Abstract

This paper summarizes the results of numerous studies aimed at improving the operating characteristics of electric motors used in light electric vehicles (LEVs). This review focuses on four types of electric motors that can be installed in the drive wheel rims of LEVs. Due to the availability of new magnetic materials and the use of advanced techniques for optimizing the design of electric motors, new motor topologies have emerged. The latest generation motors have been shown to be more efficient, have higher torque density, and generate less torque ripple. This paper indicates and discusses current trends in the topology of electric motors designed for LEV drives. In this context, the effectiveness of the proposed design modifications in terms of selected motor operational characteristics was assessed. The proposed new topologies were compared with commercial solutions, also in terms of the possibility of improving their operational parameters.

1. Introduction

The concept of using electric motors to power vehicles without the need for horses or human muscle first appeared in the 1820s and 1830s [1]. Initially, electric vehicles had limited popularity due to the limited capacity of batteries for storing electricity. Additionally, manufacturers faced significant competition from gasoline-powered vehicles. The widespread availability and low cost of fossil fuels, lobbying by oil companies, and the overall cost of cars are key factors contributing to the popularity of gasoline-powered vehicles both a century ago and today. At the beginning of the twentieth century, gasoline-powered cars were even three times cheaper than electric cars [1]. While the price difference may not be as significant today as it was in the early 20th century, it still exists, and electric cars are generally more expensive than gasoline-powered cars with similar specifications. The popularity of electric and hybrid vehicles has been growing in recent years, driven by rising fuel costs resulting from global geopolitical tensions and the trade policies of major oil producers. Moreover, due to the introduction of stricter requirements limiting the production of harmful substances, manufacturers of gasoline cars are facing increasing demands. Therefore, climate change and greenhouse gas emissions are subjects of great debate worldwide. Electric vehicles are considered the most effective alternative for achieving zero emissions compared to conventional gasoline-powered vehicles. Estimates suggest that electric car sales could reach hundreds of millions of units by 2030 and will vary regionally [2]. The Chinese market is projected to represent around 48% of the global electric vehicle market [3]. Beyond 2030, the market share of electric autonomous vehicles is expected to grow rapidly, with forecasts suggesting it could reach up to 20% of total EV sales by 2040 [4]. However, global sales of plug-in cars are expected to decline after 2030, with the Chinese market maintaining its dominance [5].

Electric vehicles have both advantages and disadvantages. The advantages of electric vehicles include lower operating costs, reduced maintenance expenses, minimal noise pollution, and easier access to urban areas compared to traditional petrol or diesel vehicles. However, electric vehicles also have several significant disadvantages, including higher initial costs compared to vehicles with traditional gasoline engines; the necessity of purchasing a new battery pack to store energy from the traction motor within a specified period of time; the high cost of disposing of old battery packs; the need for a heavy battery pack in vehicles with long ranges; and the limited range of the vehicle without battery charging. Fast charging stations can reduce charging times to 30 min, while using standard electric charger connections in private homes may require several hours.

The use of electric motors in electric vehicle drives is widely discussed and compared in the literature [6,7,8,9,10,11,12]. Various motor design solutions are analyzed based on operating conditions, vehicle range, and other specific requirements. These requirements include, for example, rapid speed changes while maintaining high efficiency; availability of increased torque for hill climbing; ability to work for long periods under high loads; offering high power at low speeds; overload capability; light construction of the vehicle; low moment of inertia; and cost-effectiveness.

In this review article, the author summarizes recent research findings on the design of electric motors used in light electric vehicles. The term light electric vehicle (LEV) refers to a wide range of vehicles, electrically powered, used to travel relatively short distances and for urban or suburban commutes. An LEV is a vehicle designed for carrying small loads of one or more passengers up to an officially specified weight. We can therefore indicate the following vehicle groups:

- -

- e-bikes with pedal assistance, e-scooters, electric kick scooters, self-balancing scooters, Segways, mopeds, electric three-wheelers, e-skateboards, and electric unicycles—called Personal Light Electric Vehicles;

- -

- e-cargo bikes for goods transport (e-rickshaws);

- -

- Mobility scooters, microcars, golf cars, BSO-buses (electric child carrier).

The following has been accepted:

- -

- e-bike vehicles with pedal assistance have a maximum construction speed of 25 km/h, the maximum mass in running order (mass of the vehicle including batteries without load) should be less than 55 kg, the maximum total mass in running order is approximately 200 kg, and the maximum width of the vehicle is 0.75 m;

- -

- e-cargo bike vehicles for goods transport have a maximum construction speed of 25 km/h, the maximum mass in running order (mass of the vehicle including batteries without load) should be less than 55 kg, the maximum total mass in running order is approximately 140 kg, and the maximum width of the vehicle is 0.75 m;

- -

- Mobility scooter vehicles have a maximum construction speed of 25 (even up to 45 for microcars) km/h, and the maximum mass in running order (mass of the vehicle including batteries without load) is greater than 55 kg but does not exceed 350 kg, maximum total mass in running order is approximately 550 kg, and the maximum width of the vehicle is 1 m;

- -

- The above-mentioned groups of vehicles are powered by electric motors with a power output of several hundred W (Personal Light Electric Vehicles) up to 3–4 kW (microcars, BSO-buses);

- -

- No license is needed for users of a large portion of these vehicles;

- -

- Vehicles are powered by an internal battery or are additionally supported by the power of human muscles.

The purpose of this investigation was to determine the appropriate motor topology and materials used in the building of the magnetic circuit. Although this article does not include an overview of developments in the design of systems that power electric motors, the literature clearly shows that these systems are crucial. Many scientists are exploring the topic of motor topology, obtaining interesting results. In their works, they use efficiency maps to demonstrate how control parameters affect an electric motor’s performance [13,14,15]. This review article is divided into the following sections: Introduction, Types of electric motors used in EV drives, A review of LEV motor designs, including topologies that improve operational performance, and Discussion and Conclusions.

2. Types of Electric Motors Used in EV Drives

Key Factors and Parameters to Consider When Selecting an Electric Motor for an Electric Vehicle

Electric vehicles can be classified into several groups based on selected criteria [10,16,17]. Each group can be matched with the most suitable types of electric motors based on factors such as the electric motor price relative to the price of the EV, motor performance, efficiency, and other important factors. Electric motors used in electric vehicles are typically categorized into three main groups: DC motors, induction motors (ACIM), and synchronous motors (SM), including those with permanent magnets (PMSM). Detailed descriptions of their structure and key operational parameters can be found in the literature [18,19,20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40]. When selecting an electric motor for a specific type of electric vehicle, it is crucial to consider numerous significant factors.

- The amount of power and torque generated is directly related to the power-to-weight ratio. A higher value of this ratio will lead to increased speed and acceleration of the electric vehicle.

- Power density influences space usage by addressing the question of whether a motor can be built to fit into a particular space.

- Peak power output is the maximum power that an electric motor can generate in a short period of time.

- Motor efficiency has a direct impact on the vehicle’s operational range.

- The battery and electronic drive system are selected based on the motor’s voltage and current specifications.

- The motor’s application area is determined by its cooling technology (air-cooled or liquid-cooled), which is crucial for improved heat management and performance.

The first factor mentioned above is one of the most important in determining the level of technology used in the production of electric motors. Recent developments have highlighted the technological advances in the production of electric motors for electric vehicles. The IDTech Ex report provides a detailed assessment of these changes, emphasizing the current technology landscape and potential challenges [41]. The report analyzed key parameters of electric motors used in various electric vehicles, including light EVs, electric cars, trucks, and buses. The study focuses on electric power units found in new vehicles sold over the past eight years. The motors examined range in power from hundreds of watts to approximately 630 kW and weight from 1 kg to 350 kg—see Table 1. It is important to note that no conventional DC motors are included in the list.

Table 1.

List of electric motor types that are currently used in EV drives [41].

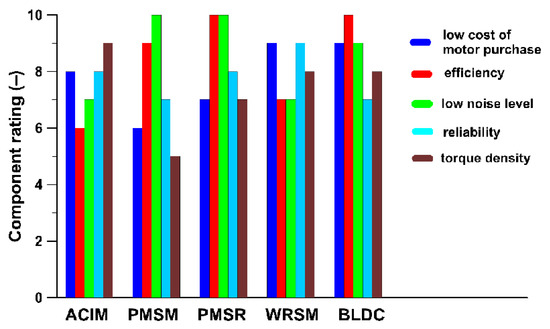

The multimedia presentation by IDTechEx Group highlighted the results of comprehensive research on electric motors for powering EVs [42]. The presentation covered five types of motors: ACIM, PMSM (permanent magnet synchronous motor), PMSR (permanent magnet switched reluctance motor), WRSM, and BLDC (brushless DC motor).

The parameters for the comprehensive evaluation were divided into four groups: operating parameters, production complications, ease of adjusting the existing operating parameters of the electric motor, and structure-related factors (such as power and torque densities). The overall rating considers parameters like controllability, motor cost, efficiency, ease of manufacturing, noise level, power density, reliability, scalability, and torque density. Each parameter was rated on a scale of 1 to 10, with 1 being the lowest and 10 being the highest. The detailed results of these evaluations are presented in Table 2 and Figure 1.

Table 2.

Benchmarking of electric motors used in EV drives (based on data from the IDTechEx report [42]).

Figure 1.

The following components are crucial for evaluating electric motors used in EV drives (based on data from the IDTechEx report [42]).

3. A Review of LEV Motor Designs, Including Topologies That Improve Operational Performance

This review analyzed the construction of four types of electric motors, taking into account the above-mentioned criteria and specifications of LEVs. The selection was made based on the nominal power range (from several hundred W to three to four kW) and weight (from approximately 1 kg to 20 kg) of a single electric motor intended for the LEV drive. The IDTechEx report, which outlines the development trends (from 2024 to 2034) of many types of electric motors intended for use in electric vehicles, was considered in the selection process [41].

3.1. In-Wheel Motors with Surface-Mounted Permanent Magnets

In recent years, in-wheel motors have gained popularity due to the integration of the electric motor with the wheel. This integration eliminates the need for a drive transmission system, significantly improving the efficiency and reliability of the design. Researchers have studied several types of electric motors, including permanent magnet motors, magnetic gear motors, switched reluctance motors, and wireless motors. In low-speed electric vehicles, permanent magnet in-wheel motors are often used, where the external rotor can be embedded into the wheel [43,44]. The main advantages of this electric motor design are its double-salient structure and good thermal stability, which is ensured by easy cooling.

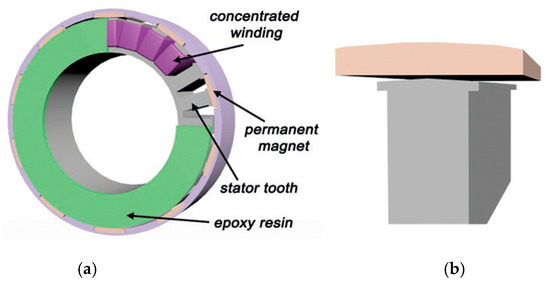

A 20-pole–24-slot surface permanent magnet synchronous motor for low-speed in-wheel direct drive is investigated in [43]. The motor’s geometry is shown in Figure 2. This is one of the potential solutions used in such a drive [45,46]. The advantage of this solution is that it reduces the use of PM material while maintaining performance during continuous operation.

Figure 2.

In-wheel motor construction. (a) General view; (b) detailed view of an uneven air gap [43].

Electric motors developed for powering electric vehicles (EVs) are currently designed to minimize the use of permanent magnet (PM) materials by introducing new topologies. Therefore, the possibility of using a design with an external rotor should be considered, but this may lead to a magnetic imbalance. This issue can be mitigated by utilizing a proper combination of pole-slot configurations and winding connections [45]. A study by researchers [43] has shown that in such cases there are limitations related to the imposed outer diameter of the motor and the axial length of the core. The dimensions must be carefully adjusted to fit a 16-inch aluminum rim. One of the key features of the proposed electric motor type is thermal stability. To achieve this stability, the authors recommend using segmented stator cores. Additionally, rectangular cross-section conductors were incorporated into the design to optimize the available slot area, thereby reducing current density and Joule loss in the winding. All stator components were enclosed in epoxy resin, providing structural strength and a path for heat transfer from the windings to the housing. The authors suggested the possibility of utilizing an uneven air gap, which reduces cogging torque, torque ripple, and induced voltage harmonics at no-load conditions. This is one of the well-known methods used to reduce vibrations, as confirmed in the work of other researchers [47,48,49,50,51,52,53,54,55,56]. In the proposed motor geometry, the use of an uneven air gap proved to be very effective, as it lowered the cogging torque amplitude fourfold [43]. This method also effectively reduced the torque ripple, which is associated with rotational smoothness. The amplitude of the torque ripple was reduced by half [43]. These design achievements significantly improved the comfort of driving an electric vehicle powered by this type of motor. Another advantage of the proposed approach is the motor’s extremely high efficiency, which reaches 94%. It should be noted that the proposed approach performs well across a variety of speeds and torque ranges [43]. The effectiveness of the proposed solution stems from the fact that the uneven air gap allows for interference in the spatial distribution of the electromagnetic field in the air gap. The theoretical basis related to the reduction in higher harmonics in the air gap can be found in the works of other researchers [57]. The literature contains examples of different strategies for creating an air gap with variable thickness than those described above—see Figure 3 and Figure 4.

Figure 3.

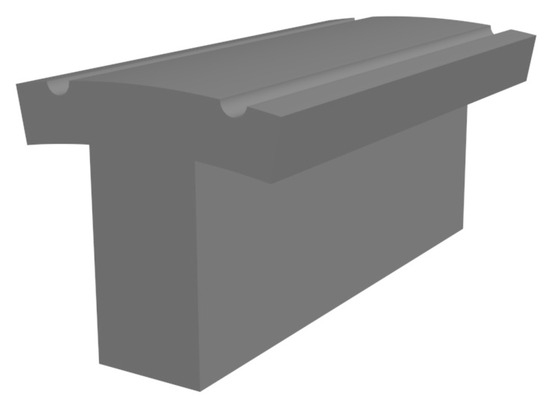

Stator tooth with recesses that control the thickness of the air gap.

Figure 4.

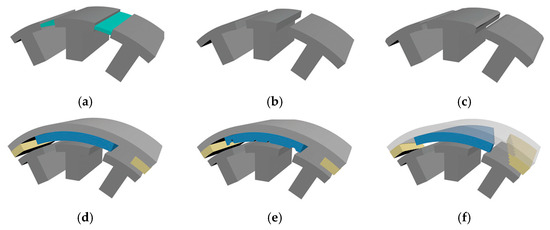

Popular design solutions for in-wheel motors: (a) wedges in slot openings, (b) variable width of neighboring teeth, (c) tooth shape profiling, (d) selection of PM width, (e) PM shape profiling, (f) PM skewing. The wedges are marked in light blue, the permanent magnets are marked in dark blue and yellow, and the teeth and motor yoke are marked in gray.

The techniques mentioned above address interference in both the geometry of the stator teeth and the shape and size of permanent magnets (PMs) in the rotor. In [58], the authors studied the impact of the size of the so-called not fully magnetized zone, which is essentially a recess in the shape of a stator tooth, as shown in Figure 3. The authors achieved a 60% reduction in cogging torque by carefully optimizing the shape and size of this recess. Similar results were reported in [59], where the authors managed to reduce cogging torque by up to 85%. A similar approach to reducing cogging torque was also presented in [60], where two recesses were created in the head of the stator tooth. By examining the optimal position and size of these recesses, a 30% reduction in cogging torque was achieved. Another modification of the topology was recommended in [61], where the authors investigated the influence of size, location, and the material used for creating the stator bridge, also known as a wedge—see Figure 4a. The stator bridge connects the heads of neighboring stator teeth and is located next to the air gap. The authors managed to reduce the cogging torque by three times while increasing the average torque by 5%. Another team of researchers studied the influence of the width of the stator tooth heads on the reduction in the cogging torque—see Figure 4b. During the study, two versions of the solutions were tested, one with the same width of tooth heads and the other examining the influence of asymmetry in the width of the tooth heads in adjacent teeth [62]. By selecting the head size, the researchers achieved a fivefold reduction in cogging torque. Even better results were achieved by pairing teeth with different head widths. More approaches to modulating the thickness of the air gap can be found in the literature. The solution proposed in [43] resulted in a considerable reduction in both cogging torque and torque ripple. In another study [63], the authors investigated four scenarios of air gap variation profiles, as shown in Figure 4c. They also highlighted the significant influence of the air gap profile on the obtained results, showing a several-fold reduction in cogging torque and a corresponding increase in average torque.

Another technique to reduce torque ripple or cogging torque is to modify the design specifications of permanent magnets (PMs), which can yield interesting results. A study conducted by the research team [62] showed that adjusting the angle of the magnet pole can reduce the cogging torque by six times. Additionally, shaping the edge of the magnet helped reduce the cogging torque by a factor of five when adjacent magnets come into contact with each other. A similar study was described in [64], where they analyzed two permanent magnet synchronous motors (PMSM): one with 24 poles and 72 slots, and another with 6 poles and 36 slots. In these studies, the widths of permanent magnets placed adjacent to one another were optimized to reduce cogging torque and torque ripple. In both scenarios, the optimization process successfully generated permanent magnet width combinations that effectively eliminated cogging torque and significantly reduced torque ripple. For the 24-pole/72-slot motor, the torque ripple was reduced by more than ten times, while the average torque decreased by about 5%. In the second scenario involving a 6-pole/36-slot motor, a six-fold reduction in torque ripple was achieved without compromising the average torque. Similar results have been reported by other researchers. In [65], the authors detailed the findings of a study on magnet pole arc reduction for an 8-pole/12-slot motor. An example of this solution can be seen in Figure 4d. Finding the optimal width of the magnet arc allowed for a seven-fold reduction in cogging torque while maintaining the average torque level. Moreover, the torque ripple amplitude has been reduced three-fold, and the back EMF waveform has been adjusted closer to a sinusoidal waveform. A slightly modified strategy was adopted by another research team, which presented the results of their research in [66]. Instead of seeking the optimal width of permanent magnets, each magnet was divided into pieces separated by an air gap. From a design standpoint, such a segmented group of permanent magnets is comparable to a single magnet of the same width. The research resulted in a reduction in cogging torque amplitude by 97% or 90%, depending on the number of segments. Interesting research results on an external rotor motor can be found in [67]. The authors’ primary goal was to determine Joule losses in individual motor parts and assess motor efficiency. The external rotor of the tested motor was equipped with 31 pairs of permanent magnets. The spacing of the magnets was chosen to ensure that the back EMF waveform closely resembled a sinusoid. Air gaps were present between the magnets, and additional air gaps were introduced in the rotor yoke, dividing it into sections with one air gap between each pair of poles. The stator teeth had trapezoidal recesses at their heads, following the concept shown in Figure 3. As a result of the study, the motor efficiency increased from 83% (in the version without additional air gaps in the rotor yoke) to 86% (in the version with slots). The same type of electric motor underwent further analysis and design modifications [68]. The width of the air gaps between permanent magnets was adjusted to discover the optimal slot/pole number combinations. The research revealed that widening the air gap between permanent magnets leads to a tenfold reduction in both cogging torque and torque ripple. It was also observed that wider gaps resulted in smaller amplitudes of both torques. Conversely, narrower gaps and an increased number of pole pairs reduced the amplitude of both torques. Unfortunately, wider gaps led to lower motor efficiency, regardless of the number of pole pairs.

It is well known that shaping the surface of permanent magnets minimizes the content of higher harmonics of the magnetic field in the air gap, thereby reducing parasitic torques. Significant research in this field has been documented in the literature [69]. An example design related to this research is shown in Figure 4e. The literature discusses the concept of creating notches in the surface of the permanent magnet, which is similar to shaping tooth surfaces by creating recesses—see Figure 3. The research team that addressed this problem designed the shape, geometric dimensions, and position of the permanent magnet notches to ensure that the back EMF waveform contains a minimum number of higher harmonics. This design effectively eliminated torque ripples, reducing the ripple amplitude by several dozen times, and decreasing cogging torque to the same level. After shaping the permanent magnets (PMs), the average torque generated by the motor remained constant, which is a significant advantage of this technique. Another effective way to regulate the higher harmonic content of the magnetic field in the air gap is to use skewed permanent magnets—see Figure 4f. Studies using this technique have shown a significant reduction in cogging torque and a decrease in the ripple torque amplitude [70,71]. By adjusting the PM skew, specific harmonics of the magnetic field can be reduced, resulting in lower cogging torque and torque ripple. In a study [70], the results of two experiments are presented. In the first experiment with an 8-pole/24-slot motor, after eliminating the first two harmonics, the cogging torque was reduced by 98%. In the second experiment with a 6-pole/27-slot motor, the torque was reduced by 86% by eliminating the second harmonic. Another team of researchers further developed this concept by proposing a sinusoidal PM shape [71]. In practice, the desired shape of permanent magnets was achieved by combining multiple magnets of different sizes, resulting in a significant reduction in magnet volume. Additionally, an almost sinusoidal back EMF waveform was obtained, the cogging torque was decreased by 86%, and the torque ripple was reduced by 75%. Importantly, the average torque generated by the motor remained constant. The proposed solutions were compared to the results obtained from a motor with skewed magnets. The motor with skewed magnets exhibited significantly lower cogging torque, but torque ripples were 50% higher. Research conducted in this area, with a slightly modified technique for obtaining the skew of permanent magnets, was described in [72]. An alternative approach was to use multiple magnets with a length shorter than the rotor package, allowing for the PM skew effect to be achieved in a different way. A group of two to five PMs was examined, each rotated by a specific angle relative to the others. As a result of the work carried out, the amplitude of the cogging torque was reduced by 5–7 times, depending on the combination of displacements of the individual magnets in the group.

As mentioned earlier, torque ripple reduction can be achieved by adjusting the air gap thickness using the designs shown in Figure 2, Figure 3 and Figure 4. Another approach to reducing torque ripple is by considering a modified motor topology, as discussed in [73]. In their research, the authors focused on improving the design of Vernier permanent magnet machines, which utilize ferrite magnets in both the stator and rotor. The research was conducted in two stages. In the first stage, changes were made to the number of stator teeth (Z), rotor pole pairs (Pr), and stator winding MMF pole-pair number (Ps) based on a proposed relationship [74]. Two configurations labeled as Ps/Z/Pr were analyzed, with the first configuration represented by Ps/Z/Pr = 1/20/21 and the second by 5/24/19. The second design showed a fivefold reduction in torque ripple. In the second stage of the research, the results were obtained for:

- Optimized 27-slot, 12-pole-pair regular PMSM with ferrite magnets or NdFeB magnets—Figure 5a;

Figure 5. Tested motor topologies. (a) Regular PMSM, (b) regular VPM, (c) consequent-pole VPM, (d) proposed topology [73].

Figure 5. Tested motor topologies. (a) Regular PMSM, (b) regular VPM, (c) consequent-pole VPM, (d) proposed topology [73]. - Optimized split-tooth, 12-slot, 19-pole-pair, regular permanent magnet Vernier motor with NdFeB magnets—Figure 5b;

- A 12-slot, 24-tooth, 19-pole-pair, consequent-pole permanent magnet Vernier motor with ferrite magnets—Figure 5c;

- A 12-slot, 24-tooth, 19-pole-pair, consequent-pole permanent magnet Vernier motor with stator-assisted ferrite magnets—Figure 5d.

The torque density of the different motor versions varied significantly. The best approach (#4) showed almost three times higher torque density than solution #1 and a 34% higher static moment compared to another optimized conventional PMSM of the same volume. The optimal approach also had a very low peak-to-peak cogging torque (only 4% of the maximum torque) and 20% lower total losses. Further analysis comparing the standard VPM (Figure 5b) and consequent-pole VPM (Figure 5c) can be found in [75], while [76] presents research results on the topology of a segmented rotor with flux barriers. The technique used resulted in a 10% reduction in total losses and increased efficiency by 1 to 3%, depending on the motor load.

Permanent magnet Vernier motors are known for their simple topology and high torque density. The high torque density is achieved through the interaction of two torque generation mechanisms. The first torque component is generated by the standard PM machine mechanism, while the second is generated by the magnetic gearing effect. Extensive research has been conducted on these motors in recent years [77,78]. In Ref. [77], the authors compared the performance of PMSM and PMVM motors with an average torque of approximately 1000 Nm. The conducted research on PMVM and PMSM showed similar values of torque per active mass, twice the torque density, a 40% reduction in PM mass, a 15% reduction in total active material cost, and a 40% reduction in cogging torque and torque ripple amplitude. In Ref. [78], various combinations of the number of stator teeth, rotor pole pairs, and stator winding MMF pole-pair number were investigated. The specific values selected had a significant impact on the motor’s average torque and torque ripple amplitude. The values of these parameters varied by 10% depending on the combinations used. Moreover, torque density changed significantly, by up to 40%. As shown in [79], a slight change in the geometry of the stator teeth compared to the solutions used in standard VPM resulted in a considerable improvement in torque density. The authors investigated a prototype design of a spoke-type permanent-magnet Vernier machine (STPMV) with an external rotor—see Figure 6. By adjusting the dimensions of the permanent magnets and the head sizes of the stator teeth, they increased torque density by 30% over typical VPM. Design considerations for this type of electric motor were previously presented by another group of authors [80].

Figure 6.

Tested motor topologies. (a) Regular VPM, (b) proposed topology [78].

Further tests on the STPMV motor, including the selection of the size and shape of the stator tooth, are presented in [81], while the topology is shown in Figure 7a. The authors investigated the harmonic content of the induction curve in the air gap, considering the dimensions and shape of the stator slots. The analysis led to the proposal of specific dimensions and shape of the stator slot, which resulted in over a 50% increase in the generated average torque. For the recommended topology, the best size ratio of the inner stator diameter to the outer stator diameter was found to be 0.5–0.7. The authors demonstrated that adjusting the thickness of the permanent magnets could reduce torque ripple in the tested motor by 2.5 times. The optimal thickness of the permanent magnets, 2–2.5 mm, also provided the highest average torque. Additionally, the optimal angular width of permanent magnets in the recommended motor topology was determined to be 24–30 degrees. Wider magnets led to lower average motor torque and higher torque ripple. Test results showed that the motor with the selected tooth and permanent magnet sizes showed an 86% lower cogging torque compared to a conventional VPM motor.

Figure 7.

Tested motor topologies. (a) STPMV motor [81], (b) V-FMPM) motor [82].

Another interesting approach can be found in the literature: the V-shape flux-modulated permanent-magnet (V-FMPM) motor [82]—see Figure 7b. This topology refers to the motor design concept known as the air gap-harmonic-oriented design technique. In the tested scenario, the stator teeth were shaped like those shown in Figure 6a, and their geometric dimensions were optimized. The magnets in the stator were arranged at a specific angle to the air gap. They, together with the stator teeth, were a key component of the “harmonics modulator” of the induction curve in the air gap. In comparison to the initial motor, the dimensional optimization method enhanced average torque by 12% and reduced torque ripple by 50%.

Table 3 summarizes the effectiveness of the described design ideas in improving the operating characteristics of in-wheel motors using surface permanent magnets.

Table 3.

The influence of design changes in in-wheel motors with surface permanent magnets on their operating parameters.

3.2. Axial-Flux Motors

Axial-flux motors are categorized into different groups based on their rotor structure: axial-flux induction motors with a squirrel cage rotor [83,84,85], axial-flux reluctance motors with direction-dependent rotor reluctance [86,87,88,89], axial-flux motors with permanent magnets mounted on the rotor surface, and axial-flux motors with internal permanent magnets integrated inside the rotor.

There are three types of stator structures in axial-flux motors: coreless [90,91,92], slotless [93,94], and slotted [95,96]. Stators are typically made of materials such as stamped laminations [97], amorphous metals [98], hybrid multi-materials [99,100,101], or soft magnetic composites [95,102,103,104]. The stator windings can also be printed on PCBs [90,105,106]. Additionally, these motors may have more than one stator or rotor.

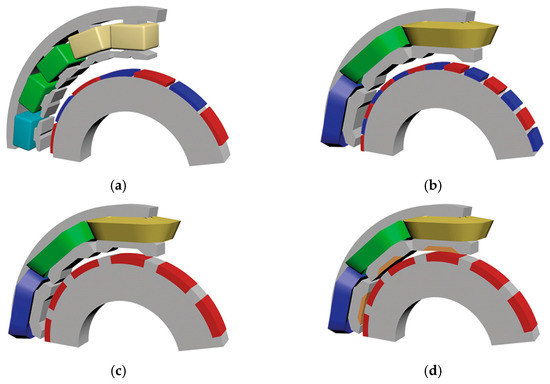

Researchers are focusing on optimizing the geometry of permanent magnets in axial-flux motors, similar to the work undertaken in the design of in-wheel motors with permanent magnets. Research conducted on single-sided axial flux permanent magnet (AFPM) machines has contributed to the reduction in torque ripple, as shown in [107]. The authors used the arc profile for the conventional hexagonal-shaped PM—see Figure 8. The proposed new hexagonal-shaped PM reduced air gap flux density, hence reducing cogging torque and torque ripple. During the study, the authors assumed that the volume of magnets in conventional and proposed hexagonal-shaped magnets would remain constant. In addition to adjusting the magnet’s dimensions, they proposed that its surface be convex, thus modulating the thickness of the air gap between the magnets and the stator teeth. This work resulted in keeping the average torque constant, reducing the THD (total harmonic distortion) coefficient from 1.33% to 0.79%, reducing torque ripples from 18.9% to 12% of the average torque, and reducing cogging torque by over 36%.

Figure 8.

Single-rotor, single-stator axial-flux permanent magnet motor tested [107]. (a) View of the motor, (b) Top view and cross-section of a permanent magnet.

A broader scope of research related to rotor topology is described in [108]. The authors’ primary goal was to reduce cogging torque, which is directly related to the reduction in higher harmonic induction content in the air gap. The study focused on an AFPM motor with one stator and one rotor. The motor had permanent magnets placed on the rotor, and their shapes were varied to find the best design. Computer simulation results were analyzed for various magnet configurations, including flat-top trapezoidal magnets, skewed magnets, curved-shaped magnets, and curved skew magnets. The study revealed that the motor with curved skew magnets had the lowest total harmonic distortion (THD) value, which was three times lower than that of flat-top trapezoidal magnets. Additionally, the peak-to-peak cogging torque decreased by more than two times, with a 10% reduction in back EMF.

An interesting study on a single-sided axial-flux motor (AFM) with one rotor and one stator can be found in [109]. The authors explored the concept of eliminating the use of permanent magnets in the design of such motors. The test results showed torque-to-weight ratios based on different excitation types (neodymium-boron magnets, ferrite magnets, and electrical) and air gap thicknesses (ranging from 0.05 to 1 mm). The authors demonstrated that for air gaps thicker than 0.1 mm, the use of neodymium-boron magnets resulted in a torque-to-weight ratio four times higher than with other excitations. The authors also noted that as the air gap thickness decreased, the increase in this ratio compared to electrical excitation was less significant. Specifically, for air gaps thinner than 0.1 mm, a motor with electrical excitation outperformed other solutions in terms of torque-to-weight ratio.

As mentioned earlier, electric motors used in electric vehicle drives should have the highest possible torque density. Research in this area has been conducted, for example, in [110]. A design solution was considered to achieve the maximum power density and average torque. The research focused on an axial-flux permanent magnet motor (AFPM) with a single stator and two rotors. In the tested motor, permanent magnets were installed on the rotor, and overlays made of SMC material were added to them. During the tests, power and torque densities were evaluated for several stator material combinations. The research included a yokeless motor, a motor with a yoke made of grain-oriented material, a motor with a yoke made of non-oriented material, and a motor with a yoke separated into two sections (tooth and yoke). In the last topology, the stator sections consisted of grain-oriented material arranged in various directions. The findings showed that the yokeless motor had a 40% higher power density and 17% higher torque density than the other examined options. In turn, the use of two parts of the stator yoke with different orientations increased both power density and torque density by approximately 2% compared to a yoke made of grain-oriented material.

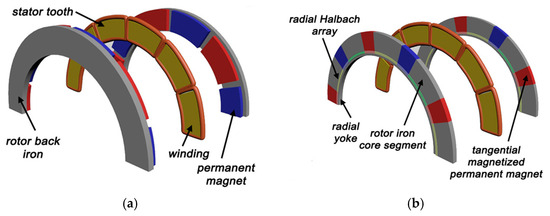

Another line of research focuses on reducing the mass of permanent magnets while increasing torque density. In [111], the authors presented an innovative concept of rotor construction. They compared two approaches: the yokeless and segmented armature axial-flux permanent magnet motor (YASA) and a parallel magnetic circuit yokeless and segmented armature axial-flux permanent magnet motor (PMC-YASA)—see Figure 9. Both designs were intended for use on a 15-inch wheel hub. The main objective of the research was to minimize total losses in both the core and permanent magnets. While the motor’s dimensions remained constant, the rotor topologies have changed significantly. Instead of using axially magnetized permanent magnets (YASA motor), tangentially magnetized permanent magnets and a radial Halbach array were used. As a result of these modifications, the axial length of the PMC-YASA motor has been reduced compared to the YASA motor. Additionally, the stator teeth, rotor back iron, rotor iron core segments, and the radial part of a yoke were made of a soft magnetic composite material. An added benefit of this proposed solution was that the PMC-YASA motor required 38% less mass of permanent magnets than the YASA motor. The new topology reduced the total harmonic distortion (THD) of the back EMF waveform by half, increased the maximum torque by 9%, and decreased total losses in the rotor iron and permanent magnets by half.

Figure 9.

Comparison of motor topologies [111]. (a) YASA motor topology, (b) PMC-YASA motor topology.

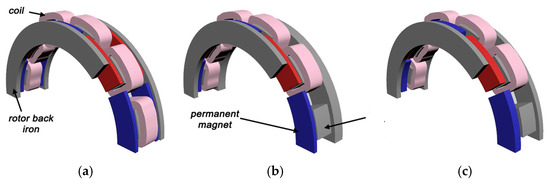

Reducing the bulk of permanent magnets used in motor manufacturing is a significant scientific challenge. In pursuit of this goal, another team of researchers examined the same type of motor (YASA) [112]. The authors studied three motor designs to determine which of them allowed for the highest overloads—examples of topologies are shown in Figure 10. The estimated total power losses generated for a given constant load torque at a specific speed indicated the possibility of overloading the motors. The following topologies were tested: the topology with one and two rotors, and the topology using ferrite and neodymium magnets. The axial length, active diameter, slot depths, and copper volume remained consistent across all three motor topologies. The stator was made of SMC material in all situations.

Figure 10.

YASA topologies of tested motors [112]. (a) Initial version, (b) single-sided motor with half the total magnet volume as the initial version, (c) single-sided motor with the same total magnet volume as the initial version. Permanent magnets are marked in blue and red, the core is marked in gray, and the windings are marked in light pink.

Research results showed that the motor with neodymium magnets generated more than twice the torque compared to the motor with ferrite magnets. Although the introduction of ferrite magnets considerably reduced the magnet losses, additional copper losses, and total stator core losses, the overall losses increased several times. Based on these observations, the authors concluded that for naturally cooled motors, the single-sided motor has better parameters than the YASA topology. For motors with high torque density and forced cooling, the YASA motor is the preferred option.

The permanent magnet vernier machine (PMVM) is a popular alternative motor topology for low-speed direct-drive applications, such as electric vehicle motors. Compared to radial-flux PMVM, axial-flux PMVM has a compact axial structure and high power density. A study on a single-stator single-rotor PMVM can be found in [113], where the authors focused on improving the geometry of the stator teeth and selecting the dimensions of the permanent magnets in the rotor. As other authors note, the relationship between the dimensions of the specified motor components and the generated torque, as well as the axial forces acting on the rotor, should be taken into account. The authors demonstrated that reducing the height of the stator tooth enhances the axial force but decreases the generated torque while increasing the magnet field arc coefficient increases both the axial forces and the generated torque. In the improved motor design, the radial force was reduced by approximately 18%, while the generated torque was reduced by only 2%.

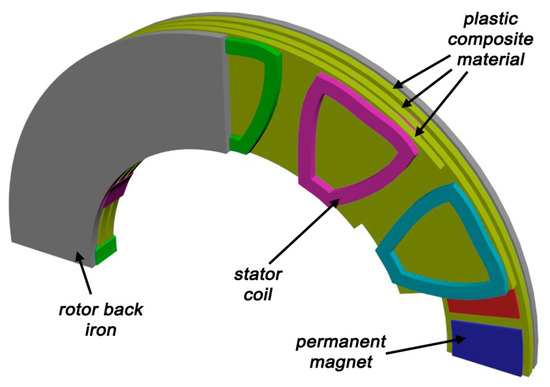

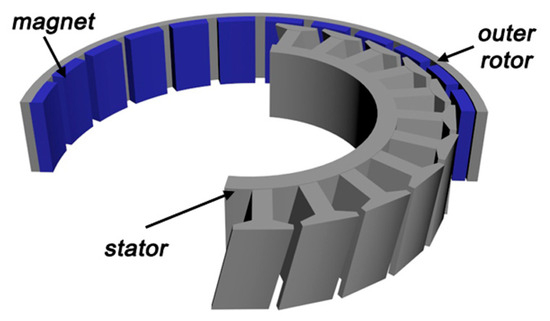

Research conducted by various teams of scientists goes beyond determining the sizes and shapes of the parts of the magnetic circuit of axial-flux motors that provide the highest possible torque density and motor efficiency. An important factor to consider is the weight of electric motors for solar-powered vehicles, as detailed in [114]. In this research, the authors compared a commercially available single rotor-single stator motor with a coreless multi-disc version with air gap concentrated windings–see Figure 11.

Figure 11.

Coreless motor with two stator discs [114].

The number of stator disks was varied during the coreless motor testing. Three models with one, two, and three stators were investigated, considering modifications in the number of poles and coils. The tests assumed that the air gap, active volume, PM mass, and steel mass remained constant. The tests showed that the highest torque density was achieved by the motor with three stator disks, while the lowest copper losses were achieved by the motor with 16 poles and 12 coils. In turn, the 32 poles/24 coils combination resulted in the lowest copper mass. Moreover, the proposed coreless motor topology was 40% lighter than the commercially available AFPM motor, while reducing the rated torque by approximately 40%. The proposed solution had the advantage of achieving more than double the rated speed.

Table 4 summarizes the effectiveness of the described design ideas in improving the operating characteristics of axial-flux motors for LEVs.

Table 4.

The influence of design changes in axial-flux motors designed for use in LEVs.

3.3. Switched Reluctance Motors

It is known that reluctance machines generate torque by utilizing the variable reluctance of the rotor. Depending on the stator topology and control system, they are classified as synchronous reluctance machines (SynRM) or switched reluctance machines (SRM). The SRM stator is salient and wound with concentrated coils around each pole, while the SynRM stator typically has a distributed winding. The rotor usually does not have windings, although there are commercial solutions that include a starting cage. The advantages of reluctance motors include durability, relatively high efficiency, low torque ripple, low production costs, and, above all, no permanent magnets in the rotor.

The search for an SRM topology that offers the highest torque density, similar to other motor types discussed, remains a significant challenge. For instance, research utilizing the metaheuristic Gray Wolf Optimization algorithm to optimize the geometric dimensions of the motor has been conducted [115]. In this study, the authors explored various SRM topologies and optimized the dimensions of the stator and rotor poles. The examined topology is depicted in Figure 12. In the initial phase of the study, conventional SRMs with 6/4, 8/6, and 12/8 topologies were compared, revealing that their rated torque, torque density, and efficiency differed by only 2–4%. In the subsequent phase of the research, the 12/8 SRM was optimized. By maintaining the same outer volume, the rated torque increased by 120%, the torque density increased by 170%, and the efficiency improved by 2% compared to a conventional 12/8 switched reluctance motor.

Figure 12.

Initial (top) and final (bottom) optimized SRM [115].

Another team studied the same type of motor, the 12/8 SRM, but focused on the winding arrangement rather than the geometric dimensions of the motor [116]. The aim of the research was to find a winding arrangement that could provide the highest average torque, the lowest torque ripple, reduce core losses (by reducing flux reversal), and maximize motor efficiency. Two winding arrangements were examined: three short-pitch winding variants for single-phase excitation and two full-pitch winding variants for two-phase excitation. In the short-pitched winding, each coil was wound around a single stator pole, while in the fully pitched winding, each coil spanned the surrounding three adjacent stator poles. Research and calculations have shown that, depending on the winding arrangement, the average torque can vary ten-fold and the torque ripple can vary by a factor of fifteen. The highest average torque was achieved by one of the fully pitched winding variants, while one of the short-pitched winding variants allowed for minimizing total losses while achieving 85% efficiency across a wide speed range.

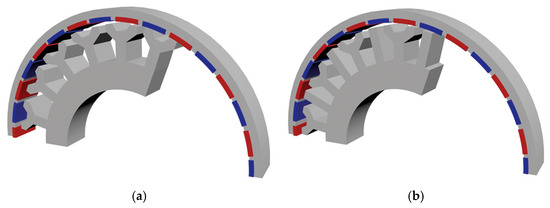

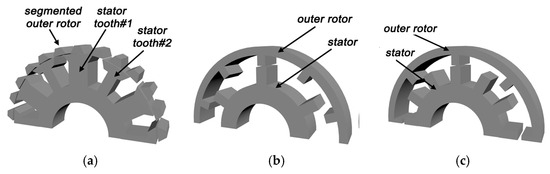

Outer-rotor SRM topologies are of interest when the motor is mounted in the wheel of an electric vehicle. Research on three topologies of this type of motor was described in [117]. All motor topologies were designed to generate the same torque of 18 Nm at a specified speed of 600 rpm. The following topologies of switched reluctance motors were tested: 12/26, 6/10, and 12/8, as shown in Figure 13. During the tests, it was assumed that the external diameter of the motors would not vary and that the maximum current density in the windings would remain constant. Moreover, the stator package would have a maximum length of 40 mm and an air gap thickness of 0.4 mm. The initially proposed topology (12/26 SRM) had an innovatively designed rotor, while the core was built in two variants with different lamination materials. The research conducted showed that the best motor efficiency (88%) was achieved by the 12/26 SRM with a core made of M27-29G material. The same motor with unchanged dimensions and a core made of M19-24G material achieved 4% less efficiency. The torque ripple of the motor with a package made of M27-29G material was more than twice that of the motor with a core package made of M19-24G material. Torque density was also 25 percent lower. At the same time, the 12/26 SRM with a core made of M19-24G material had significantly lower torque ripple and a 20% higher torque density than the other two solutions, 6/10 and 12/8 SRM.

Figure 13.

Investigated outer-rotor SRM topologies [117]. (a) 12s26p segmented rotor SRM, (b) 6s10p outer-rotor SRM, (c) 12s8p outer-rotor SRM.

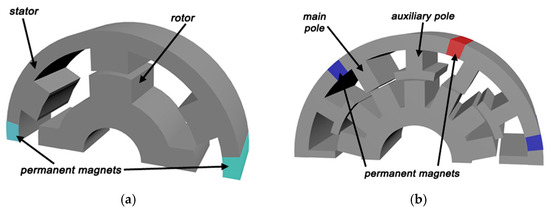

A similar line of research was conducted by a team investigating the hybrid excitation of a switched reluctance motor (HESRM). This research aimed to increase average torque and decrease torque ripple without altering the motor topology or using permanent magnets [118]. In known HESRM designs, additional permanent magnets are used to achieve the intended goal. In this case, the study was carried out on a 12/8 field 3-phase SRM with hybrid excitation. To achieve the goal, the main and auxiliary poles of the stator were separated—see Figure 14. It should be noted that in the recommended motor, both main and auxiliary windings generate effective flux. Based on the test results, the prototype motor was compared to a conventional SRM with the same geometric dimensions. The comparisons showed a several-fold increase in the average torque generated by HESRM over a wide range of excitation currents. This difference also persisted over a wide speed range (from 1200 to 3600 rpm). Additionally, the torque ripple was reduced by nearly three times compared to a conventional motor.

Figure 14.

Motor topology of 12/8 pole HESRM [118].

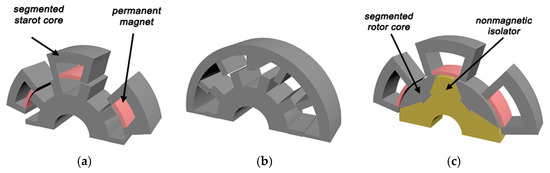

The challenges of implementing hybrid excitation in a segmented stator-switched reluctance motor (SRM) with permanent magnets were discussed in [119]. In this research, experiments were performed on a 12/10-pole PM HESRM with a segmented stator and a 12/10-pole conventional SRM. Both motors had identical geometric dimensions. The segmented stator structure proposed is illustrated in Figure 15. The stator of the segmented HESRM was composed of six separate U-shaped segments, with an NdFeB permanent magnet placed between two poles in each stator segment. For the tested motors, the difference in static torque varied from 4% to 40%, depending on the excitation current. The torque ripple for the PM HESRM was found to be 20–40% smaller than that of the conventional SRM. The proposed design is characterized by higher torque density (in the same range of up to 20–40%) and efficiency increased by 4–10%. It should be noted that all mentioned parameters depend on the control algorithm (current chopping control or angle position control) and speed. Further detailed investigations of the same motor were conducted and reported in [120]. Their goal was to analyze how the width of permanent magnets affects average torque and how the rotor pole-arc coefficient influences both average torque and torque ripple. Studies have shown that increasing the thickness of permanent magnets in the range from 2.5 to 8.5 mm led to an approximately 20% increase in the average torque (for a given current). In turn, increasing the rotor pole-arc coefficient resulted in a 44% decrease in average torque and a 12% reduction in ripple torque. A study on the effect of permanent magnets (PMs) placed between the stator teeth on a two-phase 16/18-pole SRM was discussed in [121]. The study compared two motors with the same topology, one with permanent magnets and the other without. It was demonstrated that the presence of PMs significantly reduced cogging torque. Depending on the phase current, the average torque increased by 250%, while the ripple torque remained relatively constant. Further modifications to the rotor design and detailed research on the 12/4 PM-HESRM were presented in [122]. The research team proposed a new topology of a segmented rotor with only four poles. The operational parameters of this proposed structure were compared to those of the 12/10 PM-HESRM and detailed in [119]. Both configurations had similar geometric specifications, except for the stator pole arc, which was 16 degrees for the 12/4 structure and 15 degrees for the 12/10 structure. The proposed design incorporated both ferromagnetic and nonmagnetic materials in the rotor—see Figure 15c. As a result of the research, it was found that the 12/10 motor generated higher average torque at low speeds, while the new proposed design generated higher average torque at high speeds. For instance, at 500 rpm (at 120 V), the torque values were 5 Nm and 3.8 Nm, respectively. At 1500 rpm (at 150 V), it was 1.67 Nm and 4.25 Nm, and at 2000 rpm (at 150 V), the values were 0.96 Nm and 2.55 Nm. Both designs had relatively low cogging torque (less than 1% of average torque), but the new solution had 3–4 times lower cogging torque compared to the 12/10 PM-HESRM.

Figure 15.

Investigated motor topologies. (a) Proposed segmented-stator 12/10 PM HESRM [119], (b) conventional 12/10 SRM [119], (c) proposed 12/4 PM-HESRM with both segmented stator and rotor [122].

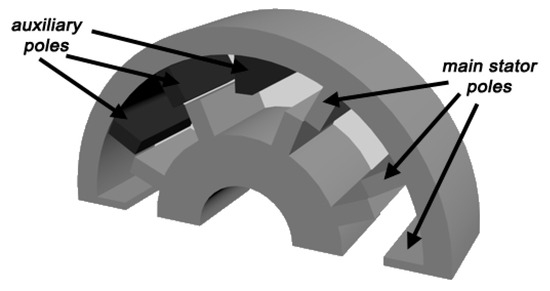

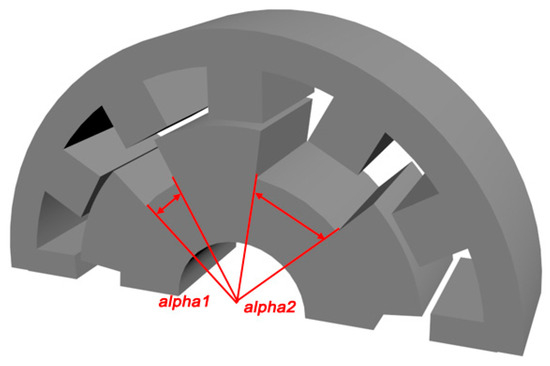

The concept of creating auxiliary stator poles is not limited to solutions using hybrid excitation, as seen in the HESRM topology. An example of such a solution for a segmented rotor SRM can be found in [123]. The SSRM solution combines the main poles (excited by current in windings) with auxiliary stator poles. The main poles have exciting windings, while the auxiliary poles serve as flux return pathways without exciting windings. The rotor consists of several separate segments, each embedded in a non-magnetic isolator, as shown in Figure 16. The tested motor was optimized by applying various geometric constraints. Compared to the initial design, the average torque increased by 40%, and the torque ripple was reduced by 66%. It is worth noting that the torque ripple in the initial design was 94% of the average torque, whereas in the optimized design it was only 32%. After optimization, the motor efficiency remained relatively stable at around 90%.

Figure 16.

Segmented rotor SRM topology [123].

A different line of research is described in [124]. Conventional SRM motors are known to have a relatively high torque ripple. Therefore, the authors focused on finding a motor topology that significantly reduces torque ripple compared to conventional designs. As a result, they proposed the use of a six-phase SRM with a misaligned rotor segment and two phases operating simultaneously—see Figure 17. It is known that torque ripple decreases as the number of rotor poles increases. Despite this, the authors suggested reducing the number of rotor poles. They conducted a study and evaluated the proposed 12/4 6-phase SRM and compared it with the conventional 12/8 3-phase SRM approach. It was assumed that the stator outer diameter, stack length, and air gap thickness of both motors would be the same during testing. A notable benefit of the suggested motor topology is a 45% reduction in torque ripple (at 1500 rpm). However, at 3000 rpm, this reduction is practically imperceptible. Another significant benefit is a 3.5-fold increase in the average static torque generated for a given current. The drawback of the longer length of the copper winding in the recommended topology is that it reduces the motor’s efficiency. Unfortunately, the authors did not provide the exact amount by which efficiency decreased. In another investigation, an identical 12/4 segmental rotor SRM was compared with a 12/10 conventional SRM and a 12/10 segmental rotor SRM [125]. These motors shared identical design and operating features, including six phases, the outer diameter of the stator and rotor, stack length, and rated current. The research found that the 12/4 segmental rotor SRM had the highest average torque for a given current. Additionally, the average torque in the 12/10 conventional SRM was 14% lower, while in the 12/10 segmental rotor SRM, it was 22% lower. The corresponding normalized torque ripples were 7.4%, 9.4%, and 13.9%, respectively.

Figure 17.

A six-phase SRM with a misaligned rotor segment [124].

Previous descriptions of SRM topologies that can increase average torque and reduce torque ripple did not mention the effect of stator pole shape or stator pole dimensions on these quantities. To address this gap, the research reported in [126] was conducted. The study focused on the 24/16 SRM and compared its operating parameters with the traction motor used in the 2010 Prius drive system. Geometric limitations were determined by the stator outer diameter and rotor axial length of the Prius traction motor. The 24/16 switched reluctance motor underwent multi-criteria optimization, where the stator pole height, stator taper angle, and rotor pole arc angle were optimized within appropriate ranges. The study revealed that increasing the stator pole height from 24 to 27 mm resulted in a 5% reduction in average torque, while the normalized torque ripple showed no decreasing trend. It was found that changing the stator taper angle from 0 to 7 mechanical degrees increased the average torque by 17% and reduced the normalized torque ripple by 30%. However, there was not much difference in the average torque and normalized torque ripple when the rotor pole arc angle was changed from 7 to 7.5 mechanical degrees. Five stator pole shoe shapes were tested but did not lead to significant improvements in the average torque or normalized torque ripple. Nevertheless, the efficiency of the motor under examination was found to be comparable to the efficiency of the traction motor used in the Prius.

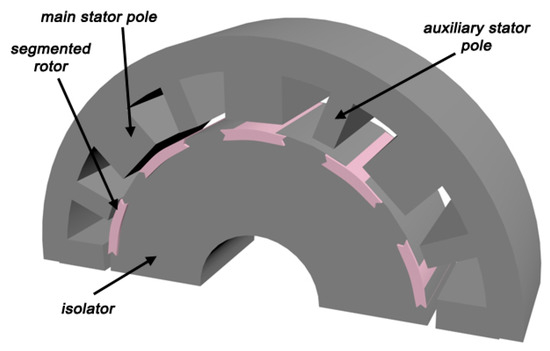

Although the original concept of switched reluctance motors did not involve the use of permanent magnets, there are examples of studies on permanent magnet switched reluctance motors (PM-SRMs) in the literature [127]. In this study, the motor topology used includes a rectangular non-rare earth magnet of the Alnico type buried in the stator yoke—see Figure 18a. Despite the use of an unusual 6/4 PM-SRM design, the study showed a significant improvement in operational metrics. Compared to the 6/4 SRM without an Alnico magnet, the average torque (for the specified current) increased by more than 60%, the normalized ripple torque remained relatively constant, and the efficiency increased by 5–7% depending on the speed. The authors of [128] provide more detailed research results on the influence of the size of SmCo permanent magnets inserted in the stator of the two-phase 8/10 PM-SRM. During the tests, the thickness of the magnets was changed in the range of 1–5 mm, and the research results were compared to those obtained for a conventional 8/10 SRM (without permanent magnets) with the same geometric dimensions. The proposed design resulted in a 46% increase in average torque and a 6–7% improvement in efficiency. It was observed that cogging torque accounts for several percent of the average torque and varies significantly with increasing PM thickness, eventually approaching zero for a thickness of 1 mm. Another research team conducted a more detailed analysis of the same type of motor [129], expanding the scope to investigate the impact of both the width and thickness of permanent magnets. During the tests, the PM width ranged from 1 to 5 mm, and the thickness varied from 1 to 10 mm. The results confirmed the findings presented in [128]. Another approach involving PMs placed in the rotor teeth was discussed in [130]. The 12/10 external rotor SRM with both main poles and auxiliary poles in the stator was analyzed. The motor core was composed of six different ferromagnetic materials with different magnetization curves and specific material losses. The study revealed that the choice of material affects the average torque generated (within 10%) but not the ripple torque. The next phase of the research focused on examining how the orientation of the magnets installed in the main poles influenced the motor’s performance. Permanent magnets (PMs) were tested in both horizontal and vertical positions relative to the main pole axis. It was shown that the motor with the PM placed vertically generated 10% more average torque compared to the alternative PM orientation, exhibited 35% less torque ripple, and had more than twice as less cogging torque.

Figure 18.

Topology of the permanent magnet switched reluctance motor (PM-SRM) [127]. (a) typical PM-SRM motor design, (b) proposed design including two types of stator poles (main and auxiliary poles).

Another team of researchers proposed a modular stator hybrid-excitation switched reluctance motor (MS-HESRM) topology that integrates permanent magnets (SmCo24) into the stator yoke to increase torque density [131]. The stator modules have a unique π-shape, with PMs placed between them (see Figure 18b). The direction of magnetization of the permanent magnets coincided with the magnetic field of the excitation coils. In the tested topology, the stator poles can take two different shapes. An excitation winding was wound around the main pole, while the auxiliary pole (without excitation winding) provided a short flux path. The rotor consisted of 14 poles with a classic shape. The researchers predicted that selecting an appropriate pole arc for the auxiliary pole would lead to a significant reduction in cogging torque. During testing, the sizes of the permanent magnets and arcs were optimized for both the main and auxiliary poles. The research revealed that the thickness of the permanent magnets had little effect on average torque but had a significant impact on cogging torque. Cogging torque decreased as the thickness of the permanent magnet decreased, although it remained minimal at all thicknesses. On the other hand, the width of the permanent magnets had a significantly larger impact on average torque. Increasing the width of the permanent magnets resulted in a corresponding increase in average torque by up to 50% for a given excitation current. It was noted that the effect of permanent magnet width on the cogging torque was less pronounced but still noticeable. The authors also noted that adjusting the arc of the auxiliary pole can increase the cogging torque amplitude by up to five times, highlighting the importance of selecting the appropriate pole arc. A comparison of operational characteristics between the proposed design and a conventional 12/14 SRM showed that the MS-HESRM generated 2.5 times higher average torque. However, the disadvantage of the proposed design was a 15% increase in torque ripple.

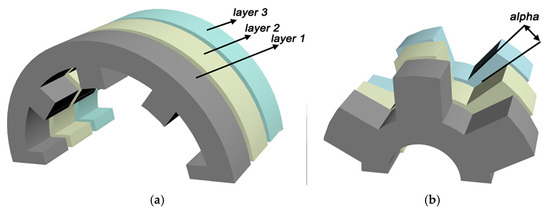

According to research conducted by various scholars, skewed rotor poles have been found to help reduce torque ripple. In practical applications, a skewed rotor is achieved by introducing multiple rotor layers that are shifted by a specific angle, as illustrated in Figure 19. This configuration, known as a multi-layer SRM, consists of a stator divided into layers that are not rotated relative to each other. Additionally, each stator layer has its own excitation windings positioned at the poles. A comparative analysis of several multi-layer SRM topologies can be found in [132]. The study investigated both the conventional multi-layer 8/6 SRM (where similar phases in different stator layers are excited simultaneously) and the proposed design of a multi-layer 8/6 SRM (where similar phases in different stator layers are excited by a phase-shifted current). The tests compared the operational parameters of the motors, increasing the number of layers from two to five and the displacement angle (in the proposed solution) from two to ten degrees. In a conventional motor, the displacement angle remained constant. The proposed design showed a significant reduction in torque ripple depending on the number of layers and displacement angle. In the conventional design, the torque ripple reached a value of 95% of the average torque, while in the proposed design it was reduced to 4.4% without reducing the average torque. It was also found that for each number of layers, there is a specific displacement angle for which the torque ripple is the smallest. For example, for five layers, the angle is 3 degrees; for four layers, it is 3.75 degrees; for three layers, it is 5 degrees; and for two layers, it is 7.5 degrees. A similar technique was used to improve the operating characteristics of a 12/8 switched reluctance motor. The conventional and recommended designs were compared using the same assumptions as for the 8/6 SRM. In this scenario, with the five-layer structure, the torque ripple was reduced from 127% (conventional design) to 6.2% (proposed topology) without affecting the average torque.

Figure 19.

Topology of multi-layer 8/6 SRM [132]. (a) Three-layer stator, (b) rotor with shifted layers.

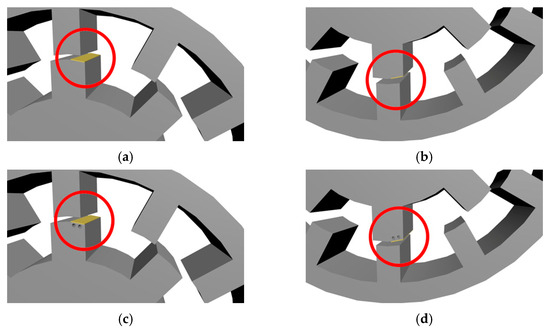

In the case of the SRM, research on the effect of non-uniform air gap thickness on torque ripple is not widely reported in the literature. However, there are examples in the literature indicating that torque ripple can be reduced using this technique [133,134]. The work [133] describes research on a 12/8 SRM. The authors proposed the use of a mirror structure to create a non-uniform air gap. The effectiveness of two solutions was tested: the first one, in which the M-type design has a cutout section on the right side of the pole, and the N-type design on the left side; and the second one in which one or two holes were drilled—see Figure 20. The first design solution reduced the average torque by 1.5% (for a given excitation current), and the second one (with one hole) reduced it by 2.2%. By changing the bevel shape (first design) and the size and position of the hole (second design), the torque ripple was reduced from 68.8% (conventional design) to 61.8% (two-hole design). Then, testing the same type of motor by manipulating the shape of the rotor poles, the authors managed to reduce the torque ripple from 69% to 39% and the average torque by only 3% [134].

Figure 20.

Bi-directional non-uniform 12/8 SRM topology [133]. (a) M-type design #1, (b) N-type design #1, (c) M-type design #2, (d) N-type design #2. The red circle marks places with a changed structure or configuration of elements.

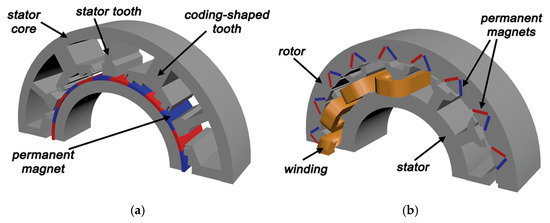

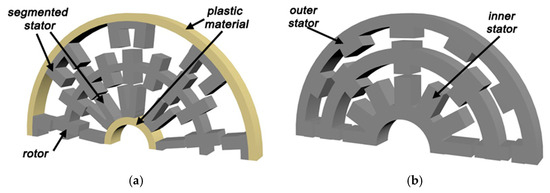

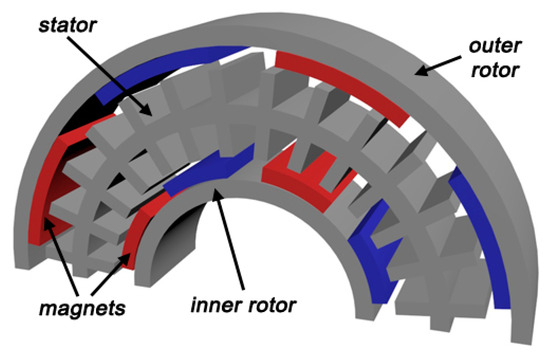

An interesting research direction regarding the construction of a double-stator is discussed in many papers [135,136,137]. For instance, in [135] the operation of a switched reluctance machine with a segmented double-stator (16/18/16 SDS-SRM) was investigated and illustrated—see the SDS-SRM topology in Figure 21. The authors’ main task was to select appropriate sequences of winding excitation for the external and internal poles of the stator. Throughout the study, the authors identified four current excitation sequences, one of which showed promise. Using this sequence, the motor underwent a more detailed analysis. The motor’s operating parameters were evaluated both when energizing the windings of individual stators and when simultaneously energizing the windings of both stators. The authors compared the average torque and torque ripple in the mentioned scenarios at a specific speed. The conducted tests revealed that the average torque when energizing the external stator windings was 6.15 Nm, with a ripple torque of 112%. However, when energizing the internal stator windings, the values were 5.12 Nm and 112%, respectively. When both stator windings were energized, the values were 11.2 Nm and 54%, respectively. In comparison, for a conventional DS-SRM, when both stator windings were excited, the values were 10.5 Nm and 115%, respectively.

Figure 21.

The topologies of double-stator switched reluctance motors [135]. (a) Segmented-double-stator SRM, (b) conventional double-stator SRM.

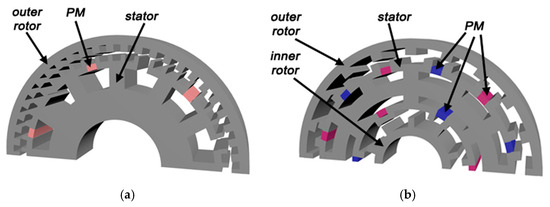

There are descriptions in the literature of switched reluctance motors that use permanent magnets to generate higher average torque while minimizing cogging torque. Based on these works, it is clear that further research is needed to recommend new topologies with reduced magnet volume. One such innovative topology is presented in [138], where the authors propose a 48/50-tooth exterior-rotor PM-SRM with the PMs embedded between specific stator poles, as shown in Figure 22a. The test results of this innovative motor were compared to the same design without PM and a conventional 12/10 SRM design. Calculations have shown that the proposed PM-SRM topology has a negligible cogging torque (tenths of a percent of average torque). Additionally, the PM-SRM generated up to 100% higher average torque compared to the conventional 12/10 SRM for given excitation currents. On the other hand, the proposed topology without PMs also generated 15–60% higher average torque than the 12/10 SRM, depending on the excitation current value. Another topology showing a double-rotor permanent magnet SRM (DR-PMSRM) using the same technique of embedding magnets between stator teeth is described in [139]. This design included permanent magnets in both portions of the stator due to the presence of two rotors. The proposed DR-PMSRM combined two SRMs: 12/10 and 24/20, as shown in Figure 22b. In order to compare operational characteristics, a conventional DR-SRM with identical construction dimensions was also constructed. Various combinations of the number of teeth per stator pole were selected to determine the optimal number of stator and rotor teeth. The research findings indicated that the proposed DR-PMSRM design can generate up to 60% higher average torque compared to the DR-SRM, depending on the excitation current value. While the suggested DR-PMSRM topology design had minimal cogging torque, the inner and outer rotors generated different cogging torques. The inner rotor generated virtually zero cogging torque, whereas the cogging torque generated by the outer rotor was several times higher but still negligible. The authors reported that at 1000 rpm, the inner rotor of the DR-PMSRM generated 50% higher average torque and 100% lower torque ripple compared to the DR-SRM. The outer rotor of the DR-PMSRM had a 25% higher average torque and a 50% lower ripple torque, respectively.

Figure 22.

The topologies of investigated PM-SRMs. (a) The 48/50-tooth exterior-rotor PM-SRM [138], (b) topology of DR-PMSRM [139].

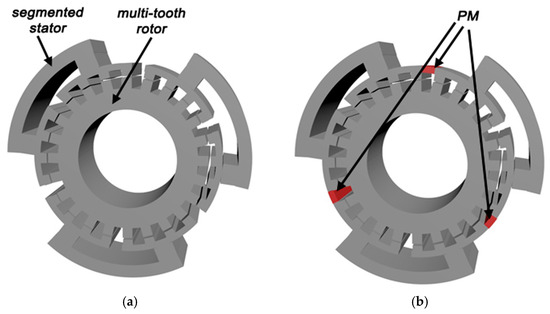

The concept of creating multi-tooth SRMs was modified and described in [140]. Two structures were tested during the research. The first topology was a 3-phase 24/25-tooth MT-SRM where the flux sources are two concentrated windings located at the stator poles. The second topology was a 3-phase 24/25-tooth MT-HESRM with PMs embedded between adjacent stator teeth belonging to different excitation phases—see Figure 23. In both topologies, the stator was composed of three separate C-shaped modules with concentrated windings. The advantage of the proposed MT-HESRM was that it generated approximately zero cogging torque because the PM flux at zero excitation current did not tend to cross the air gaps. According to the authors, depending on the speed, the proposed MT-HESRM generated 60–80% higher average torque while maintaining the same torque ripple (120% average torque).

Figure 23.

The topologies of multi-tooth SRMs [140]. (a) The 3-phase 24/25-tooth MT-SRM, (b) 3-phase 24/25-tooth MT-HESRM with PMs.

Table 5 summarizes the effectiveness of the described design ideas in improving the operating characteristics of switched reluctance motors for LEVs.

Table 5.

The influence of design changes in switched reluctance motors designed for use in LEVs.

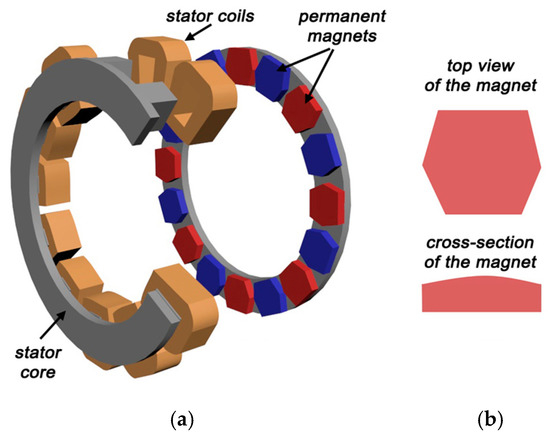

3.4. BLDC Motors

BLDC motors, thanks to their simple topology, provide high starting torque, low noise, and long operating time, achieving efficiency of up to 95% [141]. These types of motors are designed to be mounted inside the rim of a lightweight electric vehicle and are often compared to other designs such as axial flux motors (AFM). An interesting comparison can be found in [142], where the authors compared these two types of motors with the same torque-to-volume ratio. The outer diameters and axial lengths of the motors were clearly different, but they had the same volume. The study used commercial motors with comparable rated torque, efficiency of 91.46% (AFM) and 88.44% (BLDC hub), and total net weights of 22.5 kg (AFM) and 5.2 kg (BLDC hub). As a result of the optimization of both motors, the efficiency increased to 94.9% and 90.35%, respectively. The comparison showed that the AFM achieved higher efficiency, but the torque-to-weight ratio was much more favorable (four times difference) for the BLDC motor. It is known that the use of permanent magnets results in a trapezoidal flux density distribution in the air gap. Combined with the non-sinusoidal current, this is one of the causes of torque ripple. Many researchers are focusing on reducing torque ripple by using techniques such as skewing, using short pitch winding, placing wedges in slot openings, and determining the shape and dimensions of magnet poles. Choosing the appropriate control strategy is a separate aspect leading to torque ripple reduction that is not addressed in this paper. A detailed discussion and comparison of different control strategies for BLDC motors can be found in [143].

As demonstrated in [144], the reduction in cogging torque can be effectively achieved by selecting the magnet material in combination with the magnet thickness and the magnet arc. The tests were conducted on a BLDC motor with 27 slots and 4 poles, featuring a nominal torque of 3 Nm and a rated speed of 1500 rpm. Keeping the motor’s geometric dimensions constant, four types of permanent magnets were used, with their geometric dimensions selected to maintain the motor’s average torque at 3 Nm +/− 15%. The permanent magnets used in the study were Alnico, SmCo, NdFeB, and a ceramic composed of strontium carbonate and iron oxide. The authors determined that the most appropriate dimensions of the magnet are Alnico—13 mm (thickness) and 80 degrees (magnet arc); SmCo—6.35 mm and 66 degrees; NdFeB—2.56 mm and 60 degrees; and ceramic—2.5 mm and 74 degrees, respectively. The tested motors maintained a constant average torque at speeds up to 2600 rpm. In this range, the motor with NdFeB magnets generated an average torque of 3 Nm, while the motor with ceramic magnets generated only 2.55 Nm. Motors equipped with SmCo and NdFeB magnets generated the highest cogging torque, accounting for 36% of the average torque. The motor with Alnico magnets generated a significantly lower cogging torque of only 5%, and the motor with ceramic magnets generated the lowest cogging torque of 1.5%.

The authors, in search of the optimal shape and dimensions of stator slots, introduced a new direction of research on BLDC motors [145]. They tested a BLDC motor with 24 stator slots and four rotor poles composed of permanent magnets. Four different types of stator slots were used in the tests, with sizes chosen to maintain the same average output torque while keeping the slot area constant. The adjusted slot dimensions resulted in varying maximum flux densities in the stator yoke (ranging from 1.33 to 1.52 T) and stator teeth (ranging from 1.56 to 1.74 T). The authors observed torque ripple fluctuations between 45% and 55% of the average torque. A similar research approach to the selection of stator slot sizes was discussed in [146]. The study focused on a three-phase outer-rotor BLDC motor designed for a 10.5-inch rim. The authors aimed to find the optimal relationship between poles and slots, winding turns, and stator tooth width to achieve the maximum back EMF value. Starting with a commercial solution with 27 stator slots and 30 rotor poles, the research identified the motor’s optimal design specifications: 32 rotor poles, 36 stator slots, 20 winding turns (initially 14 turns), and a stator tooth width of 6.12 mm (initially 4.75 mm). This led to a nearly two-fold increase in the EMF(RMS) value and a several percent improvement in efficiency.

Another research team conducted an in-depth study on an outer-rotor BLDC motor with a higher power rating than reported in [146]. The results of their extensive research can be found in [147]. The main goal of the research was to reduce cogging torque while considering the skew of the stator slots. In the first phase of the research, the focus was on a non-skewed motor. Next, the correlation between cogging torque and the length of the magnetic core was determined by changing the core length from 40 to 60 mm. As expected, lengthening the cores resulted in higher cogging torque, with an increase of 66% greater than the ratio of the selected core lengths. In the second phase of the research, a motor with a 50 mm long core was used, in which the skew angle of the stator slots varied from 0 to 1 electrical degree—see Figure 24. The greatest reduction in cogging torque, reaching 98%, was achieved with a slot skew of 1 electrical degree. This topology resulted in a torque ripple of 30%. It is important to note that the use of a skewed topology impacted both the operating characteristics and the speed at which maximum efficiency was reached. However, the maximum efficiency did not change significantly. It is known that the change in average torque due to the skew of the stator slots is speed dependent. At low speeds, the non-skewed motor generated the highest average torque, which was 40% greater than that of the motor with a 1-degree skew. For half the rated speed, the effect of the slot skew on the generated torque was negligible. For speeds higher than the rated speed, the torque generated by the 1-degree skewed motor dominated.

Figure 24.

The topology of a skewed BLDC motor [147].

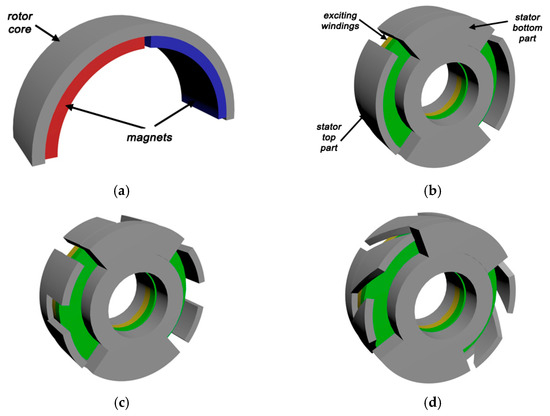

The selection of appropriate slot–pole combinations is an effective method of reducing cogging torque in BLDC motors. The results of work carried out in this area are presented in detail in [148]. The authors described the optimization process of a conventional BLDC motor with an external rotor, which was used in self-balancing electric vehicles. According to the authors, for BLDC motors operating at low speeds and high loads, a high winding ratio and flux linkage can reduce winding losses and improve efficiency. The highest flux linkage can be achieved when the ratio of the tooth tip width to the pole width is 1. However, designers can set a fixed ratio of slot opening to slot pitch. As a result, the ratio of tooth tip width to pole width depends on the slot-pole combination utilized. Therefore, the authors recommend carefully selecting the slot-pole combination that minimizes cogging torque and torque ripple. Test results showed that the cogging torque of the conventional BLDC motor tested was 2.3%. The authors demonstrated that selecting a better slot–pole combination for a conventional 27/30 BLDC motor can improve performance. By choosing the new 30/32 combination, the cogging torque of the tested motor was ten times lower compared to the 27/30 combination. The same line of research was conducted for a 2.5 kW motor [149]. It was assumed that the output power value remained constant throughout the test cycle. Five slot/pole combinations were tested to determine the operating characteristics of the motors. According to the authors, the following combinations were considered suitable for an in-wheel BLDC motor: 24/18, 24/20, 36/24, and 36/30. Studies indicated that changing the slot/pole combination under given constraints increased the rated torque by 26% and motor efficiency by 2%. In the subsequent testing phase, the 24/20 slot/pole combination was selected due to the highest motor efficiency. The stator tooth width, slot opening, slot height, and slot width were assumed to remain constant during the simulations for three different stator slot shapes. The tests revealed that the rated torque changed by 8%, while the efficiency remained almost unchanged.