Numerical Modeling and Optimization of a Quasi-Resonant Inverter-Based Induction Heating Process of a Magnetic Gear

Abstract

1. Introduction

2. Materials and Methods

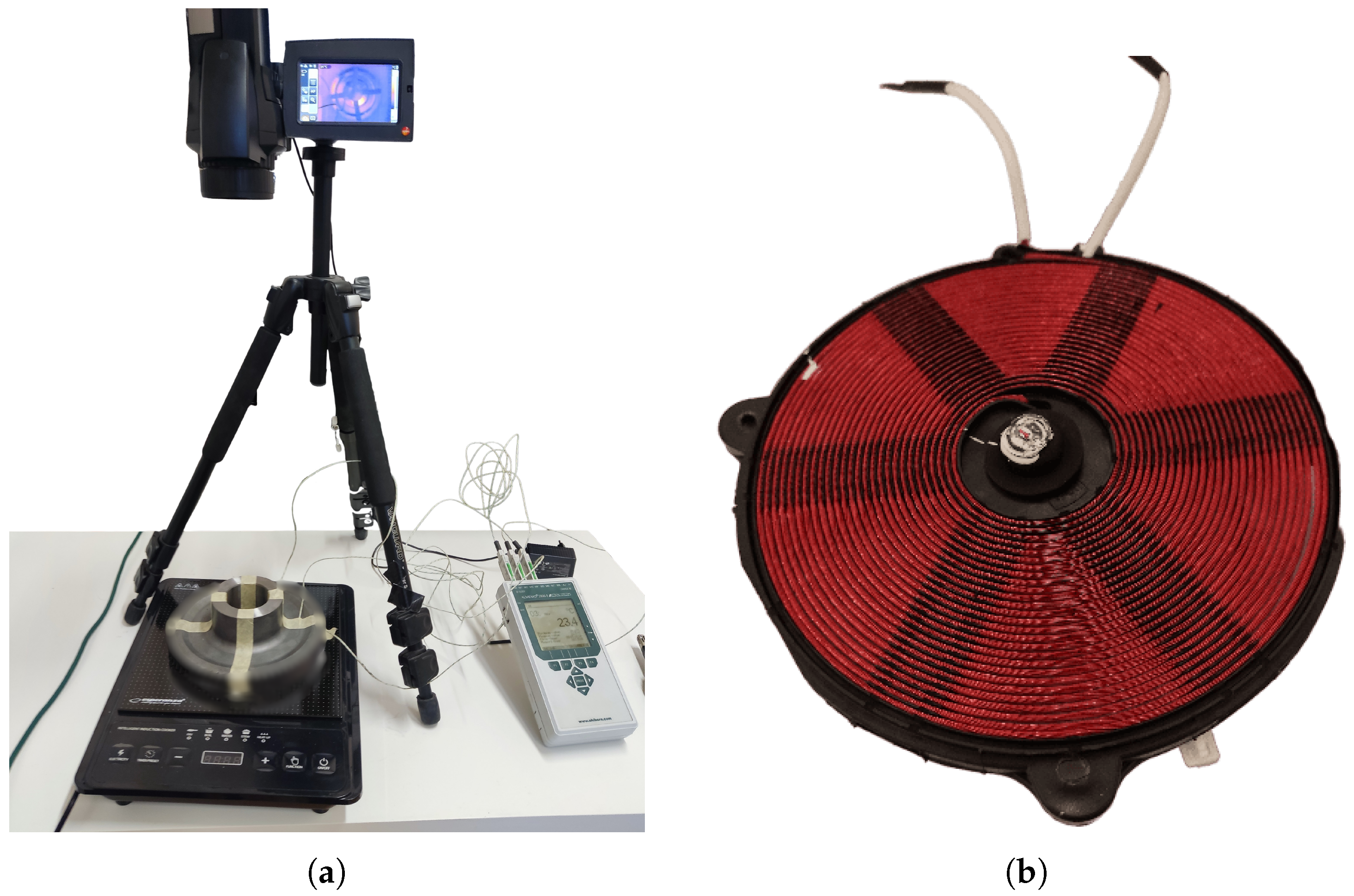

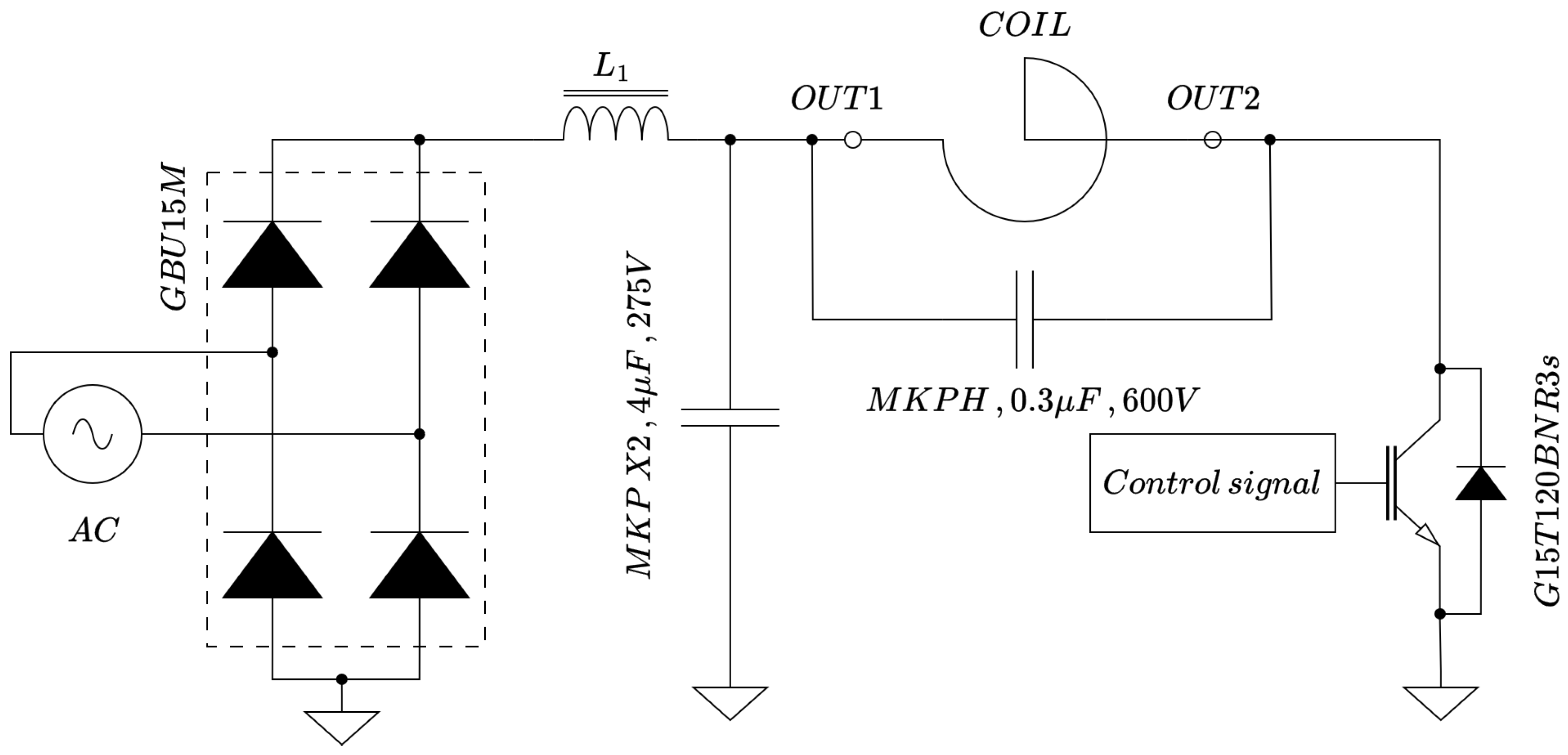

2.1. Problem Description and Experimental Test

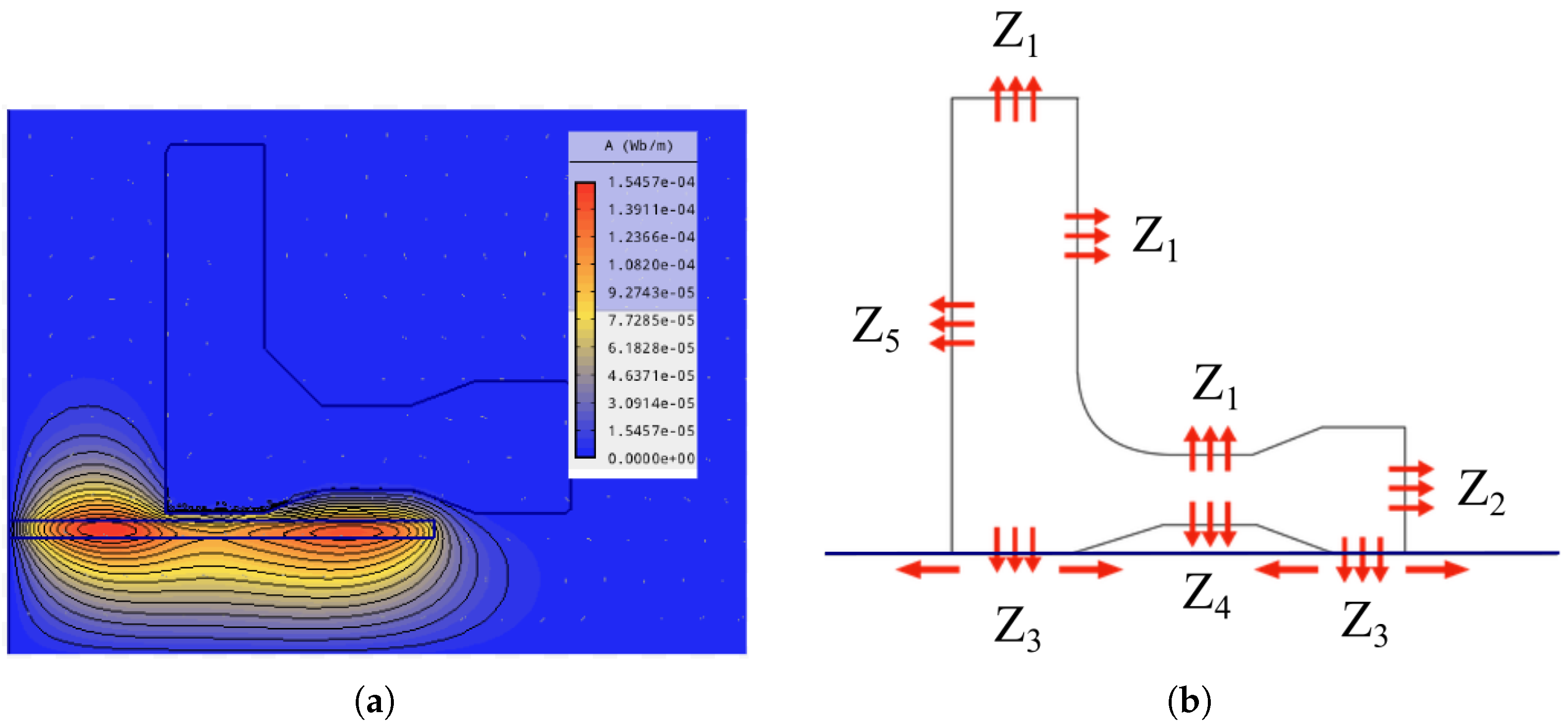

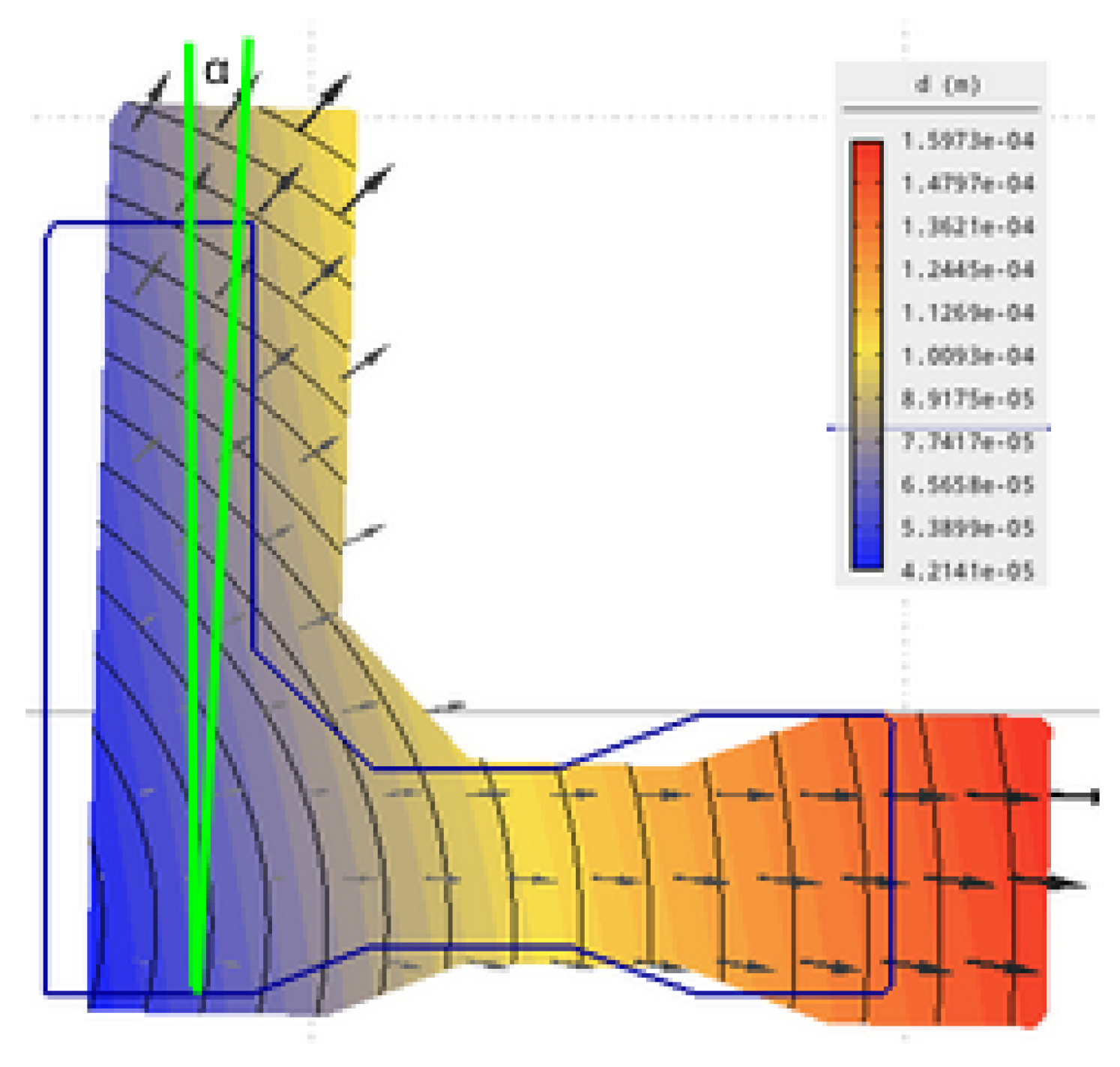

2.2. Numerical Model of the Related Physical Fields

2.3. Numerical Model of the Gear

- : this is a free surface connected directly to the air.

- : Area of the teeth, the modeled surface replaces the original surface by the mean surface of the teeth; this parameter is higher than the heat exchange between the gear material and the air in reality due to the real surface of the teeth being larger than in the applied model.

- : The contact area between the bottom of the gear and the insulation glass, which separates the induction heating coil from the gear. This area has a low heat conductivity, which is considered a small value in the model.

- : This is an air-gear contact area, where the bottom of the gear contacts with the air. However, this zone is closed by the insulator glass; due to the lack of air circulation, this parameter is much lower than .

- : Shaft connection area (the inner hole). This area is closed from the bottom. Therefore, air circulation is lower in the modeled region than in the free outer surface of the gear. Thus, the air temperature will be higher here than in the other areas. This region should be considered by smaller heat loss than the other free surfaces () connected to the free air.

3. Measurements and Numerical Results

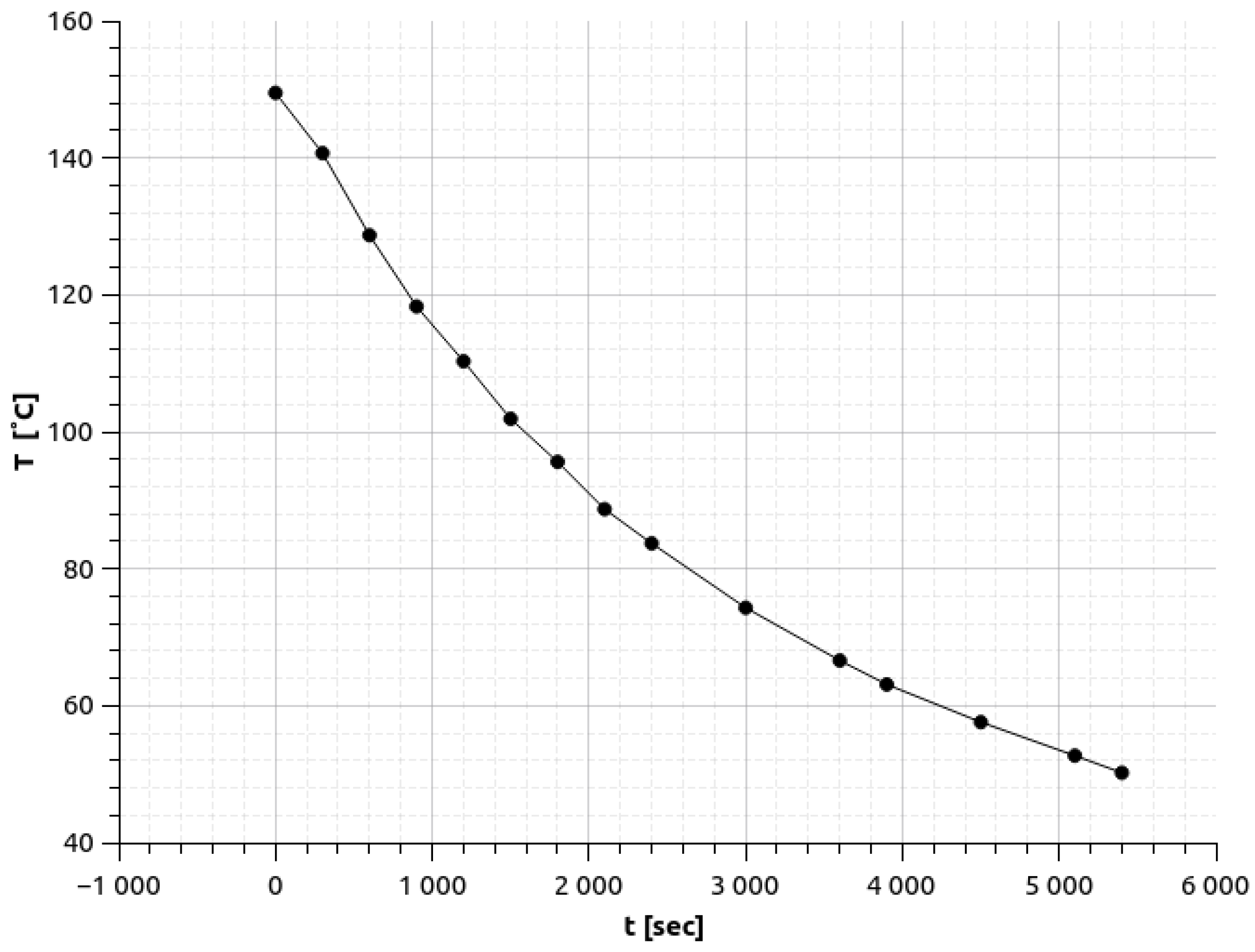

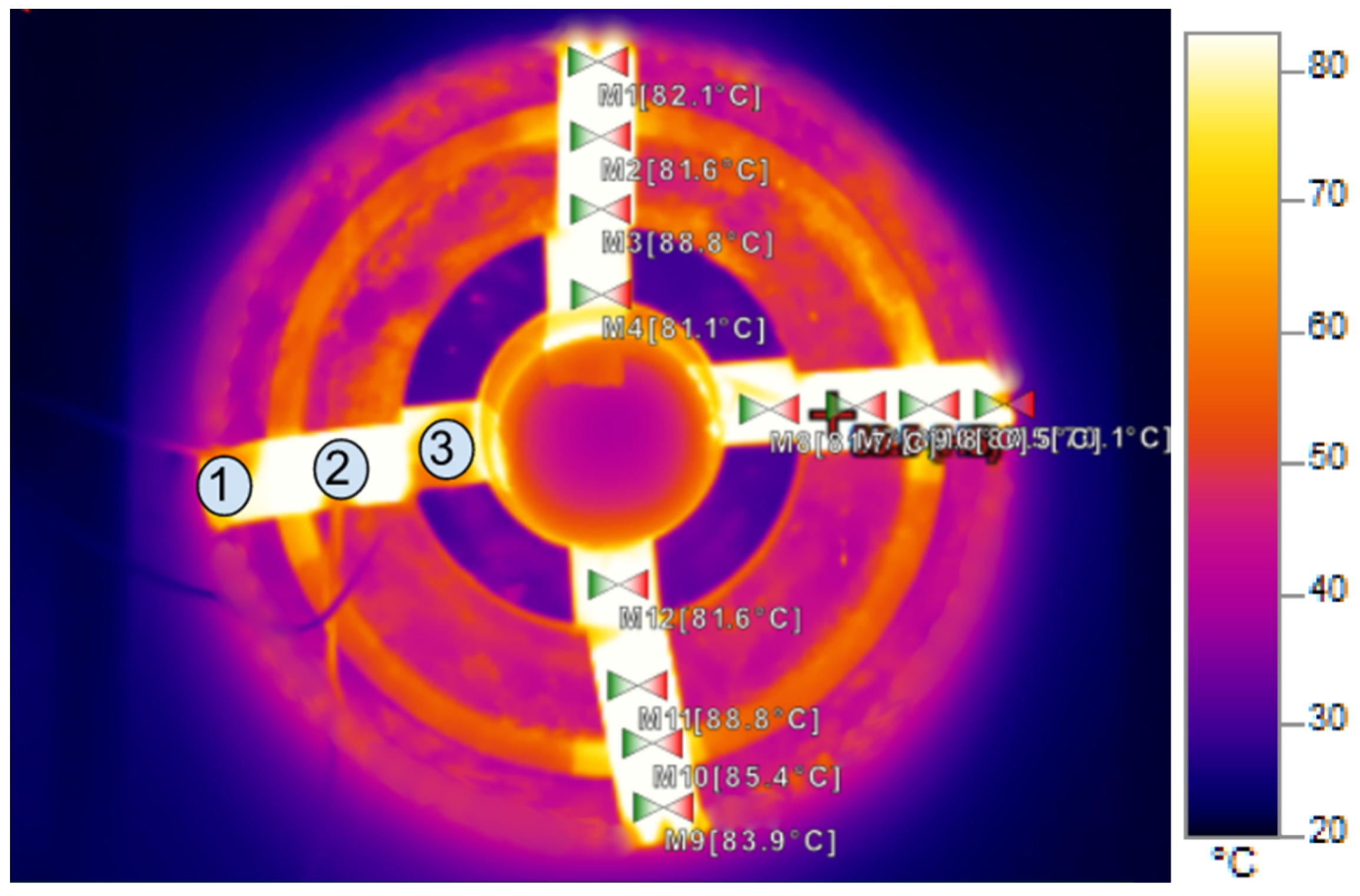

3.1. Thermal Equilibrium

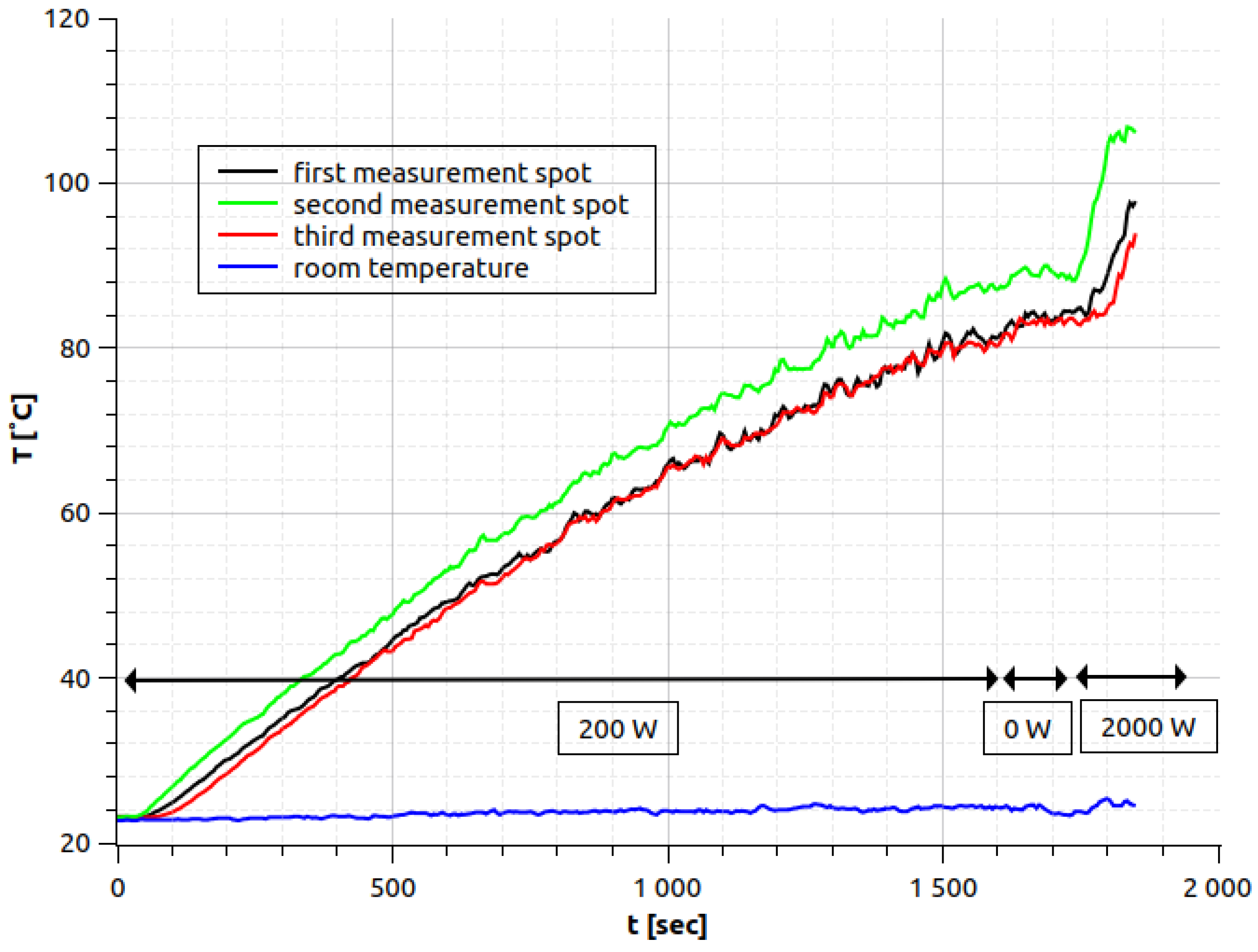

3.2. Cooling and Heating Characteristics

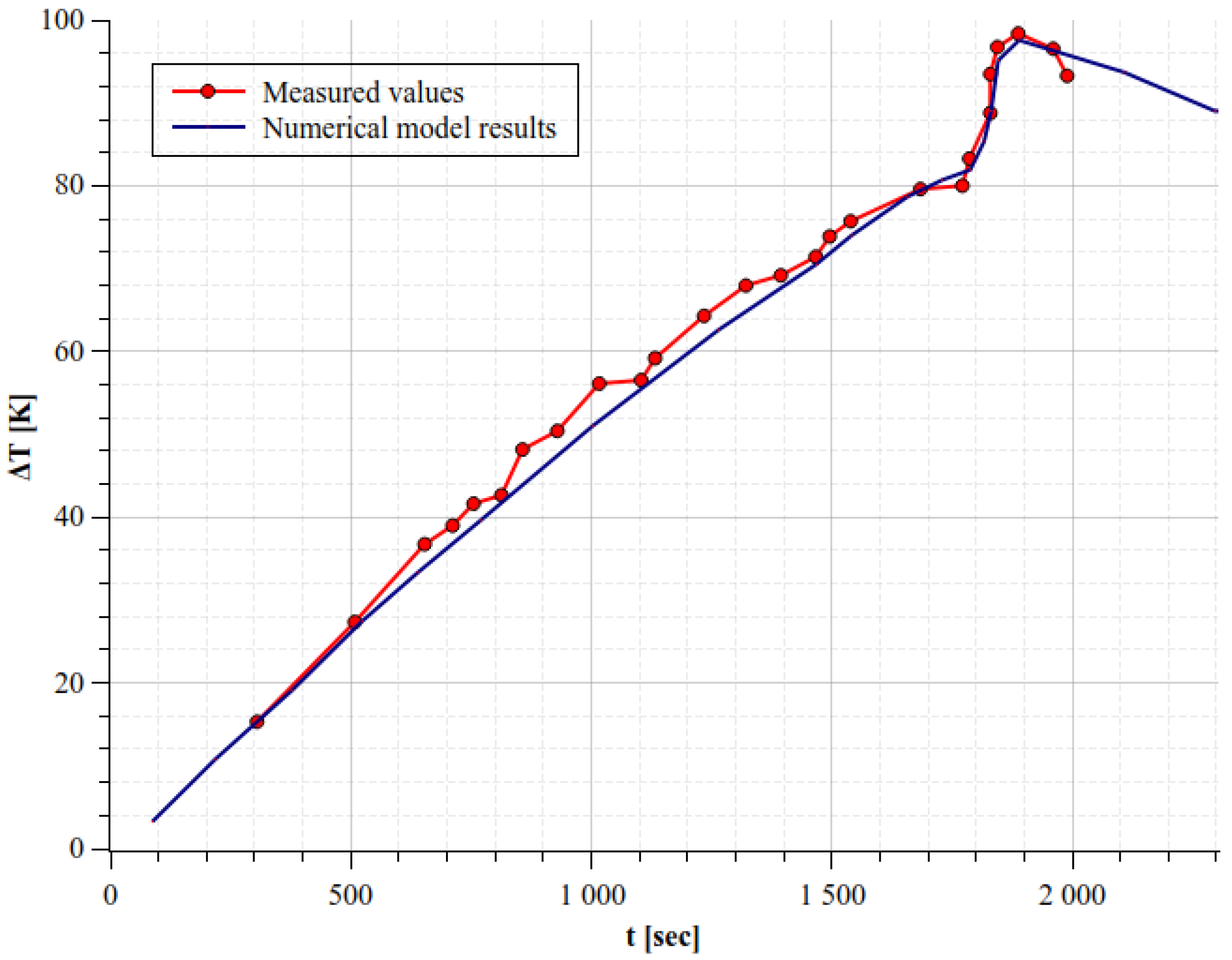

3.3. Parameter Fitting and Numerical Model Validation

- ;

- ;

- ;

- ;

- .

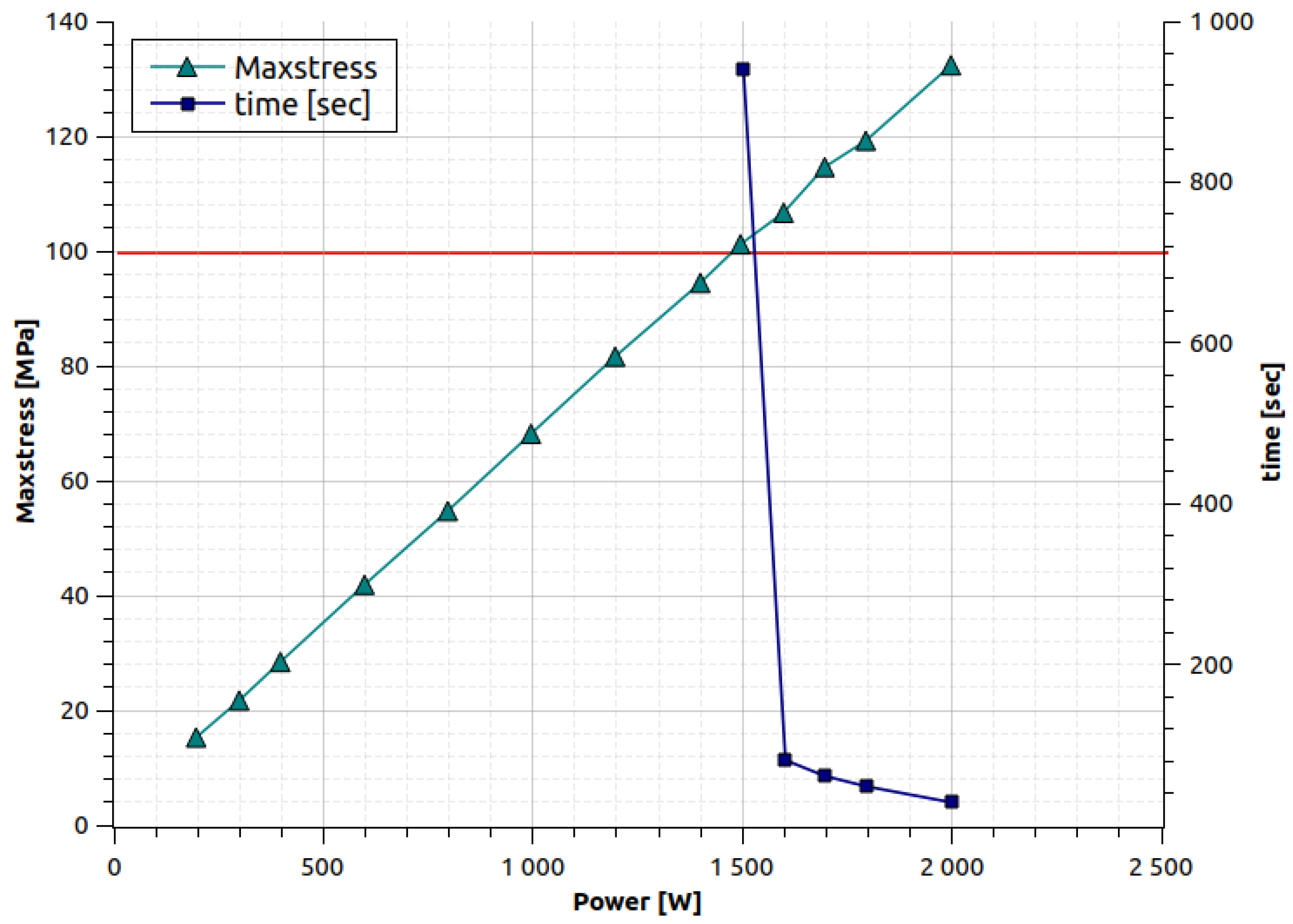

4. Discussion of the Calibrated Model Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sung, Y.T.; Hwang, S.J.; Lee, H.H.; Huang, D.Y. Study on induction heating coil for uniform mold cavity surface heating. Adv. Mech. Eng. 2014, 6, 349078. [Google Scholar] [CrossRef]

- Patidar, B.; Hussain, M.M.; Jha, S.K.; Sharma, A.; Tiwari, A.P. Analytical, numerical and experimental analysis of induction heating of graphite crucible for melting of non-magnetic materials. IET Electr. Power Appl. 2017, 11, 342–351. [Google Scholar] [CrossRef]

- Rudnev, V.; Loveless, D.; Cook, R.L. Handbook of Induction Heating; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Cui, P.; Zhu, W.; Ji, H.; Chen, H.; Hang, C.; Li, M. Analysis and optimization of induction heating processes by focusing the inner magnetism of the coil. Appl. Energy 2022, 321, 119316. [Google Scholar] [CrossRef]

- Fu, X.; Wang, B.; Tang, X.; Ji, H.; Zhu, X. Study on induction heating of workpiece before gear rolling process with different coil structures. Appl. Therm. Eng. 2017, 114, 1–9. [Google Scholar] [CrossRef]

- Drobenko, B.; Hachkevych, O.; Kournyts’kyi, T. A mathematical simulation of high temperature induction heating of electroconductive solids. Int. J. Heat Mass Transf. 2007, 50, 616–624. [Google Scholar] [CrossRef]

- Di Barba, P.; Forzan, M.; Sieni, E. Multi-objective design of a power inductor: A benchmark problem of inverse induction heating. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2014, 33, 1990–2005. [Google Scholar] [CrossRef]

- Popa, C.; Pentiuc, R. Analysis of a new induction thermal converter for heating. Energy 2012, 42, 81–93. [Google Scholar] [CrossRef]

- Puyal, D.; Bernal, C.; Burdio, J.; Acero, J.; Millan, I. Methods and procedures for accurate induction heating load measurement and characterization. In Proceedings of the 2007 IEEE International Symposium on Industrial Electronics, Vigo, Spain, 4–7 June 2007; pp. 805–810. [Google Scholar]

- Jain, I. Electromagnetic-Thermal Modeling of Induction Heating of Moving Wire. Heat Transf.—Asian Res. 2017, 46, 111–133. [Google Scholar] [CrossRef]

- Yexin, C.; Chi, C. Simulation for induction heating in forging preheating. In Proceedings of the 2018 2nd International Conference on Data Science and Business Analytics (ICDSBA), Changsha, China, 21–23 September 2018; pp. 390–393. [Google Scholar]

- Di Barba, P.; Dughiero, F.; Forzan, M.; Sieni, E. Sensitivity-based optimal shape design of induction-heating devices. IET Sci. Meas. Technol. 2015, 9, 579–586. [Google Scholar] [CrossRef]

- Oh, D.W.; Kim, T.H.; Do, K.H.; Park, J.M.; Lee, J. Design and sensitivity analysis of design factors for induction heating system. J. Korean Soc. Heat Treat. 2013, 26, 233–240. [Google Scholar] [CrossRef][Green Version]

- Kranjc, M.; Zupanic, A.; Miklavcic, D.; Jarm, T. Numerical analysis and thermographic investigation of induction heating. Int. J. Heat Mass Transf. 2010, 53, 3585–3591. [Google Scholar] [CrossRef]

- Bay, F.; Labbé, V.; Favennec, Y.; Chenot, J.L. A numerical model for induction heating processes coupling electromagnetism and thermomechanics. Int. J. Numer. Methods Eng. 2003, 58, 839–867. [Google Scholar] [CrossRef]

- Dolezel, I.; Karban, P.; Kropik, P.; Panek, D. Accurate control of position by induction heating-produced thermoelasticity. IEEE Trans. Magn. 2010, 46, 2888–2891. [Google Scholar] [CrossRef]

- Eom, H.; Park, K. Fully-coupled numerical analysis of high-frequency induction heating for thin-wall injection molding. Polym.-Plast. Technol. Eng. 2009, 48, 1070–1077. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, C.; Liu, Y. Numerical analysis and experimental research of triangle induction heating of the rolled plate. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 231, 844–859. [Google Scholar] [CrossRef]

- Di Barba, P.; Mognaschi, M.E.; Lowther, D.; Dughiero, F.; Forzan, M.; Lupi, S.; Sieni, E. A benchmark problem of induction heating analysis. Int. J. Appl. Electromagn. Mech. 2017, 53, S139–S149. [Google Scholar] [CrossRef]

- DI BARBA, P.; Mognaschi, M.E.; Bullo, M.; Dughiero, F.; Forzan, M.; Lupi, S.; Sieni, E. Field models of induction heating for industrial applications. Organ 2018, 3, 18. [Google Scholar] [CrossRef]

- Vaughan, J.; Williamson, J. Design of induction-heating coils for cylindrical nonmagnetic loads. Electr. Eng. 1945, 64, 587–592. [Google Scholar] [CrossRef]

- Baker, R. Design and calculation of induction-heating coils. Trans. Am. Inst. Electr. Eng. Part II Appl. Ind. 1957, 76, 31–40. [Google Scholar]

- Mach, F.; Kuthanova, J.; Mizerova, K.; Karban, P.; Kus, P.; Dolezel, I.; Polansky, R. Model-based determination of nonlinear material parameters of metals with low melting points. In Proceedings of the IECON 2014-40th Annual Conference of the IEEE Industrial Electronics Society, Dallas, TX, USA, 29 October–1 November 2014; pp. 3240–3245. [Google Scholar]

- Afzal, A.; Kim, K.Y.; Muralidhar, K.; Samad, A.; Benini, E. Optimization with Surrogate Models: Flow and Heat Transfer Applications. Math. Probl. Eng. 2019. [Google Scholar] [CrossRef]

- Nguyen, B.A.; Phan, Q.D.; Nguyen, D.M.; Nguyen, K.L.; Durrieu, O.; Maussion, P. Parameter identification method for a three-phase induction heating system. IEEE Trans. Ind. Appl. 2015, 51, 4853–4860. [Google Scholar] [CrossRef]

- Pánek, D.; Karban, P.; Doležel, I. Calibration of numerical model of magnetic induction brazing. IEEE Trans. Magn. 2019, 55, 1–4. [Google Scholar] [CrossRef]

- Barman, B.; Sengupta, M. Parameter Determination of a Multi-layered Induction Heating Coil: Analytical, Simulation and Experimental Studies. J. Inst. Eng. (India) Ser. B 2024, 1–19. [Google Scholar] [CrossRef]

- Spateri, E.; Ruiz, F.; Gruosso, G. Modelling and Simulation of Quasi-Resonant Inverter for Induction Heating under Variable Load. Electronics 2023, 12, 753. [Google Scholar] [CrossRef]

- Sabug, L., Jr.; Ruiz, F.; Fagiano, L. SMGO: A set membership approach to data-driven global optimization. Automatica 2021, 133, 109890. [Google Scholar] [CrossRef]

- Sabug, L., Jr.; Ruiz, F.; Fagiano, L. SMGO-Δ: Balancing caution and reward in global optimization with black-box constraints. Inf. Sci. 2022, 605, 15–42. [Google Scholar] [CrossRef]

- Barreira, E.; Almeida, R.M.; Simões, M.L. Emissivity of building materials for infrared measurements. Sensors 2021, 21, 1961. [Google Scholar] [CrossRef]

- Chudjuarjeen, S.; Hathairatsiri, V.; Pechpunsri, W.; Sangswang, A.; Koompai, C. Quasi-resonant converter for induction heating in high temperature applications. In Proceedings of the 2013 IEEE 10th International Conference on Power Electronics and Drive Systems (PEDS), Kitakyushu, Japan, 22–25 April 2013; pp. 836–839. [Google Scholar] [CrossRef]

- Infineon. Reverse-Conducting IGBTs for Induction Cooking and Resonant Applications; Infineon: Neubiberg, Germany, 2021. [Google Scholar]

- Bastos, J.P.A.; Sadowski, N. Electromagnetic Modeling by Finite Element Methods; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Kuczmann, M.; Iványi, A. The Finite Element Method in Magnetics; Akadémiai Kiadó: Budapest, Hungary, 2008. [Google Scholar]

- Boley, B.A.; Weiner, J.H. Theory of Thermal Stresses; Courier Corporation: North Chelmsford, MA, USA, 2012. [Google Scholar]

- Karban, P.; Pánek, D.; Orosz, T.; Petrášová, I.; Doležel, I. FEM based robust design optimization with Agros and Ārtap. Comput. Math. Appl. 2021, 81, 618–633. [Google Scholar] [CrossRef]

- Kuczmann, M. Fourier transform and controlling of flux in scalar hysteresis measurement. Phys. B Condens. Matter 2008, 403, 410–413. [Google Scholar] [CrossRef]

- Kuczmann, M.; Orosz, T. Temperature-Dependent Ferromagnetic Loss Approximation of an Induction Machine Stator Core Material Based on Laboratory Test Measurements. Energies 2023, 16, 1116. [Google Scholar] [CrossRef]

| Quantity | Value | Dimension |

|---|---|---|

| Thermal Conductivity | 45 | |

| Specific heat capacity | 470 | |

| Thermal Expansion coefficient | ||

| Density | 7800 | |

| Young’s modulus | 210 | GPa |

| Poisson ratio | [-] | |

| Heat Transfer coefficient | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orosz, T.; Csizmadia, M.; Nagy, B. Numerical Modeling and Optimization of a Quasi-Resonant Inverter-Based Induction Heating Process of a Magnetic Gear. Energies 2024, 17, 4130. https://doi.org/10.3390/en17164130

Orosz T, Csizmadia M, Nagy B. Numerical Modeling and Optimization of a Quasi-Resonant Inverter-Based Induction Heating Process of a Magnetic Gear. Energies. 2024; 17(16):4130. https://doi.org/10.3390/en17164130

Chicago/Turabian StyleOrosz, Tamás, Miklós Csizmadia, and Balázs Nagy. 2024. "Numerical Modeling and Optimization of a Quasi-Resonant Inverter-Based Induction Heating Process of a Magnetic Gear" Energies 17, no. 16: 4130. https://doi.org/10.3390/en17164130

APA StyleOrosz, T., Csizmadia, M., & Nagy, B. (2024). Numerical Modeling and Optimization of a Quasi-Resonant Inverter-Based Induction Heating Process of a Magnetic Gear. Energies, 17(16), 4130. https://doi.org/10.3390/en17164130