Evaluating Electrification of Fossil-Fuel-Fired Boilers for Decarbonization Using Discrete-Event Simulation

Abstract

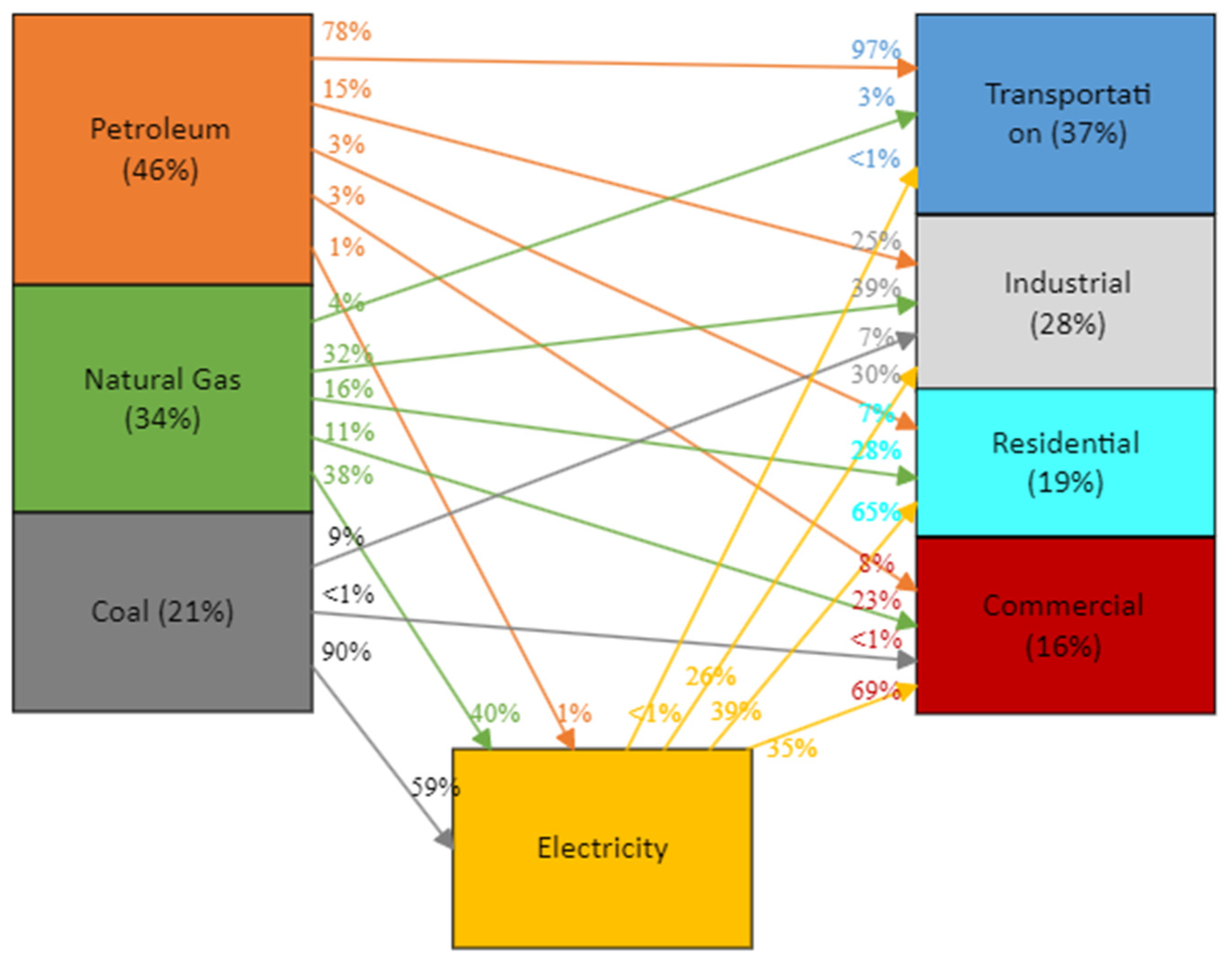

1. Introduction to Decarbonization

1.1. Decarbonization of Industrial Boiler Systems

1.2. Objectives

- Evaluate and compare the energy usage, operating cost, and CO2 emissions of fossil-fuel-fired boilers and electrical boilers for decarbonization.

- Utilize the heat energy balance and calculate the heat energy requirement from boiler systems based on the simulated hourly temperature over a year.

- Identify the system losses in a boiler and estimate the electrical boiler capacity required to replace the current fossil-fuel-fired boiler.

- Develop a user-driven and interactive simulation program in Microsoft Excel® where the user can change the input parameters to evaluate the boiler system.

- Integrate Monte Carlo Simulation in the program that can estimate the hourly temperature based on the randomness of the input.

- Develop cases to calculate energy and fuel consumption based on different scenarios of the system for program verification.

- Provide a means to analyze the boiler and steam system fuel usage and behavior for important managerial decisions.

2. Materials and Methods

2.1. Energy Calculating Factors

2.2. Case Development

2.3. Heat Balance

2.4. Simulation Tool Development

3. Results

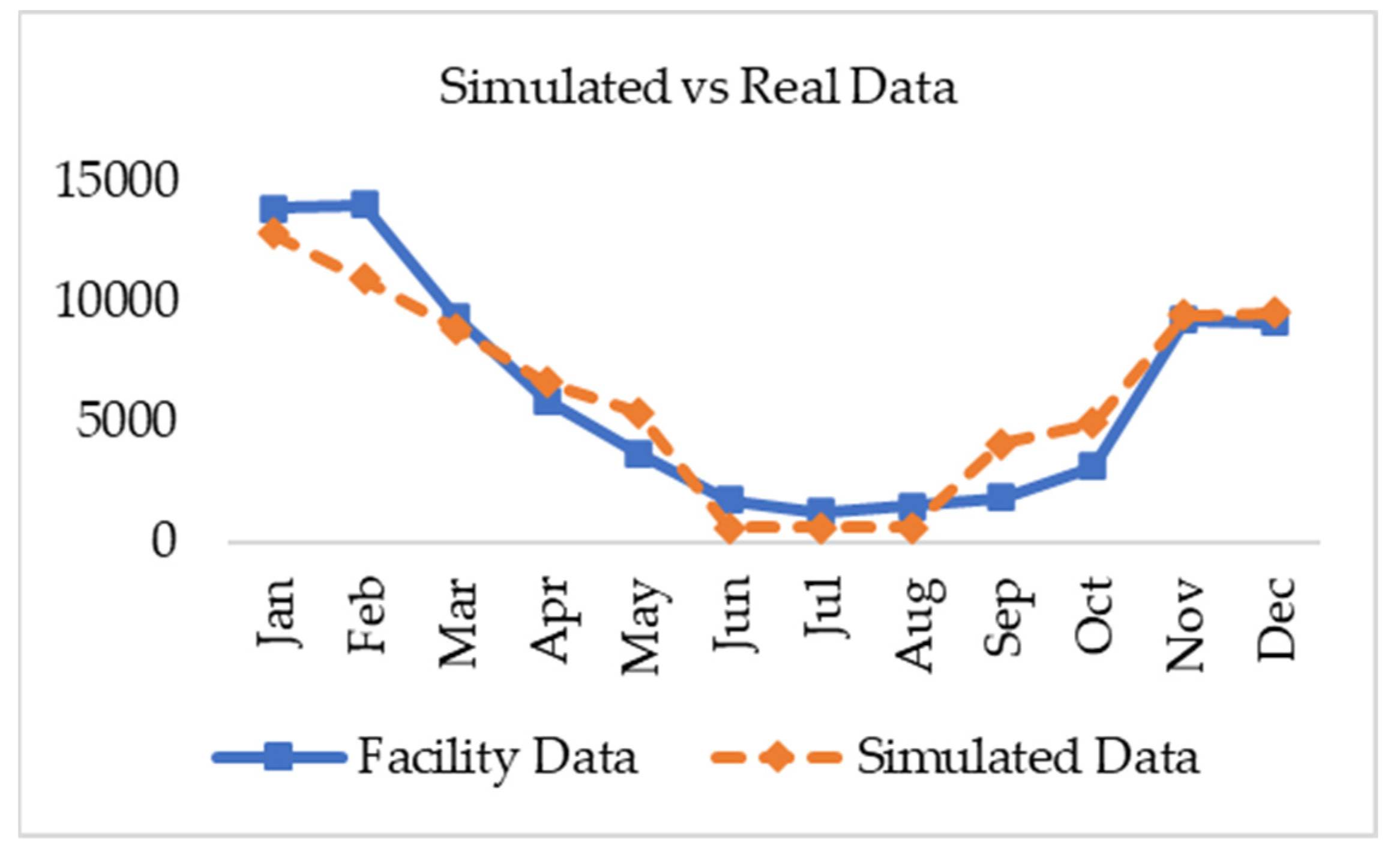

3.1. Compare Simulated Results with Real Data

3.2. Compare Simulated Results with Real Data

3.3. Sensitivity Analysis

4. Conclusions

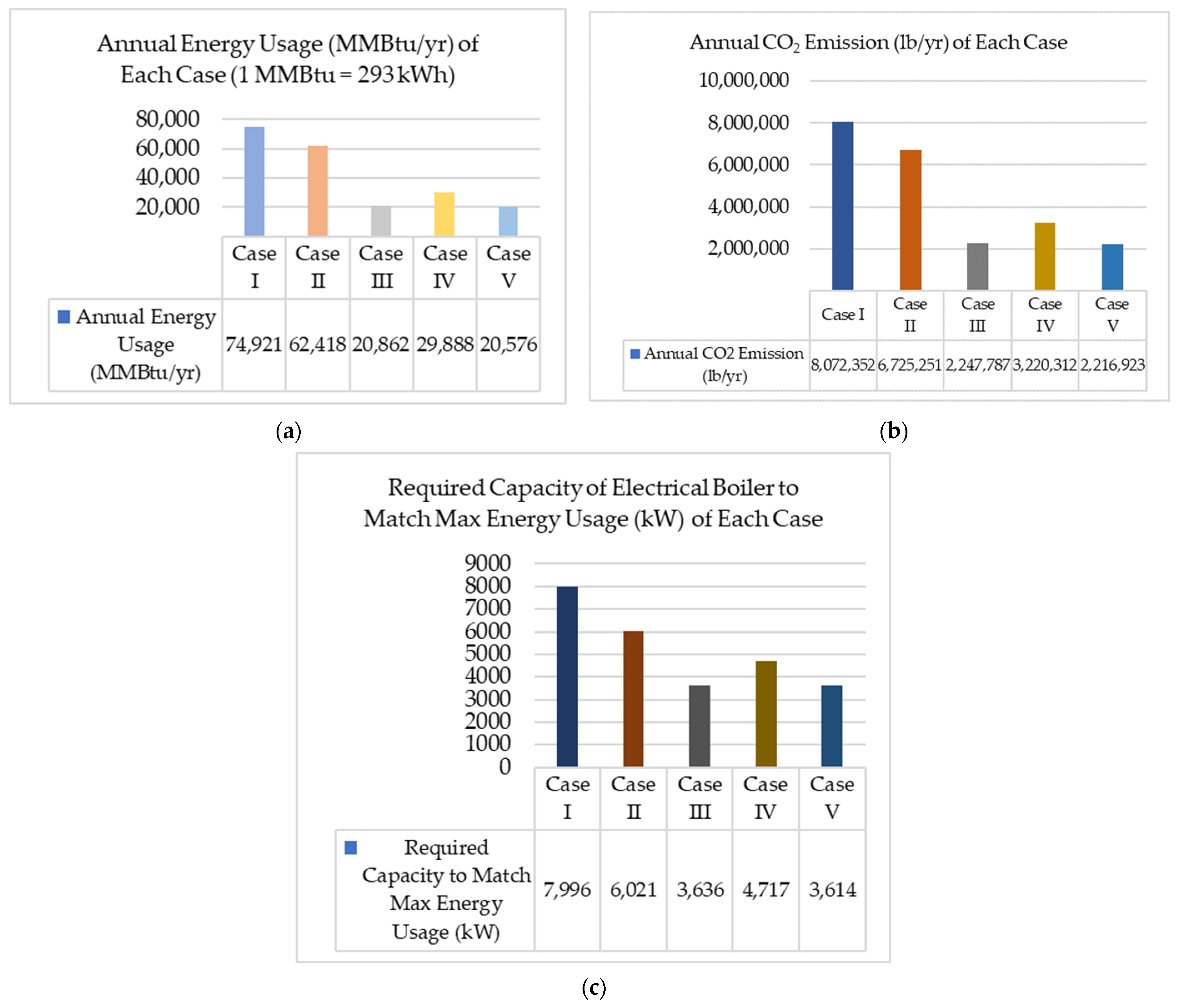

- The energy consumption of the boiler is high, with the same operating condition in a colder climate than in a temperate climate. A higher-capacity electrical boiler will be required to replace the current boiler.

- The energy consumption pattern and peak heat demand depend on the type of end user. Space heating requires heat energy throughout the day, while any process heating operation requires energy mostly during operational hours.

- Changing or improving the operating parameters of the boiler slightly reduces energy consumption, and therefore a lower-capacity electrical boiler can be used.

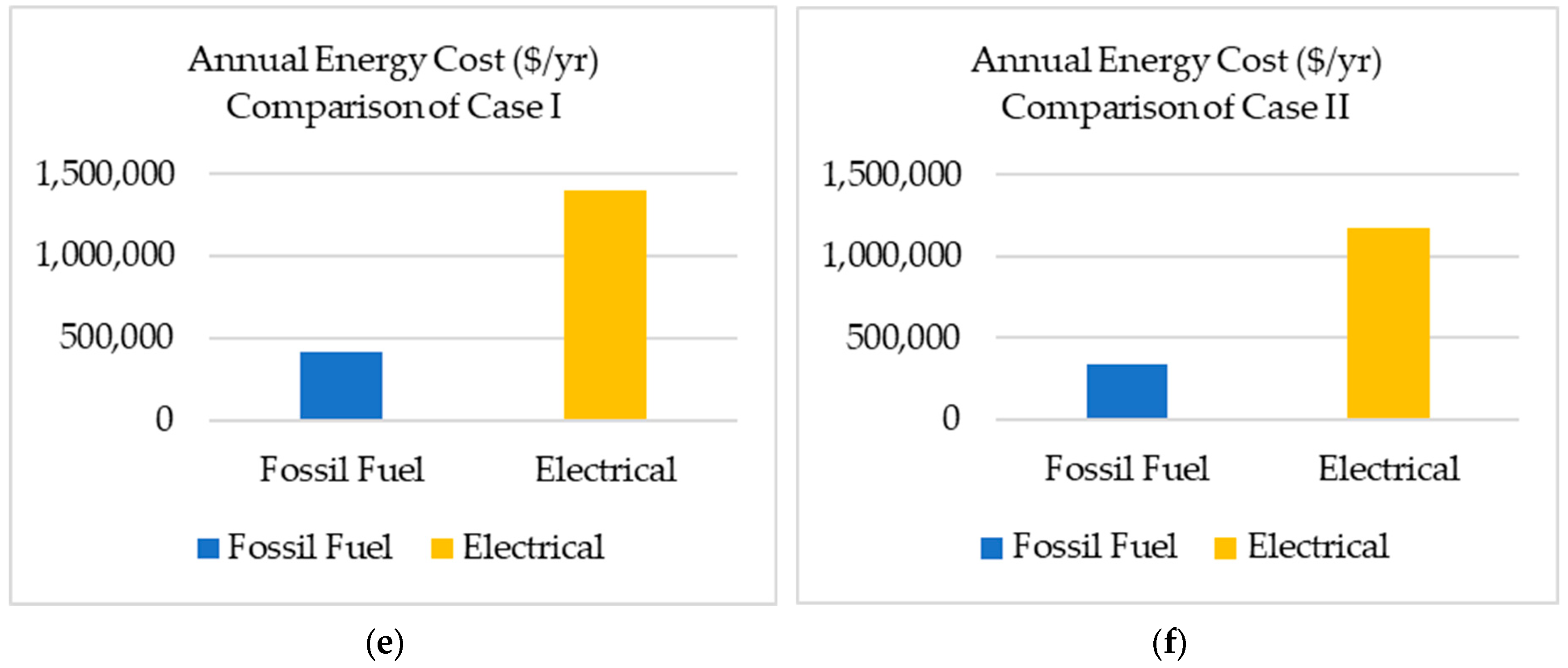

- Electrical boilers consume approximately 18% less energy on average from the simulated cases compared to fossil-fuel boilers. This is because electric boilers do not incorporate flue losses.

- The operating cost of electrical boilers is usually 240% higher on average from simulated cases than that of fossil-fuel boilers.

- The study does not include the individual operating hours of each boiler throughout the year. Including this factor in the input will more realistically reflect the energy usage of the individual boiler.

- It is assumed that the boiler operates all the time, as indicated by the facility’s working hours, and manual operation or control of the boiler needs to be addressed in the program. It is possible to consider the manual turn-on and turn-off of the boiler to calculate the energy consumption more accurately.

- To better address the changing temperature, a smaller time interval frequency than 1 h should be considered.

- Including other end users will make this simulation more usable for diverse applications.

- A wider range of energy per unit of fuel and CO2 emission values can be used to estimate a range of fuel usage and CO2 emissions by the boiler.

- Financial calculations can be included in the simulation result to better aid decision-making.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Smil, V. Energy and Civilization: A History—Vaclav Smil. Available online: https://vaclavsmil.com/2017/05/08/energy-and-civilization-a-history (accessed on 22 May 2024).

- Smil, V. What We Need to Know about the Pace of Decarbonization. Available online: https://www.schoolofpublicpolicy.sk.ca/documents/research/policy-briefs/jsgs-policybriefs-pace-of-decarbonization_web.pdf (accessed on 23 May 2024).

- United States Environmental Protection Agency. Global Greenhouse Gas Emissions Data. US Environmental Protection Agency. Available online: https://www.epa.gov/ghgemissions/global-greenhouse-gas-emissions-data (accessed on 20 January 2023).

- Hodgson, D.; Vass, T.; Levi, P.; Hugues, P. Industry—Analysis. IEA. Available online: https://www.iea.org/reports/industry (accessed on 28 January 2023).

- U.S. Environmental Protection Agency (EPA). Inventory of U.S. Greenhouse Gas Emissions and Sinks 1990–2018. 2020. Available online: https://www.epa.gov/sites/default/files/2020-04/documents/fastfacts-1990-2018.pdf (accessed on 28 January 2023).

- UNFCCC. The Paris Agreement. United Nations Framework Convention on Climate Change. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 20 January 2023).

- America’s Clean Energy Frontier: The Pathway to a Safer Climate Future. NRDC. Available online: https://www.nrdc.org/resources/americas-clean-energy-frontier-pathway-safer-climate-future (accessed on 23 January 2023).

- Nadel, S. Electrification in the Transportation, Buildings, and Industrial Sectors: A Review of Opportunities, Barriers, and Policies. Current Sustainable/Renewable Energy Reports 2019. Curr. Sustain./Renew. Energy Rep 2019, 6, 158–168. [Google Scholar] [CrossRef]

- Zuberi, M.J.S.; Hasanbeigi, A.; Morrow, W. Electrification of Industrial Boilers in the USA: Potentials, Challenges, and Policy Implications. Energy Effic. 2022, 15, 70. [Google Scholar] [CrossRef]

- Schoeneberger, C.; Zhang, J.; McMillan, C.; Dunn, J.B.; Masanet, E. Electrification Potential of U.S. Industrial Boilers and Assessment of the GHG Emissions Impact. Adv. Appl. Energy. 2022, 5, 100089. [Google Scholar] [CrossRef]

- EIA. Where Greenhouse Gases Come from—U.S. Energy Information Administration (EIA). Eia.gov. Available online: https://www.eia.gov/energyexplained/energy-and-the-environment/where-greenhouse-gases-come-from.php (accessed on 27 January 2023).

- Brown, T.W.; Bischof-Niemz, T.; Blok, K.; Breyer, C.; Lund, H.; Mathiesen, B.V. Response to “Burden of Proof: A Comprehensive Review of the Feasibility of 100% Renewable-Electricity Systems”. Renew. Sustain. Energy Rev. 2018, 92, 834–847. [Google Scholar] [CrossRef]

- Loftus, P.J.; Cohen, A.M.; Long, J.C.S.; Jenkins, J.D. A Critical Review of Global Decarbonization Scenarios: What Do They Tell Us about Feasibility? Wiley Interdiscip. Rev. Clim. Chang. 2014, 6, 93–112. [Google Scholar] [CrossRef]

- Manufacturing Thermal Energy Use in 2014|NREL Data Catalog. data.nrel.gov. Available online: https://data.nrel.gov/submissions/118 (accessed on 22 January 2023).

- Einstein, D.; Worrell, E.; Khrushch, M. Steam Systems in Industry: Energy Use and Energy Efficiency Improvement Potentials. 2001. eScholarship University of California. Available online: https://escholarship.org/uc/item/3m1781f1 (accessed on 22 January 2023).

- U.S. Dept. of Energy (DOE). Manufacturing Energy and Carbon Footprint. 2014 MECS. Sector: Forest Products (NAICS 321, 322). 2018. Available online: https://www.energy.gov/sites/prod/files/2018/10/f56/2014_mecs_forest_products_energy_footprint.pdf (accessed on 20 January 2023).

- U.S. Dept. of Energy (DOE). Manufacturing Energy and Carbon Footprint. 2014 MECS. Sector: Petroleum Refining (NAICS 324110). 2018. Available online: https://www.energy.gov/sites/prod/files/2018/10/f56/2014_mecs_petroleum_refining_energy_footprint.pdf (accessed on 28 January 2023).

- U.S. Dept. of Energy (DOE). Manufacturing Energy and Carbon Footprint. 2014 MECS. Sector: Chemicals (NAICS 325). 2018. Available online: https://www.energy.gov/sites/prod/files/2018/10/f56/2014_mecs_chemicals_energy_footprint_0.pdf (accessed on 13 January 2023).

- U.S. Dept. of Energy (DOE). Manufacturing Energy and Carbon Footprint. 2014 MECS. Sector: Iron and Steel (NAICS 331110, 3312). 2018. Available online: https://www.energy.gov/sites/prod/files/2018/10/f56/2014_mecs_iron_steel_energy_footprint.pdf (accessed on 3 February 2023).

- The White House. FACT SHEET: President Biden Sets 2030 Greenhouse Gas Pollution Reduction Target Aimed at Creating Good-Paying Union Jobs and Securing U.S. Leadership on Clean Energy Technologies. The White House. Available online: https://www.whitehouse.gov/briefing-room/statements-releases/2021/04/22/fact-sheet-president-biden-sets-2030-greenhouse-gas-pollution-reduction-target-aimed-at-creating-good-paying-union-jobs-and-securing-u-s-leadership-on-clean-energy-technologies/ (accessed on 4 January 2023).

- Abbasi, M.H.; Abdullah, B.; Ahmad, M.W.; Rostami, A.; Cullen, J. Heat Transition in the European Building Sector: Overview of the Heat Decarbonisation Practices through Heat Pump Technology. Sustain. Energy Technol. Assess 2021, 48, 101630. [Google Scholar] [CrossRef]

- Smith, M.; Bevacqua, A.; Tembe, S.; Lal, P. Life Cycle Analysis (LCA) of Residential Ground Source Heat Pump Systems: A Comparative Analysis of Energy Efficiency in New Jersey. Sustain. Energy Technol. Assess 2021, 47, 101364. [Google Scholar] [CrossRef]

- Rodrigues, A.L.; Seixas, S.R. Battery-Electric Buses and Their Implementation Barriers: Analysis and Prospects for Sustainability. Sustain. Energy Technol. Assess 2022, 51, 101896. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Kirshbaum, L.A.; Collison, B.; Gardiner, D. Electrifying U.S. Industry: Technology and Process-Based Approach to Decarbonization; Global Efficiency Intelligence: Tampa Bay, FL, USA, 2021; Available online: https://www.globalefficiencyintel.com/electrifying-us-industry (accessed on 28 January 2023).

- Madeddu, S.; Ueckerdt, F.; Pehl, M.; Peterseim, J.; Lord, M.; Kumar, K.A.; Krüger, C.; Luderer, G. The CO2 Reduction Potential for the European Industry via Direct Electrification of Heat Supply (Power-To-Heat). Environ. Res. Lett. 2020, 15, 124004. [Google Scholar] [CrossRef]

- Consumption & Efficiency—U.S. Energy Information Administration (EIA). www.eia.gov. Available online: https://www.eia.gov/consumption/manufacturing/data/201 (accessed on 28 January 2023).

- Bühler, F.; Müller Holm, F.; Elmegaard, B. Potentials for the Electrification of Industrial Processes in Denmark: 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems. In Proceedings of the ECOS 2019: 32nd International Conference on Efficiency, Cost, Optimization, Simulation and Environmental Impact of Energy Systems 2019; Available online: https://orbit.dtu.dk/files/189357718/ECOS2019_B_hler_Fabian_Article_for_proceedings_PDF.pdf (accessed on 27 January 2023).

- Wei, M.; McMillan, C.A.; de la Rue du Can, S. Electrification of Industry: Potential, Challenges and Outlook. Curr. Sustain. Renew. Energy Rep. 2019, 6, 140–148. [Google Scholar] [CrossRef]

- Heinen, S.; Mancarella, P.; O’Dwyer, C.; O’Malley, M. Heat Electrification: The Latest Research in Europe. IIEEE Power Energy Mag. 2018, 16, 69–78. [Google Scholar] [CrossRef]

- Wiertzema, H.; Åhman, M.; Harvey, S. Bottom-up Methodology for Assessing Electrification Options for Deep Decarbonisation of Industrial Processes: ECEEE Industrial Efficiency. ECEEE Ind. Summer Study Proc. 2018, 2018, 389–397. Available online: https://www.eceee.org/library/conference_proceedings/eceee_Industrial_Summer_Study/2018/4-technology-products-and-system-optimisation/bottom-up-methodology-for-assessing-electrification-options-for-deep-decarbonisation-of-industrial-processes/ (accessed on 22 January 2023).

- Lamon, E.; Raftery, P.; Schiavon, S. Boiler Retrofits and Decarbonization in Existing Buildings: HVAC Designer Interviews. Escholarship.Org. 2022. Available online: https://escholarship.org/uc/item/6k4369zv (accessed on 23 May 2024).

- Steinberg, D.; Bielen, D.; Eichman, J.; Eurek, K.; Logan, J.; Mai, T.; Mcmillan, C.; Parker, A.; Vimmerstedt, L.; Wilson, E. Electrification & Decarbonization: Exploring U.S. Energy Use and Greenhouse Gas Emissions in Scenarios with Widespread Electrification and Power Sector Decarbonization. 2017. Available online: https://www.nrel.gov/docs/fy17osti/68214.pdf (accessed on 25 January 2023).

- Jia, L.; Cheng, P.; Yu, Y.; Chen, S.; Wang, C.; He, L.; Nie, H.; Wang, J.; Zhang, J.; Fan, B.; et al. Regeneration Mechanism of a Novel High-Performance Biochar Mercury Adsorbent Directionally Modified by Multimetal Multilayer Loading. Environ. Manage. 2023, 326, 116790. [Google Scholar] [CrossRef]

- Schiro, F.; Stoppato, A.; Benato, A. Modelling and Analyzing the Impact of Hydrogen Enriched Natural Gas on Domestic Gas Boilers in a Decarbonization Perspective. Carbon Resour. Convers. 2020, 3, 122–129. [Google Scholar] [CrossRef]

- Regulagadda, P.; Dincer, I.; Naterer, G.F. Exergy Analysis of a Thermal Power Plant with Measured Boiler and Turbine Losses. Appl. Therm. Eng. 2010, 30, 970–976. [Google Scholar] [CrossRef]

- Kaya, D.; Eyidogan, M. Energy Conservation Opportunities in an Industrial Boiler System. J. Energy Eng. 2010, 136, 18–25. [Google Scholar] [CrossRef]

- Hasanuzzaman, M.D.; Rahim, N.A. (Eds.) Energy for Sustainable Development: Demand, Supply, Conversion and Management; Elsevier Academic Press: Cambridge, MA, USA, 2019; Available online: https://shop.elsevier.com/books/energy-for-sustainable-development/hasanuzzaman/978-0-12-814645-3 (accessed on 12 January 2023).

- Rightor, E.; Whitlock, A.; Elliott, R. Beneficial Electrification in Industry. 2020. Available online: https://www.aceee.org/sites/default/files/pdfs/ie2002.pdf (accessed on 12 January 2023).

- Lord, M. Zero Carbon Industry Plan: Electrifying Industry. Beyond Zero Emissions, Melbourne, Australia. 2018. Available online: https://bze.org.au/wp-content/uploads/2020/12/electrifying-industry-bze-report-2018.pdf (accessed on 26 January 2023).

- Larson, E. Net Zero America: Potential Pathways, Infrastructure, and Impacts; Princeton University: Princeton, NJ, USA, 2020; Available online: https://netzeroamerica.princeton.edu/img/Princeton_NZA_Interim_Report_15_Dec_2020_FINAL.pdf (accessed on 29 January 2023).

- Laubscher, R.; Rousseau, P. CFD Study of Pulverized Coal-Fired Boiler Evaporator and Radiant Superheaters at Varying Loads. Appl. Therm. Eng. 2019, 160, 114057. [Google Scholar] [CrossRef]

- von Bohnstein, M.; Richter, M.; Graeser, P.; Schiemann, M.; Ströhle, J.; Epple, B. 3D CFD Simulation of a 250 MWel Oxy-Fuel Boiler with Evaluation of Heat Radiation Calculation. Renew. Sustain. Energy Rev. 2021, 137, 110601. [Google Scholar] [CrossRef]

- Badur, J.; Ziółkowski, P.; Sławiński, D.; Kornet, S. An Approach for Estimation of Water Wall Degradation within Pulverized-Coal Boilers. Energy 2015, 92, 142–152. [Google Scholar] [CrossRef]

- Żymełka, P.; Nabagło, D.; Janda, T.; Madejski, P. Online Monitoring System of Air Distribution in Pulverized Coal-Fired Boiler Based on Numerical Modeling. Arch. Thermodyn. 2017, 38, 109–125. [Google Scholar] [CrossRef]

- Madejski, P.; Taler, D.; Taler, J. Modeling of Transient Operation of Steam Superheater in CFB Boiler. Energy 2019, 182, 965–974. [Google Scholar] [CrossRef]

- Zima, W. Simulation of Rapid Increase in the Steam Mass Flow Rate at a Supercritical Power Boiler Outlet. Energy 2019, 173, 995–1005. [Google Scholar] [CrossRef]

- Taler, J.; Zima, W.; Ocłoń, P.; Grądziel, S.; Taler, D.; Cebula, A.; Jaremkiewicz, M.; Korzeń, A.; Cisek, P.; Kaczmarski, K.; et al. Mathematical Model of a Supercritical Power Boiler for Simulating Rapid Changes in Boiler Thermal Loading. Energy 2019, 175, 580–592. [Google Scholar] [CrossRef]

- Chen, T.; Zhang, Y.; Liao, M.; Wang, W. Coupled Modeling of Combustion and Hydrodynamics for a Coal-Fired Supercritical Boiler. Fuel 2019, 240, 49–56. [Google Scholar] [CrossRef]

- Camaraza-Medina, Y.; Retirado-Mediaceja, Y.; Hernandez-Guerrero, A.; Luis Luviano-Ortiz, J. Energy Efficiency Indicators of the Steam Boiler in a Power Plant of Cuba. Therm. Sci. Eng. Prog 2021, 23, 100880. [Google Scholar] [CrossRef]

- Drosatos, P.; Nikolopoulos, N.; Kakaras, E. An In-House Built Code Incorporated into CFD Model for the Simulation of Boiler’s Convection Section. Fuel Process. Technol. 2020, 202, 106333. [Google Scholar] [CrossRef]

- Madejski, P. Numerical Study of a Large-Scale Pulverized Coal-Fired Boiler Operation Using CFD Modeling Based on the Probability Density Function Method. Appl. Therm. Eng. 2018, 145, 352–363. [Google Scholar] [CrossRef]

- Li, Z.; Miao, Z.; Shen, X.; Li, J. Prevention of Boiler Performance Degradation under Large Primary Air Ratio Scenario in a 660 MW Brown Coal Boiler. Energy 2018, 155, 474–483. [Google Scholar] [CrossRef]

- Ghaffari, A.; Chaibakhsh, A.; Lucas, C. Soft Computing Approach for Modeling Power Plant with a Once-through Boiler. Eng. Appl. Artif. Intell. 2007, 20, 809–819. [Google Scholar] [CrossRef]

- Wang, H.; Jin, D.; Liu, X.; Zhang, C. Analytical and Numerical Investigations on the High Temperature Upgrading Solution of Subcritical Boilers. Appl. Therm. Eng. 2022, 200, 117628. [Google Scholar] [CrossRef]

- Bennett, G.; Elwell, C. Effect of Boiler Oversizing on Efficiency: A Dynamic Simulation Study. Build. Serv. Eng. Res. Technol. 2020, 41, 709–726. [Google Scholar] [CrossRef]

- Zhang, Q.; Yi, H.; Yu, Z.; Gao, J.; Wang, X.; Lin, H.; Shen, B. Energy-Exergy Analysis and Energy Efficiency Improvement of Coal-Fired Industrial Boilers Based on Thermal Test Data. Appl. Therm. Eng. 2018, 144, 614–627. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, M.; Liu, Y.; Yin, L.; Zhou, X.R.; Xu, J.F.; Zhang, X. Fuzzy Modeling of Boiler Efficiency in Power Plants. Inf. Sci. 2021, 542, 391–405. [Google Scholar] [CrossRef]

- Said, S.M.; Hamouda, A.S.; Mahmaoud, H.; Abd-Elwahab, S. Computer-Based Boiler Efficiency Improvement. Environ. Prog. Sustain. Energy 2019, 38, 13161. [Google Scholar] [CrossRef]

- Erbas, O. Investigation of Factors Affecting Thermal Performance in a Coal—Fired Boiler and Determination of Thermal Losses by Energy Balance Method. Case Stud. Therm. Eng. 2021, 26, 101047. [Google Scholar] [CrossRef]

- American Society Mechanical Engineering. PTC 4-2013 Fired Steam Generators; ASME: New York City, NY, USA, 2013. [Google Scholar]

- Wang, P.; Wang, C.; Du, Y.; Feng, Q.; Wang, Z.; Yao, W.; Liu, J.; Zhang, J.; Che, D. Experiments and Simulation on Co-Combustion of Semicoke and Coal in a Full-Scale Tangentially Fired Utility Boiler. Energy Fuels 2019, 33, 3012–3027. [Google Scholar] [CrossRef]

- Klačková, I.; Zajačko, I.; Lenhard, R.; Gritsuk, I.; Wiecek, D. Simulation of Wood Biomass Combustion in Hot Water Boiler. IOP Conf. Ser. Mater. Sci. Eng. 2020, 776, 012033. [Google Scholar] [CrossRef]

- University of Illinois Urbana-Champaign (UIUC). Lower and Higher Heating Values of Gas, Liquid and Solid Fuels. 2018. Available online: https://courses.engr.illinois.edu/npre470/sp2018/web/Lower_and_Higher_Heating_Values_of_Gas_Liquid_and_Solid_Fuels.pdf (accessed on 28 January 2023).

| Higher Heating Value of Fuels | Btu/lb 1 |

|---|---|

| Natural Gas | 22,453 |

| #2 Fuel Oil | 18,446 |

| #6 Fuel Oil | 17,691 |

| Typical Coal | 11,723 |

| Enthalpy, Btu/lb | ||||

|---|---|---|---|---|

| Pressure, psia | Temp, F | Saturated Liquid | Latent Heat | Steam |

| 0.0886 | 32.02 | 0.00 | 1075.5 | 1075.5 |

| 0.1 | 35.02 | 3.03 | 1073.8 | 1076.8 |

| 0.2 | 45.45 | 13.50 | 1067.9 | 1081.4 |

| 0.2 | 53.16 | 21.22 | 1063.5 | 1084.7 |

| 0.3 | 64.48 | 32.54 | 1057.1 | 1089.7 |

| 0.4 | 72.87 | 40.92 | 1052.4 | 1093.3 |

| 0.5 | 79.59 | 47.62 | 1048.6 | 1096.3 |

| 0.6 | 85.22 | 53.25 | 1045.5 | 1098.7 |

| 0.7 | 90.09 | 58.10 | 1042.7 | 1100.8 |

| 0.8 | 94.38 | 62.39 | 1040.3 | 1102.6 |

| 0.9 | 98.24 | 66.24 | 1038.1 | 1104.3 |

| 1.0 | 101.74 | 69.77 | 1036.1 | 1105.8 |

| 2.0 | 126.07 | 94.03 | 1022.1 | 1116.2 |

| 3.0 | 141.47 | 109.42 | 1013.2 | 1122.6 |

| 4.0 | 152.96 | 120.92 | 1006.4 | 1127.3 |

| 5.0 | 162.24 | 130.20 | 1000.9 | 1131.1 |

| 6.0 | 170.05 | 138.03 | 996.2 | 1134.2 |

| 7.0 | 176.84 | 144.83 | 992.1 | 1136.9 |

| 8.0 | 182.86 | 150.87 | 988.5 | 1139.3 |

| 9.0 | 188.27 | 156.30 | 985.1 | 1141.4 |

| 10.0 | 193.21 | 161.26 | 982.1 | 1143.3 |

| 14.696 | 212.00 | 180.17 | 970.3 | 1150.5 |

| 15.0 | 213.03 | 181.21 | 969.7 | 1150.9 |

| 20.0 | 227.96 | 196.27 | 960.1 | 1156.3 |

| Month | Facility Data (MMBtu/Month) 2 | Simulated Data (MMBtu/Month) | Error Percentage |

|---|---|---|---|

| January | 13,958 | 12,910 | 7.51% |

| February | 14,121 | 10,994 | 22.14% |

| March | 9436 | 8958 | 5.06% |

| April | 5921 | 6662 | −12.50% |

| May | 3706 | 5445 | −46.91% |

| June | 1776 | 593 | 66.61% |

| July | 1244 | 611 | 50.94% |

| August | 1497 | 609 | 59.32% |

| September | 1835 | 4109 | −123.89% |

| October | 3140 | 4963 | −58.04% |

| November | 9311 | 9472 | −1.73% |

| December | 9163 | 9591 | −4.67% |

| Total | 75,110 | 74,916 | 0.26% |

| HDD of Location | CDD of Location | |||

|---|---|---|---|---|

| Month | Case I | Case II | Case I | Case II |

| January | 867 | 433 | 0 | 10 |

| February | 810 | 302 | 0 | 36 |

| March | 502 | 281 | 16 | 50 |

| April | 276 | 142 | 52 | 105 |

| May | 123 | 11 | 142 | 320 |

| June | 0 | 1 | 339 | 470 |

| July | 0 | 0 | 459 | 547 |

| August | 0 | 0 | 436 | 423 |

| September | 7 | 31 | 237 | 280 |

| October | 78 | 197 | 96 | 86 |

| November | 582 | 340 | 8 | 46 |

| December | 596 | 499 | 2 | 17 |

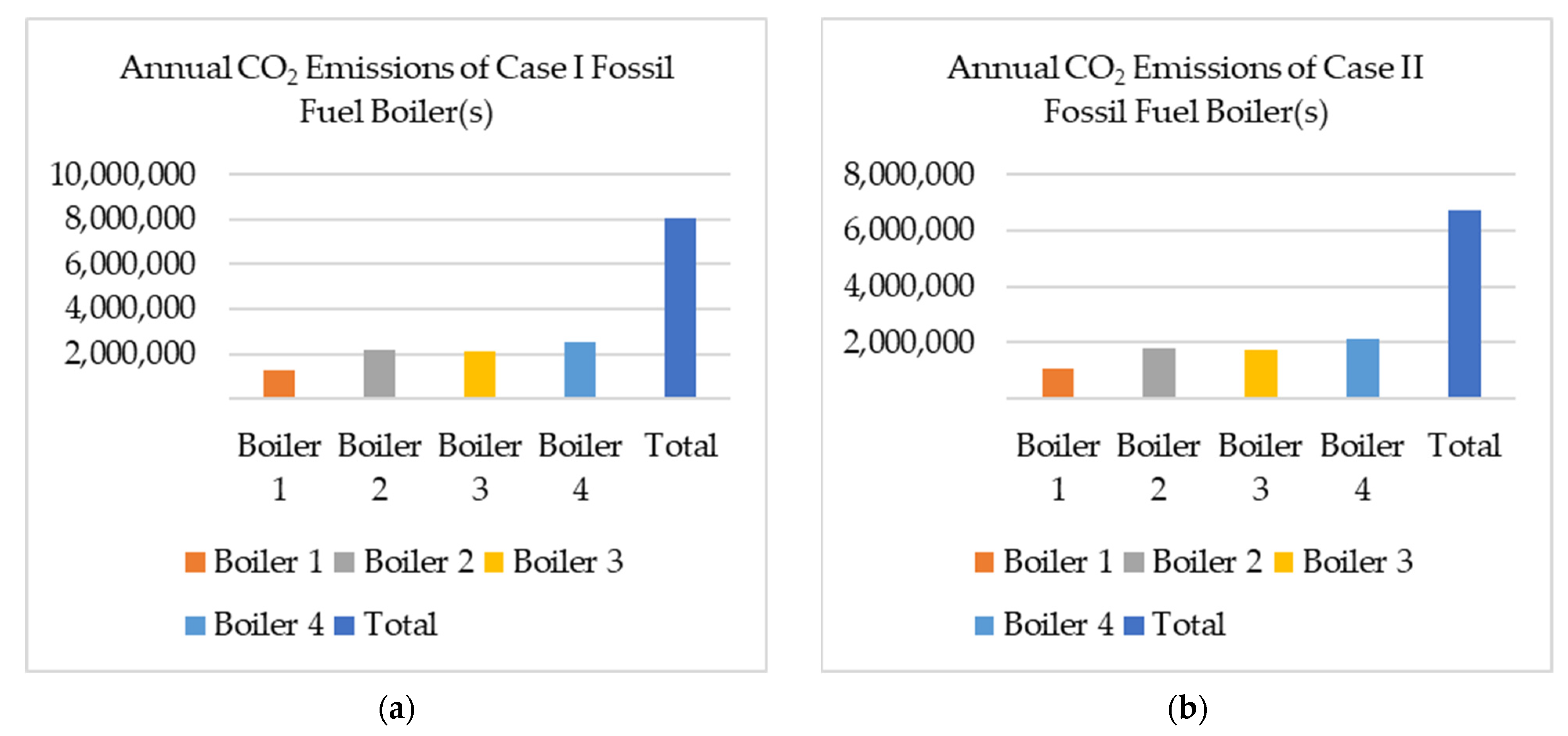

| Annual Summary of Fossil-Fuel Boiler of Case I | ||||

|---|---|---|---|---|

| Boiler | Annual Energy Usage (MMBtu/yr) | Annual Fuel Usage (lb/yr) | Annual CO2 Emission (lb/yr) | Annual Fuel Cost ($/yr) |

| Boiler 1 | 11,748 | 523,211 | 1,265,753 | 64,730 |

| Boiler 2 | 20,057 | 893,307 | 2,161,089 | 110,516 |

| Boiler 3 | 19,616 | 873,642 | 2,113,515 | 108,084 |

| Boiler 4 | 23,498 | 1,046,541 | 2,531,793 | 129,474 |

| Total | 74,919 | 3,336,702 | 8,072,150 | 412,804 |

| Annual Summary of Fossil-Fuel Boiler of Case II | ||||

|---|---|---|---|---|

| Boiler | Annual Energy Usage (MMBtu/yr) | Annual Fuel Usage (lb/yr) | Annual CO2 Emission (lb/yr) | Annual Fuel Cost ($/yr) |

| Boiler 1 | 9771 | 435,174 | 1,052,773 | 53,838 |

| Boiler 2 | 16,663 | 742,140 | 1,795,384 | 91,815 |

| Boiler 3 | 16,307 | 726,269 | 1,756,990 | 89,851 |

| Boiler 4 | 19,682 | 876,584 | 2,120,631 | 108,447 |

| Total | 62,423 | 2,780,166 | 6,725,778 | 343,951 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, N.I.; Gopalakrishnan, B.; Adhikari, N.; Li, H.; Liu, Z. Evaluating Electrification of Fossil-Fuel-Fired Boilers for Decarbonization Using Discrete-Event Simulation. Energies 2024, 17, 2882. https://doi.org/10.3390/en17122882

Chowdhury NI, Gopalakrishnan B, Adhikari N, Li H, Liu Z. Evaluating Electrification of Fossil-Fuel-Fired Boilers for Decarbonization Using Discrete-Event Simulation. Energies. 2024; 17(12):2882. https://doi.org/10.3390/en17122882

Chicago/Turabian StyleChowdhury, Nahian Ismail, Bhaskaran Gopalakrishnan, Nishan Adhikari, Hailin Li, and Zhichao Liu. 2024. "Evaluating Electrification of Fossil-Fuel-Fired Boilers for Decarbonization Using Discrete-Event Simulation" Energies 17, no. 12: 2882. https://doi.org/10.3390/en17122882

APA StyleChowdhury, N. I., Gopalakrishnan, B., Adhikari, N., Li, H., & Liu, Z. (2024). Evaluating Electrification of Fossil-Fuel-Fired Boilers for Decarbonization Using Discrete-Event Simulation. Energies, 17(12), 2882. https://doi.org/10.3390/en17122882