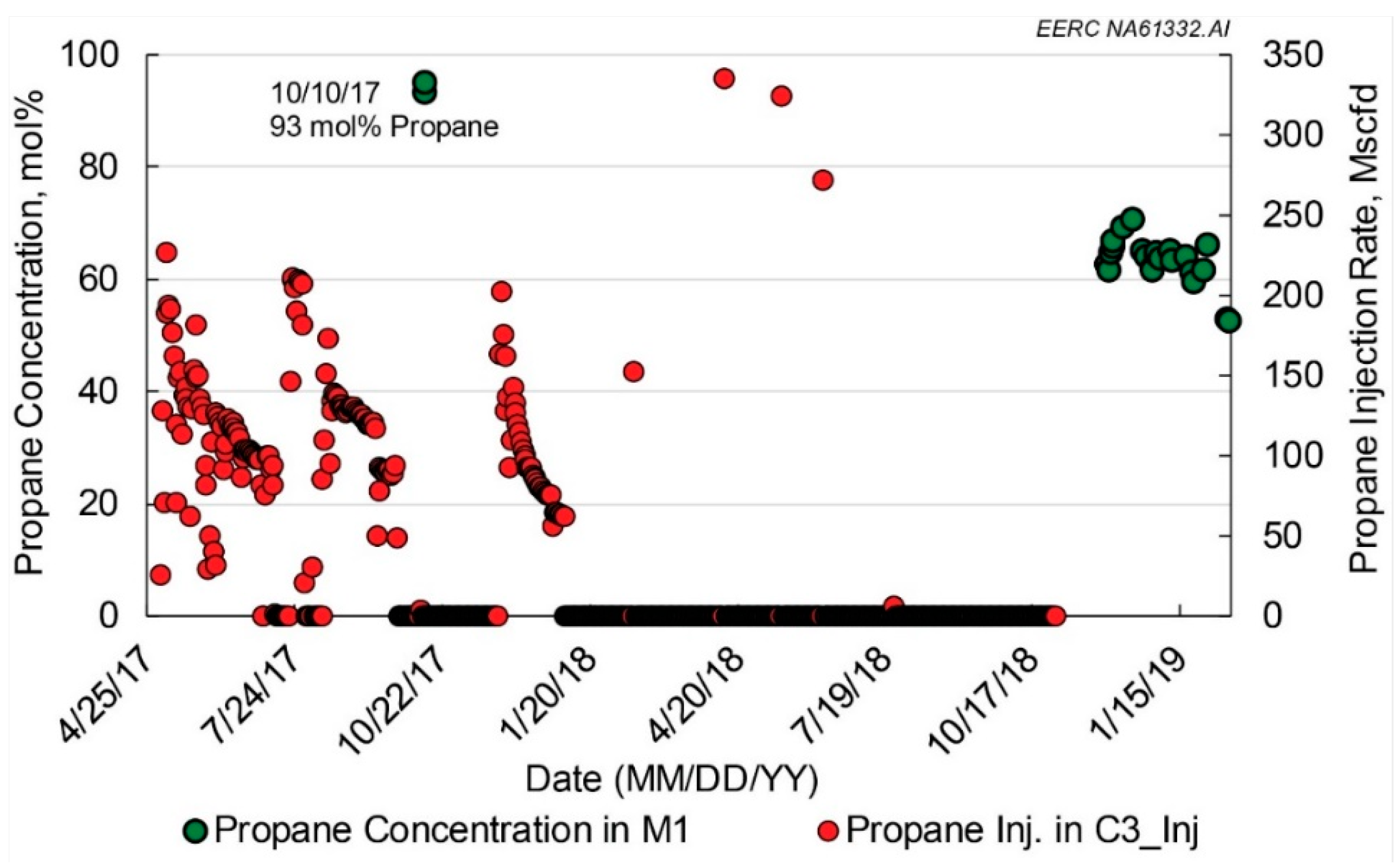

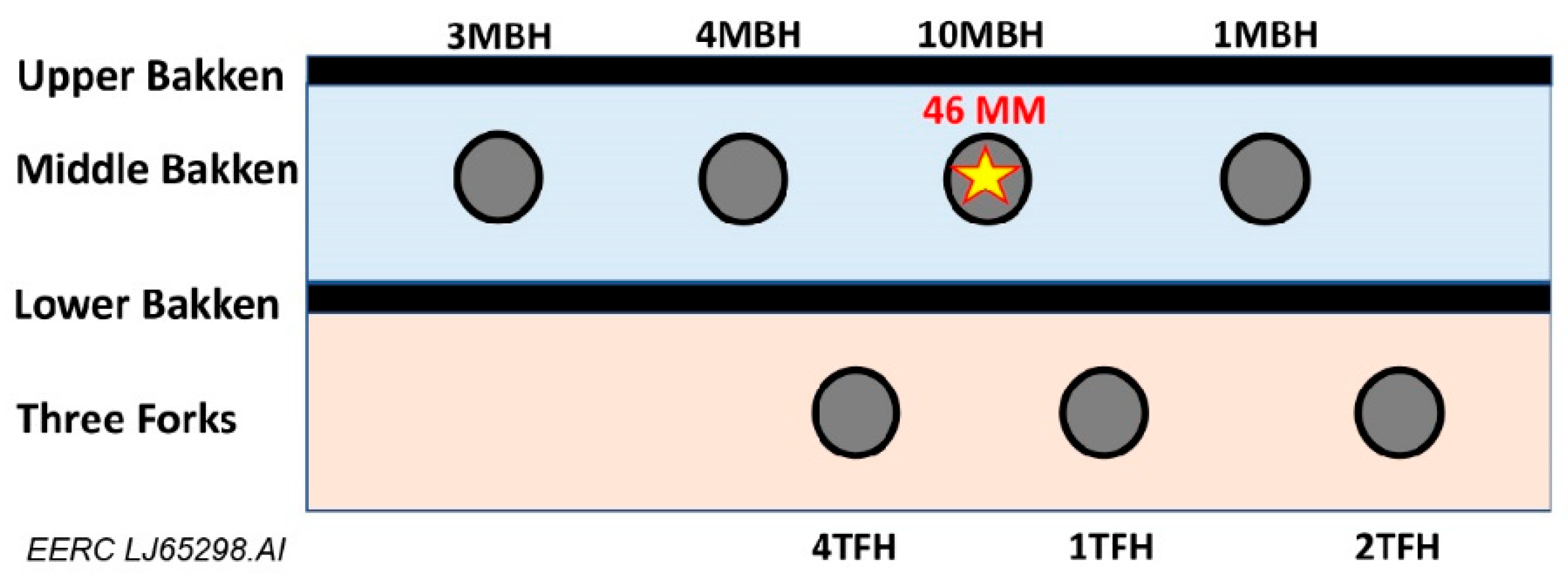

2.4. Case Study 3: Propane Flooding Test

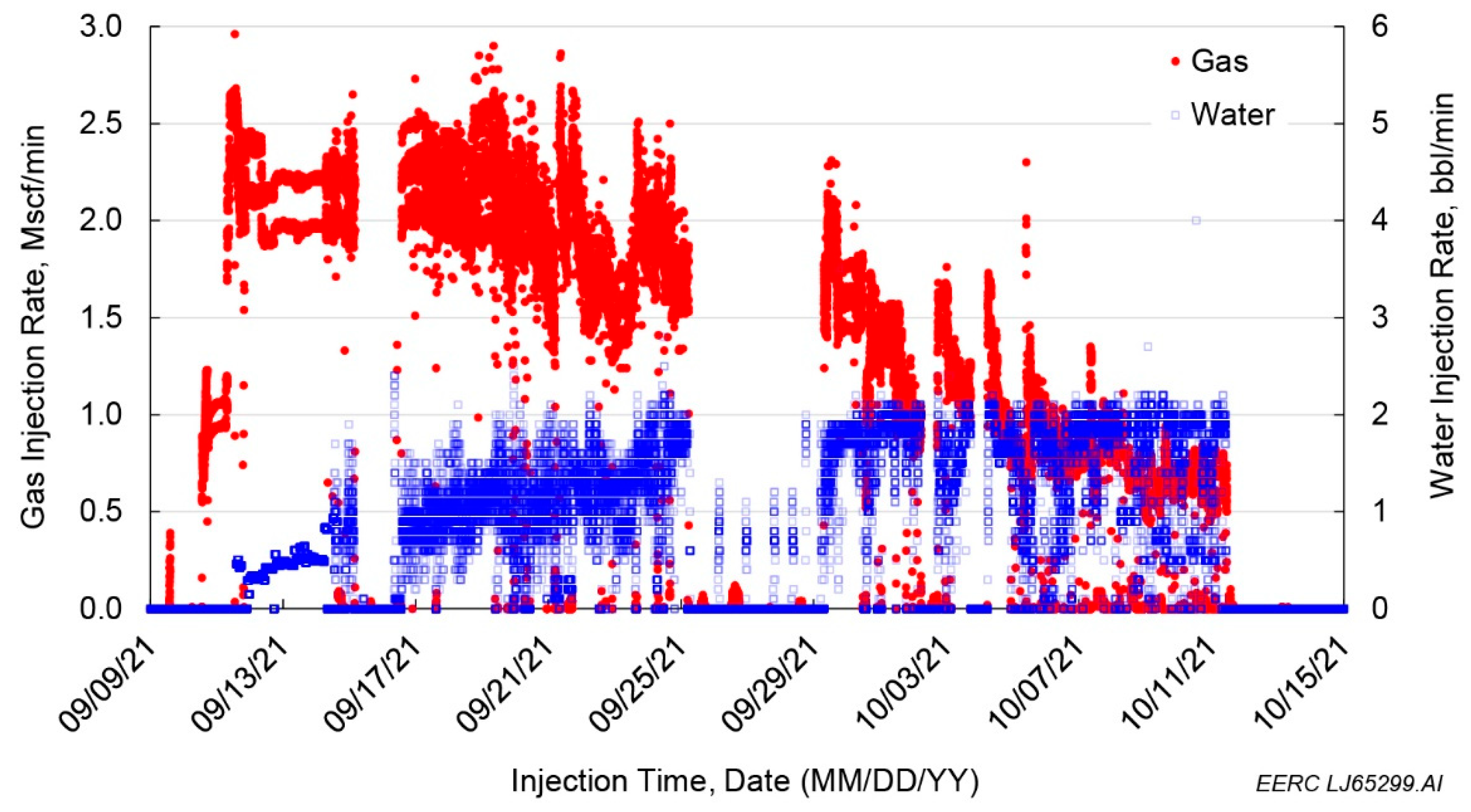

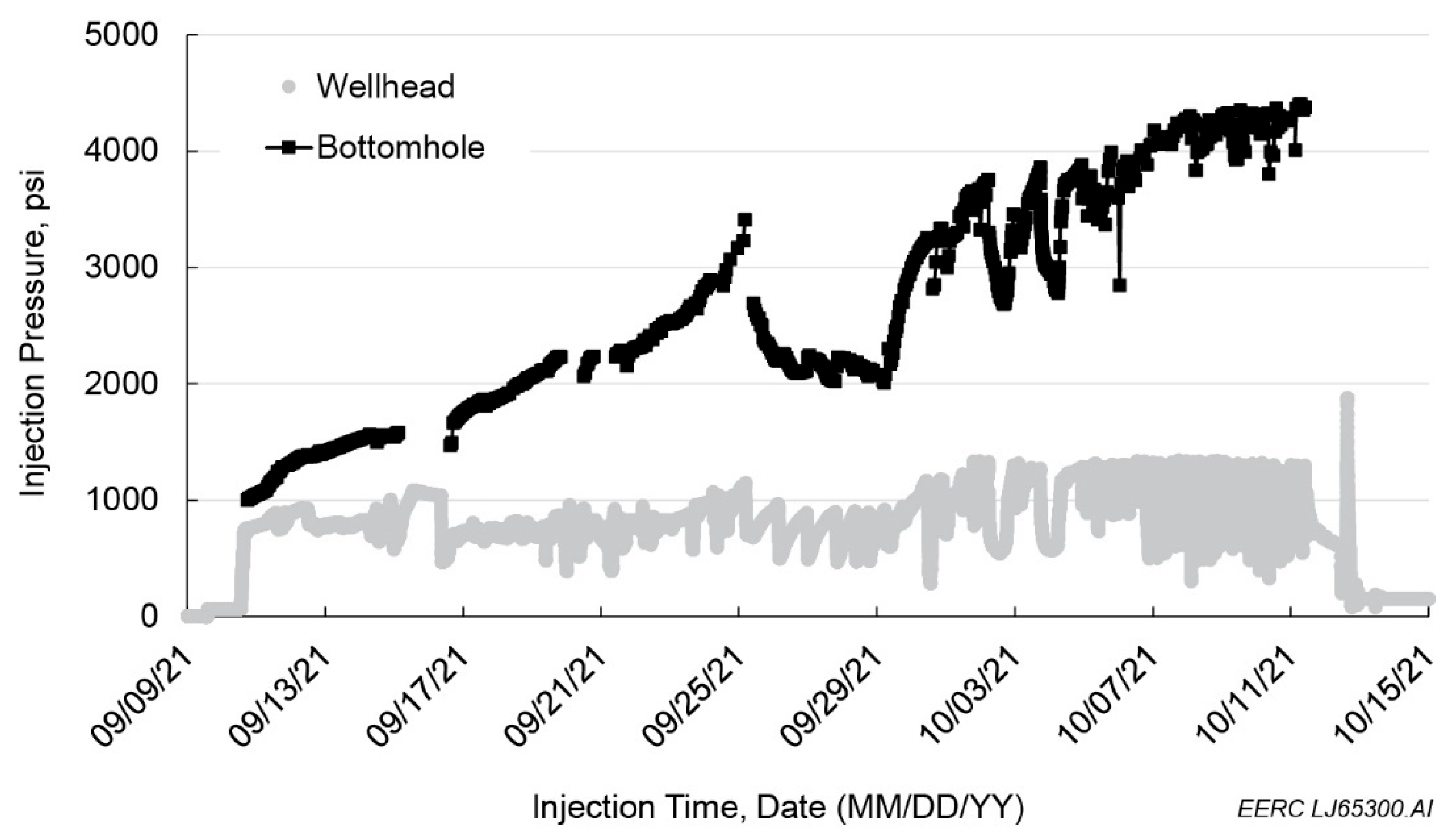

2.5. Case Study 4: Rich Gas–Water–Surfactant HnP Test

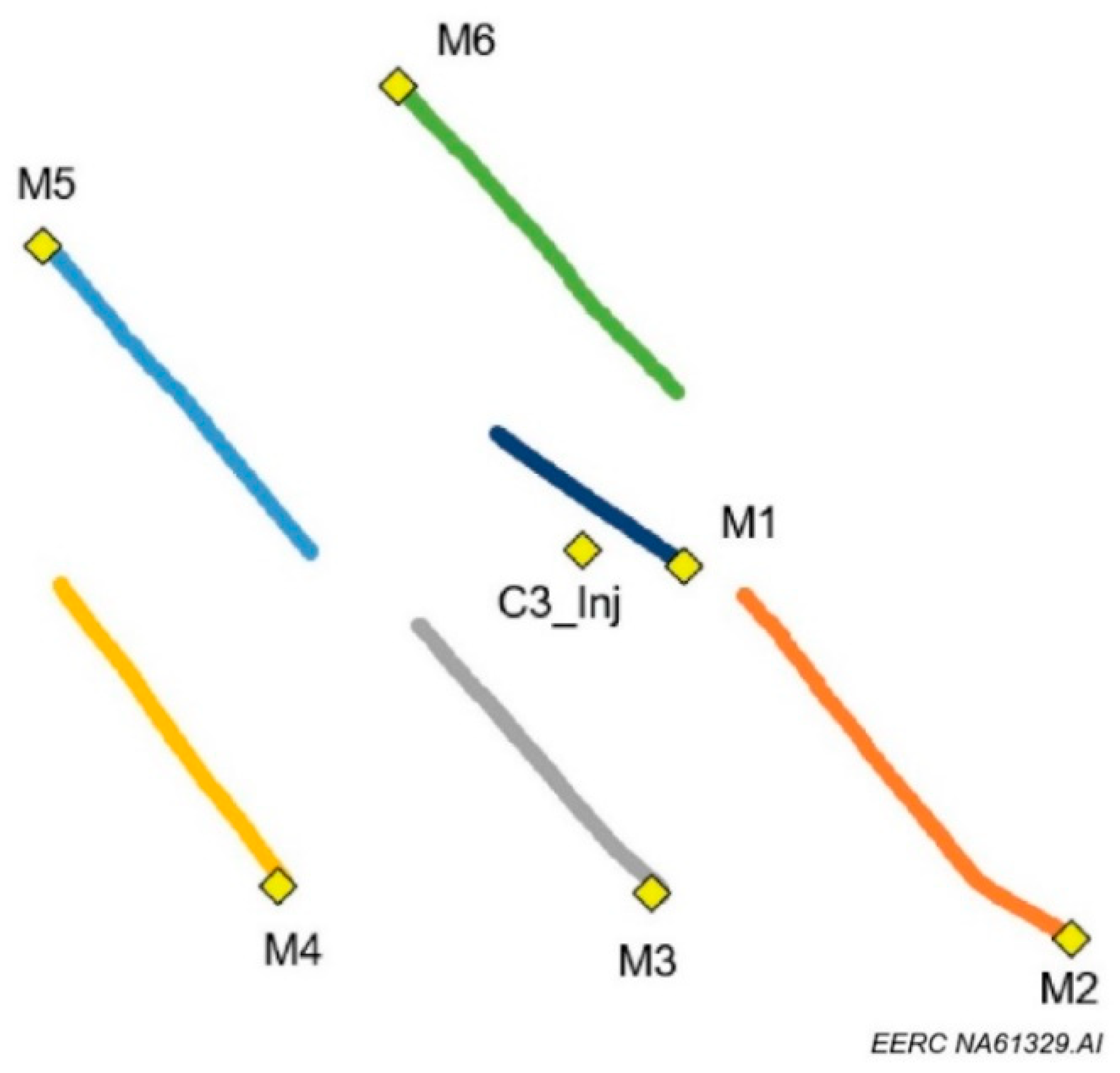

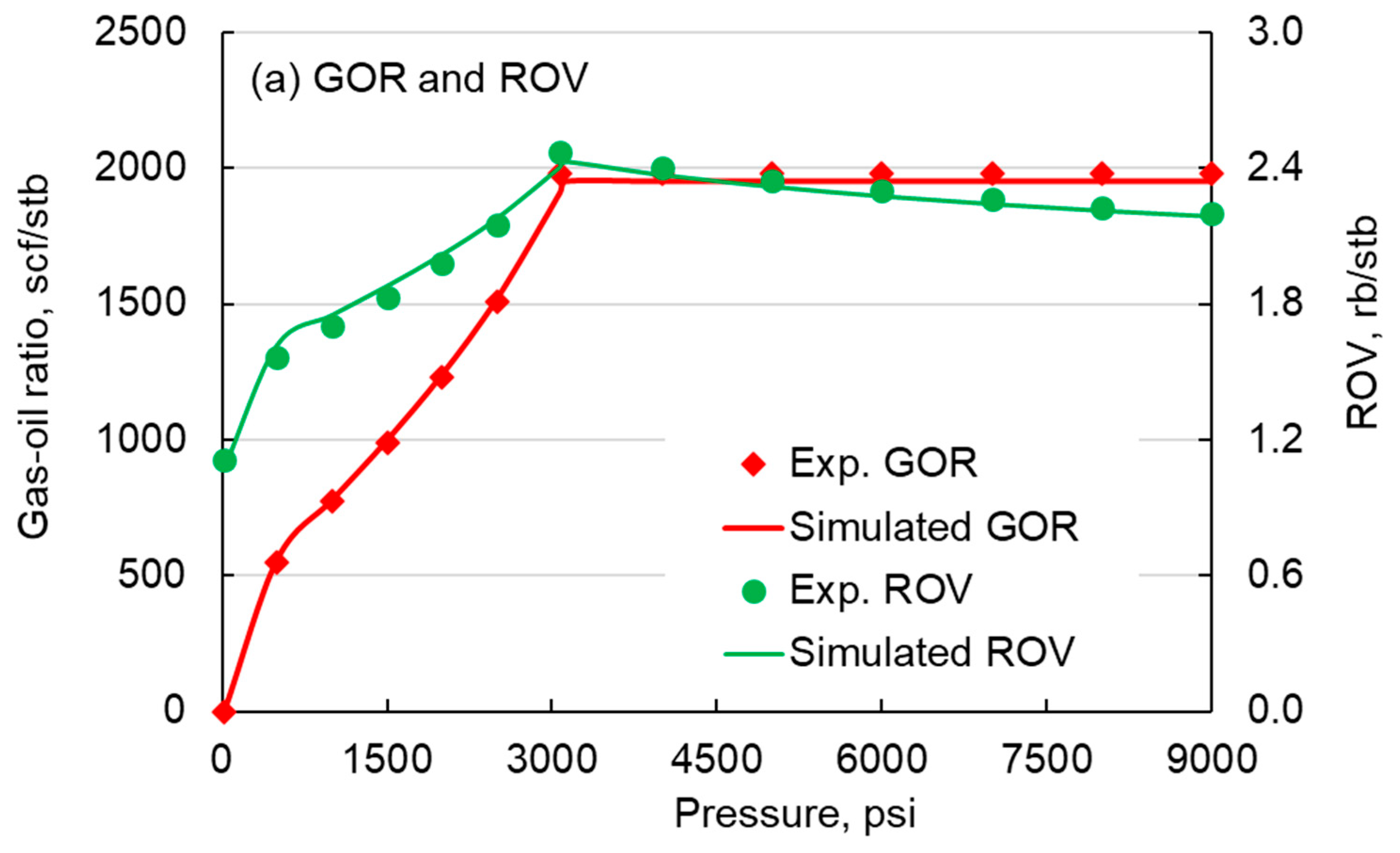

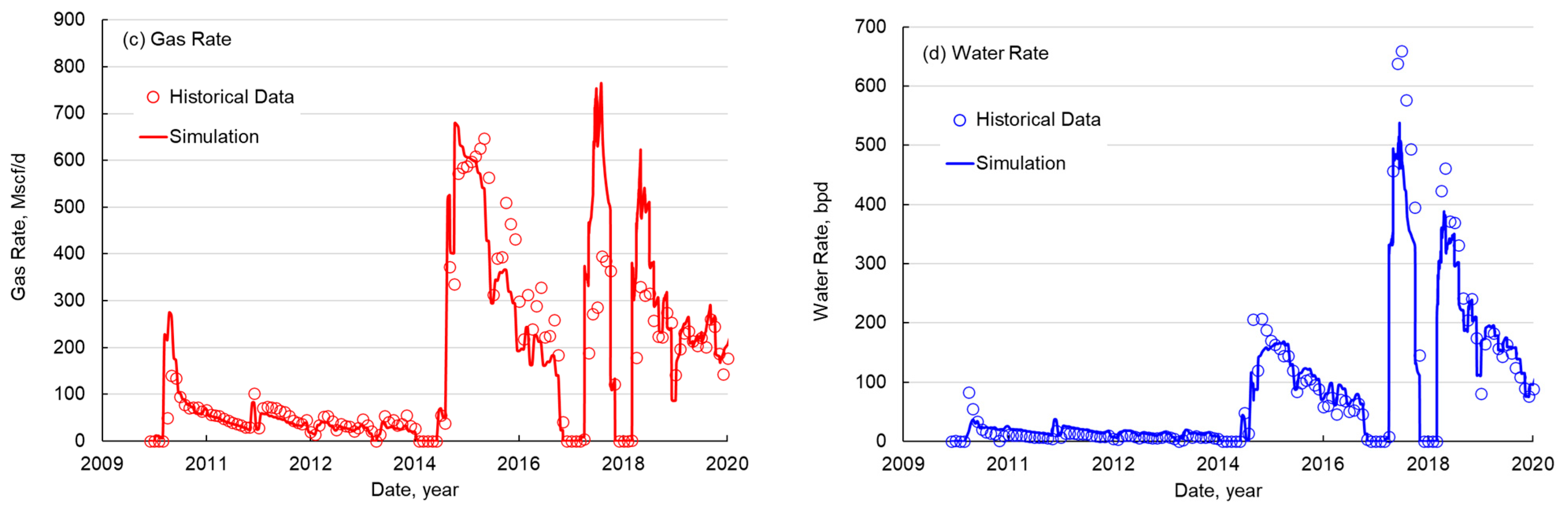

3. Simulation Model for EOR Monitoring

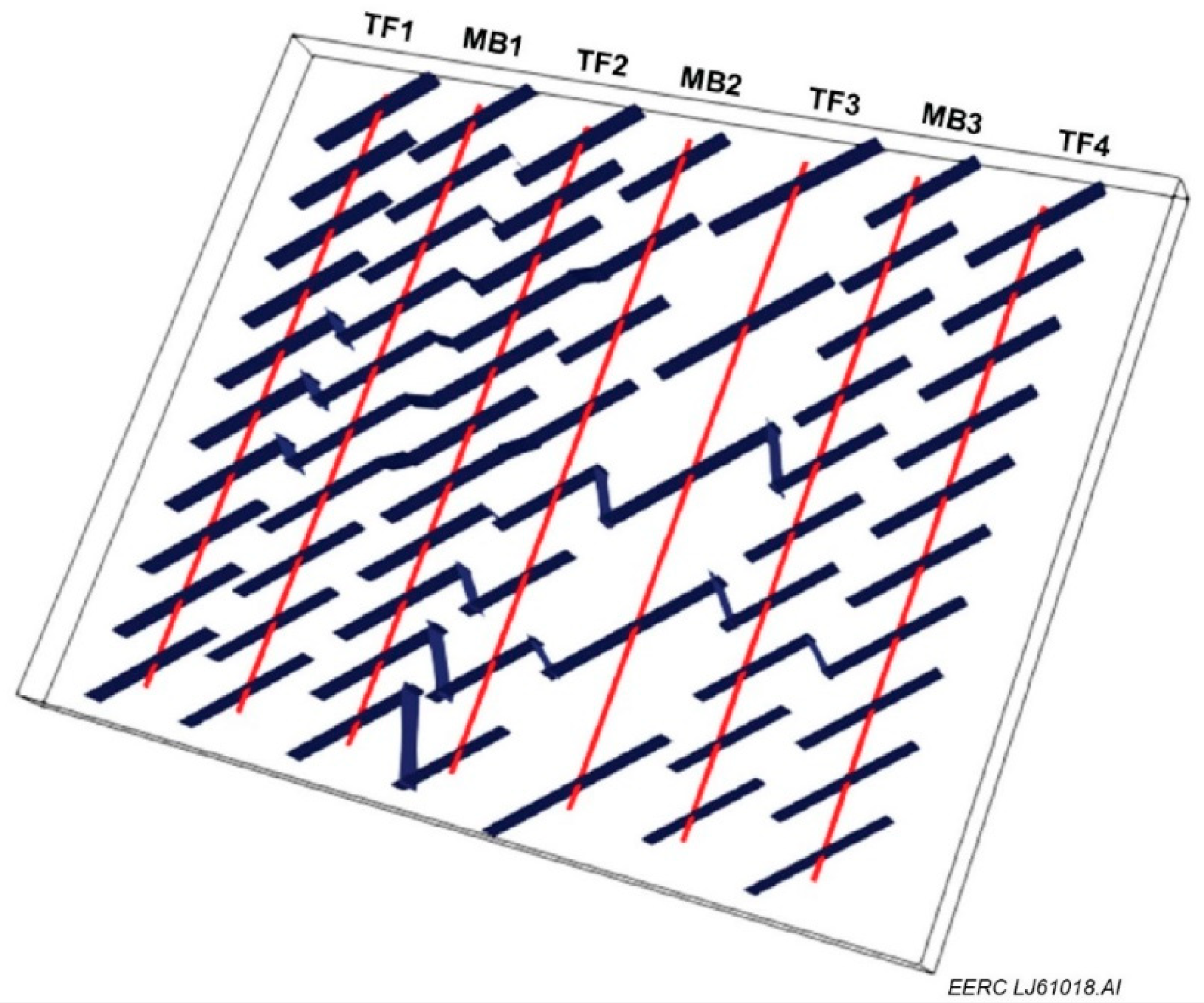

3.1. Baseline Model of a Seven-Well DSU

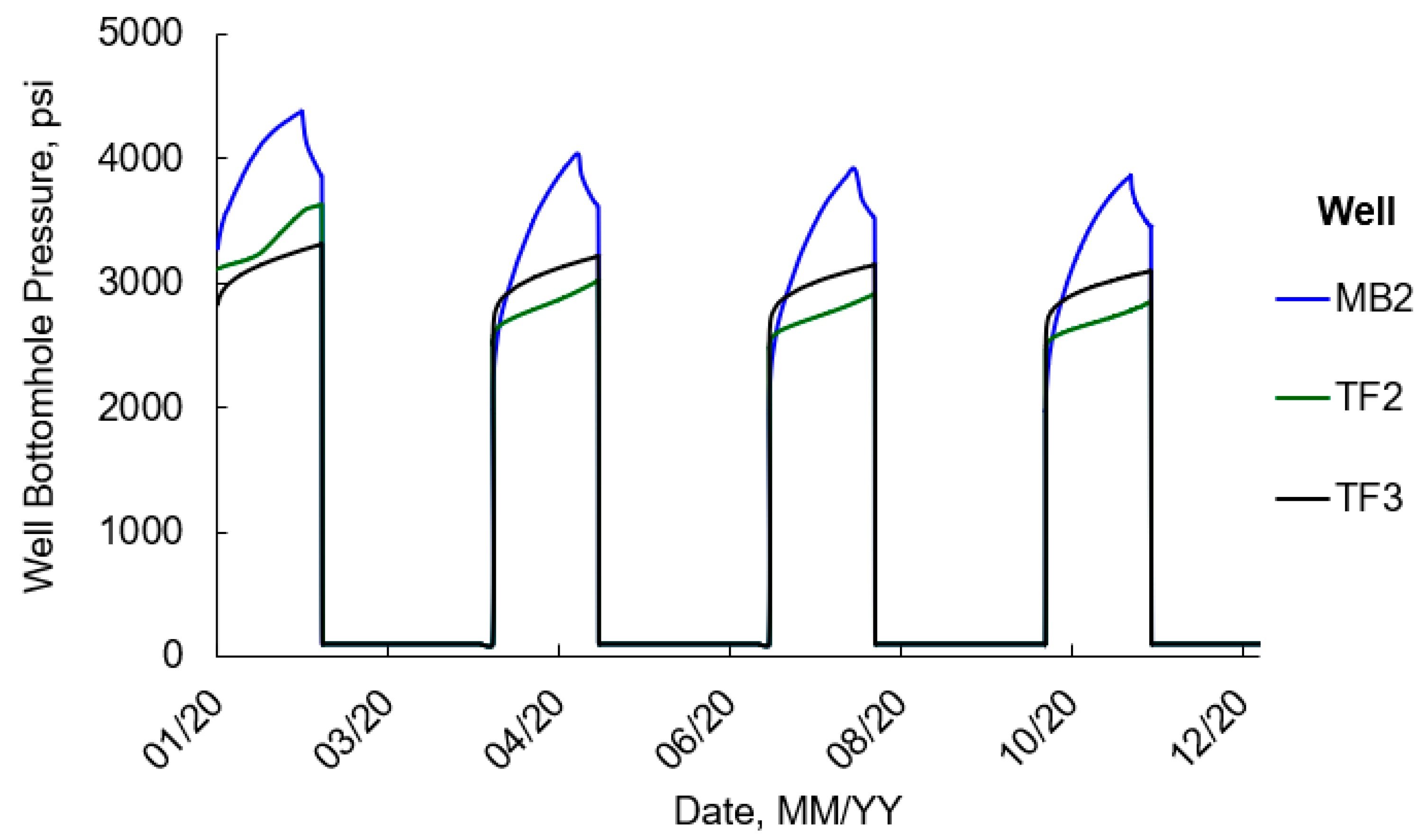

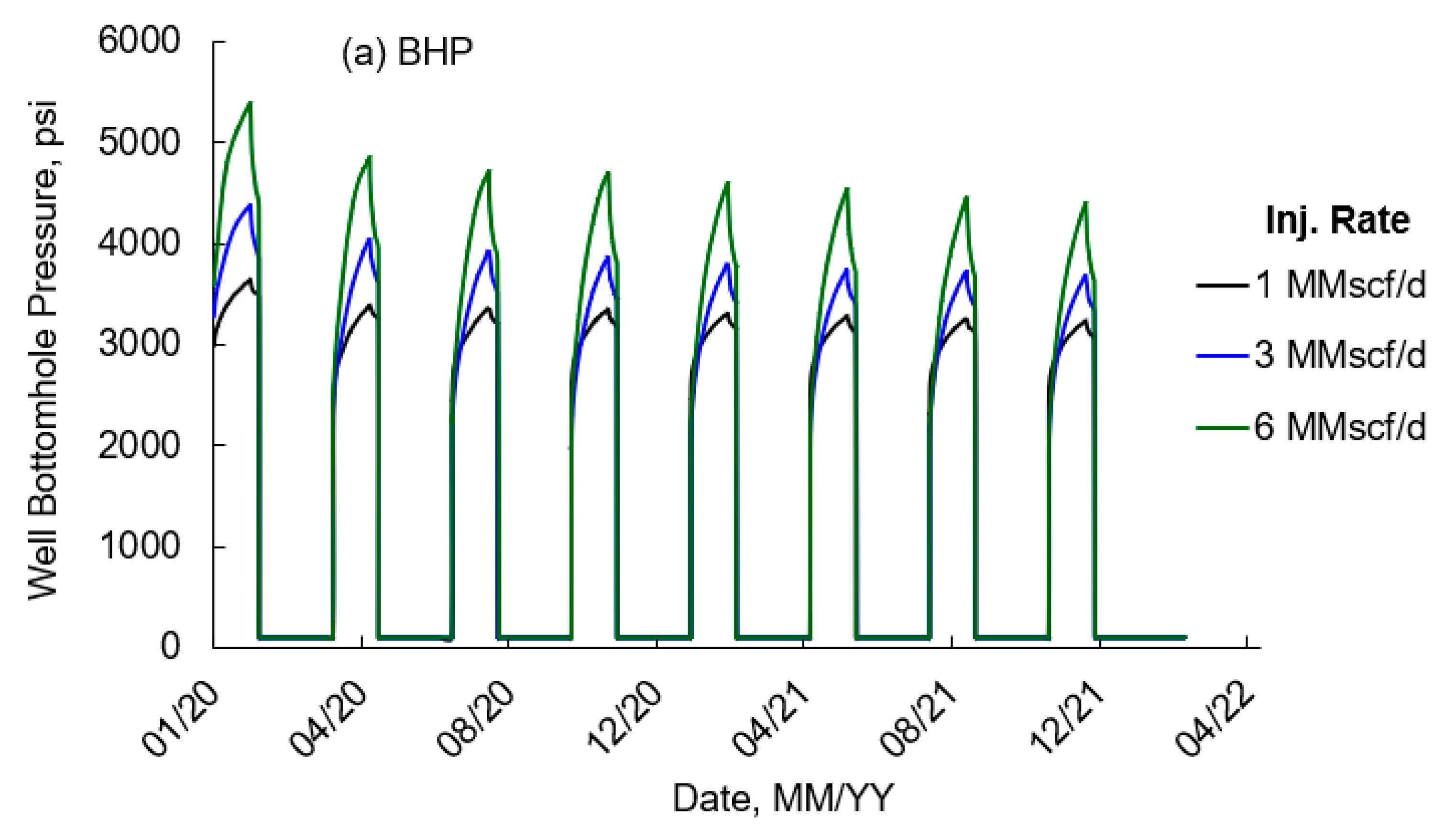

3.2. EOR Simulation

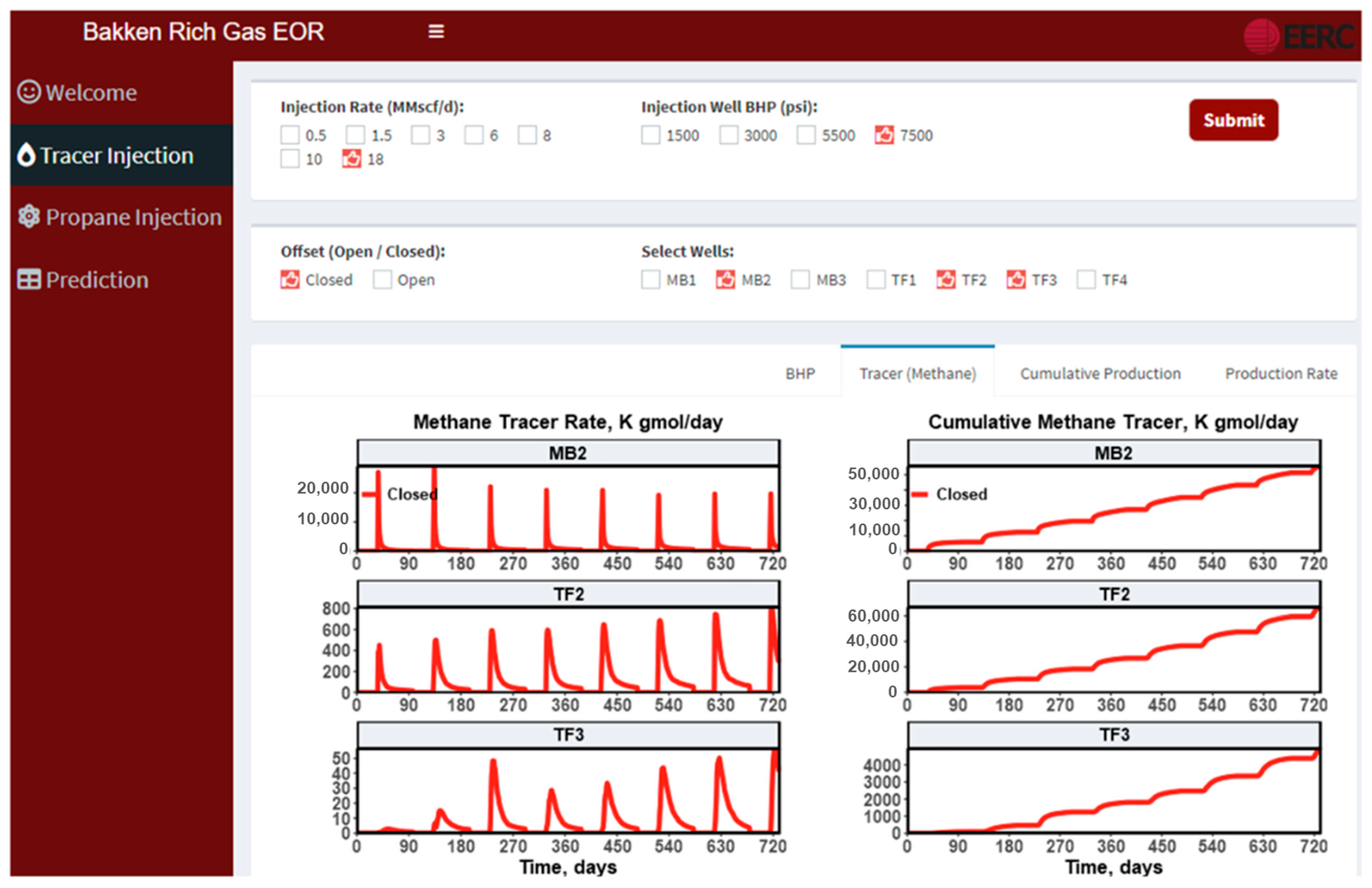

4. Real-Time Visualization and Forecasting

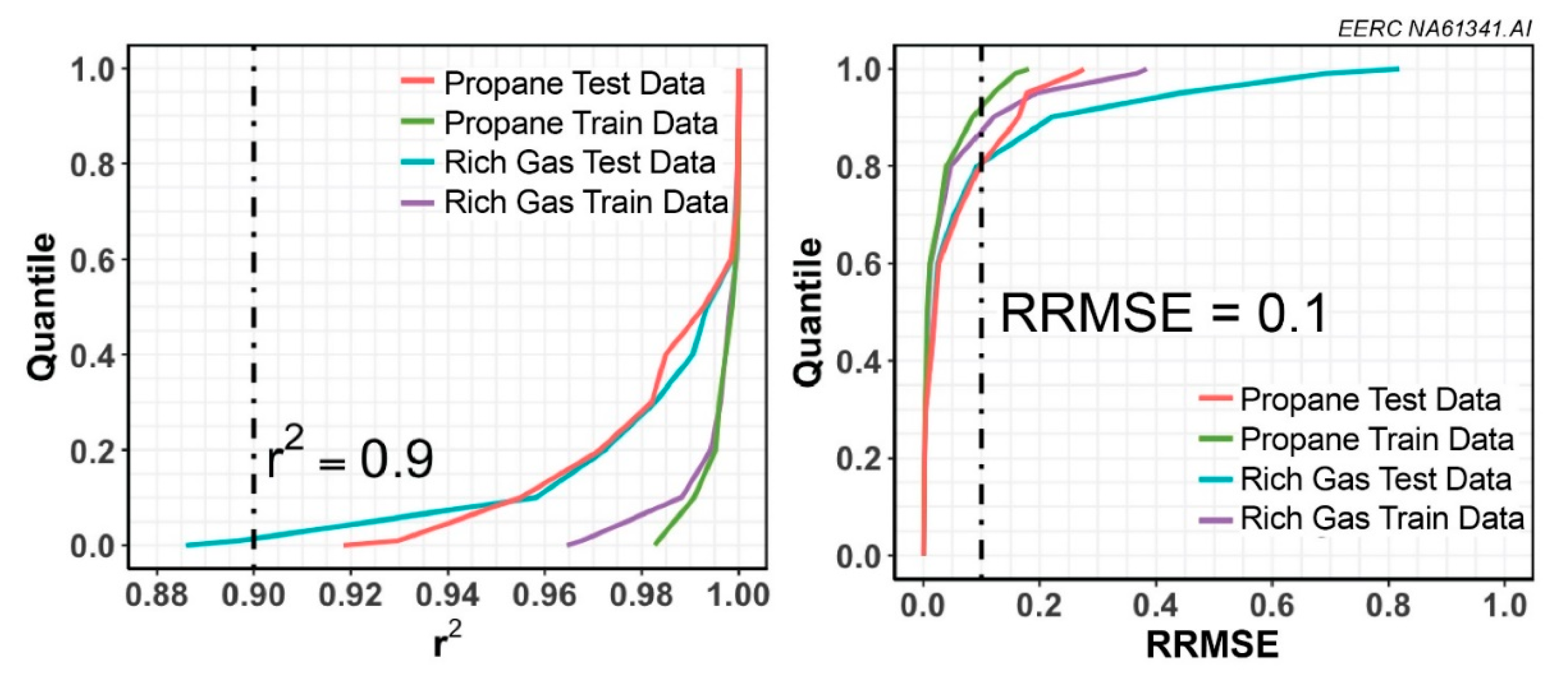

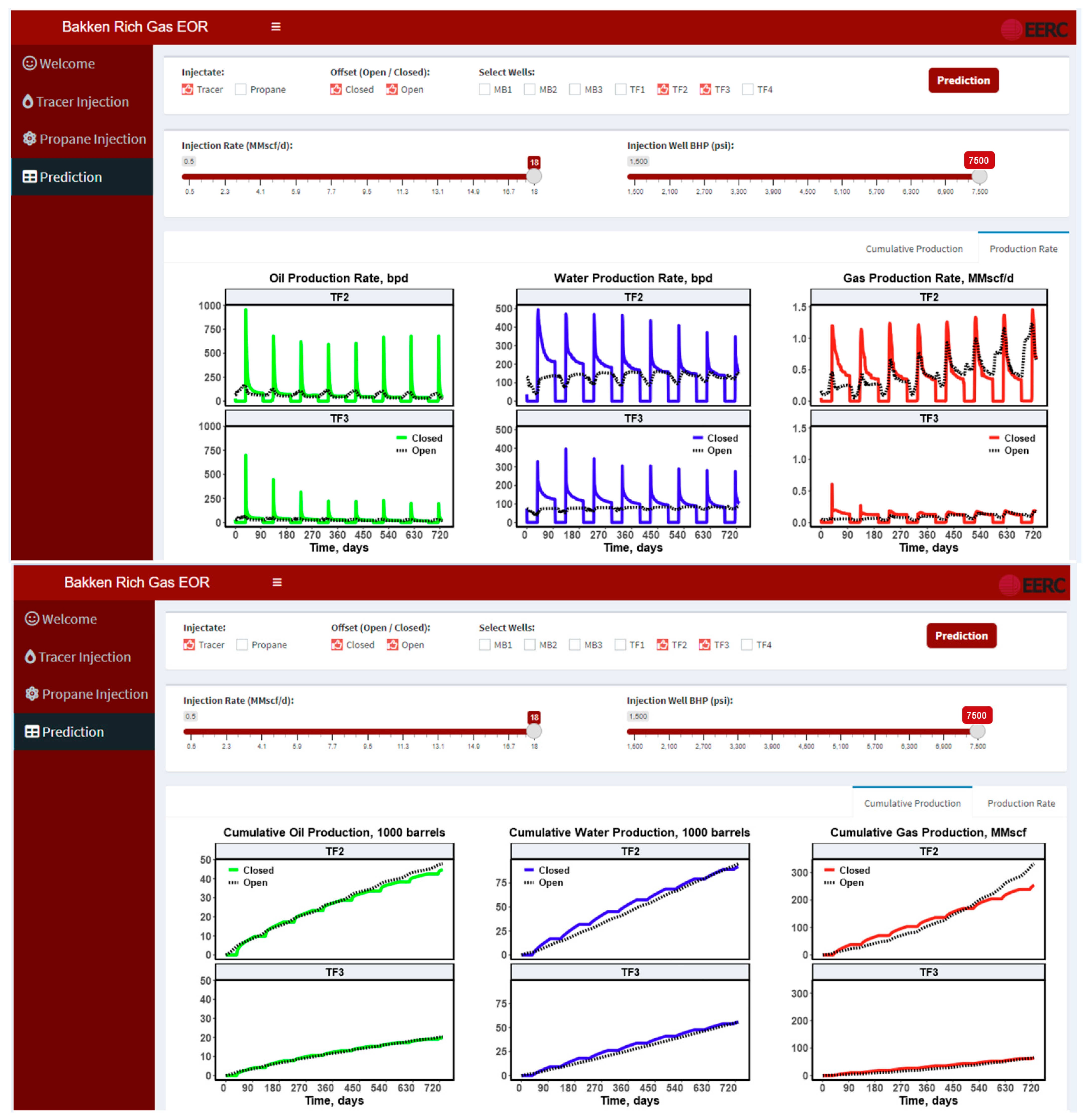

4.1. Machine Learning Tool Development

4.2. Real-Time Control

5. Conclusions

- Pressure buildup, conformance issues, and timely gas breakthrough detection were some of the main challenges for gas EOR in unconventional wells because of the interconnected fractures between injection and offset wells.

- The injectivity pilot showed that high bottomhole injection pressure is required for the injected gas to reactivate natural fractures and penetrate the tight rock matrix and extract oil from the Bakken for EOR purposes.

- Careful EOR design and continuous reservoir monitoring could be key components to mitigate these challenges. Timely gas breakthrough detection followed by immediate control actions through the RSSS system showed effective results in conformance control and pressure buildup.

- The EOR response in each well could be different, even though the wells are in the same DSU. Various factors, including completion time and formation, number of fractures, offset wells, and production history, etc., could impact the EOR results.

- Field case studies showed that well interference commonly exists in the Bakken Petroleum System, and therefore multiple-well, multiple-fracture models are required to mimic the actual EOR operations.

- The EDFM approach is an effective method to simulate the well interference and conformance issues in the Bakken and, thus, it is a more representative method to investigate the complex flow behavior between wells in the EOR processes.

- Although gas injection has been demonstrated to be useful for EOR in unconventional reservoirs, a large volume of gas is required to fill up the pore space, lift reservoir pressure to a high level, and achieve an effective EOR, given the depleted reservoir volume around the horizontal wells.

- An operation with a low gas injection rate may not yield a clear EOR response because of the well interference effect (conformance issue). Conformance control is required to confine the injected gas around the well for EOR purposes, especially where the supply of gas is limited.

- Not all the wells are suitable for EOR operations in the Bakken, so EOR and monitoring wells need to be carefully selected for EOR design and implementation. EOR performance can be improved considerably by optimizing the EOR strategies.

- Different injection/soaking/production combinations could yield different EOR results when employing the same injection rate and pressure. Therefore, optimizing key design parameters, including well selection, gas injection rate, cycle design, etc., can increase the chance of success for EOR operations.

- A workflow was developed to explore real-time visualization, forecasting, and control methods for improved reservoir surveillance during EOR processes based on the field pilots and data generated in a large set of synthetic reservoir simulations.

- ML-based models using the XGBoost algorithm were developed to rapidly forecast well performance given a set of user-defined EOR operating parameters. These predictive models allow the user to modify the offset well status, injection rate, and injection well BHP, as well as predict the potential well response during the EOR process.

- The combination of real-time visualization tools with real-time forecasting tools provides a framework for real-time control—operational changes that the EOR site operator can enact (e.g., changing gas injection rates) to affect the observed performance and potentially improve the EOR outcome.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sorensen, J.A.; Kurz, B.A.; Hawthorne, S.B.; Jin, L.; Smith, S.A.; Azenkeng, A. Laboratory Characterization and Modeling to Examine CO2 Storage and Enhanced Oil Recovery in an Unconventional Tight Oil Formation. Energy Procedia 2017, 114, 5460–5478. [Google Scholar] [CrossRef]

- Jin, L.; Sorensen, J.A.; Hawthorne, S.B.; Smith, S.A.; Pekot, L.J.; Bosshart, N.W.; Burton-Kelly, M.E.; Miller, D.J.; Grabanski, C.B.; Gorecki, C.D.; et al. Improving Oil Recovery by Use of Carbon Dioxide in the Bakken Unconventional System: A Laboratory Investigation. SPE Reserv. Eval. Eng. 2017, 20, 602–612. [Google Scholar] [CrossRef]

- Jin, L.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Kurz, B.; Smith, S.; Heebink, L.; Herdegen, V.; Bosshart, N.; Torres, J.; et al. Advancing CO2 Enhanced Oil Recovery and Storage in Unconventional Oil Play—Experimental Studies on Bakken Shales. Appl. Energy 2017, 208, 171–183. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Miller, D.J.; Grabanski, C.B.; Jin, L. Experimental Determinations of Minimum Miscibility Pressures Using Hydrocarbon Gases and CO2 for Crude Oils from the Bakken and Cut Bank Oil Reservoirs. Energy Fuels 2020, 34, 6148–6157. [Google Scholar] [CrossRef]

- Hawthorne, S.B.; Grabanski, C.B.; Jin, L.; Bosshart, N.W.; Miller, D.J. Comparison of CO2 and Produced Gas Hydrocarbons to Recover Crude Oil from Williston Basin Shale and Mudrock Cores at 10.3, 17.2, and 34.5 MPa and 110 °C. Energy Fuels 2021, 35, 6658–6672. [Google Scholar] [CrossRef]

- Wan, X.; Jin, L.; Azzolina, N.A.; Butler, S.K.; Yu, X.; Zhao, J. Applying Reservoir Simulation and Artificial Intelligence Algorithms to Optimize Fracture Characterization and CO2 Enhanced Oil Recovery in Unconventional Reservoirs: A Case Study in the Wolfcamp Formation. Energies 2022, 15, 8266. [Google Scholar] [CrossRef]

- Wan, X.; Jin, L.; Azzolina, N.A.; Zhao, J.; Yu, X.; Smith, S.A.; Sorensen, J.A. Optimization of Operational Strategies for Rich Gas Enhanced Oil Recovery Based on a Pilot Test in the Bakken Tight Oil Reservoir. Pet. Sci. 2023, 20, 2921–2938. [Google Scholar] [CrossRef]

- Rezaee, R. Editorial on Special Issues of Development of Unconventional Reservoirs. Energies 2022, 15, 2617. [Google Scholar] [CrossRef]

- Kang, W.-L.; Zhou, B.-B.; Issakhov, M.; Gabdullin, M. Advances in Enhanced Oil Recovery Technologies for Low Permeability Reservoirs. Pet. Sci. 2022, 19, 1622–1640. [Google Scholar] [CrossRef]

- Li, L.; Zhang, X.; Liu, J.; Xie, Q.; Zhou, X.; Zheng, J.; Su, Y. Research Progress and Prospect of Carbon Dioxide Utilization and Storage Based on Unconventional Oil and Gas Development. Energies 2022, 15, 9383. [Google Scholar] [CrossRef]

- Kazempour, M.; Kiani, M.; Nguyen, D.; Salehi, M.; Bidhendi, M.M.; Lantz, M. Boosting Oil Recovery in Unconventional Resources Utilizing Wettability Altering Agents: Successful Translation from Laboratory to Field. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 14–18 April 2018; SPE: Tulsa, OK, USA, 2018; p. D041S015R002. [Google Scholar] [CrossRef]

- Todd, H.B.; Evans, J.G. Improved Oil Recovery IOR Pilot Projects in the Bakken Formation. In Proceedings of the SPE Rocky Mountain Petroleum Technology Conference/Low-Permeability Reservoirs Symposium, Denver, CO, USA, 5–6 May 2016; SPE: Denver, CO, USA, 2016; p. SPE-180270-MS. [Google Scholar] [CrossRef]

- Sorensen, J.A.; Pekot, L.J.; Torres, J.A.; Jin, L.; Hawthorne, S.B.; Smith, S.A.; Jacobson, L.L.; Doll, T.E. Field Test of CO2 Injection in a Vertical Middle Bakken Well to Evaluate the Potential for Enhanced Oil Recovery and CO2 Storage. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; American Association of Petroleum Geologists: Tulsa, OK, USA; pp. 2889–2906. [Google Scholar] [CrossRef]

- Pospisil, G.; Weddle, P.; Strickland, S.; McChesney, J.; Tompkins, K.; Neuroth, T.; Pearson, C.M.; Griffin, L.; Kaier, T.; Sorensen, J.; et al. Report on the First Rich Gas EOR Cyclic Multiwell Huff N Puff Pilot in the Bakken Tight Oil Play. In Proceedings of the SPE Annual Technical Conference and Exhibition, Virtual, 26–29 October 2020; SPE: Tulsa, OK, USA, 2020; p. D041S051R002. [Google Scholar] [CrossRef]

- Pospisil, G.; Griffin, L.; Souther, T.; Strickland, S.; McChesney, J.; Pearson, C.M.; Dalkhaa, C.; Sorensen, J.; Hamling, J.; Kurz, B.; et al. East Nesson Bakken Enhanced Oil Recovery Pilot: Coinjection of Produced Gas and a Water-Surfactant Mixture. In Proceedings of the 10th Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022; American Association of Petroleum Geologists: Tulsa, OK, USA, 2022; pp. 803–823. [Google Scholar] [CrossRef]

- Torres, J.A.; Jin, L.; Bosshart, N.W.; Pekot, L.J.; Sorensen, J.A.; Peterson, K.; Anderson, P.W.; Hawthorne, S.B. Multiscale Modeling to Evaluate the Mechanisms Controlling CO2-Based Enhanced Oil Recovery and CO2 Storage in the Bakken Formation. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; American Association of Petroleum Geologists: Tulsa, OK, USA, 2018; pp. 2757–2776. [Google Scholar] [CrossRef]

- Nagarajan, N.; Stoll, D.; Litvak, M.; Prasad, R.; Shaarawi, K. Successful Field Test of Enhancing Bakken Oil Recovery by Propane Injection: Part, I. Field Test Planning, Operations, Surveillance, and Results. In Proceedings of the 8th Unconventional Resources Technology Conference, Online, 20–22 July 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020; pp. 1876–1896. [Google Scholar] [CrossRef]

- Litvak, M.; Nagarajan, N.; Prasad, R.S.; Shaarawi, K. Successful Field Test of Enhancing Bakken Oil Recovery with Propane Injection Part II. Development and Application of Innovative Simulation Technology. In Proceedings of the 8th Unconventional Resources Technology Conference, Online, 20–22 July 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020; pp. 1908–1928. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, L.; Azzolina, N.A.; Wan, X.; Yu, X.; Sorensen, J.A.; Kurz, B.A.; Bosshart, N.W.; Smith, S.A.; Wu, C.; et al. Investigating Enhanced Oil Recovery in Unconventional Reservoirs Based on Field Case Review, Laboratory, and Simulation Studies. Energy Fuels 2022, 36, 14771–14788. [Google Scholar] [CrossRef]

- Gao, Y.; Zhao, M.; Wang, J.; Zong, C. Performance and Gas Breakthrough during CO2 Immiscible Flooding in Ultra-Low Permeability Reservoirs. Pet. Explor. Dev. 2014, 41, 88–95. [Google Scholar] [CrossRef]

- Rassenfoss, S. Chevron Applies Some Unconventional Thinking to Try To Make Shale EOR a Standard Treatment. J. Pet. Technol. 2024, 76, 24–28. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, H.; Wang, Y.; Ren, B.; Ren, S.; Chen, G.; Zhang, H. CO2 Storage Safety and Leakage Monitoring in the CCS Demonstration Project of Jilin Oilfield, China. Greenh. Gases Sci. Technol. 2014, 4, 425–439. [Google Scholar] [CrossRef]

- Alfi, M.; Hosseini, S.A.; Alfi, M.; Shakiba, M. Effectiveness of 4D Seismic Data to Monitor CO2 Plume in Cranfield CO2-EOR Project. In Proceedings of the Carbon Management Technology Conference, Virtual, 20–22 July 2020; CMTC: Sugar Land, TX, USA, 2015; p. CMTC-439559-MS. [Google Scholar] [CrossRef]

- Jervis, M.; Bakulin, A.; Smith, R. Making Time-Lapse Seismic Work in a Complex Desert Environment for CO2 EOR Monitoring—Design and Acquisition. Lead. Edge 2018, 37, 598–606. [Google Scholar] [CrossRef]

- Zaluski, W.; El-Kaseeh, G.; Lee, S.-Y.; Piercey, M.; Duguid, A. Monitoring Technology Ranking Methodology for CO2-EOR Sites Using the Weyburn-Midale Field as a Case Study. Int. J. Greenh. Gas Control 2016, 54, 466–478. [Google Scholar] [CrossRef]

- Jin, L.; Barajas-Olalde, C.; Bosshart, N.; He, J.; Adams, D.; Kalenze, N.; Hamling, J.; Gorecki, C. Application of CO2 Injection Monitoring Techniques for CO2 EOR and Associated Geologic Storage. In Proceedings of the 15th Greenhouse Gas Control Technologies Conference, Abu Dhabi, United Arab Emirates, 15–18 March 2021. [Google Scholar] [CrossRef]

- Mur, A.; Barajas-Olalde, C.; Adams, D.C.; Jin, L.; He, J.; Hamling, J.A.; Gorecki, C.D. Integrated Simulation to Seismic and Seismic Reservoir Characterization in a CO2 EOR Monitoring Application. Lead. Edge 2020, 39, 668–678. [Google Scholar] [CrossRef]

- Salako, O.; Jin, L.; Barajas-Olalde, C.; Hamling, J.A.; Gorecki, C.D. Implementing Adaptive Scaling and Dynamic Well-Tie for Quantitative 4-D Seismic Evaluation of a Reservoir Subjected to CO2 Enhanced Oil Recovery and Associated Storage. Int. J. Greenh. Gas Control 2018, 78, 306–326. [Google Scholar] [CrossRef]

- Barajas-Olalde, C.; Haffinger, P.; Gisolf, D.; Zhang, M.; Droujinina, A.; Doulgeris, P.; Khatibi, S.; Jin, L.; Burnison, S.A.; Hamling, J.A.; et al. Simultaneous time-lapse WEB-AVO inversion for seismic reservoir monitoring: Application to CO2 enhanced oil recovery at the Bell Creek oil field. In Proceedings of the SEG Technical Program Expanded Abstracts; Society of Exploration Geophysicists: Houston, TX, USA, 2019; pp. 564–568. [Google Scholar]

- Barajas-Olalde, C.; Mur, A.; Adams, D.C.; Jin, L.; He, J.; Hamling, J.A.; Gorecki, C.D. Joint Impedance and Facies Inversion of Time-Lapse Seismic Data for Improving Monitoring of CO2 Incidentally Stored from CO2 EOR. Int. J. Greenh. Gas Control 2021, 112, 103501. [Google Scholar] [CrossRef]

- Smith, S.A.; Sorensen, J.A.; Kurz, B.A.; Heebink, L.V.; Azzolina, N.A.; Jin, L.; Kong, L.; Yu, X.; Wan, X.; Yu, Y.; et al. Findings on Subtask 3.1-Bakken Rich Gas Enhanced Oil Recovery Project; Energy & Environmental Research Center University of North Dakota: Grand Forks, ND, USA, 2022; p. DE-FE0024233. [Google Scholar]

- Kumar, A.; Sharma, M.M. Diagnosing Fracture-Wellbore Connectivity Using Chemical Tracer Flowback Data. In Proceedings of the 6th Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018; American Association of Petroleum Geologists: Tulsa, OK, USA, 2018. [Google Scholar] [CrossRef]

- Tayyib, D.; Al-Qasim, A.; Kokal, S.; Huseby, O. Overview of Tracer Applications in Oil and Gas Industry. In Proceedings of the SPE Kuwait oil and gas show and conference, Mishref, Kuwait, 13–16 October 2019; SPE: Mishref, Kuwait, 2019; p. D023S006R004. [Google Scholar] [CrossRef]

- Al-Qasim, A.; Kokal, S.; Hartvig, S.; Huseby, O. Reservoir Description Insights from Inter-Well Gas Tracer Test. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019; SPE: Abu Dhabi, United Arab Emirates, 2019; p. D011S014R003. [Google Scholar] [CrossRef]

- Al-Qasim, A.; Kokal, S.; Hartvig, S.; Huseby, O. Subsurface Monitoring and Surveillance Using Inter-Well Gas Tracers. Upstream Oil Gas Technol. 2020, 3, 100006. [Google Scholar] [CrossRef]

- Sharma, A.; Shook, G.M.; Pope, G.A. Rapid Analysis of Tracers for Use in EOR Flood Optimization. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 12–16 April 2014; SPE: Tulsa, OK, USA, 2014; p. SPE-169109-MS. [Google Scholar] [CrossRef]

- Sanni, M.; Abbad, M.; Kokal, S.; Ali, R.; Zefzafy, I.; Hartvig, S.; Huseby, O. A Field Case Study of an Interwell Gas Tracer Test for GAS-EOR Monitoring. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 13–16 November 2017; SPE: Abu Dhabi, United Arab Emirates, 2017; p. D031S081R004. [Google Scholar] [CrossRef]

- Huseby, O.K.; Sagen, J.; Wangen, M.; Viig, S.O. Planning and Interpretation of Offshore-Field Tracer Tests Using Accurate and Refined Tracer Simulations. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Lima, Peru, 1–3 December 2010; SPE: Lima, Peru, 2010; p. SPE-139170-MS. [Google Scholar] [CrossRef]

- Al Abbad, M.A.; Sanni, M.L.; Kokal, S.; Krivokapic, A.; Dye, C.; Dugstad, Ø.; Hartvig, S.K.; Huseby, O.K. A Step Change for Single-Well Chemical-Tracer Tests: Field Pilot Testing of New Sets of Novel Tracers. SPE Reserv. Eval. Eng. 2019, 22, 253–265. [Google Scholar] [CrossRef]

- Chen, H.; Chang, S.; Thomas, G.; Wang, W.; Mashat, A.; Shateeb, H. Comparison of Water and Gas Tracers Field Breakthrough. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 21–23 September 2021; SPE: Dubai, United Arab Emirates, 2021; p. D021S033R002. [Google Scholar] [CrossRef]

- North Dakota Industrial Commission (NDIC). 2024. Available online: www.dmr.nd.gov/oilgas/ (accessed on 25 March 2024).

- Hawthorne, S.B.; Jin, L.; Kurz, B.A.; Miller, D.J.; Grabanski, C.B.; Sorensen, J.A.; Pekot, L.J.; Bosshart, N.W.; Smith, S.A.; Burton-Kelly, M.E.; et al. Integrating Petrographic and Petrophysical Analyses with CO2 Permeation and Oil Extraction and Recovery in the Bakken Tight Oil Formation. In Proceedings of the SPE Canada Unconventional Resources Conference, Calgary, AB, Canada, 15–16 February 2017; SPE: Calgary, Alberta, Canada, 2017; p. D021S009R001. [Google Scholar] [CrossRef]

- Jia, B.; Jin, L.; Mibeck, B.A.; Smith, S.A.; Sorensen, J.A. An Integrated Approach of Measuring Permeability of Naturally Fractured Shale. J. Pet. Sci. Eng. 2020, 186, 106716. [Google Scholar] [CrossRef]

- Jia, B.; Jin, L.; Smith, S.A.; Bosshart, N.W. Extension of the Gas Research Institute (GRI) Method to Measure the Permeability of Tight Rocks. J. Nat. Gas Sci. Eng. 2021, 91, 103756. [Google Scholar] [CrossRef]

- Jin, L.; Kurz, B.A.; Ardali, M.; Wan, X.; Zhao, J.; He, J.; Hawthorne, S.B.; Djezzar, A.B.; Yu, Y.; Morris, D. Investigation of Produced Gas Injection in The Bakken for Enhanced Oil Recovery Considering Well Interference. In Proceedings of the 10th Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017; pp. 2632–2653. [Google Scholar] [CrossRef]

- Jin, L.; Wan, X.; Azzolina, N.A.; Bosshart, N.W.; Zhao, J.; Yu, Y.; Yu, X.; Smith, S.A.; Sorensen, J.A.; Gorecki, C.D. Optimizing Conformance Control for Gas Injection EOR in Unconventional Reservoirs. Fuel 2022, 324, 124523. [Google Scholar] [CrossRef]

- Jin, L.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Smith, S.; Heebink, L.; Bosshart, N.; Torres, J.; Dalkhaa, C.; Gorecki, C.; et al. Extraction of Oil from Bakken Shale Formations with Supercritical CO2. In Proceedings of the 5th Unconventional Resources Technology Conference, Austin, TX, USA, 24–26 July 2017; American Association of Petroleum Geologists: Tulsa, OK, USA, 2017. [Google Scholar] [CrossRef]

- Jin, L.; Sorensen, J.A.; Hawthorne, S.B.; Smith, S.A.; Bosshart, N.W.; Burton-Kelly, M.E.; Miller, D.J.; Grabanski, C.B.; Harju, J.A. Improving Oil Transportability Using CO2 in the Bakken System—A Laboratory Investigation. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 24–26 February 2016; SPE: Lafayette, LA, USA; p. D012S007R002. [Google Scholar] [CrossRef]

- Badrouchi, N.; Pu, H.; Smith, S.; Badrouchi, F. Evaluation of CO2 Enhanced Oil Recovery in Unconventional Reservoirs: Experimental Parametric Study in the Bakken. Fuel 2022, 312, 122941. [Google Scholar] [CrossRef]

- Karimi, S.; Saidian, M.; Kazemi, H. Experimental Study of the Effect of Aging on Fluid Distribution in Middle Bakken Cores. J. Pet. Sci. Eng. 2018, 166, 1042–1054. [Google Scholar] [CrossRef]

- Hejazi, S.; Assef, Y.; Tavallali, M.; Popli, A. Cyclic CO2-EOR in the Bakken Formation: Variable Cycle Sizes and Coupled Reservoir Response Effects. Fuel 2017, 210, 758–767. [Google Scholar] [CrossRef]

- Luo, P.; Luo, W.; Li, S. Effectiveness of Miscible and Immiscible Gas Flooding in Recovering Tight Oil from Bakken Reservoirs in Saskatchewan, Canada. Fuel 2017, 208, 626–636. [Google Scholar] [CrossRef]

- Han, L.; Gu, Y. Optimization of Miscible CO2 Water-Alternating-Gas Injection in the Bakken Formation. Energy Fuels 2014, 28, 6811–6819. [Google Scholar] [CrossRef]

- Sorensen, J.A.; Hamling, J.A. Historical Bakken test data provide critical insights on EOR in tight oil plays: The American Oil & Gas Reporter. Am. Oil Gas Rep. 2016, 59, 55–61. [Google Scholar]

- Burrows, L.C.; Haeri, F.; Cvetic, P.; Sanguinito, S.; Shi, F.; Tapriyal, D.; Goodman, A.L.; Enick, R.M. A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs. Energy Fuels 2020, 34, 5331–5380. [Google Scholar] [CrossRef]

- Milad, M.; Junin, R.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-Puff Technology for Enhanced Oil Recovery in Shale/Tight Oil Reservoirs: Progress, Gaps, and Perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Thakur, G. Enhanced Recovery Technologies for Unconventional Oil Reservoirs. J. Pet. Technol. 2019, 71, 66–69. [Google Scholar] [CrossRef]

- Owusu, P.A.; DeHua, L.; Nyantakyi, E.K.; Nagre, R.D.; Borkloe, J.K.; Frimpong, I.K. Prognosticating the Production Performance of Saturated Gas Drive Reservoir: A Theoretical Perspective. Int. J. Min. Eng. Miner. Process. 2013, 2, 24–33. [Google Scholar]

- Wu, K.; Wu, B.; Yu, W. Mechanism Analysis of Well Interference in Unconventional Reservoirs: Insights From Fracture-Geometry Simulation Between Two Horizontal Wells. SPE Prod. Oper. 2018, 33, 12–20. [Google Scholar] [CrossRef]

- Siddiqui, S.; Kumar, A. Well Interference Effects for Multiwell Configurations in Unconventional Reservoirs. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 7–10 November 2016; SPE: Abu Dhabi, United Arab Emirates, 2016; p. D021S036R004. [Google Scholar] [CrossRef]

- Datta-Gupta, A.; Huang, J.; King, M.J.; Olalotiti-Lawal, F. Modeling Well Interference and Optimal Well Spacingin Unconventional Reservoirs Using Fast Marching Method. In Proceedings of the 5th Unconventional Resources Technology Conference, Austin, TX, USA, 26–28 July 2017; American Association of Petroleum Geologists: Tulsa, OK, 2017. [Google Scholar] [CrossRef]

- Yu, W.; Wu, K.; Zuo, L.; Tan, X.; Weijermars, R. Physical Models for Inter-Well Interference in Shale Reservoirs: Relative Impacts of Fracture Hits and Matrix Permeability. In Proceedings of the 4th Unconventional Resources Technology Conference, San Antonio, TX, USA, 20–22 July 2016; American Association of Petroleum Geologists: Tulsa, OK, USA, 2016. [Google Scholar] [CrossRef]

- Iino, A.; Jung, H.Y.; Onishi, T.; Datta-Gupta, A. Rapid Simulation Accounting for Well Interference in Unconventional Reservoirs Using Fast Marching Method. In Proceedings of the 8th Unconventional Resources Technology Conference, Virtual, 20–22 July 2020; American Association of Petroleum Geologists: Tulsa, OK, USA, 2020. [Google Scholar] [CrossRef]

- Qin, J.-Z.; Zhong, Q.-H.; Tang, Y.; Yu, W.; Sepehrnoori, K. Well Interference Evaluation Considering Complex Fracture Networks through Pressure and Rate Transient Analysis in Unconventional Reservoirs. Pet. Sci. 2023, 20, 337–349. [Google Scholar] [CrossRef]

- Almasoodi, M.; Andrews, T.; Johnston, C.; Singh, A.; McClure, M. A New Method for Interpreting Well-to-Well Interference Tests and Quantifying the Magnitude of Production Impact: Theory and Applications in a Multi-Basin Case Study. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 95. [Google Scholar] [CrossRef]

- Al-Shami, T.M.; Jufar, S.R.; Kumar, S.; Abdulelah, H.; Abdullahi, M.B.; Al-Hajri, S.; Negash, B.M. A Comprehensive Review of Interwell Interference in Shale Reservoirs. Earth-Sci. Rev. 2023, 237, 104327. [Google Scholar] [CrossRef]

- Sambo, C.; Liu, N.; Shaibu, R.; Ahmed, A.A.; Hashish, R.G. A Technical Review of CO2 for Enhanced Oil Recovery in Unconventional Oil Reservoirs. Geoenergy Sci. Eng. 2023, 221, 111185. [Google Scholar] [CrossRef]

- Dung, B.; Nguyen, T.; Yoo, H. A Coupled Geomechanics-Reservoir Simulation Workflow to Estimate the Optimal Well-Spacing in the Wolfcamp Formation in Lea County. In Proceedings of the AADE National Technical Conference and Exhibition, Midland, TX, USA, 4–5 April 2023; Zenodo: Geneva, Switzerland, 2023. [Google Scholar] [CrossRef]

- Yu, H.; Xu, W.; Li, B.; Huang, H.; Micheal, M.; Wang, Q.; Huang, M.; Meng, S.; Liu, H.; Wu, H. Hydraulic Fracturing and Enhanced Recovery in Shale Reservoirs: Theoretical Analysis to Engineering Applications. Energy Fuels 2023, 37, 9956–9997. [Google Scholar] [CrossRef]

- Malozyomov, B.V.; Martyushev, N.V.; Kukartsev, V.V.; Tynchenko, V.S.; Bukhtoyarov, V.V.; Wu, X.; Tyncheko, Y.A.; Kukartsev, V.A. Overview of Methods for Enhanced Oil Recovery from Conventional and Unconventional Reservoirs. Energies 2023, 16, 4907. [Google Scholar] [CrossRef]

- Daramola, G.O.; Jacks, B.S.; Ajala, O.A.; Akinoso, A.E. Ai applications in reservoir management: Optimizing production and recovery in oil and gas fields. Comput. Sci. IT Res. J. 2024, 5, 972–984. [Google Scholar] [CrossRef]

- Reddicharla, N.; Alshehhi, S.S.; Kumar, A.; Konkati, S.; Ali, M.S.; Elmansour, A. A Novel Digital Framework for Intelligent and Real-Time Water Injection System Management. In Proceedings of the SPE Water Lifecycle Management Conference and Exhibition, Abu Dhabi, United Arab Emirates, 5–7 March 2024; SPE: Abu Dhabi, United Arab Emirates, 2024; p. D021S010R006. [Google Scholar] [CrossRef]

- Al Sawafi, M.S.; Al Ghailani, T.A.; Al Kindi, O.; Al Abri, M.; Al Hinai, S. 13 Years of Comprehensive Reservoir Monitoring and Surveillance in South of Oman EOR Polymer Project. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023; SPE: Abu Dhabi, United Arab Emirates, 2023; p. D031S077R006. [Google Scholar] [CrossRef]

- Al Jawhari, M.O.; Bazuhair, A.K.; Lopez, J.E.; Alqemzi, M.; Cremades, P. Integration of a Production Optimization System with Intelligent Well Surveillance for an Effective Reservoir Management in Abu Dhabi Field. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023; SPE: Abu Dhabi, United Arab Emirates, 2023; p. D041S130R008. [Google Scholar] [CrossRef]

- Rubio, E.; Reddicharla, N. Enhanced Back Allocation Process Assisted by Real Time AI-Based Virtual Metering. Field Case Study in a Giant Field Project. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023; SPE: Abu Dhabi, United Arab Emirates, 2023; p. D041S135R005. [Google Scholar] [CrossRef]

- Kim, J.; Yoon, H.; Hwang, S.; Jeong, D.; Ki, S.; Liang, B.; Jeong, H. Real-Time Monitoring of CO2 Transport Pipelines Using Deep Learning. Process. Saf. Environ. Prot. 2024, 181, 480–492. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, J.; Li, Y.; Wu, L.; Qiao, M. Recent Development of Smart Field Deployment for Mature Waterflood Reservoirs. Sustainability 2023, 15, 784. [Google Scholar] [CrossRef]

- Khalifa, H.; Tomomewo, O.S.; Ndulue, U.F.; Berrehal, B.E. Machine Learning-Based Real-Time Prediction of Formation Lithology and Tops Using Drilling Parameters with a Web App Integration. Eng 2023, 4, 2443–2467. [Google Scholar] [CrossRef]

- Bello, K.; Vikara, D.; Sheriff, A.; Viswanathan, H.; Carr, T.; Sweeney, M.; O’Malley, D.; Marquis, M.; Vactor, R.T.; Cunha, L. Evaluation of the Economic Implications of Varied Pressure Drawdown Strategies Generated Using a Real-Time, Rapid Predictive, Multi-Fidelity Model for Unconventional Oil and Gas Wells. Gas Sci. Eng. 2023, 113, 204972. [Google Scholar] [CrossRef]

- Al Sawafi, M.M.; Aljabri, A. South Oman Polymer Project: A Decade of Operational Excellence and Comprehensive Reservoir Monitoring and Surveillance. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 2–5 October 2023; SPE: Tulsa, OK, USA, 2024; p. D021S010R004. [Google Scholar] [CrossRef]

- Ouladmansour, A.; Ameur-Zaimeche, O.; Kechiched, R.; Heddam, S.; Wood, D.A. Integrating Drilling Parameters and Machine Learning Tools to Improve Real-Time Porosity Prediction of Multi-Zone Reservoirs. Case Study: Rhourd Chegga Oilfield, Algeria. Geoenergy Sci. Eng. 2023, 223, 211511. [Google Scholar] [CrossRef]

- Al-Rbeawi, S. A Review of Modern Approaches of Digitalization in Oil and Gas Industry. Upstream Oil Gas Technol. 2023, 11, 100098. [Google Scholar] [CrossRef]

- Shi, W.; Yin, G.; Wang, M.; Tao, L.; Wu, M.; Yang, Z.; Bai, J.; Xu, Z.; Zhu, Q. Progress of Electrical Resistance Tomography Application in Oil and Gas Reservoirs for Development Dynamic Monitoring. Processes 2023, 11, 2950. [Google Scholar] [CrossRef]

- Paroha, A.D. Real-Time Monitoring of Oilfield Operations with Deep Neural Networks. In Proceedings of the 2024 2nd International Conference on Advancement in Computation & Computer Technologies (InCACCT), Gharuan, India, 2–3 May 2024; IEEE: Gharuan, India, 2024; pp. 176–181. [Google Scholar] [CrossRef]

- Maduabuchi, E. Artificial Intelligence (AI) Application in Process Safety Cumulative Risk Visualization for Petroleum Operations: Conceptual Framework. Int. J. Eng. Adv. Technol. Stud. 2024, 12, 33–49. [Google Scholar] [CrossRef]

- Al Aamri, G.; Al Bulushi, A.; Abelazim, M.; Kurniadi, S.D.; Al-Ghaiti, A.; Siddiqui, M.; Hassan, K.; Guzman, R.C.; Mowad, B.; Alyahyaai, H. Real-Time Data Harvesting: A Confirmation of Fracture Geometry Development and Production Using Fiber Optic in Deep Tight Gas Wells. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 22–24 April 2024; SPE: Muscat, Oman, 2024; p. D011S010R005. [Google Scholar] [CrossRef]

- Patil, P.D.; Al-Qasim, A.S.; Al-Zayani, A.I.; Kokal, S.L. End-To-End Surface and Subsurface Monitoring and Surveillance for the Onshore and Offshore CCS or CCUS Projects. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 1–4 May 2023; OTC: Houston, TX, USA, 2023; p. D011S002R008. [Google Scholar] [CrossRef]

- Pi, Y.; Liu, J.; Cao, R.; Liu, L.; Ma, Y.; Gu, X.; Li, X.; Fan, X.; Zhao, M. Visualized Study on a New Preformed Particle Gels (PPG) + Polymer System to Enhance Oil Recovery by Oil Saturation Monitoring Online Flooding Experiment. Gels 2023, 9, 81. [Google Scholar] [CrossRef] [PubMed]

- Yekeen, N.; Salampessy, S.N.; Abu Bakar, A.H.; Ali, M.; Okunade, O.A.; Musa, S.A.; Bavoh, C.B. Synthesis and Pore-Scale Visualization Studies of Enhanced Oil Recovery Mechanisms of Rice Straw Silica Nanoparticles. Geoenergy Sci. Eng. 2023, 221, 111292. [Google Scholar] [CrossRef]

- Wang, S.; Schultheiss, N.; Kim, S. DDDAS Within the Oil and Gas Industry. Handb. Dyn. Data Driven Appl. Syst. 2023, 2, 331–351. [Google Scholar]

- Chang, W.; Cheng, J.; Allaire, J.J.; Sievert, C.; Schloerke, B.; Xie, Y.; Allen, J.; McPherson, J.; Dipert, A.; Borges, B. Shiny: Web Application Framework for R. R Package Version 1.6.0. 2021. Available online: https://CRAN.R-project.org/package=shiny (accessed on 1 November 2021).

- Jiang, Z.; Cao, W.; Chu, H.; Bazerbachi, F.; Siegel, L. RIMeta: An R shiny tool for estimating the reference interval from a meta-analysis. Res. Synth. Methods 2023, 14, 468–478. [Google Scholar] [CrossRef] [PubMed]

- Hernández, A.; Endesfelder, D.; Einbeck, J.; Puig, P.; Benadjaoud, M.A.; Higueras, M.; Ainsbury, E.; Gruel, G.; Oestreicher, U.; Barrios, L.; et al. Biodose Tools: An R shiny application for biological dosimetry. Int. J. Radiat. Biol. 2023, 99, 1378–1390. [Google Scholar] [CrossRef] [PubMed]

- Meyer, E.L.; Kumaus, C.; Majka, M.; Koenig, F. An Interactive R-Shiny App for Quickly Visualizing a Tidy, Long Dataset with Multiple Dimensions with an Application in Clinical Trial Simulations for Platform Trials. SoftwareX 2023, 22, 101347. [Google Scholar] [CrossRef]

- Llambrich, M.; Satorra, P.; Correig, E.; Guma, J.; Brezmes, J.; Tebe, C.; Cumeras, R. Easy-Amanida: An R Shiny application for the meta-analysis of aggregate results in clinical metabolomics using Amanida and Webchem. Res. Synth. Methods 2024, 15, e1713. [Google Scholar] [CrossRef] [PubMed]

- Yik, B.J.; Schreurs, D.G.; Raker, J.R. Implementation of an R Shiny App for Instructors: An Automated Text Analysis Formative Assessment Tool for Evaluating Lewis Acid–Base Model Use. J. Chem. Educ. 2023, 100, 3107–3113. [Google Scholar] [CrossRef]

- Zhan, L.; Luo, X.; Xie, W.; Zhu, X.-A.; Xie, Z.; Lin, J.; Li, L.; Tang, W.; Wang, R.; Deng, L.; et al. shinyTempSignal: An R Shiny Application for Exploring Temporal and Other Phylogenetic Signals. J. Genet. Genom. 2024, 51, 762–768. [Google Scholar] [CrossRef]

- Wickham, H. Ggplot2: Elegant Graphics for Data Analysis; Springer: New York, NY, USA, 2016. [Google Scholar]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; ACM: New York, NY, USA, 2016; pp. 785–794. [Google Scholar] [CrossRef]

- Bahaloo, S.; Mehrizadeh, M.; Najafi-Marghmaleki, A. Review of Application of Artificial Intelligence Techniques in Petroleum Operations. Pet. Res. 2023, 8, 167–182. [Google Scholar] [CrossRef]

- Abdalla, R.; Al-Hakimi, W.; Perozo, N.; Jaeger, P. Real-Time Liquid Rate and Water Cut Prediction From the Electrical Submersible Pump Sensors Data Using Machine-Learning Algorithms. ACS Omega 2023, 8, 12671–12692. [Google Scholar] [CrossRef]

- Li, J.; Guo, Y.; Fu, Z.; Zhang, X.; Shen, F. An Intelligent Energy Management Information System with Machine Learning Algorithms in Oil and Gas Industry. Edited by Chia-Huei Wu. Wirel. Commun. Mob. Comput. 2023, 2023, 3385453. [Google Scholar] [CrossRef]

- Elahifar, B.; Hosseini, E. A New Approach for Real-Time Prediction of Stick–Slip Vibrations Enhancement Using Model Agnostic and Supervised Machine Learning: A Case Study of Norwegian Continental Shelf. J. Pet. Explor. Prod. Technol. 2023, 14, 175–201. [Google Scholar] [CrossRef]

- Khaled, M.S.; Wang, N.; Ashok, P.; van Oort, E.; Wisian, K. Real-Time Prediction of Bottom-Hole Circulating Temperature in Geothermal Wells Using Machine Learning Models. Geoenergy Sci. Eng. 2024, 238, 212891. [Google Scholar] [CrossRef]

- Sircar, A.; Yadav, K.; Rayavarapu, K.; Bist, N.; Oza, H. Application of machine learning and artificial intelligence in oil and gas industry. Pet. Res. 2021, 6, 379–391. [Google Scholar] [CrossRef]

- Wu, C.; Merzoug, A.; Wan, X.; Ling, K.; Zhao, J.; Jiang, T.; Jin, L. Development of a New CO2 EOR Screening Approach Focused on Deep-Depth Reservoirs. Geoenergy Sci. Eng. 2023, 231, 212335. [Google Scholar] [CrossRef]

- Motaei, E.; Ganat, T. Smart Proxy Models Art and Future Directions in the Oil and Gas Industry: A Review. Geoenergy Sci. Eng. 2023, 227, 211918. [Google Scholar] [CrossRef]

- Asante, J.; Ampomah, W.; Carther, M. Forecasting Oil Recovery Using Long Short Term Memory Neural Machine Learning Technique. In Proceedings of the SPE Western Regional Meeting, Anchorage, AK, USA, 22–25 May 2023; SPE: Anchorage, AK, USA, 2023; p. D021S004R004. [Google Scholar] [CrossRef]

- Nagao, M.; Yao, C.; Onishi, T.; Chen, H.; Datta-Gupta, A.; Mishra, S. An Efficient Deep Learning-Based Workflow for CO2 Plume Imaging Considering Model Uncertainties with Distributed Pressure and Temperature Measurements. Int. J. Greenh. Gas Control 2024, 132, 104066. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Luo, X.; Adenutsi, C.D.; Zhao, G.; Lai, F. A Critical Review on Intelligent Optimization Algorithms and Surrogate Models for Conventional and Unconventional Reservoir Production Optimization. Fuel 2023, 350, 128826. [Google Scholar] [CrossRef]

- Alrowayyeh, J.; Dhote, P.; Alqenaei, A. Machine Learning Model for Efficient Surveillance of Electrostatic Pump Operations & Predictive Analytics for Early Alarming System. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 22–24 April 2024; SPE: Muscat, Oman, 2024; p. D031S032R004. [Google Scholar] [CrossRef]

- Su, S.; Zhang, N.; Wang, P.; Jia, S.; Zhang, A.; Wang, H.; Zhang, M. Investigation and Optimization of EOR Screening by Implementing Machine Learning Algorithms. Appl. Sci. 2023, 13, 12267. [Google Scholar] [CrossRef]

- Nagao, M.; Datta-Gupta, A.; Onishi, T.; Sankaran, S. Reservoir Connectivity Identification and Robust Production Forecasting Using Physics Informed Machine Learning. In Proceedings of the SPE Reservoir Simulation Conference, Galveston, TX, USA, 28–30 March 2023; SPE: Galveston, TX, USA, 2023; p. D011S004R002. [Google Scholar] [CrossRef]

- Yao, C.; Nagao, M.; Datta-Gupta, A.; Mishra, S. An Efficient Deep Learning-Based Workflow for Real-Time CO2 Plume Visualization in Saline Aquifer Using Distributed Pressure and Temperature Measurements. Geoenergy Sci. Eng. 2024, 239, 212990. [Google Scholar] [CrossRef]

- Bigdeli, A.; Delshad, M. The Evolving Landscape of Oil and Gas Chemicals: Convergence of Artificial Intelligence and Chemical-Enhanced Oil Recovery in the Energy Transition Toward Sustainable Energy Systems and Net-Zero Emissions. J. Data Sci. Intell. Syst. 2024, 2, 65–78. [Google Scholar] [CrossRef]

- Azmi, P.A.R.; Yusoff, M.; Sallehud-Din, M.T.M. A Review of Predictive Analytics Models in the Oil and Gas Industries. Sensors 2024, 24, 4013. [Google Scholar] [CrossRef] [PubMed]

- Samnioti, A.; Gaganis, V. Applications of Machine Learning in Subsurface Reservoir Simulation—A Review—Part II. Energies 2023, 16, 6727. [Google Scholar] [CrossRef]

- Mao, J.; Ghahfarokhi, A.J. A Review of Intelligent Decision-Making Strategy for Geological CO2 Storage: Insights from Reservoir Engineering. Geoenergy Sci. Eng. 2024, 240, 212951. [Google Scholar] [CrossRef]

- Fetisov, V.; Ilyushin, Y.V.; Vasiliev, G.G.; Leonovich, I.A.; Müller, J.; Riazi, M.; Mohammadi, A.H. Development of the Automated Temperature Control System of the Main Gas Pipeline. Sci. Rep. 2023, 13, 3092. [Google Scholar] [CrossRef]

- Arinze, C.A.; Ajala, O.A.; Okoye, C.C.; Ofodile, O.C.; Daraojimba, A.I. Evaluating the integration of advanced it solutions for emission reduction in the oil and gas sector. Eng. Sci. Technol. J. 2024, 5, 639–652. [Google Scholar] [CrossRef]

- Knebel, F.P.; Trevisan, R.; Nascimento, G.S.D.; Abel, M.; Wickboldt, J.A. A Study on Cloud and Edge Computing for the Implementation of Digital Twins in the Oil & Gas Industries. Comput. Ind. Eng. 2023, 182, 109363. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Anthi, E.; Rana, O.; Saxena, N.; Burnap, P. Detection and Mitigation of Field Flooding Attacks on Oil and Gas Critical Infrastructure Communication. Comput. Secur. 2023, 124, 103007. [Google Scholar] [CrossRef]

- Yuan, B.; Zhao, M.; Meng, S.; Zhang, W.; Zheng, H. Intelligent Identification and Real-Time Warning Method of Diverse Complex Events in Horizontal Well Fracturing. Pet. Explor. Dev. 2023, 50, 1487–1496. [Google Scholar] [CrossRef]

- Ramizah, A.R.; Gordon, G.K.F.; Tina, L.L.T.; Varma, G.; Muzahidin, M.S.; Willem, S.; Ahmad, S.H.; Sanggeetha, K.; Lester, T.M.; Khairul, A.M.; et al. Real-Time Surveillance and Analysis Tool for Intelligent Completion—An Ultimate Solution to Oil Recovery and Integrated Operation. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017; SPE: Jakarta, Indonesia, 2017; p. D011S004R005. [Google Scholar] [CrossRef]

- Ohalete, N.C.; Aderibigbe, A.O.; Ani, E.C.; Ohenhen, P.E.; Akinoso, A. Advancements in Predictive Maintenance in the Oil and Gas Industry: A Review of AI and Data Science Applications. World J. Adv. Res. Rev. 2023, 20, 167–181. [Google Scholar] [CrossRef]

- Ochulor, O.J.; Sofoluwe, O.O.; Ukato, A.; Jambol, D.D. Challenges and Strategic Solutions in Commissioning and Start-up of Subsea Production Systems. Magna Sci. Adv. Res. Rev. 2024, 11, 31–39. [Google Scholar] [CrossRef]

- Oyewole, A.T.; Okoye, C.C.; Ofodile, O.C.; Odeyemi, O.; Adeoye, O.B.; Addy, W.A.; Ololade, Y.J. Human resource management strategies for safety and risk mitigation in the oil and gas industry: A review. Int. J. Manag. Entrep. Res. 2024, 6, 623–633. [Google Scholar] [CrossRef]

- Jambol, D.D.; Sofoluwe, O.O.; Ukato, A.; Ochulor, O.J. Enhancing oil and gas production through advanced instrumentation and control systems. GSC Adv. Res. Rev. 2024, 19, 043–056. [Google Scholar]

- Wang, Z.-Z.; Zhang, K.; Chen, G.-D.; Zhang, J.-D.; Wang, W.-D.; Wang, H.-C.; Zhang, L.-M.; Yan, X.; Yao, J. Evolutionary-Assisted Reinforcement Learning for Reservoir Real-Time Production Optimization under Uncertainty. Pet. Sci. 2023, 20, 261–276. [Google Scholar] [CrossRef]

- Radich, A.; Filho, S.M.; Borges, R.; Scheid, C.; Meleiro, L.; Calçada, L. Real-Time Control and Monitoring of Drilling Fluids Density by Fuzzy-Based Control System. Geoenergy Sci. Eng. 2023, 222, 211421. [Google Scholar] [CrossRef]

- Zhao, J.; Jin, L.; Yu, X.; Azzolina, N.A.; Wan, X.; Smith, S.A.; Bosshart, N.W.; Sorensen, J.A. Field Implementation and Surveillance of Gas Injection Enhanced Oil Recovery in the Bakken. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 17–19 June 2024; URTeC: Houston, TX, USA, 2024; p. D021S042R001. [Google Scholar] [CrossRef]

| Case No. | Pilot Start Year | Injectate | Operational Method | Operator/ Reporter | State/ County | Routine Data | Monitoring Methods/Data Reported | Data Source |

|---|---|---|---|---|---|---|---|---|

| 1 | 1994 | Water | HnP 1 | Meridian | ND/McKenzie | MPIR 2, well logs | [41] | |

| 2 | 2012 | Water | HnP | EOG | ND/Mountrail | MPIR, well logs | [41] | |

| 3 | 2014 | Water | Flooding | Montana Tech | MT/(county N/A 3) | MPIR | Daily injection rate | [12,41] |

| 4 | 2015 | Surfactant | HnP | Nalco Champion | ND/(county N/A) | MPIR | [8] | |

| 5 | 2008 | CO2 | HnP | EOG | ND/Mountrail | MPIR, well logs | [41] | |

| 6 | 2009 | CO2 | HnP | Continental | MT/(county N/A) | MPIR | [12] | |

| 7 | 2014 | CO2 | Flooding/injectivity | Whiting | ND/Mountrail | MPIR, well logs | Daily injection rate, WHP 4, gas composition | [41] |

| 8 | 2017 | CO2 | Injectivity | XTO | ND/Dunn | MPIR, well logs | Daily injection rate, BHP, gas composition, oil composition, well logs | [13,41] |

| 9 | 2017 | Propane | Flooding | Hess | ND/Mountrail | MPIR, well logs | Daily production/injection rates, WHP, gas composition, tracer testing | [17,41] |

| 10 | 2014 | Rich gas | Flooding | EOG | ND/Mountrail | MPIR, well logs | [41] | |

| 11 | 2018 | Rich gas | HnP | Liberty | ND/Williams | MPIR, well logs | Daily production/injection rates, BHP, gas composition, tracer testing | [14,41] |

| 12 | 2021 | Rich gas, water, surfactant | HnP | Liberty | ND/Mountrail | MPIR, well logs | Minutely and daily production/injection rates, WHP, BHP | [15,41] |

| Parameter | Value/Observation |

|---|---|

| Native reservoir pressure, psi | 8668 |

| Initial bottomhole temperature, °F | 255 |

| Minimum injection rate, gallons/minute (gpm) | 4.5 |

| Maximum BHP achieved, psi | 9113 |

| Tubing integrity to the injection pressure | Held up |

| Downhole gauge measurements | Effective |

| Fluid influx into the well | Low but consistent |

| Activity | Duration, Hour | Daily Sequence |

|---|---|---|

| Site preparation | 16 | 1 |

| Cyclic injection part 1 | 16 | 2 |

| Cyclic injection part 2 | 32 | 2–3 |

| Continuous injection | 32 | 4–5 |

| Shut-in | 4 | 5 |

| Day | Activity | Cumulative CO2 Injected, Tons |

|---|---|---|

| 1 | Filling | 10.4 |

| 1 | BHP from 8200 to 8600 psi | 0.2 |

| 1 | Cyclic inj.—Part 1 | 1.0 |

| 2 | Cyclic inj.—Part 1 | 5.4 |

| 2 | Cyclic inj.—Part 2 | 4.2 |

| 2 | Cyclic inj.—Part 2 | 4.7 |

| 3 | Cont. inj. | 8.1 |

| 4 | Cont. inj. | 51.8 |

| 5 | Cont. inj. | 13.0 |

| Total | 98.9 | |

| Parameter | Value |

|---|---|

| HnP well | MB2 |

| Injection rate, MMscf/d | 1, 3, 6 |

| HnP length, year | 2 |

| Injection–soaking–production time, days/cycle | 30–7–60 |

| Injection gas composition (C1:C2:C3 in mole fraction) | 0.7:0.2:0.1 |

| Maximum injection pressure (BHP), psi | 7500 |

| Minimum production pressure (BHP), psi | 100 |

| No. | Component | Tracer | No. | Component | Tracer |

|---|---|---|---|---|---|

| 1 | N2 | N/A | 5 | IC4 to NC4 | N/A |

| 2 | CH4 | TRC-C1 | 6 | IC5 to C12 | N/A |

| 3 | C2H6 | TRC-C2 | 7 | C13 to C19 | N/A |

| 4 | C3H8 | TRC-C3 | 8 | C20 to C30 | N/A |

| Simulation Case No. | Indicator | TF2 and TF3 during Injection | MB1, MB3, TF1, and TF4 during Injection | Inj. Rate, MMscfd | Max. Inj. BHP, psi |

|---|---|---|---|---|---|

| 1–28 | Propane | Shut in | Shut in | 0.5–18 | 1500–7500 |

| 29–56 | Propane | Shut in | Open | 0.5–18 | 1500–7500 |

| 57–84 | Tracer | Shut in | Shut in | 0.5–18 | 1500–7500 |

| 85–112 | Tracer | Shut in | Open | 0.5–18 | 1500–7500 |

| Date (MM/DD/YY) | Cycle | |||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| Injection start | 01/01/20 | 04/07/20 | 07/13/20 | 10/18/20 | 01/23/21 | 04/30/21 | 08/05/21 | 11/10/21 |

| Injection end | 01/30/20 | 05/06/20 | 08/11/20 | 11/16/20 | 02/21/21 | 05/29/21 | 09/03/21 | 12/09/21 |

| Soaking start | 01/31/20 | 05/07/20 | 08/12/20 | 11/17/20 | 02/22/21 | 05/30/21 | 09/04/21 | 12/10/21 |

| Soaking end | 02/06/20 | 05/13/20 | 08/18/20 | 11/23/20 | 02/28/21 | 06/05/21 | 09/10/21 | 12/16/21 |

| Production start | 02/07/20 | 05/14/20 | 08/19/20 | 11/24/20 | 03/01/21 | 06/06/21 | 09/11/21 | 12/17/21 |

| Production end | 04/06/20 | 07/12/20 | 10/17/20 | 01/22/21 | 04/29/21 | 08/04/21 | 11/09/21 | 12/31/21 |

| Stage | Cycle 1 as an Example | Well Status | |

|---|---|---|---|

| Date (MM/DD/YY) | Open | Closed | |

| Injection | 01/01/20 to 01/30/20 | MB2 (injecting) | --- |

| Soaking | 01/31/20 to 02/06/20 | --- | MB2 |

| Producing | 02/07/20 to 04/06/20 | MB2 | --- |

| Stage | Cycle 1 as an Example | Well Status | |

|---|---|---|---|

| Date (MM/DD/YY) | Open | Closed | |

| Injection | 01/01/20 to 01/30/20 | MB2 (injecting) | TF2, TF3 |

| Soaking | 01/31/20 to 02/06/20 | --- | TF2, MB2, TF3 |

| Producing | 02/07/20 to 04/06/20 | TF2, MB2, TF3 | --- |

| Parameter | Description |

|---|---|

| nrounds | Maximum number of iterations |

| max_depth | Maximum depth of the tree |

| gamma | Regularization coefficient |

| min_child_weight | Minimum number of instances required in a child node |

| eta | Learning rate |

| subsample | Number of samples supplied to a tree |

| colsample_bytree | Number of features (variables) supplied to a tree |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Jin, L.; Yu, X.; Azzolina, N.A.; Wan, X.; Smith, S.A.; Bosshart, N.W.; Sorensen, J.A.; Ling, K. Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play—Technical Review and Machine Learning Study. Energies 2024, 17, 4200. https://doi.org/10.3390/en17174200

Zhao J, Jin L, Yu X, Azzolina NA, Wan X, Smith SA, Bosshart NW, Sorensen JA, Ling K. Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play—Technical Review and Machine Learning Study. Energies. 2024; 17(17):4200. https://doi.org/10.3390/en17174200

Chicago/Turabian StyleZhao, Jin, Lu Jin, Xue Yu, Nicholas A. Azzolina, Xincheng Wan, Steven A. Smith, Nicholas W. Bosshart, James A. Sorensen, and Kegang Ling. 2024. "Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play—Technical Review and Machine Learning Study" Energies 17, no. 17: 4200. https://doi.org/10.3390/en17174200

APA StyleZhao, J., Jin, L., Yu, X., Azzolina, N. A., Wan, X., Smith, S. A., Bosshart, N. W., Sorensen, J. A., & Ling, K. (2024). Progress of Gas Injection EOR Surveillance in the Bakken Unconventional Play—Technical Review and Machine Learning Study. Energies, 17(17), 4200. https://doi.org/10.3390/en17174200