1. Introduction

Compared with asynchronous induction motors, low-speed and high-torque direct-drive permanent magnet synchronous motors have the advantages of large torque, high efficiency, low vibration noise, and green energy saving. Thanks to this, low-speed and high-torque transmission systems have extremely wide application prospects in industrial production, oilfield exploitation, wind power generation, port lifting, and ship propulsion [

1]. However, for low-speed high-torque permanent magnet direct-drive motors, the number of poles and slots is usually large, the rated frequency is sometimes low, and the distortion of the air gap magnetic field is serious. In addition, for low-speed motors, the output harmonic component from the frequency conversion controller increases at low frequency. At the same time, different pole–slot combinations greatly affect the harmonic content of the air gap magnetic field of the motors, thus affecting the cogging torque of the motor. Therefore, selecting the appropriate slot–pole matching scheme is a major problem in the design process of low-speed high-torque direct-drive motors. Even if the ratio of the ripple to the rated torque is small, the actual torque ripple amplitude is large because the output torque is large when the speed is low [

2]. On the one hand, it affects the control accuracy of the direct drive transmission system. On the other hand, a large torque ripple may cause rigid fatigue of the motor shaft, air gap eccentricity, and other faults, shortening the service life of the transmission system [

3,

4]. Therefore, a key problem in the design and optimization of low-speed high-torque direct-drive motors is selecting a suitable scheme to weaken the pulsating torque of low-speed high-torque direct-drive motors [

5].

In response to the above problems, some researchers have proposed a variety of measures. On the one hand, the rotor structure, magnetic pole design parameters, pole slot matching, and algorithm are optimized. In Reference [

6], the surface-mounted permanent magnet magnetic field modulation motor is taken as the research object, and the structural parameters are optimized to achieve a higher power factor. In Reference [

7], a new three-vector model predictive flux control method for SPMSM with low computational complexity and a low stator flux ripple is proposed, thus improving the steady-state performance of the stator flux while reducing the computational complexity. In Reference [

8], a new type of electric excitation claw pole field modulation motor is proposed, thus improving the utilization rate of effective harmonics and further improving the torque. The research in Reference [

9] shows that the pole–slot matching method with high fundamental frequency can effectively weaken the cogging torque and reduce the torque ripple of a permanent magnet motor by selecting the appropriate pole–slot number while ensuring the other functions of the motor. Reference [

10] optimizes the distribution of air gap flux density and permeance of a surface-mounted permanent magnet rotor by making the air gap of the motor uneven similar to unequal thickness and unequal width permanent magnets. On the other hand, starting from the design of the motor body, some parameters or structures are optimized to optimize electromagnetic performance. In Reference [

11], a novel stator-shell matching method is proposed, which can improve the electromagnetic performance, thermal performance and stress deformation performance of permanent magnet synchronous motor. References [

12,

13,

14] weaken the cogging torque to reduce the torque ripple by tilting the stator cogging to a stator pitch. The research in References [

15,

16,

17,

18] shows that the high local magnetic saturation caused by the asymmetric slot on the outer surface of the stator can significantly increase the cogging torque. References [

19,

20,

21] take the V-type permanent magnet synchronous motor as the research object and show that a reasonable choice of slot width can effectively weaken the cogging torque of the V-type internal permanent magnet motor.

At the same time, through scientific optimization design and accurate parameter adjustment, many key indicators such as motor torque density, efficiency, noise, and cost can be significantly improved to meet changing market demand and complex operating environments [

22]. Reference [

23] innovatively combines fuzzy theory with the Taguchi method and successfully combines complex multi-objectives. The optimization problem is transformed into a single objective problem, which simplifies the optimization process. Reference [

24] proposes a novel method combining pattern search and the genetic algorithm to search for the optimal parameter combination of a motor in the design space. Reference [

25] uses a radial basis function neural network to construct a surrogate model and successfully establishes the mapping relationship between design variables and target performance. On this basis, combined with a multi-objective genetic algorithm for optimization, the torque performance of the motor is effectively improved. In order to capture the complex between variables and optimization objectives more accurately, in Reference [

26], a variety of proxy models are constructed for detailed analysis and comparison. From the above analysis, it can be seen that the electromagnetic optimization of low-speed permanent magnet motors has been studied by many scholars. From the current equipment manufacturing cost point of view, the low-speed high-torque permanent magnet synchronous motor has a large volume and high cost under high-power demand. The optimization of the rotor structure is relatively limited. Therefore, it is meaningful to compare the optimization of various rotor structures.

However, most of the existing research on low-speed permanent magnet motors (LSPMM) focuses on the surface-mounted type, and there are few studies on other rotor structures. In addition, there is little comprehensive comparison of several widely used rotor structures. This makes it difficult for motor designers to choose low-speed motors with both good performance and economy. Therefore, this paper selects the three most common rotor structures as research objects. The three rotor structures are comprehensively compared in terms of magnetic and loss characteristics, permanent magnet consumption, temperature distribution, etc.

Firstly, in the first section, three rotor structures are introduced, and their initial design parameters are determined. Then, in the second section, by establishing a two-dimensional finite element model, the influence of different pole–slot combinations on electromagnetic performance is analyzed, and the pole–slot combinations of three rotor structures are determined. In the third section, the single-factor influence of rotor parameters on electromagnetic performance in different rotor structures is analyzed. Next, in the fourth section, the electromagnetic and permanent magnet consumptions of the three rotor structures are optimized, the response surface between the rotor design parameters and the motor performance is established, and the optimal design parameters of the three rotor structures are summarized. Then, in the fifth section, the three rotor structures are comprehensively compared, including electromagnetic and loss performance, permanent magnet consumption, temperature distribution, etc. In the sixth section, the theoretical analysis is verified by a prototype test. Finally, the seventh section summarizes the main conclusions of this paper.

2. LSPMM Structure and Main Performance

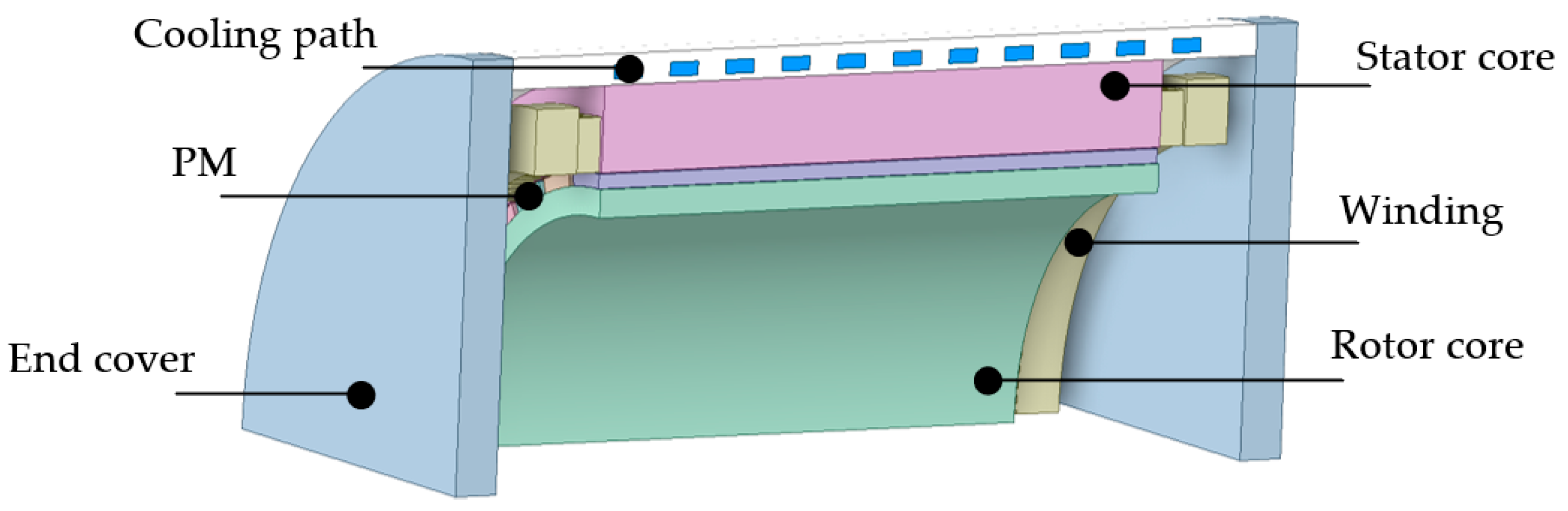

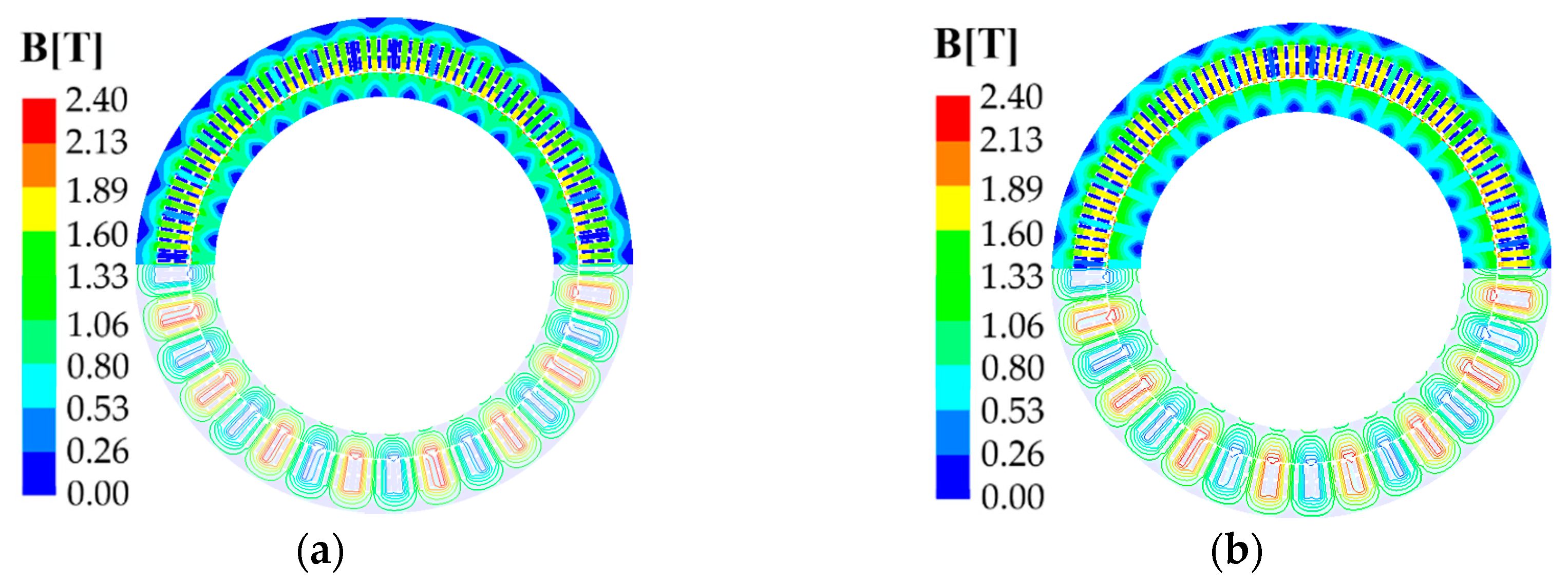

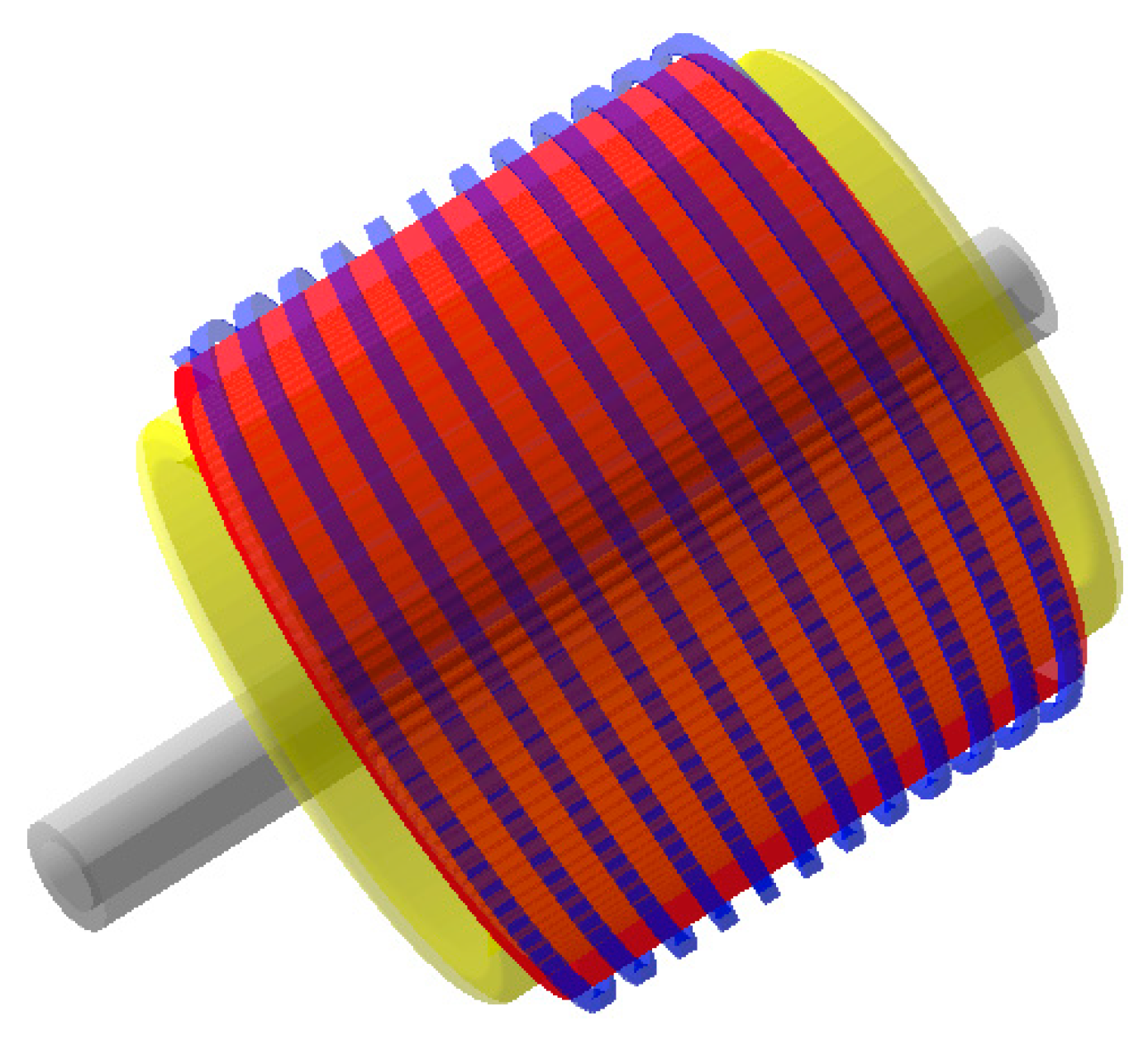

In this paper, a 500 kW, 60 rpm permanent magnet motor is taken as the research object, as shown in

Figure 1. The main design parameters of the permanent magnet motor are shown in

Table 1. In the analysis conducted in this paper, different rotor structures have the same stator design parameters.

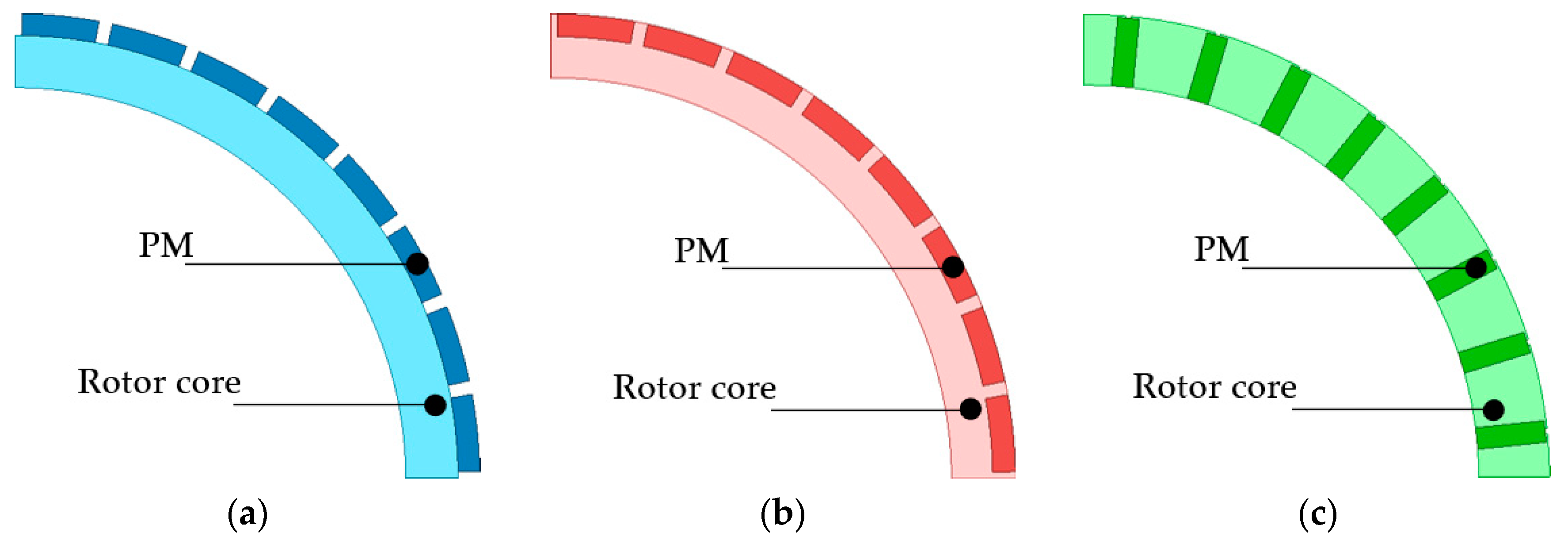

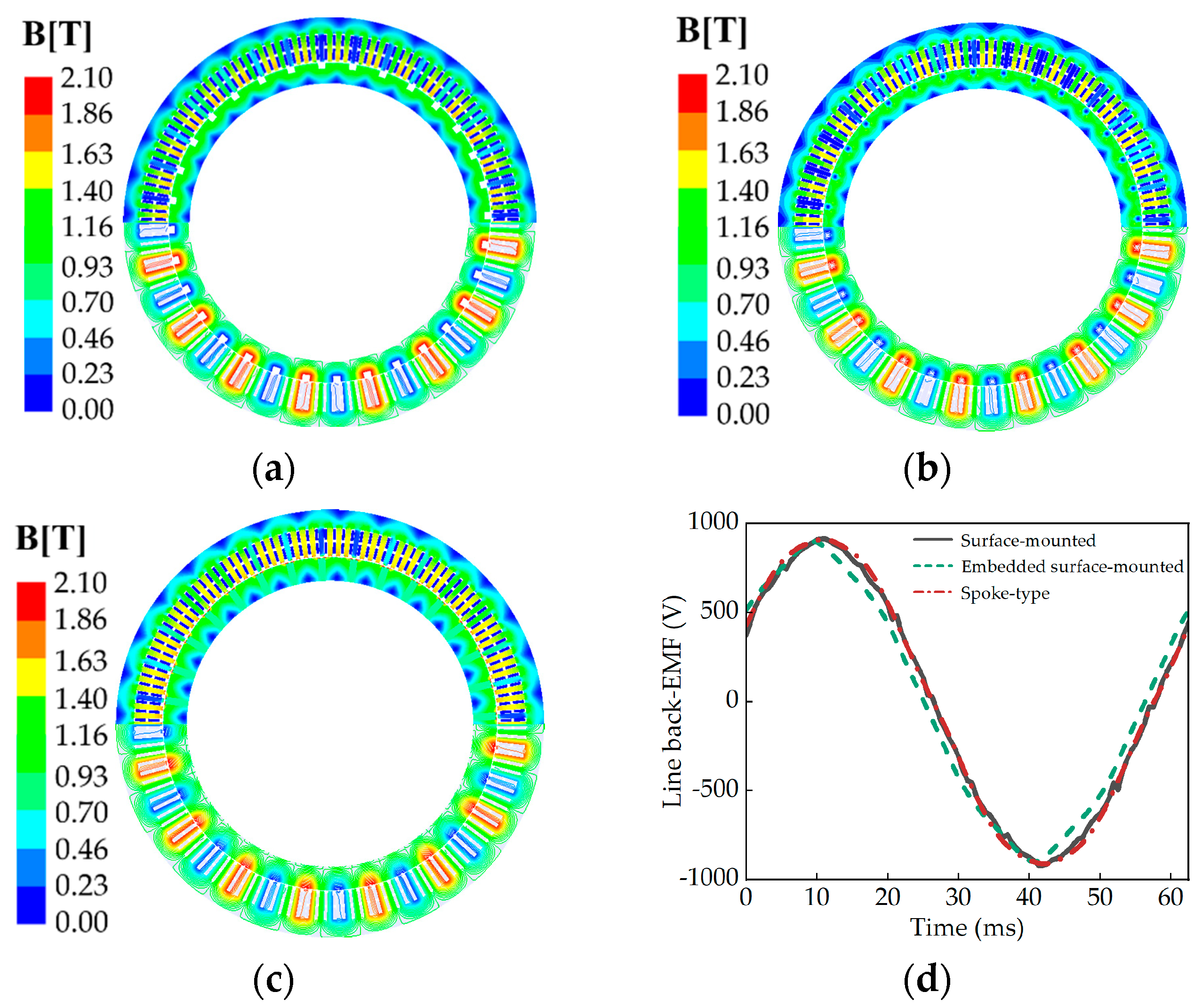

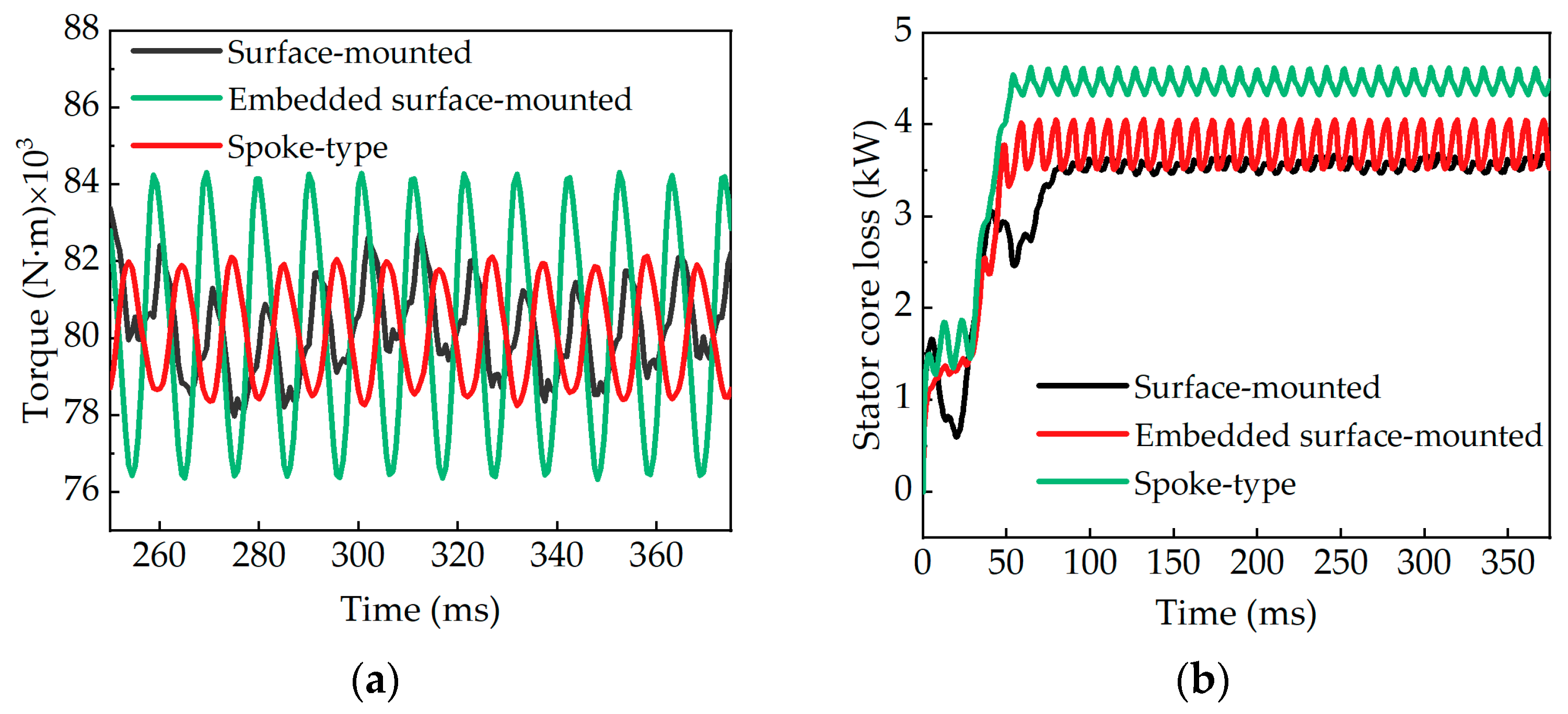

In the design process of a low-speed high-torque permanent magnet motor, in order to meet the high-power mining machinery, its volume is relatively large, and the price of permanent magnet materials is generally high, which causes the problem of high motor cost. In order to design a rotor with excellent electromagnetic characteristics and good economy, three different rotor structures are introduced, as shown in

Figure 2, which are surface-mounted, inset surface-mounted, and spoke-type rotor structures.

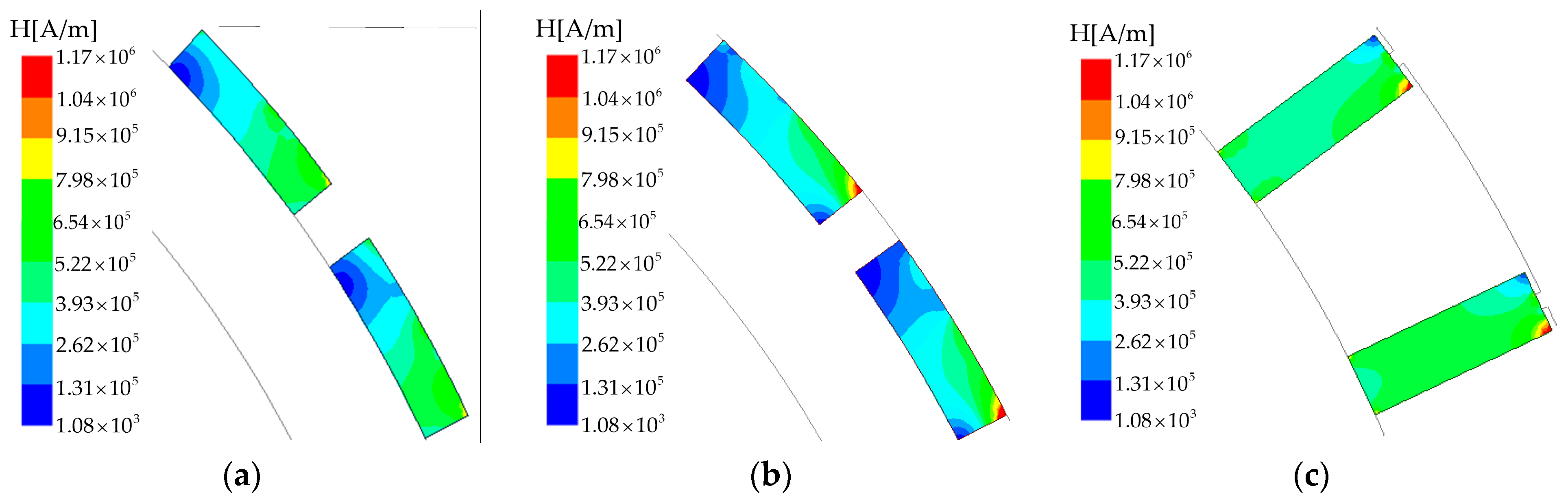

For the surface-type rotor structure, the permanent magnet is attached to the outer side of the circular core of the rotor. Because the permeability of the permanent magnet material is close to the air gap permeability, the effective air gap length is the sum of the thickness of the air gap and the radial permanent magnet. The surface-mounted permanent magnet motor is a typical non-salient pole motor, without the salient pole effect and reluctance torque. The equivalent air gap of the quadrature and direct axis magnetic circuits of this kind of motor is very large, so the armature reaction is relatively small, the flux weakening ability is poor, and the constant power flux weakening operation range is usually small. As the permanent magnet is directly exposed to the air gap magnetic field, it is easy to demagnetize, and the flux weakening ability is limited. The surface-type rotor is especially suitable for square wave permanent magnet motors because of its simple manufacturing process and low cost.

In the interior permanent magnet motor, as the name implies, the permanent magnet is buried inside the rotor core. There is a pole shoe protection of the ferromagnetic material between the surface and the air gap, and the permanent magnet is protected by the pole shoe. For the built-in permanent magnet motor, the inductance of the q-axis is greater than the inductance of the d-axis, which is beneficial to the weak magnetic acceleration. Because the permanent magnet is buried inside the rotor core, the rotor structure is more solid, which easily improves the safety of the high-speed rotation of the motor. The inset surface-mounted rotor structure has a small magnetic flux leakage coefficient, the motor shaft does not need to take magnetic isolation measures such as magnetic isolation sleeves and magnetic bridges, the mechanical strength of the rotor punching sheet is large, and the rotor is not easily deformed. The permanent magnet is placed in the permanent magnet slot along the axial direction of the motor, and the magnetic flux leakage is suppressed by the pole interval magnetic bridge. For the spoke-type rotor magnetic circuit structure, two adjacent magnetic poles are in parallel to provide a magnetic flux at a pole distance. Therefore, a larger flux per pole can be obtained, which improves the utilization rate of permanent magnet materials and can save some permanent magnet materials. When the number of pole pairs of the motor is large, the advantage of the structure is more prominent.

4. Multi-Objective Optimization of Different Rotor Structures

Combined with the analysis results of the influence of rotor parameters on the performance of the motor in

Section 3 and

Section 4, and based on the initial design scheme of the four rotor structures in

Section 4, this section carries out electromagnetic optimization considering the consumption of permanent magnets. Firstly, according to the optimization methods in the existing literature, the process and mathematical model of electromagnetic optimization are sorted out. Then, the optimization variables and optimization ranges of the three rotor structures are determined. Finally, through the establishment of the Kriging surrogate mode, the multi-objective genetic algorithm is used to find the optimal non-inferior solution, and the optimization scheme of the three rotor structures is determined.

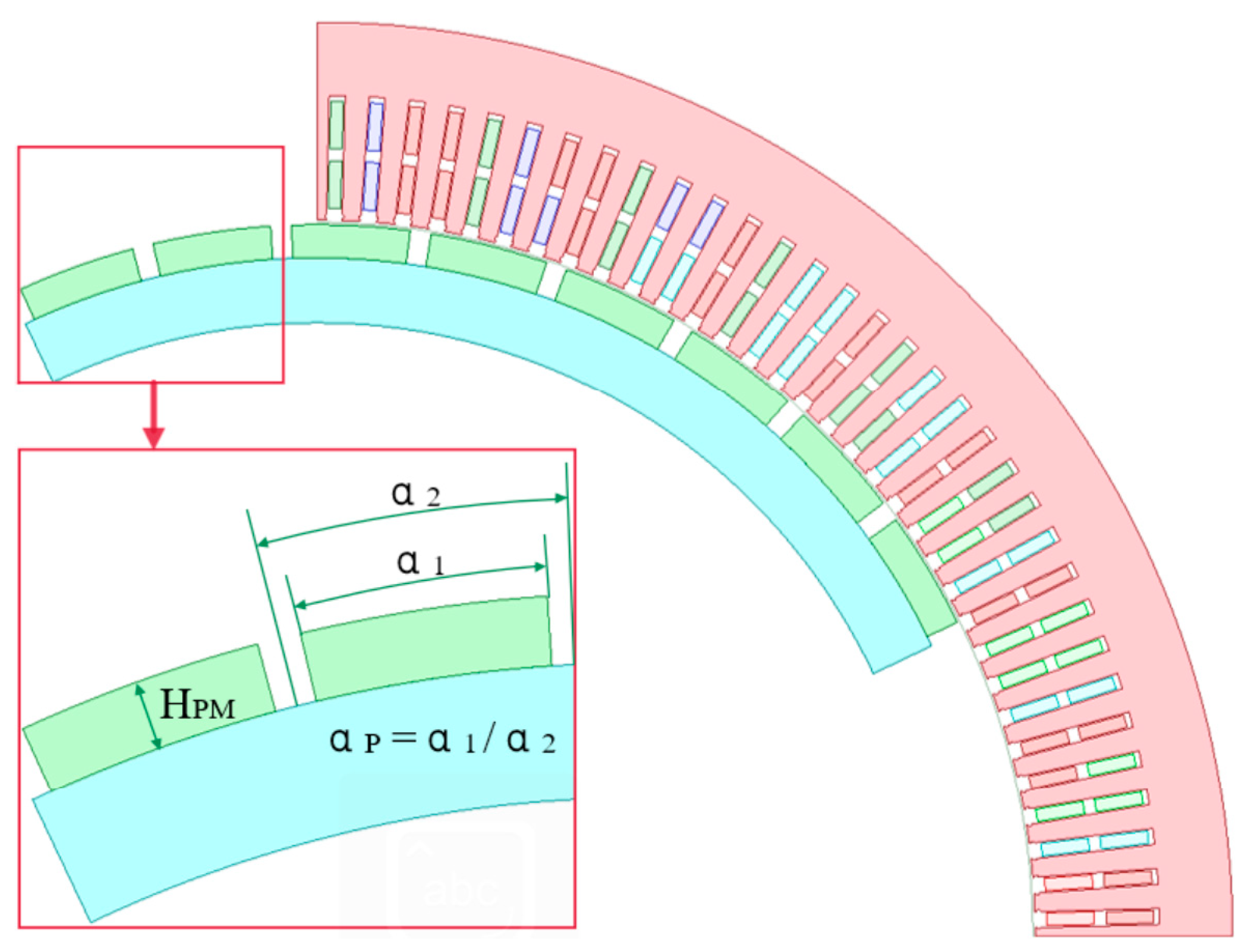

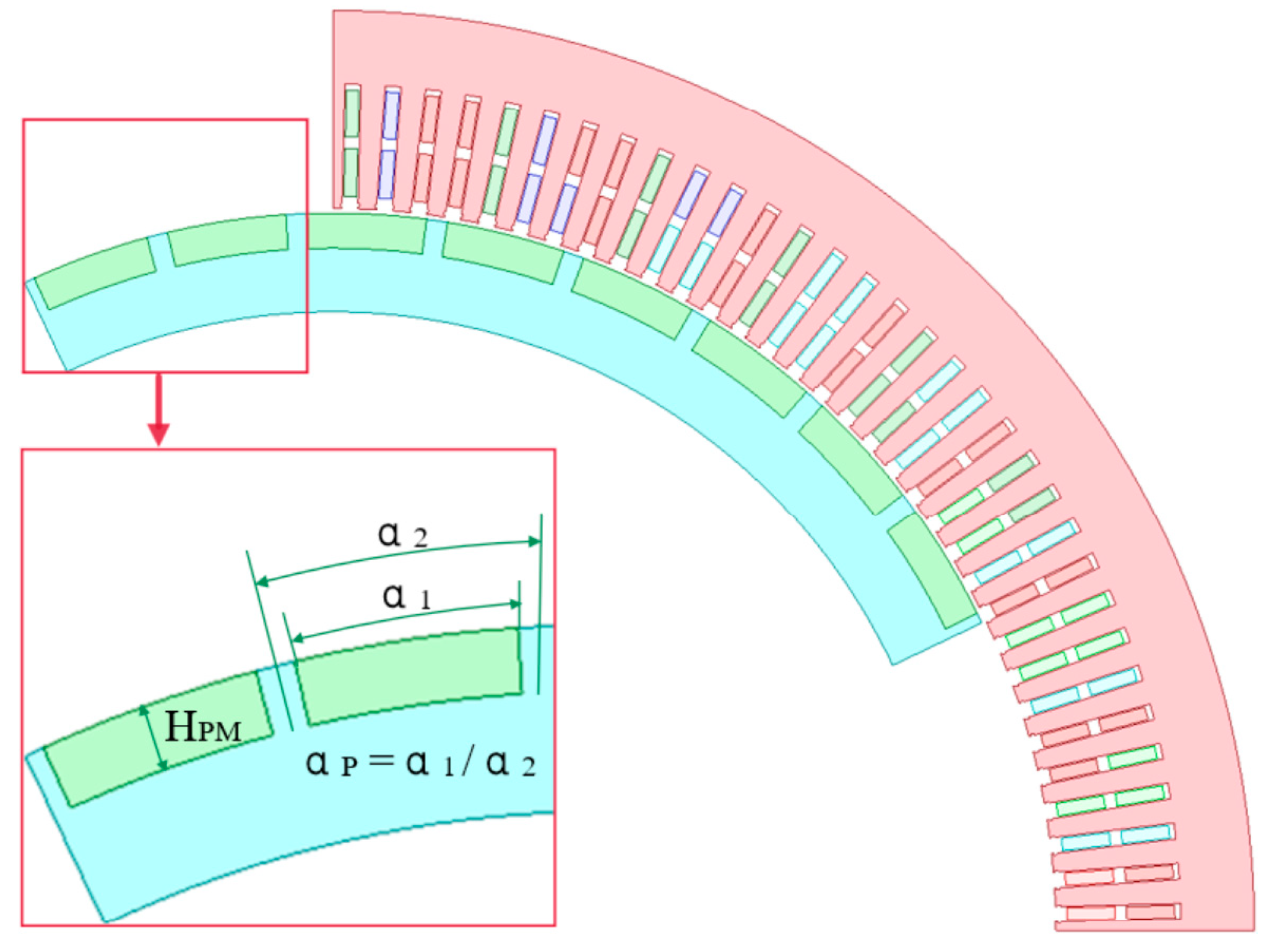

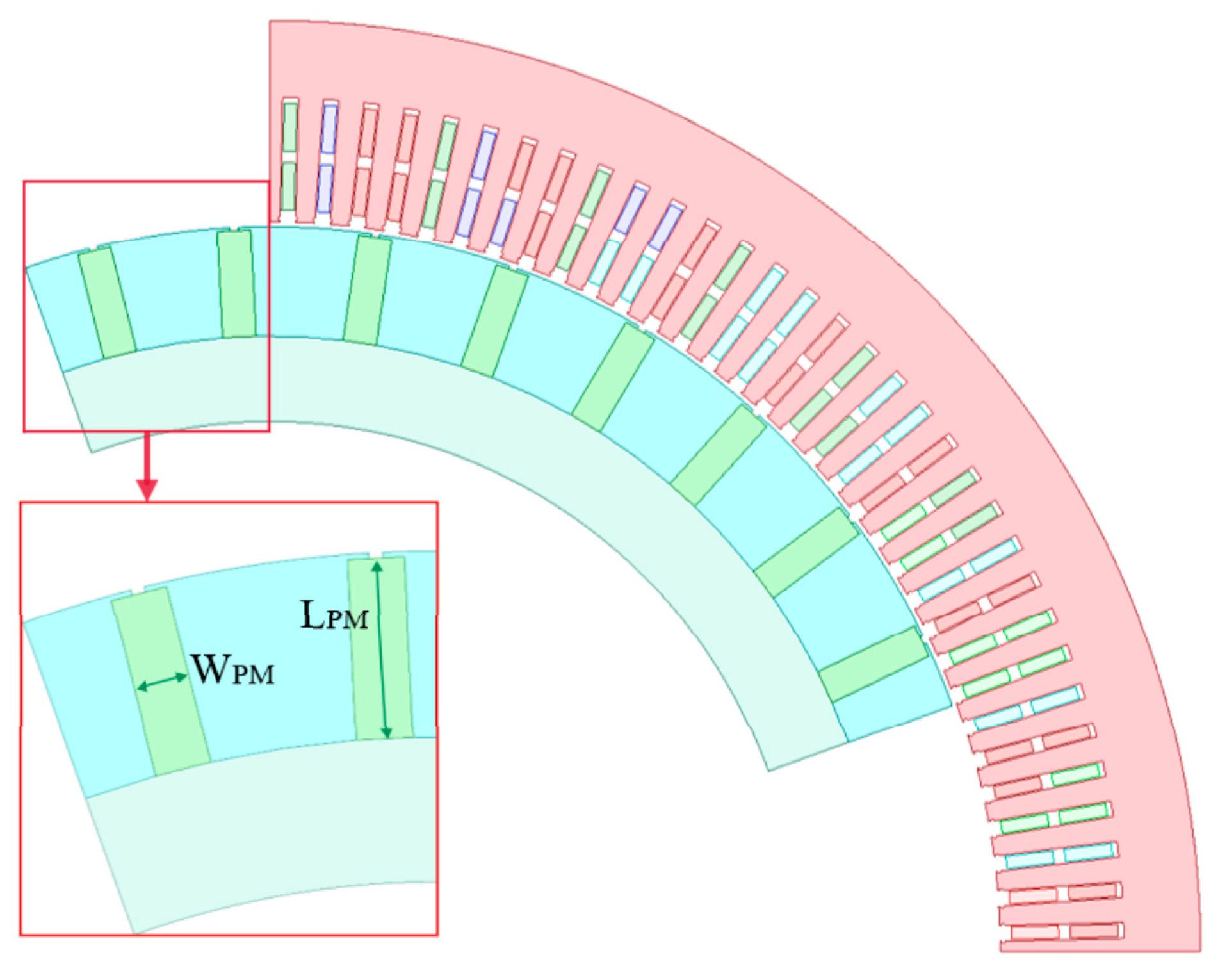

For the surface-mounted rotor structure, the permanent magnet thickness, pole arc coefficient, and core length are selected as optimization variables. For the inset surface-mounted rotor structure, the permanent magnet thickness, pole arc coefficient, and core length are selected as optimization variables. For the spoke-type rotor structure, the length of the permanent magnet, the width of the permanent magnet, and the length of the core are selected as the optimization variables.

Table 2 shows the optimization range of the three rotor structure design parameters.

4.1. Response Surface Analysis

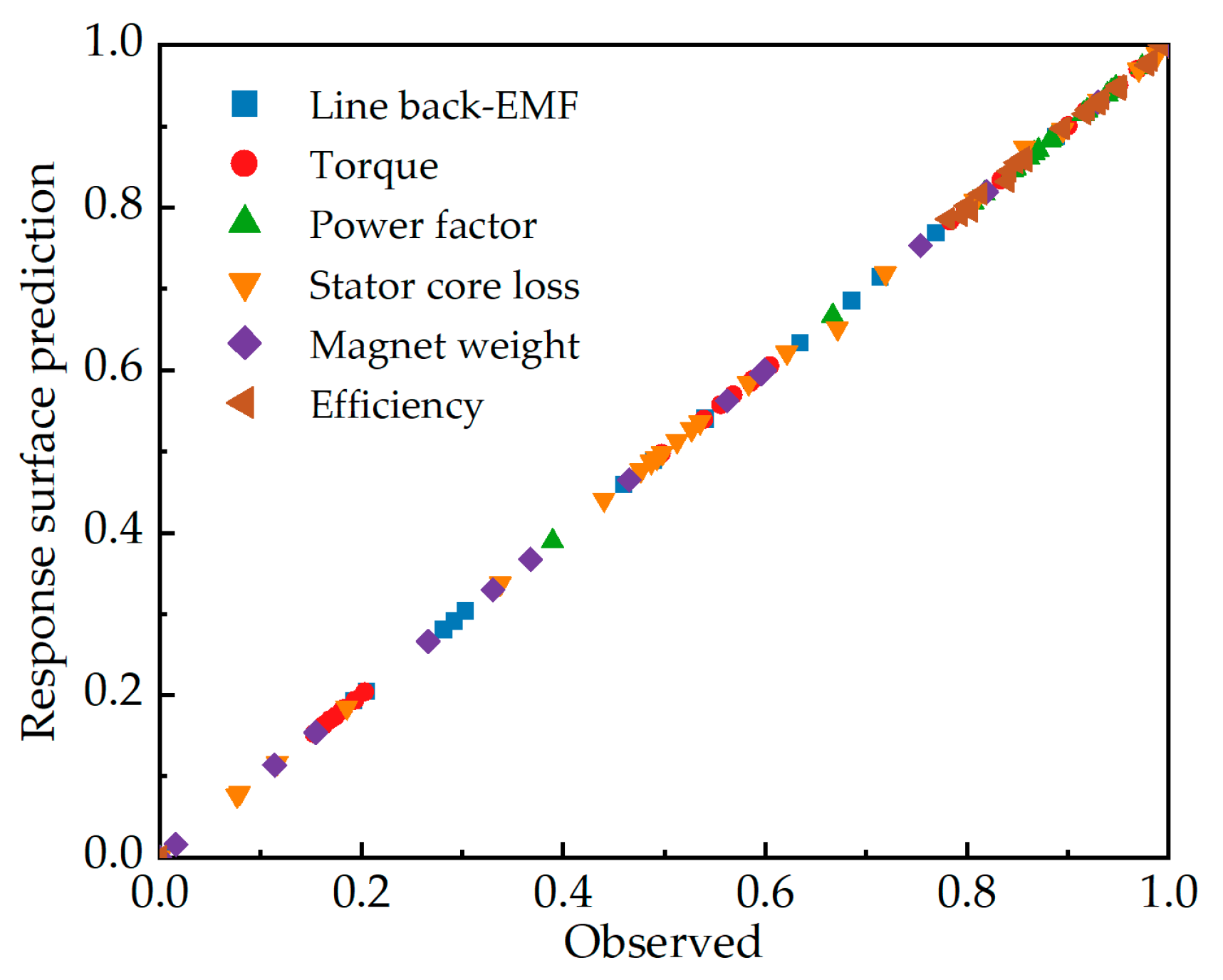

Firstly, a central composite design sampling design is used to obtain a uniform original sample. The electromagnetic analysis of the low-speed permanent magnet motors with different rotor structures is carried out for all sample data. A response surface surrogate model of rotor design parameters and motor performance is established by using the FEA results of the sample data. The Kriging surrogate model predicts the uncalculated data based on the calculated test sample data. It is an unbiased estimation model of experimental point results.

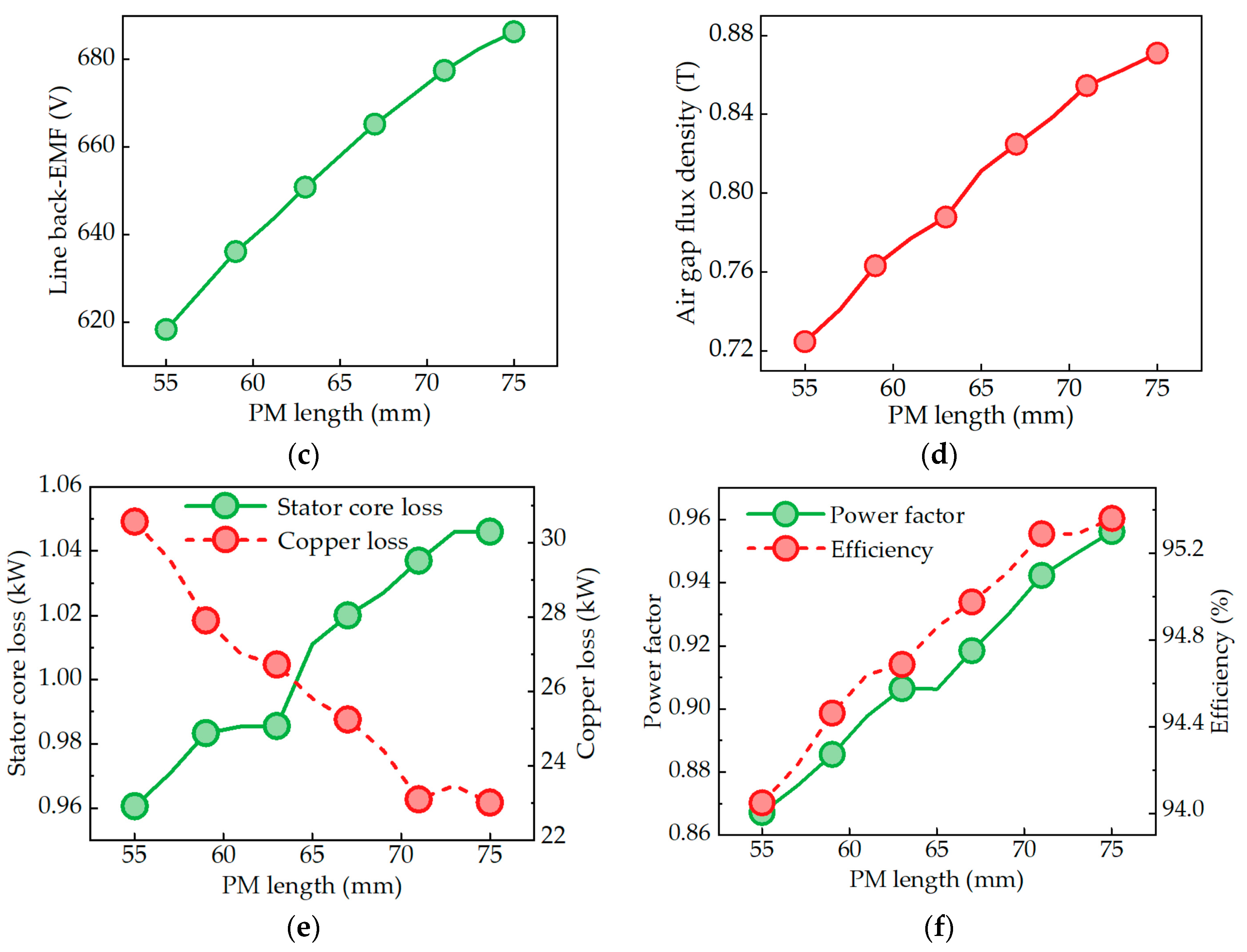

Figure 10 summarizes the results of the two-dimensional finite element calculation and the response surface surrogate model. The response surfaces of the three rotor structures are shown in

Figure 11,

Figure 12 and

Figure 13.

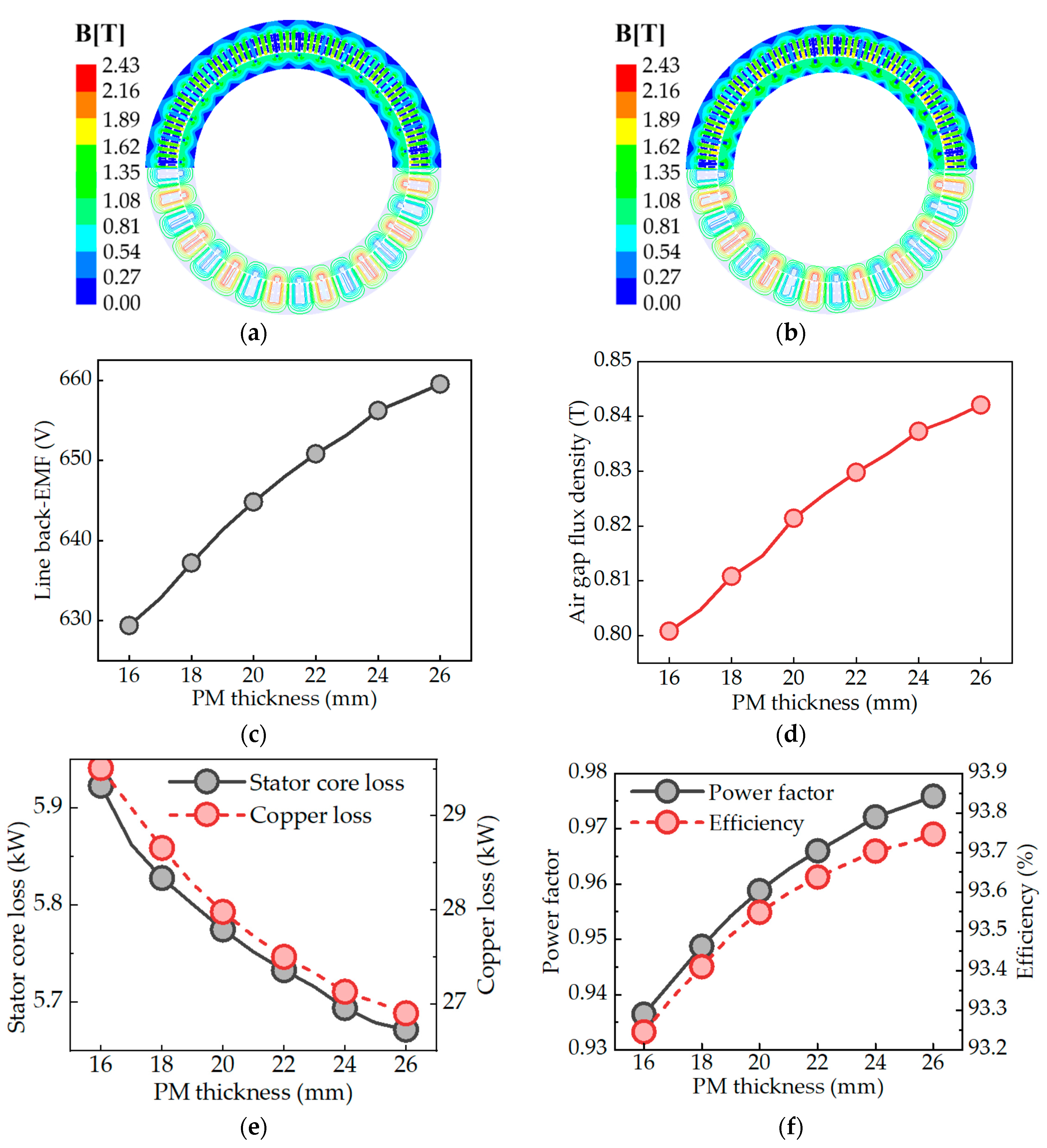

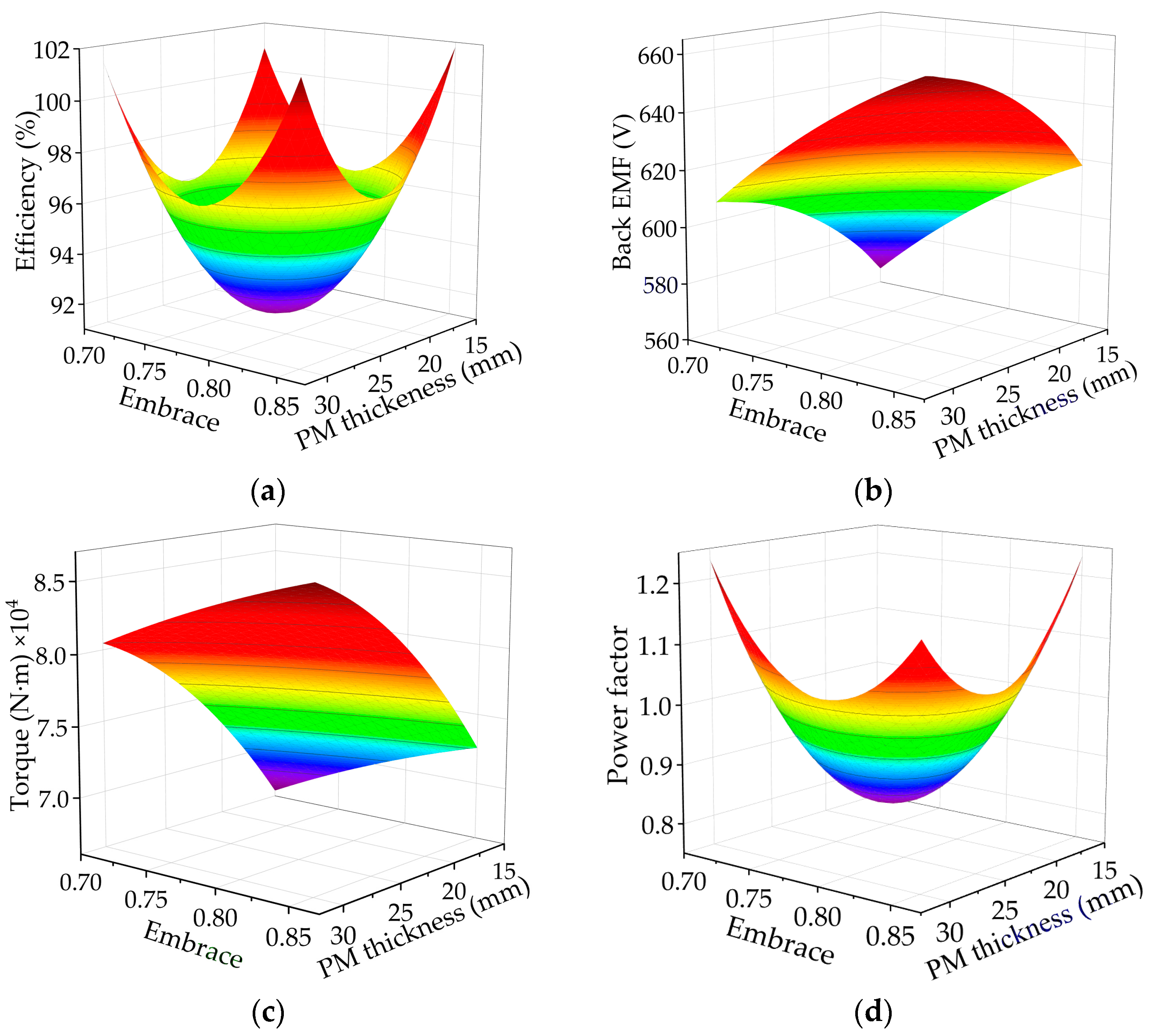

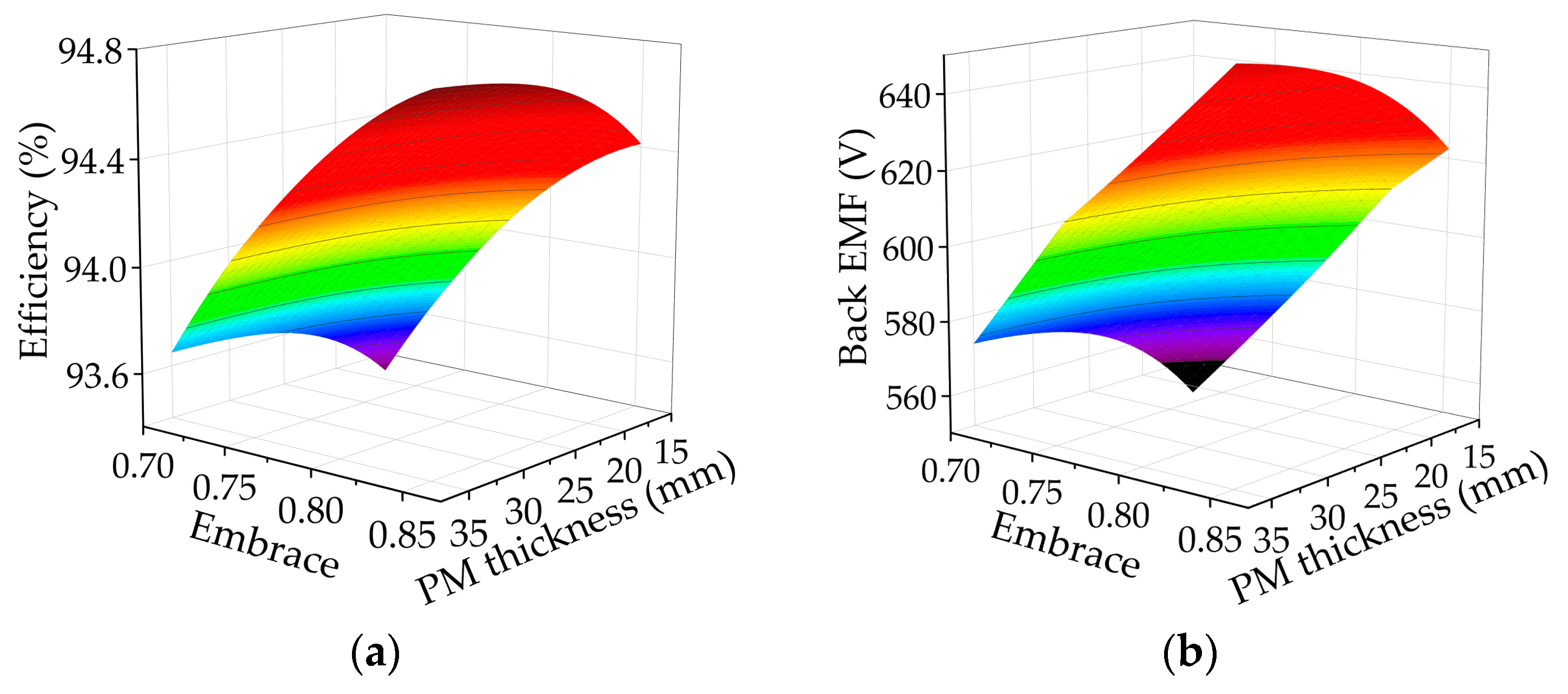

The response surface of the surface-mounted rotor design parameters to the motor performance is shown in

Figure 11. With the increase in the pole arc coefficient and permanent magnet thickness, the efficiency of the motor decreases first and then increases. In

Figure 11b, it can be seen that the thickness of the permanent magnet has a significant effect on the back electromotive force of the no-load line, and the influence of the pole arc coefficient is not significant. In addition, a higher amount of the permanent magnet means a higher torque. With the increase in the amount of the permanent magnet, the power factor decreases first and then increases.

Figure 12 shows the influence of the design parameters of the inset surface-mounted rotor on the performance of the motor. The efficiency and no-load back-EMF of the motor increase significantly with the increase in the pole arc coefficient. Similar to the surface-mounted rotor, the torque of the motor increases with the increase in the amount of the permanent magnet. The influence of the pole arc coefficient of the permanent magnet on the power factor is obvious, and the thickness of the permanent magnet has little effect on the power factor compared with the pole arc coefficient.

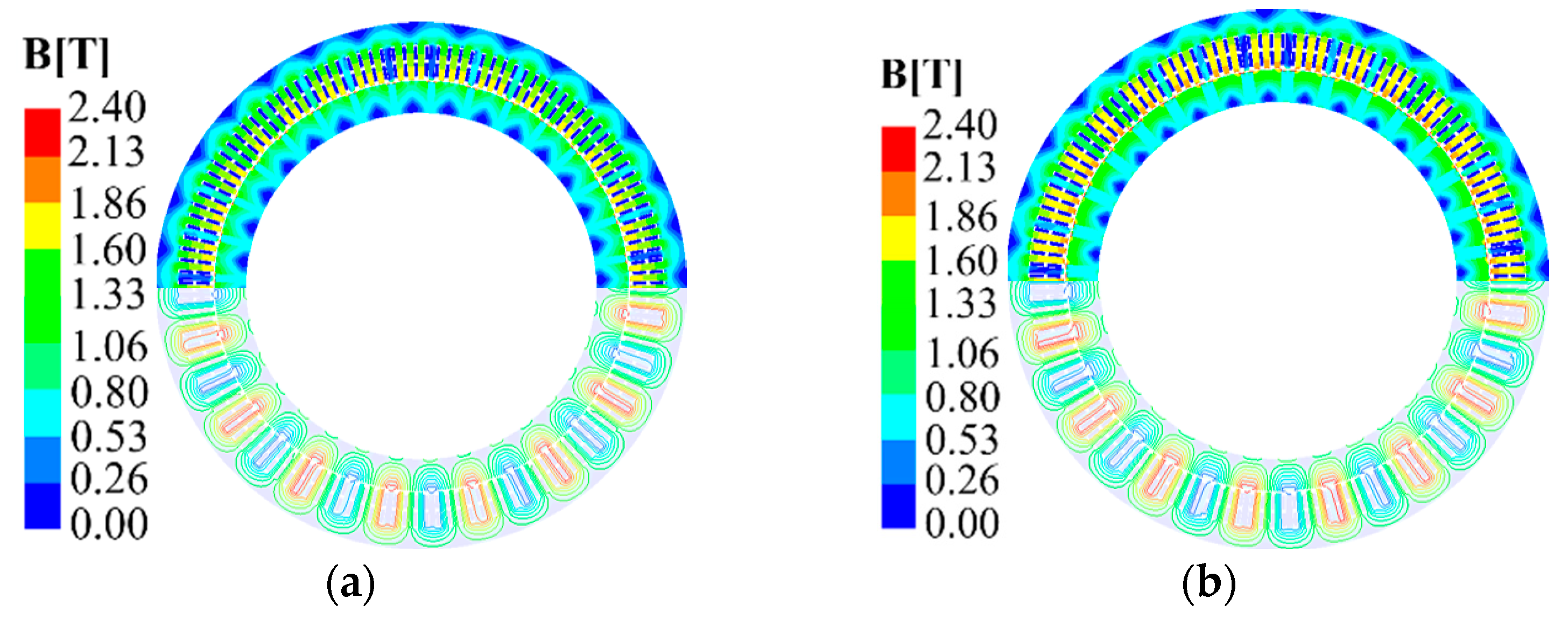

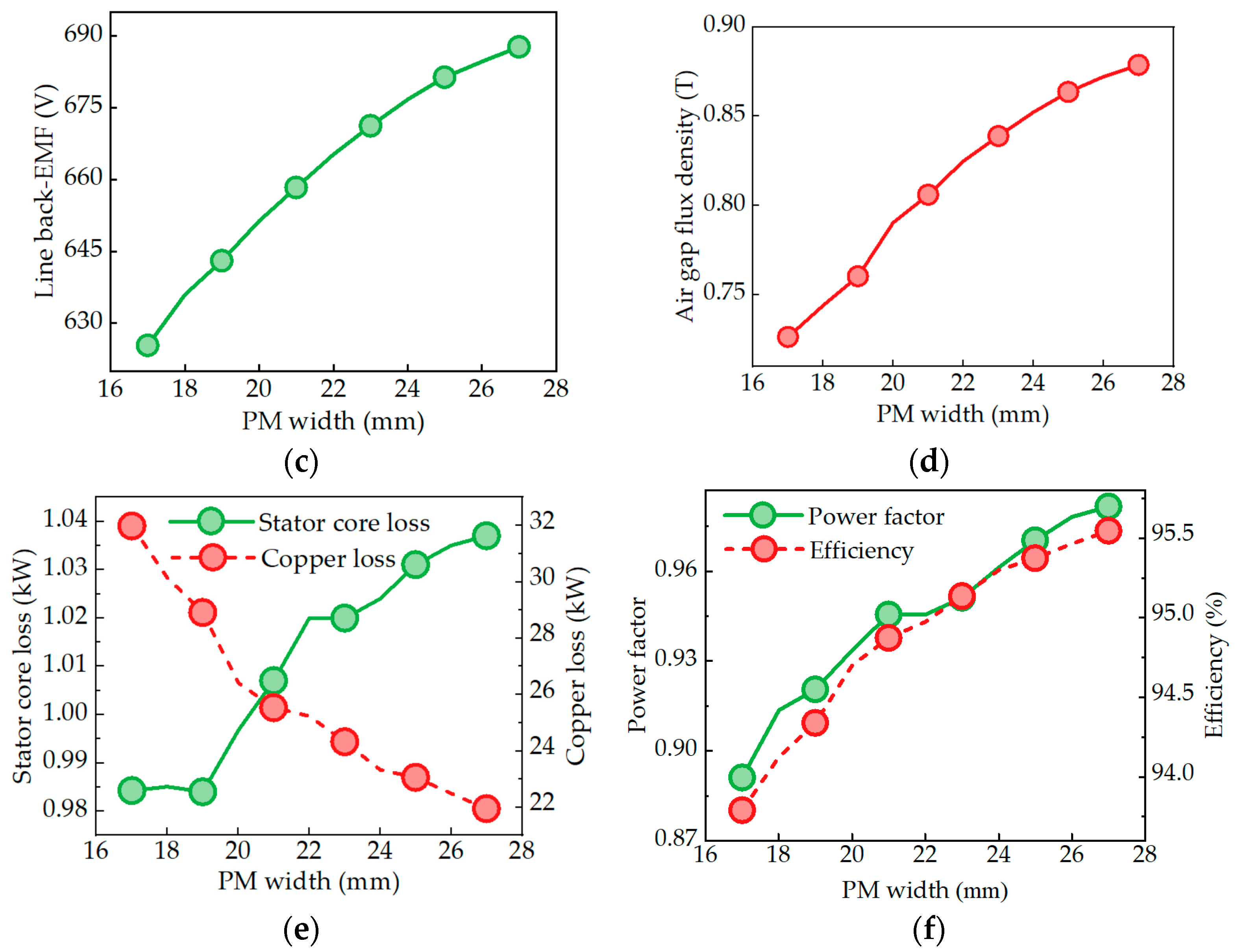

The influence of the design parameters of the spoke-type rotor on the electromagnetic characteristics is shown in

Figure 13. The no-load back-electromotive force and torque of the motor increase with the increase in the amount of the permanent magnet. When the thickness of the permanent magnet increases, the efficiency and power factor increase slightly. The width of the permanent magnet has a great influence on the electromagnetic performance. With the increase in the width of the permanent magnet, the efficiency and power factor increase significantly.

4.2. Sensitivity and Constraint Analysis

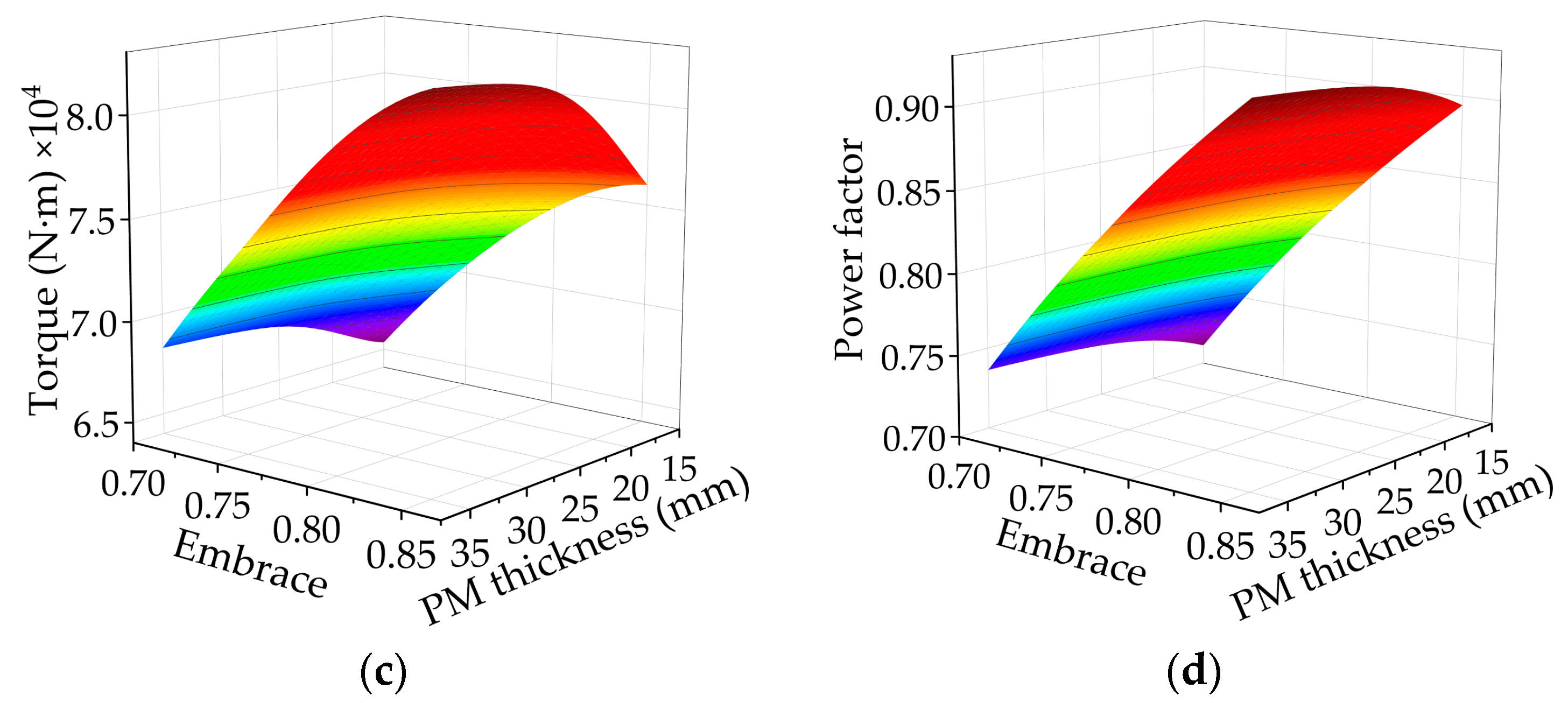

Sensitivity analysis is an effective method to evaluate the influence of a single parameter on an optimization objective. Before the electromagnetic optimization of the three rotor structure motors, a sensitivity analysis of the main optimization parameters is first carried out. The correlation coefficients of each optimization parameter for different optimization objectives are obtained. In this paper, the Pearson correlation coefficient is used to express the influence of each optimization parameter on different optimization objectives.

where

is the value of the optimization objective corresponding to the optimization variable

, and

is the average value of the optimization objective.

According to the above theoretical calculation, the finite element model is established and the sensitivity of the relevant structural parameters is calculated.

Figure 14 shows the sensitivity coefficient of the optimization objects. The larger the value of the sensitivity coefficient, the greater the impact on the optimization goal. A positive value indicates that the optimization goal increases with the increase in the optimization variable, and a negative value is the opposite.

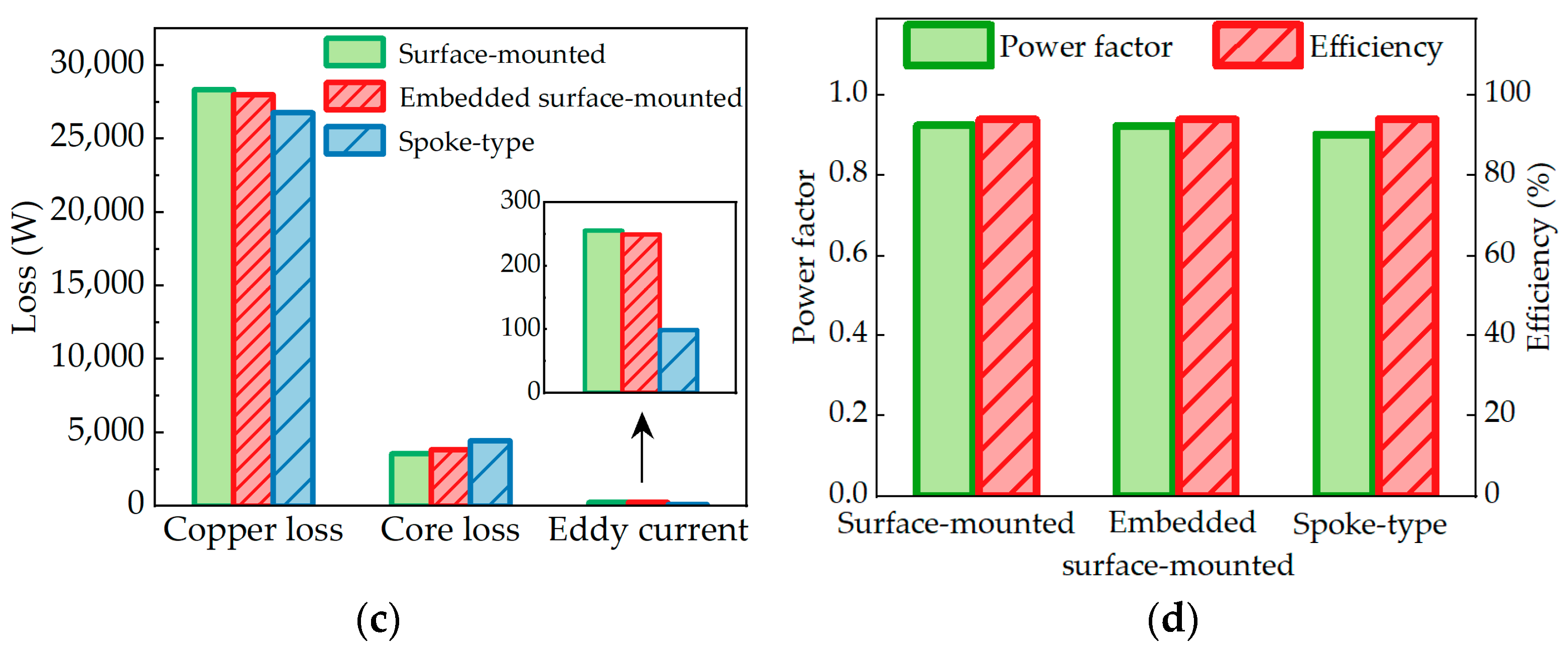

In this paper, in the process of the electromagnetic optimization of low-speed permanent magnet motors with three rotor structures, the maximum efficiency and the minimum permanent magnet volume are selected as the optimization objectives to obtain a more reasonable optimization scheme. The constraints of the optimization process of the low-speed permanent magnet motors include no-load line back-electromotive force, output torque, and power factor.

First, the no-load back-EMF of the low-speed permanent magnet motor should be slightly smaller than the rated voltage to ensure that there is sufficient excitation magnetic field to complete the electromechanical energy conversion process. Second, the torque is selected as the first constraint condition of the load operation, and the torque should be greater than the rated torque. In addition, the power factor is selected as the constraint condition. In order to obtain higher motor efficiency, the power factor is limited to 0.9 or more.

In the above formula,

V is the volume of the permanent magnet, efficiency,

E is the back-EMF of the no-load line,

Tn is the output torque, and

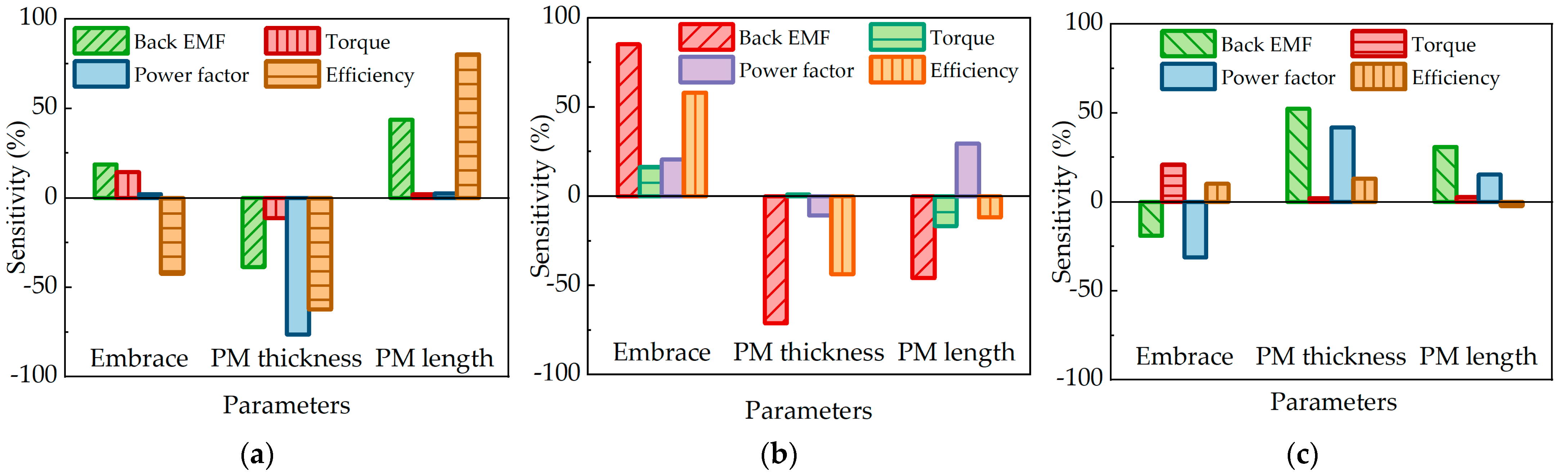

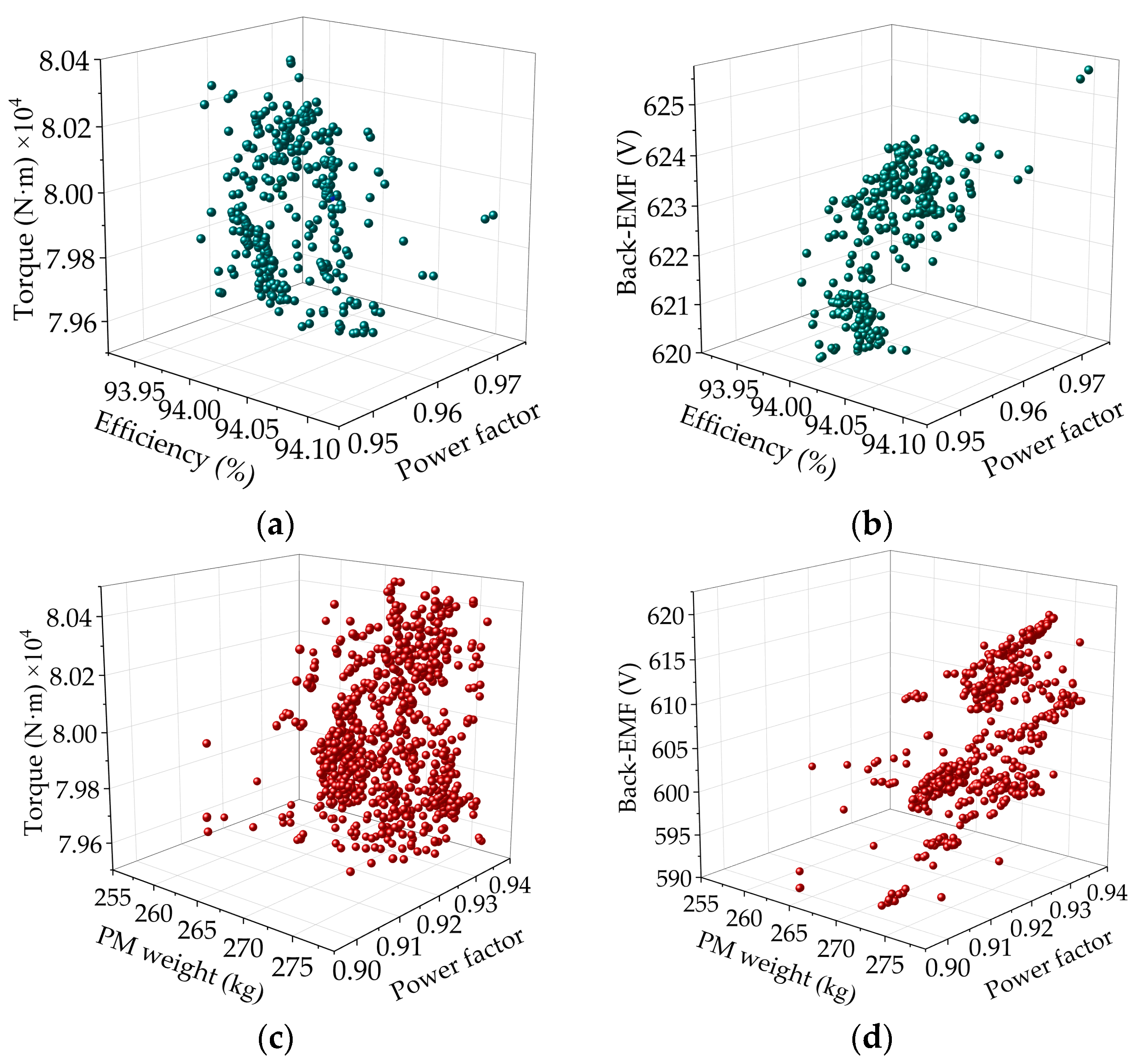

is the power factor. In the electromagnetic optimization process of this paper, the multi-objective genetic algorithm method is used to optimize the Kriging surrogate model, and the Pareto front solution set is obtained. Taking the Pareto frontier diagram in

Figure 15 of the surface-mounted rotor structure optimization as an example, based on satisfying the optimization constraints, all the solutions in the Pareto front are solutions that meet the optimization constraints. This requires that from the Pareto front, according to the design needs, a set of solutions that best meet the requirements is selected as the final optimization scheme. The optimization goal of this paper is the highest efficiency and the least consumption of permanent magnets. However, the optimization objectives cannot achieve the best results at the same time. The consumption of the permanent magnet used in the most efficient solution is not the least. Therefore, in the process of electromagnetic optimization, there is no set of optimal solutions, and all the performances of the motor achieve the best results. Instead, there is a compromise between all the optimization objectives. Finally, a compromise solution with the maximum efficiency and the minimum amount of permanent magnet is selected.

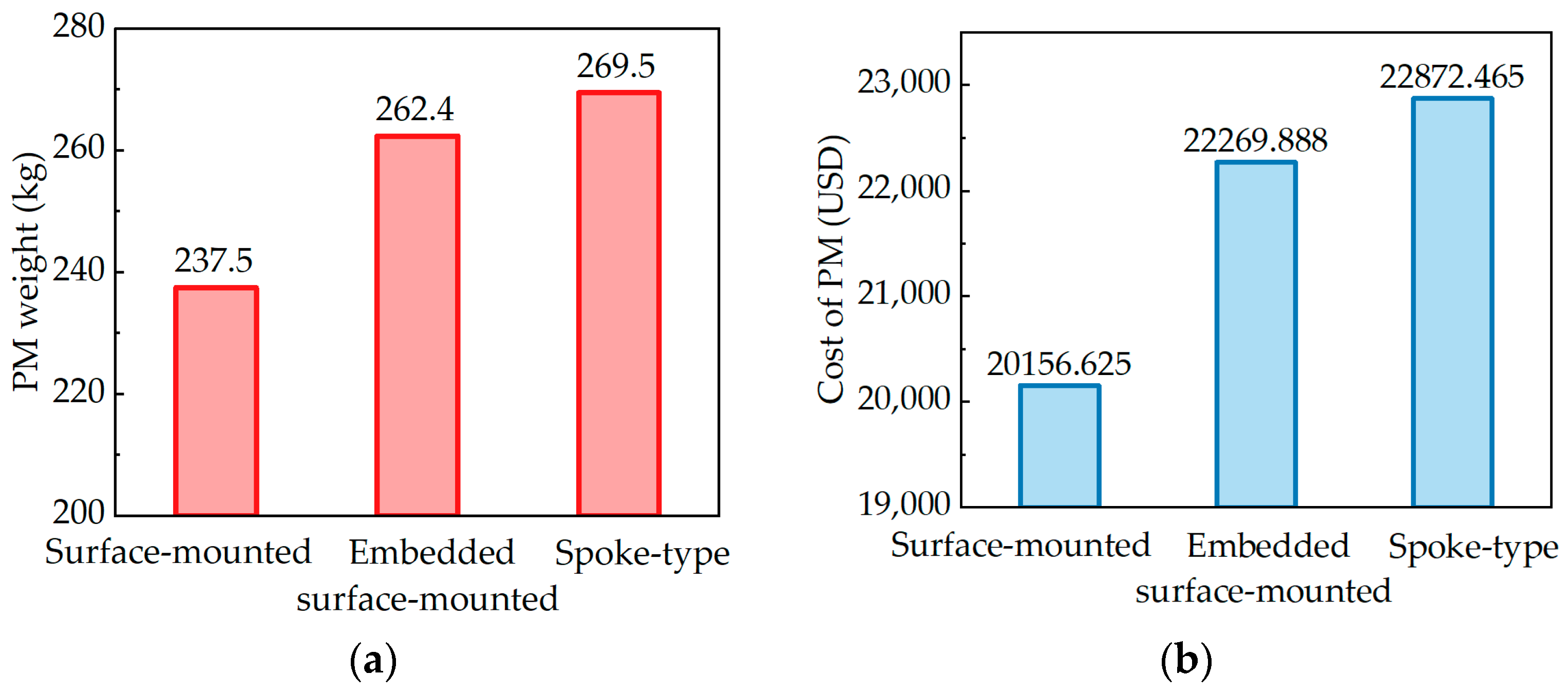

4.3. Optimal Results

For the three rotor structures, after completing the electromagnetic optimization taking into account the consumption of permanent magnets, the optimized rotor design parameters are obtained, as summarized in

Table 3.

6. Prototype and Experimental Tests

Based on the above analysis, the electromagnetic performance and temperature distribution of the surface-mounted rotor are the best of the three rotor structures. In order to verify the correctness of the theoretical analysis, a 500 kW, 60 rpm prototype is manufactured based on the surface-mounted rotor scheme, as shown in

Figure 23a,b. In conditions where the prototype is under rated, its high torque presents challenges for evaluating its performance using conventional testing equipment. To assess the no-load and load performance of the prototype, specialized testing equipment designed for low-speed and high-torque permanent magnet motors is utilized. The experiment involves driving the prototype with a frequency converter, connecting it to a load motor via a belt, and linking the load motor to a hydraulic screw, which in turn is connected to a mechanical load. The figure illustrates the extensive size and complexity of the test system. Within this testing platform, the mechanical load can be adjusted to modify the torque of the load motor connected to it, which in turn transmits torque to the prototype via a belt for load adjustment. The power analyzer is connected at the power input end of the prototype to assess its electromagnetic performance.

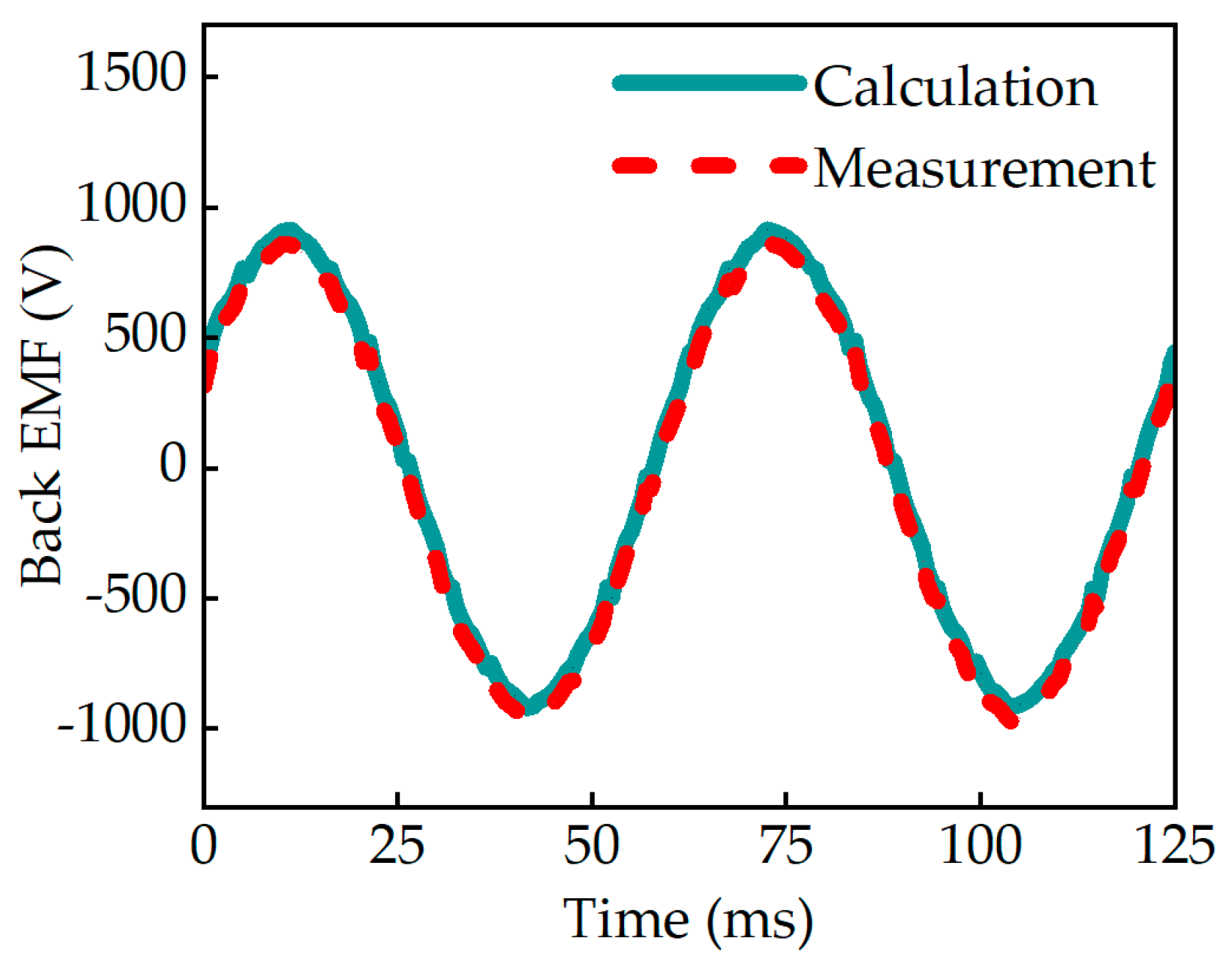

To determine the no-load back-EMF of the prototype, it is driven by a load motor operating at its rated speed. The no-load back-EMF of the prototype can be obtained by the power analyzer, as shown in

Figure 24. As shown in

Figure 24, the no-load back-EMF of the test is about 632 V, which is 8 V lower than the simulation value.

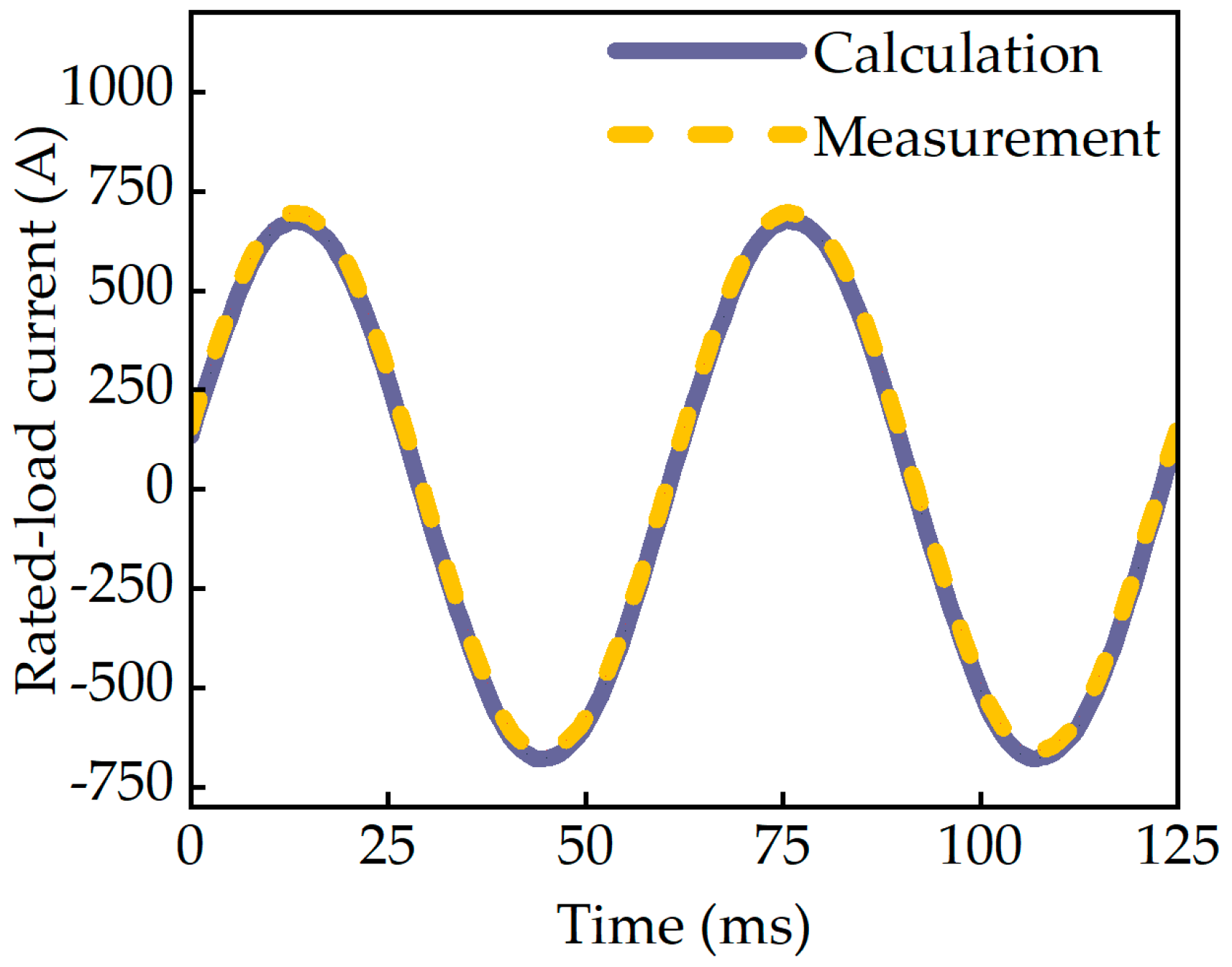

To determine the electromagnetic properties during rated operation, the prototype is powered by an inverter and operated under rated conditions by adjusting the mechanical load. The power supply voltage of the prototype is regulated to the rated voltage using a frequency converter. A high-range torque sensor is installed on the load motor side to measure the torque generated by the load motor. Consequently, the output power or torque of the prototype can be calculated based on the efficiency curve of the load motor. The power analyzer can be used to obtain the waveform of the prototype’s armature current at full load. As shown in

Figure 25, the rated current of the prototype is about 486 A, which is 5 A higher than the calculated value. In addition, under the above cooling system, the measured winding temperature is about 115.3 °C after the motor runs for several hours in the rated state, which is slightly higher than the simulation result of 112.6 °C. The comparison between the measured and calculated performances is shown in

Table 5.

The line-to-line back-EMF of the no-load operation is measured with the prototype driven by another motor. The measured peak-to-peak value of the line-to-line back-EMF at 30,000 rpm is 520 V, which is nearly the same as the designed voltage. The stator windings temperature at the rated load is measured by the Pt100 resistance temperature detectors installed in the stator slots. It can be found that the temperature of the measured windings is , which is close to the FEA calculation results of . Obviously, for the designed LSPMM, the measured value of electromagnetic performance and temperature characteristics are close to the calculated results, both satisfying the electromagnetic and thermal constraints.

In addition, the prototype worked at the rated speed for a long period. There was no damage to the rotor, which indicates that the design of the LSPMM is also reasonable, and the designed motor satisfies all of the multi-physics constraints in the real industry.

Overall, the experimental prototype tests validated that the designed motor meets all multi-physics constraints, including electromagnetic, mechanical, and thermal characteristics. This paper proposes, that the influence law of rotor length–diameter ratio on multi-physics is effective for the LSPMMs.