An Analysis of the Use of Mining Waste from Coal Mines in Flood and Road Embankments

Abstract

1. Introduction

2. Characteristics of Mining Waste and Laboratory Testing Methodology

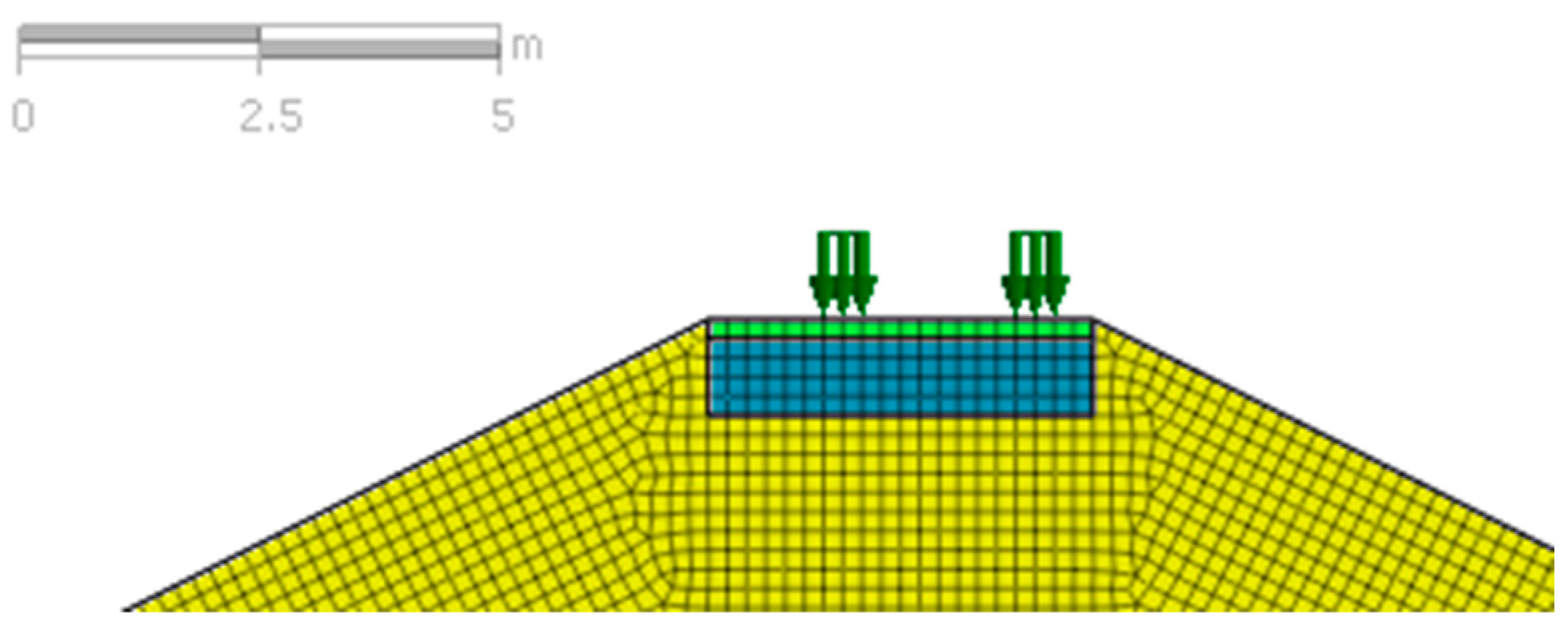

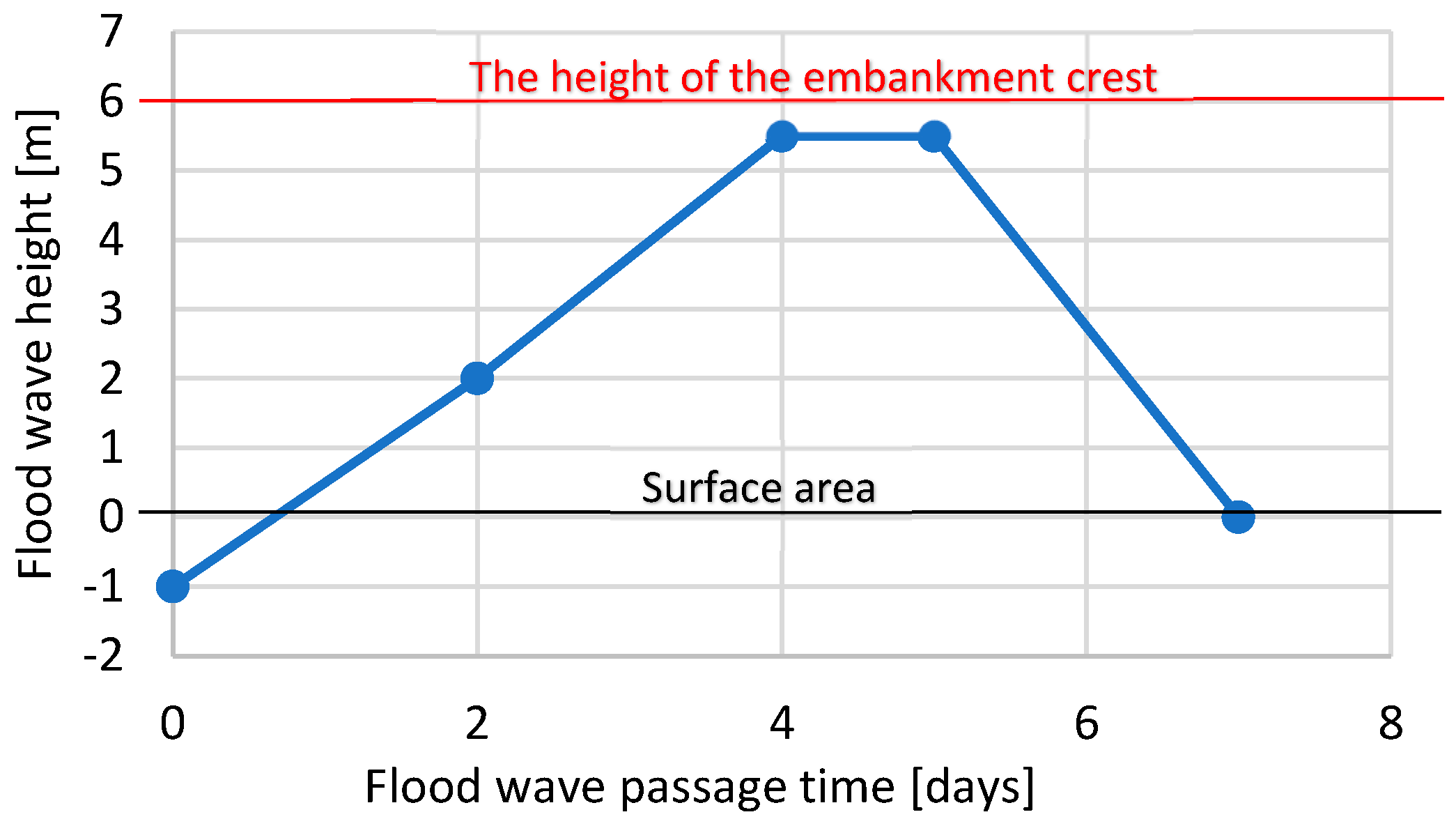

3. Research Methodology Using Finite Element Method (FEM)

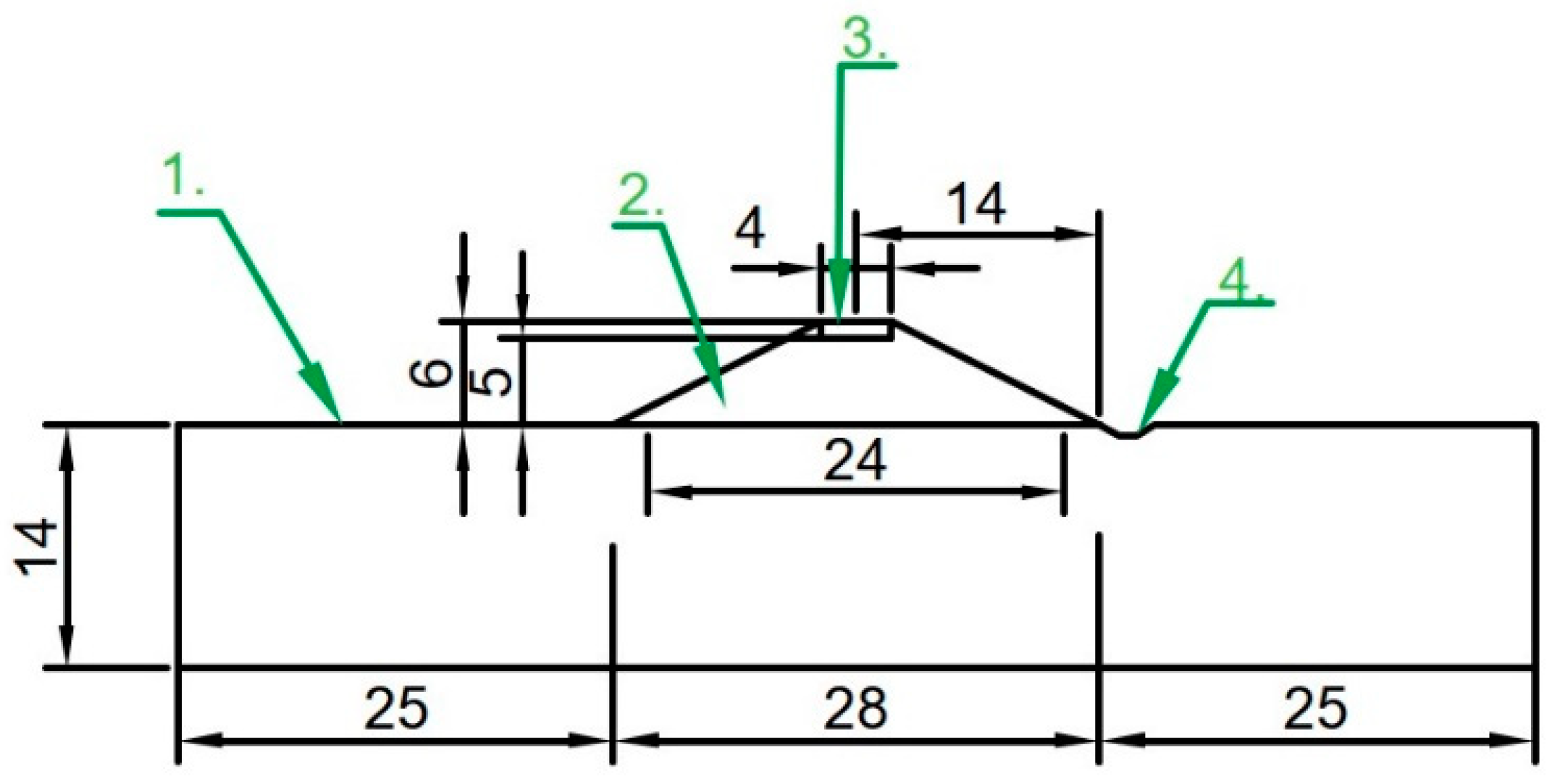

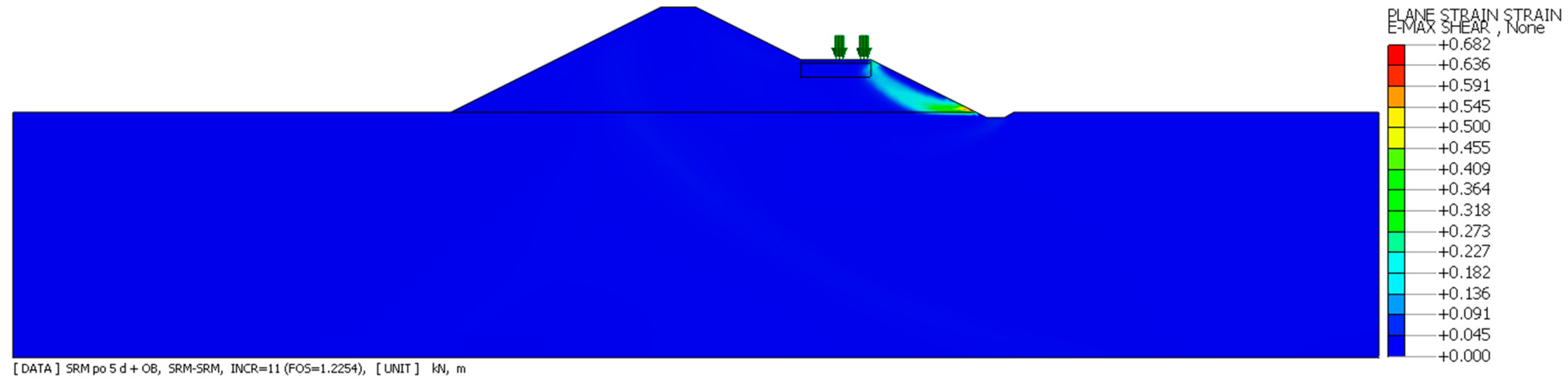

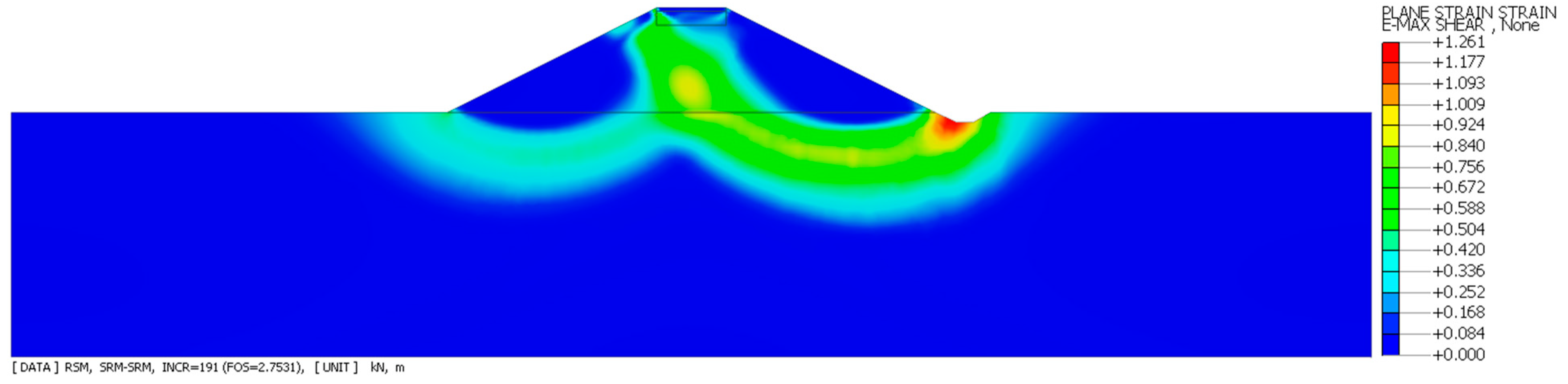

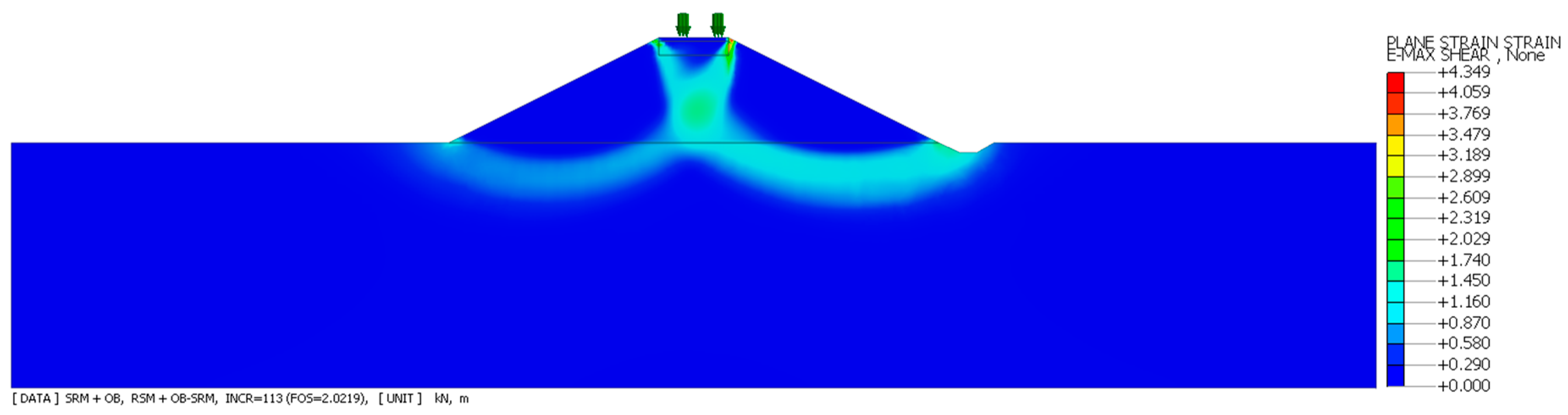

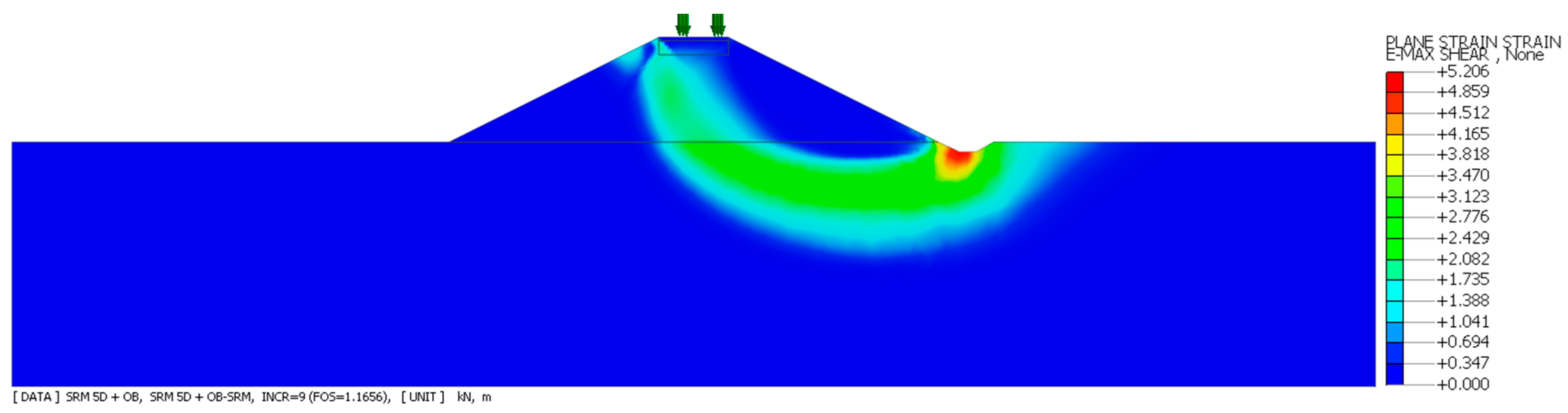

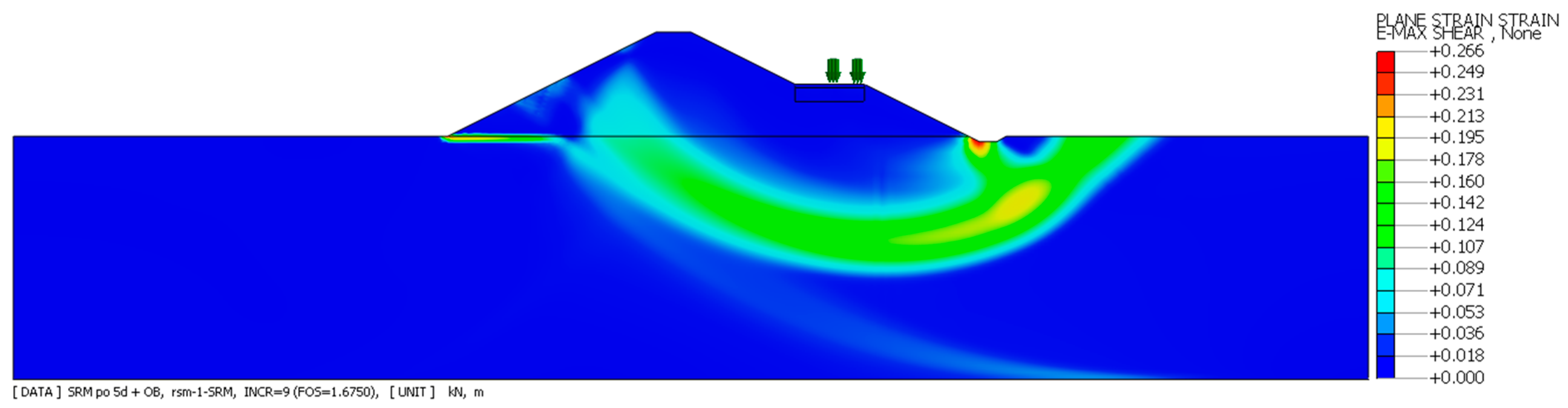

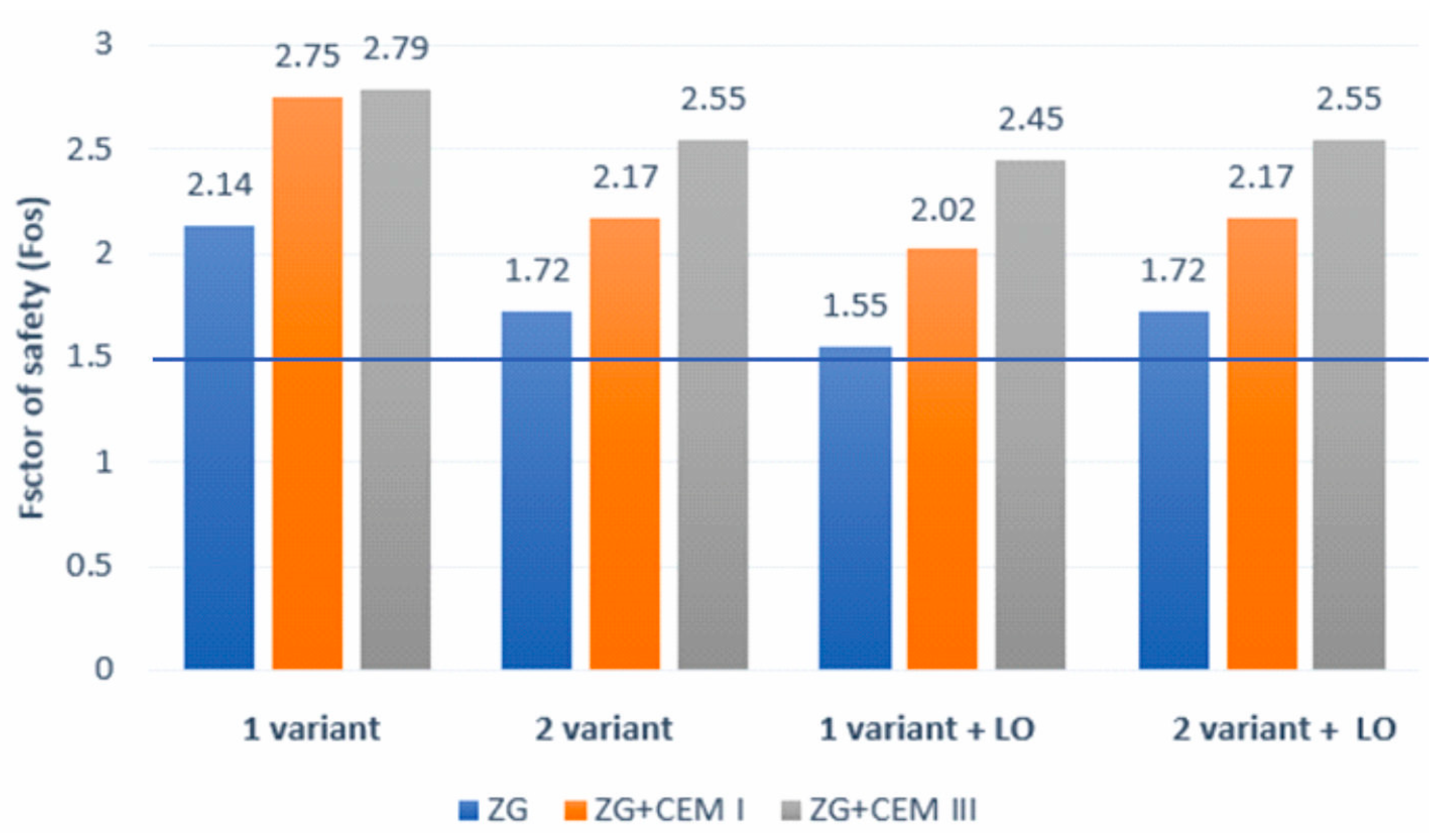

- Variant 1: a road on the embankment crest for a flood embankment unloaded or loaded with a vehicle;

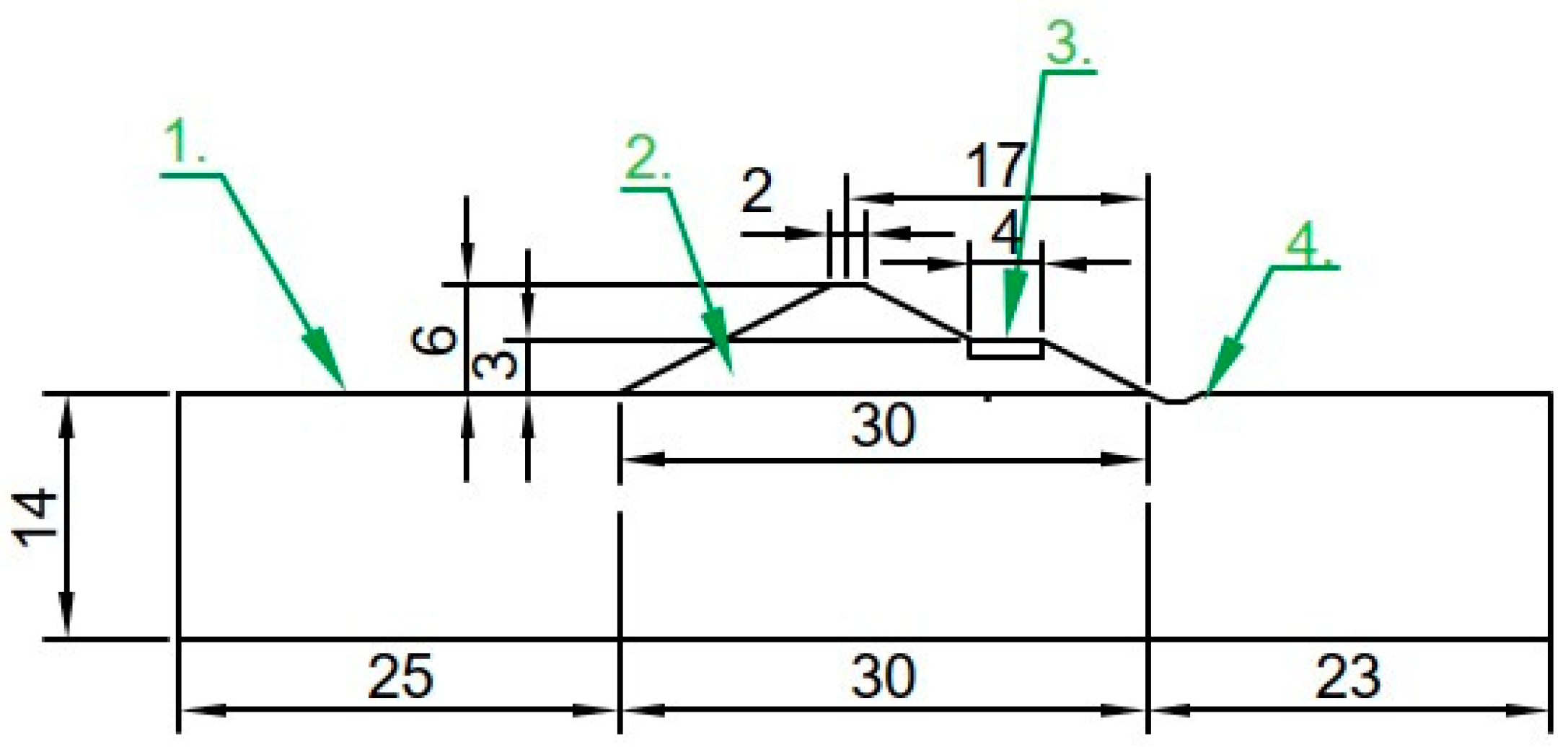

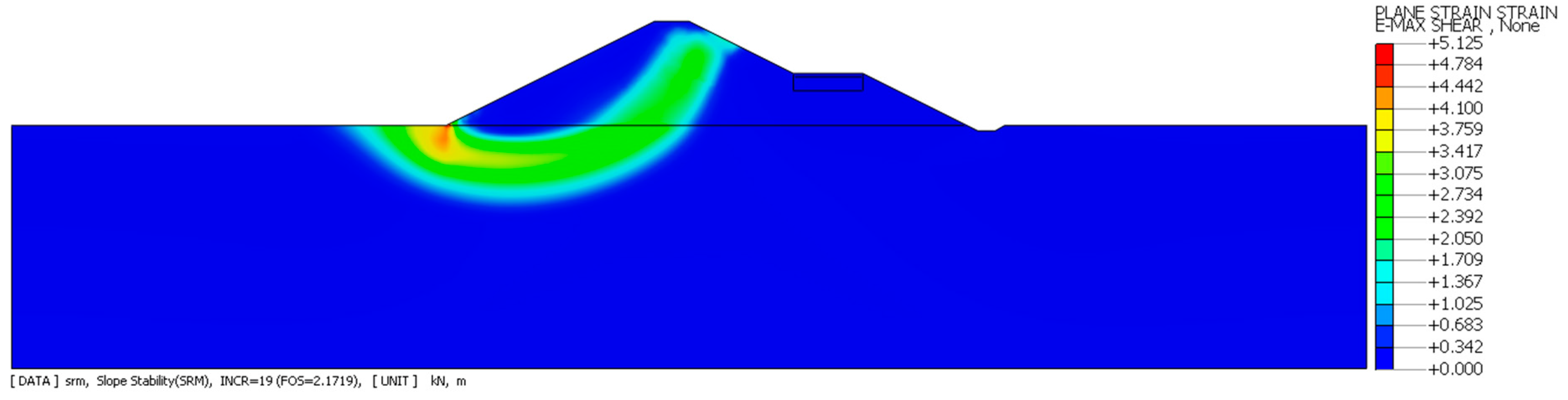

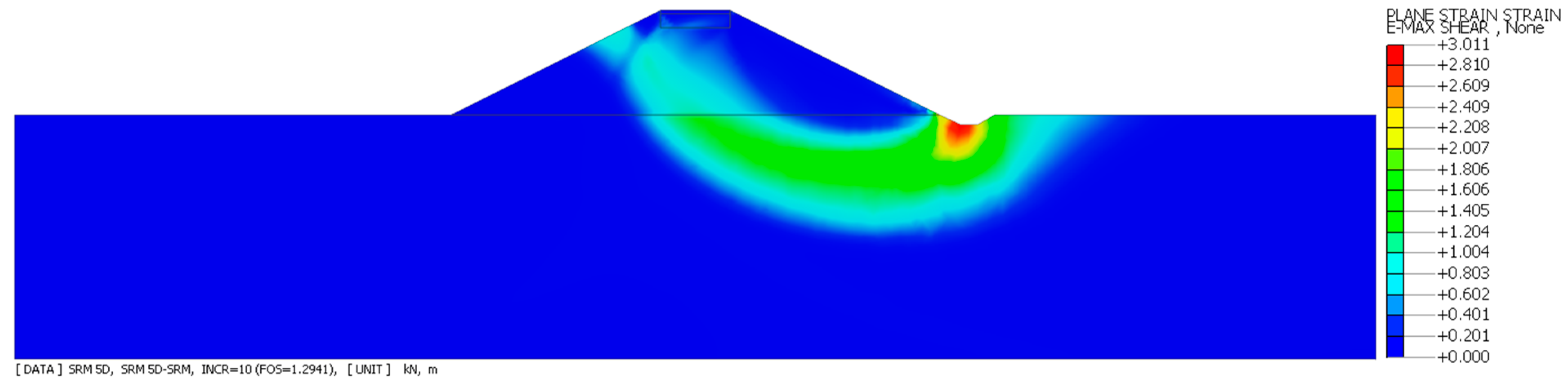

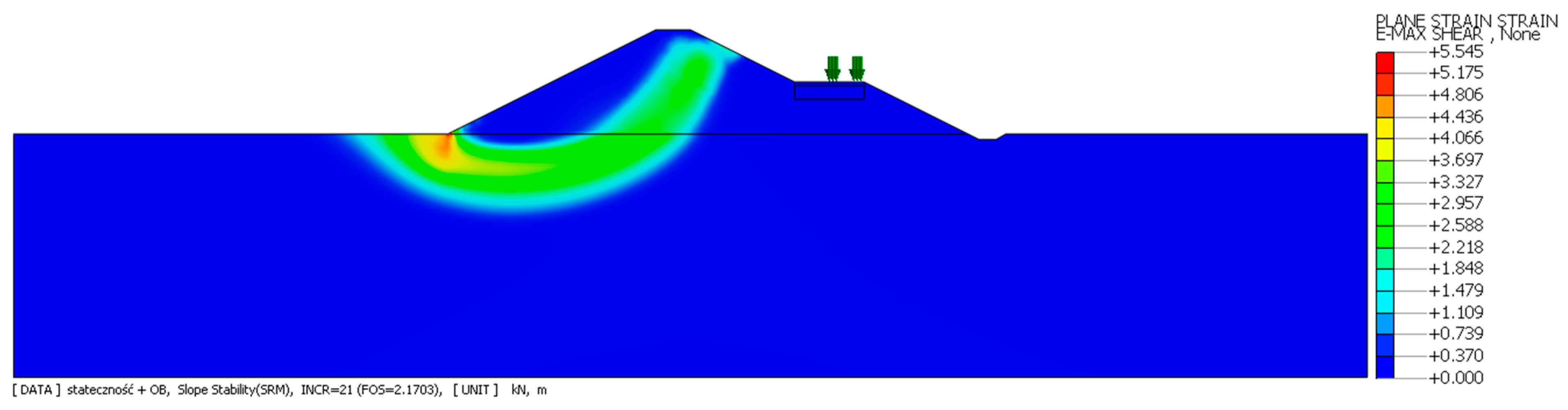

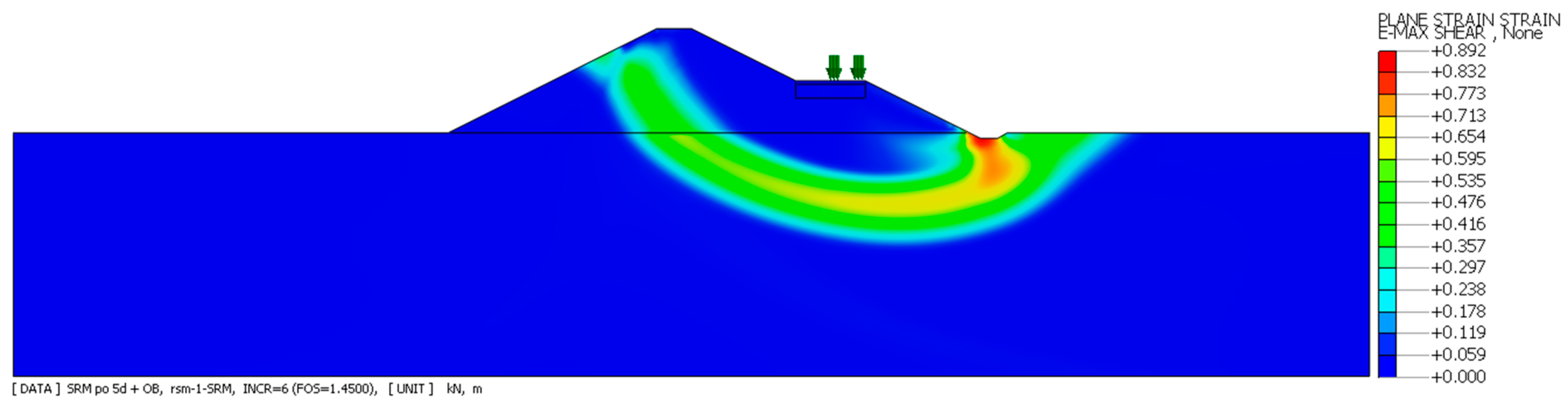

- Variant 2: a road on the ventral side of the embankment for a flood embankment unloaded or loaded with a vehicle.

4. Analysis of the Results of Tests on the Properties of Mining Waste with the Addition of Cement

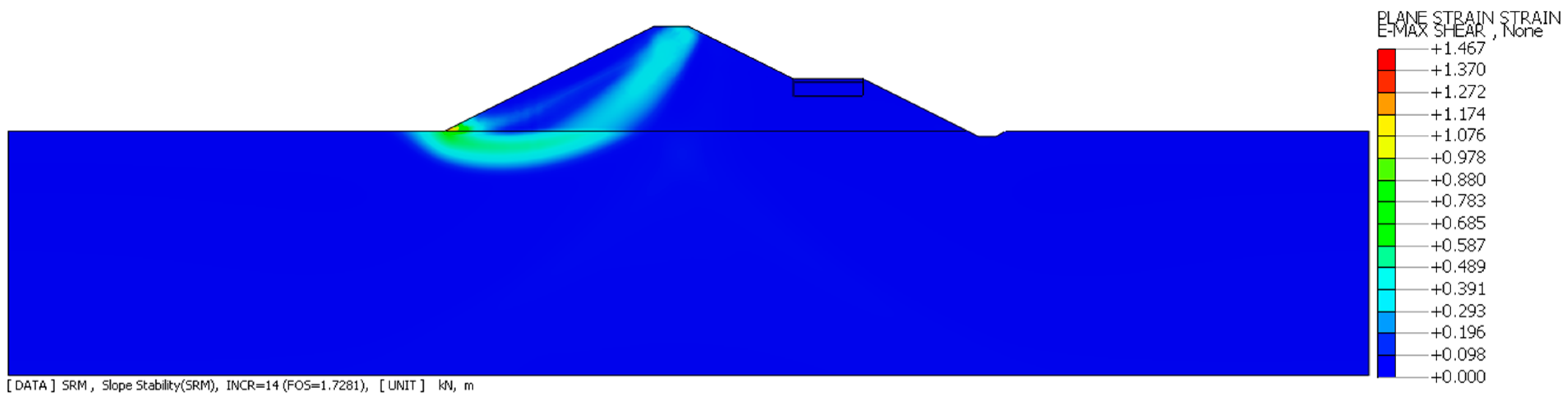

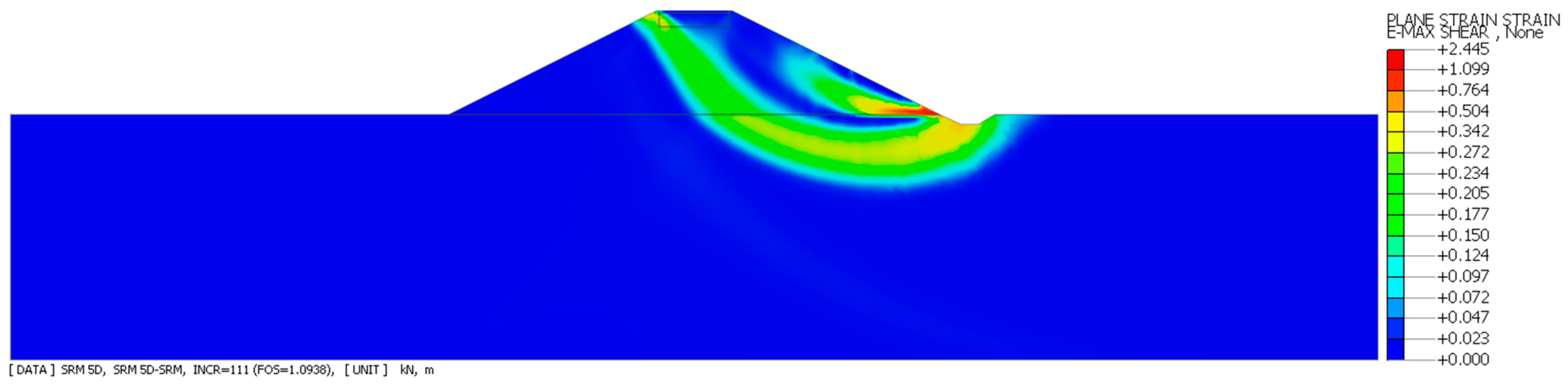

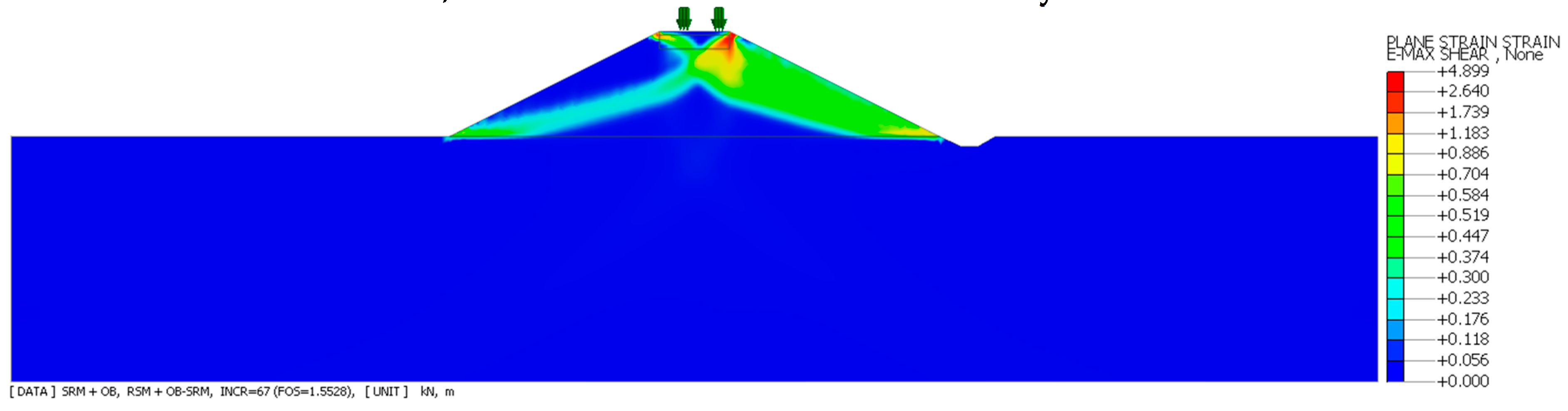

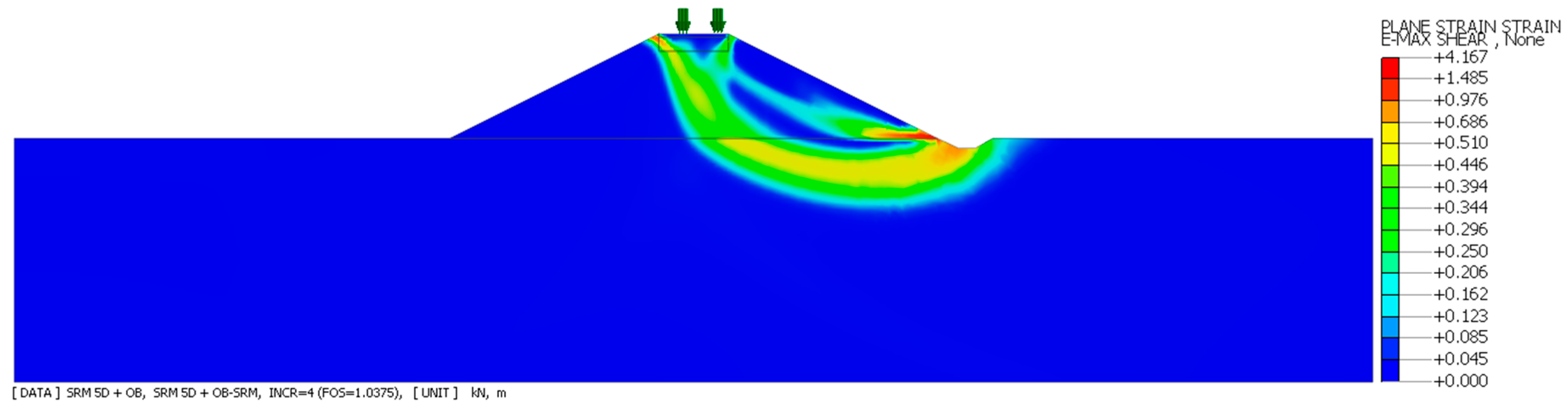

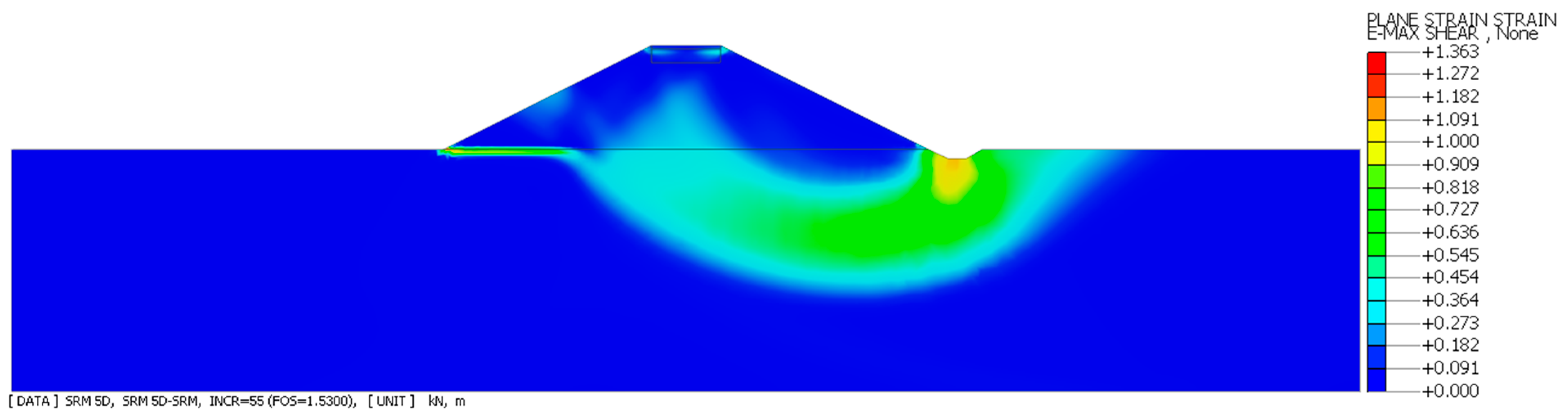

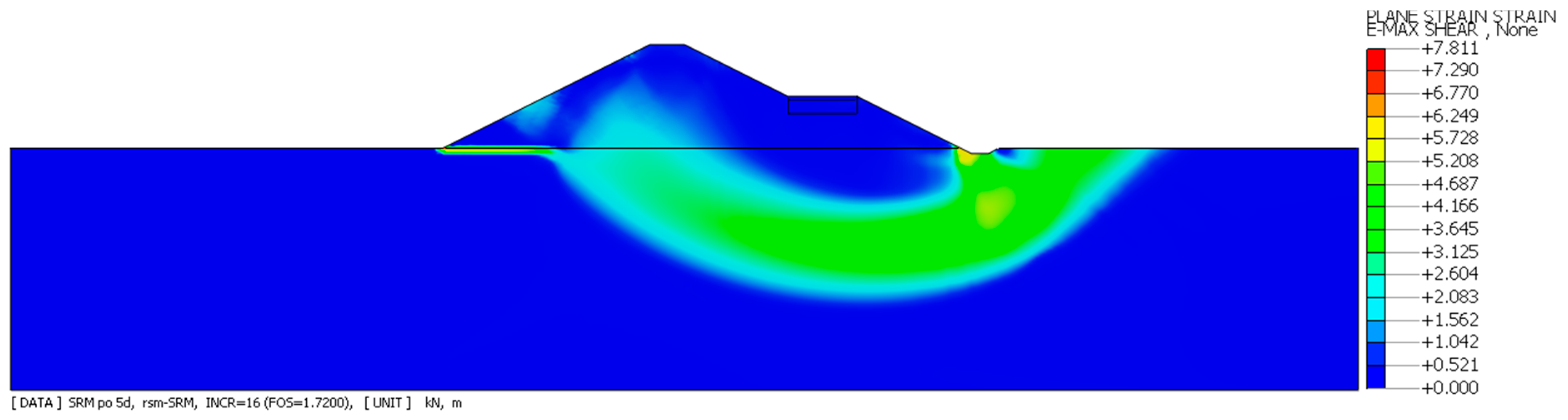

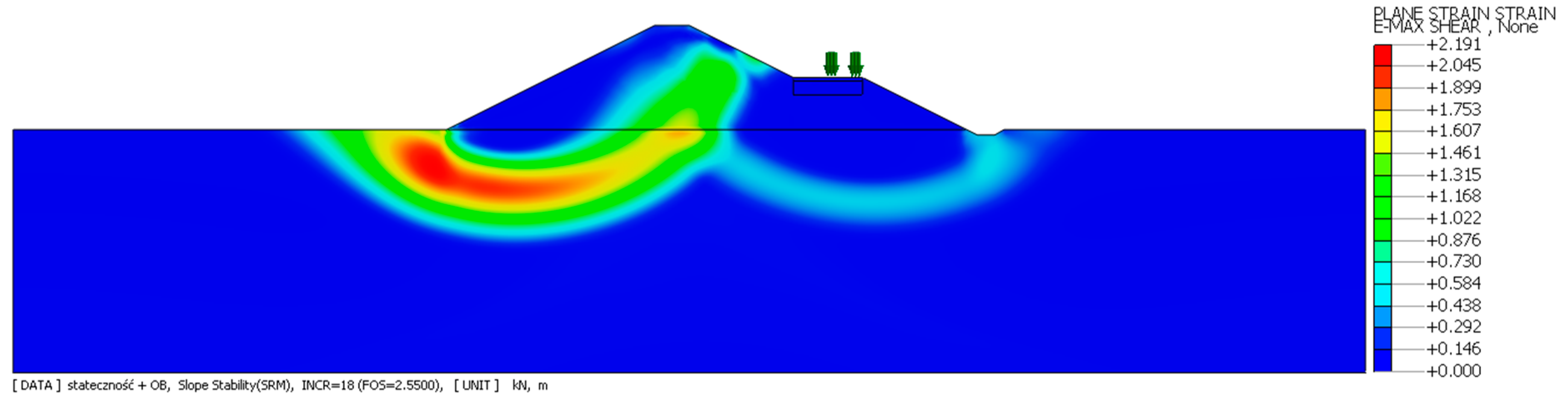

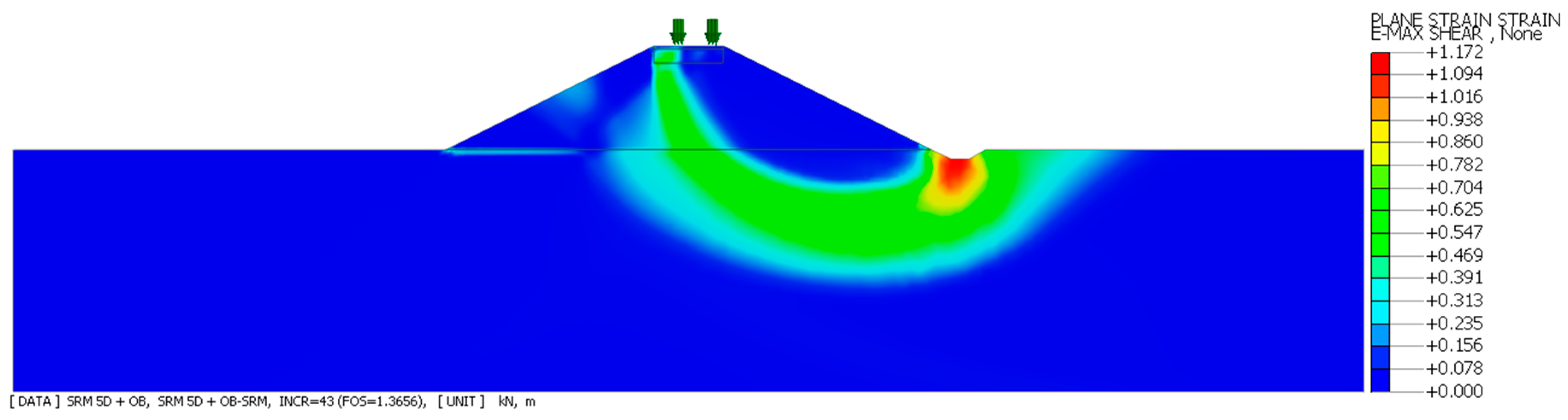

5. Discussion of the Results of the FEM Modelling Tests

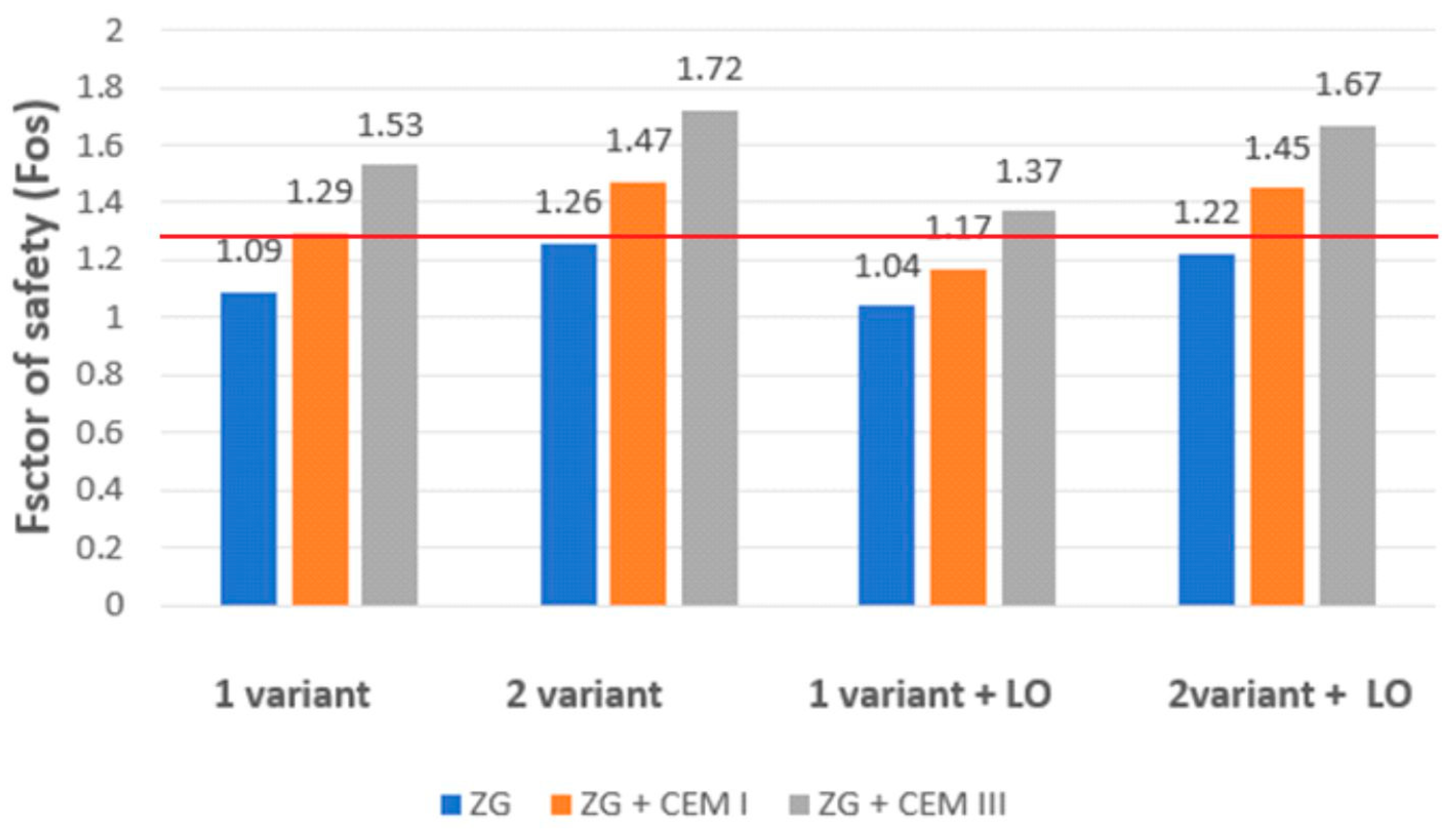

6. Conclusions

- Flood embankments made from mining waste with a binder in the form of the addition of 8% metallurgical cement (ZG + CEM III) in the first variant, with a road on the embankment crown (FoS = 1.53);

- Flood embankments made from mining waste with a binder in the form of the addition of 8% Portland cement (ZG + CEM I) in the second variant, where the road is on the side of the air slope (FoS = 1.47);

- Flood embankments made from mining waste with a binder in the form of the addition of 8% metallurgical cement (ZG + CEM III) in the second variant, where the road is on the side of the air slope (FoS = 1.72);

- Flood embankments made from mining waste with a binder in the form of the addition of 8% metallurgical cement (ZG + CEM III) in the first variant, with a road on the embankment crown additionally loaded with a vehicle (LO) (FoS = 1.37);

- Flood embankments made from mining waste with a binder in the form of the addition of 8% Portland cement (ZG + CEM I) in the second variant, where the road is on the side of the air slope additionally loaded with a vehicle (LO) (FoS = 1.45);

- Flood embankments made from mining waste with a binder in the form of the addition of 8% metallurgical cement (ZG + CEM III) in the second variant, where the road is on the side of the air slope additionally loaded with a vehicle (LO) (FoS = 1.67).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hue, N.H.; Huong, D.C.; Thanh, N.H. A Technical Solution to Improve the Existing River Dikes for both Flood Prevention and Transportation Purposes. IOP Conf. Ser. Mater. Sci. Eng. 2019, 507, 012012. [Google Scholar] [CrossRef]

- Hao, W.; Fan, H.-. h Zhang, Z.-q. Advances in Research and Technology of Levee Road in China. J. Yangtze River Sci. Res. Inst. 2018, 35, 58–63. [Google Scholar]

- Bozkurt, S.; Dekens, P.; Gartland, R.; Gragg, J.; Lawyer, J.; McGoogan, M. Evaluation of Setback Levees on the Sacramento River; University of California: Santa Barbara, CA, USA, 2000. [Google Scholar]

- Lukić, D.; Zlatanović, E.; Milosavljević, N.; Basarić, I. Road and railway embankments as flood-control dikes. In Proceedings of the 6th International Conference on Road and Rail Infrastructure, Zagreb, Croatia, 20–21 May 2021. [Google Scholar]

- Borys, M.; Filipowicz, P. Characteristics of Coal and Energy Waste for Their Use in the Construction and Modernization of Hydrotechnical Embankments; Zeszyty Problemowe Pstępów Nauk Rolniczych: Warszawa, Poland, 2005; Volume 506. (In Polish) [Google Scholar]

- Gruchot, A. The use of composites from coal waste and fly ash for the construction of flood embankments. Min. Rev. 2014, 70, 158–164. [Google Scholar]

- Gruchot, A. Utilization of Coal and Energy Waste for Engineering Purposes as a Factor in Shaping and Protecting the Environment; Wydawnictwo Uniwersytetu Rolniczego: Cracow, Poland, 2016; Volume 533. (In Polish) [Google Scholar]

- Pilecka, E.; Morman, J. Stability of Flood Embankments with a Built-in Layer of Coal Waste in the Light of Numerical Calculations; Science Notebooks; Institute of Mineral Resources and Energy Management of the Polish Academy of Sciences: Kraków, Poland, 2016; Volume 94, pp. 173–184. (In Polish) [Google Scholar]

- Pilecka, E.; Morman, J. The Use of Fine-Grained Mining Waste Reinforced with Cement for the Modernization of Flood Embankments; Scientific Journals of the Institute of Mineral Resources and Energy Management of the Polish Academy of Sciences: Kraków, Poland, 2017; Volume 101, pp. 347–360. (In Polish) [Google Scholar]

- Kuranchie, F.A.; Shukla, S.K.; Habibi, D. Mine Wastes in Western Australia and Their Suitability for Embankment Construction. In Geo-Congress 2013: Stability and Performance of Slopes and Embankments III; American Society of Civil Engineers: San Diego, CA, USA, 2013. [Google Scholar] [CrossRef]

- Durante Ingunza, M.d.; dos Santos Júnior, O.F.; Gerab, A.T.F.d.C. Potential Use of Sandy Mining Wastes as Raw Material in Road Construction. Geotech. Geol. Eng. 2020, 38, 5681–5691. [Google Scholar] [CrossRef]

- Amrani, M.; Taha, Y.; El Haloui, Y.; Benzaazoua, M.; Hakkou, R. Sustainable Reuse of Coal Mine Waste: Experimental and Economic Assessments for Embankments and Pavement Layer Applications in Morocco. Minerals 2020, 10, 85. [Google Scholar] [CrossRef]

- Segui, P.; el Mahdi Safhim, A.; Amrani, M.; Benzaazoua, M. Mining Wastes as Road Construction Material: A Review. Minerals 2023, 13, 90. [Google Scholar] [CrossRef]

- Pilecka, E.; Morman-Wątor, J. Using modified mining waste to build embankments. Build. Mater. 2022, 7, 599, 33–37. (In Polish) [Google Scholar]

- Morman-Wątor, J. Assessment of the Possibility of Using Waste from the GZW Mines for the Construction of Flood Embankments Serving as Road Embankments. Ph.D. Thesis, Cracow University of Technology Library, Cracow, Poland, 2022. (In Polish). [Google Scholar]

- Water Law of 20 July 2017 [Dz.U. 2017 poz. 1566]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170001566 (accessed on 10 June 2024).

- PN-EN ISO 14688-2:2018-05; Geotechnical Exploration and Research-Marking and Classification of Land-Part 2: Principles of Classification. Polish Committee for Standardization: Warsaw, Poland, 2018. (In Polish)

- PN-EN ISO 17892-9:2018-05; Geotechnical Exploration and Tests-Laboratory Tests of Soils-Part 9: Triaxial Compression with Consolidation on Samples Completely Saturated with Water. Polish Committee for Standardization: Warsaw, Poland, 2018. (In Polish)

- PN-B-04481:1988; Construction Land. Soil Sample Testing. Polish Committee for Standardization: Warsaw, Poland, 2018. (In Polish)

- Pisarczyk, S. Ground Engineering, Warszawa. 2014. Available online: https://ksiegarnia.pwn.pl/Gruntoznawstwo-inzynierskie,68482938,p.html (accessed on 10 June 2024). (In Polish).

- PN-S-96012:1997; Motor Roads-Subbase and Improved Subgrade Made of Cement-Stabilized Soil. Polish Committee for Standardization: Warsaw, Poland, 1997. (In Polish)

- Morman, J. Strengthening mining waste with a grain size of up to 2 mm used in flood embankments with cement binder. Contemporary construction in the research of young scientists. Gdańsk 2017, 167, 161–167. (In Polish) [Google Scholar]

- Morman, J. Results of the freeze resistance test, swelling index and coefficient of perme-ability of finegrained mining waste reinforced with cements. E3S Web Conf. 2018, 36, 03004. [Google Scholar] [CrossRef]

- Morman-Wątor, J. Comparison of physical and mechanical properties of mining waste with a grain size up to 2 mm reinforced with cement CEM I and CEM III. E3S Web Conf. 2019, 106, 01023. [Google Scholar] [CrossRef]

- Gruchot, A.; Zydroń, T. Shear Strength of Industrial Wastes and Their Mixtures and Stability of Embankments Made of These Materials. Appl. Sci. 2020, 10, 250. [Google Scholar] [CrossRef]

- PN-EN 1997-1:2008; Eurokod 7—Geotechnical Design-Part 1: General Principles. Polish Committee for Standardization: Warsaw, Poland, 2008. (In Polish)

- Judycki, J.; Judycki, J.; Jaskula, P.; Pszczola, M.; Rys, D.; Jaczewski, M.; Alenowicz, J.; Dolzycki, B.; Stienss, M. Catalog of Typical Structures of Flexible and Semi-Rigid Pavements. (In Polish). 2014. Available online: https://www.gov.pl/attachment/d7ded9b0-1b73-4c62-b3c5-9eecf20daeef (accessed on 10 June 2024).

- PN-EN 1991-2:2007; Eurokod 1—Impacts on Structures-Part 2: Moving Loads on Bridges. Polish Committee for Standardization: Warsaw, Poland, 2007. (In Polish)

- Regulation of the Minister of the Environment of April 20, 2007 on the Technical Conditions to be Met by Water Management Buildings and Their Location. [Dz.U. nr 86 poz. 579]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20070860579 (accessed on 10 June 2024). (In Polish)

- PN-B-03020:1981; Construction Land-Direct Foundation of Buildings-Static Calculations and Design. Polish Committee for Standardization: Warsaw, Poland, 1981. (In Polish)

| Parameter | Unit | ZG | ZG +8% CEMI | ZG +8% CEM III |

|---|---|---|---|---|

| Average value of optimal humidity | wopt [%] | 17.3 | 18.95 | 17.0 |

| Average value of maximum bulk density of soil skeleton. | ρds [g/cm3] | 1.42 | 1.55 | 1.58 |

| Parameter | Unit | ZG | ZG +8% CEMI | ZG +8% CEM III |

|---|---|---|---|---|

| Volume density | ρ [g/cm3] | 1.55 | 1.69 | 1.74 |

| Porosity index | e [-] | 0.75 | 0.67 | 0.62 |

| Effective angle of internal friction | φ′k [°] φ′d [°] | 38.10 (32.1) | 41.01 (34.86) | 40.96 (34.61) |

| Effective consistency | c′k [kPa] c′d [kPa] | 2.35 (1.88) | 19.29 (15.43) | 59.67 (47.76) |

| Oedometric modulus of compressibility (dla Is = 0.97, 100–200 kPa) | Eoed [kPa] | 15,630 | 23,090 | 24,160 |

| Filtration coefficient | k [m/s] | 5.1 ∙ 10−4 | 4.9 ∙ 10−7 | 8.1 ∙ 10−6 |

| Type of Soil | Humidity | Volume Density | Effective Angle of Internal Friction | Effective Consistency | Oedometric Modulus of Compressibility | Filtration Coefficient |

|---|---|---|---|---|---|---|

| [%] | [g/cm3] | [°] | [kPa] | [kPa] | [m/s] | |

| Gπz (sasiCl) | mw | 2.1 | 15 (12.10 *) | 16 (12.8 *) | 20,000 | 10−9 |

| No. | Model Variant * | Stability Coefficient (FoS) | |

|---|---|---|---|

| Initial State | 5th Day of the Wave Flood | ||

| Required Stability Coefficient | 1.5 | 1.3 | |

| 1a | ZG | 2.14 | 1.09 |

| 1b | ZG Widened | 1.72 | 1.26 |

| 2a | ZG + LO | 1.55 | 1.04 |

| 2b | ZG + LO Widened | 1.72 | 1.22 |

| 3a | ZG + 8% CEM I | 2.75 | 1.29 |

| 3b | ZG + 8% CEM I Widened | 2.17 | 1.47 |

| 4a | ZG + 8% CEM I + LO | 2.02 | 1.17 |

| 4b | ZG + 8% CEM I + LO Widened | 2.17 | 1.45 |

| 5a | ZG S1 + 8% CEM III | 2.79 | 1.53 |

| 5b | ZG + 8% CEM III Widened | 2.55 | 1.72 |

| 6a | ZG + 8% CEM III + LO | 2.45 | 1.37 |

| 6b | ZG + 8% CEM III + LO Widened | 2.55 | 1.67 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Morman-Wątor, J.; Pilecka, E. An Analysis of the Use of Mining Waste from Coal Mines in Flood and Road Embankments. Energies 2024, 17, 3303. https://doi.org/10.3390/en17133303

Morman-Wątor J, Pilecka E. An Analysis of the Use of Mining Waste from Coal Mines in Flood and Road Embankments. Energies. 2024; 17(13):3303. https://doi.org/10.3390/en17133303

Chicago/Turabian StyleMorman-Wątor, Justyna, and Elżbieta Pilecka. 2024. "An Analysis of the Use of Mining Waste from Coal Mines in Flood and Road Embankments" Energies 17, no. 13: 3303. https://doi.org/10.3390/en17133303

APA StyleMorman-Wątor, J., & Pilecka, E. (2024). An Analysis of the Use of Mining Waste from Coal Mines in Flood and Road Embankments. Energies, 17(13), 3303. https://doi.org/10.3390/en17133303