A Method for Assessing the Technical Condition of Traction Batteries Using the Metalog Family of Probability Distributions

Abstract

1. Introduction

2. Research

2.1. Research Objects

2.2. Research Bench

2.3. Methodology

3. Discussion

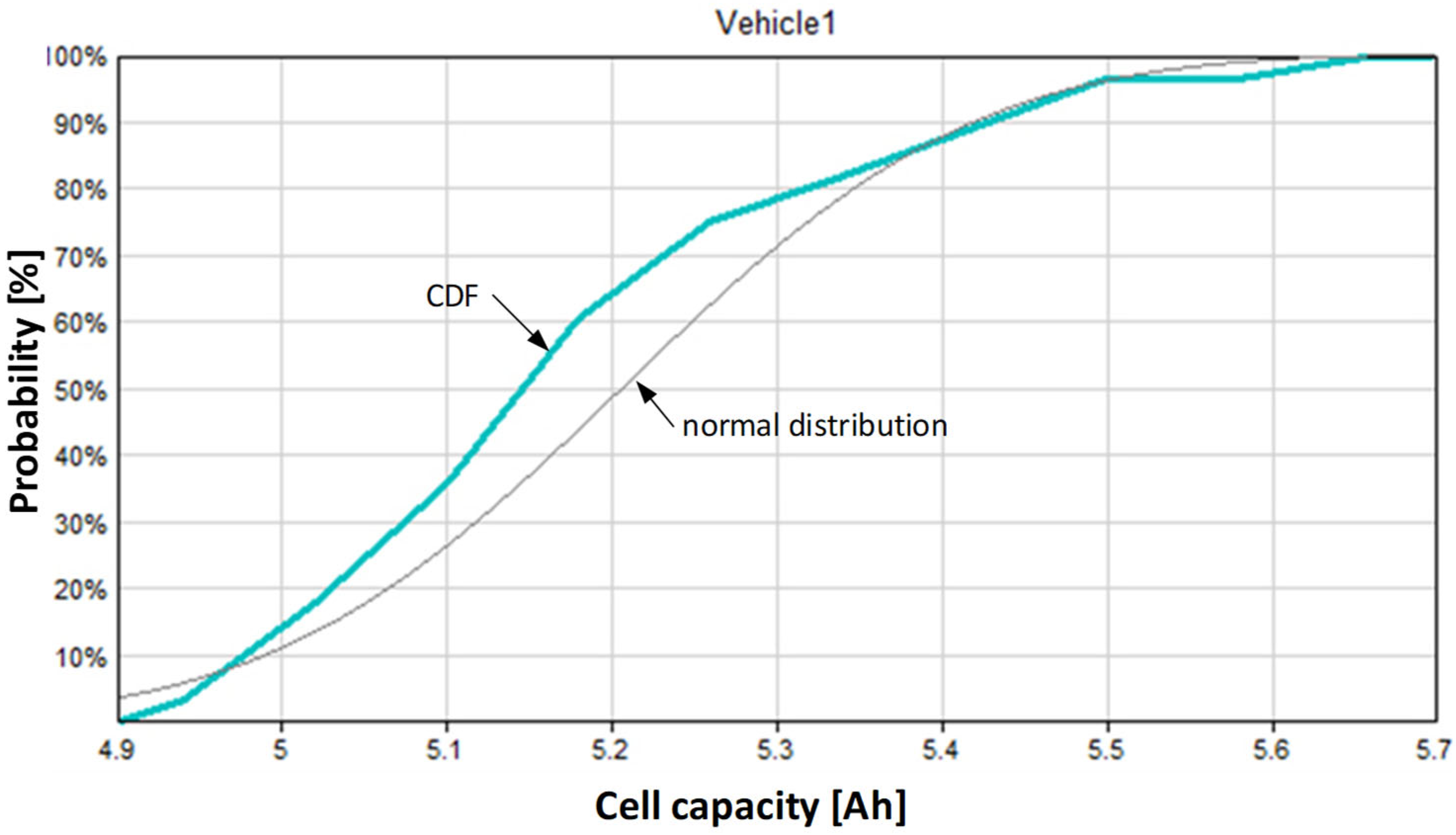

3.1. Case 1

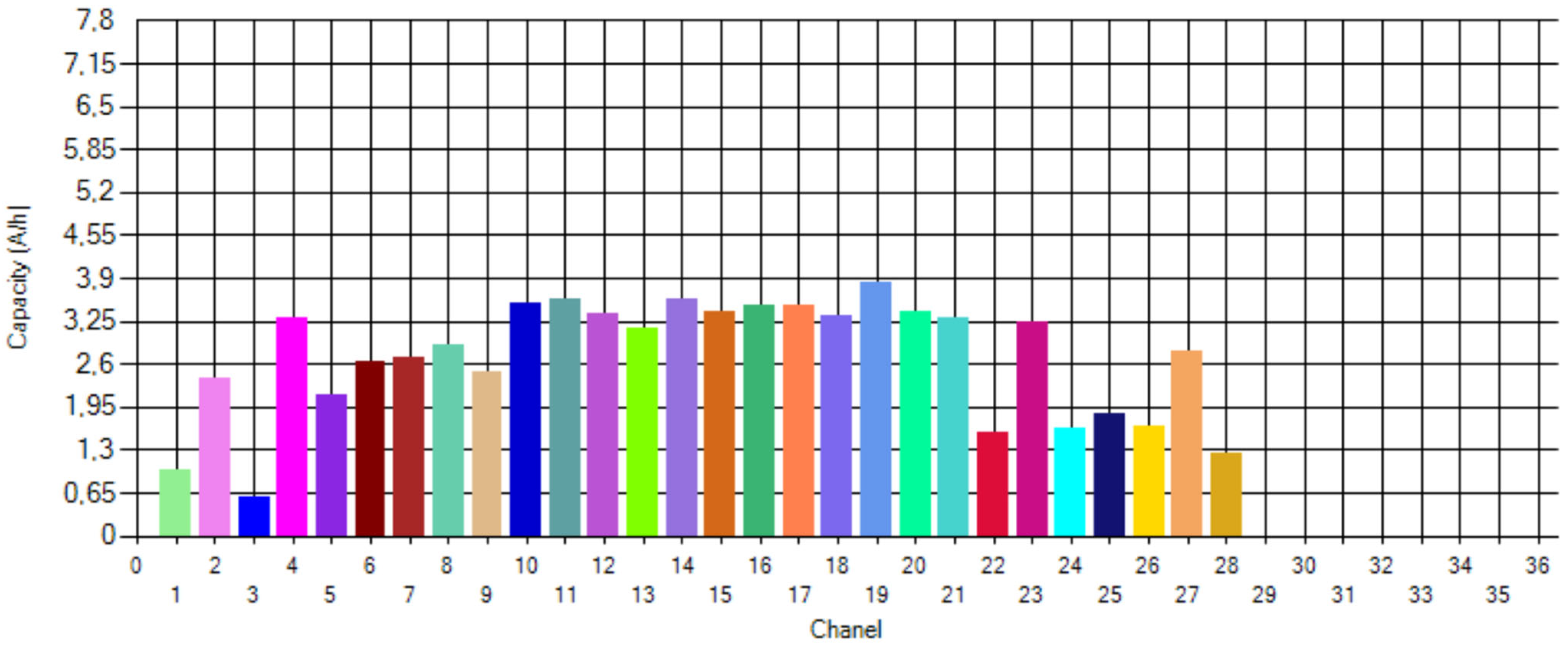

3.2. Case 2

3.3. Case 3

3.4. Case 4

4. Conclusions

- (1)

- A functional package in which the aging processes proceed properly. It is characterized by the capacity of individual battery cells ranging from 100 to 50% of the nominal capacity. The PDF waveform is close to a normal distribution with a very small standard deviation between the capacities of individual cells.

- (2)

- The package is faulty and needs to be repaired. It is characterized by the capacity of individual battery cells ranging from 0 to 100% of the nominal capacity. PDF waveform with one extreme with a very large standard deviation between the capacities of individual cells. The location of the extreme PDF indicates the purpose of repair. All cells with a capacity less than the extreme value should be replaced with cells with a capacity equal to or greater than the extreme value. All cells with a capacity greater than 50% of the nominal capacity can be reused to compose a package of a given capacity.

- (3)

- The package is beyond repair and should be disposed of. It is characterized by the capacity of individual battery cells ranging from 0 to 50% of the nominal capacity. PDF waveform with one or two extreme values with a very large standard deviation between the capacities of individual cells.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BEV | Battery Electric Vehicles |

| BMS | Battery Management System |

| CNG | Compressed Natural Gas |

| FCV | Fuel Cell Vehicle |

| HEV | Hybrid Electric Vehicle |

| HVO | Hydrogenated Vegetable Oil |

| LNG | Liquide Natural Gas |

| LPG | Liquide Petroleum Gas |

| LTO | Lithium Titanium Oxide |

| NG | Natural Gas |

| NiMH | Nickel-Metal Hydride |

| NMC | Nickel Manganese Cobalt |

| PHEV | Plug-in Hybrid Electric Vehicle |

| RES | Renewable Energy Source |

| SoC | State of Charge |

| TMS | Thermal Management System |

References

- Bayani, R.; Soofi, A.F.; Waseem, M.; Manshadi, S.D. Impact of Transportation Electrification on the Electricity Grid—A Review. Vehicles 2022, 4, 1042–1079. [Google Scholar] [CrossRef]

- Barta, D.; Mruzek, M.; Kendra, M.; Kordos, P.; Krzywonos, L. Using of non-conventional fuels in hybrid vehicle drives. Adv. Sci. Technol. Res. J. 2016, 10, 240–247. [Google Scholar] [CrossRef] [PubMed]

- Čulík, K.; Hrudkay, K.; Morgoš, J. Operating Characteristics of Electric Buses and Their Analysis. In Proceedings of the Transport Means—Proceedings of the International Conference, Kaunas, Lithuania, 6–8 October 2021; pp. 251–256. [Google Scholar]

- Čulík, K.; Hrudkay, K.; Štefancová, V. Possibilities of Legislative and Economic Support for Electromobility in Slovakia. In Lecture Notes in Intelligent Transportation and Infrastructure; Springer: Berlin/Heidelberg, Germany, 2023; Part F1379; pp. 125–134. [Google Scholar]

- Gnap, J.; Dockalik, M.; Dydkowski, G. Examination of the development of new bus registrations with alternative powertrains in Europe. LOGI—Sci. J. Transp. Logist. 2021, 12, 147–158. [Google Scholar] [CrossRef]

- Hurtova, I.; Sejkorova, M.; Verner, J.; Sarkan, B. Comparison of electricity and fossil fuel consumption in trolleybuses and buses. Eng. Rural Dev. 2018, 17, 2079–2084. [Google Scholar] [CrossRef]

- Kharchenko, V.; Kostenko, I.; Liubarskyi, B.; Shaida, V.; Kuravskyi, M.; Petrenko, O. Simulating the traction electric drive operation of a trolleybus equipped with mixed excitation motors and DC-DC converter. East.-Eur. J. Enterp. Technol. 2020, 3, 46–54. [Google Scholar] [CrossRef]

- Nicoletti, L.; Köhler, P.; König, A.; Heinrich, M.; Lienkamp, M. Parametric modelling of weight and volume effects in battery electric vehicles, with focus on the gearbox. Proc. Des. Soc. 2021, 1, 2389–2398. [Google Scholar] [CrossRef]

- Ribeiro, P.J.G.; Mendes, J.F.G. Public transport decarbonisation via urban bus fleet replacement in Portugal. Energies 2022, 15, 4286. [Google Scholar] [CrossRef]

- Settey, T.; Gnap, J.; Synák, F.; Skrúcaný, T.; Dočkalik, M. Research into the impacts of driving cycles and load weight on the operation of a light commercial electric vehicle. Sustainability 2021, 13, 13872. [Google Scholar] [CrossRef]

- Stakens, J.; Mutule, A.; Lazdins, R. Agriculture Electrification, Emerging Technologies, Trends and Barriers: A Comprehensive Literature Review. Latv. J. Phys. Tech. Sci. 2023, 60, 18–32. [Google Scholar] [CrossRef]

- Stoma, M.; Dudziak, A. Future Challenges of the Electric Vehicle Market Perceived by Individual Drivers from Eastern Poland. Energies 2023, 16, 7212. [Google Scholar] [CrossRef]

- Stopka, O.; Stopková, M.; Pečman, J. Application of Multi-Criteria Decision Making Methods for Evaluation of Selected Passenger Electric Cars: A Case Study. Commun. Sci. Lett. Univ. Zilina 2022, 24, A133–A141. [Google Scholar] [CrossRef]

- Würtz, S.; Bogenberger, K.; Göhner, U.; Rupp, A. Towards efficient battery electric bus operations: A novel energy forecasting framework. World Electr. Veh. J. 2024, 15, 27. [Google Scholar] [CrossRef]

- Beik, Y.; Dziewiątkowski, M.; Szpica, D. Exhaust emissions of an engine fuelled by petrol and liquefied petroleum gas with control algorithm adjustment. SAE Int. J. Engines 2020, 13, 739–759. [Google Scholar] [CrossRef]

- Szpica, D. Fuel dosage irregularity of LPG pulse vapor injectors at different stages of wear. Mechanika 2016, 22, 44–50. [Google Scholar] [CrossRef]

- Dittrich, A.; Beroun, S.; Zvolsky, T. Diesel gas dual engine with liquid LPG injection into intake manifold. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 1978–1983. [Google Scholar]

- Pulawski, G.; Szpica, D. The modelling of operation of the compression ignition engine powered with diesel fuel with LPG admixture. Mechanika 2015, 21, 500–505. [Google Scholar]

- Ding, S.-L.; Song, E.-Z.; Yang, L.-P.; Litak, G.; Wang, Y.-Y.; Yao, C.; Ma, X.-Z. Analysis of Chaos in the Combustion Process of Premixed Natural Gas Engine. Appl. Therm. Eng. 2017, 121, 768–778. [Google Scholar] [CrossRef]

- Gnap, J.; Dockalik, M. Impact of the operation of LNG trucks on the environment. Open Eng. 2021, 11, 937–947. [Google Scholar] [CrossRef]

- Jurkovic, M.; Kalina, T.; Skrúcaný, T.; Gorzelanczyk, P.; L’upták, V. Environmental Impacts of Introducing LNG as Alternative Fuel for Urban Buses—Case Study in Slovakia. Promet-Traffic Transp. 2020, 32, 837–847. [Google Scholar] [CrossRef]

- Szpica, D.; Dziewiatkowski, M. Catalyst Conversion Rates Measurement on Engine Fueled with Compressed Natural Gas (CNG) Using Different Operating Temperatures. Mechanika 2021, 27, 492–497. [Google Scholar] [CrossRef]

- Domański, M.; Paszkowski, J.; Sergey, O.; Zarajczyk, J.; Siłuch, D. Analysis of Energy Properties of Granulated Plastic Fuels and Selected Biofuels. Agric. Eng. 2020, 24, 1–9. [Google Scholar] [CrossRef]

- Vignesh, R.; Ashok, B.; Senthil Kumar, M.; Szpica, D.; Harikrishnan, A.; Josh, H. Adaptive neuro fuzzy inference system-based energy management controller for optimal battery charge sustaining in biofuel powered non-plugin hybrid electric vehicle. Sustain. Energy Technol. Assess. 2023, 59, 103379. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Navale, S.J. Experimental investigations on the performance and emissions of compression ignition engine fueled with lower blends of neem-based biodiesel. Arch. Autom. Engineer. Archiw. Mot. 2024, 103, 57–76. [Google Scholar]

- Duda, K.; Wierzbicki, S.; Mikulski, M.; Konieczny, Ł.; Łazarz, B.; Letuń-Łatka, M. Emissions from a medium-duty crdi engine fuelled with diesel-biodiesel blends. Transp. Probl. 2021, 16, 39–49. [Google Scholar] [CrossRef]

- Imran, M.S.; Saleh, F.A. The Influence of Using Biodiesel Prepared from Cresson Oil on Emissions and Performance of CI Engines. J. Ecol. Eng. 2024, 25, 84–98. [Google Scholar] [CrossRef] [PubMed]

- Matijošius, J.; Orynycz, O.; Kovbasenko, S.; Simonenko, V.; Shuba, Y.; Moroz, V.; Gutarevych, S.; Wasiak, A.; Tucki, K. Testing the indicators of diesel vehicles operating on diesel oil and diesel biofuel. Energies 2022, 15, 9263. [Google Scholar] [CrossRef]

- Pawlak, G.; Skrzek, T. Combustion of raw Camelina Sativa oil in CI engine equipped with common rail system. Sci. Rep. 2023, 13, 19731. [Google Scholar] [CrossRef] [PubMed]

- Szpica, D.; Czaban, J. Investigating of the combustion process in a diesel engine fueled with conventional and alternative fuels. In Proceedings of the 23rd International Scientific Conference, Transport Means—Proceedings of the International Conference 2019, Palanga, Lithuania, 2–4 October 2019; pp. 176–181. [Google Scholar]

- Dittrich, A.; Prochazka, R.; Popelka, J.; Phu, D.N. Effect of HVO CNG dual-fuel operation mode on emissions and performance of CI engine. In Proceedings of the Engineering for Rural Development, Jelgava, Latvia, 24–26 May 2023; Volume 22, pp. 58–63. [Google Scholar]

- Žvirblis, T.; Hunicz, J.; Matijošius, J.; Rimkus, A.; Kilikevičius, A.; Gęca, M. Improving diesel engine reliability using an optimal prognostic model to predict diesel engine emissions and performance using pure diesel and Hydrogenated Vegetable Oil. Eksploat. I Niezawodn.—Maint. Reliab. 2023, 25, 174358. [Google Scholar] [CrossRef]

- Gechev, T. Progress in fuel cell usage as an auxiliary power unit in heavy-duty vehicles. In Proceedings of the 29th Technical and Scientific Conference on Transport, Ecology—Sustainable Development, EKO Varna 2023, Hybrid, AIP Conference Proceedings, Varna, Bulgaria, 18–20 May 2023; Volume 3104, p. 020006. [Google Scholar]

- Sederyn, T.; Skawińska, M. Computational analysis of PEM fuel cell under different operating conditions. Appl. Comput. Sci. 2023, 19, 26–38. [Google Scholar] [CrossRef]

- Balitskii, A.I.; Abramek, K.F.; Osipowicz, T.K.; Eliasz, J.J.; Balitska, V.O.; Kochmański, P.; Prajwowski, K.; Mozga, Ł.S. Hydrogen-Containing “Green” Fuels Influence on the Thermal Protection and Formation of Wear Processes Components in Compression-Ignition Engines Modern Injection System. Energies 2023, 16, 3374. [Google Scholar] [CrossRef]

- Di Micco, S.; Romano, F.; Jannelli, E.; Perna, A.; Minutillo, M. Techno-economic analysis of a multi-energy system for the co-production of green hydrogen, renewable electricity and heat. Int. J. Hydrogen Energy 2023, 48, 31457–31467. [Google Scholar] [CrossRef]

- Gilewski, M.; Czarnigowski, J.; Hunicz, J.; Dubeński, K.; Szafran, M.; Fronc, M. Model of a prototype vehicle powered by a hybrid hydrogen system. J. Phys. Conf. Ser. 2021, 2130, 012002. [Google Scholar] [CrossRef]

- Synák, F.; Synák, J.; Skrúcaný, T. Assessing the addition of hydrogen and oxygen into the engine’s intake air on selected vehicle features. Int. J. Hydrogen Energy 2021, 46, 31854–31878. [Google Scholar] [CrossRef]

- Nadolski, R.; Ludwinek, K.; Staszak, J.; Jaśkiewicz, M. Utilization of BLDC motor in electrical vehicles. Przegląd Elektrotechniczny 2012, 88, 180–186. [Google Scholar]

- Available online: https://ev-database.org/ (accessed on 15 June 2024).

- Aghmadi, A.; Mohammed, O.A. Energy Storage Systems: Technologies and High-Power Applications. Batteries 2024, 10, 141. [Google Scholar] [CrossRef]

- Cui, Y.; Shen, X.; Zhang, H.; Yin, Y.; Yu, Z.; Shi, D.; Fang, Y.; Xu, R. Intrinsic Safety Risk Control and Early Warning Methods for Lithium-Ion Power Batteries. Batteries 2024, 10, 62. [Google Scholar] [CrossRef]

- Wang, C.; Liu, Z.; Sun, Y.; Gao, Y.; Yan, P. Aging Behavior of Lithium Titanate Battery under High-Rate Discharging Cycle. Energies 2021, 14, 5482. [Google Scholar] [CrossRef]

- Karnehm, D.; Bliemetsrieder, W.; Pohlmann, S.; Neve, A. Controlling Algorithm of Reconfigurable Battery for State of Charge Balancing Using Amortized Q-Learning. Batteries 2024, 10, 131. [Google Scholar] [CrossRef]

- Dinh, M.-C.; Le, T.-T.; Park, M. A Low-Cost and High-Efficiency Active Cell-Balancing Circuit for the Reuse of EV Batteries. Batteries 2024, 10, 61. [Google Scholar] [CrossRef]

- Etxandi-Santolaya, M.; Mora-Pous, A.; Canals Casals, L.; Corchero, C.; Eichman, J. Quantifying the Impact of Battery Degradation in Electric Vehicle Driving through Key Performance Indicators. Batteries 2024, 10, 103. [Google Scholar] [CrossRef]

- Maisuradze, M.; Li, M.; Carlomagno, I.; Gaboardi, M.; Aquilanti, G.; Plaisier, J.R.; Giorgetti, M. Aging Mechanism of Mn-Based Prussian Blue Cathode Material by Synchrotron 2D X-ray Fluorescence. Batteries 2024, 10, 123. [Google Scholar] [CrossRef]

- Sun, C.; Qin, W.; Yun, Z. A State-of-Health Estimation Method for Lithium Batteries Based on Fennec Fox Optimization Algorithm–Mixed Extreme Learning Machine. Batteries 2024, 10, 87. [Google Scholar] [CrossRef]

- Hassini, M.; Redondo-Iglesias, E.; Venet, P. Battery Passports for Second-Life Batteries: An Experimental Assessment of Suitability for Mobile Applications. Batteries 2024, 10, 153. [Google Scholar] [CrossRef]

- Young, K.-h.; Yasuoka, S. Capacity Degradation Mechanisms in Nickel/Metal Hydride Batteries. Batteries 2016, 2, 3. [Google Scholar] [CrossRef]

- Martínez-Sánchez, R.; Molina-García, A.; Ramallo-González, A.P. Regeneration of Hybrid and Electric Vehicle Batteries: State-of-the-Art Review, Current Challenges, and Future Perspectives. Batteries 2024, 10, 101. [Google Scholar] [CrossRef]

- Yang, T.; Li, J.; Xin, Q.; Zhang, H.; Zeng, J.; Agbossou, K.; Du, C.; Xiao, J. Thermal Performance Analysis of a Prismatic Lithium-Ion Battery Module under Overheating Conditions. Batteries 2024, 10, 86. [Google Scholar] [CrossRef]

- Zhang, Z.; Ji, C.; Liu, Y.; Wang, Y.; Wang, B.; Liu, D. Effect of Aging Path on Degradation Characteristics of Lithium-Ion Batteries in Low-Temperature Environments. Batteries 2024, 10, 107. [Google Scholar] [CrossRef]

- Saxon, A.; Yang, C.; Santhanagopalan, S.; Keyser, M.; Colclasure, A. Li-Ion Battery Thermal Characterization for Thermal Management Design. Batteries 2024, 10, 136. [Google Scholar] [CrossRef]

- Xu, C.; Ma, C.; Souri, M.; Moztarzadeh, H.; Nasr Esfahani, M.; Jabbari, M.; Hosseinzadeh, E. Numerical Investigation of Thermal Management of a Large Format Pouch Battery Using Combination of CPCM and Liquid Cooling. Batteries 2024, 10, 113. [Google Scholar] [CrossRef]

- Sorensen, A.; Utgikar, V.; Belt, J. A Study of Thermal Runaway Mechanisms in Lithium-Ion Batteries and Predictive Numerical Modeling Techniques. Batteries 2024, 10, 116. [Google Scholar] [CrossRef]

- Teixeira, R.S.D.; Calili, R.F.; Almeida, M.F.; Louzada, D.R. Recurrent Neural Networks for Estimating the State of Health of Lithium-Ion Batteries. Batteries 2024, 10, 111. [Google Scholar] [CrossRef]

- Zhang, X.; Gong, A.; He, W.; Cao, Y.; He, H. A Lithium Battery Health Evaluation Method Based on Considering Disturbance Belief Rule Base. Batteries 2024, 10, 129. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, C.; Meng, X.; Zhang, L.; Li, X.; Zhang, W. A Novel Feature Engineering-Based SOH Estimation Method for Lithium-Ion Battery with Downgraded Laboratory Data. Batteries 2024, 10, 139. [Google Scholar] [CrossRef]

- Olona, A.; Castejón, L. Influence of the Arrangement of the Cells/Modules of a Traction Battery on the Spread of Fire in Case of Thermal Runaway. Batteries 2024, 10, 55. [Google Scholar] [CrossRef]

- Gerold, E.; Lerchbammer, R.; Antrekowitsch, H. Recovery of Cobalt, Nickel, and Lithium from Spent Lithium-Ion Batteries with Gluconic Acid Leaching Process: Kinetics Study. Batteries 2024, 10, 120. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, F.; Chen, F.; Chen, Z.; Zeng, H.; Zhang, T.; Shen, C. Recycling of Valuable Metals from the Priority Lithium Extraction Residue Obtained through Hydrogen Reduction of Spent Lithium Batteries. Batteries 2024, 10, 28. [Google Scholar] [CrossRef]

- Mondal, A.; Fu, Y.; Gao, W.; Mi, C.C. Pretreatment of Lithium Ion Batteries for Safe Recycling with High-Temperature Discharging Approach. Batteries 2024, 10, 37. [Google Scholar] [CrossRef]

- Zanoletti, A.; Carena, E.; Ferrara, C.; Bontempi, E. A Review of Lithium-Ion Battery Recycling: Technologies, Sustainability, and Open Issues. Batteries 2024, 10, 38. [Google Scholar] [CrossRef]

- Mottaghi, M.; Pearce, J.M. A Review of 3D Printing Batteries. Batteries 2024, 10, 110. [Google Scholar] [CrossRef]

- Schütte, M.; Degen, F.; Walter, H. Reducing Energy Consumption and Greenhouse Gas Emissions of Industrial Drying Processes in Lithium-Ion Battery Cell Production: A Qualitative Technology Benchmark. Batteries 2024, 10, 64. [Google Scholar] [CrossRef]

- Mohanty, D.; Hung, I.-M.; Hsieh, C.-T.; Pan, J.-P.; Liu, W.-R. Critical Review on High-Safety Lithium-Ion Batteries Modified by Self-Terminated Oligomers with Hyperbranched Architectures. Batteries 2024, 10, 65. [Google Scholar] [CrossRef]

- Jaffal, H.; Guanetti, L.; Rancilio, G.; Spiller, M.; Bovera, F.; Merlo, M. Battery Energy Storage System Performance in Providing Various Electricity Market Services. Batteries 2024, 10, 69. [Google Scholar] [CrossRef]

- Maddipatla, S.; Kong, L.; Pecht, M. Safety Analysis of Lithium-Ion Cylindrical Batteries Using Design and Process Failure Mode and Effect Analysis. Batteries 2024, 10, 76. [Google Scholar] [CrossRef]

- Rahman, M.; Baki, A. Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature. Energy Harvest. Syst. 2024, 11, 20230039. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, W.; Kang, L.; Zhang, Y.; Zhou, Y.; Jiang, S. Highly safe lithium vanadium oxide anode for fast-charging dendrite-free lithium-ion batteries. Nanotechnol. Rev. 2024, 13, 20230179. [Google Scholar] [CrossRef]

- Tendera, L.; Pegel, H.; Gonzalez, C.; Wycisk, D.; Fill, A.; Birke, K.P. Influence of temperature, state of charge and state of health on the thermal parameters of lithium-ion cells: Exploring thermal behavior and enabling fast-charging. Future Batter. 2024, 1, 100001. [Google Scholar] [CrossRef]

- González-Morales, J.; Mosa, J.; Ishiyama, S.; Rosero-Navarro, N.C.; Miura, A.; Tadanaga, K.; Aparicio, M. Carbon-Free Cathode Materials Based on Titanium Compounds for Zn-Oxygen Aqueous Batteries. Batteries 2024, 10, 94. [Google Scholar] [CrossRef]

- Bukya, M.; Meenakshi Reddy, R.; Doddipatla, A.; Kumar, R.; Mathur, A.; Gupta, M.; Garimella, A. Electro-thermal performance evaluation of a prismatic battery pack for an electric vehicle. High Temp. Mater. Process. 2024, 43, 20220311. [Google Scholar] [CrossRef]

- Nastasi, L.; Fiore, S. Environmental Assessment of Lithium-Ion Battery Lifecycle and of Their Use in Commercial Vehicles. Batteries 2024, 10, 90. [Google Scholar] [CrossRef]

- Nkembi, A.A.; Simonazzi, M.; Santoro, D.; Cova, P.; Delmonte, N. Comprehensive Review of Energy Storage Systems Characteristics and Models for Automotive Applications. Batteries 2024, 10, 88. [Google Scholar] [CrossRef]

- Al Muala, Z.A.; Bany Issa, M.A.; Bello Bugallo, P.M. Integrating Life Cycle Principles in Home Energy Management Systems: Optimal Load PV–Battery–Electric Vehicle Scheduling. Batteries 2024, 10, 138. [Google Scholar] [CrossRef]

- Salek, F.; Resalati, S.; Babaie, M.; Henshall, P.; Morrey, D.; Yao, L. A Review of the Technical Challenges and Solutions in Maximising the Potential Use of Second Life Batteries from Electric Vehicles. Batteries 2024, 10, 79. [Google Scholar] [CrossRef]

- Rufino Júnior, C.A.; Riva Sanseverino, E.; Gallo, P.; Koch, D.; Diel, S.; Walter, G.; Trilla, L.; Ferreira, V.J.; Pérez, G.B.; Kotak, Y.; et al. Towards to Battery Digital Passport: Reviewing Regulations and Standards for Second-Life Batteries. Batteries 2024, 10, 115. [Google Scholar] [CrossRef]

- Sarniak, M.T. Influence of Selected Weather Conditions on the Photovoltaic System Efficiency in Central Poland—Case Study. Adv. Sci. Technol. Res. J. 2024, 18, 177–186. [Google Scholar] [CrossRef] [PubMed]

- Wheeler, W.; Venet, P.; Bultel, Y.; Sari, A.; Riviere, E. Aging in First and Second Life of G/LFP 18650 Cells: Diagnosis and Evolution of the State of Health of the Cell and the Negative Electrode under Cycling. Batteries 2024, 10, 137. [Google Scholar] [CrossRef]

- Małek, A.; Marciniak, A.; Bartnik, G. The selection of an electric vehicle for the existing photovoltaic system—Case study in Polish climatic conditions. Arch. Autom. Engineer. Archiw. Mot. 2024, 103, 38–56. [Google Scholar] [CrossRef]

- Novoa, L.; Brouwer, J. Dynamics of an integrated solar photovoltaic and battery storage nanogrid for electric vehicle charging. J. Power Sources 2018, 399, 166–178. [Google Scholar] [CrossRef]

- Hassan, Q.; Abbas, M.; Tabar, V.; Tohidi, S.; Sameen, A.; Salman, H. Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption. Energy Harvest. Syst. 2024, 11, 20220050. [Google Scholar] [CrossRef]

- Lewicki, W.; Niekurzak, M.; Sendek-Matysiak, E. Electromobility Stage in the Energy Transition Policy—Economic Dimension Analysis of Charging Costs of Electric Vehicles. Energies 2024, 17, 1934. [Google Scholar] [CrossRef]

- Keelin, T.W. The Metalog Distributions. Decis. Anal. 2016, 13, 243–277. [Google Scholar] [CrossRef]

- Keelin, T.W.; Howard, R.A. The Metalog Distributions: Virtually Unlimited Shape Flexibility, Combining Expert Opinion in Closed Form, and Bayesian Updating in Closed Form; Stanford University: Stanford, CA, USA, 2021. [Google Scholar]

- Available online: https://www.bayesfusion.com/2022/06/27/genie-4-0/ (accessed on 21 April 2024).

- Available online: https://blogs.sas.com/content/iml/2023/02/22/metalog-distribution.html (accessed on 19 December 2023).

| Cell | Capacity (A/h) | Percent from Maximum Capacity | Working Time | Reason for Stopping |

|---|---|---|---|---|

| 1 | 5.445 | 83.77% | 01:05:22 | Discharge minimum voltage |

| 2 | 5.316 | 81.79% | 01:03:49 | Discharge minimum voltage |

| 3 | 5.087 | 78.25% | 01:01:03 | Discharge minimum voltage |

| 4 | 5.245 | 80.7% | 01:02:59 | Discharge minimum voltage |

| 5 | 5.015 | 77.16% | 01:00:13 | Discharge minimum voltage |

| 6 | 5.13 | 78.93% | 01:01:36 | Discharge minimum voltage |

| 7 | 5.158 | 79.35% | 01:01:55 | Discharge minimum voltage |

| 8 | 5.18 | 79.69% | 01:02:11 | Discharge minimum voltage |

| 9 | 4.962 | 76.34% | 00:59:34 | Discharge minimum voltage |

| 10 | 5.084 | 78.22% | 01:01:02 | Discharge minimum voltage |

| 11 | 5.164 | 79.45% | 01:02:00 | Discharge minimum voltage |

| 12 | 5.204 | 80.06% | 01:02:28 | Discharge minimum voltage |

| 13 | 5.071 | 78.01% | 01:00:52 | Discharge minimum voltage |

| 14 | 5.146 | 79.16% | 01:01:46 | Discharge minimum voltage |

| 15 | 5.146 | 79.18% | 01:01:46 | Discharge minimum voltage |

| 16 | 5.039 | 77.52% | 01:00:30 | Discharge minimum voltage |

| 17 | 5.01 | 77.08% | 01:00:08 | Discharge minimum voltage |

| 18 | 5.063 | 77.9% | 01:00:46 | Discharge minimum voltage |

| 19 | 5.234 | 80.52% | 01:02:49 | Discharge minimum voltage |

| 20 | 5.206 | 80.09% | 01:02:29 | Discharge minimum voltage |

| 21 | 4.995 | 76.85% | 00:59:59 | Discharge minimum voltage |

| 22 | 5.236 | 80.55% | 01:02:51 | Discharge minimum voltage |

| 23 | 5.309 | 81.67% | 01:03:44 | Discharge minimum voltage |

| 24 | 5.489 | 84.44% | 01:05:55 | Discharge minimum voltage |

| 25 | 5.24 | 80.61% | 01:02:54 | Discharge minimum voltage |

| 26 | 5.42 | 83.39% | 01:05:03 | Discharge minimum voltage |

| 27 | 5.508 | 84.74% | 01:06:07 | Discharge minimum voltage |

| 28 | 5.633 | 86.67% | 01:07:39 | Discharge minimum voltage |

| Count | 28 |

|---|---|

| Minimum | 4.962 |

| Maximum | 5.633 |

| Mean | 5.20482 |

| StdDev | 0.169515 |

| Probability | |

|---|---|

| 0.05 | 4.994999885559 |

| 0.25 | 5.084000110626 |

| 0.5 | 5.179999828339 |

| 0.75 | 5.309000015259 |

| 0.95 | 5.507999897003 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caban, J.; Małek, A.; Kroczyński, D. A Method for Assessing the Technical Condition of Traction Batteries Using the Metalog Family of Probability Distributions. Energies 2024, 17, 3096. https://doi.org/10.3390/en17133096

Caban J, Małek A, Kroczyński D. A Method for Assessing the Technical Condition of Traction Batteries Using the Metalog Family of Probability Distributions. Energies. 2024; 17(13):3096. https://doi.org/10.3390/en17133096

Chicago/Turabian StyleCaban, Jacek, Arkadiusz Małek, and Dariusz Kroczyński. 2024. "A Method for Assessing the Technical Condition of Traction Batteries Using the Metalog Family of Probability Distributions" Energies 17, no. 13: 3096. https://doi.org/10.3390/en17133096

APA StyleCaban, J., Małek, A., & Kroczyński, D. (2024). A Method for Assessing the Technical Condition of Traction Batteries Using the Metalog Family of Probability Distributions. Energies, 17(13), 3096. https://doi.org/10.3390/en17133096