Abstract

This work focuses on the evolution of lubrication wedge shaping in internal combustion piston engines, taking into account liquid microflows on curved surfaces and coating microgeometries. It introduces a new approach to the analysis of friction losses by simulating the microflow of lubricating oil between the surfaces of piston rings cooperating with the cylinder surface. The models used take into account three types of microgeometry and material expansion. Key results indicate that microirregularities with a stereometry of 0.1–0.2 µm significantly influence the distribution of oil film thickness in the phase of maximum working pressure, which is critical for the functioning of the seal ring. The innovation of the work consists of demonstrating that, despite small changes in the friction force and power in the piston rings, changes in the minimum values of the oil film thickness are significant. The work highlights the failure to take into account microgeometry parameters in friction models, which leads to significant errors in the simulation results, especially in terms of oil film continuity and the contribution of mixed friction. The simulations also indicate that advanced geometric models with high mesh resolution are necessary only for the assessment of changes in oil film thickness during the highest pressure increase in the combustion chamber and taking into account various mixed friction conditions. The results suggest significant progress in engine design and performance, confirming the importance of advanced fluid and mixed friction models in piston engine lubrication research.

1. Introduction

Most of the mathematical models describing the phenomenon of oil flow in the spaces of kinematic pairs do not take into account the phenomenon of lubricating fluid microflows. In most cases, it is justified because there is significant oil film thickness in relation to the micro-inequalities of the cooperating planes throughout the engine operation cycle. On average, for internal combustion piston engines operating at an average thermodynamic load, the average oil film thickness over the engine operating cycle for the upper sealing ring is greater than 4.0 µm. There is a big drop in this value in engines with direct fuel injection, high indicated power, and a small total cylinder capacity. However, it is still a lot higher than the micro-inequality that sliding surfaces might have. The smallest oil film thickness is at the end of the compression stroke and the beginning of the expansion stroke between the top sealing ring and cylinder running surface. Under favorable conditions, this thickness may even decrease to approximately 0.1 µm. New anti-wear coating materials allow the roughness to be reduced to values ranging from 0.1 to 0.2 µm. Most authors of research on piston rings use models based on Reynolds theory. CFD models commonly used in the analysis of liquid and gas flows in this system have quite significant limitations resulting from the imposition of appropriate geometry of these elements and boundary conditions necessary for the simulation. Such simulations can be performed in a special case based on axisymmetric models, which enable us to determine the distribution of the oil film for each CA angle in the engine operating cycle. These models also allow for the determination of the movement of the piston rings and piston relative to the cylinder surface, which allows for a realistic assessment of the impact of angular changes. These models allow for the introduction of additional variables: extensibility, thermal properties of materials in the piston–ring–cylinder assembly, thermal transmittance, local changes in oil film viscosity, and others. However, most authors only introduce surface micro-irregularities in mixed and boundary friction models. Most of them ignore the parameter of surface micro-irregularities in fluid friction in axisymmetric models based on Reynolds theory. The theory of hydrodynamic lubrication is a key element in the analysis of friction and wear in piston engines.

The classic work “Theory of Hydrodynamic Lubrication” presents fundamental principles and mathematical models describing this phenomenon, laying the foundations for further research in this field [1]. The paper describes the distribution of the oil film on the cylindrical surface of a piston engine bearing. These studies provided detailed information on lubricant distribution, which is crucial for understanding and improving lubrication efficiency in internal combustion engines [2]. The problems of reducing friction losses in the piston–ring–cylinder configuration in an internal combustion engine with increased isochoric pressure increase were analyzed. The research highlighted key aspects related to the optimization of the geometry and materials used for the production of sealing rings [3]. Technologies for obtaining asymmetry of stereometric shapes of the sliding surfaces of sealing rings were the topic further research. The importance of appropriate shaping of the ring surfaces to reduce wear and friction losses was pointed out [4]. The geometry of the shape of the profiles of the sliding surface of the sealing rings and its impact on the parameters of the oil film and friction losses were the subject of analysis. Research has shown that precise shaping of ring profiles can significantly affect lubrication efficiency [5]. Another study analyzed the influence of asymmetric elliptical shapes of the sliding surface of sealing rings on the main parameters of the oil film. It has been shown that shape asymmetry can improve lubrication parameters and reduce friction losses [6]. The effect of the distribution of variable features of the asymmetry of the sliding surface of sealing rings on the values of friction loss coefficients and other selected parameters of the oil film was the subject of the next study. The results of these studies provided new information on the optimization of the shape of rings [7]. Integrated theory surface roughness provided a theoretical basis for analyzing the impact of roughness on friction and wear in the context of hydrodynamic lubrication. This work constitutes an important contribution to the understanding of phenomena related to surface microgeometry [8]. A model describing the influence of roughness on surface contact is proposed, which is crucial for friction and lubrication analyses. This work contributed to the development of more advanced theoretical models in this field [9]. The model of the random contact process of rough surfaces in the plastic state provided tools for analyzing friction and wear phenomena in the context of microgeometry. These studies are crucial for understanding and modeling lubrication processes [10]. For this reason, most authors believe that there is no need to complicate geometric meshes and limit the shape of rings to smooth surfaces.

Lubrication models have also been developed by other authors. Li et al. [11] developed a hydrodynamic lubrication (HL) model of the contact surfaces of the sleeves, rings, and cylinder and an equation of piston motion by examining friction losses at the interface. Models of mixed friction in the operating conditions of piston rings were proposed in the works [12,13]. Zhu et al. [14,15], Keribar et al. [16], Wong et al. [17], and Liu et al. [18] developed a lubrication model for the piston–ring–piston–cylinder interface, taking into account surface roughness. Meng et al. [19,20] created a lubrication model of the sleeve–cylinder assembly, taking into account the inertia of the connecting rod. In the last decade, the multi-body dynamics method has gained importance in modeling mechanical systems with lubricated joints, taking into account changes in the geometry of the lubricating wedge. Flores [21], Raven [22], and Tian [23,24] introduced the Reynolds equation into a multi-body system in order to model lubricated joints, which made it possible to conduct similar simulations in terms of the distribution of the oil film between the piston rings, the piston, and the cylinder liner. Zhao et al. [25] combined the lubrication model with the dynamic connecting rod and piston model to develop a method for modeling a multi-body system. Zhao et al. [26] established a connection between a lubricated tribological pair consisting of a piston sleeve to a connecting rod bearing, finding a clear interaction between the two types of lubricated joints, and a larger clearance increased this interaction. These studies concerned the problems of hydrodynamic lubrication, not taking into account the mechanical and thermal deformations of the piston–cylinder system. High temperatures and dynamic piston loading [27] cause inevitable mechanical and thermal deformations that must be taken into account when predicting the performance of the liner–cylinder system. Oh et al. [28] created a model of the lubricated piston and rings, taking into account the elastic deformation of the sleeve. Dursunkaya et al. [29] created a tribological model that includes elastohydrodynamic lubrication (EHL). This model can show how elastic deformations, lubrication, and secondary piston motion work. Ahmed et al. [30] investigated the influence of elastic deformation and sleeve profile on the oil film thickness. Offner et al. [31] studied the lubrication piston sleeve in the thermoelastic–hydrodynamic state. Many authors introduce the cylinder liner vibration parameter into their models, which may affect the dynamics and tribological performance of the piston [32,33,34]. Some studies also considered the hydrophobicity and hydrophilicity of materials for friction losses. However, modeling these phenomena is very difficult due to the large computational errors [35,36,37,38].

In recent years, research on modeling oil film parameters in combustion engines and tribological issues has provided significant information on optimizing engine operation and reducing energy losses. For example, research on the micro- and nanoscale Otto cycle, taking into account friction losses and boundary effects, shows that accurate modeling of these processes is key to improving the energy efficiency of engines [39]. Moreover, the identification of mechanical losses in turbochargers, carried out experimentally, allows for a better understanding and minimization of friction losses in supercharging systems [40]. Research on the characteristics of energy consumption distribution in water-lubricated screw compressors for fuel cell applications indicates the importance of a thorough analysis of these processes in the context of reducing energy consumption [41]. Comparative analysis of energy losses associated with the operation of piston rings in various types of combustion emphasize the impact of ignition technology on engine efficiency [42]. Additionally, an analysis of the properties of materials with the addition of nanofibers for air filtration in combustion engines showed that these innovative materials can significantly improve the filtration efficiency and durability of the engine [43]. Experimental research on fibrous materials for filtration of intake air in combustion engines shows that the properties of the materials can significantly affect the filtration efficiency and engine durability [44]. In the context of modeling and optimization of transport systems, Monte Carlo simulations and the semi-Markov approach have been proven to be effective in analyzing the operational processes of commercial vehicles, which has a direct impact on the design of more reliable and efficient transport systems [45]. Research on the theoretical and experimental aspects of uneven dust suction from a multi-cyclone settler in a two-stage air filter provides new perspectives on improving the efficiency of air filtration in combustion engines [46]. Thermodynamic, dynamic, and flow resistance analyses in a Stirling engine with a Scotch yoke piston mechanism show that advanced modeling can lead to a significant improvement in energy efficiency [47]. Road transport modeling problems are crucial for improving the reliability and efficiency of transport systems, which has been discussed in detail in the literature [48]. Comparative studies of engine dynamics for systems with cylinder deactivation indicate potential energy savings and reductions in exhaust emissions [49]. The development of an innovative algorithm for modeling the technical readiness factor in the automotive industry may contribute to improving vehicle management and maintenance processes [50]. These various studies indicate a multi-aspect approach to optimizing the operation of engines and transport systems, taking into account both mechanical and material aspects, as well as system aspects.

Combustion engines, despite the growing popularity of electric vehicles, still dominate as drive units in various sectors of the economy. To reduce exhaust emissions and meet legal requirements, hybrid drives with optimized combustion engines are used. Research has shown that a variable compression ratio, fuel injection time, and tribological optimization of parts can significantly reduce fuel consumption and particulate emissions [51]. The problem of friction and wear in combustion engines and air compressors was investigated, focusing on design changes in compressors and testing materials reinforcing aluminum cylinder liners. These changes contribute to reducing emissions and improving the efficiency of combustion engines [52]. It has been found that the use of alternative materials, such as ZA12 and A356 alloys, reduces power losses and improves efficiency compared to traditional materials such as tin bronze CuSn12 [53]. The introduction of modern technologies such as 3D scanning and reverse engineering allow the modification of racing engine parts, resulting in better performance and uniformity of engine operation. This technology enables accurate mapping of the geometry of parts and their serial production with high precision [54]. Additionally, research on the tribological properties of aluminum materials has shown that the use of reinforcements made of iron materials can significantly reduce energy losses caused by friction and wear in piston machines. This analysis used the Taguchi method and a model based on artificial neural networks to find optimal operating parameters [55]. Material research, as well as research on the thermal load of engines, surface texturing, and others, are crucial for mathematical models. This constitutes a starting point for accepting input data to these models and gives an idea of the values of roughness and microgeometry of the gaps up to which the model for a given material should be considered.

There is a need to study oil microflows between the sliding surfaces of piston rings and the cylinder. Many methods of deliberately creating micropores on the cylinder bearing surfaces increase oil absorption, improving the cooperation of the piston–ring–cylinder kinematic pairs. One-dimensional and two-dimensional models based on Reynolds theory are sufficient to determine the oil film thickness distribution and calculate the internal friction force. In the case of small oil film thicknesses, unforeseen phenomena may occur that affect the wettability of the surfaces of the rings, piston, and sleeves, leading to disruption of the oil film and accelerated wear. Micro-irregularities with appropriate geometry can improve lubrication by acting as an additional accumulator of lubricating fluid. Research on various micro-geometric structures and engine operating conditions is necessary to evaluate the tribological benefits of intentionally creating micro-bumps. The aim of the work is to determine the conditions affecting the flow of liquid in the micro-channels of structural sliding surfaces at low oil viscosity values. The tests concern 10 W/10 oils and micro-irregularities below 0.2 µm, aimed at achieving a minimum oil film thickness. The transition from the laminar to turbulent state is undetectable at the macroscale of flow, and turbulent oil flow does not occur due to the low Reynolds number, although it may occur with service gas in tiny labyrinth gaps.

The research examines the effects of microscale channel stereometry, including cross-sectional shape, length, height-to-width ratio, roughness, and lubricating fluid properties. They focus on how these factors affect the oil film thickness, which can be less than 0.2 µm in channels with micro-roughness, leading to high hydraulic resistance. The work’s novelty and innovation lie in determining how micro-irregularities and specific channel geometries affect the behavior of lubricating liquids, particularly in extreme engine operating conditions. The results suggest that optimizing piston ring macrogeometry with additional variables can improve engine efficiency by more than 5% and reduce oil consumption, representing a significant advancement in engine design and performance. The work mainly aims to resolve the need to use complex geometric meshes for fluid and mixed friction.

2. Methodology Section

2.1. Model Assumptions of the Physical Field of Solid Heat Transfer

In any reciprocating internal combustion engine, the heat generated in the engine’s working chamber by the combustion process and the heat generated by mixed and fluid friction cause a thermal load on the engine’s main mechanisms. The temperature distribution may lead to deformation and changes in the geometry of the rings, pistons, and cylinders, as well as local changes in dynamic oil viscosity. The study uses the model included in the work [56] due to the analysis of the temperature field in the steady state.

where n is the normal vector of the heat transfer surface, χ is the heat transfer coefficient, k is the thermal conductivity of the material, and Text is the surrounding medium temperature.

In this work, the average Reynolds equation in the lubrication area was adopted to calculate the hydrodynamic fluid pressure in the piston–cylinder jacket system [56].

and

where ρ and μ is the density and dynamic viscosity of the lubricating oil. ph is the hydrodynamic pressure of the lubricating oil and u piston speed. is the roughness of the surfaces of the cooperating kinematic pairs, which is defined as .

In addition, the parameters of p andl are the roughness of the piston and cylinder mantle surfaces. Φx and Φy denote the pressure–flow coefficients in the circumferential and axial directions of the piston skirt, respectively. Φc and Φs serve as contact and shear flow factors, respectively [56].

2.2. Rheological Compound of Oil Lubricating Engine Components

The properties of the lubricating oil depending on the temperature characterize the Vogel model included in [57]. It was used in these model studies.

where μ0 is a constant with a unit of dynamic viscosity, T is the temperature of lubricating oil, and Ta and Tb are temperature parameters derived from experimental research.

After heat transfer, the instantaneous viscosity of the lubricating oil can be calculated based on the temperature distribution of the cylinder and the position of the piston and piston rings relative to the cylinder surface. The relationship between oil viscosity and pressure was determined based on the Roeland model [58,59].

The shear rate dependence of the viscosity oil can be described by the Cross equation [51].

where μ2 and μ∞ are the low- and high-shear viscosity of the lubricant, respectively. Parameter m0 is a constant ranging from 0.5 to 1.0 for most multigrade oils. γc is the critical shear rate of the oil and is expressed as γc = 10Aγ+BγT for simplicity. Here, Aγ and Bγ are constant depending on the type of lubricating oil used. Assuming Couette flow for the oil film between the plaster and the ring, the shear rate γ is expressed by this Equation [60]:

where u is the piston velocity and hmin is the minimum oil film thickness.

The influence of pressure and temperature on the lubricating oil density was used in the Dowson–Higginson model [60].

where ρ0 is the lubricant density under the atmospheric pressure and the lubricant temperature is T0, and βT is the thermal expansion coefficient of the lubricant.

For the mixed lubrication area, the Greenwood and Tripp roughness contact model was used, described in part earlier with a detailed derivation description. This model can be found in [61,62].

and

in which E′ implies the composite elastic modulus of cooperating kinematic pairs and is calculated by Young’s modulus of the piston (Ep), piston rings (Epr), and cylinder (El) as E′ = 1/(1/Ep + 1/Epr + El).

The hydrodynamic pressure of the lubricating oil, the inertial force, and the combustion pressure can lead to the complete deformation of the piston and piston rings, which affects the distribution of the hydrodynamic oil pressure at the interface of the piston, rings, and cylinder. With small deformations in properly designed assemblies, the material of the system can react as a linear-elastic material. The equation of motion for a linear-elastic material can be expressed using the Piol–Kirchhoff stress tensor [63].

where the total deformation gradient tensor F is defined as F = FelFinel. In the next stage, Finel is the total inelastic deformation tensor and derived from thermal expansion. The scale of this depends mainly on the coating material and base materials used. Fel indicates the elastic deformation gradient tensor and usol the displacement gradient. Is is the unit matrix. S represents the stress tensor. Fv represents the volume force vector.

Based on Hooke’s law, the constitutive model for a linearly elastic material is as follows:

and

where S0 is the initial stress tensor. Sext is the external stress tensor. Sq is an extra stress tensor. Ji is the ratio between current and initial volume (or mass density).

C = C(E,ν) is the 4th order elasticity tensor, depending on Young’s modulus E and Poisson’s ratio ν of the material.

The elastic Green–Lagrange strain tensor is defined by this Equation:

For geometric nonlinearities, the deformations are expressed by the Green–Lagrange strain tensor, which can be written as follows:

After the heat exchange between the elements takes into account the materials, it is possible to calculate the thermal deformation of the piston–rings–cylinder system using the thermal expansion model [53].

where εth is the thermal strain and αth is the thermal expansion coefficient of the material. Tref is the uniform zero thermal stress reference temperature.

The dynamics equations of a multi-segment dynamic system integrating a lubricated joint in the case of assembling the main engine can be expressed as follows [56].

where M = diag (mcra, mrod, mp) is a mass matrix of a system consisting of all components included in a dynamical system. Here, mcra and mrod refer to the weight of the crank and the booster rod. mp = mpis + mpin refers to the total weight of the piston and the piston pin. J = diag (Jcra, Jrod, Jp) is the moment of the inertia matrix with respect to the center of mass for the given elements. Here, Jcra and Jrod constitute the moment of inertia of the crank and the rod. Jp = Jpis + Jpin is the moment of inertia of the piston and piston pin. ü and Ӧ are the translational and angular accelerations of a rigid domain. R is the current rotation matrix. FI is a reference to a force mainly derived from the restraints of connections, while the Fext refers to external forces, including the gravity of all elements and the lubrication force in accordance with the hydrodynamic theory of the lubrication. MI and Mext denote inertial and external moments, respectively.

The piston–ring–cylinder system is treated as a lubricated translational joint and the rest as ideal rotary joints. The crankshaft rotates at a fixed speed and the pin can rotate about the joint axis, which imposes kinematic constraints on the system [44]. The total normal force Fn and the moment Mn about the piston pin axis can be achieved through an integration of the oil film pressure and can be expressed as follows [64].

where Ω represents the lubrication domain.

In the case of mixed lubrication, the piston and piston rings are subject to seizure caused by shearing of the lubricating oil, roughness and texture of the geometry distribution, and unevenness of the planes on the macro-scale. The shear stress can be calculated using the formulas in [12,13]:

where ϕf, ϕfs, and ϕfp represent shear stress factors.

The total friction force and its moment relative to the axis of the piston pin are given by the formula:

where the contact friction is calculated using the appropriate contact roughness factor uf. These oil film forces and moments are referenced to the center of mass of the piston.

2.3. Numerical Models of the Oil Film and Energy Losses

When creating mathematical models to determine oil film parameters, such as oil pressure, layer thickness, and friction losses, there is no need to develop a complex module for solving the Reynolds equation. It is easier to compare simulation and experimental test results regarding friction losses in mechanical units. The main causes of errors in numerical calculations may be too large a calculation step and have a too low calculation accuracy, which is important for the meshing of individual components of the piston–ring–cylinder assembly. Numerical calculations often involve increasing errors. Even with an accuracy of 25 decimal places, this may not be enough. Therefore, simplifications are used, although some may lead to erroneous conclusions. A micro-roughness below 0.2 µm does not have much effect on the friction power of piston rings, so most calculations are simplified to smooth surfaces and macro shapes. However, with a minimum oil film thickness of 0.1 µm, micro-irregularities significantly affect the film thickness. The lack of additional coordinates in the geometric mesh may lead to incorrect conclusions and the occurrence of mixed friction. The model has been simplified as much as possible, taking into account micro- and macrogeometry as a result of the working processes of the piston–ring–cylinder assembly. Greatest attention was paid to the impact of micro-irregularities on the parameters of the oil film, which is crucial for reducing friction losses, fuel consumption, and gas emissions. The Reynolds equation in this calculation method has been simplified and used for further modeling [1,2,3].

On the basis of this, the relationship for is as follows:

which follows from :

The parameters a0 … a4 are constants for each grid point (i, j), and the pressure p(i,j) is a function of these constants and the four surrounding pressures. Detailed information on creating formulas defining the effects of sliding, extrusion, and inclination for a broken surface is included in works [2,3], which constituted the basis for creating a mathematical model in this work with additional micro-irregularities in fluid friction conditions.

According to this model, for the sliding surfaces of sealing rings, the dimensionless slip pressure indicator p′i(2),i+1(2) can be written by the formula:

and so

By acting analogously, the squeezing pressure index p′vi(1),i+1(1) can be expressed by the formula:

there by

where —dimensionless slip effect index, —dimensionless extrusion effect index, n—number of line sections representing the sliding surface of the ring, zi—local oil film thickness on a given segment Δxi. By calculating the dimensionless and indices, it is possible to determine the approximate value of the pressure caused by the sliding effect and extrusion :

where H2 and H1—axial height of the lower and upper sealing rings.

2.4. Analytical Models of Rough Surface Statistics

To represent the shape of the rough surfaces between the sliding surfaces of the piston rings and the cylinder, you can use four functions that characterize the random signal or enter individual coordinates with adjusted values of the coordinate differences in the calculation steps. Statistical functions include auto-correction functions, power spectral density functions, rms value, and probability density functions. These functions reflect micro-inequalities and can take any shape represented by the individual terms of the statistical equations. The geometry of individual micro-irregularities should reflect the actual shapes of these irregularities for anti-wear coatings used in the production of piston rings, pistons, and cylinder surfaces. Three geometry variants were introduced to the mathematical model based on the theory of hydrodynamic lubrication: 0 µm (smooth surface), 0.1 µm (amplitude height), and 0.2 µm (coordinate differences). Function autocorrection and power spectral density provide information about the random process in the time and frequency domains, as related by the Fourier transform.

An alternative is the exponential correlation function proposed by Whitehouse and Archard [9]:

This is related to the discontinuity in the slope, so this equation cannot be extended to the Teylor series where there are odd derivatives , , . Using the solution from [2] it is possible to obtain the surface profile properties from this function through the height distribution slopes , and curvatures . For a random process expressed by x(t), an infinite set of higher-order statistical moments and connecting moments can be computed. By introducing the given random profiles defining the character of the roughness of the cooperating planes, indirectly constituting the stereometry of the flow channel, it is possible to obtain the derivation of the autocorrection function defined on the border (−φ, +φ), wherein :

where

φ—length of the sample segment along which surface roughness parameters are defined and

—the expected value of two random variables (mean value).

This relationship is not true for a periodic process . The spectral density function G(ω) is the Fourier transform of the autocorrection function R(τ); therefore, the following equation for the G(ω) function and the transformation of the autocorrection function by the inverse Fourier transform of the spectral density function can be written:

and

where the ordinary moments on the basis of the equations of the spectral density function of the inequality geometry are expressed as follows:

Using assumptions based on the central limit theorem, one can derive a probability density distribution that is a normal distribution. It is assumed that the profile height of the micro-bumps represented by macrostereometry is a random function. A similar assumption applies to the profile inclination parameters and profile curvature . Probabilistic indices are independent of the sampling purpose and represent ergodic functions. In this assumption, for a probabilistic description, one random function is enough to determine one roughness profile. By introducing three values of random variables with zero values expected for the Gaussian distribution, the following relationships can be derived:

The matrix is assumed to be the inverse of the covariance matrix and is the determinant of . Considering the distribution of the next three heights on the surface profile for z, z, z, for covariance , i , appropriate equations for the representation of micro-inequalities can be derived. According to theoretical assumptions, the given matrix should be simplified in the fields . Taking these conditions into account, the slope m′ and the curvature κ can be simplified:

and

With such simplifying assumptions, the non-zero elements of the covariance matrix can be written as

and

wherein

Assuming the following three values of the random variable n = 3, the matrix can be derived as follows:

The above conditions can only be assumed if φ → 0. Therefore, it can be assumed that

and the slope value , = = :

In this case, you can write —= , which leads to

The quantities are equal to the statistical moments , introduced by the spectral moments in Nayak’s paper [10]. Therefore, the covariance matrix can be written as

where , which, using the variable r introduced by Nayak’s paper [3], can be expressed as , . With some reservations, it can be said that

By introducing standardized values of the height , the slopes and the curvature , this Equation (can be determined:

Assuming that |S| < ttanθ, the probability that the ordinate is a vertex of height ϛ and curvature t, it can be written according to Greenwood’s assumption [1]:

where r determines the character of the rough surface superimposed on the curve representing the macro shape of the sliding surface of the piston rings and the cylinder running surface and h is the segment along which the roughness peak profile slope is measured, that is, the m = and sampling parameter. On the basis of [8], dividing the above equation by a closed formula defining the number of peaks to the total number of peaks with a specific ordinate, we can write

and therefore,

These equations determine the probability that a given vertex with ordinate z(x) is a peak because exceptions may occur. According to Greenwood [8], the distribution of peak heights at a given curvature is close to a Gaussian distribution, with the expected value and standard deviation .

By introducing this function into the equations describing the macro-shape of the cooperating kinematic pairs of the engine, one can expect an increase in the curvature and height of the peaks representing the surface roughness on the micro-scale. In the case of microflows, taking into account micro-irregularities according to Greenwood distributions gives similar results in the distribution of the oil film for the same frequencies and amplitudes. Micro-irregularities with amplitudes of 0.1 µm and 0.2 µm significantly affect the parameters of the oil film, such as the film thickness or the amount of scraped oil. Increasing the frequency of micro-bump peaks between 50 and 200 steps does not significantly change the film parameters, since hydrodynamic pressure drops are mainly determined by amplitudes or coordinate differences. In the case of simple shapes of piston ring sliding surfaces, differences in the coordinates of the base values defining the macrospheres of parabolic–elliptic symmetry can be introduced. Taking into account all assumptions, the analysis showed that the effect of oil microflows at variable ring loads slightly affects the total friction losses. However, given the occurrence of mixed friction and the thinning of the oil film, this is deemed necessary. A thicker mesh reflecting the shape of the rings, cylinder, and smooth piston surfaces should be used in places most susceptible to reduced oil film coverage, especially at the ring barrel ends.

3. Results and Discussion

3.1. Input Data for the Simulation Model

Some key factors reflecting the actual engine operating conditions in mathematical models are data regarding engine operating conditions, geometric data of the piston-ring–cylinder assembly, oil film parameters, and material data. All data used in the simulation come from experimental or simulation tests. Selected data are presented in Table 1.

Table 1.

Selected geometrical and operation parameters of a piston internal combustion engine used during simulation tests of friction losses and oil film parameters.

Modern combustion engines are characterized by a high maximum operating pressure in the combustion chamber; therefore, a relatively high value of the isochoric pressure increase coefficient was adopted, which additionally introduces changes in material expansion. In this research, it was assumed that the introduced geometry on a micro- and macro-scale already reflects all thermal changes and the process of ring running-in in the initial period of engine operation.

Figure 1 shows the computational model’s detailed micro- and macrogeometry data for the upper sealing ring. The lower ring and scraper have a shape consistent with the model [3]. The dimensions of the macrogeometry of the rings are listed in Table 1. Data reflecting micro-inequalities are also introduced. Figure 1 shows geometry examples illustrating the problem of modeling fluid friction in microflows. For similar geometries with different microstructures, the oil film results were close to the reference geometry, even at increased sampling frequencies, consistent with the hydrodynamic lubrication theory.

Figure 1.

A generalized drawing of the surface topography introduced into the simulation.

3.2. Simulation Results Performed Only for the Fluid Friction Regime

The analyses carried out aim to demonstrate that the introduction of very advanced geometric models with high mesh resolution is necessary only when assessing changes in the oil film thickness during the period of the highest pressure increase in the combustion chamber and taking into account various mixed friction conditions. In another case, such as determining the friction power in the fluid friction regime, the differences in the results are small.

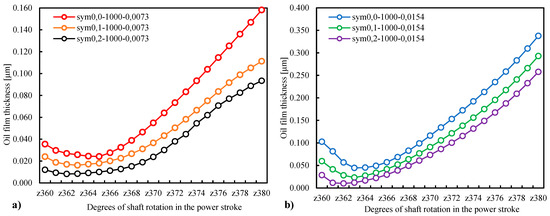

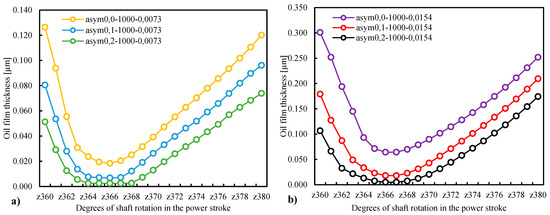

Based on Figure 2 and Figure 3, it can be concluded that the introduction of surface roughness of 0.1 and 0.2 μm in the numerical model in the field of fluid friction allows for a more accurate determination of the oil film thickness. This also allows for more precise selection of appropriate materials with appropriate surface roughness. In this case, the most important parameter is to determine the minimum oil film thickness for given engine operating conditions, in particular in the range from 360 to 380 °CA at a speed of 1000 RPM. In this area, the oil film thickness is always the smallest throughout the entire engine operation cycle (720 degrees of crankshaft rotation). This is due to the greatest load of gas force, which depends on the distribution of the unit working pressure in the combustion chamber. Figure 2 and Figure 3 show that for higher surface roughnesses, the oil film thickness decreases. For the remaining crankshaft angles, under pressure working conditions, the impact of introducing roughness is much smaller. This can be observed by very small changes in the oil film thickness and slight differences in the average friction powers of the rings. It is worth mentioning, however, that from the point of view of durability and wear of the sliding surfaces of the rings, it is worth knowing the actual value of the minimum oil film value for extreme engine operating conditions. This also allows you to select appropriate parameters of the lubricant, mainly its dynamic viscosity. The drawings also show that the distribution of oil film thickness for this engine operating range also strongly depends on the engine speed and dynamic viscosity.

Figure 2.

Distribution of oil film thickness from 360 to 380 °CA for symmetrical ring shapes, with 3 types of surface roughness—smooth, 0.1 micron, and 0.2 micron—and a shaft speed of 1000 RPM. (a) Dynamic oil viscosity 0.0073 [mPa], (b) dynamic oil viscosity 0.0154 [mPa].

Figure 3.

Distribution of oil film thickness from 360 to 380 °CA for symmetrical ring shapes, with 3 types of surface roughness—smooth, 0.1 micron, and 0.2 micron—and a shaft speed of 3000 RPM. (a) Dynamic oil viscosity 0.0073 [mPa], (b) dynamic oil viscosity 0.0154 [mPa].

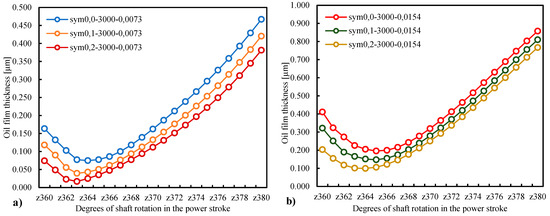

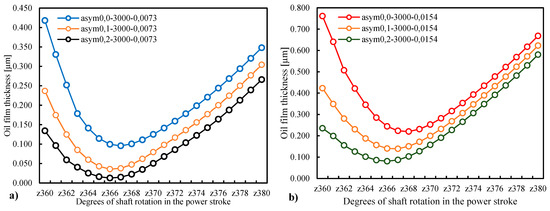

According to Figure 4 and Figure 5, it can be seen that the effect of introducing surface roughness is very large on the distribution of oil film thickness. The smallest thickness value is 0.2 μm. However, the asymmetric shape of the piston rings affects the transmission of the shaft rotation angle at which the minimum oil film thickness occurs. In the case of a symmetrical shape, it is in the range of 362–364 °CA, and for an asymmetrical shape, it is approximately 366 °CA. Moreover, it can be seen that the initial value for asymmetric shapes of oil film thickness is much higher than for symmetric shapes. The trends in film thickness changes in relation to dynamic viscosity and shaft rotation speed are similar to those in the case of symmetrical shapes.

Figure 4.

Distribution of oil film thickness from 360 to 380 °CA for asymmetrical ring shapes, with 3 types of surface roughness—smooth, 0.1 micron, and 0.2 micron—and a shaft speed of 1000 RPM. (a) Dynamic oil viscosity 0.0073 [mPa], (b) dynamic oil viscosity 0.0154 [mPa].

Figure 5.

Distribution of oil film thickness from 360 to 380 °CA for asymmetrical ring shapes, with 3 types of surface roughness—smooth, 0.1 micron, and 0.2 micron—and a shaft speed of 3000 RPM. (a) Dynamic oil viscosity 0.0073 [mPa], (b) dynamic oil viscosity 0.0154 [mPa].

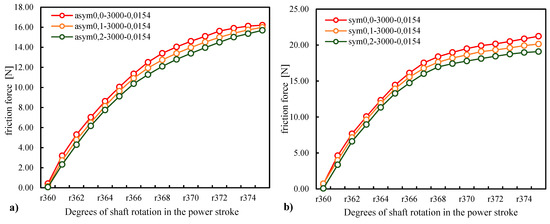

Figure 6 shows the change in the friction force of the upper sealing ring for two different ring shapes and the same parameters of engine speed and dynamic oil viscosity. In this case, the trends in the friction force values are similar for both shapes. The smallest values in both cases occur for a roughness of 0.2 μm. For symmetrical shapes, the friction force is much greater than for asymmetric shapes. On this basis, it can be concluded that the differences in the friction force values for the three roughnesses are small and will not translate into a large change in the total friction power of the rings. This means that the impact of roughness on the friction force is much smaller than on the distribution of oil film thickness in the most loaded engine operating range.

Figure 6.

Distribution of the friction force of the upper piston ring for 3000 RMP, dynamic viscosity 0.0154 [mPa], and 3 types of surface roughness. (a) Asymmetric shape, (b) symmetrical shape.

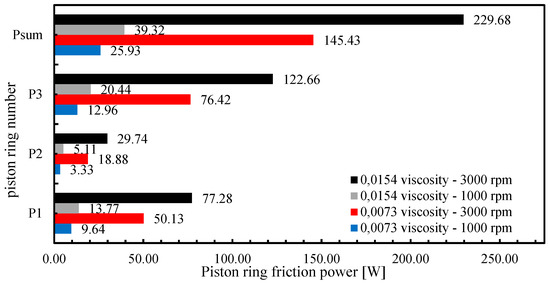

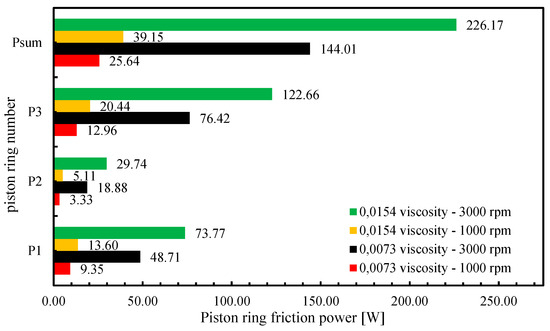

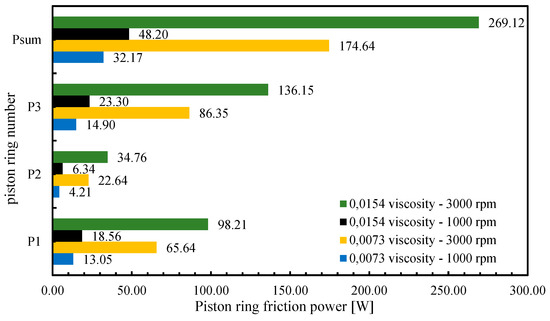

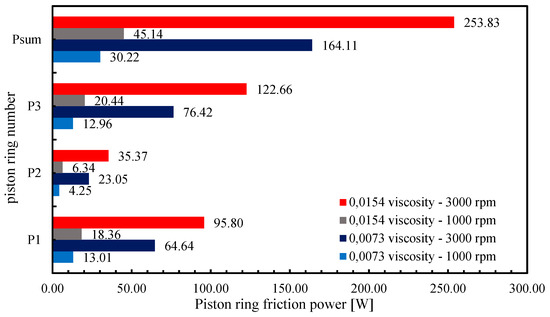

Based on Figure 7, Figure 8 and Figure 9, it can be concluded that the effect of introducing surface roughness on the sliding surfaces of the rings does not have a significant impact on the friction power of the rings in the fluid friction regime. This is due to small changes in the oil film thickness outside the combustion process. The impact of the change in oil film thickness in the range from 360 to 380 °CA is not much greater at very high values of oil film thickness in the further area of engine operation throughout its cycle from 0 to 720 °CA. Therefore, in the case of simulations enabling the determination of the friction power of piston rings in the fluid friction regime, there is no point in taking into account such precise geometric meshes representing the roughness on the main shape of the piston rings.

Figure 7.

Total friction power of piston rings for the symmetrical shape of rings in a package—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

Figure 8.

Total friction power of piston rings for the symmetrical shape of rings in a package—surface roughness 0.10 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

Figure 9.

Total friction power of piston rings for the symmetrical shape of rings in a package—surface roughness 0.20 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

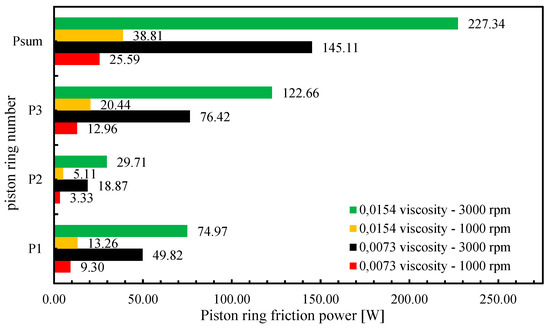

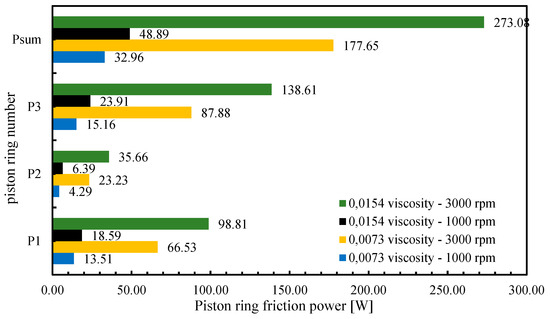

Figure 10, Figure 11 and Figure 12 show a similar relationship with respect to surface roughness as in Figure 7, Figure 8 and Figure 9. This means that the global shape of piston rings has a much greater impact on the friction power than very accurate models that reproduce the roughness shape. In this case, it can be seen that asymmetric rings have slightly lower friction power than symmetrical rings. The results indicate that the introduction of micro-irregularities with an amplitude of 0.10 µm and 0.20 µm has little effect on the total friction power under fluid friction conditions. The differences in the results are minimal, which suggests that in the case of simulations aimed at determining the friction power in the fluid friction regime, it is not necessary to take into account such precise micro-irregularities.

Figure 10.

Total friction power of piston rings for the asymmetrical shape of rings in a package—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

Figure 11.

Total friction power of piston rings the asymmetrical shape of rings in a package—surface roughness 0.10 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

Figure 12.

Total friction power of piston rings for the asymmetrical shape of rings in a package—surface roughness 0.20 µm, shaft rotation speed 1000 and 3000 [RPM], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa·s].

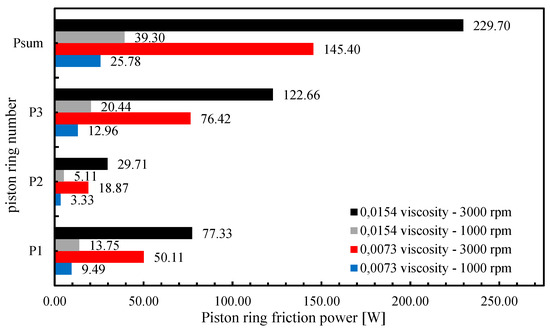

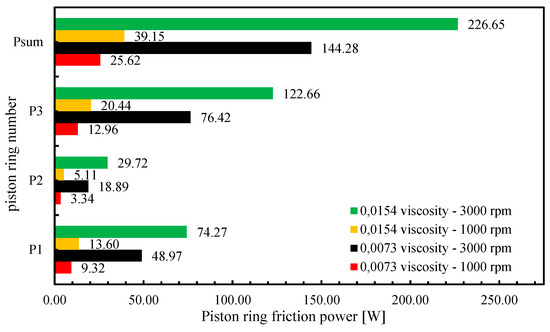

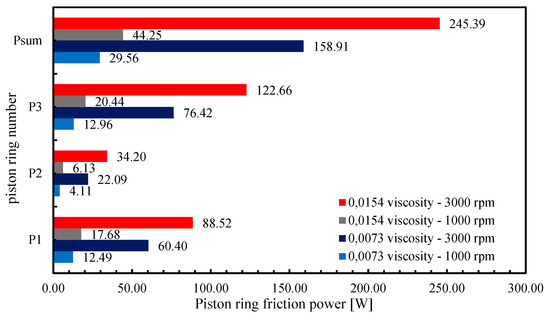

3.3. Simulation Results When Introducing a Mixed Friction Model

Figure 13, Figure 14 and Figure 15 show the total friction power of symmetrically shaped piston rings taking into account the mixed friction model for different crankshaft rotational speeds (1000 and 3000 rpm) and dynamic oil viscosities (0.0154 and 0.0073 mPa·s). The analysis of these graphs shows that the introduction of micro-irregularities with an amplitude of 0.10 µm and 0.20 µm leads to noticeable changes in the total friction power, especially in conditions of high dynamic oil viscosity and at higher crankshaft rotational speeds.

Figure 13.

Total friction power of piston rings for the symmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

Figure 14.

Total friction power of piston rings for the symmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.10 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

Figure 15.

Total friction power of piston rings for the symmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.20 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

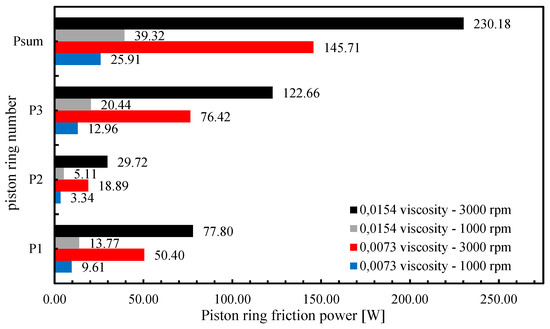

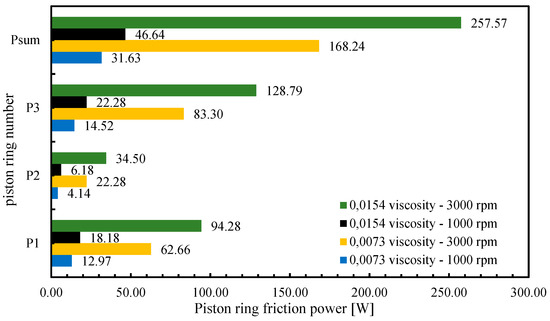

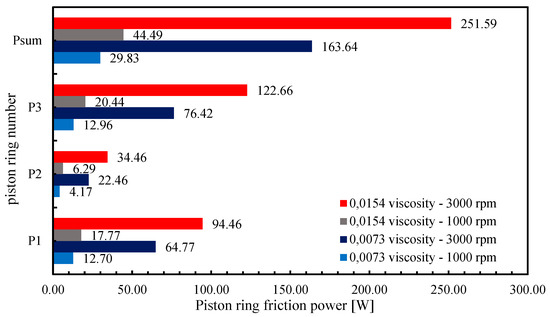

Figure 16, Figure 17 and Figure 18 show the total friction power of asymmetric piston rings taking into account the mixed friction model. The results show that asymmetrically shaped rings tend to generate lower friction losses compared to symmetrically shaped rings, especially at lower dynamic oil viscosities. This suggests that asymmetric ring shapes may be more effective in reducing friction losses, which is important for the design of piston rings in modern combustion engines. With respect to the fluid friction model, the inclusion of the mixed friction program module indicates that increasing the mesh accuracy has a significant impact on the friction power of the rings. The very complicated modeling process indicates that increasing the surface roughness on the base ring shape increases the difference in measurement results. This means that the mixed friction model can determine the differences more precisely in the achieved ring friction powers for three selected roughnesses. Therefore, it is worth using it in cases where there is a risk of mixed friction conditions. In this case, it is recommended to start model tests with the fluid friction model and then turn on the mixed friction model. However, this requires the construction of much more complex modules. The advantage of advanced models is the ability to very precisely determine not only the minimum oil film thickness but also to show changes in friction power for a given surface topography in relation to a specific material.

Figure 16.

Total friction power of piston rings for the asymmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

Figure 17.

Total friction power of piston rings for the asymmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

Figure 18.

Total friction power of piston rings for the asymmetrical shape of the rings in the package, taking into account the mixed friction model—surface roughness 0.00 µm, shaft rotation speed 1000 and 3000 [rpm], and dynamic oil viscosity η 0.0154 and 0.0073 [mPa s].

4. Conclusions

The most important conclusions arise from modeling the microflow of lubricating oil between the piston rings and cylinder in internal combustion engines, as follows:

The results showed that the introduction of microgeometric irregularities with amplitudes of 0.1 µm and 0.2 µm into the geometric model significantly affects the distribution of oil film thickness. The greatest changes are observed in the area of minimum oil film thickness, especially in the phase of high working pressure at the beginning of the power stroke.

The minimum oil film thickness, less than 0.3 µm, is crucial for the proper functioning of the upper sealing ring paired with the cylinder surface. Omitting microgeometry parameters in fluid friction models results in a significant reduction in simulation accuracy, particularly in terms of maintaining oil film continuity.

The results also indicated that the introduction of very advanced geometric models with high mesh resolution is necessary only when assessing changes in the oil film thickness during the highest pressure increase in the combustion chamber and taking into account various mixed friction conditions. Otherwise, the differences in results are small.

The results show that the distribution of oil film thickness strongly depends on the engine speed and dynamic oil viscosity. Higher surface roughnesses reduce the oil film thickness, especially in the range of 360 to 380 degrees of crankshaft rotation angle.

Increasing the frequency of micro-unevenness peaks in the range of 50 to 200 steps does not significantly change the oil film parameters. The amplitudes or differences in individual asperity coordinates have the greatest influence on changes in oil film thickness.

Author Contributions

Conceptualization, Methodology, Validation, Formal Analysis, Investigation, Writing, Original Draft Preparation, Visualization: P.W.; Writing—Review and Editing, Supervision: P.W. and S.K.; Project Administration: P.W. and S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This study received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pinkus, O.; Sternlicht, B. Theory of Hydrodynamic Lubrication; McGraw-Hill Book Company, Inc.: New York, NY, USA; Toronto, ON, Canada; London, UK, 1961. [Google Scholar]

- Iskra, A. Distribution of the Oil Film on the Cylinder Bearing Surface of a Piston Engine. Ph.D. Thesis, Wydawnictwo Politechniki Poznańskiej, Poznań, Poland, 1987. [Google Scholar]

- Wróblewski, P.; Iskra, A. Problems of Reducing Friction Losses of a Piston-Ring-Cylinder Configuration in a Combustion Piston Engine with an Increased Isochoric Pressure Gain. In Proceedings of the SAE Powertrains, Fuels & Lubricants Meeting, Online Event, 22–23 September 2020; SAE Technical Paper 2020-01-2227. SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Wróblewski, P. Technology for Obtaining Asymmetries of Stereometric Shapes of the Sealing Rings Sliding Surfaces for Selected Anti-Wear Coatings. In Proceedings of the SAE Powertrains, Fuels & Lubricants Meeting, Online Event, 22–23 September 2020; SAE Technical Paper 2020-01-2229. SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Wróblewski, P.; Iskra, A. Geometry of shape of profiles of the sliding surface of ring seals in the aspect of friction losses and oil film parameters. Combust. Engines 2016, 167, 24–38. [Google Scholar] [CrossRef]

- Wróblewski, P. Effect of asymmetric elliptical shapes of the sealing ring sliding surface on the main parameters of the oil film. Combust. Engines 2017, 168, 84–93. [Google Scholar] [CrossRef]

- Wróblewski, P. The effect of the distribution of variable characteristics determining the asymmetry of the sealing rings sliding surfaces on the values of friction loss coefficients and other selected parameters of oil film. Combust. Engines 2017, 171, 107–116. [Google Scholar] [CrossRef]

- Greenwood, J. A Unified Theory of Surface Roughness. Proc. R. Soc. A Math. Phys. Eng. Sci. 1984, 393, 133–157. [Google Scholar] [CrossRef]

- Whitehouse, D.J.; Archard, J.F. The properties of random surfaces of significance in their contact. Proc. R. Soc. Lond. A Math. Phys. Sci. 1970, 316, 97–121. [Google Scholar] [CrossRef]

- Nayak, P.B. Random process model of rough surfaces in plastic contact. Wear 1974, 26, 165–174. [Google Scholar] [CrossRef]

- Li, D.F.; Ezzat, H.A. An automotive piston lubrication model. ASLE Trans. 1983, 26, 151–160. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, H.S. An Average Flow Model for Determining Effects of Three-Determining Effects of Three-Dimensional Roughness on Partial Hydrodynamic Lubrication. J. Lubr. Technol. 1979, 100, 12–17. [Google Scholar] [CrossRef]

- Patir, N.; Cheng, M.S. Application of average flow model to lubrication between rough sliding surfaces. J. Tribol. 1979, 101, 220–229. [Google Scholar] [CrossRef]

- Zhu, D.; Cheng, H.S.; Arai, T.; Hamai, K. A numerical analysis for piston skirts in mixed lubrication-part I: Basic modeling. J. Tribol. 1992, 114, 553–562. [Google Scholar] [CrossRef]

- Zhu, D.; Hu, Y.Z.; Cheng, H.S.; Arai, T.; Hamai, K. A numerical analysis for piston skirts in mixed lubrication-part II: Deformation considerations. J. Tribol. 1993, 115, 125–133. [Google Scholar] [CrossRef]

- Keribar, R.; Dursunkaya, Z. A comprehensive model of piston skirt lubrication. J. Engines 1992, 101, 844–852. [Google Scholar] [CrossRef]

- Wong, V.W.; Tian, T.; Lang, H.; Ryan, J.P.; Sekiya, Y.; Kobayashi, Y.; Aoyama, S. A numerical model of piston secondary motion and piston slap in partially flooded elastohydrodynamic skirt lubrication. J. Engines 1994, 103, 1276–1290. [Google Scholar] [CrossRef]

- Liu, K.; Xie, Y.B.; Gui, C.L. A comprehensive study of the friction and dynamic motion of the piston assembly. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 1998, 212, 221–226. [Google Scholar] [CrossRef]

- Meng, X.; Xie, Y. A new numerical analysis for piston skirtliner system lubrication considering the effects of connecting rod inertia. Tribol. Int. 2012, 47, 235–243. [Google Scholar] [CrossRef]

- Meng, X.; Ning, L.; Xie, Y.; Wong, V.W. Effects of the connecting-rod-related design parameters on the piston dynamics and the skirt-liner lubrication. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 885–898. [Google Scholar] [CrossRef]

- Flores, P.; Ambrósio, J.; Claro, J.P. Dynamic Analysis for Planar Multibody Mechanical Systems with Lubricated Joints. Multibody Syst. Dyn. 2004, 12, 47–74. [Google Scholar] [CrossRef]

- Ravn, P.; Shivaswamy, S.; Alshaer, B.J.; Lankarani, H.M. Joint Clearances with Lubricated Long Bearings in Multibody Mechanical Systems. J. Mech. Des. 2000, 122, 484–488. [Google Scholar] [CrossRef]

- Tian, Q.; Zhang, Y.; Chen, L.; Yang, J. Simulation of planar flexible multibody systems with clearance and lubricated revolute joints. Nonlinear Dyn. 2010, 60, 489–511. [Google Scholar] [CrossRef]

- Tian, Q.; Flores, P.; Lankarani, H.M. A comprehensive survey of the analytical, numerical and experimental methodologies for dynamics of multibody mechanical systems with clearance or imperfect joints. Mech. Mach. Theory 2018, 122, 1–57. [Google Scholar] [CrossRef]

- Zhao, B.; Dai, X.D.; Zhang, Z.N.; Xie, Y.B. A new numerical method for piston dynamics and lubrication analysis. Tribol. Int. 2016, 94, 395–408. [Google Scholar] [CrossRef]

- Zhao, B.; Cui, Y.; Xie, Y.; Zhou, K. Dynamics and lubrication analyses of a planar multibody system with multiple lubricated joints. Proc. Inst. Mech. Eng. Part J Eng. Tribol. 2018, 232, 326–346. [Google Scholar] [CrossRef]

- Littlefair, B.; Cruz MD, L.; Mills, R.; Theodossiades, S.; Rahnejat, H.; Dwyer-Joyce, R.; Howell-Smith, S. Lubrication of a flexible piston skirt conjunction subjected to thermo-elastic deformation: A combined numerical and experimental investigation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2014, 228, 69–81. [Google Scholar] [CrossRef]

- Oh, K.P.; Li, C.H.; Goenka, P.K. Elastohydrodynamic lubrication of piston skirts. J. Tribol. 1987, 109, 356–362. [Google Scholar] [CrossRef]

- Dursunkaya, Z.; Keribar, R.; Ganapathy, V. A model of piston secondary motion and elastohydrodynamic skirt lubrication. J. Tribol. 1994, 116, 777–785. [Google Scholar] [CrossRef]

- Ahmed, K.; Benyoucef, K.; Redha, M.; Mourad, L. The effect of piston skirt profile on EHD lubrication in an internal combustion engine. Adv. Mater. Res. 2013, 787, 704–710. [Google Scholar] [CrossRef]

- Offner, G.; Lorenz, N.; Knaus, O. Piston Clearance Optimization Using Thermo-Elasto Hydrodynamic Simulation to Reduce Piston Slap Excitation and Friction Loss; SAE Technical Paper 2012-01-1530; SAE: Warrendale, PA, USA, 2012. [Google Scholar] [CrossRef]

- Meng, F.M.; Wang, X.F.; Li, T.T.; Chen, Y.P. Influence of cylinder liner vibration on lateral motion and tribological behaviors for piston in internal combustion engine. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 151–167. [Google Scholar] [CrossRef]

- Meng, F.; Du, M.; Wang, X.; Chen, Y.; Zhang, Q. Effect of axial piston pin motion on tribo-dynamics of piston skirt-cylinder liner system. Ind. Lubr. Tribol. 2018, 70, 140–154. [Google Scholar] [CrossRef]

- Lu, Y.; Zhang, X.; Xiang, P.; Dong, D. Analysis of thermal temperature fields and thermal stress under steady temperature field of diesel engine piston. Appl. Therm. Eng. 2017, 113, 796–812. [Google Scholar] [CrossRef]

- Wróblewski, P.; Kachel, S. The concept of the contact angle in the process of oil film formation in internal combustion piston engines. Sci. Rep. 2023, 13, 20715. [Google Scholar] [CrossRef]

- Wróblewski, P. The Theory of the Surface Wettability Angle in the Formation of an Oil Film in Internal Combustion Piston Engines. Materials 2023, 16, 4092. [Google Scholar] [CrossRef] [PubMed]

- Wróblewski, P. Reduction of friction energy in a piston combustion engine for hydrophobic and hydrophilic multilayer nanocoatings surrounded by soot. Energy 2023, 271, 126974. [Google Scholar] [CrossRef]

- Wróblewski, P. Investigation of energy losses of the internal combustion engine taking into account the correlation of the hydrophobic and hydrophilic. Energy 2023, 264, 126002. [Google Scholar] [CrossRef]

- Nie, W.; Liao, Q.; Zhang, C.; He, J. Micro-/nanoscaled irreversible Otto engine cycle with friction loss and boundary effects and its performance characteristics. Energy 2010, 35, 4658–4662. [Google Scholar] [CrossRef]

- Deligant, M.; Podevin, P.; Descombes, G. Experimental identification of turbocharger mechanical friction losses. Energy 2012, 39, 388–394. [Google Scholar] [CrossRef]

- Wang, C.; Liu, M.; Wang, B.; Xing, Z.; Shu, Y. Research on power consumption distribution characteristics of a water-lubricated twin-screw air compressor for fuel cell applications. Energy 2022, 256, 124673. [Google Scholar] [CrossRef]

- Koszalka, G.; Hunicz, J. Comparative study of energy losses related to the ring pack operation in homogeneous charge compression ignition and spark ignition combustion. Energy 2021, 235, 121388. [Google Scholar] [CrossRef]

- Dziubak, T. Material Properties Analysis with Addition of Nanofibres for Air Intake Filtration in Internal Combustion Engines. Int. J. Automot. Mech. Eng. 2021, 18, 8621–8636. [Google Scholar] [CrossRef]

- Dziubak, T.; Bąkała, L.; Dziubak, S.D.; Sybilski, K.; Tomaszewski, M. Experimental Research of Fibrous Materials for Two-Stage Filtration of the Intake Air of Internal Combustion Engines. Materials 2021, 14, 7166. [Google Scholar] [CrossRef]

- Oszczypała, M.; Ziółkowski, J.; Małachowski, J. Modelling the Operation Process of Light Utility Vehicles in Transport Systems Using Monte Carlo Simulation and Semi-Markov Approach. Energies 2023, 16, 2210. [Google Scholar] [CrossRef]

- Dziubak, T. Theoretical and Experimental Studies of Uneven Dust Suction from a Multi-Cyclone Settling Tank in a Two-Stage Air Filter. Energies 2021, 14, 8396. [Google Scholar] [CrossRef]

- Karabulut, H.; Okur, M.; Halis, S.; Altin, M. Thermodynamic, dynamic and flow friction analysis of a Stirling engine with Scotch yoke piston driving mechanism. Energy 2019, 168, 169–181. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Lęgas, A. Problem of Modelling Road Transport. J. KONBiN 2019, 49, 159–193. [Google Scholar] [CrossRef]

- Fridrichová, K.; Drápal, L.; Raffai, P.; Böhm, M. Comparative study of engine dynamics for rolling and selective cylinder deactivation. Energy 2024, 303, 131946. [Google Scholar] [CrossRef]

- Szkutnik-Rogoż, J.; Małachowski, J.; Ziołkowski, J. An innovative computational algorithm for modelling technical readiness coefficient: A case study in automotive industry. Comput. Ind. Eng. 2023, 176, 108942. [Google Scholar] [CrossRef]

- Milojević, S.; Glišović, J.; Savić, S.; Bošković, G.; Bukvić, M.; Stojanović, B. Particulate Matter Emission and Air Pollution Reduction by Applying Variable Systems in Tribologically Optimized Diesel Engines for Vehicles in Road Traffic. Atmosphere 2024, 15, 184. [Google Scholar] [CrossRef]

- Milojević, S.; Savić, S.; Mitrović, S.; Marić, D.; Krstić, B.; Stojanović, B.; Popović, V. Solving the Problem of Friction and Wear in Auxiliary Devices of Internal Combustion Engines on the Example of Reciprocating Air Compressor for Vehicles. Teh. Vjesn. 2023, 30, 122–130. [Google Scholar] [CrossRef]

- Skulić, A.; Milojević, S.; Marić, D.; Ivanović, L.; Krstić, B.; Radojković, M.; Stojanović, B. The impact of lubricant viscosity and materials on power losses and efficiency of worm gearbox. Teh. Vjesn. 2022, 29, 1853–1860. [Google Scholar]

- Milojević, S.; Džunić, D.; Marić, D.; Skrúcaný, T.; Mitrović, S.; Pešić, R. Tribological Assessment of Aluminum Cylinder Material for Piston Compressors in Trucks and Buses Brake Systems. Teh. Vjesn.-Tech. Gaz. 2021, 28, 1268–1276. [Google Scholar]

- Blagojević, M.; Bojović, M.; Milojević, S.; Marković, P.; Lazarević, D. Modification of Racing Car Cylinder Head Using 3D Digitization and Reverse Engineering. In Proceedings of the International Congress Motor Vehicles & Motors 2020, Kragujevac, Serbia, 8–9 October 2020. [Google Scholar]

- Chengwei, W.; Linqing, Z. An Average Reynolds Equation for Partial Film Lubrication with a Contact Factor. J. Tribol. 1989, 111, 189. [Google Scholar]

- Hamrock, B.J.; Schmid, S.R.; Jacobson, B.O. Fundamentals of Fluid Film Lubrication; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Ma, M.T. Incorporation of Lubricant Shear-Thinning in a Two-Dimensional Lubrication Analysis for Automotive Piston-Ring Packs; SAE Technical Paper 2000-01-1786; SAE: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Delprete, C.; Razavykia, A. Piston dynamics, lubrication and tribological performance evaluation: A review. Int. J. Engine Res. 2020, 21, 725–741. [Google Scholar] [CrossRef]

- Gu, C.; Meng, X.; Xie, Y.; Zhang, D. Mixed lubrication problems in the presence of textures: An efficient solution to the cavitation problem with consideration of roughness effects. Tribol. Int. 2016, 103, 516–528. [Google Scholar] [CrossRef]

- Greenwood, J.; Tripp, J. The contact of two nominally flat rough surfaces. Exp. Mycol. 1981, 5, 323–329. [Google Scholar] [CrossRef]

- Akalin, O.; Newaz, G.M. Piston ring-cylinder bore friction modeling in mixed lubrication regime: Part I—Analytical results. J. Tribol. 2001, 123, 211–218. [Google Scholar] [CrossRef]

- Rokad, V.; Pandya, D.H. Development of 3D improved acoustic transient model for vibro cleaner using COMSOL multiphysics. Mater. Today Proc. 2021, 44, 776–781. [Google Scholar] [CrossRef]

- Antony Samy, A.; Golbang, A.; Harkin-Jones, E.; Archer, E.; McIlhagger, A. Prediction of part distortion in Fused Deposition Modelling (FDM) of semi-crystalline polymers via COMSOL: Effect of printing conditions. CIRP J. Manuf. Sci. Technol. 2021, 33, 443–453. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).