Abstract

One of the global ecological problems is the excessive carbon dioxide emissions generated by vehicles in the transport sector, including passenger transport. Therefore, the objective of this investigation was to develop a model that supports the prediction of vehicle variants that will be satisfactory to the customer in terms of: (i) quality level and (ii) environmental impact throughout the life cycle. This model was developed with the following techniques: TOPSIS (Technique for Order of Preference by Similarity to Ideal Solution), LCA (Life Cycle Assessment), SMARTER (Specific, Measurable, Achievable, Relevant, and Time-bound), Pareto–Lorenz, and the Multi-Criteria Decision Method rule (7 ± 2). A model test was carried out for production variants of the electric vehicle BEV (battery electric vehicle) for which the quality level and life cycle assessment were estimated. Vehicle quality levels ranged from 0.15 to 0.69, with a weight of 0.75. However, vehicle life cycle scores were estimated in the range of 0.25 to 0.57, with a weight of 0.25. Ultimately, the level of the vehicles’ LCA ranged from 0.18 to 0.62. As a result, it was shown that on the basis of various modifications of the quality level of vehicle variants and the corresponding environmental impacts throughout their life cycle, it is possible to predict the vehicle variant that is most satisfactory for the customer and, at the same time, environmentally friendly. The originality of the model relies on supporting the making of sustainable design decisions and the planning of vehicle improvement actions according to customer expectations. Therefore, the model can be used to analyse different types of vehicles by producers and dealers of these products.

Keywords:

quality; LCA; TOPSIS; electric vehicles; mechanical engineering; production engineering; design; management 1. Introduction

The global climate and environmental crisis are leading organisations to strive for a low-emission and ecological transformation of society and economy [1,2,3,4,5], while also using modern technologies for this purpose [6,7]. This crisis is mainly the result of the industrialisation of production and everyday human activities that consume significant amounts of fossil energy, e.g., oil and coal [8,9]. As a result, they generate excessive greenhouse gas emissions—that is, carbon emissions [1,9,10,11]. According to data from the International Energy Agency in 2020, transport accounts for 25–30% of total carbon dioxide emissions [4,12,13]; therefore, it is the second largest source of CO2 in energy production and heating. Similarly, the declaration issued by the Second World Conference of the United Nations in 2021 confirmed that the transport sector is responsible for a quarter of greenhouse gases [14]. Therefore, transport is considered key to the promotion of low-emission development, with the reduction and neutrality of CO2 emissions being one of the development goals of this sector [14,15,16,17,18,19].

Various countries set targets to reduce carbon dioxide emissions in the transport sector. For example, the USA has committed to reducing CO2 emissions by approximately 50% by 2030 (compared to 2005). This is due to the fact that transport in the USA is the main source of greenhouse gases [19]. In turn, China has committed to achieving carbon neutrality by 2060. In this country, transport was responsible for 11% of CO2 emissions in 2020, being the third largest economic sector (after electricity and industry) [20,21]. However, the European Union (EU) has a programme to decarbonise the transport sector. The EU plays a fundamental role in global energy and climate policy. As part of the Paris Agreement, the EU committed to reducing national greenhouse gas emissions by 40% by 2050 [2] (the baseline was in 1990), with some of these emissions coming from transport [22,23]. The global importance of the need to reduce carbon dioxide emissions in the transport sector determines the need to take appropriate improvement actions.

A current and important project is, among others, the production of electric and autonomous cars [24,25,26]. According to the analysis shown in one study [27], the largest producer of electric vehicles is China. Much smaller numbers of BEVs (battery electric vehicles) are produced in a comparable manner in the USA and European countries. As part of the production of electric vehicles, but also conventional vehicles, one key is the analysis and improvement of means of transport in their total life cycle (LCA) [11,28,29,30,31]. Life cycle assessment (LCA) is a quantitative method, and it is a standardised but still developing method to assess the potential impact on the natural environment of processes, products, and actions. Their purpose is quantitatively determined, but the method also includes assessment of energy and material flows, which are used during all stages of life. During analysis, waste and environmental factors are also considered [32,33,34,35]. Therefore, due to the reduction of carbon dioxide in the transport sector, LCA is a frequently used method. For this reason, a literature review was conducted in this thematic area.

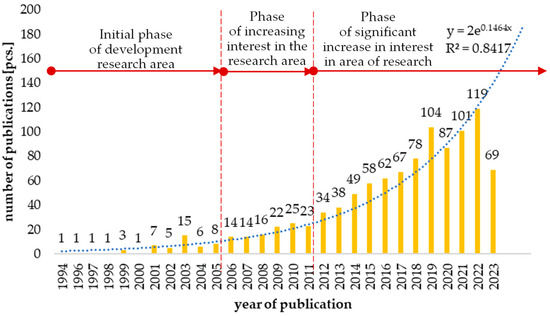

To identify publications corresponding to the research area, the following search terms were used: LCA and vehicle. The publication identification criteria were the title, abstract, and keywords. As a result, 1029 total publications were identified, of which 400 were open access publications. The first study in the research area was carried out in 1994, as shown in Figure 1.

Figure 1.

Number of publications in the area of life cycle assessment of vehicles according to the Web of Science database (checked October 2023).

Analysis of the number of publications has shown that the research area refers to vehicle life cycle assessments, which is a current and developing topic, as observed in three phases. The first phase refers to the initial publications, which occurred relatively recently, during the years 1994–2005. Then, interest in the topic was negligible (from 1 to 15 studies). The first phase refers to 2006–2011, where the number of publications increased significantly (even up to 25 in 2010). This shows the development of the analysed research area and the growth of the research theme. In turn, the third phase begins in 2012 and refers to an increase in growth in the number of publications. On the basis of this, the exponential trend line was calculated (R2 = 0.8417). This trend was created in MS Excel based on the presented data. According to these correlation coefficients, it was concluded that the trend line fits the data very well (R2 close to 1); therefore, it is expected that the number of publications will increase significantly in the coming years (and a significant development of the research area is predicted in the following years). On the basis of the results obtained, an increase in the number of publications on the analysed topic can be expected. Due to the fact that the exponential graph increases the number of publications to a large extent, it is likely that the number of publications will increase in the coming time, but not necessarily that quickly. To predict the number of publications in the future, one should also look for other fit curves to the available data, and also for different time periods. Based on the conclusions drawn, it will be possible to predict the number of publications. Current environmental problems and interest in environmental issues, but also interest in development, the development of vehicles, and the components used in them, confirm the phenomenon of development in this research area. At the same time, it indicates that it is justified to undertake the analysed research topic. Therefore, the content of the publications was analysed one by one. Due to the extensiveness of the issue, selected publications are cited in this study, including the most frequently cited publications.

For example, Hawkins et al. [35] developed an inventory of LCA for conventional and electric vehicles considering different categories of influence. As a result of the analysis, it was shown that electric vehicles powered by the European energy mix were rated 10% to 24%, thus reducing the potential to reduce global warming compared to the potential of conventional vehicles (diesel or gasoline). Tang et al. [36], using LCA, developed a traffic intensity index taking into account road conditions, time, and regions. Simulations were performed for different regions of China. The subjects of the research were electric vehicles and internal combustion vehicles. Electric vehicles have shown less carbon footprint in their life cycle in regions in China. Ulrich et al. [37] evaluated the environmental impact on the life cycle of a fleet of vehicles of U-Shift types. Seven different types of impacts were analysed, after which it was shown that the U-Shift fleet has the lowest environmental impact. Another approach to using LCA was the LCA proposed by Kawamoto et al. [38], which analysed carbon dioxide emissions from petrol and diesel engines. They compared different drive systems, e.g., battery electric vehicles. However, Raugei and Winfield [39] evaluated the life cycle of the new battery developed with lithium cobalt phosphate. They also analysed the recycling process of these batteries. Proske and Finkbeiner [40] analysed the results of the lithium ion battery, mainly due to their production. In the case of the production of these batteries, it was recognised that their carbon footprint may be less important than their toxicity. The possibility of using LCA for the analysis of ecological properties of vehicles during their exploitation was analysed by Mrozik and Merkisz-Guranowska [41]. According to their study, the simplified LCA method for vehicles, using adequate assumptions, is applicable to environmental and energetic analyses referring to operation. Social aspects of the automotive industry included in the life cycle assessment were verified by Zanchi et al. [22]. These aspects are evaluated in view of organisational and product behaviour. It showed a need for including in organisations’ actions social expectations and orientation to the product. Accardo et al. [42] analysed the life cycle assessment of three modifications of light commercial vehicles, which were diesel, electric battery, and compressed natural gas. The impact of recycling these vehicles in view of different scenarios of life cycle assessment was analysed. After analysis, it was shown that it is possible to obtain different results for different scenarios. Arvidsson et al. [43] evaluated batteries and fossil fuel vehicles. A balanced life cycle assessment was used to quantify the uncertainty of inputs and outcomes after LCA. The results showed that electrifying the Tasmanian vehicle fleet delivers the greatest reductions in greenhouse gas emissions. Nordelöf et al. [44] have reviewed the suitability of different LCA studies for vehicle analysis. They showed, for example, that effective recycling of electric vehicles will reduce the demand for primary resources and production energy [45]. Other publications analysed, in a general context, life cycle analyses of various types of vehicles in terms of various criteria, methods, and scenarios. Therefore, we deduce that:

- Vehicle life cycle analysis is a current and dynamically developing problem;

- Previous analyses of the selected research areas mainly focused on the “cradle-to-grave” assessment of the environmental impact of vehicles;

- Various types of vehicles were analysed in terms of their entire life cycle, but also based on selected life cycle phases;

- The LCA analyses for vehicles were based on various assumptions and criteria, e.g., type of power supply, recyclability, region, time, etc.;

- Modifications of the life cycle analysis were created depending on the input data to the analysis/model.

The main conclusions that describe the research gap refer to the lack of research, which allows one to predict vehicle modification [46], which will be most satisfactory to customers in terms of quality (use criteria of the vehicle) and, simultaneously, in terms of the impact on the natural environment in the whole life cycle assessment (LCA). The identified research gap was filled by developing a model, the characteristics of which are presented in the second part of this study.

The motivation for conducting this research was the significant impact of vehicles on the formation of carbon dioxide and, therefore, greenhouse gases [16,33,35,46]. Furthermore, the idea included focussing on the utility aspects of vehicles (quality of vehicles), which are essential for customers using these vehicles [46,47,48,49,50,51].

Therefore, the objective of this investigation was to develop a model that supports the prediction of vehicle alternatives according to the combined life cycle assessment and quality level. This research included testing the following thesis:

Thesis 1.

Based on the different modifications of the quality level of vehicle variants and the corresponding environmental impacts throughout the life cycle, it is possible to predict the variant of the vehicle that is the most satisfying for the customer and, simultaneously, environmentally friendly.

The originality of the model supports:

- (i)

- Assessment of the vehicle quality level according to current vehicle criteria and modified criteria;

- (ii)

- Evaluation of the vehicle life cycle for the reference vehicle and prediction of changes in environmental impact in the entire life cycle of this vehicle resulting from changes in the qualitative criteria;

- (iii)

- Predicting satisfactory alternatives for the reference vehicle, which will result simultaneously in a beneficial quality level for the customer and an environmental impact for the whole life cycle.

At the same time, the novelty of the model is the determination of a ranking of vehicle improvement activities, which will be a component of the vehicle life cycle assessment and the assessment of its quality level for various modifications of vehicle criteria. On this basis, it is possible to undertake design activities within the client’s expectations and in the context of sustainable development.

2. Materials and Methods

As part of conducting this research, a model was developed that supports the prediction of vehicle alternatives according to the combined life cycle assessment and quality level. The concept of the model refers to predicting the variant of the vehicle that will be satisfactory to the customer and simultaneously to the environment in the case of the entire life cycle (LCA). It is based on determining the current level of quality and its current impact on the whole life cycle. Then, based on the current state of the unit, it is assumed that its possible alternatives (modifications) are determined [52]. Later, vehicle quality levels are combined with the environmental impact throughout the entire life cycle. On the basis of that, the variant of the vehicle is predicted, and this variant will be the most satisfying for the producer. Then, according to the results obtained, it is possible to design a vehicle that takes into account satisfactory variants of vehicle quality criteria and the corresponding lowest possible environmental impacts on the life cycle (LCA).

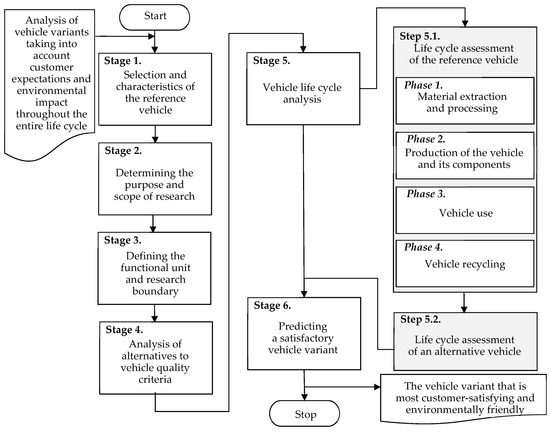

The developed model is adjusted for the analysis of the vehicle life cycle without including assessments of the battery life cycle. This is due to the idea of the model, which concerns the process of modifying only the qualitative criteria according to which changes in the LCA assessment are predicted. Additionally, accounting for battery variants is a complex issue on its own due to changing technological advancements. Battery analysis can be realised based on the literature, e.g., [38,52,53]. Therefore, future research will consist of adapting the model to analyses taking into account various types of vehicles and their batteries. The model algorithm is presented in Figure 2.

Figure 2.

Algorithm of sustainable vehicle design considering the quality level and life cycle environmental impact (LCA).

In this model, the implemented method was based on a life cycle assessment. Also, during the development of the model, it was based on data from GREET software v1.3.0.13991. The mentioned GREET software was developed at the Argonne National Laboratory. It can be used to assess the impact of energy and emission from advanced and new transportation fuels and to assess the fuel cycle and the entire vehicle cycle through material recovery and vehicle disposal [54].

For the vehicle, it was based on the TOPSIS method (Technique for Order of Preference by Similarity to Ideal Solution) [55,56,57]. This method is popular and often used to make decisions and assess any products. The TOPSIS method corresponds to the concept of the model and allows for evaluating different product alternatives according to any qualitative criteria [58,59]. Therefore, it was decided to implement it in the model being developed.

- Stage 1. Selection and characteristics of the reference vehicle

As part of the research, it was necessary to choose the reference vehicle (assigned/assumed for the analysis). Reference vehicles are subject to analysis and, generally, are vehicles of similar types. It is possible to choose any type of vehicle with regard to the needs of the analysis. The choice is made by the expert (the entity using this model, the dealer, or the producer) after consultation with customers. It can be, e.g., a conventional vehicle (for example, powered by petrol, diesel type), hybrid powered by an internal combustion engine (gasoline or diesel), electric (HVE—hybrid and electric vehicle), or an electric vehicle (for example, BEV—battery electric vehicle). The selected reference vehicle should be characterised by taking into account basic criteria, e.g., length, height, weight, battery type, etc.

According to the model database GREET v1.3.0.13991 and based on the literature review of this study, e.g., [30,54], it was concluded that:

- The main components of vehicles are:

- ○

- The body;

- ○

- The chassis;

- ○

- The drive system;

- ○

- The traction engine;

- ○

- Electronics;

- ○

- The battery.

- The main materials used in the production of vehicle components are:

- ○

- Steel;

- ○

- Iron;

- ○

- Aluminium;

- ○

- Copper;

- ○

- Glass;

- ○

- Plastic;

- ○

- Rubber.

The components and materials used in their production are the subject of further analysis.

- Stage 2. Determining the purpose and scope of the research

The purpose of the research determines the entity using the proposed model. It was assumed that the purpose is to predict the most favourable modification of the vehicle, which will refer to the quality of the vehicle and its impact on the environment throughout the life cycle. The quality of the vehicle is understood as the satisfaction of the customer based on the utility of vehicle, and it is analysed based on qualitative vehicle criteria. However, the environmental impact of the vehicle is related to the full life cycle of the vehicle and concerns the analysis of energy and material consumption, carbon dioxide (CO2) consumption, and emissions of air pollutants and waste. To precisely define your goal, you can use the SMARTER method (Specific, Measurable, Achievable, Relevant, and Time-bound) [60]. The scope of this research includes the following:

- (i)

- Analysis of the quality level of the reference vehicle and its variants/modifications;

- (ii)

- Assessing the life cycle of the reference vehicle and anticipating changes to this assessment for possible modifications to the vehicle.

Further procedures are described in the subsequent stages of the model.

- Stage 3. Defining the functional unit and research boundary

As part of the proposed model, it is necessary to determine the functional unit and the research boundary. As mentioned by the researchers of the investigation (for example, [35,51]), the functional unit allows one to normalise the database, thus allowing for comparison of several objects. Due to the fact that the model is dedicated to vehicles, the vehicle’s function concerns passenger transport. Therefore, it was assumed that the functional unit is 1 passenger kilometre (pkm) travelled by the vehicle. According to the authors of the studies [30,61,62], the mileage of a passenger vehicle throughout its entire life cycle is approximately 150,000 km. Hence, the functional unit is 150,000 pkm.

The research is set by the subject (expert). It is a temporal and a spatial boundary. The time limit concerns the year during which data are obtained for analysis. However, the spatial boundary concerns the area of analysis, e.g., a country, a region, several countries, etc. The time and space boundaries are arbitrary and result from the nature of the research being carried out [43,63,64].

- Stage 4. Analysis of alternatives to vehicle quality criteria

The proposed model included an analysis of the qualitative alternatives of the vehicle. Qualitative criteria of the vehicle are criteria that refer to satisfaction of the customer based on the utility of the vehicle, e.g., dimensions, weight, speed, etc. It was assumed that it will be analysed using different variants of these criteria (so-called alternatives). The qualitative criteria are the current criteria (currently present in the vehicle analysed). It was assumed that alternatives to these criteria will be hypothetical criteria occurring in the vehicle. Therefore, alternative criteria are the so-called modifications of the current criteria.

The choice of qualitative criteria is made by experts (based on the results of customer research) and based on the vehicle’s specification. According to the review of the literature on the subject, it is necessary to determine about 10 different criteria. Then, each criterion should be described by a parameter that characterises it. Initially, all criteria should be described according to current (actually existing) parameters, e.g., value, value range, description, etc. Based on the current criteria parameters, their modifications (the so-called alternative vehicle design/construction solutions) should be determined. Based on the decision rules, that is, [65], it was assumed that 5 9 design solutions were determined, including, for example, criteria based on the current state and at least four different modifications of the states of the criteria. According to one study [66], it was assumed that modification of the states of the criterion expressed by the number parameter can be determined according to the Pareto–Lorenz rule (20/80). Then, the modifications of the criteria states change in proportion to the remaining ones, e.g., by 20% of the value of a given parameter. For criteria that are not described as numerical values, their various modifications should be given in a descriptive manner. A summary of the criteria and their alternatives can be presented in a table.

Then, the quality levels of the current vehicle and the alternatives are assessed. For this, the TOPSIS method is used [55,56,57]. For this aim, the customer assessed all criteria of current and modified states (i.e., alternatives). It was assumed that assessments are performed based on a 7-point scale, where 1—the condition of the criterion is slightly satisfactory, and 7—the condition of the criterion is very satisfactory. Based on the customer’s assessment, a decision matrix is created , where i—alternatives, and j—criteria. Then, a normalised decision matrix is created, , as shown in Equation (1) [57]:

where x—assessment of criterion state, i—alternative (state of vehicle criterion), j—vehicle criterion, and m—type of vehicle.

Later, a weighted normalised decision matrix is determined , as shown in Equation (2) [58]:

where r—normalised value of the decision matrix, w—criterion weight, i—alternative, and j—criterion.

Subsequently, it is possible to determine the ideal positive solution () and the ideal negative solution () (3) [58]:

Then, the distance from each decision variant is determined () for the ideal positive solution () or the ideal negative solution () (4) [59]:

Subsequently, the coefficient of relative closeness of the decision variants () to the most preferred solution is determined (5) [55]:

The last step is to develop a ranking that takes into account the proximity values of the coefficients of the decision variants to the ideal solution. It is assumed that the higher the value of this coefficient, the better the decision-making variant. The first position in the ranking is the most advantageous variant in terms of quality. The last position in the ranking is the least favourable variant in terms of quality. The values of the relative proximity factor in this approach represent the quality level of the vehicles (), hence (=). This coefficient is further processed in Stage 6 of the model.

- Stage 5. Vehicle life cycle analysis

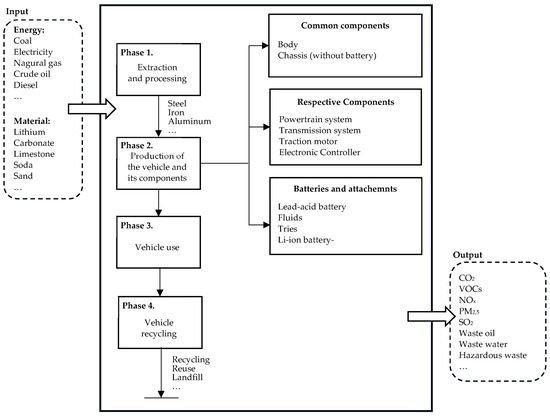

A life cycle assessment (LCA) of a vehicle is a quantitative method that is used to determine the potential impact on the environment. This impact is related to the entire vehicle life cycle and refers to the analysis of energy and materials, demand for carbon dioxide (CO2), and emission of pollutants from air and waste (Figure 3).

Figure 3.

System boundary of a vehicle life cycle analysis. Our own study, based on [67,68,69].

Based on the analysis of the life cycle, it is possible to calculate the total emission of carbon dioxide (CO2) for any vehicle.

In the proposed approach, the life cycle analysis was performed according to the traditional LCA methodology for vehicles. If the LCA results can be different in the case of the type and specification of the vehicle, it was assumed that the results obtained by LCA can be modelled according to the alternative (modifications) of the vehicle. This refers to the fact that, based on the life cycle assessment of the reference vehicle, it will be predicting the life cycle assessment of modified vehicles (alternatives to the reference vehicle). It is performed according to assumptions of the modification of the qualitative criteria of the vehicle and the Pareto–Lorenz rule (20/80). If the modifications of the criteria states change proportionally to the remaining ones by, e.g., 20% of the parameter value, the LCA results change proportionally to the remaining ones by a given percentage of the total carbon dioxide emissions in the vehicle’s life cycle. The percentage value can be adopted in accordance with the Pareto principle (i.e., 20%) or another value that results from the need for analysis and is supported by expert knowledge. This is represented by Equation (6) [69]:

where —total emission of carbon dioxide in life cycle vehicle, —carbon emissions from extraction and processing of the material, CVA—carbon dioxide emissions from the production of the vehicle and the components, CVU—carbon dioxide emissions from vehicle use, CRE—carbon dioxide emissions in vehicle recycling, i—ith alternative vehicle, and ref—reference vehicle.

Therefore, in the initial stage, it is necessary to calculate the total CO2 emission in the life cycle of the reference vehicle. Then, it is necessary to model the change of the vehicle LCA value adequately to the alternative (modification determined in stage 4) in relation to the change according to the adopted percentage value.

- Step 5.1. Life cycle assessment of the reference vehicle

The life cycle assessment of the reference vehicle is carried out in four phases. Their characteristics are presented in the next part of this study.

- Phase 1. Material extraction and processing

Material extraction and processing are concerned with the extraction and processing of raw materials that are used in the construction of vehicle components. This phase mainly includes mining, enrichment, smelting, refining, etc. [67]. To calculate carbon emissions from this process, use Equation (7) [68,69]:

where —carbon dioxide emissions from fuel consumption during material production, —carbon dioxide emissions from electricity consumption during material production, x—material, m—mass (kg), n—production process, —energy consumption per unit of material in its production process (kJ/kg), k—fuel, —share of fuel consumption in , —share of electricity consumption in , and —fuel carbon emission factor .

- Phase 2. Production of the vehicle and its components

The production of a vehicle and its components involves the storage of the parts of the vehicle necessary to create the vehicle. In this phase, the analysis refers to calculating the emissions that occurred during processing and assembly of the main components of the vehicle. The assembly refers, e.g., to stamping, welding, and painting. It is possible to include the distribution of vehicles, i.e., transport [67]. To calculate the carbon dioxide from the production vehicle and its components, Equation (8) is used [69]:

where —carbon dioxide emissions from fuel consumption produced by the production of the component, —carbon dioxide emissions from electricity consumption in the production of the component, y—component (part), —electricity consumption during vehicle assembly, q—production process, —energy consumption of a component in the production process (kJ), —share of fuel consumption in , —share of electricity in , and —fuel carbon emission factor .

- Phase 3. Vehicle use

The first phase is the utility of the vehicle, which refers to the energy consumption and carbon emissions during the use of the vehicle. It concerns fuel consumption and vehicle maintenance [58]. In this approach, it was assumed that to calculate carbon dioxide emissions resulting from utility of the vehicle, Equation (9) is used [69,70,71]:

where PE—electricity consumption per 100 km by an electric vehicle (kWh/km), CE—charging efficiency, d—total driving distance of the electric vehicle (km), Fk—fuel consumption per 100 km for a vehicle with an internal combustion engine or diesel engine (l), —fuel density, k—fuel, —lower thermal value of the fuel (kJ/kg), and Ck—carbon emissions per unit k in fuel production.

- Phase 4. Vehicle recycling

The fourth phase is vehicle recycling, so an analysis of emission during the recycling of selected components of the vehicle is necessary. The recycling phase refers to the dismantling of vehicle components. Then, the metal and other non-metallic materials of these components are separated and cleaned. Metal is recycled (without the battery). Despite that, other non-metallic material (plastic, glass, etc.) is disposed of in landfills or incineration. In this phase, the components are recycled, used, and reused [67]. Due to the nature of the model, in this case, phase 4 covers vehicle recycling without including battery recycling. To estimate carbon dioxide emissions in vehicle recycling (without the battery), Equation (10) should be used [69,72,73,74,75]:

where —carbon dioxide emissions from fuel consumption in vehicle recycling, —carbon dioxide emissions from electricity consumption in vehicle recycling, —energy consumption per unit of material x in the recycling phase (kJ/kg), x—recycled material, —share of fuel consumption in , —share of electricity consumption in , m—mass (kg), and —energy consumption when dismantling the vehicle.

Based on the calculated indicators, it is possible to calculate the total carbon dioxide emissions during the life cycle of the reference vehicle. Equation (6) is used for this purpose. Then, it is possible to predict the life cycle assessment of the alternative vehicle, as presented in the next step.

- Step 5.2. Life cycle assessment of an alternative vehicle

Based on the life cycle assessment of the reference vehicle, it is possible to predict the life cycle assessment of the alternative vehicle (i.e., modified in the case of qualitative criteria). This refers to the fact that for each vehicle quality level (resulting from the modification of qualitative criteria), it is necessary to predict the results of the life cycle assessment. Then, the simplified modelling of the change in LCA values, which is adequate for the change in the vehicle’s quality level, is made according to the Pareto–Lorenz rule (20/80) [66]. Equation (6) is used for it. For example, at the current quality level, the results of life cycle assessments are noted. If the modified quality level increased, for example, by 20% of the current level, then the expected result of the life cycle assessment should be increased by 20% of the current life cycle assessment. The modelled results of the life cycle assessment can be saved, for example, in a summary table.

- Stage 6. Predicting a satisfactory vehicle variant

The model is designed to predict the modification of the vehicle that satisfies customers in view of the quality level and the environmental impact of the vehicle throughout its life cycle [71,72,73,74,75]. Therefore, it was decided to combine the values of total carbon dioxide emission in the vehicle life cycle () with an indicator of the vehicle’s quality level (), where these indicators are combined depending on alternatives (modifications). In this case, the indicator is calculated for each alternative (variant) of the vehicle. These alternatives have resulted in different vehicle qualitative levels and environmental impacts in the life cycle, which are modelled for these levels. In cases where values of indicators and differ in size, it is necessary to normalise them. It was assumed that the values of the indicator would be reduced to decimal values, in which the indicator is presented.

Additionally, customer satisfaction with vehicle modifications may depend on the importance to the customer of the vehicle’s environmental impact and, respectively, the importance to the customer of the vehicle’s quality level. Therefore, it is necessary to determine their weights. The validity is determined by the entity (expert) after consultation with the client. Weights can be selected as values in the range , where the higher the weight value, the greater the significance.

The assessment of the quality and environmental level in the context of LCA for vehicle variants/alternatives is estimated according to Equation (11):

where —importance (weight) of the vehicle’s environmental impact in its life cycle, —importance (weight) of the vehicle’s quality level, —the value of the indicator of total carbon dioxide emissions over the vehicle’s life cycle (for the reference vehicle or the reference vehicle alternative, respectively), —quality level of the i-th vehicle variant, and i = 1, 2, 3, …, n.

Based on the values of the indicator, it is possible to predict the customers’ satisfaction with vehicle modification. The most favourable decision variant has the highest value of the indicator. Based on ranking the indicator, the modification of the vehicle can be determined to meet the customer’s expectations (quality) while also considering the environmental impact of vehicle modification in the whole life cycle.

Modifying the reference vehicle according to the predicted most favourable modification (alternative) allows one to achieve satisfaction from the utility of the vehicle and reduce its negative impact on the natural environment. It is the last stage of the model.

3. Results

A test of the model was carried out according to the assumed procedure in the six main stages. Detailed characteristics of the implementation of these stages are presented in the further part of this study.

- Stage 1. Selection and characteristics of the reference vehicle

The model test was carried out for a light passenger electric vehicle from one of the leading manufacturers. This vehicle was the so-called reference vehicle (any vehicle that constitutes a generalisation of light passenger electric vehicles). The choice of an electric vehicle was the result of the individual preferences of the customer for whom the most advantageous vehicle variant was sought. It is possible to distinguish electric vehicles with two types of drive: those using hydrogen (so-called fuel cell vehicles, FCEV) and those using electricity from a battery (BEV, battery electric vehicle). The subject of this research was a BEV [52], which, according to [76], is the most popular electric vehicle.

Electric vehicles and their charging stations are finding increasing use with the development of large-scale electrification of transport [62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77]. Batteries used most frequently in these vehicles are lithium ion batteries (LFP, LiFePO4). They are characterised by a stable structure and high durability [78]. The main benefits of using electric vehicles include being more environmentally friendly, being cheaper to operate compared to conventional vehicles, having greater efficiency and durability, being comfortable to drive (quiet operation), safety, and having a relatively low failure rate. However, the disadvantages of these vehicles include, for example, the high price, the limited travel range, and poor accessibility to charging stations [52,77].

- Stage 2. Determining the purpose and scope of the research

The purpose of this research was to predict the most favourable variant for the electric vehicle (BEV). This variant is analysed based on modification of the qualitative criteria of the vehicle and the impact on the environment of these modifications throughout the life cycle. Therefore, the scope of the investigation included analysis of the quality level of the electric vehicle and its modification and life cycle assessment as part of these modifications. The scope of this research is focused on vehicle life cycle assessment without batteries. This resulted from the nature of the research, which consisted of modelling the expected changes in the results of the vehicle life cycle assessment as a result of modifying its quality criteria. However, future research will consist of adapting the model to analyses taking into account various types of vehicles.

- Stage 3. Defining the functional unit and research boundary

According to the adopted model, the functional unit was 150,000 passenger km [52]. This means that the mileage of a passenger vehicle throughout its entire life cycle is approximately 150,000 km [30,54]. The time limit includes data from 2021–2023, the source of which was a review of the subject literature, data from the GREET v1.3.0.13991 model, and data from the customer (customer expectations of an electric vehicle).

- Stage 4. Analysis of alternatives to vehicle quality criteria

As assumed in the proposed methodology, at this stage of the model, it was necessary to select quality criteria for the reference vehicle. After consultation with the customer, the nine main criteria of the electric vehicle were selected:

- Dimensions;

- Own weight;

- Maximum engine power;

- Size of the central touch screen;

- Max. speed;

- Number of seats;

- Basic warranty;

- Upholstery colour;

- Car colour.

The indicated criteria were adopted for the purposes of model testing. However, the expert may change these criteria. The expert can also reduce or increase their number.

Then, each criterion is characterised by its current state, i.e., the state characterising the current criterion of the reference vehicle. The reference vehicle catalogue was used for this purpose. Later, four modified states were defined for the current states. According to the concept adopted, the modified states expressed by a numerical parameter were determined according to the Pareto principle. As assumed, the modifications of the criteria states were changed in proportion to the remaining values of a given parameter by 20%. For criteria that are not described as numerical values, various modifications have been proposed, as shown in Table 1.

Table 1.

Characterisation of vehicle quality criteria states.

Then, the customer assessed all criteria and their states. The 7-point scale was used for that, where 1—the state of the criterion is slightly satisfactory, 7—the state of the criterion is very satisfactory. A decision matrix was created based on the customer’s ratings , where i—alternatives, and j—criteria. The decision matrix with the customer’s ratings is presented in Table A1.

Then, using Equation (1), the normalised decision matrix was determined, as shown Table A2.

Then, according to Equation (2), the weighted normalised decision matrix was calculated. In this calculation, the customer determined the importance of the quality criteria according to a scale of <0;1> where 0,1—criterion practically irrelevant, 1,0—most important (necessary) criterion. The result is shown in Table A3.

Next, ideal positive solutions () and ideal negative solutions () were determined. Equation (3) was used for that. The results are shown in Table A4.

Later, the distance of each alternative from these solutions was calculated. Equation (4) was used for this purpose. Then, according to Equation (5), the coefficient of relative closeness of decision variants was determined, which represents the quality level of the reference vehicle and its modifications. On this basis, a ranking of vehicle variants was created, as shown in Table A5.

It has been shown that the most favourable quality level is that of the current reference vehicle (i.e., the vehicle currently on sale). However, it was observed that a vehicle with a modified condition of 1 has a satisfactory value of the quality indicator. However, in the proposed approach, the final result is influenced by the assessment of the vehicle’s life cycle according to the modification of its quality criteria.

- Stage 5. Vehicle life cycle analysis

At this stage of the model, an electric vehicle life cycle analysis was performed to calculate the total carbon dioxide emissions from the extraction of materials and raw materials to recycling. As adopted in stage 4 of the model, four variants of modifications of the current electric vehicle were proposed. According to the concept of the adopted model, the LCA results will constitute an assessment of the life cycle of the current reference vehicle and will be successively modelled according to the alternatives (modifications) of the vehicle.

- Step 5.1. Life cycle assessment of the reference vehicle

The life cycle assessment of the analysed electric vehicle was carried out in four phases. This is presented in the next part of this study.

- Phase 1. Material extraction and processing

The main components of the vehicle were included in the analysis of material extraction and processing. Each of these items contains multiple materials. Only the most important materials were included in the analysis (where low-mass materials were omitted).

To calculate carbon emissions from the extraction and processing of materials, a list of materials and an emission factor during their extraction and processing were determined. This was based on data from the GREET model and a review of the literature on the subject [79,80,81]. This is presented in Table 2.

Table 2.

Electric vehicle materials (light passenger vehicle).

Then, based on the data from the GREET model and data from the literature review (for example, [65,69,72,79]), the energy consumption factor for the production of materials in the reference vehicle and the CO2 emission factor throughout the life cycle for the energy types were determined. Coefficients with negligible values were omitted from the analysis in Table 3.

Table 3.

Energy consumption factor for material production and energy life cycle CO2 emission factor for the reference vehicle.

Subsequently, using Equation (7), carbon dioxide emissions from the extraction and processing of materials for the electric vehicle were calculated (Table 4).

Table 4.

Carbon dioxide emissions from the extraction and processing of materials for an electric vehicle.

The total carbon dioxide emission in the first phase of the LCA for the analysed vehicle was = 1023.24 (kJ) = 0.28 (kWh). Fuel emissions during material extraction and processing were found to contribute more to this process than energy emissions.

- Phase 2. Production of the vehicle and its components

The emissions generated during the processing and assembly of the main components were calculated. Based on the GREET model and a review of the literature on the subject [65,69], it was assumed that the electricity consumption during assembly of the main components of the vehicle (without batteries) is 862 (MJ). According to the literature on the subject [80], energy consumption and carbon dioxide emissions were determined for other vehicle production processes. The main processes include material transformation, machining, vehicle painting, HVAC and lighting, heating, material handling, welding, and compressed air (Table 5).

Table 5.

Energy consumption and carbon dioxide emissions for vehicle production processes.

Based on the developed data and using Equation (8), the total emissions during the production of the vehicle and its components were calculated. This was equal to = 35,947.24 (MJ) = 9985.34 (kWh).

- Phase 3. Vehicle use

Energy consumption and carbon emissions during vehicle use were calculated. In the case of electric vehicles, carbon emissions come primarily from the generation of electricity. On the basis of the data characterising the selected reference vehicle, it was possible to determine the emissions when using electric vehicles of a similar type. It was assumed that:

- Electricity consumption per 100 km by an electric vehicle is PE = 17.28 kWh/km;

- The total driving distance of an electric vehicle is d = 531 km;

- The charging efficiency is CE = 0.94 (94%).

Using Equation (9), it was estimated that energy consumption and carbon emissions during one complete trip are = 97.62 kWh. The mileage of a passenger vehicle in its life cycle was assumed to be 150,000 passenger km. Throughout the life cycle of the electric vehicle, energy consumption and carbon emissions during its useful life are equal to = 27,574.45 kWh. The value obtained also proves that this is a current research problem due to the large number of electric cars currently in use.

- Phase 4. Vehicle recycling

Then, the emissions during recycling of the selected vehicle components (without the battery) were calculated. In this phase, vehicle components are dismantled, separated, cleaned, recycled, disposed of, and reused [69]. Based on data from the literature review, the report, and the GREET model data, emissions during EV recycling were determined, as shown in Table 6.

Table 6.

Energy consumption in the recycling phase of an electric vehicle.

Using Equation (10), it was estimated that the carbon dioxide emission in the vehicle recycling phase is = 1760.22 kWh (excluding the battery).

It was observed that the use phase dominates the environmental impact cycle. However, it has been observed that the production phase of the vehicle and its components is also significant. Similar conclusions are presented by the authors of other articles, e.g., [76]. In turn, the phase of extraction and processing of materials has the lowest environmental impact. This is due to the small share of electricity in this process. Finally, using Equation (6), the total carbon dioxide emissions in all phases of the LCA were calculated for the reference electric vehicle, i.e., 39,320.29 (kWh).

- Step 5.2. Life cycle assessment of an alternative vehicle

According to the LCA results of the reference electric vehicle (BEV), the LCA results of alternative vehicles (i.e., modified with respect to quality criteria) were predicted. According to the adopted methodology, the result of the life cycle assessment was predicted for each level of vehicle quality (resulting from the modification of the quality criteria). This was performed as part of a simplified model of the change in the LCA value corresponding to the change in the vehicle quality level, which was made according to the Pareto–Lorenz principle (20/80). Equation (6) is used for this purpose. The results are recorded in Table 7.

Table 7.

Quality level of the reference vehicle variants and expected changes in LCA values.

The result from this stage of the model was used to predict a satisfactory vehicle variant. This represents the last stage of the model.

- Stage 6. Predicting a satisfactory vehicle variant

At this stage, the values of the total carbon dioxide emission indicator over the vehicle life cycle were combined with the vehicle quality level indicator . Indicators were combined for the corresponding vehicle alternatives (modifications). For this purpose, the index was calculated for each alternative vehicle. According to the proposed model, it was necessary to determine the importance of quality and its environmental impact for the customer throughout its life cycle. According to the assumptions, the validity is determined by the entity (expert) after consulting with the client. The importance of the vehicle’s quality level was determined with a weight of 0.75, while the importance of the vehicle’s environmental impact was determined with a weight of 0.25. The assessment of the environmental quality level in the context of LCA for the reference vehicle’s variants/alternative was estimated using Equation (11). The result is shown in Table 8.

Table 8.

Predicted satisfaction with reference electric vehicle variants.

It was observed that the current reference vehicle is the most satisfactory for the customer (QLCA = 0.62). Although its impact on the environment during its life cycle is not the least harmful, it is characterised by the highest level of quality. In this case, the quality level was definitely more important to the customer, and the life cycle assessment of this vehicle was ranked third. Therefore, this determines the final position of the current vehicle as the most favourable to the customer. Relatively similar dependencies occur, for example, for modification 1 and modification 2, for which the QLCA index values reached 0.58 and 0.56, respectively. Therefore, it is possible to consider possible design changes to the vehicle according to modifications 1 and 2. These changes may be more beneficial from an environmental or qualitative point of view; therefore, they may also be financially profitable for the manufacturer. In turn, the worst variant of the vehicle is modification 4, which, despite the expected least harmful impact on the environment, has the lowest quality index. In this case, the ranking was influenced by the importance of the level of quality and the environmental impact for the customer. However, it should be remembered that the results obtained constitute an analysis of the expectations of an individual customer. Therefore, it is possible to obtain different results, which largely depend on the customer’s expectations and, therefore, on the analysed reference vehicle. Therefore, the final decision to choose a vehicle variant depends on the customer. Furthermore, based on the results obtained, it is possible to consider design changes for the current reference vehicle. These decisions are made by the vehicle manufacturer depending on preferences and expectations. However, to undertake design activities for new vehicle variants produced on a large scale, it is necessary to increase the research sample.

The originality of this study refers to simultaneously analysing the quality level of the vehicle and its environmental impact during its life cycle. Hence, the developed model allows for assessment of the vehicle’s quality level according to the current vehicle’s criteria and modified criteria. Additionality, it is possible to predict changes in the environmental impact throughout the entire life cycle of the vehicle from resulting changes in the qualitative criteria. The obtained ranking could be used to select satisfactory alternatives for reference vehicles, which will result simultaneously from a beneficial quality level for the customer and the environmental impact of the whole life cycle. On this basis, it is possible to undertake design activities within the customers’ expectations and in the context of sustainable development.

4. Discussion

The rapid development of the automotive industry has resulted in vehicle production reaching nearly 100 million vehicles per year in recent years. This generates approximately 6 million tonnes of carbon dioxide from the manufacturing sector, which is one third of the carbon dioxide emissions resulting from energy [76,77,78,79]. Therefore, various types of vehicles are being created to reduce CO2 emissions, with electric vehicles being one of the most popular. The analysis of the environmental impact of vehicles is carried out according to the life cycle assessment (LCA). Although these analyses have already been carried out in a variety of applications, e.g., [16,33,35,46], no research has been found that would allow one to predict the vehicle modification that will be the most satisfactory for the customer in terms of quality (vehicle performance criteria) and, at the same time, in terms of the environmental impact throughout the life cycle (LCA) [80,81,82].

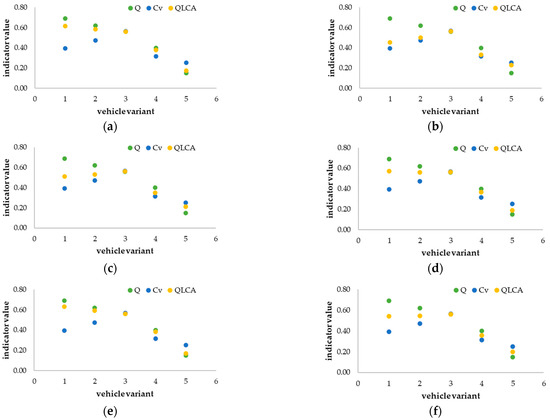

Therefore, the objective of this investigation was to develop a model that supports the prediction of vehicle alternatives according to the combined life cycle assessment and quality level. The model test was carried out for an electric vehicle (BEV). The test results showed that based on various modifications of the vehicle’s quality level and the corresponding environmental impacts throughout its life cycle, it is possible to predict the vehicle variant that will be most satisfactory for the customer and, at the same time, environmentally friendly. In this case, the current reference vehicle was shown to be the most satisfactory for the customer (QLCA = 0.62). The result obtained was influenced by the weight (importance) of the vehicle’s quality level and its environmental impact throughout the vehicle’s life cycle. Therefore, differences in model results due to the introduction of different weights for indicators were checked. This is shown in Figure 4.

Figure 4.

Analysis of reference vehicle variants due to different weights of the vehicle quality level and environmental impact throughout the life cycle in the following proportions: (a) 0.75:0.25, (b) 0.20:0.80, (c) 0.40:0.60, (d) 0.60:0.40, (e) 0.80:0.20, (f) 0.50:0.50.

Based on the analysis of the impact of vehicle quality level weights and environmental impact throughout the entire life cycle, it was concluded that:

- Weights affect the final model result if the indicator values differ in a relatively noticeable way;

- The greater the weight of the indicator, the greater its impact on the final result of the model;

- Small disproportions in indicator weights have a relatively small impact on the final model result.

At the same time, the final result of the model depends on the individual preferences of the client. Therefore, the final results of the model should be interpreted depending on the needs of the entity that uses it. The advantages of the proposed model include:

- Estimation of the current level of the vehicle’s quality due to the expectations of an individual customer;

- Estimation of the environmental impact of the vehicle throughout its life cycle for any reference vehicles;

- Inclusion of the share of customer expectations in the entire decision-making process regarding the selection of the most advantageous vehicle variant;

- Predicting customer satisfaction with vehicle variants based on current quality levels and environmental impact throughout the life cycle;

- The possibility of designing or improving vehicles by taking into account their quality level and, at the same time, their environmental impact during the life cycle (LCA).

However, the disadvantages of the model include the possibility of designing a vehicle for an individual customer and the lack of rules developed to take into account analyses dedicated to the vehicle’s battery.

Therefore, future research will focus on extending the model to analyse the expectations of a larger number of customers and ensuring that the results of the vehicle battery quality level, its alternatives, and their corresponding environmental impacts throughout the life cycle are taken into account. In future research, it is planned to realise the model as part of a statistical analysis to support the prediction results and verify the proposed model.

5. Conclusions

The need to reduce carbon dioxide emissions generated in the transport sector results in the search for new vehicle design solutions. However, in accordance with the principles of sustainable development, design solutions should not only ensure protection of the natural environment but should also enable meeting customer expectations. Therefore, the objective of this investigation was to develop a model that supports the prediction of vehicle alternatives according to the combined life cycle assessment and quality level. The model test was performed for an electric vehicle (BEV). The model was developed in six main stages and adapted to analyse any type of vehicle. On the basis of the model results, its variants (design alternatives) will be predicted, which are assessed by the client in terms of the level of quality and environmental impact throughout the entire life cycle. The functioning of the model is supported by various techniques, including, for example, TOPSIS, LCA, SMARTER, the Pareto–Lorenz rule, the principle of decision support , and others. The model test was carried out for an electric vehicle (BEV) from one of the key manufacturers of this type of vehicle. The model test showed that, based on various modifications of the vehicle’s quality level and the corresponding environmental impacts throughout its life cycle, it is possible to predict the vehicle variant that will be the most satisfying for the customer and, at the same time, environmentally friendly.

The originality of the model lies in assessing the vehicle’s life cycle and predicting the change in the environmental impact resulting from a change in its quality criteria. The novelty of the model is its capacity to support the prediction of a satisfactory alternative to the reference vehicle, which will result simultaneously from a level of quality beneficial to the customer and the environmental impact throughout the entire life cycle.

This model can be used by manufacturers or dealers to select a vehicle that satisfies the customer or to undertake vehicle design activities to meet the customer’s expectations. Used in this way, the model can support the sustainable design of vehicles by taking into account their quality level and environmental impact during the life cycle (LCA); therefore, it is up to date from the point of view of sustainable development.

Author Contributions

Conceptualisation, R.U., A.P. and D.S.; methodology, A.P. and D.S.; software, D.S.; validation, R.U.; formal analysis, R.U. and A.P.; investigation, D.S.; resources, D.S.; data curation, A.P. and D.S.; writing—original draft preparation, R.U., A.P. and D.S.; writing—review and editing, A.P. and D.S.; visualisation, D.S.; supervision, R.U. and A.P.; project administration, R.U. and A.P.; funding acquisition, R.U. All authors have read and agreed to the published version of the manuscript.

Funding

Publication financed by the statutory research fund of the Czestochowa University of Technology SPB-600/3016/2023.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Decision matrix with assessments of the state of vehicle criteria.

Table A1.

Decision matrix with assessments of the state of vehicle criteria.

| Vehicle Variant | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| Current status | 5 | 3 | 5 | 5 | 4 | 7 | 5 | 7 | 5 |

| Modification 1 | 6 | 6 | 6 | 6 | 6 | 5 | 7 | 2 | 6 |

| Modification 2 | 5 | 3 | 7 | 7 | 7 | 4 | 7 | 5 | 2 |

| Modification 3 | 4 | 4 | 4 | 4 | 3 | 2 | 3 | 3 | 6 |

| Modification 4 | 2 | 3 | 3 | 3 | 2 | 2 | 2 | 4 | 1 |

Where C1–C9—as in Table 1.

Table A2.

Standardised decision matrix.

Table A2.

Standardised decision matrix.

| Vehicle Variant | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| Current status | 0.49 | 0.34 | 0.43 | 0.43 | 0.37 | 0.71 | 0.43 | 0.69 | 0.50 |

| Modification 1 | 0.58 | 0.68 | 0.52 | 0.52 | 0.56 | 0.51 | 0.60 | 0.20 | 0.59 |

| Modification 2 | 0.49 | 0.34 | 0.60 | 0.60 | 0.66 | 0.40 | 0.60 | 0.49 | 0.20 |

| Modification 3 | 0.39 | 0.45 | 0.34 | 0.34 | 0.28 | 0.20 | 0.26 | 0.30 | 0.59 |

| Modification 4 | 0.19 | 0.34 | 0.26 | 0.26 | 0.19 | 0.20 | 0.17 | 0.39 | 0.10 |

Where C1–C9—as in Table 1.

Table A3.

Weighted normalised decision matrix.

Table A3.

Weighted normalised decision matrix.

| Vehicle Variant | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| Criteria weights | 0.55 | 0.45 | 0.70 | 0.35 | 0.65 | 0.80 | 0.50 | 0.70 | 0.75 |

| Current status | 0.27 | 0.15 | 0.30 | 0.15 | 0.24 | 0.57 | 0.21 | 0.48 | 0.37 |

| Modification 1 | 0.32 | 0.30 | 0.36 | 0.18 | 0.37 | 0.40 | 0.30 | 0.14 | 0.45 |

| Modification 2 | 0.27 | 0.15 | 0.42 | 0.21 | 0.43 | 0.32 | 0.30 | 0.34 | 0.15 |

| Modification 3 | 0.21 | 0.20 | 0.24 | 0.12 | 0.18 | 0.16 | 0.13 | 0.21 | 0.45 |

| Modification 4 | 0.11 | 0.15 | 0.18 | 0.09 | 0.12 | 0.16 | 0.09 | 0.28 | 0.07 |

Where C1–C9—as in Table 1.

Table A4.

Positive and negative solutions.

Table A4.

Positive and negative solutions.

| Solutions | C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 |

|---|---|---|---|---|---|---|---|---|---|

| 0.32 | 0.30 | 0.42 | 0.21 | 0.43 | 0.57 | 0.30 | 0.48 | 0.45 | |

| 0.11 | 0.15 | 0.18 | 0.09 | 0.12 | 0.16 | 0.09 | 0.14 | 0.07 |

Where C1–C9—as in Table 1.

Table A5.

Quality level of the electric car and its modifications.

Table A5.

Quality level of the electric car and its modifications.

| Vehicle Variant | Ranking | |||

|---|---|---|---|---|

| Current status | 0.30 | 0.67 | 0.69 | 1 |

| Modification 1 | 0.39 | 0.64 | 0.62 | 2 |

| Modification 2 | 0.44 | 0.56 | 0.56 | 3 |

| Modification 3 | 0.62 | 0.41 | 0.40 | 4 |

| Modification 4 | 0.79 | 0.14 | 0.15 | 5 |

References

- Xiao, M.; Peng, X. Decomposition of Carbon Emission Influencing Factors and Research on Emission Reduction Performance of Energy Consumption in China. Front. Environ. Sci. 2023, 10, 1096650. [Google Scholar] [CrossRef]

- Khanam, T.; Rahman, A.; Xu, X.; Mola-Yudego, B.; Moula, M.M.E.; Pelkonen, P. Assessing the Awareness and Willingness of European Experts to Reduce Their Carbon Footprint in Everyday Consumption. Environ. Impact Assess. Rev. 2022, 97, 106889. [Google Scholar] [CrossRef]

- Pacana, A.; Czerwińska, K. Indicator Analysis of the Technological Position of a Manufacturing Company. Prod. Eng. Arch. 2023, 29, 162–167. [Google Scholar] [CrossRef]

- Wolniak, R. European Union Smart Mobility–Aspects Connected with Bike Road System’s Extension and Dissemination. Smart Cities 2023, 6, 1009–1042. [Google Scholar] [CrossRef]

- Kuzior, A.; Vyshnevskyi, O.; Trushkina, N. Assessment of the Impact of Digitalization on Greenhouse Gas Emissions on the Example of EU Member States. Prod. Eng. Arch. 2022, 28, 407–419. [Google Scholar] [CrossRef]

- Kuzior, A.; Sira, M.; Brozek, P. Using Blockchain and Artificial Intelligence in Energy Management as a Tool to Achieve Energy Efficiency. Virtual Econ. 2022, 5, 69–90. [Google Scholar] [CrossRef] [PubMed]

- Kuzior, A.; Postrzednik-Lotko, K.A.; Postrzednik, S. Limiting of Carbon Dioxide Emissions through Rational Management of Pro-Ecological Activities in the Context of CSR Assumptions. Energies 2022, 15, 1825. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W.W. An Econometric Model of the Operation of the Steel Industry in POLAND in the Context of Process Heat and Energy Consumption. Energies 2022, 15, 7909. [Google Scholar] [CrossRef]

- Ulewicz, R.; Siwiec, D.; Pacana, A.; Tutak, M.; Brodny, J. Multi-Criteria Method for the Selection of Renewable Energy Sources in the Polish Industrial Sector. Energies 2021, 14, 2386. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Model Supporting Development Decisions by Considering Qualitative–Environmental Aspects. Sustainability 2021, 13, 9067. [Google Scholar] [CrossRef]

- Wolniak, R. Problems of Use of FMEA Method in Industrial Enterprise. Prod. Eng. Arch. 2019, 23, 12–17. [Google Scholar] [CrossRef]

- Asim, M.; Usman, M.; Abbasi, M.S.; Ahmad, S.; Mujtaba, M.A.; Soudagar, M.E.M.; Mohamed, A. Estimating the Long-Term Effects of National and International Sustainable Transport Policies on Energy Consumption and Emissions of Road Transport Sector of Pakistan. Sustainability 2022, 14, 5732. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R.; Grebski, W.W. Electricity and Heat Demand in Steel Industry Technological Processes in Industry 4.0 Conditions. Energies 2023, 16, 787. [Google Scholar] [CrossRef]

- Jing, Q.-L.; Liu, H.-Z.; Yu, W.-Q.; He, X. The Impact of Public Transportation on Carbon Emissions—From the Perspective of Energy Consumption. Sustainability 2022, 14, 6248. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B.; Alves, D.E. Ecodesign of Automotive Components Making Use of Natural Jute Fiber Composites. J. Clean. Prod. 2010, 18, 313–327. [Google Scholar] [CrossRef]

- Moro, A.; Lonza, L. Electricity Carbon Intensity in European Member States: Impacts on GHG Emissions of Electric Vehicles. Transp. Res. D Transp. Environ. 2018, 64, 5–14. [Google Scholar] [CrossRef] [PubMed]

- Csete, M.S.; Baranyi, T. Can smart city planning enhance the sustainable transition of the E.U. capitals? A project and strategy-based smart, sustainable performance analysis in the programming period 2014–2020. Prod. Eng. Arch. 2023, 29, 461–473. [Google Scholar] [CrossRef]

- Kuzior, A.; Staszek, M. Energy management in the railway industry: A case study of rail freight carrier in Poland. Energies 2021, 14, 6875. [Google Scholar] [CrossRef]

- Jiang, R.; Wu, P.; Wu, C. Driving Factors behind Energy-Related Carbon Emissions in the U.S. Road Transport Sector: A Decomposition Analysis. Int. J. Environ. Res. Public Health 2022, 19, 2321. [Google Scholar] [CrossRef]

- Li, X.; Lv, T.; Zhan, J.; Wang, S.; Pan, F. Carbon Emission Measurement of Urban Green Passenger Transport: A Case Study of Qingdao. Sustainability 2022, 14, 9588. [Google Scholar] [CrossRef]

- Wang, Y.-Z.; Zhou, S.; Ou, X.-M. Development and Application of a Life Cycle Energy Consumption and CO2 Emissions Analysis Model for High-Speed Railway Transport in China. Adv. Clim. Chang. Res. 2021, 12, 270–280. [Google Scholar] [CrossRef]

- Bhat, A.; Ordóñez Garcia, J. Sustainability and EU Road Transport Carbon Emissions from Consumption of Diesel and Gasoline in 2000 and 2018. Appl. Sci. 2021, 11, 7601. [Google Scholar] [CrossRef]

- Wolniak, R.; Skotnicka-Zasadzień, B. Development of Wind Energy in EU Countries as an Alternative Resource to Fossil Fuels in the Years 2016–2022. Resources 2023, 12, 96. [Google Scholar] [CrossRef]

- Kot, S. Chapter 9—Carsharing Concept Implementation in Relation to Sustainability—Evidence from Poland, Energy Transformation Towards Sustainability; Elsevier: Amsterdam, The Netherlands, 2020; pp. 179–197. [Google Scholar]

- Knop, K.; Ulewicz, R. Solving Critical Quality Problems by Detecting and Eliminating their Root Causes—Case-Study from The Automotive Industry. Mater. Res. Proc. 2022, 24, 181–188. [Google Scholar]

- Alatawneh, A.; Torok, A. Potential autonomous vehicle ownership growth in Hungary using the Gompertz model. Prod. Eng. Arch. 2023, 29, 155–161. [Google Scholar] [CrossRef]

- Bakhtyar, B.; Qi, Z.; Azam, M.; Rashid, S. Global Declarations on Electric Vehicles, Carbon Life Cycle and Nash Equilibrium. Clean. Technol. Environ. Policy 2023, 25, 21–34. [Google Scholar] [CrossRef]

- Smit, R.; Kennedy, D.W. Greenhouse Gas Emissions Performance of Electric and Fossil-Fueled Passenger Vehicles with Uncertainty Estimates Using a Probabilistic Life-Cycle Assessment. Sustainability 2022, 14, 3444. [Google Scholar] [CrossRef]

- Zanchi, L.; Delogu, M.; Zamagni, A.; Pierini, M. Analysis of the Main Elements Affecting Social LCA Applications: Challenges for the Automotive Sector. Int. J. Life Cycle Assess. 2018, 23, 519–535. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Model to Predict Quality of Photovoltaic Panels Considering Customers’ Expectations. Energies 2022, 15, 1101. [Google Scholar] [CrossRef]

- Galík, J.; Varecha, D.; Drbúl, M.; Madaj, R.; Konstantová, V. Design and optimization of the construction of a mobile disinfection chamber for small communication devices and small objects. Prod. Eng. Arch. 2023, 29, 201–215. [Google Scholar] [CrossRef]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wäger, P.; Stamp, A.; Zah, R.; Althaus, H.-J. Contribution of Li-Ion Batteries to the Environmental Impact of Electric Vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Pacana, A.; Siwiec, D.; Bednárová, L.; Petrovský, J. Improving the Process of Product Design in a Phase of Life Cycle Assessment (LCA). Processes 2023, 11, 2579. [Google Scholar] [CrossRef]

- Skaar, C.; Lausselet, C.; Bergsdal, H.; Brattebø, H. Towards a LCA Database for the Planning and Design of Zero-Emissions Neighborhoods. Buildings 2022, 12, 512. [Google Scholar] [CrossRef]

- Hawkins, T.R.; Singh, B.; Majeau-Bettez, G.; Strømman, A.H. Comparative Environmental Life Cycle Assessment of Conventional and Electric Vehicles. J. Ind. Ecol. 2013, 17, 53–64. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, M.; Bu, F. Vehicle Environmental Efficiency Evaluation in Different Regions in China: A Combination of the Life Cycle Analysis (LCA) and Two-Stage Data Envelopment Analysis (DEA) Methods. Sustainability 2023, 15, 11984. [Google Scholar] [CrossRef]

- Ulrich, C.; Feinauer, M.; Bieber, K.; Schmid, S.A.; Friedrich, H.E. Life Cycle Analysis of an On-the-Road Modular Vehicle Concept. Sustainability 2023, 15, 10303. [Google Scholar] [CrossRef]

- Kawamoto, R.; Mochizuki, H.; Moriguchi, Y.; Nakano, T.; Motohashi, M.; Sakai, Y.; Inaba, A. Estimation of CO2 Emissions of Internal Combustion Engine Vehicle and Battery Electric Vehicle Using LCA. Sustainability 2019, 11, 2690. [Google Scholar] [CrossRef]

- Raugei, M.; Winfield, P. Prospective LCA of the Production and EoL Recycling of a Novel Type of Li-Ion Battery for Electric Vehicles. J. Clean. Prod. 2019, 213, 926–932. [Google Scholar] [CrossRef]

- Proske, M.; Finkbeiner, M. Obsolescence in LCA–Methodological Challenges and Solution Approaches. Int. J. Life Cycle Assess. 2020, 25, 495–507. [Google Scholar] [CrossRef]

- Mrozik, M.; Merkisz-Guranowska, A. Environmental Assessment of the Vehicle Operation Process. Energies 2020, 14, 76. [Google Scholar] [CrossRef]

- Accardo, A.; Dotelli, G.; Miretti, F.; Spessa, E. End-of-Life Impact on the Cradle-to-Grave LCA of Light-Duty Commercial Vehicles in Europe. Appl. Sci. 2023, 13, 1494. [Google Scholar] [CrossRef]

- Arvidsson, R.; Tillman, A.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Nordelöf, A.; Messagie, M.; Tillman, A.-M.; Ljunggren Söderman, M.; Van Mierlo, J. Environmental Impacts of Hybrid, Plug-in Hybrid, and Battery Electric Vehicles—What Can We Learn from Life Cycle Assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef]

- Bauer, C.; Hofer, J.; Althaus, H.-J.; Del Duce, A.; Simons, A. The Environmental Performance of Current and Future Passenger Vehicles: Life Cycle Assessment Based on a Novel Scenario Analysis Framework. Appl. Energy 2015, 157, 871–883. [Google Scholar] [CrossRef]

- Eriksson, O.; Carlsson Reich, M.; Frostell, B.; Björklund, A.; Assefa, G.; Sundqvist, J.-O.; Granath, J.; Baky, A.; Thyselius, L. Municipal Solid Waste Management from a Systems Perspective. J. Clean. Prod. 2005, 13, 241–252. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Arcese, G.; Bella, G. Recycling Technologies of Nickel–Metal Hydride Batteries: An LCA Based Analysis. J. Clean. Prod. 2020, 273, 123083. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, A. Method of Improve the Level of Product Quality. Prod. Eng. Arch. 2021, 27, 1–7. [Google Scholar] [CrossRef]

- Chen, W.; Zuo, W. Component Sensitivity Analysis of Conceptual Vehicle Body for Lightweight Design under Static and Dynamic Stiffness Demands. Int. J. Veh. Des. 2014, 66, 107. [Google Scholar] [CrossRef]

- Pacana, A.; Siwiec, D. Method of Determining Sequence Actions of Products Improvement. Materials 2022, 15, 6321. [Google Scholar] [CrossRef]

- Zuo, W.; Yu, J.; Saitou, K. Stress Sensitivity Analysis and Optimization of Automobile Body Frame Consisting of Rectangular Tubes. Int. J. Automot. Technol. 2016, 17, 843–851. [Google Scholar] [CrossRef]

- De Wolf, D.; Smeers, Y. Comparison of Battery Electric Vehicles and Fuel Cell Vehicles. World Electr. Veh. J. 2023, 14, 262. [Google Scholar] [CrossRef]

- Gezelius, M.; Mortazavi, R. Effect of Having Solar Panels on the Probability of Owning Battery Electric Vehicle. World Electr. Veh. J. 2022, 13, 125. [Google Scholar] [CrossRef]

- Wong, E.Y.C.; Ho, D.C.K.; So, S.; Tsang, C.-W.; Chan, E.M.H. Life Cycle Assessment of Electric Vehicles and Hydrogen Fuel Cell Vehicles Using the GREET Model—A Comparative Study. Sustainability 2021, 13, 4872. [Google Scholar] [CrossRef]

- Ishizaka, A.; Nemery, P. TOPSIS. In Multi-Criteria Decision Analysis; John Wiley & Sons Ltd.: Chichester, UK, 2013; pp. 213–221. [Google Scholar]

- Ostasz, G.; Siwiec, D.; Pacana, A. Model to Determine the Best Modifications of Products with Consideration Customers’ Expectations. Energies 2022, 15, 8102. [Google Scholar] [CrossRef]

- Chen, C.-T. Extensions of the TOPSIS for Group Decision-Making under Fuzzy Environment. Fuzzy Sets Syst. 2000, 114, 14345. [Google Scholar] [CrossRef]

- Hameed, A.Z.; Kandasamy, J.; Aravind Raj, S.; Baghdadi, M.A.; Shahzad, M.A. Sustainable Product Development Using FMEA ECQFD TRIZ and Fuzzy TOPSIS. Sustainability 2022, 14, 14345. [Google Scholar] [CrossRef]

- Kacprzak, D. Przedziałowa Metoda TOPSIS Dla Grupowego Podejmowania Decyzji. Optimum. Econ. Stud. 2018, 94, 256–273. [Google Scholar] [CrossRef]

- Lawor, B.; Hornyak, M. Smart goals: How the application of smart goals can contribute to achievement of student learning outcomes. Dev. Bus. Simul. Exp. Learn. 2012, 39, 259–267. [Google Scholar]

- Yang, L.; Yu, B.; Yang, B.; Chen, H.; Malima, G.; Wei, Y.-M. Life Cycle Environmental Assessment of Electric and Internal Combustion Engine Vehicles in China. J. Clean. Prod. 2021, 285, 124899. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Luo, X. Life Cycle Assessment of Electric Vehicles and Internal Combustion Engine Vehicles: A Case Study of Hong Kong. Res. Transp. Econ. 2022, 91, 101112. [Google Scholar] [CrossRef]

- Frischknecht, R.; Wyss, F.; Büsser Knöpfel, S.; Lützkendorf, T.; Balouktsi, M. Cumulative Energy Demand in LCA: The Energy Harvested Approach. Int. J. Life Cycle Assess. 2015, 20, 957–969. [Google Scholar] [CrossRef]

- Bonilla-Alicea, R.J.; Fu, K. Social Life-Cycle Assessment (S-LCA) of Residential Rooftop Solar Panels Using Challenge-Derived Framework. Energy Sustain. Soc. 2022, 12, 7. [Google Scholar] [CrossRef]

- Saaty, T.L. Decision-Making with the AHP: Why Is the Principal Eigenvector Necessary. Eur. J. Oper. Res. 2003, 145, 85–91. [Google Scholar] [CrossRef]

- Hoła, A.; Sawicki, M.; Szóstak, M. Methodology of Classifying the Causes of Occupational Accidents Involving Construction Scaffolding Using Pareto-Lorenz Analysis. Appl. Sci. 2018, 8, 48. [Google Scholar] [CrossRef]

- Hemavathi, S.; Shinisha, A. A Study on trends and developments in electric vehicle charging technologies. J. Energy Storage 2022, 52, 105013. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Rajaeifar, M.A.; Rostom, M.; Malmir, B.; Yazdani, M.; Suh, S.; Heidrich, O. Integrating Life Cycle Assessment and Multi Criteria Decision Making for Sustainable Waste Management: Key Issues and Recommendations for Future Studies. Renew. Sustain. Energy Rev. 2022, 168, 112819. [Google Scholar] [CrossRef]

- Tang, B.; Xu, Y.; Wang, M. Life Cycle Assessment of Battery Electric and Internal Combustion Engine Vehicles Considering the Impact of Electricity Generation Mix: A Case Study in China. Atmosphere 2022, 13, 252. [Google Scholar] [CrossRef]

- Zuo, W.J.; Bai, J.T. Cross-Sectional Shape Design and Optimization of Automotive Body with Stamping Constraints. Int. J. Automot. Technol. 2016, 17, 1003–1011. [Google Scholar] [CrossRef]

- Siwiec, D.; Pacana, J.; Pacana, A. A Novelty Procedure to Identify Critical Causes of Materials Incompatibility. Materials 2023, 16, 3884. [Google Scholar] [CrossRef]

- Bai, J.; Li, Y.; Zuo, W. Cross-Sectional Shape Optimisation for Thin-Walled Beam Crashworthiness with Stamping Constraints Using Genetic Algorithm. Int. J. Veh. Des. 2017, 73, 76. [Google Scholar] [CrossRef]

- Lu, S.; Ma, H.; Xin, L.; Zuo, W. Lightweight Design of Bus Frames from Multi-Material Topology Optimization to Cross-Sectional Size Optimization. Eng. Optim. 2019, 51, 961–977. [Google Scholar] [CrossRef]

- Ostasz, G.; Siwiec, D.; Pacana, A. Universal Model to Predict Expected Direction of Products Quality Improvement. Energies 2022, 15, 1751. [Google Scholar] [CrossRef]