Abstract

Lithium-ion battery pack performance, safety, and lifespan are significantly influenced by temperature, yet little research has focused on the specific effects of temperature during the drying phase in paint booths. This study aims to analyse how drying temperatures affect battery modules compared to operational conditions (e.g., driving, charging) and to analyse the influence of the battery state of charge on the temperature reached by the traction battery during the drying phase. Various temperature measurement methods, including diagnostic equipment and thermocouples, were employed to conduct tests. Results indicate that the battery pack temperature during the drying phase remains below 60 °C. Comparisons with temperature measurements in other scenarios (e.g., charging, high-temperature parking) show significantly higher temperatures, highlighting the relatively low impact of paint booth drying temperatures on battery thermal management.

1. Introduction

Temperature is a critical factor influencing the safety, cycle lifetime, and performance of lithium-ion batteries (LiBs). Extensive research has focused on how temperature affects the degradation of various LiB components. Studies have examined the degradation of the anode at elevated temperatures [1], the thermal ageing of cathode materials like LiCoO2 and LiMn2O2 [2], and the effects on electrolytes [3]. It has been established that increased degradation rates and decreased state of health (SoH) at higher temperatures are primarily due to changes in electrode surface films and the structure of the LCO electrode [4]. The safe operating temperature range for lithium-ion batteries is typically between 15 °C and 40 °C [5,6] as temperatures above 40 °C can cause significant issues [7,8]. High temperatures can drastically reduce the capacity and lifespan of LiBs, with studies showing a loss of nearly 70% capacity after 500 discharge cycles at 55 °C [9]. This effect greatly shortens the life of LIBs [10]. Failures in lithium-ion batteries can be mechanical, electrical, or thermal, occurring at the cell, module, or battery pack levels [11], potentially leading to Thermal Runaway (TR). Overheating, often due to poor contact connections or excessive heat near the battery pack, is a major concern. High temperatures are also encountered during fast charging and when electric vehicles (EVs) are parked outdoors on hot summer days.

During EV repairs, especially in the paint booth, equipment is used to accelerate the drying process, typically operating from 60 °C to 80 °C for 30 min. While some paint manufacturers have developed products that lower drying temperatures, this usually increases the time the vehicle remains in the booth.

The temperature of lithium-ion batteries must be controlled as it affects their performance, health, and safety. Catastrophic failures sometimes occur due to particularly high excessive temperature variations, which can cause TR leading to fire and consequent explosion. When the separators between the anode and cathode break or melt, the electrodes stop working properly or disappear, and a chemical reaction begins in the lithium that releases oxygen, carbon dioxide, other noxious gases, and a lot of heat. This chemical reaction causes the battery to heat up in a process called TR, a chemical reaction that generates heat and is accelerated by the very temperature it generates, causing it to enter a flashover that often results in fire. The TR is sustained by the heat of the battery, generating more and more heat.

Chemical reactions occur one after the other, forming chain reactions once the temperature increases abnormally under very high mechanical load. The cyclic heat–temperature reaction is the cause of the chain reactions. High heat causes the temperature of the cell to rise, initiating new side reactions, such as the decomposition of SEI (Solid Electrolyte Interphase). These secondary reactions release more heat, thus forming a feedback loop. This cycling at extremely high temperatures continues until the cell undergoes TR.

Lithium batteries can experience TR due to battery defects, battery damage, heat, rapid discharge, or overcharging, resulting in temperatures exceeding 550 °C for lithium-ion batteries and 760 °C for lithium metal batteries. If a single cell generates enough heat for adjacent cells to experience TR, cell-to-cell and module-to-module propagation occurs. TR can result in the release of flammable electrolytes and, in the case of lithium metal, the release of molten and burning lithium.

We can ask ourselves the following question: what could cause a lithium-ion battery in an electric vehicle to burn? A burning battery could be due to overheating or a rupture and leakage of electrolytes. Regarding overheating, under normal conditions, lithium-ion batteries have a protection system that regulates the charge and prevents overheating. When electrolytes rupture and leakage occurs, elements mix and gases are released, which occupy more and more space, generate heat, and crack the battery walls, eventually bursting the battery walls.

On the other hand, operating temperature can also affect the performance of the lithium-ion battery which, over time, will reduce its lifetime.

Most vehicle manufacturers recommend not exceeding a temperature of 60 °C on the battery surface during the drying process for more than 60 min. For this reason, every time an electric or hybrid vehicle drying process is performed, the temperature to which the traction battery is exposed should be controlled and monitored.

Some manufacturers even indicate that the lithium-ion traction battery must be disassembled before the electric vehicle is brought into the paint booth to prevent degradation. Car manufacturers provide procedures to repair electric and hybrid vehicles safely.

Here is what different vehicle manufacturers indicate:

- BMW i3

BMW states that the maximum permissible temperature in the paint booth must not exceed 80 °C with the high-voltage battery unit mounted in the vehicle. To avoid excessive ageing of the high-voltage battery cells, the dwell time should be a maximum of 60 min [12].

- 2.

- Nissan

For the Nissan Leaf, the following is stated [13]:

To use the paint booth, the outer footboard must be kept at a T ≤ 60 °C to prevent damage to the lithium-ion battery.

NOTES:

- -

- Measure the temperature with a non-contact thermometer.

- -

- If there is a cover (resin) over the footboard, it must be removed to measure the temperature.

If the temperature of the outer footboard exceeds 60 °C, remove the lithium-ion battery beforehand and then bring the vehicle into the paint booth. Figure 1 bellow shows the location of the footboard in the Nissan Leaf.

Figure 1.

Location of the footboard [13]. Picture showing the position of the high-voltage battery and the position of the footboard [14].

- 3.

- TESLA

The manufacturer Tesla indicates that before placing the vehicle in the drying booth it must remain indoors, i.e., not outside, at a temperature < 35 °C for at least 12 h [15].

Before putting the vehicle into the drying booth if repairs to the thermal system (air conditioning and heating) have not been completed, the 12 V and high voltage battery must be disconnected to prevent these systems from being activated during drying.

Once the Model S, X, and 3 have been painted, they can be put into the drying booth with the high voltage battery installed, provided the following parameters are not exceeded [16]:

- -

- Maximum drying time: 45 min;

- -

- Maximum firing temperature: 74 °C.

- 4.

- TOYOTA

Toyota does not indicate specific precautions to be taken when preparing an electric vehicle for introduction into the drying booth, this position is based on the assertion that temperatures capable of damaging the high-voltage battery cannot be reached during drying cycles in a paint booth [17].

- 5.

- HONDA

Honda indicates that high temperatures can damage the high-voltage battery, therefore, during the drying phase in the paint booth, ensure that the temperature does not exceed 65 °C [18,19].

- 6.

- AUDI

Audi states the following for the Audi Q5 with high-voltage battery [20]: The drying time for repairs using commercial, depending on the material and manufacturer, ranges between 30 and 60 min at 60 °C. Audi vehicles with high-voltage batteries are equipped with a robust battery that operates efficiently up to 55 °C. However, the cells can sustain damage if the temperature exceeds 70 °C. To prevent exceeding 70 °C, Audi vehicles should not remain in the paint booth for more than 60 min during drying.

If the materials used for the repair require a drying time longer than 60 min, an alternative drying method, such as infrared rays, must be used.

Additionally, it is important to note that during workshop repair procedures, the high-voltage system must typically be disconnected for safety reasons when working on electric vehicles. Disconnecting the high-voltage system also shuts down the battery cooling system, which could otherwise overheat and be damaged.

High temperatures can impact the service life of traction batteries. It is important to note that, during the vehicle painting process in the final phase (colour + varnish), the varnish typically requires drying in the booth at 60 °C for 30 min, as recommended by several suppliers. Alternatively, another approach is to use a varnish type that can air-dry or be booth-dried at 40 °C, albeit requiring more than 30 min. While effective, this method doubles the drying time, slowing down repairs and reducing overall workshop efficiency.

Audi has also highlighted another potential solution for drying the paintwork of electric vehicles without causing damage or compromising workshop performance: shortwave infrared drying technology. This technology penetrates directly into the substrate surface, whether metal, plastic, or other materials, heating and curing the coating from the inside out, focusing specifically on the painted panels.

In summary, it can be stated that most manufacturers indicate that when an electric vehicle is introduced into a paint booth during the drying phase, it should not exceed 60 °C for more than 60 min. There are exceptions, such as Tesla, which allows 74 °C but for less time (45 min). In other words, if the drying temperature is increased, the time spent in the paint booth must be shorter to avoid degradation and damage to the high-voltage traction battery.

The traction batteries of electric/hybrid vehicles must meet safety requirements, as defined in UN/ECE Regulation No. 100: Uniform provisions concerning the approval of vehicles with regard to the specific requirements of the electric powertrain. Therefore, these batteries undergo thermal tests as part of these safety requirements that must be fulfilled.

Annex 9 B of Regulation No. 100 specifies the thermal shock and cycle tests to which the battery is subjected. These tests are designed to assess the SAEER’s (Rechargeable Electrical Energy Storage System’s) resistance to abrupt temperature changes. The procedure involves subjecting the battery to a defined number of temperature cycles, starting from ambient temperature and alternating between high- and low-temperature extremes. This simulation replicates the rapid ambient temperature changes that a SAEER may encounter during its operational lifespan.

Before testing the battery, the State of Charge (SoC) must be adjusted by charging it to the maximum SoC specified by the manufacturer for normal operation, ensuring the charging process is completed. If the device being tested does not regulate SoC independently, it should be charged to at least 95% of the maximum SoC defined by the manufacturer for its specific configuration.

Furthermore, all protective devices that could impact the battery’s operation during testing and are relevant to the test results must be active. The battery under test should undergo cooling and heating over multiple cycles. Initially, the battery should be stored for a minimum of six hours at a test temperature of 60 ± 2 °C, or higher if required by the manufacturer. This is followed by a storage period of at least six hours at a test temperature of −40 ± 2 °C, or lower if specified by the manufacturer.

The maximum time interval between the extremes of test temperatures should not exceed 30 min. This operation must be repeated until a minimum of five complete cycles have been conducted. Following these cycles, the tested battery should be stored for 24 h at an ambient temperature of 22 ± 5 °C. After this storage period, a standard cycle, as specified in the Regulation, must be performed. The test concludes with a one-hour observation period under ambient temperature conditions in the test environment.

Nevertheless, comparisons with temperature measurements in other scenarios (e.g., charging, high-temperature parking) show significantly higher temperatures. A more in-depth literature review of VE temperature measurements in other scenarios has been carried out in order to compare them with the results obtained in this work.

Studies have analysed [21] the impact of high ambient temperatures on the efficiency of vehicles travelling in a region of high temperatures (>50 °C) in Kuwait compared to those recorded by Liu et al. [22] (<35 °C). The negative impact of high temperatures on electric vehicle efficiency was observed. Vehicles with excellent thermal management systems can still control temperature even in an extreme environment. However, for vehicles with worse thermal management systems, the situation will be worse. The load curves between −20 °C and 50 °C have been analysed. In the high-temperature charging test at 50 °C, the charging current fluctuates between 32 A and 100 A to control the battery temperature below 40 °C. It is agreed that there is low charging efficiency at extreme temperatures to control the battery temperature to be in a safe range [23].

DC fast charge tests were conducted at different temperatures including tests measuring charge duration, energy transfer, and energy used to thermally regulate the energy storage system (ESS) for charging events at different temperatures: 0, 25, and 50 °C [24]. Fast Charge at 50 °C could not be carried out during the tests to avoid an event, i.e., for safety reasons. It is observed that in the test at 0 °C the maximum temperature reached in the battery is 6.1 °C and in the test at 25 °C the maximum temperature reached in the battery is 27.8 °C.

Battery temperature has a major impact on the charging speed of electric vehicles, which is why most vehicles use a heating system to warm their battery and improve charging time. There are comprehensive analysis reports that help to understand the strategy chosen by each car manufacturer. In this −20 °C fast charge, the Hyundai Ioniq 5 and Mercedes EQS use coolant heaters to increase the battery temperature by up to 25 °C during charging. The maximum power of the Ioniq 5 heater is 5 kW and the EQS is 8 kW. The Tesla Model S Plaid’s strategy is different, as charging only starts when the battery temperature is above 0 °C and keeps it around 50 °C. The powertrains are used as coolant heaters with a peak power of 12 kW. Additional tests are conducted at −7 °C, 22 °C, 35 °C, and 45 °C to understand the thermal management strategy of the high-voltage battery [25].

Given the critical impact of temperature on LiB performance, health, and safety, this study aims to investigate the thermal behaviour of high-voltage battery systems in EVs under various conditions. The primary objectives are to understand how temperature variations during different operational scenarios affect battery performance and to develop effective thermal management strategies.

Motivation and Novelty:

This work is motivated by the need to enhance the safety and efficiency of lithium-ion batteries in electric vehicles, particularly under extreme temperature conditions encountered during various operational and maintenance scenarios. The novelty of this study lies in its comprehensive approach to examining thermal behaviour across a wide range of conditions, including the drying phase in paint booths, battery charging, summer parking, and driving. By employing advanced diagnostic equipment and thermocouple temperature measurements, this research provides detailed insights into temperature trends, compressor performance, and battery module behaviour. These findings will inform the development of improved thermal management systems and safety protocols, ultimately extending the lifespan and reliability of EV batteries.

This study will also address specific gaps in current research by proposing future investigations into the installation of thermocouples in battery modules for continuous temperature monitoring, the effects of seasonal variations on battery temperatures, and the impact of different driving styles on temperature distribution within battery packs. These proposed research avenues aim to deepen our understanding of battery temperature management in diverse operational conditions, contributing to the advancement of electric vehicle technology.

2. Materials and Methods

The experimental principles focus on evaluating the thermal impact on the traction battery of a BMW i3 during the drying phase in a paint booth. By leveraging a combination of direct temperature measurements using T-type thermocouples and diagnostic tools connected to the vehicle’s OBD, this study aims to monitor and record the battery’s temperature at different states of charge (SoC). The paint booth conditions are carefully controlled, with the temperature set to 60 °C for 60 min, followed by a ventilation phase, to replicate typical automotive manufacturing and repair processes.

This setup ensures that the thermal response of the battery can be observed under realistic conditions that the vehicle might encounter in a paint booth. The data collected provide insights into the thermal behaviour of the battery cells, highlighting potential hotspots and the effectiveness of the vehicle’s cooling system. This information is critical for assessing the safety and longevity of the battery, as prolonged exposure to high temperatures can accelerate degradation and pose safety risks.

Overall, the experimental procedure combines precise temperature monitoring with controlled environmental conditions to understand the thermal dynamics of EV batteries during manufacturing processes. This approach allows for the identification of optimal operational parameters to ensure battery safety and performance.

2.1. Vehicle Used in the Tests

A BMW i3 60 Ah, Model Year 2013, was used in the tests carried out. The specifications of the battery used in this vehicle are provided below (Table 1).

Table 1.

Specifications of the high-voltage battery unit of the BMW i3 vehicle used in the tests.

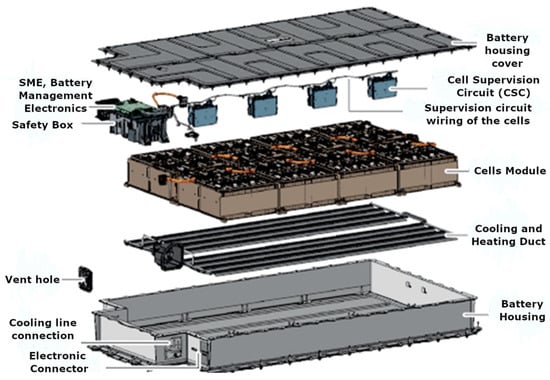

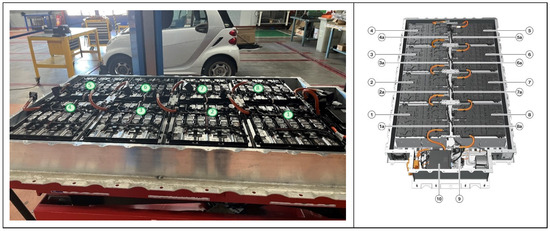

The different parts of the traction battery of the tested vehicle are shown in Figure 2.

Figure 2.

Different parts of the high-voltage battery unit of the BMW i3 vehicle used in the tests. Source: BMW manuals.

The battery management electronics (SME), which can be seen in Figure 2, continuously monitor the condition of the battery cells and the parameters required for safe battery operation. The SME control unit performs the following functions.

- -

- Control of the start and stop of the high-voltage system is carried out on request via the Electrical Machine Electronics (EMEs).

- -

- Evaluation of the voltage and temperature measurement signals of all battery cells and the current level in the high-voltage circuit.

- -

- Monitoring of the cooling system of the high-voltage battery unit.

- -

- Determination of the SoC and SoH of the high-voltage battery.

- -

- Determination of the available power of the high voltage battery.

- -

- Safety functions (e.g., voltage and temperature monitoring, high voltage interlock loop monitoring, and high voltage system monitoring for insulation faults).

On the other hand, the safety box, which can be seen in Figure 2, includes the following:

1. Switching contactors:

The high-voltage battery is connected to/disconnected from the high-voltage electrical system by two electromechanical contactors that are activated by the SME. A third switching contactor is used for pre-charging: before the electromechanical contactors are switched, the connection to the high-voltage electrical system is checked.

2. Voltage and current sensor at the current path of the negative battery terminal:

A voltage and current sensor measures the voltage and current at the output of the high-voltage battery and at the connection of the high-voltage electrical system. This sensor is connected to the battery management electronics (SME) via a local internal control network.

3. Safety fuse in the current path at the positive terminal of the battery.

4. Heating control electronics (depending on the options installed):

Depending on the equipment, heating may be installed in the high-voltage battery unit. The control electronics are located in the safety box and connected to the voltage and current sensor via the LIN bus.

The SME supplies the cell monitoring circuits with a 5 V supply voltage. A CSC monitors the status of 12 lithium-ion cells (the number of cells in a module):

- -

- Measuring and monitoring the voltage of each individual cell in the battery.

- -

- Measuring and monitoring the temperature at various points in the cell block.

- -

- Communicating the measured variables to the SME.

- -

- Performing the voltage adjustment process on the battery cells.

The high-voltage battery unit in this vehicle is cooled by coolant. For this reason, the air-conditioning circuit is extended to include the high-voltage battery unit. In the high-voltage battery unit, beneath the cell block, there is an aluminium flat-tube heat exchanger which is connected to the air-conditioning refrigerant circuit.

The following system functions are described for the high-voltage battery unit:

- -

- Control of the switching contactors for switching the high-voltage system on and off.

- -

- Monitoring of the high-voltage system for insulation faults.

- -

- Control of the cooling and heating of the high-voltage battery.

- -

- Balancing of individual battery cells (balancing).

The start-up of the high-voltage system occurs through the interaction between the EME and SME control units. The EME requests the start of the high-voltage system when Terminal 15 is connected or when there is a request for stationary cooling or charging. This start-up is performed in several stages:

- -

- High-voltage electrical system check (pre-charge): this involves verifying the operation of the high-voltage electrical system, including closing the pilot line circuit.

- -

- Voltage increase: Capacitors are present, causing a potential for high switching currents that could lead to damage to both capacitors and switching contactors over time. Therefore, voltage is increased gradually to mitigate this risk.

- -

- Closing the contacts of the switching contactor: When disconnecting the high-voltage system, a distinction is made between regular disconnection and fast disconnection. During regular disconnection, the protection of the electrical components and the testing of the high-voltage system is stopped. For example, the contacts of the contactor of the electromechanical switch must only be opened once the current level has fallen to a value close to 0 A, otherwise, they are subject to a high voltage.The BMW i3 vehicle tested features a central control station (Cell Supervision Circuits, CSCs) as seen in Figure 2, overseeing each of the eight modules. The CSC analyzes measurements from temperature sensors (four per module) and monitors the voltages of individual cells. Apart from data collection, the CSC’s primary role involves periodic cell rebalancing using its integrated shunt resistor. This process is essential because battery cells can become slightly unbalanced during use, with some cells reaching lower states of charge and associated open-circuit voltages compared to others. Without rebalancing, relying solely on module voltage to determine charge and discharge limits can result in issues. For instance, during charging, a high state-of-charge (SoC) cell might be overcharged while other cells lag behind in voltage. Conversely, during discharge, a low SoC cell might reach a lower voltage than intended. Overcharging and over-discharging can damage cells, leading to safety concerns or reduced cycle life. Therefore, cell balancing plays a crucial role in maintaining optimal battery function and longevity.

The temperature (T) of the battery is continuously monitored, with the CSC collecting information to relay to the SME. Additionally, the CSC performs cell rebalancing using an integrated shunt resistor.

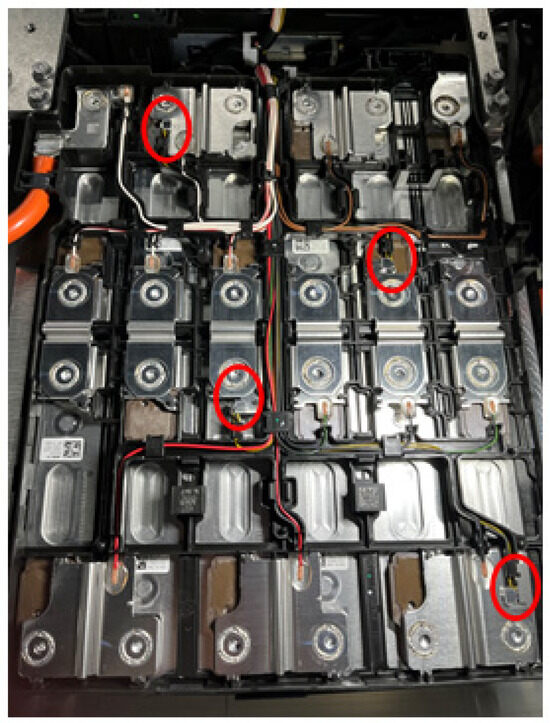

The temperature sensors are identified by two wires each. Figure 3 shows the locations of the four T-sensors in each module. To create a larger electrical unit with higher voltage, typically called a module, a specific number of cells are connected in series.

Figure 3.

Image of a module from the traction battery of the BMW i3 vehicle used in the testing of the paint booth and location of the temperature sensors.

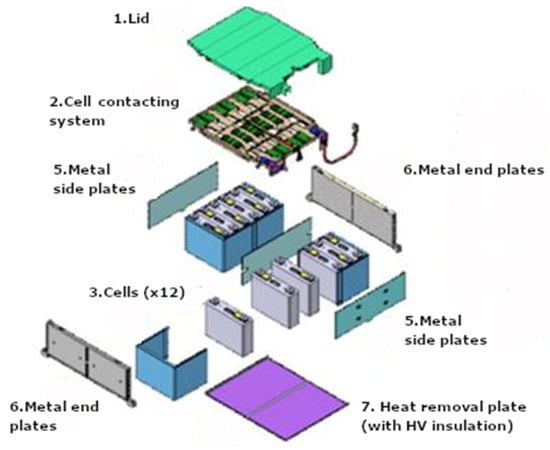

In the traction battery of the BMW i3 vehicle used in the tests, each module contains twelve 60 Ah prismatic cells (refer to Figure 4). To prevent short circuits between cells or between a cell and its housing, the cell assemblies are encased in round structures. The components are then electrically interconnected using a top-mounted cell contact system (CCS) (2). Aluminium side plates and outer plates are added, along with a lid and a bottom plate (7), specifically designed to dissipate heat from the cells. Due to the tendency of lithium-ion cells to expand during operation, which can impact performance, measures are taken to prevent this expansion. The outer plates (6) are press-fitted and secured by the side plates (5). Additionally, multiple temperature sensors are strategically placed around the module, as depicted in Figure 3, to monitor cell temperatures. Accurate temperature readings are crucial for the control system. Once these components are assembled, the module is ready for integration into a storage system.

Figure 4.

Components and module layout of the energy storage system of the BMW i3 vehicle [26].

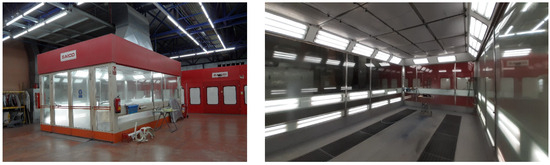

2.2. Paint Booth Used in the Tests

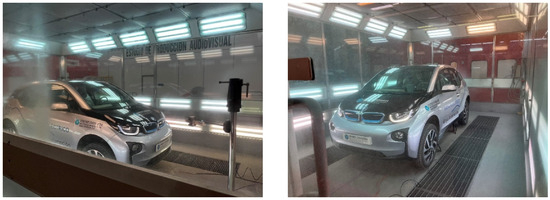

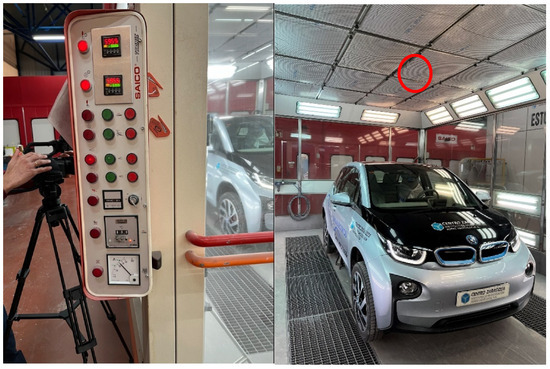

The paint booth (Figure 5 and Figure 6) used in the tests is supplied by SAICO, model KL/78, and is equipped with a TRONIC control panel. The AZ-20 burner employed is a diesel burner, with a minimum power of 128 kW and a maximum power of 249 kW (equivalent to 112,000 and 214,000 Kcal, respectively). It consumes fuel nominally at a rate of from 6.9 to 15 kg/h. To initiate the drying phase in the paint booth, the temperature controller is adjusted to the desired temperature, typically set at 60 °C for vehicle repair applications. The heating timer for the drying phase is then adjusted by turning it clockwise until the indicator aligns with the set drying time. For instance, if the drying time is 30 min, the timer should be set to 40 min because the temperature (T) does not instantly reach the set value.

Figure 5.

Different painting works in the paint booth of CENTRO ZARAGOZA.

Figure 6.

Image of the exterior (left) and interior (right) of the CENTRO ZARAGOZA paint booth used during the tests.

Following this, the ventilation timer is adjusted for the drying phase. The ventilation time should exceed the heating time to ensure effective cooling of both the system and the vehicle or painted part.

It is important to note that, for a drying temperature of 60 °C, the recommended cooling time is 10 min.

Refer to the following regarding the operation of the booth during the drying phase:

- -

- After setting the heating timer to 40 min, the ventilation timer should be set to 50 min to ensure adequate cooling.

- -

- To initiate the drying phase, both the heating and ventilation timers should be activated simultaneously by pressing the switches located at the centre of each timer.

- -

- Then, the drying phase starts.

The dimensions of the paint booth are given below:

- -

- Floor plan: Inner dimensions: length 7080 mm, width 4280 mmExternal dimensions: length 7320 mm, width 4520 mm

- -

- Plenum height (upper ceiling where heat is distributed). External dimensions: length 7420 mm, width 4520 mm.

- -

- Height: Inside 3080 mmOutside 3630 mm

- -

- As for the enclosure of the cabin, the walls are made of 20/11 mm glass and the floor has 40 × 2 mm gratings in 2 shafts.

- -

- The generator group (heating booster) is made up of two 5.5 kW three-phase asynchronous electric motors and two fans, with a total airflow of 24,000 m3/h. On the other hand, the extractor group (expulsion scrubber), is made up of two three-phase 5.5 kW electric motors, with a suction airflow of 22,500 m3/h.

2.3. Equipment Used for Temperature Measurement

To measure the temperature of the battery, temperature-measuring equipment has been used, consisting of the following:

- -

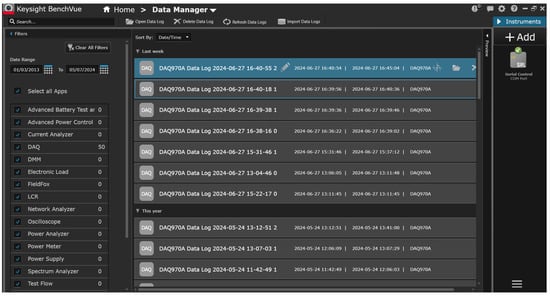

- Keysight 970A Datalogger (see Figure 7) measures, records, and stores data, together with a 20-channel acquisition module. This data logger can also read/store electrical variables by changing the type of recording module.

Figure 7. Image of the Keysight 970A Datalogger and 20-channel acquisition module.

Figure 7. Image of the Keysight 970A Datalogger and 20-channel acquisition module. - -

- Includes visualization and recording software: BenchVue. 2020 Update 2.0.

- -

- Panel for 12 T-type mini-thermocouples.

The following Figure 8 shows a screenshot of the BenchVue software screen:

Figure 8.

Screenshot of the BenchVue viewing and recording software.

It also includes a panel for 12 class 1 (±0.5 °C accuracy) mini-T-type thermocouples and a box for screwing them inside the paint booth and has a corrugated tube for conducting them. T-type thermocouples up to 100 °C give good accuracy. They have a 4-m cable so that we can measure inside the climatic chamber.

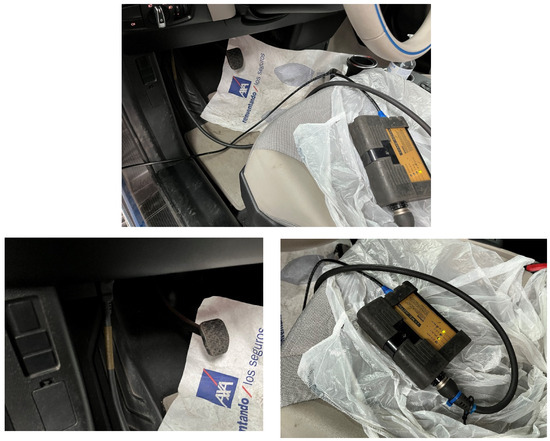

T-type thermocouples are placed on the surface to be measured, have a 4-m cable (see Figure 9), and are then placed in the thermocouple connection panel, which has a 4-m cable to the datalogger, allowing the data extraction equipment to be located outside the cabin during the tests.

Figure 9.

Image of the T-type thermocouple with a 4-m cable for connection to the thermocouple panel.

2.4. Characterisation of the Tests Carried Out

The objective of this study is to measure the temperature experienced by the battery modules when the vehicle is in the paint booth (according to the manufacturer’s specifications) during the drying phase.

After conducting the tests, these temperature values will be compared with those experienced by the battery in other scenarios:

- -

- During charging: analyzing the impact of charging speed based on power and charger specifications and assessing how the state of charge influences temperature.

- -

- In different driving situations and vehicle stresses.

- -

- When the electric vehicle is parked outside during the summer, exposed to elevated ambient temperatures.

To carry out the test, it is necessary to measure the temperature of the paint booth, on the one hand, the temperature indicated on the thermometer in the booth itself has been noted, and, on the other hand, the temperature and relative humidity inside the booth have been measured by placing a thermometer inside the booth.

Additionally, temperature measurements were taken at points on the bodywork near the location of the battery, specifically in the lower area and around the footboard. A thermographic camera was used for this purpose.

The battery temperature was measured using diagnostic equipment. In the specific case of the BMW i3 vehicle used for the tests, the diagnostic equipment allows us to measure the temperature in four modules of the battery. At various intervals between 0 and 90 min with intervals of 15 min, the temperature was measured at the four points of the battery, it was established that if at any point the temperature measured in the battery exceeded 60 °C, the test would be interrupted.

These measurements were carried out at different battery states of charge to also analyse the influence of the battery state of charge on the temperature reached by the traction battery.

To measure the battery temperature, we will use the following measurement methods:

- -

- BMW diagnostic equipment, which is connected to the vehicle’s OBD (Onboard Diagnostics). With this device, individual temperatures, and voltages of individual modules, can be measured, i.e., eight temperature measurements can be obtained.

- -

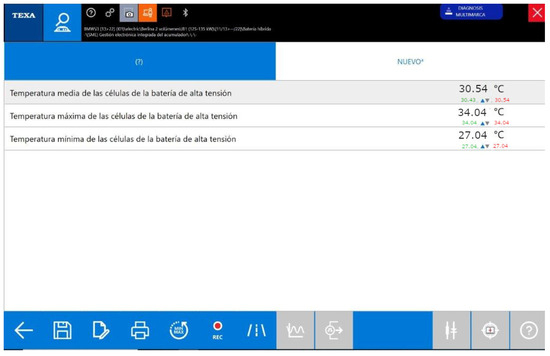

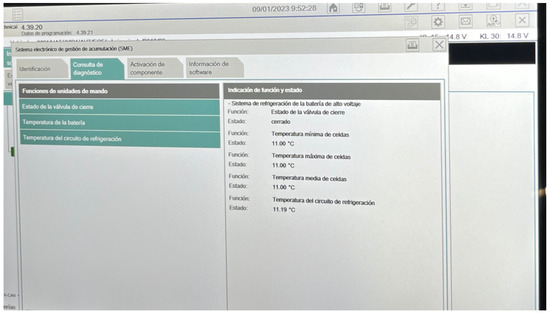

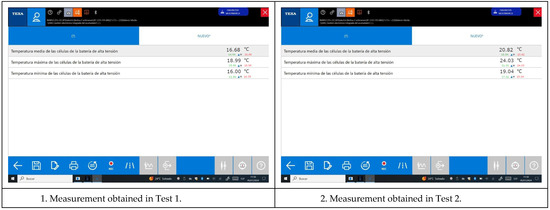

- Multibrand TEXA diagnostic equipment, which connects to the vehicle’s OBD. With this diagnostic equipment we can obtain, in the case of the BMW i3 tested, an average battery temperature value (see Figure 10), even though the battery, as we have seen in the analysis of its specifications and components, has a CSC for each of the eight modules.

Figure 10. Image of the information displayed by the TEXA diagnostic equipment regarding the temperature of the traction battery.

Figure 10. Image of the information displayed by the TEXA diagnostic equipment regarding the temperature of the traction battery. - -

- Temperature-measuring equipment, using T-type thermocouples.

For the test, the vehicle contact is activated. The battery is charged to 100% SoC in the first tests, but then the tests are repeated with the battery charged to 50% SoC.

Regarding the programming of the temperature in the paint booth during drying, we consider what BMW states: “the maximum permissible temperature in the paint booth must not exceed 80 °C with the high-voltage battery unit fitted. To avoid excessive ageing of the high-voltage battery cells, the dwell time should be a maximum of 60 min”, and what the paint supplier indicates is not to exceed 60 °C for more than 60 min.

As for the paint booth schedule, considering the indications of BMW and the paint supplier, the maximum test levels are set at 60 °C and 60 min.

3. Results

The results obtained using different methods to measure the temperature in the traction battery of the electric vehicle BMW i3 are shown below.

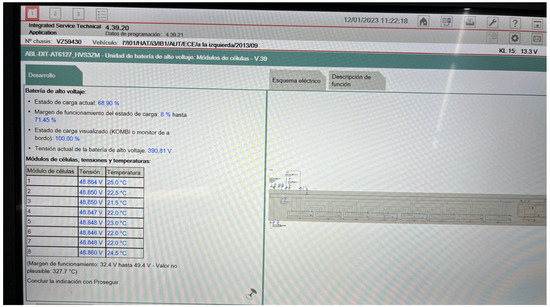

3.1. Temperature Measurement Using BMW Diagnostic Equipment

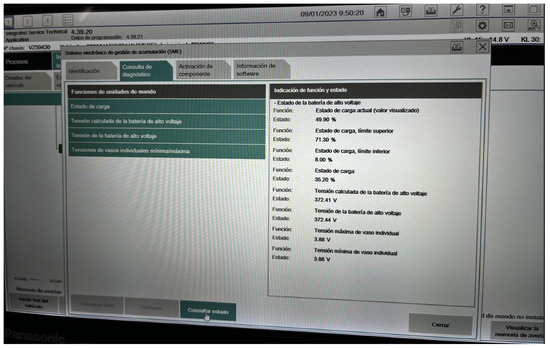

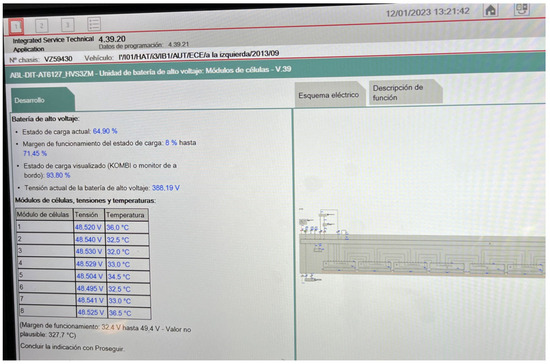

The data are obtained by connecting the BMW diagnostic machine to the OBD of the BMW i3 vehicle (see Figure 11). The software used is BMW ISTA (Integrated Service Technical Application) 4.39.20. ISTA consists of several components designed to communicate with each other via LAN, WLAN, and Internet. The entire system provides up-to-date information and diagnostic data from BMW headquarters. It is an important diagnostic tool, offering various options for vehicle identification, searching for very specific information and guided troubleshooting.

Figure 11.

Image of the connection of the BMW diagnostic equipment to the OBD of the BMW i3 vehicle.

The customer software is installed on devices with Integrated Service Information Display (ISID) and on the workshop PC.

The following Figure 12 shows two images of the BMW i3 inside the paint booth:

Figure 12.

Image of the BMW i3 vehicle inside the paint booth, ready for the temperature measurement test.

And Figure 13 shows two moments during the tests:

Figure 13.

Images during the tests with the BMW diagnostic equipment.

The test is carried out with the BMW i3 vehicle connected, as the ignition of the vehicle must be switched on for the diagnostic machine to connect. The machine is connected to the OBD II (On Board Diagnostics) connector.

The paint booth is programmed to 60 °C for 60 min. As the paint booth takes approximately 60 min to reach 60 °C, we then extend this by a further 60 min. The booth is then programmed to reach 80 °C, but it does not reach 80 °C, the maximum temperature reached is 65 °C.

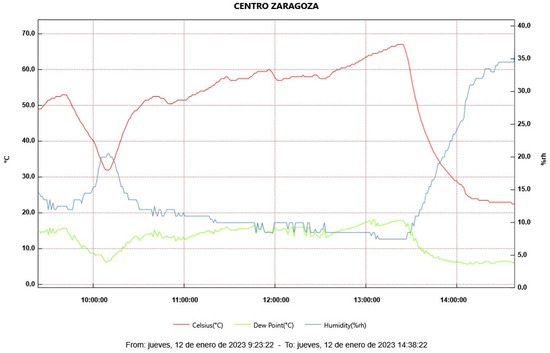

The paint booth controls the temperature by means of a probe located in the central part of the roof, as shown in the picture (Figure 14). On the other hand, the temperature inside the cabin and the humidity are measured with an EL-USB-2-LCD temperature meter (Figure 15), which is programmed to measure every minute. It is placed inside the cabin with support to measure the evolution of the temperature and humidity, as well as the dew point (Dew Point °C), over time.

Figure 14.

Image of the paint booth control panel, showing the temperature and the programmed time (left). Image of the location of the probe that controls the temperature inside the booth (right).

Figure 15.

Image of the EL-USB-2-LCD meter used to measure the temperature and humidity inside the spray booth during the tests.

An HTI 03 THERMAL IMAGER (120 × 90) thermal imaging camera (see Figure 16) was used to measure the temperature at various points on the bodywork near the location of the high-voltage battery, specifically in the lower area of the vehicle and in the footboard area.

Figure 16.

Image of the HTI 03 THERMAL IMAGER thermal imaging camera (120 × 90) used to measure the temperature at various points on the bodywork near the location of the high-voltage battery.

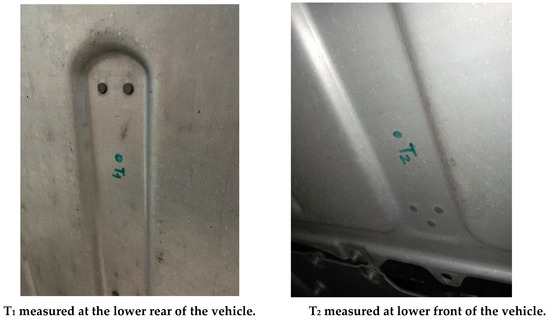

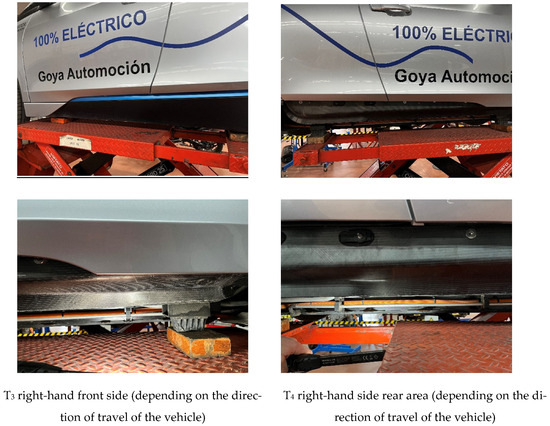

The four points to be measured using the HTI 03 THERMAL IMAGER thermographic camera (120 × 90) are shown below (see Figure 17).

Figure 17.

Images of the measurement points on the underside of the vehicle (under the high-voltage battery).

To measure the temperature in the footboard area, the outer plastic must first be removed (see Figure 18).

Figure 18.

Images of the measuring point in the footboard area.

The results of the measurements for different battery states of charge are shown below, firstly for a 50% SoC and then for a 100% SoC.

3.1.1. Battery 50% SoC

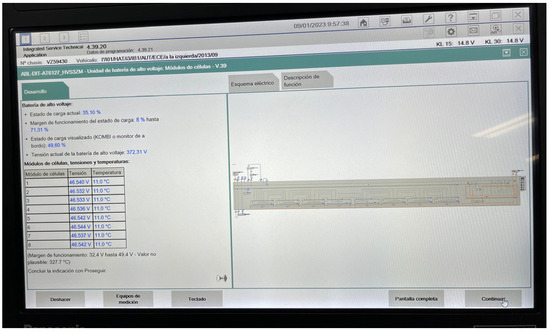

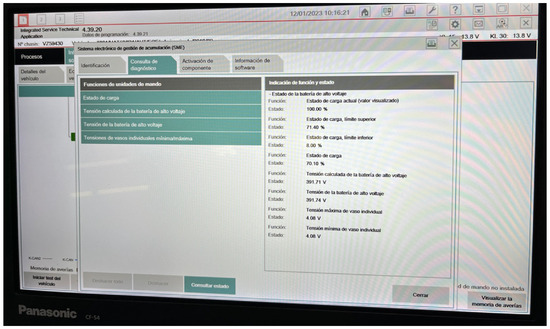

In the first test conducted with BMW diagnostic equipment, the high voltage battery has a displayed SoC of 49.9%, however, upon checking the actual state of charge recorded by the BMW diagnostic equipment, it is 35.20%. This discrepancy is intended to provide greater security and peace of mind to the driver. The following image (Figure 19) displays the state of charge value of the battery obtained with the BMW diagnostic equipment.

Figure 19.

Image of the values displayed by the diagnostic equipment, in the case of the test with a battery 50% SoC, among which the current state of charge value (displayed value) and the state of charge can be seen.

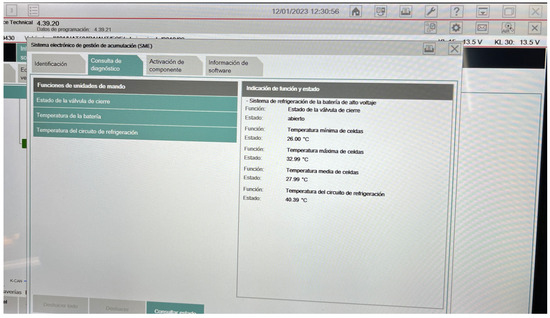

At the beginning of the test, the state of charge of the high-voltage battery cooling system’s shut-off valve is closed, and the average cell temperature is 11 °C, as indicated in the following image (Figure 20).

Figure 20.

Image showing the state of the shut-off valve of the high-voltage battery cooling system and the average cell temperature.

The following image (Figure 21) displays the temperature and voltage reading for each of the high-voltage battery modules obtained with the BMW diagnostic equipment.

Figure 21.

Image showing the temperature and voltage of each of the modules of the voltage battery tested (test battery 50% SoC).

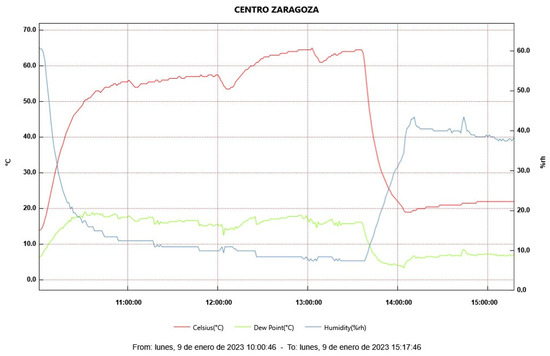

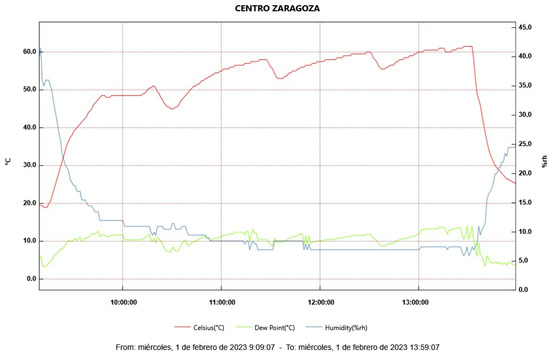

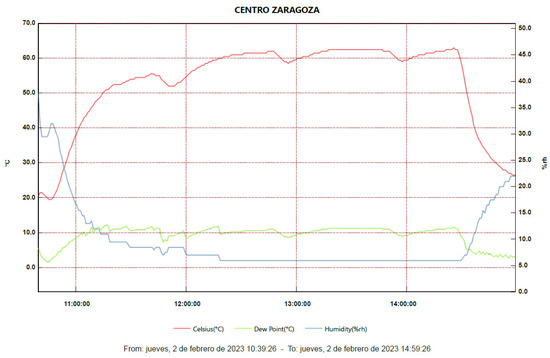

Below is a graph (Figure 22) depicting the temperature and humidity levels inside the paint booth during the test. These measurements were recorded by the EL-USB-2-LCD temperature meter positioned inside the booth.

Figure 22.

Graph displaying the temperature (red line) and humidity (blue line) recorded by the EL-USB-2-LCD meter inside the cabin during the test conducted with the battery at 50% SoC.

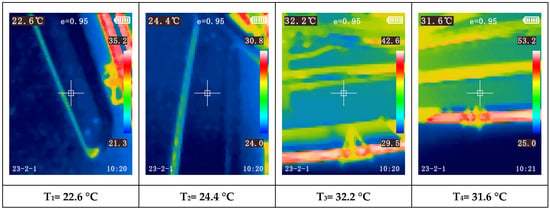

The temperature was also measured at various points on the body of the BMW i3 vehicle using a thermal imaging camera (Figure 23), as outlined in the preceding section.

Figure 23.

Image of the temperature measurement on the underside of the BMW i3 vehicle using the thermal imaging camera.

For the analysis of different SoCs, specifically 50% SoC, four tests have been defined. First is the reference test, which is performed by programming the cabin temperature to 60 °C for the first 60 min, then it is measured again at 60 °C after a further 60 min, then it is programmed at 80 °C and the measurement is taken after 60 min, and the measurement is taken again after a further 35 min.

A table with the defined tests to be carried out is given below (Table 2).

Table 2.

Definition of tests carried out with the traction battery at 50% state of charge.

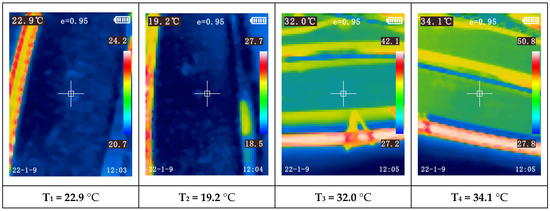

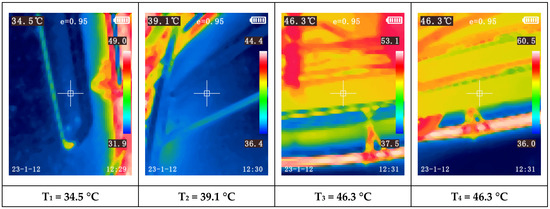

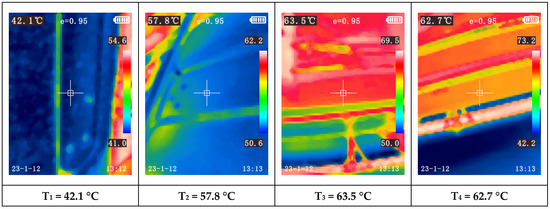

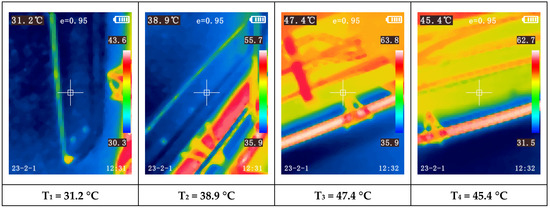

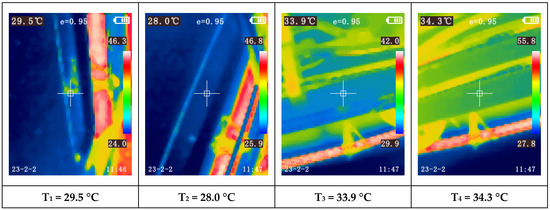

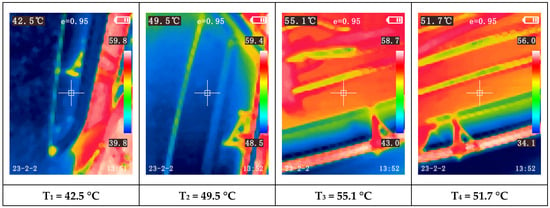

The following pictures (Figure 24) display the thermal imaging camera images capturing measurements at the four designated points, as defined in the previous section.

Figure 24.

Images captured with the thermal imaging camera at the four defined measurement points, at the end of Test 1, as specified in Table 2.

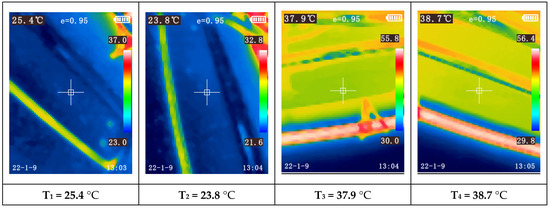

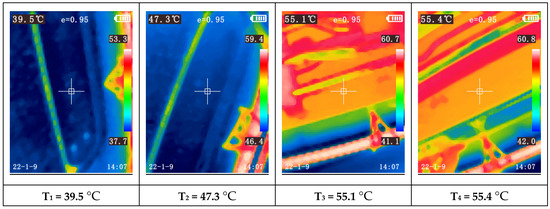

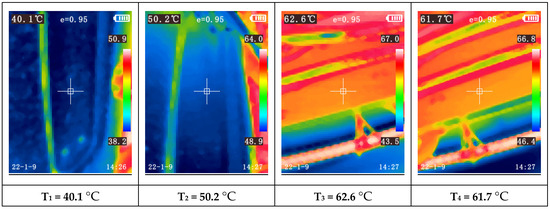

In the images (Figure 24, Figure 25, Figure 26 and Figure 27) it can be observed that the areas reaching the highest temperatures are the footboard areas. Additionally, it is evident that the highest temperatures are reached in the last test, corresponding to when the cabin temperature reaches its peak.

Figure 25.

Images captured with the thermal imaging camera at the four defined measurement points, at the end of Test 2, as specified in Table 2.

Figure 26.

Images captured with the thermal imaging camera at the four defined measurement points, at the end of Test 3, as specified in Table 2.

Figure 27.

Images captured with the thermal imaging camera at the four defined measurement points, at the end of Test 4, as specified in Table 2.

The following Table 3 shows the grouped temperatures obtained at the four measurement points defined on the bodywork for the four tests carried out.

Table 3.

Results of measurements at the four measurement points defined on the bodywork for the four tests conducted.

By examining all temperature values in Table 3, several conclusions can be drawn. Test 4 consistently recorded the highest temperature values compared to the reference test. Moreover, the area that consistently reached the highest temperature is the right-hand side rear area (relative to the vehicle’s direction of travel).

Finally, Table 4 below presents the temperature data for each individual module, obtained from the BMW diagnostic equipment.

Table 4.

Temperature in each of the traction battery modules obtained from the BMW diagnostic equipment for the four tests carried out.

The analysis of the data in Table 4 confirms that Modules 1 and 8 consistently reach the highest temperatures across all tests. These modules correspond to the first and last positions in the battery pack.

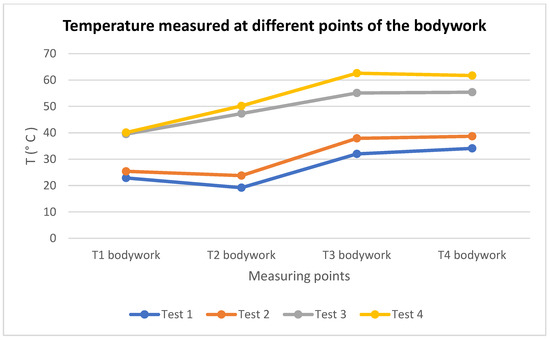

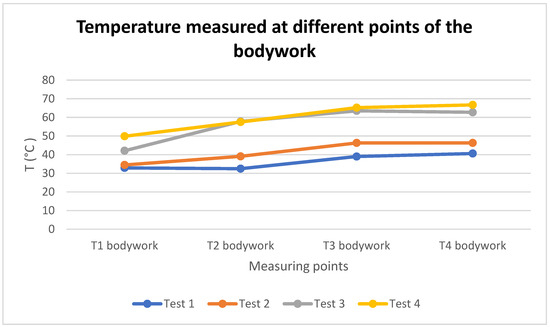

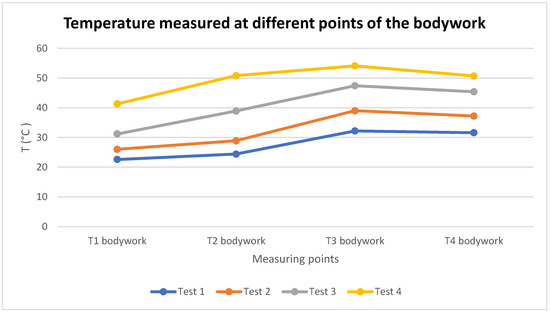

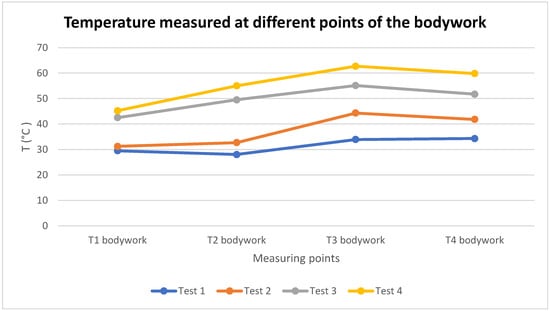

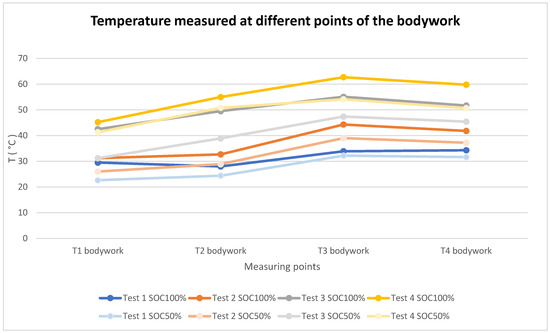

The following graph (Figure 28) shows the temperature at the various measuring points on the bodywork.

Figure 28.

Graph of the temperature measured at different points of the bodywork with a thermographic camera in the four tests carried out with the battery at 50% SoC.

The graph above (Figure 28) indicates that, as the paint booth temperature increases and the duration of the measurement test extends, the temperature at various points measured on the bodywork also rises. On the other hand, across all tests conducted, the highest temperatures were consistently recorded at the footboard in the rear area, relative to the direction of travel of the vehicle. Notably, temperatures in the footboard area are higher than in the lower part, which is likely influenced by the presence of a cooling plate situated between the measurement point and the high-voltage battery.

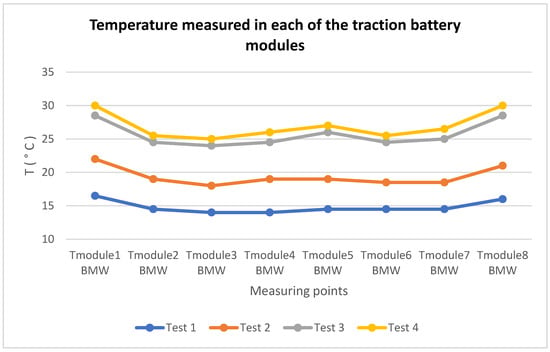

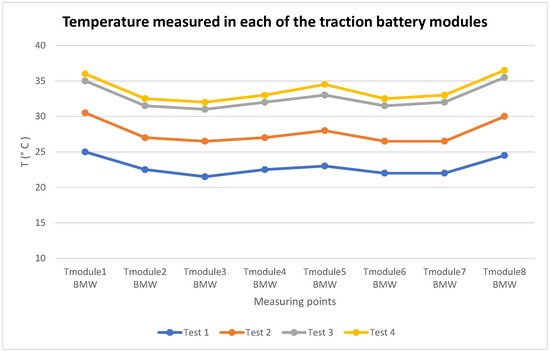

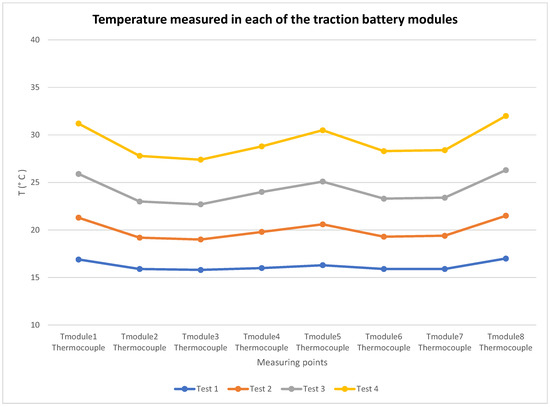

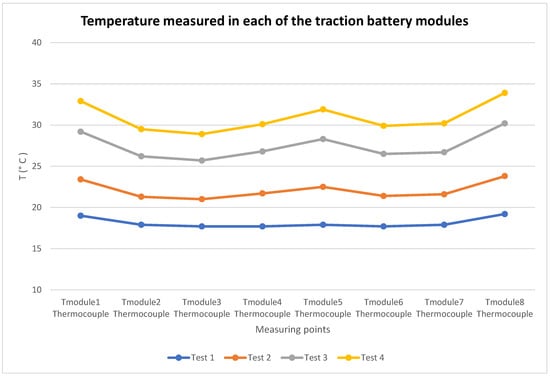

Below is a graph (Figure 29) of the temperature in the individual modules of the traction battery obtained with the BMW diagnostic equipment.

Figure 29.

Temperature graph of each of the traction battery modules obtained with the BMW diagnostic equipment in the four tests carried out with the battery at 50% SoC.

The graph above (Figure 29) demonstrates that, similarly to the temperature measured at different points on the bodywork, as the temperature within the paint booth and the duration of the test increase, the temperature within the different modules also increases. Across all tests conducted, Modules 1 and 8 consistently exhibit the highest temperatures, followed by Module 5. Interestingly, in Test 4, none of the modules exceeded 30 °C due to active cooling initiated by the opening of the cooling valve.

Analysing the placement of the modules within the traction battery, it is evident that modules located at the ends—specifically Module 1, Module 8, and Module 5—consistently reach the highest temperatures.

The following Figure 30 illustrates the positioning of the individual modules within the traction battery, by giving each of them a number (from 1 to 8).

Figure 30.

Identification of the position of the modules in the battery pack. Source: BMW i01 manual.

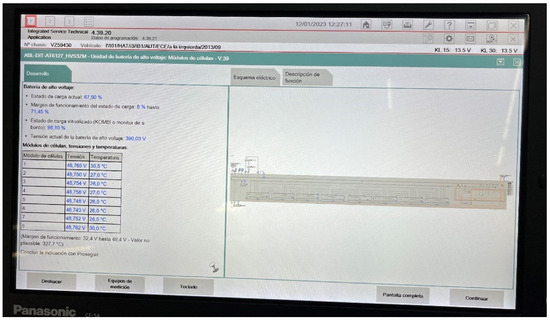

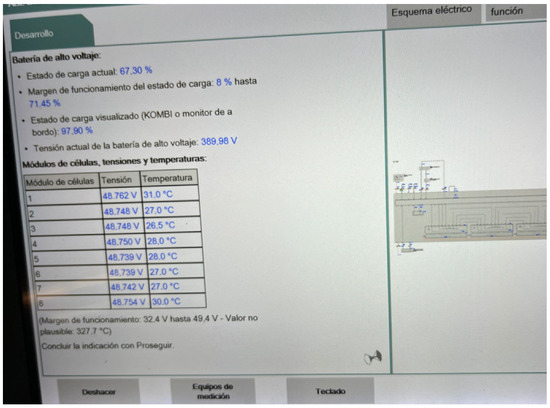

3.1.2. Battery 100% SoC

The same test as in the previous section is repeated, but, in this case, the battery is at 100% SoC. The objective is to analyse how the SoC influences the temperature of the battery when introduced into the paint booth during the drying phase. Data are obtained by connecting the BMW diagnostic equipment to the OBD II of the BMW i3 vehicle. The test requires the ignition of the vehicle to be switched on, as this is necessary to connect the diagnostic equipment to the OBD II (On Board Diagnostics).

Similar to the previous test, the paint booth is programmed to maintain a temperature of 60 °C for 60 min. Since it takes approximately 60 min for the booth to reach 60 °C, an additional 60 min is added for a new measurement. Subsequently, the booth is programmed to reach the manufacturer-specified 80 °C, but it reaches a maximum of 67 °C.

As in the previous test, the temperature and humidity inside the booth are measured using an EL-USB-2-LCD temperature meter.

In the second test with the BMW diagnostic equipment, the high voltage battery displays 100% SoC, however, upon checking the actual state of charge recorded by the BMW diagnostic equipment, it shows 70.10% (see Figure 31). This discrepancy ensures greater security and peace of mind for the driver.

Figure 31.

Image of the values displayed by the diagnostic equipment, in the case of the test with a battery SoC 100%, among which the current state of charge value (displayed value) and the state of charge can be seen.

At the beginning of the test, the state of the battery shut-off valve of the high-voltage battery cooling system is closed, and the average cell temperature is 11 °C.

Below is Figure 32, displaying the temperature and humidity of the paint booth during the test, recorded by the EL-USB-2-LCD temperature meter placed inside the booth.

Figure 32.

Graph showing the temperature (red) and humidity (blue) recorded by the EL-USB-2-LCD meter inside the cabin during the test carried out with the battery at 100% SoC.

The reason it starts at 49 °C is because, after warming up for 50 min, 10 min to 60 min, the thermometer was switched on. At 9.40 h (53 °C), the temperature drops because we are alerted by the BMW technician who arrives later, and we turn off the cabin. By 9.55 h, we switched on the paint booth, but, since the door was open to connect the equipment to the OBD, the temperature continued to drop to 32 °C (10.11 h). From there, we started warming up again for 60 min. We took a temperature measurement, and it was 56 °C, we continued heating at 60 °C for another 60 min, reaching 58.5 °C.

When the temperature in the cabin was 56 °C (at 11:21 h), the temperature in each module was as shown in the figure below (Figure 33).

Figure 33.

Image showing the temperature and voltage of each of the modules of the voltage battery tested (test battery 100% SoC).

The highest temperature is reached in Module 1, which is 25.0 °C. After 60 min, at 12:26 h, the temperature in the cabin is 58.5 °C, and the temperature of each module is as shown in Figure 34 below.

Figure 34.

Image showing the temperature and voltage of each of the modules of the voltage battery tested, when the cabin temperature is 58.5 °C.

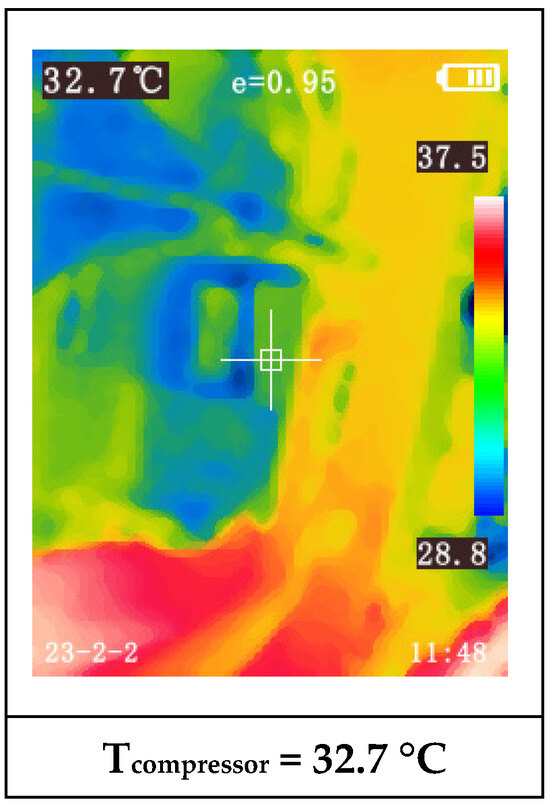

At 12:31 h, the shut-off valve of the compressor cooling system, which cools the battery, is open, with a maximum cell temperature of 32.99 °C, Figure 35.

Figure 35.

Image showing that the shut-off valve of the cooling system is open.

However, the temperature of the modules does not decrease but continues to increase, as can be seen in the following, Figure 36.

Figure 36.

Image showing the temperature of each of the modules after opening the shut-off valve of the refrigeration system.

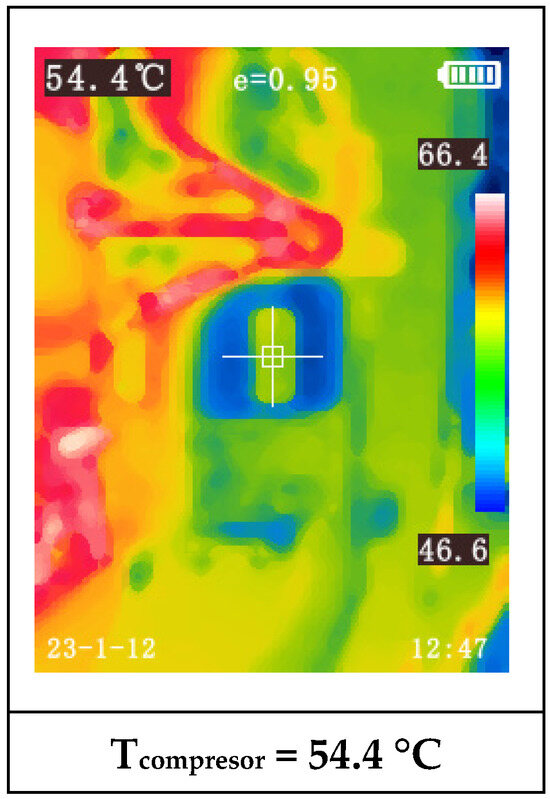

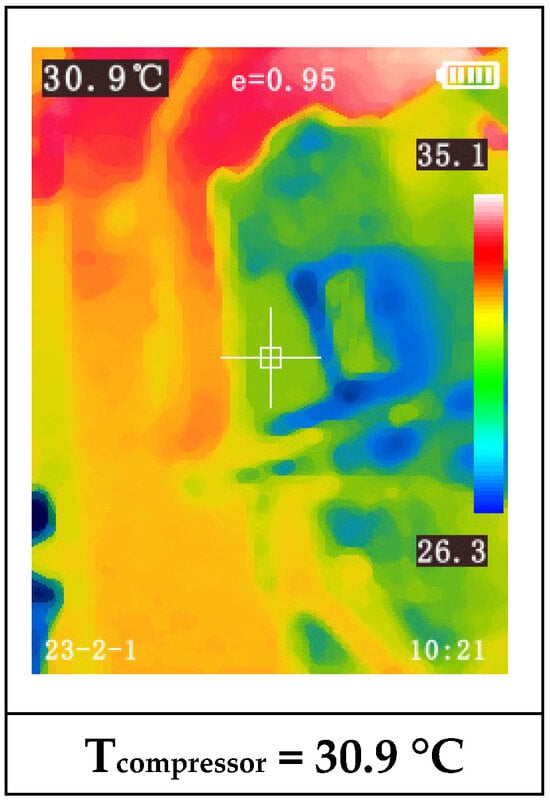

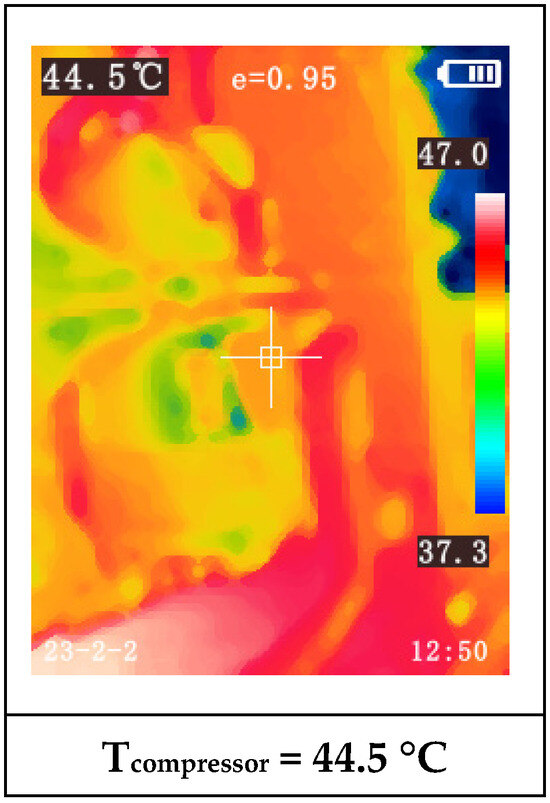

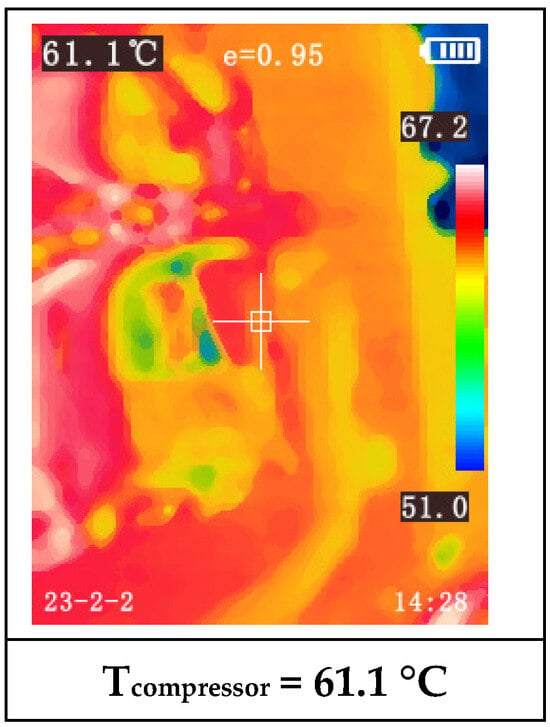

It is confirmed that the compressor responsible for cooling the high-voltage battery is not operational; however, upon inspection, it is noted that the fan is operational. It is unusual that the compressor is not activating despite the fan running. Subsequently, the temperature of the coolant in the inverter is measured and found to be 41.13 °C. This elevated temperature triggers the fan, which cools the coolant circulating through the inverter, the load module, and the electrical machine, Additionally, it cools the condenser that manages the air-conditioning gas. The coolant pump, responsible for cooling all high-voltage components (inverter, electrical machine, converter…) excluding the high-voltage battery, is operational. This measurement of the inverter coolant temperature is conducted because the fan was observed to be running at maximum speed, and the objective is to verify if the fan activation is due to excessive temperature in the inverter. After checking, it was found that the compressor does not receive voltage or current. Using a thermographic camera, the temperature of the compressor was measured at 54.4 °C. It is deduced that the compressor remains inactive because it has reached a high temperature that could potentially cause damage. As a safety precaution, the system prevents the compressor from operating, as starting it could further increase its temperature.

Subsequently, the fault memory was read, revealing a fault code (IHKA 801251 Electric air conditioning compressor: switch-off due to start-up phase errors). This code indicates that the electric compressor of the air-conditioning unit (EKK) may have encountered an overtemperature condition. After ruling out other potential causes, such as excessive refrigerant pressure in the coolant circuit, a defective refrigerant shut-off valve, or mechanical issues in the EKK, it can be concluded that the fault code was triggered due to the detection of overtemperature in the EKK. By 13:12 h, the temperature in the paint booth had risen to 65 °C, and the temperature of each module continued to increase. Attempts to activate the compressor using both BMW’s diagnostic equipment and TEXA’s diagnostic equipment were unsuccessful. At 13:20 h, the final measurement was taken with the paint booth temperature at 67 °C, prompting the test to be stopped for safety reasons as the temperatures in the battery cells were still rising. The temperatures reached in each of the modules are detailed below (Figure 37).

Figure 37.

Image showing the temperature and voltage of each of the modules of the voltage battery tested reached when the test was stopped.

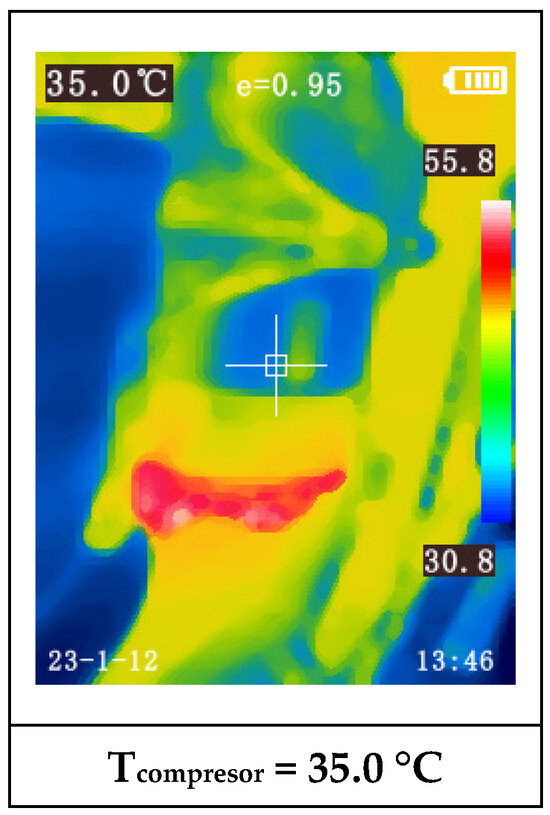

It is then cooled by air until it reaches a temperature of 55.5 °C. It is confirmed that the compressor is activated at 13:45 h when the compressor temperature reaches 35.0 °C (Figure 38). When the compressor is activated, the shut-off valve of the cooling system closes.

Figure 38.

Image showing the temperature reached in the compressor now it is activated.

A table with the defined tests that have been conducted is given below (Table 5).

Table 5.

Definition of tests carried out with the traction battery at 100% state of charge.

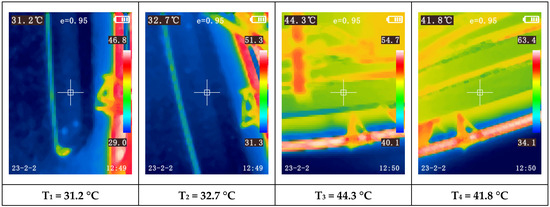

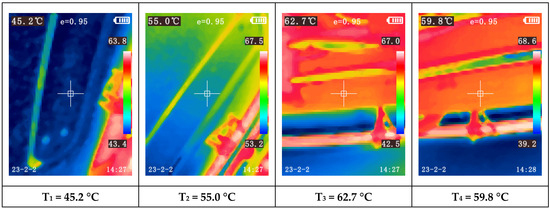

The following images (Figure 39 and Figure 40) display the result of the measurements at the four measurement points defined above.

Figure 39.

Images captured with the thermal imaging camera at the four defined measurement points at the end of Test 1, as specified in Table 5.

Figure 40.

Images captured with the thermal imaging camera at the four defined measurement points at the end of Test 2, as specified in Table 5.

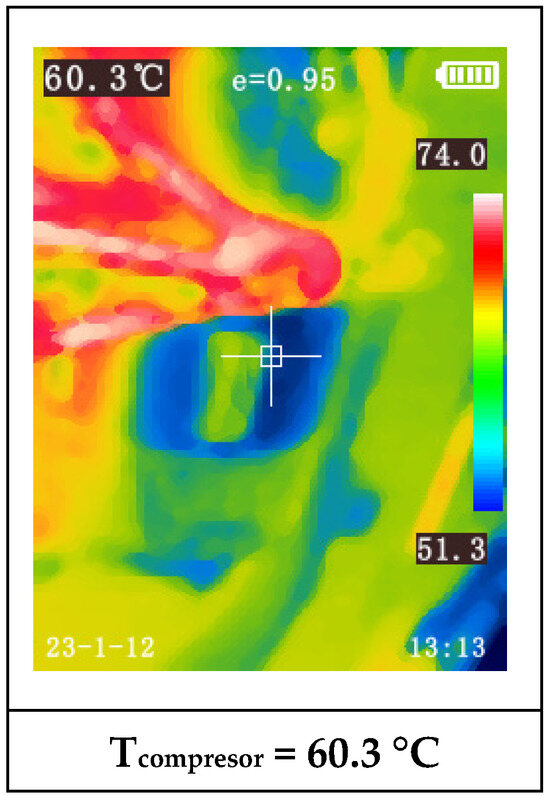

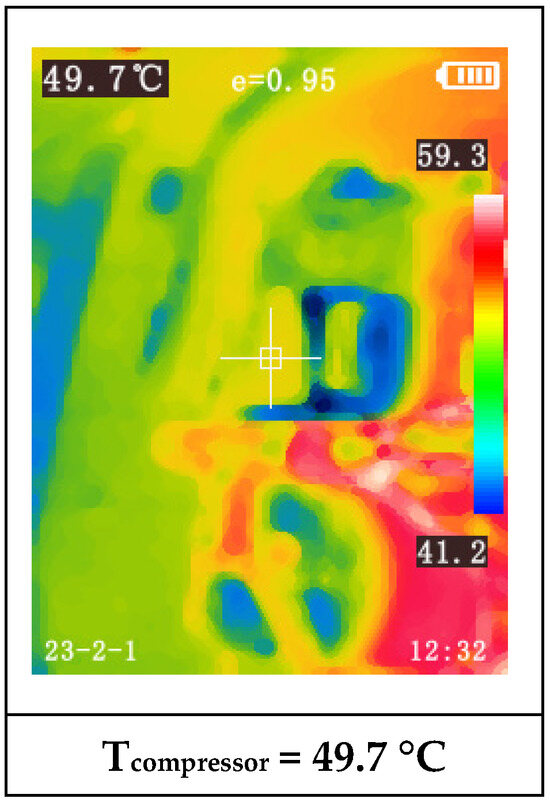

The temperature reached in the compressor is then measured to check its operation during Test 2 (Figure 41).

Figure 41.

Image captured with the thermal imaging camera on the compressor to check its operation in Test 2.

After 43 min, the third test is stopped to check the temperature of the modules and the compressor, which are found to be still rising, so the test is stopped for measurement and assessment.

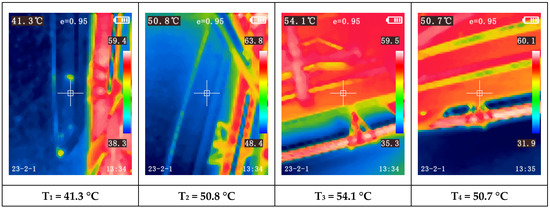

The following images (Figure 42) display the result of the measurements at the four measurement points defined above.

Figure 42.

Images captured with the thermal imaging camera at the four defined measurement points at the end of Test 3, as specified in Table 5.

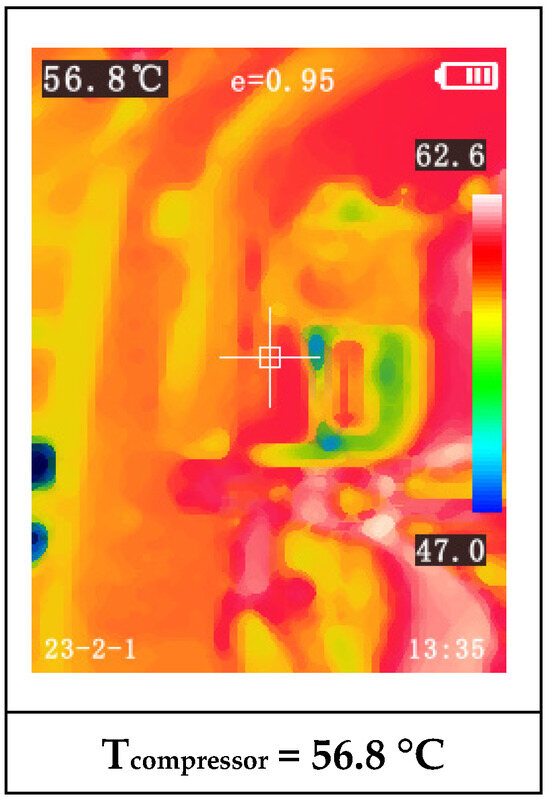

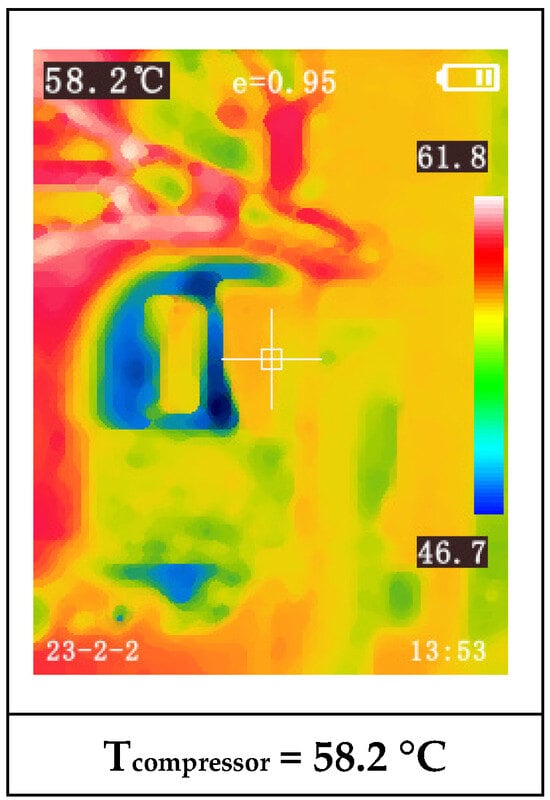

The temperature reached in the compressor is then measured to check its operation during Test 3 (Figure 43).

Figure 43.

Image captured with the thermal imaging camera on the compressor to check its operation in Test 3.

After 10 min, the fourth test is stopped as the compressor still does not work and so the test is stopped for safety reasons.

The following images (Figure 44) display the result of the measurements at the four measurement points defined above.

Figure 44.

Images captured with the thermal imaging camera at the four defined measurement points at the end of Test 4, as specified in Table 5.

The temperature reached in the compressor is then measured to check its operation during Test 4 (Figure 45).

Figure 45.

Image captured with the thermal imaging camera on the compressor to check its operation in Test 4.

At this point, the compressor is cooled with air until it reaches 35 °C and starts to operate, as mentioned earlier.

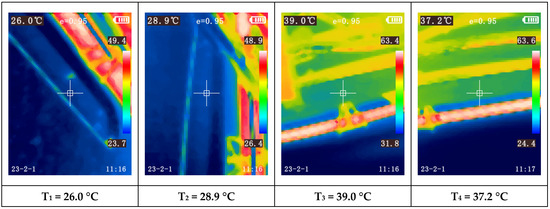

In the previous images (Figure 39, Figure 40, Figure 42 and Figure 44), it can be observed that the footboard areas reach the highest temperatures. It is also evident that the highest temperatures were reached in the last test, coinciding with the highest cabin temperature.

The compressor temperature was observed to rise to 60.3 °C, after which it was cooled with air and its temperature began to decrease.

Below is Table 6, which displays the temperatures recorded at the four designated measurement points on the bodywork across the four conducted tests.

Table 6.

Results of the measurements at the four measurement points defined on the bodywork for the four tests carried out.

Finally, Table 7 presents the temperature data for the individual modules, obtained from the BMW diagnostic equipment.

Table 7.

Temperature in each of the traction battery modules obtained from the BMW diagnostic equipment for the four tests conducted with an SoC at 100% battery.

The following graph (Figure 46) illustrates the temperature at various measuring points on the bodywork.

Figure 46.

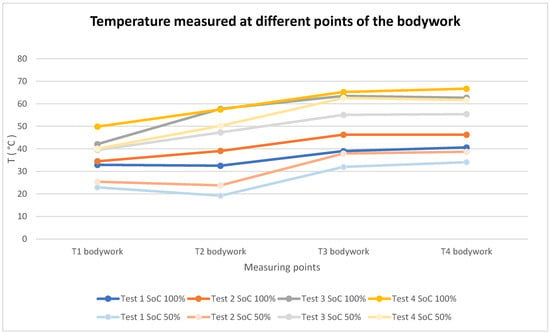

Graph of the temperature measured at different points of the bodywork with a thermal imaging camera in the four tests conducted with the battery at 100% SoC.

The graph above (Figure 46) illustrates that, as the paint booth temperature increases and the duration of the measurement test extends, the temperature at various points on the bodywork increases, similar to observations with a 50% SoC battery. Additionally, in each test conducted, the footboard area in the rear exhibits the highest temperatures, depending on the vehicle’s direction of travel. Notably, temperatures in the footboard area surpass those in the lower part, potentially due to the presence of a cooling plate between the measurement point and the high-voltage battery.

Below is a graph (Figure 47) of the temperature reading from individual modules of the traction battery obtained using BMW diagnostic equipment.

Figure 47.

Temperature graph of each of the traction battery modules obtained with the BMW diagnostic equipment in the four tests conducted with the battery at 100% SoC.

The graph above illustrates that, as the temperature inside the paint booth increases over the course of each test, the temperature recorded in the traction battery modules also rises. Modules 1 and 8 consistently show the highest temperatures across all tests, with module 5 following closely behind.

Notably, in Test 3, Modules 1, 4, 5, 7, and 8 exceed 32 °C. Similarly, in Test 4, all modules surpass this temperature threshold. This is attributed to the compressor’s non-operation due to overtemperature conditions, preventing effective cooling as previously discussed.

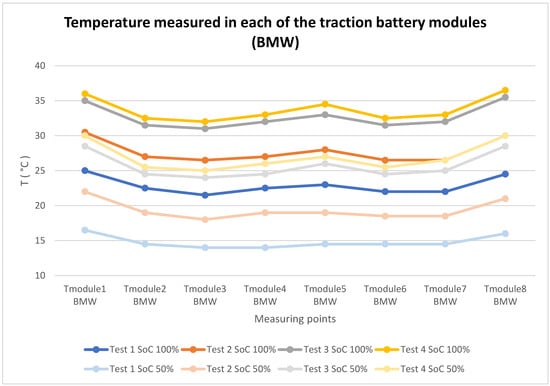

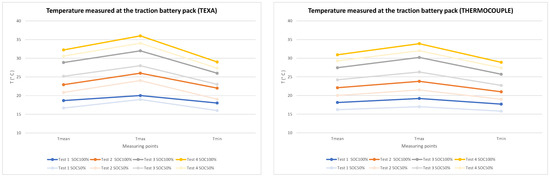

The following figures (Figure 48 and Figure 49) will provide a comparative analysis of temperature values recorded at various bodywork measurement points and in the traction battery modules across different states of charge (SoCs) of the battery.

Figure 48.

Graph of the temperature measured at different points of the bodywork with a thermal imaging camera in the four tests conducted for different battery SoCs analysed.

Figure 49.

Temperature graph of each of the traction battery modules obtained with the BMW diagnostic equipment in the four tests conducted for different battery SoCs analysed.

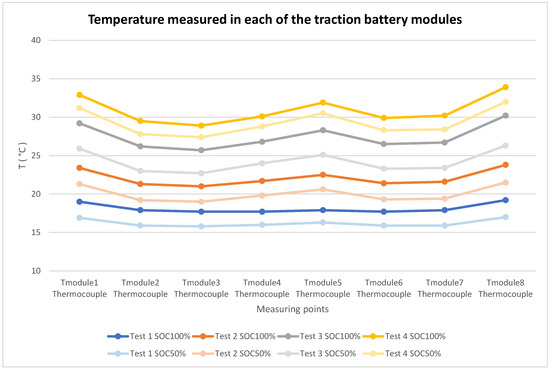

- -

- Across all states of charge (SoCs) of the battery, Modules 1 and 8 consistently reach the highest temperatures, followed closely by Module 5.

- -

- Regardless of the SoC, the temperature measured at the right side footboard in the rear area (T4) is consistently higher than that in the lower part. This difference is likely due to the presence of a cooling plate located between the measurement point and the lower section of the high-voltage traction battery.

- -

- The temperature trends in the traction battery modules remain consistent irrespective of the battery’s SoC. Modules 1 and 8 consistently exhibit the highest temperatures.

- -

- Modules generally reach higher temperature values when the battery is at 100% SoC. Specifically, the temperature increase from 50% SoC to 100% SoC is most pronounced in Test 1, with subsequent tests showing reduced temperature differences. Test 4, in particular, shows lower temperature increases compared to Test 1, likely due to the operation of the cooling system during tests 3 and 4 at 50% SoC.

- -

- It is important to note that the compressor has a temperature limit: above 35 °C, it will not operate due to safety precautions aimed at preventing cell temperatures from exceeding 32 °C. This limitation ensures safe operation even when the vehicle is subjected to conditions such as those in a paint booth.

3.2. Temperature Measurement Using TEXA Multi-Brand Diagnostic Equipment

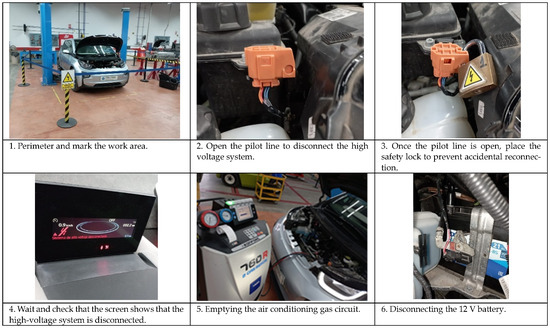

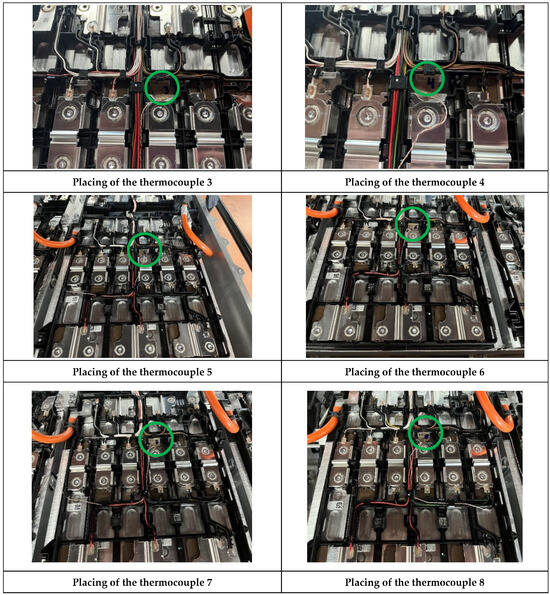

In the following tests, data are collected using the TEXA multi-brand diagnostic equipment connected to the OBD port of the BMW i3 vehicle. The diagnostic software, IDC5 76.5.0.a-31, facilitates comprehensive communication among its components via LAN, WLAN, and the Internet. This system provides real-time diagnostic information and data, offering various functionalities such as vehicle identification, detailed information searches, and guided troubleshooting. It automatically scans diagnosable electronic control units (ECUs), records parameters and errors during dynamic test drives, and instantly links error readings to corresponding components on wiring diagrams. The TEXA equipment enables the calculation of mean temperature (Tmean) as well as the recording of maximum temperature (Tmax) and minimum temperature (Tmin) values reached within the battery pack. Concurrently, temperature measurements are obtained using thermocouples placed in each module of the battery pack. The positioning of the thermocouples is determined based on the location of the temperature sensors identified in the system. While the measurements are conducted using the TEXA equipment, simultaneous readings are also taken using thermocouples positioned within each module of the battery pack. Prior to placing the thermocouples, the specific locations for temperature sensors are identified (Figure 50).

Figure 50.

Image of the BMW i3 being tested inside the paint booth with the thermocouple connection panel (left). Detail of the panel showing the cables from the 8 thermocouples placed in each of the battery modules and the thermocouple positioned in the compressor (right).

The test is performed with the BMW i3 vehicle powered on, as the vehicle’s ignition must remain active to enable connectivity for both TEXA and BMW diagnostic equipment via the OBD II connector (Onboard Diagnostics) (see Figure 51). All other test conditions remain consistent with those employed in tests conducted using BMW diagnostic equipment.

Figure 51.

Image showing the connection of the TEXA diagnostic equipment to the OBD II port of the BMW I3 vehicle (left) and another image displaying the temperature measurement equipment alongside the TEXA equipment (right).

When placing the thermocouples on the modules and on the compressor, they are insulated to avoid problems, as it is verified that the housing of each cell is connected to the positive terminal.

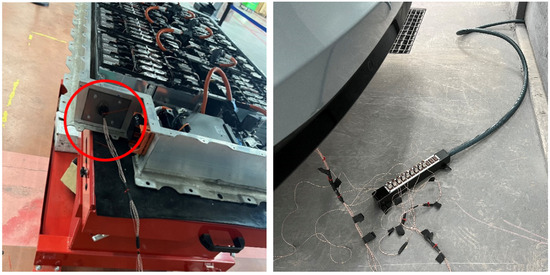

3.2.1. Placement of Thermocouples in Traction Battery

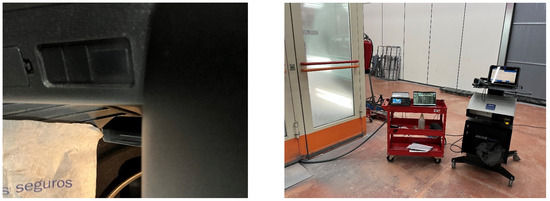

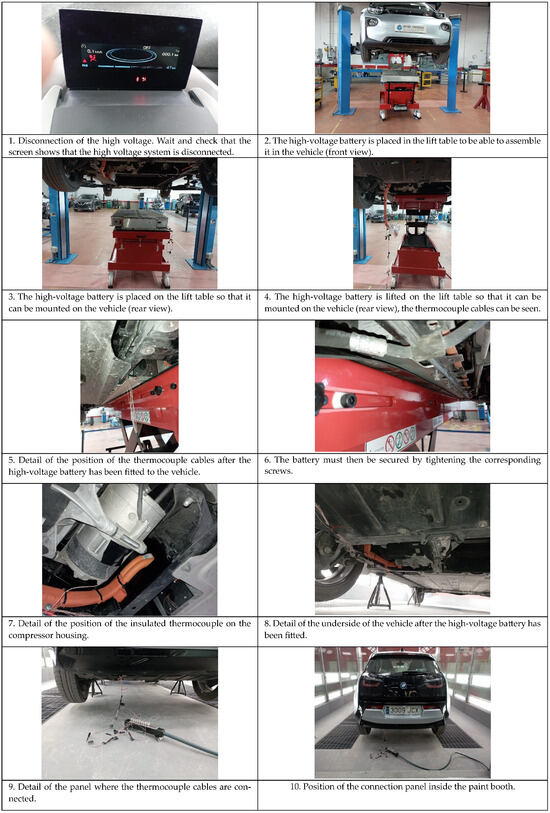

First, the high-voltage battery of the BMW i3 vehicle to be tested is dismantled. The procedure indicated by the manufacturer is followed as shown below (Figure 52).

Figure 52.

Disassembly procedure of the high voltage battery of the BMW i3 vehicle to be tested.

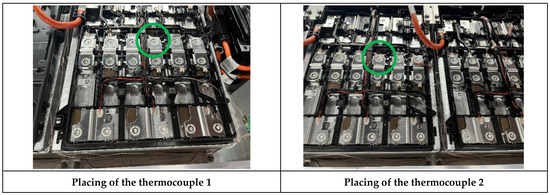

The following images (Figure 53) show where the thermocouples have been placed in each of the modules, following the numbering established by BMW so that they correspond with the readings made by the BMW equipment and can be compared. The wiring has been routed along the same path as the rest of the cables and taken out through the relief valve hole after disassembling and removing the relief valve, as can be seen in the images.

Figure 53.

Placement of the thermocouples in each of the eight high-voltage battery modules of the BMW i3 vehicle to be tested.

The following Figure 54 illustrates the positioning of the individual modules within the traction battery, by giving each of them a number (from 1 to 8) taking into account the numbering provided by the manufacturer:

Figure 54.

Image showing the numbering assigned to each of the traction battery modules of the BMW i3 vehicle (left), taking into account the numbering provided by the manufacturer (right).

The thermocouples have been positioned according to the arrangement used by BMW to ensure that the numbering of the measurements taken with the thermocouples corresponds to those taken by the BMW equipment. Below is an image (Figure 55) showing the aperture through which the wiring of the thermocouples placed in the traction battery is routed out.

Figure 55.

Image showing the hole (relief valve) through which the wiring of the thermocouples is passed out, which will later be connected to a connection panel (left). Image of the connection panel where the thermocouple cables are connected to display the temperature in the measured area using the datalogger (right).

The following images (Figure 56) show the battery being reassembled after placing the thermocouples on each of the battery modules.

Figure 56.

Assembly procedure of the high-voltage battery of the BMW i3 vehicle to be tested, after placing the thermocouples on the modules where their temperature will be measured during the tests.

To visualize the temperature data measured with the thermocouples, the thermocouples are connected to the connection panel and then the datalogger is connected to a computer running the Keysight BenchVue program. This setup allows visualization of the temperature data recorded by the thermocouples placed on each of the traction battery modules and the thermocouple placed on the compressor. This program enables the configuration of temperature data recording; the temperature from all nine channels is recorded every 30 s for one hour and the recorded data are exported in Excel format.

3.2.2. Battery SoC 50%

In the initial test conducted using the TEXA multi-brand diagnostic equipment, the high-voltage battery displayed an SoC of 50.0%.

Below is Figure 57, a graph depicting the temperature and humidity inside the paint booth during the test, recorded by the EL-USB-2-LCD temperature meter placed inside the paint booth.

Figure 57.

Graph illustrating the temperature (red line) and humidity (blue line) recorded by the EL-USB-2-LCD meter inside the paint booth during the test conducted with the battery at 50% SoC (TEXA diagnostic equipment + thermocouples).

Despite the continuous heating process, the previous graph shows occasional temperature drops at different intervals. These occur when the cabin door is opened for inspections, causing temporary cooling before resuming the heating process.

Similar to tests conducted using BMW diagnostic equipment, temperatures are also measured at various points on the bodywork of the BMW i3 vehicle using a thermal imaging camera. For analysis across different states of charge, specifically at 50% SoC, four tests are defined. Initially, the reference test sets the paint booth temperature to 60 °C for the first 60 min, followed by a temperature check at 60 °C after an additional 60 min. Subsequently, the booth temperature is set to 80 °C, with measurements taken again after 60 min and another 60 min interval. A table with the defined tests to be carried out is given below (Table 8).

Table 8.

Definition of tests conducted with the traction battery at 50% state of charge (TEXA diagnostic equipment + thermocouples).

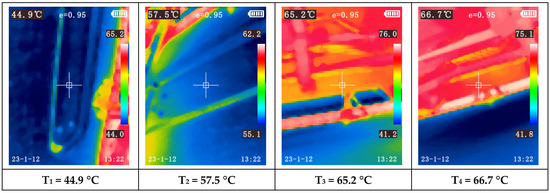

The following image (Figure 58) display the measurements obtained at the four designated points.

Figure 58.

Thermal images captured at the end of Test 1, as outlined in Table 8, using a thermal imaging camera.

The temperature of the compressor is subsequently measured to verify its operation during Test 1 (Figure 59).

Figure 59.

Image captured with the thermal imaging camera of the compressor to verify its operation during Test 1.

The following image (Figure 60) display the measurements obtained at the four designated points.

Figure 60.

Images captured with the thermal imaging camera at the four defined measurement points, at the conclusion of Test 2, as specified in Table 8.

The temperature of the compressor is then measured to verify its operation during Test 2 (Figure 61).

Figure 61.

Image captured with the thermal imaging camera of the compressor to verify its operation during Test 2.

The following image (Figure 62) display the measurements obtained at the four designated points.

Figure 62.

Images captured with the thermal imaging camera at the four designated measurement points, at the conclusion of Test 3, as specified in Table 8.

The temperature of the compressor is then measured to verify its operation during Test 3 (Figure 63).

Figure 63.

Image captured with the thermal imaging camera of the compressor to verify its operation during Test 3.

The following image (Figure 64) display the measurements obtained at the four designated points.

Figure 64.

Images captured with the thermal imaging camera at the four designated measurement points, at the end of Test 4, as specified in Table 8.

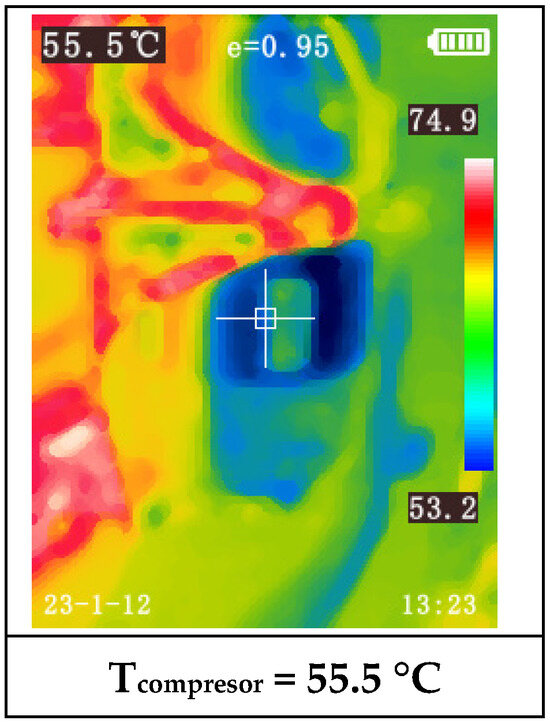

The temperature of the compressor is then measured to verify its operation during Test 4 (Figure 65).

Figure 65.

Image captured with the thermal imaging camera of the compressor to verify its operation during Test 4.

The following Table 9 shows the temperatures recorded at the four measurement points on the bodywork and the temperature on the compressor, for the four tests conducted.

Table 9.

Temperature measurement at the four designated points on the bodywork and the temperature of the compressor for the four tests conducted.

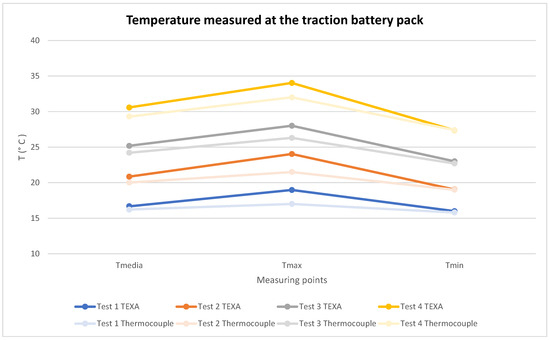

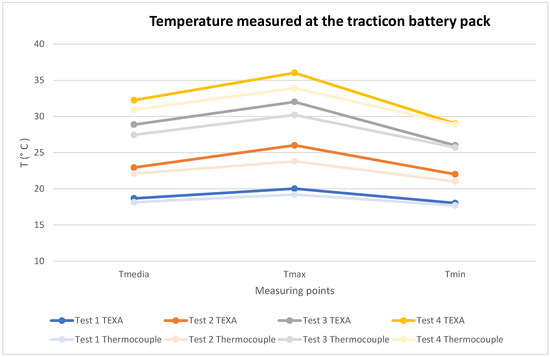

Additionally, Table 10 below displays the Tmax, Tmin, and Tmean temperatures of the battery pack, obtained from the TEXA diagnostic equipment.

Table 10.

Traction battery pack temperatures obtained from the TEXA diagnostic equipment for the four tests conducted.

Below (Figure 66) are snapshots of the measurements taken with the TEXA diagnostic equipment during the tests.

Figure 66.

Temperature measurements obtained using the TEXA diagnostic equipment for the various tests conducted.

Finally, Table 11 below presents the temperature data for each of the traction battery modules and the compressor, obtained from the thermocouple temperature measurement equipment.

Table 11.

Temperatures in each of the traction battery modules obtained from the thermocouple temperature measurement equipment for the four tests carried out.

Figure 67 displays the temperature at various measuring points on the bodywork.

Figure 67.

Graph showing the temperature measured at various points of the bodywork using a thermal imaging camera during the four tests conducted with the battery at 50% SoC.

The graph above (Figure 67) illustrates that, as the temperature inside the paint booth increases and the duration of the measurement test extends, the temperature at different points on the bodywork also increases, similar to the results obtained with the BMW equipment. Additionally, each test reveals that the highest temperature is consistently recorded at the front footboard area, depending on the vehicle’s travel direction. In contrast, the BMW equipment test showed the highest temperature at the rear footboard area. In both tests, it is observed that temperatures in the footboard area are higher than in the lower part, possibly due to the presence of a cooling plate between the measuring point and the high-voltage battery.

Figure 68 displays the temperature readings from each of the traction battery modules obtained using temperature-measuring equipment (thermocouples).

Figure 68.

Graph showing the temperature in each of the traction battery modules obtained with temperature-measuring equipment (thermocouples) during the four tests conducted with the battery at 50% SoC.

The graph above (Figure 68) illustrates that, similarly to the temperature measured at different points on the bodywork, as the temperature inside the paint booth increases and the duration of the measurement test extends, the temperature in the different modules also increases. Furthermore, in each of the tests conducted, it is evident that Modules 1 and 8 consistently reach the highest temperatures, followed by Module 5.

During this test, the cooling valve remained closed throughout as none of the module temperatures exceeded 32 °C.

Since the mean, maximum, and minimum temperatures of the battery pack for each test were measured using TEXA diagnostic equipment, these temperatures will be compared with those obtained from thermocouple measurements (Table 12).

Table 12.

Traction battery pack temperatures obtained from TEXA diagnostic equipment for the four tests conducted.

The following graph (Figure 69) illustrates how the temperature measurements with thermocouples yield lower values compared to those obtained with TEXA diagnostic equipment. There is a notable difference in both maximum and minimum temperature measurements.

Figure 69.

Graph depicting temperatures measured in the battery pack using TEXA diagnostic equipment and the average values from thermocouples in the modules.

3.2.3. Battery SoC 100%

In the second test conducted with the TEXA multi-brand diagnostic equipment, the high-voltage battery displayed an SoC of 100.0%.

Below is a graph (Figure 70) illustrating the temperature and humidity inside the paint booth during the test, recorded by the EL-USB-2-LCD temperature meter placed inside the paint booth.

Figure 70.

Graph showing the temperature (red line) and humidity (blue line) recorded by the EL-USB-2-LCD meter inside the paint booth during the test conducted with the battery at 100% SoC (TEXA diagnostic equipment + thermocouples).

Similar to tests conducted with the BMW diagnostic equipment, temperature readings were taken at various points on the BMW i3 vehicle’s bodywork using a thermal imaging camera. For analysis at different states of charge, in this instance, 100% SoC, four tests were defined. These include the initial reference test where the paint booth temperature was set at 60 °C for the first 60 min, followed by a second measurement at 60 °C after an additional 60 min. Subsequently, the booth temperature was raised to 80 °C, with a measurement taken after 60 min, and again after an extra 33 min, due to the maximum temperature reaching 36.0 °C in this final test leading to a safety stoppage. A table with the defined tests to be conducted is given below (Table 13).

Table 13.

Definition of tests conducted with the traction battery at 100% state of charge (TEXA diagnostic equipment + thermocouples).

The following image (Figure 71) depict the results of the measurements at the four designated points mentioned above, across the test 1 conducted.

Figure 71.

Images captured with the thermal imaging camera at the four designated measurement points, at the conclusion of Test 1, as specified in Table 13.

The temperature of the compressor is then measured to verify its operation during Test 1 (Figure 72).

Figure 72.

Thermal imaging camera image capturing the operation of the compressor during Test 1.

The following image (Figure 73) depict the results of the measurements at the four designated points mentioned above, across the test 2 conducted.

Figure 73.

Images captured with the thermal imaging camera at the four specified measurement points, at the conclusion of Test 2, as outlined in Table 13.

The temperature of the compressor is then measured to verify its operation during Test 2 (Figure 74).

Figure 74.

Image captured with the thermal imaging camera on the compressor to verify its operation during Test 2.

The following image (Figure 75) depict the results of the measurements at the four designated points mentioned above, across the test 3 conducted.

Figure 75.

Images captured with the thermal imaging camera at the four defined measurement points, at the conclusion of Test 3, as outlined in Table 13.

The temperature of the compressor is then measured to verify its operation during Test 3 (Figure 76).

Figure 76.

Image captured with the thermal imaging camera on the compressor to verify its operation during Test 3.

After 33 min, the fourth test is stopped for safety as the maximum temperature measurement of the battery pack reaches 36.0 °C. The results of the temperature measurement at the four defined body points after 33 min are shown below (Figure 77).

Figure 77.

Images captured with the thermal imaging camera at the four specified measurement points, at the conclusion of Test 4, as outlined in Table 13.

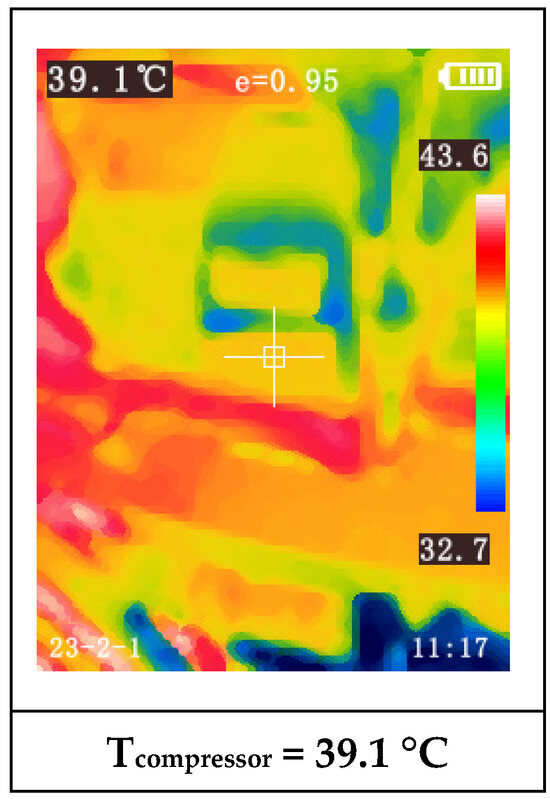

The temperature of the compressor is then measured to verify its operation during Test 4 (Figure 78).

Figure 78.

Image captured with the thermal imaging camera on the compressor to verify its operation during Test 4.

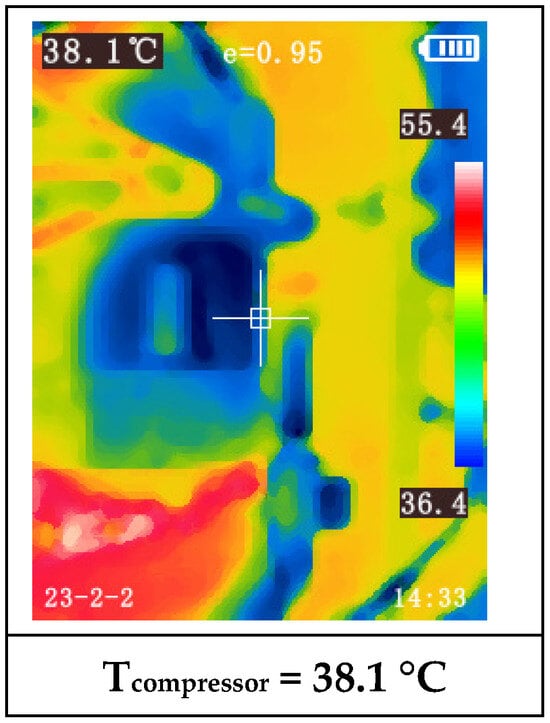

After stopping the test and checking the compressor temperature, the access door to the paint booth is opened for cooling. After 5 min, the compressor temperature is rechecked, and it has decreased to 38.1 °C (Figure 79).

Figure 79.

Image captured with the thermal imaging camera on the compressor 5 min after stopping the test.

From this point onward, the compressor begins to be cooled with air until it reaches 35 °C and starts operating after the vehicle has been put into READY mode.

Additionally, Table 14 displays the temperatures obtained at the four defined measurement points on the bodywork and the temperature on the compressor, for the four tests conducted with a 100% SoC in the battery pack.

Table 14.

Result of the measurement at the four defined points on the bodywork and the measurement on the compressor for the four tests conducted with a 100% SoC in the battery pack.

Additionally, Table 15 shows the Tmax, Tmin and Tmean temperatures of the battery pack, obtained from the TEXA diagnostic equipment.

Table 15.

Traction battery pack temperature obtained from the TEXA diagnostic equipment for the four tests conducted with a 100% SoC in the battery pack.

Finally, Table 16 displays the temperature data of the modules and in the compressor, obtained from the thermocouple temperature measurement equipment.

Table 16.

Temperatures in each of the traction battery modules obtained from the thermocouple temperature measurement equipment for the four tests conducted with 100% SoC in the battery pack.

Figure 80 displays the temperature at various measurement points on the bodywork.

Figure 80.

Graph of the temperature measured at different points of the bodywork with a thermal imaging camera in the four tests carried out with the battery at 100% SoC.

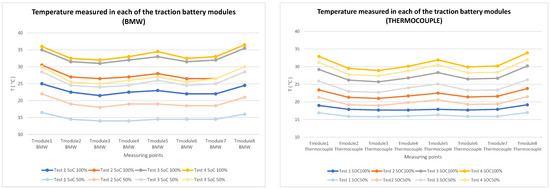

The graph above (Figure 80) illustrates that, as the paint booth temperature and the duration of the measurement test increase, the temperature at different points on the bodywork also rises, similar to the findings in the test conducted with BMW diagnostic equipment. Moreover, in each test conducted, the highest temperature is consistently observed at the footboard in the front area, depending on the vehicle’s direction of travel. Conversely, in tests conducted with BMW diagnostic equipment, the highest temperature point is at the footboard in the rear area. Both tests conclude that temperatures in the footboard area are higher than in the lower parts, possibly due to the cooling plate located between the measurement point and the high-voltage battery.