Use of Dampers to Improve the Overspeed Control System with Movable Arms for Butterfly Wind Turbines

Abstract

1. Introduction

| Category | Subcategory | Cost | Controllability | Simplicity | Driving Power | Durability | Reference |

|---|---|---|---|---|---|---|---|

| Mechanical | Disc brake | × | ✓ | × | × | − | [4] |

| Pump load | − | × | × | ✓ | ✓ | [8] | |

| Centrifugal force + spring | ✓ | − | − | ✓ | × | [9] | |

| Electrical | Load resistance | × | ✓ | − | × | ✓ | [6] |

| Pitch control | Centrifugal force + spring | − | − | − | ✓ | × | [11,12] |

| Link mechanism | × | − | × | ✓ | × | [10,13,14,25] | |

| Aerodynamic | Flap/Spoiler | ✓ | − | − | ✓ | × | [15,16,17] |

| Flat plate upon rotational shaft | − | − | − | ✓ | × | [18] | |

| Variable arm | ✓ | − | ✓ | ✓ | − | [24] | |

| Variable geometry | Tilting blade to tangential | × | × | × | ✓ | × | [19] |

| Musgrove rotor | × | ✓ | × | × | − | [20,21] | |

| Variable rotor height | − | − | − | − | − | [22] | |

| Others | Magnus force | × | ✓ | − | × | − | [21,23] |

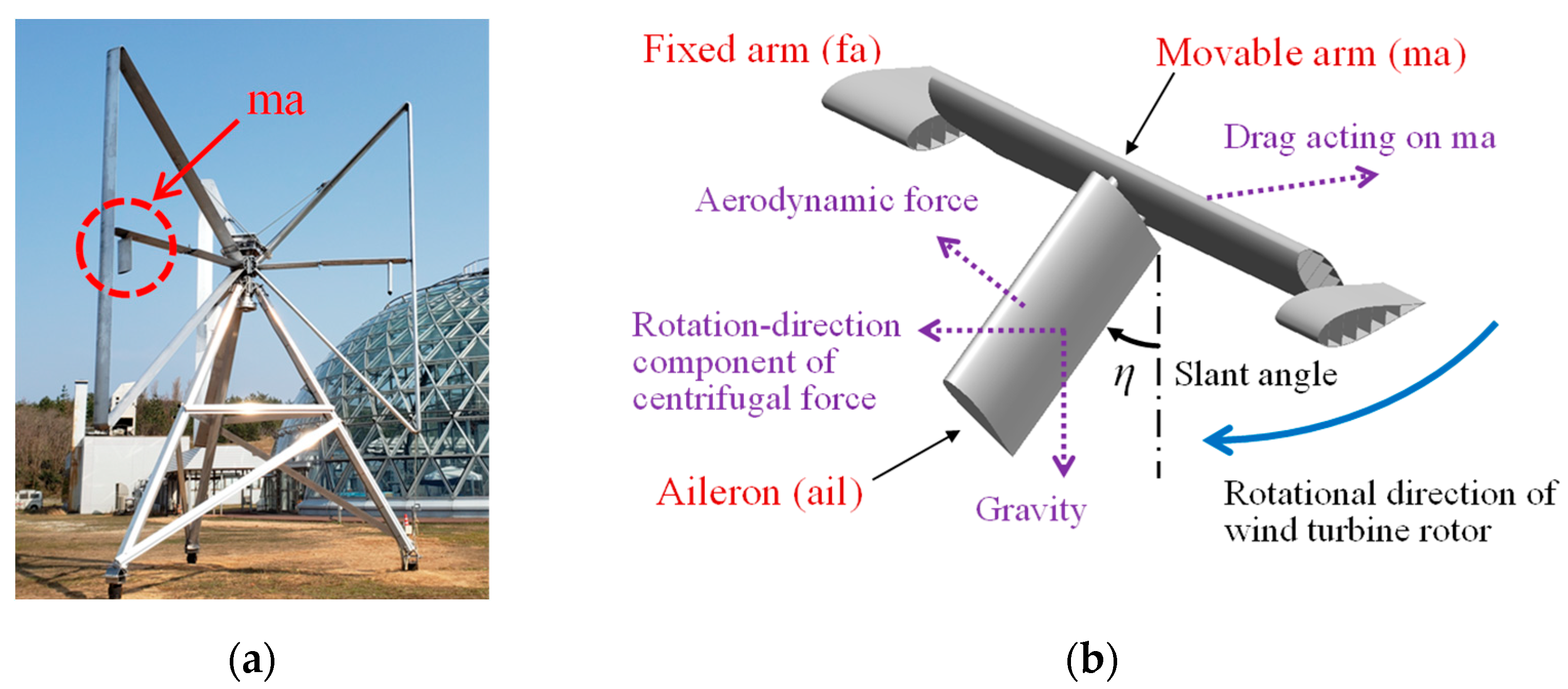

2. Prototype of Butterfly Wind Turbine Equipped with Overspeed Control System

3. Theoretical Prediction

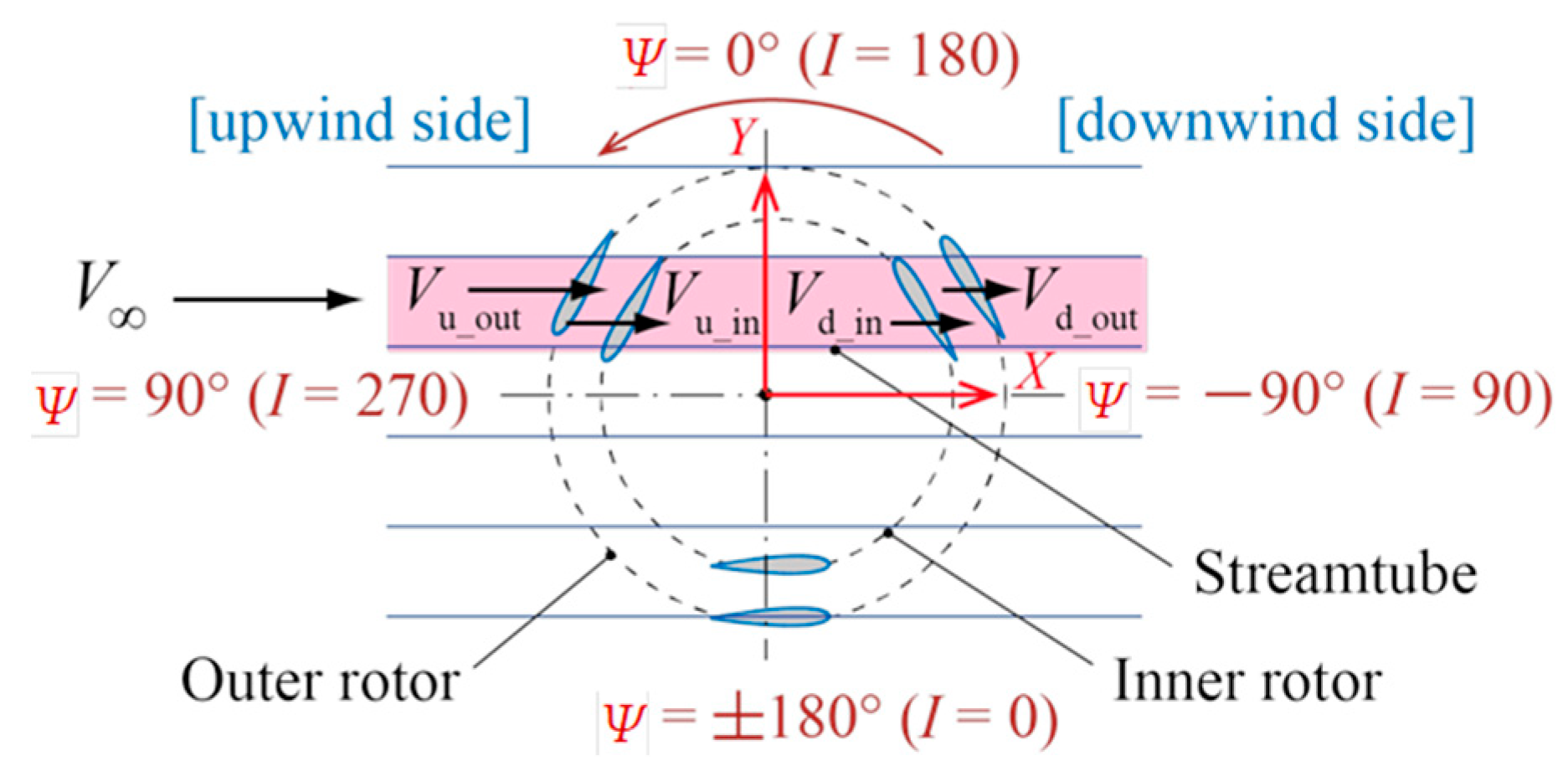

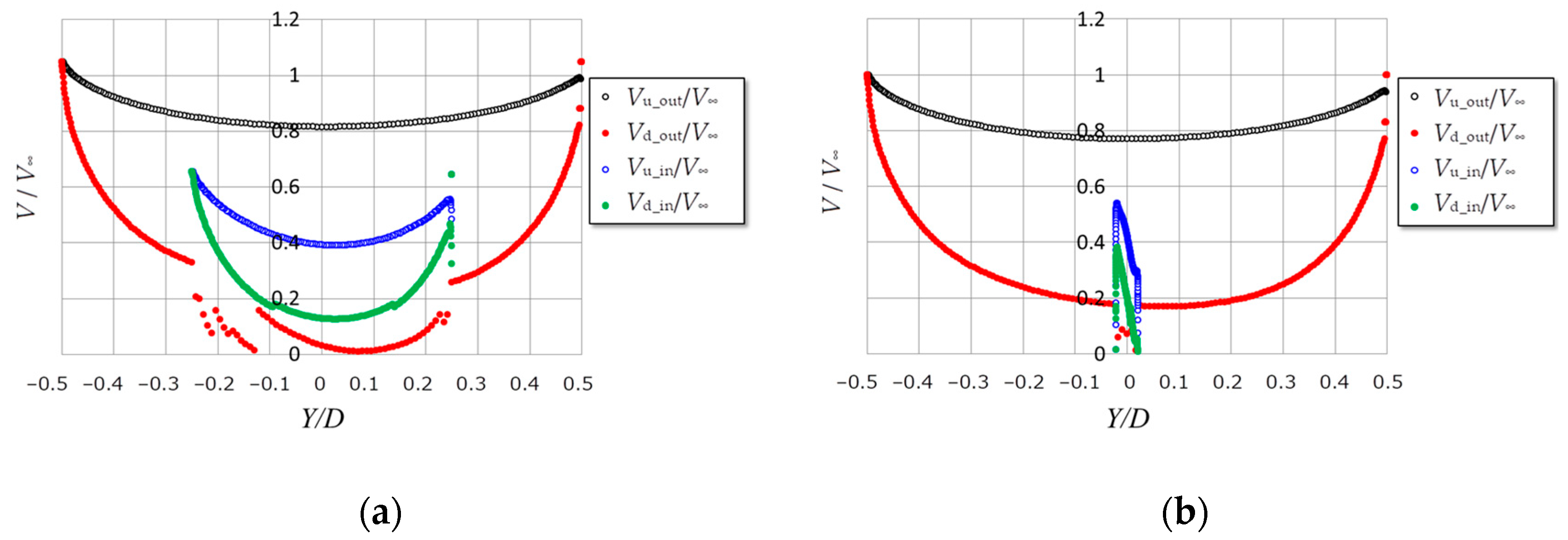

3.1. Prediction of Flow Speed Distribution

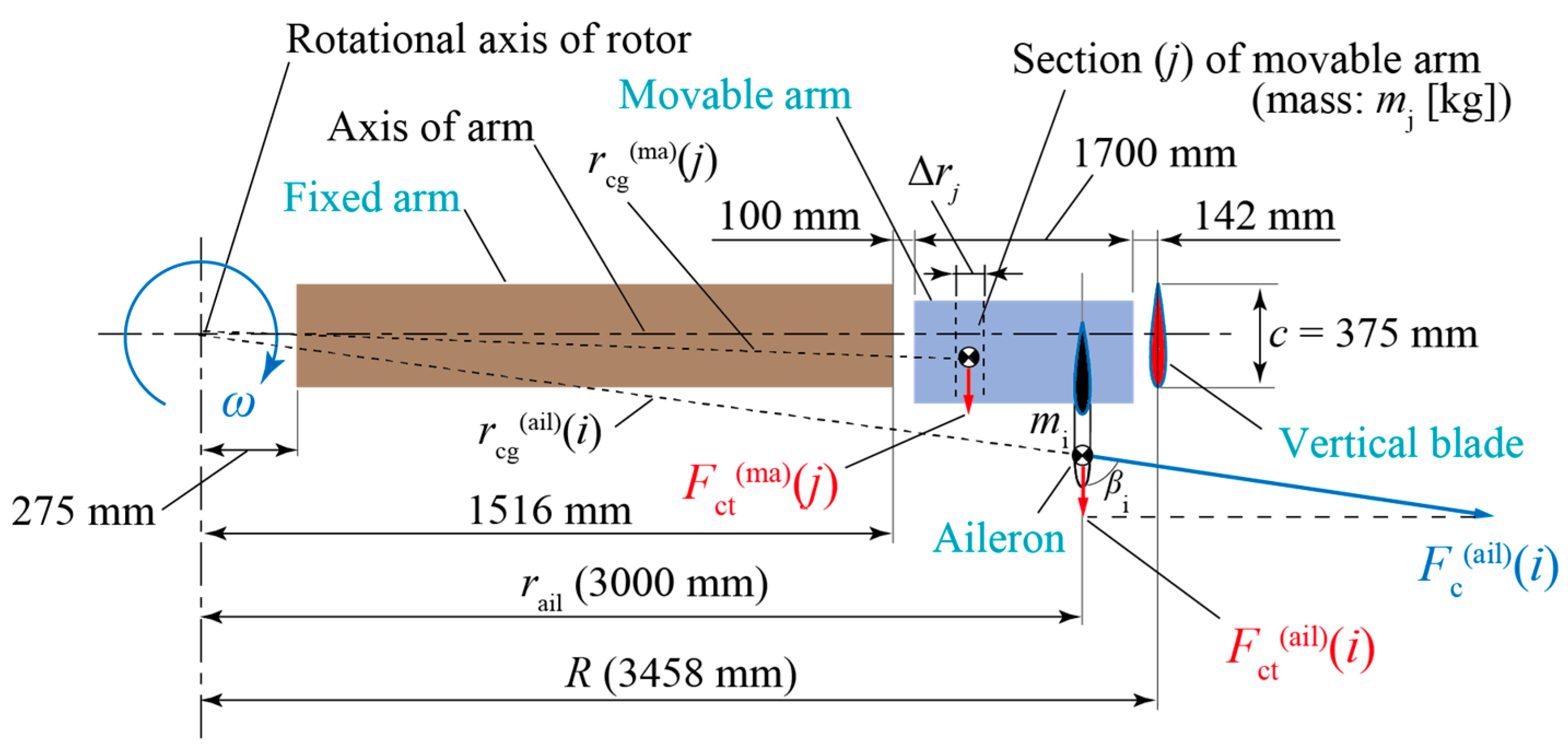

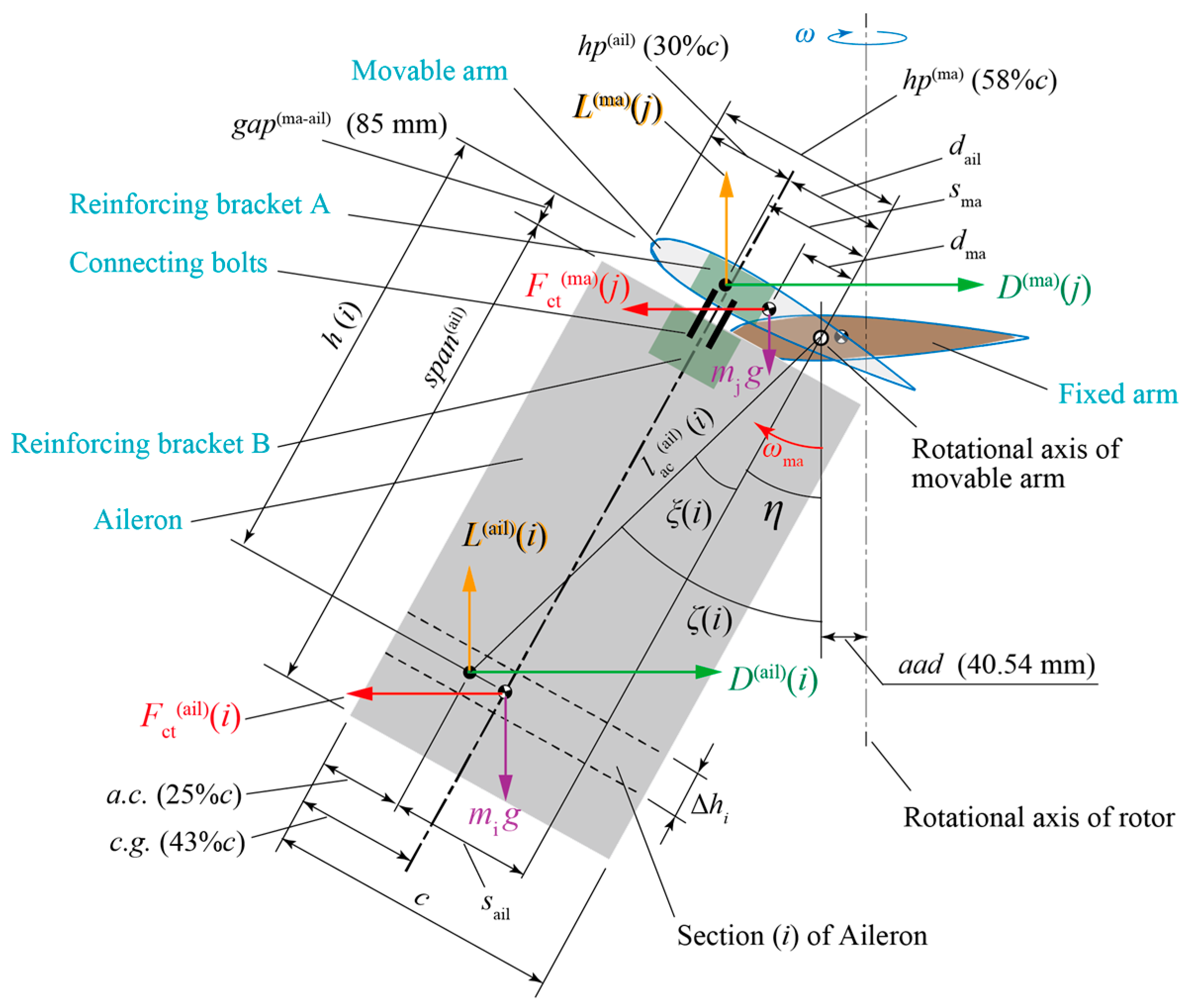

3.2. Equation of Motion of Movable Arm System

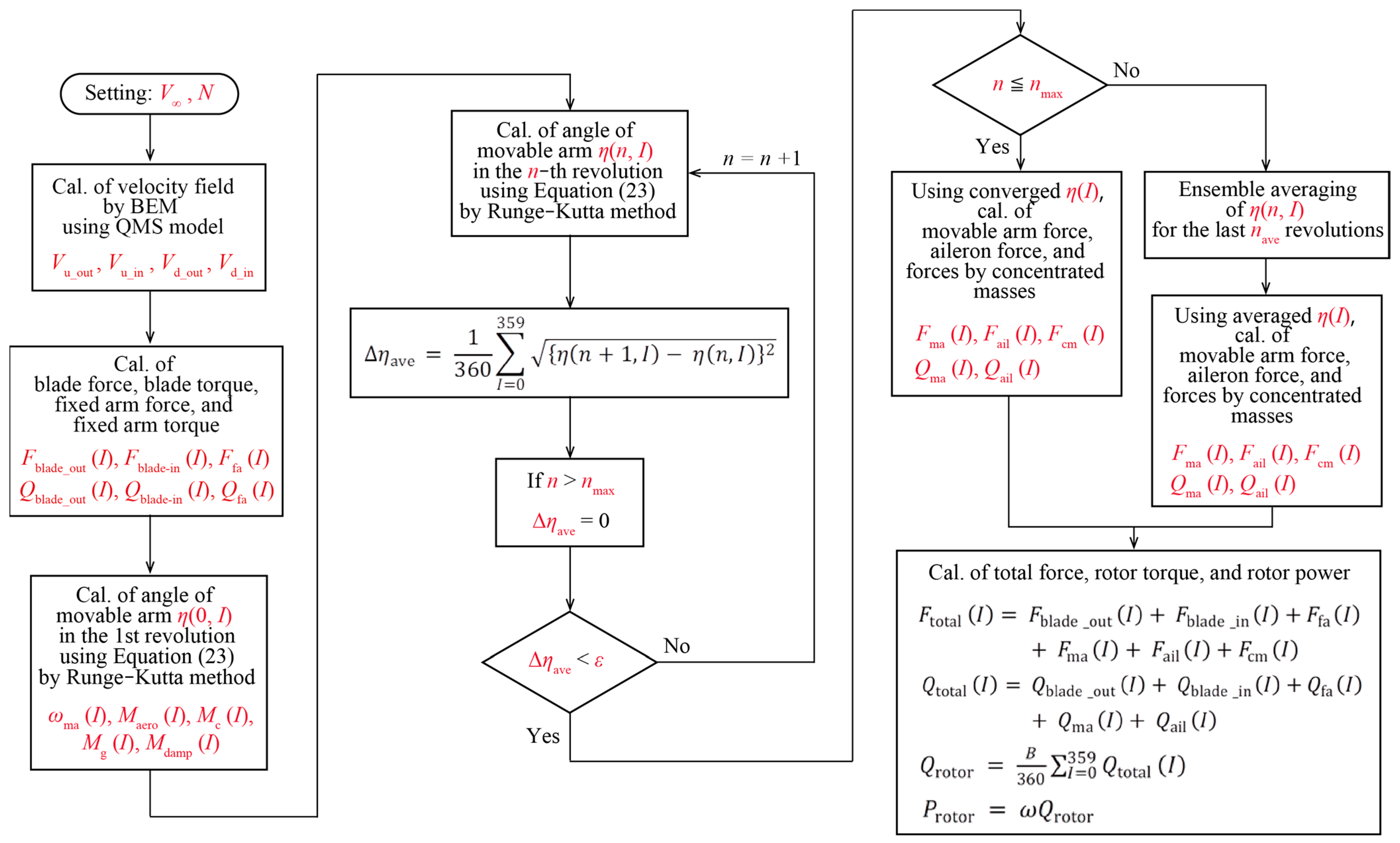

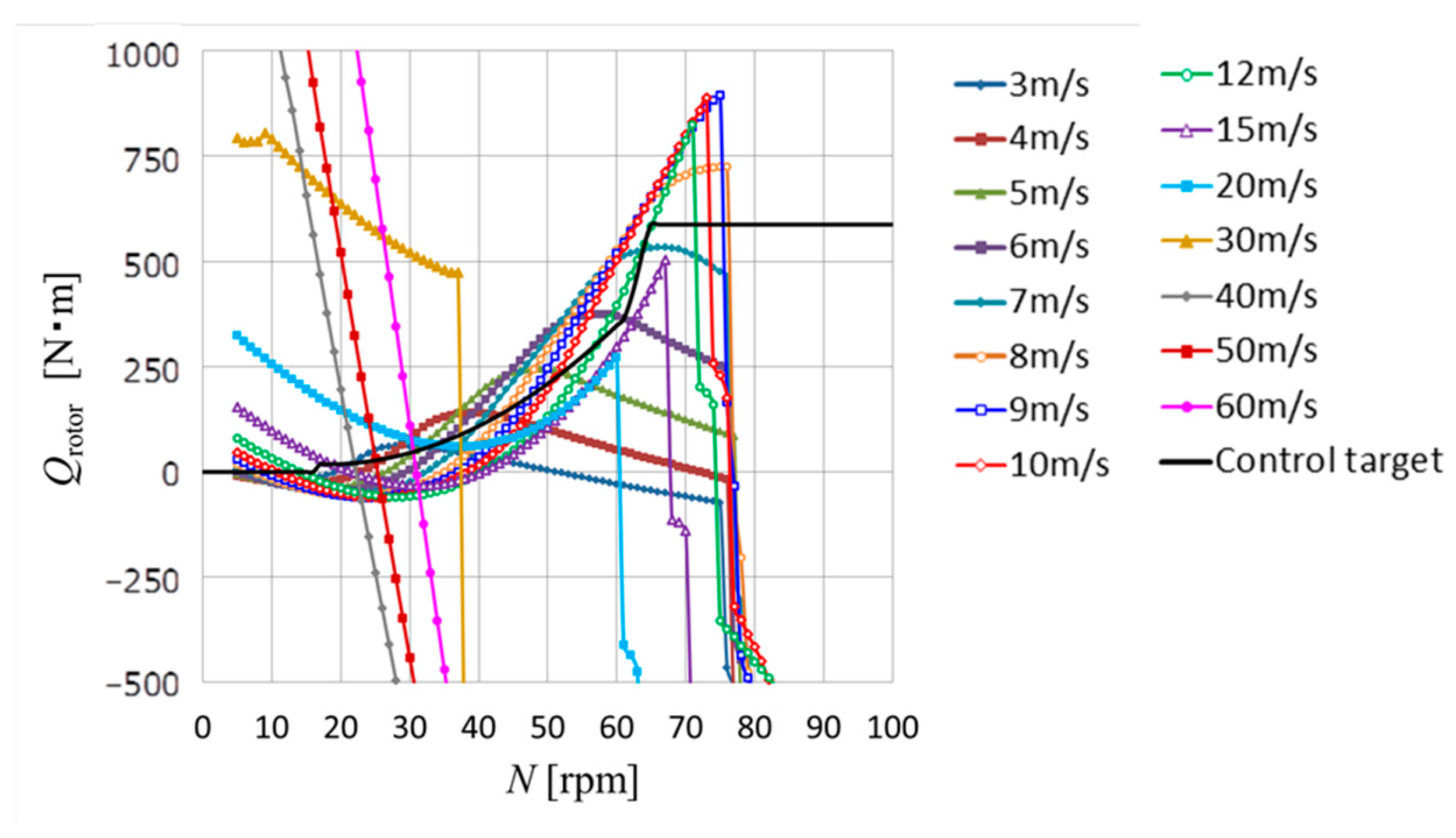

3.3. Prediction of Movable Arm Behavior and Rotor Performance

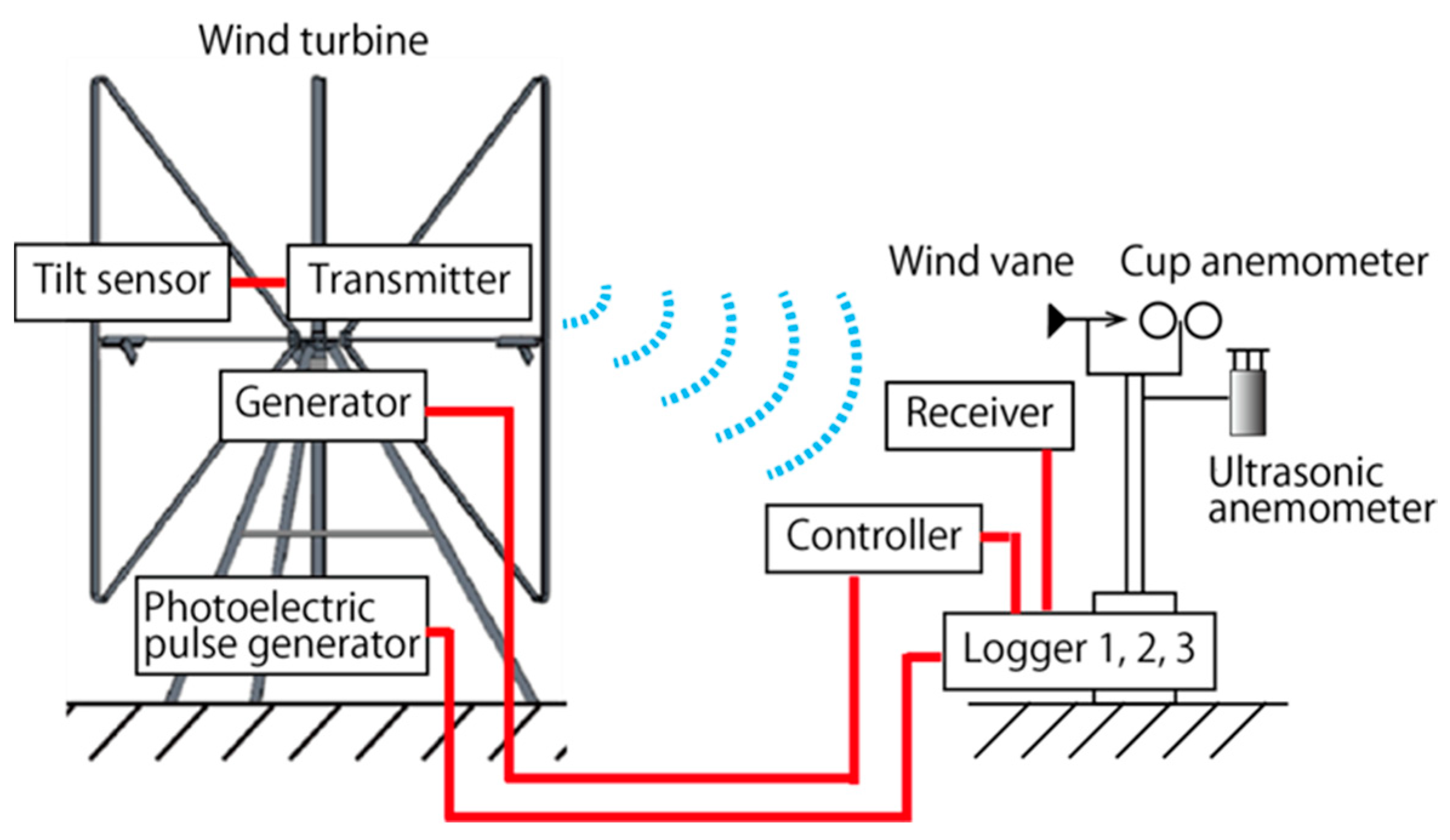

4. Experimental Setup

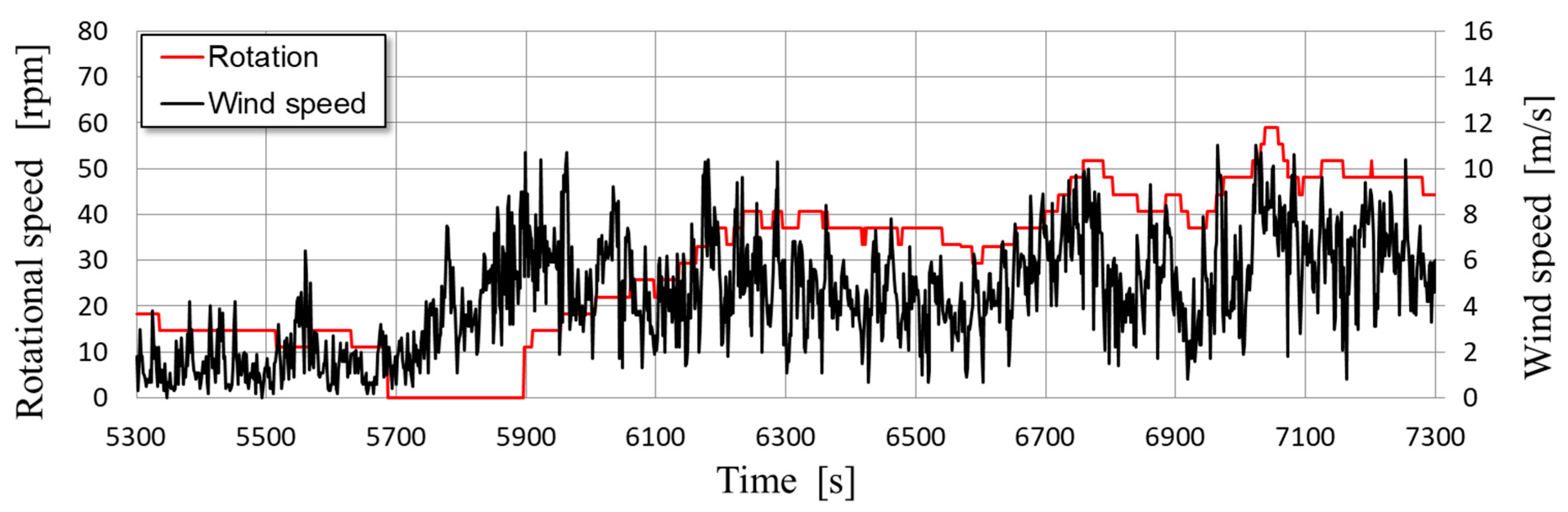

5. Results and Discussion

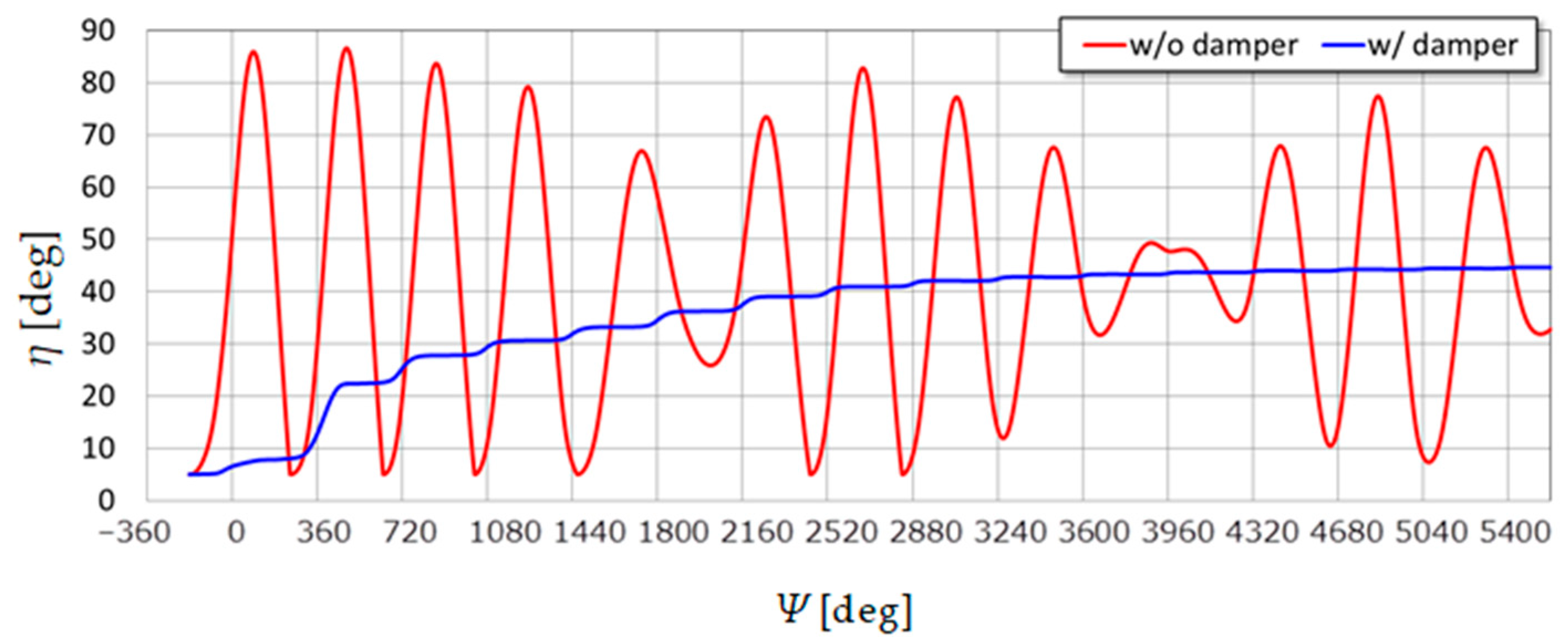

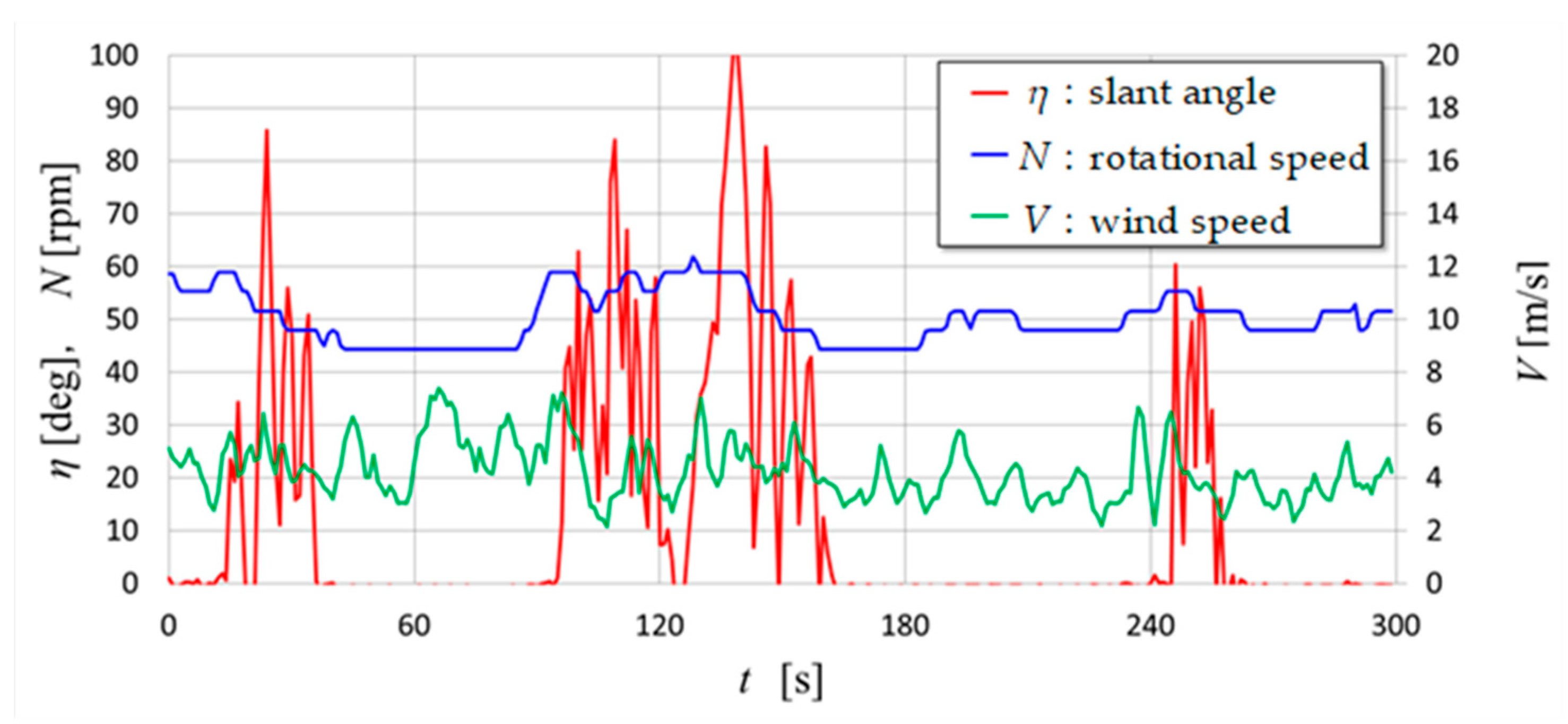

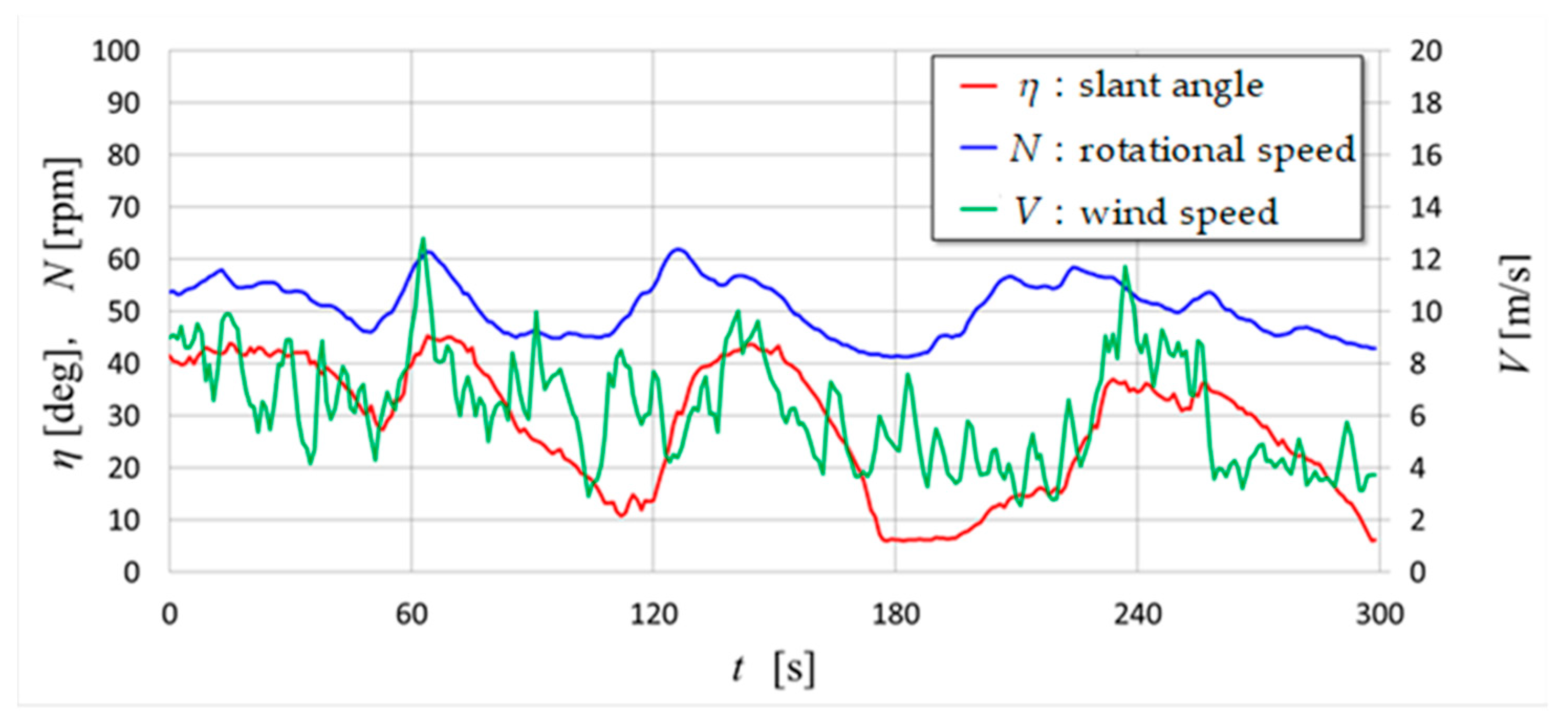

5.1. Comparison of Behavior of Movable Arm between with and without Dampers

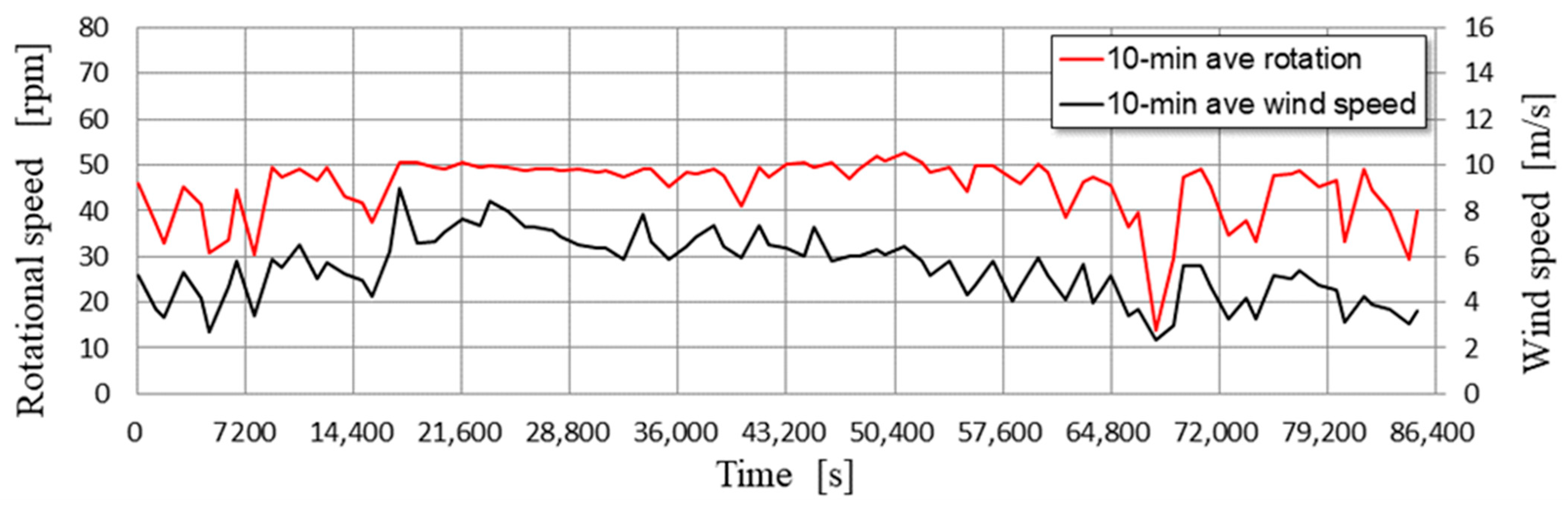

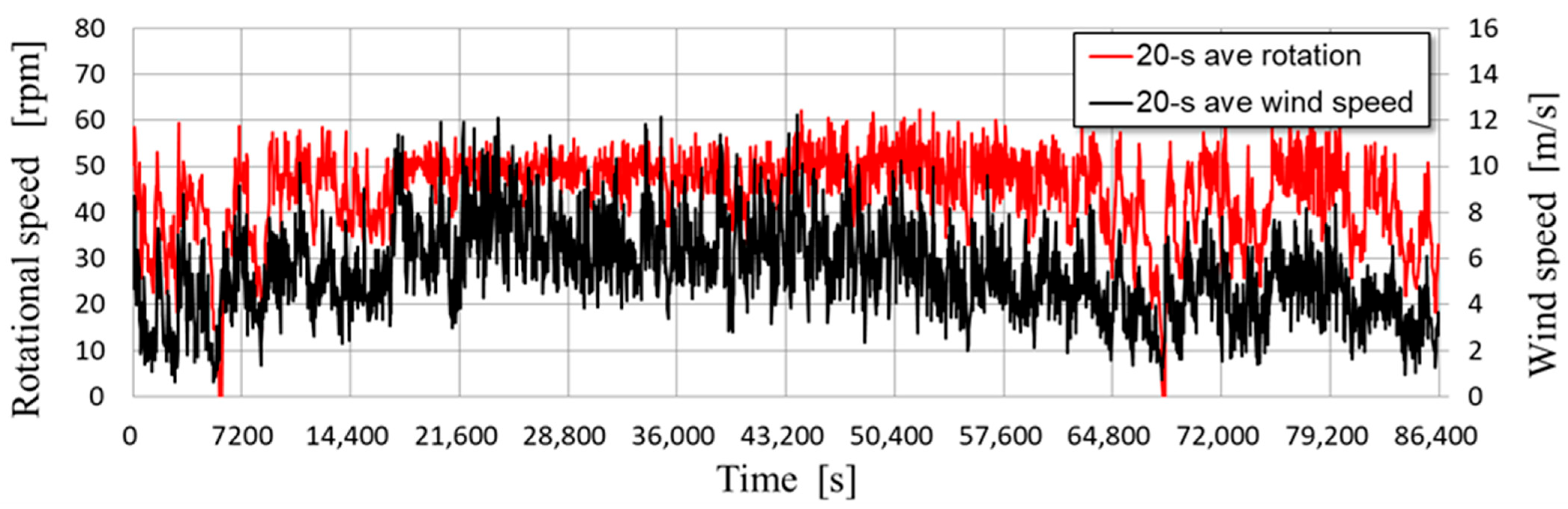

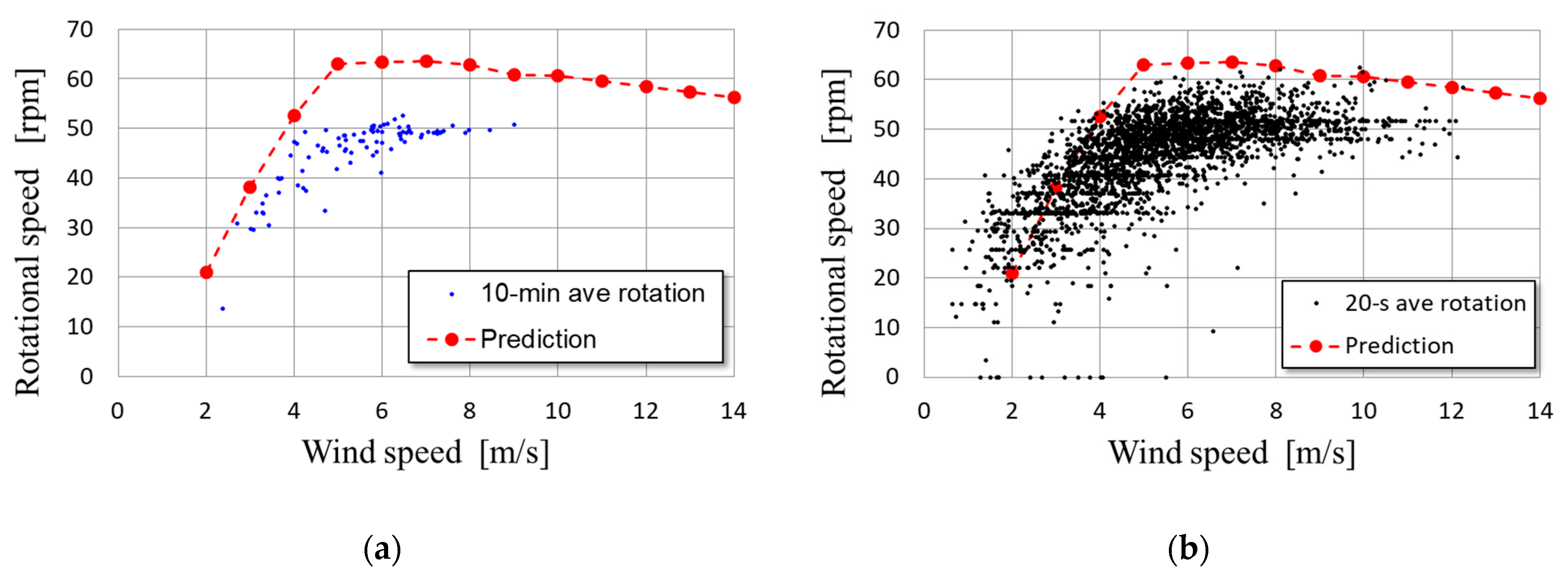

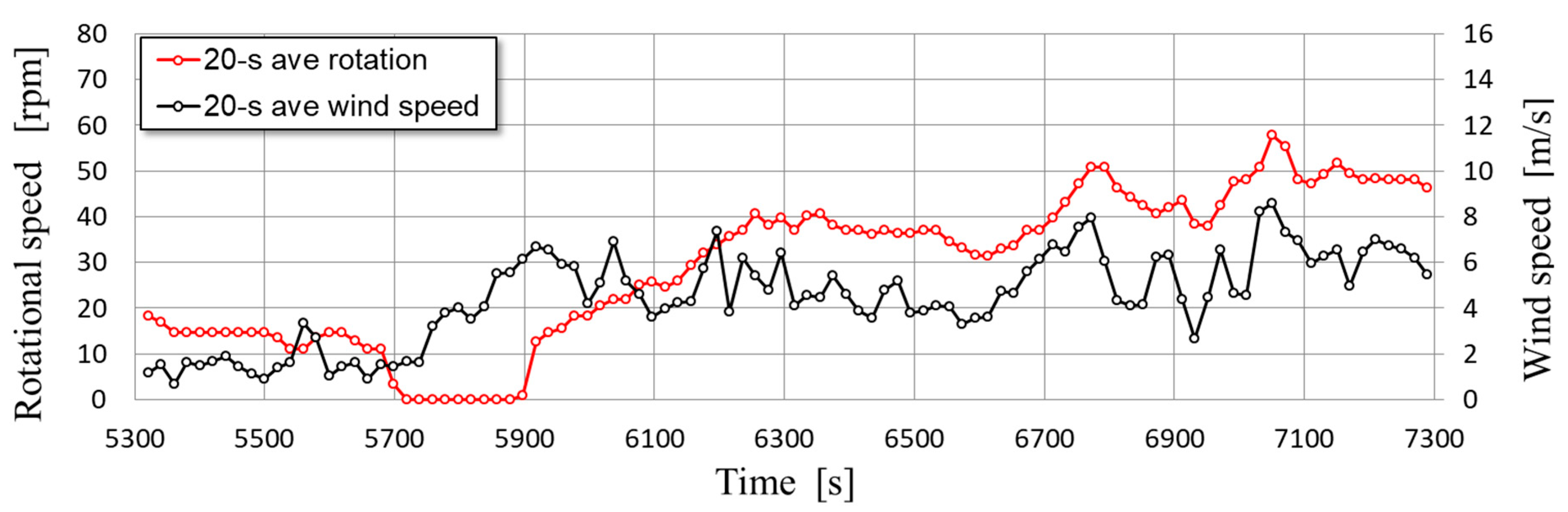

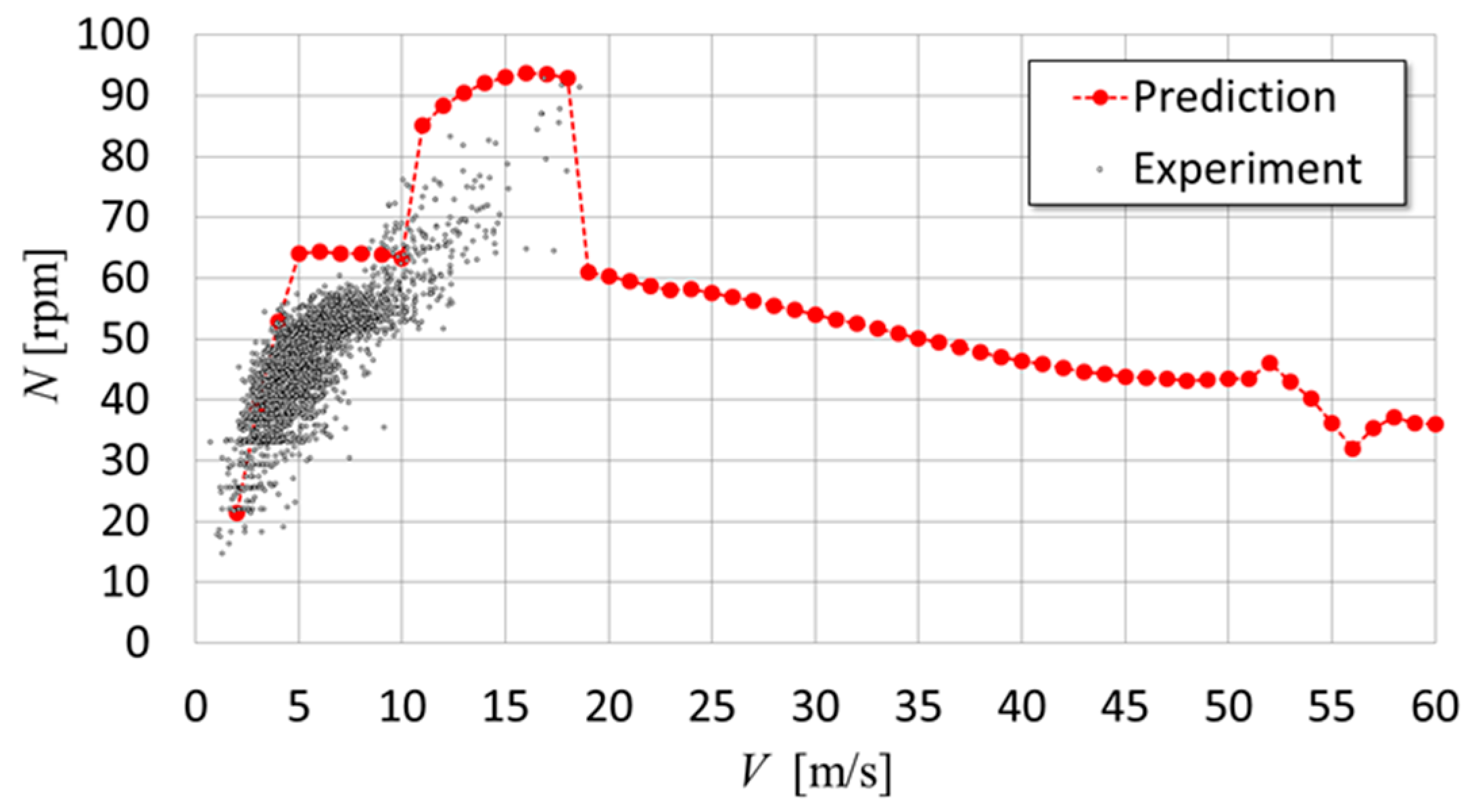

5.2. Comparison of Wind Speed Dependence of Rotational Speed between Prediction and Experiments

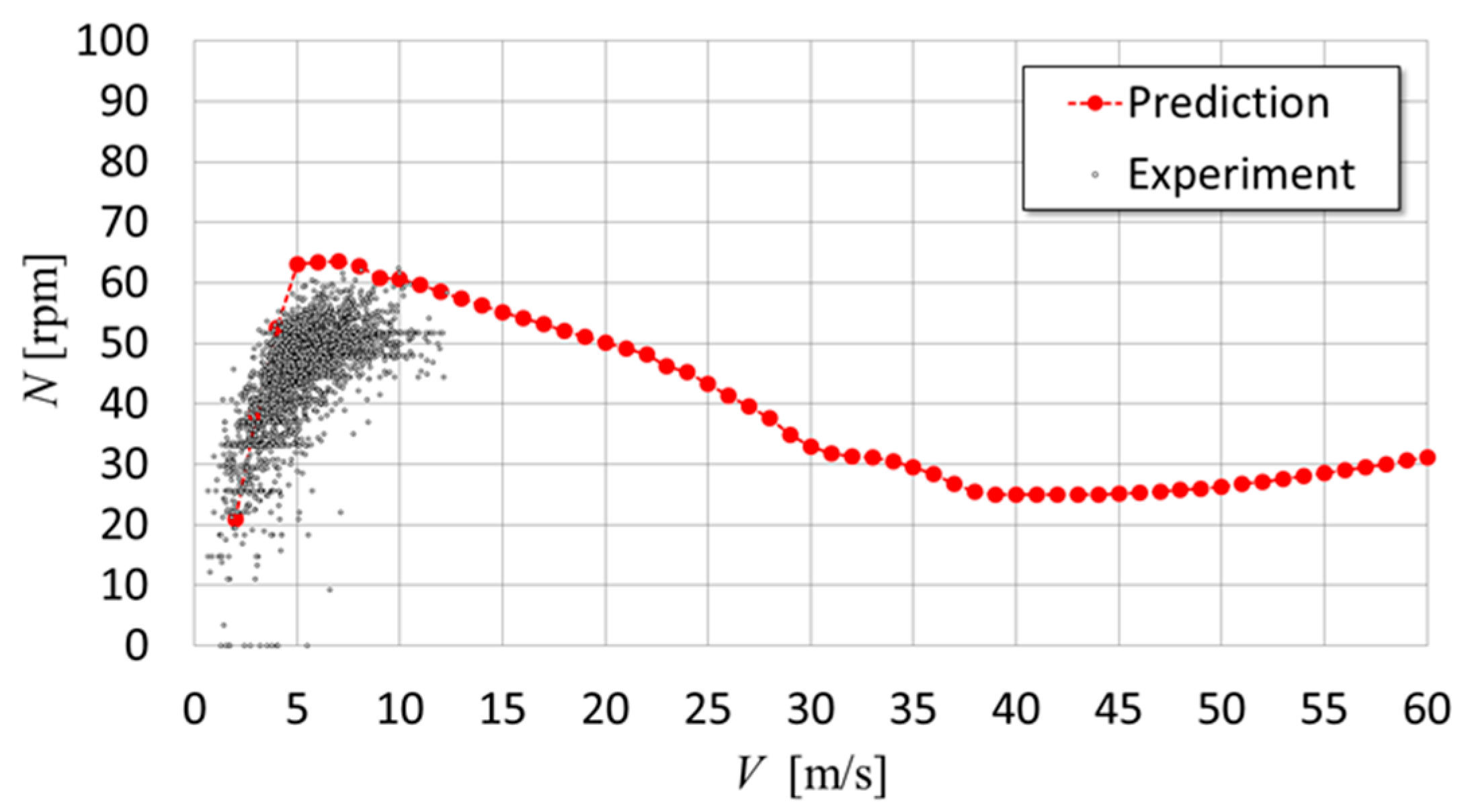

5.3. Prediction and Experimental Data after Replacement with Short Ailerons

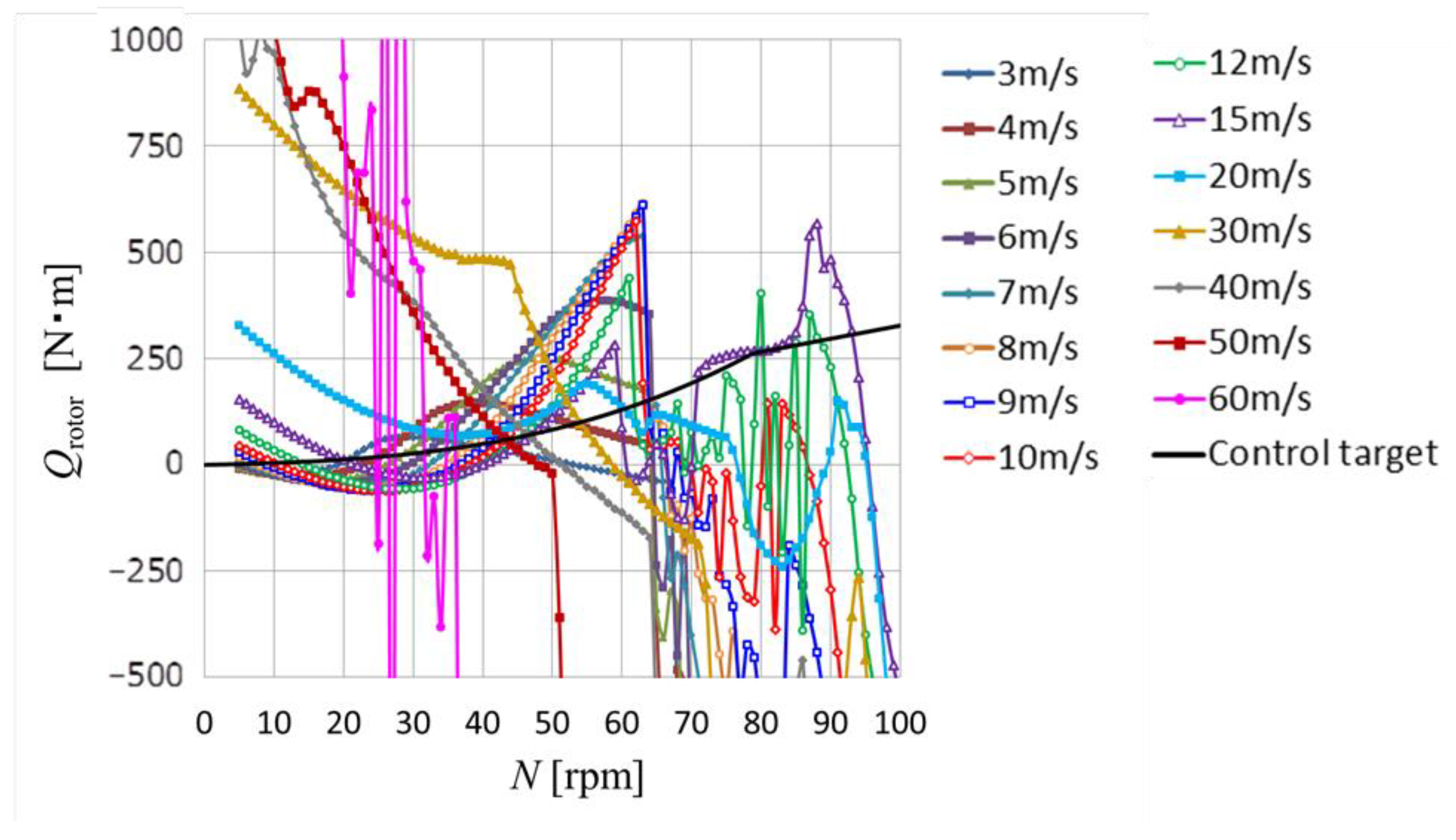

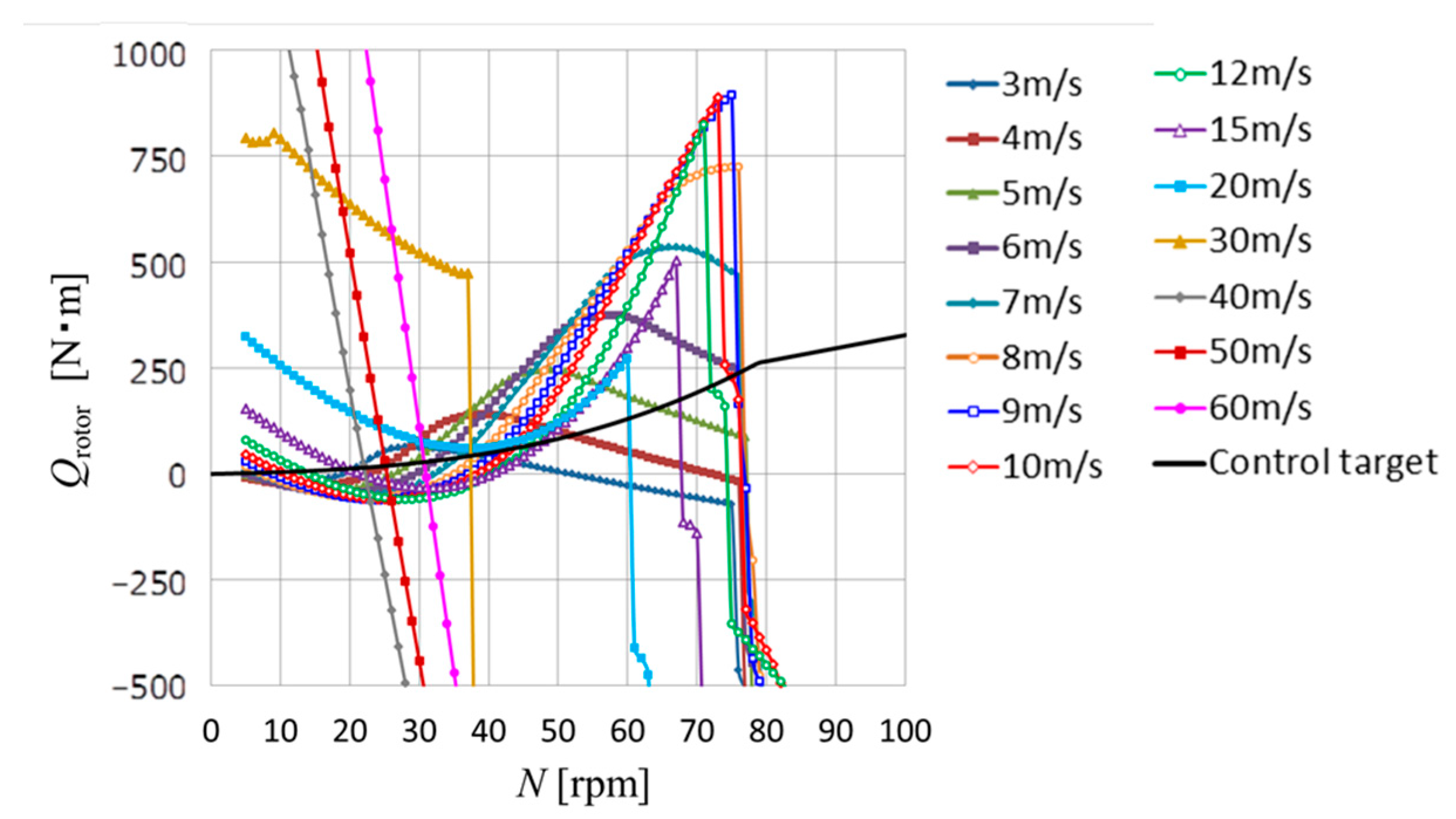

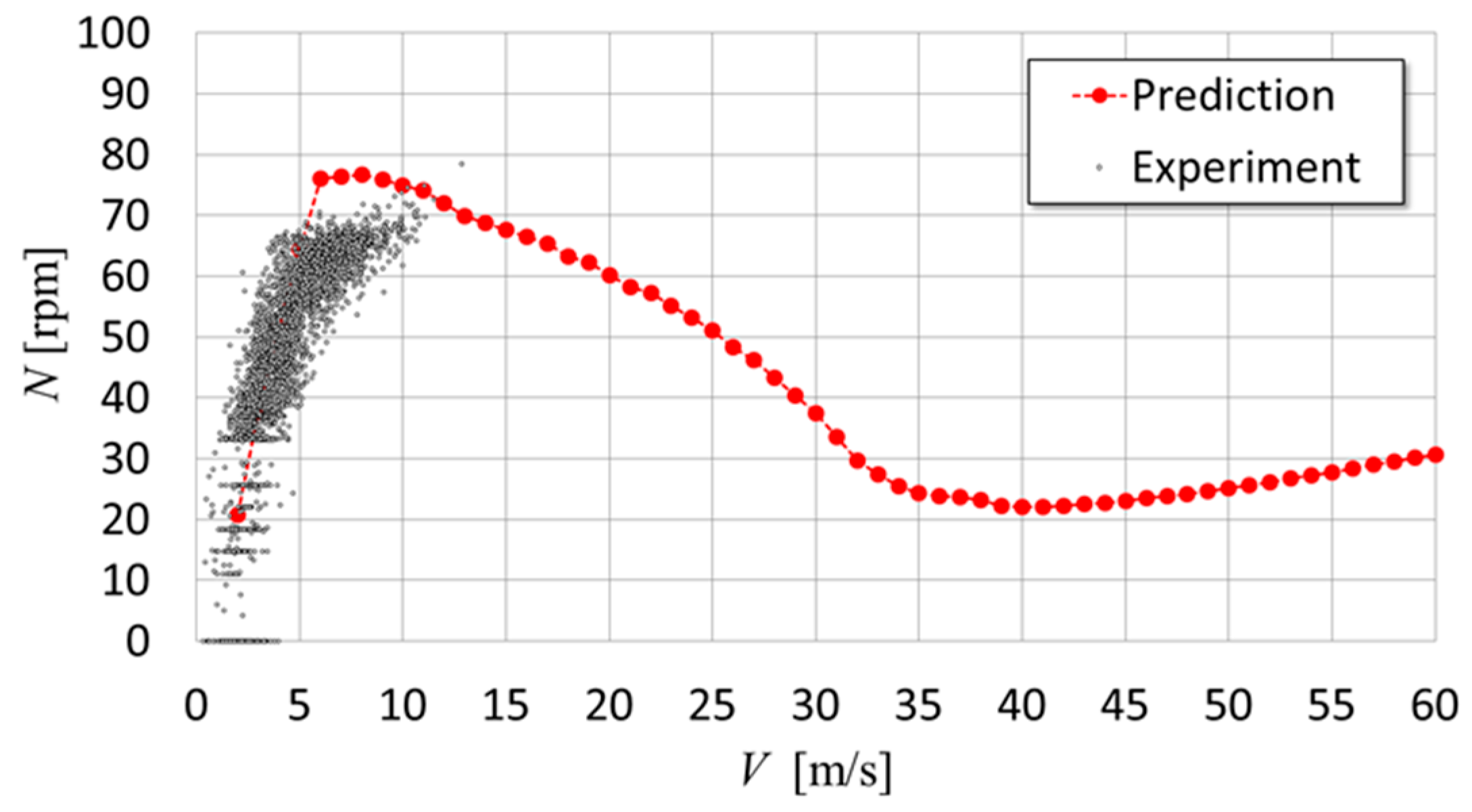

5.4. Prediction and Experimental Data after Changing Control Target Data

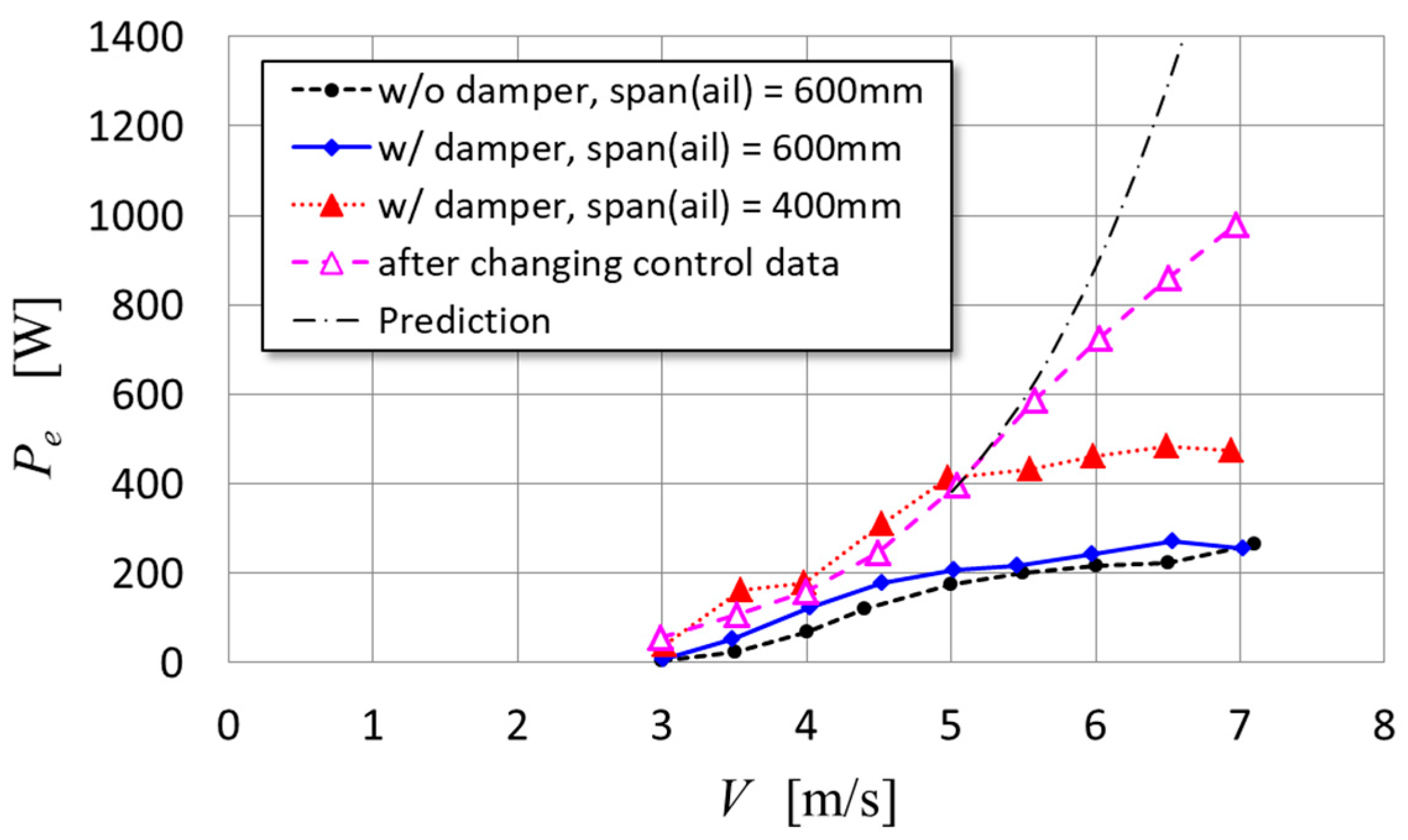

5.5. Comparison of Power Generation

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| A | Rotor swept area [m2] |

| aad | Distance between rotor rotation axis and movable arm axis [m] |

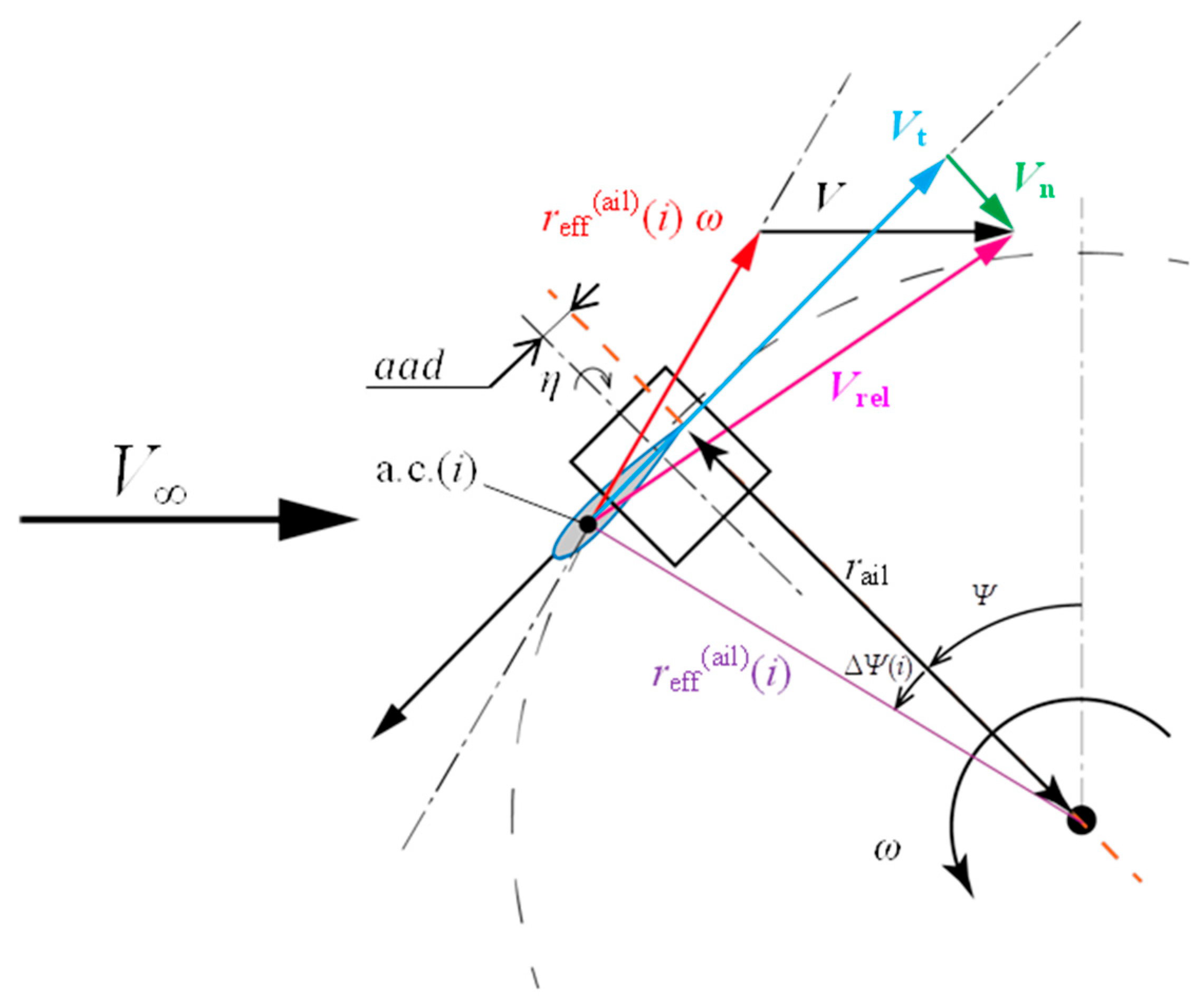

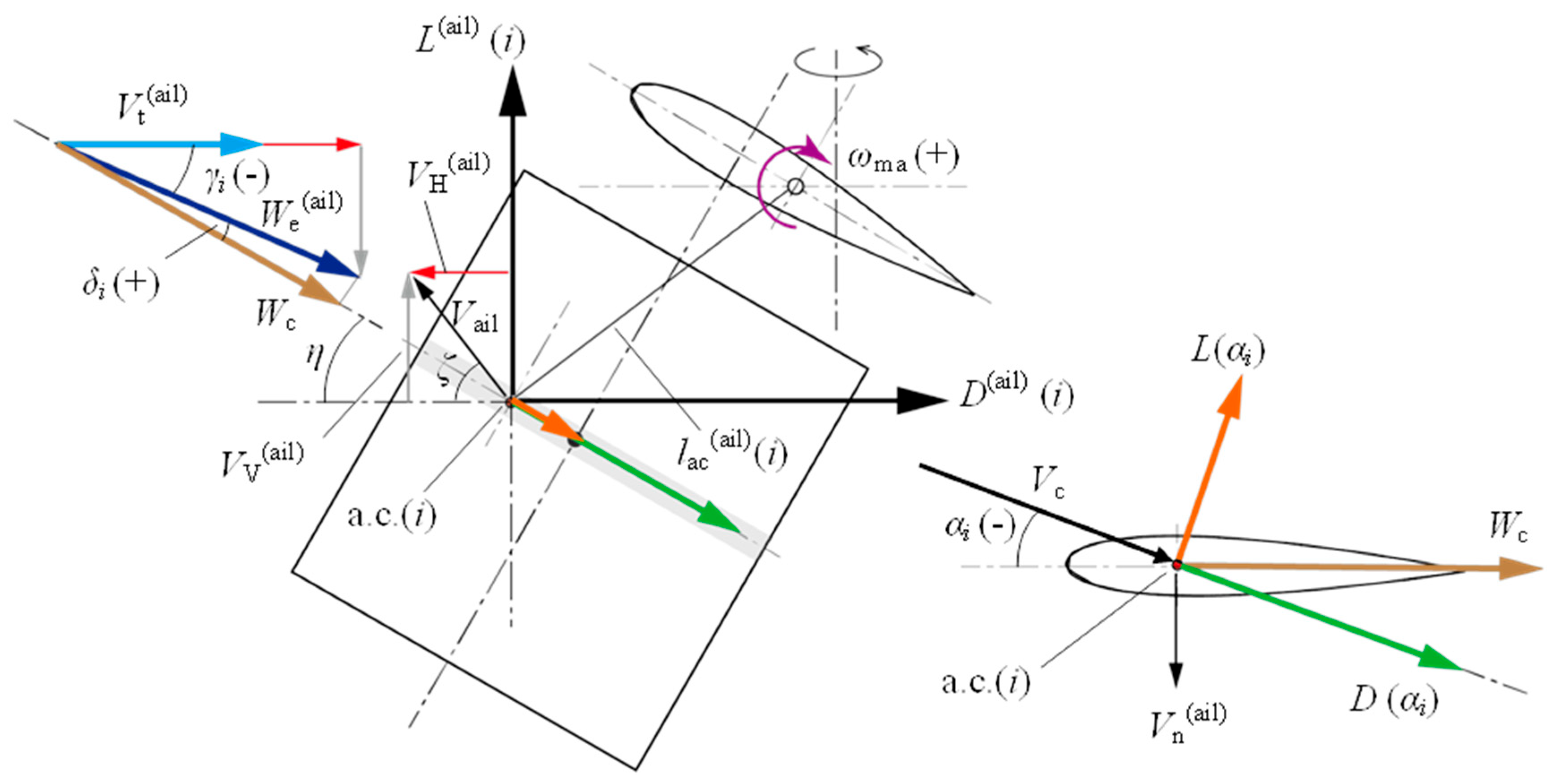

| a.c.(i) | Aerodynamic center of section i of aileron [-] |

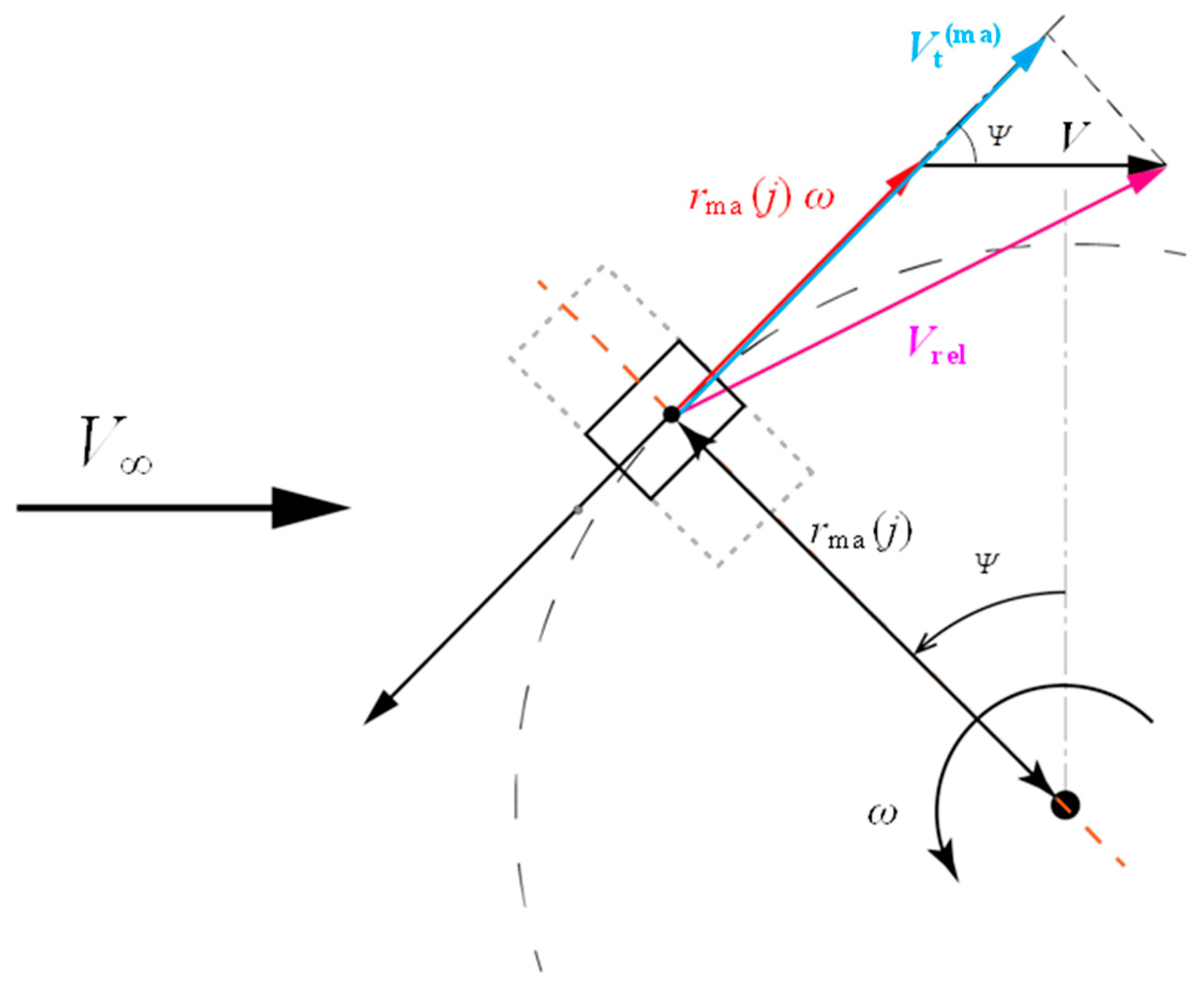

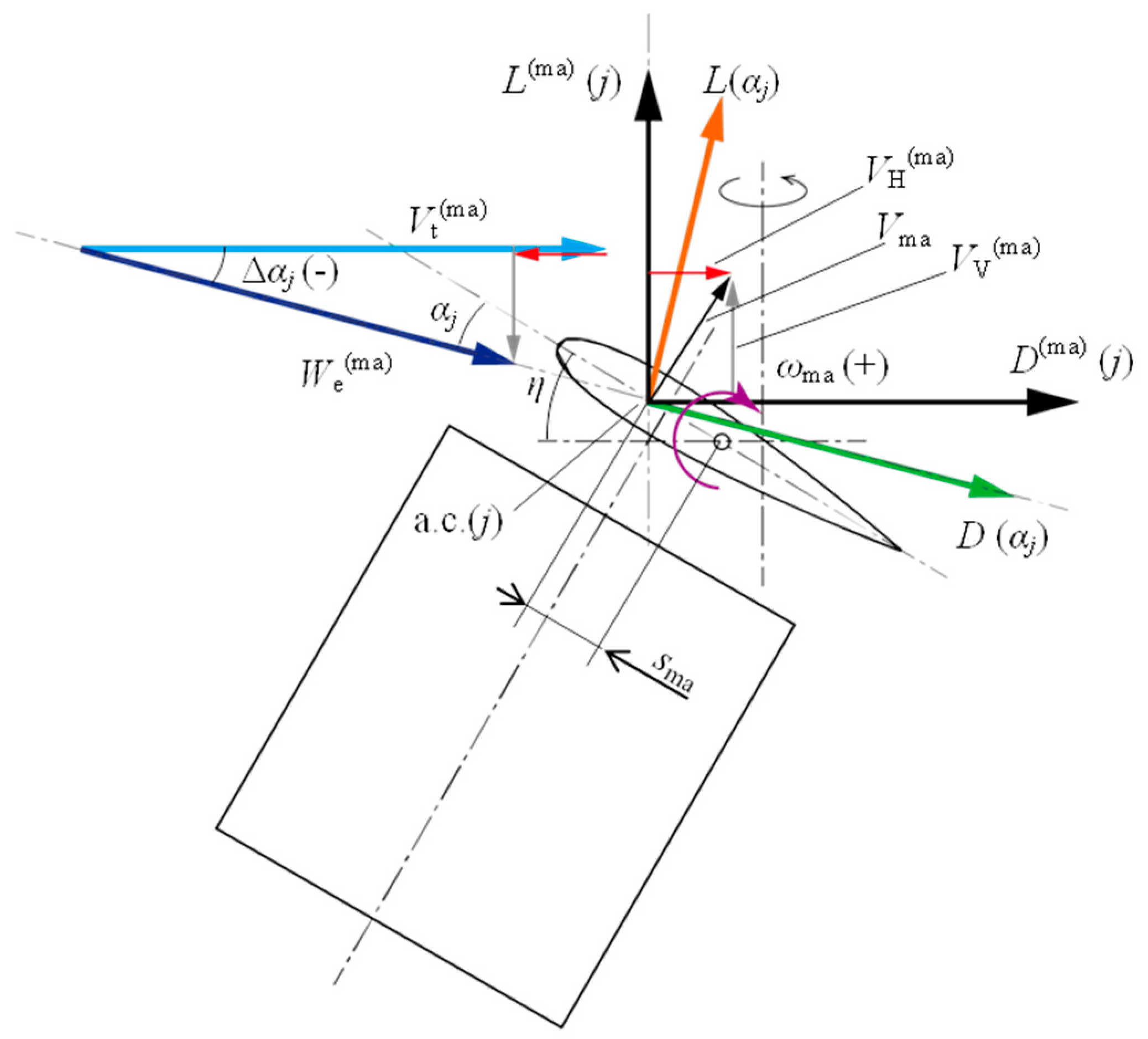

| a.c.(j) | Aerodynamic center of section j of movable arm [-] |

| B | Number of blades [-] |

| CD(αi, Re) | Drag coefficient of section i of aileron [-] |

| CD(αj, Re) | Drag coefficient of section j of movable arm [-] |

| CL(αi, Re) | Lift coefficient of section i of aileron [-] |

| CL(αj, Re) | Lift coefficient of section j of movable arm [-] |

| Cp | Power coefficient of wind turbine [-] |

| c | Chord length [m] |

| D | Diameter of wind turbine rotor [m] |

| D(ail)(i) | Horizontal aerodynamic force of section i of aileron [N] |

| D(ma)(j) | Horizontal aerodynamic force of section j of movable arm [N] |

| D(αi) | Drag force of section i of aileron [N] |

| D(αj) | Drag force of section j of movable arm [N] |

| dail | Chordwise distance between center of gravity of aileron and movable arm axis [m] |

| dma | Chordwise distance between center of gravity of movable arm and movable arm axis [m] |

| Fail(I) | Force acting on an aileron in azimuth I [N] |

| Fblade_in(I) | Force acting on an inner blade in azimuth I [N] |

| Fblade_out(I) | Force acting on an outer blade in azimuth I [N] |

| Fc(ail)(i) | Centrifugal force acting on section i of aileron [N] |

| Fc(ma)(j) | Centrifugal force acting on section j of movable arm [N] |

| Fcm(I) | Force acting on concentrated masses in azimuth I [N] |

| Fct(ail)(i) | Tangential component of centrifugal force acting on section i of aileron [N] |

| Fct(ma)(j) | Tangential component of centrifugal force acting on section j of movable arm [N] |

| Ffa(I) | Force acting on a fixed arm in azimuth I [N] |

| Fma(I) | Force acting on a movable arm in azimuth I [N] |

| Ftotal(I) | Total force acting on a blade in azimuth I [N] |

| g | Gravitational acceleration [m/s2] |

| gap(ma-ail) | Distance between aileron top end and movable arm axis [m] |

| H | Rotor height [m] |

| h(i) | Distance between aerodynamic center of section i of aileron and movable arm chord line [m] |

| hp(ail) | Holding point of aileron [m] |

| hp(ma) | Holding point of movable arm [m] |

| Δhi | Width of section i of aileron [m] |

| I | Integer parameter of azimuth [-] |

| Ima | Inertial moment of movable arm system around the axis [kgm2] |

| i | Integer parameter specifying a section of aileron [-] |

| j | Integer parameter specifying a section of movable arm [-] |

| L(ail)(i) | Vertical aerodynamic force of section i of aileron [N] |

| L(ma)(j) | Vertical aerodynamic force of section j of movable arm [N] |

| L(αi) | Lift force of section i of aileron [N] |

| L(αj) | Lift force of section j of movable arm [N] |

| lac(ail)(i) | Distance between aerodynamic center of section i of aileron and movable arm axis [m] |

| Maero | Total moment by aerodynamic forces acting on aileron and movable arm [N·m] |

| Maero(ail) | Moment by aerodynamic force acting on an aileron [N·m] |

| Maero(ma) | Moment by aerodynamic force acting on a movable arm [N·m] |

| Mc | Total moment by centrifugal forces acting on aileron, movable arm, and concentrated mass [N·m] |

| Mc(ail) | Moment by centrifugal force acting on an aileron [N·m] |

| Mc(cm) | Moment by centrifugal force acting on concentrated mass [N·m] |

| Mc(ma) | Moment by centrifugal force acting on a movable arm [N·m] |

| Mdamp | Resistant moment of dampers [N·m] |

| Mg | Total moment by gravity forces acting on aileron, movable arm, and concentrated mass [N·m] |

| Mg(ail) | Moment by gravity force acting on an aileron [N·m] |

| Mg(cm) | Moment by gravity force acting on concentrated mass [N·m] |

| Mg(ma) | Moment by gravity force acting on a movable arm [N·m] |

| mi | Mass of section i of aileron [kg] |

| mj | Mass of section j of movable arm [kg] |

| N | Rotor rotational speed [rpm] |

| n | Number of rotor rotations [-] |

| nave | Number of rotor rotations for ensemble averaging [-] |

| nmax | Maximum number of rotor rotations for calculation of movable arm behavior [-] |

| Protor | Power of wind turbine rotor [W] |

| p | Index of power law of vertical distribution of wind speed [-] |

| Qail(I) | Torque generated by an aileron in azimuth I [N·m] |

| Qblade_in(I) | Torque generated by an inner blade in azimuth I [N·m] |

| Qblade_out(I) | Torque generated by an outer blade in azimuth I [N·m] |

| Qfa(I) | Torque generated by a fixed arm in azimuth I [N·m] |

| Qma(I) | Torque generated by a movable arm in azimuth I [N·m] |

| Qrotor | Torque of wind turbine rotor [N·m] |

| Qtotal(I) | Total torque generated by a blade in azimuth I [N·m] |

| R | Radius of wind turbine rotor [m] |

| Re | Reynolds number based on chord length and relative wind speed [-] |

| rail | Distance between the installation position of aileron and rotational axis of rotor [m] |

| rcg(ail)(i) | Distance between the center of gravity of section i of aileron and rotational axis of rotor [m] |

| reff(ail)(i) | Distance between aerodynamic center of section i of aileron and rotational axis of rotor [m] |

| rma(j) | Distance between installation position of section j of movable arm and rotational axis of rotor [m] |

| Δrj | Width of section j of movable arm [m] |

| sail | Chordwise distance between aerodynamic center of aileron and movable arm axis [m] |

| sma | Chordwise distance between aerodynamic center of movable arm and movable arm axis [m] |

| span(ail) | Span length of aileron [m] |

| t | Time [s] |

| V | Wind speed [m/s] |

| V∞ | Upstream wind speed [m/s] |

| Vail | Rotational speed of aerodynamic center of each section of aileron around movable axis [m/s] |

| Vc | Relative wind velocity in cross-section of aileron [m/s] |

| Vd_in | Wind speed through inner rotor in downwind side [m/s] |

| Vd_out | Wind speed through outer rotor in downwind side [m/s] |

| VH(ail) | Horizontal component of Vail [m/s] |

| VH(ma) | Horizontal component of Vma [m/s] |

| Vhub | Wind speed at hub height [m/s] |

| Vma | Rotational speed of aerodynamic center of movable arm around movable axis [m/s] |

| Vn(ail) | Normal component of Vrel in each section of aileron [m/s] |

| Vrel | Relative wind velocity in horizontal plane [m/s] |

| Vt(ail) | Tangential component of Vrel in each section of aileron [m/s] |

| Vt(ma) | Tangential component of Vrel in each section of movable arm [m/s] |

| Vu_in | Wind speed through inner rotor in upwind side [m/s] |

| Vu_out | Wind speed through outer rotor in upwind side [m/s] |

| VV(ail) | Vertical component of Vail [m/s] |

| VV(ma) | Vertical component of Vma [m/s] |

| Vz | Wind speed at altitude of z [m/s] |

| W | Integer parameter of height level in rotor [-] |

| Wc | Chord-wise component of We(ail) [m/s] |

| We(ail) | Relative wind velocity from Vt(ail) by considering Vail [m/s] |

| We(ma) | Relative wind velocity modified from Vt(ma) by considering Vma [m/s] |

| X, Y, Z | Absolute coordinate [m] |

| z | Coordinate in the vertical direction [m] |

| zhub | Hub height [m] |

| αi | Angle of attack defined in cross-section of section i of aileron [°] |

| αj | Angle of attack defined in cross-section of section j of movable arm [°] |

| Δαj | Angle between Vt(ma) and We(ma) [rad] |

| βi | Angle between Fc(ail)(i) and Fct(ail)(i) [rad] |

| βj | Angle between Fc(ma)(j) and Fct(ma)(j) [rad] |

| γi | Angle between Vt(ail) and We(ail) [rad] |

| δi | Angle between We(ail) and Wc [rad] |

| ε | Convergence judgment threshold of Δηave [°] |

| ζ(i) | Angle between lac(ail)(i) and vertical direction [rad] |

| η | Slant angle of movable arm [°] or [rad] |

| ηave | Averaged slant angle of movable arm in one rotor revolution [°] |

| η(I) | Converged or ensemble averaged slant angle of movable arm in azimuth I [°] or [rad] |

| η(n, I) | Slant angle of movable arm in azimuth I in n-th rotor rotation [°] or [rad] |

| ηini | Initial slant angle of movable arm [°] |

| ηt | Total efficiency [%] |

| Δηave | Evaluation value of convergence of slant angle variation [°] |

| λ | Tip speed ratio [-] |

| ξ(i) | Angle between lac(ail)(i) and span-wise direction of aileron [rad] |

| ρ | Air density [kg/m3] |

| Ψ | Azimuth angle [°] or [rad] |

| ΔΨ(i) | Difference in azimuth between rail and reff(ail)(i) [°] or [rad] |

| ω | Angular velocity of rotor rotation [rad/s] |

| ωma | Angular velocity of slant movement of movable arm [rad/s] |

Appendix A

Appendix B

Appendix C

References

- Cheng, C.; Blakers, A.; Stocks, M.; Lu, B. 100% renewable energy in Japan. Energy Convers. Manag. 2022, 255, 115299. [Google Scholar] [CrossRef]

- Gipe, P. Wind Power For Home & Business; Chelsea Green: White River Junction, VT, USA, 1993; pp. 133–143. [Google Scholar]

- Phadnis, M.; Zalkind, D.; Pao, L. Advanced wind turbine control development using field test analysis for generator overspeed mitigation. Wind Energy 2023, 1–17. [Google Scholar] [CrossRef]

- Tjiu, W.; Marnoto, T.; Mat, S.; Ruslan, M.H.; Sopian, K. Darrieus vertical axis wind turbine for power generation I: Assessment of Darrieus VAWT configurations. Renew. Energy 2015, 75, 50–67. [Google Scholar] [CrossRef]

- Hau, E. Windturbines; Springer: Berlin/Heidelberg, Germany, 2000; pp. 242–246. [Google Scholar]

- Performance Evaluation of a 700 W Vertical Axis Wind Turbine. Available online: https://sustainabletechnologies.ca/home/renewable-energy/wind/performance-evaluation-of-a-700-w-vertical-axis-wind-turbine/ (accessed on 11 May 2024).

- Erturk, E. Sizing a Stand-alone Off-grid Wind Turbine-battery Power System for a Remote House in Catalca Istanbul Turkey. Int. J. Renew. Energy Res. 2018, 8, 1591–1603. [Google Scholar] [CrossRef]

- Motohashi, H.; Goto, M.; Tan, S. Development of over speed protector for small scale wind turbines. In Proceedings of the 26th Wind Energy Utilization Symposium, Tokyo, Japan, 26 November 2004; pp. 413–416. [Google Scholar]

- Solomin, E.V. Centrifugal controller of rotation frequency for vertical axis wind turbines. J. King Saud Univ.-Eng. Sci. 2023, 35, 549–556. [Google Scholar] [CrossRef]

- Moran, W.A. Giromill Wind Tunnel Test and Analysis; McDonnell Aircraft Company: St. Louis, MO, USA, 1977. [Google Scholar] [CrossRef]

- Noda, M.; Nagao, F.; Shinomiya, A. Aerodynamic autonomous control of gyromill wind turbine. In Proceedings of the Annual Meeting of Japan Association for Wind Engineering, Kitakyushu, Japan, 30 April 2007; pp. 255–256. [Google Scholar]

- Noda, M.; Nagao, F.; Shinomiya, A. Development of Safe Vertical AxisS Wind Turbine for Over Speed Rotation. In Proceedings of the Seventh Asia-Pacific Conference on Wind Engineering, Taipei, Taiwan, 8–12 November 2009. [Google Scholar]

- Kiwata, T.; Yamada, T.; Kita, T.; Takata, S.; Komatsu, N.; Kimura, S. Performance of a Vertical Axis Wind Turbine with Variable-Pitch Straight Blades utilizing a Linkage Mechanism. J. Environ. Eng. 2010, 5, 213–225. [Google Scholar] [CrossRef]

- Yamada, T.; Kiwata, T.; Kita, T.; Hirai, M.; Komatsu, N.; Kono, T. Overspeed Control of a Variable-Pitch Vertical-Axis Wind Turbine by Means of Tail Vanes. J. Environ. Eng. 2012, 7, 39–52. [Google Scholar] [CrossRef]

- Suzuki, M. The Vertical Blades of the Vertical Axis Wind Turbine. JP Patent JP4616918B, 19 January 2011. [Google Scholar]

- Suzuki, M. Blade of Wind Turbine. JP Patent JP2011-027054A, 10 February 2011. [Google Scholar]

- Mohan Kumar, P.; Sivalingam, K.; Lim, T.-C.; Ramakrishna, S.; Wei, H. Review on the Evolution of Darrieus Vertical Axis Wind Turbine: Large Wind Turbines. Clean Technol. 2019, 1, 205–223. [Google Scholar] [CrossRef]

- Tanzawa, Y.; Shimizu, S.; Inoue, Y.; Shimizu, Y. Study on the aerodynamic brake of small gyro-mill type vertical axis wind turbine (1st report, method of the rotational speed continuous control under the strong wind). Trans. Jpn. Soc. Mech. Eng. Part B 2013, 79, 12–21. [Google Scholar] [CrossRef]

- Hara, Y.; Tagawa, K.; Saito, S.; Shioya, K.; Ono, T.; Makino, K.; Toba, K.; Hirobayashi, T.; Tanaka, Y.; Takashima, K.; et al. Development of a Butterfly Wind Turbine with Mechanical Over-Speed Control System. Designs 2018, 2, 17. [Google Scholar] [CrossRef]

- Musgrove, P.J. Wind energy conversion: Recent progress and future prospects. Sol. Wind. Technol. 1987, 4, 37–49. [Google Scholar] [CrossRef]

- Divone, V.L. Evolution of Modern Wind Turbine. In Wind Turbine Technology, 1st ed.; Spera, A.D., Ed.; ASME Press: New York, NY, USA, 1998; pp. 94–95. [Google Scholar]

- Whitehouse, G.R.; Sibilia, M.J.; Bilanin, A.J.; Veers, P. Variable geometry wind turbine for performance enhancement, improved survivability and reduced cost of energy. Wind Energy 2014, 18, 1303–1311. [Google Scholar] [CrossRef]

- Challenergy. Available online: https://challenergy.com/magnus/ (accessed on 11 May 2024).

- Hara, Y.; Saito, S.; Park, O.; Ishikawa, H.; Ono, T.; Higami, H. Behavior analysis of 7 m Butterfly Wind Turbine with over-speed control using movable arms. In Proceedings of the 26th National Symposium on Power and Energy Systems, Saga, Japan, 13–14 July 2022. C213. [Google Scholar]

- Jain, P.; Abhishek, A. Performance prediction and fundamental understanding of small scale vertical axis wind turbine with variable amplitude blade pitching. Renew. Energy 2016, 97, 97–113. [Google Scholar] [CrossRef]

- Ando, H.; Hara, Y.; Miura, T.; Yoshida, S. The selection of blade cross section of a vertical axis wind turbine with a diameter of 14 m and the evaluation of rotor performance. In Proceedings of the 50th Student Graduation Research Presentation Conference of the Japan Society of Mechanical Engineering Chugoku-Shikoku Branch, Hiroshima University, Hiroshima, Japan, 5 March 2020; 04a1. Available online: https://repository.lib.tottori-u.ac.jp/record/2000017/files/jsme50_04a1.pdf (accessed on 11 May 2024).

- Paraschivoiu, I. Wind Turbine Design: With Emphasis on Darrieus Concept; Polytechnic International Press: Montreal, QC, Canada, 2002; pp. 147–264. [Google Scholar]

- Hara, Y.; Kawamura, T.; Akimoto, H.; Tanaka, K.; Nakamura, T.; Mizumukai, K. Predicting Double-Blade Vertical Axis Wind Turbine Performance by a Quadruple-Multiple Streamtube Model. Int. J. Fluid Mach. Syst. 2014, 7, 16–27. [Google Scholar] [CrossRef]

- JIS C 1400-2:2020(J); Wind Energy Generation Systems―Part 2: Small Wind Turbines. Japanese Standards Association: Tokyo, Japan, 2020.

- Sheldahl, R.E.; Klimas, P.C. Aerodynamic Characteristics of Seven Symmetrical Airfoil Sections through 180-Degree Angle of Attack for Use in Aerodynamic Analysis of Vertical Axis Wind Turbines; Sandia National Laboratories: Albuquerque, NM, USA, 1981; p. 6548367. [Google Scholar] [CrossRef]

- Durgam, R.; Karampuri, R.; Rangarajan, S.S.; Subramaniam, U.; Collins, E.R.; Senjyu, T. Investigations on the Modulation Strategies for Performance Improvement of a Controlled Wind Energy System. Electronics 2022, 11, 3931. [Google Scholar] [CrossRef]

| Wind Turbine Condition | Electric Power: Pe [W] | Total Efficiency: ηt [%] | Relative Improvement [%] |

|---|---|---|---|

| without damper, span(ail) = 600 mm | 217 | 3.52 | - |

| with damper, span(ail) = 600 mm | 241 | 3.92 | 11.4 |

| with damper, span(ail) = 400 mm | 461 | 7.50 | 91.3 |

| after changing control data | 726 | 11.82 | 57.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hara, Y.; Higami, H.; Ishikawa, H.; Ono, T.; Saito, S.; Ichinari, K.; Yamamoto, K. Use of Dampers to Improve the Overspeed Control System with Movable Arms for Butterfly Wind Turbines. Energies 2024, 17, 2727. https://doi.org/10.3390/en17112727

Hara Y, Higami H, Ishikawa H, Ono T, Saito S, Ichinari K, Yamamoto K. Use of Dampers to Improve the Overspeed Control System with Movable Arms for Butterfly Wind Turbines. Energies. 2024; 17(11):2727. https://doi.org/10.3390/en17112727

Chicago/Turabian StyleHara, Yutaka, Hiroyuki Higami, Hiromitsu Ishikawa, Takeshi Ono, Shigenori Saito, Kenichiro Ichinari, and Katsushi Yamamoto. 2024. "Use of Dampers to Improve the Overspeed Control System with Movable Arms for Butterfly Wind Turbines" Energies 17, no. 11: 2727. https://doi.org/10.3390/en17112727

APA StyleHara, Y., Higami, H., Ishikawa, H., Ono, T., Saito, S., Ichinari, K., & Yamamoto, K. (2024). Use of Dampers to Improve the Overspeed Control System with Movable Arms for Butterfly Wind Turbines. Energies, 17(11), 2727. https://doi.org/10.3390/en17112727