Analysis of Fracturing Expansion Law of Shale Reservoir by Supercritical CO2 Fracturing and Mechanism Revealing

Abstract

1. Introduction

2. Materials and Methods

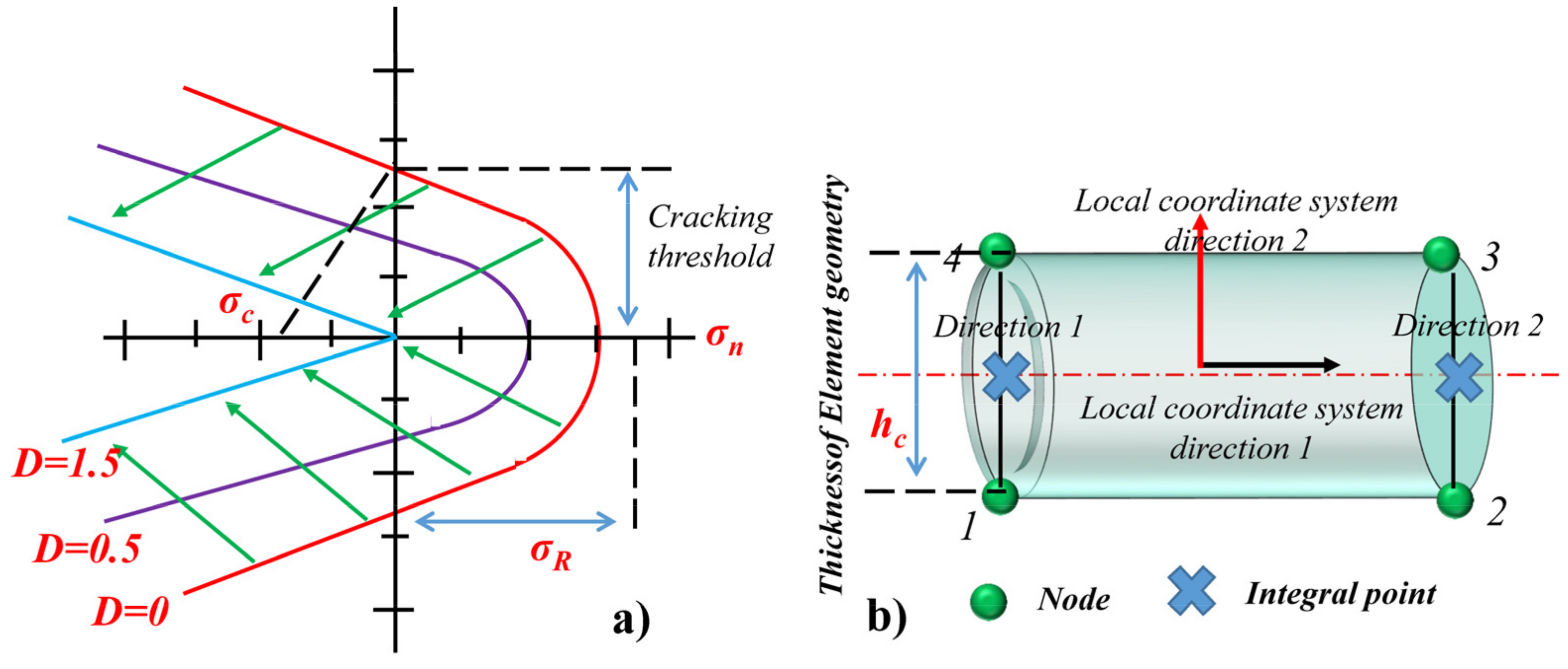

2.1. Cohesive Element Damage Criterion

2.2. Crack Initiation Criterion of CO2 Fracturing in Shale Reservoir

2.3. Crack Propagation Criterion of CO2 Fracturing in Shale Reservoir

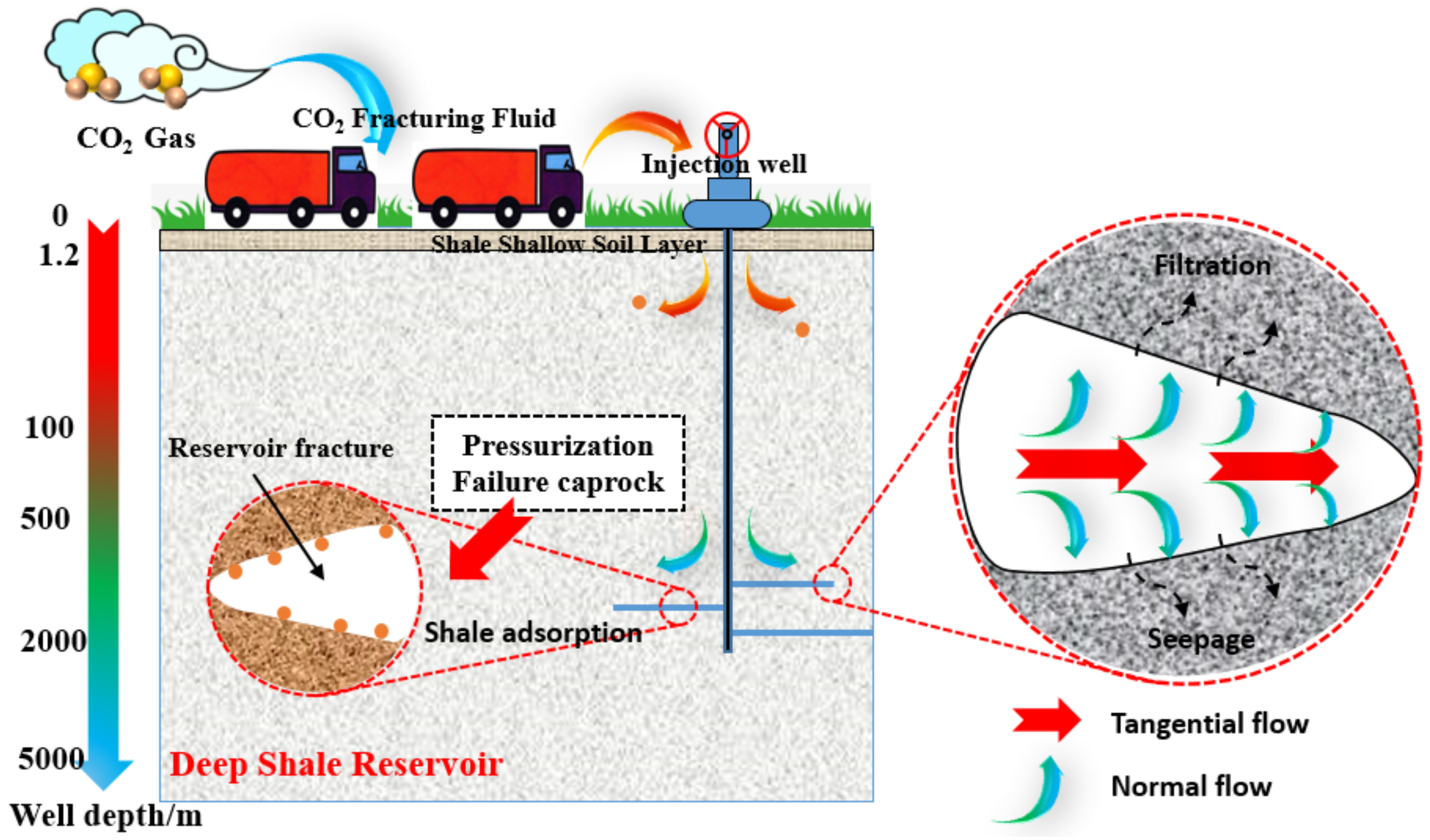

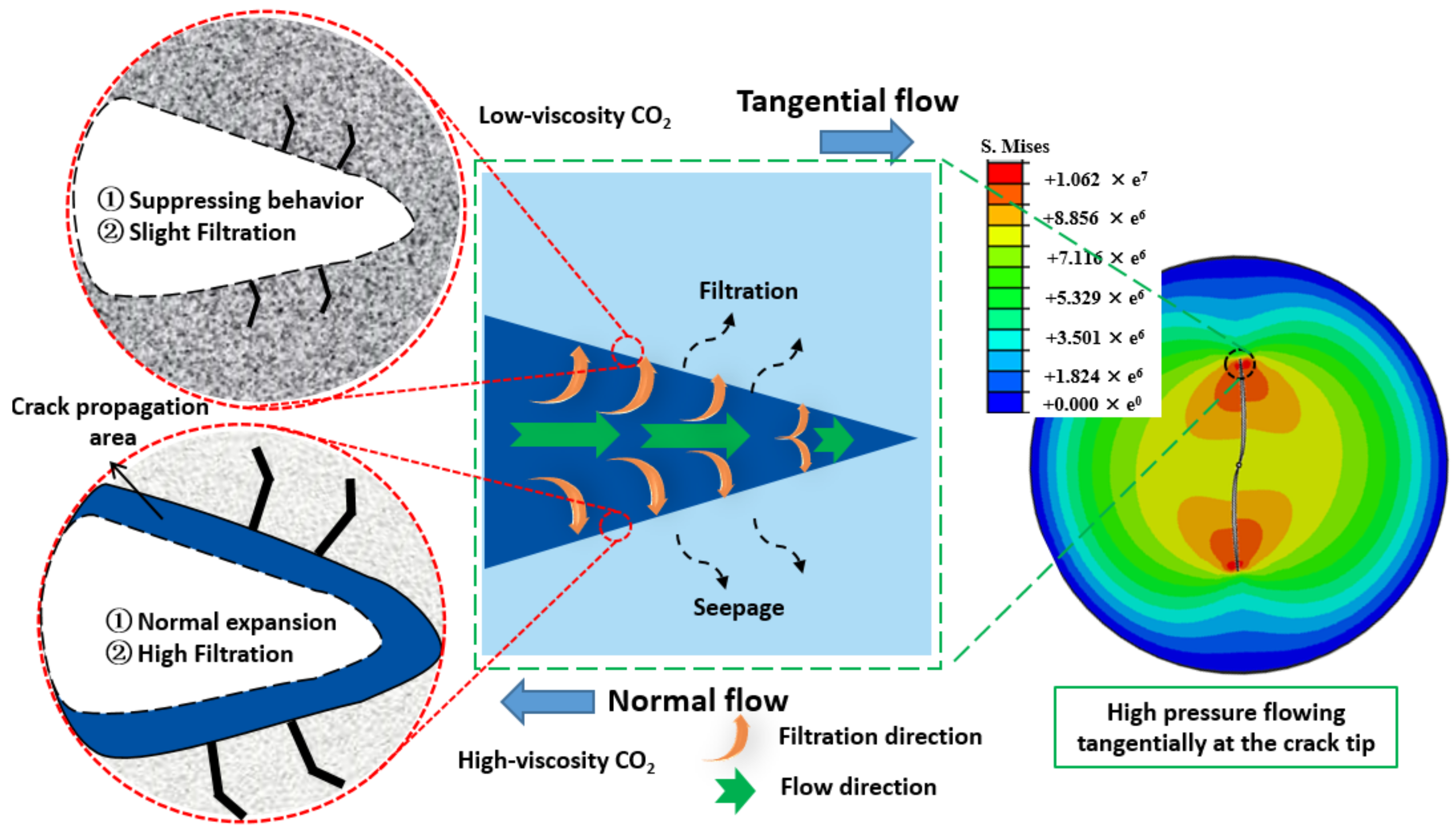

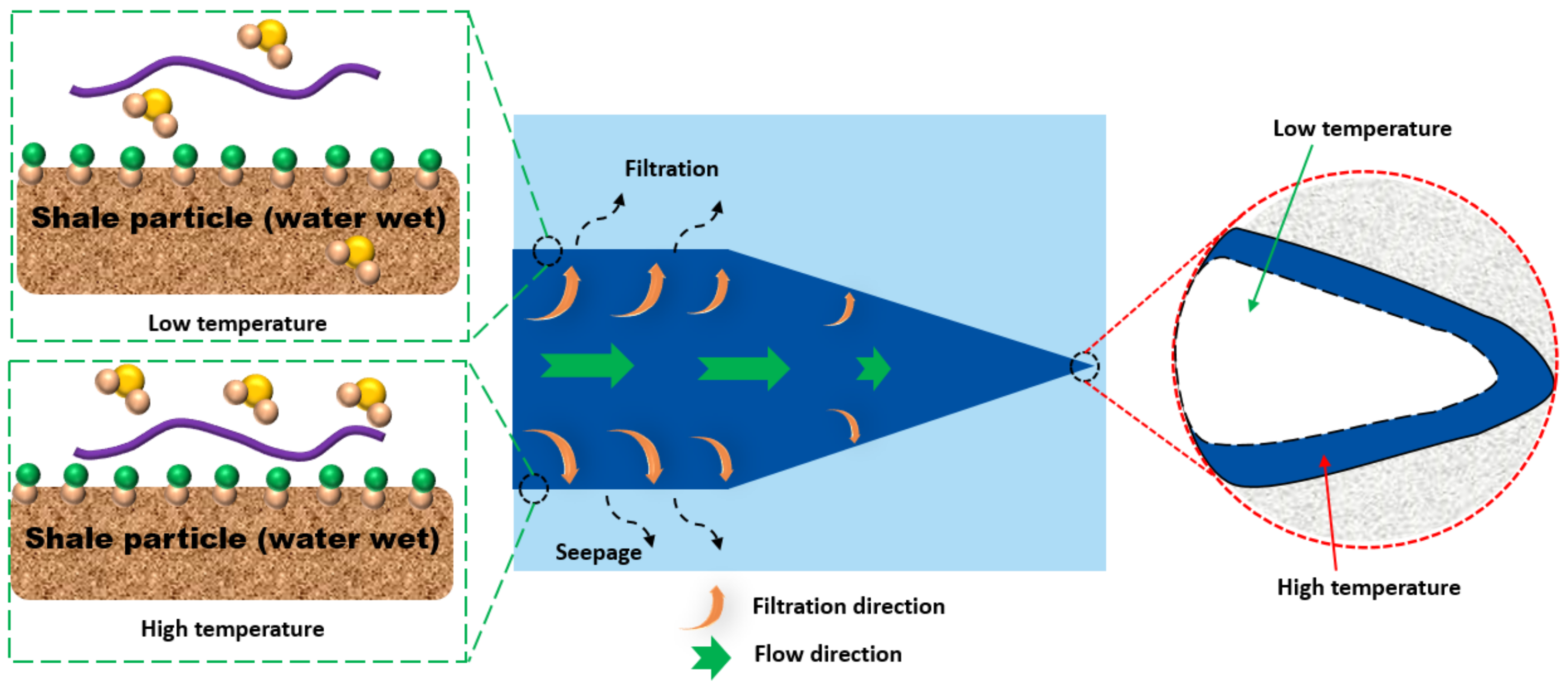

2.4. Flow and Stress of Supercritical CO2 in Shale Fractures

2.5. Fracturing Model of Supercritical CO2 in Shale Fractures

3. Results and Discussion

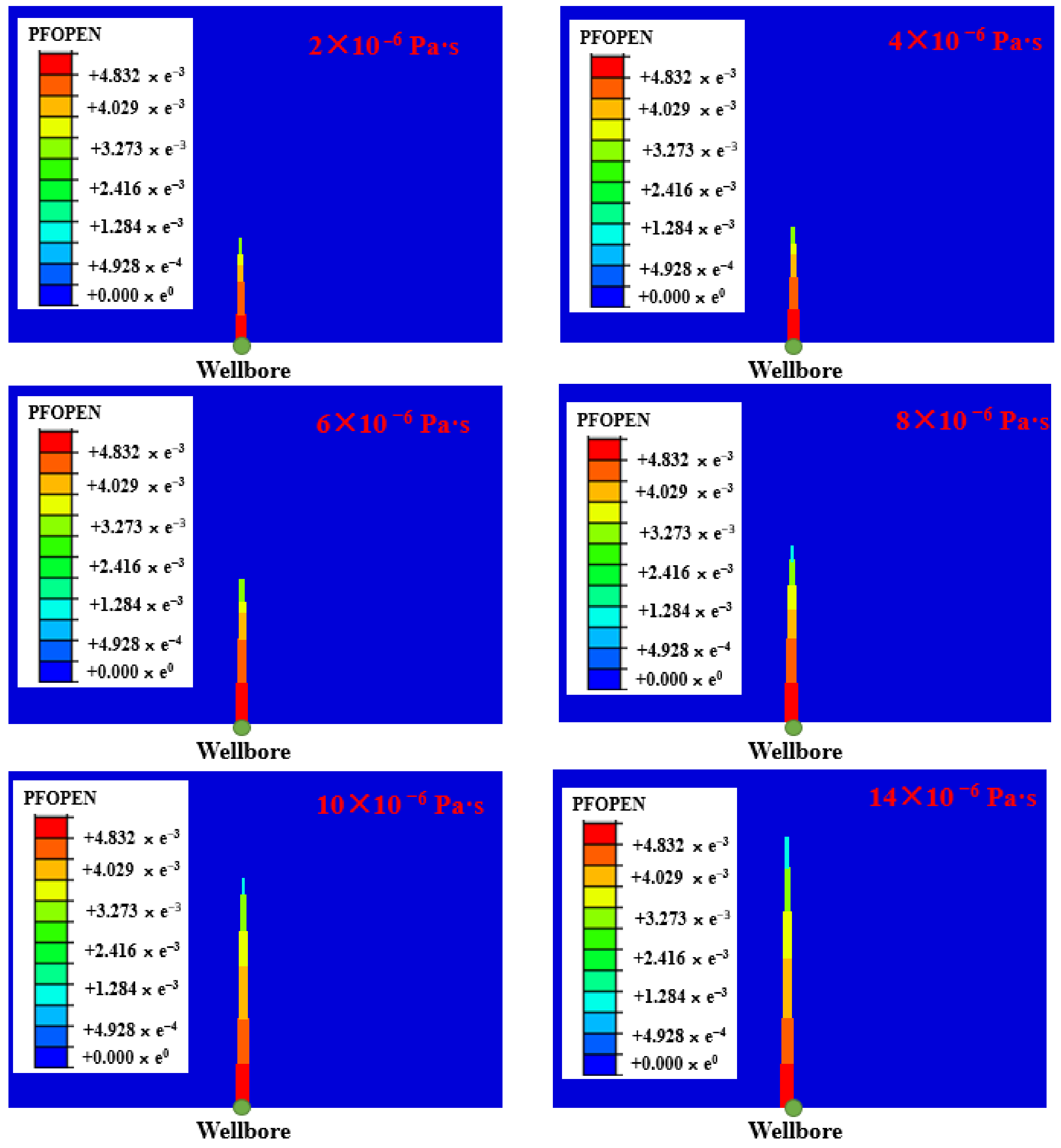

3.1. Effect of CO2 Fracturing Fluid Viscosity on Shale Fracture Propagation

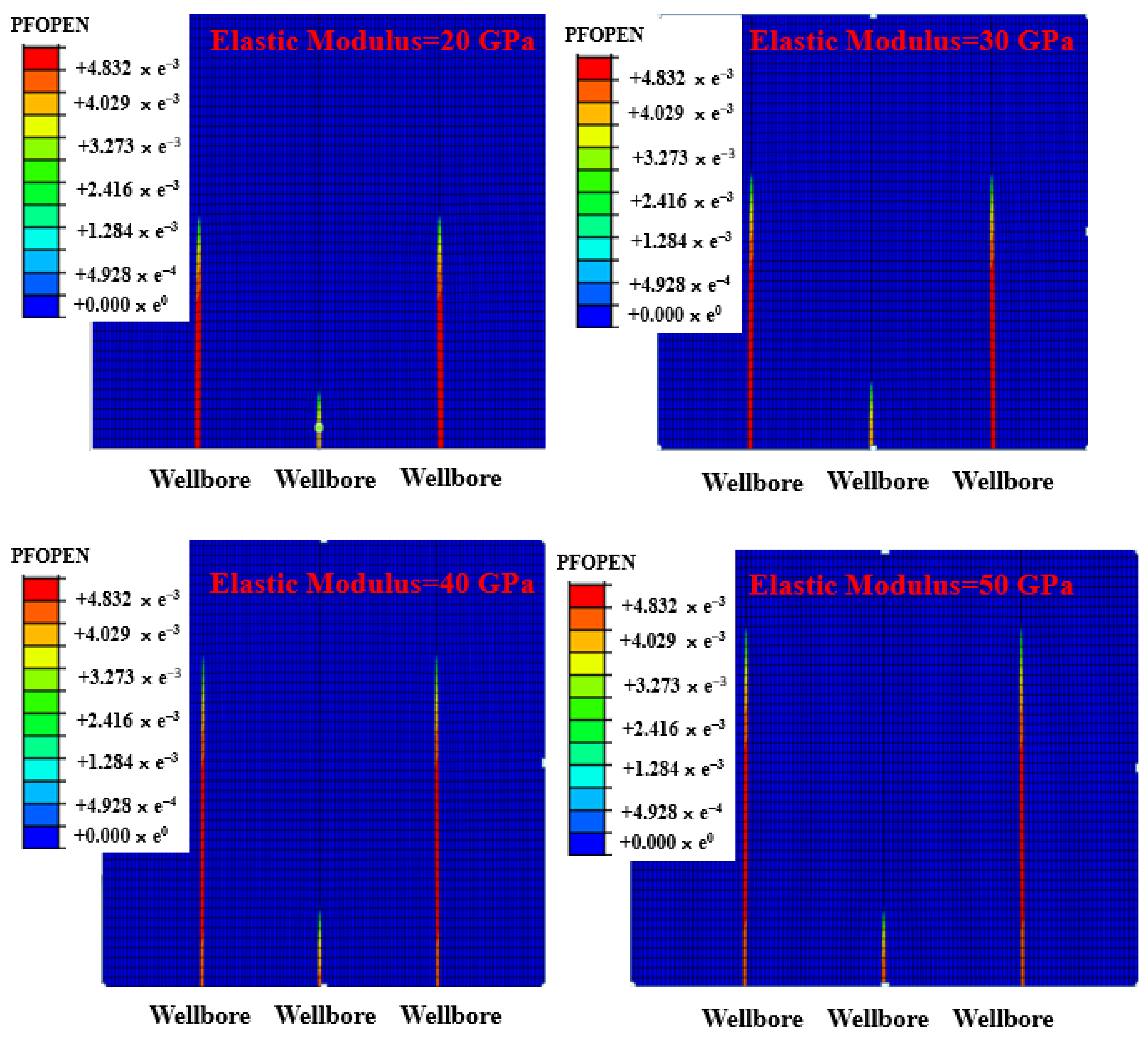

3.2. Effects of Mineral Properties on Reservoir Fractures

3.3. Effects of Fracturing Fluid Injection Rate on Reservoir Fractures

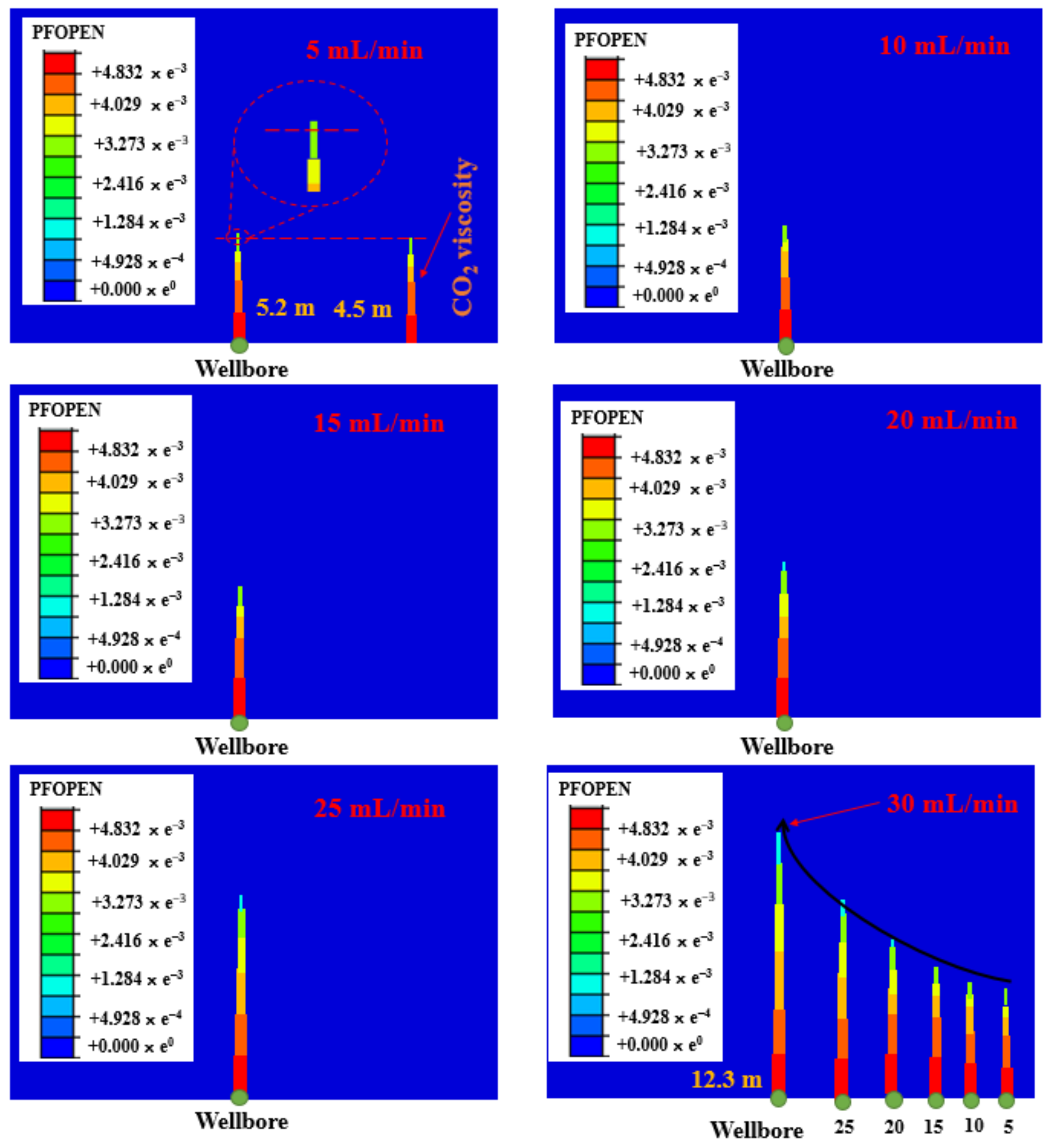

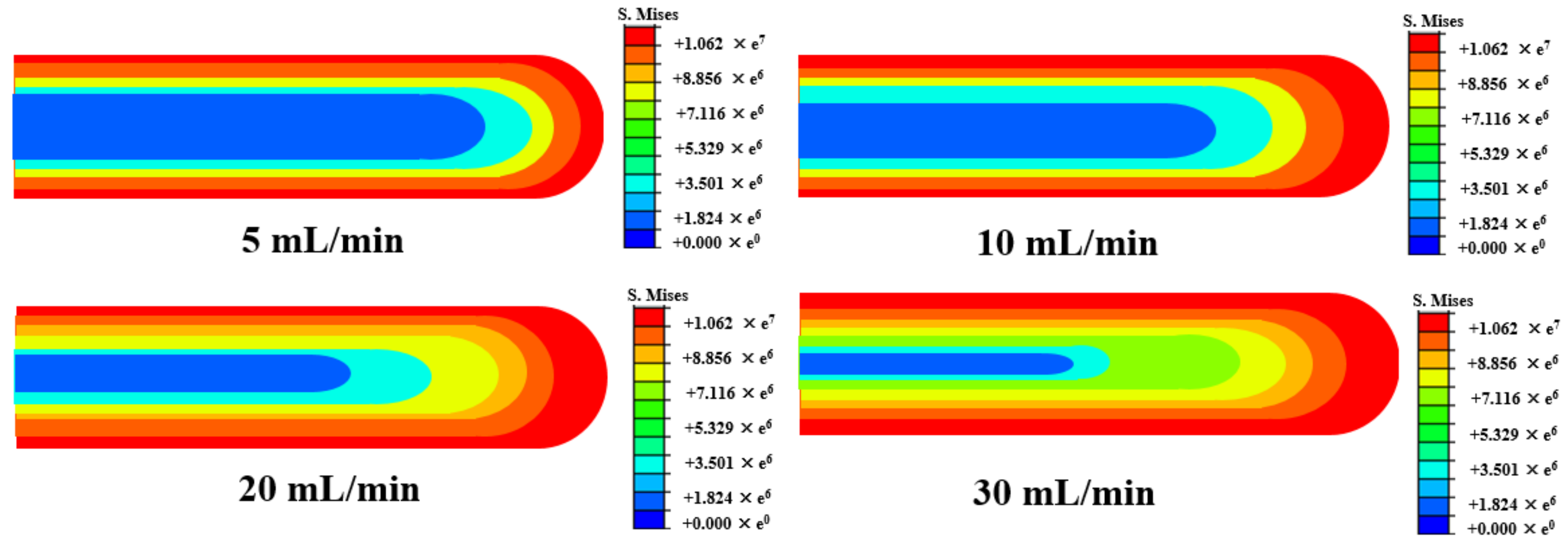

3.4. Effects of Crack Azimuth on the Reservoir Fractures

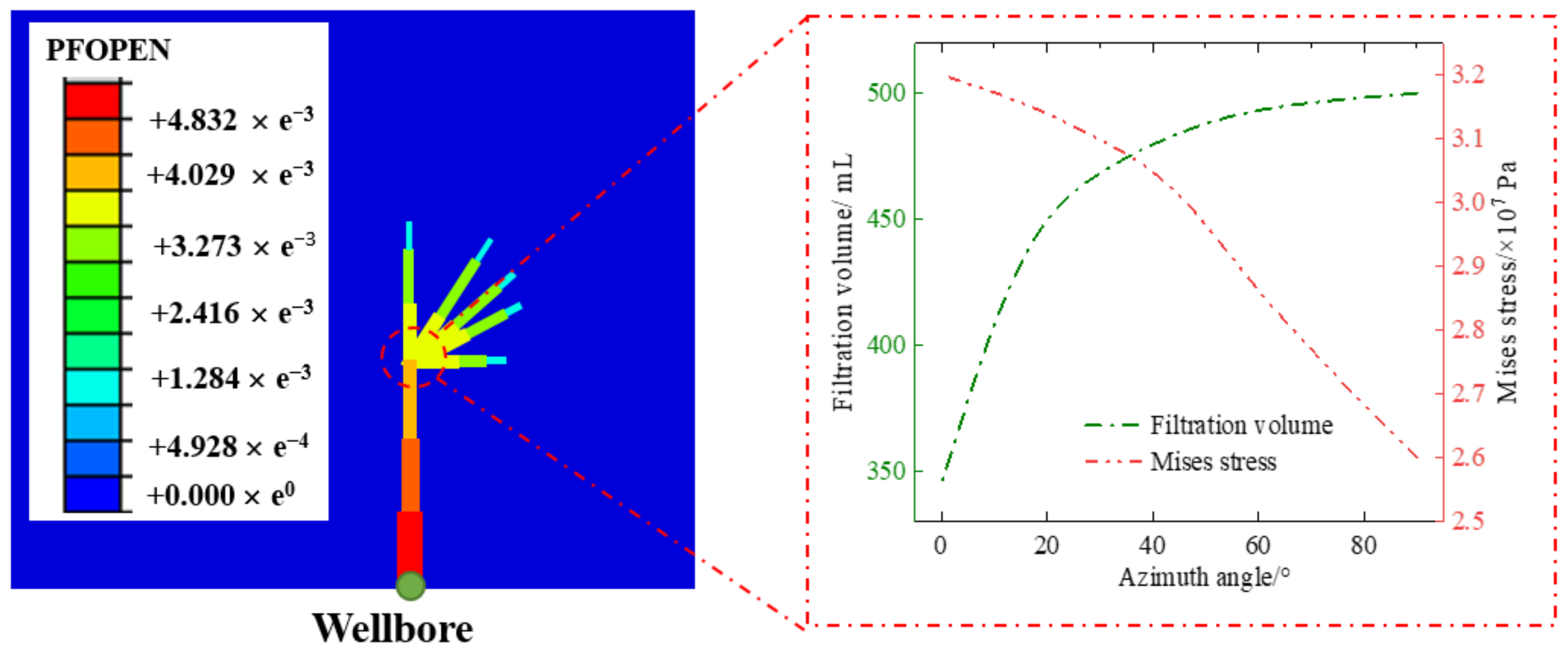

3.5. Effects of Reservoir Condition on the Reservoir Fractures

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Tang, Y.; Chang, Q.; Ma, C.; He, S.; Yuan, L. Development of a novel heat- and shear-resistant nano-silica gelling agent. Nanotechnol. Rev. 2022, 11, 2786–2799. [Google Scholar] [CrossRef]

- Lv, Q.; Li, Z.; Li, B.; Zhang, C.; Shi, D.; Zheng, C.; Zhou, T. Experimental study on the dynamic filtration control performance of N2/liquid CO2 foam in porous media. Fuel 2017, 202, 435–445. [Google Scholar] [CrossRef]

- Chuang, M.C.; Ma, H.W. Energy security and improvements in the function of diversity indices—Taiwan energy supply structure case study. Renew. Sustain. Energy Rev. 2013, 24, 9–20. [Google Scholar] [CrossRef]

- Emblemsvåg, J. Wind energy is not sustainable when balanced by fossil energy. Appl. Energy 2022, 305, 117748. [Google Scholar] [CrossRef]

- Willow, A.J.; Zak, R.; Vilaplana, D.; Sheeley, D. The contested landscape of unconventional energy development: A report from Ohio’s shale gas country. J. Environ. Stud. Sci. 2014, 4, 56–64. [Google Scholar] [CrossRef]

- Fleming, D.A.; Measham, T.G. Local economic impacts of an unconventional energy boom: The coal seam gas industry in Australia. Aust. J. Agric. Resour. Econ. 2015, 59, 78–94. [Google Scholar] [CrossRef]

- Bijay, K.C.; Ghazanfari, E. Geothermal reservoir stimulation through hydro-shearing: An experimental study under conditions close to enhanced geothermal systems. Geothermics 2021, 96, 102200. [Google Scholar]

- Sahu, Q.; Fahs, M.; Hoteit, H. Optimization and uncertainty quantification method for reservoir stimulation through carbonate acidizing. ACS Omega 2022, 8, 539–554. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Xie, H.; Hu, J.; Li, C. A critical review of the experimental and theoretical research on cyclic hydraulic fracturing for geothermal reservoir stimulation. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 7. [Google Scholar] [CrossRef]

- Liew, M.S.; Danyaro, K.U.; Zawawi, N.A.W.A. A comprehensive guide to different fracturing technologies: A review. Energies 2020, 13, 3326. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, S.; Wang, G.; Cheng, W. Evaluating the changes of sorption and diffusion behaviors of Illinois coal with various water-based fracturing fluid treatments. Fuel 2021, 283, 118884. [Google Scholar] [CrossRef]

- Wang, J.; Elsworth, D.; Wu, Y.; Liu, J.; Zhu, W.; Liu, Y. The influence of fracturing fluids on fracturing processes: A comparison between water, oil and SC-CO2. Rock Mech. Rock Eng. 2018, 51, 299–313. [Google Scholar] [CrossRef]

- Zhang, C.P.; Ranjith, P.G.; Perera, M.S.A.; Li, X.; Zhao, J. Simulation of flow behaviour through fractured unconventional gas reservoirs considering the formation damage caused by water-based fracturing fluids. J. Nat. Gas Sci. Eng. 2018, 57, 100–121. [Google Scholar] [CrossRef]

- Papavasileiou, K.D.; Michalis, V.K.; Peristeras, L.D.; Vasileiadis, M.; Striolo, A.; Economou, I.G. Molecular dynamics simulation of water-based fracturing fluids in kaolinite slit pores. J. Phys. Chem. C 2018, 122, 17170–17183. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Ma, X.; Zou, Y.; Li, N.; Chen, M.; Cao, T.; Bo, Z. Hydraulic fractures induced by water-/carbon dioxide-based fluids in tight sandstones. Rock Mech. Rock Eng. 2019, 52, 3323–3340. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Forson, K.; Cao, L.; Zhang, C.; Chen, J. Experimental investigation on the high-pressure sand suspension and adsorption capacity of guar gum fracturing fluid in low-permeability shale reservoirs: Factor analysis and mechanism disclosure. Environ. Sci. Pollut. Res. 2022, 29, 53050–53062. [Google Scholar] [CrossRef]

- Carmon, N.; Shamir, U.; Meiron-Pistiner, S. Water-sensitive urban planning: Protecting groundwater. J. Environ. Plan. Manag. 1997, 40, 413–434. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical insights into factors affecting collapse behavior of horizontal wellbore in clayey silt hydrate-bearing sediments and the accompanying control stratege. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Li, Q.; Wang, F.; Bemardo, J.; Zhang, Y.; Bai, B.; Liu, F. Performance Improvement of Thickened Liquid CO2 by Introducing a Philic-CO2 Silicone Polymer. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Bali, Indonesia, 29–31 October 2019; SPE: Bali, Indonesia, 2020. [Google Scholar] [CrossRef]

- Li, Q.; Han, Y.; Liu, X.; Ansari, U.; Cheng, Y.; Yan, C. Hydrate as a by-product in CO2 leakage during the long-term sub-seabed sequestration and its role in preventing further leakage. Environ. Sci. Pollut. Res. 2022, 29, 77737–77754. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Liao, X. Evaluation method of CO2 sequestration and enhanced oil recovery in an oil reservoir, as applied to the Changqing Oilfields, China. Energy Fuels 2012, 26, 5350–5354. [Google Scholar] [CrossRef]

- Song, X.; Wang, F.; Ma, D.; Gao, M.; Zhang, Y. Progress and prospect of carbon dioxide capture, utilization and storage in CNPC oilfields. Pet. Explor. Dev. 2023, 50, 229–244. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Li, Q.; Kobina, F.; Bai, H.; Yuan, L. Effect of a modified silicone as a thickener on rheology of liquid CO2 and its fracturing capacity. Polymers 2019, 11, 540. [Google Scholar] [CrossRef] [PubMed]

- Doherty, M.D.; Lee, J.J.; Dhuwe, A.; O’Brien, M.J.; Perry, R.J.; Beckman, E.J.; Enick, R.M. Small molecule cyclic amide and urea based thickeners for organic and sc-CO2/organic solutions. Energy Fuels 2016, 30, 5601–5610. [Google Scholar] [CrossRef]

- Tadepalli, K.M.; Chakrabarty, S.; Patil, P.; Kumar, R. Design of CO2 Thickeners and Role of Aromatic Rings in Enhanced Oil Recovery Using Molecular Dynamics. Langmuir 2023, 39, 989–996. [Google Scholar] [CrossRef]

- Wang, K.; Pan, H.; Zhang, T. Experimental study of prefabricated crack propagation in coal briquettes under the action of a CO2 gas explosion. ACS Omega 2021, 6, 24462–24472. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, J.; Zhou, N.; Wang, Y. Quantitative characterization of crack propagation behavior under the action of stage-by-stage fracturing induced by SC-CO2 fluid. Eng. Fract. Mech. 2021, 256, 107984. [Google Scholar] [CrossRef]

- Pouya, A.; Yazdi, P.B. A damage-plasticity model for cohesive fractures. Int. J. Rock Mech. Min. Sci. 2015, 73, 194–202. [Google Scholar] [CrossRef]

- Van Eekelen, H.A.M. Isotropic yield surfaces in three dimensions for use in soil mechanics. Int. J. Numer. Anal. Methods Geomech. 1980, 4, 89–101. [Google Scholar] [CrossRef]

- Gillemot, L.F. Criterion of crack initiation and spreading. Eng. Fract. Mech. 1976, 8, 239–253. [Google Scholar] [CrossRef]

- Gonçalves da Silva, B.; Einstein, H.H. Modeling of crack initiation, propagation and coalescence in rocks. Int. J. Fract. 2013, 182, 167–186. [Google Scholar] [CrossRef]

- Moaveni, B.; Conte, J.P.; Hemez, F.M. Uncertainty and sensitivity analysis of damage identification results obtained using finite element model updating. Comput. Aided Civ. Infrastruct. Eng. 2009, 24, 320–334. [Google Scholar] [CrossRef]

- Klatte, D. On a Frank-Wolfe type theorem in cubic optimization. Optimization 2019, 68, 539–547. [Google Scholar] [CrossRef]

- Hou, L.; Zhang, S.; Elsworth, D.; Liu, H.; Sun, B.; Geng, X. Review of fundamental studies of CO2 fracturing: Fracture propagation, propping and permeating. J. Pet. Sci. Eng. 2021, 205, 108823. [Google Scholar] [CrossRef]

- Cong, Z.; Li, Y.; Pan, Y.; Liu, B.; Shi, Y.; Wei, J.; Li, W. Study on CO2 foam fracturing model and fracture propagation simulation. Energy 2022, 238, 121778. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, D.; Liu, J.; Wang, J.; Li, X.; Zhou, Z. Numerical simulations of fracture propagation in jointed shale reservoirs under CO2 fracturing. Geofluids 2019, 2019, 2624716. [Google Scholar] [CrossRef]

- Vilarrasa, V.; Laloui, L. Potential fracture propagation into the caprock induced by cold CO2 injection in normal faulting stress regimes. Geomech. Energy Environ. 2015, 2, 22–31. [Google Scholar] [CrossRef]

- Li, Q.; Wang, Y.; Wang, F.; Ning, X.; Chuanbao, Z.; Zhang, J.; Zhang, C. Factor analysis and mechanism disclosure of supercritical CO2 filtration behavior in tight shale reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 17682–17694. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, Z.; Sarmadivaleh, M.; Lebedev, M.; Barifcani, A.; Yu, H.; Iglauer, S. Micro-scale fracturing mechanisms in coal induced by adsorption of supercritical CO2. Int. J. Coal Geol. 2017, 175, 40–50. [Google Scholar] [CrossRef]

- Berstad, T.; Dørum, C.; Jakobsen, J.P.; Kragset, S.; Li, H.; Lund, H.; Østbya, E. CO2 pipeline integrity: A new evaluation methodology. Energy Procedia 2011, 4, 3000–3007. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, L.; Pan, Z.; Han, Z. Numerical investigation of fluid-driven near-borehole fracture propagation in laminated reservoir rock using PFC2D. J. Nat. Gas Sci. Eng. 2016, 36, 719–733. [Google Scholar] [CrossRef]

- Zhang, B.; Li, X.; Zhang, Z.; Wu, Y.; Wu, Y.; Wang, Y. Numerical investigation of influence of in-situ stress ratio, injection rate and fluid viscosity on hydraulic fracture propagation using a distinct element approach. Energies 2016, 9, 140. [Google Scholar] [CrossRef]

- Kalantariasl, A.; Farajzadeh, R.; You, Z.; Bedrikovetsky, P. Nonuniform external filter cake in long injection wells. Ind. Eng. Chem. Res. 2015, 54, 3051–3061. [Google Scholar] [CrossRef]

- Jiang, Y.; Qin, C.; Kang, Z.; Zhou, J.; Li, Y.; Liu, H.; Song, X. Experimental study of supercritical CO2 fracturing on initiation pressure and fracture propagation in shale under different triaxial stress conditions. J. Nat. Gas Sci. Eng. 2018, 55, 382–394. [Google Scholar] [CrossRef]

- Oldenburg, C.M. Migration Mechanisms and Potential Impacts of CO2 Leakage and Seepage. 2006. Available online: https://escholarship.org/content/qt015944r2/qt015944r2.pdf (accessed on 1 July 2024).

- Yang, K.; Wang, L.; Ge, J.; He, J.; Sun, T.; Wang, X.; Zhao, Y. Impact of formation dip angle and wellbore azimuth on fracture propagation for shale reservoir. Processes 2023, 11, 2419. [Google Scholar] [CrossRef]

- Eshiet, K.I.I.; Sheng, Y. The role of rock joint frictional strength in the containment of fracture propagation. Acta Geotech. 2017, 12, 897–920. [Google Scholar] [CrossRef]

- Liu, W.; Zeng, Q.; Yao, J. Numerical simulation of elasto-plastic hydraulic fracture propagation in deep reservoir coupled with temperature field. J. Pet. Sci. Eng. 2018, 171, 115–126. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, T.; Qu, Z.; Wang, J.; Chen, M.; Liu, X. Numerical simulation of fracture propagation and production performance in a fractured geothermal reservoir using a 2D FEM-based THMD coupling model. Energy 2023, 273, 127175. [Google Scholar] [CrossRef]

- Zhou, D.; Zhang, G.; Prasad, M.; Wang, P. The effects of temperature on supercritical CO2 induced fracture: An experimental study. Fuel 2019, 247, 126–134. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 376, 121394. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Zhang, J.; Yu, X.; Zhao, M.; Zhou, C.; Forson, K.; Shi, S.; Zhao, Y.; et al. Influence of organoboron cross-linker and reservoir characteristics on filtration and reservoir residual of guar gum fracturing fluid in low-permeability shale gas reservoirs. Environ. Sci. Pollut. Res. 2022, 29, 82975–82985. [Google Scholar] [CrossRef]

- Luo, X.; Wang, S.; Wang, Z.; Jing, Z.; Lv, M.; Zhai, Z.; Han, T. Experimental investigation on rheological properties and friction performance of thickened CO2 fracturing fluid. J. Pet. Sci. Eng. 2015, 133, 410–420. [Google Scholar] [CrossRef]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Elastic Modulus, E/GPa | 20 | Poisson’s ratio, ν | 0.28 |

| Minimum horizontal principal stress, σh/MPa | 35 | Maximum horizontal principal stress, σH/MPa | 40 |

| Tensile strength, C/MPa | 4 | Initial pore pressure, Pip/MPa | 17 |

| Initial porosity, ϕ/% | 7 | Permeability, K/m2 | 5 × 10−16 |

| Leak-off coefficient | 1.2 × 10−12 | Total fracturing time, T/min | 10 |

| Elastic Modulus, E/GPa | 20 | 30 | 40 | 50 |

|---|---|---|---|---|

| Crack length/m | 12.3 | 12.9 | 14.5 | 16.9 |

| Crack width/×10−2 m | 2 | 1.8 | 1.5 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zheng, A.; Lu, W.; Shen, T.; Wang, W.; Wei, L.; Chang, Z.; Li, Q. Analysis of Fracturing Expansion Law of Shale Reservoir by Supercritical CO2 Fracturing and Mechanism Revealing. Energies 2024, 17, 3865. https://doi.org/10.3390/en17163865

Wang L, Zheng A, Lu W, Shen T, Wang W, Wei L, Chang Z, Li Q. Analysis of Fracturing Expansion Law of Shale Reservoir by Supercritical CO2 Fracturing and Mechanism Revealing. Energies. 2024; 17(16):3865. https://doi.org/10.3390/en17163865

Chicago/Turabian StyleWang, Li, Aiwei Zheng, Wentao Lu, Tong Shen, Weixi Wang, Lai Wei, Zhen Chang, and Qingchao Li. 2024. "Analysis of Fracturing Expansion Law of Shale Reservoir by Supercritical CO2 Fracturing and Mechanism Revealing" Energies 17, no. 16: 3865. https://doi.org/10.3390/en17163865

APA StyleWang, L., Zheng, A., Lu, W., Shen, T., Wang, W., Wei, L., Chang, Z., & Li, Q. (2024). Analysis of Fracturing Expansion Law of Shale Reservoir by Supercritical CO2 Fracturing and Mechanism Revealing. Energies, 17(16), 3865. https://doi.org/10.3390/en17163865