In-Plane Liftout and Push-to-Pull for In Situ Mechanical Testing of Irradiated Inconel X-750

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

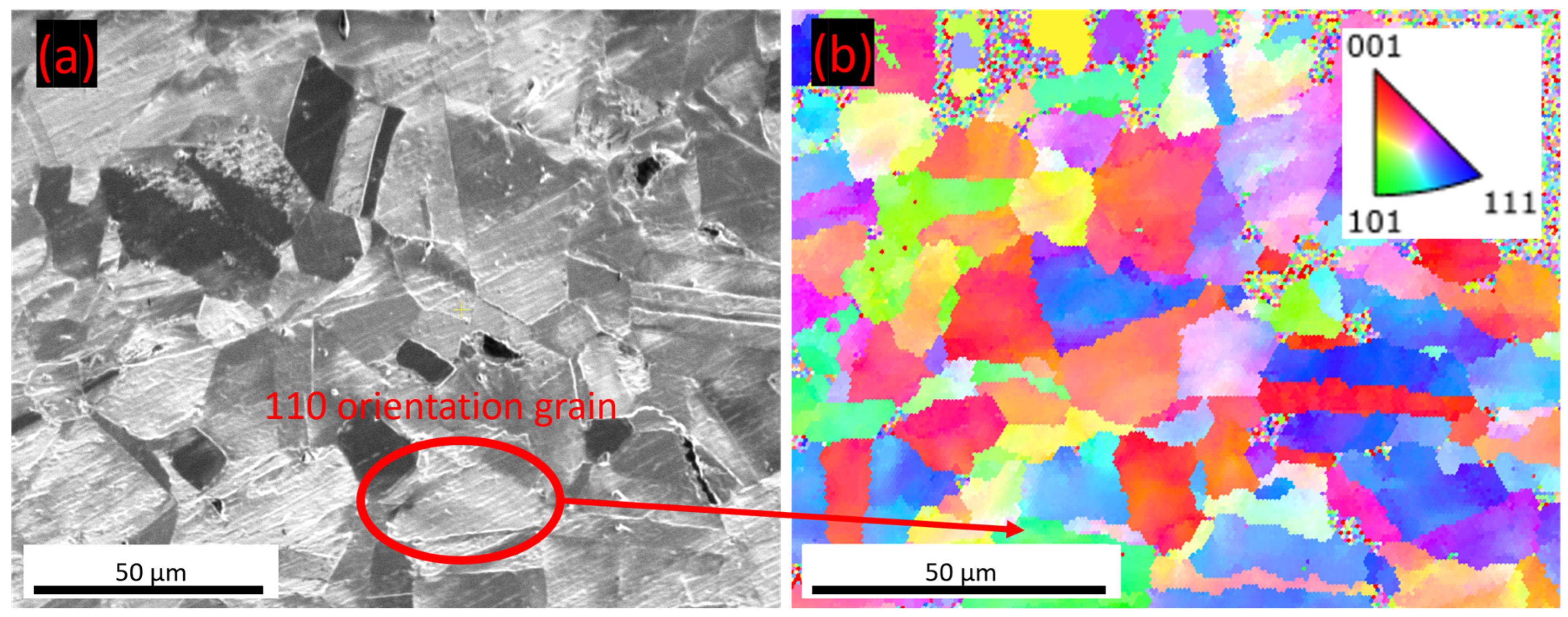

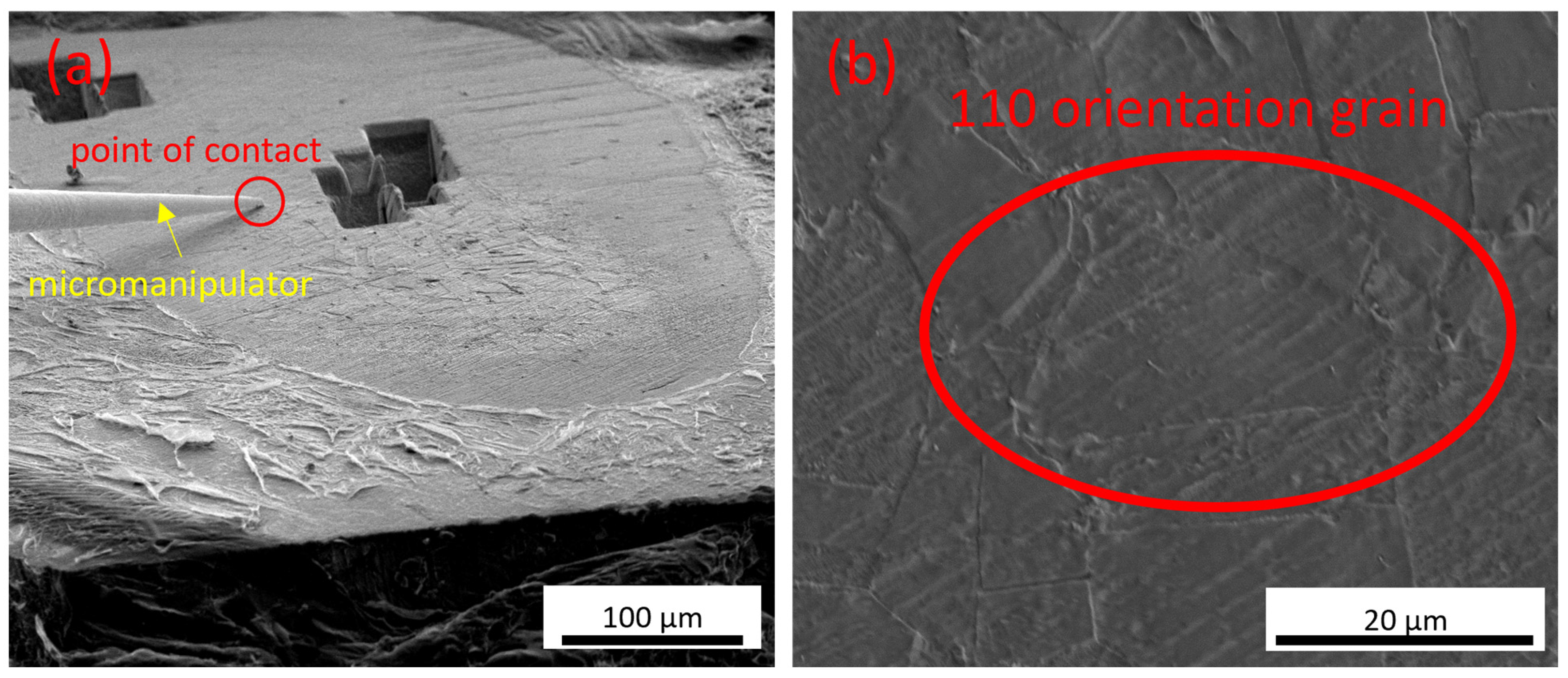

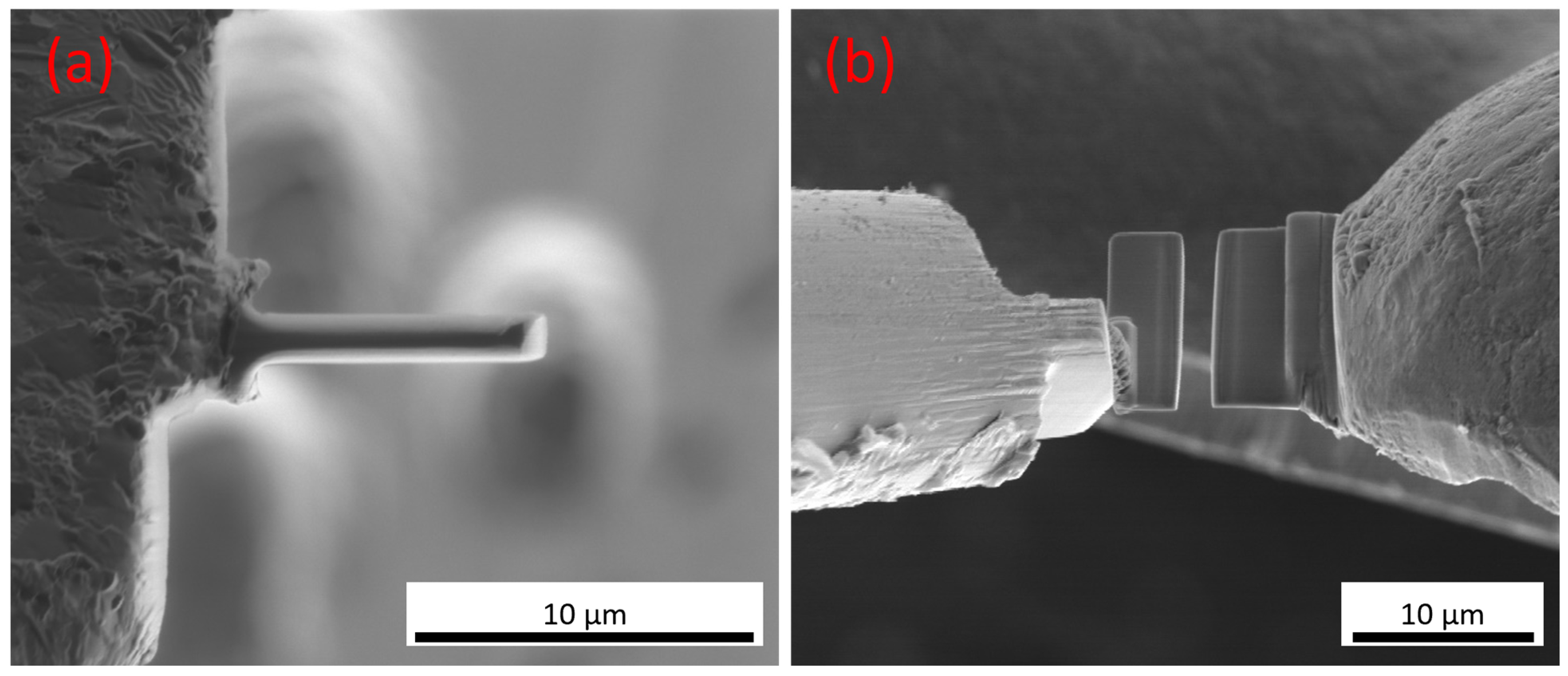

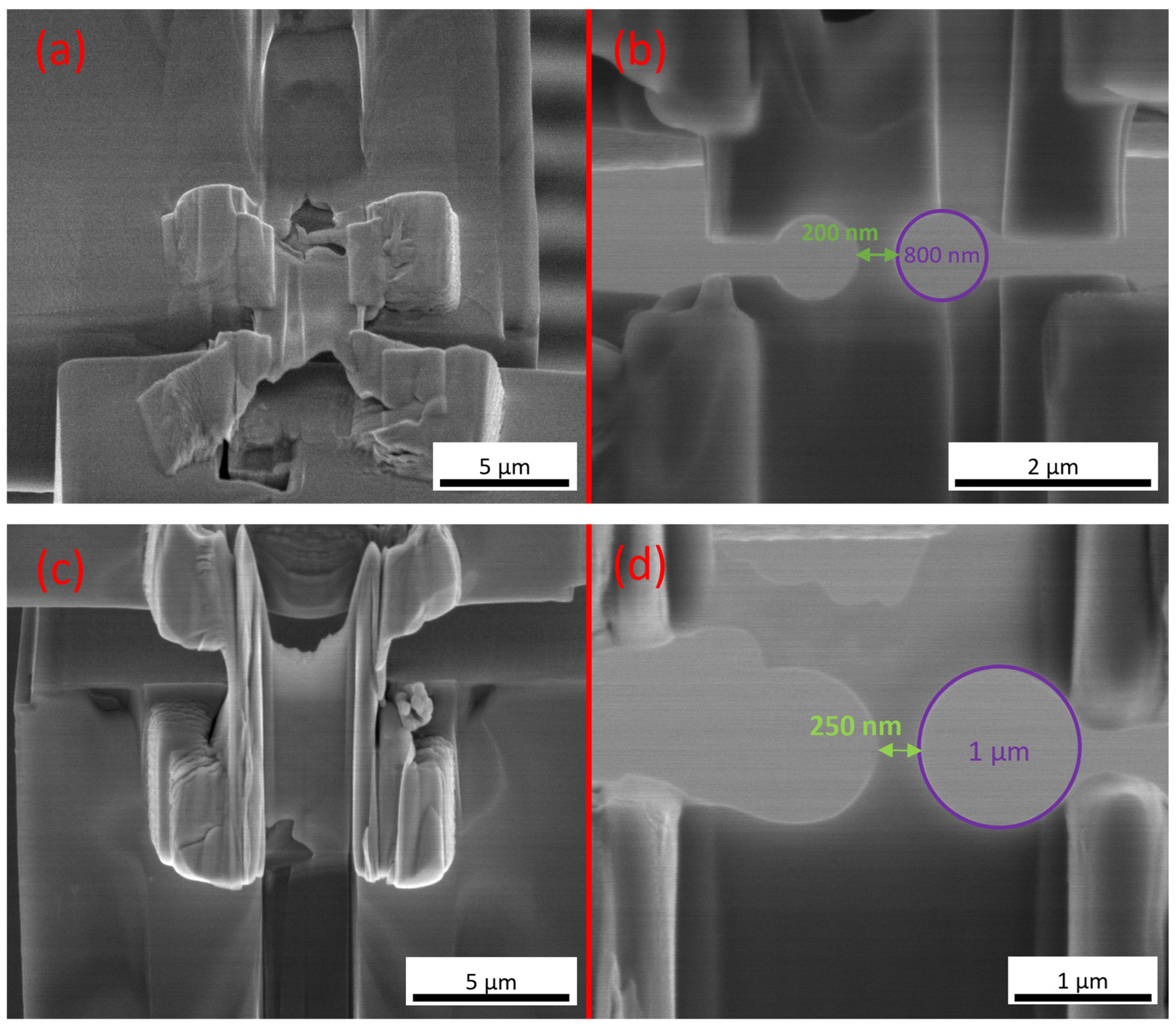

3.1. In-Plane Liftout

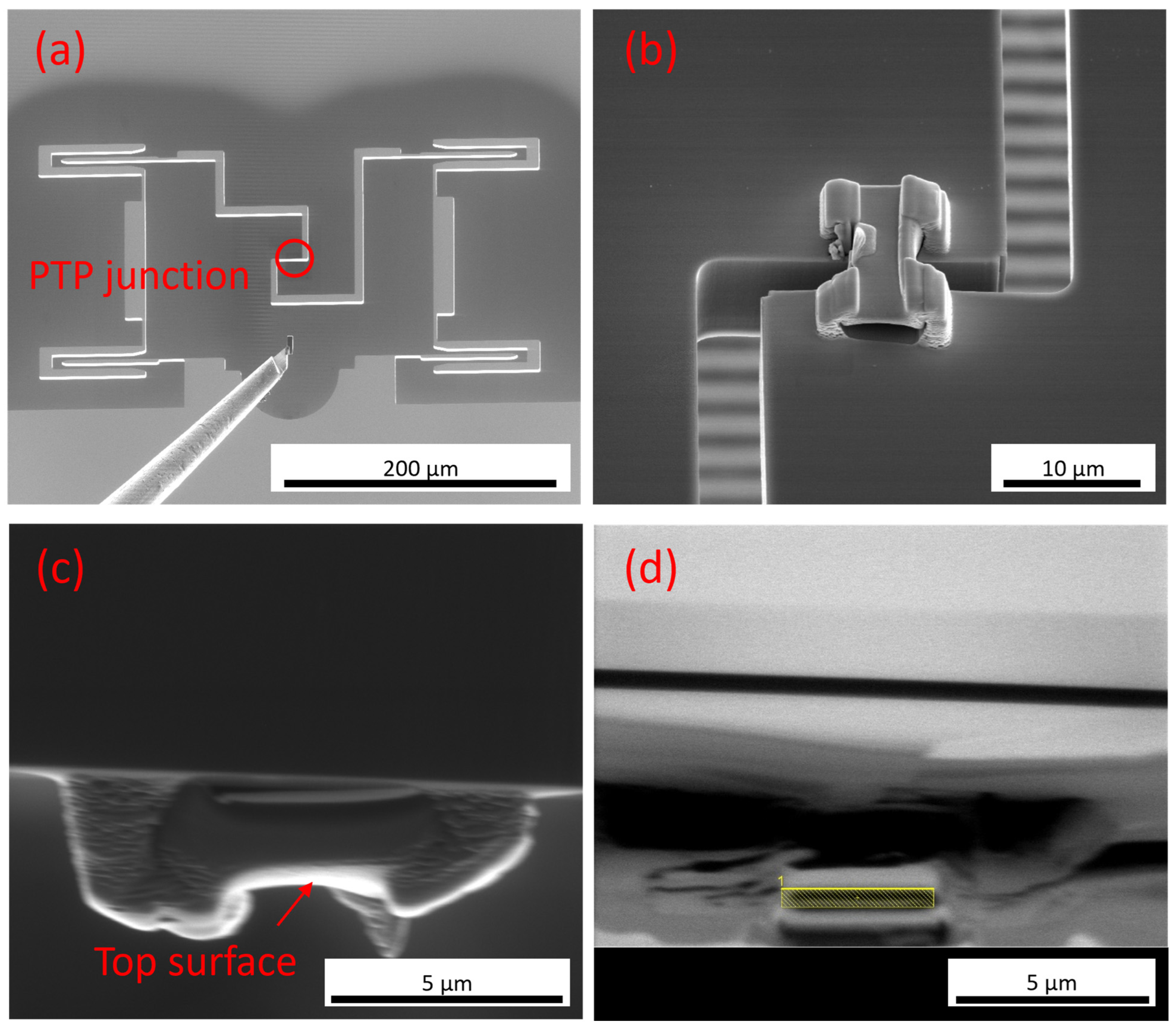

3.2. Post-Irradiation Examination and Nanomechanical Testing

4. Discussion

4.1. On the In-Plane Sample Preparation Method

4.2. On the In Situ Mechanical Testing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Kiener, D.; Motz, C.; Rester, M.; Jenko, M.; Dehm, G. FIB damage of Cu and possible consequences for miniaturized mechanical tests. Mater. Sci. Eng. A 2007, 459, 262–272. [Google Scholar] [CrossRef]

- Mayer, J.; Giannuzzi, L.A.; Kamino, T.; Michael, J. TEM Sample Preparation and FIB-Induced Damage. MRS Bull. 2007, 32, 400–407. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Busby, J.T. Structural materials for fission & fusion energy. Mater. Today 2009, 12, 12–19. [Google Scholar] [CrossRef]

- Dey, G.K. Structural Materials in Nuclear Energy Sector. In Future Landscape of Structural Materials in India; Bhattacharjee, D., Chakrabarti, S., Eds.; Springer Nature: Singapore, 2022; pp. 59–77. [Google Scholar]

- Murty, K.L.; Charit, I. Structural materials for Gen-IV nuclear reactors: Challenges and opportunities. J. Nucl. Mater. 2008, 383, 189–195. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Judge, C.D.; Griffiths, M.; Walters, L.; Wright, M.; Bickel, G.A.; Woo, O.T.; Stewart, M.; Douglas, S.R.; Garner, F.A. Embrittlement of Nickel Alloys in a CANDU Reactor Environment. In Effects of Radiation on Nuclear Materials: 25th Volume; Yamamoto, T., Ed.; ASTM International: West Conshohocken, PA, USA, 2013; pp. 161–175. [Google Scholar]

- Bruemmer, S.M.; Simonen, E.P.; Scott, P.M.; Andresen, P.L.; Was, G.S.; Nelson, J.L. Radiation-induced material changes and susceptibility to intergranular failure of light-water-reactor core internals. J. Nucl. Mater. 1999, 274, 299–314. [Google Scholar] [CrossRef]

- Griffiths, M. Ni-Based Alloys for Reactor Internals and Steam Generator Applications. In Structural Alloys for Nuclear Energy Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 349–409. [Google Scholar]

- Zhang, H.K.; Yao, Z.; Kirk, M.A.; Daymond, M.R. Stability of Ni3(Al, Ti) Gamma Prime Precipitates in a Nickel-Based Superalloy Inconel X-750 Under Heavy Ion Irradiation. Metall. Mater. Trans. A 2014, 45, 3422–3428. [Google Scholar] [CrossRef]

- Changizian, P.; Brooks, A.; Yao, Z.; Daymond, M.R. Nano-scale Mechanical Properties and Microstructure of Irradiated X-750 Ni-Based Superalloy. Metall. Mater. Trans. A 2018, 49, 498–514. [Google Scholar] [CrossRef]

- Mills, W.J. The deformation and fracture characteristics of inconel X-750 at room temperature and elevated temperatures. Metall. Trans. A 1980, 11, 1039–1047. [Google Scholar] [CrossRef]

- Gabrielli, F.; Pelloux, R.M. Effect of Environment on Fatigue and Creep Crack Growth in Inconel X-750 at Elevated Temperature. Metall. Trans. A 1982, 13, 1083–1090. [Google Scholar] [CrossRef]

- Venkiteswaran, P.K.; Taplin, D.M.R. The Creep Fracture of Inconel X-750 at 700 °C. Met. Sci. 1974, 8, 97–106. [Google Scholar] [CrossRef]

- Kacher, J.; Kirchlechner, C.; Michler, J.; Polatidis, E.; Schwaiger, R.; Van Swygenhoven, H.; Taheri, M.; Legros, M. Impact of in situ nanomechanics on physical metallurgy. MRS Bull. 2019, 44, 465–470. [Google Scholar] [CrossRef]

- Greer, J.R.; Kim, J.-Y.; Burek, M.J. The in-situ mechanical testing of nanoscale single-crystalline nanopillars. JOM 2009, 61, 19–25. [Google Scholar] [CrossRef]

- Yu, Q.; Legros, M.; Minor, A.M. In situ TEM nanomechanics. MRS Bull. 2015, 40, 62–70. [Google Scholar] [CrossRef]

- Kobler, A.; Brandl, C.; Hahn, H.; Kübel, C. In situ observation of deformation processes in nanocrystalline face-centered cubic metals. Beilstein J. Nanotechnol. 2016, 7, 572–580. [Google Scholar] [CrossRef] [PubMed]

- Kobler, A.; Kashiwar, A.; Hahn, H.; Kübel, C. Combination of in situ straining and ACOM TEM: A novel method for analysis of plastic deformation of nanocrystalline metals. Ultramicroscopy 2013, 128, 68–81. [Google Scholar] [CrossRef]

- Kiener, D.; Motz, C.; Dehm, G.; Pippan, R. Overview on established and novel FIB based miniaturized mechanical testing using in-situ SEM. Int. J. Mater. Res. 2009, 100, 1074–1087. [Google Scholar] [CrossRef]

- Legros, M.; Gianola, D.S.; Motz, C. Quantitative In Situ Mechanical Testing in Electron Microscopes. MRS Bull. 2010, 35, 354–360. [Google Scholar] [CrossRef]

- Griffiths, M.; Walters, L.; Greenwood, L.; Garner, F. Accelerated materials evaluation for nuclear applications. J. Nucl. Mater. 2017, 488, 46–62. [Google Scholar] [CrossRef]

- Greenwood, L.R.; Smither, R.K. SPECTER: Neutron Damage Calculations for Materials Irradiations; ANL/FPP/TM-197; Argonne National Laboratory: Argonne, IL, USA, 1985. [Google Scholar]

- Howard, C.; Judge, C.; Poff, D.; Parker, S.; Griffiths, M.; Hosemann, P. A novel in-situ, lift-out, three-point bend technique to quantify the mechanical properties of an ex-service neutron irradiated inconel X-750 component. J. Nucl. Mater. 2018, 498, 149–158. [Google Scholar] [CrossRef]

- Aitkaliyeva, A.; Madden, J.; Miller, B.; Hyde, T. Radioactive Sample Preparation using Focused Ion Beam. Microsc. Microanal. 2013, 19, 904–905. [Google Scholar] [CrossRef]

- Wirth, R. Focused Ion Beam (FIB) combined with SEM and TEM: Advanced analytical tools for studies of chemical composition, microstructure and crystal structure in geomaterials on a nanometre scale. Chem. Geol. 2009, 261, 217–229. [Google Scholar] [CrossRef]

- Bikmukhametov, I.; Koenig, T.R.; Tucker, G.J.; Thompson, G.B. A rapid preparation method for in situ nanomechanical TEM tensile specimens. J. Mater. Res. 2021, 36, 2315–2324. [Google Scholar] [CrossRef]

- Tang, L.J.; Zhang, Y.J.; Bosman, M.; Jasmine, W. Study of ion beam damage on FIB prepared TEM samples. In Proceedings of the 2010 17th IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA 2010), Singapore, 5–9 July 2010; pp. 1–4. [Google Scholar]

- Drezner, Y.; Greenzweig, Y.; Tan, S.; Livengood, R.H.; Raveh, A. High resolution TEM analysis of focused ion beam amorphized regions in single crystal silicon—A complementary materials analysis of the teardrop method. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Pheno 2017, 35, 011801. [Google Scholar] [CrossRef]

- Bufford, D.C.; Stauffer, D.; Mook, W.M.; Syed Asif, S.A.; Boyce, B.L.; Hattar, K. High Cycle Fatigue in the Transmission Electron Microscope. Nano Lett. 2016, 16, 4946–4953. [Google Scholar] [CrossRef]

- Gammer, C.; Kacher, J.; Czarnik, C.; Warren, O.L.; Ciston, J.; Minor, A.M. Local and transient nanoscale strain mapping during in situ deformation. Appl. Phys. Lett. 2016, 109, 081906. [Google Scholar] [CrossRef]

- Samaeeaghmiyoni, V.; Idrissi, H.; Groten, J.; Schwaiger, R.; Schryvers, D. Quantitative in-situ TEM nanotensile testing of single crystal Ni facilitated by a new sample preparation approach. Micron 2017, 94, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Warren, P.H.; Warren, G.; Dubey, M.; Burns, J.; Wu, Y.Q.; Wharry, J.P. Method for Fabricating Depth-Specific TEM In Situ Tensile Bars. JOM 2020, 72, 2057–2064. [Google Scholar] [CrossRef]

- Idrissi, H.; Samaee, V.; Lumbeeck, G.; Van Der Werf, T.; Pardoen, T.; Schryvers, D.; Cordier, P. In Situ Quantitative Tensile Testing of Antigorite in a Transmission Electron Microscope. JGR Solid Earth 2020, 125, e2019JB018383. [Google Scholar] [CrossRef]

- Changizian, P.; Lu, C.; Yao, Z.; Wang, L. Indentation behaviour of ion-irradiated X-750 Ni-based superalloy. Philos. Mag. Lett. 2017, 97, 101–109. [Google Scholar] [CrossRef]

- Iakoubovskii, K.; Mitsuishi, K.; Nakayama, Y.; Furuya, K. Thickness measurements with electron energy loss spectroscopy. Microsc. Res Tech. 2008, 71, 626–631. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, X.; Murray, D.J.; Teng, F.; Jiang, W.; Bachhav, M.; Hawkins, L.; Perez, E.; Sun, C.; Bai, X.; et al. Measurement of grain boundary strength of Inconel X-750 superalloy using in-situ micro-tensile testing techniques in FIB/SEM system. Mater. Sci. Eng. A 2022, 849, 143475. [Google Scholar] [CrossRef]

- Howard, C.; Bhakhri, V.; Dixon, C.; Rajakumar, H.; Mayhew, C.; Judge, C.D. Coupling multi-scale mechanical testing techniques reveals the existence of a trans-granular channel fracture deformation mechanism in high dose Inconel X-750. J. Nucl. Mater. 2019, 517, 17–34. [Google Scholar] [CrossRef]

- Wang, K.; Du, D.; Liu, G.; Pu, Z.; Chang, B.; Ju, J. Microstructure and mechanical properties of high chromium nickel-based superalloy fabricated by laser metal deposition. Mater. Sci. Eng. A 2020, 780, 139185. [Google Scholar] [CrossRef]

- Slone, C.E.; Miao, J.; Mills, M.J. Ultra-high strength and ductility from rolling and annealing of a Ni-Cr-Co superalloy. Scr. Mater. 2018, 155, 94–98. [Google Scholar] [CrossRef]

- Petley, V.; Sathishkumar, S.; Thulasi Raman, K.H.; Rao, G.M.; Chandrasekhar, U. Microstructural and mechanical characteristics of Ni–Cr thin films. Mater. Res. Bull. 2015, 66, 59–64. [Google Scholar] [CrossRef]

- Bauer, J.; Costa, J.F.; Carvalho, C.N.; Grande, R.H.M.; Loguercio, A.D.; Reis, A. Characterization of two Ni–Cr dental alloys and the influence of casting mode on mechanical properties. J. Prosthodont. Res. 2012, 56, 264–271. [Google Scholar] [CrossRef]

- Zhang, H.K.; Yao, Z.; Morin, G.; Griffiths, M. TEM characterization of in-reactor neutron irradiated CANDU spacer material Inconel X-750. J. Nucl. Mater. 2014, 451, 88–96. [Google Scholar] [CrossRef]

- Judge, C.D.; Gauquelin, N.; Walters, L.; Wright, M.; Cole, J.I.; Madden, J.; Botton, G.A.; Griffiths, M. Intergranular fracture in irradiated Inconel X-750 containing very high concentrations of helium and hydrogen. J. Nucl. Mater. 2015, 457, 165–172. [Google Scholar] [CrossRef]

- Howard, C.; Judge, C.D.; Hosemann, P. Applying a new push-to-pull micro-tensile testing technique to evaluate the mechanical properties of high dose Inconel X-750. Mater. Sci. Eng. A 2019, 748, 396–406. [Google Scholar] [CrossRef]

| Element | Al | C | Co | Cr | Cu | Fe | Mn | Ni | S | Si | Ti | Nb + Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concentration (wt %) | 0.4–1 | 0.08 | 1 | 14–17 | 0.5 | 5–9 | 1 | 70 | 0.01 | 0.5 | 2.25–2.75 | 0.7–1.2 |

| Solution Treatment | 1093–1204 °C | |||||||||||

| Precipitation Hardening | 732 ± 14 ℃ for 16.5 hrs., air cool | |||||||||||

| Reference | Material | Sample Condition | System | UTS (GPa) |

|---|---|---|---|---|

| This work | Inconel X-750 | Irradiated (67 dpa) | PTP–TEM | 2.41 |

| Ref. [37] | Inconel X-750 | Non-irradiated | Cantilever–SEM | 1.4 |

| Irradiated (1.5 dpa) | 1.3 | |||

| Non-irradiated | PTP–SEM | 2.05 | ||

| Irradiated (1.5 dpa) | 2.20 | |||

| Ref. [38] | Inconel X-750 | Non-irradiated | PTP–SEM | 0.956 |

| Irradiated (84 dpa) | 1.817 | |||

| Ref. [39] | K648 | Additively manufactured | Indentation–SEM | 0.83 |

| Ref. [40] | Inconel 740H | Rolled and annealed | Electro-thermal Mechanical Tester | 1.099 |

| Ref. [41] | Ni-Cr | Thin film | Nanoindentation | 1.05 |

| Ref. [42] | Ni-Cr | Casting | Mechanical Tester | 1.057 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gomez-Hurtado, L.R.; Yao, T.; Teng, F.; Matos, M.D., II; Hawkins, L.; Yang, G.; Wang, Y. In-Plane Liftout and Push-to-Pull for In Situ Mechanical Testing of Irradiated Inconel X-750. Energies 2024, 17, 4199. https://doi.org/10.3390/en17174199

Gomez-Hurtado LR, Yao T, Teng F, Matos MD II, Hawkins L, Yang G, Wang Y. In-Plane Liftout and Push-to-Pull for In Situ Mechanical Testing of Irradiated Inconel X-750. Energies. 2024; 17(17):4199. https://doi.org/10.3390/en17174199

Chicago/Turabian StyleGomez-Hurtado, Lucia R., Tiankai Yao, Fei Teng, Mario D. Matos, II, Laura Hawkins, Ge Yang, and Yachun Wang. 2024. "In-Plane Liftout and Push-to-Pull for In Situ Mechanical Testing of Irradiated Inconel X-750" Energies 17, no. 17: 4199. https://doi.org/10.3390/en17174199

APA StyleGomez-Hurtado, L. R., Yao, T., Teng, F., Matos, M. D., II, Hawkins, L., Yang, G., & Wang, Y. (2024). In-Plane Liftout and Push-to-Pull for In Situ Mechanical Testing of Irradiated Inconel X-750. Energies, 17(17), 4199. https://doi.org/10.3390/en17174199