Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids

Abstract

1. Introduction

2. Methodology

2.1. System Description

2.2. Working Fluid Selection

2.3. Thermodynamic Modeling

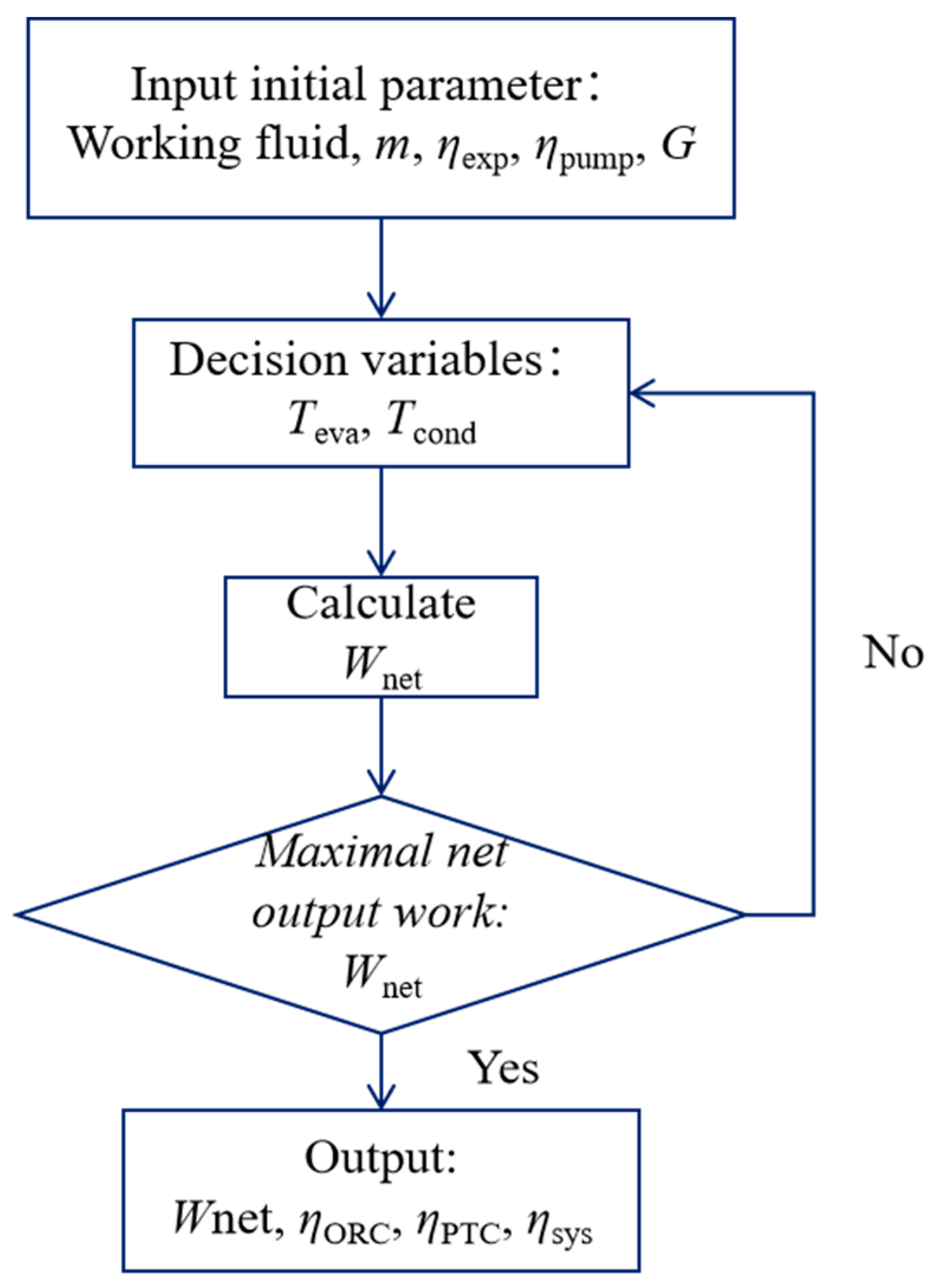

2.4. System Optimization

3. Results and Discussion

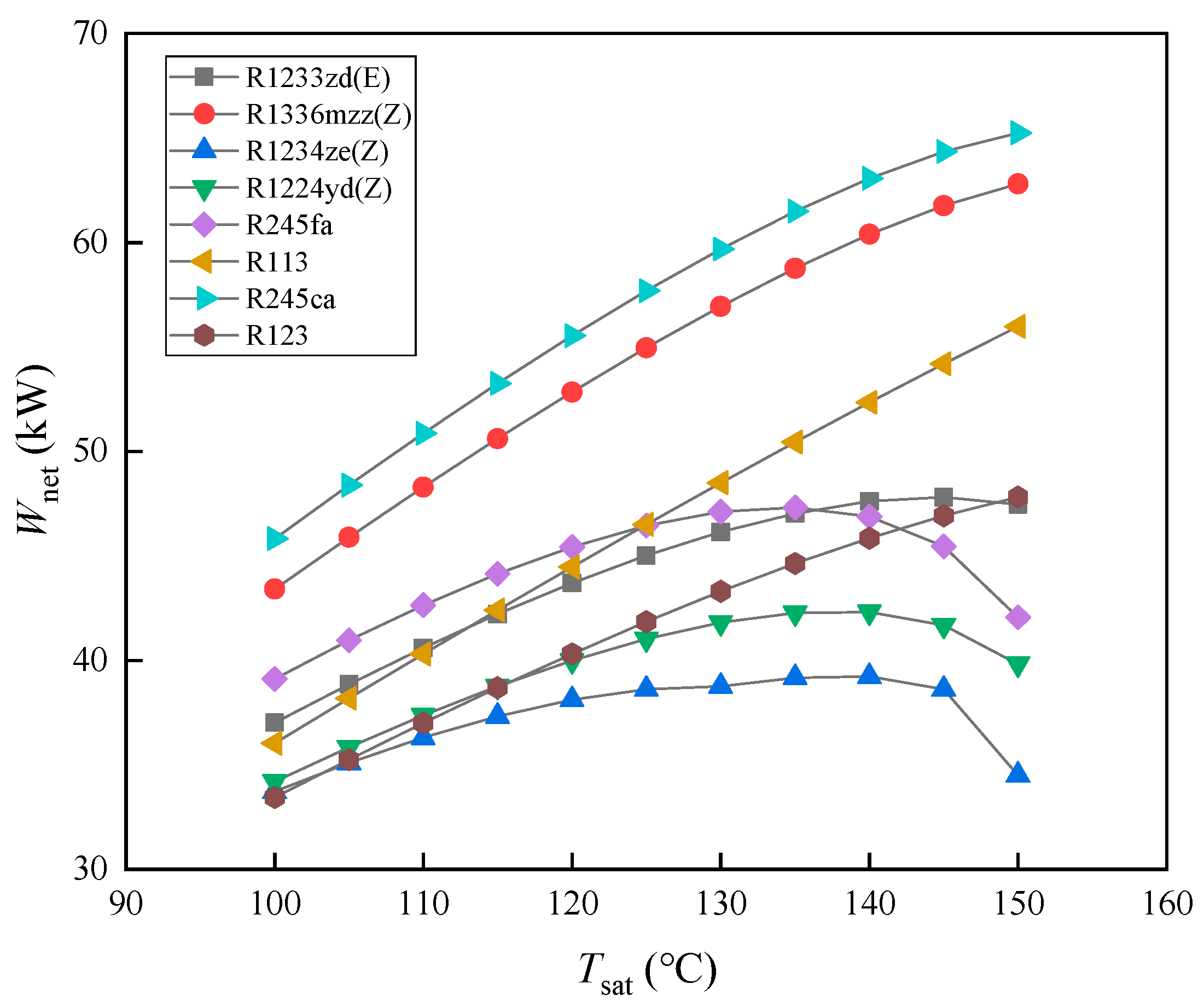

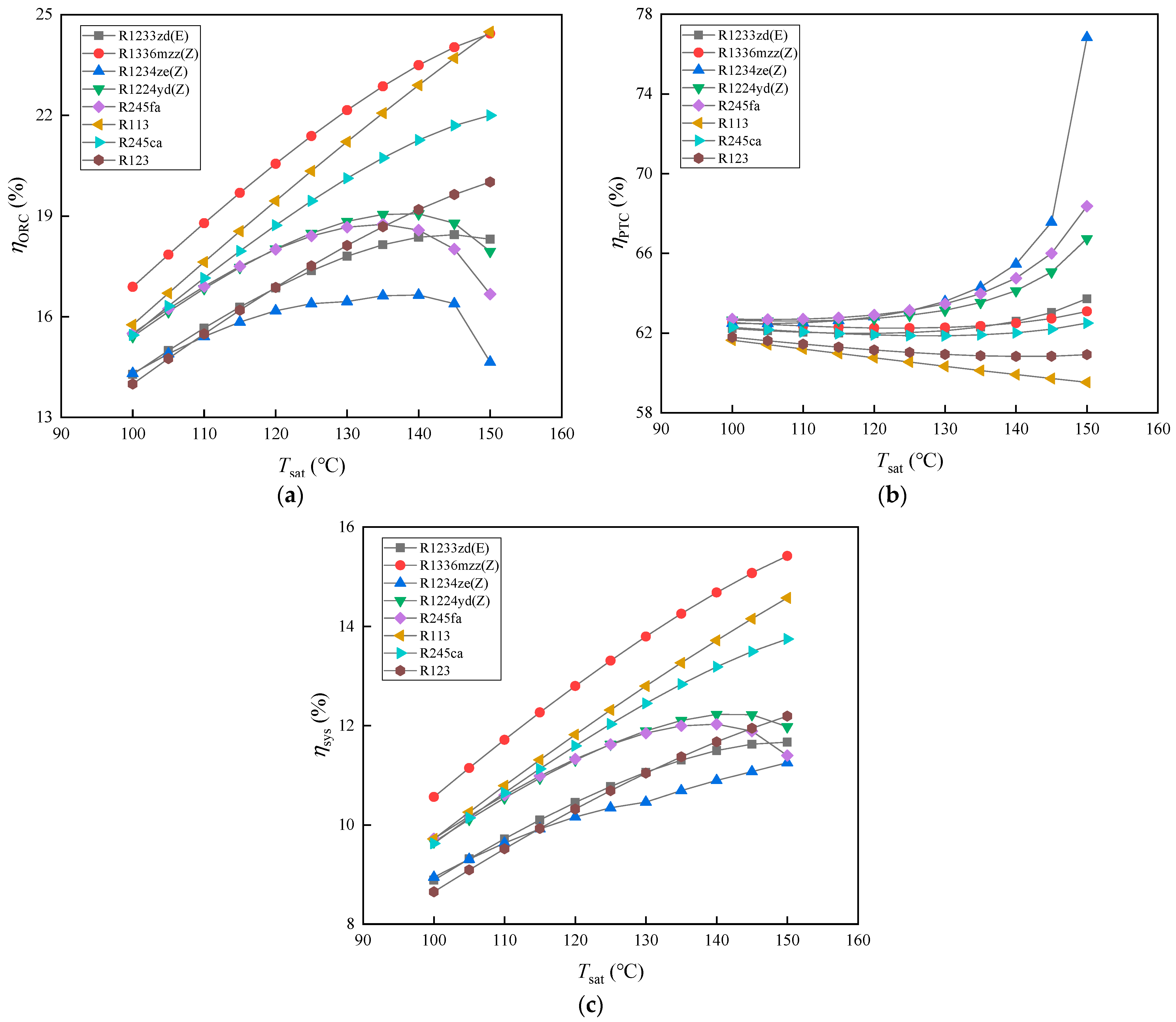

3.1. The Impact of Saturation Temperature on System Performance

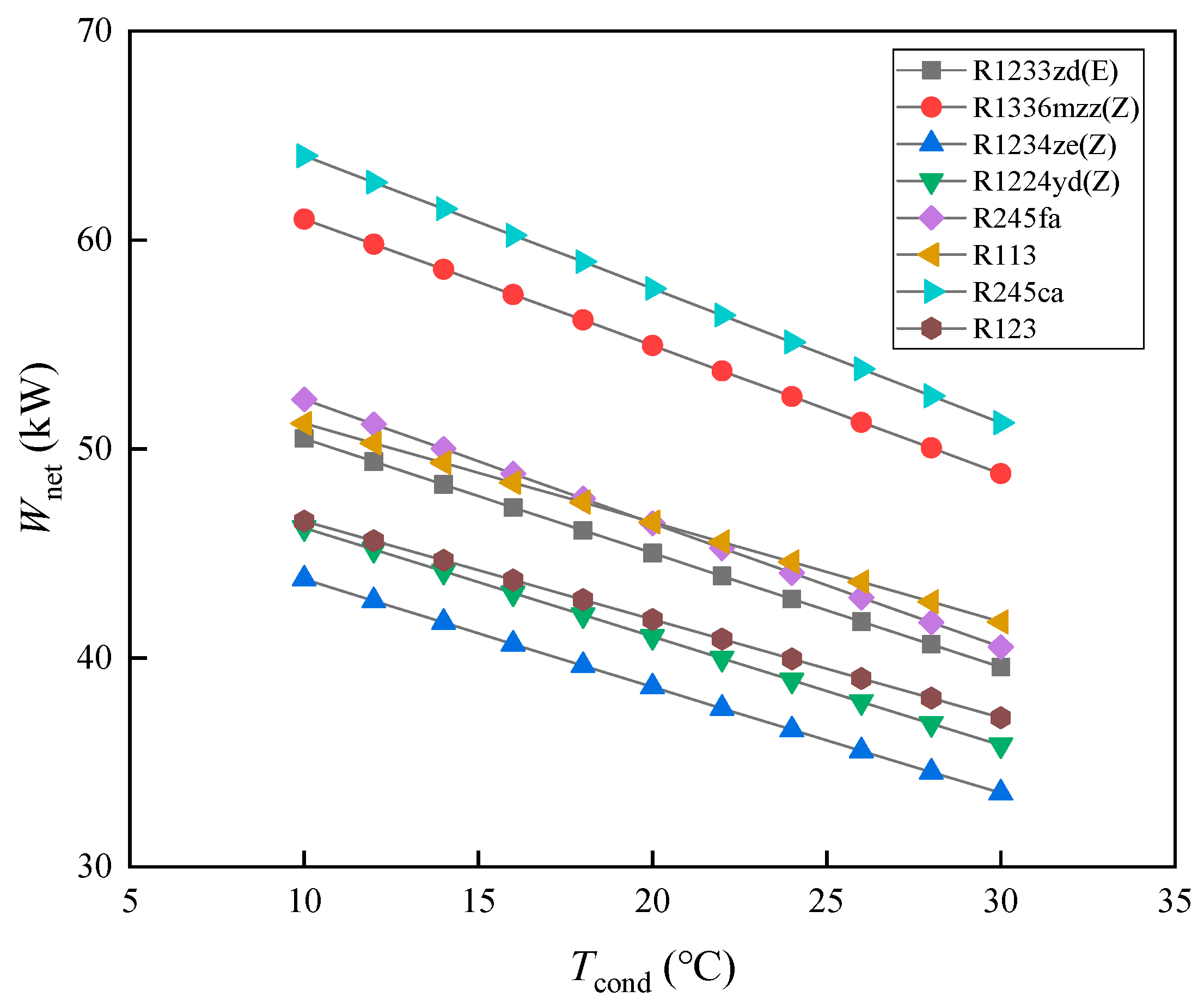

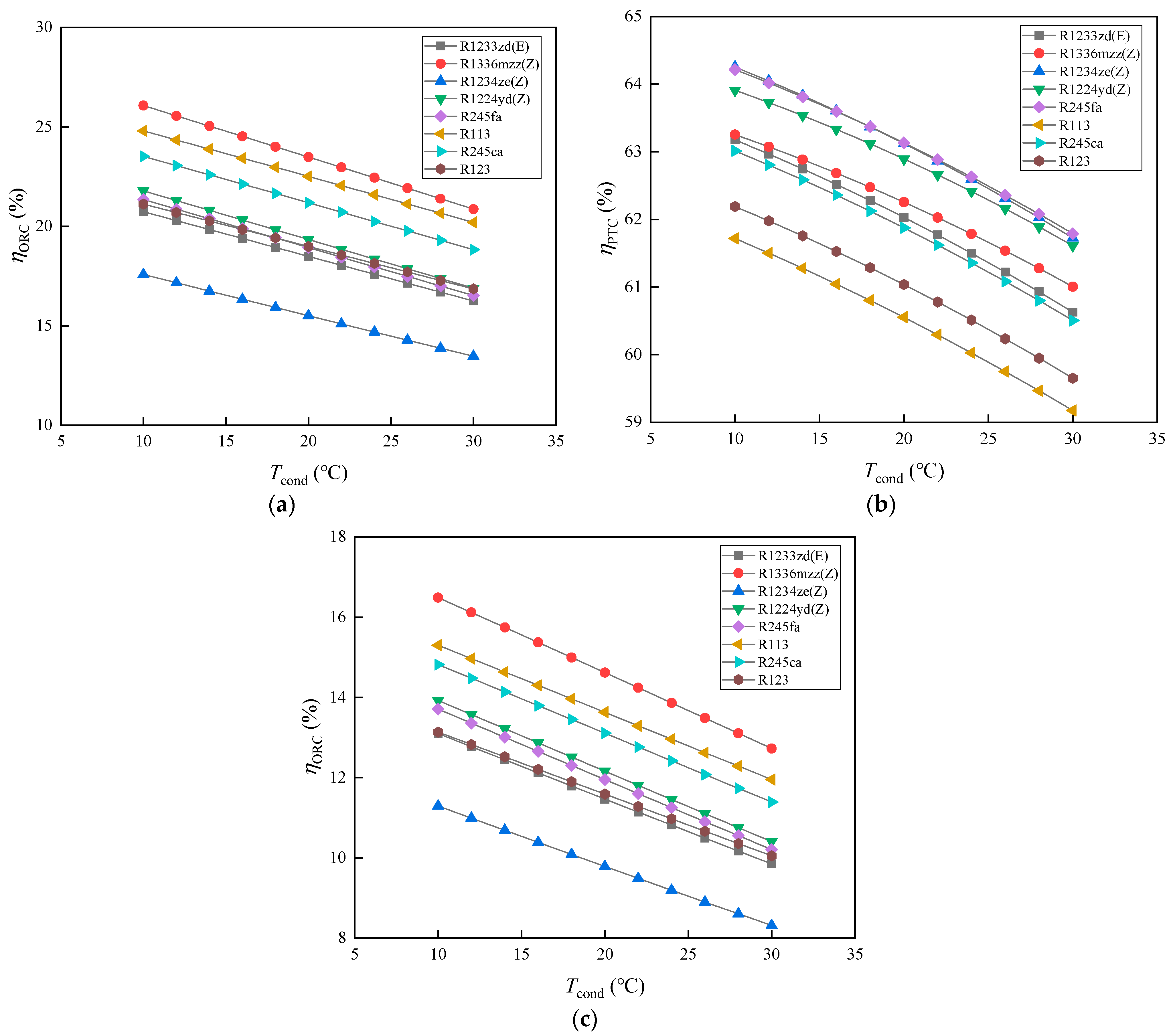

3.2. The Impact of Condensation Temperature on System Performance

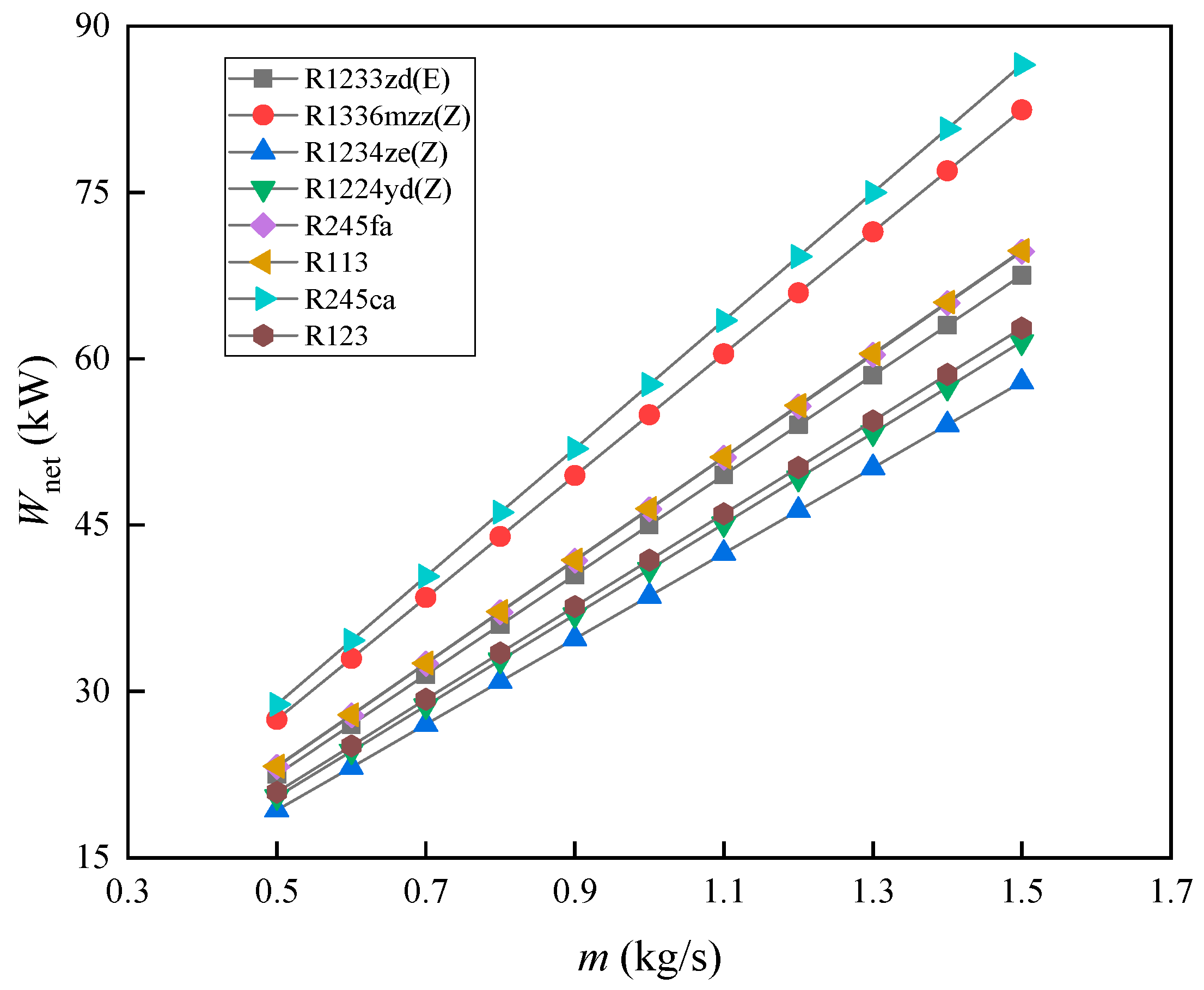

3.3. The Impact of Mass Velocity on System Performance

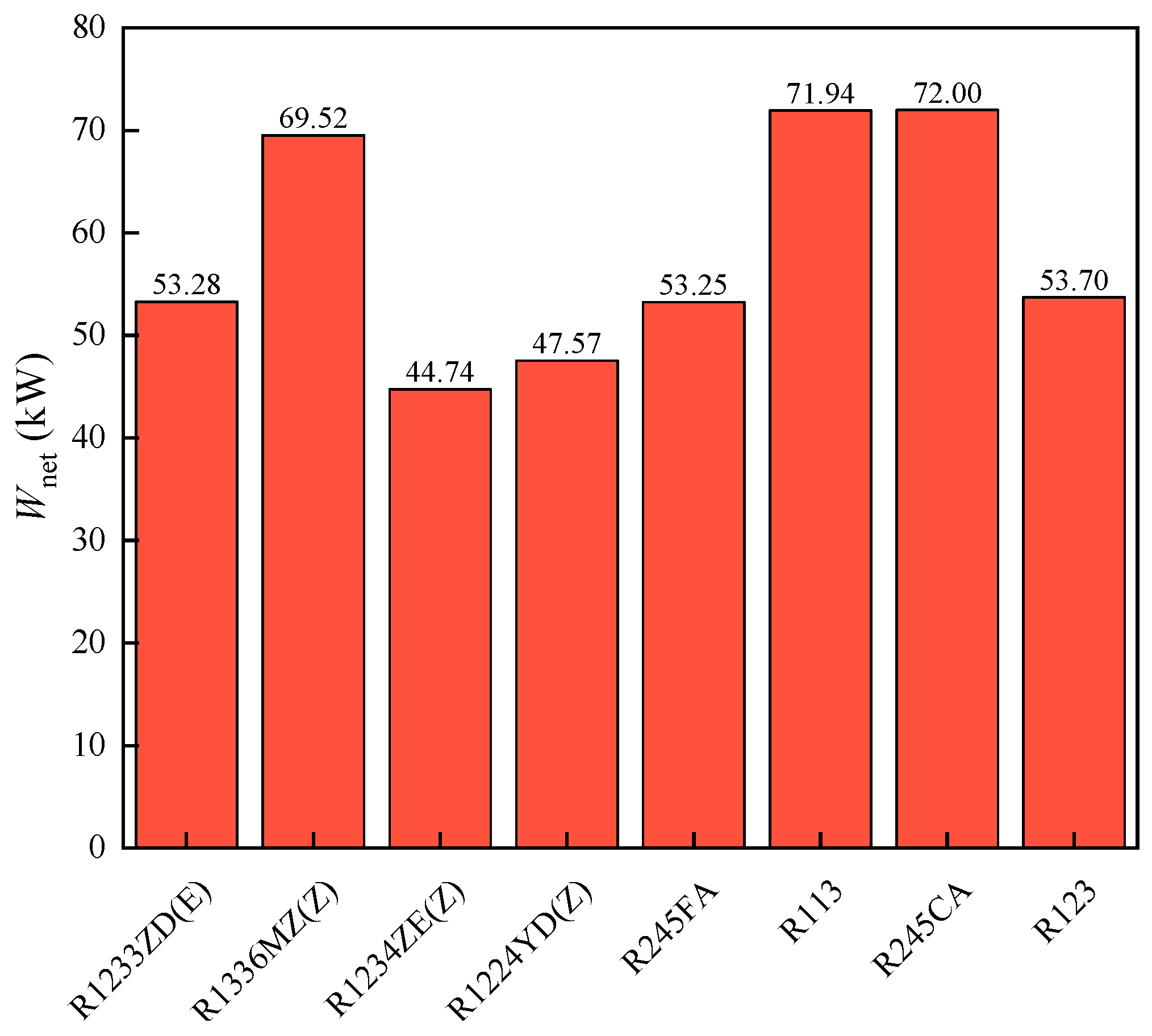

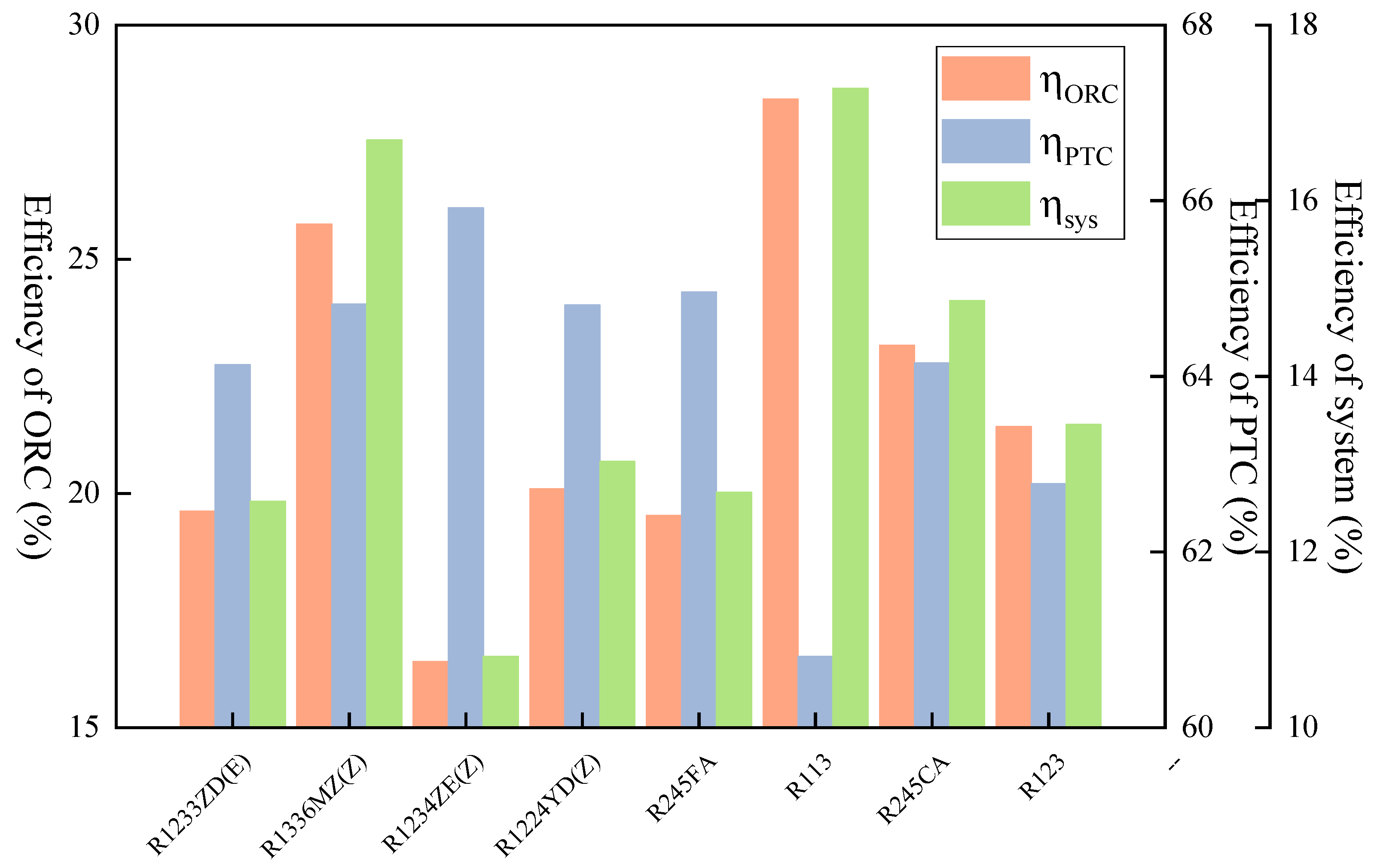

3.4. Results of Optimization

4. Conclusions

- R245ca and R1336mzz(Z), as high- and low-GWP working fluids, respectively, exhibit high net output power at different evaporating temperatures. R1336mzz(Z) reduces net output power by only 3.73–5.26% compared to R245ca. At lower evaporating temperatures, R1336mzz(Z) has the highest ORC efficiency, but at 150 °C, R113’s ORC efficiency is 0.22% higher than that of R1336mzz(Z). However, R1336mzz(Z) achieves the highest system efficiency due to its higher PTC efficiency.

- The performance of each working fluid decreases with increasing condensing temperature, indicating the negative impact of higher condensing temperatures on system performance. R1336mzz(Z) has a net output power slightly lower than R245ca, decreasing only by 4.73–4.75%. Although working fluids with higher ORC efficiency may have lower PTC efficiency, the ranking of system efficiency values for each working fluid is the same as that of ORC efficiency values. Considering that, ORC efficiency may have a significant impact on system efficiency at different condensing temperatures.

- Changes in mass flow rate do not affect the efficiency of the system. The net output power of each working fluid increases with increasing mass flow rate. R1336mzz(Z) has a net output power slightly lower than R245ca. Moreover, R1234ze(Z) has the lowest net output power.

- Optimization results based on net output power as the objective show that the net output power of low-GWP working fluid R1336mzz(Z) is only 3.44% lower than that of R245ca, which yields the maximum net output power. Additionally, among low-GWP working fluids, R1336mzz(Z) has the highest ORC efficiency and system efficiency. Due to its good environmental and safety characteristics, it can be considered the most suitable working fluid for the DVG-ORC system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Alvi, J.Z.; Feng, Y.; Wang, Q.; Imran, M.; Pei, G. Effect of working fluids on the performance of phase change material storage based direct vapor generation solar organic Rankine cycle system. Energy Rep. 2021, 7, 348–361. [Google Scholar] [CrossRef]

- Wang, Q.; Duan, L.; Lu, Z.; Zheng, N. Thermodynamic and economic analysis of a multi-energy complementary distributed CCHP system coupled with solar thermochemistry and active energy storage regulation process. Energy Conver. Manag. 2023, 292, 117429. [Google Scholar] [CrossRef]

- Pantaleo, A.M.; Camporeale, S.M.; Sorrentino, A.; Miliozzi, A.; Shah, N.; Markides, C.N. Hybrid solar-biomass combined Brayton/organic Rankine-cycle plants integrated with thermal storage: Techno-economic feasibility in selected Mediterranean areas. Renew. Energy 2020, 147, 2913–2931. [Google Scholar] [CrossRef]

- Hu, M.; Zhao, B.; Ao, X.; Ren, X.; Cao, J.; Wang, Q.; Su, Y.; Pei, G. Performance assessment of a trifunctional system integrating solar PV, solar thermal, and radiative sky cooling. Appl. Energy 2020, 260, 114167. [Google Scholar] [CrossRef]

- Zarei, A.; Akhavan, S.; Rabiee, M.B.; Elahi, S. Energy, exergy and economic analysis of a novel solar driven CCHP system powered by organic Rankine cycle and photovoltaic thermal collector. Appl. Therm. Eng. 2021, 194, 117091. [Google Scholar] [CrossRef]

- Kazemian, A.; Salari, A.; Hakkaki-Fard, A.; Ma, T. Numerical investigation and parametric analysis of a photovoltaic thermal system integrated with phase change material. Appl. Energy 2019, 328, 734–746. [Google Scholar] [CrossRef]

- Feng, Y.Q.; Hung, T.C.; He, Y.L.; Wang, Q.; Wang, S.; Li, B.X.; Lin, J.-R.; Zhang, W. Operation characteristic and performance comparison of organic Rankine cycle (ORC) for low-grade waste heat using R245fa, R123 and their mixtures. Energy Conver. Manag. 2017, 144, 153–163. [Google Scholar] [CrossRef]

- Karimi, S.; Mansouri, S. A comparative profitability study of geothermal electricity production in developed and developing countries: Exergoeconomic analysis and optimization of different ORC configurations. Renew. Energy 2018, 115, 600–619. [Google Scholar] [CrossRef]

- Yari, M. Exergetic analysis of various types of geothermal power plants. Renew. Energy 2010, 35, 112–121. [Google Scholar] [CrossRef]

- Macchi, E. Theoretical Basis of the Organic Rankine Cycle; Elsevier Ltd.: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Kumar, A.; Shukla, S.K. Analysis and Performance of ORC Based Solar Thermal Power Plant Using Benzene as a Working Fluid. Procedia Technol. 2016, 23, 454–463. [Google Scholar] [CrossRef][Green Version]

- Molés, F.; Navarro-Esbrí, J.; Peris, B.; Mota-Babiloni, A. Experimental evaluation of HCFO-1233zd-E as HFC-245fa replacement in an Organic Rankine Cycle system for low temperature heat sources. Appl. Therm. Eng. 2016, 98, 954–961. [Google Scholar] [CrossRef]

- Eyerer, S.; Wieland, C.; Vandersickel, A.; Spliethoff, H. Experimental study of an ORC (Organic Rankine Cycle) and analysis of R1233zd-E as a drop-in replacement for R245fa for low temperature heat utilization. Energy 2016, 103, 660–671. [Google Scholar] [CrossRef]

- Yang, J.; Ye, Z.; Yu, B.; Ouyang, H.; Chen, J. Simultaneous experimental comparison of low-GWP refrigerants as drop-in replacements to R245fa for Organic Rankine cycle application: R1234ze(Z), R1233zd(E), and R1336mzz(E). Energy 2019, 173, 721–731. [Google Scholar] [CrossRef]

- Zhou, X.; Xin, Z.; Tang, W.; Sheng, K.; Wu, Z. Comparative study for waste heat recovery in immersion cooling data centers with district heating and organic Rankine cycle (ORC). Appl. Therm. Eng. 2024, 242, 122479. [Google Scholar] [CrossRef]

- Su, W.; Hwang, Y.; Deng, S.; Zhao, L.; Zhao, D. Thermodynamic performance comparison of Organic Rankine Cycle between zeotropic mixtures and pure fluids under open heat source. Energy Conver. Manag. 2018, 165, 720–737. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Cheng, Z.; Wang, J.; Zhao, P.; Dai, Y. Thermodynamic and economic optimization of a double-pressure organic Rankine cycle driven by low-temperature heat source. Renew. Energy 2020, 147, 2822–2832. [Google Scholar] [CrossRef]

- Li, J.; Alvi, J.Z.; Pei, G.; Ji, J.; Li, P.; Fu, H. Effect of working fluids on the performance of a novel direct vapor generation solar organic Rankine cycle system. Appl. Therm. Eng. 2016, 98, 786–797. [Google Scholar] [CrossRef]

- Al Kindi, A.A.; Sapin, P.; Pantaleo, A.M.; Wang, K.; Markides, C.N. Thermo-economic analysis of steam accumulation and solid thermal energy storage in direct steam generation concentrated solar power plants. Energy Conver. Manag. 2022, 271, 116222. [Google Scholar] [CrossRef]

- Taccani, R.; Obi, J.B.; De Lucia, M.; Micheli, D.; Toniato, G. Development and Experimental Characterization of a Small Scale Solar Powered Organic Rankine Cycle (ORC). Energy Procedia. 2016, 101, 504–511. [Google Scholar] [CrossRef]

- Baral, S.; Kim, D.; Yun, E.; Kim, K.C. Experimental and thermoeconomic analysis of small-scale solar organic rankine cycle (SORC) system. Entropy 2015, 17, 2039–2061. [Google Scholar] [CrossRef]

- Dickes, R.; Dumont, O.; Bell, L.H.; Declaye, S.; Quoilin, S.; Bell, L. Experimental Investigation of an ORC System for a Micro-Solar Power Plant Energy Management View Project Dispa-SET View Project. 2014. Available online: https://www.researchgate.net/publication/267324701 (accessed on 14 July 2014).

- Helvaci, H.U.; Khan, Z.A. Experimental study of thermodynamic assessment of a small scale solar thermal system. Energy Convers. Manag. 2016, 117, 567–576. [Google Scholar] [CrossRef]

- Maytorena, V.M.; Buentello-Montoya, D.A. Multiphase simulation and parametric study of direct vapor generation for a solar organic Rankine Cycle. Appl. Therm. Eng. 2022, 216, 119096. [Google Scholar] [CrossRef]

- Dami, K.E.; Beltran-Chacon, R.; Islas, S.; Leal-Chavez, D. Numerical simulation of direct solar vapor generation of acetone for an organic rankine cycle using an evacuated tube collector. J. Sol. Energy Eng. 2021, 143, 021010. [Google Scholar] [CrossRef]

- Xu, G.; Song, G.; Zhu, X.; Gao, W.; Li, H.; Quan, Y. Performance evaluation of a direct vapor generation supercritical ORC system driven by linear Fresnel reflector solar concentrator. Appl. Therm. Eng. 2015, 80, 196–204. [Google Scholar] [CrossRef]

- Marion, M.; Voicu, I.; Tiffonnet, A.L. Wind effect on the performance of a solar organic Rankine cycle. Renew. Energy 2014, 68, 651–661. [Google Scholar] [CrossRef]

- Li, P.; Lin, H.; Li, J.; Cao, Q.; Wang, Y.; Pei, G.; Jie, D.; Zhao, Z. Analysis of a direct vapor generation system using cascade steam-organic Rankine cycle and two-tank oil storage. Energy 2022, 257, 124776. [Google Scholar] [CrossRef]

- UN Environment Programme. 38th 2016 Proceedings of the Open-Ended Working Group (OEWG 38) of the Parties to the Montreal Protocol on Substances that Deplete the Ozone Layer and 28th Meeting of the Parties to the Montreal Protocol (MOP 28), Kigali, Rwanda, 10–15 October 2016; UNEP: Nairobi, Kenya, 2016; pp. 10–14. [Google Scholar]

- Soares, J.; Oliveira, A.C.; Valenzuela, L. A dynamic model for once-through direct steam generation in linear focus solar collectors. Renew. Energy 2021, 163, 246–261. [Google Scholar] [CrossRef]

- Lei, D.; Fu, X.; Ren, Y.; Yao, F.; Wang, Z. Temperature and thermal stress analysis of parabolic trough receivers. Renew. Energy 2019, 136, 403–413. [Google Scholar] [CrossRef]

- Wang, X.D.; Zhao, L. Analysis of zeotropic mixtures used in low-temperature solar Rankine cycles for power generation. Sol. Energy 2009, 83, 605–613. [Google Scholar] [CrossRef]

- Yamada, N.; Mohamad, M.N.A.; Kien, T.T. Study on thermal efficiency of low- to medium-temperature organic Rankine cycles using HFO−1234yf. Renew. Energy 2012, 41, 368–375. [Google Scholar]

| Working Fluid | Critical Temperature [°C] | ODP | GWP | Toxicity | Flammability |

|---|---|---|---|---|---|

| R1233zd(E) | 161.45 | 0.00034 | 1 | None | None |

| R1336mzz(Z) | 166.35 | 0 | 7 | - | None |

| R1234ze(Z) | 145.12 | 0 | <1 | None | Low |

| R1224yd(Z) | 150.54 | 0.00023 | 0.88 | None | None |

| R245fa | 148.86 | 0 | 1030 | None | None |

| R113 | 209.06 | 1.0 | 6130 | Low | None |

| R245ca | 169.42 | 0 | 693 | - | - |

| R123 | 178.681 | 0.02 | 77 | High | None |

| Parameter | Value |

|---|---|

| G | 500 W/m2 |

| m | 1 kg/s |

| ηexp | 0.75 |

| ηpump | 0.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Zhang, X.; Zhang, Z.; Hao, L.; Cao, Z.; Li, S.; Guo, B.; Zheng, Y.; Dong, C.; Zhao, L. Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids. Energies 2024, 17, 3133. https://doi.org/10.3390/en17133133

Jiang Y, Zhang X, Zhang Z, Hao L, Cao Z, Li S, Guo B, Zheng Y, Dong C, Zhao L. Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids. Energies. 2024; 17(13):3133. https://doi.org/10.3390/en17133133

Chicago/Turabian StyleJiang, Youtao, Xunda Zhang, Zhengao Zhang, Lei Hao, Zhaozhi Cao, Shuyang Li, Bowen Guo, Yawen Zheng, Chunhai Dong, and Li Zhao. 2024. "Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids" Energies 17, no. 13: 3133. https://doi.org/10.3390/en17133133

APA StyleJiang, Y., Zhang, X., Zhang, Z., Hao, L., Cao, Z., Li, S., Guo, B., Zheng, Y., Dong, C., & Zhao, L. (2024). Performance Evaluation and Working Fluid Screening of Direct Vapor Generation for Solar ORC Using Low-Global Warming Potential (GWP) Working Fluids. Energies, 17(13), 3133. https://doi.org/10.3390/en17133133