Review of Various Sensor Technologies in Monitoring the Condition of Power Transformers

Abstract

1. Introduction

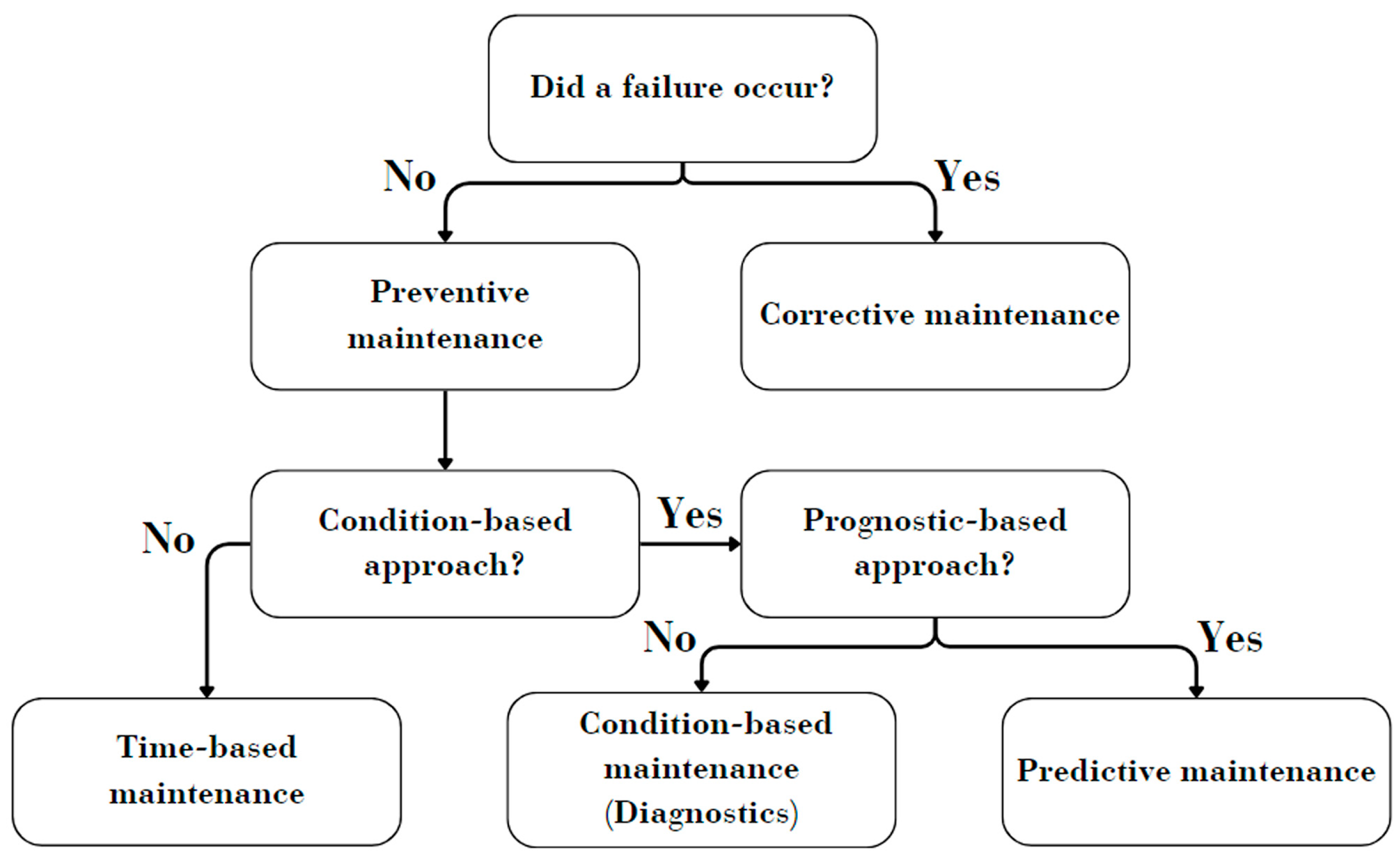

2. Background

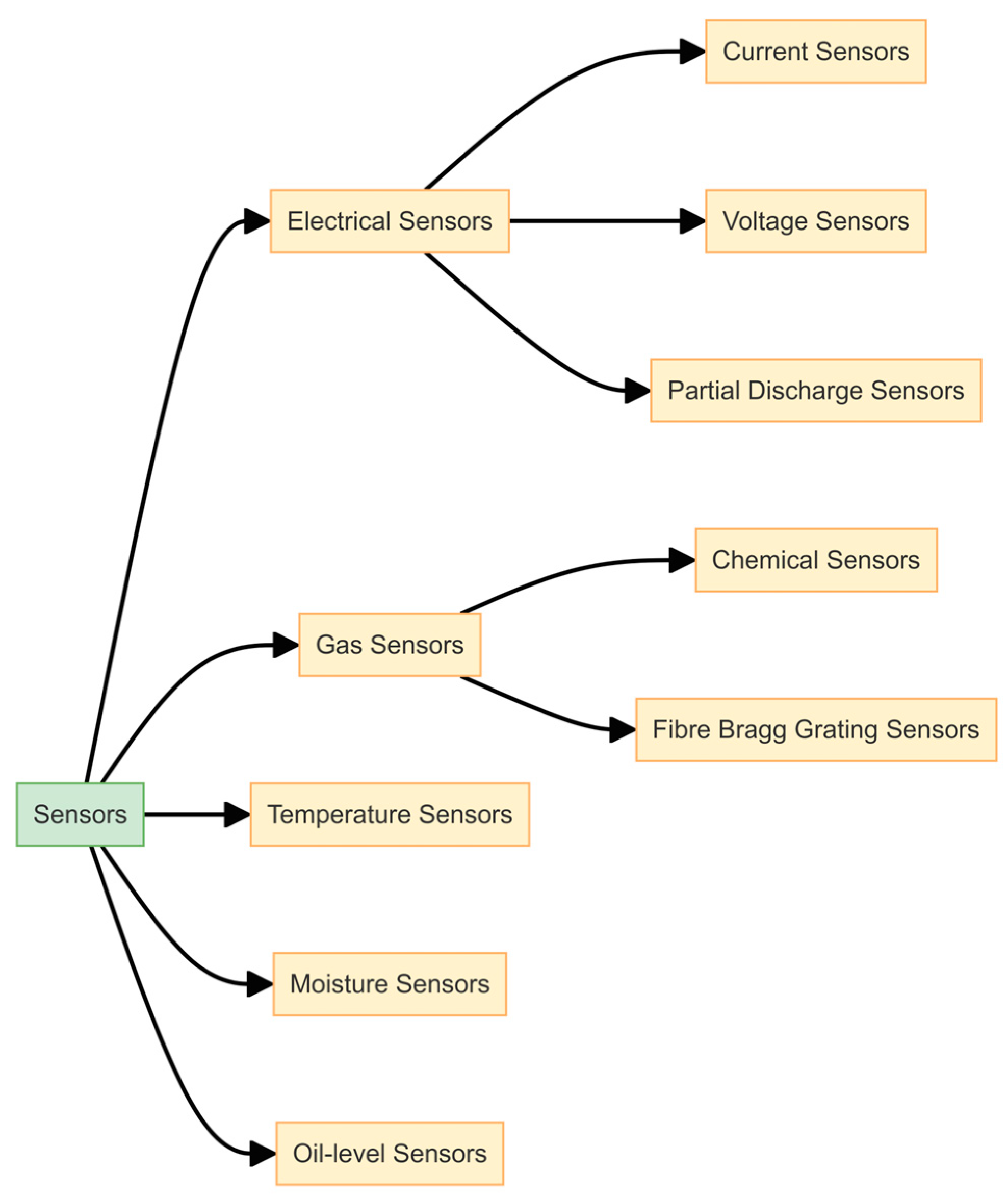

3. Sensor Technologies for Measuring Different Parameters

3.1. Core Sensors

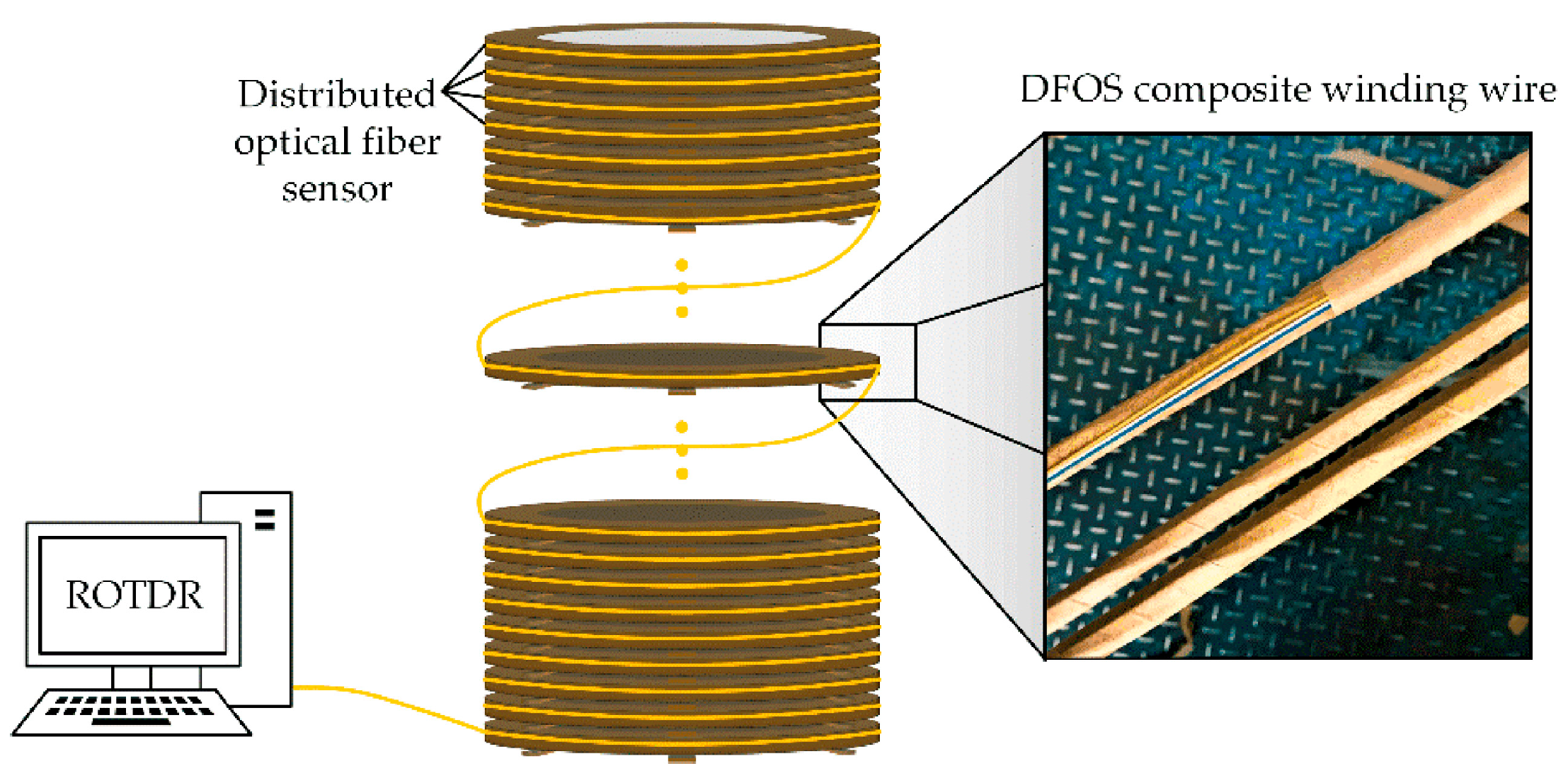

3.2. Winding Sensors

3.3. Vibration Sensors

3.4. Temperature Sensors

3.5. Oil Quality Sensors

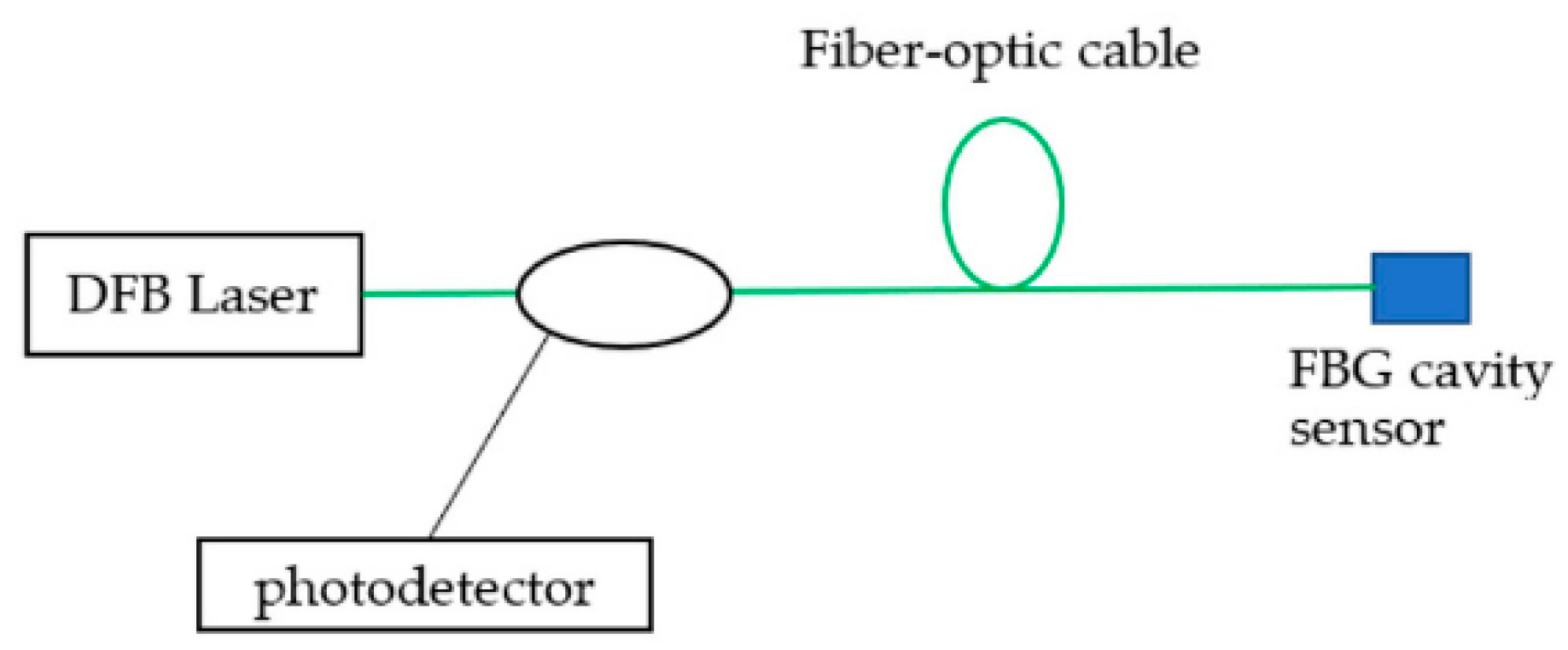

3.6. Dissolved Gas Sensors

3.7. Moisture Sensors

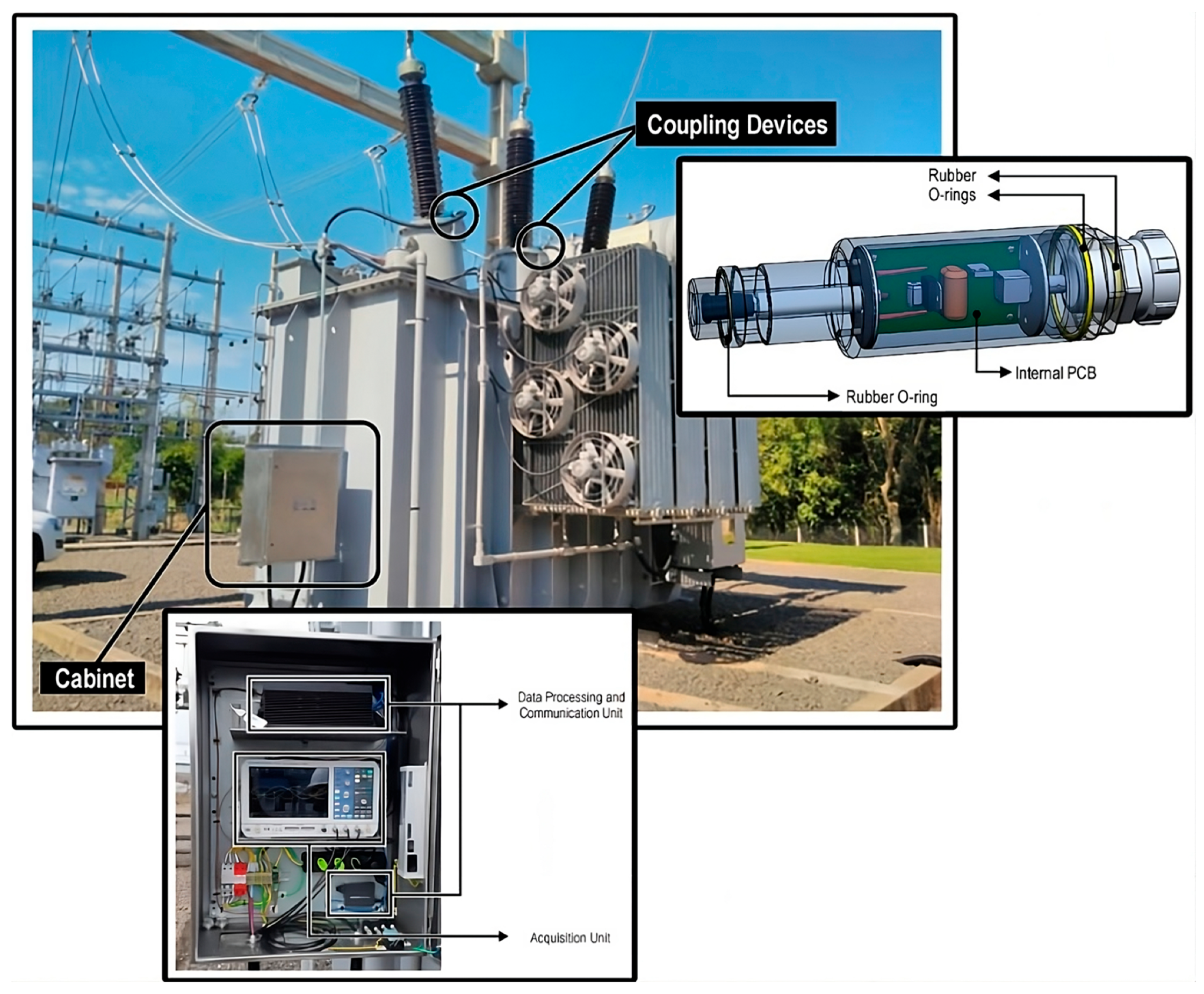

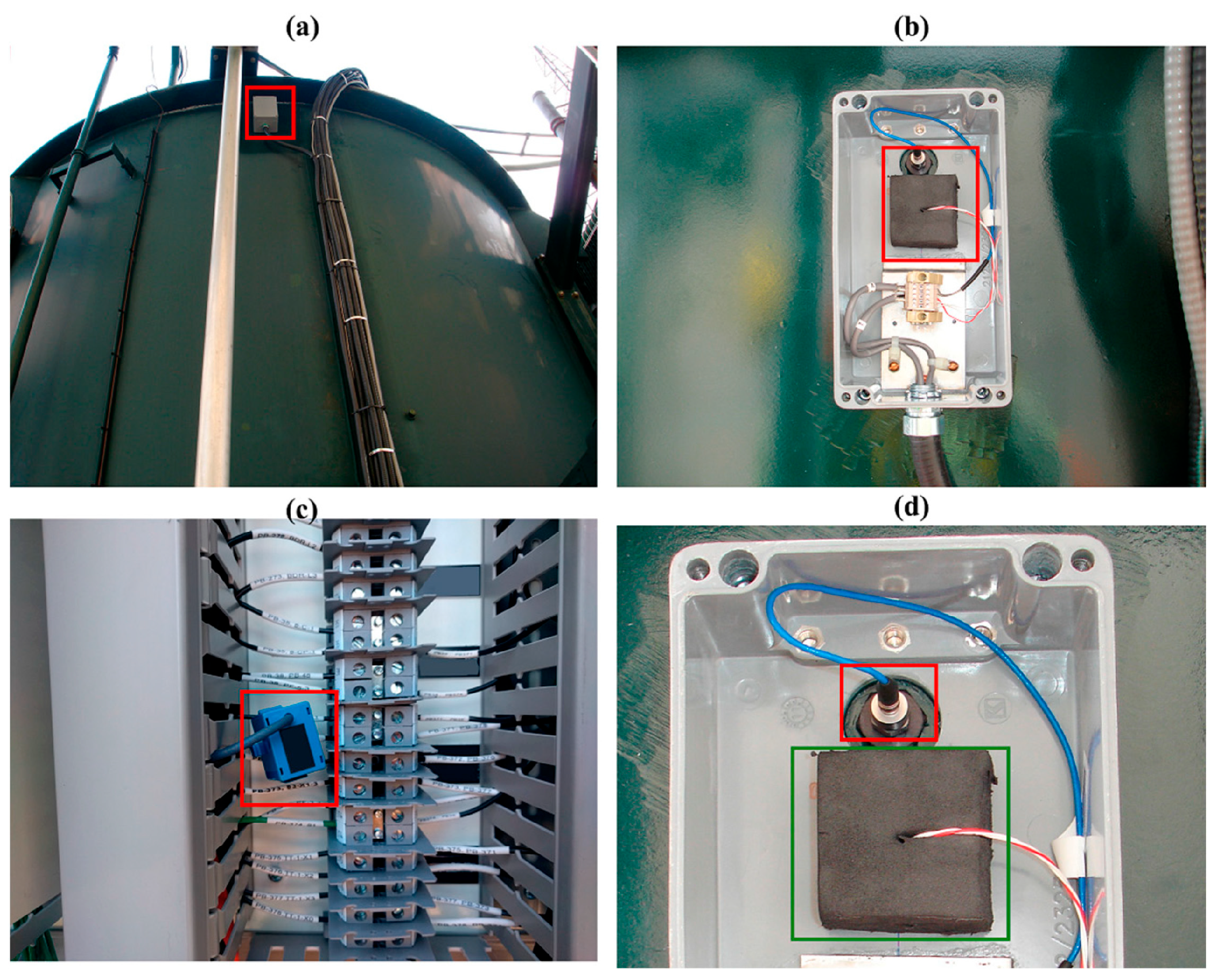

3.8. Partial Discharge Sensors

3.9. Bushing Sensing

3.10. Tap-Changer Condition Sensing

3.11. Commercially Available Sensors

- Compatibility with Transformer Specifications: Sensors must be compatible with the transformer’s operating specifications such as voltage levels, current ratings, and frequency ranges.

- Positioning: Sensors should be strategically placed throughout the transformer, so operators can gather comprehensive data on its condition, enabling predictive maintenance and enhancing operational reliability. For example, monitoring core and windings involves placing sensors near the core and windings to monitor temperature and detect hot spots, while gas and moisture sensors should be placed in areas prone to gas and moisture buildup, such as near insulation materials or gaskets.

- Measurement Accuracy: Sensors should provide accurate measurements of parameters critical to transformer health, such as temperature, oil level, and vibration.

- Reliability and Durability: Sensors must be reliable and durable to withstand the harsh operating conditions typical of transformer environments, including temperature extremes and electromagnetic interference.

- Response Time: Sensors should have a fast response time to promptly detect and respond to changes in transformer conditions, helping to prevent damage or failure.

- Ease of Installation and Maintenance: Sensors should be easy to install and maintain, minimizing downtime during installation or replacement.

- Compatibility with Monitoring System: Sensors should be compatible with the monitoring and control system used for centralized monitoring of transformers, ensuring seamless integration and data transmission.

- Cost-Effectiveness: Consideration of the initial cost of sensors and their long-term operational costs should align with the budget constraints of the asset management program.

- Safety Standards: Sensors must comply with relevant safety standards and regulations to ensure safe operation within the transformer environment.

3.12. Theoretical Sensors

4. Utilization of Failure Modes and Effect Analysis

- identification of all potential failure modes that could occur within the unit. Table 5 summarizes the main failure modes;

- analysis of the impact of each identified failure mode on the overall system performance;

- determination of the underlying causes of each failure mode;

- ranking of failure modes based on their potential impact, likelihood of occurrence, and detectability;

- development and implementation of strategies to mitigate or eliminate identified failure modes;

- documentation of the FMEA process and regular review and update as new information becomes available.

5. Discussion

5.1. Key Findings and Advancements

5.2. Advantages of the Review

5.3. Challenges and Limitations

5.4. Future Directions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Adhikari, K.; Sarkar, B.; Jasper, D.; Roy, N.K. Development of Optical Fiber Sensor for PartialDischarge Detection in High Voltage Power Transformers. In Proceedings of the 2020 IEEE International Conference on Power Systems Technology (POWERCON), Virtual, 7–8 December 2020; pp. 1–6. [Google Scholar]

- Fofana, I.; Hadjadj, Y. Electrical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 679. [Google Scholar] [CrossRef]

- N’cho, J.; Fofana, I.; Hadjadj, Y.; Beroual, A. Review of Physicochemical-Based Diagnostic Techniques for Assessing Insulation Condition in Aged Transformers. Energies 2016, 9, 367. [Google Scholar] [CrossRef]

- Mahanta, D.K.; Laskar, S. Transformer condition monitoring using fiber optic sensors: A review. ADBU J. Eng. Technol. 2016, 4, 142–145. [Google Scholar]

- Simplice, A.; Behjat, V.; Kung, P.; Fofana, I. Assessing Water Content and Vibration from Dynamic Measurement in Transformer; Springer Nature: Singapore, 2019. [Google Scholar]

- Singh, R.P.; Sonawane, A.V.; Satpute, M.S.; Shirsath, D.Y.; Thakre, M.P. A Review on Traditional Methods of Condition Monitoring of Transformer. In Proceedings of the 2020 International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 2–4 July 2020; pp. 1144–1152. [Google Scholar]

- Abbasi, A.R. Fault detection and diagnosis in power transformers: A comprehensive review and classification of publications and methods. Electr. Power Syst. Res. 2022, 209, 107990. [Google Scholar] [CrossRef]

- Ramnarine, V.; Peesapati, V.; Djurović, S. Fibre Bragg Grating Sensors for Condition Monitoring of High-Voltage Assets: A Review. Energies 2023, 16, 6709. [Google Scholar] [CrossRef]

- Poczekajło, P.; Suszyński, R.; Antosz, A. Review of the usage of fiber optic technologies in electrical power engineering and a development outline in Poland. Energy Rep. 2024, 11, 5227–5234. [Google Scholar] [CrossRef]

- Teng, C.; Min, R.; Zheng, J.; Deng, S.; Li, M.; Hou, L.; Yuan, L. Intensity-Modulated Polymer Optical Fiber-Based Refractive Index Sensor: A Review. Sensors 2022, 22, 81. [Google Scholar] [CrossRef] [PubMed]

- Nilakanta Meitei, S.; Borah, K.; Chatterjee, S. Review on monitoring of transformer insulation oil using optical fiber sensors. Results Opt. 2023, 10, 100361. [Google Scholar] [CrossRef]

- Elele, U.; Nekahi, A.; Arshad, A.; Fofana, I. Towards Online Ageing Detection in Transformer Oil: A Review. Sensors 2022, 22, 7923. [Google Scholar] [CrossRef]

- Zhao, D.; Zhu, B.; Li, L.; Liu, X.; Wen, L.; Song, Y.; Shen, H.; Li, M.; Li, X.; Wu, D. A review of methods for measuring oil moisture. Measurement 2023, 217, 113119. [Google Scholar] [CrossRef]

- Meitei, S.N.; Borah, K.; Chatterjee, S. Partial Discharge Detection in an Oil-Filled Power Transformer Using Fiber Bragg Grating Sensors: A Review. IEEE Sens. J. 2021, 21, 10304–10316. [Google Scholar] [CrossRef]

- Chai, H.; Phung, B.T.; Mitchell, S. Application of UHF Sensors in Power System Equipment for Partial Discharge Detection: A Review. Sensors 2019, 19, 1029. [Google Scholar] [CrossRef]

- Meitei, S.N. Partial Discharge Detection Using Piezoelectric Sensors on Power Transformer: A Review. IEEE Sens. J. 2024, 24, 13730–13742. [Google Scholar] [CrossRef]

- Costa, J.V.; Silva, D.F.F.d.; Branco, P.J.C. Large-Power Transformers: Time Now for Addressing Their Monitoring and Failure Investigation Techniques. Energies 2022, 15, 4697. [Google Scholar] [CrossRef]

- Jin, L.; Kim, D.; Abu-Siada, A.; Kumar, S. Oil-Immersed Power Transformer Condition Monitoring Methodologies: A Review. Energies 2022, 15, 3379. [Google Scholar] [CrossRef]

- Swain, A.; Abdellatif, E.; Mousa, A.; Pong, P.W.T. Sensor Technologies for Transmission and Distribution Systems: A Review of the Latest Developments. Energies 2022, 15, 7339. [Google Scholar] [CrossRef]

- CIGRE. Ageing High Voltage Substation Equipment and Possible Mitigation Techniques; CIGRE Technical Brochures 725; CIGRE: Paris, France, 2018. [Google Scholar]

- Bustamante, S.; Manana, M.; Arroyo, A.; Castro, P.; Laso, A.; Martinez, R. Dissolved Gas Analysis Equipment for Online Monitoring of Transformer Oil: A Review. Sensors 2019, 19, 4057. [Google Scholar] [CrossRef] [PubMed]

- Nanfak, A.; Samuel, E.; Fofana, I.; Meghnefi, F.; Ngaleu, M.G.; Hubert Kom, C. Traditional fault diagnosis methods for mineral oil-immersed power transformer based on dissolved gas analysis: Past, present and future. IET Nanodielectrics 2024, 1, 1–34. [Google Scholar] [CrossRef]

- Darwish, M.M.F.; Hassan, M.H.A.; Abdel-Gawad, N.M.K.; Lehtonen, M.; Mansour, D.-E.A. A new technique for fault diagnosis in transformer insulating oil based on infrared spectroscopy measurements. High Volt. 2024, 9, 319–335. [Google Scholar] [CrossRef]

- IEC 60247; Insulating Liquids—Measurement of Relative Permittivity, Dielectric Dissipation Factor (tan d) and d.c. Resistivity. IEC: London, UK, 2004; p. 53.

- IEC 61620; Insulating Liquids—Determination of the Dielectric Dissipation Factor by Measurement of the Conductance and Capacitance—Test Method. IEC: London, UK, 1998; p. 43.

- ASTM A924; Standard Specification for General Requirements for Steel Sheet, Metallic-Coated by the Hot-Dip Process. ASTM: West Conshohocken, PA, USA, 2022; p. 14.

- DL/T 911-2016; Frequency Response Analysis on Winding Deformation of Power Transformers. The Electric Power Industry Standard of People’s Republic of China. China Water & Power Press: Beijing, China, 2016.

- CIGRE. Mechanical-Condition Assessment of Transformer Windings Using Frequency Response Analysis (FRA); CIGRE Technical Brochure 342; CIGRE: Paris, France, 2008. [Google Scholar]

- IEC 60076-18; Measurement of Frequency Response. IEC: London, UK, 2012.

- C57.149-2012; IEEE Guide for the Application and Interpretation of Frequency Response Analysis for Oil-Immersed Transformers. IEEE Standards Association: Piscataway, NJ, USA, 2013; pp. 1–72. [CrossRef]

- CIGRE. Guide for Transformer Maintenance; CIGRÉ Technical Brochures 445; CIGRE: Paris, France, 2011. [Google Scholar]

- IEEE Std 43-2013; IEEE Recommended Practice for Testing Insulation Resistance of Electric Machinery—Redline; Revision of IEEE Std 43-2000—Redline. IEEE Standards Association: Piscataway, NJ, USA, 2014; pp. 1–75.

- IEEE Std C57.12.90-2021; IEEE Standard Test Code for Liquid-Immersed Distribution, Power, and Regulating Transformers; Revision of IEEE Std C57.12.90-2015. IEEE Standards Association: Piscataway, NJ, USA, 2022; pp. 1–119. [CrossRef]

- IEC 60076-3:2013; Power Transformers—Part 3: Insulation Levels, Dielectric Tests, and External Clearances in Air. IEC: London, UK, 2013.

- CIGRE. Dielectric Response Methods for Diagnostics of Power Transformers; Technical Brochures 254; CIGRE: Paris, France, 2004; p. 42. [Google Scholar]

- IEEE Std C57.161-2018; IEEE Guide for Dielectric Frequency Response Test. IEEE Standards Association: Piscataway, NJ, USA, 2018; pp. 1–76. [CrossRef]

- IEEE Std 62-1995; IEEE Guide for Diagnostic Field Testing of Electric Power Apparatus—Part 1: Oil Filled Power Transformers, Regulators, and Reactors. IEEE Standards Association: Piscataway, NJ, USA, 1995; pp. 1–64. [CrossRef]

- ASTM D1816-12; Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using VDE Electrodes. ASTM: West Conshohocken, PA, USA, 2019; p. 5.

- ASTM D877; Standard Test Method for Dielectric Breakdown Voltage of Insulating Liquids Using Disk Electrodes. ASTM: West Conshohocken, PA, USA, 2019.

- IEC 60156; Insulating Liquids—Determination of the Breakdown Voltage at Power Frequency—Test Method. IEC: London, UK, 2018; p. 37.

- ASTM D3612-02; Standard Test Method for Analysis of Gases Dissolved in Electrical Insulating Oil by Gas Chromatography. ASTM: West Conshohocken, PA, USA, 2017; p. 22.

- ASTM D3284-05; Standard Practice for Combustible Gases in the Gas Space of Electrical Apparatus Using Portable Meters. ASTM: West Conshohocken, PA, USA, 2019; p. 3.

- IEC 60567; Oil-Filled Electrical Equipment—Sampling of Gases and Analysis of Free and Dissolved Gases-Guidance. IEC: London, UK, 2011; p. 127.

- 44. IEEE Std C57.104-2019; IEEE Guide for the Interpretation of Gases Generated in Mineral Oil-Immersed Transformers; Revision of IEEE Std C57.104-2008. IEEE Standards Association: Piscataway, NJ, USA, 2019; pp. 1–98. [CrossRef]

- CIGRE. DGA in Non-Mineral Oils and Load Tap Changers and Improved DGA Diagnosis Criteria; CIGRÉ Technical Brochure 443; CIGRE: Paris, France, 2010; p. 33. [Google Scholar]

- ASTM D5837-15; Standard Test Method for Furanic Compounds in Electrical Insulating Liquids by High-Performance Liquid Chromatography (HPLC). ASTM: West Conshohocken, PA, USA, 2005; p. 9.

- IEEE Std C57.156-2016; IEEE Guide for Tank Rupture Mitigation of Liquid-Immersed Power Transformers and Reactors. IEEE Standards Association: Piscataway, NJ, USA, 2016; pp. 1–26. [CrossRef]

- IEC 61198; Methods for the Determination of 2-Furfural and Related Compounds. IEC: London, UK, 1993.

- ASTM D1533-20; Standard Test Method for Water in Insulating Liquids by Coulometric Karl Fischer Titration. ASTM: West Conshohocken, PA, USA, 2020; p. 5.

- IEC 60814; Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration. IEC: London, UK, 1997; p. 43.

- ASTM E1252-98; Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. ASTM: West Conshohocken, PA, USA, 2021.

- ASTM E2412-10; Standard Practice for Condition Monitoring of In-Service Lubricants by Trend Analysis Using Fourier Transform Infrared (FT-IR) Spectrometry. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM D974-22; Standard Test Method for Acid and Base Number by Color-Indicator Titration. ASTM: West Conshohocken, PA, USA, 2017; p. 7.

- IEC 62021-1:2003; Insulating Liquids—Determination of Acidity—Part 1: Automatic Potentiometric Titration. IEC: London, UK, 2003; p. 25.

- ASTM D971-20; Standard Test Method for Interfacial Tension of Insulating Liquids Against Water by the Ring Method. ASTM: West Conshohocken, PA, USA, 2020.

- ISO 6295:1983; Petroleum Products—Mineral Oils—Determination of Interfacial Tension of Oil against Water—Ring Method. ISO: Geneva, Switzerland, 1983.

- ASTM D7151; Standard Test Method for Determination of Elements in Insulating Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES). ASTM: West Conshohocken, PA, USA, 2015; p. 8.

- ASTM D1524; Standard Test Method for Visual Examination of Used Electrical Insulating Liquids in the Field. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D1500; Standard Test Method for ASTM Color of Petroleum Products (ASTM Color Scale). ASTM: West Conshohocken, PA, USA, 2012.

- Myers, S.D.; Kelly, J.J.; Parrish, R.H. A Guide to Transformer Maintenance; Transformer Maintenance Institute: Cuyahoga Falls, OH, USA, 1981. [Google Scholar]

- IEC 60666:2010; Detection and Determination of Specified Anti-Oxidant Additives in Insulating Oils. IEC: London, UK, 2010.

- ASTM D2864-10e1; Standard Terminology Relating to Electrical Insulating Liquids and Gases. ASTM: West Conshohocken, PA, USA, 2010.

- IEC 62535; Insulating Liquids—Test Method for Detection of Potentially Corrosive Sulfur in Used and Unused Insulating Oil. IEC: London, UK, 2008.

- ASTM D1275; Standard Test Method for Corrosive Sulfur in Electrical Insulating Oils. ASTM: West Conshohocken, PA, USA, 2015.

- CIGRE. Effect of Particles on Transformer Dielectric Strength; CIGRE Technical Brochure 443; CIGRE: Paris, France, 2000. [Google Scholar]

- ASTM D6786; Standard Test Method for Particle Count in Mineral Insulating Oil Using Automatic Optical Particle Counters. ASTM: West Conshohocken, PA, USA, 2020.

- IEC 60422; Mineral Insulating Oils in Electrical Equipment-Supervision and Maintenance Guidance 4.0. IEC: London, UK, 2013.

- ASTM D6181-97; Standard Test Method for Measurement of Turbidity in Mineral Insulating Oil. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D6802-02; Test Method for Determination of the Relative Content of Dissolved Decay Products in Mineral Insulating Oils by Spectrophotometry. ASTM: West Conshohocken, PA, USA, 2010.

- ISO 18434-1:2008; Condition Monitoring and Diagnostics of Machines—Thermography. ISO: Geneva, Switzerland, 2008; p. 24.

- ASTM D1903-01; Standard Test Method for Coefficient of Linear Thermal Expansion of Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2013.

- ASTM D2717-95; Standard Test Method for Thermal Conductivity of Liquids. ASTM: West Conshohocken, PA, USA, 2012.

- IEEE Std C57.19.100-2012; IEEE Guide for Application of Power Apparatus Bushings; Revision of IEEE Std C57.19.100-1995. IEEE Standards Association: Piscataway, NJ, USA, 2013; pp. 1–42. [CrossRef]

- IEC 60137; Insulated Bushings for Alternating Voltages above 1000 V. IEC: London, UK, 2017; p. 14.

- IEC 60214-1:2014; Tap-Changers—Part 1: Performance Requirements and Test Methods. IEC: London, UK, 2014; p. 156.

- 76. IEEE Std C57.131-2012; IEEE Standard Requirements for Tap Changers; Revision of IEEE Std C57.131-1995. IEEE Standards Association: Piscataway, NJ, USA, 2012; pp. 1–73. [CrossRef]

- 77. IEEE Std C57.143-2012; IEEE Guide for Application for Monitoring Equipment to Liquid-Immersed Transformers and Components. IEEE Standards Association: Piscataway, NJ, USA, 2012; pp. 1–83. [CrossRef]

- IEC 60599:2015; Mineral Oil-Filled Electrical Equipment in Service–Guidance on the Interpretation of Dissolved and Free Gases Analysis. IEC: London, UK, 2015.

- IEEE Std C57.152-2013; IEEE Guide for Diagnostic Field Testing of Fluid-Filled Power Transformers, Regulators, and Reactors. IEEE Standards Association: Piscataway, NJ, USA, 2013; pp. 1–121. [CrossRef]

- IEEE Std C57.91-2011; IEEE Guide for Loading Mineral-Oil-Immersed Transformers and Step-Voltage Regulators; Revision of IEEE Std C57.91-1995. IEEE Standards Association: Piscataway, NJ, USA, 2012; pp. 1–123. [CrossRef]

- IEC 60076-7; Power Transformers—Part 7: Loading Guide for Mineral-Oil-Immersed Power Transformers. IEC: London, UK, 2018; p. 89.

- Wang, J.; Zhao, L.; Li, J.; Liu, F.; You, R.; Lv, S.; Yang, Z.; He, J.; Hao, Y.; Yan, X.; et al. Stabilized zirconia-based solid state electrochemical gas sensor coupled with CdTiO3 for acetylene detection. Sens. Actuators B Chem. 2020, 316, 128199. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, Y.; Wang, N.; Han, X.; Li, J. Partial discharge ultrasonic signals pattern recognition in transformer using BSO-SVM based on microfiber coupler sensor. Measurement 2022, 201, 111737. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Gao, Y.; Zhang, H.; Wang, D.; Jin, B. Partial Discharge Ultrasound Detection Using the Sagnac Interferometer System. Sensors 2018, 18, 1425. [Google Scholar] [CrossRef]

- Rathod, V.B.; Kumbhar, G.B.; Bhalja, B.R. Performance analysis of acoustic sensors based time reversal technique for partial discharge localization in power transformers. Electr. Power Syst. Res. 2023, 215, 108965. [Google Scholar] [CrossRef]

- Besharatifard, H.; Hasanzadeh, S.; Heydarian-Forushani, E.; Alhelou, H.H.; Siano, P. Detection and Analysis of Partial Discharges in Oil-Immersed Power Transformers Using Low-Cost Acoustic Sensors. Appl. Sci. 2022, 12, 3010. [Google Scholar] [CrossRef]

- Jangjoo, M.A.; Allahbakhshi, M.; Mirzaei, H.R. UHF sensors positioning on the power transformer tank to enhance the partial discharge localization accuracy. Electr. Power Syst. Res. 2023, 218, 109174. [Google Scholar] [CrossRef]

- Binotto, A.; Castro, B.A.D.; Santos, V.V.D.; Rey, J.A.A.; Andreoli, A.L. A Comparison between Piezoelectric Sensors Applied to Multiple Partial Discharge Detection by Advanced Signal Processing Analysis. Eng. Proc. 2020, 2, 55. [Google Scholar] [CrossRef]

- Hamed Samimi, M.; Dadashi Ilkhechi, H. Survey of different sensors employed for the power transformer monitoring. IET Sci. Meas. Technol. 2020, 14, 1–8. [Google Scholar] [CrossRef]

- Wang, Z.; Fan, Z.; Li, X.; Xu, K.; Yu, R. Measurement of Magnetic and Magnetostrictive Characteristics of Transformer Core Based on Triaxial Strain Gauge and B-H Vector Sensor. Sensors 2023, 23, 5926. [Google Scholar] [CrossRef] [PubMed]

- Grenda, P.; Kutyła, M.; Nowicki, M.; Charubin, T. Bendductor—Transformer Steel Magnetomechanical Force Sensor. Sensors 2021, 21, 8250. [Google Scholar] [CrossRef]

- Nowicki, M. Tensductor—Amorphous Alloy Based Magnetoelastic Tensile Force Sensor. Sensors 2018, 18, 4420. [Google Scholar] [CrossRef]

- Ferenc, J.; Kowalczyk, M.; Cieślak, G.; Kulik, T. Magnetostrictive iron-based bulk metallic glasses for force sensors. IEEE Trans. Magn. 2014, 50, 2003203. [Google Scholar] [CrossRef]

- Búa-Núñez, I.; Posada-Román, J.E.; García-Souto, J.A. Multichannel Detection of Acoustic Emissions and Localization of the Source with External and Internal Sensors for Partial Discharge Monitoring of Power Transformers. Energies 2021, 14, 7873. [Google Scholar] [CrossRef]

- Riehl, R.R.; de Castro, B.A.; Fraga, J.R.C.P.; Puccia, V.; Lucas, G.B.; Andreoli, A.L. Assessment of Rogowski Coils for Measurement of Full Discharges in Power Transformers. Eng. Proc. 2021, 10, 16. [Google Scholar] [CrossRef]

- Wu, Y.; Tian, C.; Zhang, Z.; Chen, B.; Liu, S.; Chen, Y. A Novel Current Transformer Based on Virtual Air Gap and its Basic Measuring Characteristics. IEEE Trans. Power Deliv. 2023, 38, 13–25. [Google Scholar] [CrossRef]

- Wang, W.; Ma, G.; Liu, H.; Wang, L.; Fan, Z.; Du, H.; Zhou, S.; Qin, W. Fast Transient Measurement at Transformer Terminal Based on Built-In Capacitive Sensor. IEEE Trans. Instrum. Meas. 2024, 73, 9002208. [Google Scholar] [CrossRef]

- Rathnayaka, S.B.; See, K.Y.; Li, K. On-line impedance monitoring of transformer based on inductive coupling approach. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1273–1279. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Q.; Ni, H.; Li, Y.; Gao, M.; Ding, Y.; Yuan, W.; Zang, Y. Capacitive voltage sensor array for detecting transient voltage distribution in transformer windings. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 3182–3189. [Google Scholar] [CrossRef]

- Wu, T.; Yang, F.; Farooq, U.; Jiang, J.; Hu, X. Real-time calculation method of transformer winding temperature field based on sparse sensor placement. Case Stud. Therm. Eng. 2023, 47, 103090. [Google Scholar] [CrossRef]

- Ranasingh, S.; Pradhan, T.; Raju, D.K. Novel Winding Arrangements for Measuring High-Amplitude Current With Interference Error Compensation Scheme. IEEE Sens. J. 2024, 24, 6331–6339. [Google Scholar] [CrossRef]

- Bashir, S.; Paul, S.; Chang, J. Novel Core Airgap Profiles Design Scheme for Winding and Thermal Loss Reduction in High-Frequency Current Transformer Sensors. IEEE Sens. J. 2020, 20, 892–898. [Google Scholar] [CrossRef]

- Liu, F.; Du, J.; Shi, Y.; Zhang, S.; Wang, W. Localization of Dual Partial Discharge in Transformer Windings Using Fabry–Pérot Optical Fiber Sensor Array. Energies 2024, 17, 2537. [Google Scholar] [CrossRef]

- Akre, S.; Fofana, I.; Yéo, Z.; Brettschneider, S.; Kung, P.; Sékongo, B. On the Feasibility of Monitoring Power Transformer’s Winding Vibration and Temperature along with Moisture in Oil Using Optical Sensors. Sensors 2023, 23, 2310. [Google Scholar] [CrossRef] [PubMed]

- de Melo, A.G.; Benetti, D.; de Lacerda, L.A.; Peres, R.; Floridia, C.; Silva, A.D.A.; Rosolem, J.B. Static and Dynamic Evaluation of a Winding Deformation FBG Sensor for Power Transformer Applications. Sensors 2019, 19, 4877. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Cheung, Y.; Wang, Y.; Jing, Z.; Peng, W. Fast Interrogation of Single-Fiber Integrated FBG-FP Sensors Based on Programmable Spectrum Acquisitions. IEEE Sens. J. 2023, 23, 24533–24538. [Google Scholar] [CrossRef]

- Kuhn, G.G.; Sousa, K.M.; Martelli, C.; Bavastri, C.A.; Silva, J.C.C.d. Embedded FBG Sensors in Carbon Fiber for Vibration and Temperature Measurement in Power Transformer Iron Core. IEEE Sens. J. 2020, 20, 13403–13410. [Google Scholar] [CrossRef]

- Monteiro, C.S.; Rodrigues, A.V.; Viveiros, D.; Linhares, C.; Mendes, H.; Silva, S.O.; Marques, P.V.S.; Tavares, S.M.O.; Frazão, O. Optical Fiber Sensors for Structural Monitoring in Power Transformers. Sensors 2021, 21, 6127. [Google Scholar] [CrossRef] [PubMed]

- Bao, G.; Gao, X.; Jiang, R.; Huang, K. A Novel Differential High-Frequency Current Transformer Sensor for Series Arc Fault Detection. Sensors 2019, 19, 3649. [Google Scholar] [CrossRef] [PubMed]

- Zdanowski, M. Electrostatic Charging Tendency Analysis Concerning Retrofilling Power Transformers with Envirotemp FR3 Natural Ester. Energies 2020, 13, 4420. [Google Scholar] [CrossRef]

- Song, D.; Liu, W.; Yin, Z.; Li, X.; Wang, Q.; Yan, X.; Zhang, X.; Wang, F.; Qin, Y.; Shen, Y.; et al. A temperature sensor based on Er3+/Yb3+ co-doped tellurite fiber for real-time thermal monitoring of transformers. Ceram. Int. 2023, 49, 28878–28885. [Google Scholar] [CrossRef]

- Chai, Q.; Luo, Y.; Ren, J.; Zhang, J.; Yang, J.; Yuan, L.; Peng, G.-D. Review on fiber-optic sensing in health monitoring of power grids. Opt. Eng. 2019, 58, 072007. [Google Scholar] [CrossRef]

- N’cho, J.S.; Fofana, I. Review of Fiber Optic Diagnostic Techniques for Power Transformers. Energies 2020, 13, 1789. [Google Scholar] [CrossRef]

- Hurezeanu, I.; Nicola, C.I.; Sacerdotianu, D.; Nicola, M.; Aciu, A.M.; Nitu, M.C. Temperature control and monitoring system for power transformer windings using fiber optic sensors. In Proceedings of the 2016 International Symposium on Fundamentals of Electrical Engineering (ISFEE), Bucharest, Romania, 30 June–2 July 2016. [Google Scholar]

- Cilliyuz, Y.; Bicen, Y.; Aras, F.; Aydugan, G. Measurements and performance evaluations of natural ester and mineral oil-immersed identical transformers. Int. J. Electr. Power Energy Syst. 2021, 125, 106517. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Li, H.; Fan, X. Global Temperature Sensing for an Operating Power Transformer Based on Raman Scattering. Sensors 2020, 20, 4903. [Google Scholar] [CrossRef] [PubMed]

- Duan, R. Real-Time Hotspot Tracing and Model Analysis of a Distributed Optical Fiber Sensor Integrated Power Transformer. IEEE Access 2022, 10, 57242–57254. [Google Scholar] [CrossRef]

- Abdali, A.; Abedi, A.; Masoumkhani, H.; Mazlumi, K.; Rabiee, A.; Guerrero, J.M. Magnetic-thermal analysis of distribution transformer: Validation via optical fiber sensors and thermography. Int. J. Electr. Power Energy Syst. 2023, 153, 109346. [Google Scholar] [CrossRef]

- Tian, T.; Zhou, X.; Wang, S.; Luo, Y.; Li, X.; He, N.; Ma, Y.; Liu, W.; Shi, R.; Ma, G. A π-Phase-Shifted Fiber Bragg Grating Partial Discharge Sensor toward Power Transformers. Energies 2022, 15, 5849. [Google Scholar] [CrossRef]

- Zhou, H.-Y.; Ma, G.-M.; Zhang, M.; Zhang, H.-C.; Li, C.-R. A high sensitivity optical fiber interferometer sensor for acoustic emission detection of partial discharge in power transformer. IEEE Sens. J. 2019, 21, 24–32. [Google Scholar] [CrossRef]

- Zheng, S.; Li, C.; Tang, Z.; Chang, W.; He, M. Location of PDs inside transformer windings using UHF methods. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 386–393. [Google Scholar] [CrossRef]

- Raju, B.; Kumar, R.; Dhanalakshmi, S. Design and Implementation of Tilted FBG for Concurrent Temperature and Humidity Measurement using Machine Learning. Opt. Fiber Technol. 2024, 82, 103630. [Google Scholar] [CrossRef]

- Elele, U.; Nekahi, A.; Arshad, A.; McAulay, K.; Fofana, I. Sensitivity Analysis of Intensity-Modulated Plastic Optical Fiber Sensors for Effective Aging Detection in Rapeseed Transformer Oil. Sensors 2023, 23, 9796. [Google Scholar] [CrossRef] [PubMed]

- Udos, W.; Ooi, C.-W.; Kah Hong Goh, B.; Lim, K.-S.; Aizam Talib, M.; Azil Illias, H.; Kumar Mishra, A.; Ahmad, H. Ge-Sb-Se-Te -coated tilted fiber Bragg gratings sensor for the refractive index measurement of transformer oils. Opt. Fiber Technol. 2023, 79, 103336. [Google Scholar] [CrossRef]

- Srivastava, R.; Kumar, Y.; Banerjee, S.; Kale, S.N. Real-time transformer oil monitoring using planar frequency-based sensor. Sens. Actuators A Phys. 2022, 347, 113892. [Google Scholar] [CrossRef]

- Hayber, Ş.E.; Tabaru, T.E.; Güçyetmez, M. Evanescent Field Absorption-Based Fiber Optic Sensor for Detecting Power Transformer Oil Degradation. Fiber Integr. Opt. 2021, 40, 229–248. [Google Scholar] [CrossRef]

- Rashed, A.K.; Mansour, D.-E.A.; Rezk, A.; Ghali, M. Developing a novel optical sensor for condition assessment of aged mineral oil based on carbon dots. Measurement 2024, 225, 113956. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Castilla, A.E.; Sánchez-Fernández, J.Á.; Platero, C.A. Fluid Degradation Measurement Based on a Dual Coil Frequency Response Analysis. Sensors 2020, 20, 4155. [Google Scholar] [CrossRef] [PubMed]

- Talebi, V.; Soofi, H. Distributed strain sensing, employing apodized π-phase shifted FBG: Application in power transformer oil breakdown detection. Optik 2022, 268, 169781. [Google Scholar] [CrossRef]

- Saimon, S.M.; Noor, M.Y.M.; Azmi, A.I.; Abdullah, A.S.; Ibrahim, M.H.; Salim, M.R.; Ahmad, M.H.; Othman, A.F. Single-Mode-Multimode Silica Rod-Single-Mode High Refractive Index Fiber Sensor. IEEE Sens. J. 2022, 22, 10559–10566. [Google Scholar] [CrossRef]

- Chen, S.; Ding, J.; Ou, C.; Zhang, C.; Yang, H.; Liu, Z.; Li, X. New Measurement Method of Viscosity, Density, and Dielectric Constant of Transformer Oil Based on Quartz Tuning Fork. IEEE Sens. J. 2022, 22, 16711–16718. [Google Scholar] [CrossRef]

- Pesavento, M.; Marchetti, S.; De Maria, L.; Zeni, L.; Cennamo, N. Sensing by molecularly imprinted polymer: Evaluation of the binding properties with different techniques. Sensors 2019, 19, 1344. [Google Scholar] [CrossRef]

- Uzun, L.; Turner, A.P. Molecularly-imprinted polymer sensors: Realising their potential. Biosens. Bioelectron. 2016, 76, 131–144. [Google Scholar] [CrossRef]

- Cennamo, N.; Massarotti, D.; Galatus, R.; Conte, L.; Zeni, L. Performance comparison of two sensors based on surface plasmon resonance in a plastic optical fiber. Sensors 2013, 13, 721–735. [Google Scholar] [CrossRef] [PubMed]

- Gupta, B.D.; Verma, R.K. Surface plasmon resonance-based fiber optic sensors: Principle, probe designs, and some applications. J. Sens. 2009, 2009, 979761. [Google Scholar] [CrossRef]

- Iga, M.; Seki, A.; Watanabe, K. Gold thickness dependence of SPR-based hetero-core structured optical fiber sensor. Sens. Actuators B Chem. 2005, 106, 363–368. [Google Scholar] [CrossRef]

- Kanso, M.; Cuenot, S.; Louarn, G. Sensitivity of optical fiber sensor based on surface plasmon resonance: Modeling and experiments. Plasmonics 2008, 3, 49–57. [Google Scholar] [CrossRef]

- De Maria, L.; Arcadio, F.; Pesavento, M.; Profumo, A.; Cennamo, N.; Zeni, L. Optical Chemo-Sensors for Specific Markers in Transformer Insulating Oil Exploiting Molecularly Imprinted Polymers and Plasmonic Optical Fibers. Eng. Proc. 2021, 11, 13. [Google Scholar] [CrossRef]

- Yang, T.; Zhou, K.; Jin, L.; Liu, R.; Chen, W. Optimization of Photoacoustic Cell for Trace Acetylene Detection in Transformer Oil. Atmosphere 2023, 14, 801. [Google Scholar] [CrossRef]

- Rahman, O.; Islam, T.; Khera, N.; Khan, S.A. A Novel Application of the Cross-Capacitive Sensor in Real-Time Condition Monitoring of Transformer Oil. IEEE Trans. Instrum. Meas. 2021, 70, 9513212. [Google Scholar] [CrossRef]

- Kantamani, T.; George, B.; Kumar, V.J. Assay of Inductive-Capacitive Probe for the Measurement of the Conductivity of Liquids. IEEE Trans. Ind. Electron. 2021, 68, 8911–8918. [Google Scholar] [CrossRef]

- Elaraby, S.; Abuelenin, S.M.; Moussa, A.; Sabry, Y.M. Deep Learning on Synthesized Sensor Characteristics and Transmission Spectra Enabling MEMS-Based Spectroscopic Gas Analysis beyond the Fourier Transform Limit. Foundations 2021, 1, 304–317. [Google Scholar] [CrossRef]

- Chen, X.; Li, Y.; Zhao, X.; Zhang, W. Research on Detection Technology of Gas Content in Transformer Oil Based on Optical Fiber Sensing Technology. In Proceedings of the 2023 IEEE 11th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 8–10 December 2023; pp. 820–824. [Google Scholar]

- Haque, M.S.; Moniruzzaman, M.; Choi, S.; Kwak, S.; Okilly, A.H.; Baek, J. A Fast Loss Model for Cascode GaN-FETs and Real-Time Degradation-Sensitive Control of Solid-State Transformers. Sensors 2023, 23, 4395. [Google Scholar] [CrossRef]

- Kondalkar, V.V.; Park, J.; Lee, K. MEMS hydrogen gas sensor for in-situ monitoring of hydrogen gas in transformer oil. Sens. Actuators B Chem. 2021, 326, 128989. [Google Scholar] [CrossRef]

- Chatterjee, A.; Bhattacharjee, P.; Roy, N.; Kumbhakar, P. Usage of nanotechnology based gas sensor for health assessment and maintenance of transformers by DGA method. Int. J. Electr. Power Energy Syst. 2013, 45, 137–141. [Google Scholar] [CrossRef]

- Ma, G.-M.; Zhao, S.-J.; Jiang, J.; Song, H.-T.; Li, C.-R.; Luo, Y.-T.; Wu, H. Tracing acetylene dissolved in transformer oil by tunable diode laser absorption spectrum. Sci. Rep. 2017, 7, 14961. [Google Scholar] [CrossRef] [PubMed]

- Samsudin, M.R.; Shee, Y.G.; Adikan, F.R.M.; Razak, B.B.A.; Dahari, M. Fiber Bragg gratings hydrogen sensor for monitoring the degradation of transformer oil. IEEE Sens. J. 2016, 16, 2993–2999. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, D.; Tang, M.; Chen, Q.; Zhang, H.; Shao, X. Construction of ultra-fast hydrogen sensor for dissolved gas detection in oil-immersed transformers based on titanium dioxide quantum dots modified tin dioxide nanosheets. Sens. Actuators B Chem. 2023, 393, 134141. [Google Scholar] [CrossRef]

- Lin, H.; Guo, J.; Yang, D.; Li, S.; Liu, D.; Liu, C.; Zhang, Z.; Wang, B.; Zhang, H. Pd/C-Based Sensor for Gas Sensing in Transformer Oil. Catalysts 2023, 13, 1113. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, Q.; Wang, Z.; Dai, J. A highly sensitive low-pressure TDLAS sensor for detecting dissolved CO and CO2 in transformer insulating oil. Opt. Laser Technol. 2024, 174, 110622. [Google Scholar] [CrossRef]

- Chen, B.; Li, P.; Wang, B.; Wang, Y. Flame-annealed porous TiO2/CeO2 nanosheets for enhenced CO gas sensors. Appl. Surf. Sci. 2022, 593, 153418. [Google Scholar] [CrossRef]

- Hong, S.; Hong, Y.; Jeong, Y.; Jung, G.; Shin, W.; Park, J.; Lee, J.-K.; Jang, D.; Bae, J.-H.; Lee, J.-H. Improved CO gas detection of Si MOSFET gas sensor with catalytic Pt decoration and pre-bias effect. Sens. Actuators B Chem. 2019, 300, 127040. [Google Scholar] [CrossRef]

- Liu, H.; Yu, H.; Wang, J.; Xia, F.; Wang, C.; Xiao, J. LaNbO4 as an electrode material for mixed-potential CO gas sensors. Sens. Actuators B Chem. 2022, 352, 130981. [Google Scholar] [CrossRef]

- Yin, X.-T.; Wu, S.-S.; Dastan, D.; Nie, S.; Liu, Y.; Li, Z.-G.; Zhou, Y.-W.; Li, J.; Faik, A.; Shan, K. Sensing selectivity of SnO2-Mn3O4 nanocomposite sensors for the detection of H2 and CO gases. Surf. Interfaces 2021, 25, 101190. [Google Scholar] [CrossRef]

- Mousavi, H.; Mortazavi, Y.; Khodadadi, A.A.; Saberi, M.H.; Alirezaei, S. Enormous enhancement of Pt/SnO2 sensors response and selectivity by their reduction, to CO in automotive exhaust gas pollutants including CO, NOx and C3H8. Appl. Surf. Sci. 2021, 546, 149120. [Google Scholar] [CrossRef]

- Simões, A.N.; Lustosa, G.M.M.M.; de Souza Morita, E.; de Souza, A.N.; Torres, F.; Bizzo, W.A.; Mazon, T. Room-temperature SnO2-based sensor with Pd-nanoparticles for real-time detection of CO dissolved gas in transformer oil. Mater. Chem. Phys. 2024, 311, 128576. [Google Scholar] [CrossRef]

- Chen, T.; Ma, F.; Zhao, Y.; Zhao, Y.; Wan, L.; Li, K.; Zhang, G. Portable ppb-level acetylene photoacoustic sensor for transformer on-field measurement. Optik 2021, 243, 167440. [Google Scholar] [CrossRef]

- Wang, J.; Wang, H. Ammonia, carbon dioxide and water vapor detection based on tunable fiber laser photoacoustic spectroscopy. Optik 2016, 127, 942–945. [Google Scholar] [CrossRef]

- Samanta, D.; Sivaram, M.; Rashed, A.N.Z.; Boopathi, C.; Amiri, I.; Yupapin, P. Distributed feedback laser (DFB) for signal power amplitude level improvement in long spectral band. J. Opt. Commun. 2024, 44, s125–s130. [Google Scholar] [CrossRef]

- Wysocki, P.F.; Judkins, J.B.; Espindola, R.P.; Andrejco, M.; Vengsarkar, A.M. Broad-band erbium-doped fiber amplifier flattened beyond 40 nm using long-period grating filter. IEEE Photonics Technol. Lett. 1997, 9, 1343–1345. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, M.S.; Jung, H.; Choe, Y.-S.; Kim, W.; Song, Y.G.; Kang, C.-Y.; Lee, H.-S.; Lee, W. Selective C2H2 detection with high sensitivity using SnO2 nanorod based gas sensors integrated with a gas chromatography. Sens. Actuators B Chem. 2020, 307, 127598. [Google Scholar] [CrossRef]

- Tang, S.; Chen, W.; Jin, L.; Zhang, H.; Li, Y.; Zhou, Q.; Zen, W. SWCNTs-based MEMS gas sensor array and its pattern recognition based on deep belief networks of gases detection in oil-immersed transformers. Sens. Actuators B Chem. 2020, 312, 127998. [Google Scholar] [CrossRef]

- Alharbi, A.A.; Sackmann, A.; Weimar, U.; Bârsan, N. A highly selective sensor to acetylene and ethylene based on LaFeO3. Sens. Actuators B Chem. 2020, 303, 127204. [Google Scholar] [CrossRef]

- Ma, F.; Zhao, Y.; Li, C.; An, R.; Zhu, F.; Hang, C.; Chen, K. Analysis system of dissolved gas in oil based on optical fiber photoacoustic sensing. Chin. J. Quantum Electron. 2023, 40, 597–605. [Google Scholar] [CrossRef]

- Aasi, A.; Javahersaz, R.; Mehdi Aghaei, S.; Panchapakesan, B. Novel green phosphorene as a superior gas sensor for dissolved gas analysis in oil transformers: Using DFT method. Mol. Simul. 2022, 48, 541–550. [Google Scholar] [CrossRef]

- Atanasova-Höhlein, I.; Končan-Gradnik, M.; Gradnik, T.; Čuček, B.; Przybylek, P.; Siodla, K.; Liland, K.B.; Leivo, S.; Liu, Q. Experience with capacitive on-line sensors for moisture evaluation in transformer insulation. IEEE Electr. Insul. Mag. 2019, 35, 18–26. [Google Scholar] [CrossRef]

- Howe, A. Diffusion of moisture through power-transformer insulation. In Proceedings of the Institution of Electrical Engineers; IET Digital Library: Stevenage, UK, 1978; pp. 978–986. [Google Scholar]

- CIGRE. Moisture Measurement and Assessment in Transformer Insulation—Evaluation of Chemical Methods and Moisture Capacitive Sensors; CIGRE Brochure 741; CIGRE: Paris, France, 2018. [Google Scholar]

- Lelekakis, N.; Wijaya, J.; Martin, D.; Susa, D. The effect of acid accumulation in power-transformer oil on the aging rate of paper insulation. IEEE Electr. Insul. Mag. 2014, 30, 19–26. [Google Scholar] [CrossRef]

- Martin, D.; Lelekakis, N.; Guo, W.; Odarenko, Y. Further studies of a vegetable-oil-filled power transformer. IEEE Electr. Insul. Mag. 2011, 27, 6–13. [Google Scholar] [CrossRef]

- Ansari, M.A.; Martin, D.; Saha, T.K. Advanced Online Moisture Measurements in Transformer Insulation Using Optical Sensors. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1803–1810. [Google Scholar] [CrossRef]

- García, B.; García, D.; Robles, G. Development of a Moisture-in-Solid-Insulation Sensor for Power Transformers. Sensors 2015, 15, 3610–3624. [Google Scholar] [CrossRef] [PubMed]

- Münster, T.; Werle, P.; Hämel, K.; Preusel, J. Development of a novel optical sensor for condition assessment of insulating paper in transformers. In Proceedings of the 22nd International Symposium on High Voltage Engineering (ISH 2021), Xi’an, China, 21–26 November 2021; pp. 230–235. [Google Scholar]

- Pavan Kumar Chaganti, L.G.; Mat Saman, N.; Hafizi Ahmad, M.; Yusof Mohd Noor, M.; Izam Azmi, A. PVAc based SCMS optical fiber humidity sensor and its application in transformer oil. Opt. Fiber Technol. 2023, 80, 103439. [Google Scholar] [CrossRef]

- Kumar Shakya, A.; Singh, S. Design of novel Penta core PCF SPR RI sensor based on fusion of IMD and EMD techniques for analysis of water and transformer oil. Measurement 2022, 188, 110513. [Google Scholar] [CrossRef]

- Kumar, S.; Raina, K.K.; Islam, T. Anodic aluminium oxide based humidity sensor for online moisture monitoring of power transformer. Sens. Actuators B Chem. 2021, 329, 128908. [Google Scholar] [CrossRef]

- Wani, S.A.; Murugan, A.; Sarathi, R.; Subramanian, V. Measurement of Moisture in Transformer Insulation Using the Intelligent High-Frequency Sensor System. IEEE Trans. Instrum. Meas. 2023, 72, 2511410. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, R.; Liu, J.; Wu, X.; Wu, Q.; Ranjan, P.; Zhang, X.; Liu, J. S-Taper Fiber Based Moisture Sensing in Power Transformer Oil. IEEE Trans. Instrum. Meas. 2023, 72, 9001208. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, X.; Wang, Z.; Zhang, C.; Ma, G.; Li, X. Moisture Content Measurement in Transformer Oil Using Micro-nano Fiber. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1829–1836. [Google Scholar] [CrossRef]

- Li, J.; Jiang, T.; Cheng, C.; Wang, C. Hilbert fractal antenna for UHF detection of partial discharges in transformers. IEEE Trans. Dielectr. Electr. Insul. 2013, 20, 2017–2025. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Du, L.; Cao, M.; Qian, G. An Intelligent Sensor for the Ultra-High-Frequency Partial Discharge Online Monitoring of Power Transformers. Energies 2016, 9, 383. [Google Scholar] [CrossRef]

- Ghorat, M.; Gharehpetian, G.B.; Latifi, H.; Hejazi, M.A.; Bagheri, M. High-Resolution FBG-Based Fiber-Optic Sensor with Temperature Compensation for PD Monitoring. Sensors 2019, 19, 5285. [Google Scholar] [CrossRef] [PubMed]

- IEEE Std C57.127-2018; IEEE Guide for the Detection, Location, and Interpretation of Sources of Acoustic Emissions from Electrical Discharges in Power Transformers and Power Reactors. IEEE: New York, NY, USA, 2018.

- Qiao, J.; Zhang, W.; Wang, Y.; Shao, Q.; Cai, J.; Zhao, H. Ultra-High SNR Demodulation Method for Optical Fiber Sensors Applied in Power Transformer Partial Discharge Detection. Sensors 2022, 22, 2828. [Google Scholar] [CrossRef] [PubMed]

- Florkowski, M. Partial Discharges in High-Voltage Insulating Systems: Mechanisms, Processing and Analytics; Wydawnictwa AGH: Kraków, Poland, 2020. [Google Scholar]

- Crescentini, M.; Traverso, P. An empirical dynamic model of Hall-effect sensors. J. Phys. Conf. Ser. 2018, 1065, 052008. [Google Scholar] [CrossRef]

- de Castro, B.A.; dos Santos, V.V.; Lucas, G.B.; Ardila-Rey, J.A.; Riehl, R.R.; Andreoli, A.L. A Comparative Analysis Applied to the Partial Discharges Identification in Dry-Type Transformers by Hall and Acoustic Emission Sensors. Sensors 2022, 22, 1716. [Google Scholar] [CrossRef]

- Si, W.; Yao, W.; Guan, H.; Fu, C.; Yu, Y.; Su, S.; Yang, J. Numerical Study of Vibration Characteristics for Sensor Membrane in Transformer Oil. Energies 2021, 14, 1662. [Google Scholar] [CrossRef]

- Sikorski, W.; Walczak, K.; Gil, W.; Szymczak, C. On-Line Partial Discharge Monitoring System for Power Transformers Based on the Simultaneous Detection of High Frequency, Ultra-High Frequency, and Acoustic Emission Signals. Energies 2020, 13, 3271. [Google Scholar] [CrossRef]

- Dhara, S.; Koley, C.; Chakravorti, S. An Ultrawideband Partial Discharge Sensor for High-Voltage Power Transformers. IEEE Sens. J. 2024, 24, 16261–16269. [Google Scholar] [CrossRef]

- Qiao, J.; Zhang, W.; Chen, Q.; Wang, X.; Zhao, H. DFB-FL Applied in the Liquid-Solid Composite Dielectric for Ultra-High Sensitive Partial Discharge Acoustic Emission Detection. IEEE Sens. J. 2021, 21, 20960–20968. [Google Scholar] [CrossRef]

- Si, W.; Guan, H.; Yao, W.; Fu, C.; Yuan, P. Combined in-oil PD sensor with AE and UHF methods for PD detection in transformer. Energy Rep. 2022, 8, 177–191. [Google Scholar] [CrossRef]

- Beura, C.P.; Beltle, M.; Tenbohlen, S. Study of the Influence of Winding and Sensor Design on Ultra-High Frequency Partial Discharge Signals in Power Transformers. Sensors 2020, 20, 5113. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Zhao, M.; Zhang, C.; Chen, M.; Liu, H.; Albarracín, R. Partial Discharge Analysis in High-Frequency Transformer Based on High-Frequency Current Transducer. Energies 2018, 11, 1997. [Google Scholar] [CrossRef]

- Yang, Z.; Li, H.; Chen, R. An acoustic emission onset time determination method based on Transformer. Struct. Health Monit. 2024, 23, 14759217231223078. [Google Scholar] [CrossRef]

- Wu, P.; Su, S.; Zuo, Z.; Guo, X.; Sun, B.; Wen, X. Time difference of arrival (TDoA) localization combining weighted least squares and firefly algorithm. Sensors 2019, 19, 2554. [Google Scholar] [CrossRef] [PubMed]

- Thungsuk, N.; Mungkung, N.; Songruk, A.; Tunlasakun, K.; Tikakosol, K.; Nilawat, S.; Boonsomchuae, K.; Yuji, T.; Arunrungrusmi, S.; Kinoshita, H. The Investigation of Detect Position of Partial Discharge in Cast-Resin Transformer Using High-Frequency Current Transformer Sensor and Acoustic Emission Sensor. Appl. Sci. 2022, 12, 1310. [Google Scholar] [CrossRef]

- Sharifinia, S.; Allahbakhshi, M.; Ghanbari, T.; Akbari, A.; Mirzaei, H.R. A New Application of Rogowski Coil Sensor for Partial Discharge Localization in Power Transformers. IEEE Sens. J. 2021, 21, 10743–10751. [Google Scholar] [CrossRef]

- Beura, C.P.; Beltle, M.; Tenbohlen, S.; Siegel, M. Quantitative Analysis of the Sensitivity of UHF Sensor Positions on a 420 kV Power Transformer Based on Electromagnetic Simulation. Energies 2020, 13, 3. [Google Scholar] [CrossRef]

- Giglia, G.; Ala, G.; Castiglia, V.; Imburgia, A.; Miceli, R.; Rizzo, G.; Romano, P.; Schettino, G.; Viola, F. Electromagnetic Full-Wave Simulation of Partial Discharge Detection in High Voltage AC Cables. In Proceedings of the 2019 IEEE 5th International forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 166–171. [Google Scholar]

- Rubinstein, R.Y.; Kroese, D.P. Simulation and the Monte Carlo Method; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- CST Microwave Studio; CST Studio Suite: Johnston, RI, USA, 2008.

- Ward, S.A.; El-Faraskoury, A.; Badawi, M.; Ibrahim, S.A.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. Towards Precise Interpretation of Oil Transformers via Novel Combined Techniques Based on DGA and Partial Discharge Sensors. Sensors 2021, 21, 2223. [Google Scholar] [CrossRef]

- Hu, S.; Huang, Z.; Liu, X.; Chen, J.; Wang, Y.; Zhao, T.; Yang, C. Study on High Energy Discharge Characteristics Caused by Arc Faults in Transformer Turret. IEEE Access 2023, 11, 106924–106933. [Google Scholar] [CrossRef]

- Smith, D.J.; Mcmeekin, S.G.; Stewart, B.G.; Wallace, P.A. The modelling of electric field, capacitance and dissipation factor of a high voltage bushing over varying frequency. In Proceedings of the 2012 47th International Universities Power Engineering Conference (UPEC), London, UK, 4–7 September 2012; pp. 1–6. [Google Scholar]

- Setayeshmehr, A.; Akbari, A.; Borsi, H.; Gockenbach, E. A novel method to on-line measuring of power factor (tan/spl delta/) and capacitance of transformers’ bushings. In Proceedings of the IEEE International Conference on Dielectric Liquids, ICDL, Portugal, Coimbra, 26 June–1 July 2005; pp. 289–292. [Google Scholar]

- Jiang, J.; Chen, J.; Li, J.; Yang, X.; Bie, Y.; Ranjan, P.; Zhang, C.; Schwarz, H. Partial Discharge Detection and Diagnosis of Transformer Bushing Based on UHF Method. IEEE Sens. J. 2021, 21, 16798–16806. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, L.; Wang, W.; Han, Y.; Pu, L.; Wu, J.; Wu, H. Intelligent monitoring of EHV transformer bushing based on multi-parameter composite sensing technology. IET Sci. Meas. Technol. 2023, 17, 373–384. [Google Scholar] [CrossRef]

- Jiang, J.; Song, Y.; Wang, K.; Lu, Y.; Li, J.; Ranjan, P.; Zhang, C. Partial Discharge Detection and Sensitivity Improvement for Bushing Based on Optical Interference Technique. IEEE Trans. Power Deliv. 2022, 37, 2797–2804. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, T.; Li, Y.; Zeng, S.; Liu, Q.; Bi, M. Highly-Efficient Graphene Pressure Sensor with Hierarchical Alarm for Detecting the Transient Internal Pressure of Transformer Bushing. J. Electr. Eng. Technol. 2023, 18, 3071–3082. [Google Scholar] [CrossRef]

- Damião, L.; Guimarães, J.; Ferraz, G.; Bortoni, E.; Rossi, R.; Capelini, R.; Salustiano, R.; Tavares, E. Online Monitoring of Partial Discharges in Power Transformers Using Capacitive Coupling in the Tap of Condenser Bushings. Energies 2020, 13, 4351. [Google Scholar] [CrossRef]

- Liu, J.; Wang, G.; Zhao, T.; Shi, L.; Zhang, L. The research of OLTC on-line detection system based on embedded and wireless sensor networks. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; pp. 1–4. [Google Scholar]

- Liang, X.; Wang, Y.; Gu, H. An Antinoise Feature Extraction and Improved Harris Hawks Optimization for On-Load Tap Changer Mechanical Fault Diagnosis. IEEE Sens. J. 2024, 24, 10400–10418. [Google Scholar] [CrossRef]

- Cheng, L.; Huang, Q.; Luo, C.; Zhang, J.; Zhan, H.; Liu, M. Experimental Study on Fault Process of High Energy Arch Discharge in the Oil Chamber of OLTC. In Proceedings of the 2023 IEEE International Conference on Electrical, Automation and Computer Engineering (ICEACE), Changchun, China, 29–31 December 2023; pp. 265–268. [Google Scholar]

- Dabaghi-Zarandi, F.; Behjat, V.; Gauvin, M.; Picher, P.; Ezzaidi, H.; Fofana, I. Power Transformers OLTC Condition Monitoring Based on Feature Extraction from Vibro-Acoustic Signals: Main Peaks and Euclidean Distance. Sensors 2023, 23, 7020. [Google Scholar] [CrossRef] [PubMed]

- Dixit, A.; Ekanayake, C.; Ma, H.; Saha, T.K.; Ansari, M.H. Thermal Analysis of Natural Cooling Type Distribution Transformer Retrofilled with Natural Ester Oil. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 231–239. [Google Scholar] [CrossRef]

- Calil, W.V.; Salazar, P.D.P.; Melo, A.S.D.; Costa, E.C.M. An Efficient Procedure for Temperature Calculation of High Current Leads in Large Power Transformers. IEEE Access 2020, 8, 222371–222376. [Google Scholar] [CrossRef]

- Nicola, M.; Nicola, C.-I.; Duţă, M.; Sacerdoţianu, D.; Hurezeanu, I. System for monitoring of hot spot temperature of power transformer windings using fiber optic sensors, Kalman Filter and SCADA integration. In Proceedings of the 2018 International Conference on Development and Application Systems (DAS), Suceava, Romania, 24–26 May 2018; pp. 99–104. [Google Scholar]

- Xuewei, Z.; Hanshan, L. Research on transformer fault diagnosis method and calculation model by using fuzzy data fusion in multi-sensor detection system. Optik 2019, 176, 716–723. [Google Scholar] [CrossRef]

- Zheng, M.; Yang, K.; Shang, C.; Luo, Y. A PCA-LSTM-Based Method for Fault Diagnosis and Data Recovery of Dry-Type Transformer Temperature Monitoring Sensor. Appl. Sci. 2022, 12, 5624. [Google Scholar] [CrossRef]

- Wang, Q.; Zheng, M.; Yang, K.; Shang, C.; Luo, Y. Research and implementation of fault data recovery method for dry-type transformer temperature control sensor based on ISSA-LSTM algorithm. Measurement 2024, 228, 114333. [Google Scholar] [CrossRef]

- Nikolic, A.B.; Zigic, A.; Miladinovic, N. Wireless Sensor Network based monitoring system for high power transformers. In Proceedings of the 2012 15th International Power Electronics and Motion Control Conference (EPE/PEMC), Novi Sad, Serbia, 4–6 September 2012; pp. LS4e.4-1–LS4e.4-5. [Google Scholar]

- Waikat, J.; Jelidi, A.; Lic, S.; Sopidis, G.; Kähler, O.; Maly, A.; Pestana, J.; Fuhrmann, F.; Belavić, F. First Measurement Campaign by a Multi-Sensor Robot for the Lifecycle Monitoring of Transformers. Energies 2024, 17, 1152. [Google Scholar] [CrossRef]

- Gielniak, J.; Czerniak, M. Investigation of Distribution Transformers Vibrations in Terms of Core and Winding Condition Assessment. Energies 2022, 15, 13. [Google Scholar] [CrossRef]

- Elahi, O.; Behkam, R.; Gharehpetian, G.B.; Mohammadi, F. Diagnosing Disk-Space Variation in Distribution Power Transformer Windings Using Group Method of Data Handling Artificial Neural Networks. Energies 2022, 15, 8885. [Google Scholar] [CrossRef]

- Sikorski, W. Development of Acoustic Emission Sensor Optimized for Partial Discharge Monitoring in Power Transformers. Sensors 2019, 19, 1865. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, R.; Li, H.; Guo, Z.; Cheetham, P. The Effects of PWM With High dv/dt on Partial Discharge and Lifetime of Medium-Frequency Transformer for Medium-Voltage (MV) Solid State Transformer Applications. IEEE Trans. Ind. Electron. 2023, 70, 3857–3866. [Google Scholar] [CrossRef]

- Wotzka, D.; Sikorski, W.; Szymczak, C. Investigating the Capability of PD-Type Recognition Based on UHF Signals Recorded with Different Antennas Using Supervised Machine Learning. Energies 2022, 15, 3167. [Google Scholar] [CrossRef]

- Karami, H.; Askari, F.; Rachidi, F.; Rubinstein, M.; Sikorski, W. An Inverse-Filter-Based Method to Locate Partial Discharge Sources in Power Transformers. Energies 2022, 15, 1988. [Google Scholar] [CrossRef]

- Polužanski, V.; Kartalović, N.; Nikolić, B. Impact of Power Transformer Oil-Temperature on the Measurement Uncertainty of All-Acoustic Non-Iterative Partial Discharge Location. Materials 2021, 14, 1385. [Google Scholar] [CrossRef]

- Arcones, E.; Álvarez, F.; Ortego, J.; Garnacho, F. Novel Reference Method for the Characterization of PD Measuring Systems Using HFCT Sensors. Sensors 2024, 24, 3788. [Google Scholar] [CrossRef]

- Jancarczyk, D.; Bernaś, M.; Boczar, T. Classification of Low Frequency Signals Emitted by Power Transformers Using Sensors and Machine Learning Methods. Sensors 2019, 19, 4909. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, Z.; Dong, Z.; Wu, Y.; Xiao, R.; Deng, J.; Pan, Z. Research on distribution characteristics of vibration signals of ±500 kV HVDC converter transformer winding based on load test. Int. J. Electr. Power Energy Syst. 2021, 132, 107200. [Google Scholar] [CrossRef]

- Li, B.; Hao, Z.; Li, S.; Pan, S.; Xiong, J.; Zhang, B. Response Characteristics of the Buchholz Relay and Novel Non-Electric-Parameter Protection Methods. IEEE Trans. Power Deliv. 2023, 38, 4103–4113. [Google Scholar] [CrossRef]

- Xu, S.; Shang, Y.; Li, Z.; Lu, Y.; Liu, M.; Liu, W.; Wang, Z.; Tang, W. Transformer Monitoring with Electromagnetic Energy Transmission and Wireless Sensing. Sensors 2024, 24, 1606. [Google Scholar] [CrossRef] [PubMed]

- Valenta, L.; Černý, I.; Maternik-Demontoux, A. Power Transformers and Environmental Protection. IFAC Pap. 2016, 49, 18–22. [Google Scholar] [CrossRef]

- Darcherif, A.M.; Prigent, S.; Dedulle, J.M.; Magnier, P.; Scheurer, D. Global Finite Element Model to Study Power Transformers Behaviour during and after Inner Electrical Faults. Application to Explosion and Fire Protection. In Proceedings of the EUROCON 2005—The International Conference on “Computer as a Tool”, Belgrad, Serbia, 21–24 November 2005; pp. 1430–1433. [Google Scholar]

- Kumar, S.; Mishra, P.; Islam, T. Condition Monitoring of Transformer Breather Using Smart Photodiodes Array. IEEE Trans. Instrum. Meas. 2024, 73, 3505907. [Google Scholar] [CrossRef]

- Elânio Bezerra, F.; Zemuner Garcia, F.A.; Ikuyo Nabeta, S.; Martha de Souza, G.F.; Chabu, I.E.; Santos, J.C.; Junior, S.N.; Pereira, F.H. Wavelet-Like Transform to Optimize the Order of an Autoregressive Neural Network Model to Predict the Dissolved Gas Concentration in Power Transformer Oil from Sensor Data. Sensors 2020, 20, 2730. [Google Scholar] [CrossRef] [PubMed]

- Alshehawy, A.M.; Mansour, D.-E.A.; Ghali, M.; Lehtonen, M.; Darwish, M.M.F. Photoluminescence Spectroscopy Measurements for Effective Condition Assessment of Transformer Insulating Oil. Processes 2021, 9, 732. [Google Scholar] [CrossRef]

- Islam, T.; Tehseen, Z.; Kumar, L. Highly sensitive thin-film capacitive sensor for online moisture measurement in transformer oil. IET Sci. Meas. Technol. 2020, 14, 416–422. [Google Scholar] [CrossRef]

- Guerrero, J.M.; Castilla, A.E.; Fernández, J.A.S.; Platero, C.A. Transformer Oil Diagnosis Based on a Capacitive Sensor Frequency Response Analysis. IEEE Access 2021, 9, 7576–7585. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Xiao, Y.; Zhang, Y.; Yang, X.; Zhang, W. An Improved U-Net Segmentation Model That Integrates a Dual Attention Mechanism and a Residual Network for Transformer Oil Leakage Detection. Energies 2022, 15, 4238. [Google Scholar] [CrossRef]

- Islam, T.; Maurya, O.P.; Khan, A.U. Design and Fabrication of Fringing Field Capacitive Sensor for Non-Contact Liquid Level Measurement. IEEE Sens. J. 2021, 21, 24812–24819. [Google Scholar] [CrossRef]

- Wotzka, D.; Cichoń, A. Study on the Influence of Measuring AE Sensor Type on the Effectiveness of OLTC Defect Classification. Sensors 2020, 20, 3095. [Google Scholar] [CrossRef] [PubMed]

- Cichoń, A.; Włodarz, M. OLTC Fault detection Based on Acoustic Emission and Supported by Machine Learning. Energies 2024, 17, 220. [Google Scholar] [CrossRef]

- Mu, L.; Chen, D.; Cui, H. Single Pd atom embedded Janus HfSeTe as promising sensor for dissolved gas detection in transformer oil: A density functional theory study. Surf. Interfaces 2022, 35, 102398. [Google Scholar] [CrossRef]

- Gao, L.; Feng, P.; Sun, Y.; Jia, L. Pd-decorated C3N monolayer as a potential toxic gas sensor in dry-type transformers: A first-principles study. Comput. Theor. Chem. 2022, 1209, 113611. [Google Scholar] [CrossRef]

- Liu, H.; Tan, Z.; Niu, Y.; Wang, S.; Wang, Y. Ir-decorated MoS2 monolayer as a promising candidate to detect dissolved gas in transformer oil: A DFT study. Chem. Phys. Lett. 2023, 818, 140410. [Google Scholar] [CrossRef]

- Chen, D.; Li, Y.; Xiao, S.; Yang, C.; Zhou, J.; Xiao, B. Single Ni atom doped WS2 monolayer as sensing substrate for dissolved gases in transformer oil: A first-principles study. Appl. Surf. Sci. 2022, 579, 152141. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, W.; Zhang, S.; He, H.; Zhang, X. Sensing response of Pd-modified Ti3C2O2 for dissolved gas molecules in power transformer oil. Mater. Today Commun. 2023, 34, 105453. [Google Scholar] [CrossRef]

- Wang, H.; Wu, H.; Cui, H. First-principles screening in Cu-embedded PtSe2 monolayer as a potential gas sensor upon CO and HCHO in dry-type transformers. Comput. Theor. Chem. 2022, 1209, 113586. [Google Scholar] [CrossRef]

- Pan, Z.; Wang, J.; Si, Q.; Shi, T.; Ma, S. Cu-decorated ZnO monolayer as a promising gas sensor in dry-type transformers: A first-principles study. Comput. Theor. Chem. 2021, 1204, 113429. [Google Scholar] [CrossRef]

- CIGRÉ. Final Report of 2004–2007 International Enquiry on Reliability of High Voltage Equipment, Part 2—Reliability of High Voltage Circuit Breakers; CIGRE Technical Brochure; CIGRE: Paris, France, 2012; p. 510. [Google Scholar]

- Chen, H.C.; Zhang, Y.; Chen, M. Online DGA Sensor Calibration Using GANN and Data Augmentation. In Proceedings of the 2022 IEEE 5th International Electrical and Energy Conference (CIEEC), Nanjing, China, 27–29 May 2022; pp. 1426–1430. [Google Scholar]

- Liu, H.; Lian, H.; Zhang, J. Operation quality index and evaluation system of on-line monitoring device for gases dissolved in transformer oil. High Volt. Appar. 2021, 57, 143–149. [Google Scholar]

| Types | Method | Description |

|---|---|---|

| Electrical Tests | Dissipation or Power Factor Testing | Measures the dissipation factor (tan δ) to indicate contamination and deterioration of the insulating fluid. Conducted by applying an AC voltage and measuring the resulting current, in line with IEC 61620 (or 60247 under DC [24]) [25] and ASTM 924 [26] standards. |

| Electrical Tests | Frequency Response Analyses (FRA) | FRA is a non-intrusive monitoring and diagnostic technique allowing the assessment of the mechanical integrity and validating the structural design. It involves measuring the impedance of transformer windings over a frequency range (usually from a few Hz up to a couple MHz). Interpretations are performed according to standard DL/T 911-2016 [27] or technical reports such as CIGRE [28], IEC [29] and IEEE C57.149-2012 [30]. |

| Electrical Tests | Leakage Reactance Test | Measures the leakage reactance of transformer windings to detect mechanical displacement or deformation according to the CIGRE 445 standard [31]. |

| Electrical Tests | Insulation Resistance Test | Measures the resistance of the transformer’s insulation to detect deterioration and contamination [32], as outlined in the CIGRE Guide for Transformer Maintenance [31]. |

| Electrical Tests | Ratio and Polarity Test | Confirms the correct winding ratio and polarity of the transformer windings, in compliance with IEEE Std C57.12.90-2010 [33]. |

| Electrical Tests | Impulse Tests | Assesses the ability of the transformer insulation to withstand high-voltage surges in accordance with IEEE C57.12.90 [33] and IEC 60076-3:2013 [34] standards. |

| Electrical Tests | Polarization Depolarization Current Measurement | Assesses the condition of the transformer’s insulation [2] based on CIGRE 254 Dielectric response methods for diagnostics of power transformers [35]. |

| Electrical Tests | Recovery Voltage Method | Assesses the condition of the transformer’s insulation by measuring the recovery voltage after applying a direct current voltage, as specified in CIGRE 254 and the CIGRE Guide for Transformer Maintenance [31,35]. |

| Electrical Tests | Frequency Domain Spectroscopy | Analyzes the frequency response of transformer insulation to assess its condition (moisture content and aging). Conducted by applying a range of AC frequencies and measuring the dielectric response, as outlined in IEEE C57.161-2018 [36]. |

| Electrical Tests | Absorption Ratio/Polarization Index Test | Evaluates the condition of the transformer insulation [37] as specified in the CIGRE Guide for Transformer Maintenance [31] and IEEE Std 62-1995 [37]. |

| Electrical Tests | Breakdown Voltage Test | Measures the voltage at which the insulation becomes conductive, indicating its dielectric strength. This test is conducted by gradually increasing the voltage until breakdown occurs, following ASTM D1816-12 [38], ASTM D877 [39], and IEC 60156 [40] standards. |

| Chemical Tests | Dissolved Gas Analysis | Diagnoses incipient failures by detecting dissolved gases like hydrogen, carbon monoxide, carbon dioxide, ethylene, acetylene, etc. This analysis involves extracting oil samples and analyzing gas content using gas chromatography as per ASTM D3612 [41], D3284 [42], and IEC 60567 [43] standards. Interpretation guidelines for gas can be found in technical references such as IEEE C57.104-2019 [44] and CIGRE brochure 443 [45]. |

| Chemical Tests | Furan Analysis | Analyzes furan compounds in the transformer oil to assess the condition of the paper insulation [46], following IEEE Std C57.156-2016 [47], ASTM D5837 [46], and IEC 61198 [48]. |

| Chemical Tests | Moisture content | Measures water content in insulating liquids. This is performed using Karl Fischer titration, which quantifies moisture content as per ASTM D1533 [49] and CEI 60814 [50]. |

| Chemical Tests | Fourier Transform Infrared Spectroscopy | Identifies chemical changes in the insulation by analyzing its spectral fingerprints [51], as outlined in ASTM E2412-10 standard [52]. |

| Chemical Tests | Total Acid Number | Measures the acid concentration in the oil, which increases with aging. The test involves titrating the oil with a base and determining the acid number, as specified by ASTM D974 [53] and IEC 62021 [54]. |

| Chemical Tests | Interfacial Tension | Monitor the presence of polar compounds as per ASTM D971 [55] and ISO 6295 [56]. For in-service fluids, a decrease in this value indicates an increase in the concentration of contaminants, including oxidation by-products [55]. |

| Chemical Tests | Dissolved Metals Analysis | Detects metals dissolved in the oil to identify wear and tear of transformer components. This is typically conducted using atomic absorption spectroscopy or inductively coupled plasma analysis according to ASTM D7151 standard [57]. |

| Chemical Tests | Color/Visual Examination | This involves visually examining an oil sample by passing a beam of light through it to determine transparency and identify foreign matter. Poor transparency, cloudiness, or observation of particles indicates contamination [3] as specified in ASTM D974-22 standard [58] and STM D1500 [59]. |

| Chemical Tests | Inhibitor Content | Measures the content of oxidation inhibitors in the oil. Inhibitors protect the oil from oxidation and extend its life. Common inhibitors include 2,6-di-tert-butyl-paracresol and 2,6-di-tert-butyl-phenol [60], following IEC 60666 Standard [61]. |

| Chemical Tests | Corrosive Sulfur | Measures the presence of corrosive sulfur compounds in the oil, which can corrode metal surfaces and reduce the electrical strength of conductor insulation as per ASTM D2864-10e1 standard [62], IEC 62535 [63], and ASTM D1275 [64]. |

| Chemical Tests | Particle Count | This measures the number and size of particles in the oil. Particles can significantly affect the dielectric strength of insulating liquids and increase the risk of static electrification, partial discharge activity, and tracking [3] as outlined in CIGRE 157 [65], ASTM D6786 [66], and IEC 60422 standard [67]. |

| Chemical Tests | Turbidity Analysis | Measures the cloudiness of a liquid caused by suspended solids, indicating contamination levels. Higher turbidity signifies more suspended particles, affecting the fluid’s insulating properties and cooling efficiency as specified in ASTM D6181 [68]. |

| Physicochemical Tests | Photoluminescence and Ultraviolet-Visible (UV-Vis) Spectroscopy | Assesses the optical properties of the oil as per ASTM D6802-02 [69]. |

| Thermal Tests | Thermography | Detects overheating and pinpoints potential faults through temperature measurements. Infrared cameras are used to capture thermal images of the transformer, identifying hot spots as per ISO 18434-1:2008 [70], ASTM D1903-01 [71], and IEEE C57.156 [47]. |

| Thermal Tests | Heat Transfer Properties | Evaluates thermal conductivity, specific heat, viscosity, pour point, and relative density to determine cooling efficiency. Improves heat transfer, while low viscosity aids in better flow. The pour point indicates the lowest temperature for oil flow, following ASTM D2717-95 [72]. |

| Structural and Mechanical Assessments | Bushing Monitoring | Assesses the condition of transformer bushings. This involves measuring parameters like capacitance and power factor to detect insulation degradation, following IEEE C57.19.100-2012 standards [73] and IEC 60137 [74]. |

| Structural and Mechanical Assessments | OLTC Monitoring | Monitors the performance and condition of on-load tap changers. This method involves measuring parameters such as operation times and contact wear, as specified by IEC 60214-1 [75] and IEE Std C57.137 [76]. |

| Comprehensive Condition Assessments | Condition Assessment and Diagnostics | General guidelines for diagnostic testing of transformers. This comprehensive approach involves a range of electrical, chemical, and physical tests to assess transformer health, guided by IEEE 62-1995 [37], IEEE C57.143-2012 standards [77], IEC 60599 [78], and IEEE Std C57.152-2013 [79]. |

| Components | Description | Online Monitoring Possibilities |

|---|---|---|

| Active part | The core is prone to defects like displacement of blades due to electromagnetic forces and high eddy currents, causing mechanical deformation and efficiency loss. Failures due to mechanical, thermal, or dielectric stresses. Mechanical anomalies include loosening, displacement, or deformation due to improper maintenance, corrosion, or vibrations. Thermal stresses create “hot spots” that damage the windings. Dielectric anomalies arise from disruptions in the insulating material, leading to short circuits and local burning. The insulation degrades over time through hydrolysis, pyrolysis, and oxidation, reducing dielectric and mechanical properties. | Transformer load current, Core ground current primary/secondary/tertiary voltages Winding temperature, Short-circuit current of the transformer, Peak voltage of the transformer surge Top oil temperature Moisture (and temperature) in oil tank PD measurements Dissolved gases in oil |

| Tank, oil containment, and preservation | Oil leaks, corrosion, condensation, aging and degradation, welding defects, buckling/deformation, vibration-induced issues, faulty breather or pressure relief devices are some of potential faults of transformer tanks. | Oil level in the tank Sudden pressure Moisture and temperature in oil Ambient moisture |

| Bushings | Degraded due to contamination, water ingress, and aging, leading to PDs and overheating. | Capacitance and power/Dissipation factor, Leakage current, Bushing voltage from capacitive coupler |

| Tap-Changer | Failures due to mechanical wear, lack of maintenance, and electrical issues, disrupting voltage regulation. | Motor driving current and vibration signals, Current accumulated in individual taps, Tap position indicator, AC supply voltage, number of accumulated changes on each tap, Total number of operations of the OLTC, RMS phase-to-earth transformer voltage, OLTC oil level, OLTC oil temperature, Gas content in insulating oil, Moisture content in the OLTC oil. |

| Cooling System | Wears and tears may lead to cracks and oil leaks. Cooling system failures due to pump or fan malfunctions may cause overheating and increased pressure. | Oil pump motor current, Cooling system AC supply voltage status of the oil pumps (on/off), Transformer load current, Fan motor currents, Ambient temperature, Winding temperature (thermal imaging), Top oil temperature, Bottom oil temperature |

| Sensor Type | Key Findings | Parameter |

|---|---|---|

| Bragg grating-based fiber optic sensors | Found slightly higher winding temperatures in transformers with natural ester oil compared to mineral oil, confirmed by CFD simulations [217]. | Temperature |

| Fluorescing-tipped or gallium arsenide (GaAs)-tipped fiber optic sensors | Validated a new temperature calculation method for high current busbar leads in large transformers with a maximum error of 0.78%, outperforming traditional methods [218]. | Temperature |

| Optical frequency-domain reflectometry system with single-mode fibers | Achieved high spatial resolution (1 cm) and temperature accuracy (0.1 °C) for transformer core temperature monitoring, validated against infrared thermography and FEM simulations [218]. | Temperature |

| Fiber optic sensors and Kalman filter | Embedded in SCADA systems to monitor hotspot temperatures on transformer windings using a FBG-based quasi-distributed thermal sensing method [219]. | Temperature |

| Photoelectric infrared thermal imaging and discharge circuit detection sensors | Measured internal temperatures and discharge signals, using a fuzzy data fusion model to improve fault diagnosis precision and accuracy, reducing data fluctuation and increasing diagnostic reliability [220]. | Temperature |

| PT1000 platinum resistance sensors | Combined with PCA, LSTM neural networks, and decision trees to diagnose sensor faults with over 96% recognition rate and under 1 millisecond diagnosis time; LSTM model predicted temperature with an error margin within 0.1 °C [221,222]. | Temperature |

| Pt100 temperature sensors | Strategically placed on transformer oil pipes for precise measurements of oil temperature to monitor and control transformer cooling processes. Modular and scalable, allows for remote monitoring and updates [223]. | Temperature |

| Tunable diode laser absorption spectroscopy (TDLAS) | Detects acetylene dissolved in transformer oil with high sensitivity (7.1 mV/ppm), low detection limit (0.49 ppm), quick response, and no need for carrier gas [147]. | Temperature |

| Robotic system with multiple sensors | Used thermal cameras, RGB cameras, AEs, depth cameras, LiDAR, humidity, and temperature sensors to monitor transformer lifecycle and detect hot spots, mechanical irregularities, and environmental conditions [224]. | Temperature |

| Piezoelectric Accelerometers | Measured vibration acceleration in transformer tanks to assess core and winding conditions, finding optimal sensor placement in the middle of the tank, and indicating higher vibration acceleration in older transformers [225]. | Core |

| Impedance Analyzer | Detected Disk-Space Variation faults in transformer windings with high accuracy using transfer function results and artificial neural networks (94.72% for Multi-layer Perceptron and 87.22% for Group Method of Data Handling) [226]. | Winding |

| Acoustic Sensor | Compared Time Difference of Arrival and Acoustic Time Reversal methods for measuring PD [85]. | Partial Discharge |

| Acoustic Emission Sensors | Prototype AE sensor displayed greater sensitivity and stability in detecting PDs, with higher amplitude PD pulses and a wider range of detectable PD signals compared to commercial sensors [227]. | Partial Discharge |

| High-speed optical sensors | Detected PD in medium-frequency transformers under high dv/dt switching transients, finding that higher PWM frequencies increased PD susceptibility and reduced insulation lifespan [228]. | Partial Discharge |

| UHF Disk Sensor, UHF Drain Valve Sensor, Commercially Antennas | Detected PDs in transformer insulation systems, with the log-periodic antenna achieving the highest defect-recognition efficiency. Machine learning algorithms classified PD types with high accuracy [229]. | Partial Discharge |

| UHF sensors and dipole antennas | Measured electromagnetic waves from PDs, achieving high accuracy in locating PD sources using the inverse filter method with a 3D localization error of 5 mm [230]. | Partial Discharge |

| Microfiber Composite sensor PZT sensor | Designed for detecting AEs from PDs, with the MFC sensor showing higher sensitivity and the PZT sensor providing detailed frequency analysis. Combining RMS and STFT analyses improved PD detection [88]. | Partial Discharge |

| Piezoelectric ultrasound sensors | To detect acoustic signals from PDs in transformer oil, with sensor placement optimization reducing measurement uncertainty due to temperature variations. MUA software version 1.0 helped quantify and minimize uncertainties [231]. | Partial Discharge |

| High-Frequency Current Transformer Sensors | Characterized PD systems using HFCT sensors with a modular test platform. Evaluated sensitivity, noise rejection, and defect localization. Ensured accurate PD diagnostics [232]. | Partial Discharge |

| Commercially microphones | Measured low-frequency noise generated by power transformers, with preamplifiers and digital signal meters registering sound pressure levels [233]. | Vibration |

| Piezoelectric acceleration sensors) | Measured vibration signals in a ±500 kV HVDC converter transformer, finding increased vibration intensities with load current and significant components at 100 Hz, 200 Hz, 300 Hz, and 400 Hz [234]. | Vibration |

| Buchholz Relays | Detected gas accumulation and oil surges in oil-immersed transformers, providing early fault detection [235,236]. | Gas Accumulation |

| Transformer Protector | Involves a fast-acting rupture disk that opens within milliseconds to depressurize the transformer tank, preventing explosive gas production and channeling gases to a remote area where they can safely burn [237,238]. | Prevention of explosive gas production |

| Smart Photodiodes Array | Monitors color changes in silica gel of transformer breathers, indicating saturation levels [239]. | Breather Health Monitoring |

| Commercially DGA Sensors | DGA is the leading technology in industry for early detection of many incipient transformer failures and degradation mechanisms. Measured dissolved gas concentrations in transformer oil, achieving high prediction accuracy with mean absolute percentage errors ranging from 1.525% to 5.763% using a wavelet-like transform and autoregressive neural network model [240]. | Dissolved gas in Oil |

| PL spectrometers and UV-Vis spectrophotometers | Measured PL and UV-Vis spectra of transformer oil samples for condition assessment, with PL spectroscopy showing higher sensitivity and accuracy (98% and 99% correlation with DDF results) [241]. | Oil’s degradation |

| Thin-Film Capacitive Sensor | Improving the capacitive sensor for real-time moisture measurement in transformer oil [242,243]. | Moisture in oil |

| UV light source (365 nm), digital camera, fluorescence images | Captures fluorescence images of transformer oil under UV light for accurate oil leak detection using a U-net model [244]. | Oil leak detector |

| Fringing Field Capacitive Sensor | To measure liquid levels in vessels without direct contact, showing linear response and high sensitivity [245]. | Oil level detector |

| AE sensors | Evaluated effectiveness of various AE in detecting and classifying defects in OLTCs. The sensors demonstrated the best overall performance with ensemble subspace discriminant (ESD) algorithms [246]. | Tap-Changer’s condition |

| Acoustic Emission Sensors | Developed a method using AE signals and machine learning to detect OLTC faults. AE signals were recorded with piezoelectric transducers and analyzed using wavelet decomposition and ML models, achieving high classification accuracy [247]. | Tap-Changer’s condition |

| Accelerometer, Temperature, Current Clamp sensor | Detecting faults in OLTC by using vibro-acoustic signal analysis, Hilbert Transform, and Low Pass Filter to simplify the complex signal [216]. | Tap-Changer’s condition |

| Material | Target Gases | Key Findings | Notes |

|---|---|---|---|

| Pd-doped Janus HfSeTe monolayers | H2, CO, CH4, C2H2, C2H4 | High stability and selectivity, particularly for C2H4 detection [248] | Promising for resistance-type and work-function-type gas sensors in transformer oil |

| Pd-C3N monolayers | HCHO, C2H3Cl | Enhanced conductivity and sensitivity with strong binding energies, stable under moisture [249] | Effective for real-time monitoring in dry-type transformers |

| Ir-decorated MoS2 monolayers | CH4, C2H4, C2H2 | High sensitivity to C2H4 and C2H2, significant electronic property changes [250] | Enhances transformer condition monitoring, weak sensitivity to CH4 |

| Ni-doped WS2 monolayers | H2, C2H2, CO | High sensitivity and selectivity, substantial improvements in adsorption energy and conductivity [251] | Suitable for DGA in transformer oil |