Abstract

The treatment of produced water is a major challenge faced by oil and gas industries worldwide. As a result of the increase in industrial activities, the generation of produced water has increased significantly. The most commonly used method for produced water oil–water separation is de-oiling hydrocyclone technology due to its simple construction, compact design, easy maintenance, and high efficiency. A wide breadth of scientific research studies has been carried out on performance evaluation, design optimisation, geometric parametrisation, external interventions, etc., to enhance the performance of hydrocyclones. These studies mostly rely on either experimental data obtained from the field, in laboratories under a controlled environment, or the application of numerical techniques for oil-in-water separation. Considering the extensive research studies published on hydrocyclone technology, this study aims to provide a comprehensive review of recent technological advancements in hydrocyclone technology in order to identify key areas where scientific research efforts should be concentrated. This will help make well-informed decisions for strategic investments in this wide area of research. Furthermore, it will widen the scope of applicability of hydrocyclones in the industrial sector.

1. Introduction to Produced Water

The term Produced Water (PW) refers to the water present in the formations of oil and gas reservoirs. It is an inherent by-product of natural gas and petroleum extraction. It comes in large quantities in multiphase flows (oil/solids/water), which can be reused or disposed of after treatment. During oil and gas exploration, various processes form the produced water. Initially, the extraction of oil and gas from the reservoir causes a drop in its pressure, prompting the injection of water into the reservoir to maintain hydraulic pressure and enhance oil recovery. As the production of oil and gas continues, it reaches a point where the formation of water eventually reaches the production well, leading to water production alongside the hydrocarbons. This is referred to as Produced Water, which is also known as oil-field brine. In summary, produced water can be said to be a combination of injected water, hydrocarbons, treating chemicals, and formation water [1], and can be classified as either oilfield PW, coal bed methane (CBM) PW, or natural gas PW, depending on the origin [2,3]. Oil-field PW accounts for approximately 60% of the daily generated water globally [2]. During the gas and oil recovery processes, produced water accounts for the largest amount of by-products generated; it represents approximately 80% of all the wastewater generated [4], which is projected to be more than 70 billion barrels per year globally [5]. On a daily basis, approximately 250 million barrels (39 million m3) of produced water are generated by oil and gas operations around the world, and over 40% of this is released into the environment [2]. An overview of the generated and discharged amounts of produced water is given in [3]. Produced water from natural gas and oil extraction has no fixed volume; it is dependent on the location of extraction, the exploitation technique used, and the type and age of the reservoir. Therefore, for a specific reservoir, the volume of produced water is not constant, and the amount of produced water increases with the age of the reservoir [6,7].

Due to the growing amount of produced water, which is an inherent by-product of the extraction of natural gas and petroleum, and ecological concerns associated with its disposal, the purification of water has become a serious issue [8,9,10]. The discharge of produced water into the environment can result in highly negative environmental effects, especially in the context of UN sustainable development goals 6: Clean Water and Sanitation, 12: Responsible Consumption and Production, and 13: Climate Action. As a result, strict regulatory criteria are in place to manage produced water in the environment, which presents a significant challenge for the global oil and gas industry [11]. According to Clark and Veil [5], the United States Environmental Protection Agency (U.S. EPA) permits a monthly average limit of 29 mg/L and a daily maximum limit of 42 mg/L for oil and grease. The composition of produced water changes during the course of field life production and is largely dependent on the reservoir’s lifetime, the geologic formation in which the reservoir is located—also referred to as the field’s geographic position—the history of injected water, and the type of hydrocarbon product that is produced. In this regard, produced water is generally considered to have a complex composition [9,12]. The components of produced water can be broadly classified into the following compounds: formation minerals, dissolved gases, dissolved and dispersed oil compounds, production solids, and production chemical compounds. The fundamental elements of the aforementioned compound categories are summarised in Table 1.

Table 1.

Main components of produced water.

Table 2 provides a summary of further essential constituents of produced water and their typical concentrations. Produced water typically contains the following main constituents: toluene [20], benzene [13], polyaromatic hydrocarbons (PAHs) [21], total dissolved solids (TDS) [16], oils and greases (O&G) [22], ethylbenzene and xylenes [23], naturally occurring inorganic and organic substances [24] such as magnesium, sulphate, barium, and calcium, which can cause flaking and hardness [25], acids [26], organics [27], phenols [28], and chemical additives used in drilling, fracturing, and related operations (additives such as corrosion inhibitors and biocides) [3]. Because the release of produced water into the environment can have extremely detrimental effects, stringent regulatory criteria have been developed to manage this produced water [29,30]. This presents an enormous challenge to the global oil and gas industry.

Table 2.

The main constituents of oilfield produced water and their concentrations.

2. Oil-in-Water Separation Technologies

The constant exploitation of oilfields has resulted in variations in produced water properties, for instance, increased water content, serious emulsification of oil droplets, and increased viscosity. These variations have made the separation of oil-in-water, which is a significant aspect of treating produced water from oilfields, more difficult. The disposal of produced water can lead to considerable pollution of the surface, soil, and groundwater, and danger arises from the lack of proper treatment. Therefore, over the years, researchers have continued to innovate and develop new techniques to clean produced water [31]. Typically, the most desirable approach is to opt for the most cost-effective technique. The expense of water treatment is primarily contingent upon the quality of the influent, price of electricity, capacity of the facility, and targeted quality of the effluent [32]. As a result, numerous approaches to cleaning produced water have been developed over time by researchers [31,33]. These approaches can be categorised as biological, chemical, or physical. Choosing a suitable treatment system that can efficiently separate water and oil and remove most pollutants from produced water is a difficult task.

The cost of treating water is primarily determined by the influent quality, electricity costs, facility capacity, and the desired effluent quality [34,35]. The physical separation method remains frequently employed today due to its many benefits, including ease of operation, environmental protection, and effective separation. Table 3 provides an overview of the different physical treatment technologies, along with their benefits and drawbacks. Al-Ghouti [3] states that there are three primary steps in the physical treatment of produced water, i.e., pre-treatment, main treatment, and final treatment. The pre-treatment process removes large oil droplets, gritty particles, and gas bubbles to reduce the dissemination of pollutants. The elimination of tiny oil droplets and particles is a critical step in the main treatment phase. API separators, plate pack interceptors, and skimmers are the tools used for this purpose. The next phase of the treatment process involves the removal of minuscule oil droplets and particles using centrifuges, hydrocyclones, and gas flotation. In the oil and gas industry, hydrocyclone technology has been widely used for a long time and is considered the most preferable physical treatment method for oil–water separation among these technologies. Cyclones, which use centrifugal force to separate a continuous phase from a dispersed phase, are the predecessors of hydrocyclones. When the primary phase is a liquid, it becomes a hydrocyclone. Hydrocyclones can, therefore, be used to separate liquids from solids, liquids from liquids, liquids from gases, and liquids from mixtures of solids and gases. The review presented here focuses only on liquid-liquid hydrocyclones, specifically those used for de-oiling produced water. A hydrocyclone is a stationary, passive device that separates particles of varying densities using a pressurised intake flow powered by centrifugal force. It leverages the difference in density of the two immiscible liquids to create a centrifugal force during high-speed fluid rotation [36,37]. The hydrocyclone separation method is widely used in industry because it has the advantages of a simple operation mode, environmental protection, and effective separation efficiency.

Table 3.

Different physical treatment technologies.

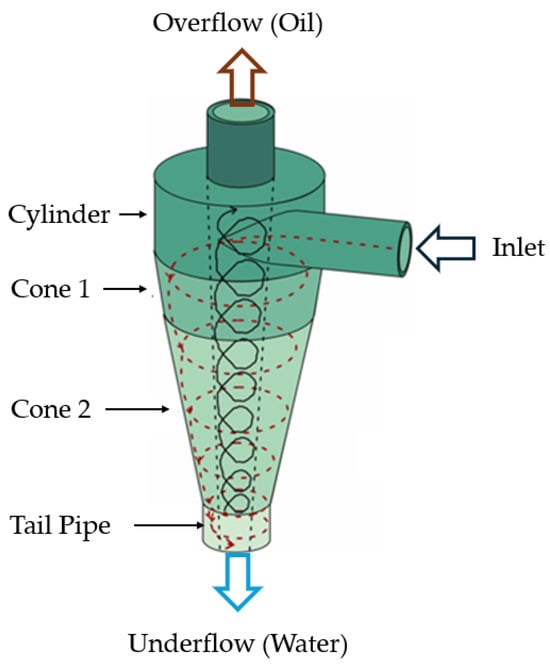

Conventionally, hydrocyclones have one inlet and a minimum of two outlets: one for oil and the other for clean water. The geometry of a conventional de-oiling hydrocyclone is shown in Figure 1. It comprises of a cylindrical section where the feed enters, a conical section where the feed is accelerated as a result of diameter reduction, a long conical section where most of the mixture separation occurs, and a tail section where the dense phase outlet (water) is located [49]. The basic separation operation of hydrocyclones is that in conjunction with an external pump, and because of the wall curvature of the cylindrical body, the oil–water mixture entering the axial or tangential inlet at high pressure produces a swirling flow pattern. With the swirling motion, under the action of centrifugal force, utilising the variation in density between the water and oil phases, the water phase moves towards the walls of the hydrocyclones and subsequently moves downward towards the underflow outlet, forming an outer vortex regarded as the secondary vortex. Meanwhile, the lighter phase (oil) moves towards the middle of the hydrocyclone and flows upward, forming an inner vortex regarded as the primary vortex, and it flows out through the vortex finder to the overflow outlet [50,51]. Nevertheless, a certain amount of water also leaves the hydrocyclone through the overflow outlet along with the oil. Thus, hydrocyclones are not 100% efficient for separating oil from water. The parameters that influence the performance of de-oiling hydrocyclones include the geometrical structure of the device, which can be adjusted to meet specific and desired requirements, and the operating parameters, which include the flow rate of the feed, pressure drop, temperature, oil concentration, and size of the oil droplet.

Figure 1.

Geometrical features of a conventional single-inlet hydrocyclone.

Hydrocyclones have been in use for more than four decades now [52]. Almost 90% of the offshore produced water treatment facilities are based on hydrocyclone technology. Their irreplaceable merits are not only for liquid-liquid separation, but also for solid-liquid, gas-liquid, and gas-solid-liquid separation. The advantages of hydrocyclone technology include low energy consumption, small cut size, high separation efficiency, wide operating range, no moving parts, and low cost of operation [29,53]. Thus, hydrocyclones are the most popular separation technology in the industry. The separation efficiency of hydrocyclones is influenced by many factors; however, the separation rate is fast, maintenance is convenient, and the equipment is light and compact, requiring no extra gases or chemicals to be introduced for operation [54,55], making it desirable for subsea and offshore environments.

Numerous scientific research studies have been conducted to explore various aspects of hydrocyclones, including performance evaluation, design optimisation, geometric parametrisation, and external interventions. These studies primarily rely on either experimental data collected from field observations, laboratory experiments conducted in controlled environments, or numerical techniques employed to investigate oil-in-water separation. Several research studies have been conducted to examine the impact of process parameters on the fluid and flow behaviour within hydrocyclones, with the aim of expanding their range of applicability. This study seeks to conduct a comprehensive review of the latest advancements in hydrocyclone technology. The objective is to identify specific areas within the field that warrant further scientific research efforts. Moreover, this study sheds light on the existing obstacles encountered by industries and researchers in relation to technological advancements in the field of hydrocyclone technology. This will facilitate the process of making informed decisions regarding strategic investments within this expansive field of research.

3. Effects of Geometrical Parameters on Hydrocyclone Performance

Contemporary configurations of de-oiling hydrocyclones have undergone significant alterations in terms of both size and geometric characteristics over the past four decades. Moreover, the performance of a hydrocyclone that is contingent upon specific geometric relations like inlet diameter, cylinder diameter, and vortex finder length is subject to further improvement/optimisation. Thus, the examination of these components is imperative and indispensable in order to accurately define the features of any new centrifugal separator [34,56]. The geometrical characteristics illustrated in Figure 1, namely the inlet section, cylindrical section, conical section, overflow and underflow sections, vortex finder, and size of the hydrocyclone, are sequentially examined.

3.1. Inlet of the Hydrocyclone

The inlet size, type, shape, and number of inlets of the de-oiling hydrocyclones have a significant impact on the de-oiling hydrocyclone separation efficiency due to the considerable changes in the phase transport characteristics, as summarised in Table 4. De-oiling hydrocyclones are generally classified into axial and tangential hydrocyclones, based on the method of feeding into the separator [36]. Some drawbacks of a conventional hydrocyclone that incorporates tangential input for its swirl formation have been identified by [57,58,59]. These drawbacks are due to the hydrocyclone’s asymmetric feed entrance, leading to a breakup of oil droplets, an increase in turbulence intensity, and a reduction in the separation efficiency. The tangential input also causes significant bulk and substantial energy expenditure. Mao et al. [59] have identified issues with an unstable oil core in the outlet section caused by an axial inlet hydrocyclone. Numerical analyses have been carried out by researchers on the optimisation of the inlet design of hydrocyclones [60,61,62,63]. From their findings, it has been observed that an optimised design of the inlets can significantly enhance the separation efficiency of de-oiling hydrocyclones.

Table 4.

Summary of the effects of hydrocyclone inlet on separation efficiency.

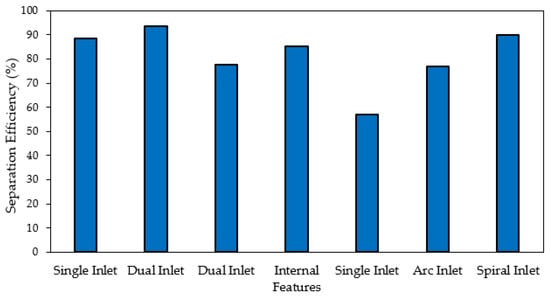

Al-Kayiem et al. [62] carried out a numerical study for flow visualisation of an oil–water mixture and their effects on single and dual-inlet hydrocyclone with varying inlet flow rates. This was performed with the aim of understanding how the oil–water mixture migrates within hydrocyclones and how the flow structure affects the efficiency of the separation process. It has been reported that dual-inlet hydrocyclones have a higher separation efficiency than single-inlet hydrocyclones, as shown in Figure 2. With single-inlet hydrocyclones, an efficiency of 73.7% and 88.5% were achieved at flow rates of 0.5 m3/h and 1.0 m3/h, respectively. This was against the 82.3% and 93.6% achieved with a dual-inlet hydrocyclone at the same respective flow rates. Moreover, it has been observed that a singlet inlet hydrocyclone results in an unsteady wavering flow as a result of flow imbalance just after flow entry into the hydrocyclone. Furthermore, there are frequent recirculation zones which cause some fluid droplets to be unseparated. In the dual-inlet hydrocyclone, a uniform, unwavering fluid flow structure has been observed. This assists in the segregation of oil and water into their respective core regions as an oil-rich core (inner) and a water-rich core (outer).

Liu et al. [50] carried out numerical investigations on the effects of double tangential inlets with interval interventions/features. The features consist of one separating block and 3 division plates following the block. The mechanism behind the new design has been stated to be that the feed mixture passing through the inlet with rearrangement of internals flows into different layers in accordance with their densities. The re-arranged low-density phase moves directly to the middle region, while the high-density phase flows to the near-wall region. The different separating blocks were designed to be semi-cylindrical, triangular prisms, and trapezoidal bodies. Their oil–water separation efficiency, velocity distribution, and oil-phase distribution results were compared to those of a conventional hydrocyclone, as shown in Figure 2. The accuracy of the simulation results was validated against the PIV tests reported in the literature [70,71]. It has been reported that a hydrocyclone with a semi-cylindrical block inlet provides an optimal rearrangement effect and the lowest pressure drop. Conventional hydrocyclones, when compared to hydrocyclones with internal features, have been observed to have a lower oil-phase concentration, fluid tangential velocity, and separation efficiency. The separation efficiency of hydrocyclones with features was 6.4–8% higher than that of conventional hydrocyclones.

Numerical investigations have been conducted on hydrocyclones with different inlet pipe structural configurations like linear, spiral-line, and arc-type inlet pipes and the separation efficiency compared to conventional hydrocyclones, as depicted in Figure 2. Li et al. [72] have reported that hydrocyclones with spiral-line inlet pipes achieve higher separation efficiency compared to arc-type and linear inlet types. Rocha et al. [73] carried out experimental analyses to study the influence of rectangular and square feed duct solid-liquid hydrocyclone on the separation efficiency against the conventional circular feed duct [74]. It has been stated that non-circular cross-section inlets result in higher separation efficiency and an increase in the underflow-to-throughput ratio, with the highest efficiency observed in square feed duct hydrocyclones.

Figure 2.

Variations in the separation efficiency of hydrocyclones due to changes in the inlet geometry [50,62,72]. Reproduced with permission from [50] 2021 and [72] 2020, Elsevier.

3.2. Cylindrical and Conical Sections of the Hydrocyclone

The cylindrical and conical sections are among the most crucial sections of hydrocyclones as far as their separation efficiency is concerned. Feed enters the main body of the hydrocyclone, which is effectively the cylindrical section, and then flows through to the conical region, where the feed flow velocity accelerates due to a reduction in diameter, and most separation of the mixture takes place. Due to its conical design, only a fraction of the heavy stream (water) exits from the underflow outlet; nevertheless, this fraction can be regulated by adjusting the cone angle and diameter of the tail pipe [49,75]. The capacity of separation and the general performance of the hydrocyclone is greatly affected by the angle of the conical section [76]. The cone angle in a hydrocyclone refers to the angle formed by the conical section’s wall relative to the axis of the hydrocyclone. This angle is a critical design parameter as it influences the separation efficiency of the hydrocyclone [77]. Two options are available for the conical sections: single-cone and bi-conical hydrocyclones. The bi-conical sections are designed to sustain the intensity of the swirling stream and induced vortexes, and with this, a constant centrifugal separation is guaranteed [78]. The efficiency of separation reduces due to shorter cylindrical lengths. This happens due to insufficient rotational velocity of the fluid within this particular region, resulting in a lack of separation when compared to other regions of the hydrocyclone. Simultaneously, the fluid experiences a reduction in its angular momentum due to the drag exerted by the wall of the cylindrical section [79,80].

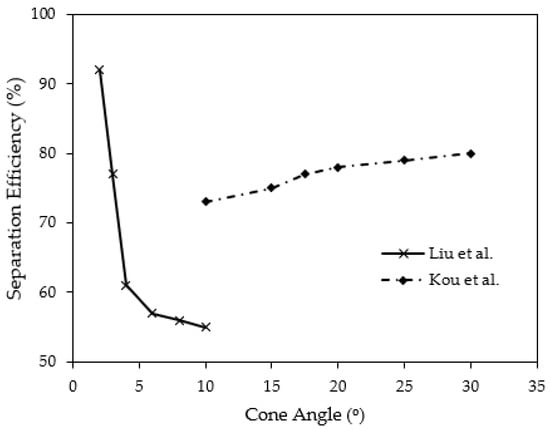

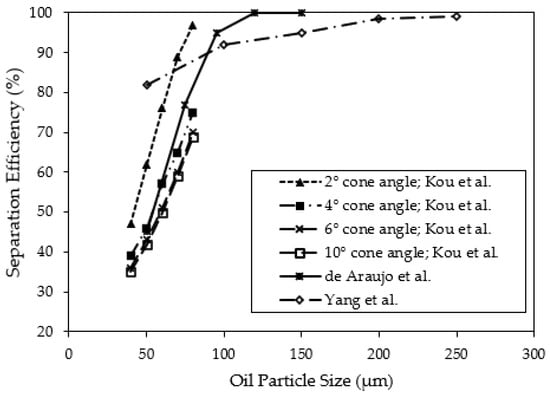

In the numerical investigations conducted by Kou et al. [81], the pressure and velocity fields of a hydrocyclone with guide vanes and four variable cone angles have been analysed for separation efficiency. It has been noted that the peak tangential velocity and the static radial pressure increase significantly as the cone angle increases. Moreover, as the cone angle decreases, the forward velocity steadily increases at a position near the wall, but at the intermediate region, the forward flow velocity decreases with decreasing cone angle. It has been reported that alterations in cone angle significantly alter the centrifugal acceleration, which leads to different reverse flow lengths. It has been observed that in some cases, reverse flow was unable to reach the overflow outlet specifically for smaller droplets; thus, the separation efficiency was reduced. To resolve this, it has been stated that an additional underflow tube was designed for the collection of oil droplets flowing at the underflow outlet, and the separation efficiency was significantly improved. The separation efficiency has been observed to increase with decreasing cone angle and increasing oil droplet size.

Zeng et al. [82] conducted numerical investigations on a separator with three swirl chamber design configurations and multiple light phase outlets with the aim of studying the separation efficiency and the flow fields. The swirl chamber designs considered are (i) cylindrical tube (ii) a combination of conical tube, conical diffuser, and cylindrical tube (iii) a combination of cylindrical and conical tube. It has been observed that with a conical tube, higher tangential velocity is experienced than in the cylindrical tube, which implies a larger centrifugal force with higher separation efficiency. The design with cylindrical and conical tubes has the maximum G force distribution, pressure gradient, and separation efficiency. Zeng et al. [83] compared conical tubes against cylindrical tubes by oil droplet trajectories using a high-speed camera. It has been observed that a conical tube provides higher tangential velocity than a cylindrical tube; thus, separation time is reduced. Zhao et al. [84], in their numerical investigations on an axial oil–water separator with two separation chambers, each consisting of conical and cylindrical sections, two swirling impellers with differences in structural parameters, and three light phase outlets, reported that altering the diameter of the cylindrical section affects the separation efficiency the most. A decrease in the cylindrical diameter elevates the separation efficiency and the pressure drop. For the conical sections, it has been observed that an increase in the length of the primary conical section causes an increase in the pressure drop and separation efficiency, which later decreases. Meanwhile, an increase in the length of the second conical section causes a continual increase in the separation efficiency. Altering the diameter of the cylindrical section has been stated to affect the oil core outlet flow split. Je et al. [85] carried out numerical analyses on the separation efficiency of an axial oil–water separator considering five design parameters, which include (i) a number of vanes, (ii) conical diameter, (iii) conical length, (iv) angel of vane, and (v) thickness of vane. It has been observed that the vane angle has the most significant influence on the separation efficiency, followed by conical diameter, number of vanes, the thickness of the vane, and conical length respectively. An increase in vane angle leads to an increase in the separation efficiency and pressure drop.

Liu et al. [58] carried out analyses to study the impact of cone angle, guide vanes, and cone angle on the separation of oil using Computational Fluid Dynamics (CFD). It has been reported that changing the cone angle has no effect on the flow field’s ultimate distribution of velocity. Nonetheless, the severity of the vortex’s turbulence decreases as the cone angle increases. There was a slight improvement in the pressure drop and separation efficiency when the cone angle was increased from 10° to 30°, as shown in Figure 3, indicating that a wider cone angle may improve downward particle flow by reducing recirculation zones. This is contrary to what has been observed by other researchers [81,86], who, in their investigations, reported that increasing the cone angle increases the tangential velocity and the pressure gradient in the hydrocyclone but reduces the separation efficiency. It has been noted that a small cone angle keeps oil droplets in the separation region for quite a long period; thus, a decrease in cone angle increases the separation efficiency. Differences in results obtained also arise from varying experimental settings and the accuracy of the measurement techniques [87].

Figure 3.

Effect of cone angle on separation efficiency of hydrocyclones [58,81]. Reproduced with permission from [58] 2018 and [81] 2020, Elsevier.

3.3. Outlets of the Hydrocyclone

Hydrocyclones generally have two discharge outlets; the overflow outlet is usually located at the top of the hydrocyclone for the ejection of oil, and the underflow outlet is located at the bottom of the hydrocyclone for the ejection of water [76]. The occurrence of the oil reverse flow towards the overflow outlet can be attributed to the existence of a pressure gradient resulting from the conical design configuration. During the swirling process, the wall region experiences high pressure while the centreline exhibits low pressure. This creates a decrease in pressure differential from the downstream end to the upstream end, ultimately leading to a reversal of the oil-phase flow [49,88].

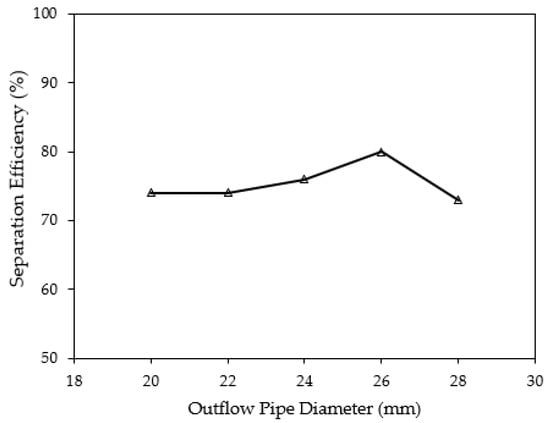

Kyriakidis et al. [34] conducted experimental as well as numerical investigations to evaluate the effects of underflow outlet diameter and length, along with the length of the vortex finder, on the separation efficiency of a hydrocyclone. It has been reported that an increase in the underflow orifice diameter increases the total separation efficiency by 9% while also increasing the underflow-to-throughput ratio by 125%. The vortex finder length has been stated to have a non-linear effect on the separation efficiency. Nevertheless, the highest separation efficiency has been observed for the 6.5 mm length of the vortex finder and for 5 mm underflow orifice diameter. In the numerical analyses carried out by Liu et al. [58] on axial hydrocyclones with a high handling capacity for the purpose of tackling oil–water separation challenges, it has been observed that an increase in the overflow pipe diameter from 20 mm to 26 mm leads to a steady increase in the separation efficiency but when increased above 26 mm, the separation efficiency drops, as shown in Figure 4. This improvement in the separation efficiency is due to the balance between centrifugal force and the fluid flow. The larger outflow pipe diameter in this range lowers the velocity of the overflow stream, giving the oil droplets more time to separate from water [89]. Above 26 mm outflow pipe diameter, the tangential velocity and vortex strength decrease, resulting in insufficient centrifugal force to efficiently separate the oil droplets [90,91]. Consequently, more oil remains in the water phase, reducing overall separation efficiency. Therefore, to maintain high separation efficiency without exceeding the critical threshold, the overflow pipe diameter needs to be carefully selected. de Araujo et al. [92] conducted numerical investigations to analyse the effects of geometrical parameters of a tangential dual-inlet hydrocyclone in order to enhance its separation efficiency for high oil content (40%), which is experienced in mature reservoirs. Using Design of Experiments (DoE), the hydrocyclone’s geometric variables that result in the maximum separation efficiency have been identified. This design is the one with a bigger overflow diameter of 20 mm. The experimental result from the optimally designed hydrocyclone has been reported to provide a total separation efficiency of 93% with a flow ratio of 7%.

Figure 4.

Effect of overflow pipe diameter on separation efficiency of hydrocyclones [58]. Reproduced with permission from [58] 2018, Elsevier.

Zeng et al. [83] proposed a novel approach for draining the oil stream from the two outlets in an experimental investigation carried out on a compact axial liquid-liquid separator, operating from 3 m3/h to 7 m3/h of water flow rate and 1% to 10% of oil fraction. It has been reported that multiple outlets for the oil stream guarantee higher separation efficiency and a lower split ratio. Zeng et al. [93] conducted experimental investigations on an axial oil–water separator with three stages of separation and five oil outlets, with the aim of improving the separation efficiency by maintaining a low split ratio. It has been reported that multiple oil outlets increase the split ratio from 20% to 45%; however, with reasonable or proper oil outlet scheduling, a significant reduction in the split ratio with enhanced separation efficiency could be achieved. Moreover, it has been stated that oil outlets located on the two sides of the oil core help in the discharge of oil droplets with elevated swirl flow, while the oil outlet positioned downstream has a high possibility of separating smaller-sized droplets. Moreover, a novel method for draining oil from multiple outlets in an axial liquid-liquid separator has been proposed, enhancing separation efficiency and reducing split ratios. The experimental setup, operating at various water flow rates and oil fractions, demonstrated improved performance with strategic oil outlet placement, particularly for smaller droplets and elevated swirl flows.

Abdi et al. [94] carried out experimental investigations on the performance of hydrocyclone in an oil spill recovery system. In the design of the experiments, control valves and a capacitance-based sensor were integrated into the system to improve the separation efficiency. The overflow control valve has an automatic operation, while the underflow control valve is operated manually. It has been reported that by adjusting the overflow valve while maintaining oil–water conditions, the separation efficiency can be optimised. It has been stated that an overall separation efficiency of 67.6% for inlet oil concentrations of 20% and 35.2% for an inlet oil concentration of 40% is achieved. Moreover, it has been observed that with slower underflow flow rates, liquid can accumulate in the overflow and result in slower overflow rates and, subsequently, a higher content of oil in the underflow, hence, the need for the control valves. Table 5 summarises the review presented in this section on the effects of geometrical parameters on hydrocyclone performance.

Table 5.

Summary of the effects of geometrical parameters on the de-oiling hydrocyclone performance.

4. Effects of Operating Parameters on Hydrocyclone Performance

Operating/process parameters are among the factors that significantly affect the performance of de-oiling hydrocyclones. These parameters include the flow rate of the feed, pressure drop, temperature, particle cut size, concentration of the oil, size of the oil droplet. A number of scientific studies have been carried out to investigate the influence of process parameters on the separation efficiency and general performance of hydrocyclones. A comprehensive understanding of the flow dynamics within a de-oiling hydrocyclone is crucial for the accurate prediction, enhancement, and comprehension of its operational efficiency.

4.1. Inlet Flow Rate

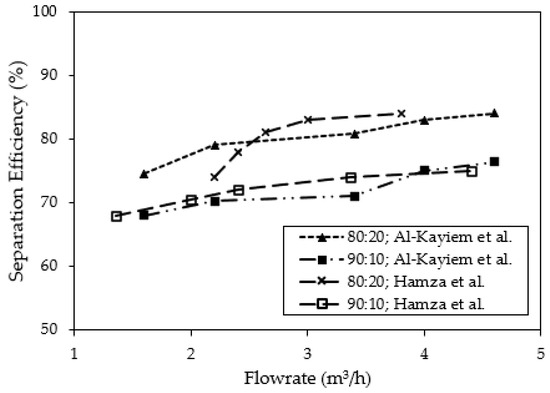

Hamza et al. [96] carried out experimental investigations on a compact axial inlet hydrocyclone with the aim of improving the separation efficiency of the oil–water mixture. The oil–water mixture used for the parametric analyses is based on oil and brine. The separation efficiency was evaluated at different flow rates ranging between 1.5 m3/h and 4 m3/h with oil-to-water ratios of 10:90, 20:80, and 30:70, and mean droplet size of 37 µm. It has been reported that an increase in the flow rate leads to an enhancement in separation efficiency, as shown in Figure 5. It has been further noticed that the pressure drop at the water outlet is higher than the pressure drop at the oil outlet, and an increase in the flow rate leads to an increase in both pressure drops. It has been observed that a higher pressure drop ratio between oil and water leads to a higher separation efficiency. In the experimental investigations carried out by Xiaobo et al. [97] on an axial separator to evaluate the influence of the inlet flow rate on the separation efficiency of gear oil and tap water, it was observed that an increase in the inlet flow rate led to an increase in the separation efficiency. The flow rate considered ranged between 3 m3/h and 7 m3/h. Angelim et al. [98] carried out numerical analyses to study the separation efficiency of a heavy oil–water mixture in hydrocyclones. Using the k-ε turbulent model and Euler-Euler multiphase approach, the influence of varying inlet velocities ranging between 1 m/s and 10 m/s on the separation efficiency, pressure drop, and streamlines was analysed, and the results validated against experimental data. It has been reported that an increase in the inlet velocity leads to an increase in the pressure drop and separation efficiency. Moreover, an increase in the inlet velocity up to 4 m/s increases the separation efficiency to 90%, while the separation efficiency decreases to approximately 58% with a further increase in the inlet velocity to 10 m/s. The separation efficiency remains constant for inlet velocities between 10 m/s and 32 m/s. For the streamline, it has been noticed that an increase in the inlet velocity increases the centrifugal and drag forces, thus increasing the number of turns inside the hydrocyclone. The water stream has been observed to tend to flow towards the wall while the oil stream flows internally.

Figure 5.

Variation in separation efficiency at different flow rates and oil concentrations [36,96]. Reproduced with permission from [96] 2020, Elsevier.

Li et al. [99] conducted numerical investigations on a hydrocyclone subjected to periodic external excitation with the aim to analyse the internal flow characteristics. With periodic excitement, a decrease in the free vortex region of the hydrocyclone has been observed, while the axial velocity was significantly influenced in the middle region of the hydrocyclone. Increasing the length of the oil core region and the outflow velocity resulted in a decrease in the uniformity of the radial velocity in an area far away from the entrance, while the radial velocity fluctuates significantly with time. Moreover, under the influence of periodic excitement, it has been reported that the oil-phase slip velocity increases over a longer range, and the separation efficiency increases as well. Al-Kayiem et al. [36] carried out numerical analyses on an axial concurrent hydrocyclone with the aim of enhancing the swirl generator design. In the analysis, five different angles, ranging from 37° to 76°, were considered at five inlet flow rates and water-to-oil ratios. It has been reported that a swirl generator with a 45° deflection angle and an inlet feed velocity of 2 m/s results in a maximum tangential velocity of 7.06 m/s, while that with a 68° deflection angle (the least defection vane angle considered) and 2 m/s inlet feed velocity results in a minimum tangential velocity of 4.17 m/s. Furthermore, it has been observed that a 45° swirl generator produces a higher turbulent intensity than a 68° swirl generator, while a 45° swirler results in the maximum separation efficiency of the separator. In all the designs considered, it has been noted that the separation efficiency increases with an increase in the flow rate, while the pressure drop increases with a decrease in the vane angle, as shown in Figure 5.

Zhao et al. [100] observed an increase in separation efficiency from 89.02–94.04% when the inlet velocity increased from 2 m/s–12 m/s. Zhang et al. [101] carried out numerical investigations to evaluate the effects of the inlet flow rate on the separation efficiency of the hydrocyclone. It has been reported that an increase in inlet velocity from 1 m/s–5 m/s leads to an increase in the radial velocity from 0.20 to 1.16 m/s, tangential velocity from 1.97 to 11.16 m/s, static pressure from 5.49 to 182.78 kPa and radial pressure gradient while decreasing the split ratio in the swirling field, enhancing the separation efficiency of the hydrocyclone. It has been stated that an increase in inlet velocity reduces the formation of air columns and alters the locus of zero vertical velocity, which has been considered to be favourable toward hydrocyclone’s flow stability. In an experimental investigation conducted by Zeng et al. [83] and the numerical analysis carried out by Amori and Al-Ammar [102] on an axial inlet hydrocyclone to evaluate the influence of variable flow rates on the separation efficiency, it has been reported that as the inlet flow rate increases, the oil cumulated in the core region increases, leading towards enhancement in the separation efficiency.

4.2. Oil Concentration and Particle Size

Gorobets and Tarabara [103] carried out a laboratory-scale evaluation of the separation efficiency of a de-oiling hydrocyclone by analysing the effects of oil-particle aggregates. The input feeds used for this evaluation comprised two-phase (oil/water) and three-phase (water/particulate SiO2/mineral oil). It has been observed that oil-particle aggregates do not affect the separation efficiency of the hydrocyclone; however, they degrade the separation of the solid phase. It has been reported that oil-particle aggregates are preferably split into the overflow stream with oil as the lead phase and SiO2 as the secondary phase. Araújo et al. [92] carried out numerical investigations on the effects of oil particle size on the separation efficiency of the hydrocyclone. It has been observed that as the oil particle size decreases, the separation efficiency of the hydrocyclone also decreases due to the inertial effects becoming dominant. Zeng et al. [104] conducted a numerical study on an axial liquid-liquid separator with double swirls and double separation chambers. The analyses were performed at variable inlet volumetric oil fractions ranging between 1% and 10%. It has been reported that an increase in the volumetric oil fraction insignificantly decreases the separation efficiency and causes a high-pressure change, while at a lower volumetric oil fraction, the change between the central and wall pressure becomes higher.

Yang et al. [105] conducted a numerical study to evaluate the mechanism of oil–water separation and the influencing factors, i.e., particle size, inlet velocity, pressure, and oil concentration, on the separation efficiency of a de-oiling hydrocyclone. It has been reported that at a constant oil concentration, the oil particle size, the inlet flow pressure, and velocity are directly proportional to the separation efficiency, while at a constant inlet velocity, increasing the oil concentration reduces the separation efficiency. Figure 6 presents a comparative analysis of the effects of oil particle size on the separation efficiency. It has been reported that an oil–water mixture entering hydrocyclones generates both internal and external swirls, forming a stable oil core at the centre.

Figure 6.

Variations in the separation efficiency for different oil particle sizes [81,92,105]. Reproduced with permission from [81] 2020, [92] 2020, [105] 2021, Elsevier.

Liu et al. [106] carried out numerical studies to evaluate the separation efficiency of discrete phases with varying particle sizes and densities using hydrocyclones of different main diameters, all classified under mini-hydrocyclones and conventional hydrocyclones. For both high and low feed oil concentrations, it has been observed that mini-hydrocyclones provide higher separation efficiency than conventional hydrocyclones when subjected to a similar feed flow velocity. The mini-hydrocyclone oil–water separation efficiency has been reported to be more evident between 60 µm and 300 µm oil particle sizes. When the particle size is below 20 µm and above 400 µm, the efficiency becomes insignificant. For silica–water separation, the mini-hydrocyclone has been stated to have a maximum separation efficiency compared to the conventional hydrocyclone. The separation efficiency of both hydrocyclones was similar when the particle size was above 60 µm, but when the particle size was less than 5 µm, the conventional hydrocyclone provided no separation, while the mini-hydrocyclone still provided separation. It has been noted that for both oil–water and silica–water separation, the pressure loss of mini-hydrocyclones is higher than that of conventional hydrocyclones. Xing et al. [107] carried out numerical analyses of a coalescence hydrocyclone with the aim of improving the separation efficiency. The design was based on the principles of hydraulic droplet collision coalescence and centrifugal separation. The mixture model and the discrete phase model (for transport of the particles) together with the Reynolds Stress turbulence model (RSM), have been used to obtain the velocity distributions, particle diameter, and oil concentration in the hydrocyclone. It has been reported that there is a maximum separation efficiency of 99.4% at a flow rate of 5.5 m3/h and a 25% split ratio in the hydrocyclone as a result of the increase in the size of the oil particles by collision coalescence before entering the hydrocyclone. Moreover, it has been stated that the average diameter of the oil particles increases from 32.42 μm at the entrance to 1350 μm after coalescing.

Mohammadi et al. [108] conducted numerical investigations on oil-in-water separation in a hydrocyclone. It has been reported that for a 25% inlet oil concentration, increasing the oil particle diameter increases the separation efficiency up to 99.5% when the oil particle diameter is above 100 μm. It has been stated that when water is in the discrete phase, 60% and 69% separation efficiencies are achieved at water droplet sizes of 150 μm and 200 μm, respectively. Al-Kayiem et al. [109] conducted an experimental investigation in order to deduce novel experimental data comparison on particle size distribution as a result of the shear effect using a high-speed single-stage C-pump (2950 rpm) and a low-speed gear pump (1450 rpm). The investigations were carried out at five different water-to-oil ratios (70:30, 75:25, 80:20, 85:25, and 90:10). In this research, mineral oil (FOMI 70) was used as crude oil. It has been reported that the C-pump results in a smaller particle size distribution with an average particle diameter of 21.39 µm, while the gear pump gives a higher particle size distribution with an average particle of 33.5 µm. Furthermore, it has been reported that as the water cut increases, the shear rate also increases, resulting in smaller particle sizes [110]. The effects of temperature on the particle size have been reported to be minimal. It has been observed that oil particles settling on top of the cylindrical section increase and separate rapidly for samples with higher particle diameters. In an experimental investigation carried out by Hamza et al. [96] for separation efficiency enhancement considering oil-to-water ratios of 10:90, 20:80, and 30:70 and a mean inlet droplet size of 37 µm, it was observed that the optimal separation efficiency was achieved at an oil-to-water ratio of 20:80 and the minimum efficiency was achieved at a 30:70 ratio.

Khodadadi et al. [77] conducted a numerical study on de-oiling hydrocyclones using the Eulerian-Lagrangian approach to evaluate the influence of particle interactions, phase-coupling schemes, and inlet size distribution on the performance of hydrocyclones. The breakup-dominated areas together with the coalescence regions in different designs of de-oiling hydrocyclones, were investigated. It has been identified from the different designs investigated that significant alterations in the cone angle produce areas of high turbulence and an increase in the breakup of particles. It has been reported that the size distribution of oil particles inside the hydrocyclone follows a log-normal distribution; the mode diameter increases in the cylindrical and first conical regions, then decreases while moving towards the tail area. The breakup- and coalescence-dominated regions have been found to depend on the water turbulence level. The smooth area reduction decreases the oil droplet breakup. Liu et al. [111] carried out a theoretical and experimental investigation on the influence of gas on oil–water separation efficiency, oil concentration, and flow field stability of an axial hydrocyclone. It has been observed that a small amount of gas improves the separation of the oil–water mixture, but a larger amount of gas reduces the separation efficiency. As the gas-liquid ratio increases, the frequency of pressure fluctuations increases, enhancing the separation efficiency, but when above 20%, the efficiency reduces. It has been reported that in the bubble flow regime at a ratio of 8% and in the slug flow regime at a ratio of 5%, the inflection points increase, and the oil concentration gradually increases. But when the ratio is above 8%, the oil concentration rapidly increases, requiring gas removal treatment. For various split ratios and water cuts, it has been noticed that the influence of the gas-liquid ratio on the mixture separation followed a similar pattern.

Raesi and Maddahiann [29] carried out numerical analyses to study the influence of injecting air on de-oiling hydrocyclones. The simulation was carried out using CFD together with the Population Balance Model, RSM, and the Eulerian-Eulerian multiphase model. It was observed that injected air establishes an air core into the system, which flows out through the overflow and causes the disappearance of the oil core generated at the centre of the hydrocyclone. It has been reported that injected air bubbles, because of their low density, increase the migration velocity of the oil particles and the reverse flow region length, enhancing the separation efficiency to as high as 95.6%. Moreover, it has been noted that the injected air increases the oil volume fraction in the accumulated sections of the conical and cylindrical areas and reduces the fraction in the tail region. It has been stated that with the injection of air, the turbulence level inside the hydrocyclone increases, enhancing the breakage rate of the particles and thereby reducing the size of the oil particles. However, injecting air bubbles with small diameters has been observed to be more effective in improving the separation efficiency. Table 6 summarises the review presented in this section on the effects of the operating parameters on hydrocyclone performance.

Table 6.

Summary of the effects of operating parameters on de-oiling hydrocyclone performance.

This study did not include reviews pertaining to fluid properties like the viscosity of the feed mixture, temperature of the inlet feed, any specific geometric relationships, and optimisation of the hydrocyclones. However, these topics could be explored in a separate scientific review, offering valuable insights. The results would provide evidence for enhancing the operational efficiency of hydrocyclone technology and mitigating the ecological consequences of an oil spill. Moreover, Scanning Electron Microscopy (SEM) [112], Electron Dispersive Spectroscopy (EDS) [113], and extensive experimental studies [114] can be used to further analyse the complex flow structure and optimise the separation efficiency of hydrocyclones.

5. Conclusions

The increasing volume of produced water and environmental concerns surrounding its disposal have increased the significance of produced water treatment in the exploration and extraction of natural gas and crude oil resources. The continuous exploitation of oilfields has led to the significant emulsification of oil particles and an increase in viscosity, thereby posing challenges regarding the separation of oil from water. This separation process is a crucial aspect in the treatment of produced water from oilfields. The hydrocyclone method for removing oil from produced water in oilfields has emerged as a highly effective and well-established technology. This can be attributed to its compact design, durability, and cost-effectiveness, in terms of both production and maintenance costs. Despite extensive numerical and experimental investigations of hydrocyclones, certain phenomena remain inadequately understood and warrant further scrutiny. Specifically, the impact of turbulence on particle motion, breakup, coalescence, and spatial distribution, as well as the characteristics of the central core, such as shape, dimensions, behaviour, and the influence of gas (dissolved or free) or solids on the flow fields, require additional attention. This study provides a comprehensive review of recent advancements in hydrocyclone technology for the purpose of oil-in-water separation, drawing upon a wide range of existing research. The present study is briefly outlined through the subsequent key points:

- Single-inlet hydrocyclones are characterised by an unsteady and wavering flow, whereas dual-inlet hydrocyclones exhibit a uniform and stable fluid flow structure. In terms of separation efficiency, dual-inlet hydrocyclones outperform single-inlet hydrocyclones.

- The underlying principle of the hydrocyclone inlet design that involves the utilisation of internal features is that it allows the feed mixture to be distributed into distinct layers based on their respective densities. Consequently, this design enhancement leads to a notable improvement in separation efficiency compared to that of conventional hydrocyclones.

- The length of the conical section, the diameter of the underflow pipe, and the diameter of the overflow pipe exhibit a direct proportionality to the separation efficiency. However, it should be noted that a larger diameter of the overflow pipe results in a reduction in the effectiveness of the separation process.

- The efficiency of the separation is indirectly proportional to the cone angle, cylindrical diameter, and length of the vortex finder.

- The separation efficiency is directly influenced by the inlet flow rate, inlet velocity, and oil droplet size, as these parameters exhibit a direct proportionality. Conversely, an increase in the volumetric oil fraction leads to a reduction in the separation efficiency.

Author Contributions

Conceptualization, O.M.E. and T.A.; methodology, O.M.E.; formal analysis, O.M.E.; investigation, O.M.E.; resources, T.A. and H.K.H.; data curation, O.M.E.; writing—original draft preparation, O.M.E., T.A. and H.K.H.; writing—review and editing, T.A. and H.K.H.; supervision, T.A.; project administration, O.M.E. All authors have read and agreed to the published version of the manuscript.

Funding

The research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pichtel, J. Oil and Gas Production Wastewater: Soil Contamination and Pollution Prevention. Appl. Environ. Soil Sci. 2016, 2016, 2707989. [Google Scholar] [CrossRef]

- Igunnu, E.T.; Chen, G.Z. Produced Water Treatment Technologies. Int. J. Low-Carbon Technol. 2014, 9, 157–177. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Al-Kaabi, M.A.; Ashfaq, M.Y.; Da’na, D.A. Produced Water Characteristics, Treatment and Reuse: A Review. J. Water Process Eng. 2019, 28, 222–239. [Google Scholar] [CrossRef]

- Costa, T.C.; Hendges, L.T.; Temochko, B.; Mazur, L.P.; Marinho, B.A.; Weschenfelder, S.E.; Florido, P.L.; da Silva, A.; Ulson de Souza, A.A.; Guelli Ulson de Souza, S.M.A. Evaluation of the Technical and Environmental Feasibility of Adsorption Process to Remove Water Soluble Organics from Produced Water: A Review. J. Pet. Sci. Eng. 2022, 208, 109360. [Google Scholar] [CrossRef]

- Clark, C.E.; Veil, J.A. Produced Water Volumes and Management Practices in the United States; Argonne National Lab.: Argonne, IL, USA.

- Judd, S.; Qiblawey, H.; Al-Marri, M.; Clarkin, C.; Watson, S.; Ahmed, A.; Bach, S. The Size and Performance of Offshore Produced Water Oil-Removal Technologies for Reinjection. Sep. Purif. Technol. 2014, 134, 241–246. [Google Scholar] [CrossRef]

- Asim, T.; Hawez, H.K. Effects of CO2 Geosequestration on Opalinus Clay. Energies 2024, 17, 2431. [Google Scholar] [CrossRef]

- Padaki, M.; Surya Murali, R.; Abdullah, M.S.; Misdan, N.; Moslehyani, A.; Kassim, M.A.; Hilal, N.; Ismail, A.F. Membrane Technology Enhancement in Oil-Water Separation. A Review. Desalination 2015, 357, 197–207. [Google Scholar] [CrossRef]

- Dudek, M.; Vik, E.A.; Aanesen, S.V.; Øye, G. Colloid Chemistry and Experimental Techniques for Understanding Fundamental Behaviour of Produced Water in Oil and Gas Production. Adv. Colloid Interface Sci. 2020, 276, 102105. [Google Scholar] [CrossRef] [PubMed]

- Ghafoori, S.; Omar, M.; Koutahzadeh, N.; Zendehboudi, S.; Malhas, R.N.; Mohamed, M.; Al-Zubaidi, S.; Redha, K.; Baraki, F.; Mehrvar, M. New Advancements, Challenges, and Future Needs on Treatment of Oilfield Produced Water: A State-of-the-Art Review. Sep. Purif. Technol. 2022, 289, 120652. [Google Scholar] [CrossRef]

- Onyems Igwe, C.; AL Saadi, A. Optimal Options for Treatment of Produced Water in Offshore Petroleum Platforms. J. Pollut. Eff. Control 2013, 1, 1–5. [Google Scholar] [CrossRef]

- Singh, D.; Charlton, M.; Asim, T.; Mishra, R.; Townsend, A.; Blunt, L. Quantification of Additive Manufacturing Induced Variations in the Global and Local Performance Characteristics of a Complex Multi-Stage Control Valve Trim. J. Pet. Sci. Eng. 2020, 190, 107053. [Google Scholar] [CrossRef]

- Bayati, F.; Shayegan, J.; Noorjahan, A. Treatment of Oilfield Produced Water by Dissolved Air Precipitation/Solvent Sublation. J. Pet. Sci. Eng. 2011, 80, 26–31. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, Y.; Woo, Y.C.; Hwang, I. Water Management and Produced Water Treatment in Oil Sand Plant: A Review. Desalination 2023, 567, 116991. [Google Scholar] [CrossRef]

- Mahbouba, Z.N.; Abdulkhalik, M.K.; Mussa, J.H. Characteristics and Management of Produced Water in Al-Ahdab Oil Field. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012090. [Google Scholar] [CrossRef]

- Miranda, M.A.; Ghosh, A.; Mahmodi, G.; Xie, S.; Shaw, M.; Kim, S.; Krzmarzick, M.J.; Lampert, D.J.; Aichele, C.P. Treatment and Recovery of High-Value Elements from Produced Water. Water 2022, 14, 880. [Google Scholar] [CrossRef]

- Duraisamy, R.T.; Heydari, A.; Henni, A. State of the Art Treatment of Produced Water. In Water Treatment; InTech: Vienna, Austria, 2013; pp. 6–7. ISBN 0071418725. [Google Scholar]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.A.; Madaeni, S.S.; Abidin, Z.Z. Review of Technologies for Oil and Gas Produced Water Treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef] [PubMed]

- Brinn, M.; Wylde, S. Compact Oxygen Removal for Waterflood Projects. In Proceedings of the Offshore Technology Conference, OTC, Houston, TX, USA, 6 May 2013. [Google Scholar]

- Bi, F.; Ma, S.; Gao, B.; Liu, B.; Huang, Y.; Qiao, R.; Zhang, X. Boosting Toluene Deep Oxidation by Tuning Metal-Support Interaction in MOF-Derived Pd@ZrO2 Catalysts: The Role of Interfacial Interaction between Pd and ZrO2. Fuel 2024, 357, 129833. [Google Scholar] [CrossRef]

- Pan, E.C.; Sun, H.; Xu, Q.; Zhang, Q.; Liu, L.F.; Chen, X.D.; Xu, Y. Polycyclic Aromatic Hydrocarbons Concentrations in Drinking Water in Villages along the Huai River in China and Their Association with High Cancer Incidence in Local Population. Biomed. Res. Int. 2015, 2015, 762832. [Google Scholar] [CrossRef] [PubMed]

- Judd, S.J.; Khraisheh, M.; Al-Jaml, K.L.; Jarman, D.M.; Jahfer, T. Influence of Composite Particle Formation on the Performance and Economics of Grit Removal. Water Res. 2017, 108, 444–450. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhao, Y.; Hu, S.; Gliege, M.E.; Liu, Y.; Liu, R.; Scudiero, L.; Hu, Y.; Ha, S. Electrochemical Reduction of Carbon Dioxide to Formic Acid in Ionic Liquid [Emim][N(CN)2]/Water System. Electrochim. Acta 2017, 247, 281–287. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, H.; Li, Y.; Xu, H.; Pan, Z.; Dai, P.; Wang, H.; Yang, Q. A Review of Treatment Technologies for Produced Water in Offshore Oil and Gas Fields. Sci. Total Environ. 2021, 775, 145485. [Google Scholar] [CrossRef] [PubMed]

- Jain, P.; Sharma, M.; Dureja, P.; Sarma, P.M.; Lal, B. Bioelectrochemical Approaches for Removal of Sulfate, Hydrocarbon and Salinity from Produced Water. Chemosphere 2017, 166, 96–108. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.; Jha, N.K.; Pal, N.; Keshavarz, A.; Hoteit, H.; Sarmadivaleh, M. Recent Advances in Carbon Dioxide Geological Storage, Experimental Procedures, Influencing Parameters, and Future Outlook. Earth-Sci. Rev. 2022, 225, 103895. [Google Scholar] [CrossRef]

- Dandekar, A.Y. Petroleum Reservoir Rock and Fluid Properties, 2nd ed.; CRC Press: New York, NY, USA, 2013; ISBN 9781439876459. [Google Scholar]

- Vichaphund, S.; Wimuktiwan, P.; Soongprasit, C.; Sricharoenchaikul, V.; Atong, D. Aromatic and Aliphatic Production of Catalytic Pyrolysis of Lignin Using ZSM-5/Al-SBA-15 Catalyst Derived from High-Calcium Fly Ash. Energy Rep. 2021, 7, 232–247. [Google Scholar] [CrossRef]

- Raesi, R.; Maddahian, R. Numerical Investigation of Air-Injected Deoiling Hydrocyclones Using Population Balance Model. Chem. Eng. Sci. 2022, 248, 117103. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, G.; Asim, T.; Mishra, R. Combustion Characterization of Hybrid Methane-Hydrogen Gas in Domestic Swirl Stoves. Fuel 2023, 333, 126413. [Google Scholar] [CrossRef]

- Show, P.L.; Thangalazhy-Gopakumar, S.; Foo, D.C.Y. Sustainable Technologies for Waste Reduction and Pollutants Removals. Clean Technol. Environ. Policy 2021, 23, 1–2. [Google Scholar] [CrossRef]

- Dolan, F.C.; Cath, T.Y.; Hogue, T.S. Assessing the Feasibility of Using Produced Water for Irrigation in Colorado. Sci. Total Environ. 2018, 640–641, 619–628. [Google Scholar] [CrossRef]

- Alsarayreh, M.; Almomani, F.; Khraisheh, M.; Nasser, M.S.; Soliman, Y. Biological-Based Produced Water Treatment Using Microalgae: Challenges and Efficiency. Sustainability 2022, 14, 499. [Google Scholar] [CrossRef]

- Kyriakidis, Y.N.; Silva, D.O.; Barrozo, M.A.S.; Vieira, L.G.M. Effect of Variables Related to the Separation Performance of a Hydrocyclone with Unprecedented Geometric Relationships. Powder Technol. 2018, 338, 645–653. [Google Scholar] [CrossRef]

- Hawez, H.K.; Asim, T. Impact of Regional Pressure Dissipation on Carbon Capture and Storage Projects: A Comprehensive Review. Energies 2024, 17, 1889. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Hamza, J.E.; Lemmu, T.A. Experimental investigation of the separation performance Liquid–Liquid Hydrocyclone Separator through Optimization of the Swirler Vane Angle. J. Pet. Explor. Prod. Technol. 2020, 10, 2957–2967. [Google Scholar] [CrossRef]

- Gerrie, C.; Islam, S.Z.; Gerrie, S.; Turner, N.; Asim, T. 3D CFD Modelling of Performance of a Vertical Axis Turbine. Energies 2023, 16, 1144. [Google Scholar] [CrossRef]

- da Silva Almeida, F.B.P.; Esquerre, K.P.S.O.R.; Soletti, J.I.; De Farias Silva, C.E. Coalescence Process to Treat Produced Water: An Updated Overview and Environmental Outlook. Environ. Sci. Pollut. Res. 2019, 26, 28668–28688. [Google Scholar] [CrossRef] [PubMed]

- Multon, L.M.; Viraraghavan, T. Removal of Oil from Produced Water by Coalescence/Filtration in a Granular Bed. Environ. Technol. 2006, 27, 529–544. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Kang, Y.; Cui, S. Oil and Water Separation Using a Glass Microfiber Coalescing Bed. J. Dispers. Sci. Technol. 2014, 35, 103–110. [Google Scholar] [CrossRef]

- Shammas, N.K.; Pouet, M.-F.; Grasmick, A. Flotation Technology; Wang, L.K., Shammas, N.K., Selke, W.A., Aulenbach, D.B., Eds.; Humana Press: Totowa, NJ, USA, 2010; Volume 12, ISBN 978-1-58829-494-4. [Google Scholar]

- Al-Dulaimi, S.L.; Al-Yaqoobi, A.M. Separation of Oil/Water Emulsions by Microbubble Air Flotation. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1076, 012030. [Google Scholar] [CrossRef]

- Saththasivam, J.; Loganathan, K.; Sarp, S. An Overview of Oil-Water Separation Using Gas Flotation Systems. Chemosphere 2016, 144, 671–680. [Google Scholar] [CrossRef] [PubMed]

- Iritani, E.; Katagiri, N.; Sengoku, T.; Yoo, K.M.; Kawasaki, K.; Matsuda, A. Flux Decline Behaviors in Dead-End Microfiltration of Activated Sludge and Its Supernatant. J. Memb. Sci. 2007, 300, 36–44. [Google Scholar] [CrossRef]

- Charlton, M.; Mishra, R.; Asim, T. The Effect of Manufacturing Method Induced Roughness on Severe Service Control Valve Performance. In Proceedings of the 6th International and 43rd National Conference on Fluid Mechanics and Fluid Power, Allahabad, India, 15–17 December 2016. [Google Scholar]

- Alzahrani, S.; Mohammad, A.W. Challenges and Trends in Membrane Technology Implementation for Produced Water Treatment: A Review. J. Water Process Eng. 2014, 4, 107–133. [Google Scholar] [CrossRef]

- Ghodrat, M.; Qi, Z.; Kuang, S.B.; Ji, L.; Yu, A.B. Computational Investigation of the Effect of Particle Density on the Multiphase Flows and Performance of Hydrocyclone. Miner. Eng. 2016, 90, 55–69. [Google Scholar] [CrossRef]

- Bai, Z.; Wang, H.; Tu, S.T. Oil-Water Separation Using Hydrocyclones Enhanced by Air Bubbles. Chem. Eng. Res. Des. 2011, 89, 55–59. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, Z.; Qiao, C.; Yang, W.; Huang, Y.; McKay, P.; Yang, D.; Liu, Q.; Zeng, H. Techniques for Treating Slop Oil in Oil and Gas Industry: A Short Review. Fuel 2020, 279, 118482. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Sun, Y.; Gao, S.; Jiang, M.; Jiang, M.; Rosso, D. Separation Performance of Hydrocyclones with Medium Rearrangement Internals. J. Environ. Chem. Eng. 2021, 9, 105642. [Google Scholar] [CrossRef]

- Liu, B.; Chen, B.; Ling, J.; Matchinski, E.J.; Dong, G.; Ye, X.; Wu, F.; Shen, W.; Liu, L.; Lee, K.; et al. Development of Advanced Oil/Water Separation Technologies to Enhance the Effectiveness of Mechanical Oil Recovery Operations at Sea: Potential and Challenges. J. Hazard. Mater. 2022, 437, 129340. [Google Scholar] [CrossRef] [PubMed]

- Kharoua, N.; Khezzar, L.; Nemouchi, Z. Hydrocyclones for De-Oiling Applications-a Review. Pet. Sci. Technol. 2010, 28, 738–755. [Google Scholar] [CrossRef]

- Tian, J.; Ni, L.; Song, T.; Olson, J.; Zhao, J. An Overview of Operating Parameters and Conditions in Hydrocyclones for Enhanced Separations. Sep. Purif. Technol. 2018, 206, 268–285. [Google Scholar] [CrossRef]

- Vallabhan, M.; Holden, C.; Skogestad, S. A First-Principles Approach for Control-Oriented Modeling of De-Oiling Hydrocyclones. Ind. Eng. Chem. Res. 2020, 59, 18937–18950. [Google Scholar] [CrossRef]

- Liu, X.; Asim, T.; Zhu, G.; Mishra, R. Theoretical and Experimental Investigations on the Combustion Characteristics of Three Components Mixed Municipal Solid Waste. Fuel 2020, 267, 117183. [Google Scholar] [CrossRef]

- Taimoor, A. Computational Fluid Dynamics Based Diagnostics and Optimal Design of Hydraulic Capsule Pipelines. Doctoral Thesis, University of Huddersfield, Huddersfield, UK, 2013. [Google Scholar]

- Wang, J.; Bai, Z.; Yang, Q.; Fan, Y.; Wang, H. Investigation of the Simultaneous Volumetric 3-Component Flow Field inside a Hydrocyclone. Sep. Purif. Technol. 2016, 163, 120–127. [Google Scholar] [CrossRef]

- Liu, M.; Chen, J.; Cai, X.; Han, Y.; Xiong, S. Oil–Water Pre-Separation with a Novel Axial Hydrocyclone. Chin. J. Chem. Eng. 2018, 26, 60–66. [Google Scholar] [CrossRef]

- Mao, R.; Li, Y.; Liu, Y.; Zhu, H.; Wang, N.; Yang, Q.; Lu, H. Separation Characters of an Axial-Flow Hydrocyclone with Oil Collecting Pipe. Sep. Purif. Technol. 2023, 305, 122139. [Google Scholar] [CrossRef]

- Noroozi, S.; Hashemabadi, S.H. CFD Simulation of Inlet Design Effect on Deoiling Hydrocyclone Separation Efficiency. Chem. Eng. Technol. 2009, 32, 1885–1893. [Google Scholar] [CrossRef]

- Tang, B.; Xu, Y.; Song, X.; Sun, Z.; Yu, J. Effect of Inlet Configuration on Hydrocyclone Performance. Trans. Nonferrous Met. Soc. China 2017, 27, 1645–1655. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Osei, H.; Hashim, F.M.; Hamza, J.E. Flow Structures and Their Impact on Single and Dual Inlets Hydrocyclone Performance for Oil–Water Separation. J. Pet. Explor. Prod. Technol. 2019, 9, 2943–2952. [Google Scholar] [CrossRef]

- Zhang, C.; Cui, B.; Wei, D.; Zhao, Q.; Luo, N.; Feng, Y. Predicting the Optimum Range of Feed Flow Rate in a Hydrocyclone Using the Method Combined Flow Pattern and Equation Model. Powder Technol. 2017, 319, 279–288. [Google Scholar] [CrossRef]

- Li, F.; Liu, P.; Yang, X.; Zhang, Y.; Zhao, Y. Effects of Inlet Concentration on the Hydrocyclone Separation Performance with Different Inlet Velocity. Powder Technol. 2020, 375, 337–351. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Z.; Yan, X.; Zhang, H.; Wang, L. Hydrocyclone Separation Enhancement of Fine Particles Based on Interface Control. Miner. Eng. 2024, 209, 108628. [Google Scholar] [CrossRef]

- Liu, P.; Fu, W.; Jiang, L.; Zhang, Y.; Li, X.; Yang, X.; Chen, B. Effect of Back Pressure on the Separation Performance of a Hydrocyclone. Powder Technol. 2022, 409, 117823. [Google Scholar] [CrossRef]

- Concha, F. Flow Pattern in Hydrocyclones. KONA Powder Part. J. 2007, 25, 97–132. [Google Scholar] [CrossRef][Green Version]

- Patra, G.; Velpuri, B.; Chakraborty, S.; Meikap, B.C. Performance Evaluation of a Hydrocyclone with a Spiral Rib for Separation of Particles. Adv. Powder Technol. 2017, 28, 3222–3232. [Google Scholar] [CrossRef]

- Zhao, Q.; Hou, D.; Cui, B.; Wei, D.; Song, T.; Feng, Y. Development of an Integrated Multichannel Inlet for Improved Particle Classification in Hydrocyclones. Adv. Powder Technol. 2021, 32, 4546–4561. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Yang, X.; Wang, Y.; Xu, B.; Liang, B. Innovative Design and Study of an Oil-Water Coupling Separation Magnetic Hydrocyclone. Sep. Purif. Technol. 2019, 213, 389–400. [Google Scholar] [CrossRef]

- Craig, M.; Asim, T. Numerical Investigations on the Propagation of Fire in a Railway Carriage. Energies 2020, 13, 4999. [Google Scholar] [CrossRef]

- Li, F.; Liu, P.; Yang, X.; Zhang, Y. Numerical Simulation on the Effects of Different Inlet Pipe Structures on the Flow Field and Seperation Performance in a Hydrocyclone. Powder Technol. 2020, 373, 254–266. [Google Scholar] [CrossRef]

- Rocha, C.A.O.; Ullmann, G.; Silva, D.O.; Vieira, L.G.M. Effect of Changes in the Feed Duct on Hydrocyclone Performance. Powder Technol. 2020, 374, 283–289. [Google Scholar] [CrossRef]

- Freegah, B.; Asim, T.; Albarzenji, D.; Pradhan, S.; Mishra, R. Effect of the Shape of Connecting Pipes on the Performance Output of a Closed-Loop Hot Water Solar Thermo-Syphon. In Proceedings of the 3rd International Workshop and Congress on eMaintenance, Lulea, Sweden, 17–18 June 2014; pp. 45–59. [Google Scholar]

- Liu, X.; Zhu, G.; Asim, T.; Zhang, Y.; Mishra, R. The Innovative Design of Air Caps for Improving the Thermal Efficiency of CFB Boilers. Energy 2021, 221, 119844. [Google Scholar] [CrossRef]

- Nasiri, M.; Jafari, I. Produced Water from Oil-Gas Plants: A Short Review on Challenges and Opportunities. Period. Polytech. Chem. Eng. 2017, 61, 73–81. [Google Scholar] [CrossRef]

- Khodadadi, S.; Maddahian, R.; Ramezani Mouziraji, H.A. Eulerian-Lagrangian Investigation of de-Oiling Hydrocyclones: The Effects of Droplet Interaction and Size Distribution. Chem. Eng. Sci. 2023, 277, 118855. [Google Scholar] [CrossRef]

- Kollár, L.E.; Mishra, R.; Asim, T. Particle Size Effects on Optimal Sizing and Lifetime of Pipelines Transporting Multi-Sized Solid-Liquid Mixtures. Procedia CIRP 2013, 11, 317–322. [Google Scholar] [CrossRef]

- Young, G.A.B.; Wakley, W.D.; Taggart, D.L.; Andrews, S.L.; Worrell, J.R. Oil-Water Separation Using Hydrocyclones: An Experimental Search for Optimum Dimensions. J. Pet. Sci. Eng. 1994, 11, 37–50. [Google Scholar] [CrossRef]

- Hawez, H.; Sanaee, R.; Faisal, N.H. Multiphase Flow Modelling in Fractured Reservoirs Using a Novel Computational Fluid Dynamics Approach. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Virtual, 20–23 June 2021. [Google Scholar]

- Kou, J.; Chen, Y.; Wu, J. Numerical Study and Optimization of Liquid-Liquid Flow in Cyclone Pipe. Chem. Eng. Process. Process Intensif. 2020, 147, 107725. [Google Scholar] [CrossRef]

- Zeng, X.; Xu, Y.; Zhao, L.; Fan, G.; Yan, C. Numerical Investigation on Axial Liquid-Liquid Separators with Different Swirl Chambers. Chem. Eng. Process. Process Intensif. 2021, 161, 108324. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, L.; Zhao, W.; Hou, M.; Zhu, F.; Fan, G.; Yan, C. Experimental Study on a Compact Axial Separator with Conical Tube for Liquid-Liquid Separation. Sep. Purif. Technol. 2021, 257, 117904. [Google Scholar] [CrossRef]

- Zhao, L.; Zeng, X.; Zhao, W.; Zhu, F.; Hou, M.; Fan, G. Structural Optimization for an Axial Oil-water Separator with Multi-stage Separation. Heat Mass Transf. Und Stoffuebertragung 2021, 57, 1949–1963. [Google Scholar] [CrossRef]

- Je, Y.W.; Kim, Y.J.; Kim, Y.J. The Prediction of Separation Performance of an In-Line Axial Oil–Water Separator Using Machine Learning and CFD. Processes 2022, 10, 375. [Google Scholar] [CrossRef]

- Asim, T.; Mishra, R.; Ubbi, K.; Zala, K. Computational Fluid Dynamics Based Optimal Design of Vertical Axis Marine Current Turbines. Procedia CIRP 2013, 11, 323–327. [Google Scholar] [CrossRef]

- Zheng, Y.; Min, F.; Wang, C. Multiphase Flow Characteristics in the Classification Process of a Novel Wide Neck Thickener: Experiment and Simulation. ACS Omega 2022, 7, 38660–38673. [Google Scholar] [CrossRef] [PubMed]

- Asim, T.; Mishra, R.; Kaysthagir, S.N.; Aboufares, G. Performance Comparison of a Vertical Axis Wind Turbine Using Commercial and Open Source Computational Fluid Dynamics Based Codes. In Springer Proceedings in Physics; Springer: Berlin/Heidelberg, Germany, 2016; Volume 185, pp. 589–594. ISBN 9783319306001. [Google Scholar]

- Chen, W.; Wan, W.; Zhao, Y.; He, H.; Wu, Q.; Zhou, Y.; Xie, S. Mechanical Damage Evolution and Mechanism of Sandstone with Prefabricated Parallel Double Fissures under High-Humidity Condition. Bull. Eng. Geol. Environ. 2022, 81, 245. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, X.; Chen, F.; Zhang, H.; Xiao, X. Numerical Simulation on Crack–Inclusion Interaction for Rib-to-Deck Welded Joints in Orthotropic Steel Deck. Metals 2023, 13, 1402. [Google Scholar] [CrossRef]

- Chen, W.; Wan, W.; He, H.; Liao, D.; Liu, J. Temperature Field Distribution and Numerical Simulation of Improved Freezing Scheme for Shafts in Loose and Soft Stratum; Springer: Vienna, Austria, 2024; Volume 57, ISBN 0123456789. [Google Scholar]

- de Araújo, C.A.O.; Scheid, C.M.; Loureiro, J.B.R.; Klein, T.S.; Medronho, R.A. Hydrocylone for Oil-Water Separations with High Oil Content: Comparison between CFD Simulations and Experimental Data. J. Pet. Sci. Eng. 2020, 187, 106788. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, L.; Fan, G.; Yan, C. Experimental Study on the Design of Light Phase Outlets for a Novel Axial Oil-Water Separator. Chem. Eng. Res. Des. 2021, 165, 308–319. [Google Scholar] [CrossRef]

- Abdi, P.; Lidster, D.; Talimi, V.; Thodi, P.; Masek, V.; Abdi, M.A. Hydrocyclone Performance for Mechanical Oil Spill Recovery Systems in Offshore Harsh Environment. J. Ocean Technol. 2021, 16, 96–118. [Google Scholar]

- Freegah, B.; Asim, T.; Mishra, R. Computational Fluid Dynamics Based Analysis of a Closed Thermo-Siphon Hot Water Solar System. In Proceedings of the 26th International Congress of Condition Monitoring and Diagnostic Engineering Management, Helsinki, Finland, 11–13 June 2013. [Google Scholar]

- Hamza, J.E.; Al-Kayiem, H.H.; Lemma, T.A. Experimental Investigation of the Separation Performance of Oil/Water Mixture by Compact Conical Axial Hydrocyclone. Therm. Sci. Eng. Prog. 2020, 17, 100358. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, L.; Fan, G.; Zhang, R.; Yan, C. Experimental Investigation on a New Axial Separator for Oil-Water with Small Density Difference. Ind. Eng. Chem. Res. 2021, 60, 9560–9569. [Google Scholar] [CrossRef]

- Angelim, K.; Lima, A.; Souza, J.; Neto, S.; Oliveira, V.; Moreira, G. Applying CFD in the Analysis of Heavy Oil/Water Separation Process via Hydrocyclone. Int. J. Multiphys. 2017, 11, 151–168. [Google Scholar] [CrossRef]

- Li, S.; Li, R.; Nicolleau, F.C.G.A.; Wang, Z.; Yan, Y.; Xu, Y.; Chen, X. Study on Oil–Water Two-Phase Flow Characteristics of the Hydrocyclone under Periodic Excitation. Chem. Eng. Res. Des. 2020, 159, 215–224. [Google Scholar] [CrossRef]

- Zhao, S.; Sun, J.; Wang, S.; Sun, Z. Modeling and Numerical Simulation of the Inlet Velocity on Oil–Water Two-Phase Vapor Separation Efficiency by the Hydrocyclone. Energies 2022, 15, 4900. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, M.; Duan, Y.; Yang, X.; Yang, J.; Tang, X. Influence of Feed Rate on the Performance of Hydrocyclone Flow Field. Separations 2022, 9, 349. [Google Scholar] [CrossRef]

- Amori, D.K.E.; Al-Ammar, Z.H. Numerical Study of Oil-Water Separation in Inline Axial Hydrocyclone. J. Pet. Res. Stud. 2022, 12, 154–172. [Google Scholar] [CrossRef]

- Gorobets, A.V.; Tarabara, V.V. Separation Performance of Desanding and Deoiling Hydrocyclones Treating Three-Phase Feeds: Effect of Oil-Particle Aggregates. Sep. Purif. Technol. 2020, 237, 116466. [Google Scholar] [CrossRef]

- Zeng, X.; Zhao, L.; Fan, G.; Yan, C. Numerical and Experimental Study on a New Axial Separator for Liquid-Liquid Separation. J. Taiwan Inst. Chem. Eng. 2021, 123, 104–114. [Google Scholar] [CrossRef]

- Yang, M.; Jiang, R.; Wu, X.; Hu, Z.; Yue, Y.; Chen, Y. Numerical Analysis of Flow Field and Separation Characteristics in an Oilfield Sewage Separation Device. Adv. Powder Technol. 2021, 32, 771–778. [Google Scholar] [CrossRef]

- Liu, L.; Zhao, L.; Wang, Y.; Zhang, S.; Song, M.; Huang, X.; Lu, Z. Research on the Enhancement of the Separation Efficiency for Discrete Phases Based on Mini Hydrocyclone. J. Mar. Sci. Eng. 2022, 10, 1606. [Google Scholar] [CrossRef]

- Xing, L.; Jiang, M.; Zhao, L.; Gao, J.; Liu, L. Design and Analysis of De-Oiling Coalescence Hydrocyclone. Sep. Sci. Technol. 2022, 57, 749–767. [Google Scholar] [CrossRef]

- Mohammadi, M.; Sarafi, A.; Kamyabi, A.; Soltani Goharrizi, A.; Abolpour, B. Simulation of Separation of Salt Solution from Crude Oil in a Hydrocyclone. J. Eng. 2022, 2022, 9558553. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Hamza, J.E.; Al-Azawiey, S.S. Droplet Shear in Oil/Water Emulsion Produced By Centrifugal Pump and Gear Pump. Int. J. Energy Prod. Manag. 2022, 7, 193–206. [Google Scholar] [CrossRef]

- Asim, T. Capacity Testing of X-Stream Valves for Single-Component Single-Phase Flows; Weir Valves and Controls: Elland, UK, 2013. [Google Scholar]

- Liu, M.; Kong, C.; Zhang, Y.; Chen, J.; Peng, S. Effect of Gas on Separation Performance of an Axial Hydrocyclone for Preliminary Water Separation. Powder Technol. 2023, 425, 118581. [Google Scholar] [CrossRef]

- Chen, W.; Liu, J.; Liu, W.; Peng, W.; Zhao, Y.; Wu, Q.; Wang, Y.; Wan, W.; Li, S.; Peng, H.; et al. Lateral Deformation and Acoustic Emission Characteristics of Dam Bedrock under Various River Flow Scouring Rates. J. Mater. Res. Technol. 2023, 26, 3245–3271. [Google Scholar] [CrossRef]

- Chen, W.; Liu, J.; Peng, W.; Zhao, Y.; Luo, S.; Wan, W.; Wu, Q.; Wang, Y.; Li, S.; Tang, X.; et al. Aging Deterioration of Mechanical Properties on Coal-Rock Combinations Considering Hydro-Chemical Corrosion. Energy 2023, 282, 128770. [Google Scholar] [CrossRef]

- Luo, Y.; Liao, P.; Pan, R.; Zou, J.; Zhou, X. Effect of Bar Diameter on Bond Performance of Helically Ribbed GFRP Bar to UHPC. J. Build. Eng. 2024, 91, 109577. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).